Braided fabric needled felt aggregate and preparation method thereof

A knitted fabric and needle-punched felt technology is applied in the field of knitted fabric needle-punched felt aggregate and its preparation, which can solve the problems of long production cycle, excessive labor, and fiber waste, eliminate thermal stress and thermal strain, and save fiber raw materials. , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a knitted fabric needle felt assembly, comprising the following steps:

[0038] Composite the continuous functional fiber braided fabric layer and the continuous functional fiber bulked yarn coarse braided fabric layer to obtain an integrated fabric;

[0039] Combining the chopped functional fiber needled felt layer with the continuous functional fiber bulked yarn coarse braid layer of the integrated fabric through needle punching to obtain a braided needle felt assembly.

[0040] In the invention, the continuous functional fiber braided fabric layer and the continuous functional fiber bulked yarn coarse braided fabric layer are combined to obtain an integrated fabric.

[0041]In the present invention, the continuous functional fiber braid layer is a single-layer or more than two-layer long fiber bundle braid commonly used in the field, which can be made of continuous functional fibers by weaving or braiding. T...

Embodiment 1

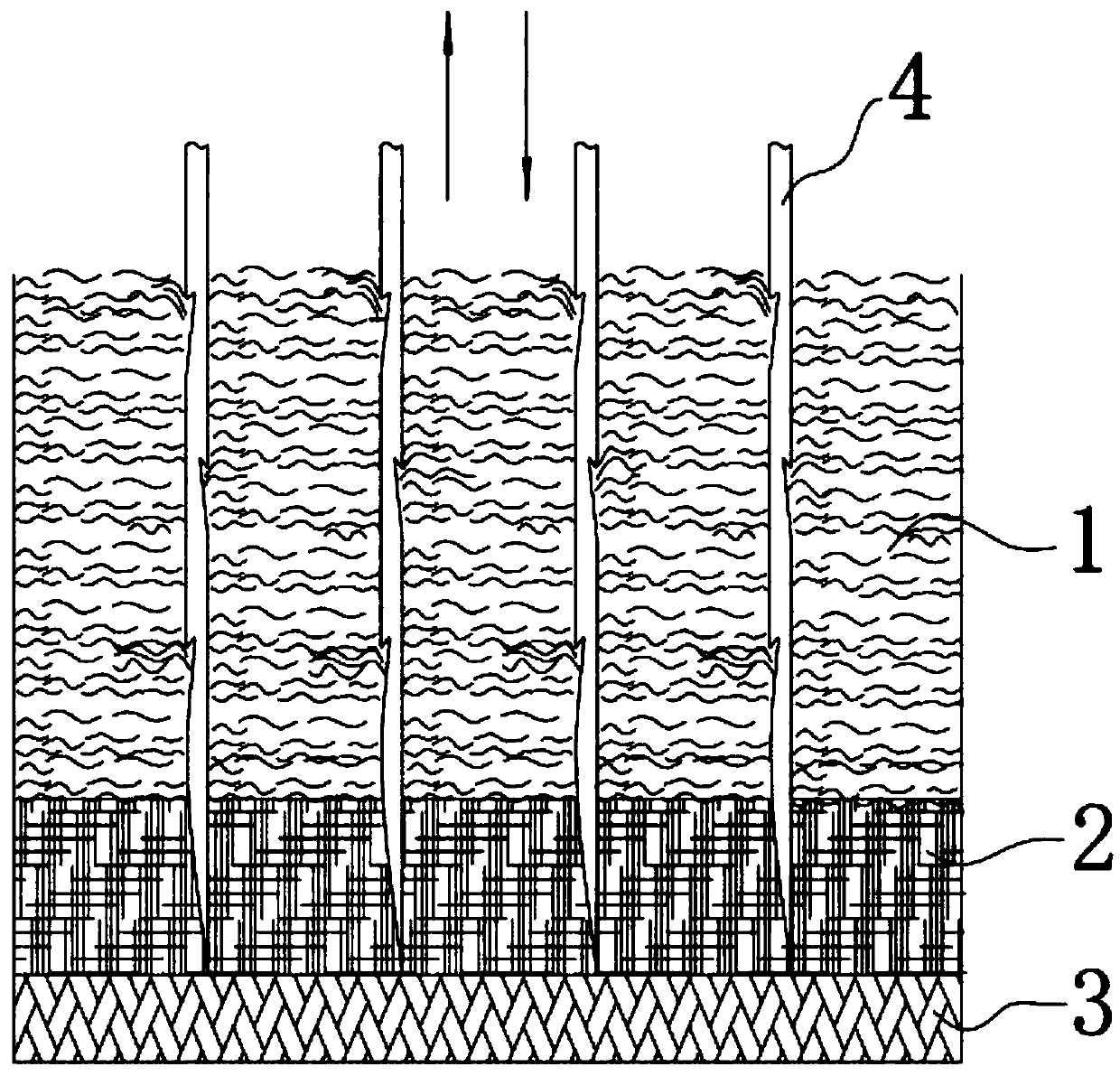

[0053] The 12K carbon fiber is made into a single-layer two-up and one-down twill weave fabric by weaving method, and its thickness is 1.5mm; Two upper and lower twill coarse braids connected by two upper and lower twill fabrics, the thickness of which is 6mm, constitutes an integrated fabric;

[0054] The chopped carbon fiber with a length of 55mm and 6K is carded into a net in the non-woven technology to make a needle-punched felt with a thickness of 8mm, and then the inner surface of the integrated fabric is attached to the inner core mold of the flat plate, and passed Acupuncture: the chopped carbon fibers in the needle felt are inserted into the bulked yarn roving layer to obtain a flat plate fiber assembly; wherein, the process conditions of the needle punch are: the needle punch density is 20 needles / cm2 ; Acupuncture depth is 25mm.

[0055] figure 1 It is a schematic diagram of the needling action in the preparation method of the woven needle felt assembly provided i...

Embodiment 2

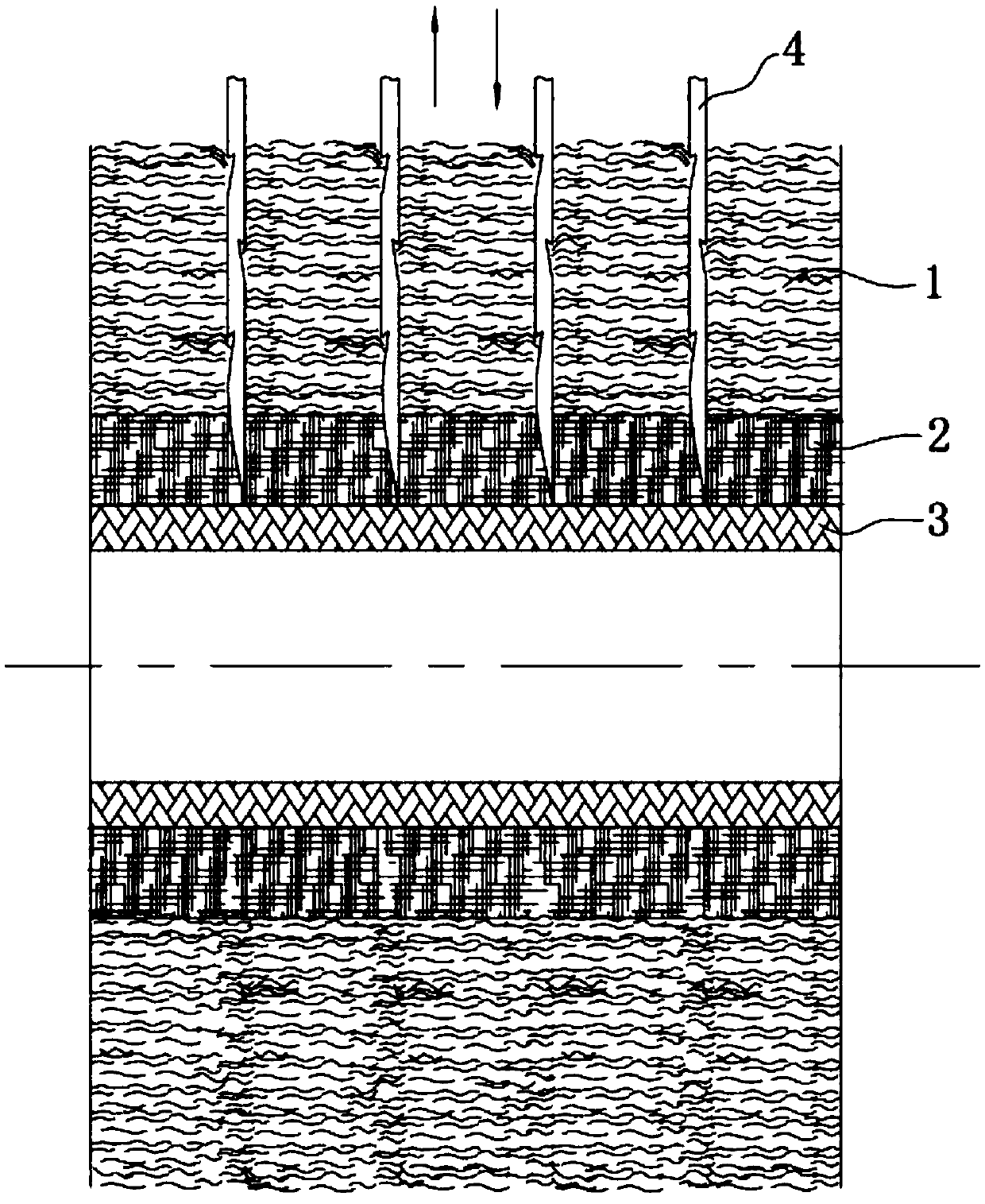

[0058] The 12K carbon fiber is made into a single-layer plain weave fabric with one up and one down by weaving method, and its thickness is 1mm; An upper and a lower plain weave coarse braid connected with an upper and a lower plain weave, the thickness of which is 6 mm, forming an integrated fabric;

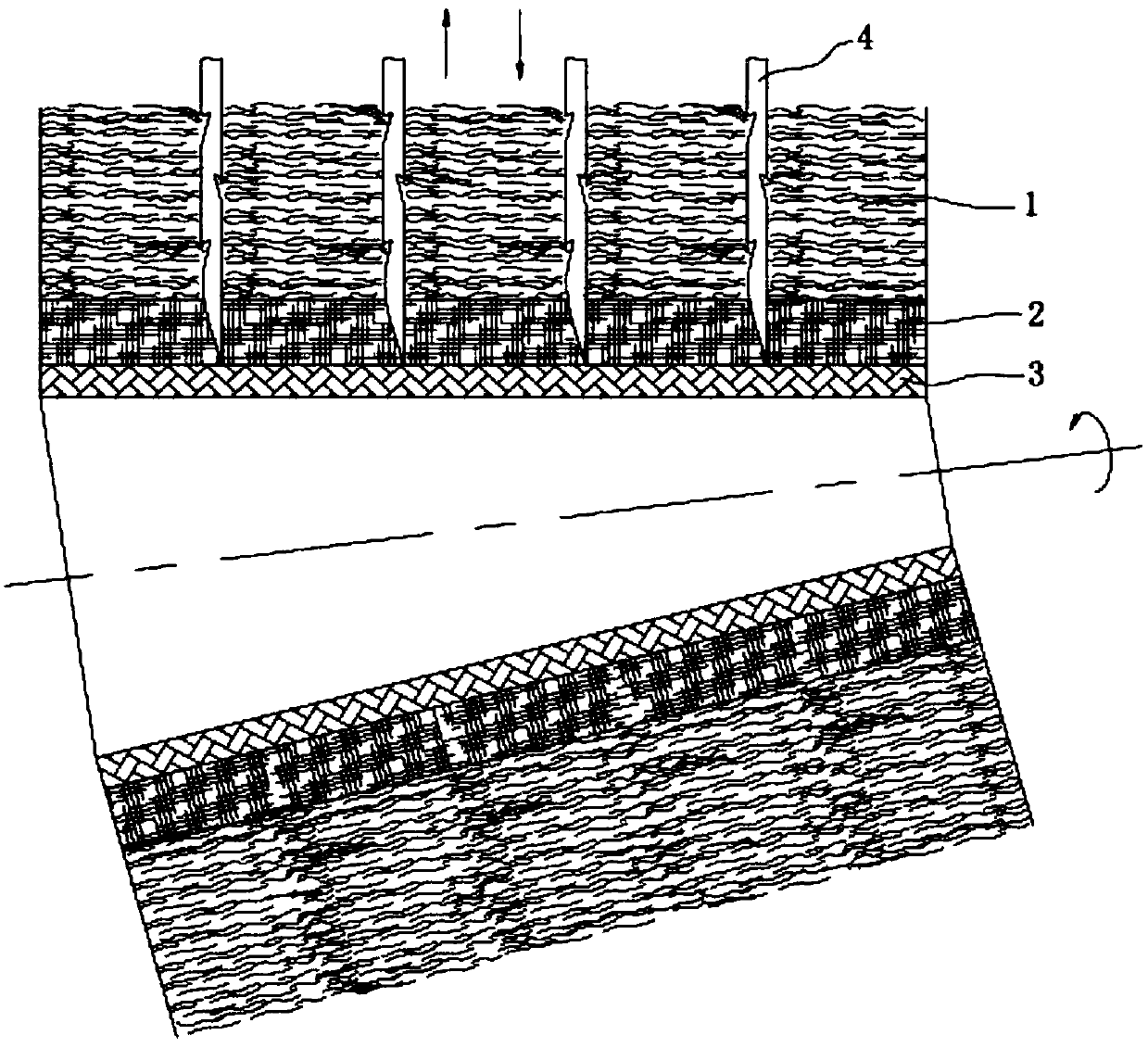

[0059] The chopped carbon fiber with a length of 60mm and 12K is carded into a net in the non-woven technology to make a needle-punched felt with a thickness of 6mm, and then the inner surface of the integrated fabric is attached to the cylindrical inner mandrel, and passed Acupuncture: the chopped carbon fibers in the needle-punched felt are inserted into the bulked yarn roving layer to obtain a cylindrical fiber aggregate; wherein, the process conditions of the needle-puncture are: the needle-punched density is 50 needles / cm2; The acupuncture depth is 8mm.

[0060] figure 2 Schematic diagram of the needling action in the preparation method of the woven needle felt assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com