Patents

Literature

544results about How to "Reduce cleanup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost foam paint and method for producing the same

InactiveCN101497104AGood flow parallelEasy to clean upFoundry mouldsFoundry coresEmulsionWater soluble

The invention discloses an expendable pattern casting (EPC) coating and a method for producing the same. The EPC coating comprises a refractory aggregate, a bonding agent, a suspending agent, a wetting agent, a defoaming agent, an addition agent and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, quartz powder and olivine powder; the bonding agent comprises B01 water soluble resin or polyvinyl alcohol resin aqueous solution, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethyl cellulose; the wetting agent comprises tween or / and span; the defoaming agent comprises monobasic alcohol octanol; the addition agent comprises sodium carbonate, cryolite and ferric oxide powder; and the dispersing agent is water. The EPC coating has the advantages that by selecting proper coating components and adjusting the contents thereof, and selecting a proper mixing process, the normal temperature and high temperature strengths, the suitable high temperature air permeability, and the excellent flow parallel and suspension properties and the brushability for a coating layer are completely satisfied. The coating is applicable to gray cast iron pieces with different brands, and particularly the coating layer sheds off automatically and gradually in the cooling process of a cast after pouring and mold dismantling so that the surface of the cast is bright and clean, and the process for cleaning the cast is greatly simplified and saved.

Owner:杨玉光

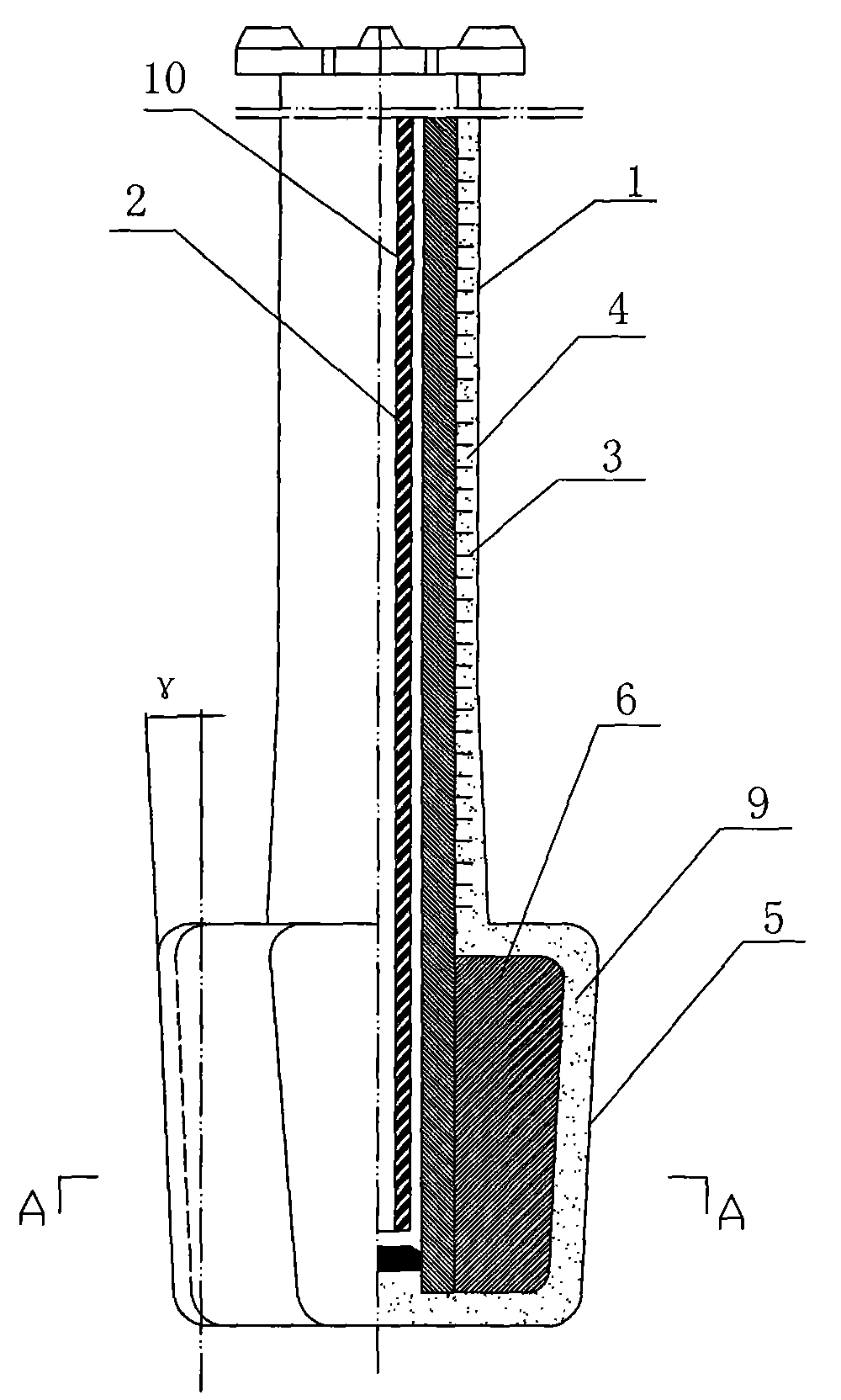

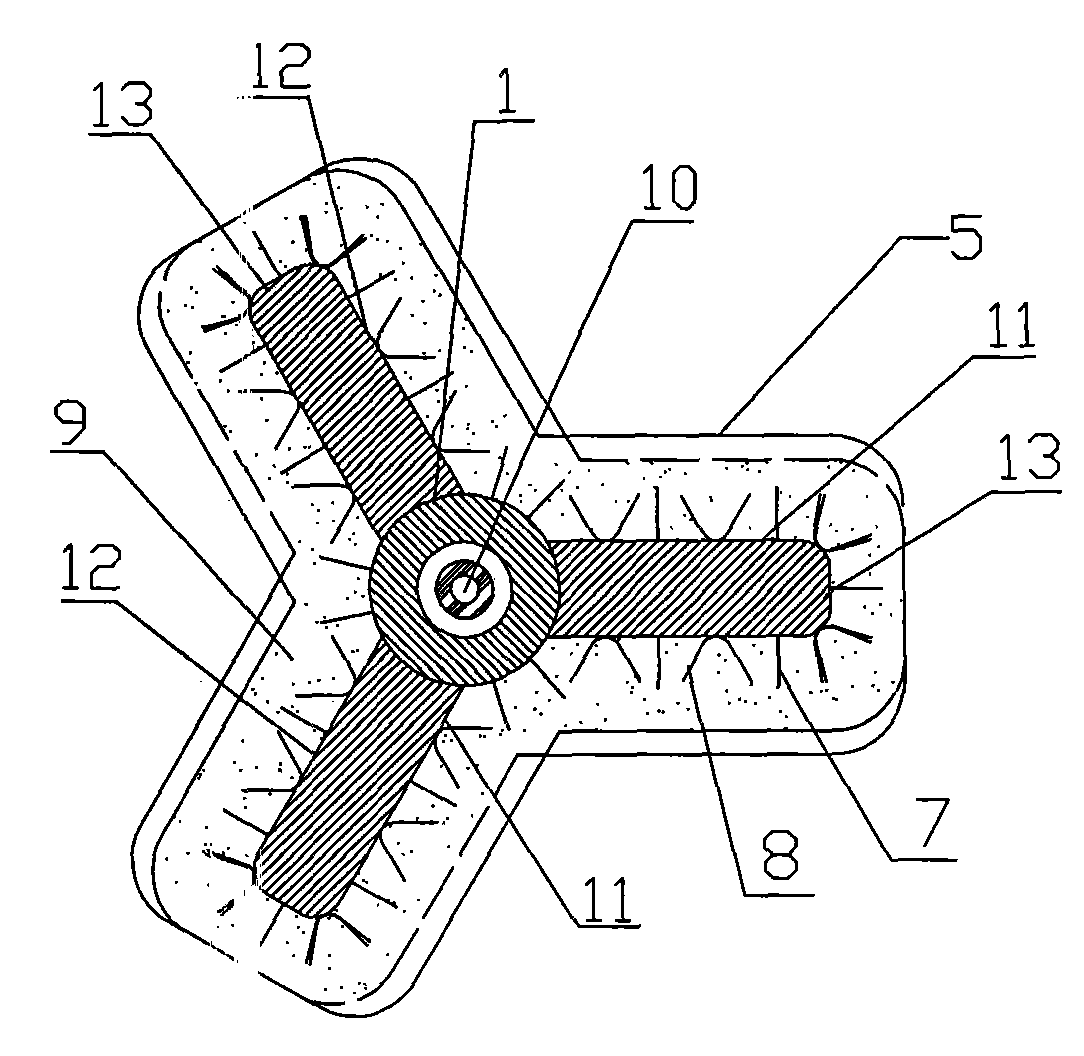

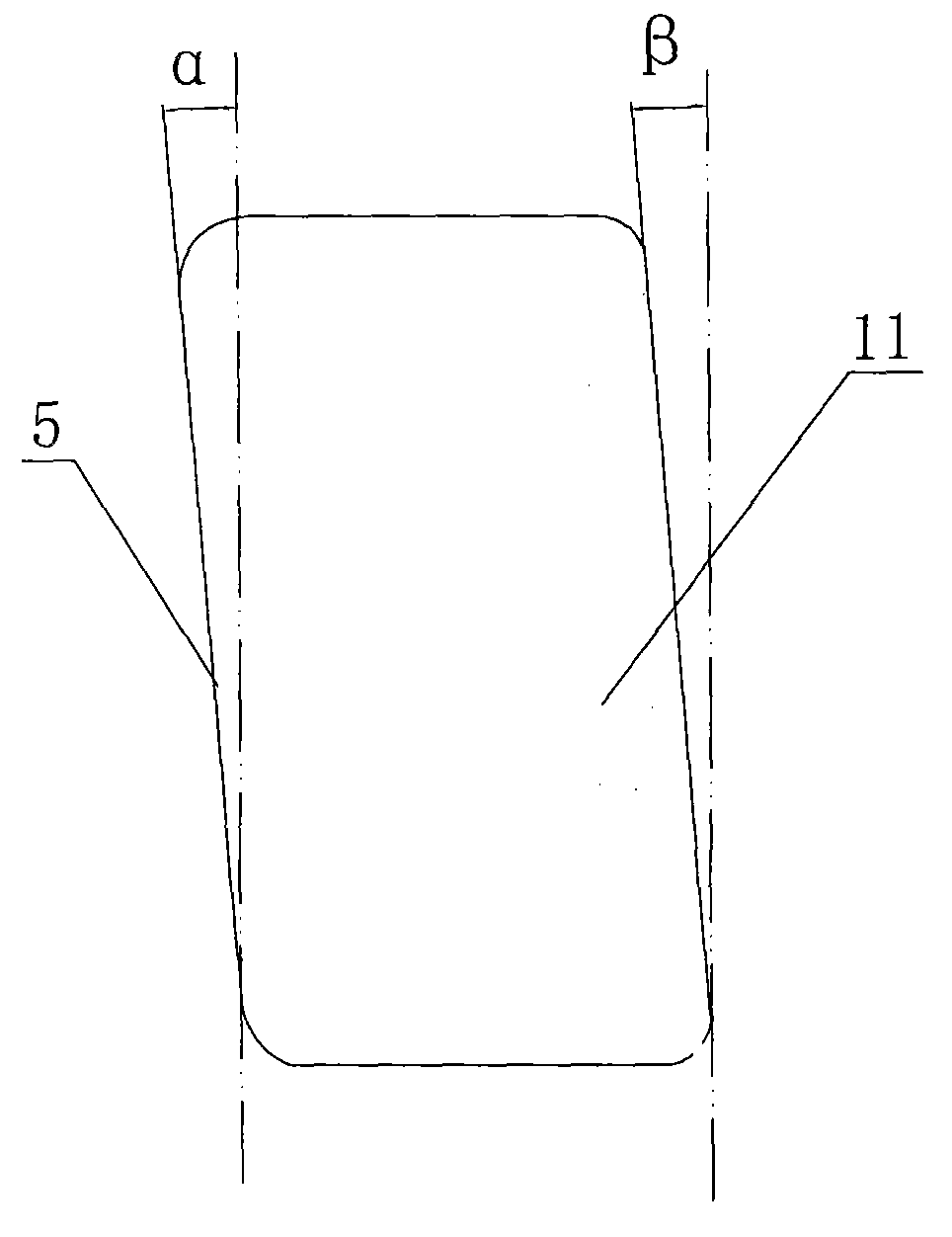

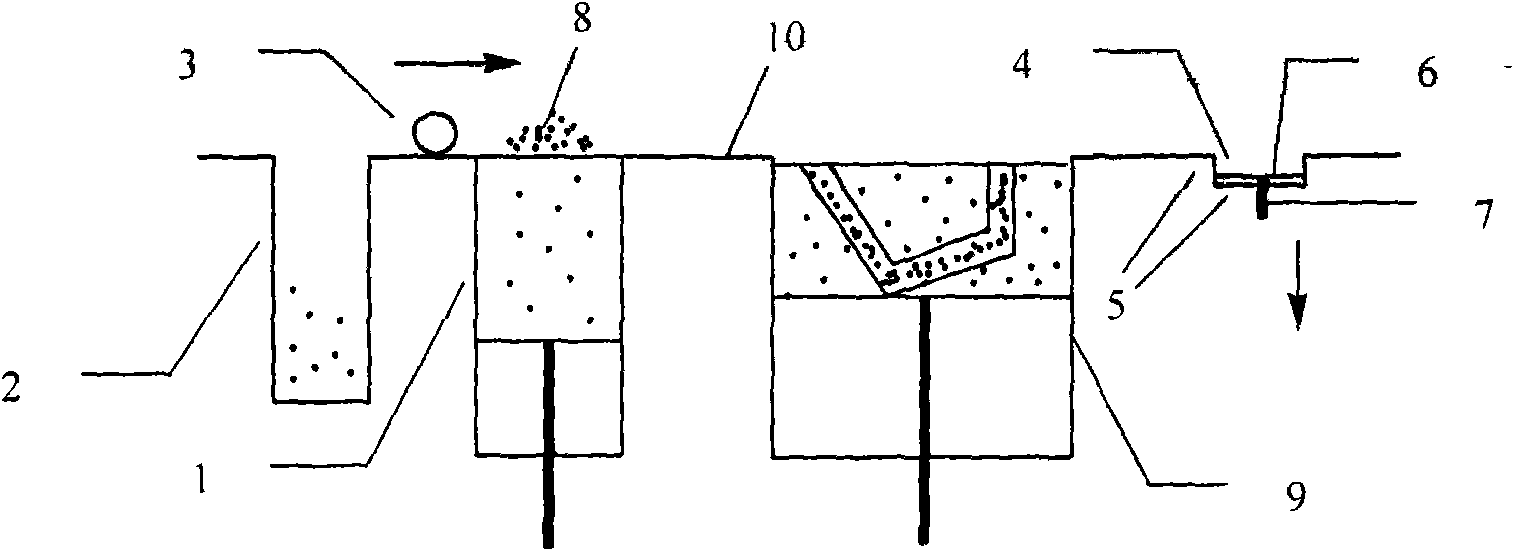

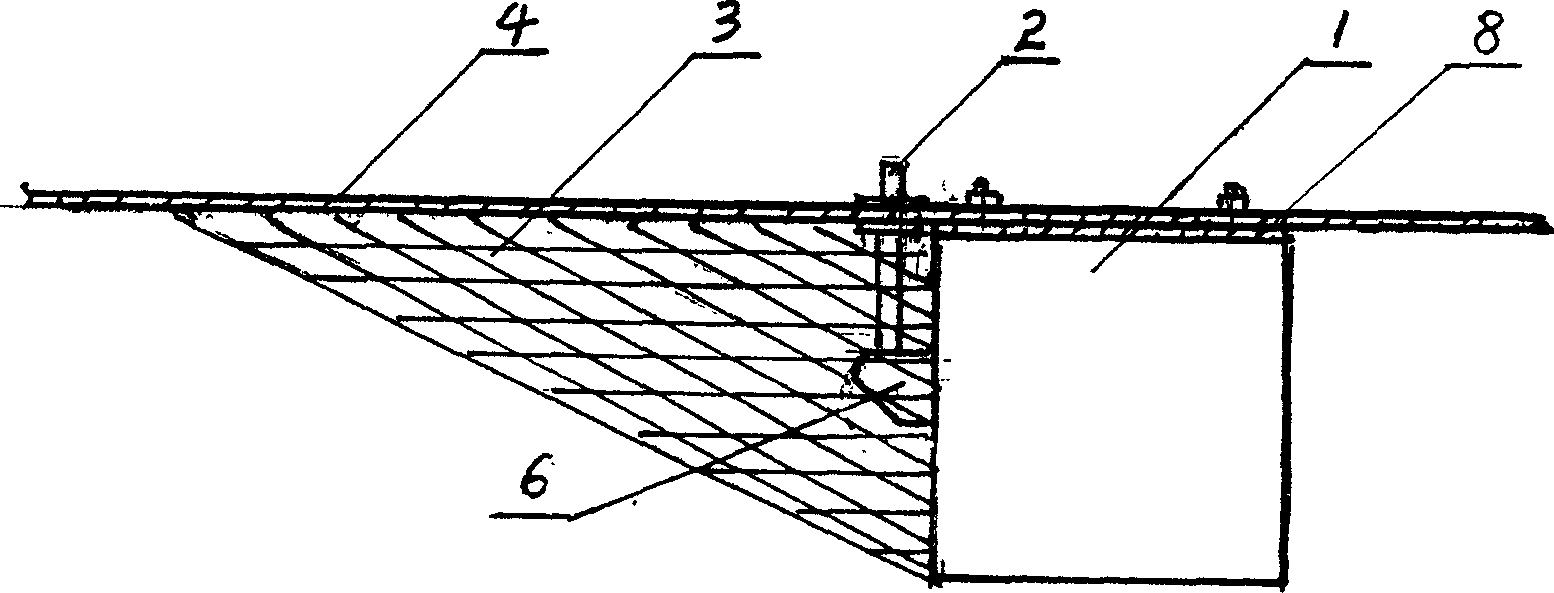

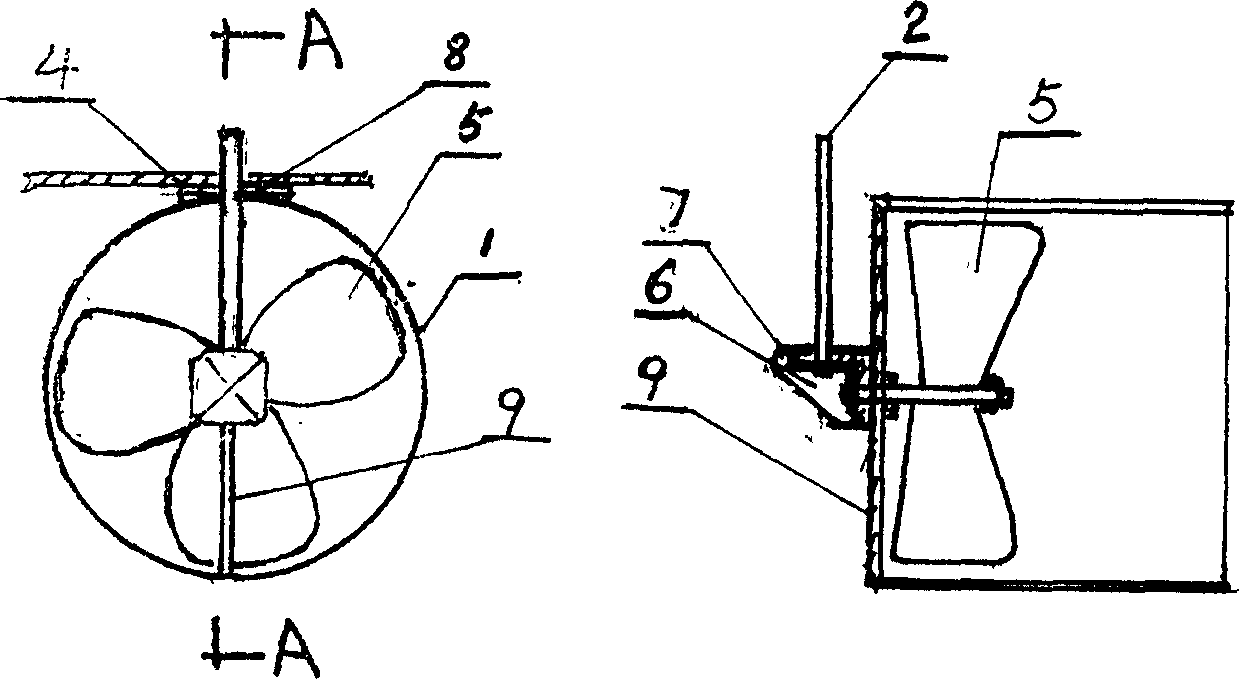

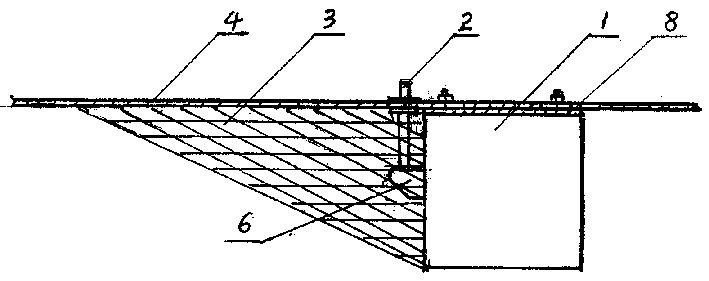

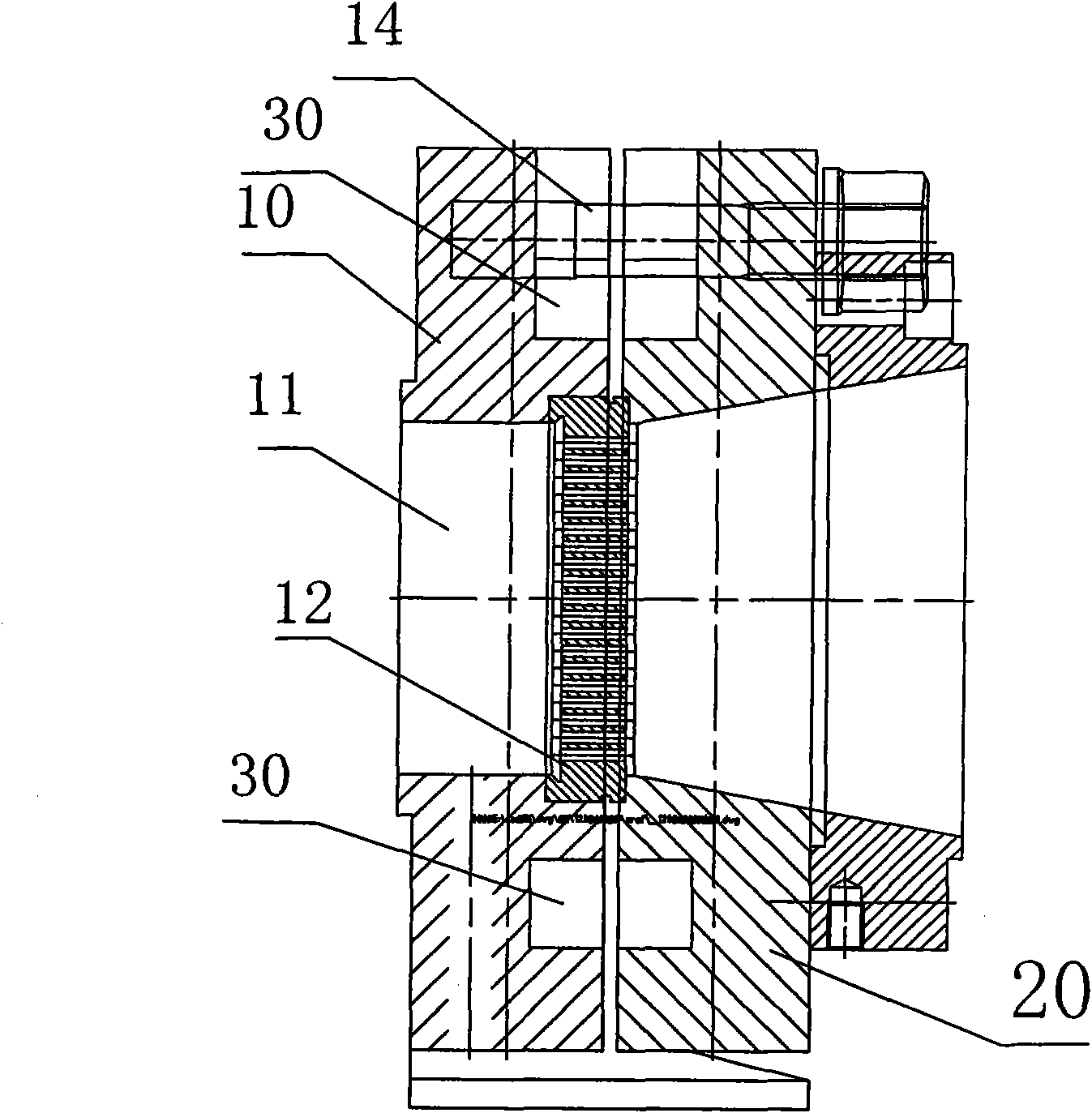

Stirrer for desulphurization of molten iron

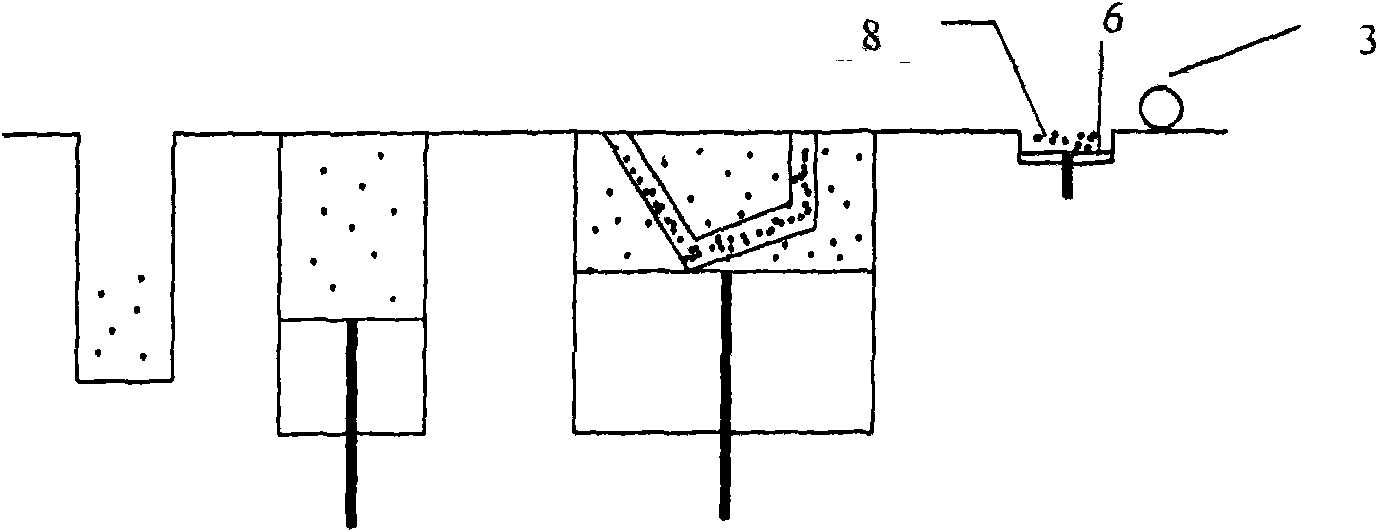

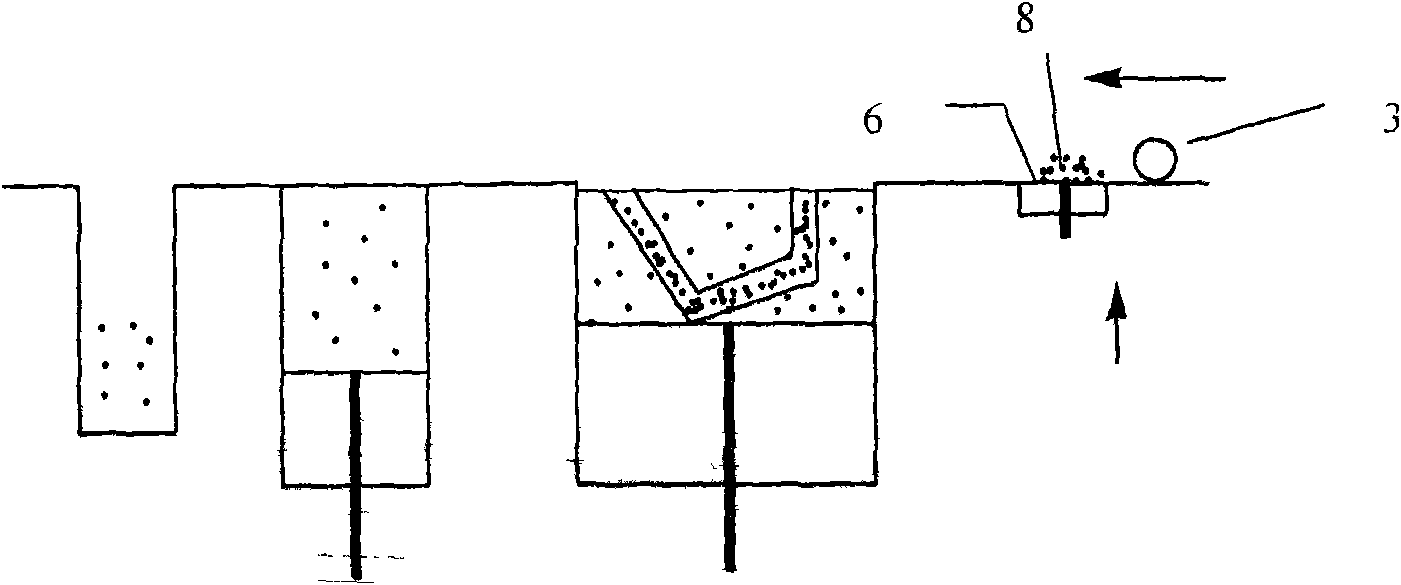

The invention relates to a stirrer for external stirring desulphurization of molten iron before converter steelmaking, aiming at solving the existing deficiencies at present that slags among mixing blades are numerous, large intensity of vortex at the bottom of the metal opposing side of the mixing blades is disadvantageous to the discharging of the involved desulphurization slags. The invention comprises the following measures: the stirrer for desulphurization of molten iron is composed of a metal core 2, a V-shaped rivet firmware 3, a refractory liner 4, a metal chip 6, a V-shaped rivet firmware 7, a double V-shaped rivet firmware 8, a refractory liner 9 and an air cooling tube 10; the metal core 2, the V-shaped rivet firmware 3 and the refractory liner 4 constitute a rotation axis 1; the metal chip 6, the V-shaped rivet firmware 7, the double V-shaped rivet firmware 8, the refractory liner 9 and the air cooling tube 10 constitute mixing blades 5; three mixing blades 5 above the rotation axis 1 are evenly distributed; the front rake angle alpha of the inclined plane from bottom to top of the metal facing water surfaces 11 of the mixing blades 5 is 4.1-30 degrees, the front rake angle beta of the inclined plane from bottom to top of the metal opposing surfaces 12 is 0.1-30 degrees, the camber angle gamma of the inclined plane from bottom to top of the outside surface 13 is 4.1-15 degrees. In the invention, slags among the mixing blades are small, the dynamic condition for stirring desulphurization is excellent, the service life is long and the structure is simple.

Owner:武汉钢铁有限公司 +1

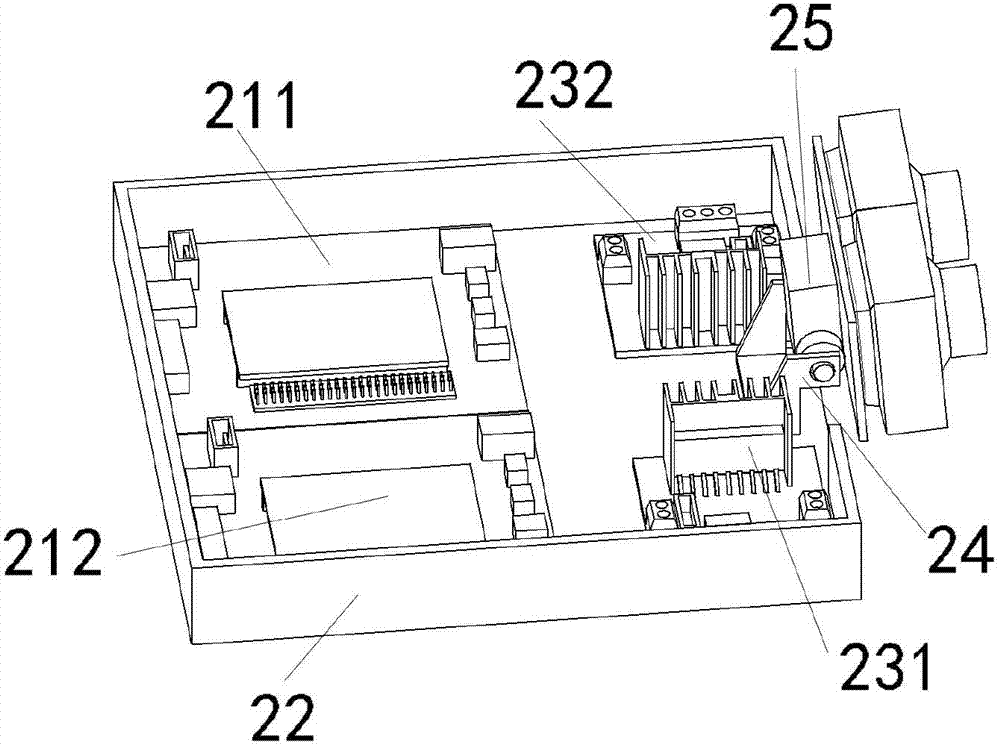

Road cleaning system and method through intelligent robot

The invention discloses a road cleaning system and method through an intelligent robot for mainly solving the problem of frequent happening of accidents of environmental sanitation workers due to large effects of prior road environmental sanitation cleaning systems on traffic. The system comprises a controller (2), a binocular camera (7), a central processor (3), a supersonic distance measurement unit (6), a cleaning mechanism (4) and a moving mechanism (5). The controller (2) reads data of the supersonic distance measurement unit (6) and uploads the encoded data to the central processor (3); the central processor (3) reads images shot by the binocular camera (7), signal lamp states of a road section where the central processor (3) is in and the data of the supersonic distance measurement unit (6), performs recognition processing to determine the moving direction and cleaning actions of the system and transmits the moving direction and cleaning actions to the controller (2); and the controller (2) controls the moving mechanism (5) to drive the whole system to move towards the garbage direction and the cleaning mechanism (4) to clean cleaning mechanism (4). By means of the intelligent robot road cleaning system and cleaning method, roads can be cleaned automatically and actively, environmental sanitation workers can be replaced or assisted to check and study roads for cleaning in heavy-traffic or high-vehicle-sapped dangerous sections.

Owner:XIDIAN UNIV

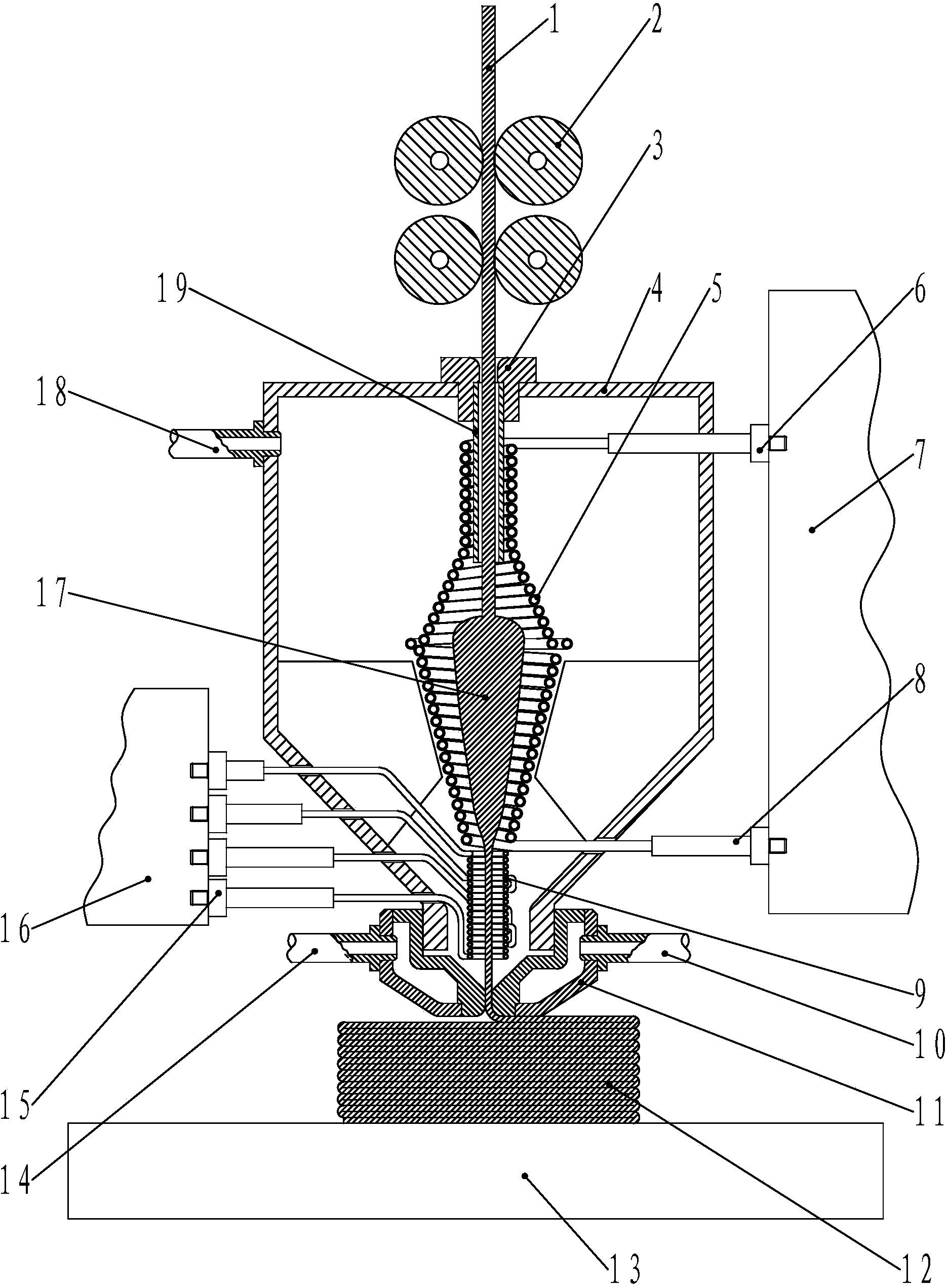

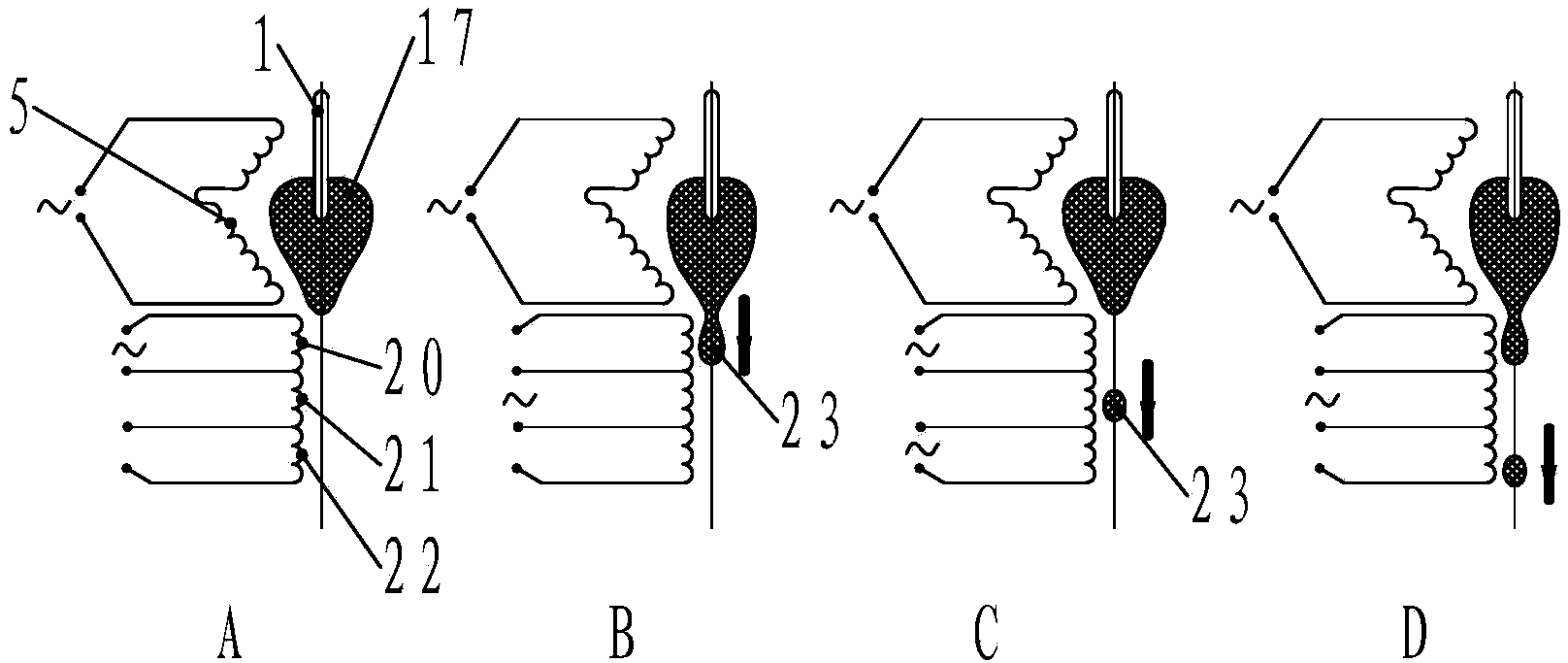

Electromagnetic modulation fusion emitting device

The invention discloses an electromagnetic modulation fusion emitting device which comprises an induction heating coil, a three-phase linear induction heating coil and a spray nozzle, wherein the three-phase linear induction heating coil is arranged under the induction heating coil; a support cylinder is arranged at the periphery of the induction heating coil; the lower end of the support cylinder is connected with the spray nozzle; two ends of the induction heating coil are connected to an alternating power supply; the three-phase linear induction heating coil is arranged into a three-phase four-wire system circuit structure; four ends of the three-phase linear induction heating coil are respectively connected to a three-phase pulse alternating power supply. A levitation melting technology and a linear induction motor principle technology adopted by the electromagnetic modulation fusion emitting device are both common electromagnetic induction technologies in a traditional industry, the process is mature, the manufacturing cost and the durability are superior to those of a selected laser sintering (SLS) technology adopting a high-power laser, and the electromagnetic modulation fusion emitting device is more suitable for applicable in the traditional industry.

Owner:曹炜喜

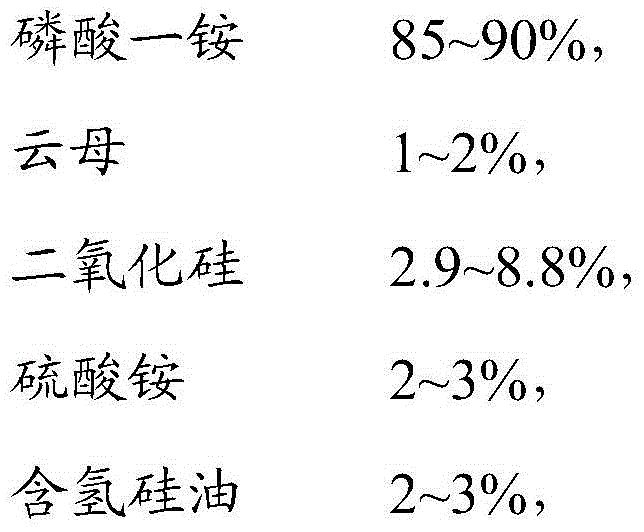

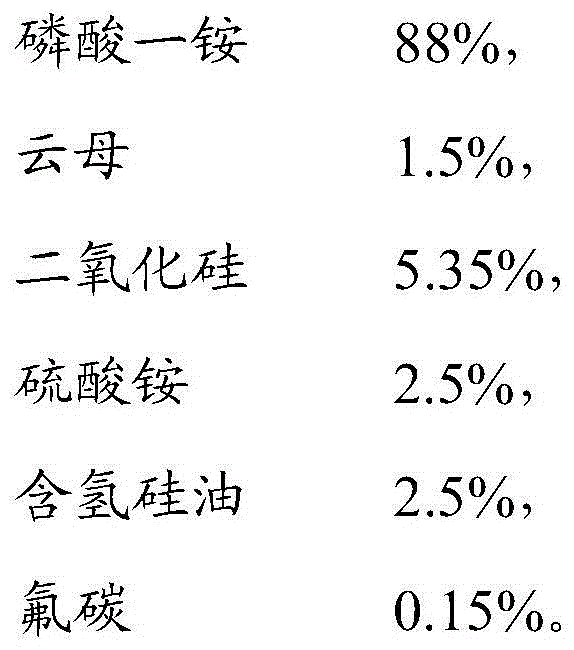

ABC superfine dry powder anti-reburning fire extinguishing agent and preparation method thereof

InactiveCN104096335AQuick fire responseGood dispersion of powderFire extinguisherAmmonium sulfateDecomposition

The invention discloses an ABC superfine dry powder anti-reburning fire extinguishing agent. The fire extinguishing agent comprises the following components in percentage by weight: 85-90% of monoammonium phosphate, 1-2% of mica, 2.9-8.8% of silicon dioxide, 2-3% of ammonium sulfate, 2-3% of hydrogen-containing silicone oil, and 0.1-0.2% of fluorocarbon. The fire extinguishing agent is fast in fire extinguishing response, is good in powder diffusing performance, is easily suspended in burning space to form stable aerosol, is fast in heated decomposition, is quick in endothermic reaction, has strong capacity of capturing free radicals, has largely improved fire extinguishing efficiency. Moreover, the fire extinguishing agent is good in water repellency, is strong in flowing property, is strong in electrical insulating property and caking resistance, is low in corrosion, and is not easy to cake. The fire extinguishing agent can be preserved for a long time in a sealed container filled with nitrogen and argon. Because silicon dioxide, mica and ammonium sulfate are low in cost and can be easily purchased, the fire extinguishing agent can be conveniently produced in large scale. The fire extinguishing agent is simple in preparation process, causes no harm to humans, animals and the environment, and after the fire is extinguished, the environment is easy to clean and corrosion of equipment is low.

Owner:JIANGXI JIN XIAN FIRE CHEM IND

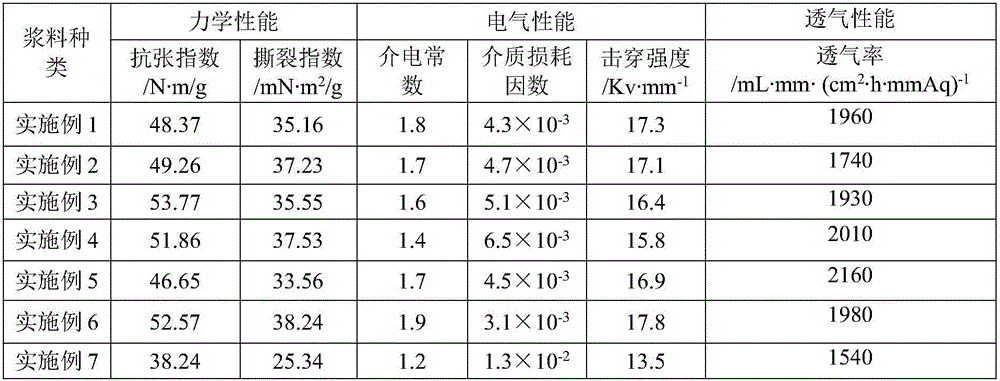

Preparation method of polyimide fiber paper

ActiveCN106436441AHigh surface energyIncrease roughnessDefoamers additionPaper/cardboardFiberPapermaking

The invention discloses a preparation method of polyimide fiber paper, and belongs to the field of paper-making industries and materials. The method comprises the steps that polyimide chopped fiber is treated by a chemical reagent, the treated fiber is washed to be neutral, then, the fiber, a binder and a dispersing agent M are mixed according to a certain mass ratio, the fiber raw materials are dispersed into a pulp suspension, papermaking is performed through a paper making machine to obtain raw polyimide fiber paper, and finally hot pressing is performed through a hot press to obtain the polyimide fiber paper. According to the preparation method, the fiber is subjected to modification treatment, fiber surface active groups are added, the fiber surface energy and roughness are improved, the binding force of components in paper pages can be improved, the binder flows in the paper pages to achieve the effect of viscose fiber through hot pressing and melting, the preparation method can remarkably reduce chemical auxiliaries added in the polyimide fiber raw paper making process, environmental pollution caused in the paper making process can be reduced, and the mechanical performance, the electrical performance and the gas permeability of the polyimide fiber paper can be effectively improved.

Owner:JIANGNAN UNIV +2

Method for welding electric machine rotor copper bar coil by using high-frequency soldering machine

InactiveCN101134259AQuality improvementIncrease profitWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The present invention discloses welding process of copper bar and coils in motor rotor with a high frequency brazing machine. The welding process includes the following steps: 1. pressing the welded workpieces on the inducer; 2. heating weld junction, repair welding and shaping; 3. turning the copper bar automatically and welding its other weld junction; turning the copper bar automatically to the initial welding position; and 5. ending. The present invention has the advantages of high welding efficiency, high welding quality, high material utilizing rate, etc.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Triazole crosslinked polymers in recyclable energetic compositions and method of preparing the same

A recyclable energetic composition and method of processing energetic compositions cured by cyclo-addition of azido groups of the polymer binder with di- and / or tri-acetylene curatives (components) to form triazole linkages, such that the cure reaction is accelerated or delayed at will without degradation, allowing storage and later recycling of unused material for reduction of hazardous waste, and reduction of pollution.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Lost foam casting production low-carbon steel upper core disc and impact seat processing method

InactiveCN104162633AAvoid crackingImprove compromiseFoundry mouldsFoundry coresManufacturing technologyHigh volume manufacturing

The invention discloses a lost foam casting production low-carbon steel upper core disc and impact seat processing method. The method comprises the following steps: making foam polystyrene EPS into a foaming member, which has the same shape as a cast and is a little bigger than the cast; painting a plurality of fireproof coatings on the surface of the foaming member, placing the foaming member in non-adhesive moulding sands, carrying out casting on the foaming member, wherein during the casting process, the foam polystyrene EPS foaming member is burnt and gasified under the assistance of vacummizing and vibration during the casting process, and finally the molten liquid replaces the foaming member as the cast. The lost foam technology is used to manufacture upper core disc and impact seat, is capable of reducing the metal tissue defects and improving the compactness and anti-fatigue strength of metals, moreover has the advantages of high precision in size, reducing on cleanness, reduced processing time, compact tissue of products, suitability for massive production, and high automation, can greatly improve the operation environment, and has greater advantages and a vaster prospect, compared to the conventional manufacture technology of upper core disc and impact seat.

Owner:XIANGTAN SANTAI MACHINERY MFG

Method for producing degradable material with manioc waste and wine stillage

InactiveCN101302734AWith foldableCompressive and folding resistantNatural cellulose pulp/paperReinforcing agents additionCartonPaperboard

The invention discloses a method for producing a novel degradable material by manioc dreg and pot ale and comprises the following steps: the manioc dreg or the pot ale is purified, ground, cleaned, drained and mixed with dry paper pulp according to the weight proportion of a to b; wherein, the a lies between 2 and 5, and the b lies between 5 and 8; a papermaking addition agent is added, and the mixture is molded and parched, thus obtaining the degradable material product. Paper pulps of vegetable fiber such as waste newspapers, carton paper, paperboards and other paper pulps of vegetable fiber materials can be taken as the dry paper pulp. The method for producing the novel degradable material by the manioc dreg and the pot ale adequately utilizes wastes of manioc resources such as the manioc dreg, the pot ale to produce the novel industrial degradable material with good quality and low cost, replaces degradable materials of cellular plastics, and not only solves the difficult processing problem of wastes and changes wastes into valuable, but also effectively generates the actions of controlling and eliminating the white pollution; furthermore, the method for producing the novel degradable material by the manioc waste and the pot ale has uncomplicated technique, short production period, low cost, low energy consumption, simple and convenient operation, high product stability and good economic, social and environment-protective benefits.

Owner:广西农垦明阳生化有限公司

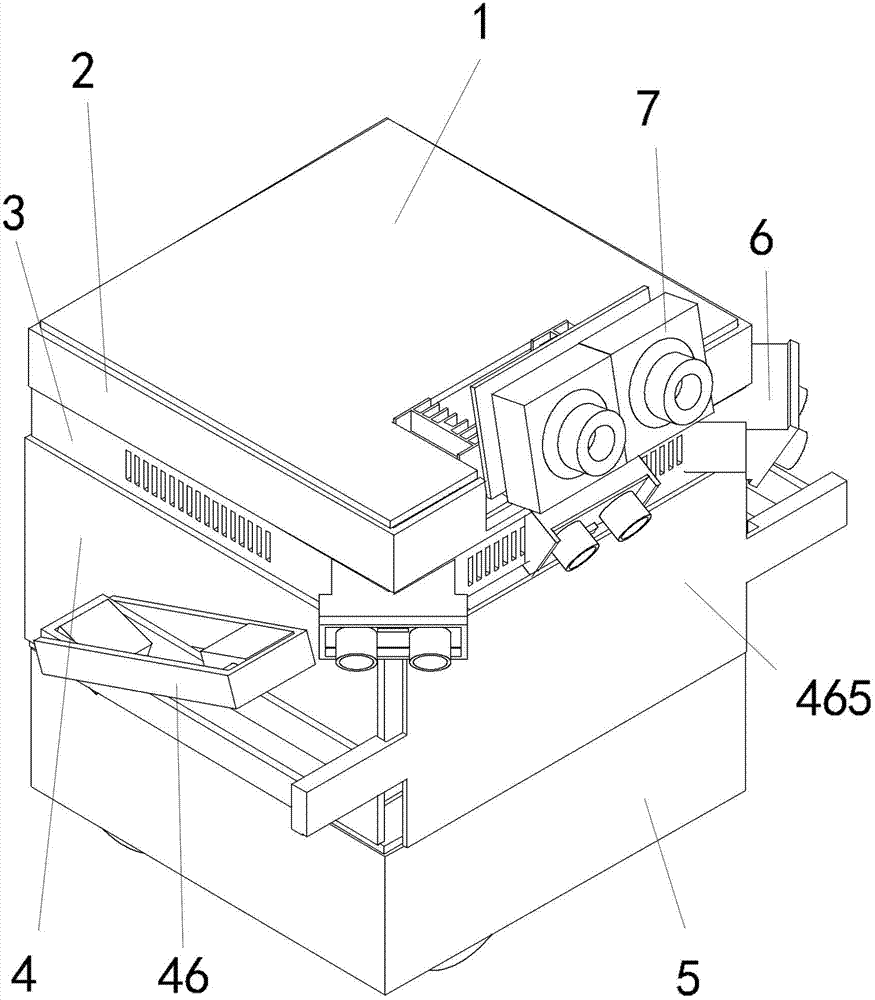

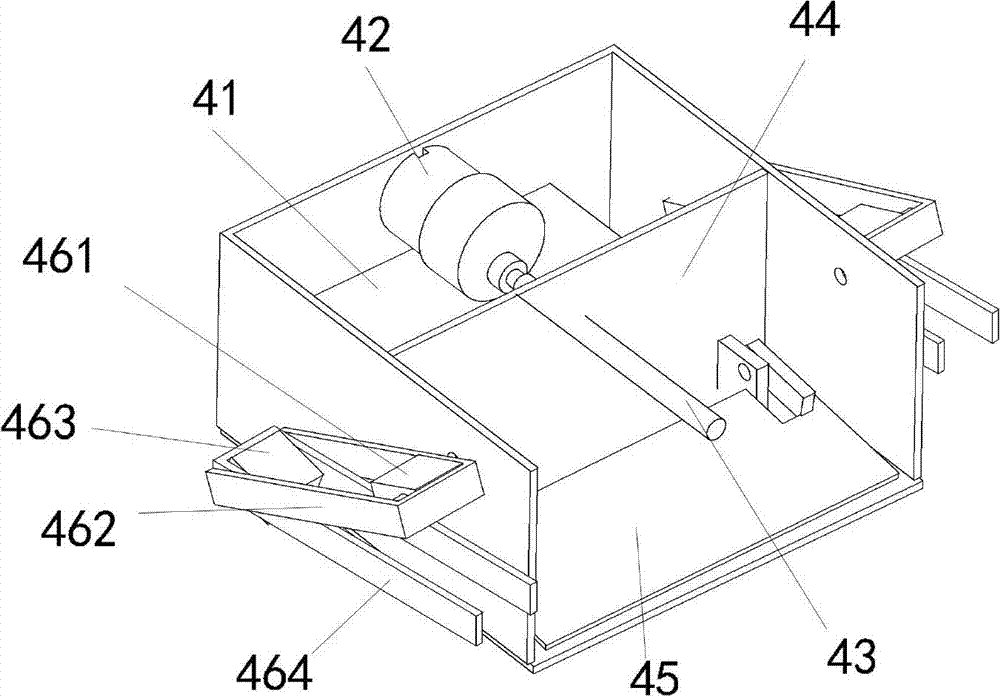

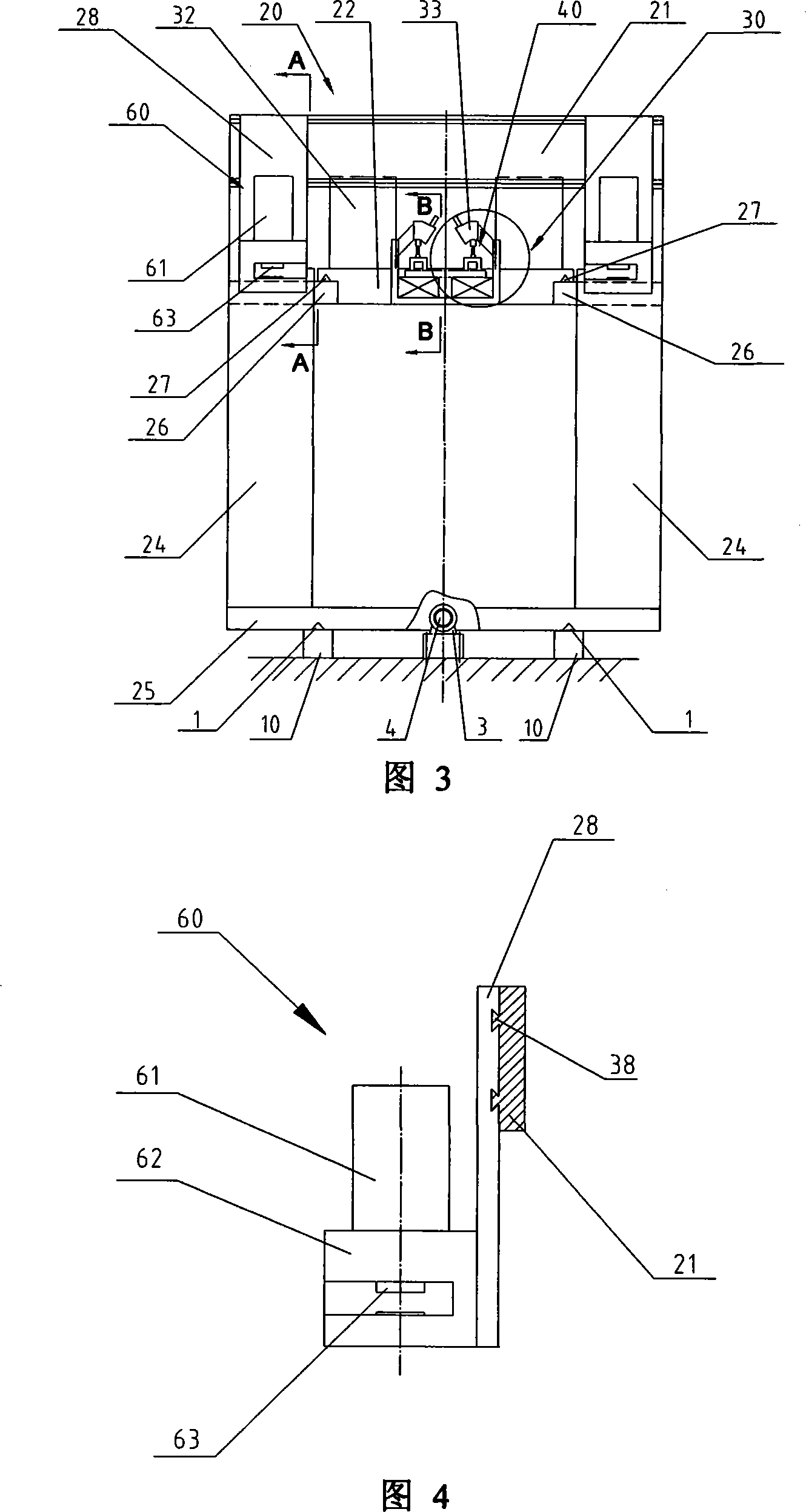

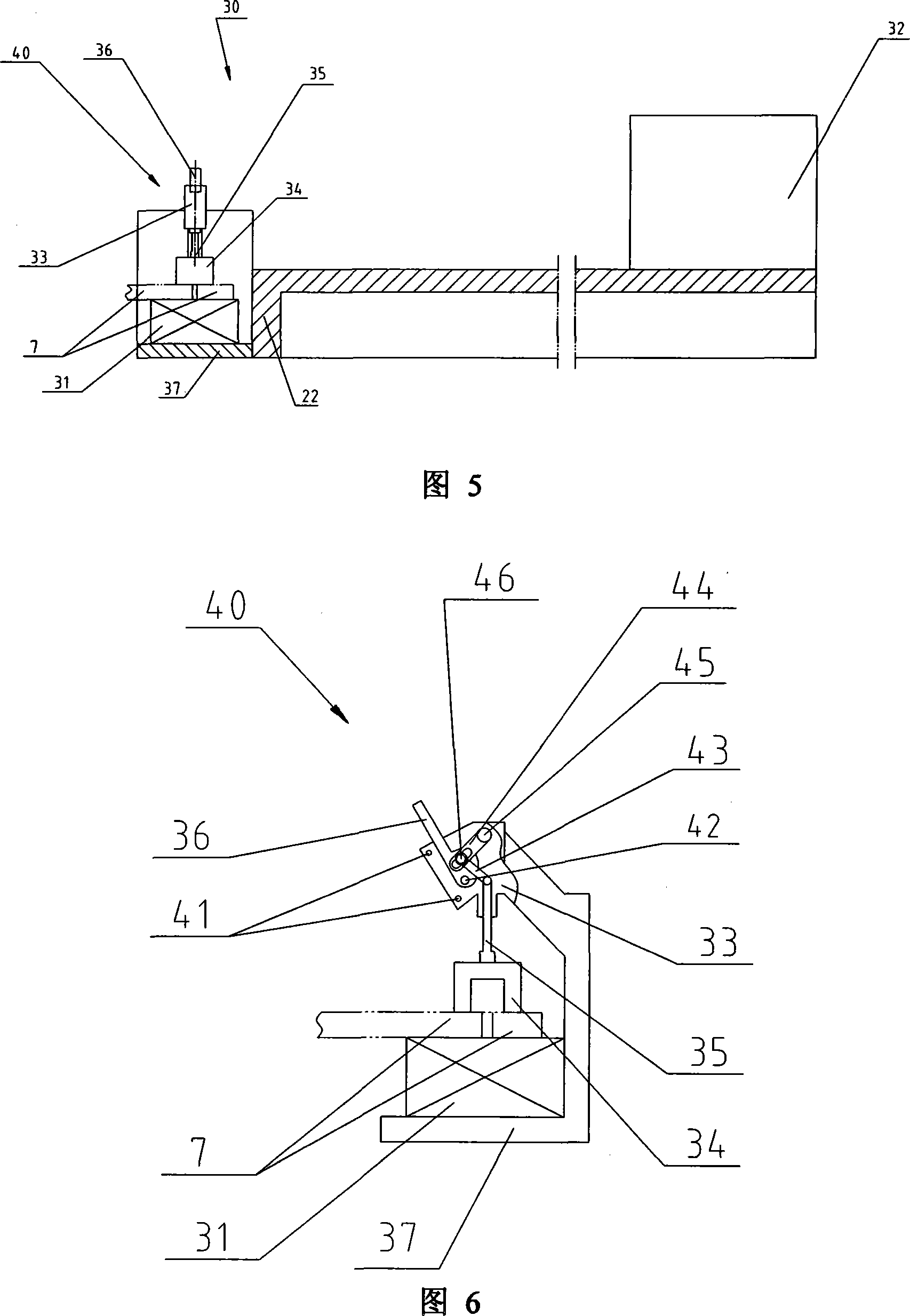

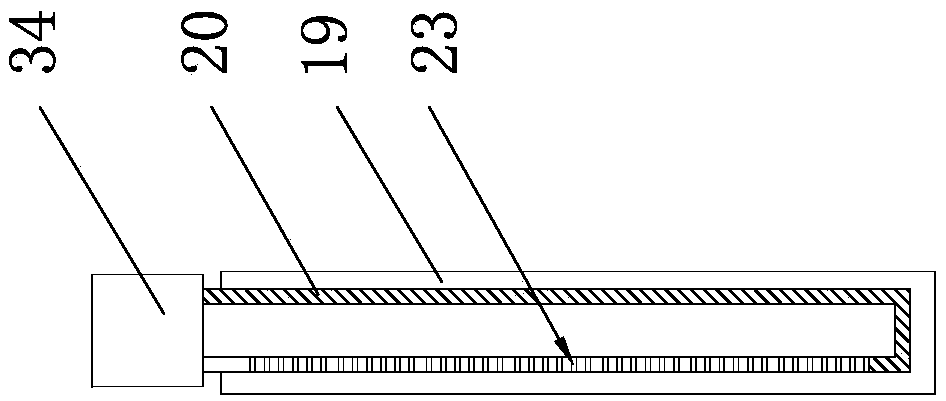

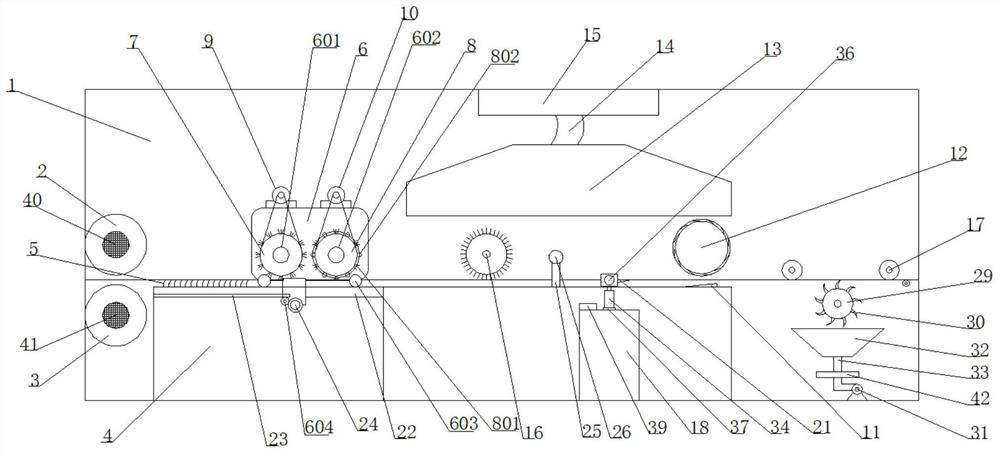

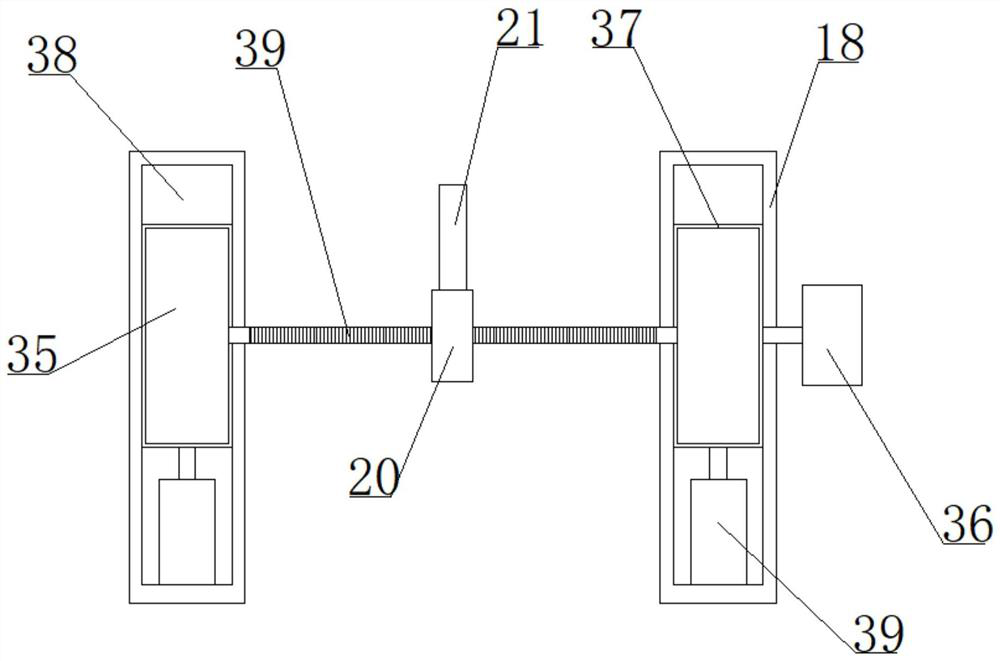

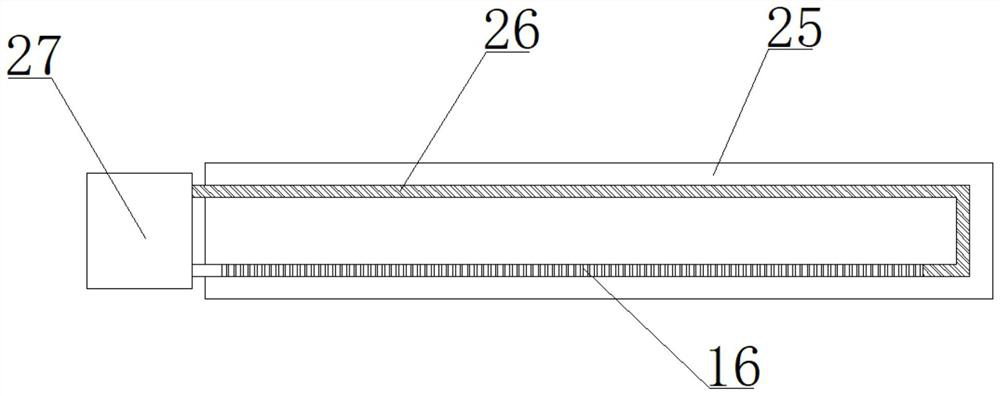

Selective laser sintered single-face powder supplying device realized by adopting powder returning groove

InactiveCN102126293AIncrease profitSave equipment spaceIncreasing energy efficiencyLaser beam welding apparatusMetallurgySelective laser sintering

The invention provides a selective laser sintered single-face powder supplying device realized by adopting a powder returning groove. The selective laser sintered single-face powder supplying device comprises a powder spreading roller, a powder supplying cylinder, a powder overflowing cylinder and the powder returning groove, wherein the single-face powder supplying device only needs to install one powder supplying cylinder and one powder overflowing cylinder at one side of a worktable and install one powder returning groove at the other side of the worktable; and the powder returning groove comprises a cylinder body, a movable bottom plate, and a control shaft connected with the movable bottom plate. In the invention, the equipment space is saved; the equipment dimension is reduced; the equipment complexity is reduced; the equipment cost is effectively reduced; the equipment reliability is improved; and the SLS (Set Location Stack) process requirements are further met.

Owner:湖南美纳科技有限公司

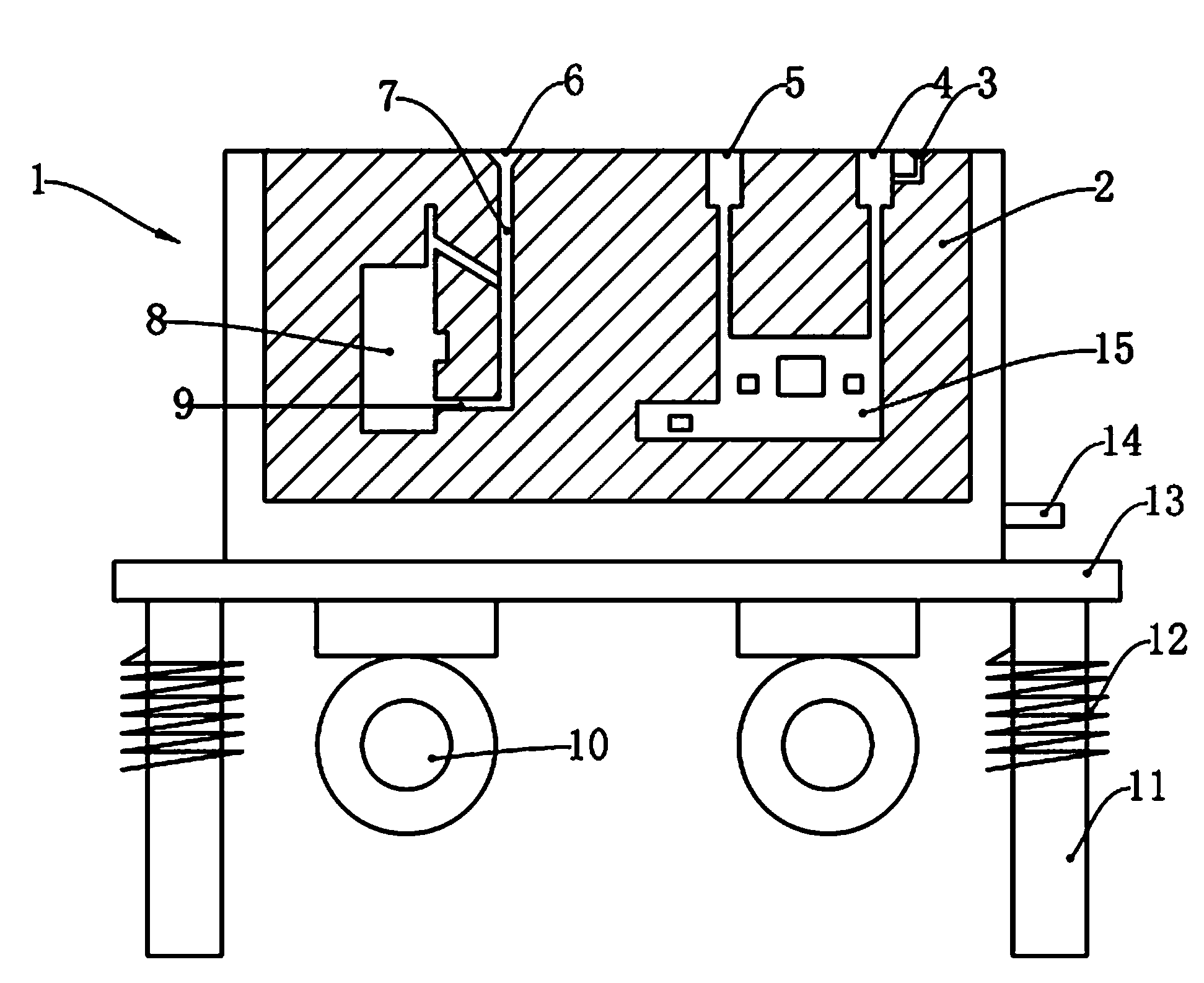

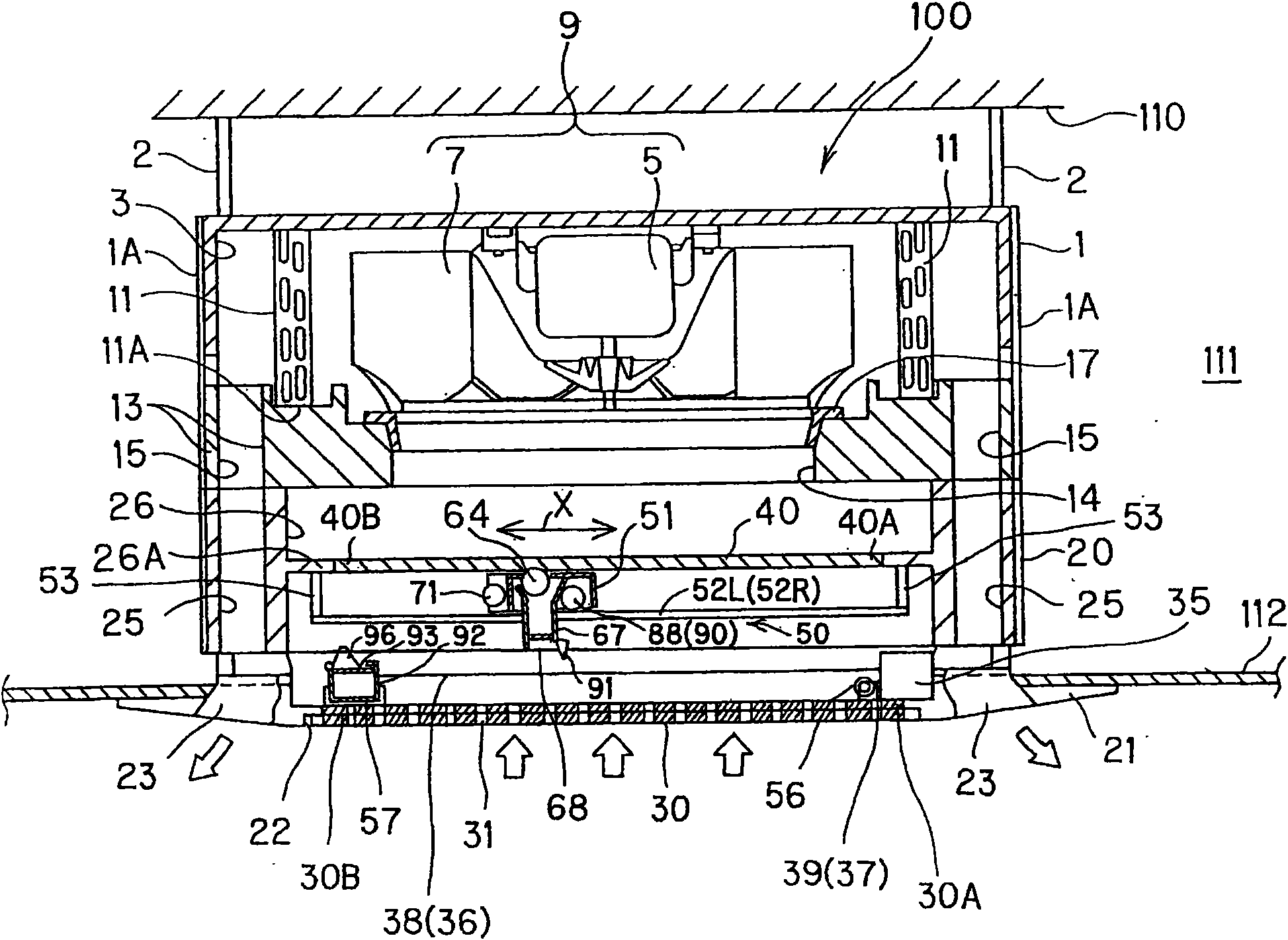

Air conditioner

InactiveCN101650054AReduce loadEasy to removeMechanical apparatusDispersed particle filtrationFiltrationAir filter

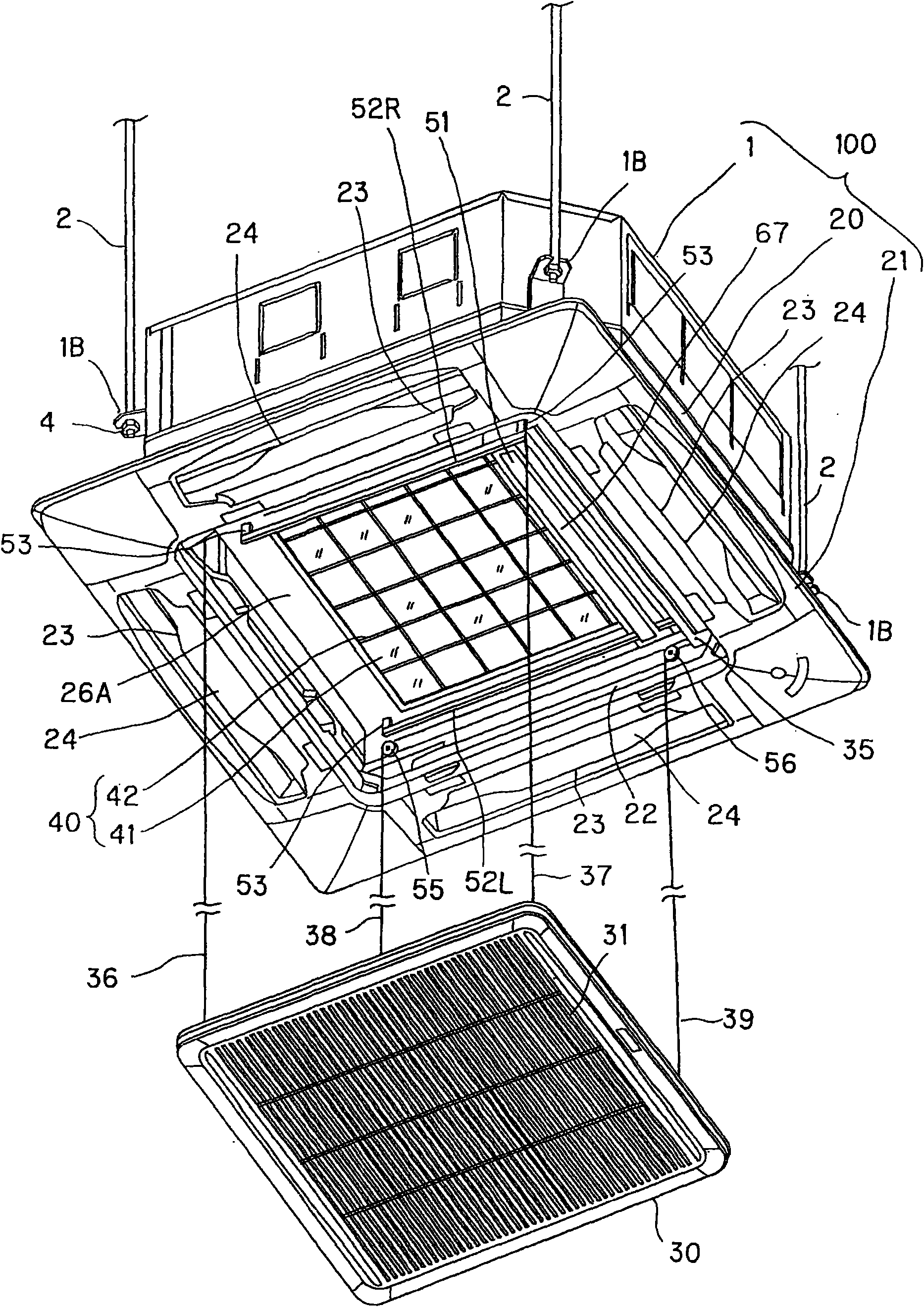

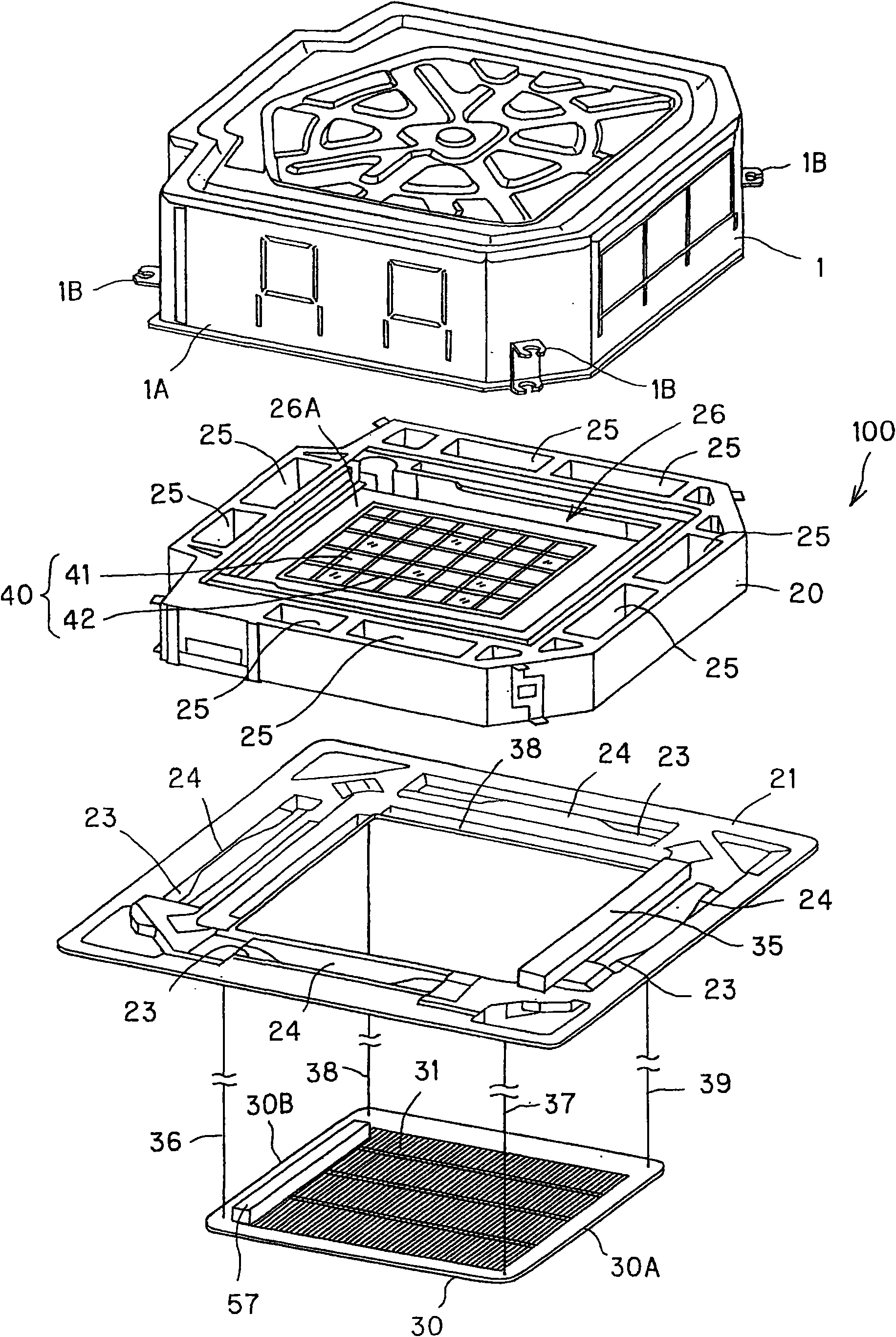

The present invention provides an air conditioner, which can reduce the load when the dust collection box goes up and down, and can easily remove dust in the dust collection box. The air conditioner has a filtration chamber (20) between the main body unit (1) and the decorative sheet (21), and has an air filter (40) and a cleaning mechanism (50) in the filtration chamber (20), wherein the air filter (40) captures dust sucked into the air through the suction grille (30) of the decorative sheet (21), and the cleaning mechanism (50) removes the dust adhered to the air filter. The air conditioneralso has a dust collection box (57), wherein the dust removed by the cleaning mechanism (50) is transferred from the cleaning mechanism (50) and collected in the dust collection box. The air conditioner also has an suction grille (30) and a lifting mechanism (35) capable of supporting the dust collection box (57) in an elevating way.

Owner:SANYO ELECTRIC CO LTD

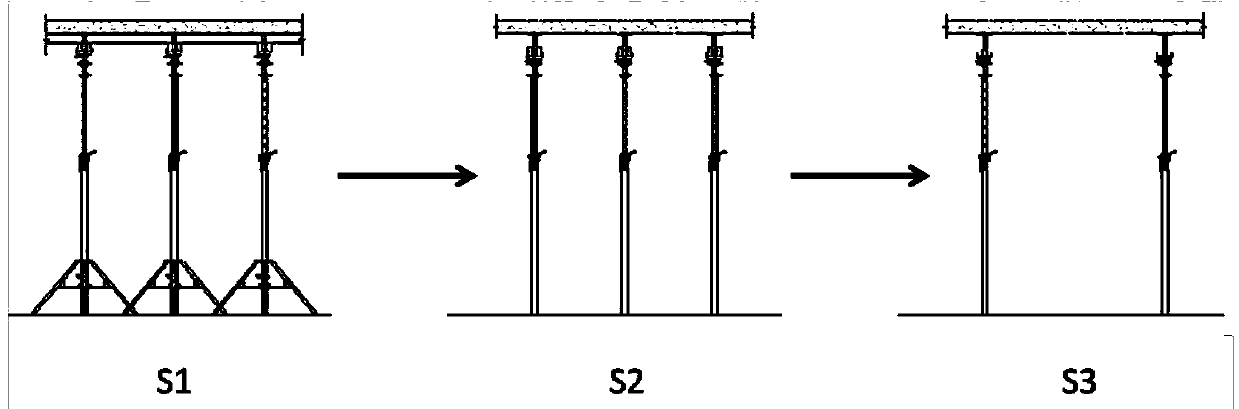

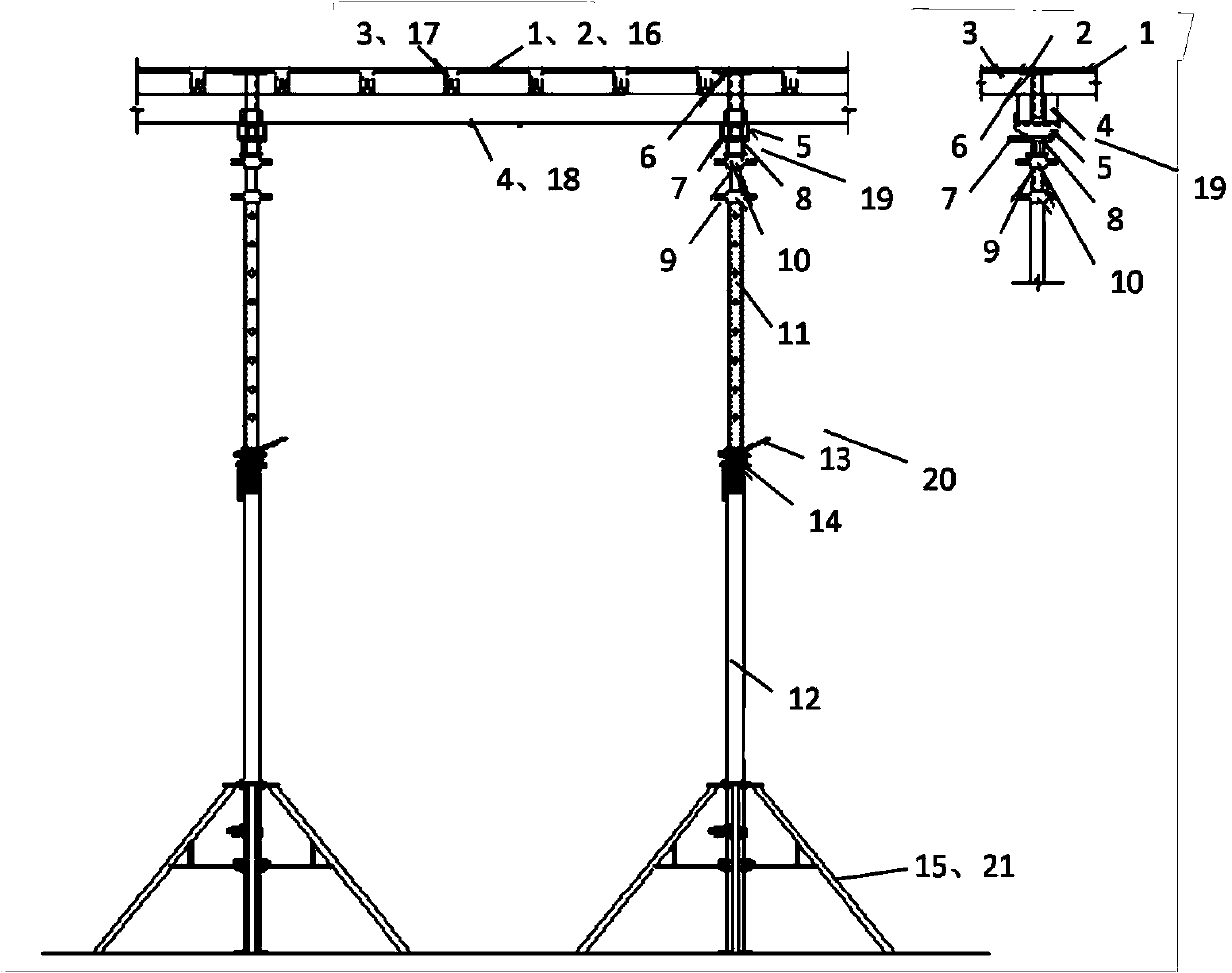

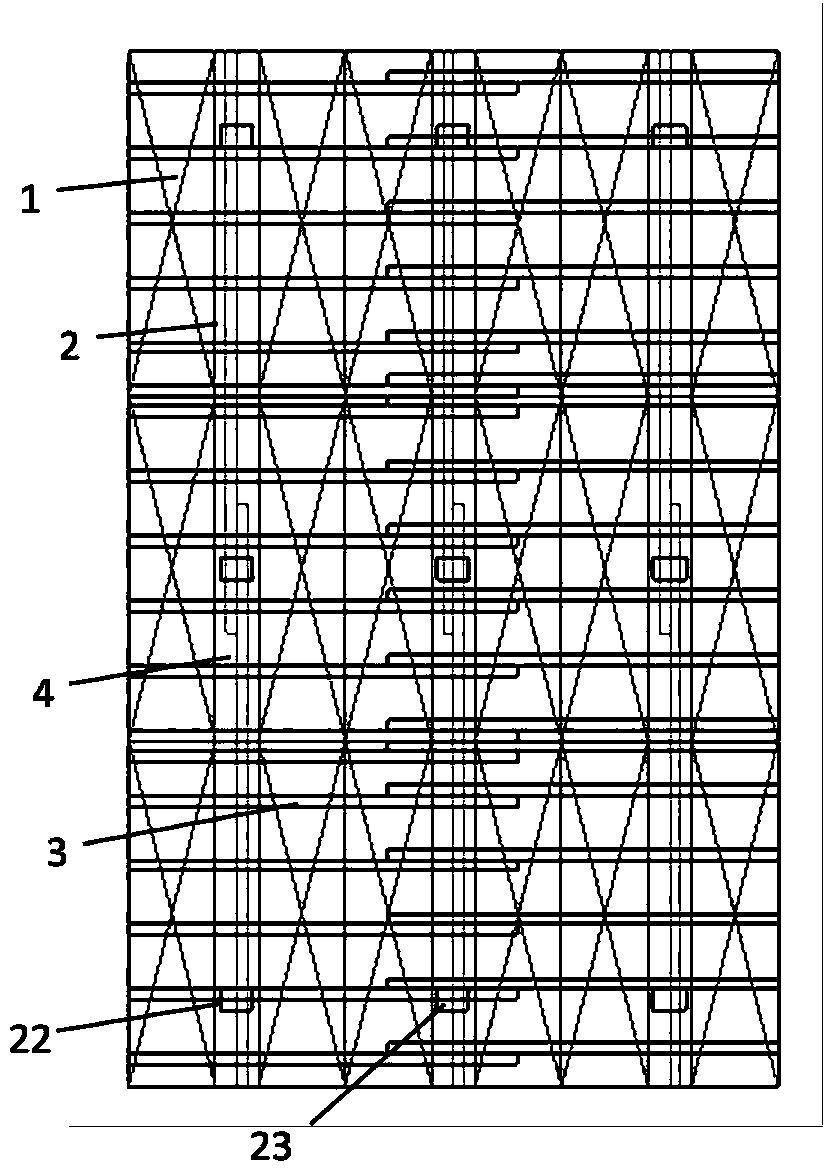

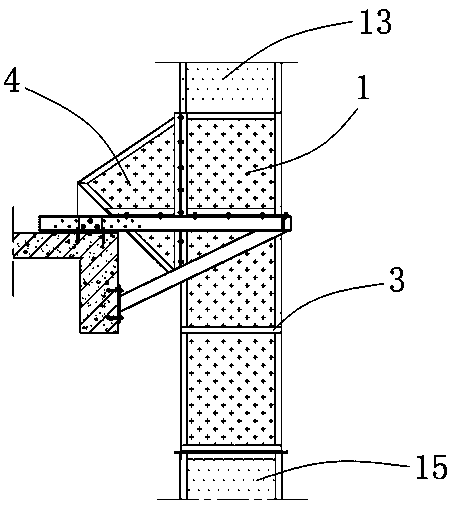

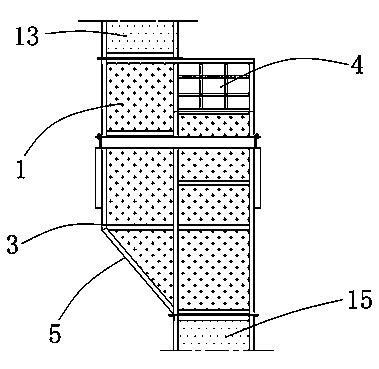

Formwork early-removal construction method allowing three-dimensional space size to be adjustable

ActiveCN103806646AMany turnover timesGood technical and economic benefitsForms/shuttering/falseworksShoresHollow coreMechanical engineering

A formwork early-removal construction method allowing the three-dimensional space size to be adjustable comprises the following steps that S1 an early-removal supporting system is installed; S2 formworks are removed; S3 a main beam (4) is removed. The early-removal supporting system comprises a formwork part (16), a secondary beam part (17), a main beam part (18), a hollow screw double-adjustment knocking-down type early-removal supporting head part (19), an independent supporting part (20) and a tripod part (21). According to the formwork early-removal construction method, the one-time input number of the formworks can be greatly reduced, the arrangement number of the formworks is reduced by 1 / 3-1 / 2, service lives of the formworks and service life of the supporting system can be prolonged, construction costs are saved by more than 20%, the construction period is effectively shortened, construction speed is increased, and work efficiency is improved by more than30%.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +3

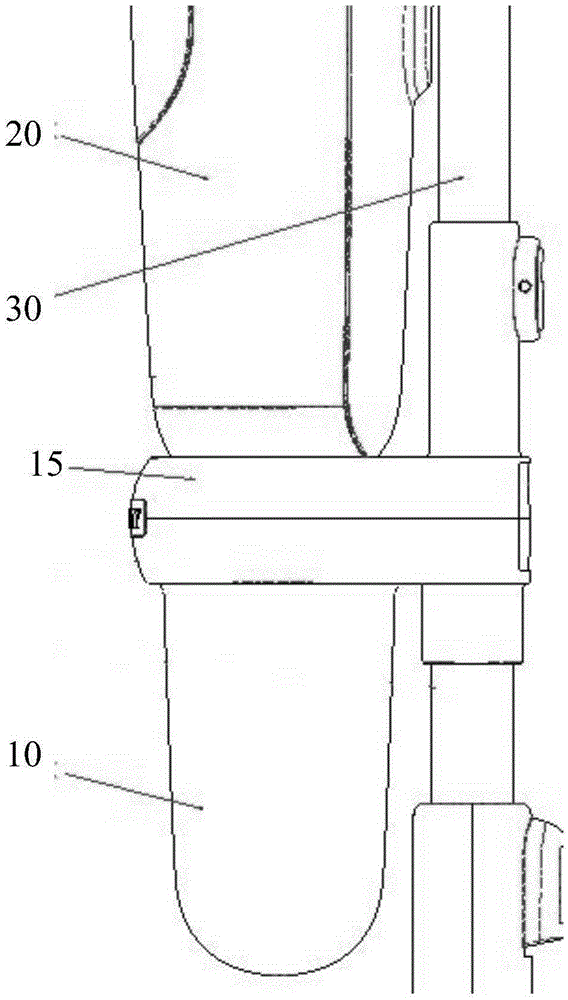

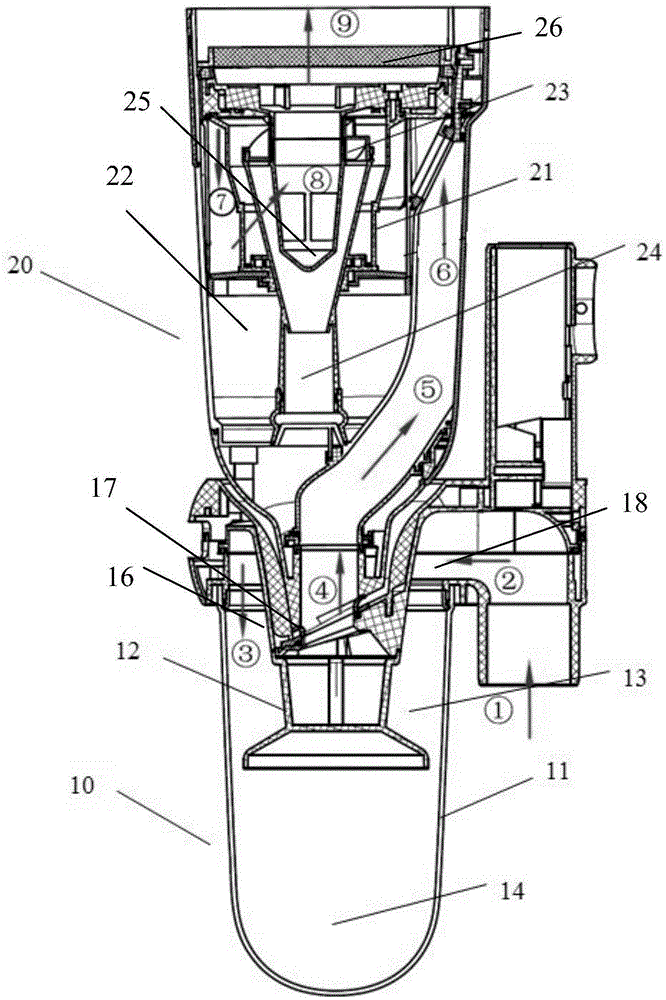

Three-stage tornado dust cup filtering system and dust collector comprising same

The invention discloses a three-stage tornado dust cup filtering system and a dust collector comprising the same. The filtering system comprises a spiral two-stage dust-air separation device and a one-stage filtering device, which are arranged detachably. The filtering system comprises two dust cups namely a large-body dust cup and a handheld dust collector dust cup, so that the dust storage capacity of the whole system is increased, the separating efficiency of the dust cups is improved, air volume loss is reduced, and the separating efficiency of the large-body one-stage dust cup reaches 95% or above and is obviously improved in comparison with that of a similar one-stage cyclone system. Through carrying out dust-air separation for three times by cyclone, the HEPA is not blocked easily and cleaning of the HEPA by a user is reduced. Meanwhile, dust of larger particles and small particles is fed into two dust cups, so that the user can clean conveniently, the large-body dust cup structure is simple and high convenience in dust pouring is realized.

Owner:KINGCLEAN ELECTRIC

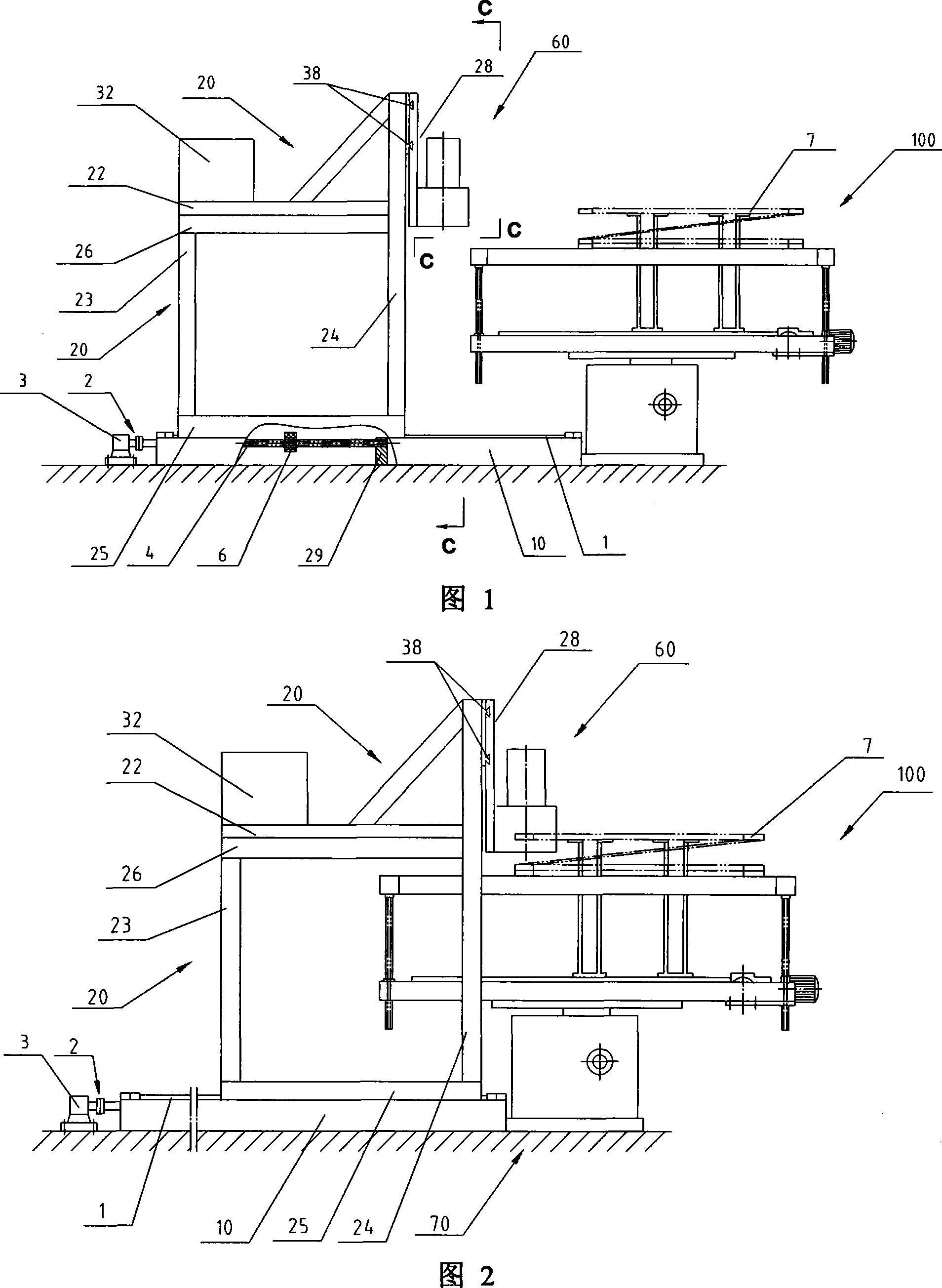

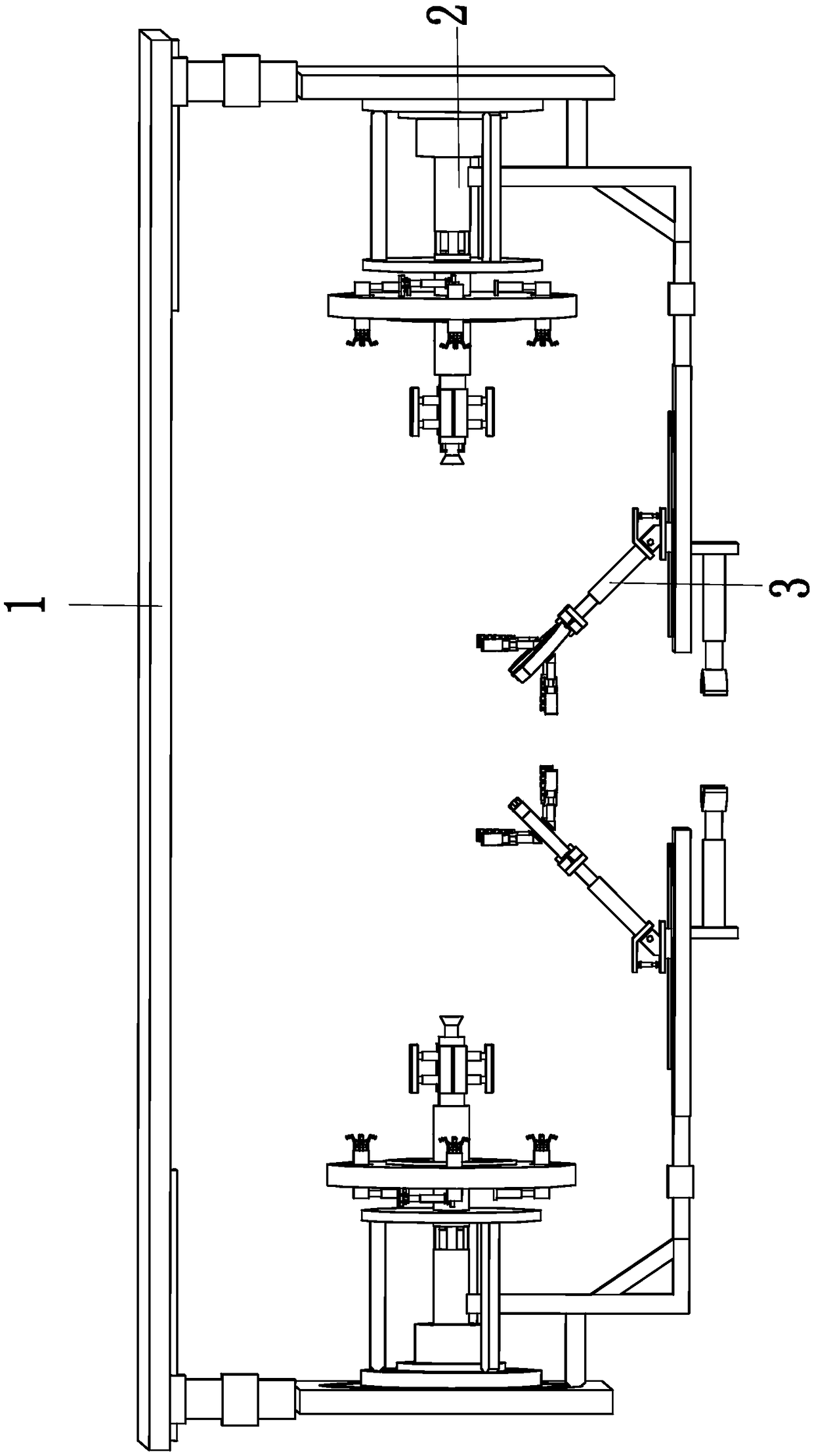

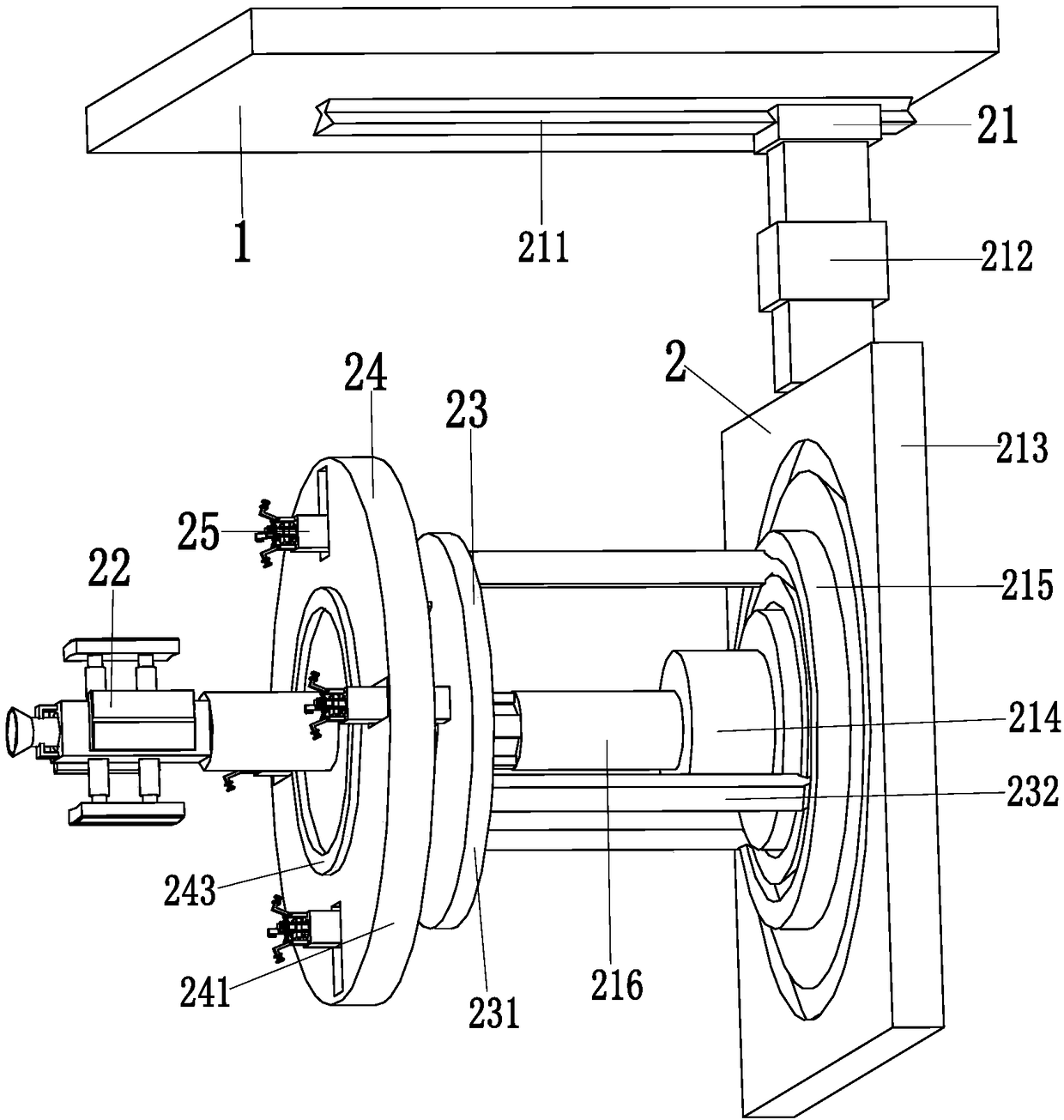

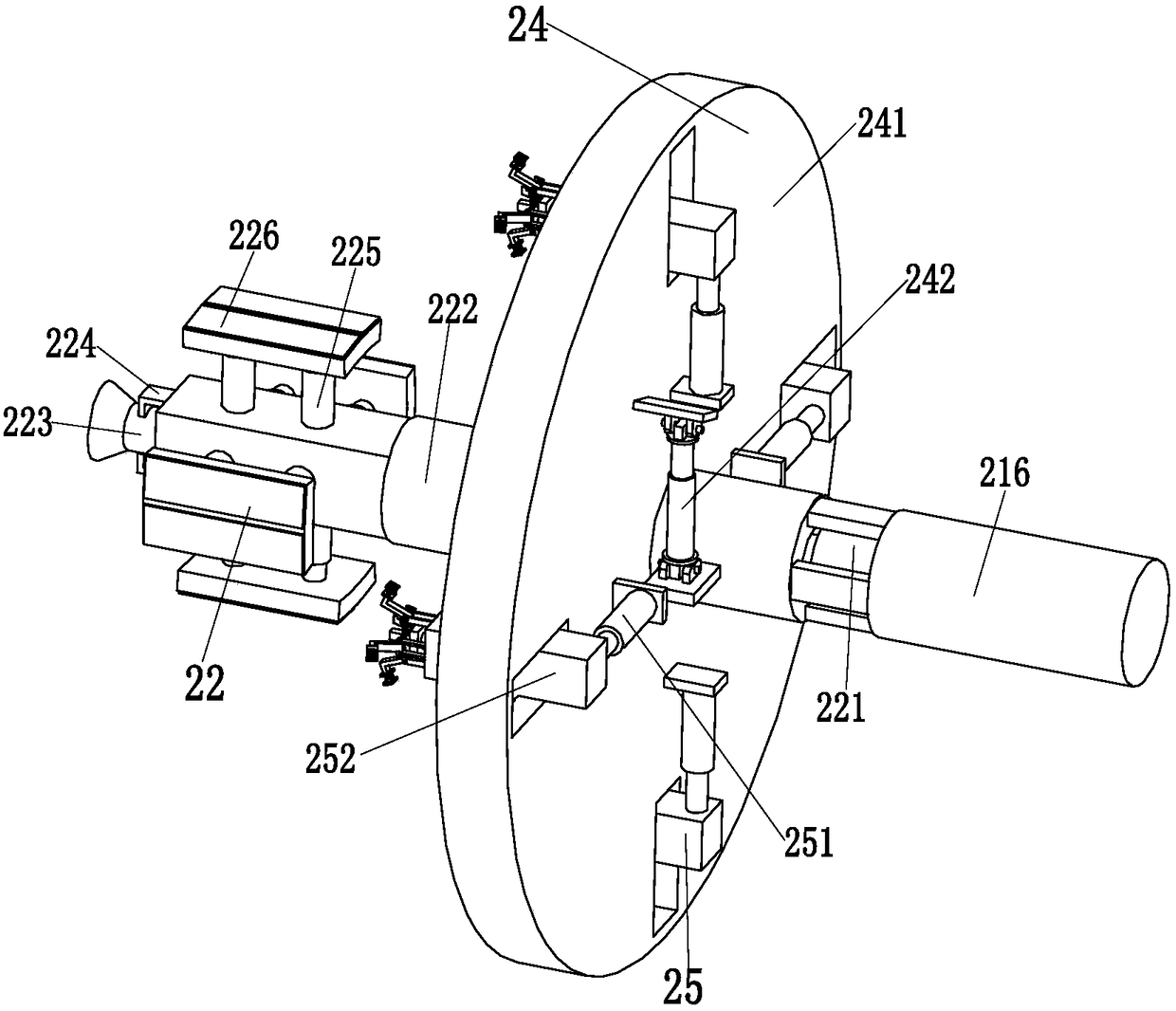

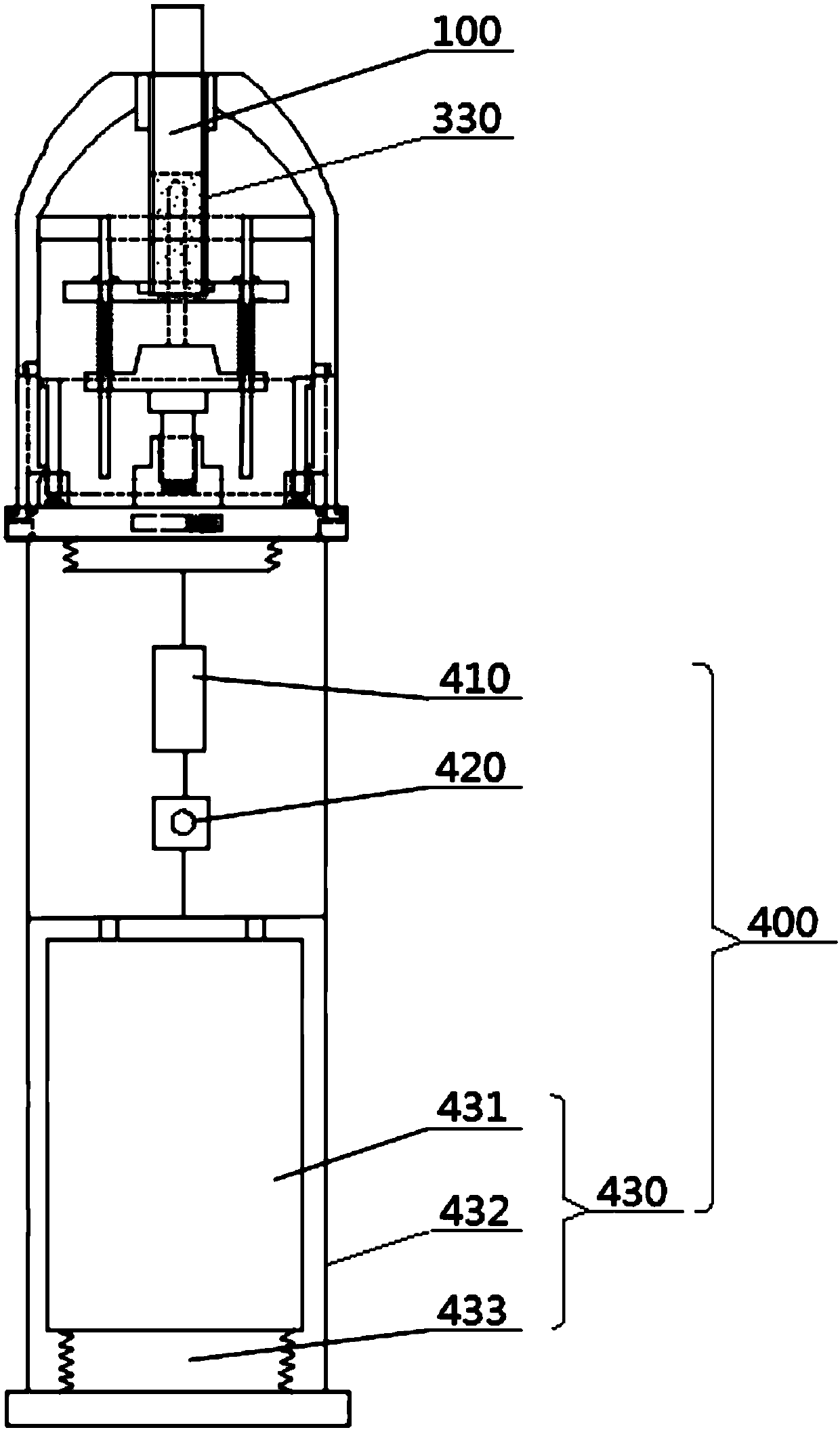

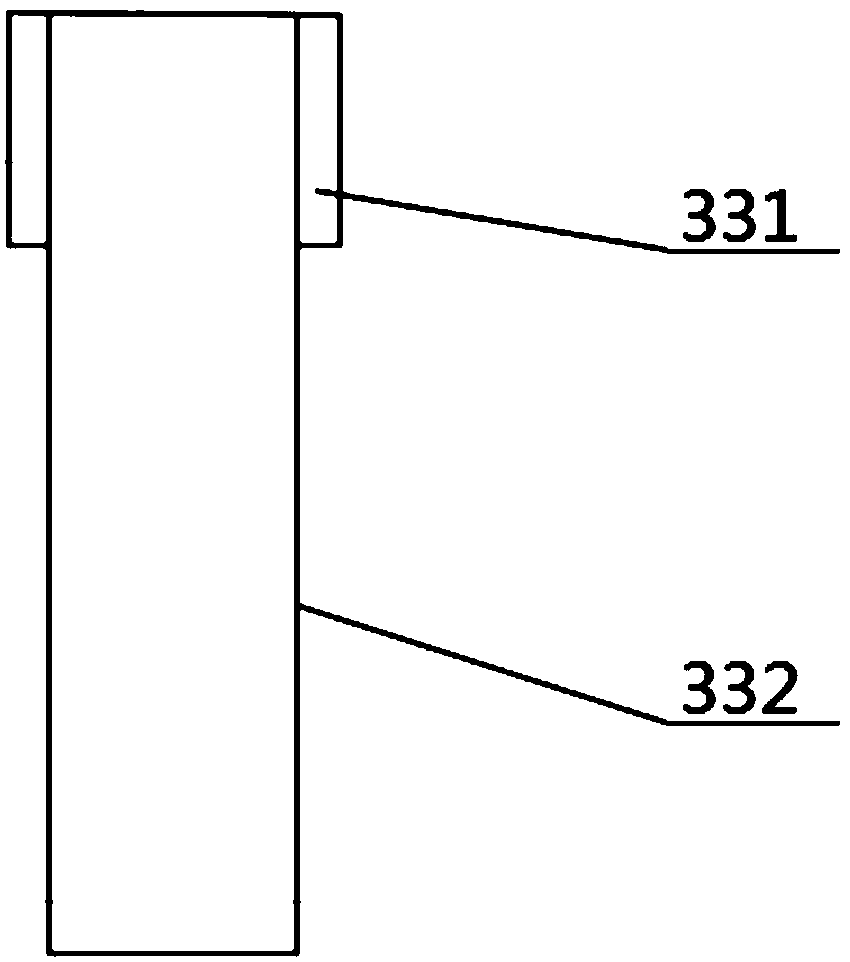

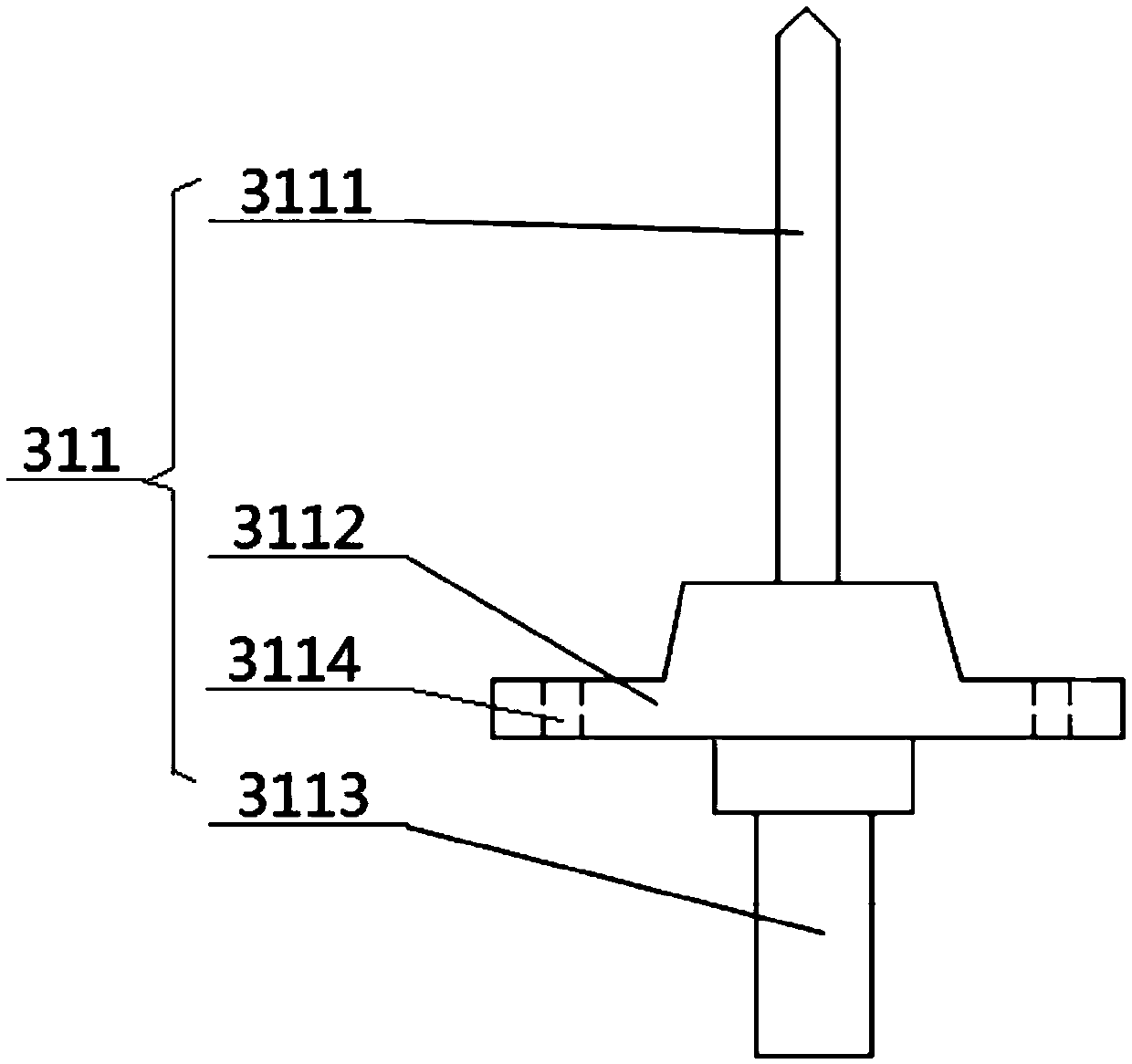

Municipal pipeline installation lifting machine

InactiveCN108455439AReduce cleanupEasy to cleanHollow article cleaningLoad-engaging elementsEngineeringUltimate tensile strength

The invention relates to a municipal pipeline installation lifting machine. The municipal pipeline installation lifting machine includes a support top plate, two location cleaning devices and fixing devices; the location cleaning devices are mounted at the left and right ends of the bottom of the support top plate respectively, and one fixing device is mounted on each location cleaning device; each location cleaning device includes a location adjusting mechanism, a location cleaning mechanism, a stable branch chain, a block-out mechanism and four clamp mechanisms. By the adoption of the municipal pipeline installation lifting machine, the difficulties can be overcome that according to current T-shaped pipe lifting, the labor intensity is high, human assistance is needed to fix T-shaped pipes, the interiors of the T-shaped pipes cannot be automatically cleaned, the effect of manually cleaning the T-shaped pipes is poor, the T-shaped pipes cannot be fixed regarding the structures of theT-shaped pipes, the T-shaped pipes of different types need different lifting appliances, the T-shaped pipes can waggle when lifted, and the T-shaped pipes cannot automatically rotate to suitable installation angles.

Owner:潘岳燕

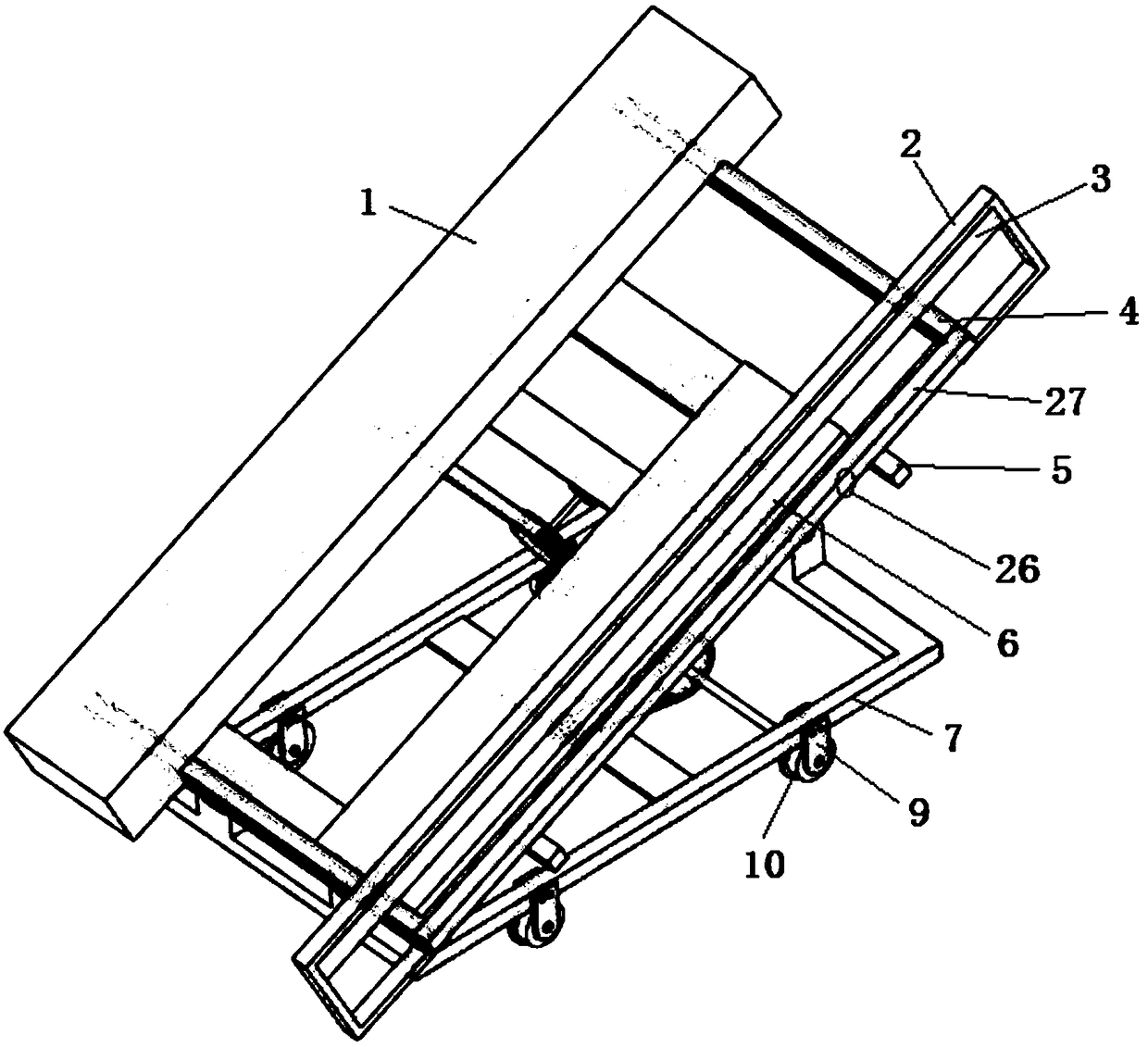

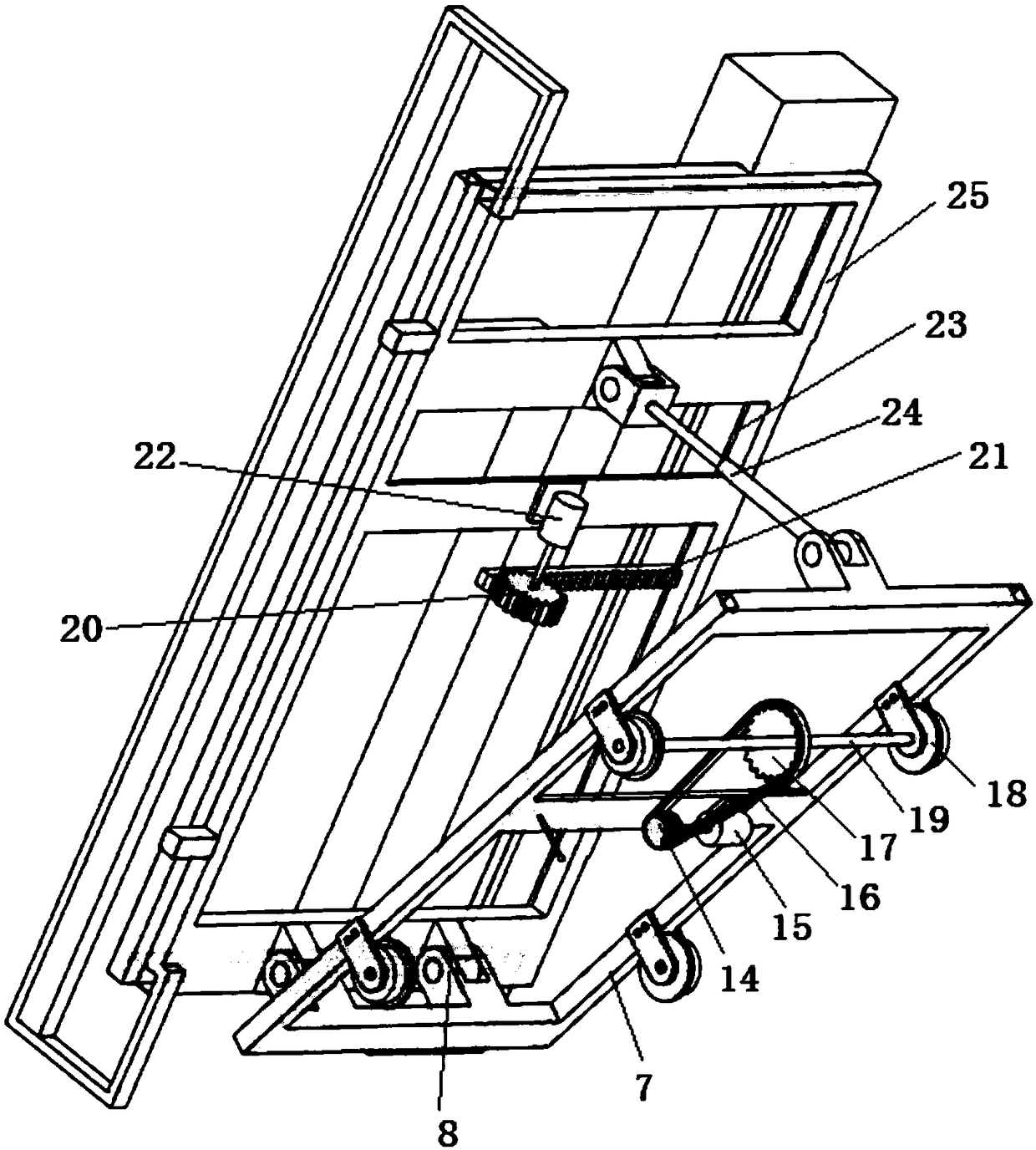

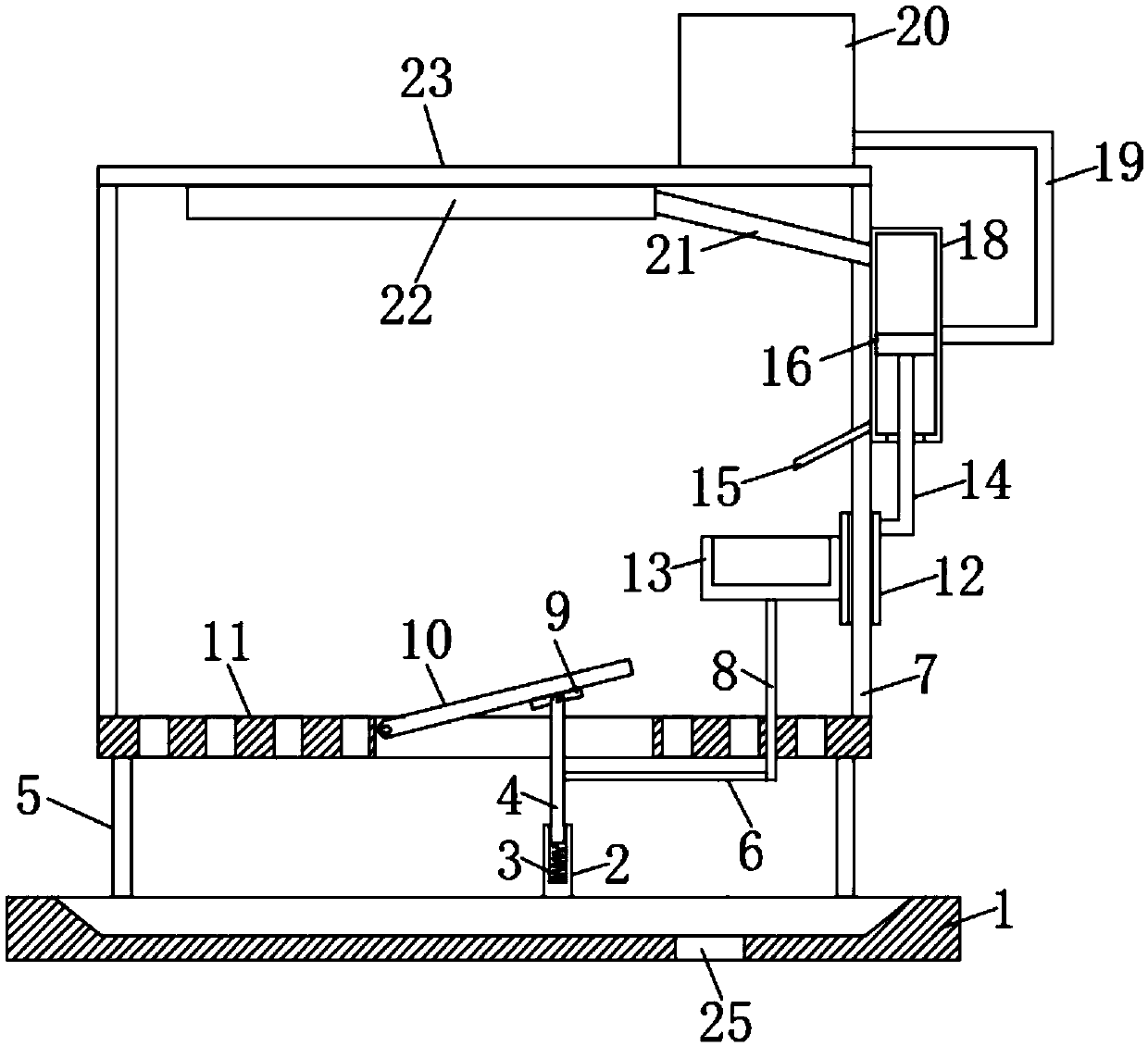

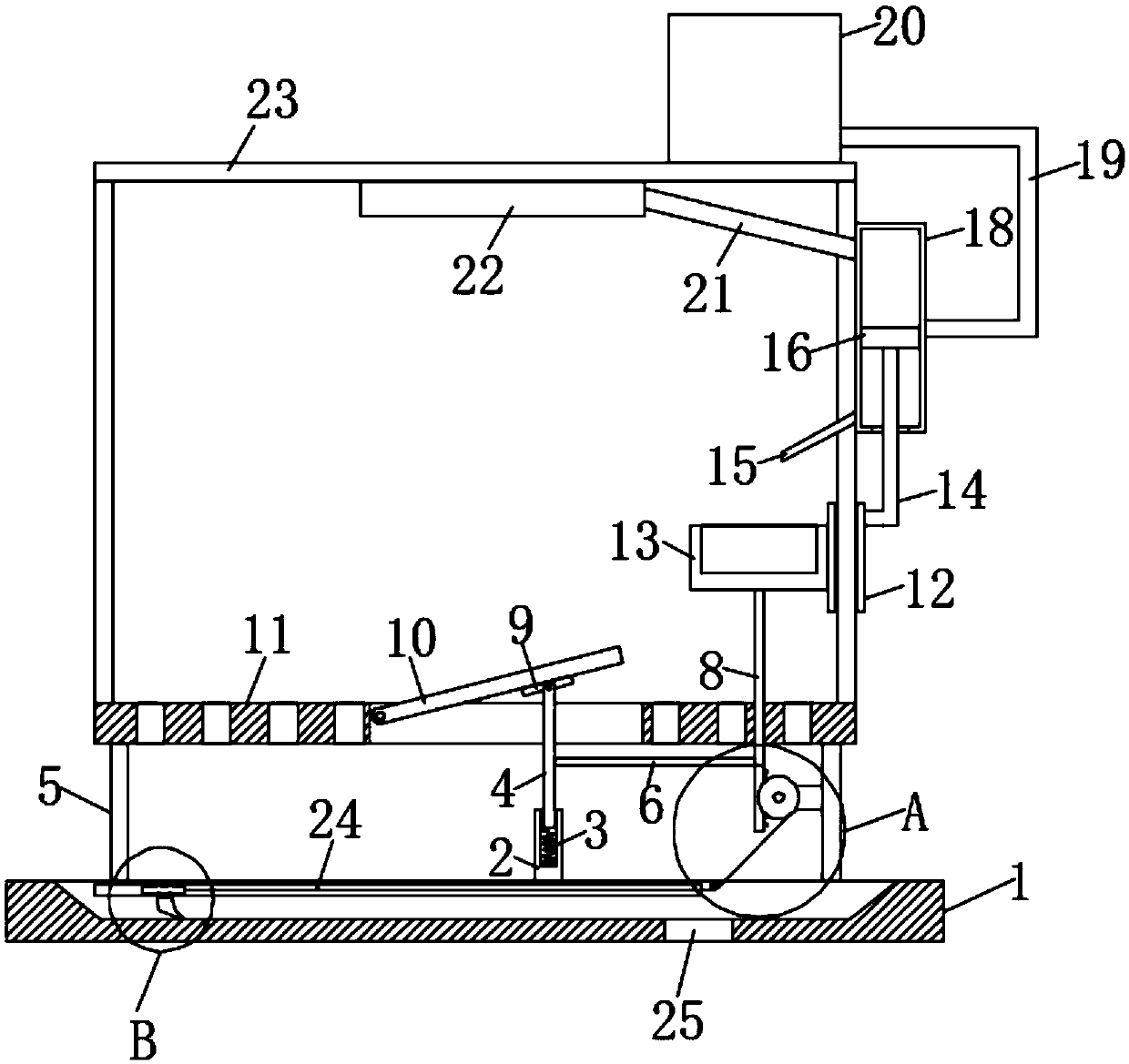

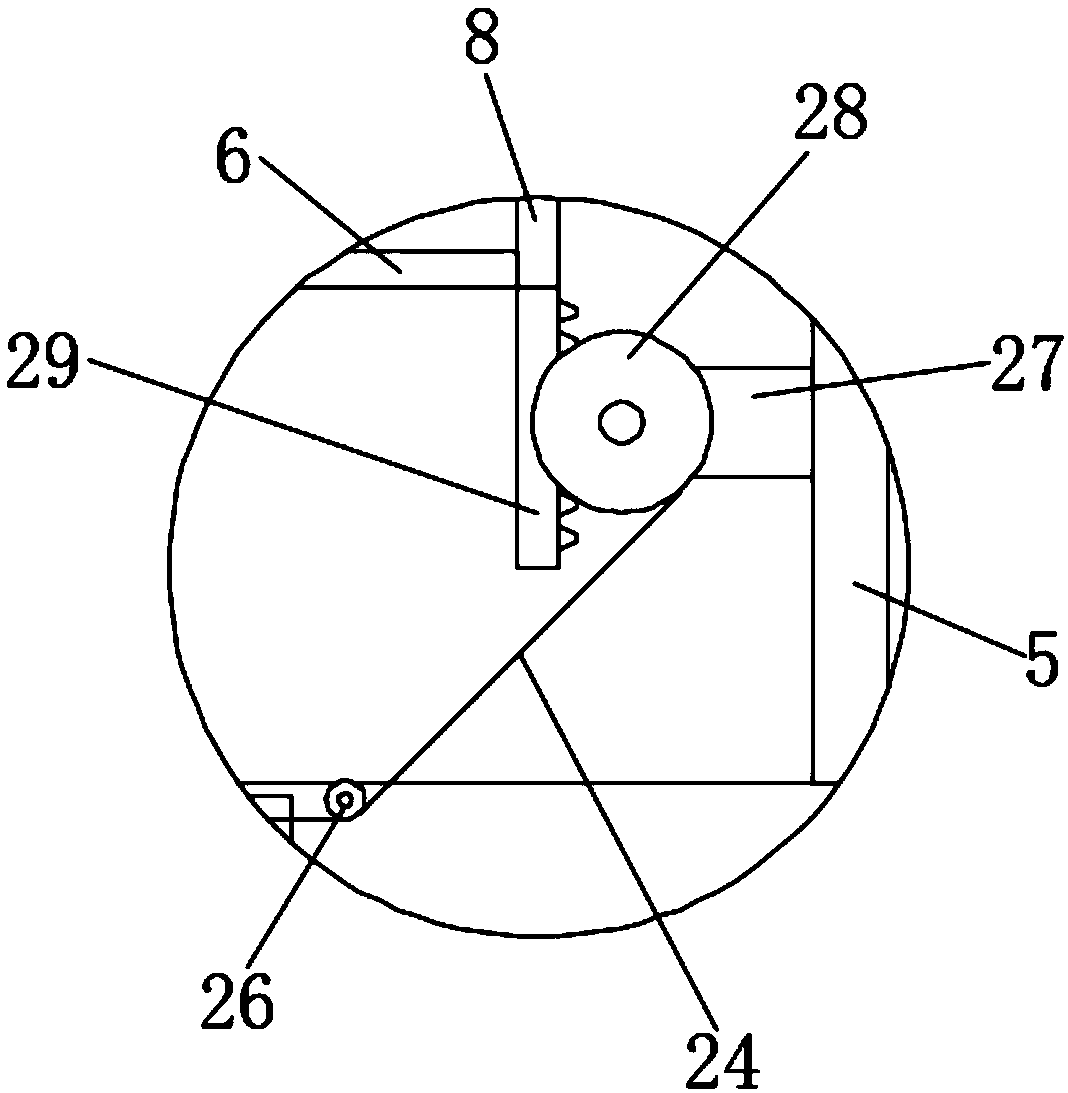

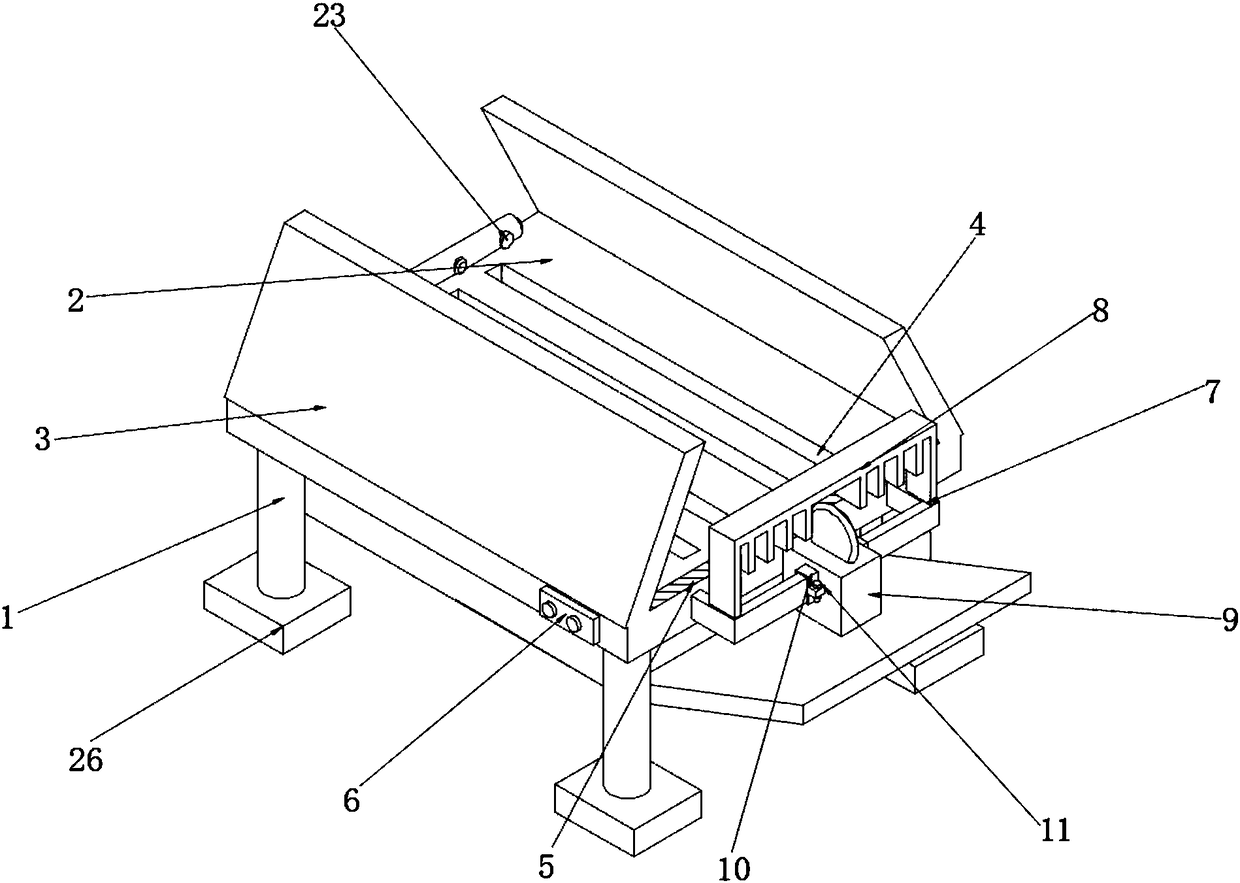

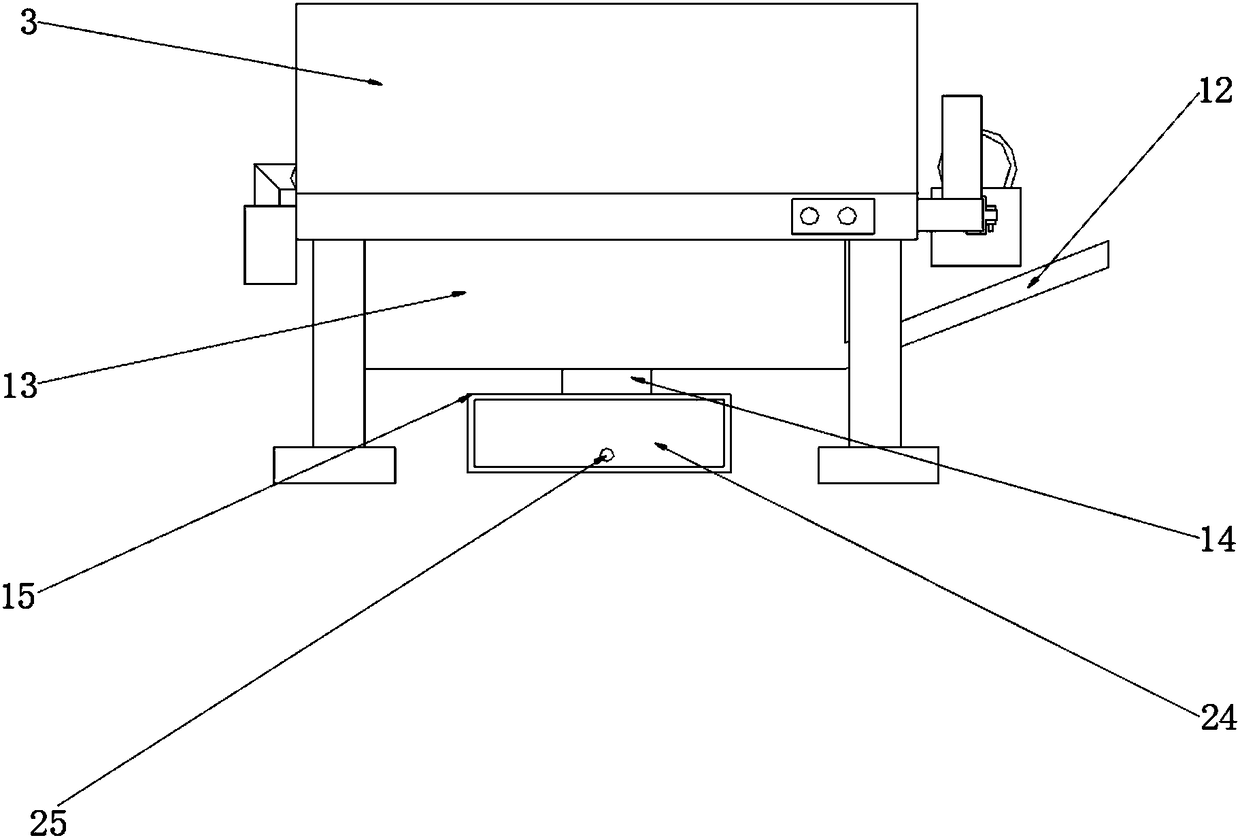

Full-automatic solar photovoltaic electric panel cleaning and detection robot

PendingCN108745998ASmooth in and outAvoid secondary pollutionPhotovoltaicsCleaning using toolsUniversal jointSteel frame

The invention discloses a full-automatic solar photovoltaic electric panel cleaning and detection robot. The full-automatic solar photovoltaic electric panel cleaning and detection robot comprises a cover plate, a cleaning mechanism, a deformation fixing mechanism, a robot traveling mechanism. The deformation fixing mechanism comprises an upper rack, a lower rack, a connecting rod I and a connecting rod II. One side of the cover plate is hinged to the connecting rod I, and the other side of the cover plate is slidably connected with the connecting rod II. The cleaning mechanism comprises a rolling brush assembly and universal joints I. The rolling brush assembly can rotate. The universal joints I are arranged at the two ends of the rolling brush assembly. The other ends of the two universal joints are rotatably connected with the upper rack and the lower rack. The full-automatic solar photovoltaic electric panel cleaning and detection robot can automatically travel on a photovoltaic panel array group steel frame guide rail and can automatically adapt to different inclination angles and staggered conditions of photovoltaic electric panels in the parallel and perpendicular directionsto achieve full-automatic cleaning of the photovoltaic electric panels. Besides, the full-automatic solar photovoltaic electric panel cleaning and detection robot can conduct image scanning on the surfaces of the photovoltaic electric panels through image scanning sensors, transmits scanned images and position information to a cloud platform to conduct defect detection like breakage and hot spotsand facilitates guidance, maintenance and replacement.

Owner:NANJING NORMAL UNIVERSITY

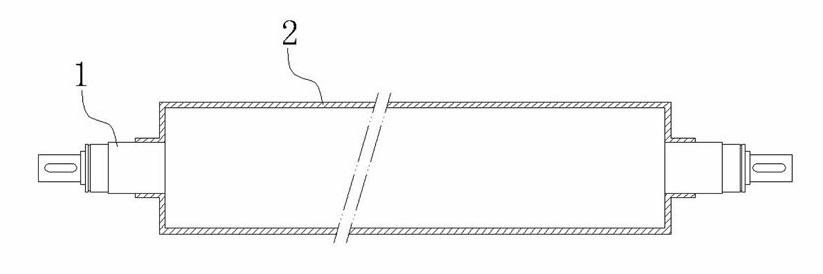

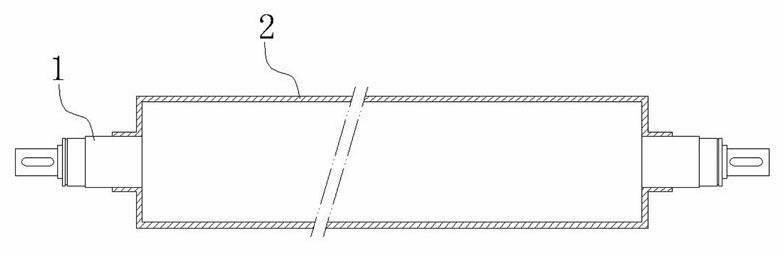

Rewinding shaft for electrolytic copper foil production and using method thereof

ActiveCN102161452ASolve the imprinting problemReduce usageElectroforming processesElectrolysisMetallurgy

The invention discloses a rewinding shaft for electrolytic copper foil production and a using method thereof and belongs to the technical field of copper foil processing. The technical key points are that: the rewinding shaft comprises a rolling wheel, wherein a rubber layer is covered on the outer surface of the rolling wheel. The using method comprises the following steps of: (1) starting a cathode roller and adjusting rotating speed of the cathode roller to be between 1.5 and 2.5 m / min; (2) wetting the surface, opposite to the rewinding shaft, of the opening of the copper foil with water; (3) adhering the wetted opening of the copper foil to the surface of the rubber layer on the rewinding shaft; (4) starting the rewinding shaft and controlling the range of the rotating tensile force of the rewinding shaft to be between 200 and 300 N; and (5) dragging and rotating the copper foil on the rewinding shaft for 2 to 5 loops, fastening the copper foil on the rewinding shaft, and adjusting the rotating speed of the cathode roller to be in the range according to the gram weight and thickness of the copper foil required to be produced. The rewinding shaft for the electrolytic copper foil production solves the problem of reel bottom imprint during the production of ultrathin copper foil, increases qualification rate of the products and reduces production cost, and is applied to electrolytic copper foil production.

Owner:梅州市梅县区金象铜箔有限公司

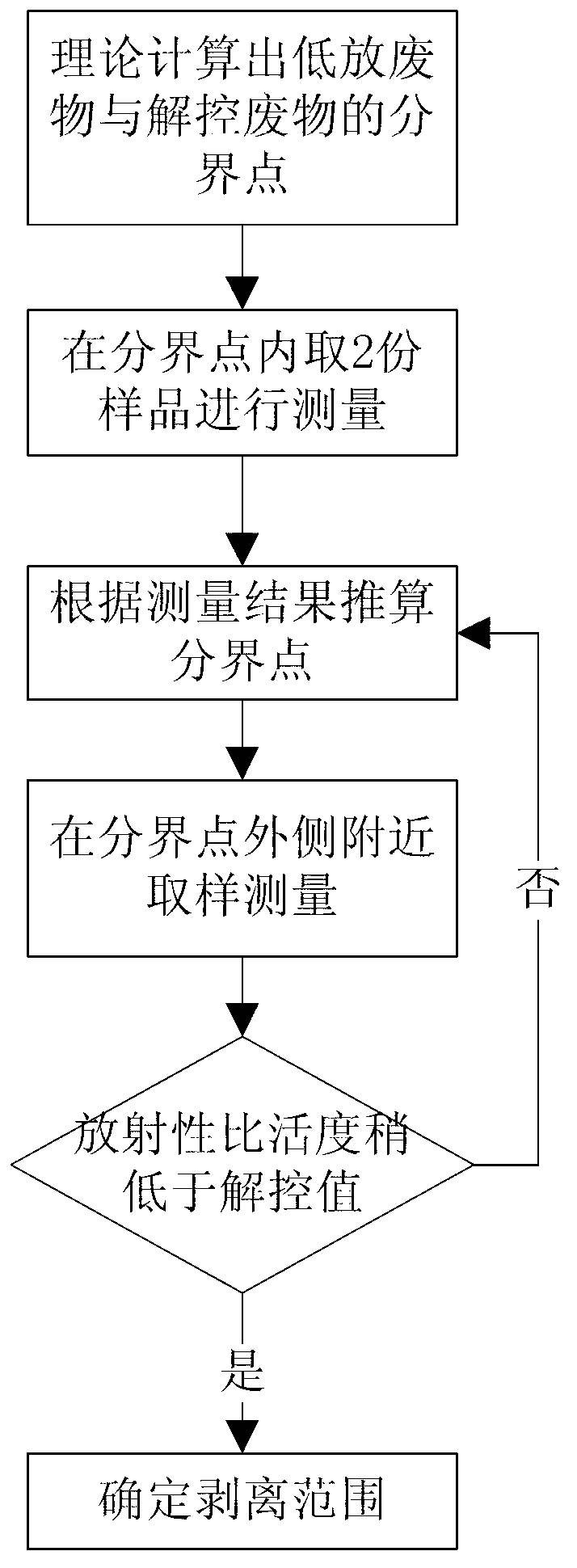

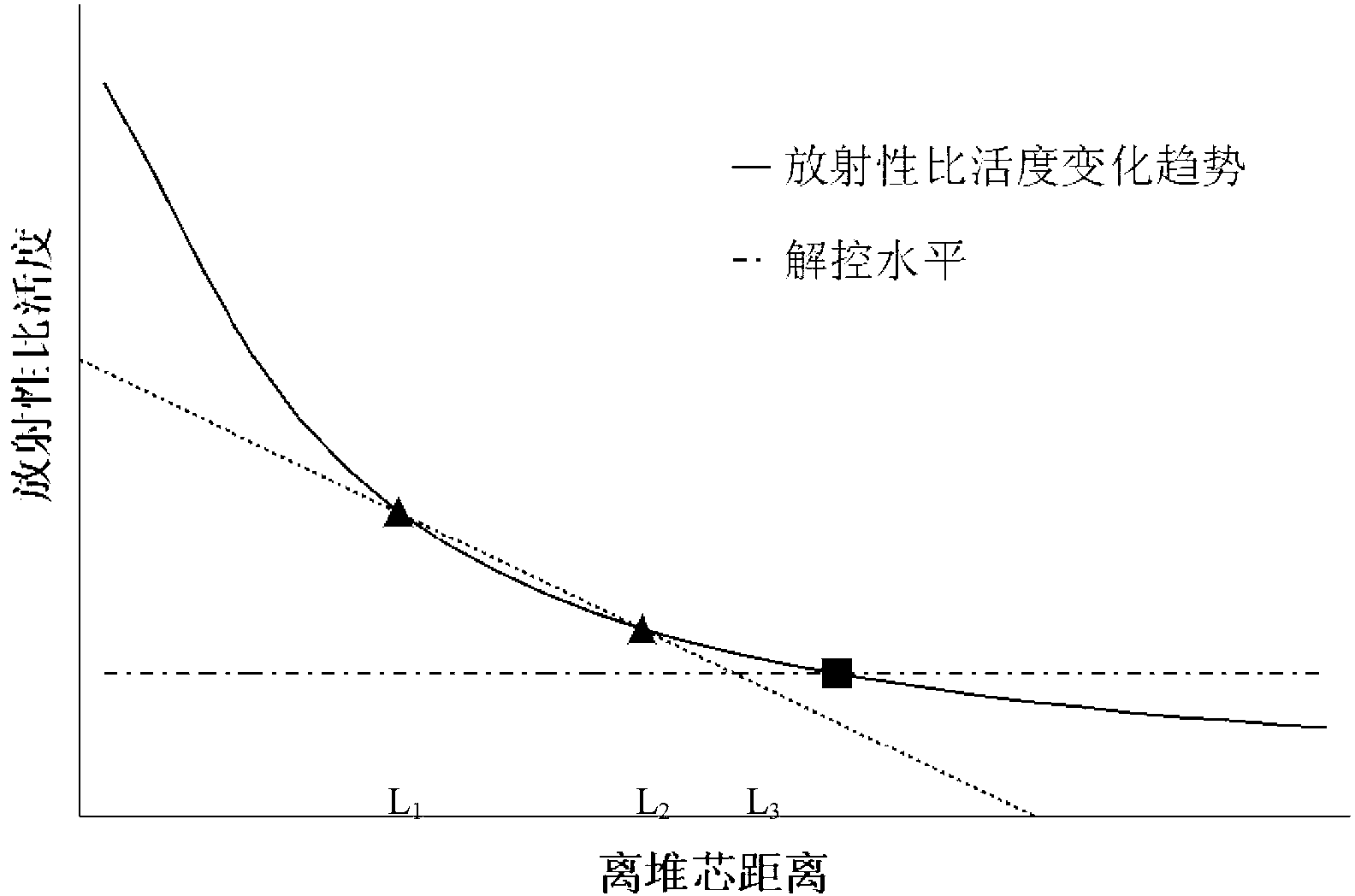

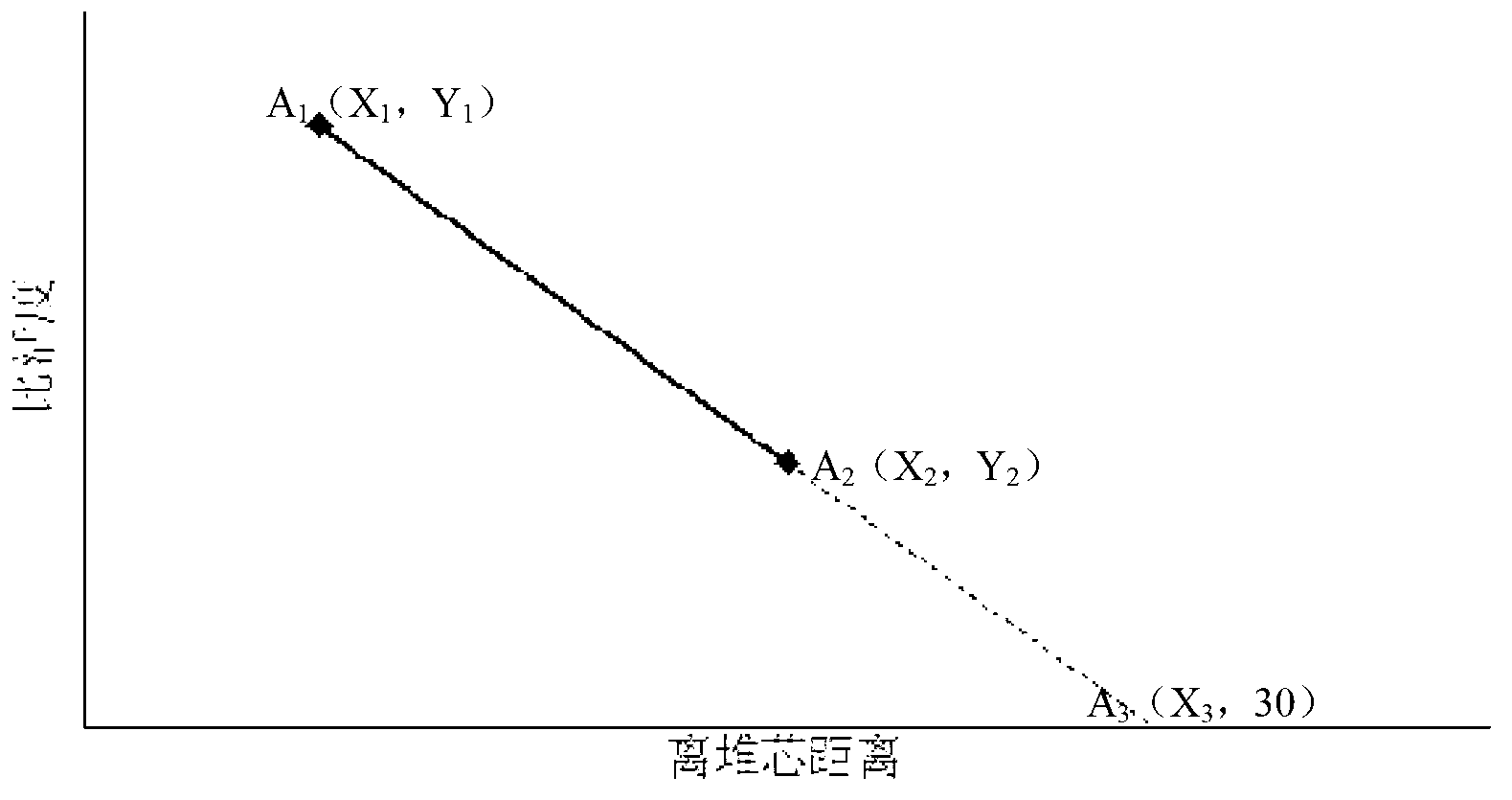

Reactor pool cleaning method used for miniature neutron source reactor decommissioning

InactiveCN103308936AAccurately determineReduce cleanupX/gamma/cosmic radiation measurmentRadioactive decontaminationDemarcation pointLow-level waste

The invention discloses a reactor pool cleaning method used for miniature neutron source reactor decommissioning. The method includes the following steps: (1), theoretically calculating demarcation points of low level waste and deregulated waste; (2) sampling two points within the demarcation points for gamma spectrum analysis to acquire radioactive nuclide specific activity; (3), reasoning positions of the demarcation points according to nuclide specific activity and the position thereof; (4), sampling at positions closed to the outer sides of the demarcation points for gamma spectrum analysis to acquire radioactive nuclide specific activity; (5), comparing the acquired activity with a deregulating value, if the activity is smaller than the deregulating value, determining the positions to be the interface of the deregulating waste and the low level waste, peeling the portion within the positions and cleaning, and if the activity is larger than the deregulating value, repeating step (3) and (4) until the acquired activity is smaller than the deregulating value, and cleaning. By the method, sampling and measuring while peeling can be realized, secondary radioactive waste quantity can be reduced, and measuring workload and classifying time of radioactive waste can be reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Sleeve screw propeller thrustor

A propeller with sleeve barrel for ship features that the propeller is arranged in a sleeve barrel whose diameter is consistent with that of propeller, said sleeve barrel is fixed to the ship tail under ship body, and a protecting net is arranged between sleeve barrel and ship bottom. The rotating propeller can generate a cylindrical water stream for increasing speed of ship. Said protecting net can prevent the propeller from being wound by other material.

Owner:傅德俐

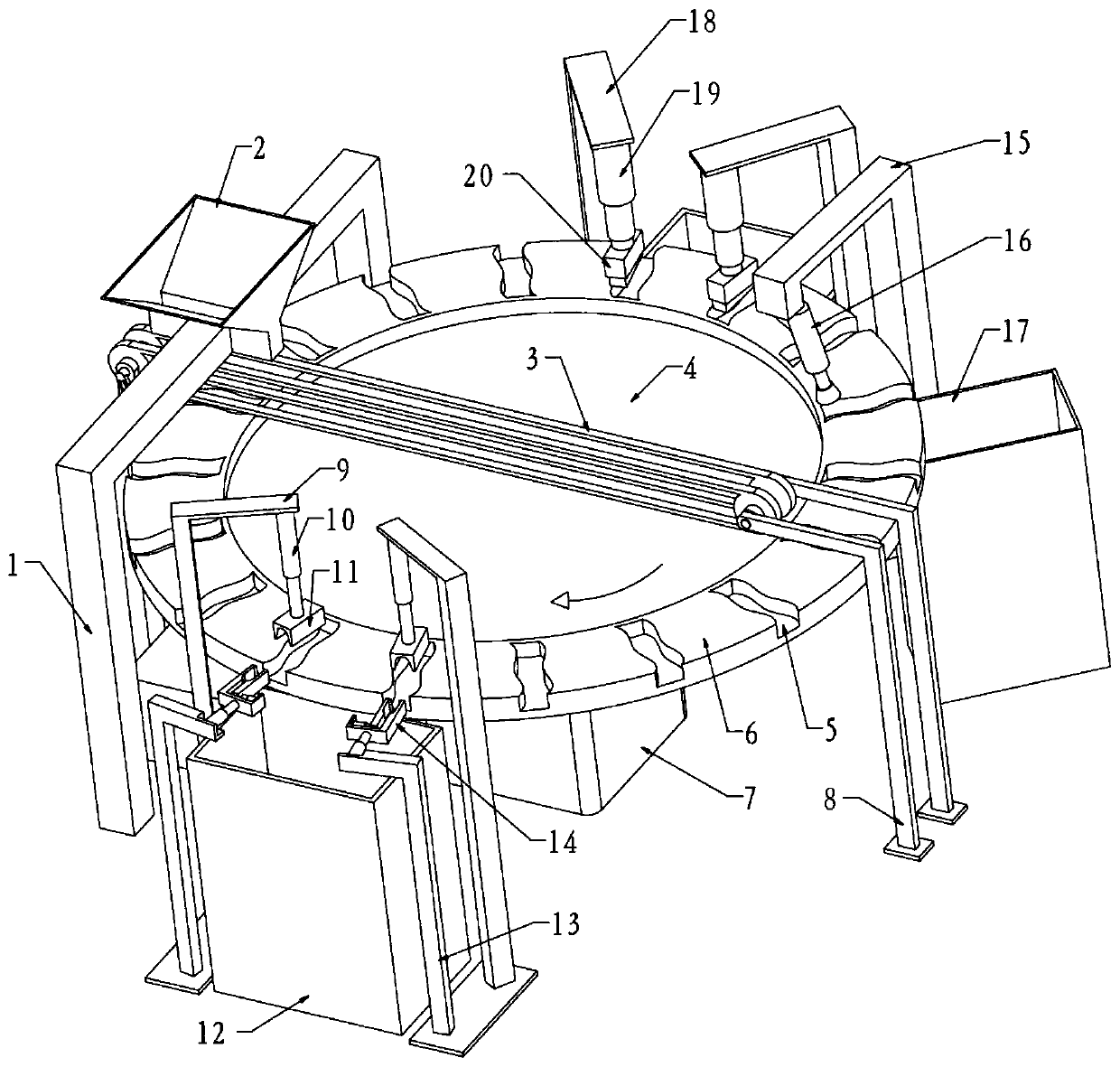

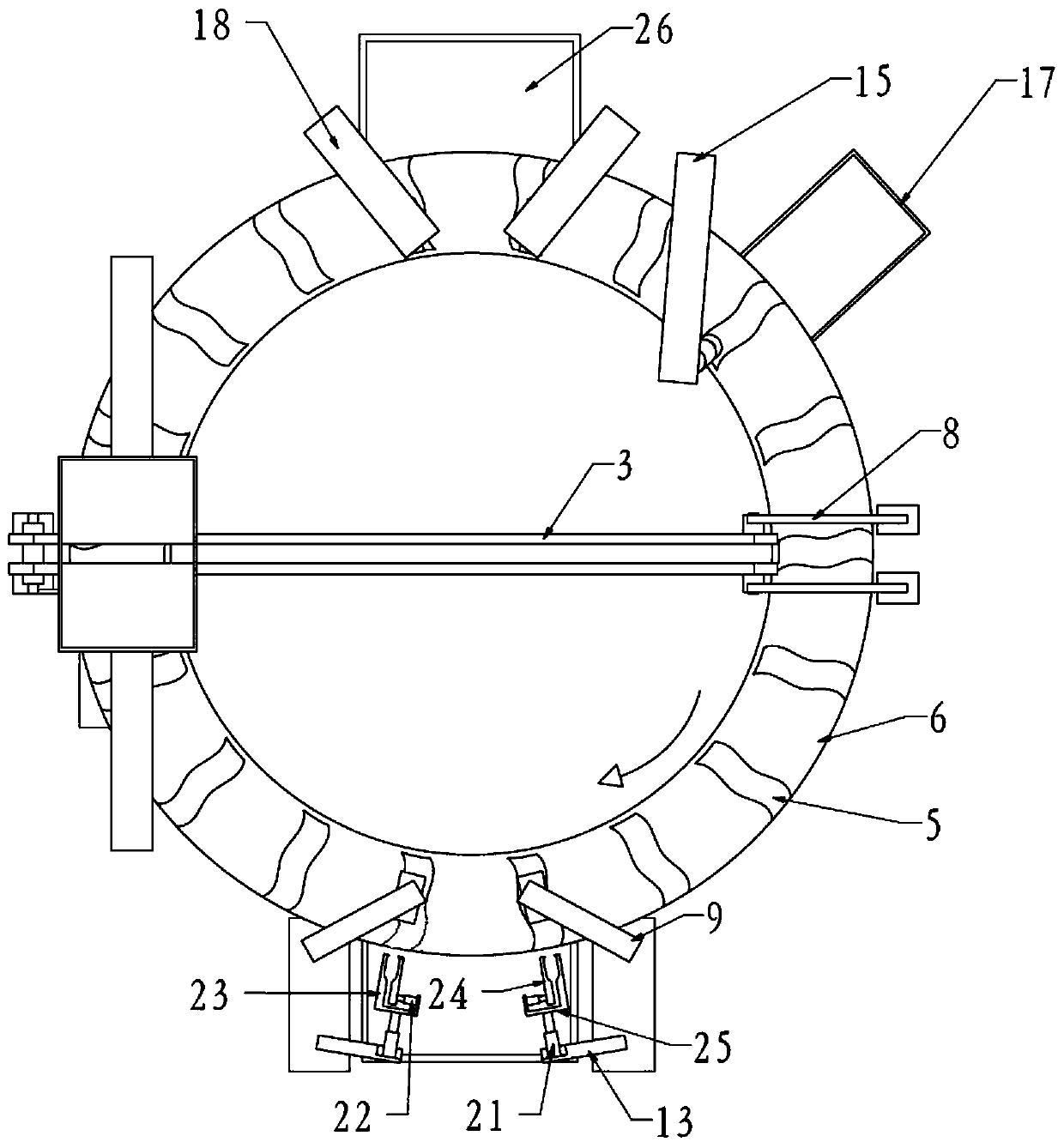

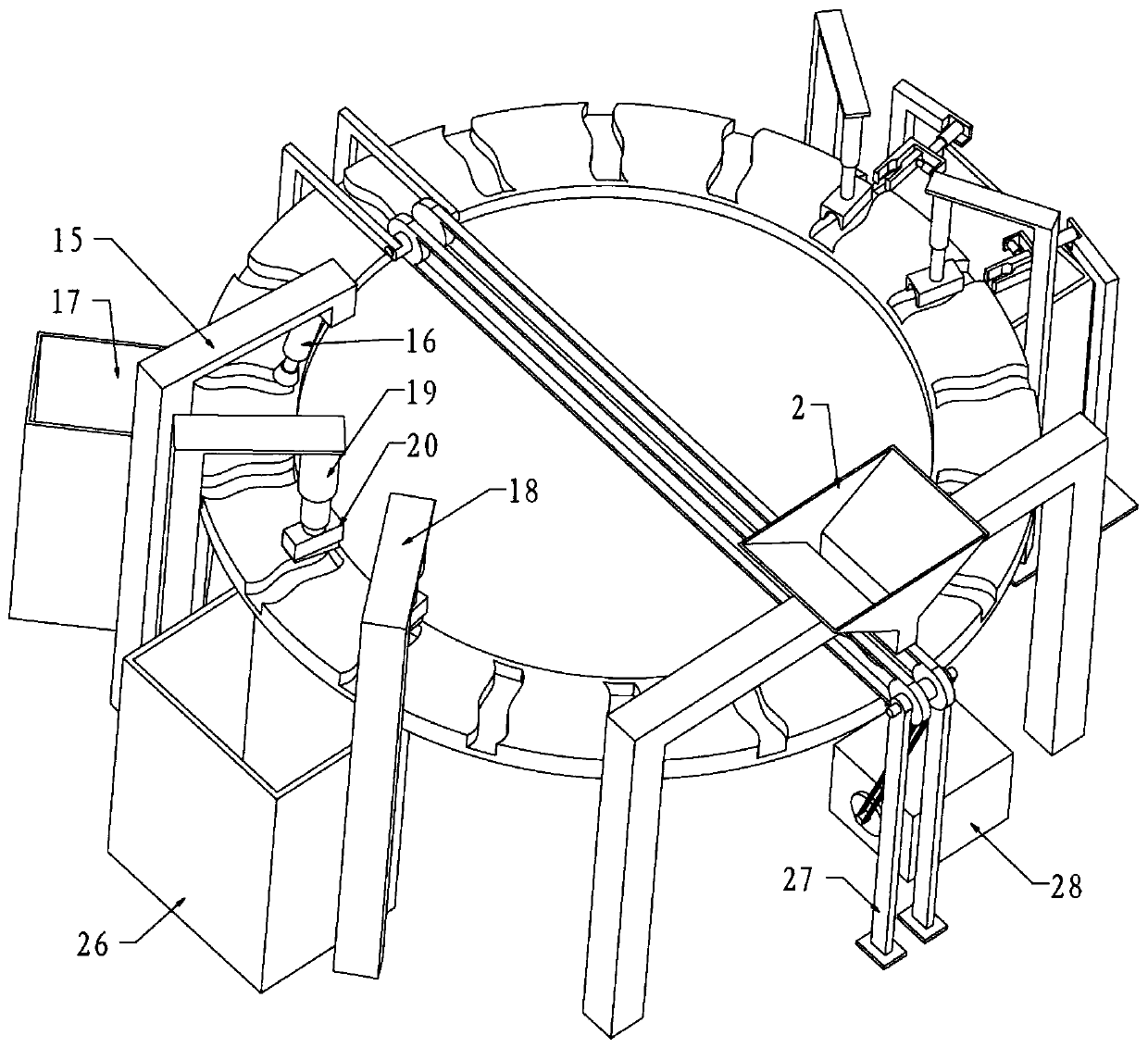

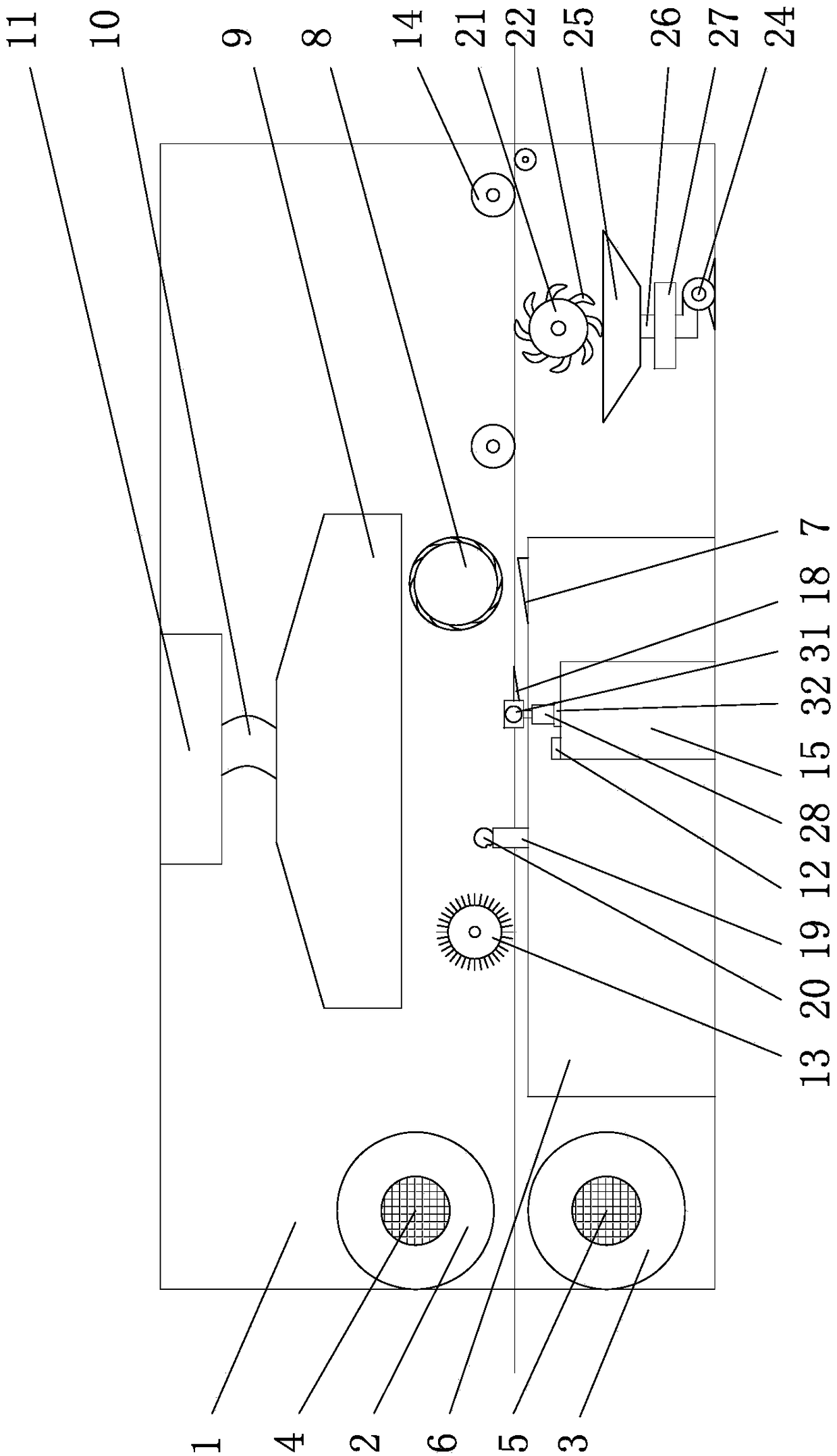

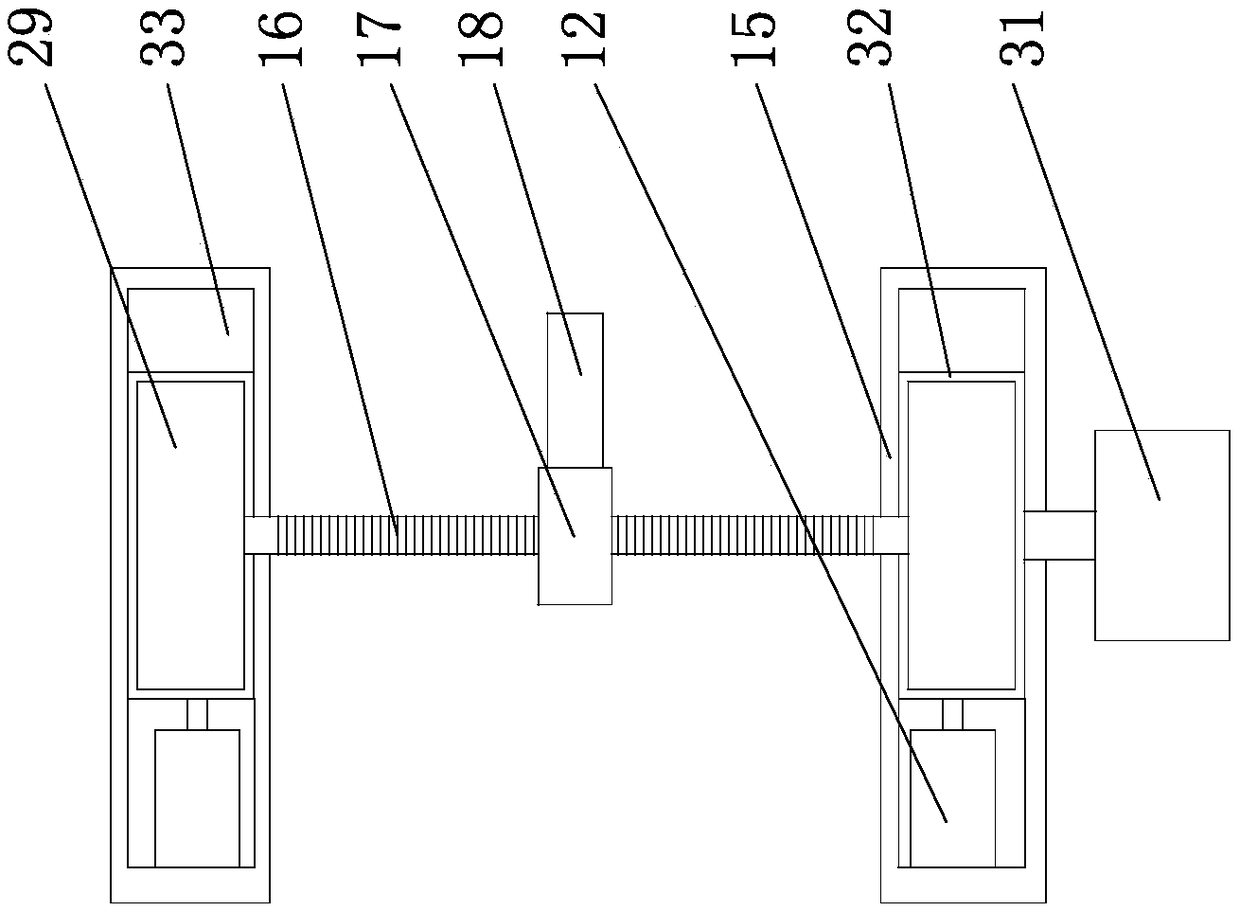

Crayfish shell removing device

PendingCN111011465AImprove convenienceSmall space requirementShrimp/lobster processingShrimpEngineering

The invention discloses a crayfish shell removing device, and belongs to the field of crayfish processing devices. The crayfish shell removing device comprises a rotating disc, a boss is arranged on the rotating disc, grooves are formed in the boss in an annular array, and a conveying belt is arranged above the rotating disc; a clamping device is movably arranged above the boss, the clamping device is connected to a piston rod of a first air cylinder, and the first air cylinder is installed on a third support; a head removing device is movably arranged on the outer side of the boss, the head removing device is connected to a piston rod of a third air cylinder, and the third air cylinder is installed on a fourth support; an extrusion device is movably arranged above the boss, the extrusiondevice is connected to a piston rod of a second air cylinder, and the second air cylinder is installed on a sixth support; an air spraying pipe is arranged above the boss and installed on a fifth support. According to the crayfish shell removing device, shrimp heads and shrimp lines can be synchronously removed, the rotating disc type annular integrated design is adopted, the space requirement ofa workshop is reduced, meanwhile, overall management and operation are facilitated, and the production efficiency is further improved.

Owner:国联(益阳)食品有限公司

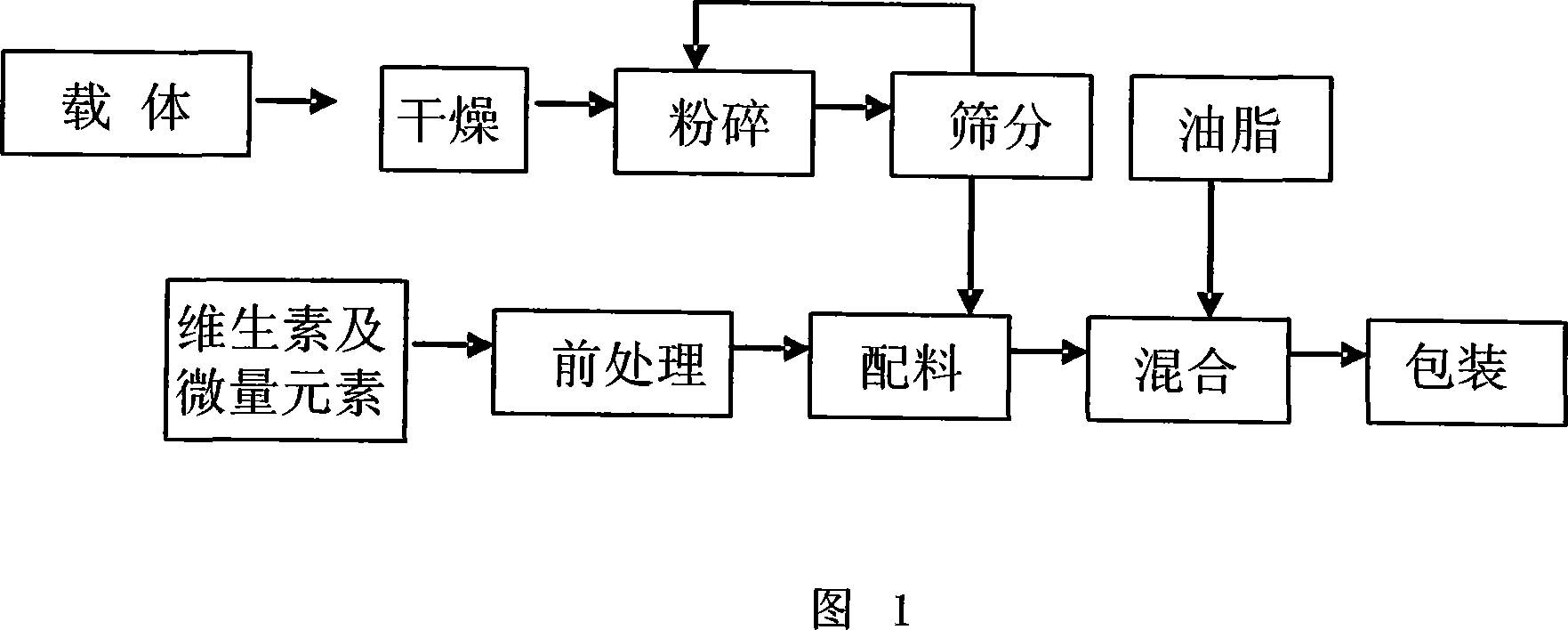

Compound pre-mixed feed for chicken

InactiveCN101124952AImprove uniformityImprove survival rateAnimal feeding stuffAccessory food factorsIron saltsPantothenic acid

The present invention provides a chicken compound premix, which is mainly suitable for the Roman breeding hens before breeding and in the laying period. The premix has 1 percent premix and 5 percent premix. The premix of the present invention comprises Vit A, Vit D3, Vit E, Vit K3, Vit B1, Vit B2, Vit B6, Vit B12, pantothenic acid, nicotinic acid, folic acid, biotin, choline chloride, iron salt, zinc salt, cupric salt, manganese salt, iodine salt, selenium salt and carriers, and also amino acid, calcium, total phosphorus and common salt. As proved by a small scale breeding experiment, the premix unit of the present invention has the advantages that the egg laying rate of the breeding hens is increased by 2.1 percent, the egg damaging rate is decreased by 0.6 percent, the daily consumption is reduced by 2 g, the yearly breeding hens unit consumption is reduced by 1131.5 kg, the egg laying performance of the breeding hens is improved, the mature of the breeding hens is early, the egg laying peak is obvious and the egg laying ability is durable after the peak compared with the outside purchasing premix unit.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

Low-temperature baking cigarette withdrawing tool

PendingCN108669658AResidue reductionAvoid frequent cleaningTobacco pipesTobacco devicesEngineeringSmoke

The invention discloses a low-temperature baking cigarette withdrawing tool. The low-temperature baking cigarette withdrawing tool comprises a heating tip and an electric rod assembly for supplying power to the heating tip, wherein a heating body for heating a cigarette is arranged in the heating tip; a cigarette withdrawing body used for supporting the cigarette is movably arranged on the heatingbody; the cigarette withdrawing body is provided with a through hole matched with the heating body; the cigarette withdrawing body has a first position and a second position; when the cigarette withdrawing body is positioned at the first position, the heating body passes through the through hole, enters the cigarette and heats the cigarette; when the cigarette withdrawing body is positioned at the second position, the heating body exits from the through hole in order to be separated from the cigarette. According to the low-temperature baking cigarette withdrawing tool, the cigarette withdrawing body in the tool is used for supporting the cigarette, so that residue on the heating body can be scraped in conjunction with the through hole of the heating body after finishing of heating, separation of the cigarette and the heating body is realized, the situation of cigarette residue in the tool due to direct pull and insertion of the cigarette is avoided, and frequent cleaning of the cigarette is avoided effectively.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

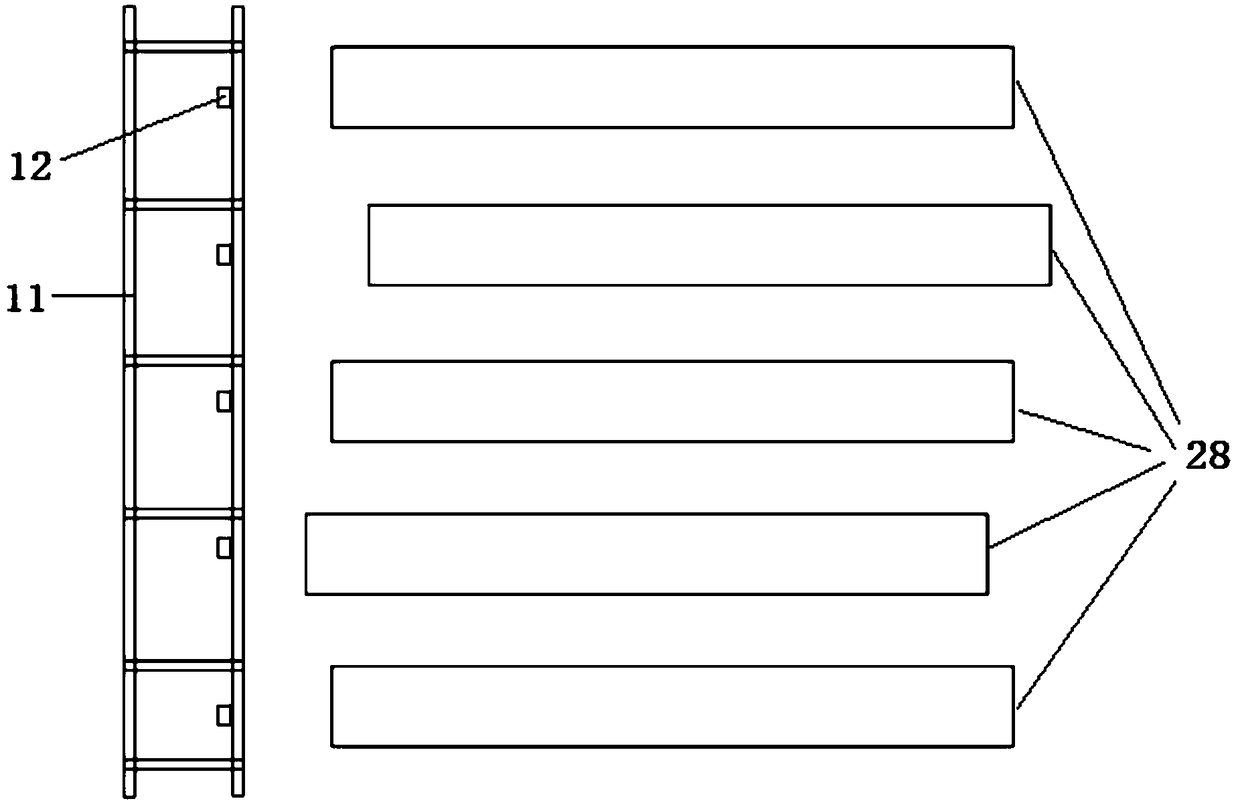

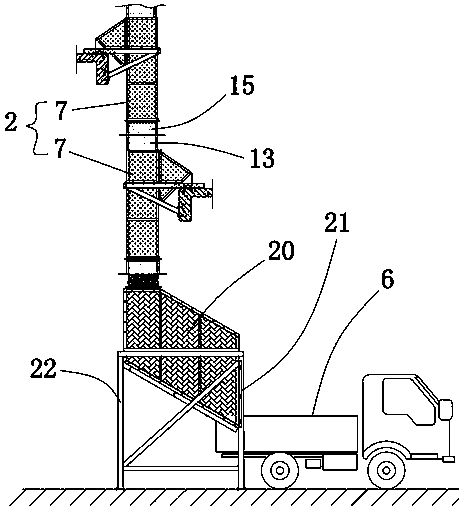

Refuse chute for high-rise building construction

ActiveCN104234388AReduce falling speedReduce cleanupBuilding material handlingVertical ductsHigh riseConstruction waste

The invention relates to the field of building engineering, in particular to a refuse chute for high-rise building construction. The refuse chute comprises a refuse chute body formed by splicing a plurality of side plates; the inside of the refuse chute body is hollow and a channel for refuses to fall is formed inside the refuse chute body; a plurality of refuge dumping opening mounting devices in different positions are arranged on the refuse chute body at intervals; a plurality of buffer plates are arranged in the refuse chute body at intervals. The buffer plates are arranged on the inner wall of the refuse chute body at intervals, so that when the refuses fall in a refuse channel in the refuse chute, the falling speed of the refuses is reduced due to the stop of the buffer plates, and further the impact of the refuses on the refuse chute, transportation equipment positioned below the refuse chute and a foundation is weakened. Furthermore, the refuse chute disclosed by the invention is still suitable for the construction of high-rise buildings with higher height and can be applied to the conveying of construction refuses in the high-rise building construction.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Novel shearing machine

The invention provides a novel shearing machine, and belongs to the technical field of textiles. The novel shearing machine comprises a rack, a dust collecting mechanism and a shearing mechanism; thedust collecting mechanism and the shearing mechanism are both arranged on the rack, the rack is provided with a driving roller assembly, and the driving roller assembly comprises an upper driving roller and a lower driving roller; the rack is further provided with a conveying platform, and the conveying platform is located at one sides of the upper driving roller and the lower driving roller; theshearing mechanism comprises a flat knife located on the conveying platform and a spiral circular knife located above the flat knife, the conveying platform is further provided with a hairbrush roller, bristles are evenly distributed on the hairbrush roller, the side close to an output end of the conveying platform is provided with a patting mechanism, the two sides of the patting mechanism are provided with pressing rollers, the left and right sides of the conveying platform in the conveying direction are provided with supporting bases, a lead screw is rotatably connected between the two supporting bases and is in threaded connection with a movable block, and the side, close to the flat knife, of the movable block is provided with a grinding block. The novel shearing machine can improve the shearing quality of the textiles and reduce the damage to the shearing mechanism.

Owner:浙江波罗蜜新材料有限公司

Water-addition-free self-cleaning poultry cage

The invention discloses a water-addition-free self-cleaning poultry cage, which comprises a chicken cage base plate and a plurality of vertical rods arranged on the chicken cage base plate. The upperends of the vertical rods are fixedly connected to a chicken cage top plate. Manure outlets are uniformly distributed in the upper end of the chicken cage base plate. The upper end of the chicken cagebase plate is provided with a groove. The inner wall of the groove is rotatingly connected to a pedal. The lower end of the pedal is slidingly connected to a slide block. The activity space for poultry is increased, the feeding becomes convenient, when the poultry is fed, a water trough is lowered to the ground, poultry can conveniently eats food, water in a water storage tank is introduced intothe water trough through a water outlet, the cleanness of the drinking water is improved, the safety of drinking water is guaranteed, the poultry is washed during the eating process, the incidence rate of diseases and pests is reduced; poultry manures in the bottom of a tray is scraped off by a scraper, and the labor for cleaning manures is reduced.

Owner:JIANYANG LONGSHENG ARTS CO LTD

Wool grabbing and cutting combined machine with good wool scrap cleaning effect

PendingCN112553821AImprove clean upImprove the effectMechanical cleaningPressure cleaningWoolManufacturing engineering

The invention relates to a wool grabbing and cutting combined machine with a good wool scrap cleaning effect. The wool grabbing and cutting combined machine comprises a rack, a wool grabbing mechanism, a dust collection mechanism and a wool cutting mechanism, wherein the wool grabbing mechanism, the dust collection mechanism and the wool cutting mechanism are all arranged on the rack, and a driving roller assembly and a conveying platform are arranged on the rack. A napping needle roller and a finishing roller are driven by a power box to pass through the surface of knitted fabric, and napping, ironing and carding processes of the knitted fabric are completed; Cleaning of scraps on the knitted fabric to be cut is enhanced through the dust collection mechanism and a blowpipe on a support rod, the knitted fabric after cutting can be discontinuously beaten through a beating mechanism to separate the wool scraps attached to the knitted fabric during cutting, and the wool scraps are collected in time through a cleaning mechanism, so that the quality of the knitted fabric after cutting is greatly improved, and meanwhile, subsequent unnecessary cleaning procedures can be reduced; and through arranging the wool grabbing mechanism and the wool cutting mechanism, a wool grabbing function and a wool cutting function are integrated on one machine, so that the production cost is reduced, and the production space is saved.

Owner:佛山市安星阳管理咨询服务有限公司

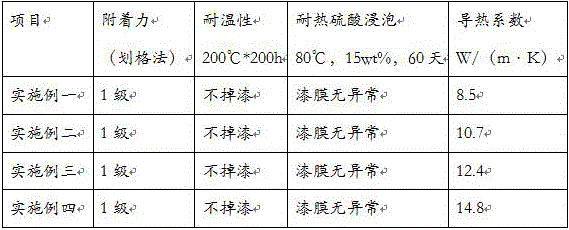

Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

ActiveCN106366928AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsFiberMetallurgy

The invention discloses graphene coating for corrosion prevention of a thermal power plant desulfurization chimney. The graphene coating consists of the following raw materials in parts by weight: 90 to 100 parts of film-forming resin, 0.5 to 3 parts of graphene, 0.5 to 2 parts of reinforced fibers, 10 to 20 parts of fillers, 10 to 20 parts of a curing agent, 15 to 30 parts of a diluents, 1 to 5 parts of polyacrylic acid, 1 to 5 parts of a polyethylenimin crosslinking agent, 1 to 3 parts of stearate and 2 to 6 parts of aids. By the mode of adding the raw materials, such as the reinforced fibers, the fillers, the polyethylenimin crosslinking agent and the polyacrylic acid, the defect that the existing corrosion-resistant coating has low durability and heat stability is overcome, the problem that the corrosion-resistant coating layer is easy to pollute and difficult to clean is solved, the developed graphene corrosion-resistant coating can completely adapt to the high-temperature strong-acid environment, the manufacturing process is simple, the practicability is high and the graphene coating is particularly suitable for thermal power plant desulfurization chimneys and flues.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

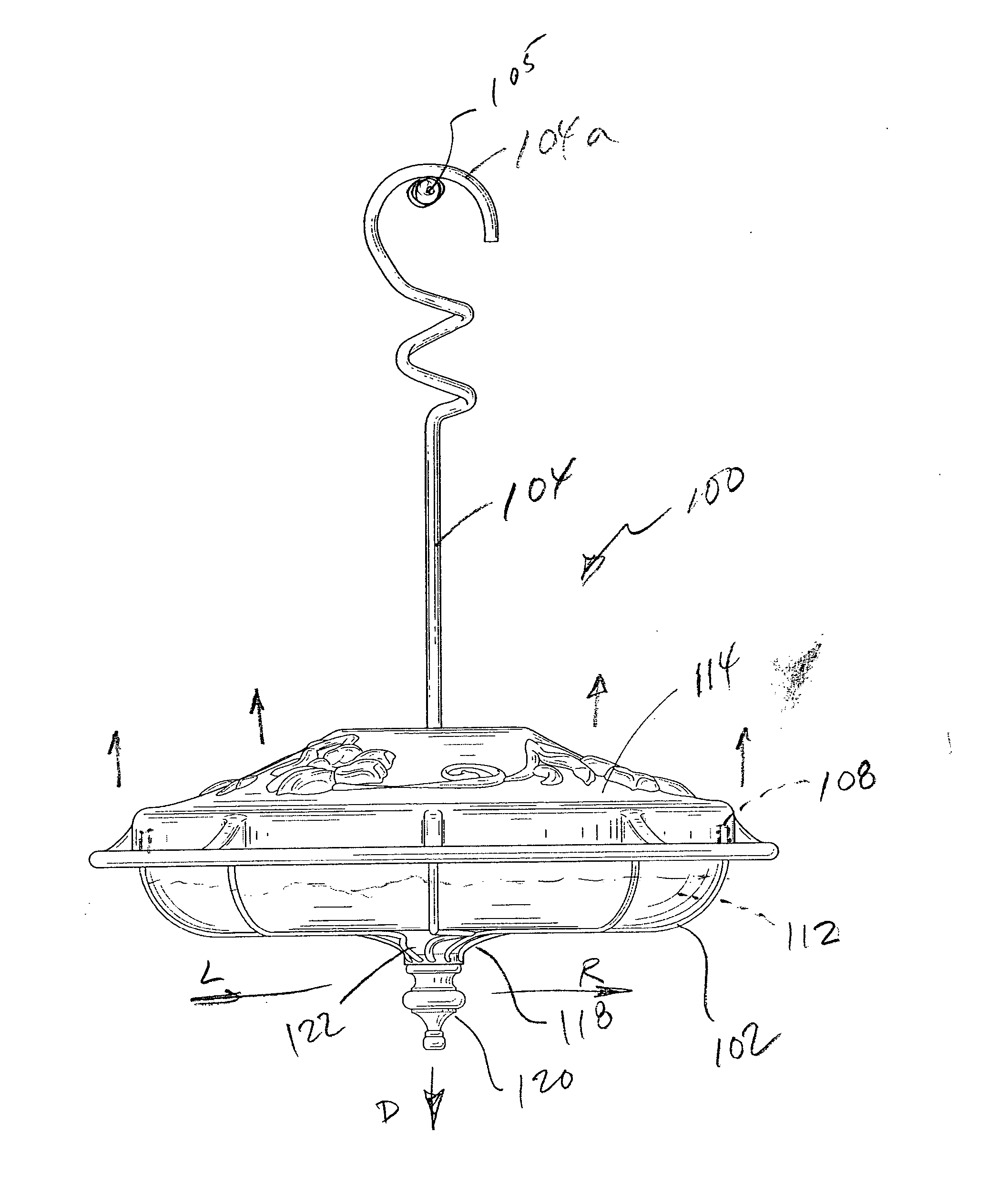

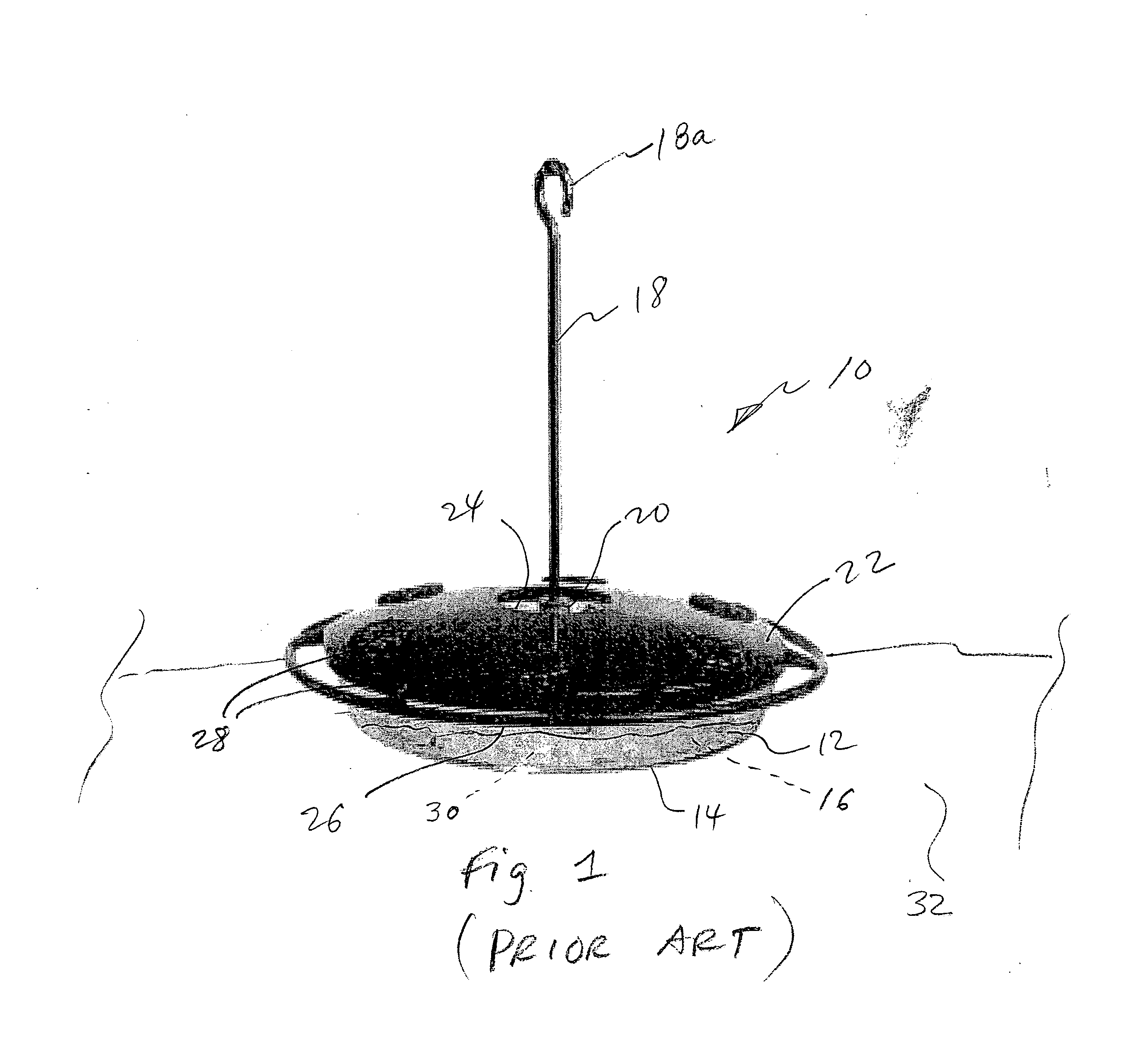

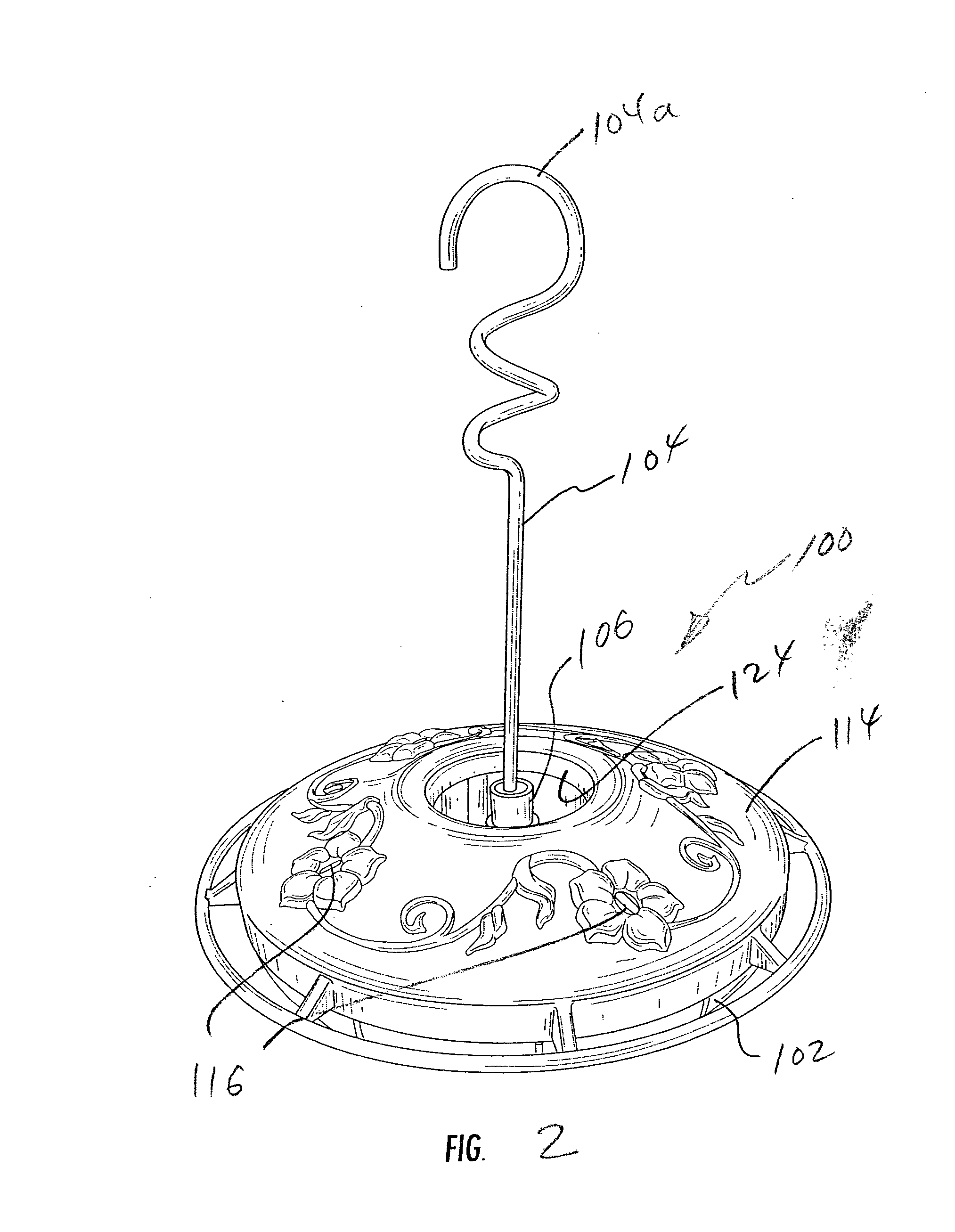

Basin nectar bird feeder with improved stability

InactiveUS20070039554A1Improve stabilityEvenly filledAnimal watering devicesAvicultureBird feederEngineering

The nectar bird feeder, which has improved stabilization, includes a base with a bottom surface, a central portion, and a trough-shaped reservoir positioned about the central portion for containing nectar therein. A hanger is connected to the central portion of the base and extends upwardly therefrom. An extension stabilizing member is connected to the base and downwardly depends therefrom, such as from the bottom surface of the base. An annular-shaped cover, having a top surface and lower edges, is releasably attached to the base and co-extensive with the trough of the base with an aperture therein. The center of gravity of the feeder, with the stabilizing member, is located below the bottom surface of the base for improved stabilization thereof during filling and use of the feeder.

Owner:ASPECTS

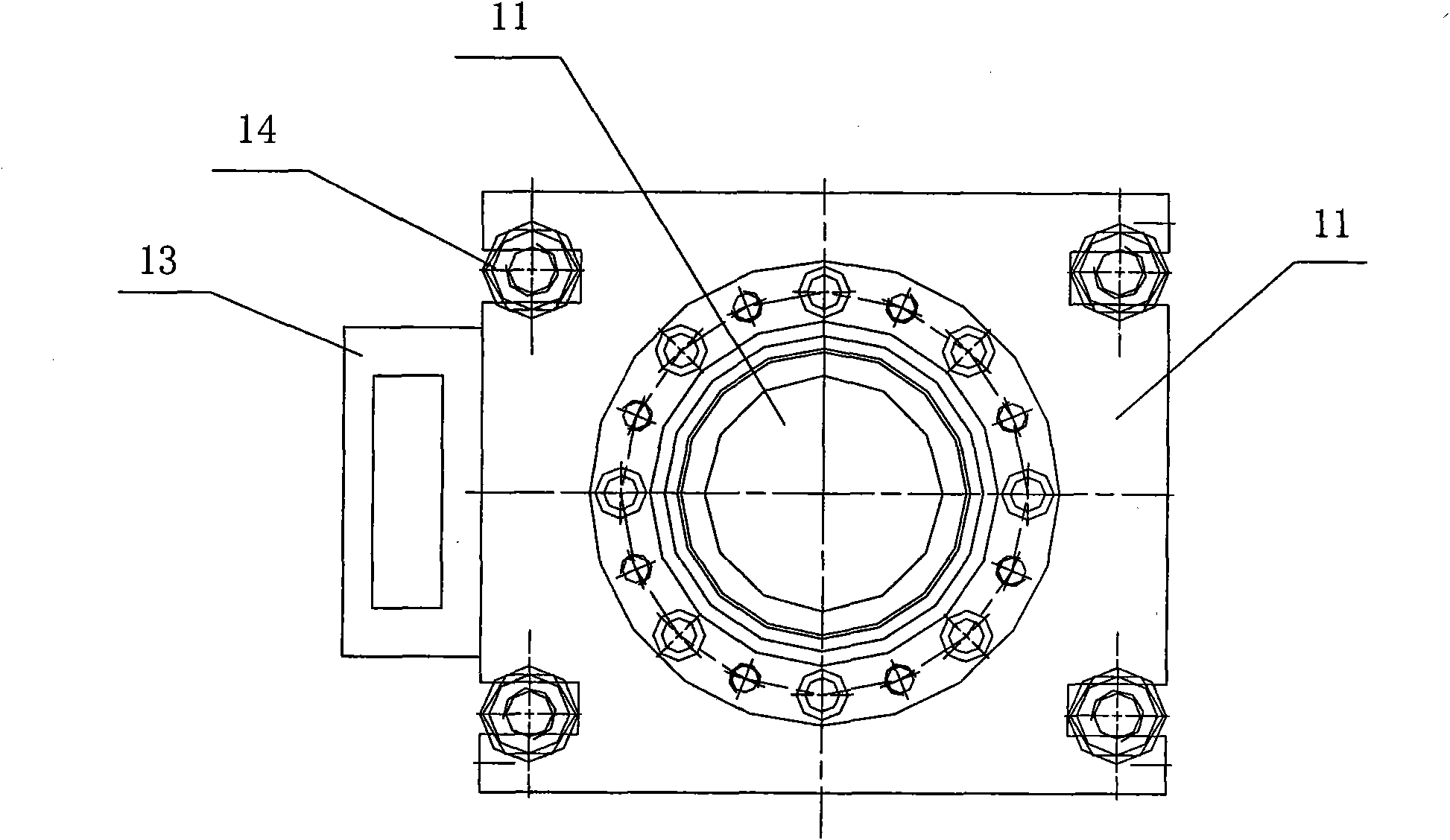

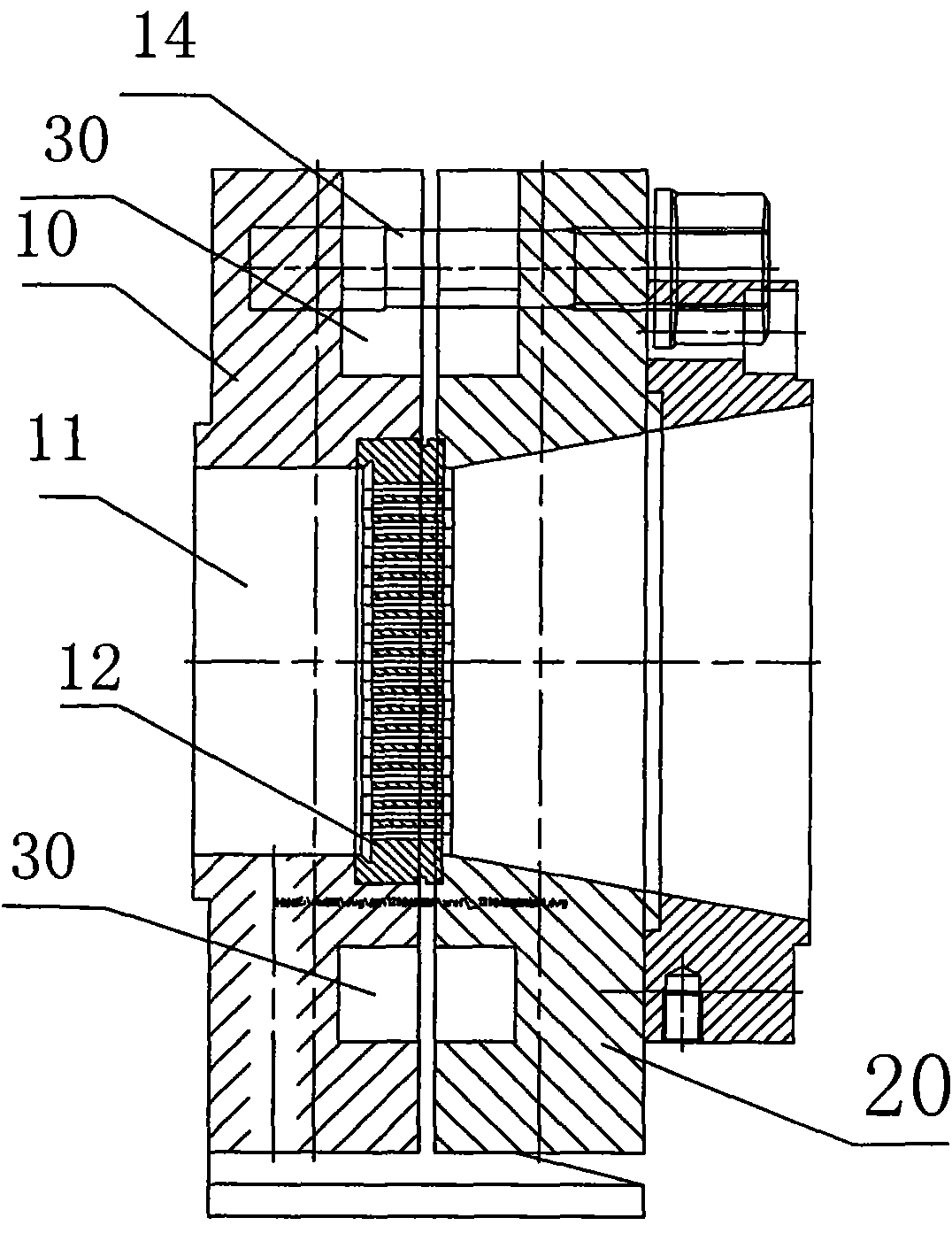

Quick-open type screen change structure with heater

The invention discloses a quick-open type screen change structure with a heater, comprising a perforated plate and a filter screen arranged in the perforated plate. The screen change structure is characterized by also comprising a clamping plate device used for fixing the perforated plate and the filter screen, wherein the clamping plate device is internally provided with a heater used for heating melting charges; and the heater is in an annular shape and surrounds the perforated plate and the filter screen for a circle. In the invention, the perforated plate and the filter screen are fixed between a front plate and a rear plate, and the front clamping plate and the rear clamping plate are connected through a movable hinge so as to be convenient for opening the front clamping plate and the rear clamping plate and quickly replacing and mounting the filter screen; the heater is arranged between the front clamping plate and the rear clamping plate to avoid the condition that the melting charges are condensed into blocks to block the filter screen, thereby guaranteeing the smooth flow of the melting charges and reducing the replacement and the cleaning of the filter screen. The quick-open type screen change structure has the advantages of convenient disassembly, time and labor saving and convenient cleaning.

Owner:KUSN KESUN RUBBER & PLASTIC MACHINERY

Wood cutting machinery favorable for clearing wood dust

InactiveCN108247768AEasy to cleanPromote absorptionProfiling/shaping machinesCleaning using toolsWorking environmentPulp and paper industry

The invention discloses wood cutting machinery favorable for clearing wood dust. The wood cutting machinery comprises a bracket, a base, baffle plates, leaking slots, a graduation ruler, a control plate, a sliding rod, a pressure plate, a servo motor, a locating rod and a threaded rod, wherein the base is mounted at the top end of the bracket. The wood cutting machinery is scientific and reasonable in structure and safe and convenient to use; by arrangement of a hair brush, a worker can clean the surface of wood effectively and conveniently after the wood is processed, and inhalation of the wood dust by the worker can be effectively reduced, thereby effectively guaranteeing the health of the worker and improving the quality of a working environment; by the arrangement of a cyclone dust collector, the worker can collect the wood dust produced by processing effectively and conveniently, and the labor intensity of the worker is relieved, thereby improving the working efficiency of the worker and improving the working efficiency; by the arrangement of the pressure plate, the wood dust can be compressed effectively, thereby facilitating transportation and reuse of wood dust wastes.

Owner:佛山市博蓄科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com