Double-parallel efficient pre-oxidation furnace

A pre-oxidizing furnace, dual-parallel technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as untimely activation of fire protection systems, increased risk of fire, and chaos in the hearth furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

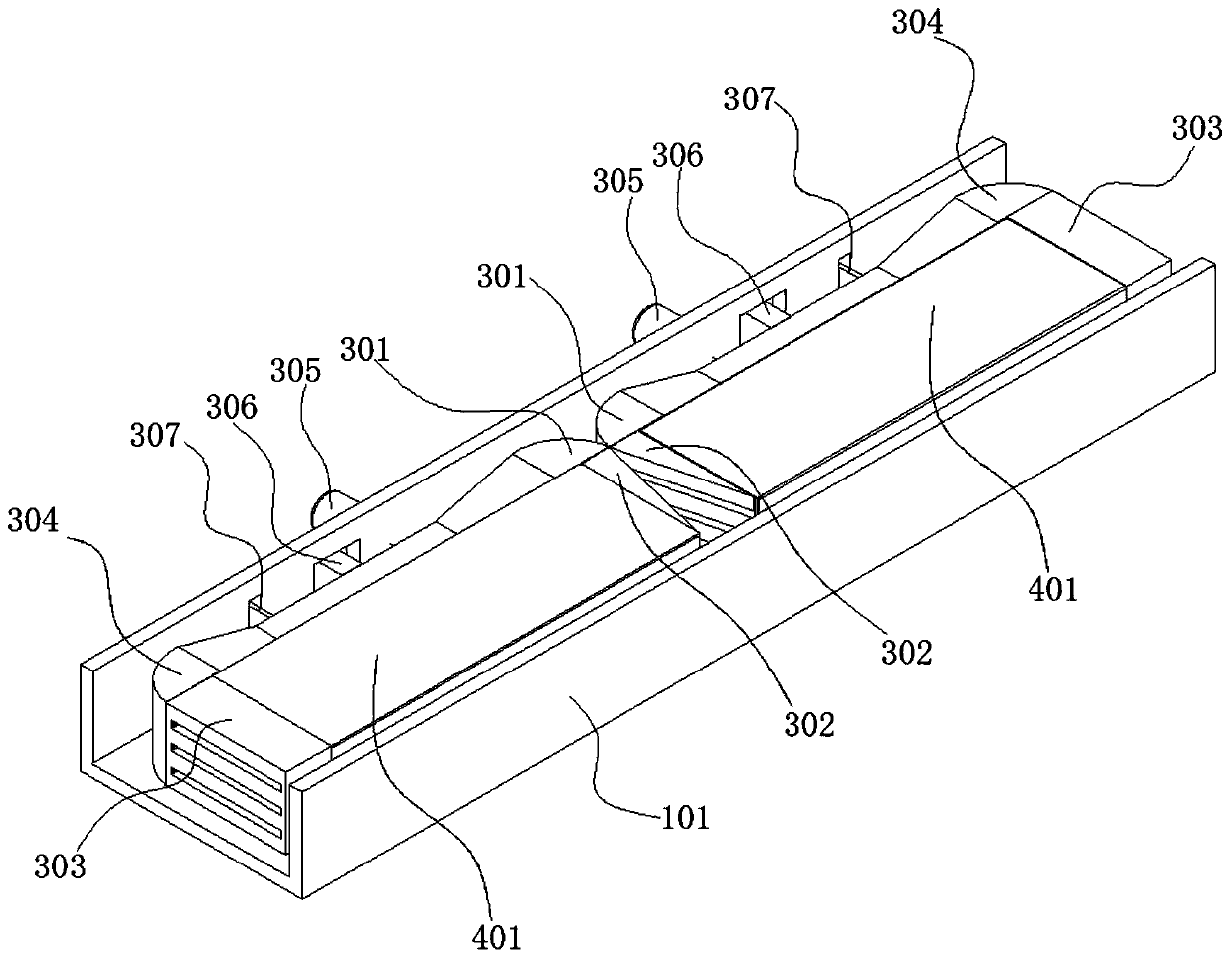

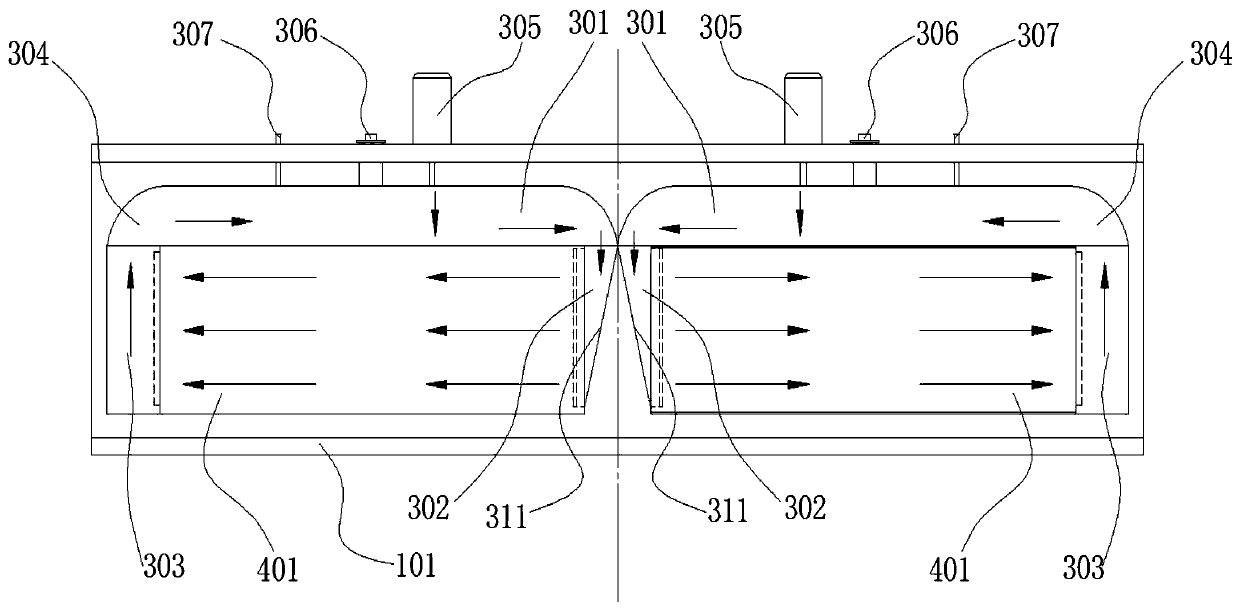

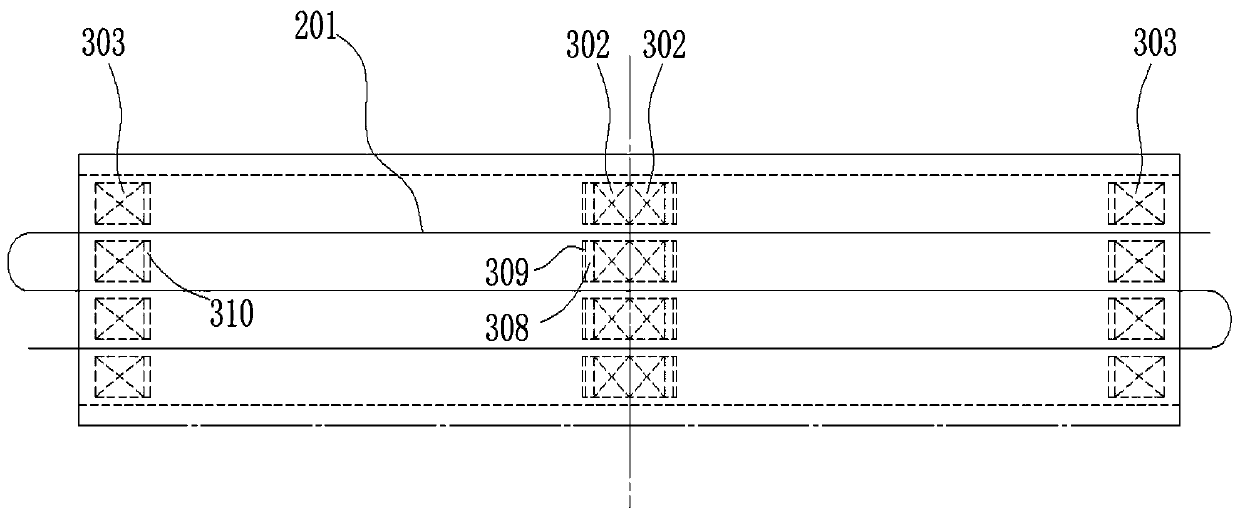

[0053] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0054] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0055] 101 is the thermal insulation frame, 201 is the original wire, 301 is the air inlet duct, 302 is the air inlet cavity, 303 is the return air cavity, 304 is the return air duct, 305 is the circulation fan, 306 is the heater, 307 is the filter , 308 is the orifice plate of the blowing nozzle, 309 is the honeycomb plate of the blowing nozzle, 310 is the suction nozzle, 311 is the wind deflector inclined plate, and 401 is the pre-oxidation chamber;

[0056] The reference signs of the furnace end equipment are as follows:

[0057] 501 is the pre-oxidation furnace, 502 is the porch, 503 is the roller frame system, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com