Patents

Literature

42results about How to "Volume content reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

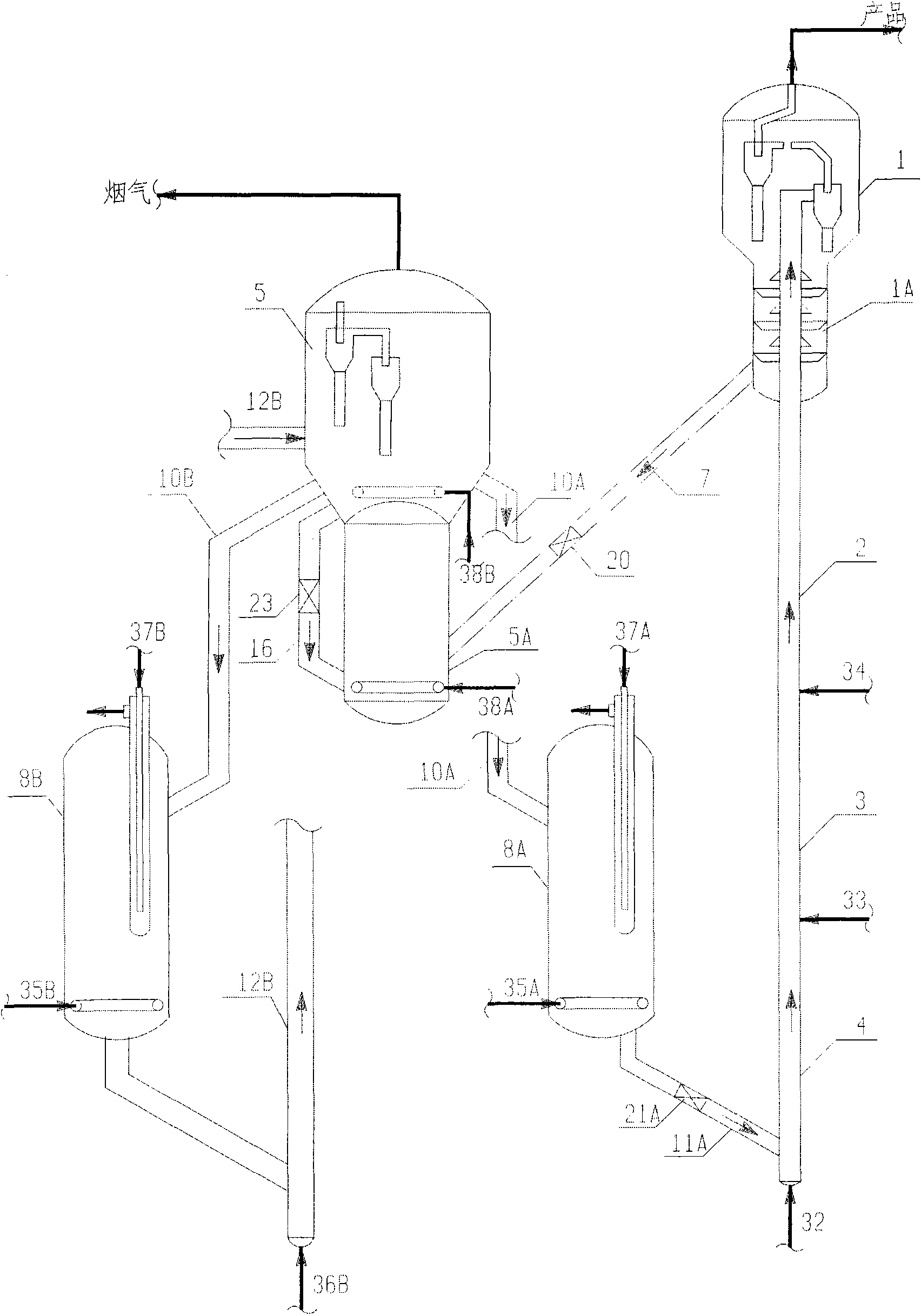

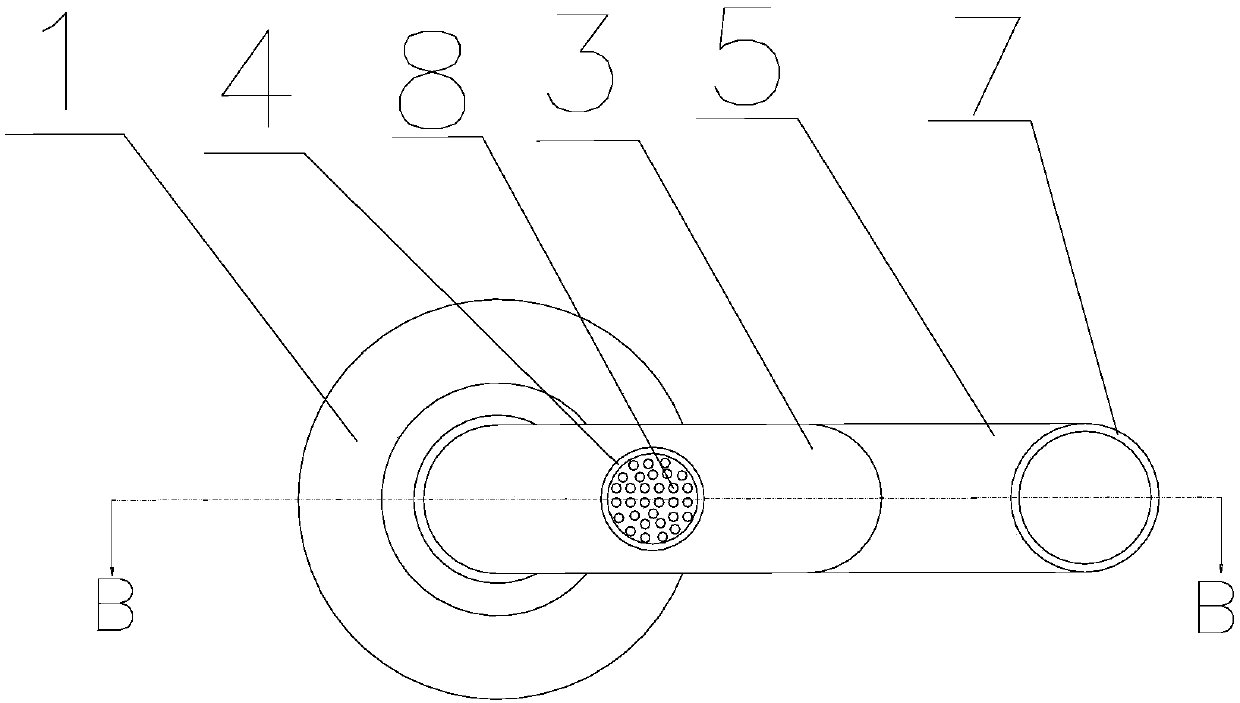

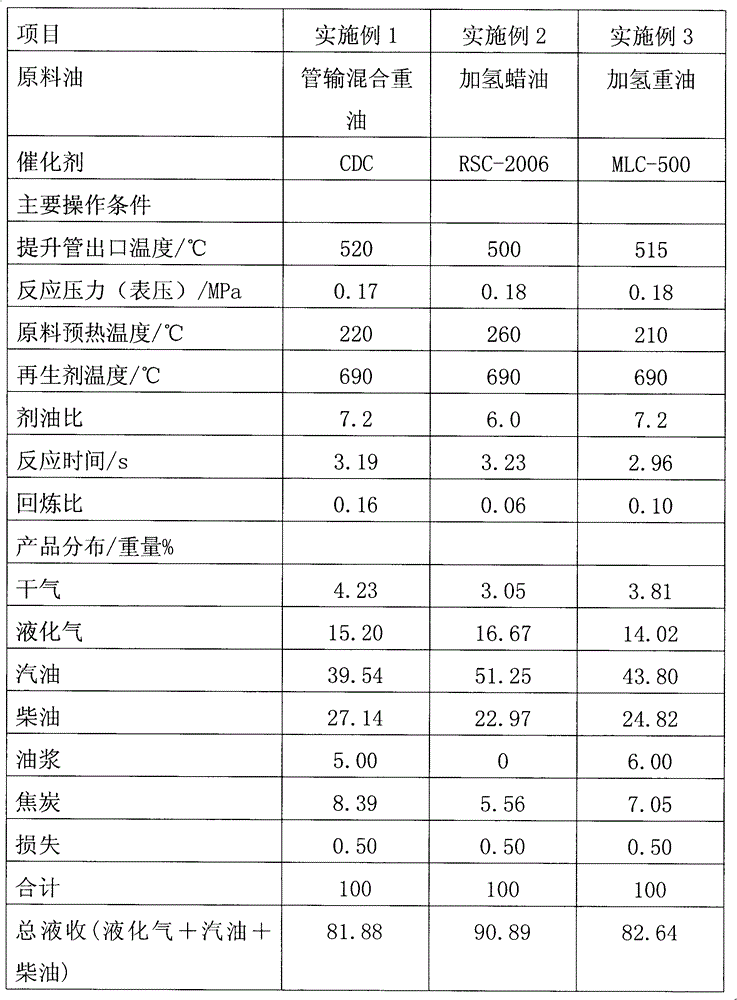

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

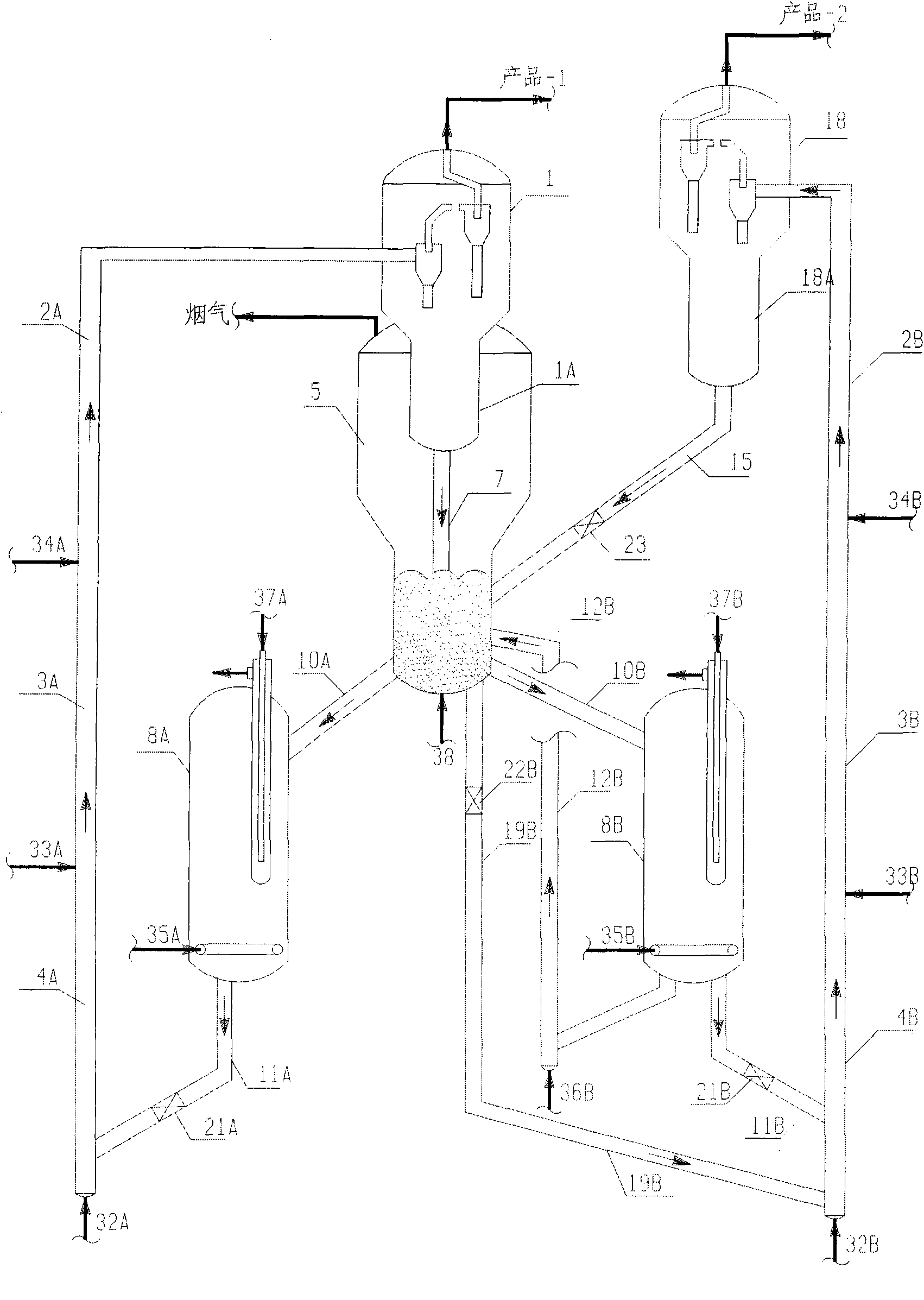

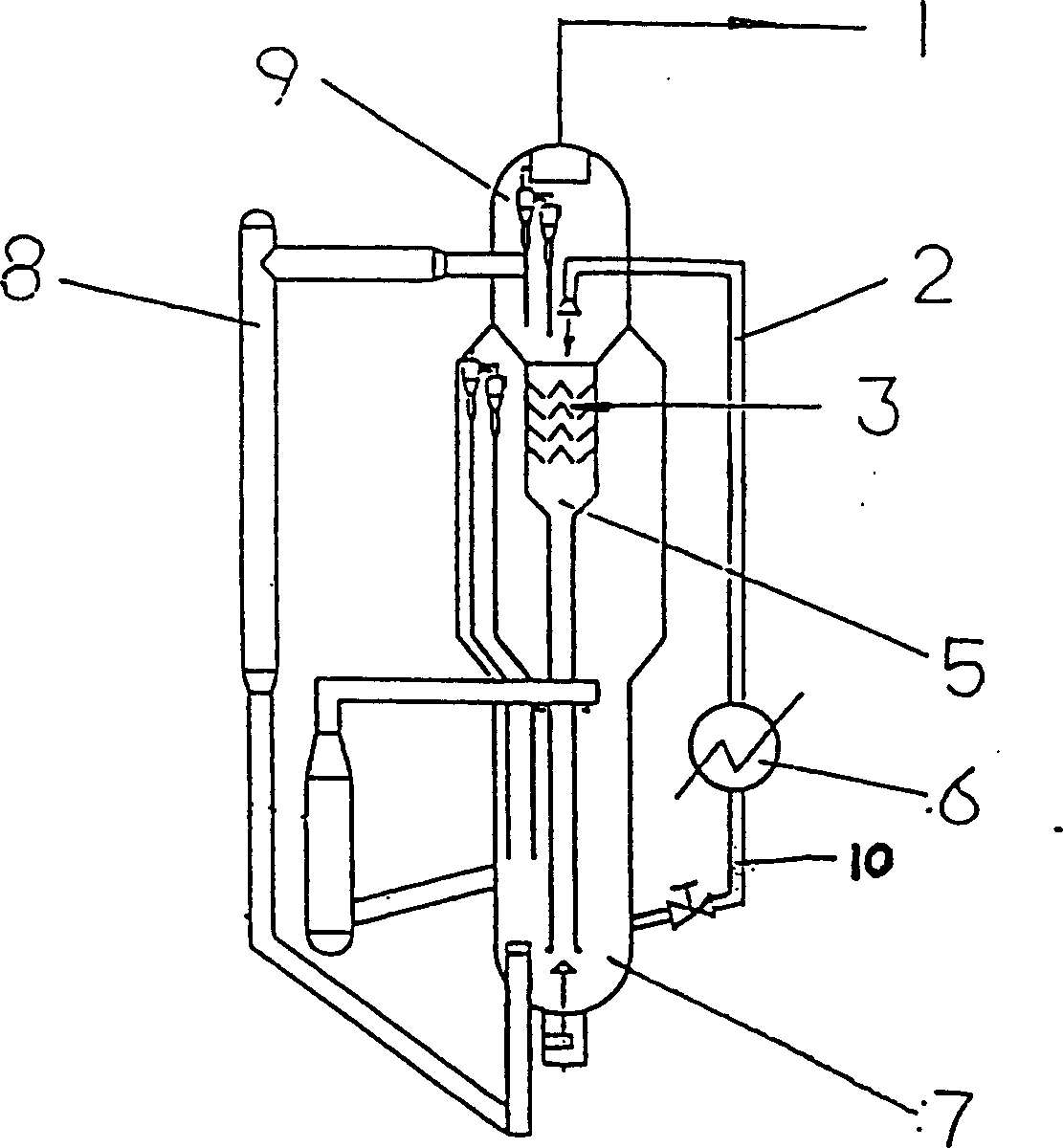

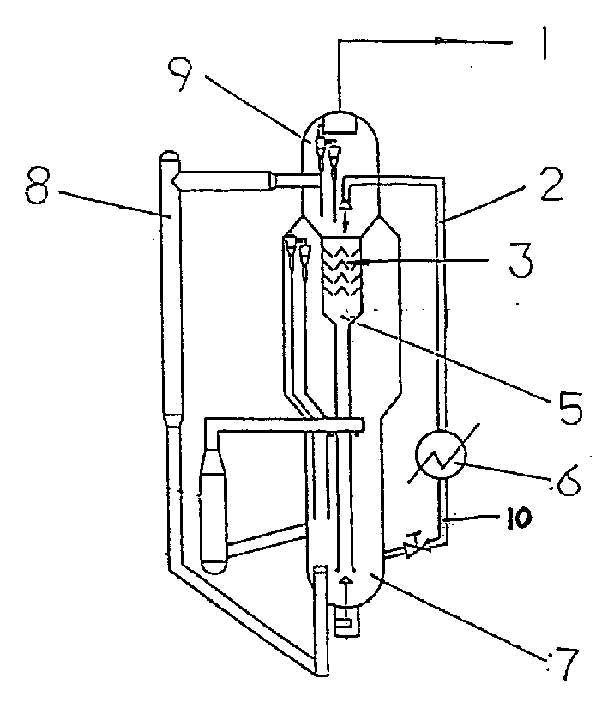

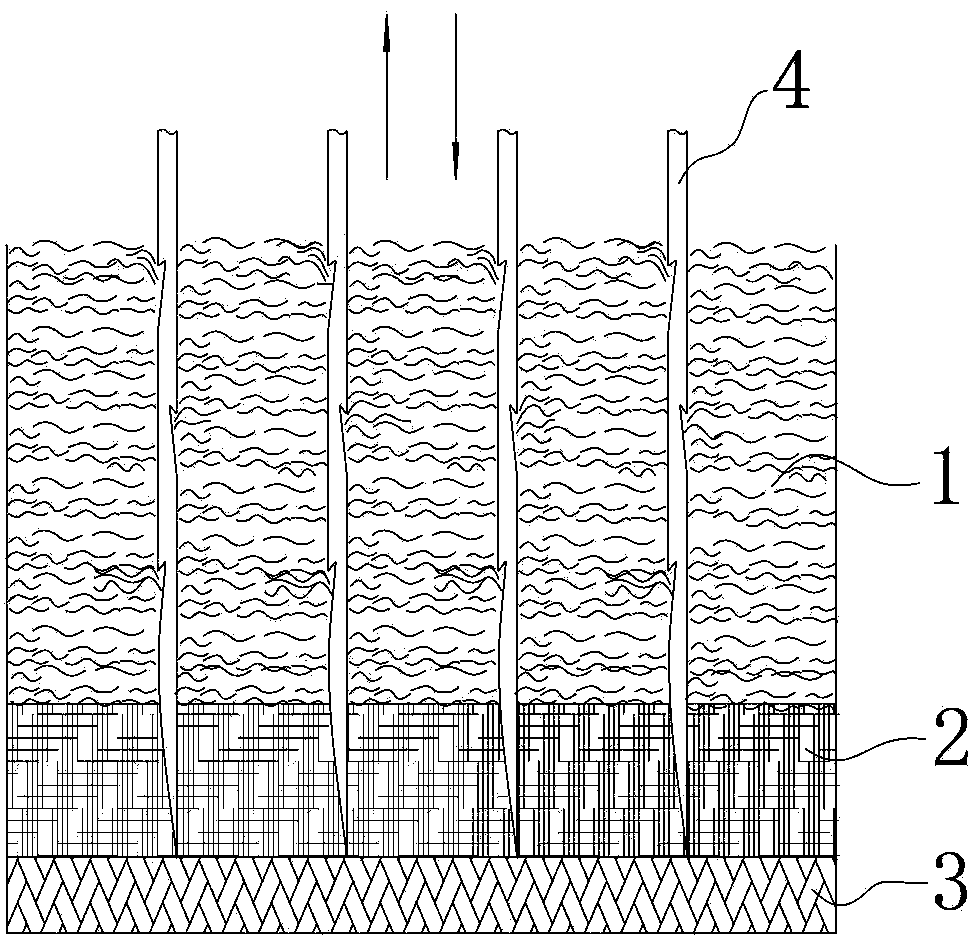

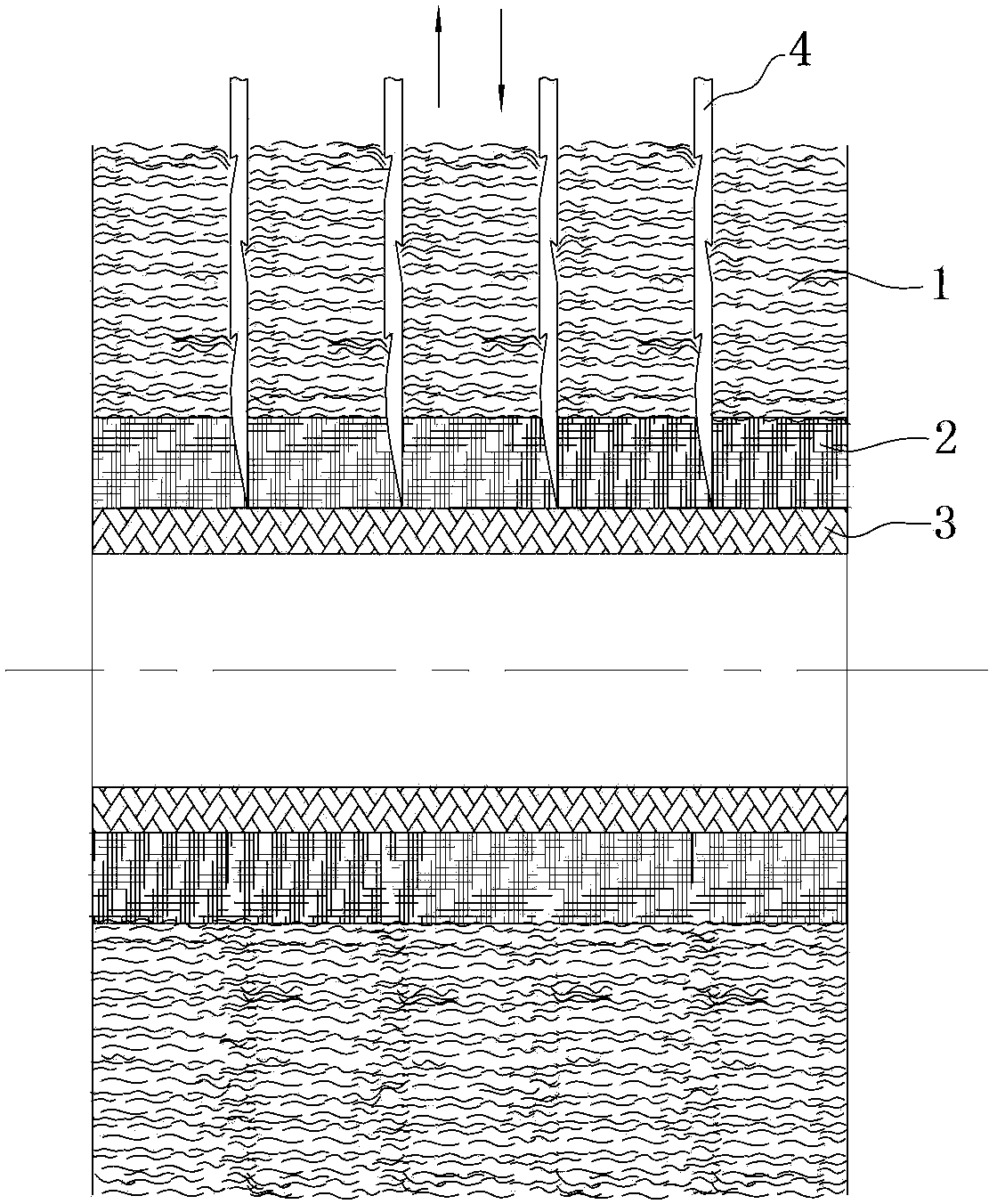

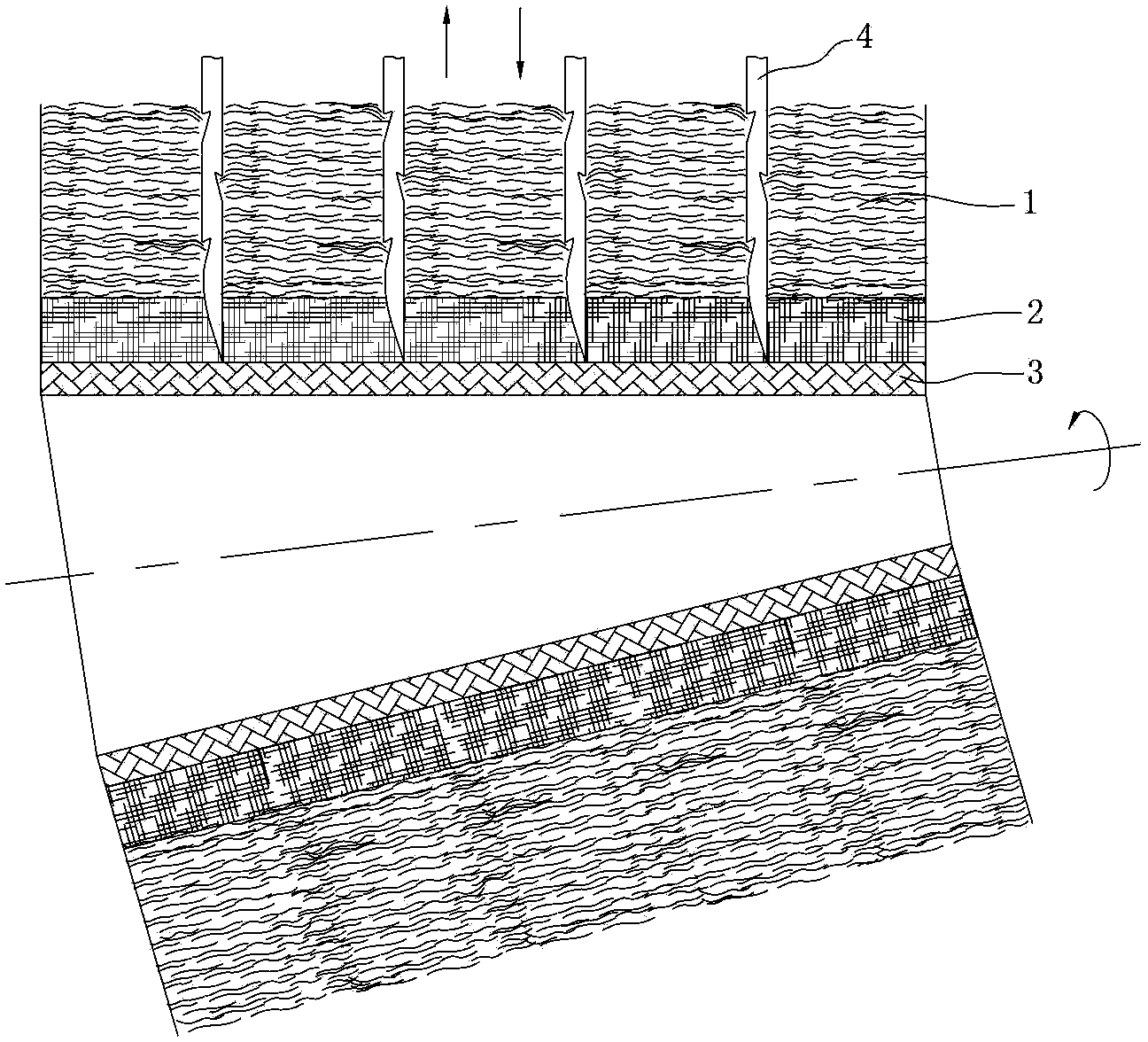

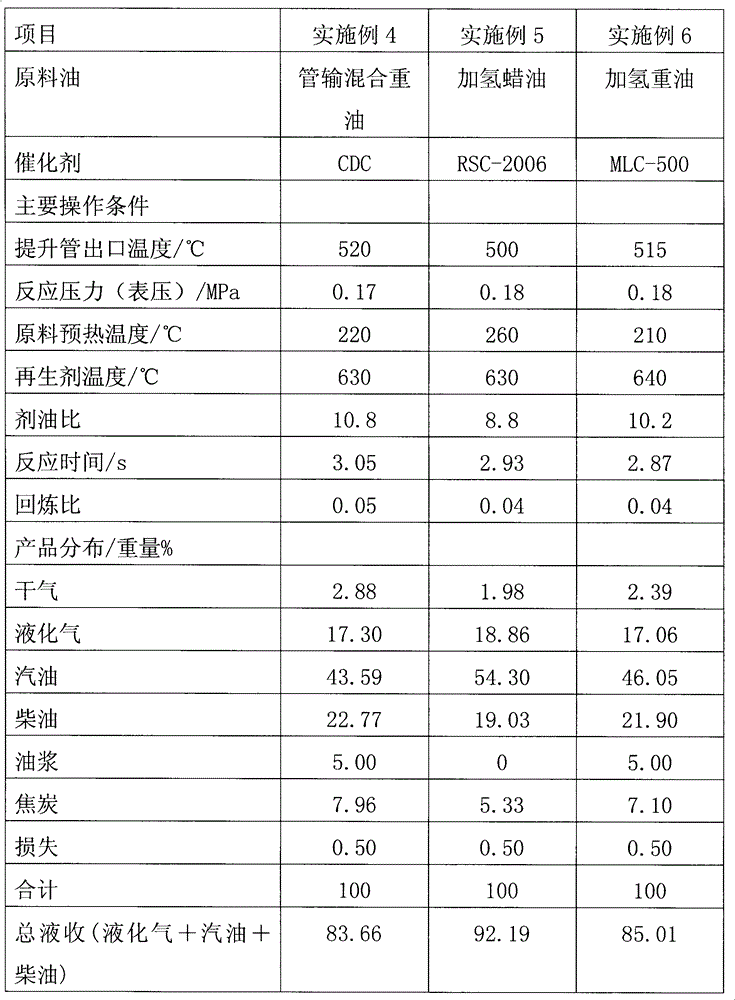

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

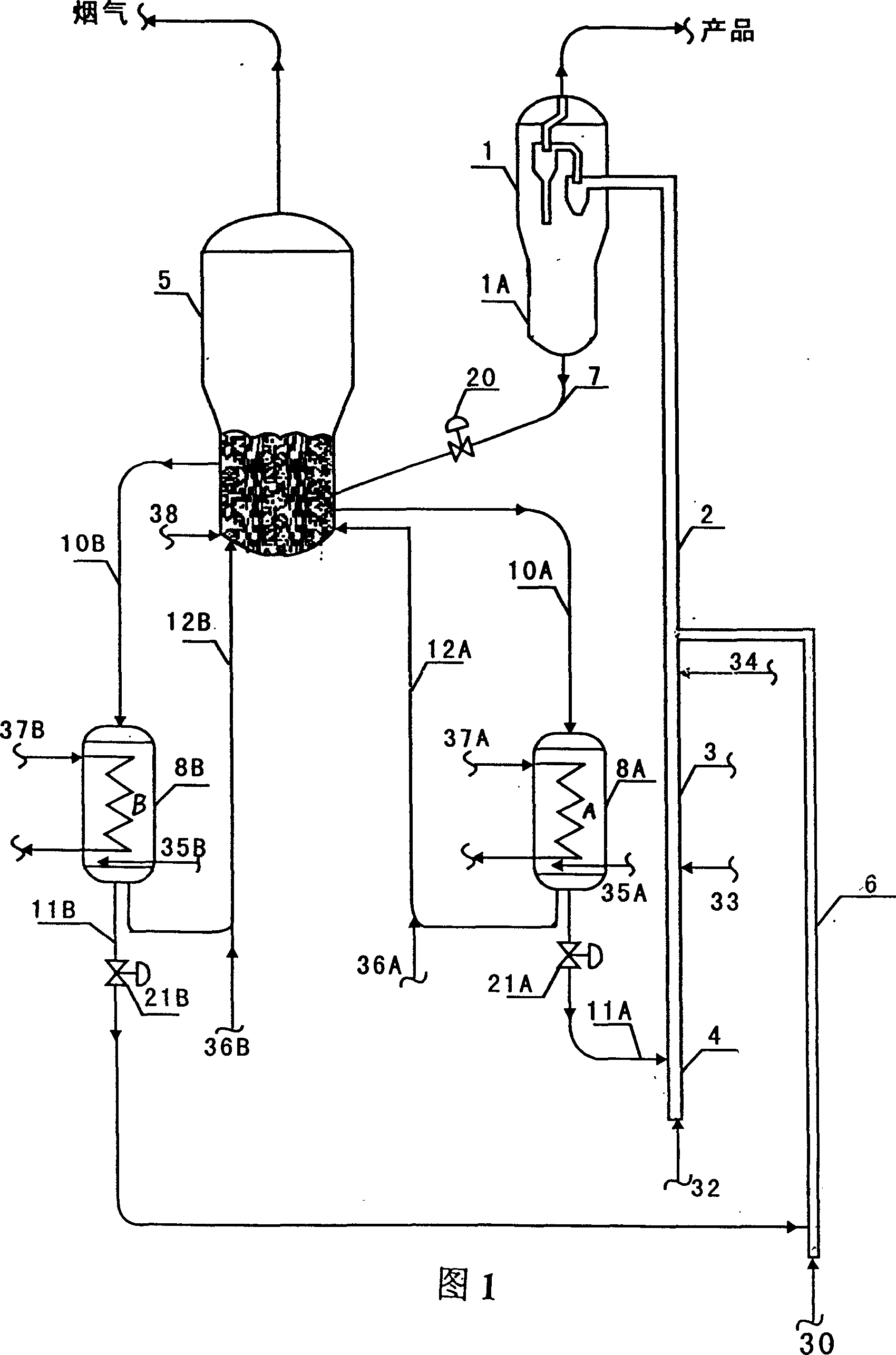

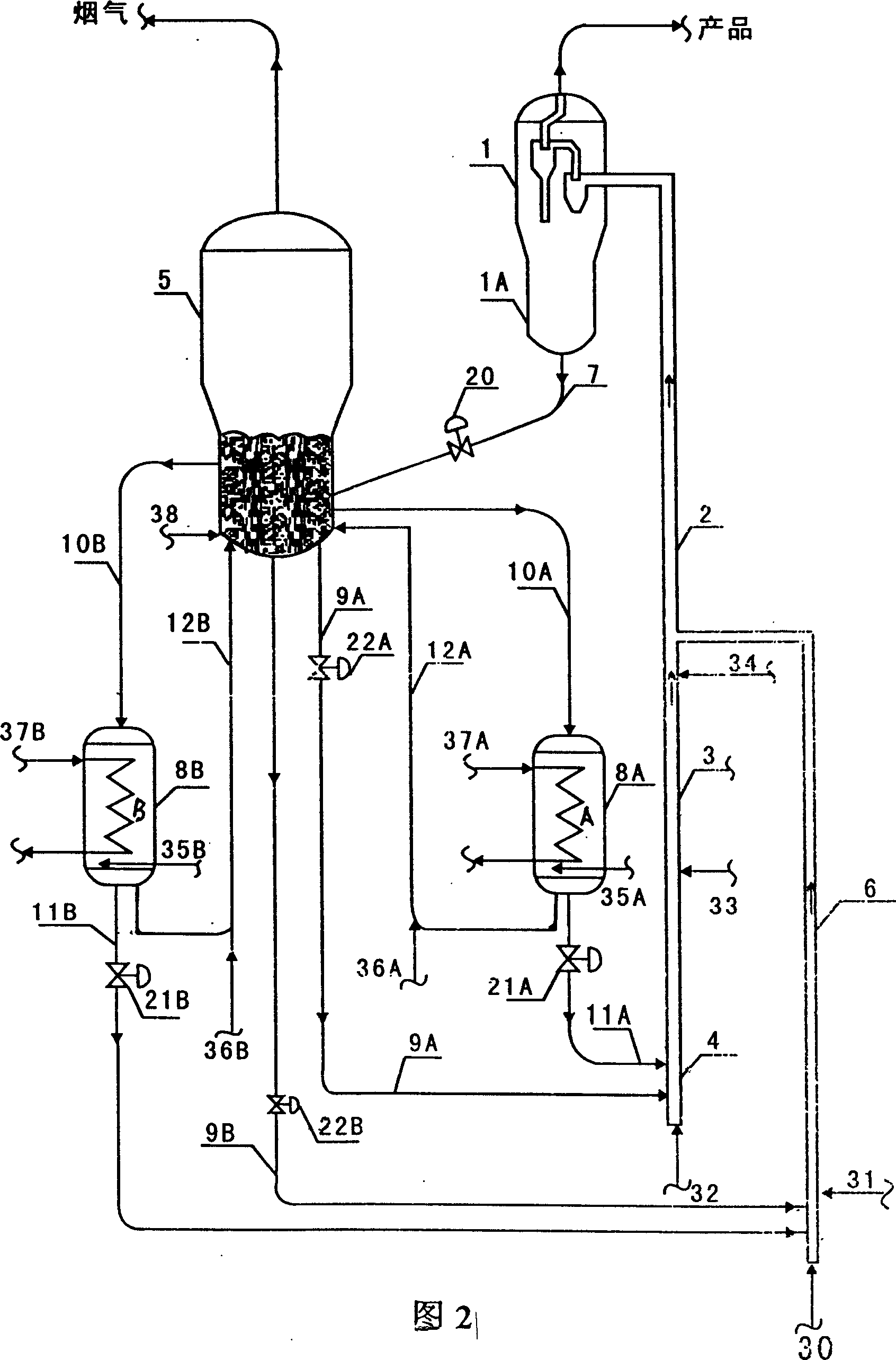

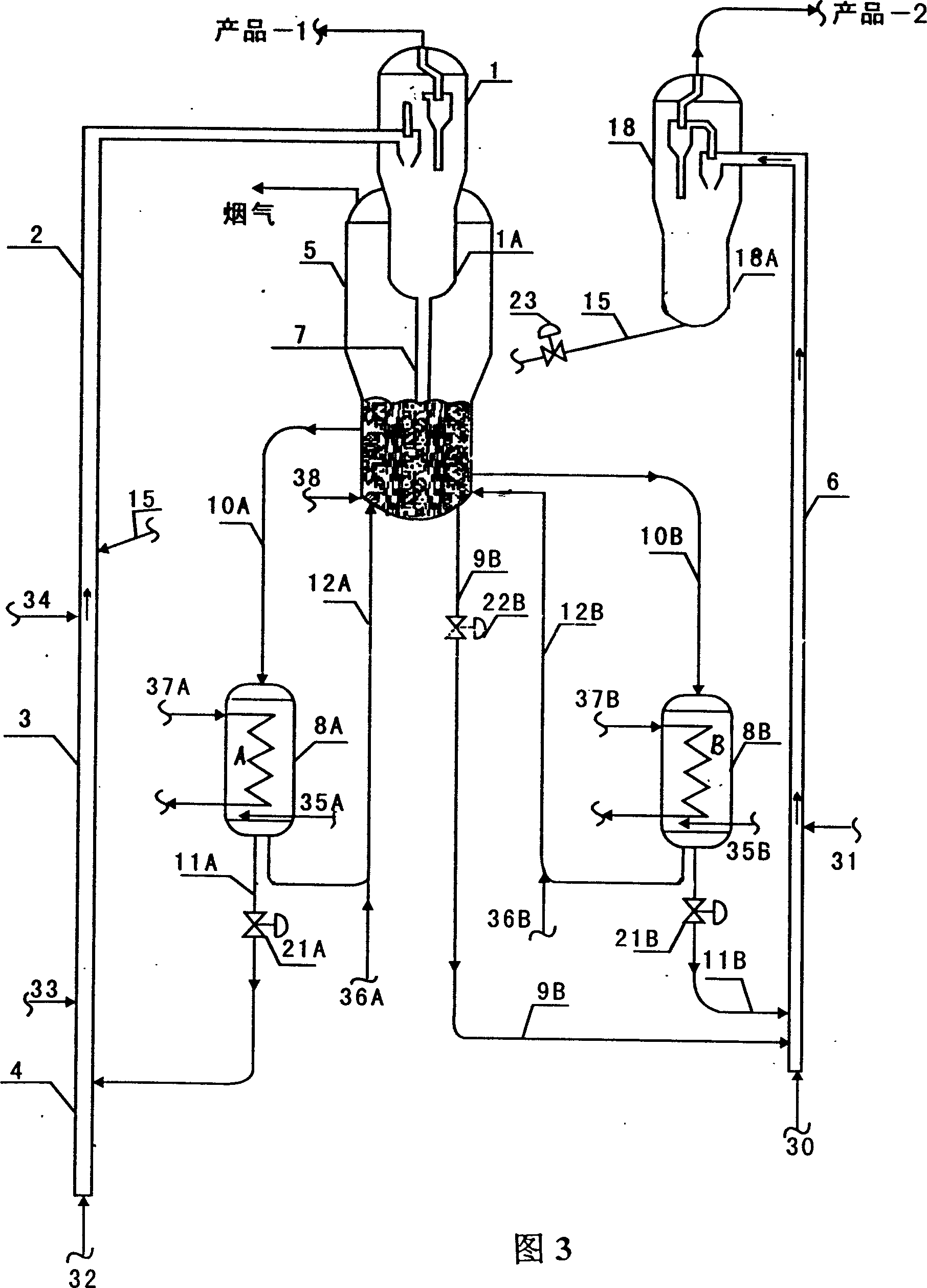

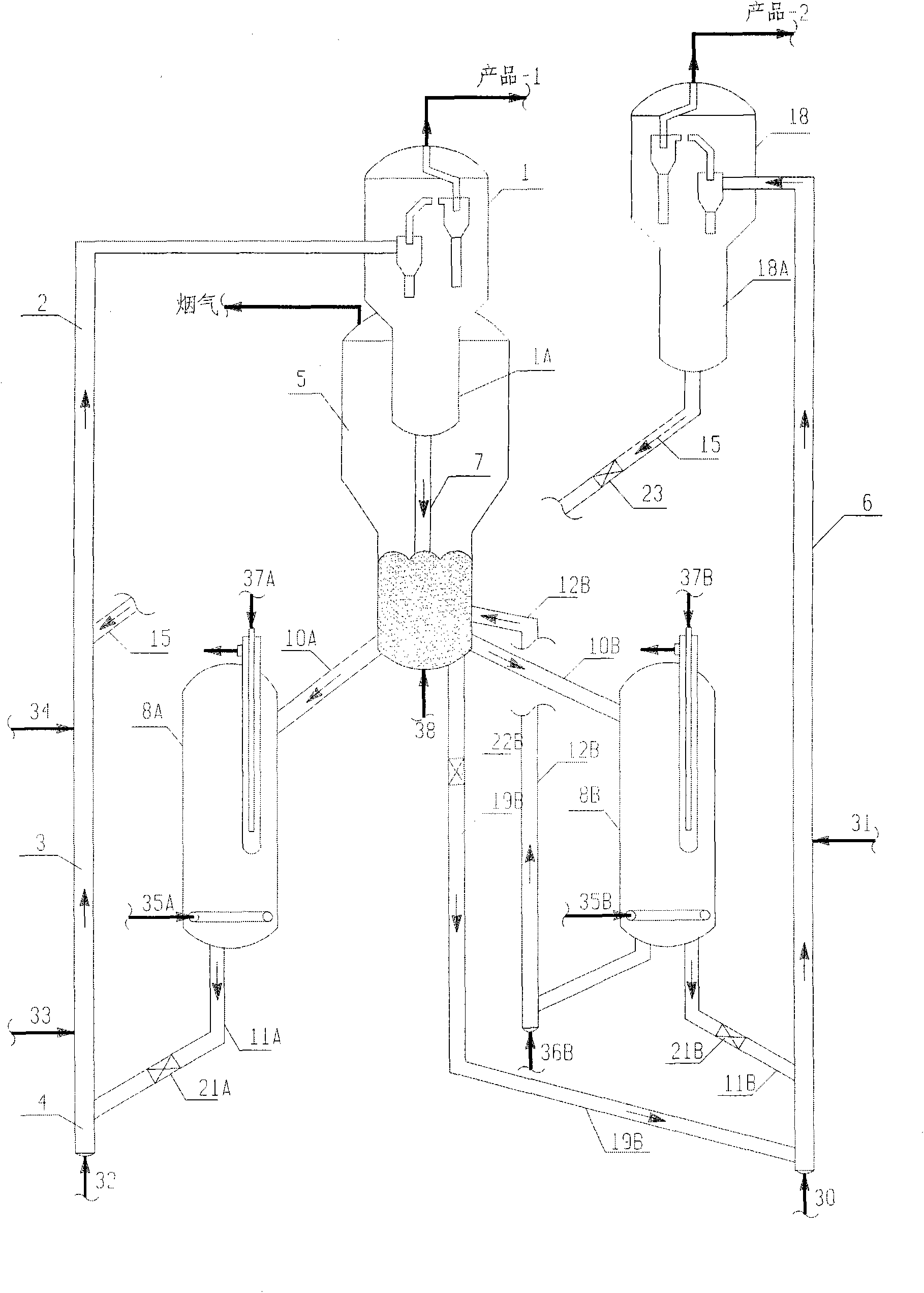

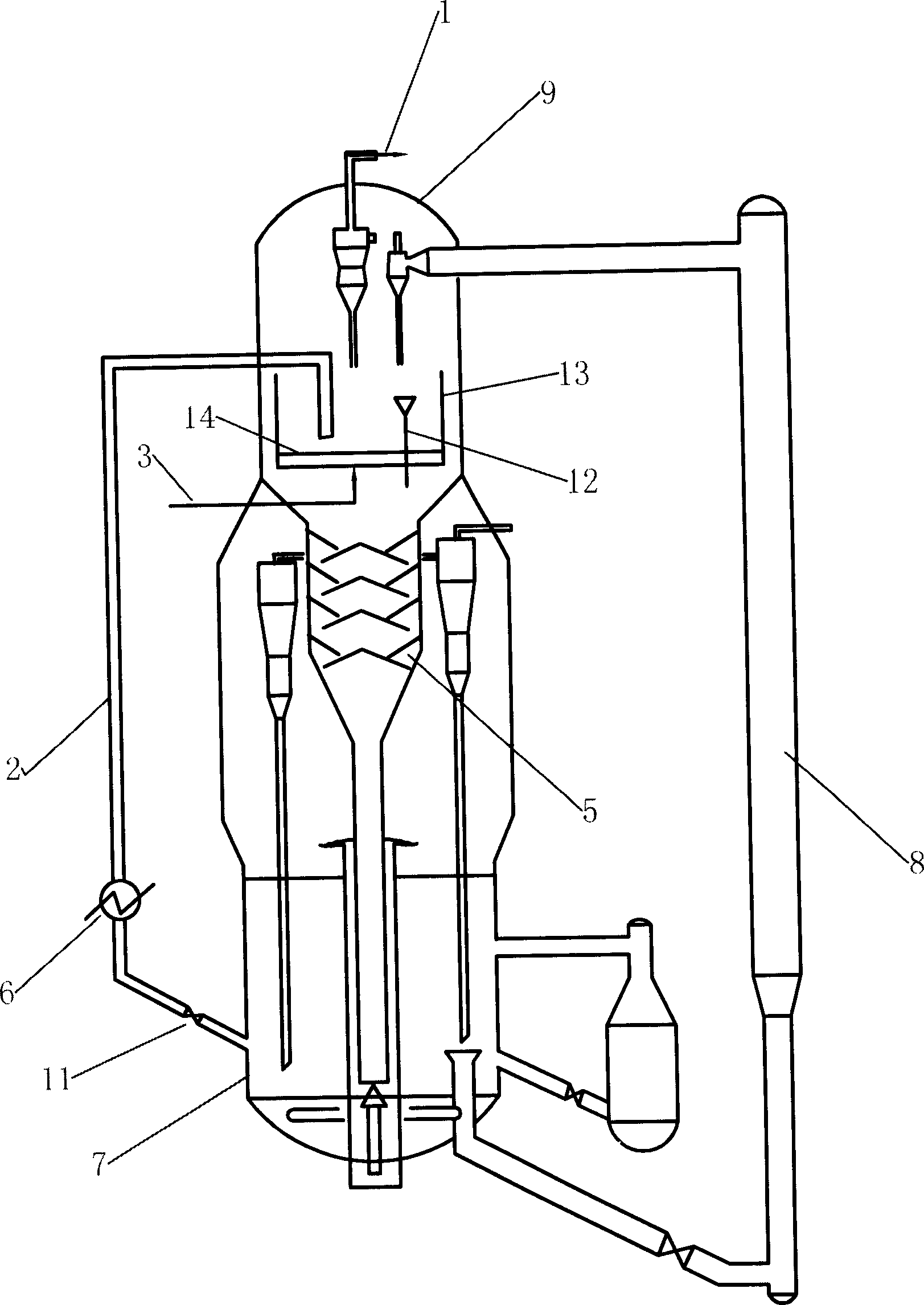

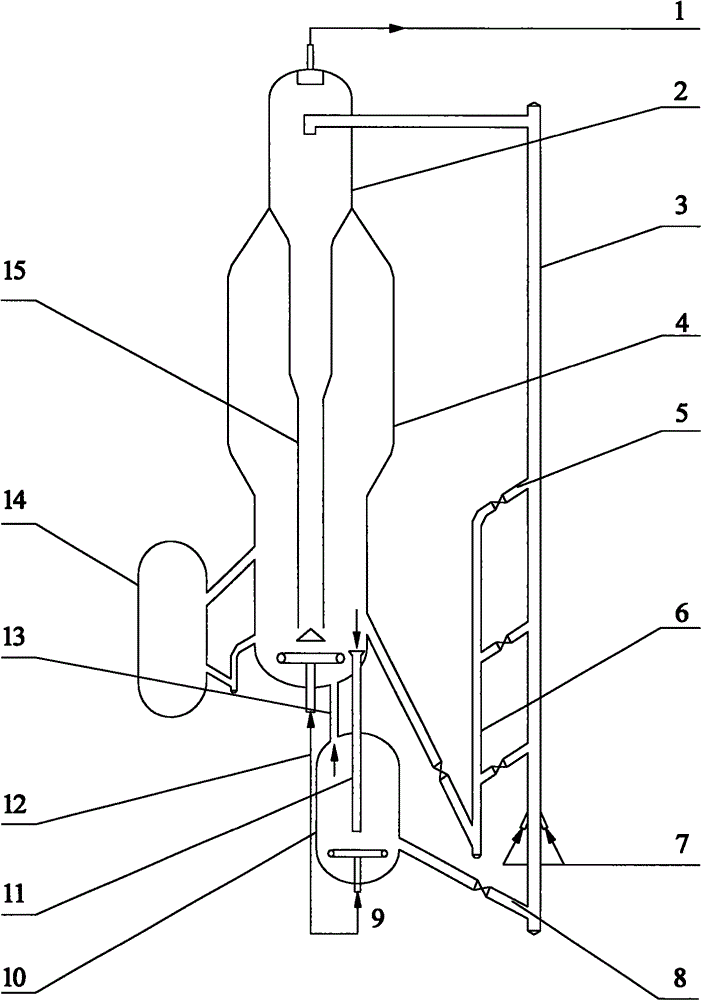

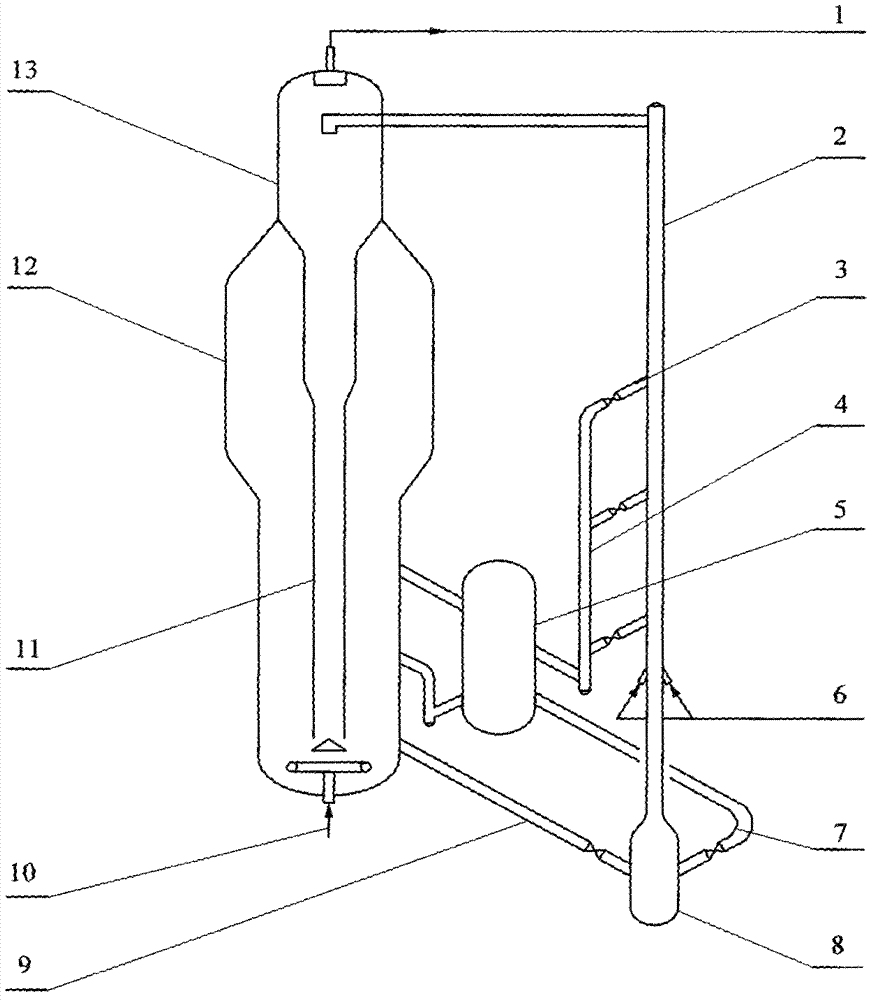

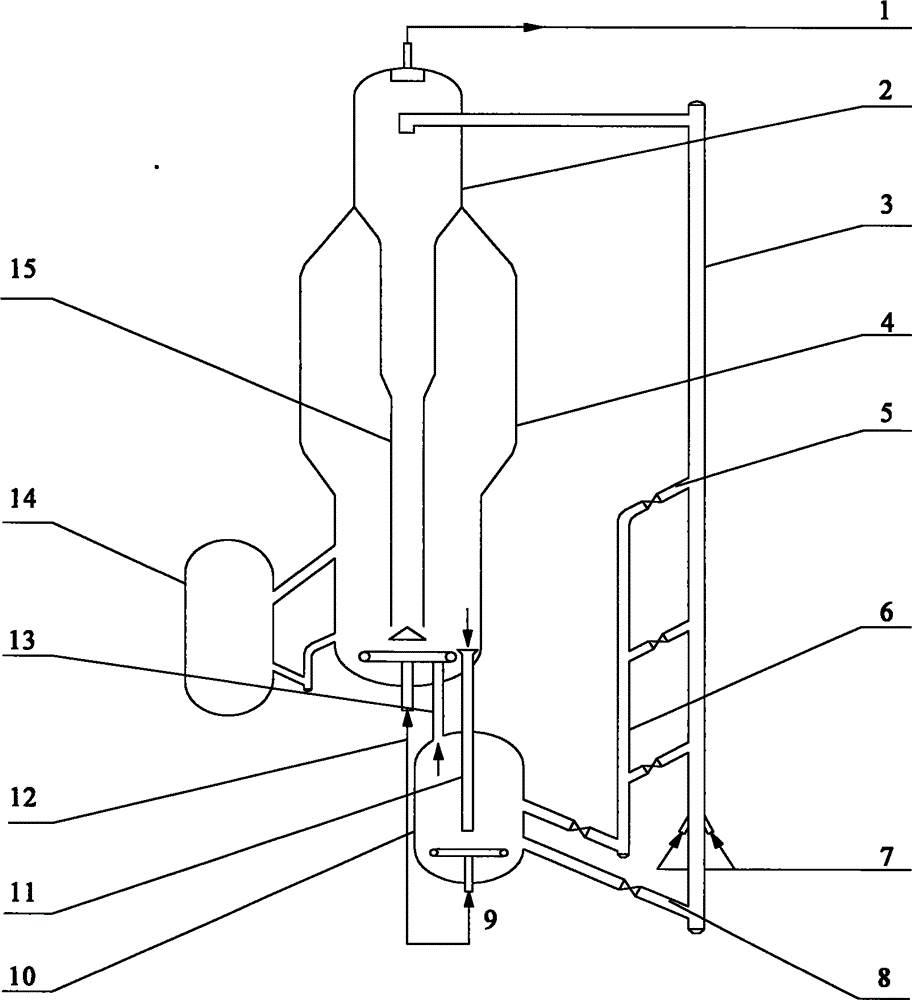

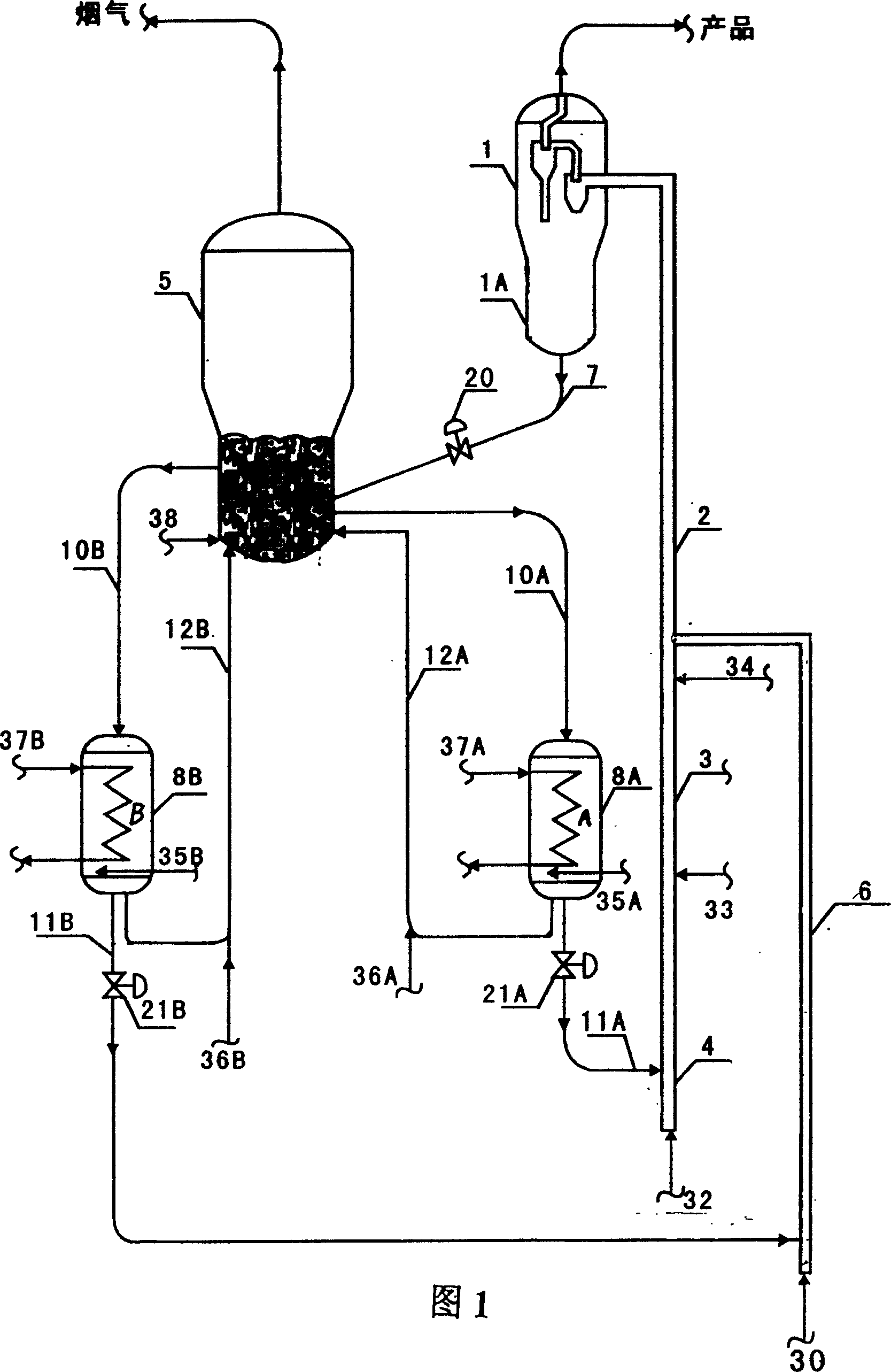

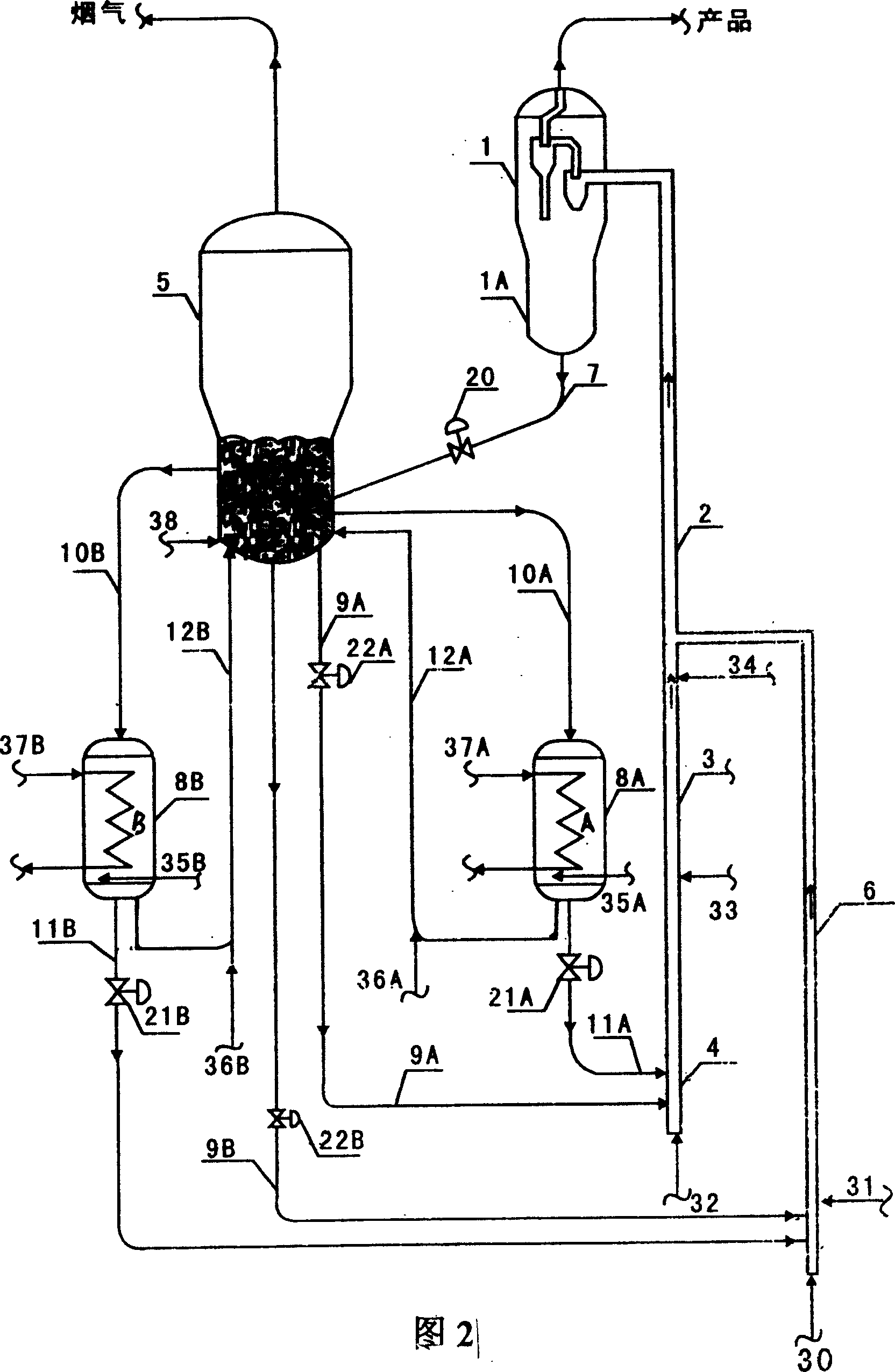

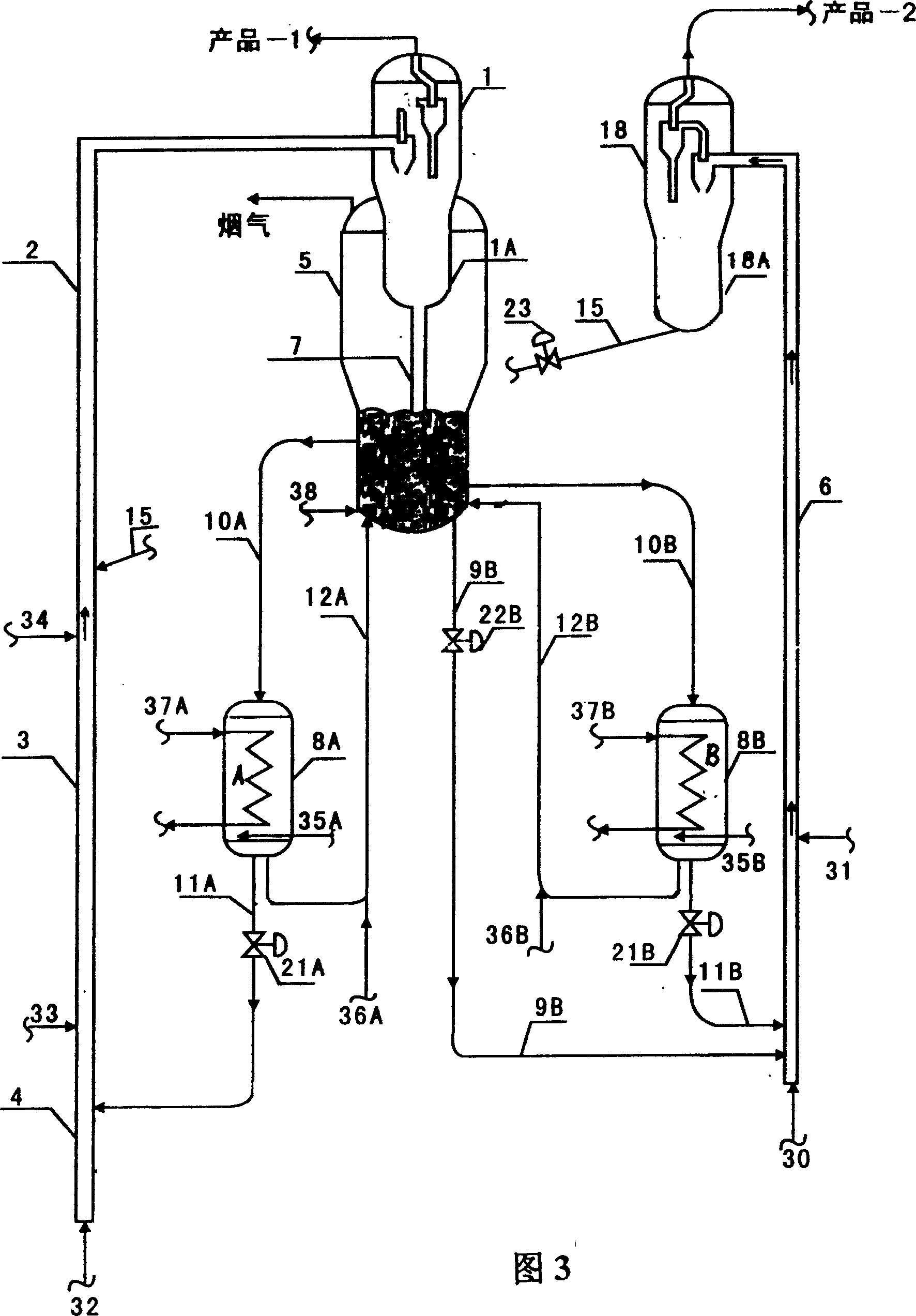

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

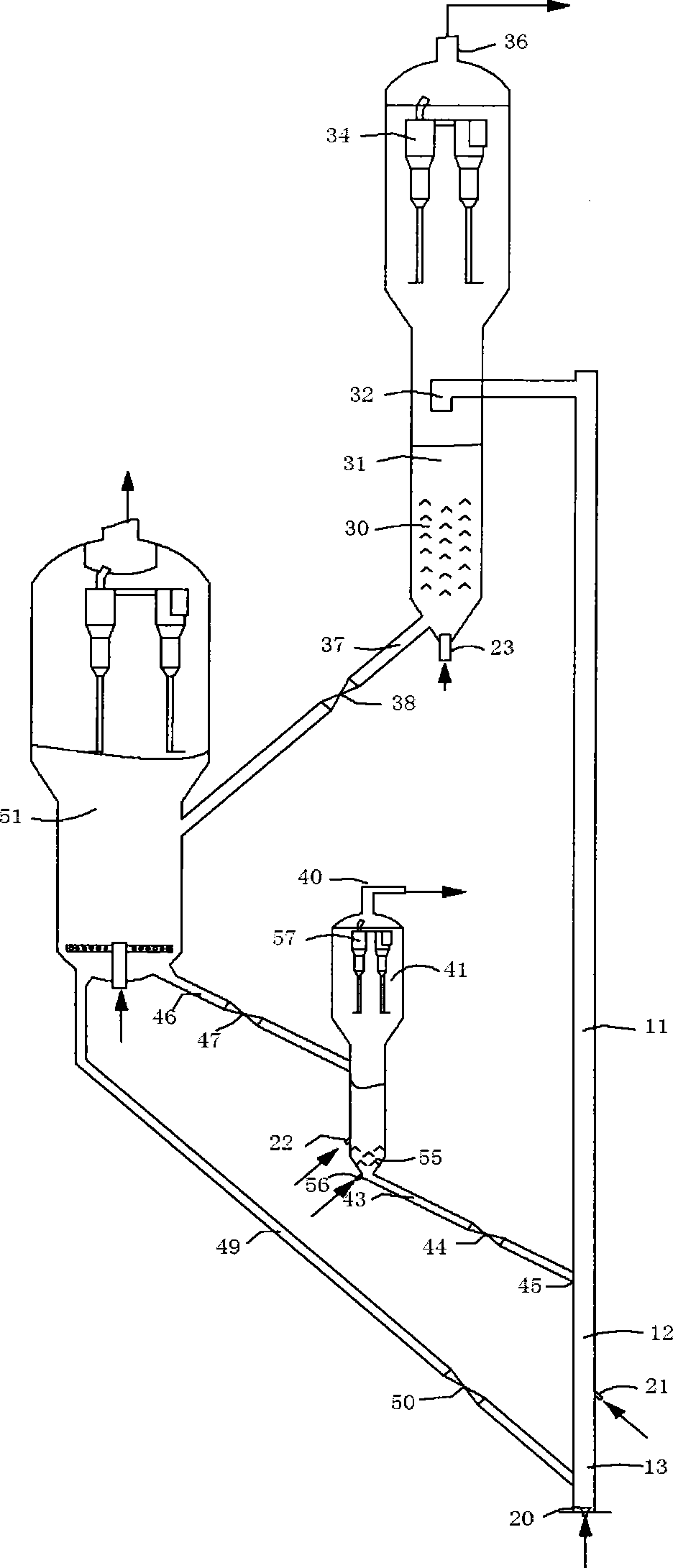

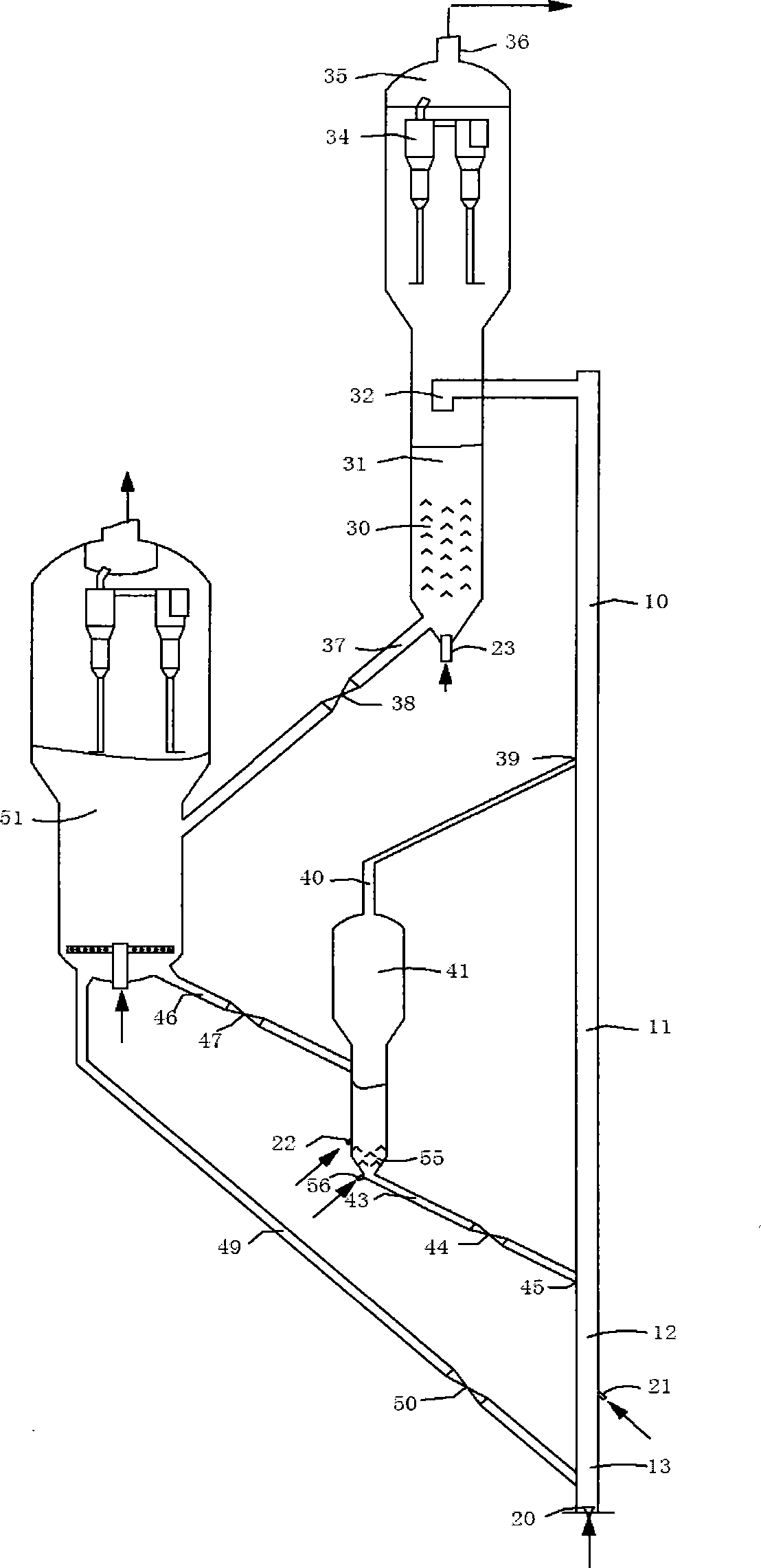

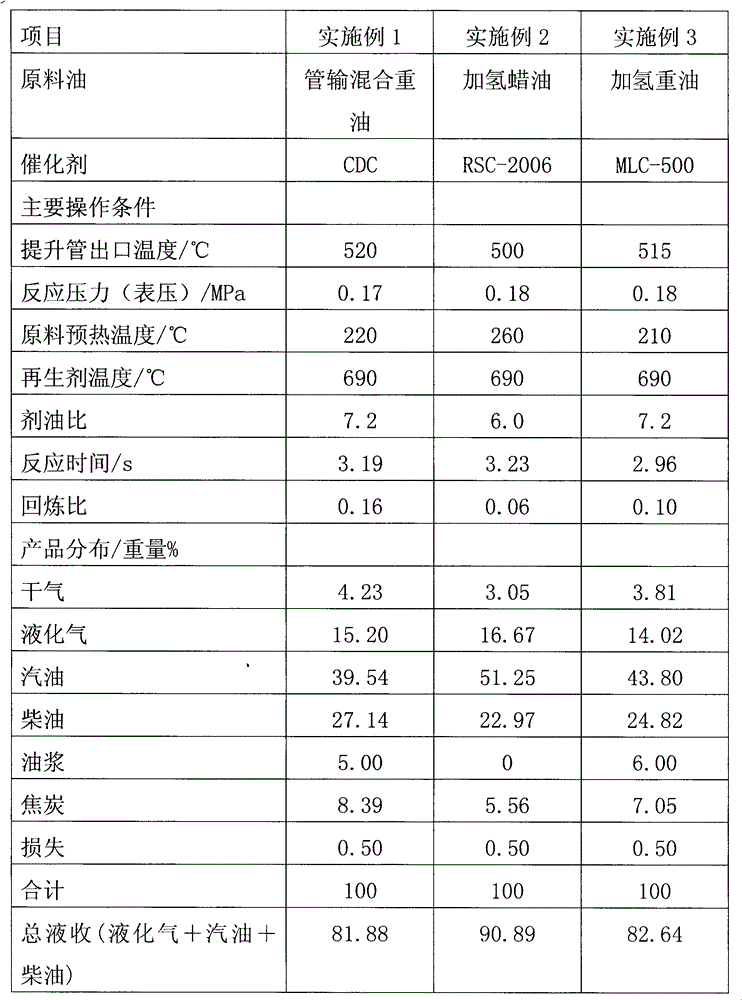

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Catalytic conversion method for reducing benzene content in gasoline

The invention provides a catalysis conversion method used for reducing the content of gasoline benzene; the gasoline raw material and gases containing small molecule alkene contact normal catalytic cracking catalyst, so as to carry out the alkylation reaction inside a fluidized bed reactor under the conditions of 250-550 DEG C of temperature, 2-100h<-1> of weight hourly space velocity, 0.1-1.0MPa of pressure, 1-30 of weight ratio of catalyst to gasoline raw material, 2-30 of gasoline raw material to small molecule alkene and 0.05-1.0 of weight ratio of water vapour to raw material; the materials after reaction are separated, and the reaction outcome is sent to a subsequent separation system for outcome separation so as to gain the object outcome; the catalyst after reaction is regenerated after being stripped and burned; the regenerated catalyst is returned to a reactor after being cooled for recycling. The method reduces the volume content of the benzene in the gasoline raw material by more than 50% and improves the octane and yield of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

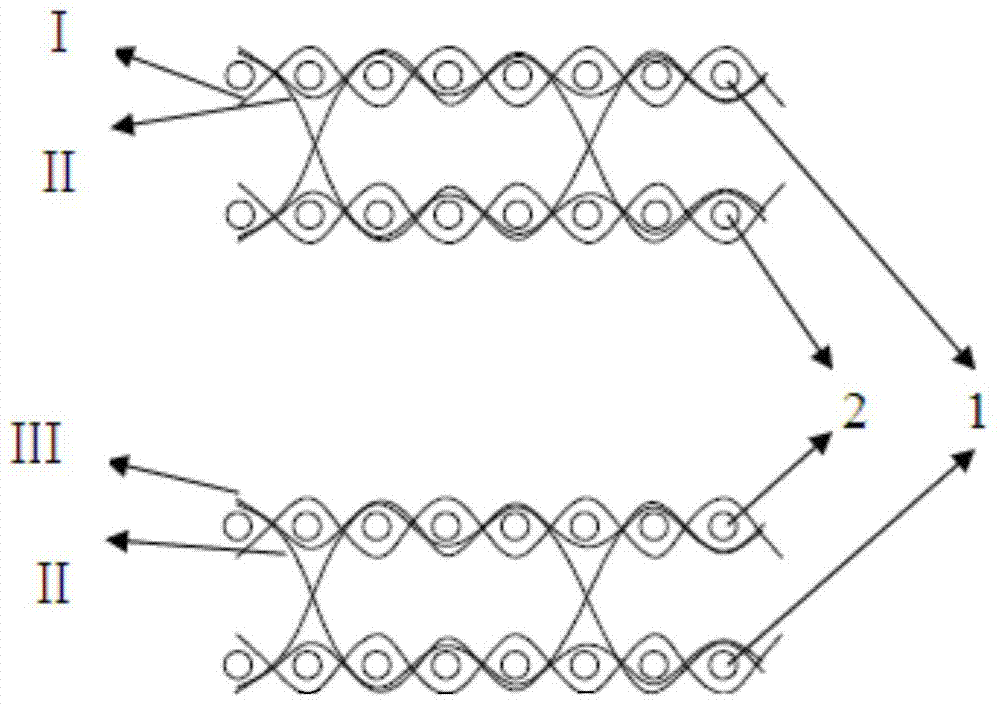

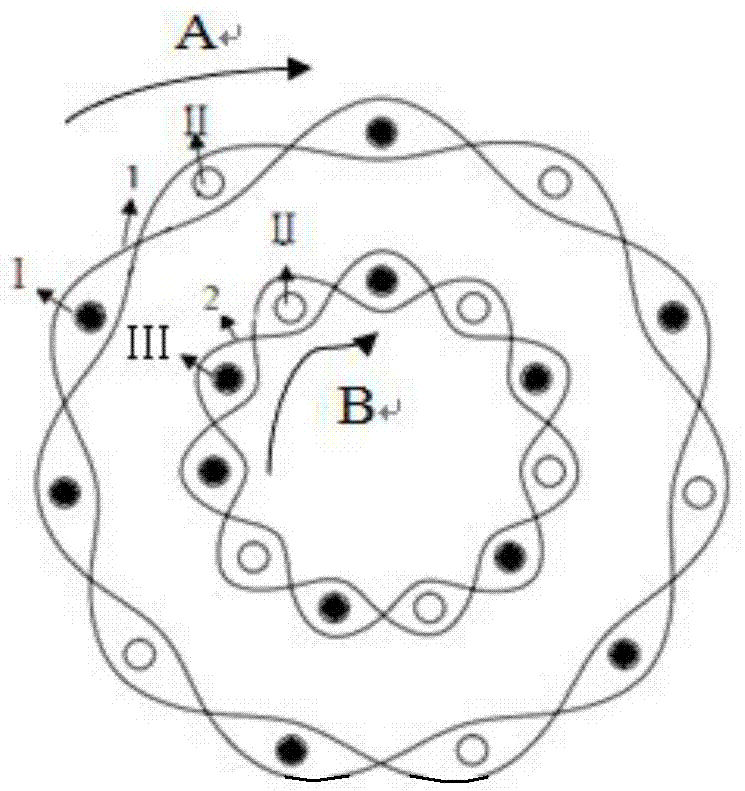

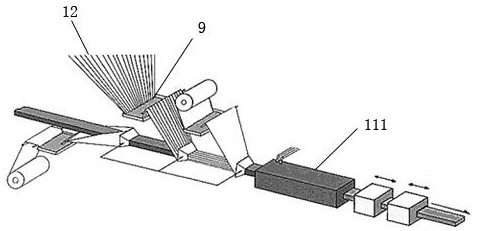

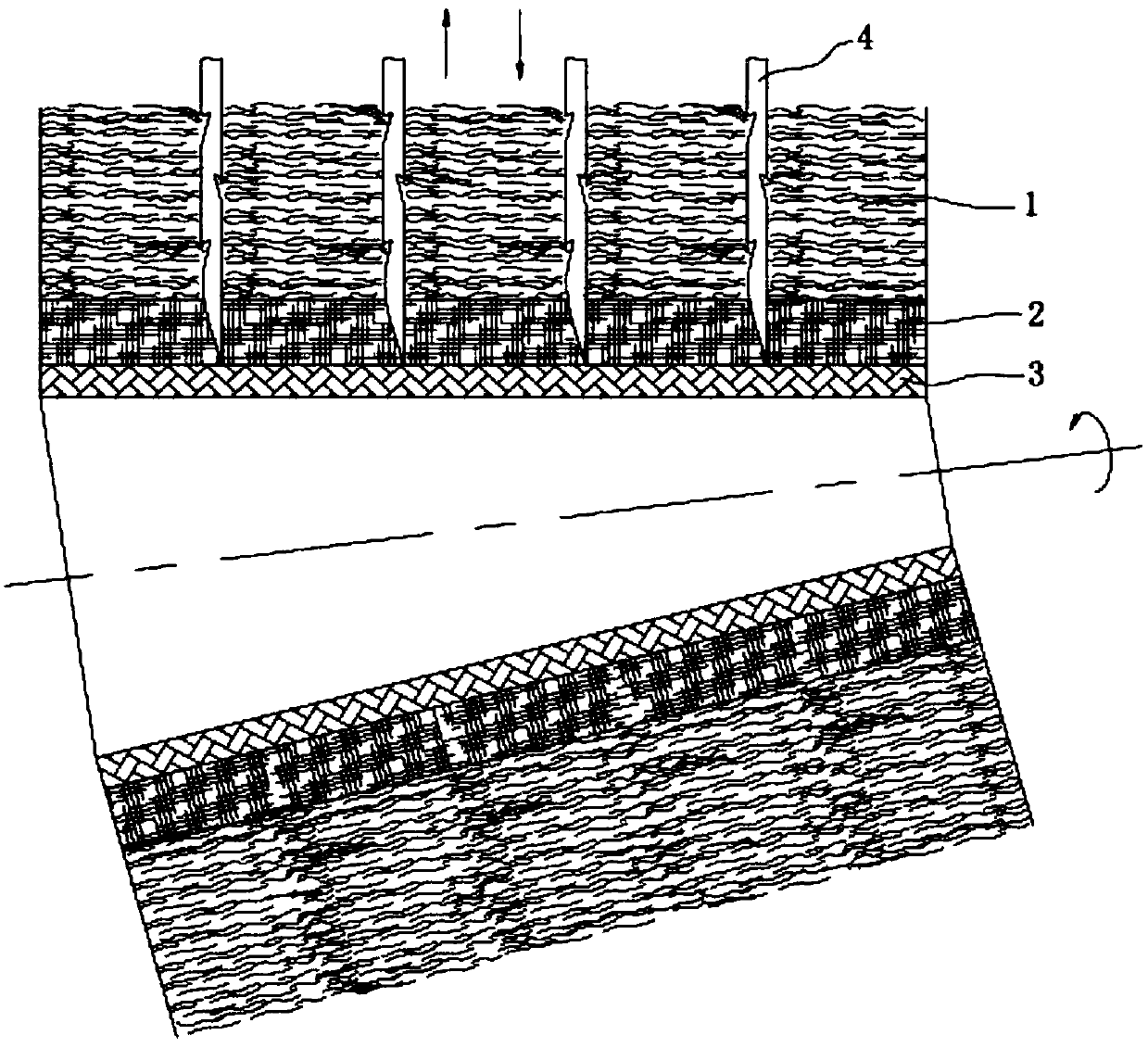

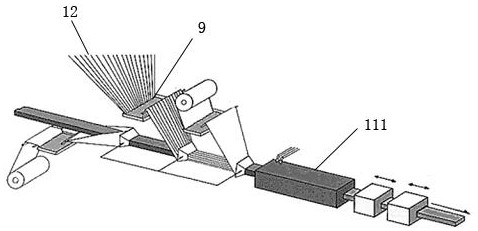

Hollow core sandwich rotary body fabric and application thereof

ActiveCN104499149AGood electrical performanceUniform wave transparencyRadiating element housingsMulti-ply fabricsHollow coreYarn

The invention discloses a hollow core sandwich rotary body fabric and application thereof. The hollow core sandwich rotary body fabric comprises an inner layer, a middle core layer and an outer layer from inside to outside in sequence, wherein the inner layer is formed by interweaving an inner layer warp system and an inner layer weft system; the outer layer is formed by interweaving an outer layer warp system and an outer layer weft system; the middle core layer is formed by interweaving a pile warp system with the inner layer weft system and the outer layer weft system respectively. The hollow core sandwich rotary body fabric disclosed by the invention is good in electrical property, light in weight and high in strength, and is relatively applicable to communication antenna covers; due to adoption of single yarns, the distribution and the movement modes of axial yarns among unit tissue structures of the hollow core sandwich rotary body fabric are all identical, and a composite material made of the fabric is uniform in wave transmissivity at different parts; the fabric can be used in a reinforced mobile communication antenna cover body which is made of a glass steel composite material of a hollow core sandwich structure, the dielectric constant epsilon of the fabric is less than 2, and the loss tangent tg delta of the fabric is less than 0.007.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Method for preventing electrostatic dust collection explosion venting in converter double-slag smelting process

InactiveCN107805683AAvoid explosive conditionsPrevent explosion ventingManufacturing convertersSmelting processNitrogen

The invention discloses a method for preventing electrostatic dust collection explosion venting in the converter double-slag smelting process. The method includes the steps that when lance carrying deslagging is carried out for the first time in the converter smelting process, an oxygen lance is carried to a fire hole for nitrogen flushing, and as for the volume contents of gases in a dust remover, nitrogen flushing is stopped after O2 is smaller than or equal to 6% and CO is smaller than or equal to 9%. According to the method, by optimizing the primary slagging gas supply system, the converter oxygen lance is used for nitrogen flushing, the volume content of O2 entering the electrostatic field dust remover after converting is stopped is controlled to be 6% or below, the explosion conditions of a gas mixture of CO and O2 are effectively evaded, and therefore explosion venting of the electrostatic field dust remover in converter double-slag operation can be avoided, and the effects ofstabilizing the converter production rhythm, reducing the damage to dust removing equipment and prolonging the service life are achieved. Meanwhile, the double-slag operation is adopted in a converter, P controllability of the converter is improved and the volume production needs of high-end branded steel are met.

Owner:HEBEI IRON AND STEEL

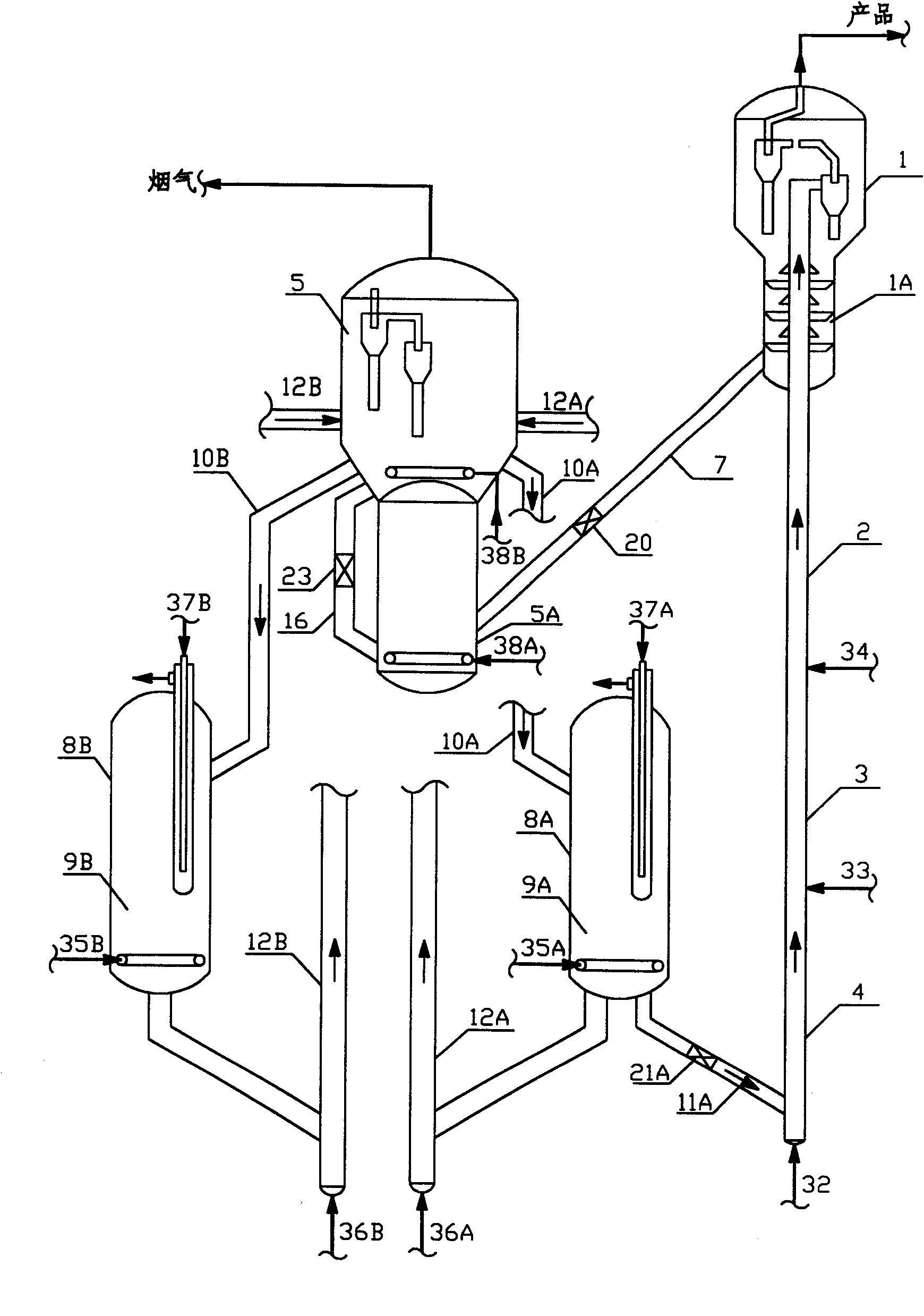

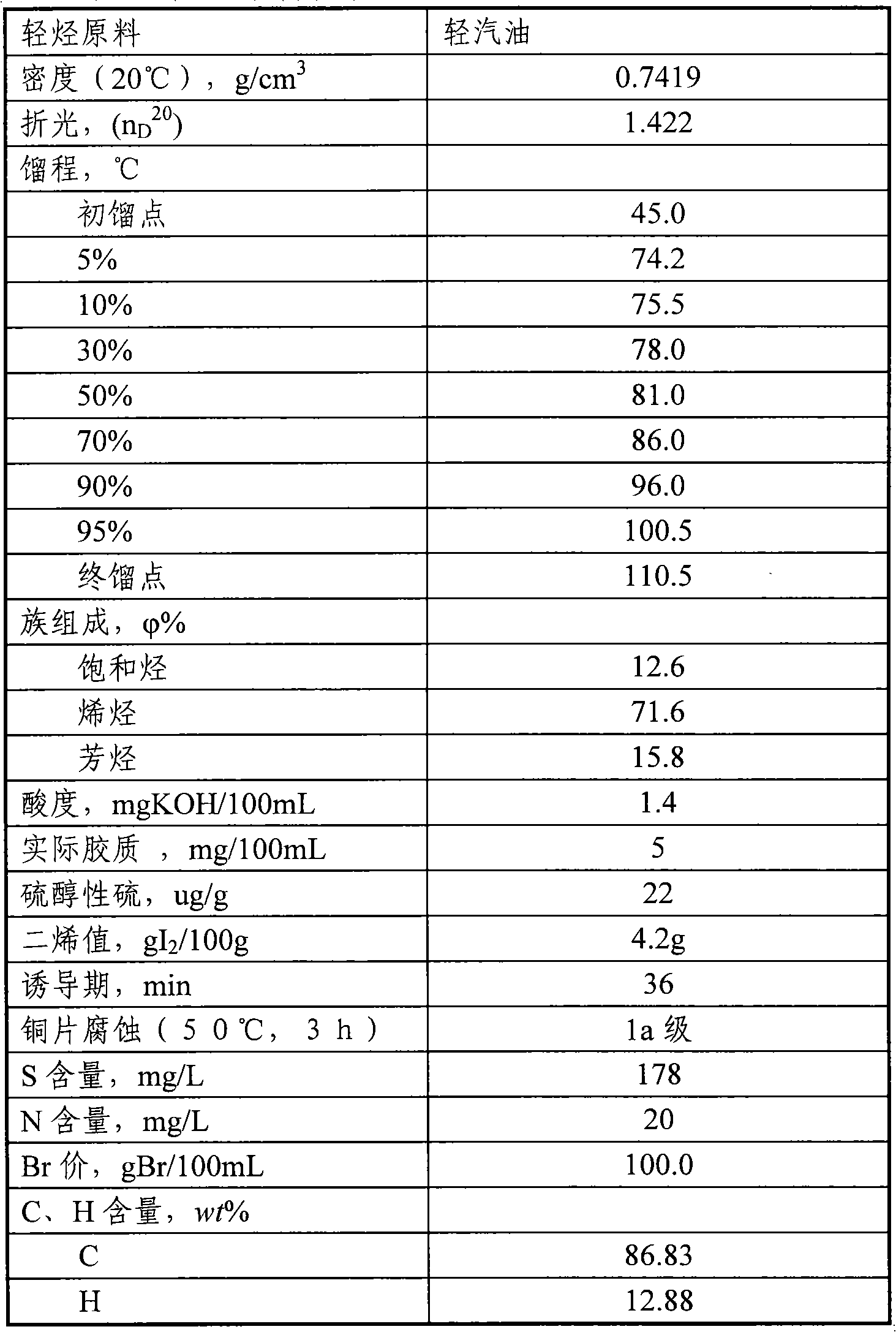

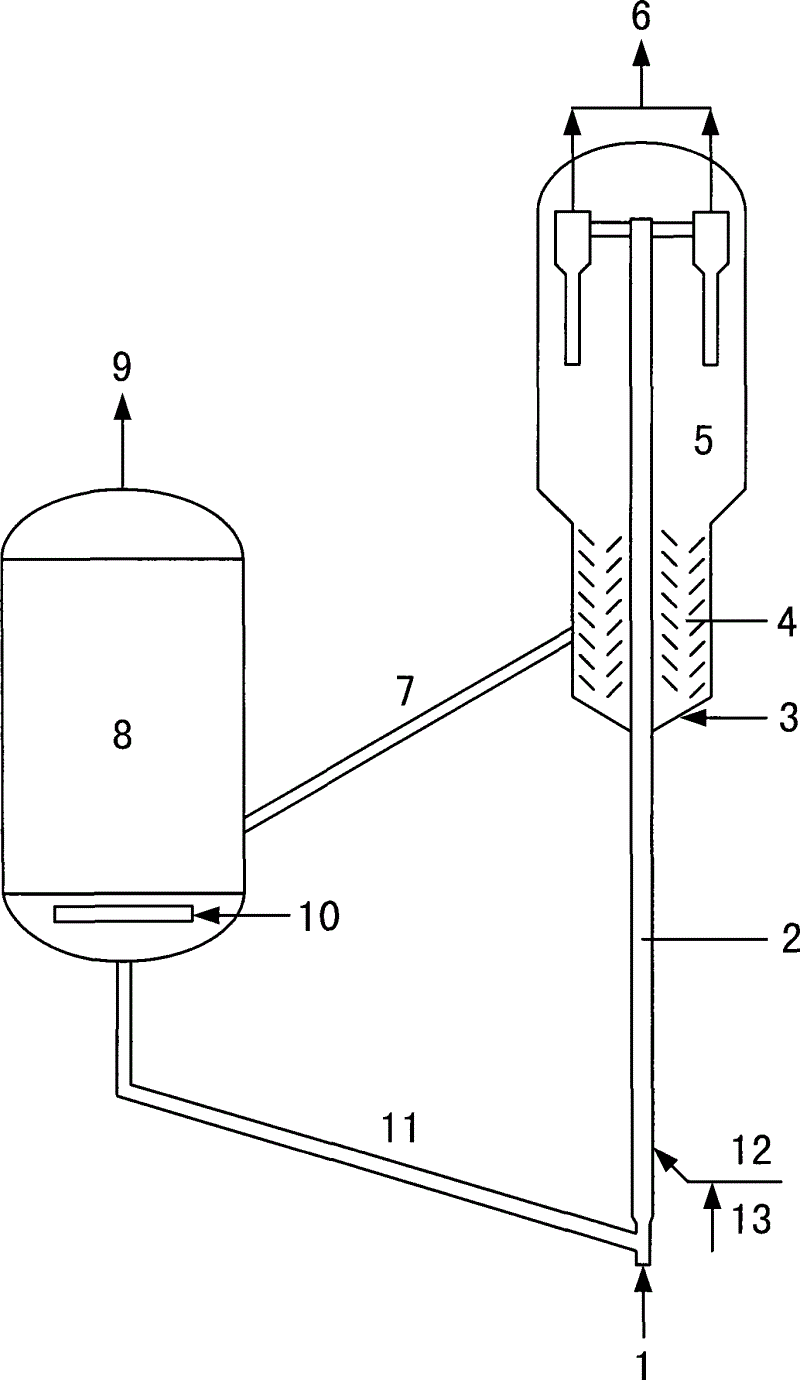

Method and apparatus for catalytic upgrading poor gasoline

InactiveCN1401742AVolume content reductionBoost octaneTreatment with plural serial stages onlyGasolineChemistry

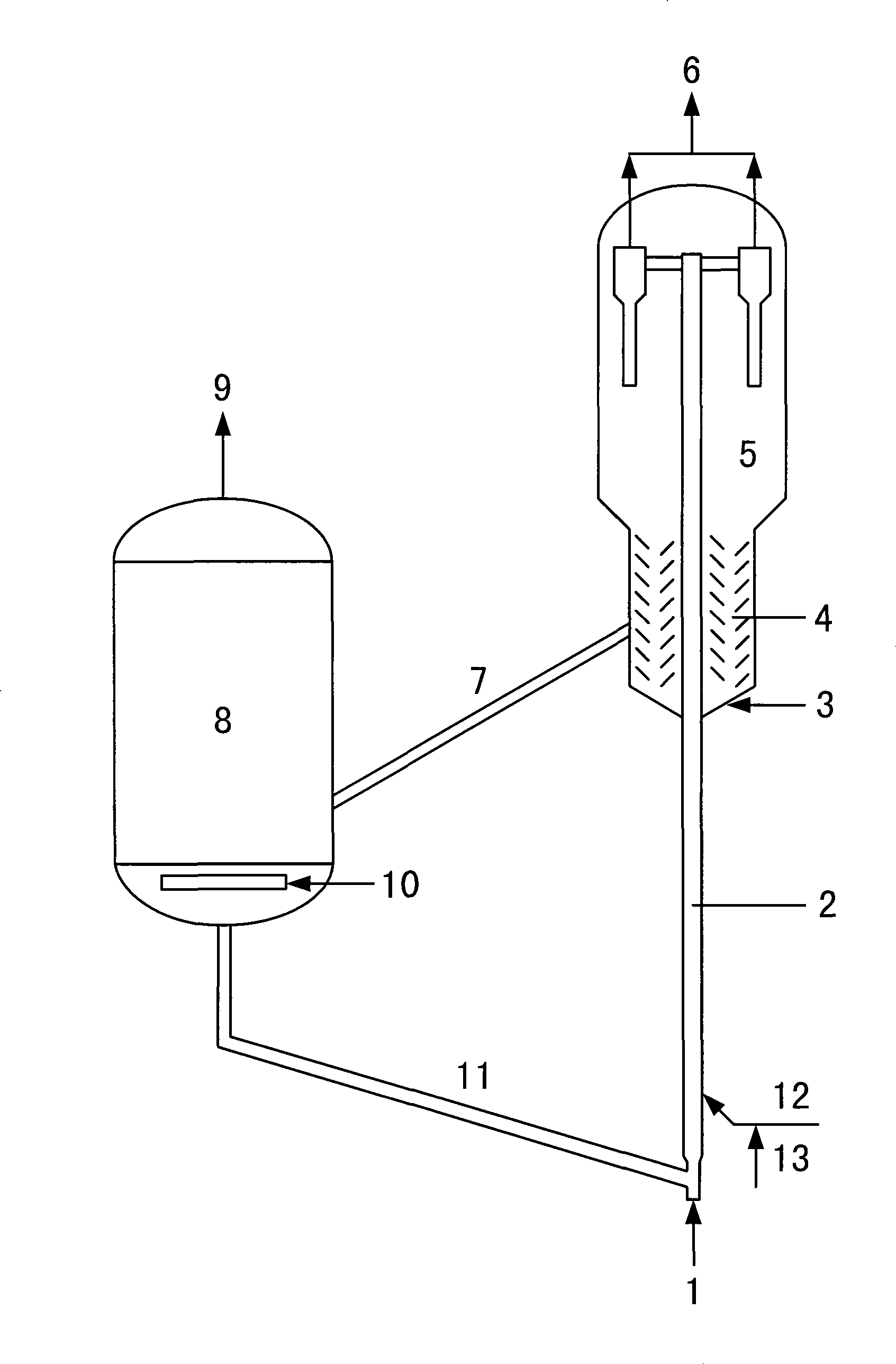

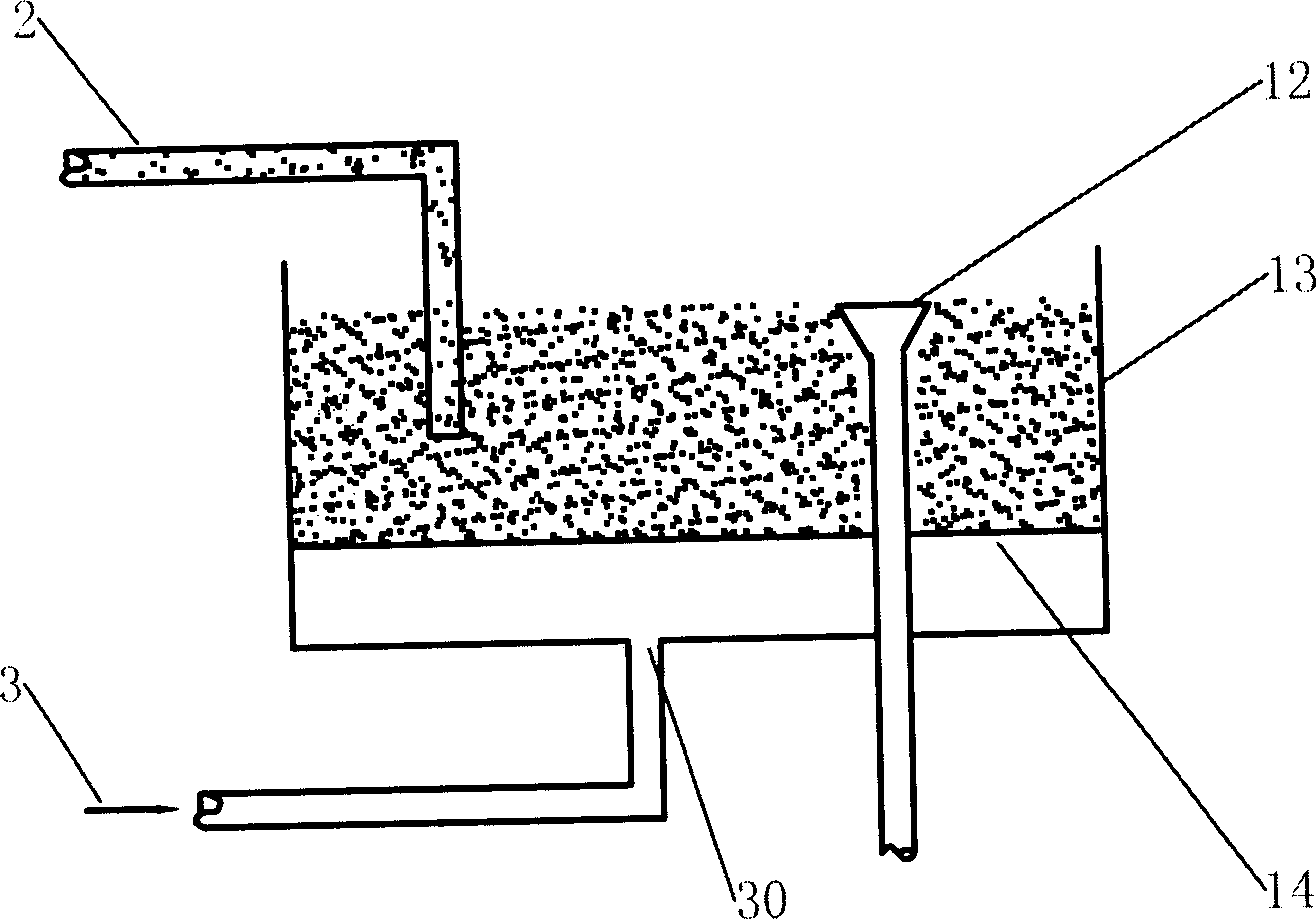

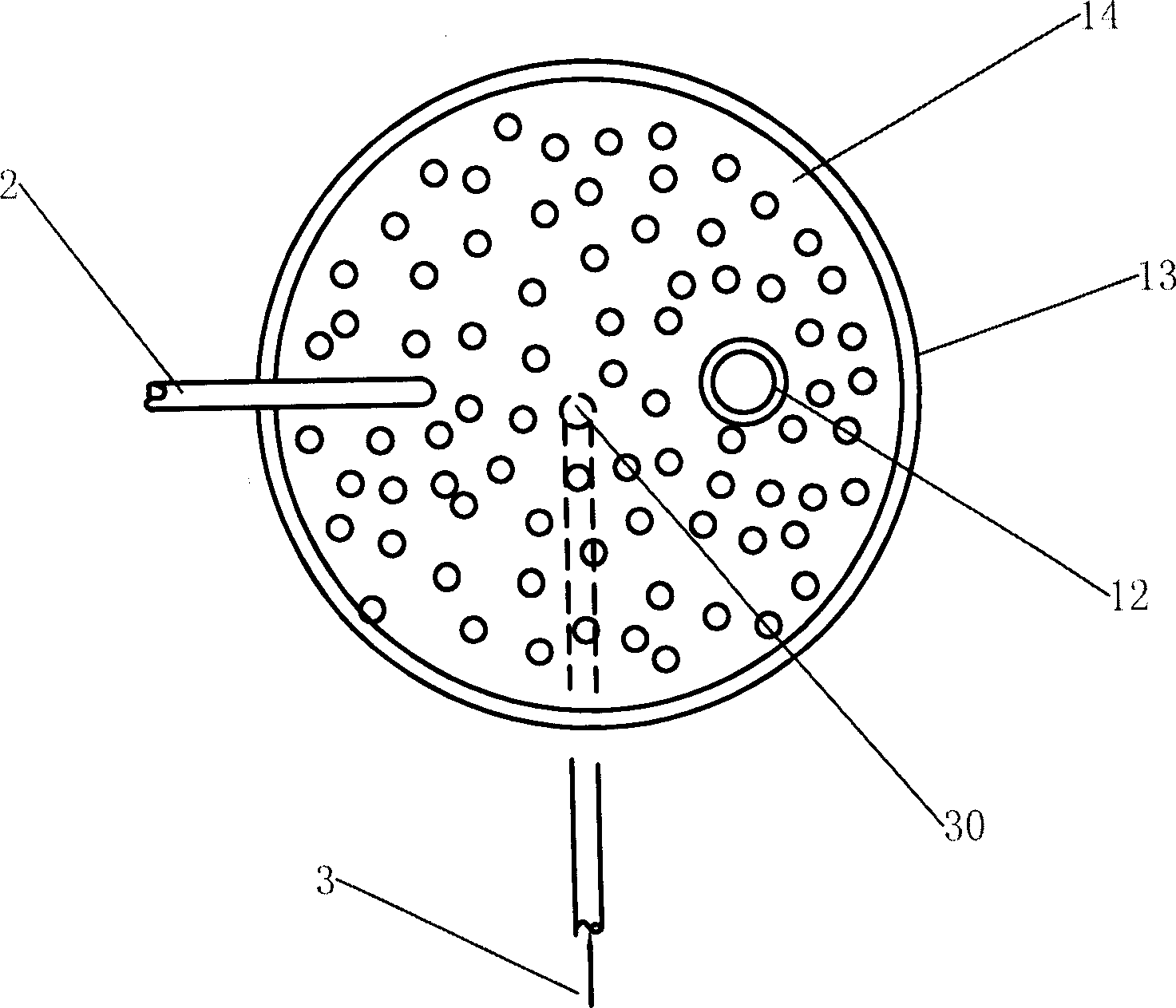

A catalytic process for upgrading the poor gasoline by used of the stripping zone of settling unit in catalytic cracking apparatus includes cooling the regenerated catalyst to 300-550 deg.C, feeding the mixture of regenerated catalyst and the catalyst to be regenerated into said stripping zone, and counterflow contact of said mixture and the poor gasoline in the stripping zone for upgrading at 350-550 deg.C and 0.1-0.4 MPa for 0.5-3 seconds. It can decrease olefine content by 15-45% and S content by 10-30%, and increase RON by 0.5-2 unit.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

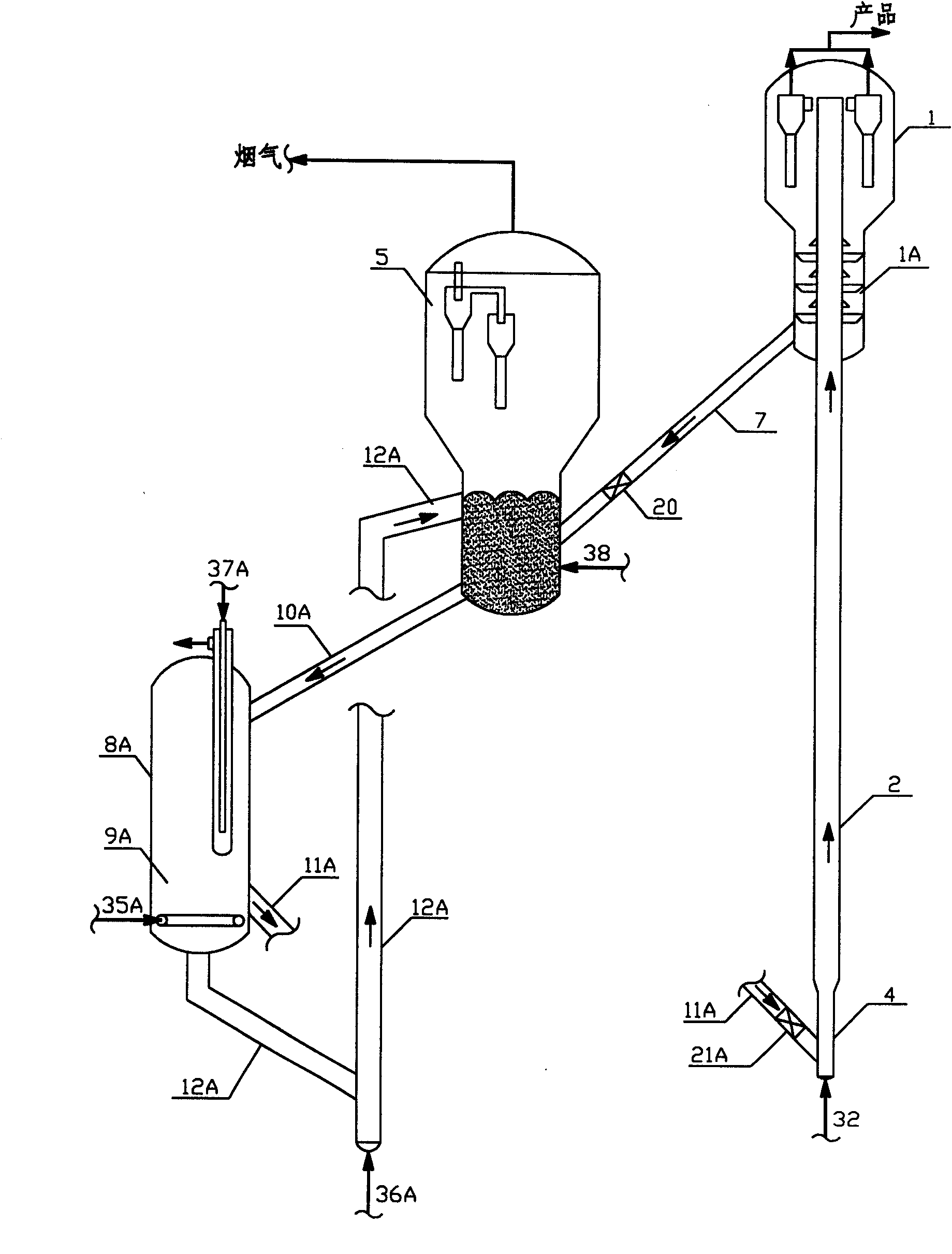

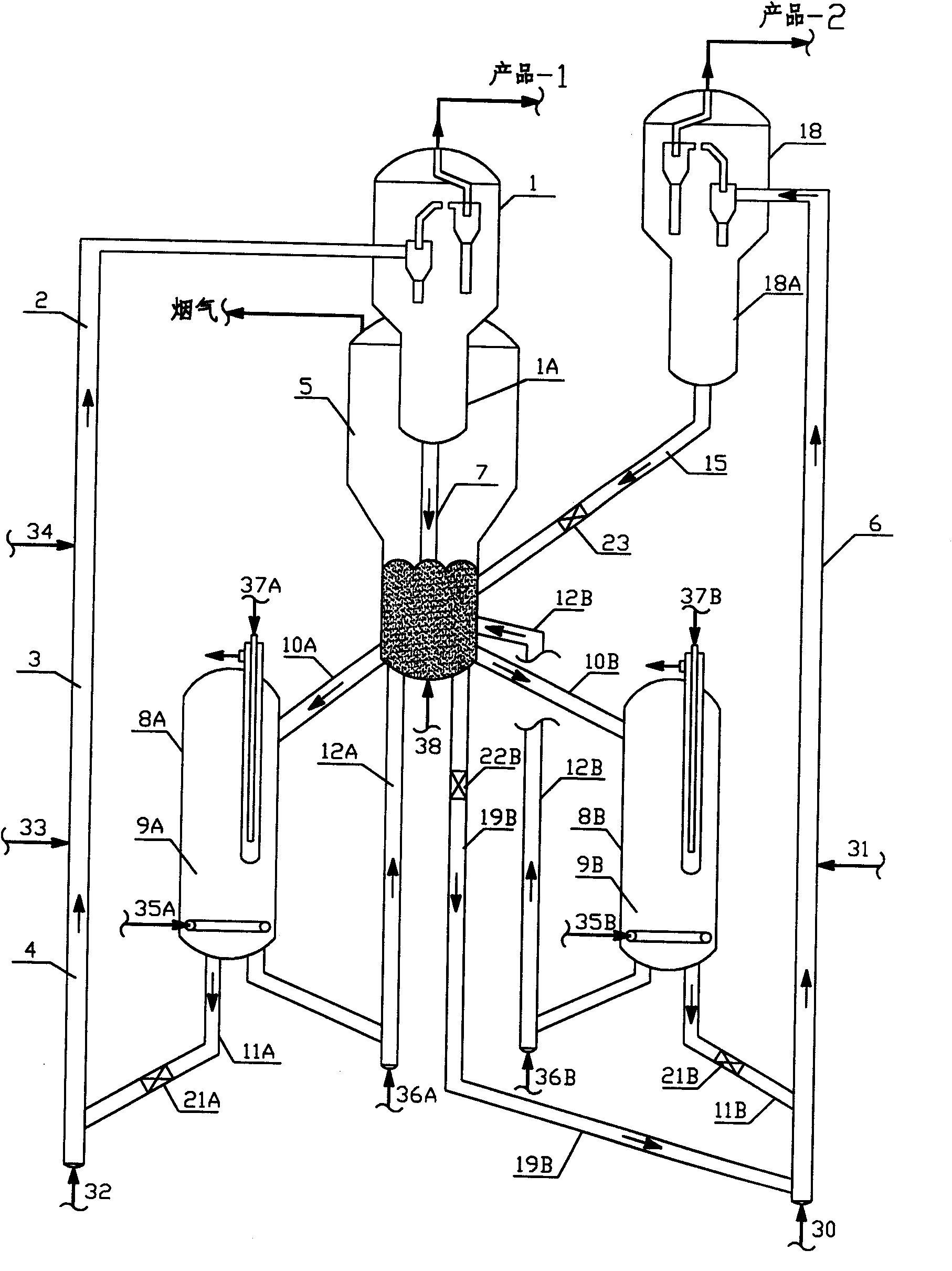

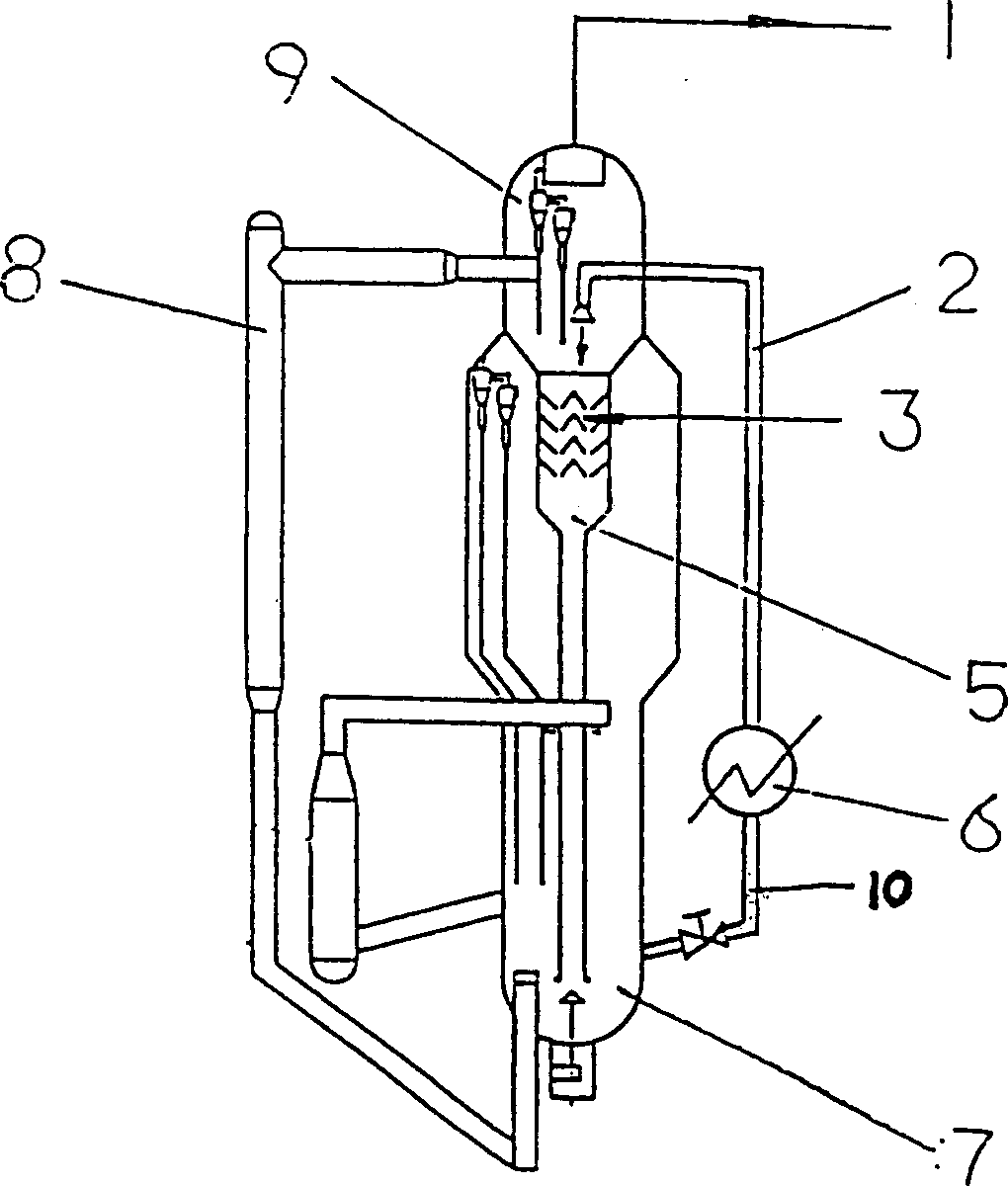

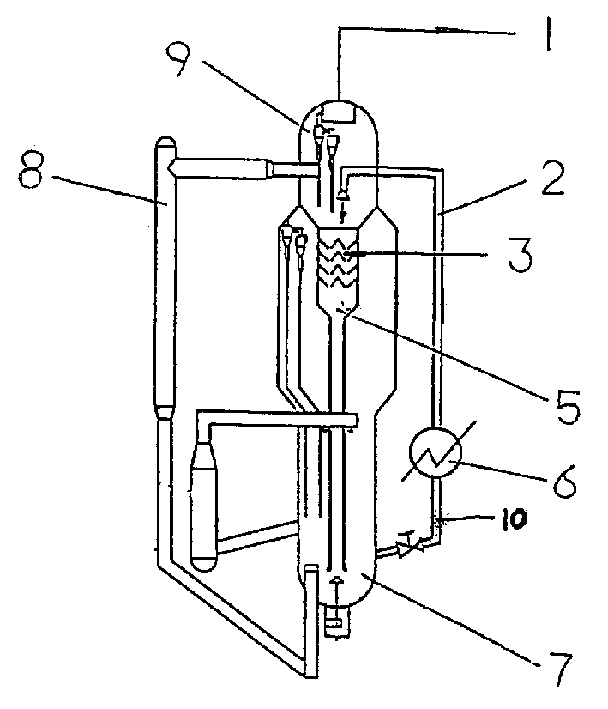

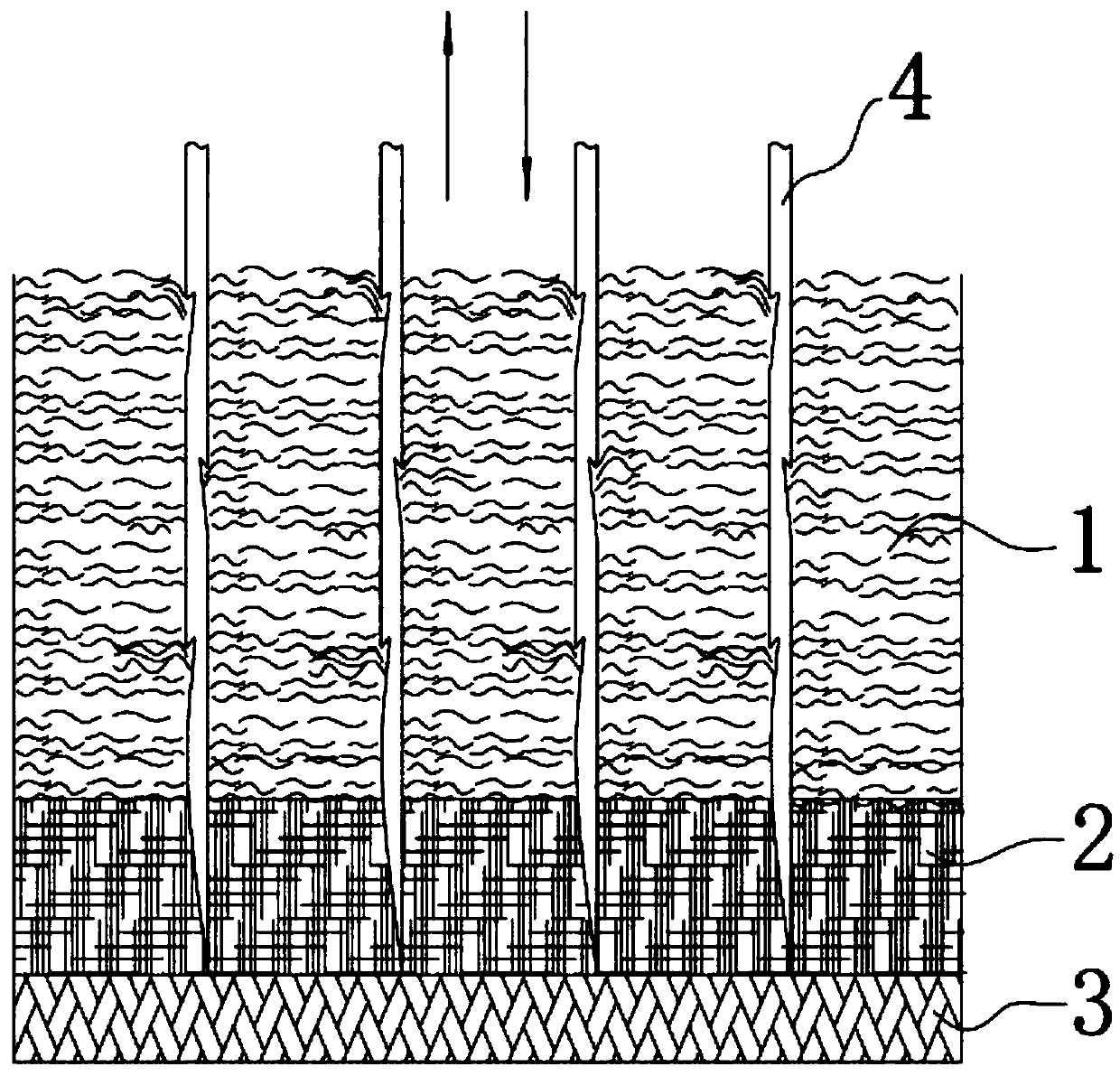

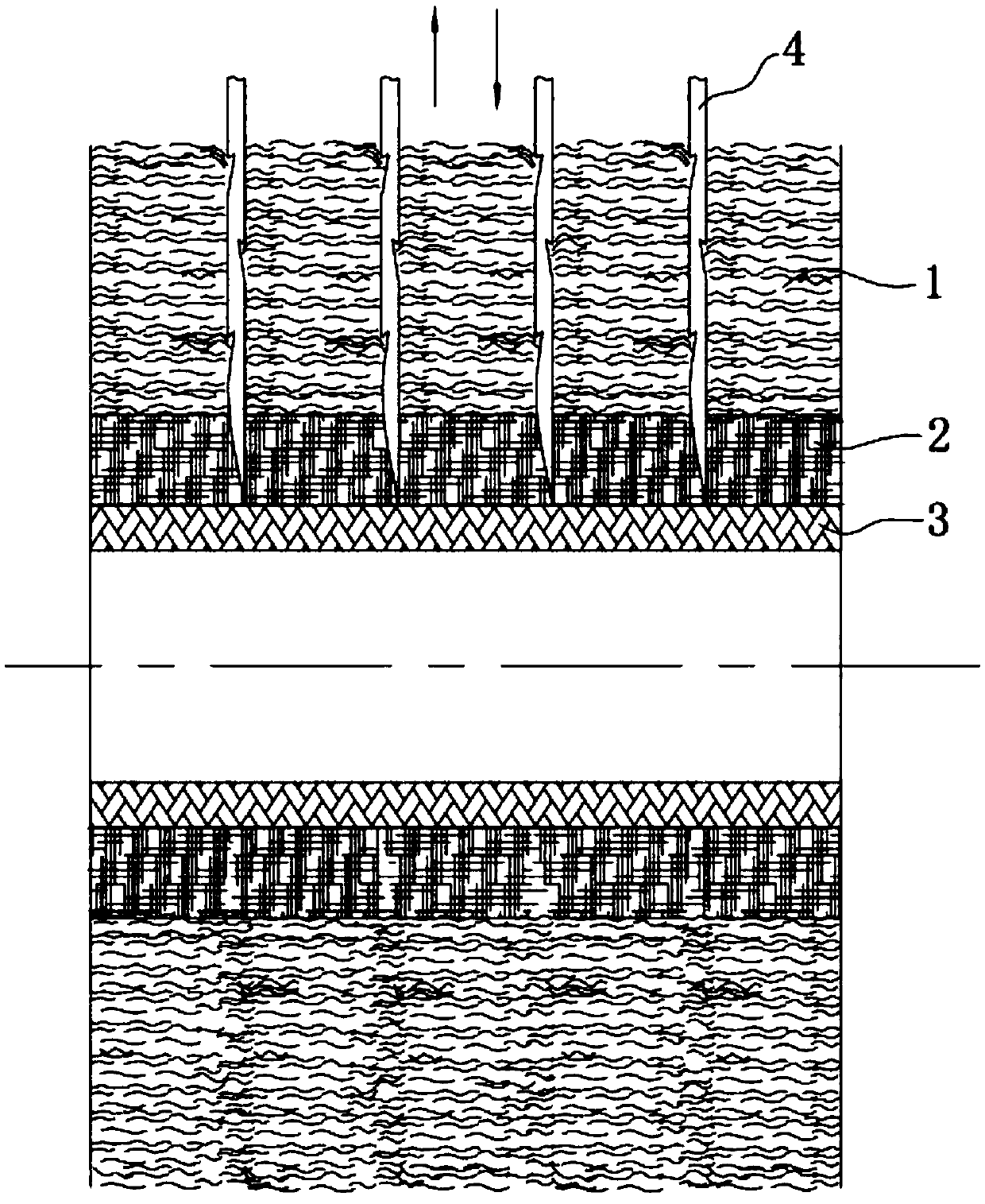

Method and apparatus for catalytic modification of poor gasoline

InactiveCN1470605AReduce sulfur contentVolume content reductionCatalytic crackingGasolineLower grade

The present invention discloes a method for catalytic upgrading low-grade gasoline, said method include a fluidized catalytic cracking process, and is characterized by that the partial regenerated catalyst is led out from regenerator, and passed through catalyst coveying pipe and injected into the bed reactor over stripper zone of the settler, and the low-grade gasoline is fed into the bed reactor and contacted with catalyst bed to implement catalytic upgrading treatment of low-grade gasoline. The olefine volume content of the upgraded gasoline can be reduced by 20-50 %, and sulfur content can be reduced by 10-35%.

Owner:CHINA PETROCHEMICAL CORP +1

Method for modifying low-grade gasoline

ActiveCN1283762CHigh yieldReduce hydrogen consumptionTreatment with hydrotreatment processesHydrogenLower grade

The invention discloses a method for modifying low-quality gasoline. The low-quality gasoline is cut into light and heavy fractions, wherein the light fraction accounts for 10-50% by weight, and the rest is heavy fractions. The distillate is mixed with hydrogen first, and then contacted with a pre-hydrogenation catalyst. The pre-hydrogenated oil is contacted with a hydrogenation catalyst for hydrotreating. The hydrotreated oil is then washed with alkali to remove the light fraction of mercaptans. Mixed to get the product gasoline. When the method is used to treat the catalytic cracking gasoline, the sulfur content of the gasoline can be reduced below 150 μg / g, the olefin content can be reduced by 15-30 percentage points, and the gasoline anti-knock index can be increased by 0.1-2.0 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Method and apparatus for catalytic upgrading poor gasoline

InactiveCN1177020CVolume content reductionBoost octaneTreatment with plural serial stages onlyPtru catalystPhysical chemistry

A catalytic process for upgrading the poor gasoline by used of the stripping zone of settling unit in catalytic cracking apparatus includes cooling the regenerated catalyst to 300-550 deg.C, feeding the mixture of regenerated catalyst and the catalyst to be regenerated into said stripping zone, and counterflow contact of said mixture and the poor gasoline in the stripping zone for upgrading at 350-550 deg.C and 0.1-0.4 MPa for 0.5-3 seconds. It can decrease olefine content by 15-45% and S content by 10-30%, and increase RON by 0.5-2 unit.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Fabric punched felt complex and preparation method thereof

ActiveCN103879076AEquivalent mechanical propertiesImprove mechanical propertiesGlass/slag layered productsNatural mineral layered productsIntensity changeEngineering

The invention provides a fabric punched felt complex and a preparation method thereof. The preparation method comprises the following steps: compounding a continuous functional fiber fabric layer and a continuous functional fiber bulked yarn crude fabric layer together so as to obtain integrated fabric; then compounding a chopped functional fiber punched felt layer with the continuous functional fiber bulked yarn crude fabric layer of the integrated fabric through needling so as to obtain the fabric punched felt complex. The fabric punched felt complex has a light and high strength structure with stepped intensity changes. The weight of the fabric punched felt complex is 30% lighter than that of complete fabric with a same volume, while the mechanical performance of the fabric punched felt complex is equal to that of complete fabric with a same volume, and is better than that of complete chopped fiber punched felt. At the same time the fiber raw material is saved by 30% or more, moreover the preparation technology is simple, and the production period is short.

Owner:HUNAN JIUHUA CARBON HI TECH

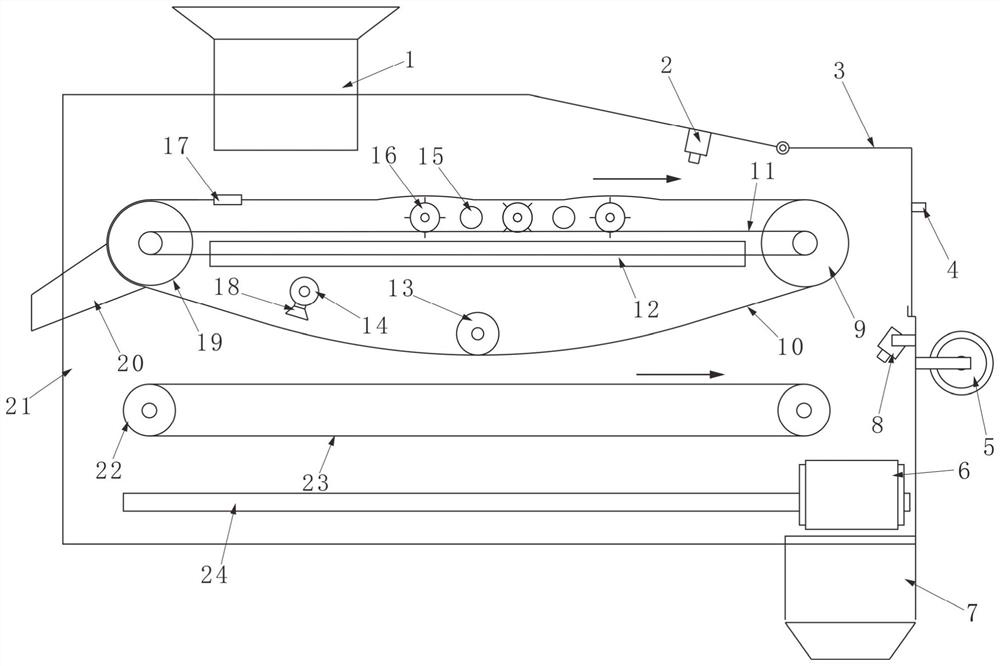

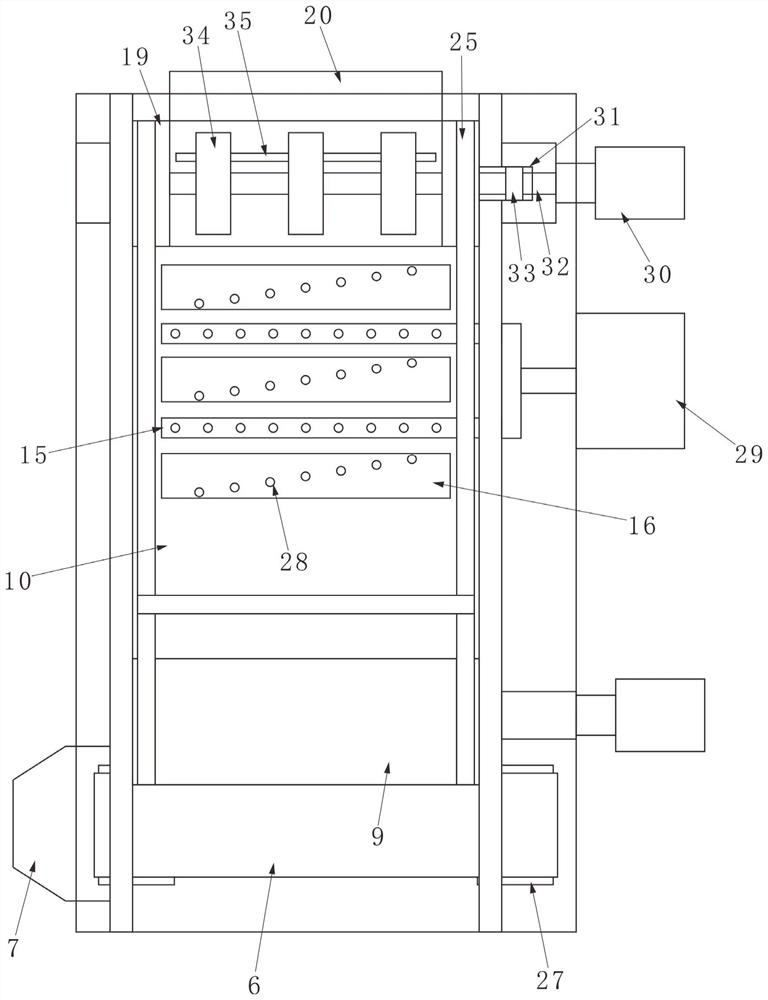

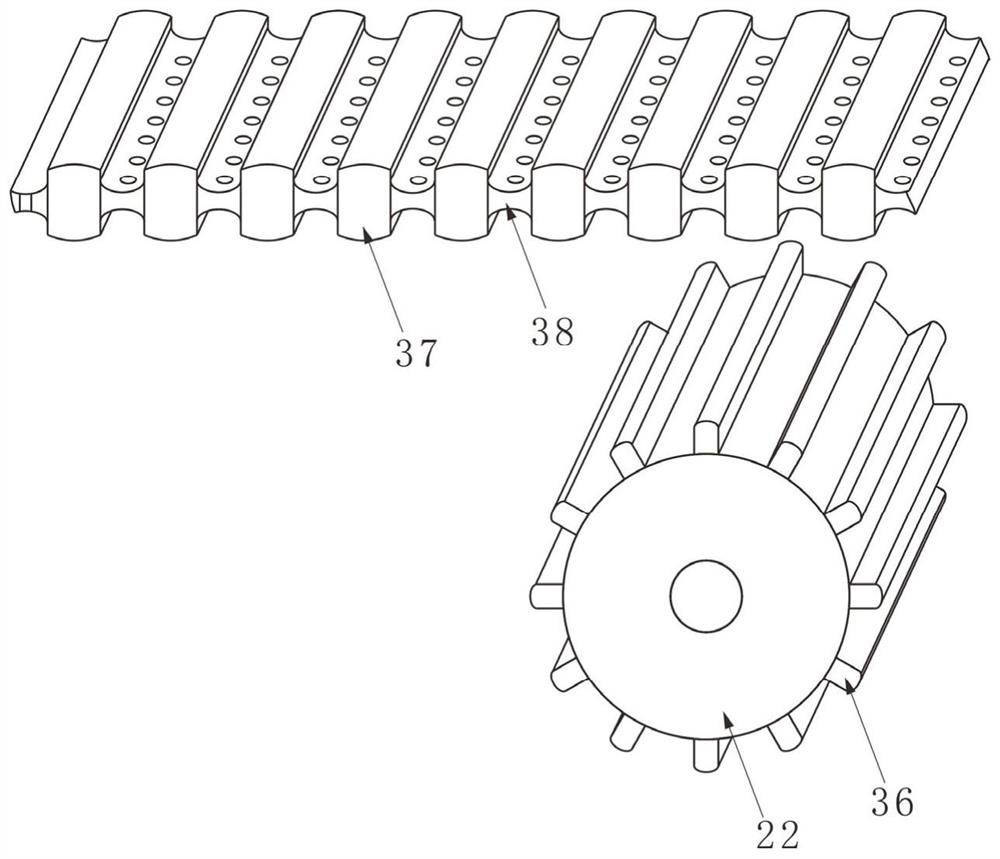

Drilling mud negative pressure screen

PendingCN112791495AEasy to controlReduce riskMoving filtering element filtersWorking environmentEngineering

The invention discloses a drilling mud negative pressure screen which comprises a screen body shell, a mud inlet is formed in the upper end of the screen body shell, a screening device is arranged below the mud inlet and comprises a horizontal soft screen, and the two ends of the screen are wound around a first winding drum and a second winding drum respectively. A plurality of vibration cylinders are arranged between the first winding drum and the second winding drum and located between the two layers of screens, a plurality of negative pressure exhaust pipes are arranged among the vibration cylinders in a crossed mode, and the negative pressure exhaust pipes are connected with a first negative pressure device; a first water receiving disc is arranged below the vibration cylinder and the negative pressure exhaust pipe, and is communicated with a slurry discharging opening in the screen body shell; a conveying belt is arranged below the first winding drum and located above the discharging port. The scheme can enhance oil well control and reduce environmental risks. Completely closed processing is performed, the air negative pressure principle and the conveying belt are adopted, oil mist emission is avoided, noise generated by low-frequency vibration is avoided, and the working environment can be effectively improved.

Owner:四川宝石机械石油钻头有限责任公司

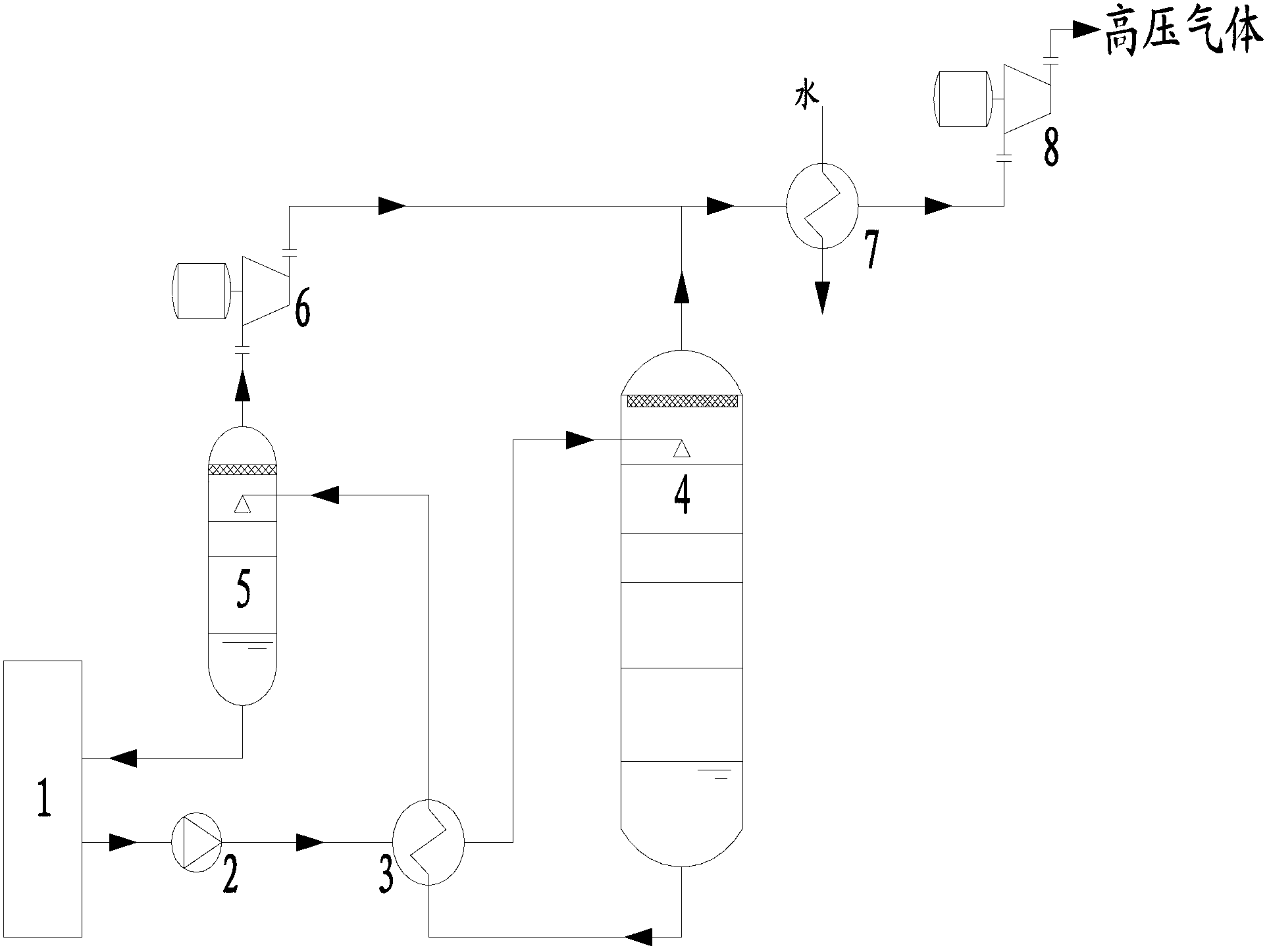

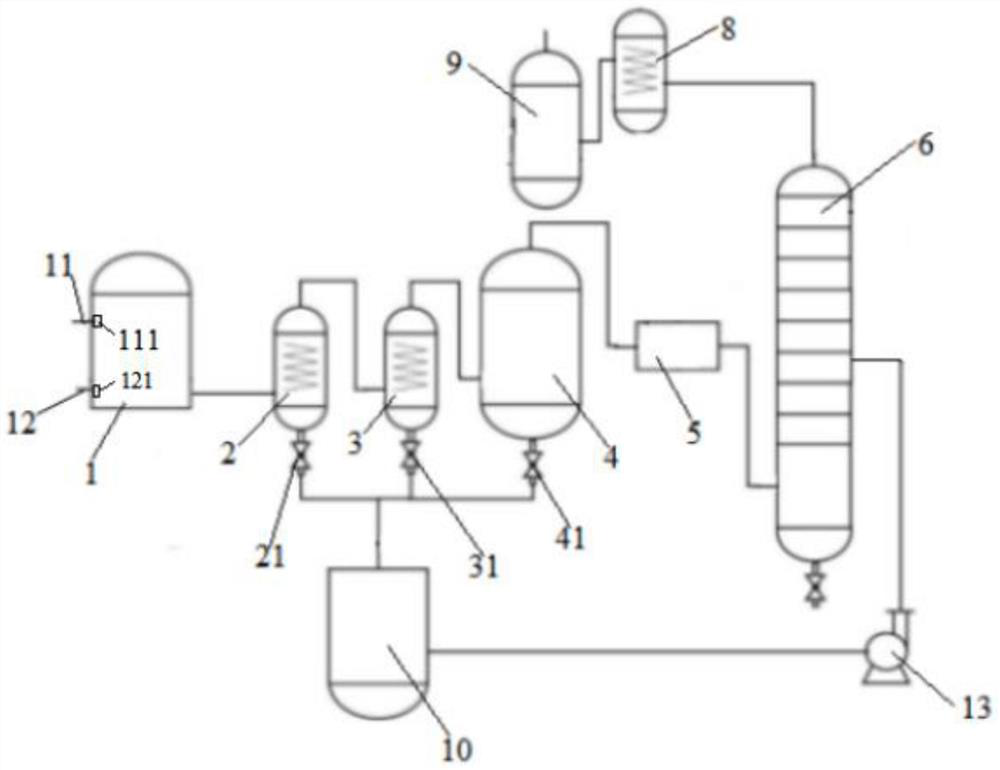

High and medium pressure regeneration system for flue gas decarbonization

The invention discloses a high and medium pressure regeneration system, which comprises a medium pressure regeneration tower and a high pressure liquid pump which are connected with an absorption device, a lean-rich liquid heat exchanger connected with the high pressure liquid pump, a high pressure regeneration tower and a medium pressure regeneration tower which are connected with the lean-rich liquid heat exchanger, a carbon dioxide supercharger connected with the medium pressure regeneration tower, a carbon dioxide cooler which is merged and communicated with the top of the high pressure regeneration tower and the carbon dioxide outlet of the carbon dioxide supercharger, and a carbon dioxide compressor communicated with the carbon dioxide cooler. The system can be used for boilers in coal-fired power plants and the field of chemical engineering, and has a characteristic of regenerating carbon dioxide under high and medium pressure; the regenerated carbon dioxide only requires low compression work and can be compressed to have the pressure suitable for storage, while the energy consumed by the high pressure pump for improving liquid pressure is much less than compressed air; meanwhile, the medium pressure regeneration tower is added behind the high pressure regeneration tower, the regeneration degree of a solution is further improved and the desorption of the carbon dioxide is promoted.

Owner:HUANENG CLEAN ENERGY RES INST

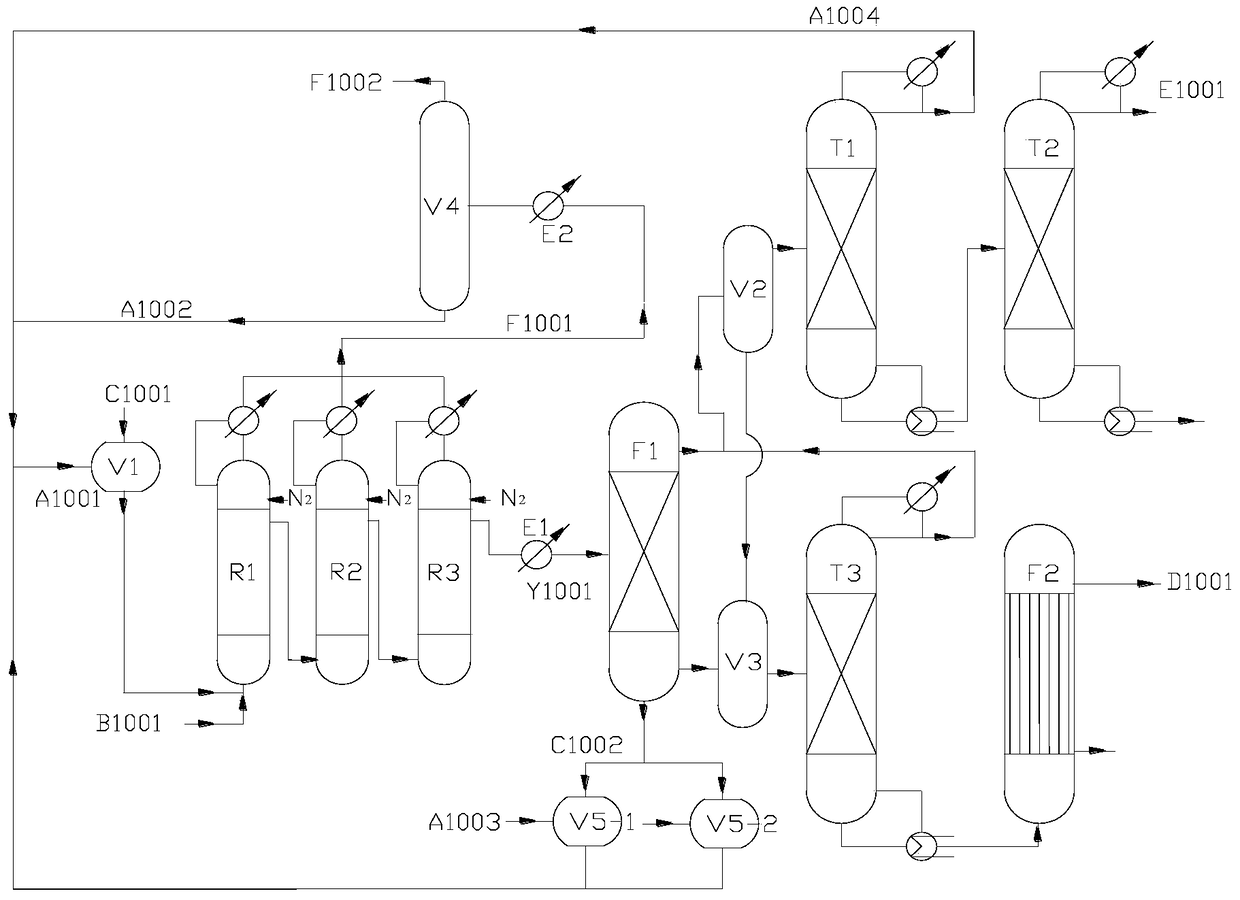

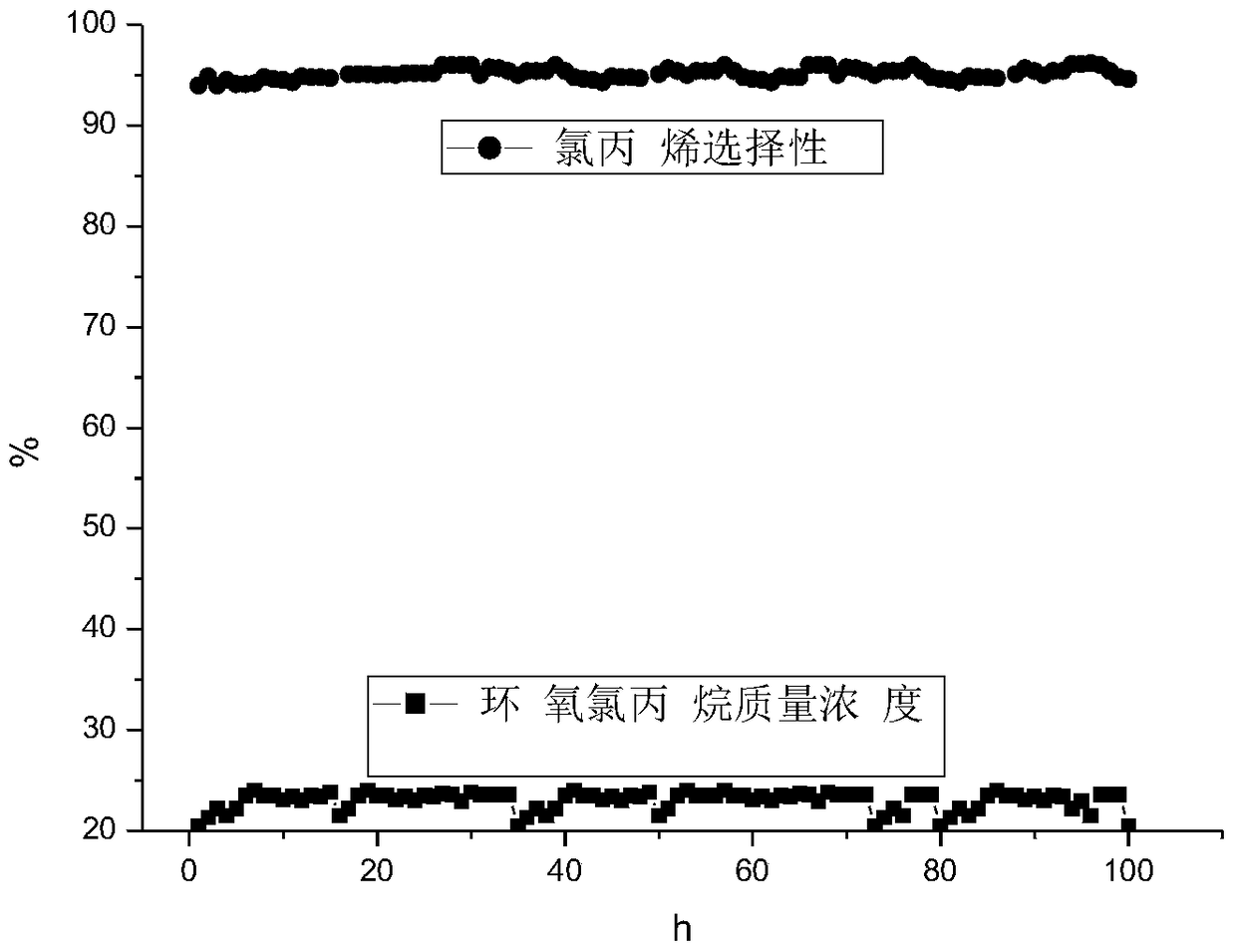

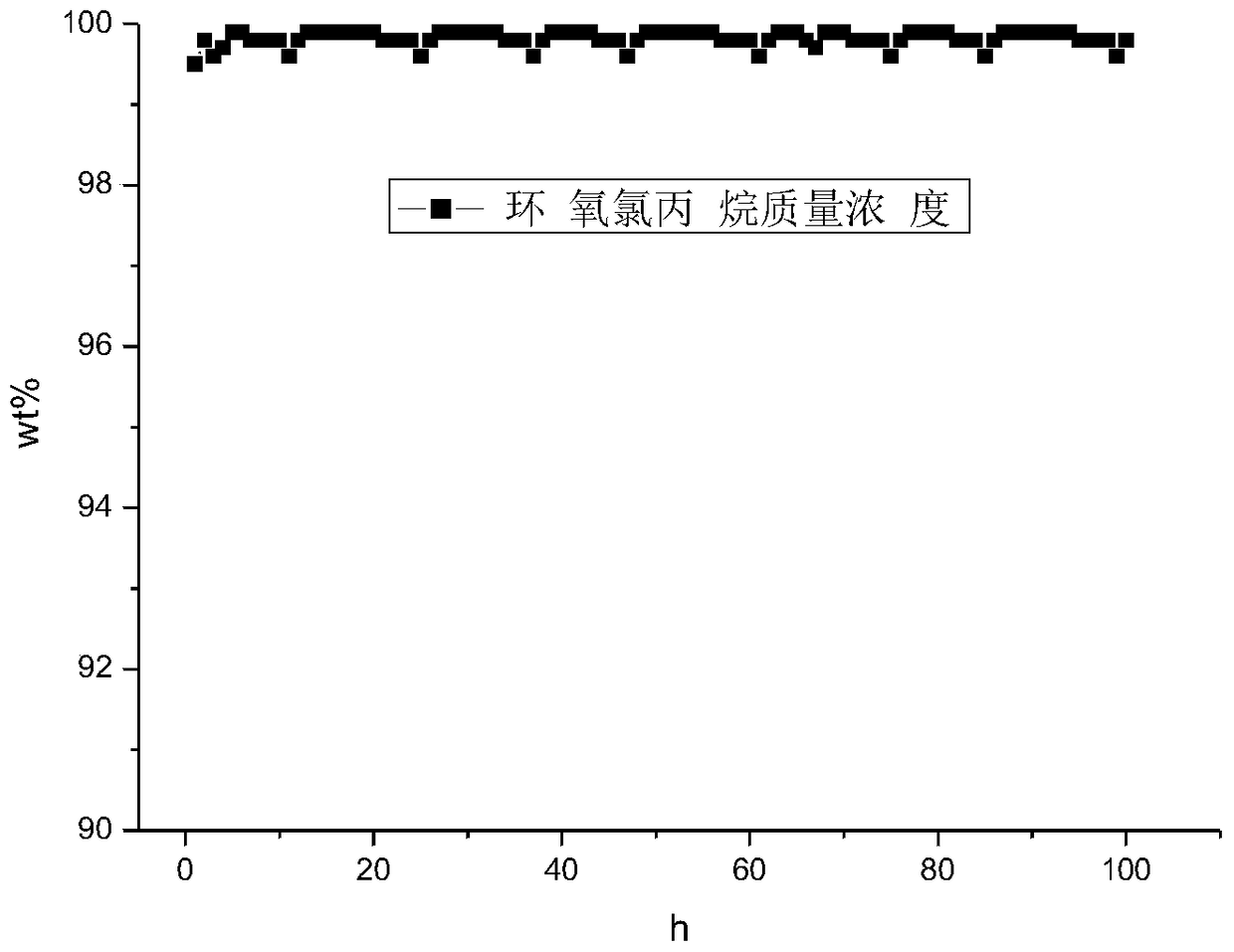

A kind of technological process of producing epichlorohydrin by epoxidation of propylene chloride

ActiveCN105712955BReduce lossesLow oxygen volume contentOrganic chemistryChemical recyclingHigh energyOil phase

A process flow for producing epichlorohydrin by epoxidation of propylene chloride provided by the present invention, including a reaction part, a separation part and a tail gas treatment part, is characterized in that phosphotungstic heteropolyacid quaternary ammonium salt is used as a catalyst and hydrogen peroxide is used as an oxidant , to prepare epichlorohydrin by epoxidation of propylene chloride under the condition of inert gas pressure. The materials produced by the reaction are separated by a three-phase separator to separate the oil phase, water phase and solid phase catalyst; the oil phase passes through the chloropropene tower to recover the chloropropene, and then passes through the epichlorohydrin tower to separate the product epichlorohydrin and by-product di Chloropropanol; the water phase is passed through the water refining tower to separate the by-product monochloropropanediol, and then discharged after membrane filtration; the solid-phase catalyst is recycled to the catalyst slurry tank after re-dosing. The technological process provided by the present invention is simple, less three wastes, high energy and low, and mild reaction conditions, and is suitable for the industrial production of epichlorohydrin.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

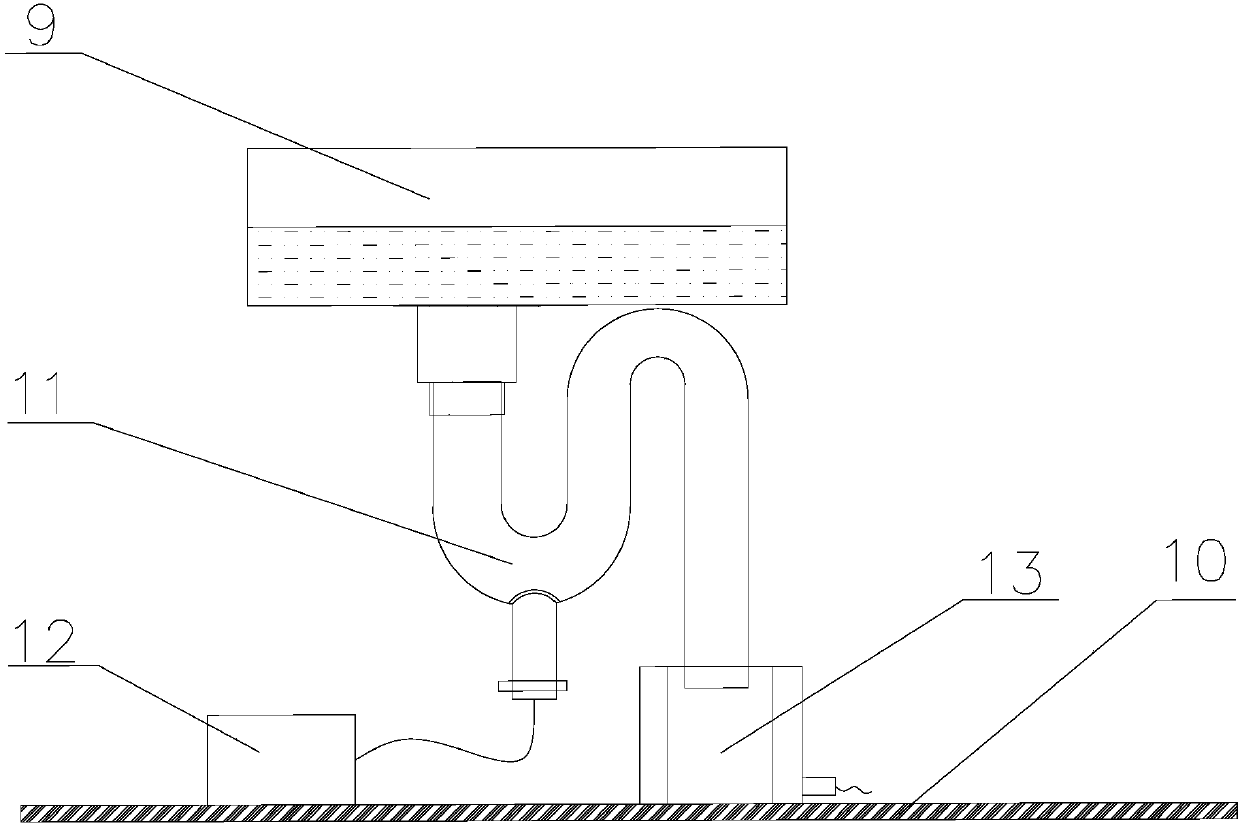

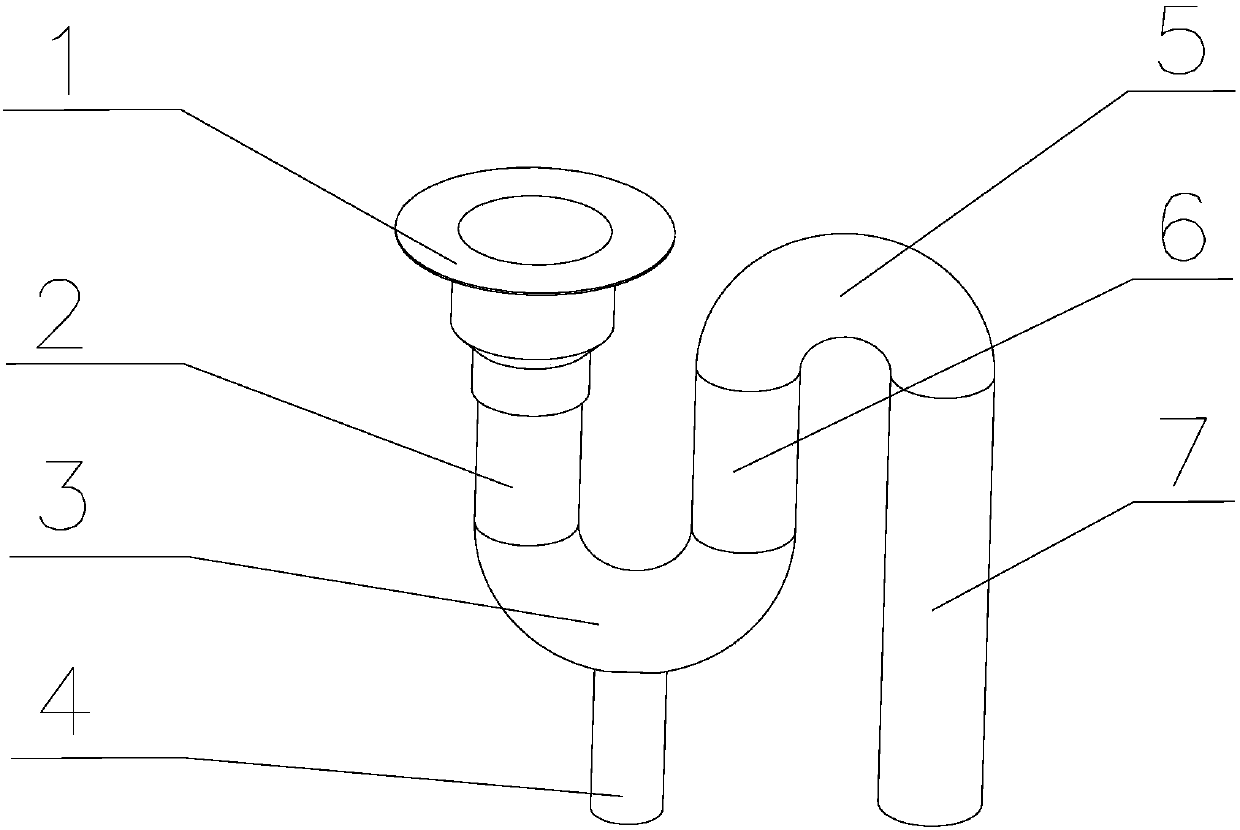

High-water-oil ratio catering liquid waste grease collecting device and high-water-oil ratio catering liquid waste grease collecting method

The invention discloses a high-water-oil ratio catering liquid waste grease collecting device and a high-water-oil ratio catering liquid waste grease collecting method, belonging to the technical field of kitchen waste oil collection. The device comprises a Y-shaped washing pool discharging connection pipe fitting including a U-shaped connection pipe, and an oil-water separator. The Y-shaped washing pool discharging connection pipe fitting including the U-shaped connection pipe is used for preprocessing catering liquid waste before the catering liquid waste enters the oil-water separator, andcan directly shunt most part of catering liquid waste in a washing pool into a discharging pipeline, so as to bring most part of grease into the oil-water separator. According to the high-water-oil ratio catering liquid waste grease collecting device, the Y-shaped washing pool discharging connection pipe fitting including the U-shaped connection pipe is additionally arranged between the washing pool and the oil-water separator, and through the tee-joint pipeline shunting principle and U-shaped communicating vessel principle, kitchen waste oil in dish water and pot washing water can be collected maximally, the minimum workload of the oil-water separator is realized, and the revenue maximization of the device can be achieved.

Owner:成都蔚蓝星生物科技有限公司

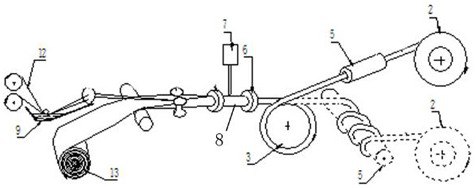

Continuous deformation composite material profile and preparation method thereof

The invention discloses a continuous deformation composite material profile and a preparation method thereof. The preparation method comprises the following steps in sequence: S1, impregnating continuous longitudinal fibers with resin to obtain prepreg, and continuously welding or extruding metal to obtain a tube blank; S2, continuously bringing the prepreg into the tube blank to obtain a materialto be deformed; S3, synchronously driving the prepreg and the tube blank of the material to be deformed, changing the section of the tube blank through a drawing or rolling process or / and deforming the spatial form of the tube blank through a mold to obtain continuous materials to be formed with the same or different spatial forms; and S4, heating the materials to be formed to obtain the continuous deformation composite material profile with the same or different spatial forms, wherein the continuous deformation composite material profile comprises a core material formed by crosslinking and curing the prepreg and an armor layer formed by deforming the tube blank. The continuous deformation composite material profile can be continuously prepared, and the availability of the continuous deformation composite material profile can guarantee the value engineering design requirement of a composite material needing to integrate various performance requirements.

Owner:JIANGSU YIDING COMPOSITE TECH CO LTD

Cold rolling method for beta titanium alloy thin plate

ActiveCN108906890AAvoid elevationAvoid the situationMetal rolling arrangementsBeta phaseRoom temperature

The invention discloses a cold rolling method for a beta titanium alloy thin plate. The method includes the first step of placing a beta titanium alloy thin plate blank into a vacuum annealing furnacefor vacuum annealing at the temperature of 10 DEG C to 20 DEG C below the beta phase transformation point and then controlling the cooling rate and cooling to the room temperature; the second step ofconducting segment rolling on the cooled beta titanium alloy thin plate blank with a small-convexity cold rolling roll to obtain the beta titanium alloy thin plate in the target size. According to the method, the beta titanium alloy thin plate blank is subjected to vacuum annealing at the temperature of 10 DEG C to 20 DEG C below the beta phase transformation point, and the cooling rate is controlled, so that the primary alpha phase is sufficiently grown, and the residual beta phase volume content is reduced. The fact that the second phase precipitates too much and strengthens the alloy whichis then not easy to machine in the process of cooling to the room temperature with the furnace is avoided. By segment rolling, the orientation of most alpha phases tends to be uniform, and the defectlike cracking caused by uncoordinated deformation during the subsequent rolling process is overcome. The problem that the beta titanium alloy is difficult roll after the vacuum annealing is solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

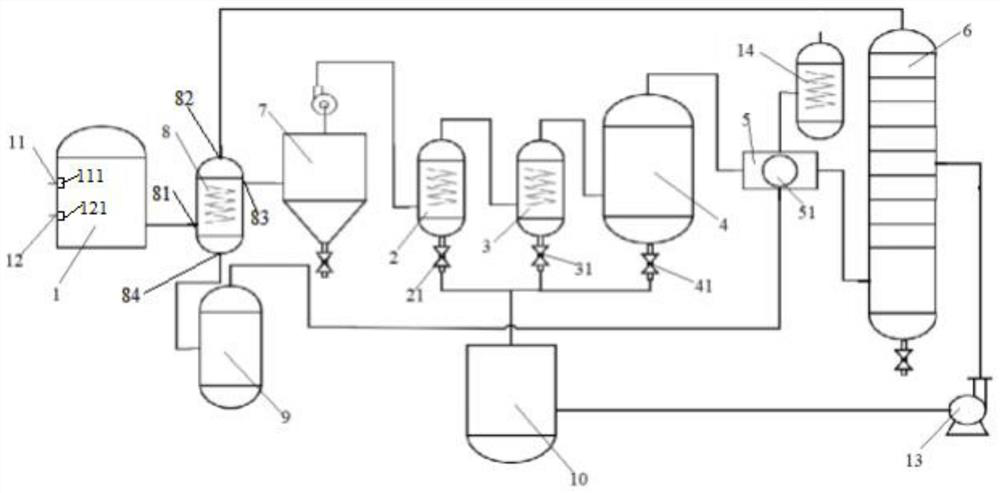

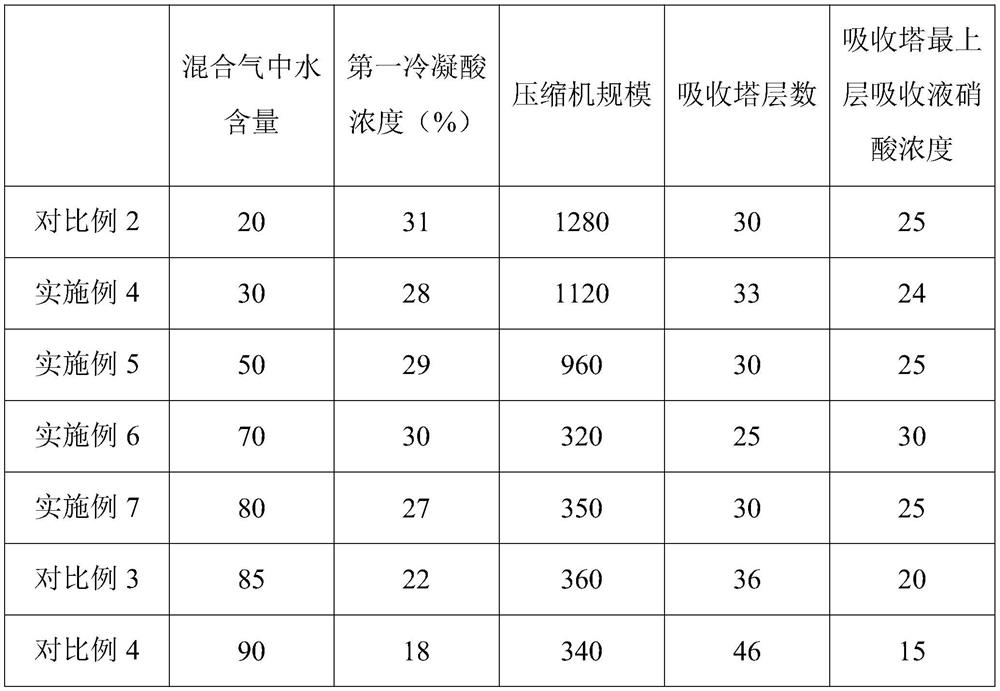

Device system for preparing nitric acid and using method of device system

The invention relates to a device system for preparing nitric acid and a use method of the device system. The device system comprises a steam mixing chamber, a cooler assembly, a buffer tank, a compressor, an absorption tower and a tail gas treatment device which are connected in sequence; the steam mixing chamber is used for receiving nitrate decomposition tail gas or NO2 prepared by an ammonia oxidation method, and water vapor and then carrying out a mixing reaction; the cooler assembly is used for receiving mixed gas discharged from the steam mixing chamber and cooling the mixed gas to obtain condensed acid; the mixed gas sequentially passes through the buffer tank, the compressor and the absorption tower. When the device system is adopted to produce nitric acid, with the yield and thegeneration speed of the nitric acid not influenced, the scale of the compressor can be effectively reduced, the height of the absorption tower can be reduced, the equipment investment can be reduced,and therefore, good economic benefits are brought about.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

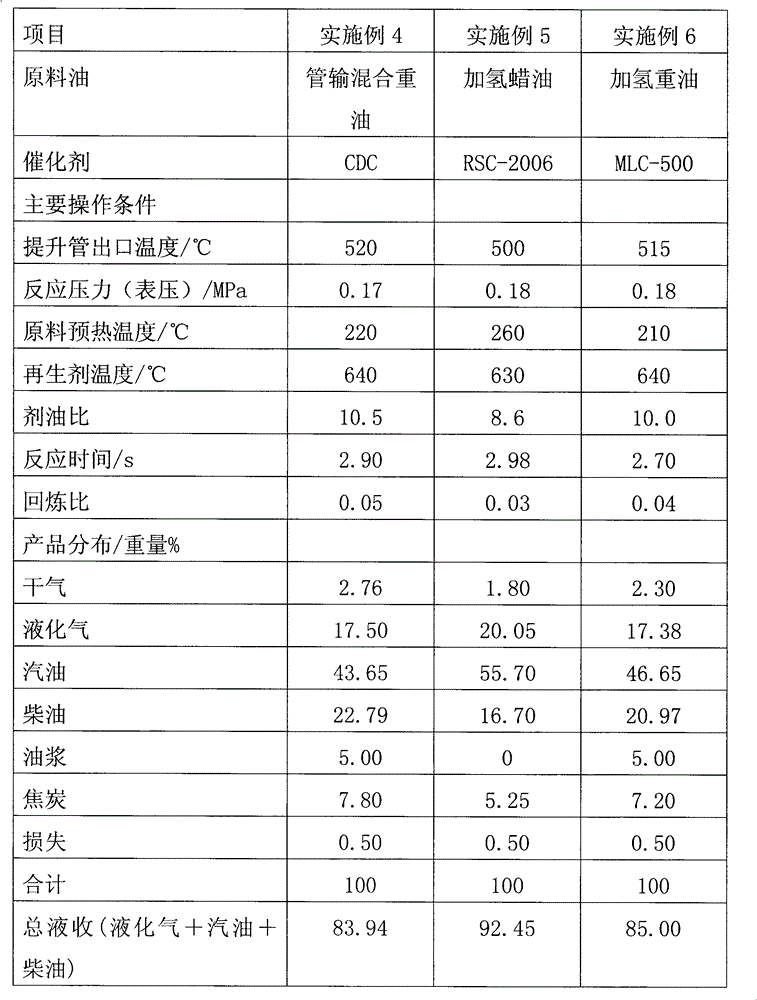

Catalytic cracking method and device

InactiveCN102746893APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyGasolineTower

The invention discloses a catalytic cracking method and device. The method is characterized by comprising the following steps: introducing raw oil into bottom of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; sending part of the regenerated catalyst into the riser reactor from different height positions of the riser; and carry out heat transfer on the other part of the regenerated catalyst by a heat exchanger and entering the other part of the regenerated catalyst into bottom of the riser reactor. The method of the invention can lower total yield of dry gas and coke by 0.5-1.5 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by more than 1 percentage, and reduce gasoline olefin volume content by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

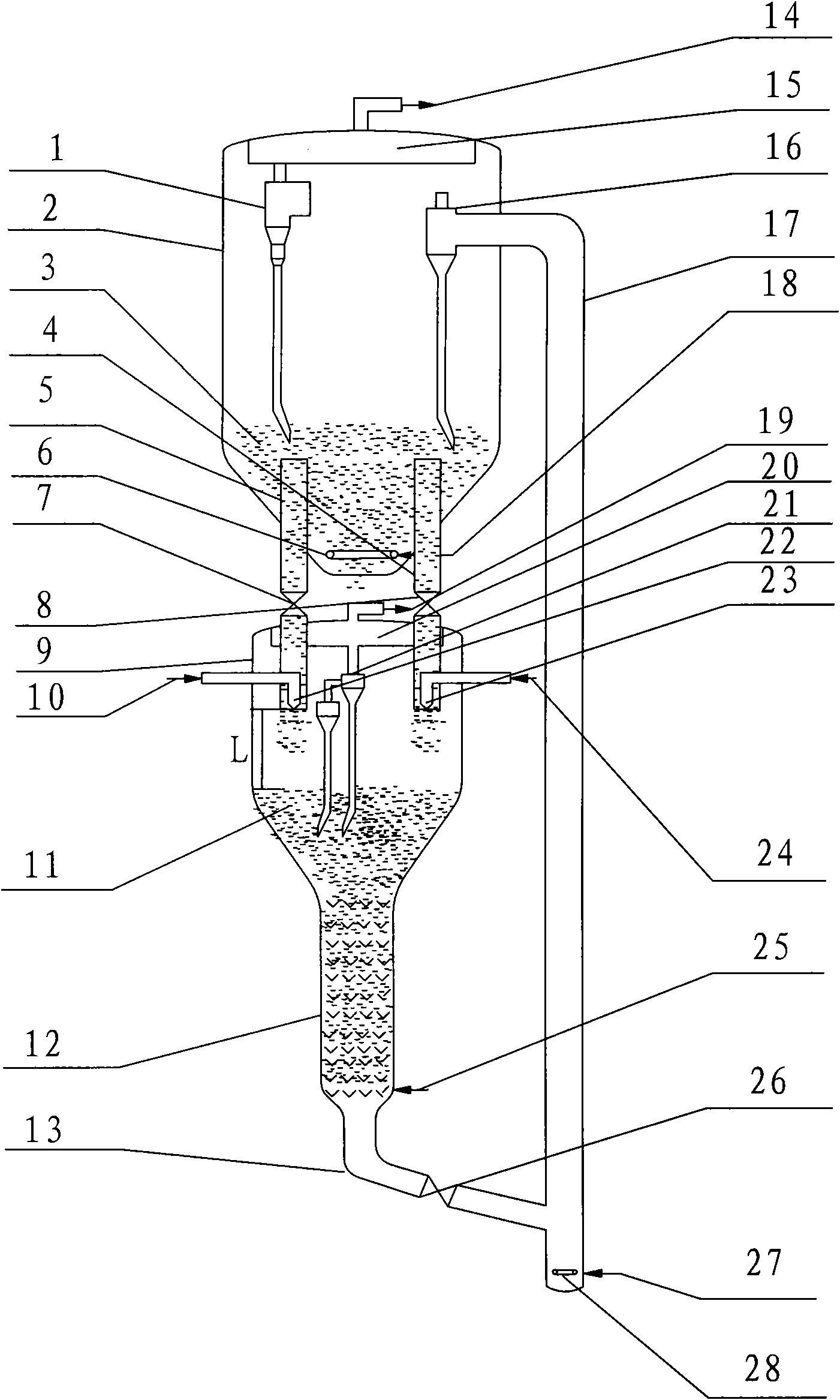

Catalytic cracking method

InactiveCN103087768AImprove the ratio of agent to oilTotal yield dropCatalytic crackingTreatment with plural serial stages onlyFlue gasGasoline

The invention discloses a catalytic cracking method and a catalytic cracking device. According to the invention, raw oil enters the lower part of a riser reactor, and is subjected to a contact reaction with a catalyst from a catalyst pre-lift mixer; oil gas obtained after reaction is separated from spent catalyst; reaction oil gas obtained by separation is delivered into a fractionating tower, and the separated spent catalyst is regenerated; part of high-temperature regenerated catalyst after regeneration enters an external heat remover; part of cooled regenerated catalyst is delivered back to the regenerator, another part of the cooled regenerated catalyst enters the catalyst pre-lift mixer, and a third part of the cooled regenerated catalyst enters the riser reactor from different height positions of the riser. The method provided by the invention can be used for reducing dry gas and coke total yield. A total liquid yield is increased by more than 1.5 percentage points; gasoline olefin volume content is reduced by 5-15 percentage points; and SOx content in flue gas is reduced by more than 30%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method and device capable of increasing propylene yield and improving properties of gasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for reducing benzene content in gasoline

The invention provides a catalysis conversion method used for reducing the content of gasoline benzene; the gasoline raw material and gases containing small molecule alkene contact normal catalytic cracking catalyst, so as to carry out the alkylation reaction inside a fluidized bed reactor under the conditions of 250-550 DEG C of temperature, 2-100h<-1> of weight hourly space velocity, 0.1-1.0MPaof pressure, 1-30 of weight ratio of catalyst to gasoline raw material, 2-30 of gasoline raw material to small molecule alkene and 0.05-1.0 of weight ratio of water vapour to raw material; the materials after reaction are separated, and the reaction outcome is sent to a subsequent separation system for outcome separation so as to gain the object outcome; the catalyst after reaction is regenerated after being stripped and burned; the regenerated catalyst is returned to a reactor after being cooled for recycling. The method reduces the volume content of the benzene in the gasoline raw material by more than 50% and improves the octane and yield of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Braided fabric needled felt aggregate and preparation method thereof

InactiveCN109866479ASmall bulk densityVolume content reductionLaminationLamination apparatusCompound aFiber

The invention provides a braided fabric needled felt aggregate and a preparation method thereof. The method comprises the steps: compounding a continuous functional fiber braided fabric layer with a continuous functional fiber bulk yarn coarse braided fabric layer to obtain an integrated fabric; and then, compounding a chopped functional fiber needled felt layer with the continuous functional fiber bulk yarn coarse braided fabric layer of the integrated fabric to obtain the braided fabric needled felt aggregate. The braided fabric needled felt aggregate provided by the invention is of a fiberaggregate structure which is light in weight and high in strength and has stepped density change, the weight of the braided fabric needled felt aggregate can be reduced by 30% or above than that of afully-braided fabric on the premise that the volumes are equal, but the mechanical properties are equivalent, and the mechanical properties of the braided fabric needled felt aggregate are better thanthose of a fully-chopped fiber needled felt; and meanwhile, the fiber raw materials can also be saved by 30% or above, the preparation process is simple, and the production period is relatively short.

Owner:重庆璨月新材料有限公司

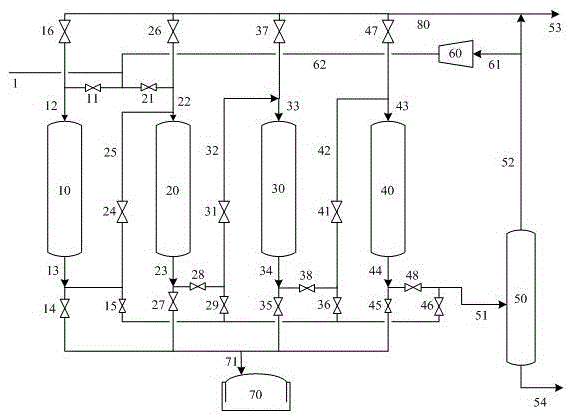

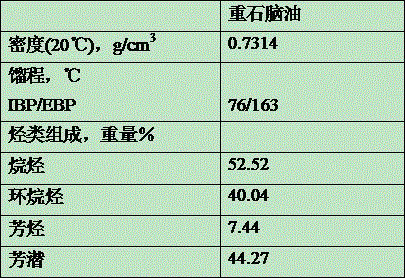

Naphtha catalytic reforming method of by-product reduction hydrogen

ActiveCN106753548AHigh hydrogenolysis activityMeet the needs of starting workNaphtha treatmentHydrocarbon oils treatment productsRheniumCatalytic reforming

The invention discloses a naphtha catalytic reforming method of by-product reduction hydrogen. When a reforming apparatus is normally operated, a random reforming reactor is cut, a platinum rhenium catalyst in the reactor is subjected to regeneration processing; then the reduced reforming catalyst has high hydrogenolysis activity, the reforming hydrogen obtained by the other reactor is processed, the contained C2<+> hydrocarbon is subjected to hydrogenolysis to carbon and methane, volume content of C2<+> in hydrogen storage is greatly reduced, and the requirement of commencement of works of the reforming catalyst is satisfied. Compared with the prior art, disadvantages of the low octane number of the gasoline obtained by catalytic reforming due to low temperature hydrogen storage, usage amount of C2<+> hydrocarbon used for active carbon adsorption, and low equipment utilization rate are overcome, and the method has the characteristic of flexible process operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method and device

InactiveCN102746892APromote circulationLower contact temperatureCatalytic crackingTreatment with plural serial stages onlyPartial systemGlobal wind patterns

The invention discloses a catalytic cracking method and device. The method comprises the following steps: introducing raw oil into a lower part of a riser reactor to contact and react with a catalyst from a catalyst heat exchanger; separating oil gas after the reaction from a coked catalyst; introducing separated reaction oil gas into a fractionating tower; carrying out steam stripping on the separated coked catalyst and sending the coked catalyst into a regenerator for regeneration; carrying out heat transfer and cooling on the regenerated catalyst and part of system prevailing wind within the catalyst heat exchanger; sending part of the regenerated catalyst into the riser reactor from different heights of the riser; and sending the other part of the regenerated catalyst into the lower part of the riser reactor. The method can reduce total yield of dry gas and coke by 0.8-2 percentage, increase total liquid yield of liquefied gas, gasoline and diesel by 1.2 percentage, and reduce volume content of gasoline olefin by 5-15 percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for high-friction oil strain-accommodating wiping material

InactiveCN109181005AImprove surface friction performanceImprove friction performanceCarpet cleanersOther chemical processesPorosityMaterials preparation

The invention discloses a preparation method for a high-friction oil strain-accommodating wiping material and belongs to the technical field of wiping material preparation. According to the preparation method, after purified algal cellulose is added into a precursor sol, the purified algal cellulose can slowly absorb water and swell; mullite whiskers can grow in the swelling purified algal cellulose during an ageing process; under high temperature, the instantaneous temperature on a friction surface is higher, and meanwhile, a softer material is generated and transferred to the friction surface of a harder material, so as to form a transferring film on the friction surface; yeast fermentation modification is adopted by the preparation method, and the blind holes and inner channels of the fiber sponge can be simultaneously opened by oily substances, such as a dimethyl silicone polymer, under the microbial action; the algal cellulose aerogel according to the invention has moderate pore size and high porosity; the wiping material provided by the invention comprises the main components as follows: plant cellulose, mountain flour sol and common nontoxic organic matters; a large amount of wastewater and slags are avoided in the production process; the preparation method has a wide application prospect.

Owner:赵建平

Catalytic cracking method and device

ActiveCN102268290BRaise oil ratioTotal yield dropTreatment with plural serial stages onlyFractionating columnProduct gas

The invention discloses a catalytic cracking method and device, overcoming the defects of high gas and coke yields and low liquid yield which are caused by secondary cracking in the prior art. The method comprises the following steps: introducing a raw material oil into the lower part of a riser reactor so as to be contacted and reacted with a catalyst from a heat exchanger; carrying out crude separation on oil gas after reaction and a spent catalyst; further separating fine catalyst powder out of the reaction oil gas obtained by separation and then introducing the reaction oil gas without the fine catalyst powder into a fractionating column; carrying out steam stripping on the spent catalyst obtained by separation, and then introducing the spent catalyst subjected to steam stripping into a regenerator for regeneration; and introducing a part of regenerated high temperature reclaiming agent into the riser reactor from different heights of the riser reactor, introducing the other part of regenerated high temperature reclaiming agent into the heat exchanger, and the cooled reclaiming agent is recycled.

Owner:CHINA PETROCHEMICAL CORP +1

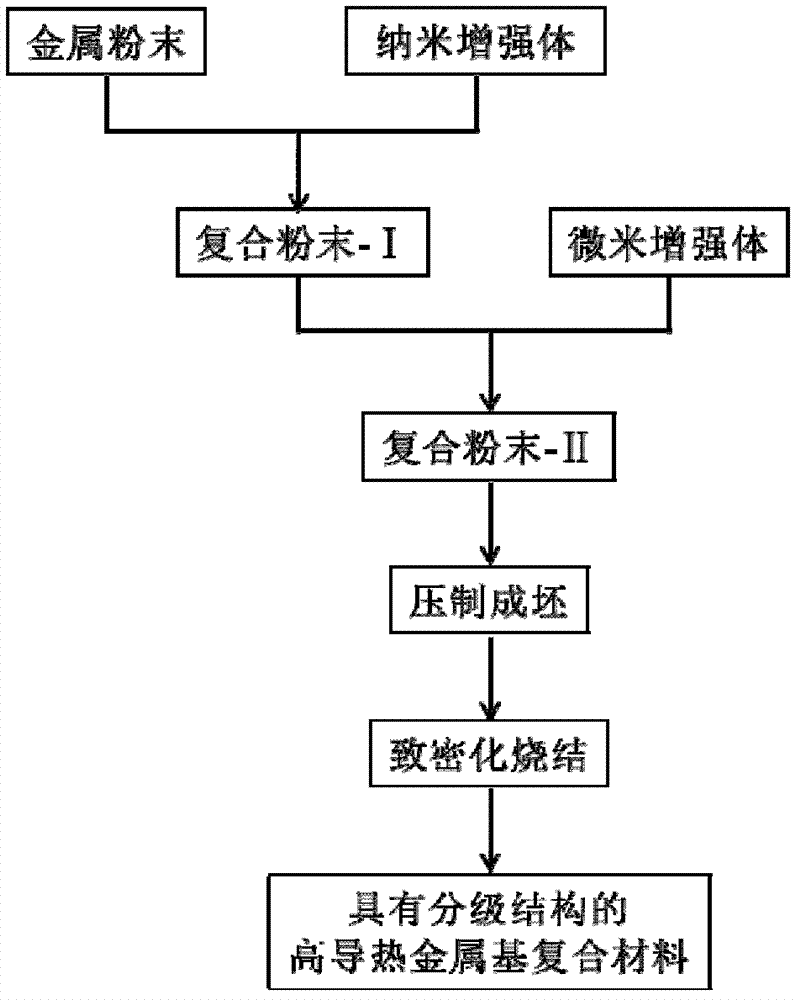

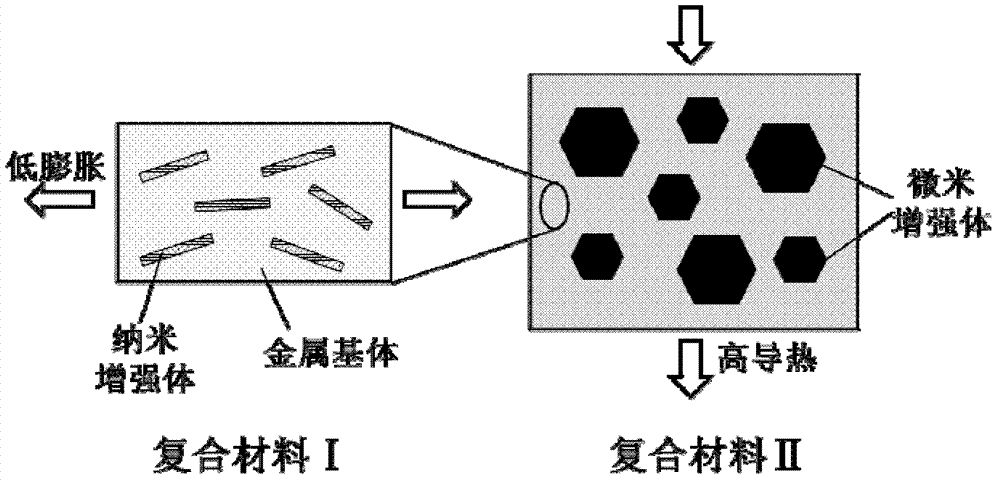

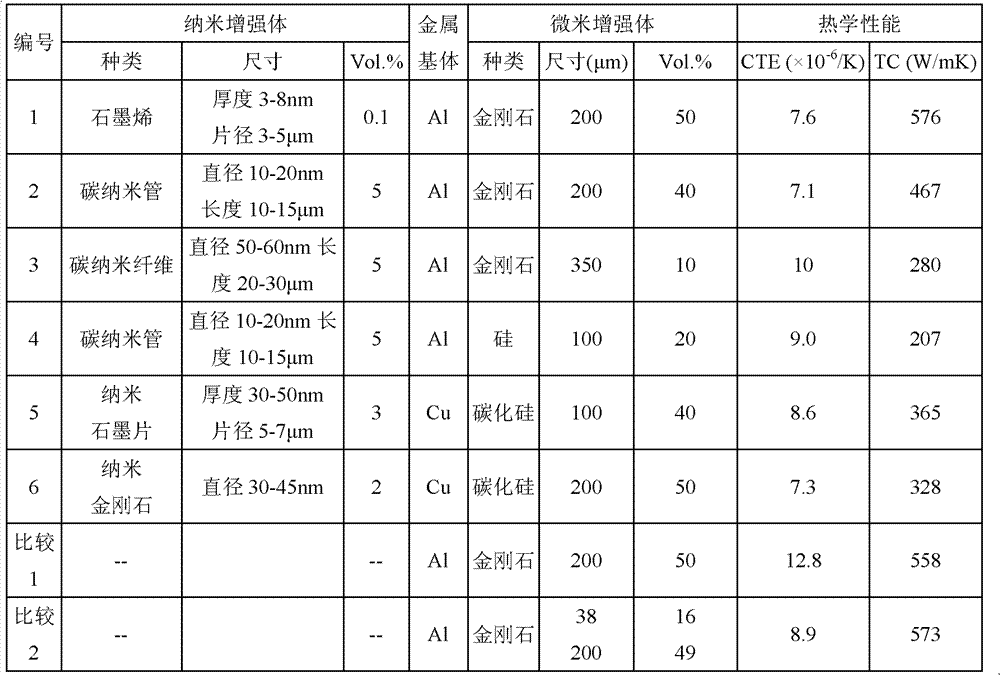

High thermal conductivity metal-based composite material with hierarchical structure, and preparation method thereof

ActiveCN102605208BVolume content reductionSuppression of thermal expansion coefficientFiberHeat management

Owner:SHANGHAI JIAOTONG UNIV

A continuous deformation composite profile and its preparation method

The invention discloses a continuous deformation composite material profile and a preparation method thereof. The preparation method comprises the following steps in sequence: S1. impregnating continuous longitudinal fibers with resin to obtain a prepreg, and continuously welding or extruding the metal to obtain a tube blank; S2 .Continuously bring the prepreg into the tube blank to obtain the material to be deformed; S3. Synchronously drive the prepreg and tube blank of the material to be deformed, change the section of the tube blank by drawing or rolling process or / and deform the tube blank through the action of the mold Spatial form, to obtain continuous materials to be formed with the same or different spatial forms; S4. Heating the materials to be formed, to obtain continuous deformation composite material profiles with the same or different spatial forms, including core materials formed by cross-linking and curing of prepregs And the armor layer formed by deformation of the tube blank can continuously prepare the continuous deformation composite material profile, and the availability of the continuous deformation composite material profile can guarantee the value engineering design of the composite material that needs to integrate all aspects of performance requirements.

Owner:JIANGSU YIDING COMPOSITE TECH CO LTD

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1324116CRaise the preheat temperaturePromote atomizationCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationGasoline

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com