Unidirectional reinforcement material laminating system and method

A bonding system and reinforcing material technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of large volume, uneven heating, small pressure, etc., achieve small volume, save equipment space, and simplify production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

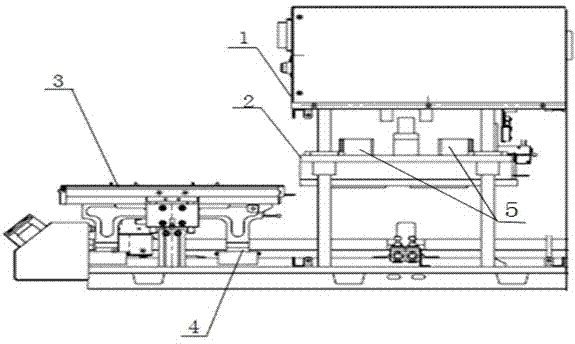

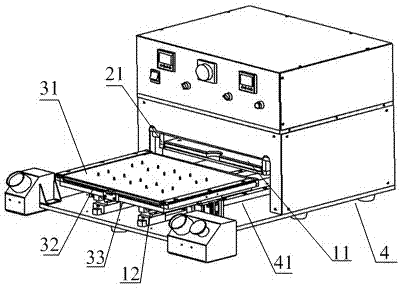

[0035] First install the crimping jig plate 21 on the crimping device 2, first install the laminating base plate 33 on the laminating device 3, install the first positioning jig unit 32 on the laminating jig unit 31, and place the first positioning jig unit 32 on the laminating jig unit 31. The second positioning jig unit 33 is sleeved on the first positioning jig unit 31 , so that the positioning pins are exposed through the holes on the second positioning jig unit 32 . The control device 1 includes an upper heating module 11 and a lower heating module 12 , the upper heating module 11 is arranged on the pressing jig plate 21 , and the lower heating module 12 is arranged on the bonding bottom plate 33 . Use fixtures to heat and pressurize the bonding bottom plate 33 and pressing fixture plate 21 of the reinforcing material bonding system, and add heating sheets at the same time to ensure that the upper and lower sides are heated at the same time.

[0036] The laminating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com