Patents

Literature

89results about How to "Save equipment space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

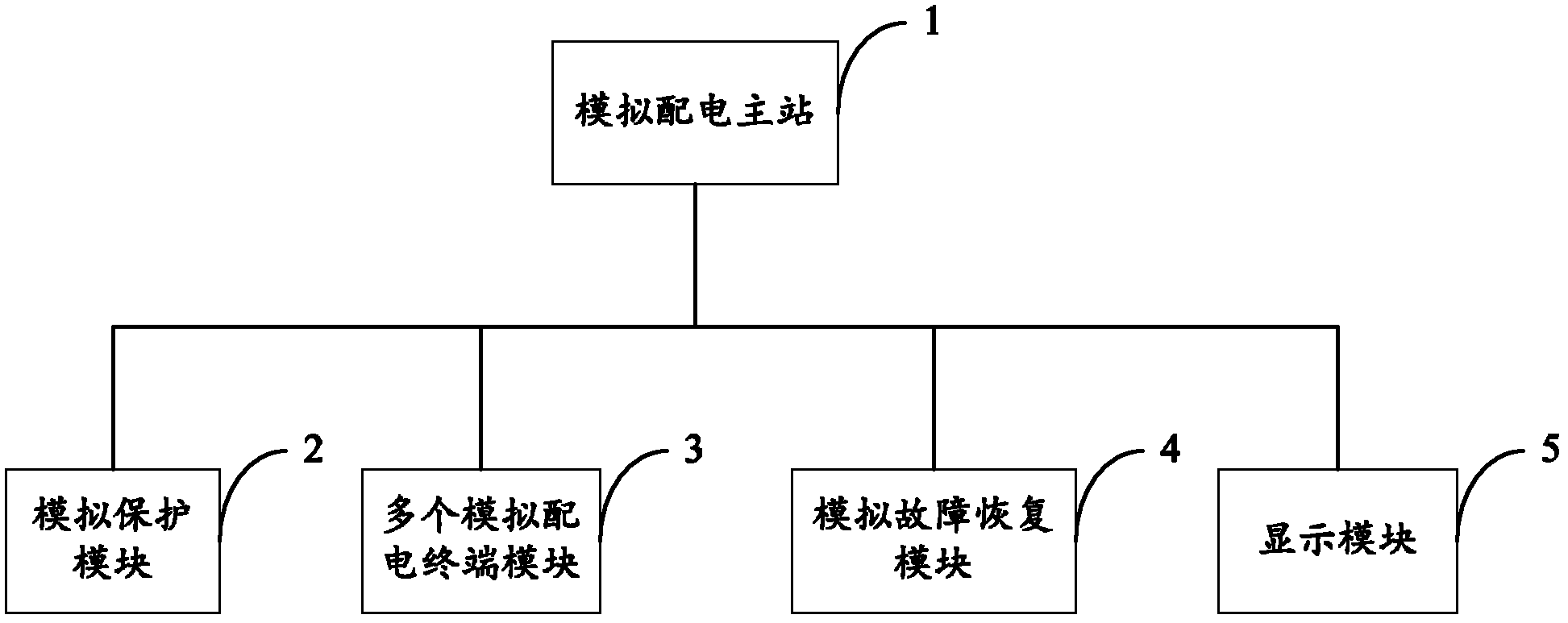

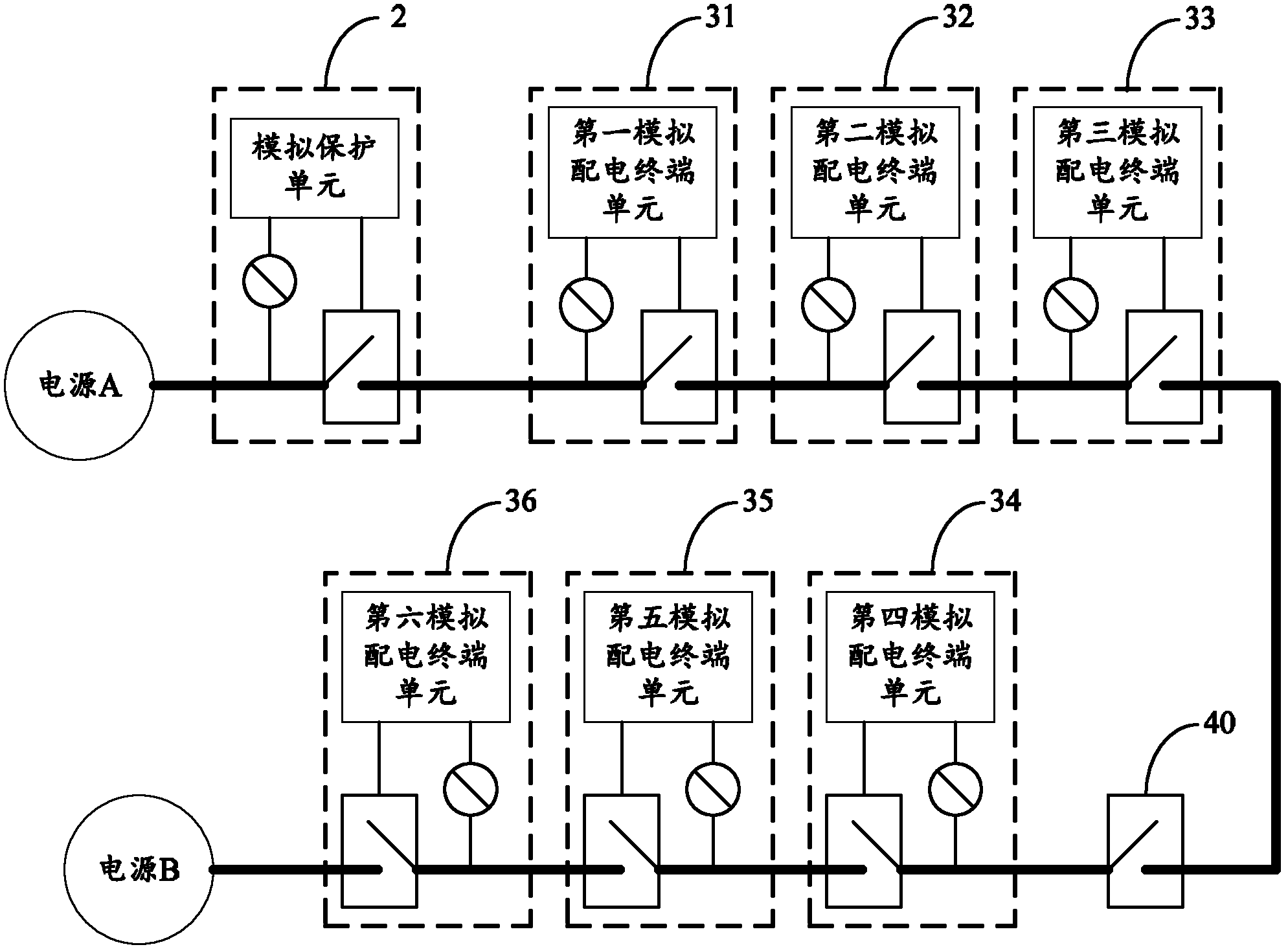

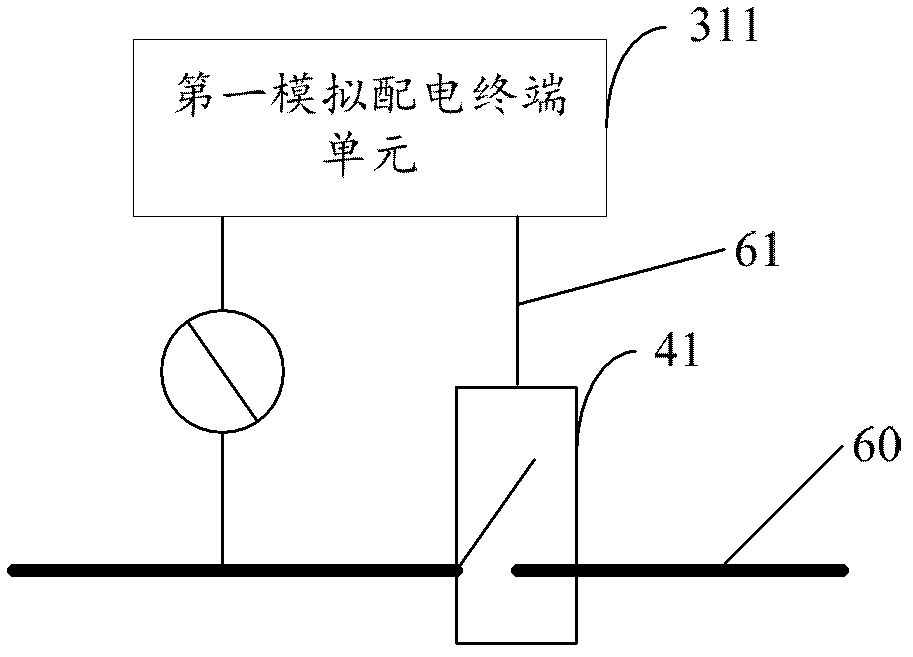

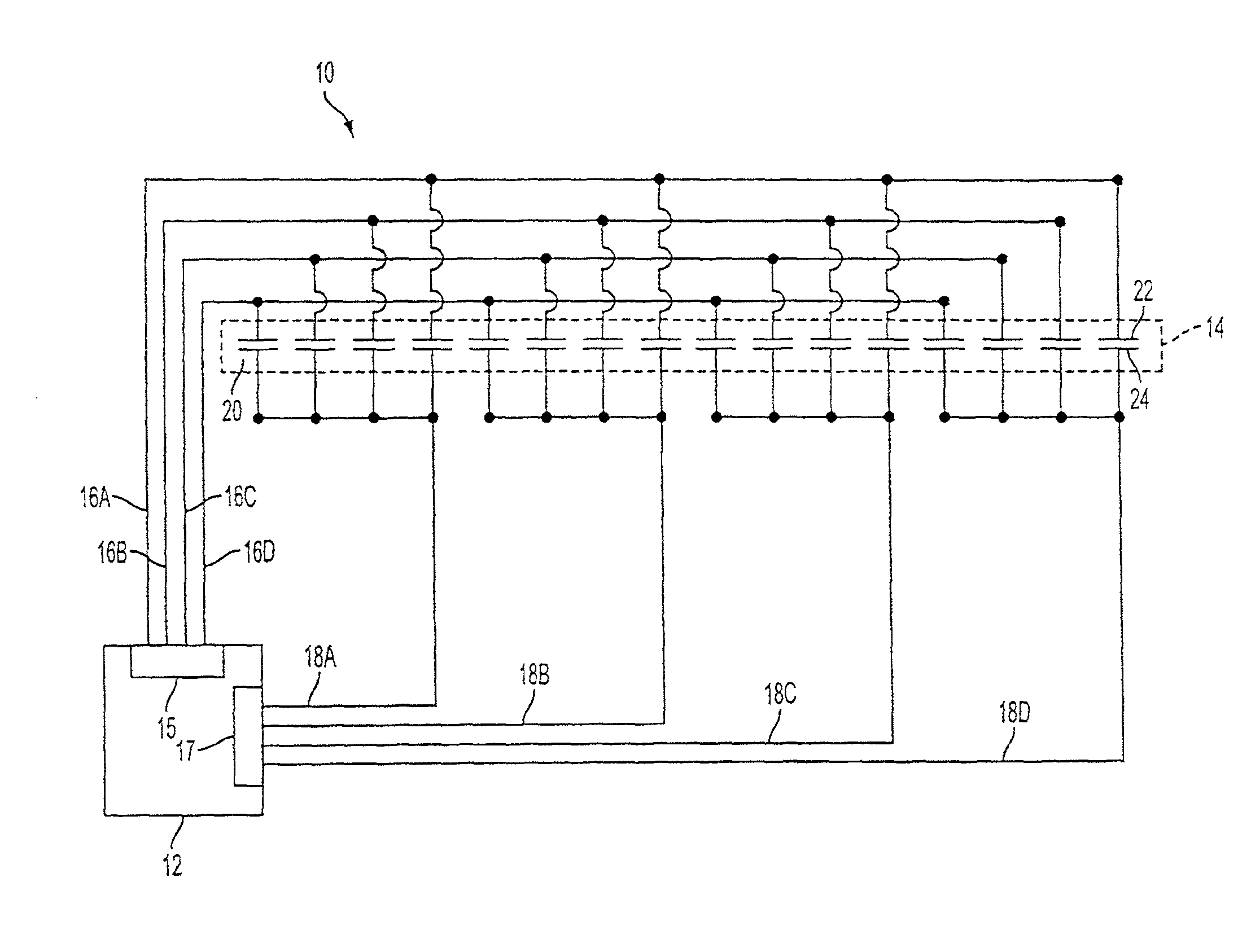

Distribution network fault simulating method and device and distribution network system

The invention belongs to the field of simulation and particularly relates to a distribution network fault simulating method, a distribution network fault simulating device and a distribution network system. The distribution network fault simulating device comprises a double-source power supply circuit, a simulation protecting module, a plurality of simulative distribution terminal modules and a simulative fault recovering module; and the distribution network fault simulating device can simulate on-site equipment and a fault, simulate the communication of the simulation protecting module and the plurality of simulative distribution terminal modules of a transformer substation with a simulative distribution main station, simulate an actual load current, simulate a fault current and report fault information, simulate to execute remote-control switching-on and switching-off operations to simulate the cutoff of the fault current and switch on a normal current. The distribution network fault simulating device can completely replace a protective device and actual hardware equipment of a distribution terminal, reduce the field occupancy of the equipment and the wire-connecting and debugging workload of the equipment, save manpower and improve the working efficiency.

Owner:AEROSPACE SCI & IND SHENZHEN GROUP

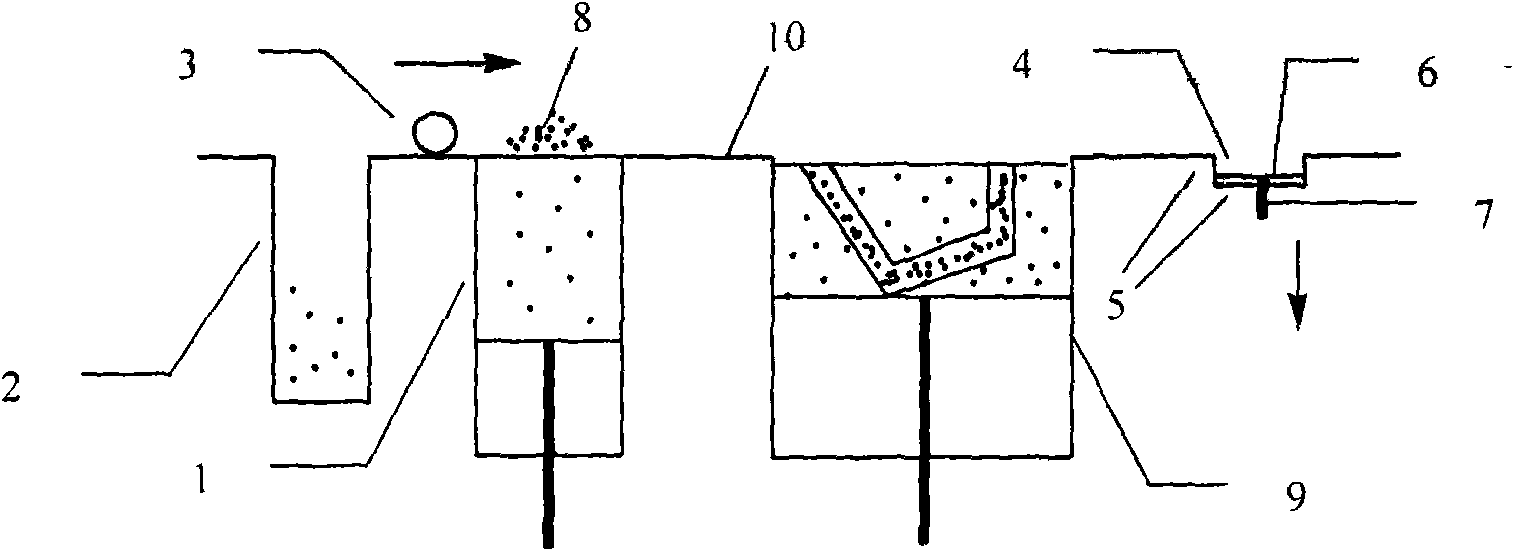

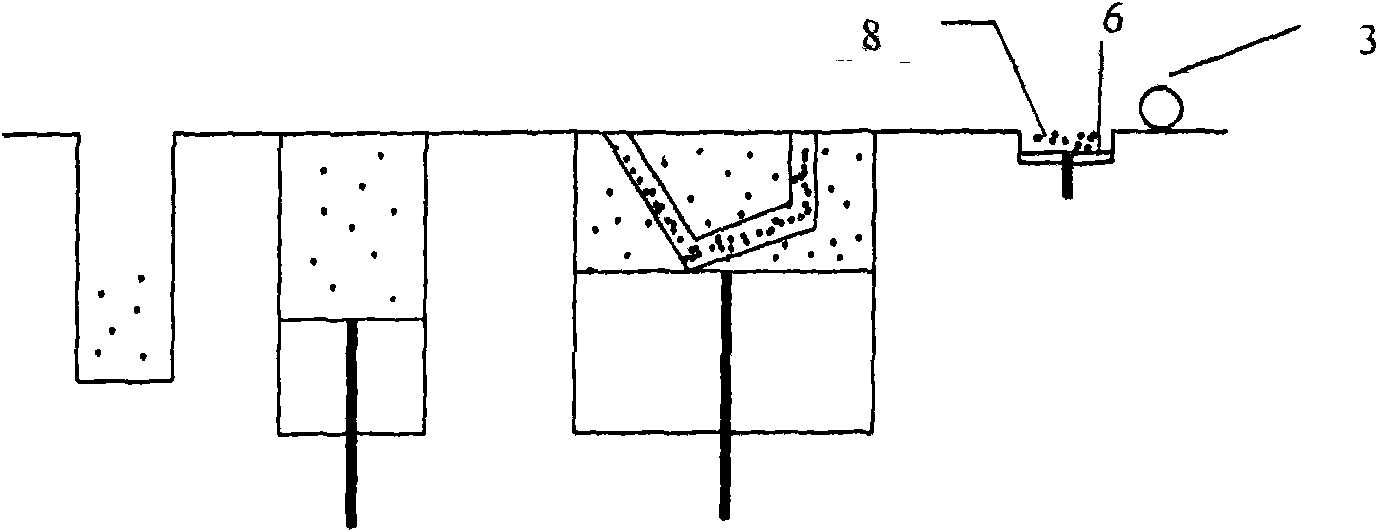

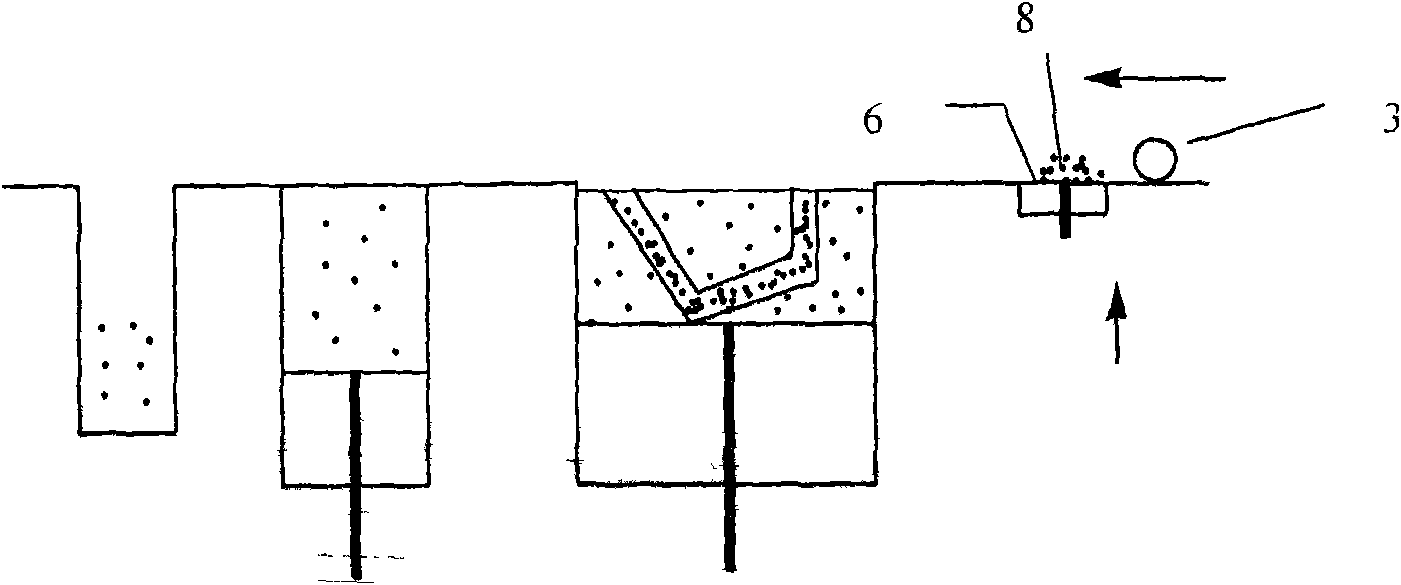

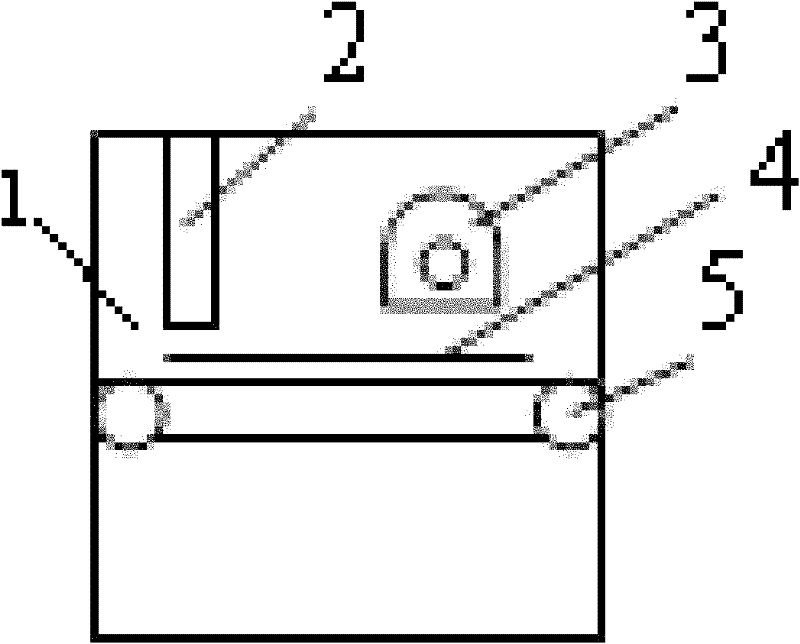

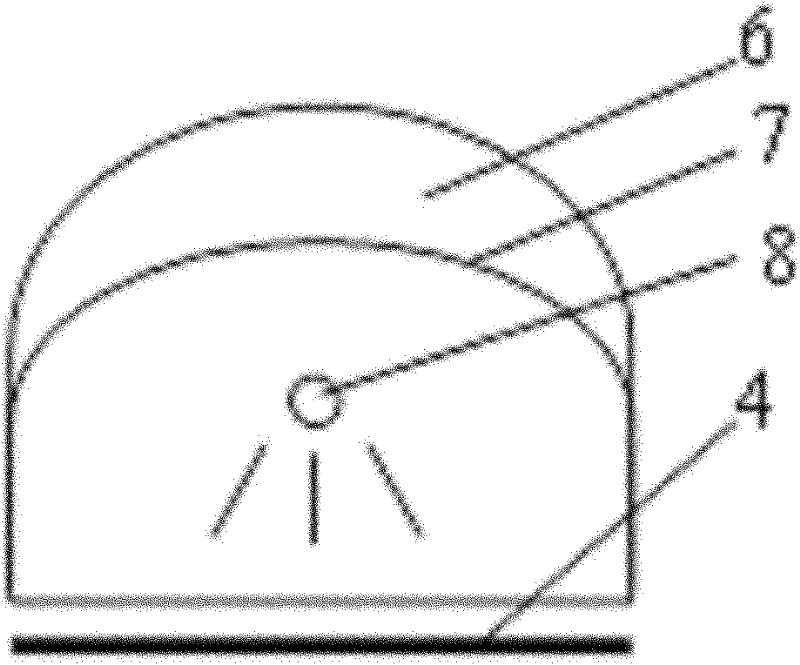

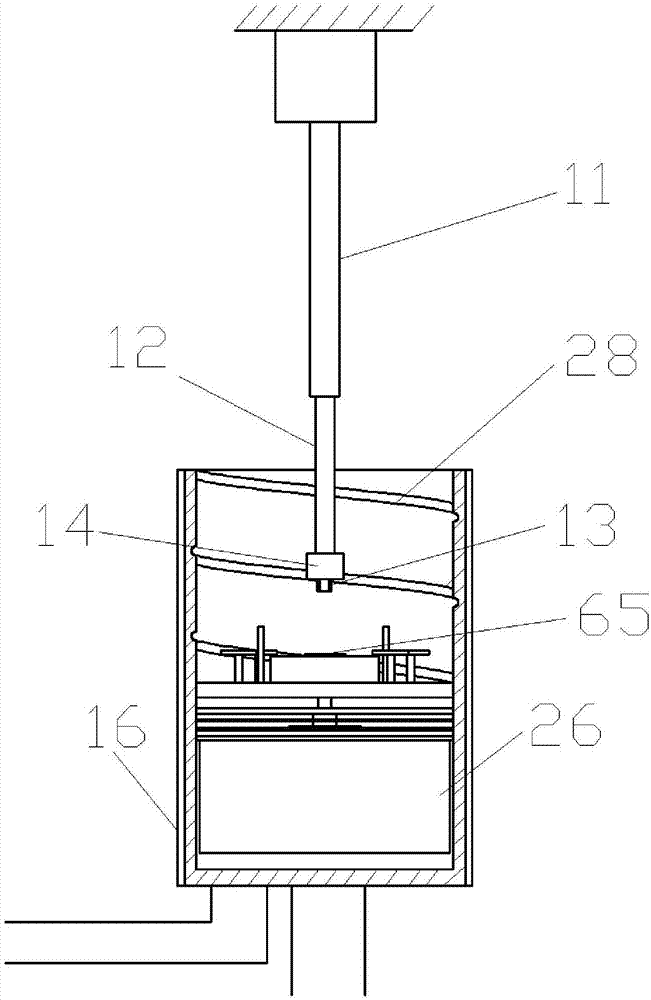

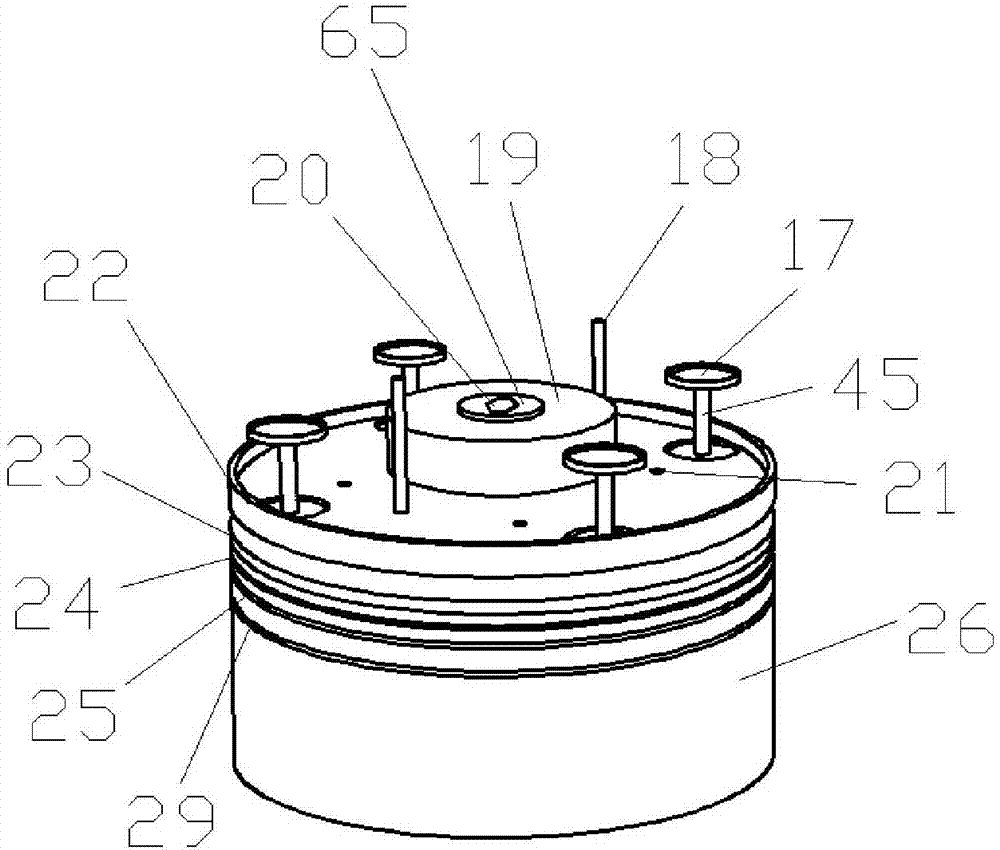

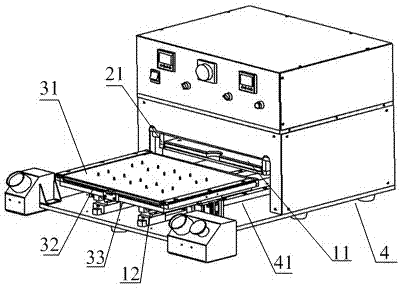

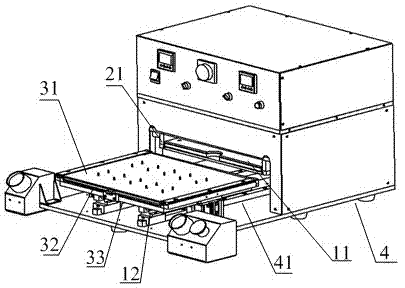

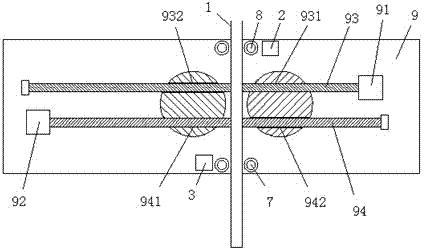

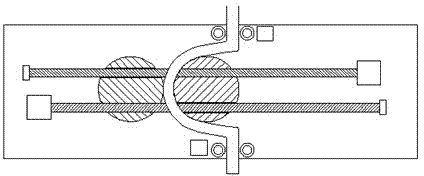

Selective laser sintered single-face powder supplying device realized by adopting powder returning groove

InactiveCN102126293AIncrease profitSave equipment spaceIncreasing energy efficiencyLaser beam welding apparatusMetallurgySelective laser sintering

The invention provides a selective laser sintered single-face powder supplying device realized by adopting a powder returning groove. The selective laser sintered single-face powder supplying device comprises a powder spreading roller, a powder supplying cylinder, a powder overflowing cylinder and the powder returning groove, wherein the single-face powder supplying device only needs to install one powder supplying cylinder and one powder overflowing cylinder at one side of a worktable and install one powder returning groove at the other side of the worktable; and the powder returning groove comprises a cylinder body, a movable bottom plate, and a control shaft connected with the movable bottom plate. In the invention, the equipment space is saved; the equipment dimension is reduced; the equipment complexity is reduced; the equipment cost is effectively reduced; the equipment reliability is improved; and the SLS (Set Location Stack) process requirements are further met.

Owner:湖南美纳科技有限公司

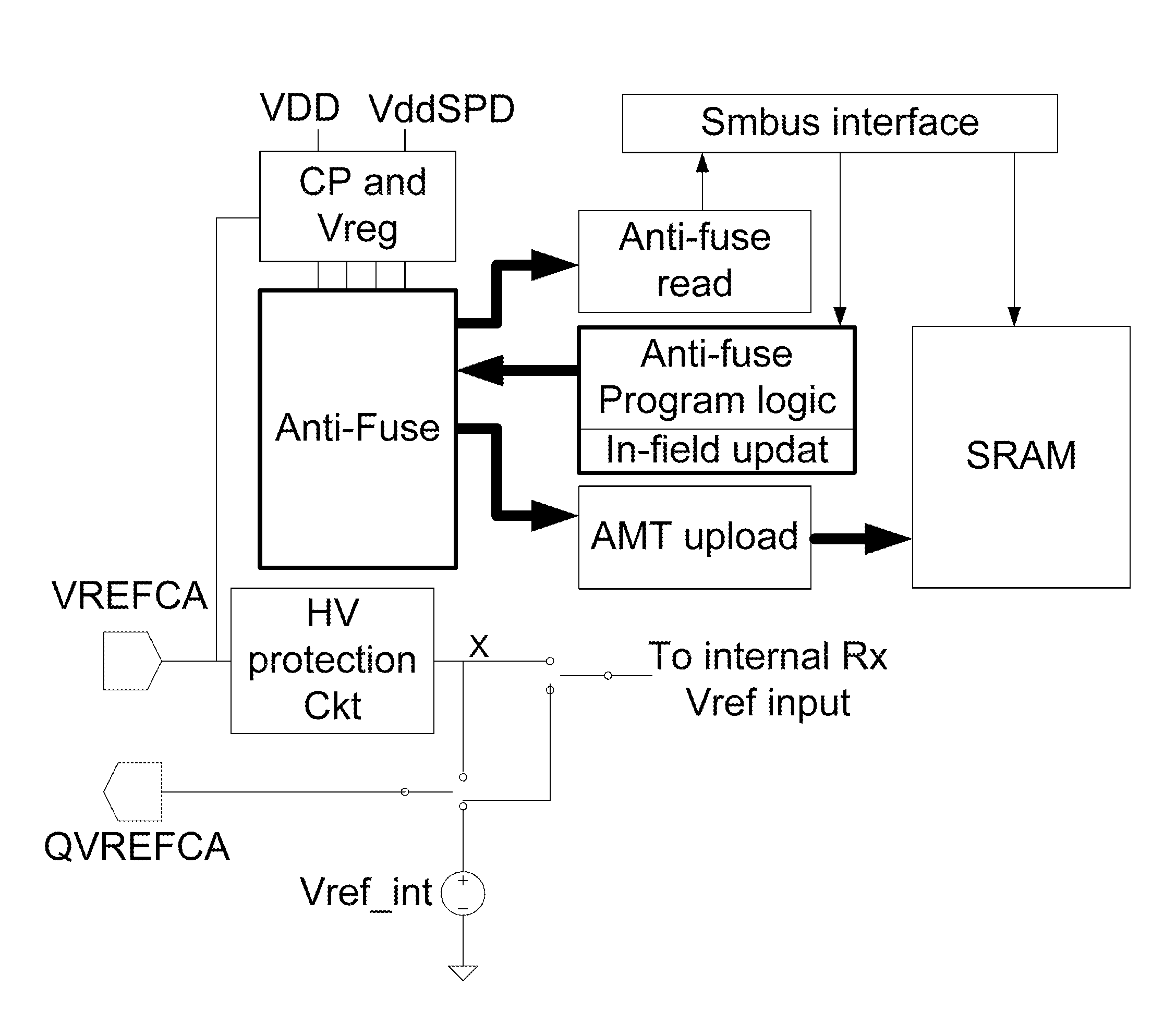

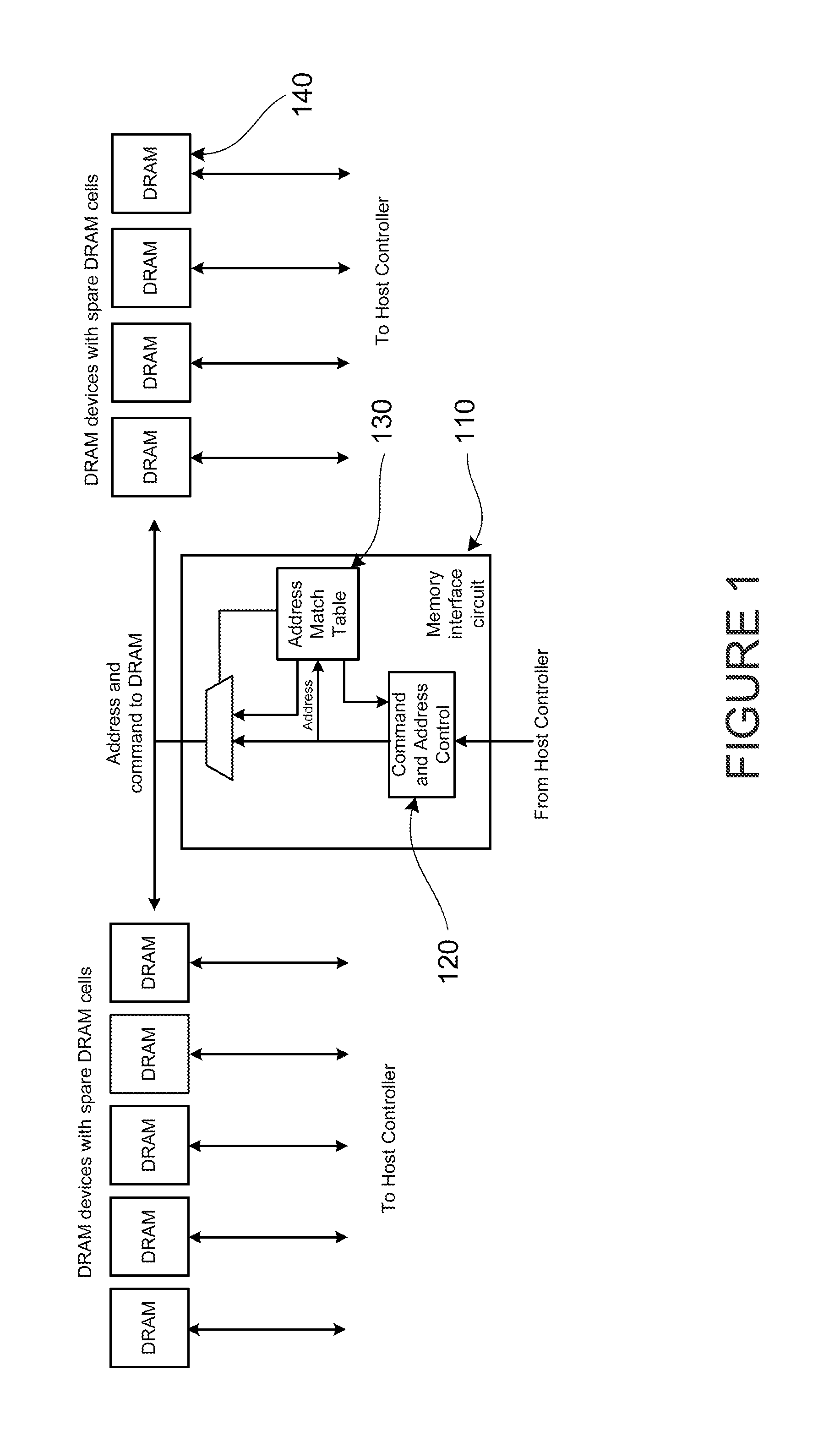

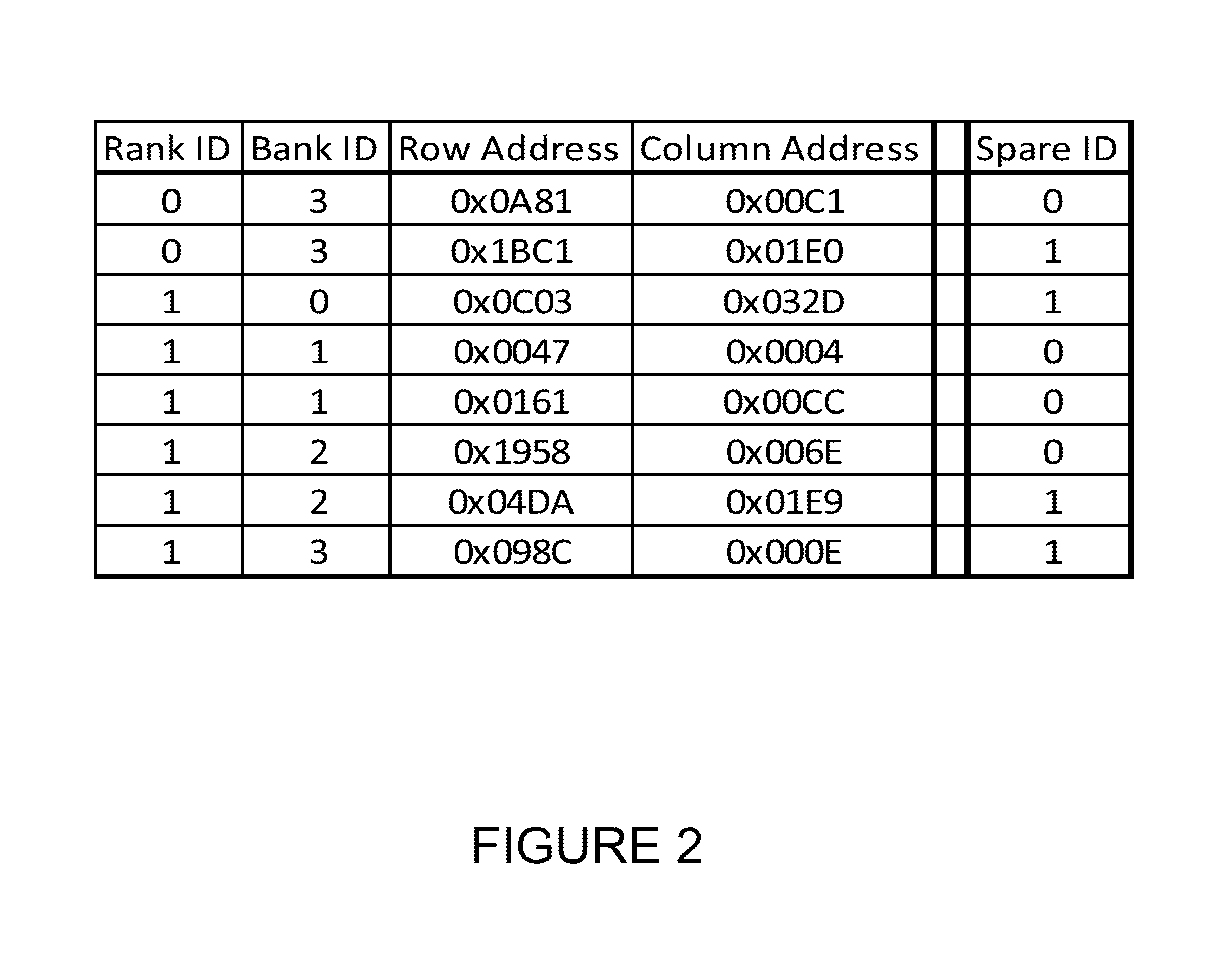

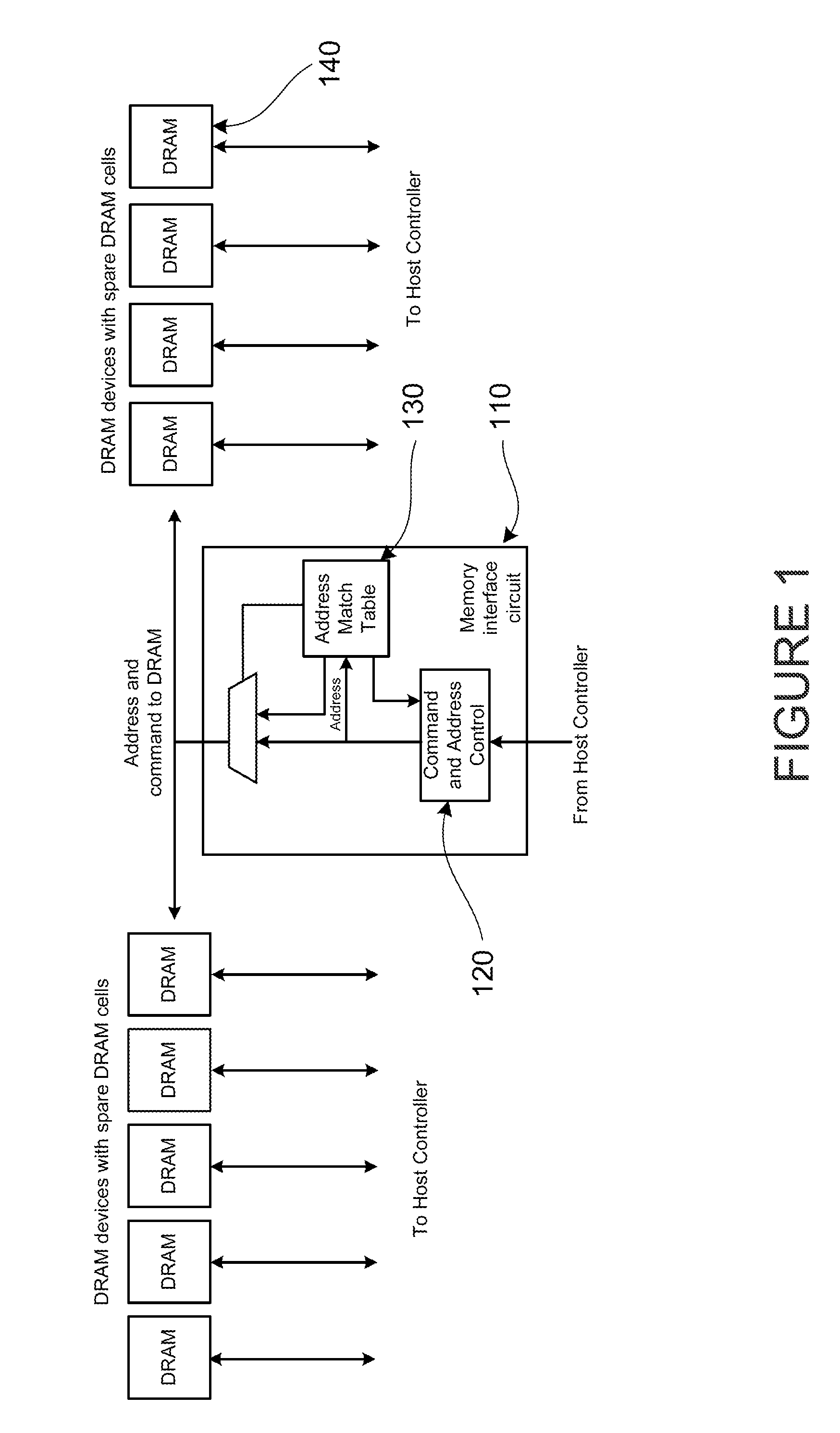

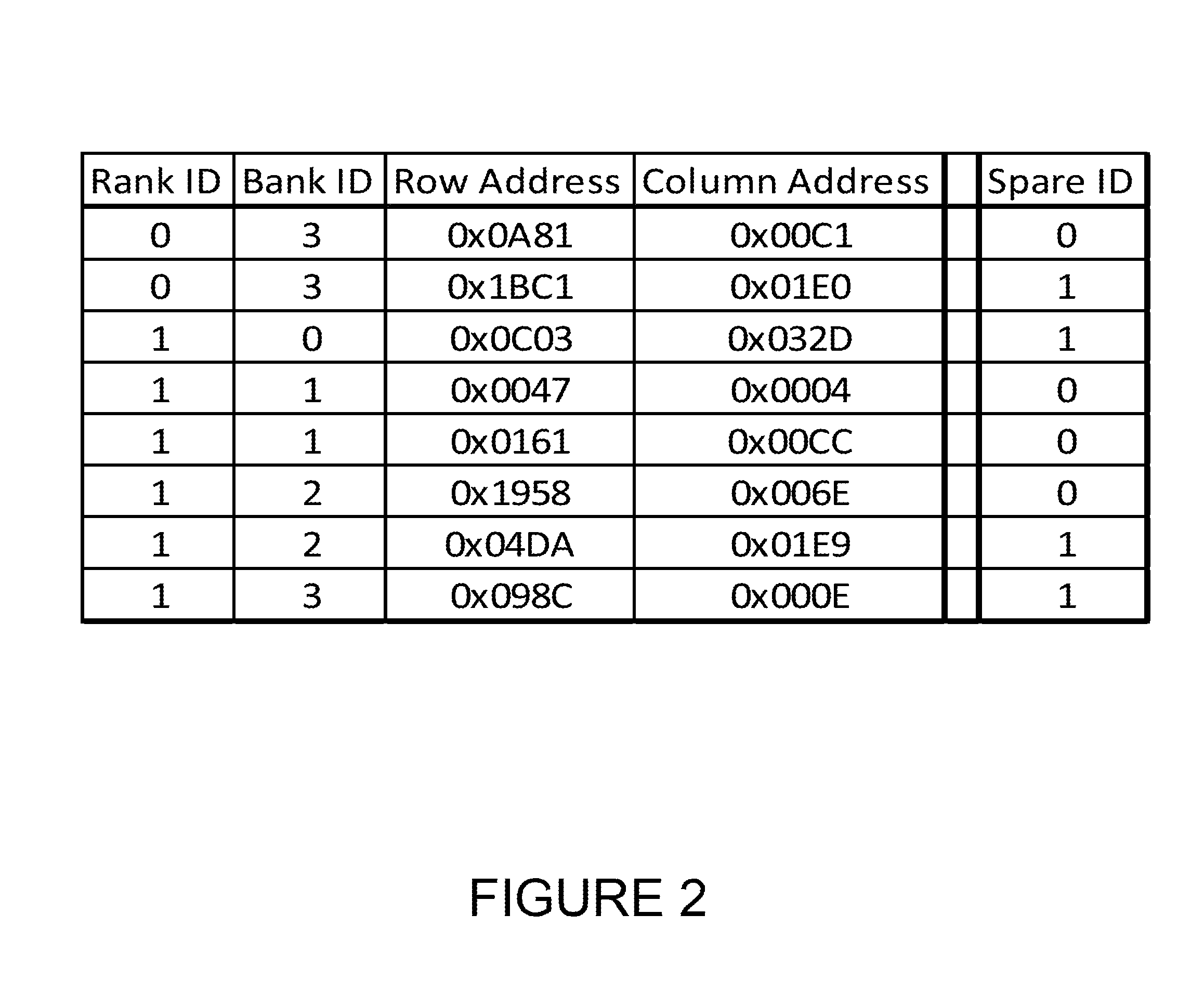

Method of using non-volatile memories for on-DIMM memory address list storage

ActiveUS8861277B1Improve performanceImproved lifetimeRead-only memoriesDigital storageMemory addressDIMM

An integrated circuit device. The device includes an address input(s) configured to receive address information from an address stream from an address command bus coupled to a host controller and an address output(s) configured to drive address information, and is coupled to a plurality of memory (DRAM) devices provided on a DIMM. The device has an address match table comprising a non-volatile memory device configured to store at least a revised address corresponding to a spare memory location and a bad address of at least one of the plurality of memory (DRAM) devices. The device has a control module configured to process and determine whether each address matches with a stored address in the address match table to identify the bad address and configured to replace the bad address with the revised address of the spare memory location.

Owner:RAMBUS INC

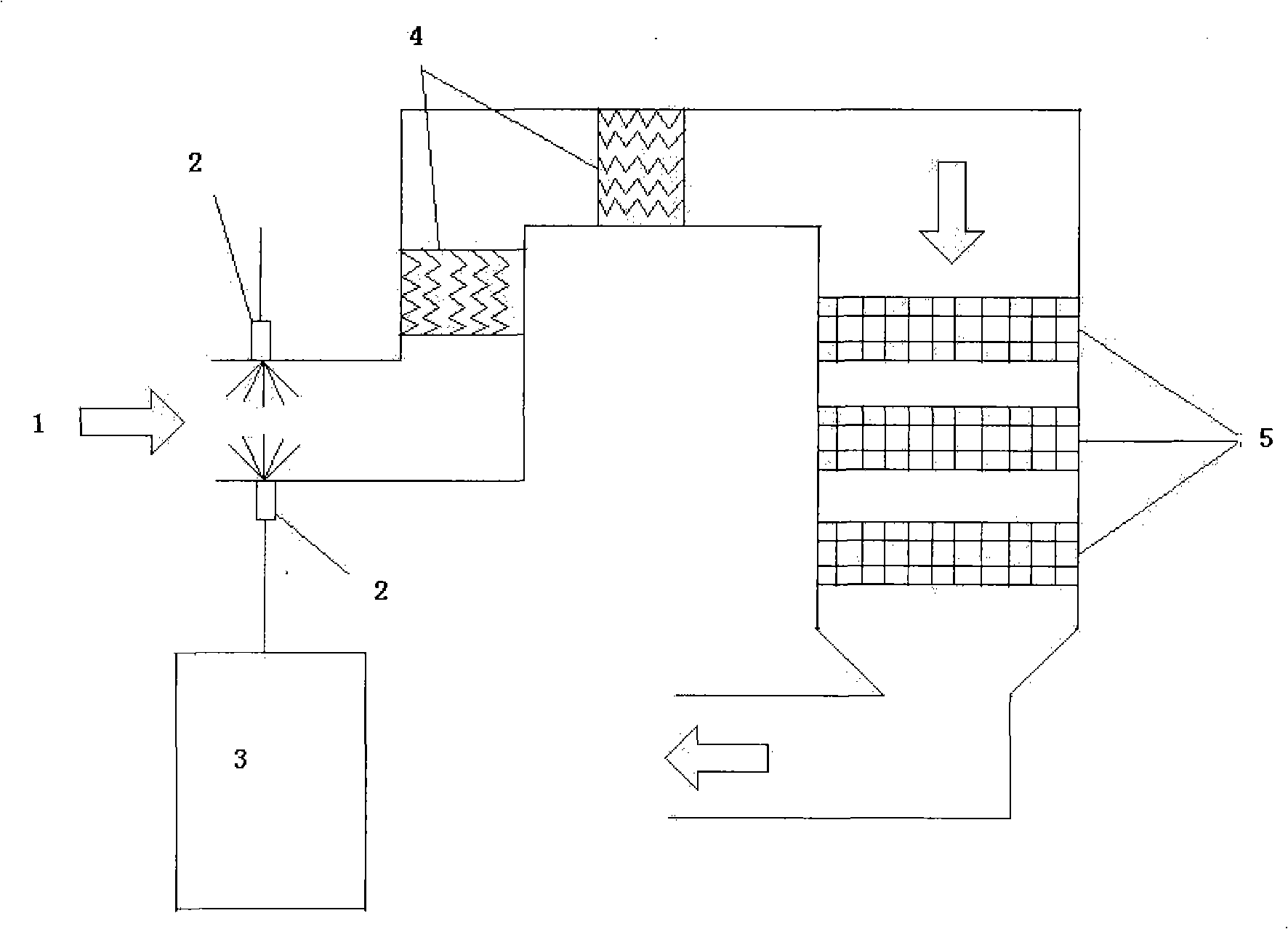

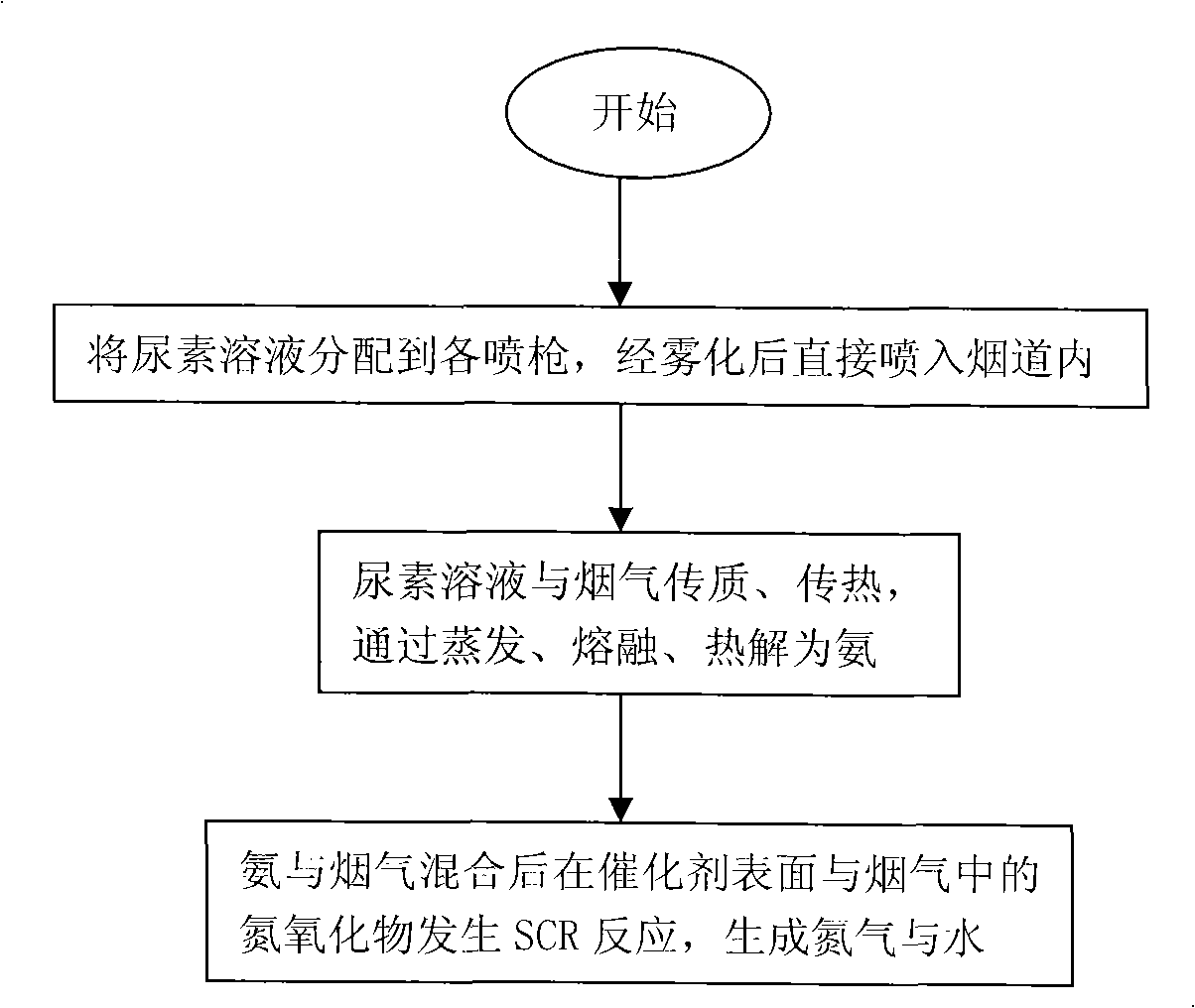

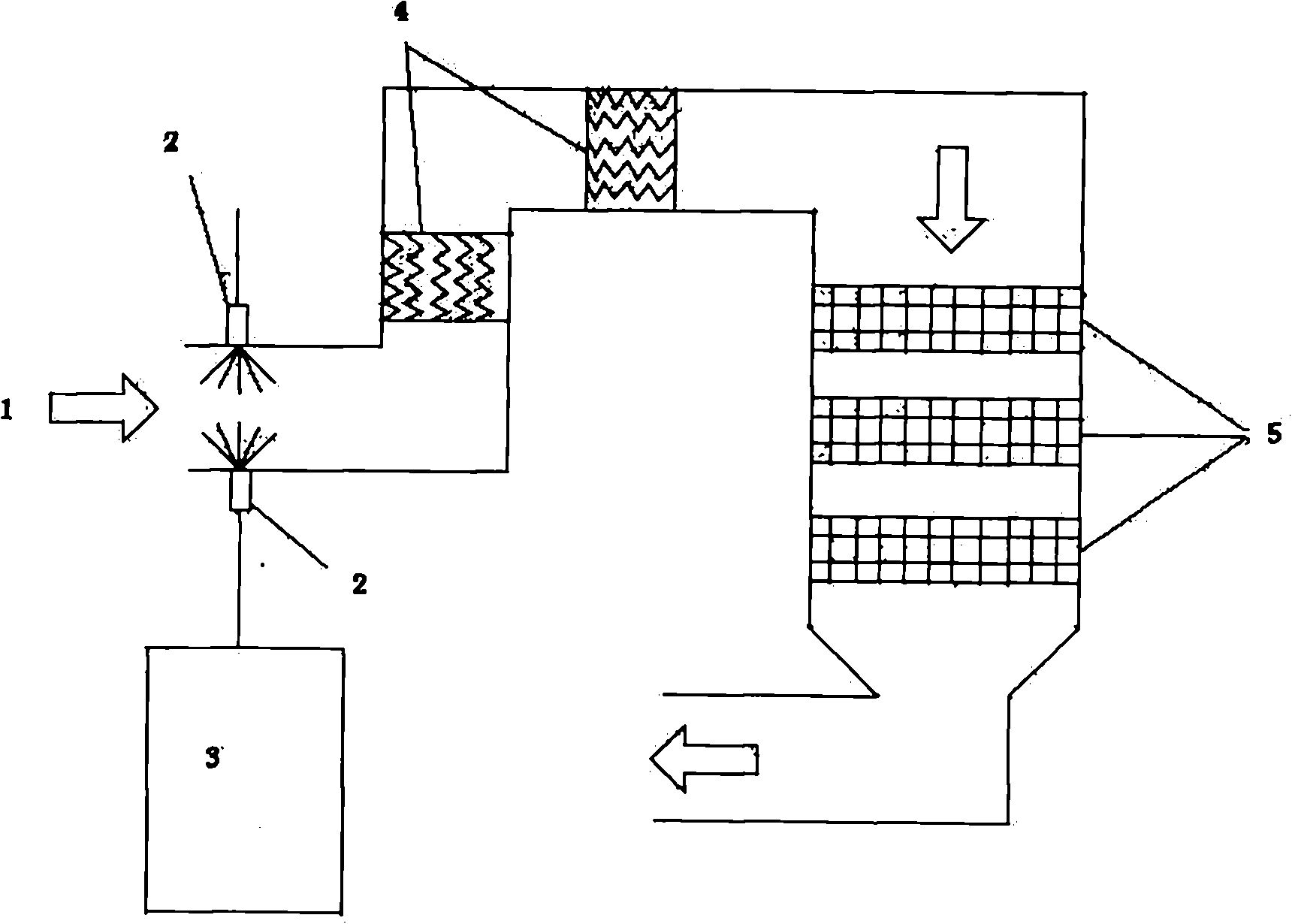

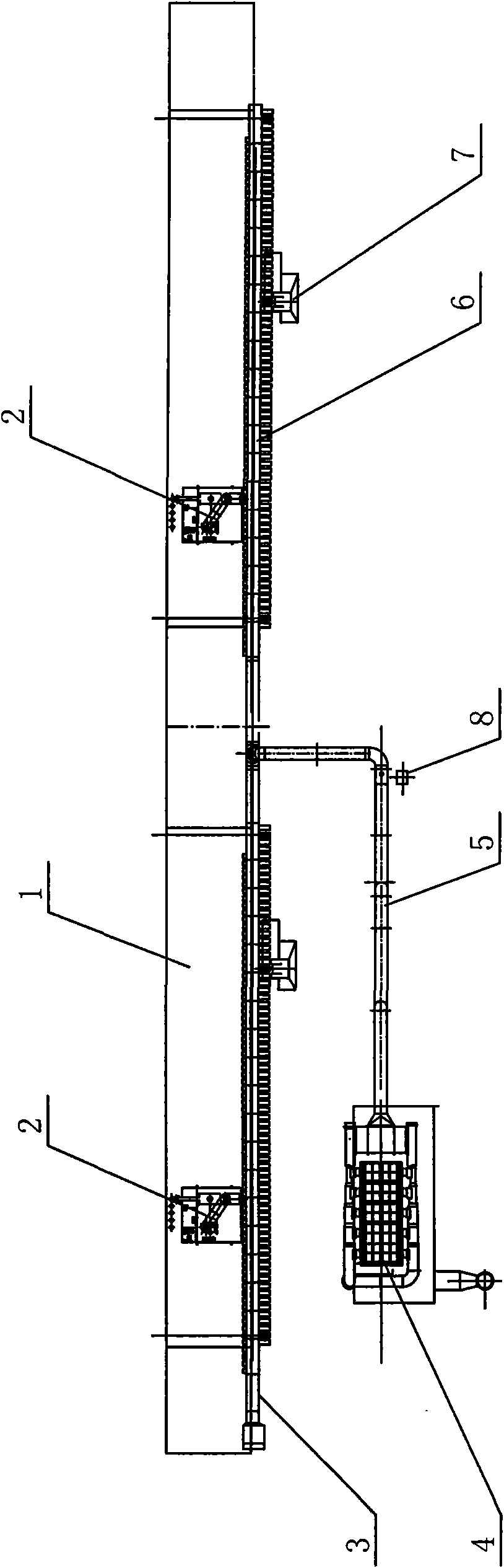

Selective catalytic reduction device by directly spraying urea solution and method thereof

InactiveCN102210974ALow investment and operating costsSave equipment spaceDispersed particle separationAmmonia preparation/separationFlueChemistry

The invention discloses a selective catalytic reduction device by directly spraying a urea solution and a method thereof, and relates to the technical field of environmental protection. The device comprises a plurality of groups of spray guns for spraying the urea solution, which are arranged at an inlet flue before a selective catalytic reduction (SCR) reactor, and a mixer and a catalyst which are arranged along the flowing direction of flue gas in turn, wherein each spray gun is connected with a urea solution tank through a metering distributor. Compared with the prior art, the invention has the advantages that: the urea solution is directly sprayed into the flue to thermally decompose the supplied ammonia, the operating cost and equipment investment are reduced, the space is saved, and the device is safe and reliable to use.

Owner:TONGFANG ENVIRONMENT

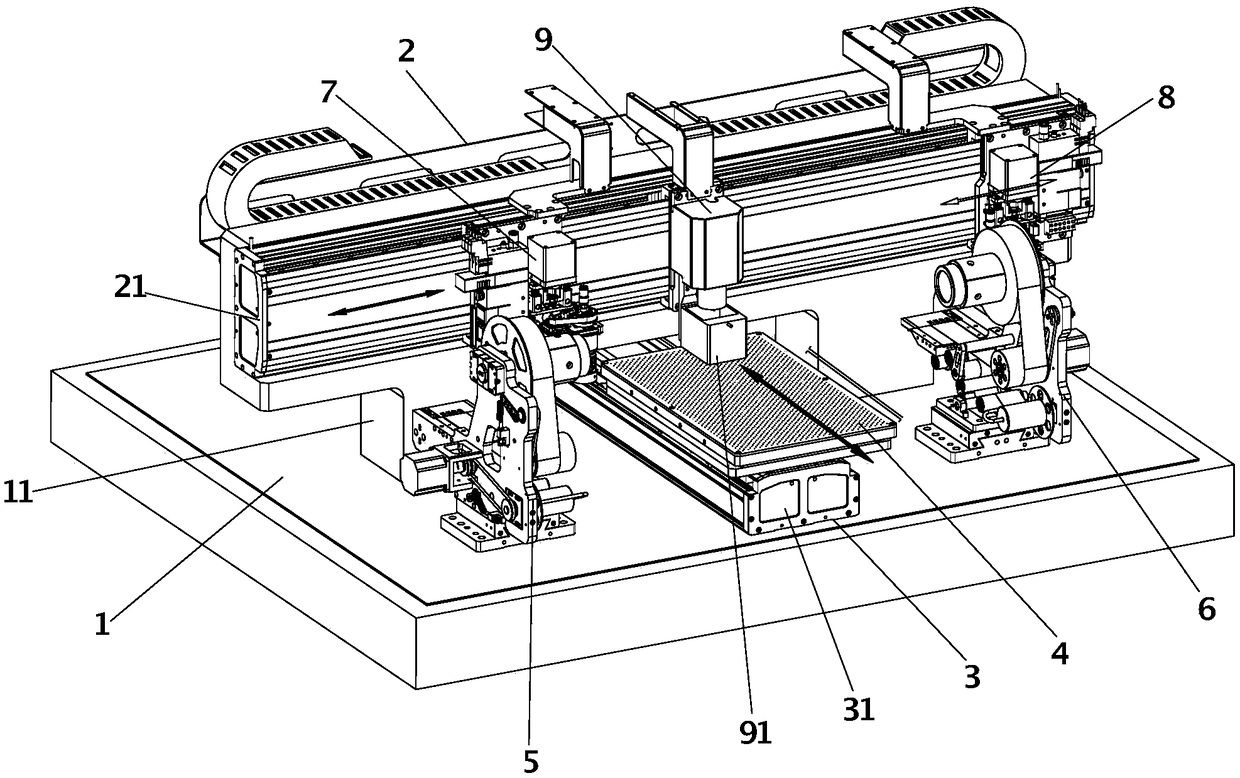

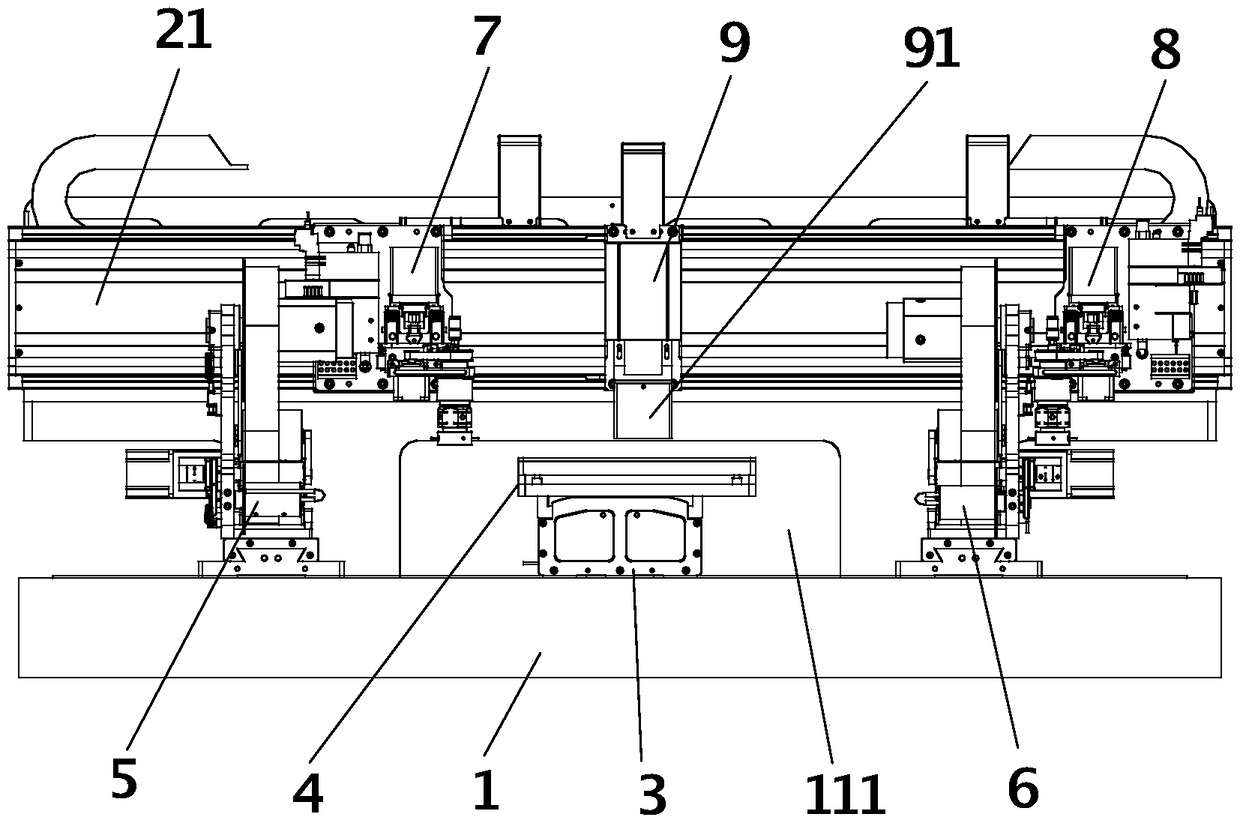

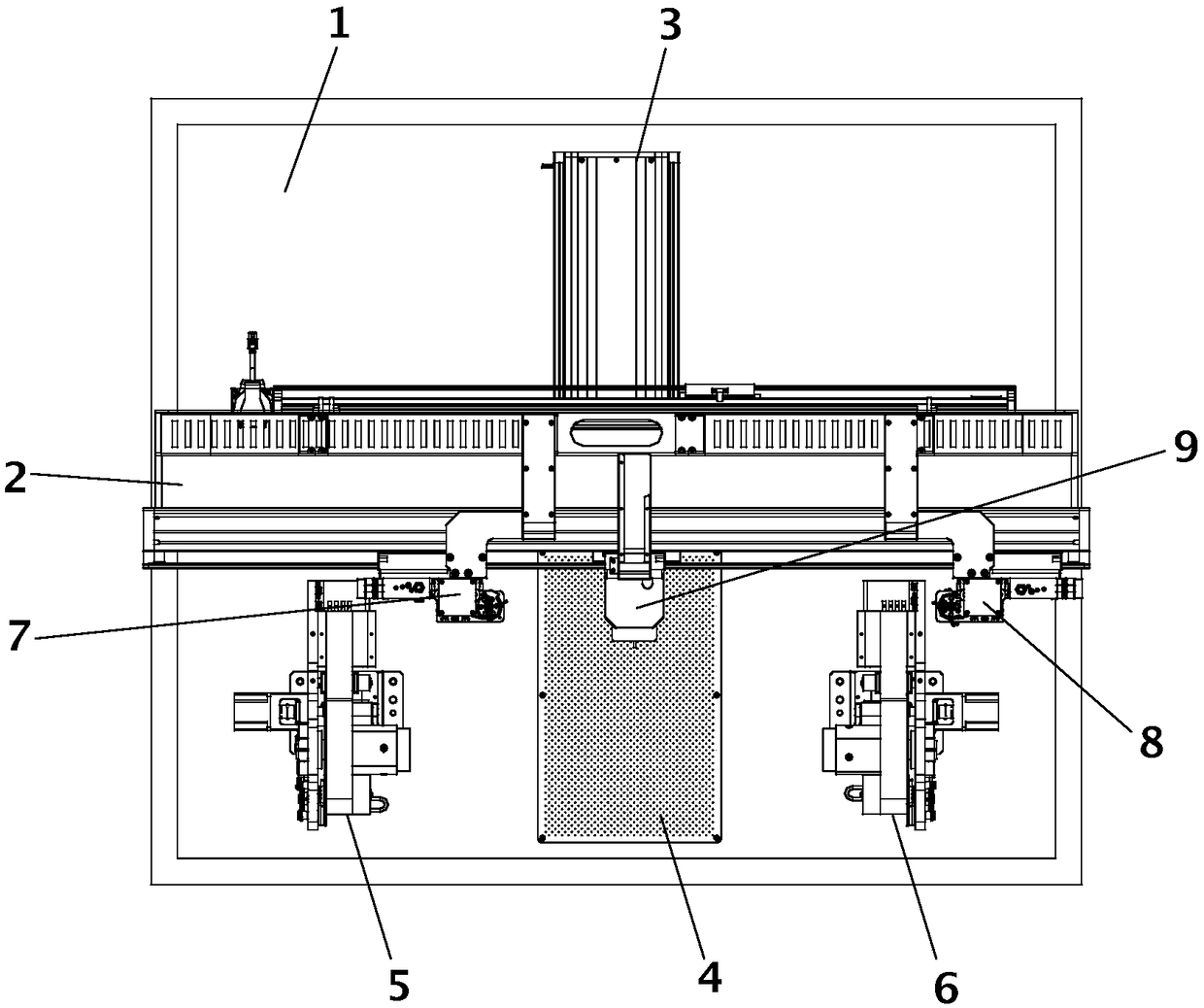

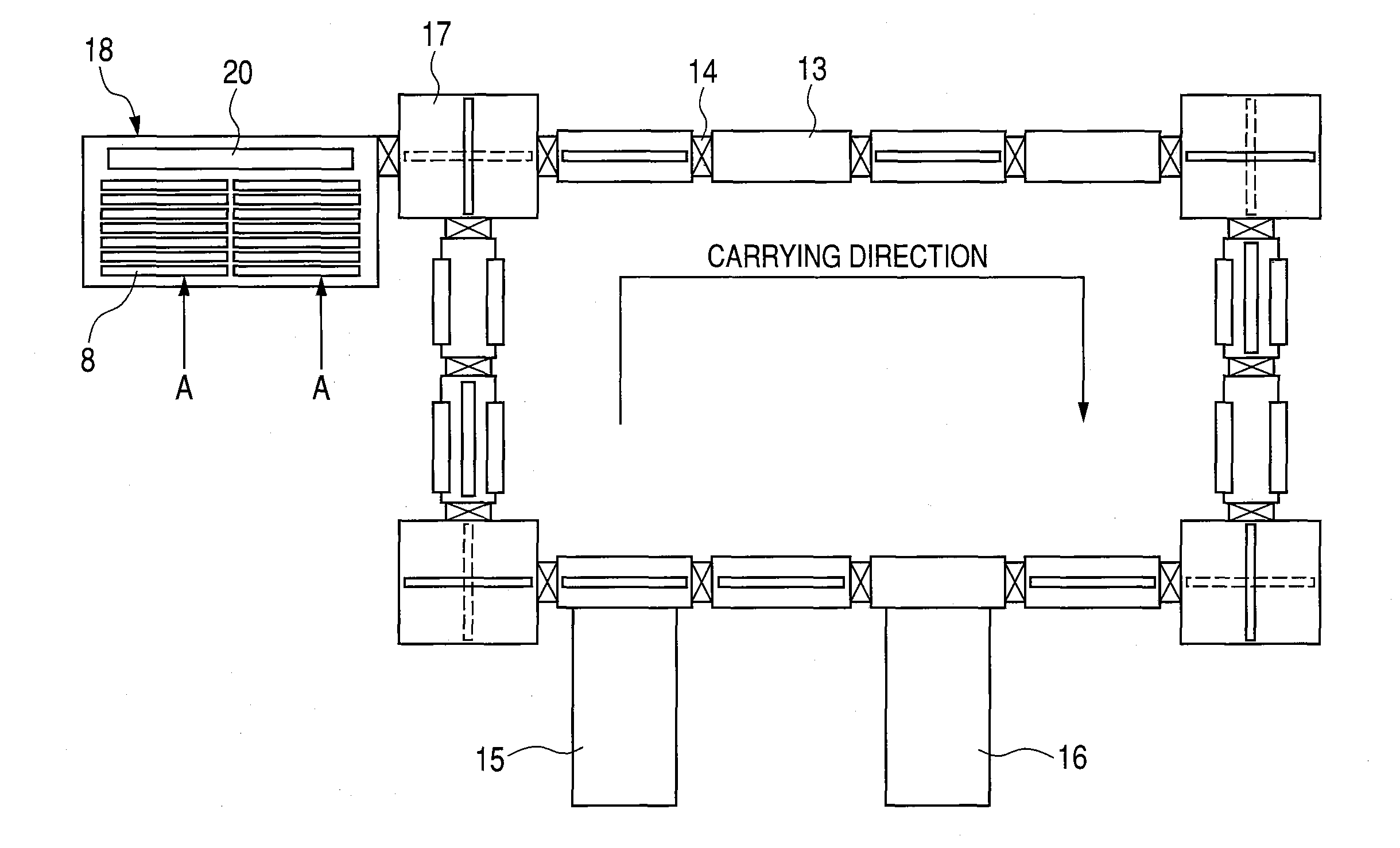

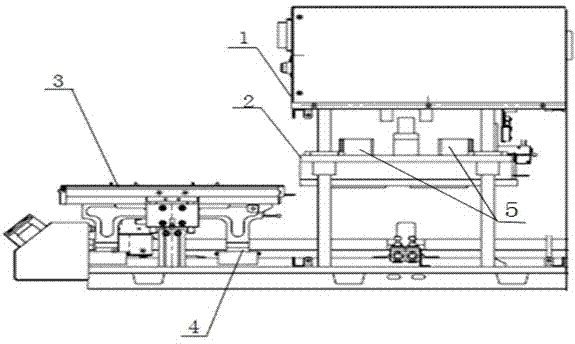

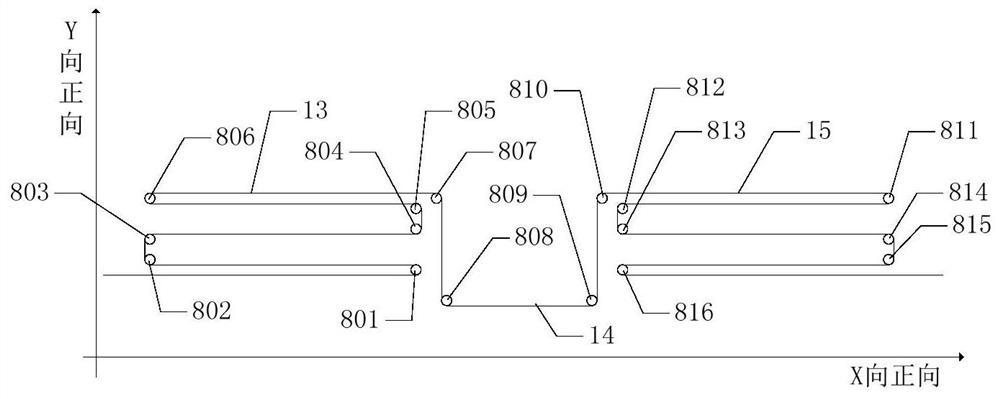

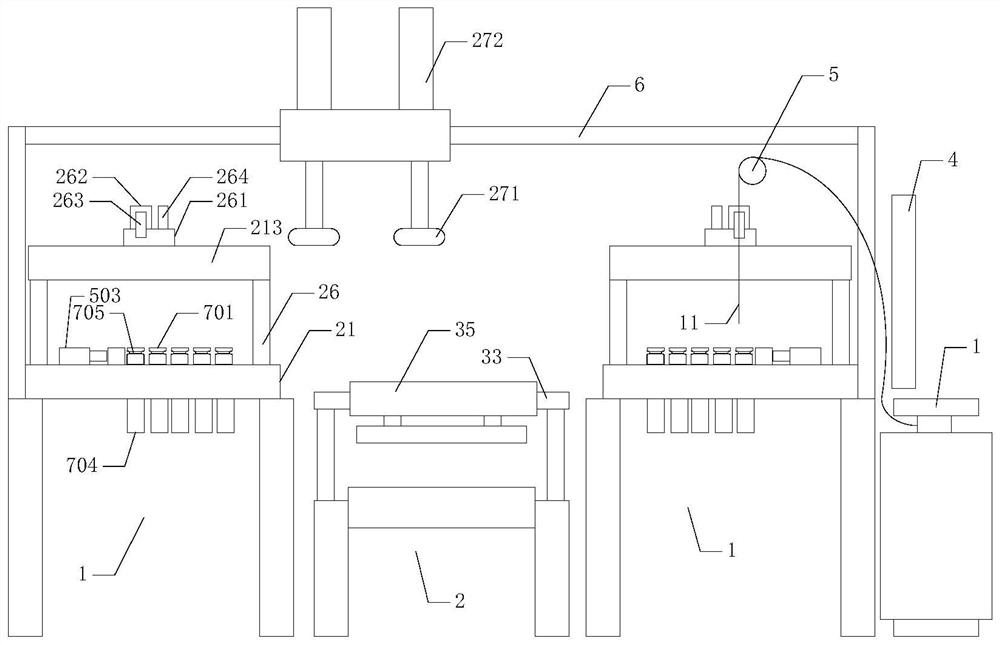

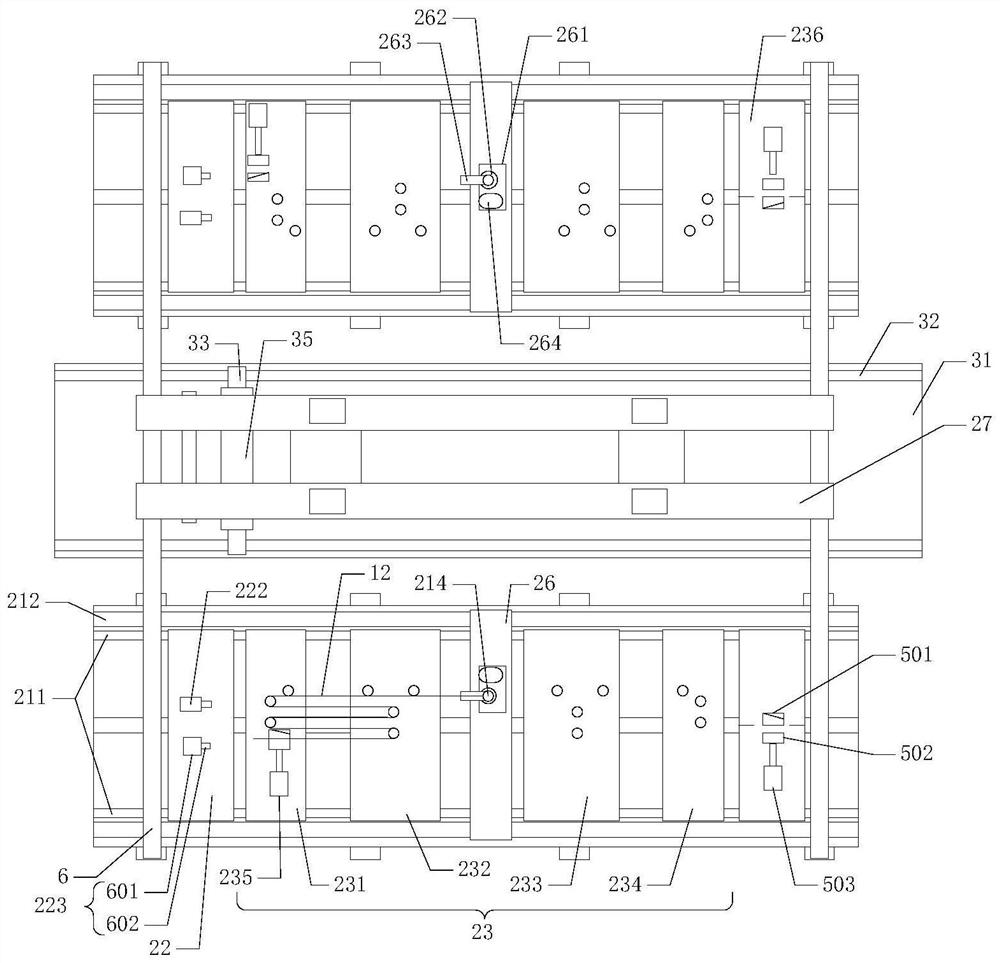

High-speed visual positioning and double-station flexible mounting device, and mounting method thereof

PendingCN108882669AEasy to operateMeet high speed requirementsElectrical componentsEngineeringVisual positioning

The invention discloses a high-speed visual positioning and double-station flexible mounting device, and mounting method thereof. The high-speed visual positioning and double-station flexible mountingdevice comprises a base, an X-axis motion module, a Y-axis motion module, a vacuum adsorption platform, a first material conveying device, a second material conveying device, a left mounting module,a right mounting module and a CCD visual positioning module; the X-axis motion module and the Y-axis motion module are arranged on the base, and the X-axis motion module can move left and right on thebase, the Y-axis motion module can move front and back on the base, the X-axis motion module and the Y-axis motion module are arranged vertically, and the Y-axis motion module is located below the X-axis motion module, the vacuum adsorption platform is fixed on the Y-axis motion module, and the left mounting module, the right mounting module and the CCD visual positioning module are arranged on the X-axis motion module. According to the device and the mounting method thereof, can effectively save the movement distance and the device space, and greatly improve the mounting speed and precisionrequirements.

Owner:深圳市纳迪洱科技有限公司

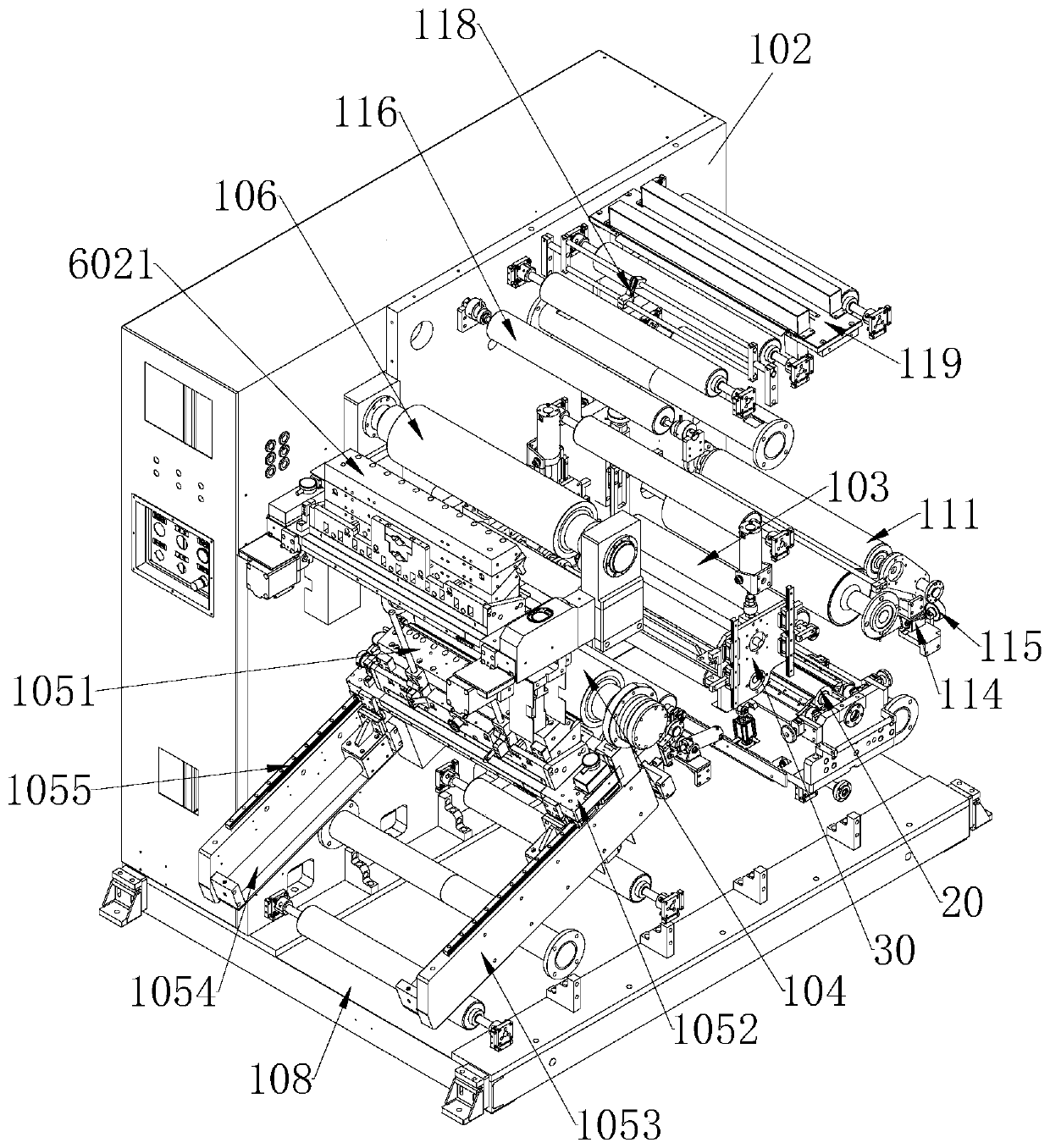

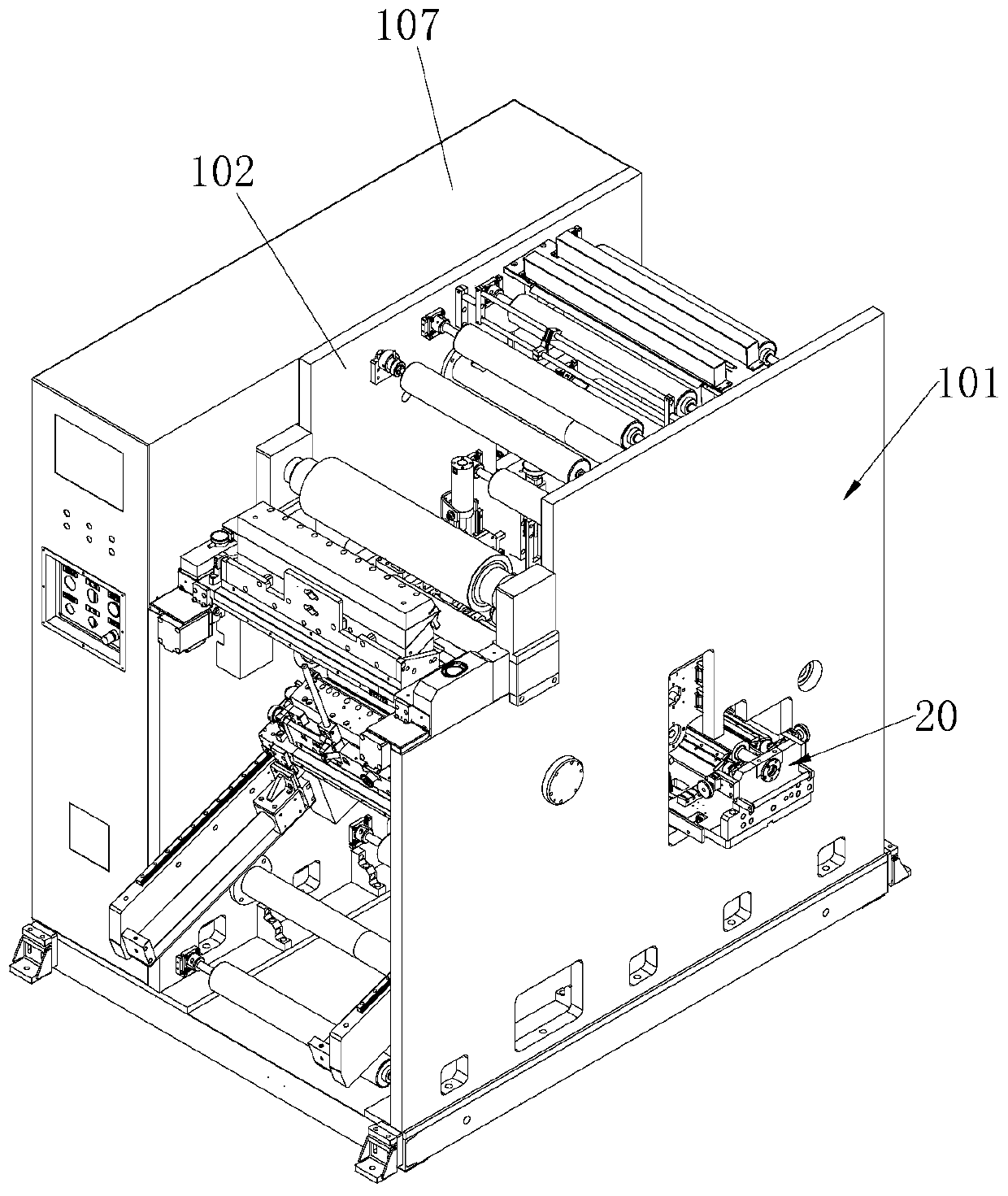

Device combining various coating methods

PendingCN110721872AAchieve gap coatingEnables continuous coatingLiquid surface applicatorsCoatingsProcess engineeringMaterial resources

The invention discloses a device combining various coating methods and relates to the technical field of coating equipment. The device comprises a first big board, a second large board, a pull roll, agravure roll coating mechanism, a swinging mechanism, a second coating roll, an inclined extrusion coating mechanism, a die head coating mechanism and a first coating roll, wherein the swinging mechanism is located above the gravure roll coating mechanism; the pull roll is located at one side of the gravure roll coating mechanism; the inclined extrusion coating mechanism comprises a second die head; the second coating roll is located at one side of the second die head; the die head coating mechanism comprises a first die head; the first coating roll is located at one side of the first die head; and after passing through a space between the second coating roll and the second die head, a pole piece enters a space between the first die head and the first coating roll. The device disclosed bythe invention has the beneficial effects that the proofing requirements of products in the current market can be met and the device does not need to be equipped with several equipment with differentcoating methods, so that the equipment cost, equipment space and manpower and material resources of users are saved.

Owner:JIANGSU KATOP AUTOMATION CO LTD

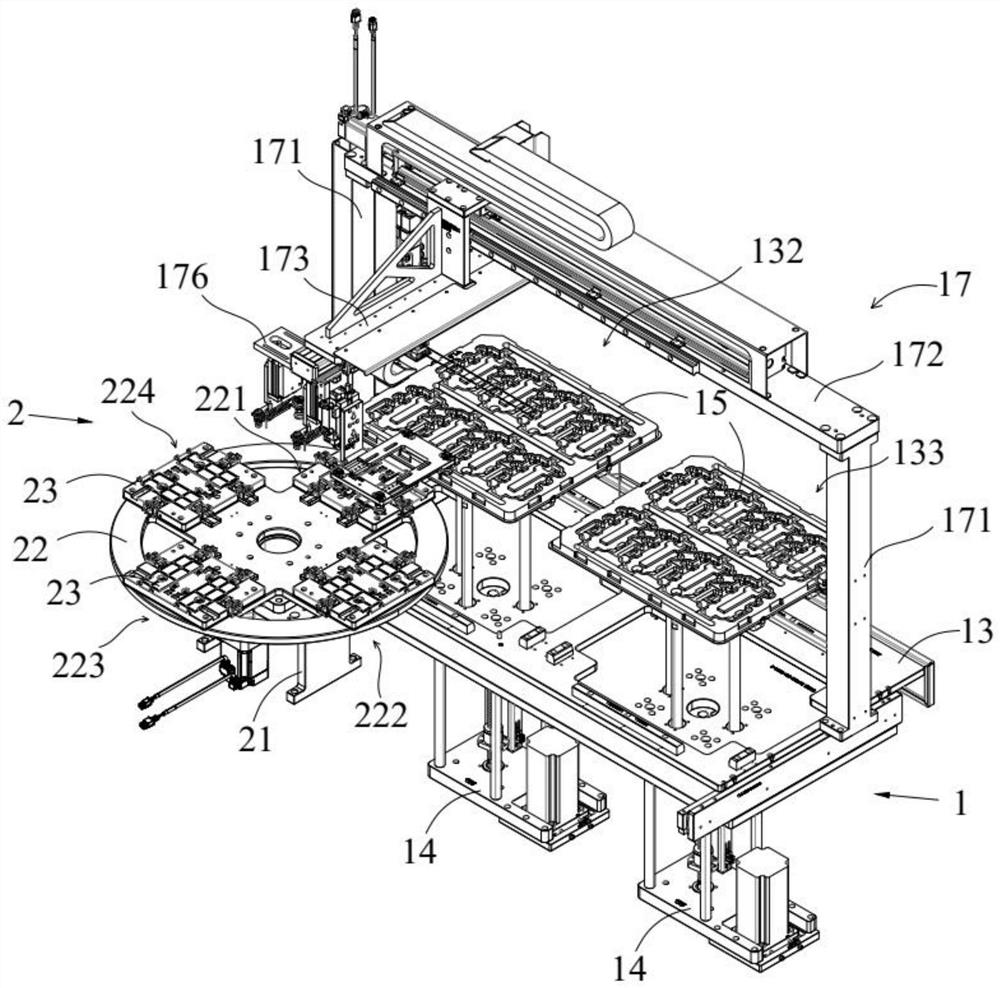

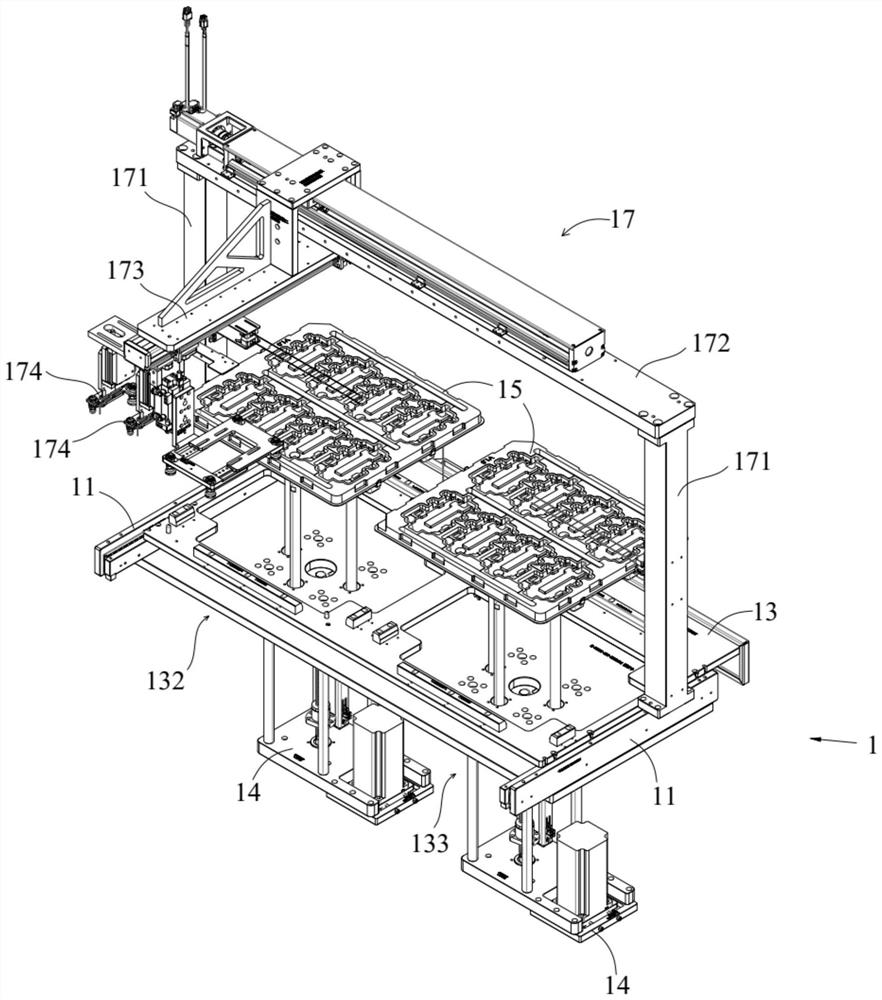

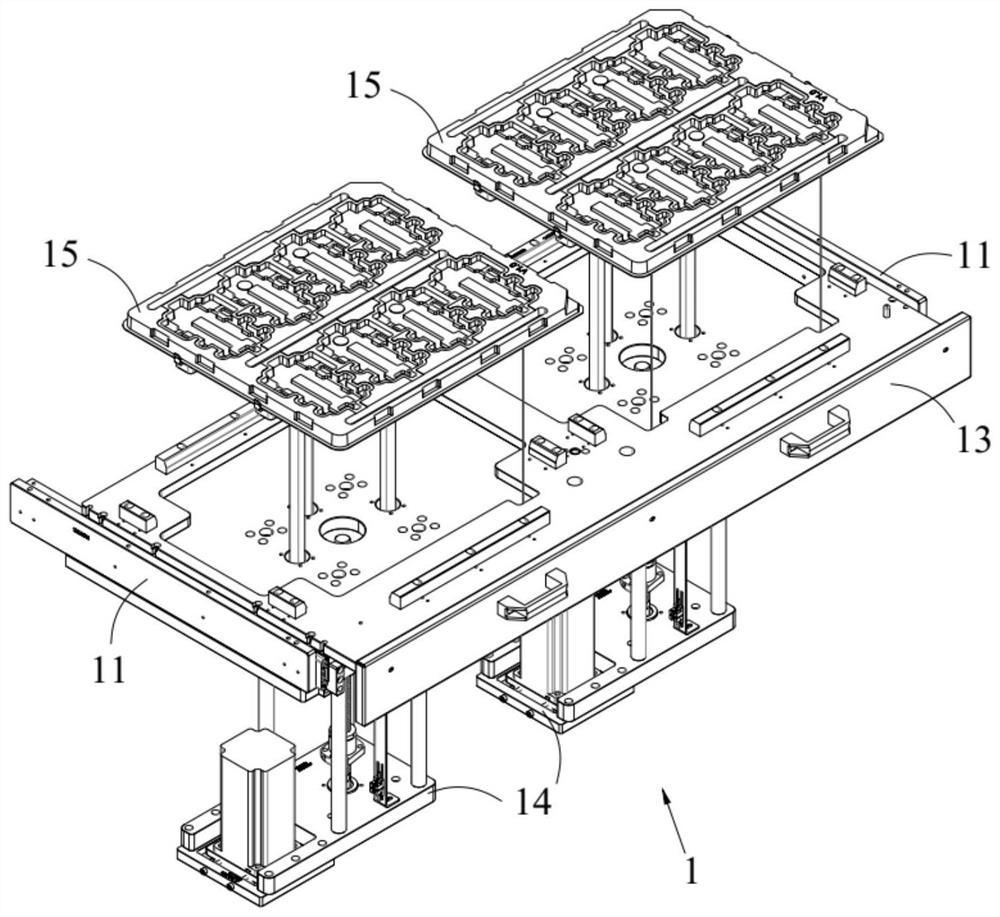

Feeding and transferring integrated feeding and discharging device

ActiveCN113044517AImprove space utilizationSave equipment spaceConveyorsStacking articlesTransfer mechanismElectrical and Electronics engineering

The invention discloses a feeding and transferring integrated feeding and discharging device, which comprises a feeding and discharging mechanism and a turnover type transferring mechanism arranged on the side of the feeding and discharging mechanism; the feeding and discharging mechanism comprises a material preparing assembly, and a material feeding station and a material disc recycling station are sequentially arranged on the material preparing assembly in the linear direction; two material tray supporting plates arranged on the material feeding station and the material tray recycling station respectively; the two sets of jacking assemblies, which are arranged in parallel, and each set of jacking assembly abuts against the bottom face of the corresponding material tray supporting plate; a carrying assembly, which comprises a carrying cross beam stretching across the upper portion of the material preparing assembly, a suction module in sliding connection with the carrying cross beam and a transverse movement driver in transmission connection with the suction module; the turnover type transferring mechanism comprises a fixedly-arranged turntable base; and a turntable, which is rotatably connected to the top of the turntable base at the center. According to the feeding and transferring integrated feeding and discharging device provided by the invention, the feeding and discharging efficiency of materials is improved.

Owner:SUZHOU RS TECH

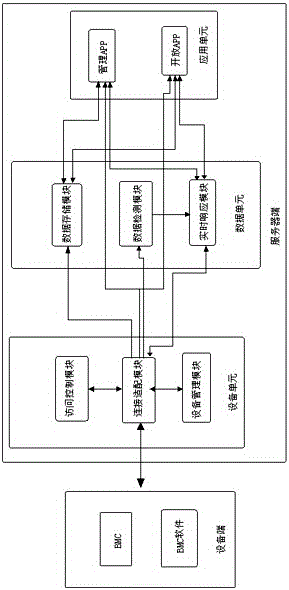

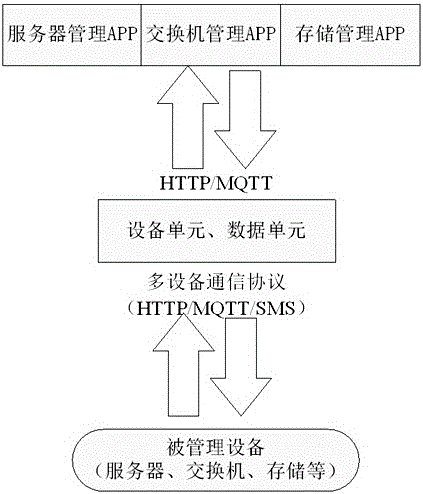

Software-defined data center equipment management-control method and system

InactiveCN106549812ASave hardware cost and equipment spaceSave network bandwidthData switching networksTelemetry EquipmentServer-side

The invention discloses a software-defined data center equipment management-control method and system. The method is characterized in that a cloud computation platform is utilized, a software-defined method is adopted, and relevant cloud infrastructure of a data center is managed and controlled uniformly in a (cloud + end) way by a uniform interface and protocol. A server side provided by the invention can be deployed on any public or private cloud by universal cloud resources without special equipment or high processing capacity. An MQTT (Message Queuing Telemetry Transport) protocol based on Internet of things is adopted, so that the requirements of equipment monitoring on a small data quantity and real-time performance can be met well. Through adoption of the software-defined data center equipment management-control method, the cloud resources are utilized fully; the hardware cost and equipment space are saved; and the network bandwidth is saved. The software-defined data center equipment management-control method has the advantages of high flexibility, high extensibility, and convenience in migration, upgrade and maintenance of the platform. The method can be widely applied to infrastructure such as cloud computation and big data. The adopted system architecture can be protected as a private intellectual property to improve the competitive power of Inspur products, and has great significance to promotion of industry development.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

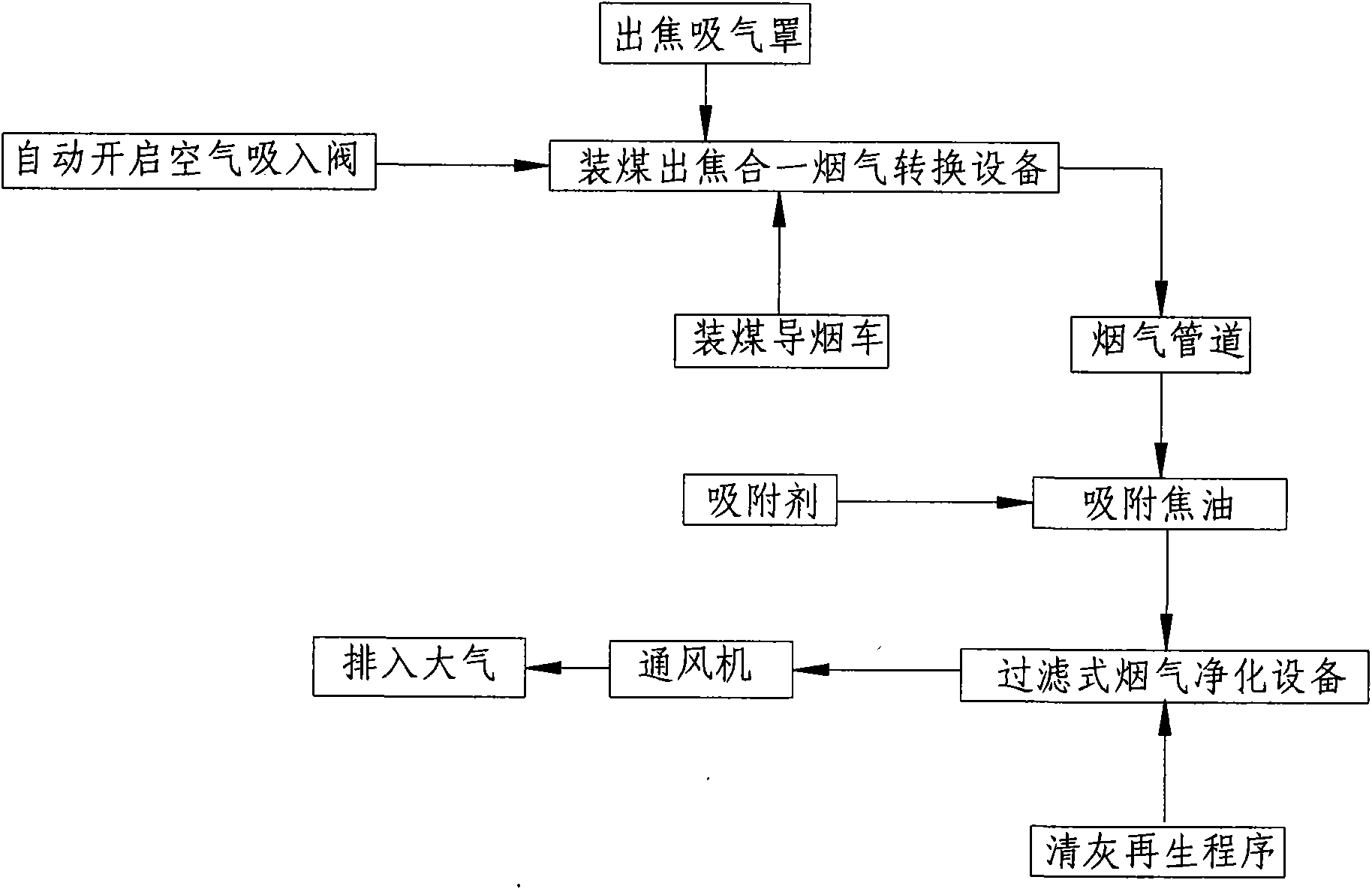

Coal-charging and coke-discharging flue gas integration dust-removal process for side coal-charging coke oven

InactiveCN101602951ASave civil costSave equipment costsCharging-discharging device combinationsOven incrustations prevention/removalAtmospheric airFlue gas

The invention relates to a coal-charging and coke-discharging flue gas integration dust-removal process for a side coal-charging coke oven. A two-way connector valve is arranged on an oven column for the coke oven, the flue gas generated during the coal charging process of the coke oven and the flue gas generated during the coke discharging process of the coke oven enter in a common flue gas pipeline respectively through the two-way connector valve, and the dust removal is performed through a filtering type flue gas dust-removal device connected with the flue gas pipeline; the tar adsorption adopts a method that active powder adsorbent is sprayed in the flue gas pipeline, and the flue gas is discharged into atmosphere through a ventilator after being filtered and purified in a filtering type flue gas purification device; and the filtering type flue gas purification device performs off-line dust-cleaning regeneration after finishing coke discharging until the next coke discharging of the coke oven. No dust deposits in the process pipeline, the tar adsorption is complete, the dew point is not reached, the filter bag dust-cleaning regeneration is good, and the system is reliable and stable, thereby effectively ensuring the normal running of the coke oven with flue gas dust removal.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

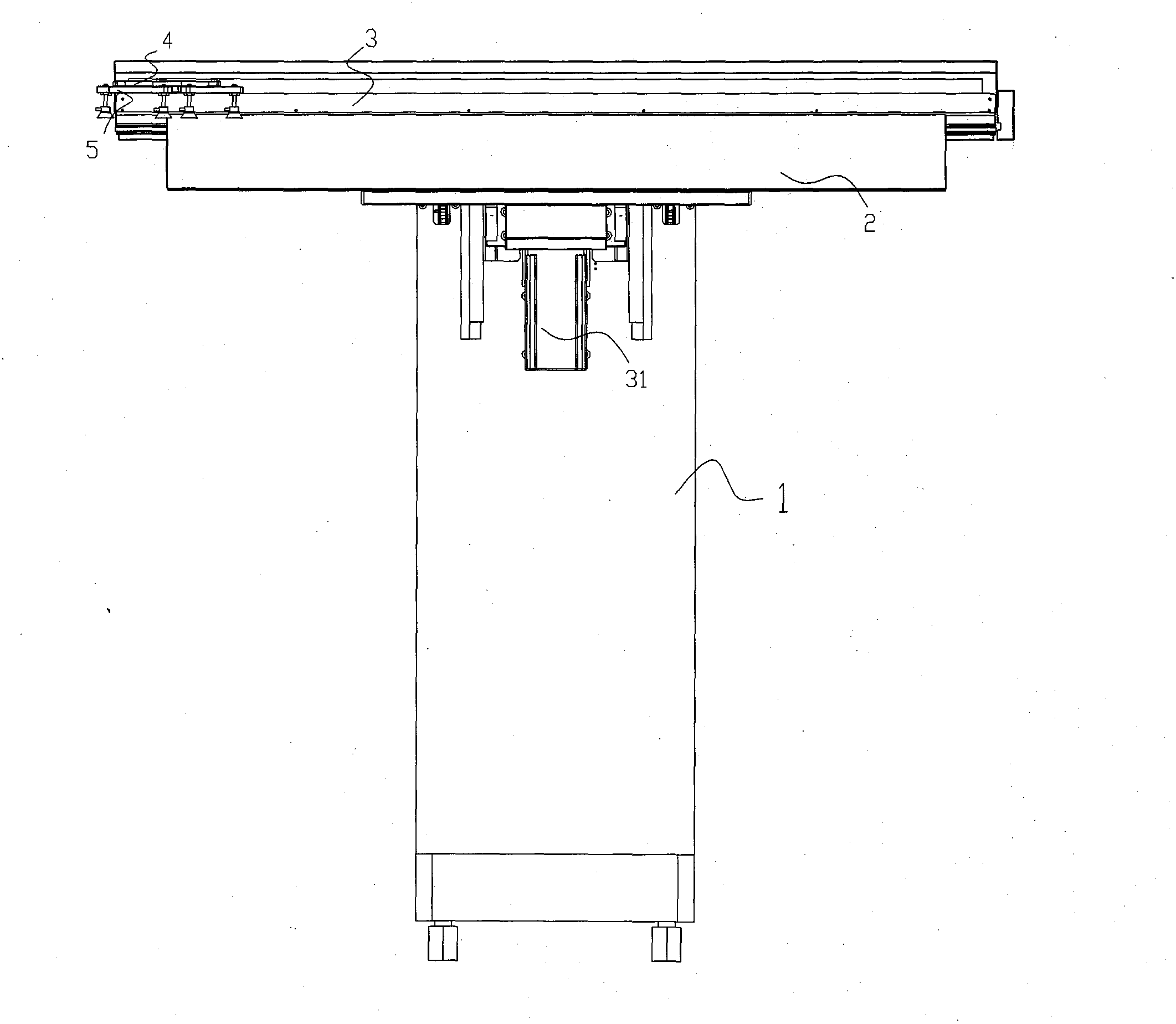

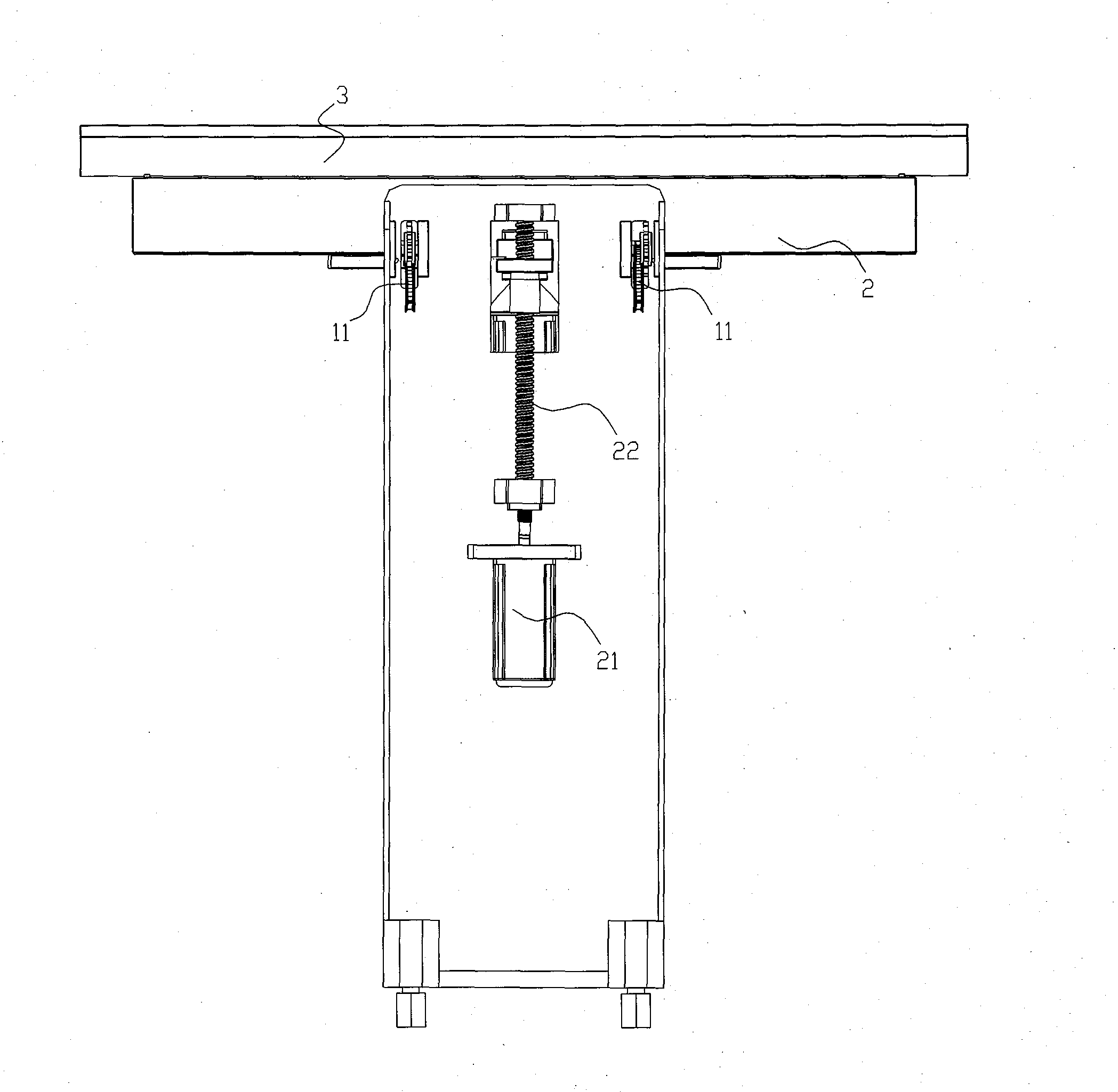

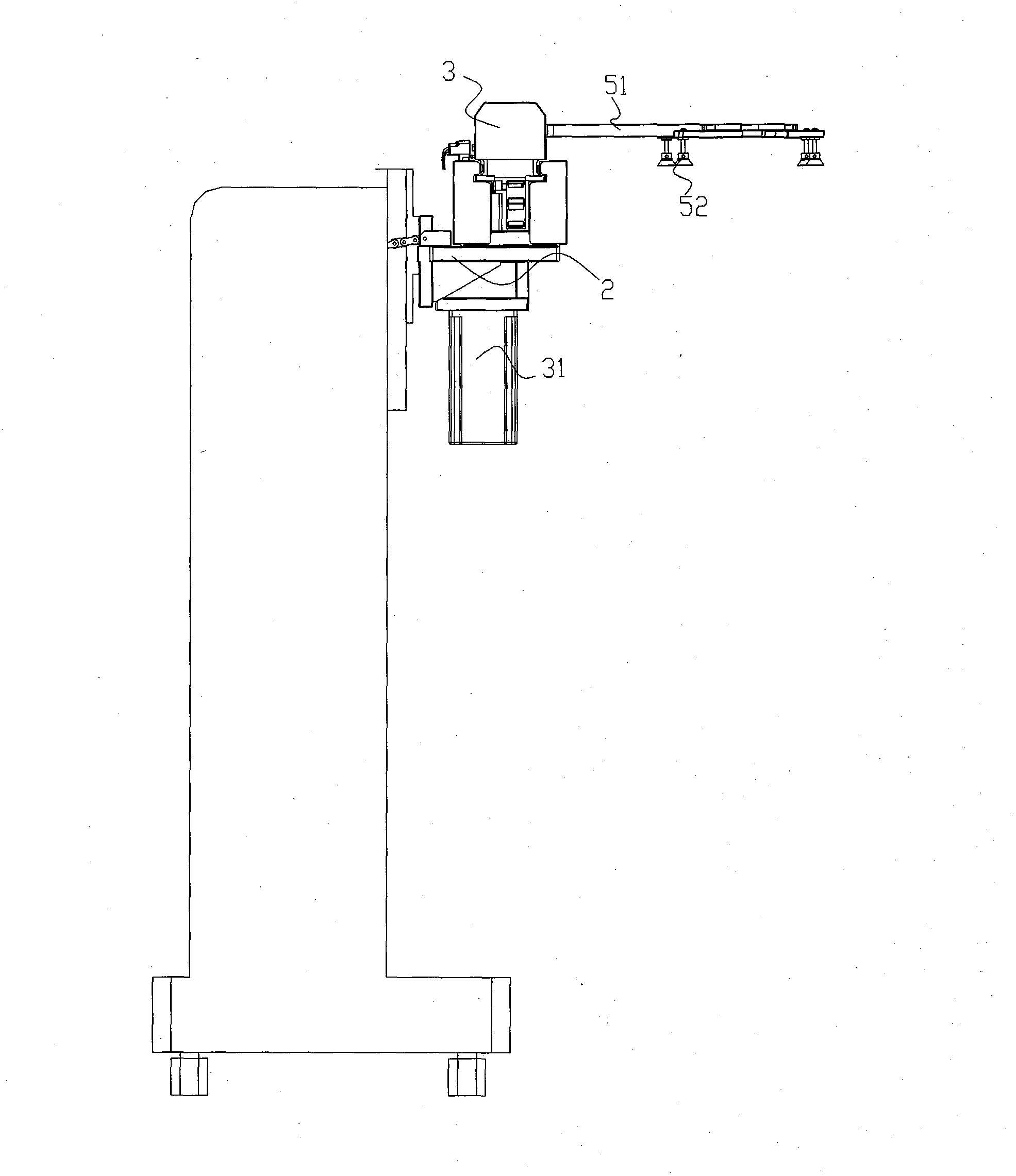

Mechanical arm

InactiveCN103447408AIncrease movement speedSave equipment spaceProgramme-controlled manipulatorMetal-working feeding devicesProcessing accuracyManipulator

The invention discloses a mechanical arm comprising a rack, a Z-axis moving component, an X-axis moving component and a hand grab. The Z-axis moving component is arranged on the rack and can move up and down, the X-axis moving component is arranged on the Z-axis moving component and can move to the left and the right, and the hand grab is arranged on the X-axis moving component comprising a main shaft and an auxiliary shaft. The main shaft can move to the left and the right around the X axis, the auxiliary shaft is assembled on the main shaft and can move to the left and the right on the main shaft along the X axis, and corresponding driving devices are arranged on the Z-axis moving component, the main shaft and the auxiliary shaft. The X-axis moving component is designed to be a double-shaft moving structure with the main shaft and the auxiliary shaft, relative moving speed of a single hand grab on the auxiliary shaft is greatly increased, long-distance X-axis travel equipment space is greatly reduced, the mechanical arm is superior to and can replace a traditional middle material grabbing switching mode, a middle switching procedure is omitted, setup time are saved, and working efficiency and processing accuracy are improved.

Owner:何芳

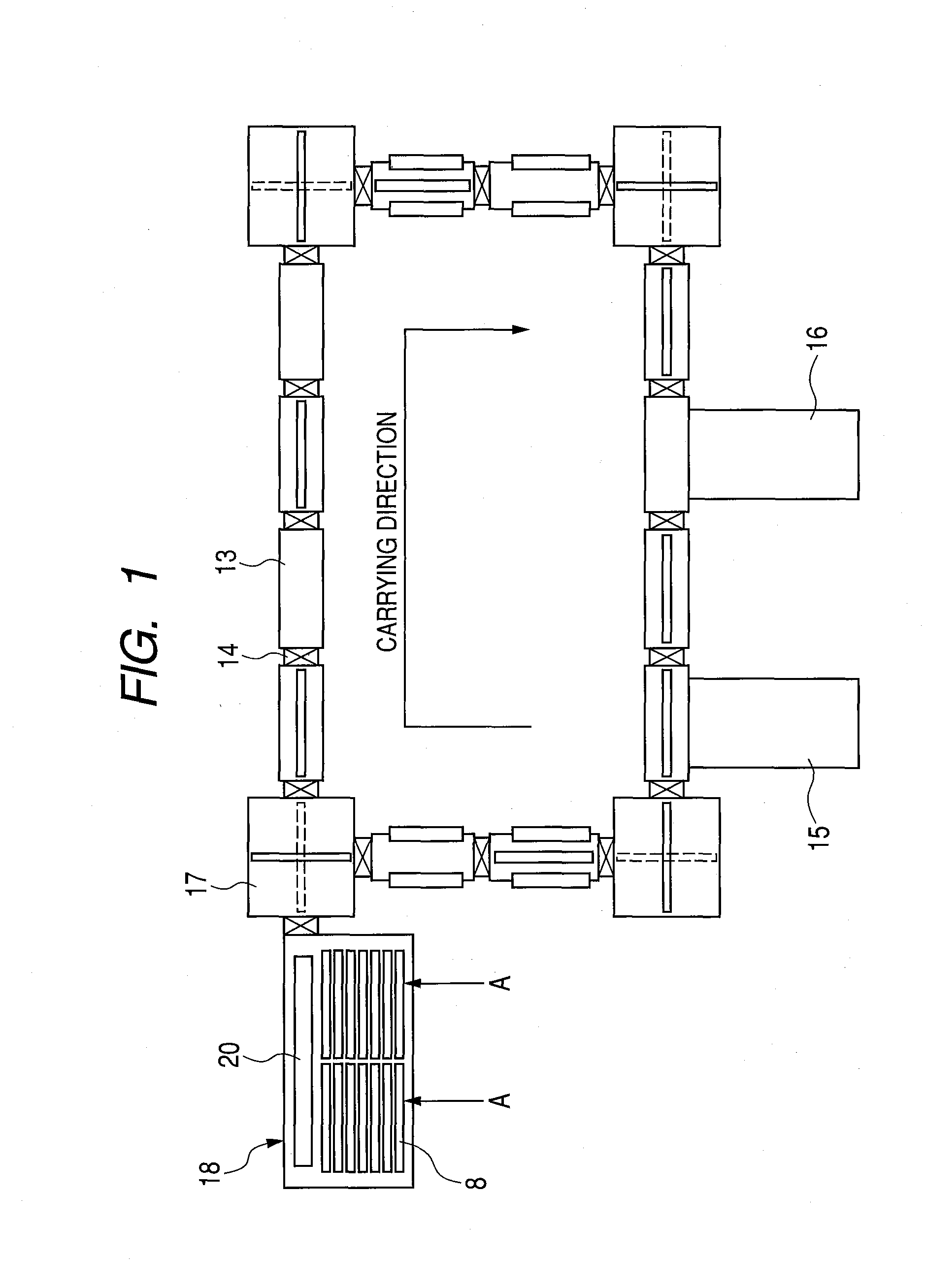

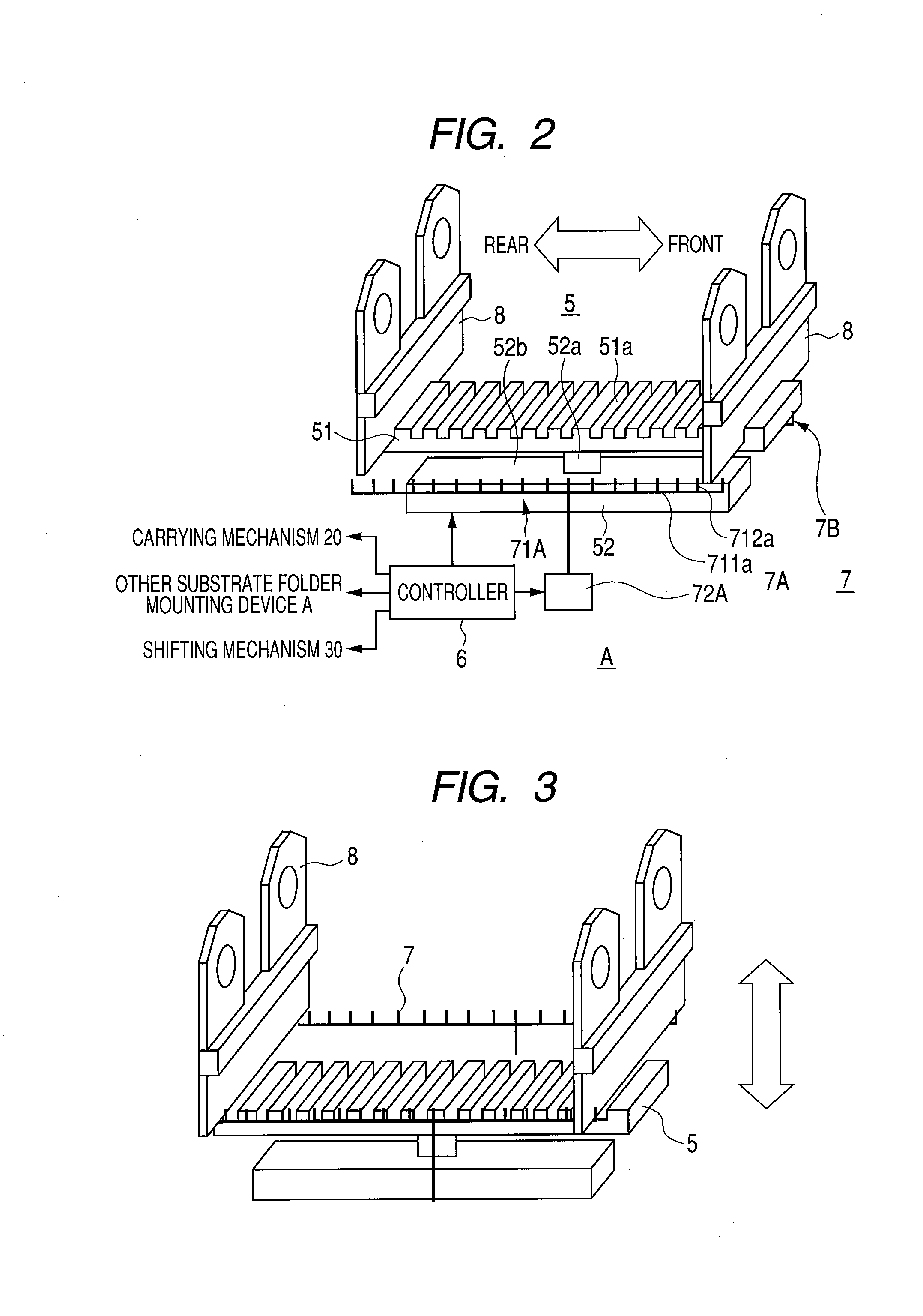

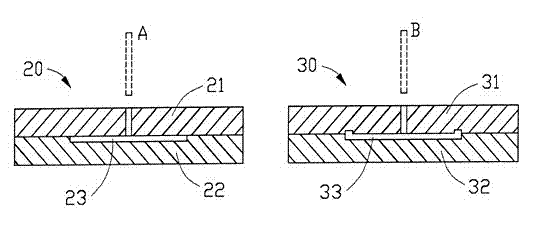

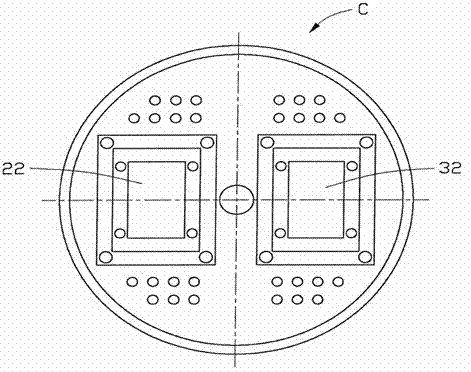

Substrate holder mounting device and substrate holder container chamber

InactiveUS20100129539A1Small sizeImprove heating efficiencySemiconductor/solid-state device manufacturingCoatingsEngineeringChange positions

Owner:CANON ANELVA CORP

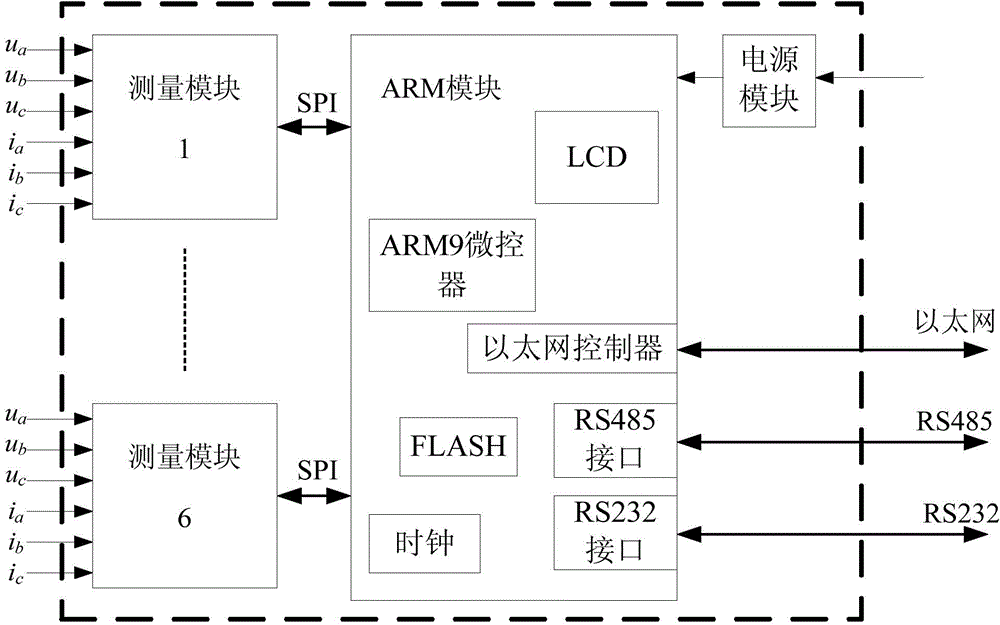

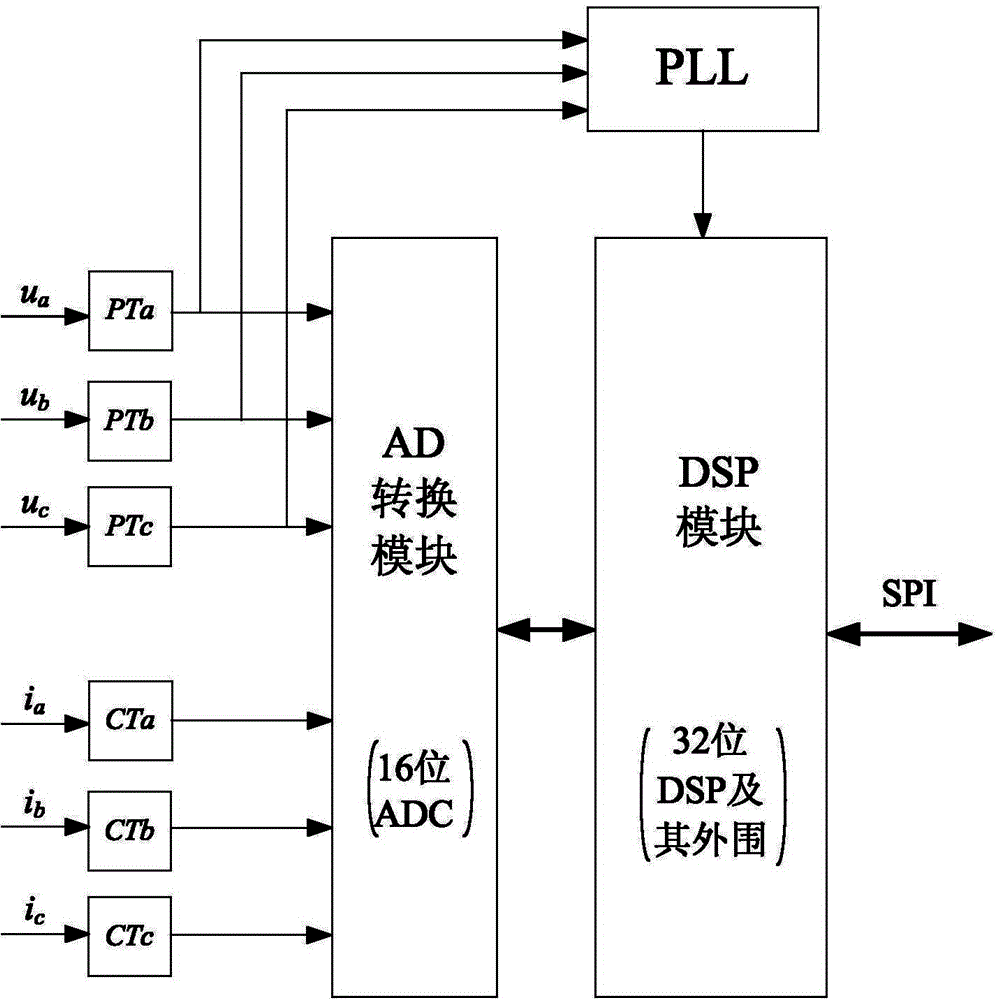

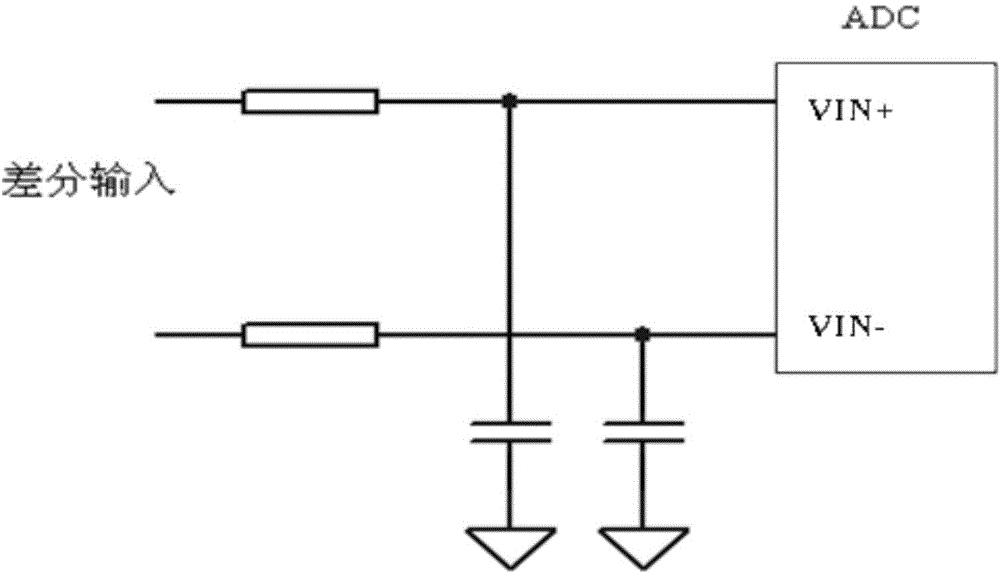

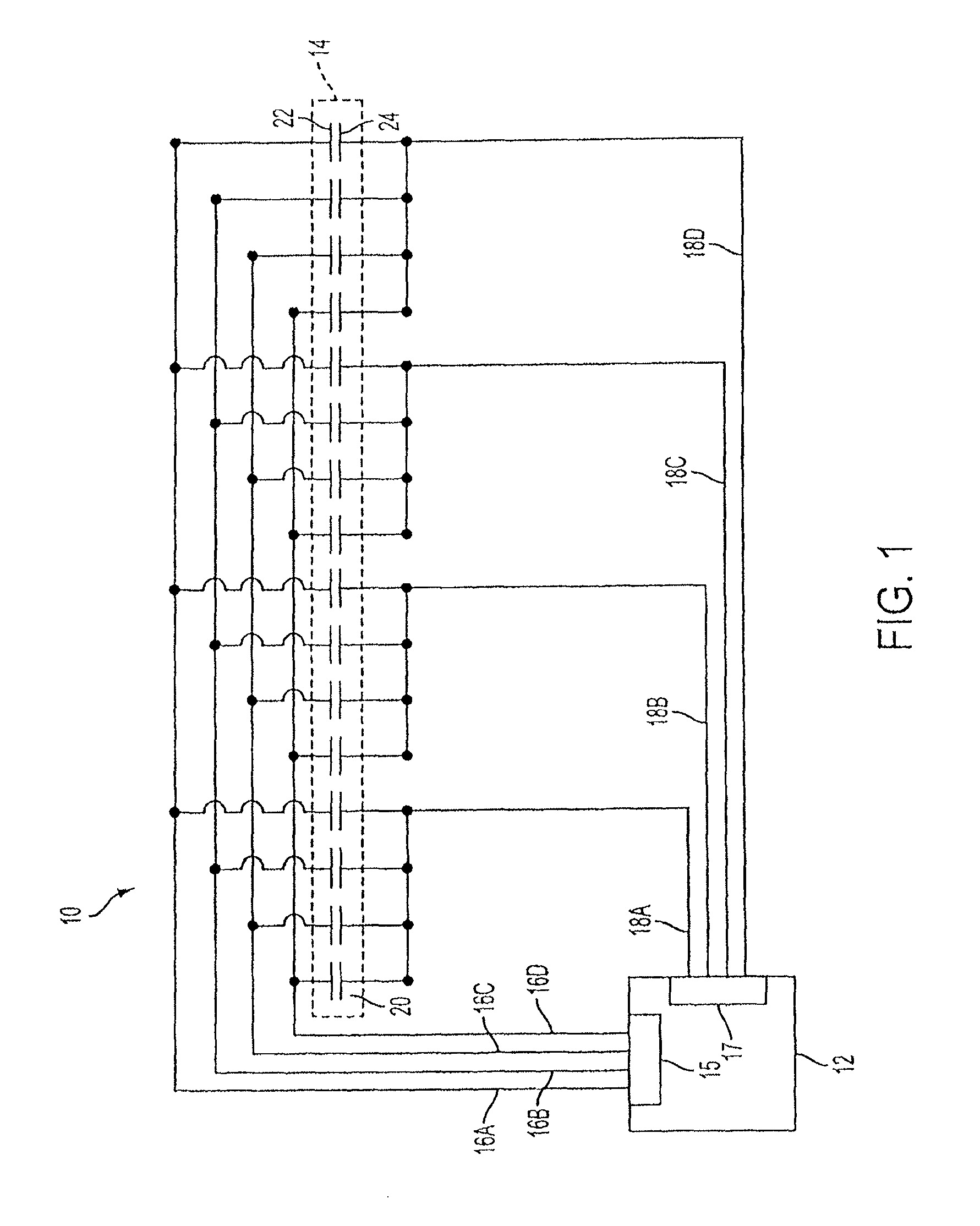

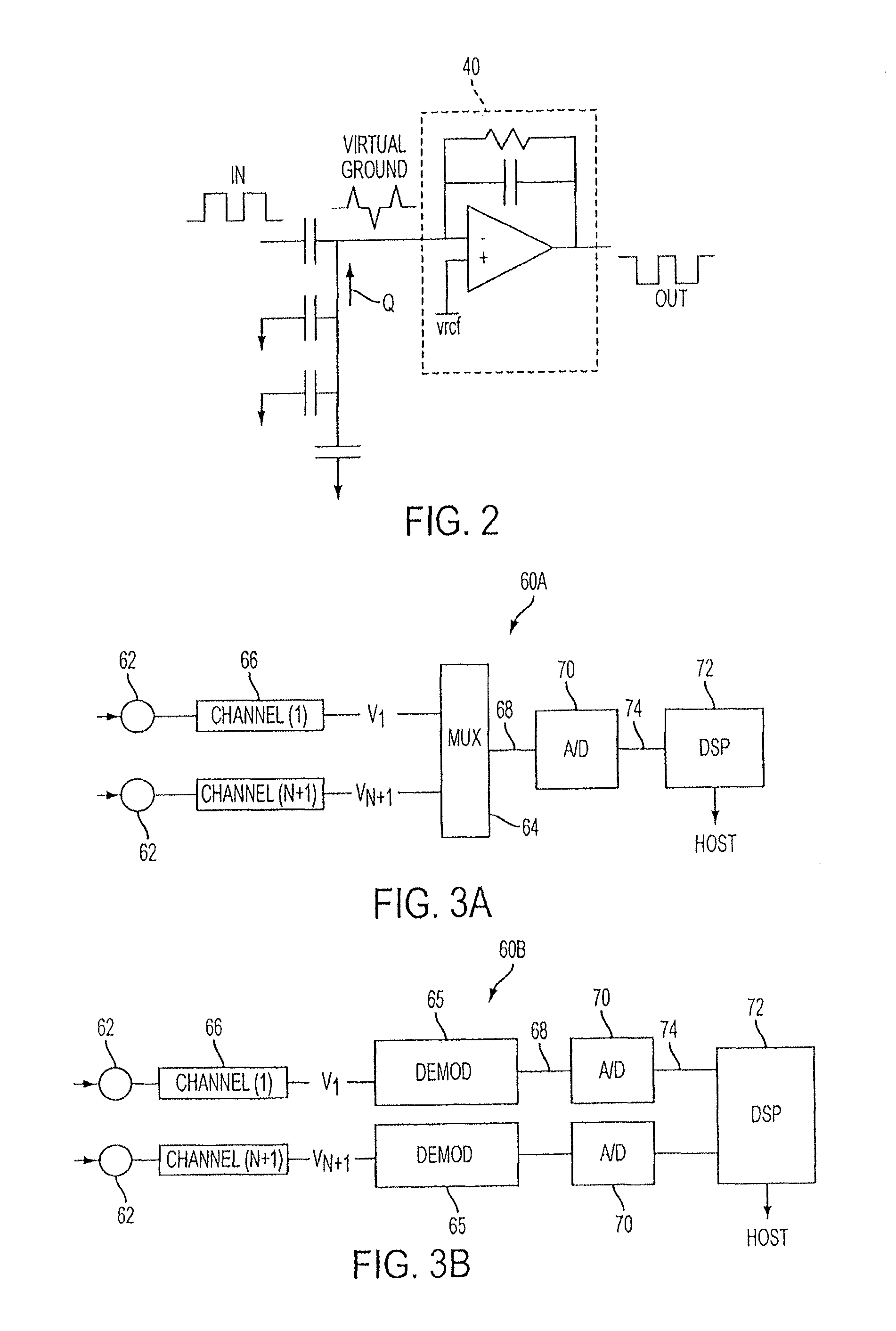

ARM and DSP based multi-circuit power quality online monitoring device

InactiveCN104101806AReduce monitoring device costsSave equipment spaceElectrical testingPower qualityElectric energy

The invention provides an ARM and DSP based multi-circuit power quality online monitoring device. The ARM and DSP based multi-circuit power quality online monitoring device comprises one or more than one measurement module, an ARM module and a power supply module; the measurement module is used for sampling grid signals and performing data computation processing related to the power quality; the ARM module which serves as a control core of the online detection device is connected with the measurement module and used for controlling the data interaction between the measurement module and the ARM module and providing an external communication interface; the power module is used for supplying power for the measurement module and the ARM module; the measurement module comprises three pairs of voltage transformers and current transformers which are used for simultaneously monitoring the three-phase voltage and the three-phase current respectively; output ends of the voltage transformers and the current transformers are connected with an AD (Analog to Digital) conversion module which is connected with a DSP module; the output ends of the voltage transformers are connected with the DSP module through a phase-locked loop; the DSP module is connected with the ARM module. According to the ARM and DSP based multi-circuit power quality online monitoring device, the continuous monitoring and analysis can be performed on a plurality of monitoring points simultaneously and the remote data transmission function is implemented.

Owner:STATE GRID CORP OF CHINA +2

Integrating injection moulding method

InactiveCN102357979ASave equipment spaceImprove processing efficiencyWork in processContinuous production

The invention provides an integrating injection moulding method. Injection moulding equipment for injection moulding of two different raw materials is arranged on a revolving stage of an injection machine; then a first injection moulding is carried out in a first injection mould, namely one injection moulding apparatus is utilized to fill a first raw material into the first injection mould, so as to form a semi-finished product; then rotation of a revolving stage is employed to enable the first injection mould together with the semi-finished product thereon to change position with a second injection mould; then a second injection moulding is carried out that a second injection moulding apparatus is utilized to inject a second raw material into a mould cavity containing the semi-finished product, so as to form a product. Meanwhile, a first injection moulding is carried out in another mould cavity to form a semi-finished product; the finished product is taken out; and the above operations are repeated for continuous production. The method can not only increase product performance and qualified rate but also improve product quality.

Owner:胡海波

Method of using non-volatile memories for on-dimm memory address list storage

ActiveUS20150016192A1Improved performance and lifetimePromote repairRead-only memoriesDigital storageDIMMMemory address

An integrated circuit device. The device includes an address input(s) configured to receive address information from an address stream from an address command bus coupled to a host controller and an address output(s) configured to drive address information, and is coupled to a plurality of memory (DRAM) devices provided on a DIMM. The device has an address match table comprising a non-volatile memory device configured to store at least a revised address corresponding to a spare memory location and a bad address of at least one of the plurality of memory (DRAM) devices. The device has a control module configured to process and determine whether each address matches with a stored address in the address match table to identify the bad address and configured to replace the bad address with the revised address of the spare memory location.

Owner:RAMBUS INC

Offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method

InactiveCN102176107AEliminate exposure washoutOmit retouchingPhotomechanical apparatusPrintingResistUltraviolet

The invention discloses an offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method which comprises the following steps: firstly jetting a water-borne UV photo-sensitive resist on a hydrophilic metal base by using an ink-jet printing device, and forming an oiliness information recording region on the surface of the metal base; and in addition, curing a information recording region on the surface of the metal base by using an ultraviolet lamp, and then printing on the machine. The offset print water-borne UV photo-sensitive resist jetting plate-making method is simple in process, rapid in printing plate drying speed, less in energy consumption, good in printing plate quality, good in printing-resistance rate, and free from environment pollution.

Owner:XIAN UNIV OF TECH

Soil remediation system and method based on combined technology

ActiveCN106890847AFix lack ofWith stirring functionSoil lifting machinesContaminated soil reclamationSoil remediationWater flow

The invention discloses a soil remediation system based on a combined technology. The soil remediation system comprises a soil source conveying unit, a soil source crushing unit, an iron material adsorption unit, a soil source screening unit, a stone conveying unit, a thermal volatilization unit, a chemical cleaning precipitation unit, a dehydration unit, an air drying unit, a faeces conveying unit, a sterilization and deodorization unit, a soil and fertilizer mixing unit and a clean soil source conveying unit. According to the soil remediation system, the combined technology of physical remediation, chemical remediation and fertilizer adding treatment is adopted, and the problems that soil desertification is severe and nutrients are insufficient are further solved under the condition that soil is sufficiently remediated; a cleaning liquid recycling module has a stirring function as well, so that cost is reduced, and equipment space is decreased; disturbance of waterflow in a filter screen zone is guaranteed during the recycling process of the cleaning liquid recycling module, and the problem that a filter screen is liable to block is solved; and disturbance for bottom sediment is effectively inhibited through the cleaning liquid recycling module, and a recycled cleaning liquid does not contain soil impurities.

Owner:SHAOXING ENVIRONREM ENVIRONMENTAL TECH CO LTD

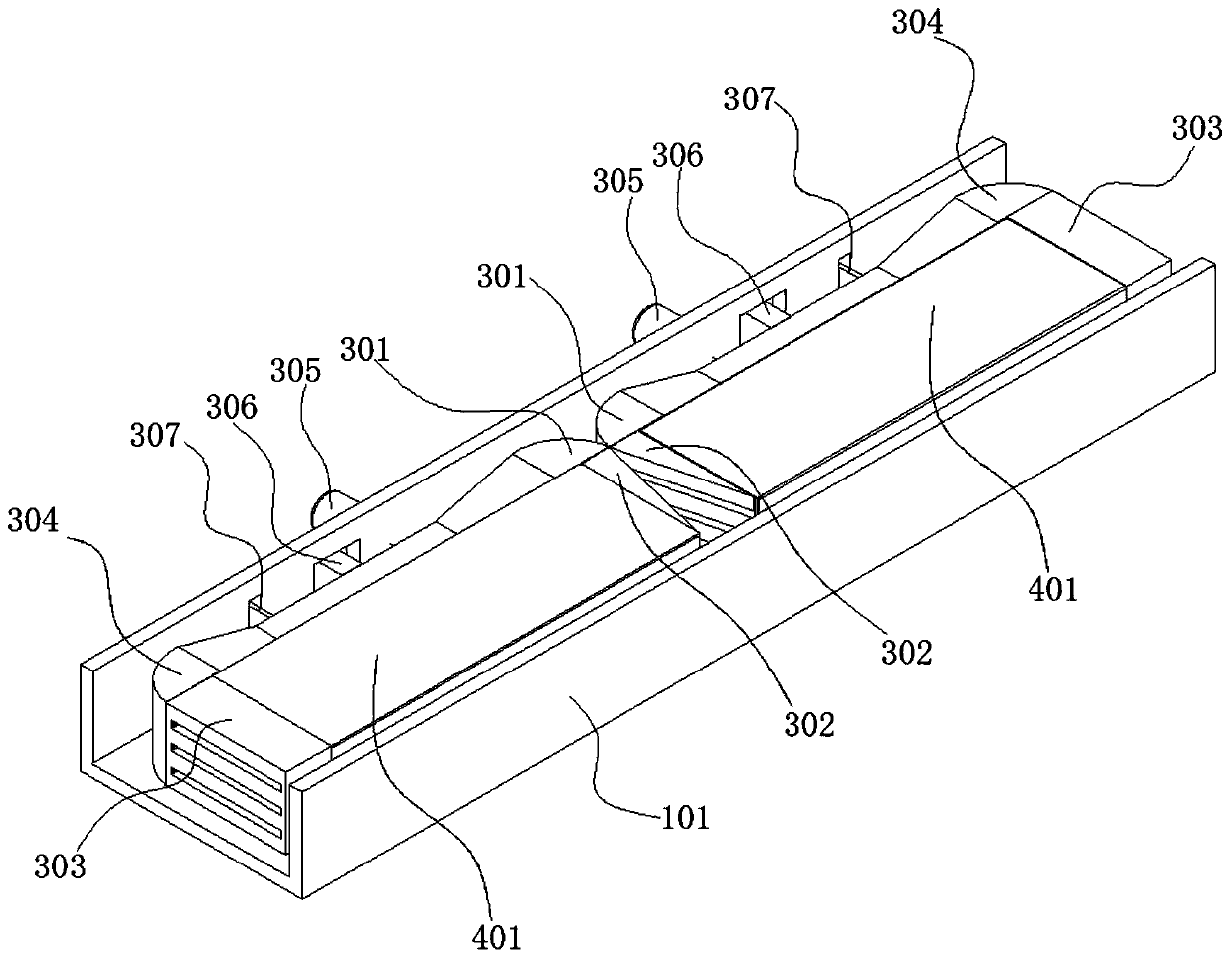

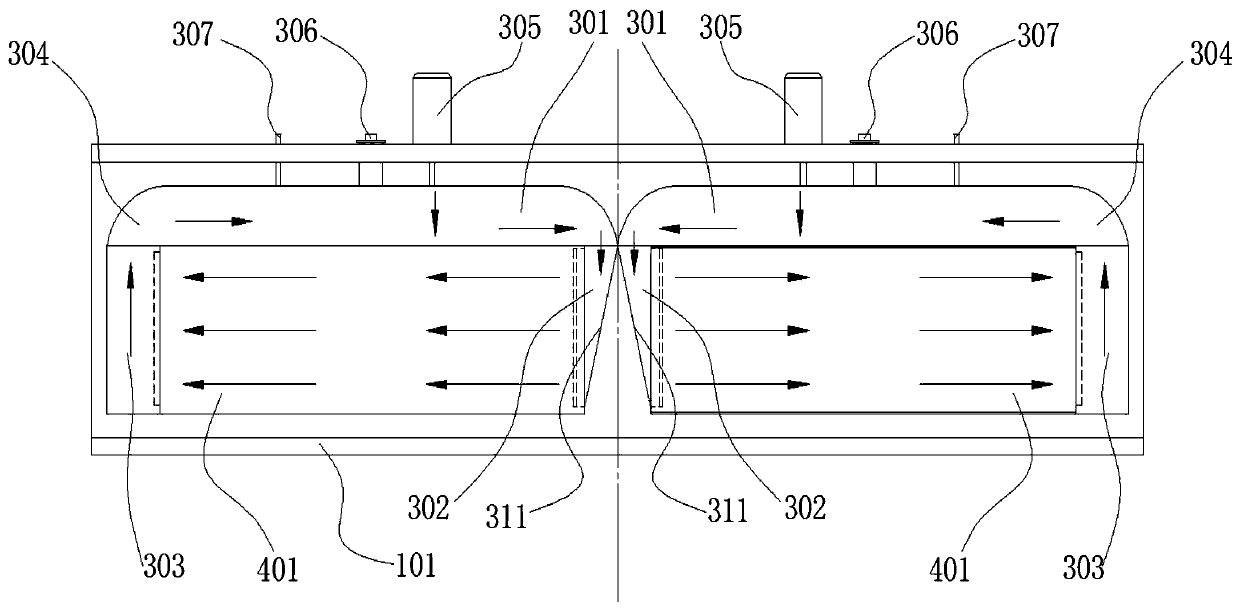

Double-parallel efficient pre-oxidation furnace

The invention relates to a double-parallel efficient pre-oxidation furnace comprising a heat-insulating frame and two sets of hot air circulating equipment symmetrically arranged on the heat-insulating frame; all the hot air circulating systems are sequentially stacked together; each set of hot air circulating system comprises a circulating fan, an air inlet pipeline connected with the output endof the circulating fan, an air blowing mechanism in communication with the outlet of the air inlet pipeline, a pre-oxidation cavity, a return air mechanism and a return air pipeline; a plurality of the air blowing mechanisms are provided, and each air blowing mechanism comprises an air inlet cavity, an air blowing nozzle and an air guide inclined plate, the air blowing nozzle is positioned in theair inlet cavity, and the air guide inclined plate is positioned in the air inlet cavity; all the air blowing mechanisms are arranged in sequence, a first tow channel is formed between every two adjacent air inlet cavities, each air blowing nozzle comprises a pore plate and a honeycomb plate, and wind sequentially passes through the air guide inclined plates, the pore plates and the honeycomb plates along a wind circulation path. The pre-oxidation furnace can meet the requirements, such as high load, high efficiency, high safety and low cost, of industrial circles on pre-oxidation equipment and pre-oxidation processes and belongs to the technical field of pre-oxidation furnaces.

Owner:ATA CARBON FIBER TECH GUANGZHOU

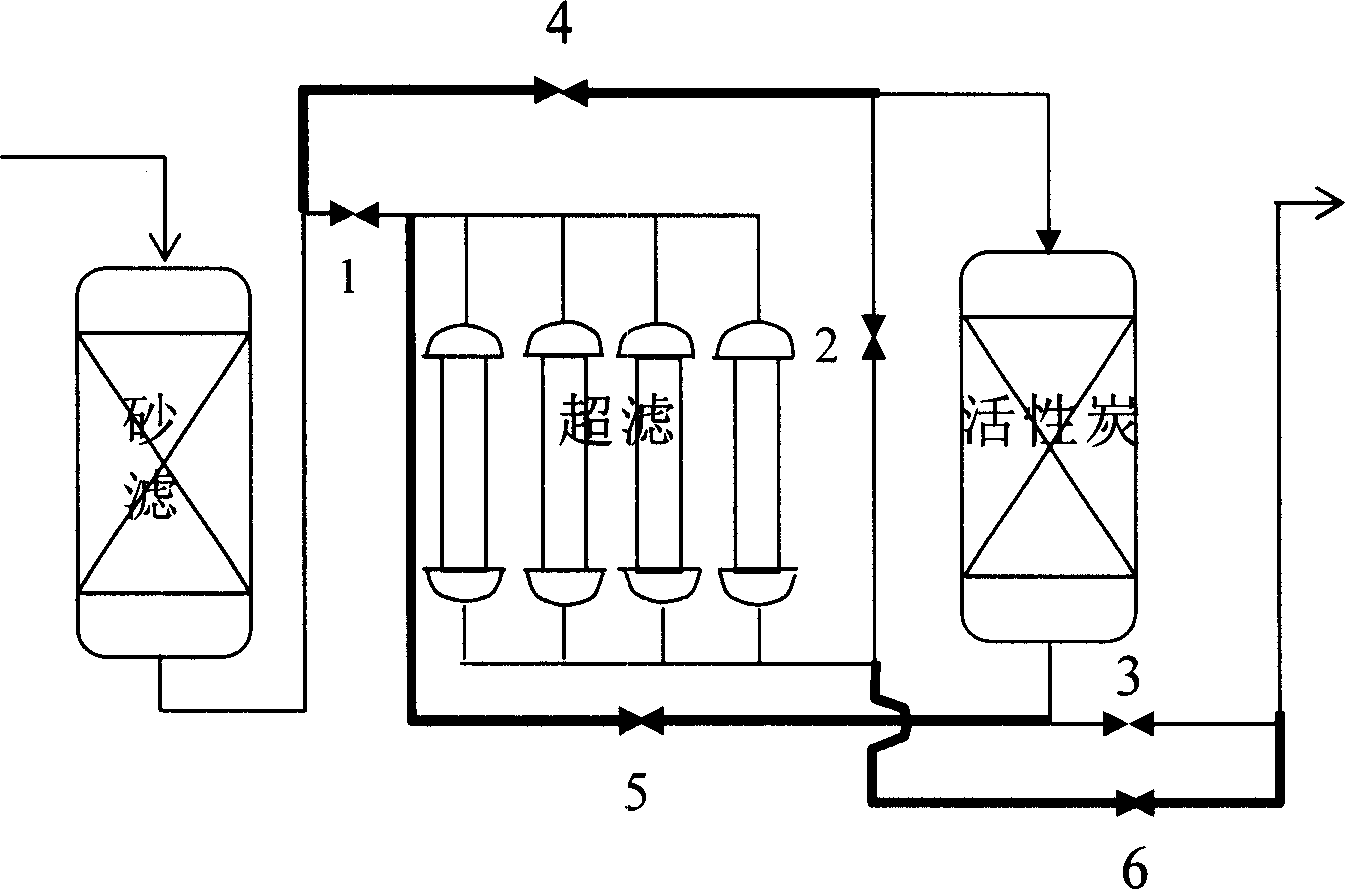

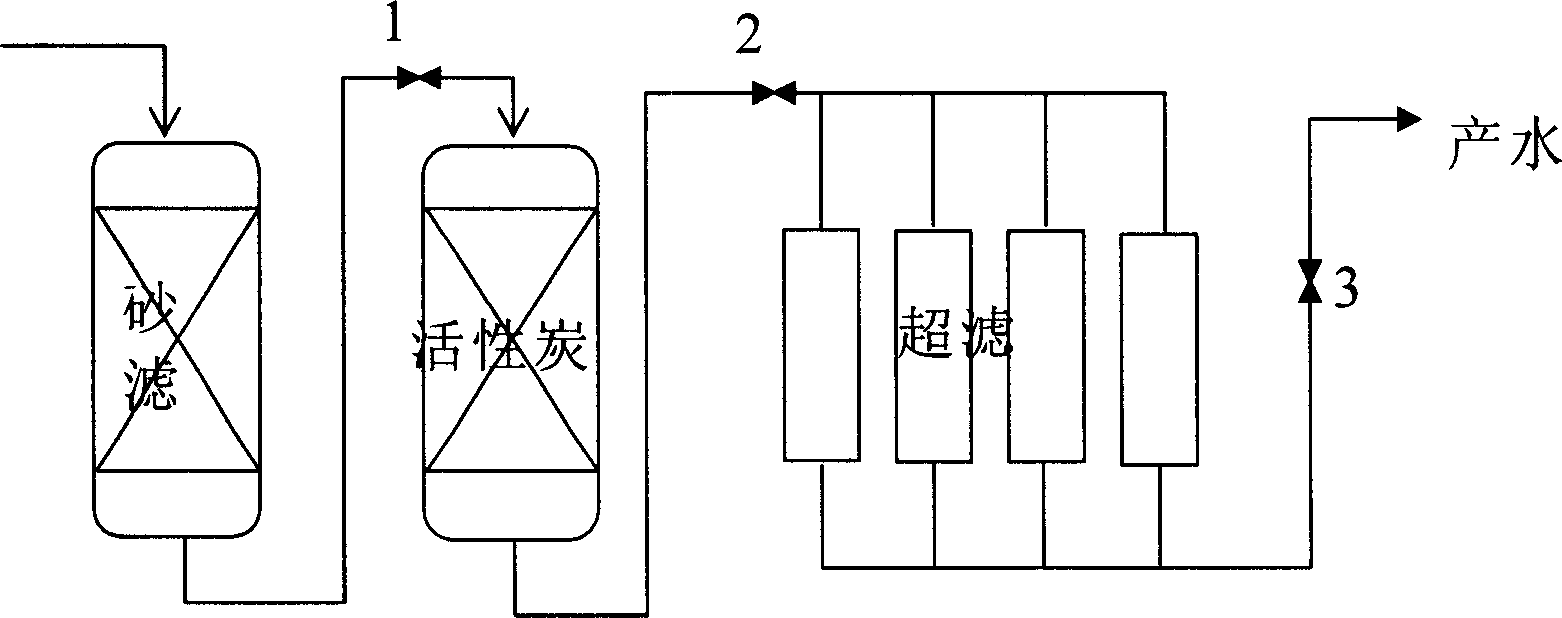

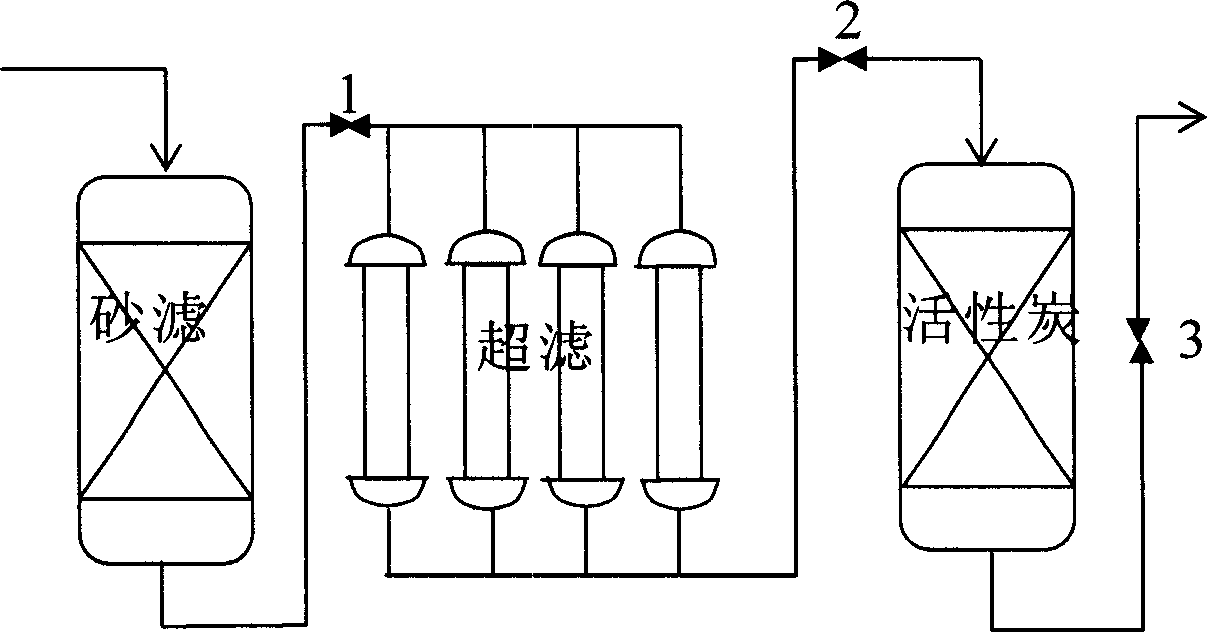

Sewage treating system with changeable water treating process

InactiveCN1810659AImprove water qualitySave equipment spaceWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment bu osmosis/dialysisActivated carbon filtrationUltrafiltration

The sewage treating system with changeable water treating process includes a sand filter apparatus, an ultrafiltering apparatus connected via the first valve to the water outlet of the sand filter apparatus, an active carbon filtering apparatus connected via the second valve to the water outlet of the ultrafiltering apparatus and connected via the third valve to the next treating unit, a first pipe part including the fourth valve connected between the water inlet of the ultrafiltering apparatus and the water inlet of the active carbon filtering apparatus, a second pipe part including the fifth valve connected between the water inlet of the ultrafiltering apparatus and the water outlet of the active carbon filtering apparatus, and a third pipe part including the sixth valve between the water outlet of the ultrafiltering apparatus and the water outlet of the active carbon filtering apparatus. The present invention has flexibly selected technological process to ensure water product quality in low cost and small apparatus space.

Owner:BEIJING MATSUSHITA COLOR CRT CO LTD

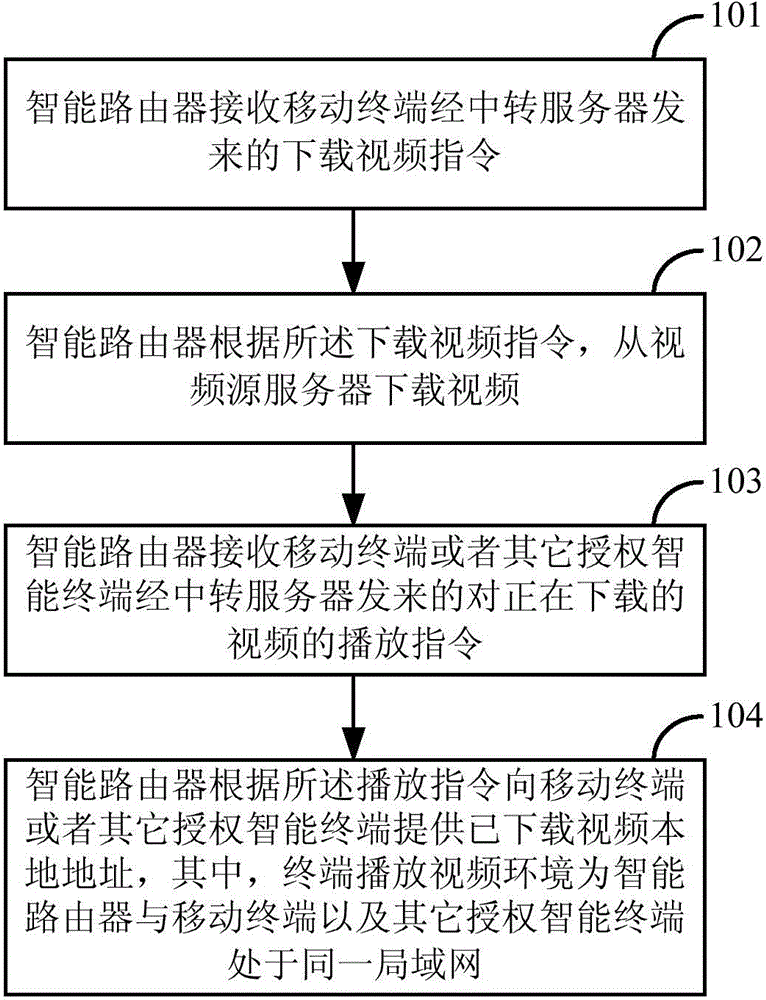

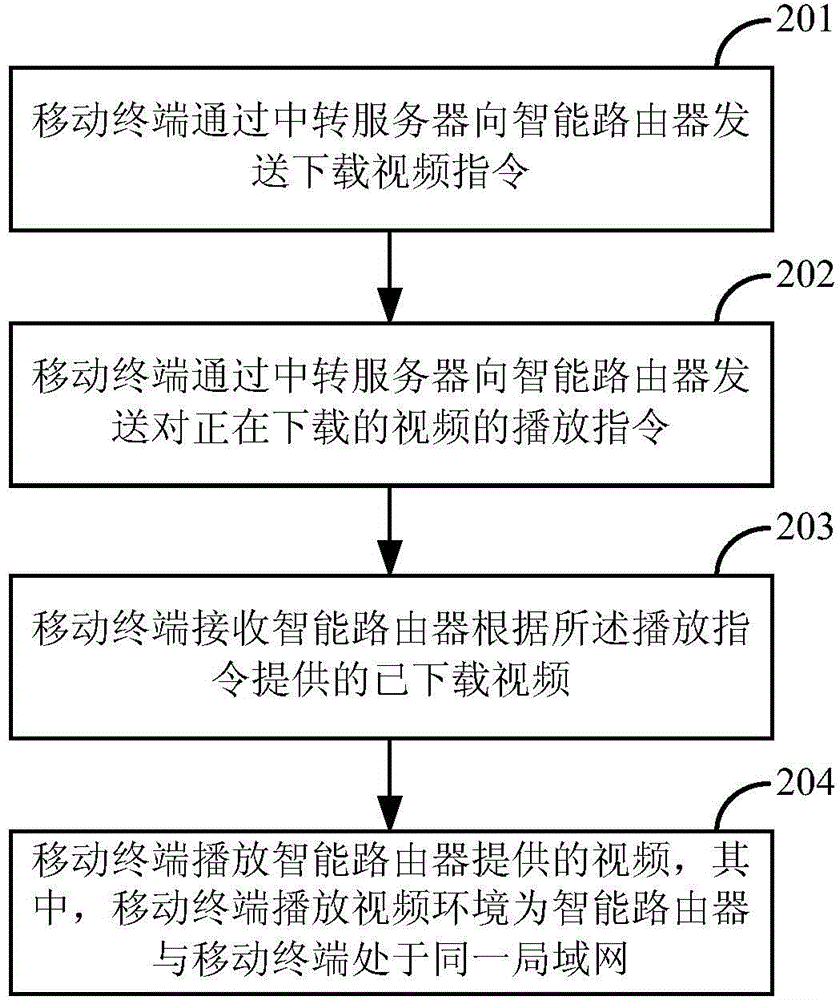

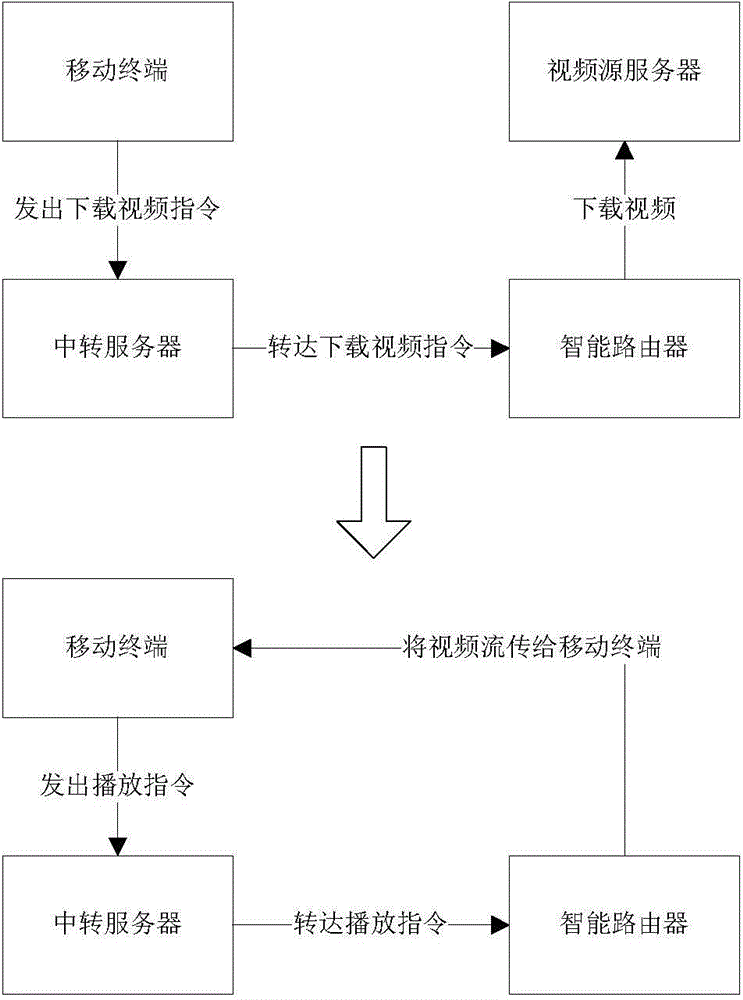

Method for downloading video while playing, intelligent router and mobile terminal

InactiveCN106162371ASave equipment spaceThe device has less computing resourcesSelective content distributionLocal area network

The invention discloses a method for playing video while downloading, an intelligent router and a mobile terminal, wherein the method includes: the intelligent router receives a download video instruction sent by the mobile terminal via a transfer server; The source server downloads the video; the intelligent router receives the playback instruction of the video being downloaded from the mobile terminal or other authorized intelligent terminal via the transfer server; the intelligent router provides the mobile terminal or other authorized intelligent terminal with the downloaded video local Address, wherein, the video playing environment of the terminal is that the intelligent router, the mobile terminal and other authorized intelligent terminals are in the same local area network. The present invention can improve the fluency of video playing, is more convenient for users to share, and is more flexible in application.

Owner:中科云网科技集团股份有限公司

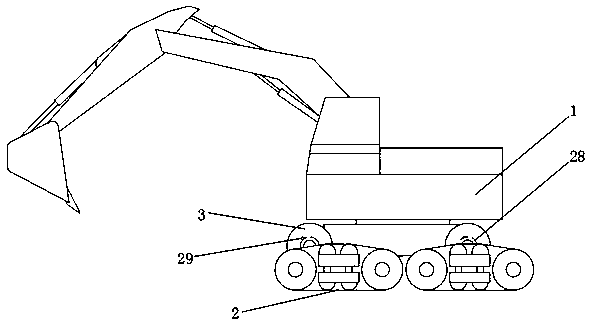

Automatic inflating wheel changing excavator and wheel changing method thereof

InactiveCN108951733ASolve problems that hurt paved surfacesSave manufacturing costMechanical machines/dredgersHydraulic cylinderControl system

The invention provides an automatic inflating wheel changing excavator and a wheel changing method thereof. The automatic inflating wheel changing excavator comprises an excavator body, four caterpillar band moving mechanisms, a wheel type moving mechanism, a power connecting mechanism, an auxiliary supporting device and a control system. The caterpillar band moving mechanisms are arranged at thebottom of the excavator body and are connected to a hydraulic cylinder I; a walking wheel, a bending track, a bevel gear I and an automatic detecting and air supplementing device are arranged on the wheel type moving mechanism; the bending track is fixed below the excavator body; the walking wheel is movably connected to the bending track in a sleeving mode and is connected to a hydraulic cylinderII; the power connecting mechanism is connected to an engine of the excavator and is provided with a rhombic bidirectional bevel gear; the rhombic bidirectional bevel gear is connected to the caterpillar band moving mechanisms and corresponds to the bevel gear I; and the auxiliary supporting device is arranged at the bottom of the excavator body. The automatic inflating wheel changing excavator is skillful in design and unique and practical in wheel changing form. The tire pressure is kept normal, and the automatic inflating wheel changing excavator can be flexibly applied to excavator equipment.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

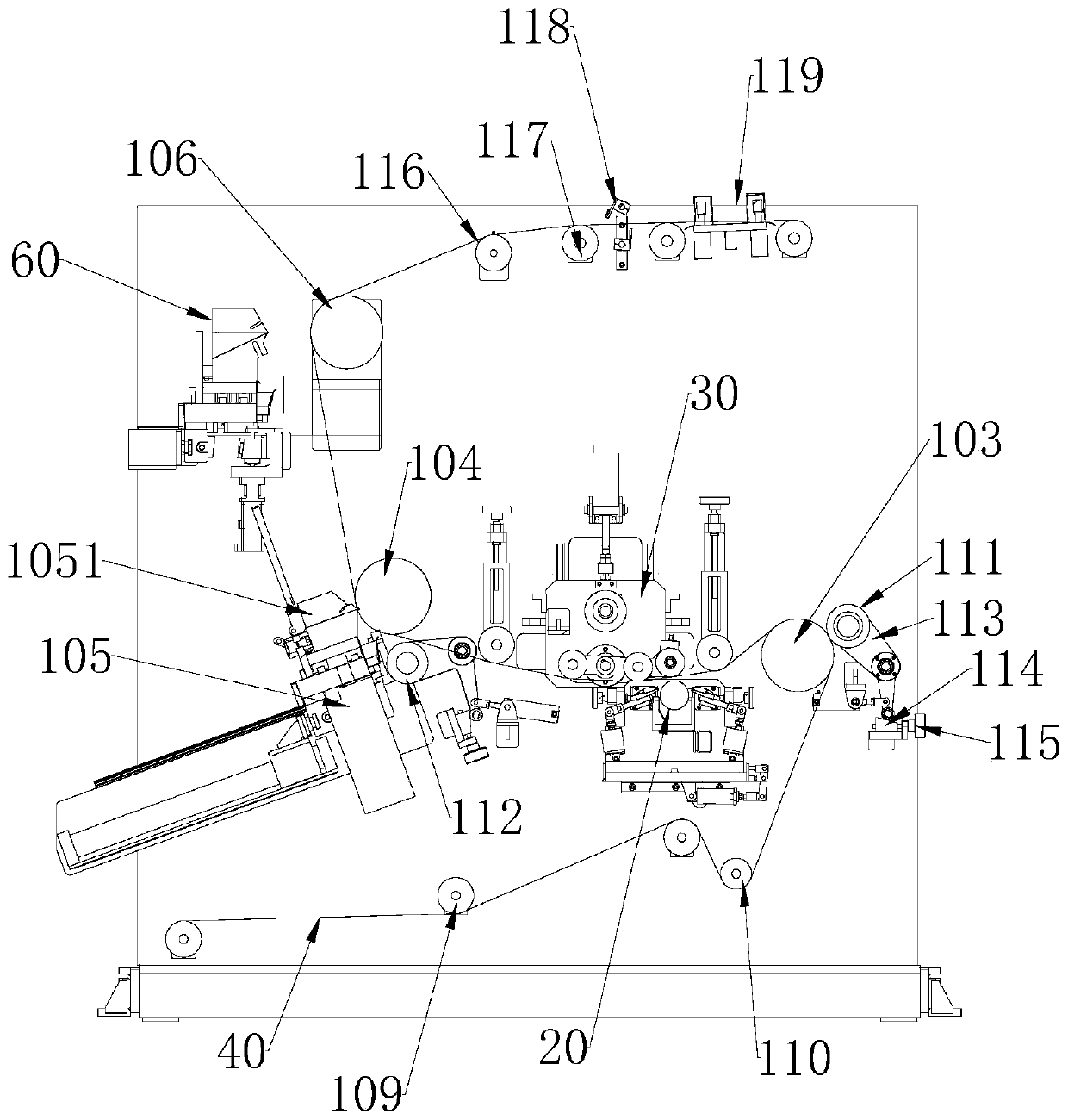

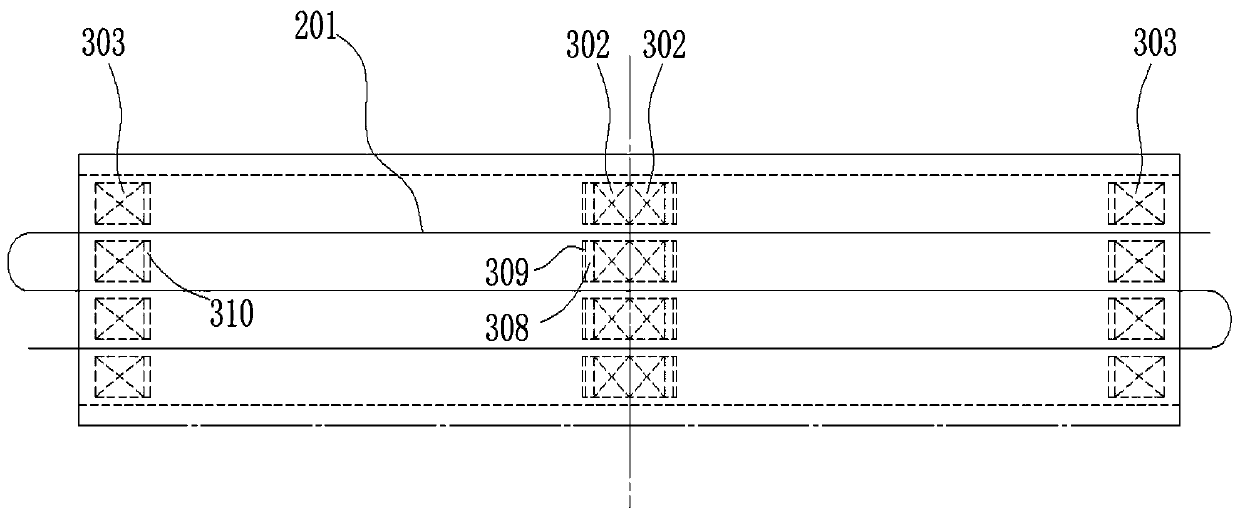

Unidirectional reinforcement material laminating system and method

ActiveCN102333416AReduce volumeSave equipment spacePrinted circuit manufactureEngineeringMechanical engineering

The invention provides a unidirectional reinforcement material laminating system and method. The unidirectional reinforcement material laminating system comprises a base device, a laminating device, a pressing device, a heating device and a control device, wherein the base device is arranged at the bottom of the system; the laminating system comprises a guide rail, a laminating baseplate and a positioning jig unit, wherein one end of the guide rail is used as a pushing station, the other end of the guide rail is used as a material releasing and extracting station, the laminating baseplate is movably connected with the guide rail, and the positioning jig unit is arranged on the laminating baseplate and matched with a workpiece to be laminated in shape; the pressing device comprises a pressing jig plate and an air cylinder unit, wherein the pressing jig plate is arranged over against the pushing station, and the air cylinder unit is used for driving the pressing jig plate to press down;the heating device comprises a lower heating module for heating the laminating baseplate and an upper heating module for heating the pressing jig plate; and the control device is used for cooperativeoperation of all the devices. The unidirectional reinforcement material laminating system and method provided by the invention has the beneficial effects that: the reinforcement material lamination function can be semi-automatically or automatically finished in a smaller space, the production process is simplified, and the product quality is improved.

Owner:ZHUHAI ZIXIANG ELECTRONICS TECH

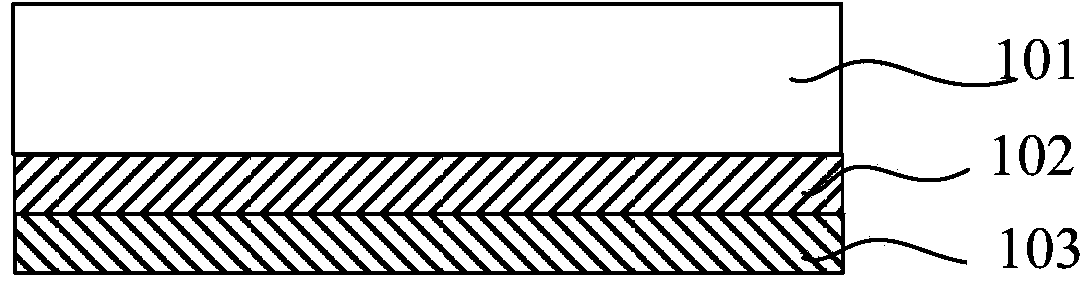

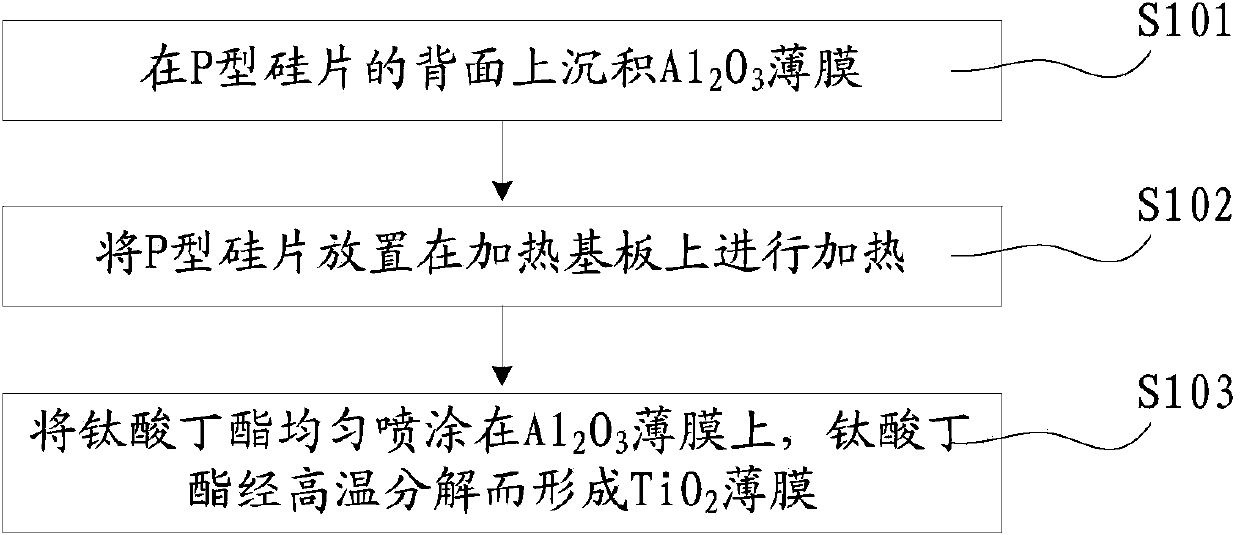

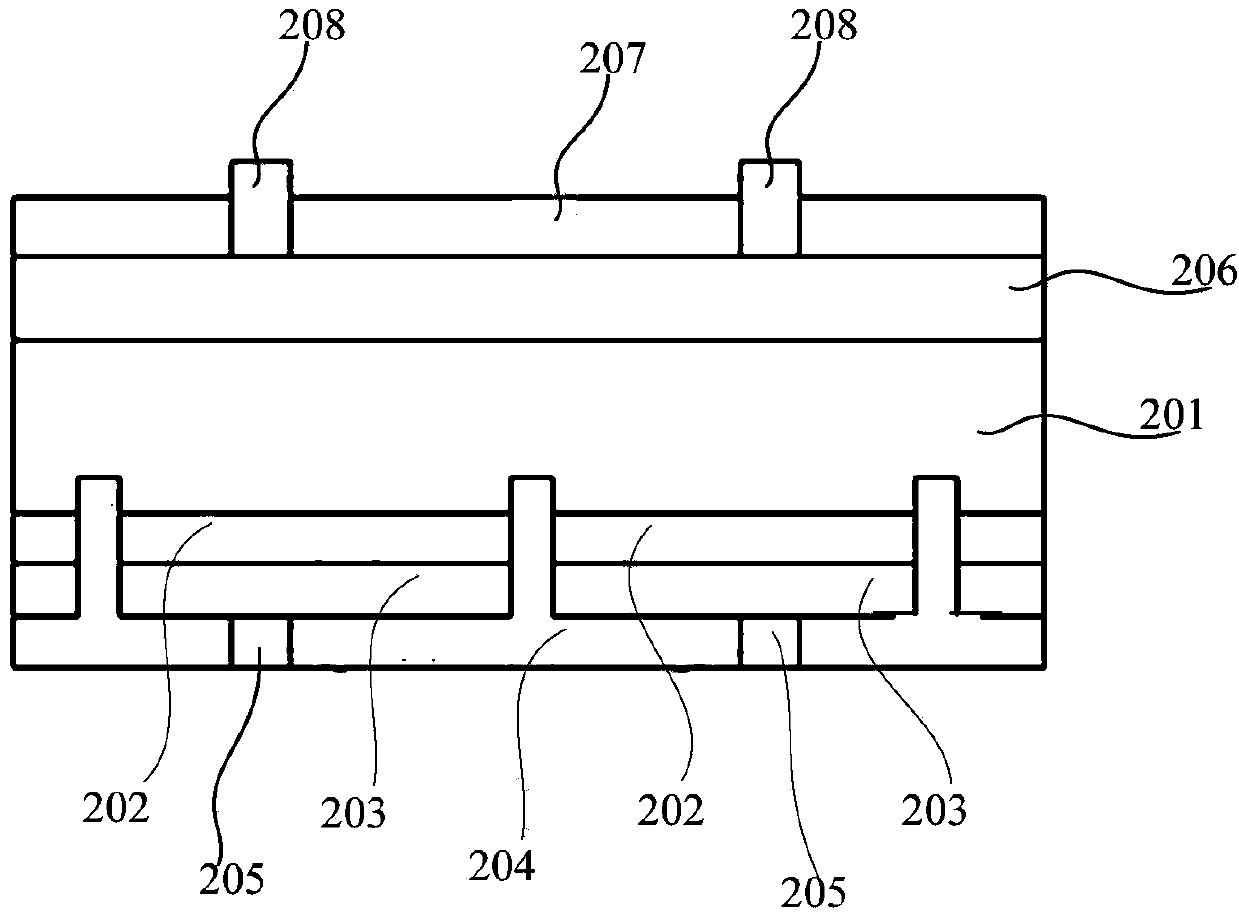

Back passivation layer structure, back passivation P type solar cell, preparation method of back passivation layer structure and preparation method of back passivation P type solar cell

InactiveCN104009102AEasy to prepareSave equipment spaceFinal product manufacturePhotovoltaic energy generationFilm structurePyrolysis

The invention discloses a back passivation layer structure and a preparation method of the back passivation layer structure. A laminated film structure of an Al2O3 thin film and a TiO2 thin film serves as the back passivation layer structure. The TiO2 thin film can be manufactured by conducting pyrolysis on butyl titanate according to a spray method, wherein specifically, a silicon wafer is placed on a heating substrate, the butyl titanate is evenly sprayed on the upper face of the silicon wafer, and the butyl titanate forms the TiO2 thin film through butyl titanate; thus, the back passivation layer structure is quite easy to prepare, and no complex preparation devices are needed. Compared with a PECVD vacuum coating device for preparing a SiN thin film, the space occupied by the device is small, and the device is simple in structure and low in price; thus, possibility is provided for refitting a back passivation cell through a normal production line. Meanwhile, the invention further discloses a back passivation P type solar cell and a preparation method of the back passivation P type solar cell. According to the cell, the laminated film structure of the Al2O3 thin film and the TiO2 thin film serves as the back passivation layer structure.

Owner:SPIC XIAN SOLAR POWER CO LTD

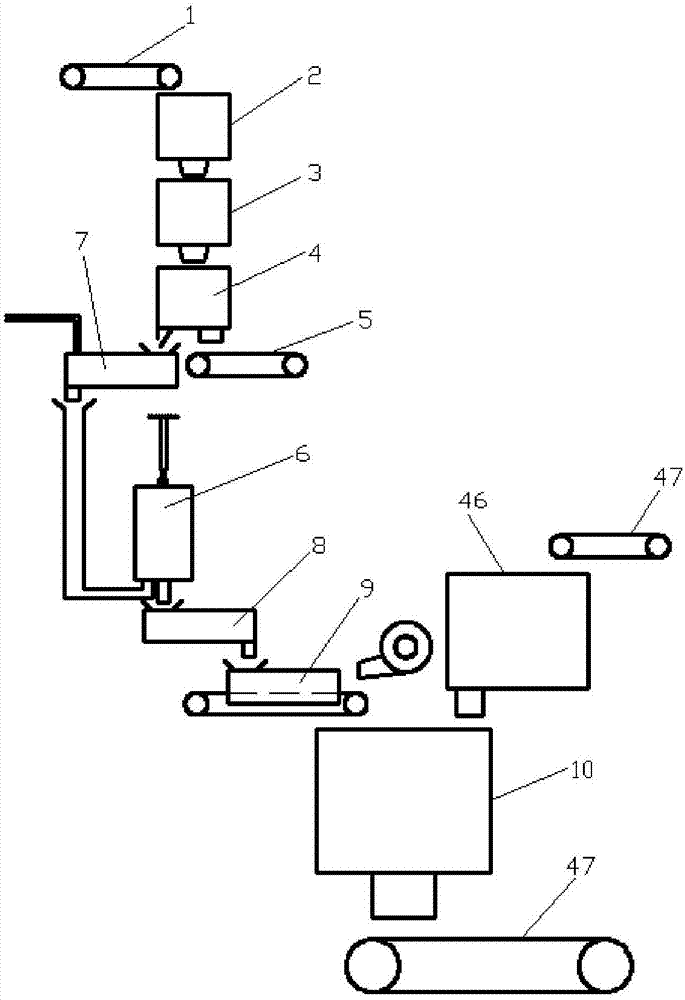

Continuous production method and equipment for built-in condenser forming and attaching

ActiveCN111958197AImprove efficiencyReduce manufacturing costEvaporators/condensersPositioning apparatusProcess engineeringContinuous production

The invention provides a continuous production method and equipment for built-in condenser forming and attaching, and relates to the technical field of the built-in condenser forming and attaching. The continuous production method comprises the following steps of: carrying out condenser pipe raw material blanking; carrying out condenser forming, and carrying out end part processing, bending forming and cutoff processing on condenser pipe raw materials to obtain a condenser; on a shell line, conveying a shell plate to an attaching area to stop, tightly attracting the shell plate by an electrified magnet, and directly moving the condenser to the shell plate in the attaching area; and starting a rubberizing device to carry out rubberizing, finishing attaching, cutting off the electrified magnet, and conveying the shell plate which finishes being attached through the shell line. The continuous production equipment comprises a forming part, an attaching part, a transferring tool for hoisting the condenser, and a controller, wherein the forming part carries out the end part processing and the bending forming on the condenser pipe raw materials, and the attaching part attaches the condenser to the shell plate. By use of the continuous production method and equipment, built-in condenser forming and attaching equipment can be subjected to integrated design, continuous forming and attaching production can be carried out, efficiency is effectively improved, cost is lowered, and product quality is stable.

Owner:青岛恒恩智能装备有限公司

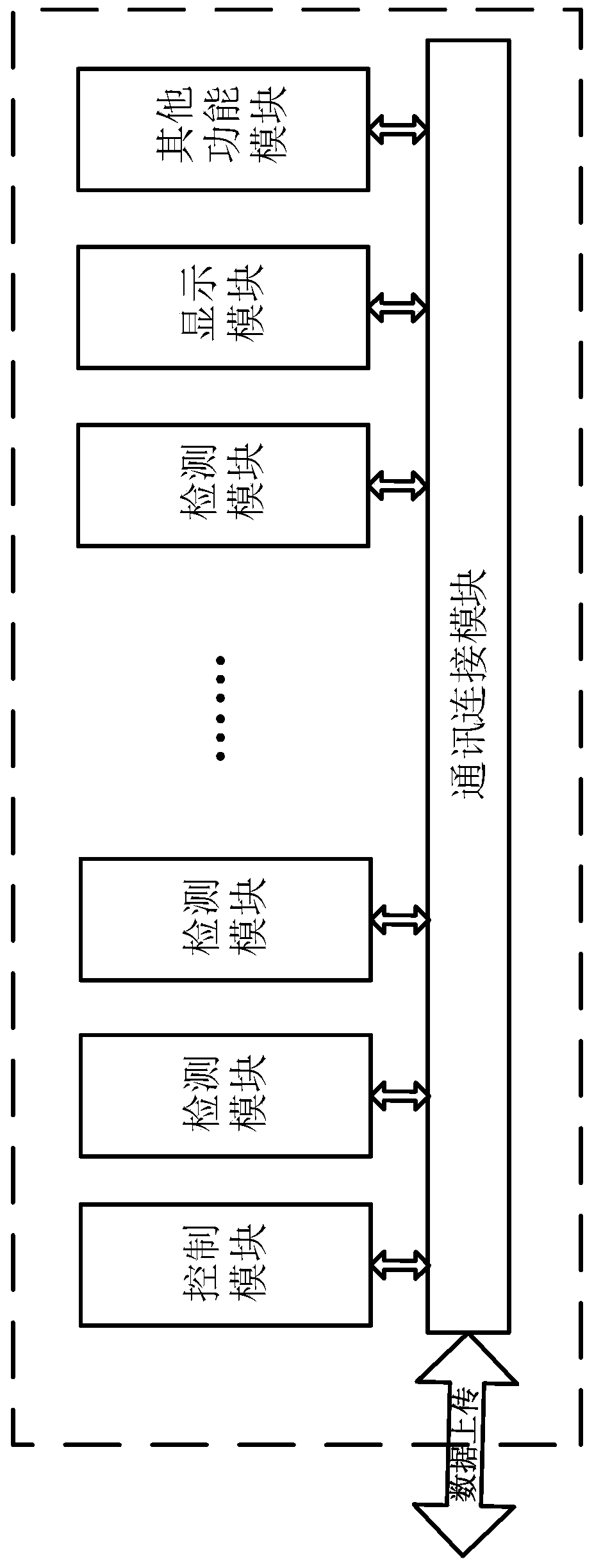

Modular combined power detection device

InactiveCN110632426AHighly integratedSave equipment spaceElectrical testingModular compositionTransmission function

The invention discloses a modular combined power detection device, which comprises a communication connection module provided with a connector. Besides, the modular combined power detection device also includes a control module and a plurality of detection modules; and all detection modules are used for simultaneously collecting electrical parameters and environmental parameters of the power system. According to the modular combined power detection device disclosed by the invention, the functions of control, detection, communication, display and the like are designed in a modular mode and themodules are combined by the connector in a plugging in manner, thereby realizing high integration, saving a large amount of equipment space, and simplifying the mounting steps substantially. Meanwhile, more abundant transmission functions are provided; and the limitation that the existing monitoring products on the market can only be detected and judged independently is eliminated; and after datacollection and transmission, systematic monitoring and statistical analysis can be carried out on the electric information of various application occasions at the cloud server.

Owner:ZHEJIANG JUZI INTELLIGENT TECH

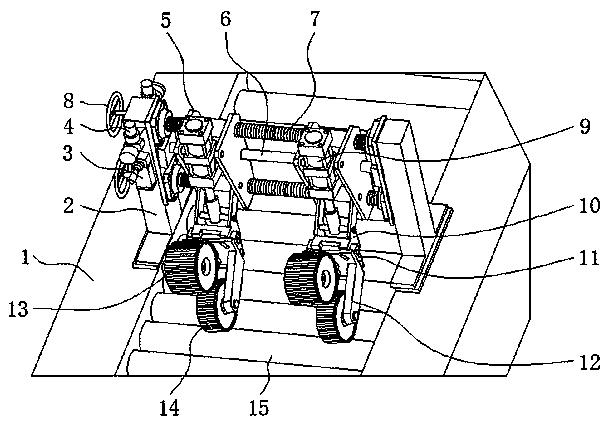

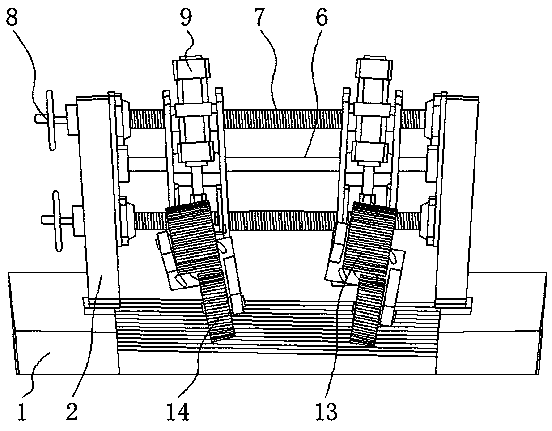

Electricity transmission cable bending equipment with watering device and bending method thereof

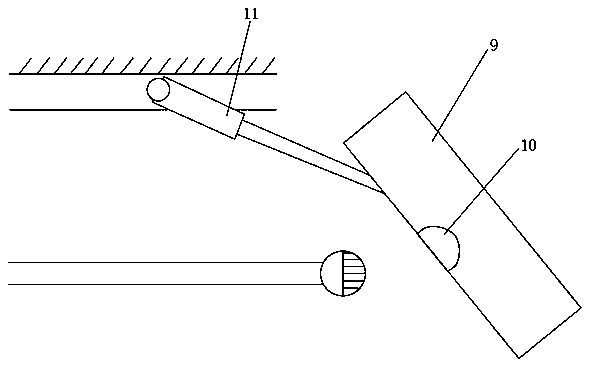

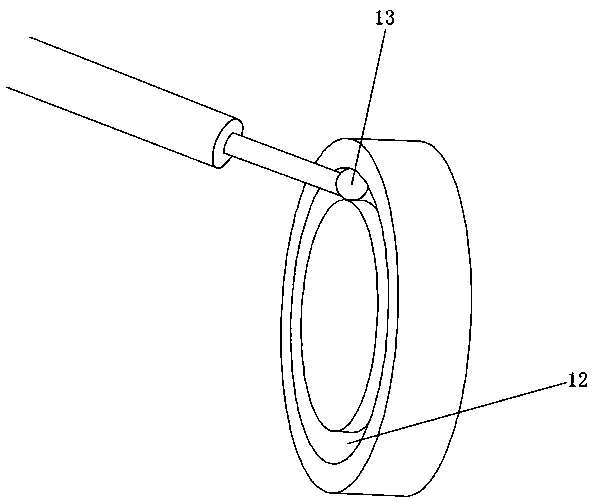

ActiveCN104779561ASave equipment spaceLow costApparatus for joining/termination cablesElectricityPower equipment

The invention discloses electricity transmission cable bending equipment and a bending method thereof. The bending equipment is used for bending the head of a cable (1) to be in fastened connection with electric equipment in a shape fit mode. The bending equipment comprises a machine frame (9) and a left sliding forming die and a right sliding forming die which are arranged left and right. An upper guide roller pair (8) and a lower guide roller pair (7) are arranged in the middles of the upper edge and the lower edge of the machine frame (9) respectively. The space between two rollers of the upper guide roller pair (8) and the space between two rollers in the lower guide roller pair (7) are aligned to each other to allow the cable (1) to penetrate therein.

Owner:泰州敬道电力工程有限公司

Mutual capacitance touch sensing device

ActiveUS9405421B2Reduce in quantitySave equipment spaceInput/output processes for data processingTouch SensesEngineering

Owner:APPLE INC

Triangle rubber strip double-acting pressure exhausting line device for all-steel truck radical tire

The invention discloses a triangle rubber strip double-acting pressure exhausting line device for an all-steel truck radical tire and relates to the technical field of tire manufacturing. The device comprises a base, an upper embossing gear and a lower embossing gear. Supporting frames are assembled on the two sides of the upper surface of the base correspondingly. A pneumatic pressure reducing valve is arranged above a pneumatic hand-operated reversing valve. An installing frame is arranged above the base in a suspending manner. A polishing shaft transversely penetrates through the middle ofthe installing frame. Screw rods are arranged on the upper side and the lower side of the polishing shaft correspondingly in parallel. A hand wheel is arranged on one end of each screw rod. An air cylinder is fixed to the inner side of the installing frame. A first air cylinder swing base is connected to the moving end of the bottom of the air cylinder. The upper embossing gear and the lower embossing gear are installed on a third air cylinder swing base in a sleeving manner. According to the triangle rubber strip double-acting pressure exhausting line device for the all-steel truck radical tire, a set of triangle rubber strip pressure exhausting line device replaces two sets of triangle rubber strip pressure exhausting line device, and therefore the purposes of saving equipment space andreducing the equipment cost are achieved.

Owner:CHAOYANG LONG MARCH TIRE

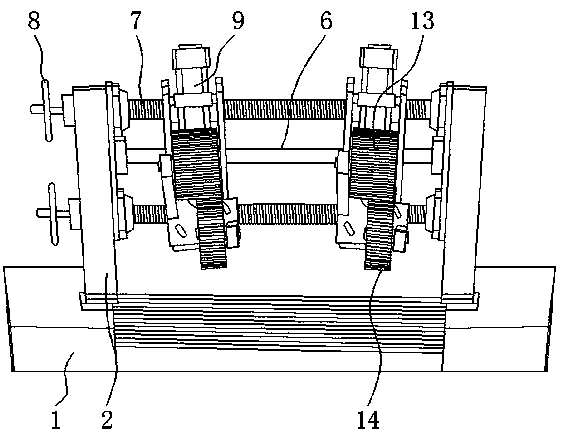

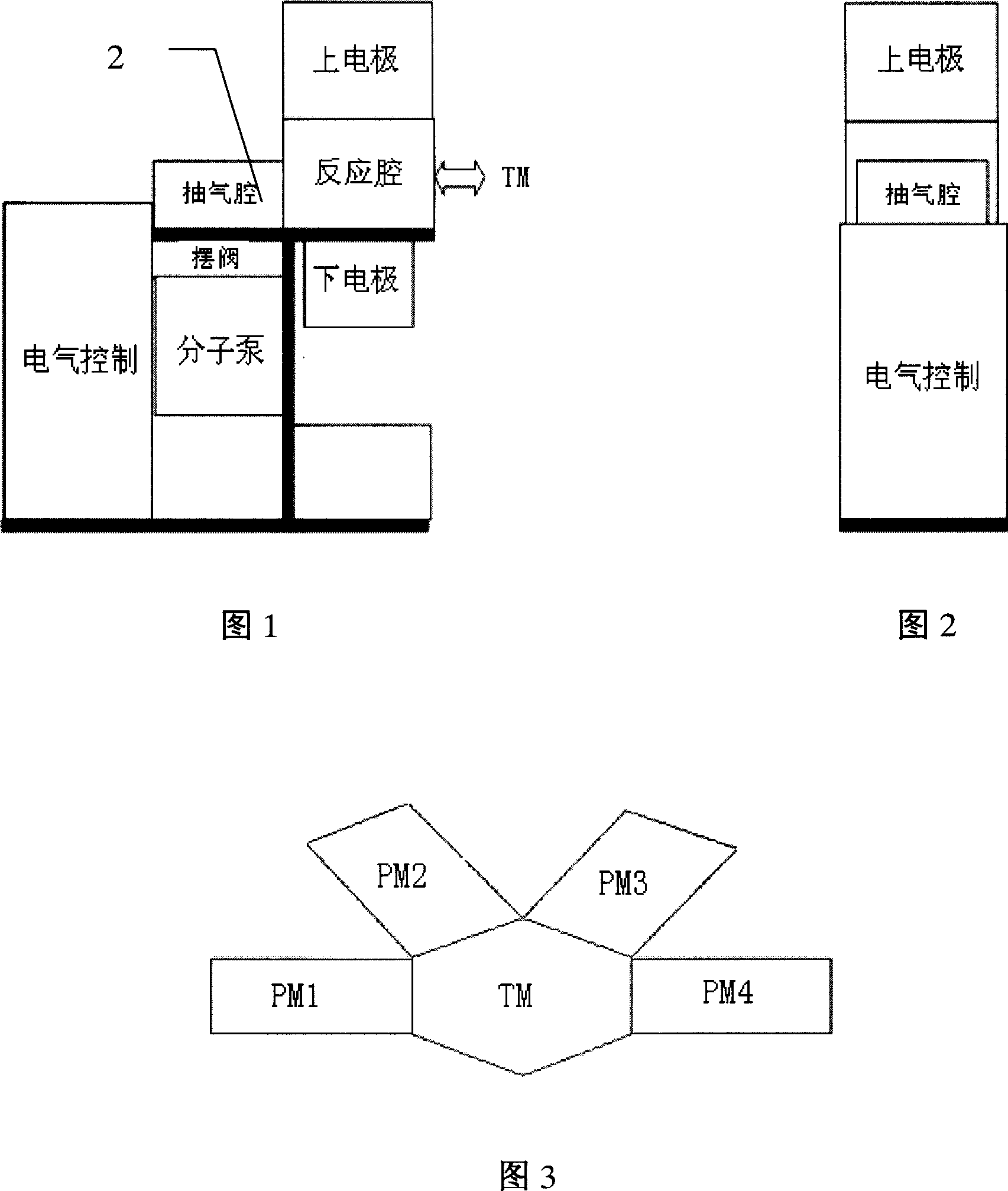

Method for dismounting-mounting semiconductor vacuum-pumping equipment

InactiveCN1935467ASimple structureSave equipment spaceMetal-working hand toolsVacuum pumpingSemiconductor

The present invention relates to an evacuation equipment for disassembling and assembling semiconductor. Said evacuation equipment includes the following several portions: supporting frame, upper beam, slide supporting component, evacuation cavity, swinging valve, reaction cavity, molecular pump and assembling and disassembling carriage. Besides, said invention also provides its concrete operation method for disassembling and assembling semiconductor.

Owner:四川中安恒科技有限公司

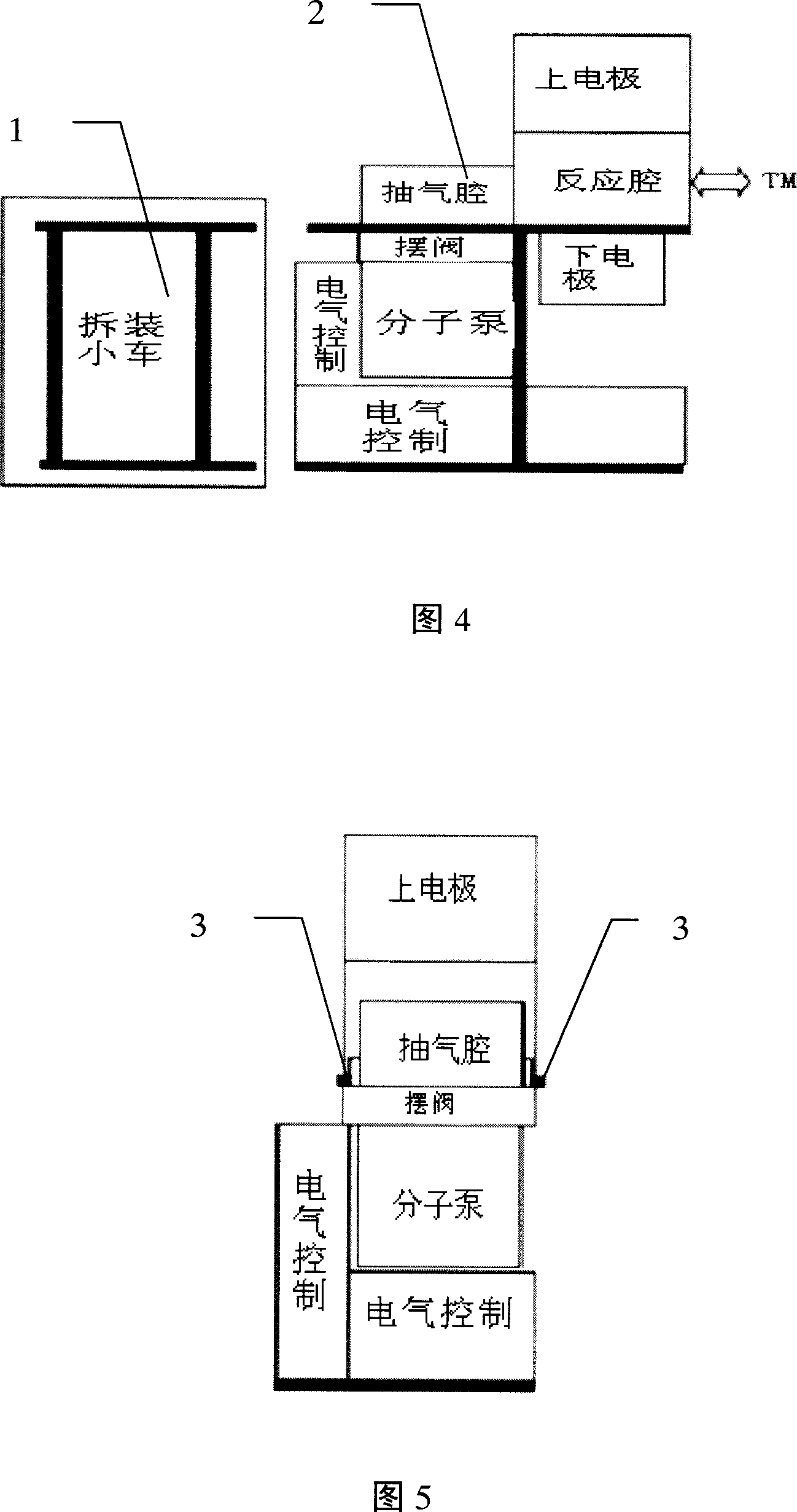

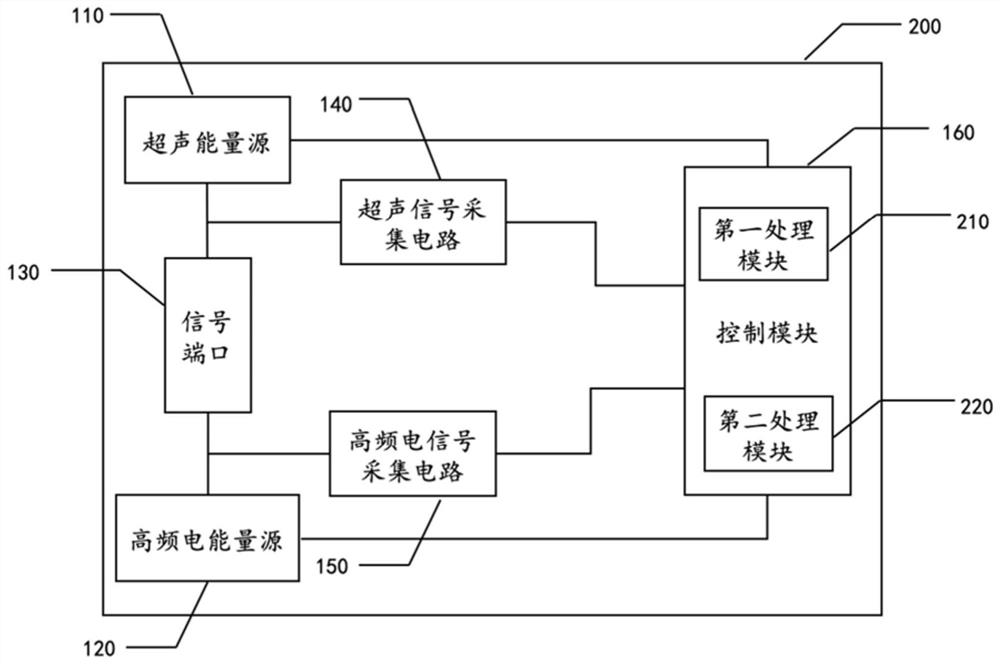

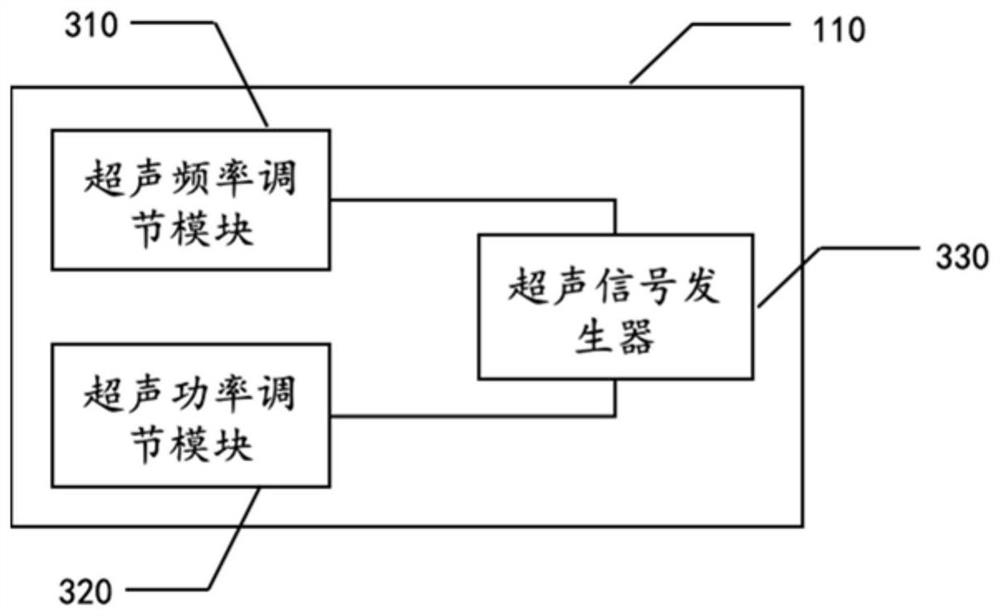

Equipment for outputting driving signal to surgical instrument and surgical operation system

PendingCN114209395ASave equipment spaceIncrease costSurgical instruments for heatingSurgical forcepsSurgical instrumentEnergy source

The embodiment of the invention provides output equipment for outputting a driving signal to a surgical instrument and a surgical operation system. The equipment comprises an ultrasonic energy source, a high-frequency electric energy source, a signal port, an ultrasonic signal acquisition circuit, a high-frequency electric signal acquisition circuit and a control module, wherein the ultrasonic energy source and the high-frequency electric energy source are positioned in the same shell. The control module is used for obtaining adjustment parameters based on the feedback signals and controlling the ultrasonic energy source and the high-frequency electric energy source to output driving signals based on the adjustment parameters. The surgical instrument comprises one or more of an ultrasonic electrotome, an ultrasonic knife, a unipolar electrotome and a bipolar electrotome. According to the technical scheme, the ultrasonic energy source and the high-frequency electric energy source are packaged in the same shell of the output equipment, the output equipment can drive the ultrasonic surgical instrument and the high-frequency electric surgical instrument at the same time, the equipment space is saved, extra cost is not increased, control is convenient, the operation efficiency is improved, and a better operation effect is obtained.

Owner:青岛迈博思医疗科技有限公司

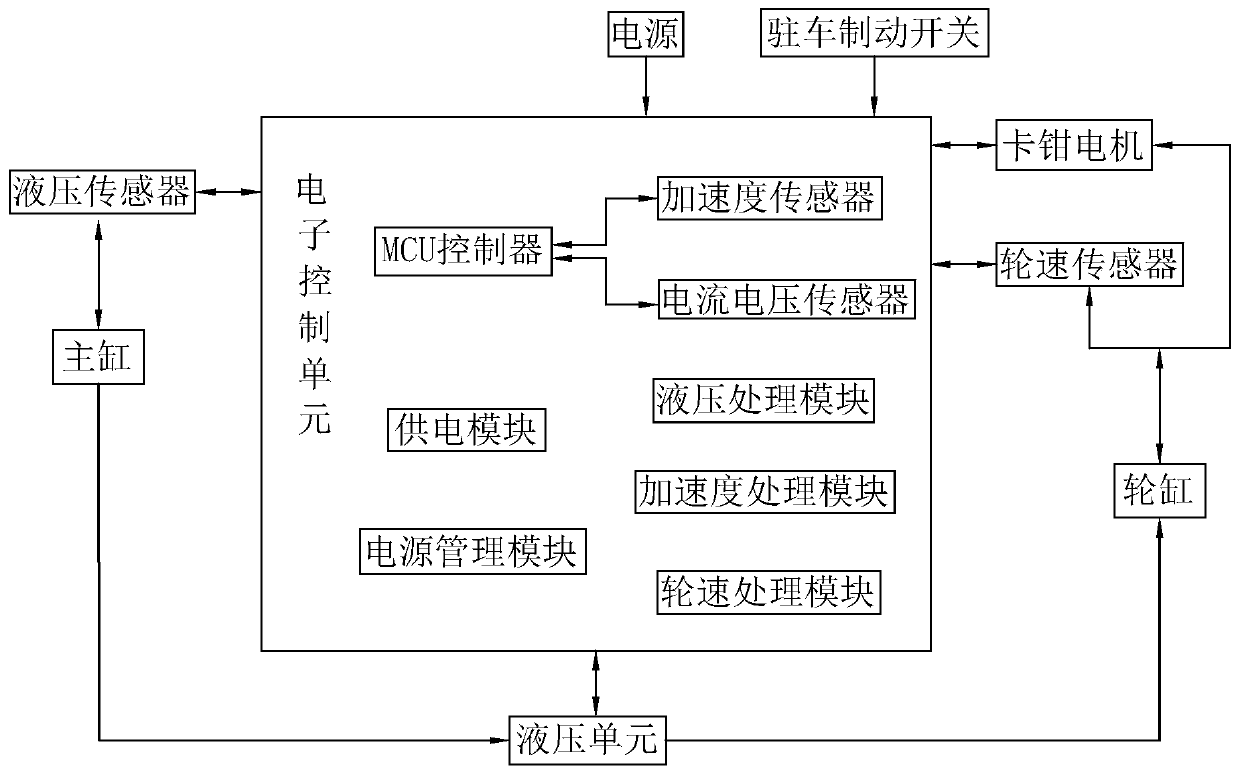

Integrated control system of braking anti-lock braking system and electronic parking braking system

InactiveCN111267804ARealize comprehensive utilizationReduce the possibility of errorBraking action transmissionBrake safety systemsWheel speed sensorControl system

The invention discloses an integrated control system of a braking anti-lock braking system and an electronic parking braking system, and relates to the technical field of automobile intelligent driving. The system comprises an electronic control unit and a hydraulic unit, wherein the electronic control unit is in bidirectional signal connection with the hydraulic unit; the electronic control unitcomprises an MCU controller, a wheel speed processing module, a hydraulic processing module and an acceleration processing module; the MCU controller is connected with a power supply, a parking control switch, a caliper motor, a wheel speed sensor and a hydraulic sensor through electric signals; the MCU controller comprises an acceleration sensor and a current and voltage sensor; the accelerationsensor is used for measuring the acceleration of wheels; and the current and voltage sensor is used for measuring the current and voltage of the caliper motor. According to the invention, the parkingbraking response time is effectively shortened, two original control systems are integrated into one control system, and the cost is reduced while the intelligent performance of the system is improved.

Owner:上海擎度汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com