Naphtha catalytic reforming method of by-product reduction hydrogen

A catalytic reforming and naphtha technology, which is applied in the treatment of naphtha, petroleum industry, and hydrocarbon oil, etc., can solve the problems of large amount of activated carbon and low utilization rate of equipment, and overcome the problems of large amount of use and process operation. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

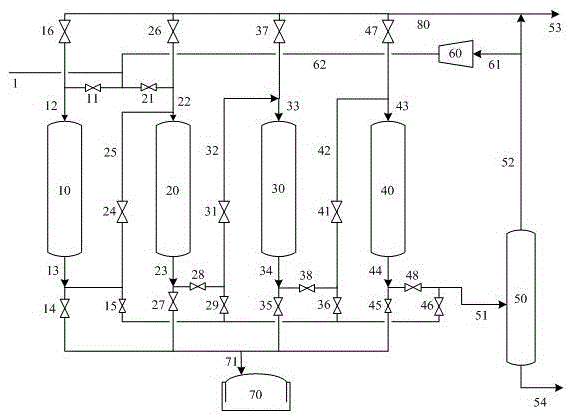

[0045] When it is necessary to prepare hydrogen storage for reforming and reduction, it is assumed that "preparing reduced hydrogen for reforming" is carried out at the end of an operation cycle. Taking the reforming reactor 10 as an example, the reactor 10 is first cut out of the process, and the The reforming catalyst in the reactor 10 is regenerated. The remaining 3 reactors continue to carry out the reforming reaction, and the materials go through process 2.

[0046] It can be seen from Table 3 that the catalytic reforming reaction conditions of Example 1 are: weighted average temperature 484.9°C, reaction pressure 1.33MPa, volume space velocity 1.59h -1 , The volume ratio of hydrogen to oil is 1200. The resulting oil had an octane number of 93.9.

[0047] As can be seen from Table 4, after hydrogenolysis, C 2 + The hydrocarbon content was 0.06% by volume.

Embodiment 2

[0049] Material flow process is identical with embodiment 1.

[0050] It can be seen from Table 3 that the catalytic reforming reaction conditions of Example 2 are: weighted average temperature 486.6°C, reaction pressure 1.33MPa, volume space velocity 1.73h -1 , The volume ratio of hydrogen to oil is 1200. The resulting oil had an octane rating of 94.0.

[0051] As can be seen from Table 4, after hydrogenolysis, C 2 + The hydrocarbon content was 0.12% by volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com