High-water-oil ratio catering liquid waste grease collecting device and high-water-oil ratio catering liquid waste grease collecting method

A technology for oil collection and high water and oil, applied in water supply installations, indoor sanitary pipeline installations, buildings, etc., can solve the problems of low oil collection efficiency and large workload of oil-water separators, and achieve equipment benefits and maximum equipment benefits. reduce the effect of solid slag cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

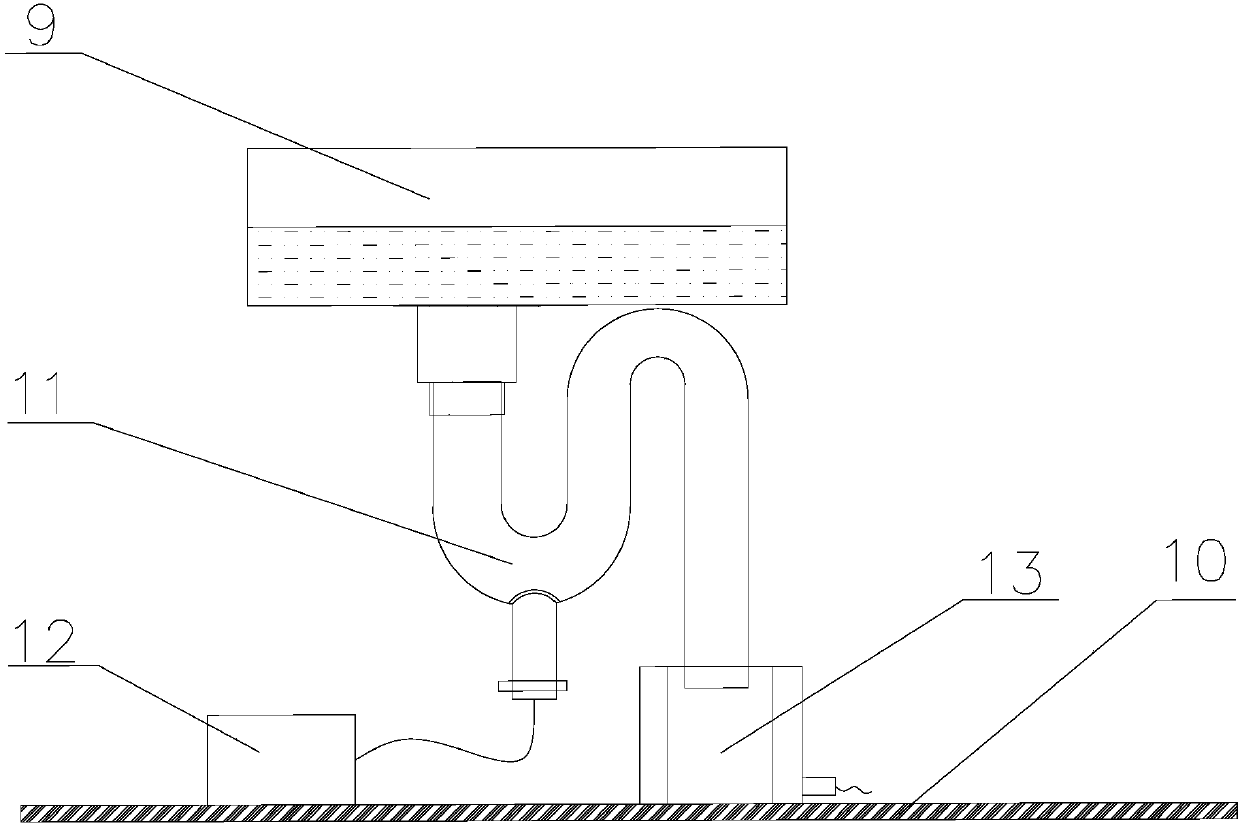

[0038] like figure 1 As shown, the high water-to-oil ratio catering waste liquid oil collection device in Example 1 includes a sink water connection pipe 11 , an oil-water separator 12 and a solid residue collection bucket 13 . -The water inlet end of the U-shaped connecting pipe outlet pipe is connected with the bottom drain outlet of the sink 9, and the U-shaped pipe shunt pipe 4 at the bottom of the connecting pipe fitting 11 of the sink is connected with the inlet of the oil-water separator 12, and the sink is drained The drain pipe 7 connecting the pipe fitting 11 communicates with the inlet of the solid slag collection barrel 13 .

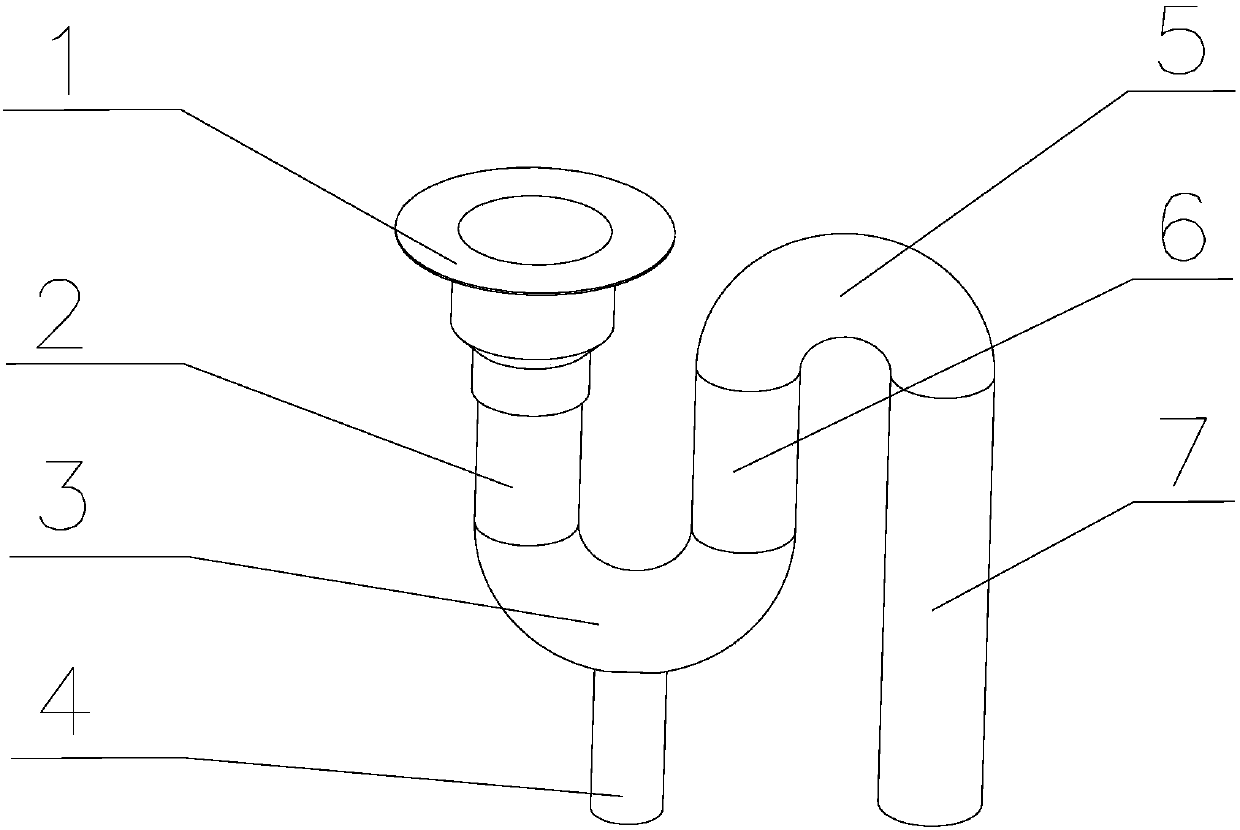

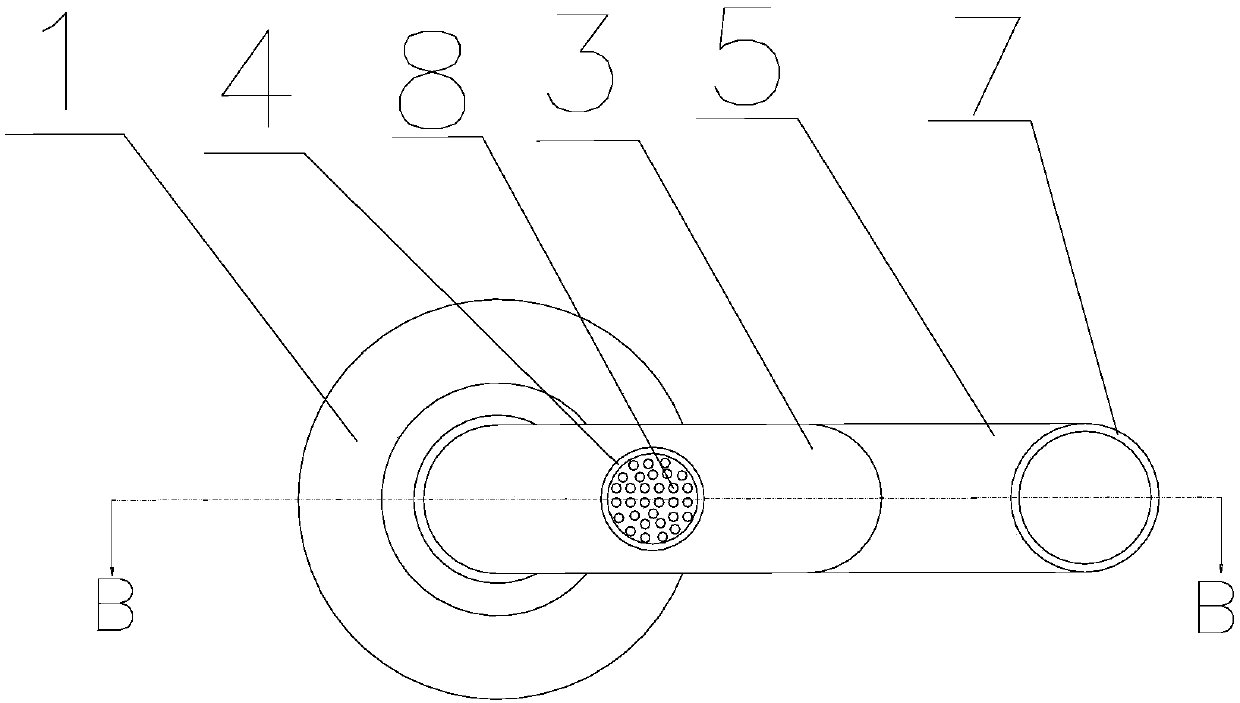

[0039] The structure of the sink water connection pipe fitting 11 is as Figure 2 to Figure 5 As shown, it includes a U-shaped connecting pipe, and the U-shaped connecting pipe includes a U-shaped connecting pipe inlet pipe 2 , a U-shaped connecting pipe bottom 3 and a U-shaped connecting pipe outlet pipe 6 . The bottom of the U-shaped conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com