Selective catalytic reduction device by directly spraying urea solution and method thereof

A selective, urea technology, applied in chemical instruments and methods, separation methods, ammonia preparation/separation, etc., can solve problems such as large space, increase investment and occupation of subsequent equipment, reduce investment and operating costs, and save equipment. Space, use safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

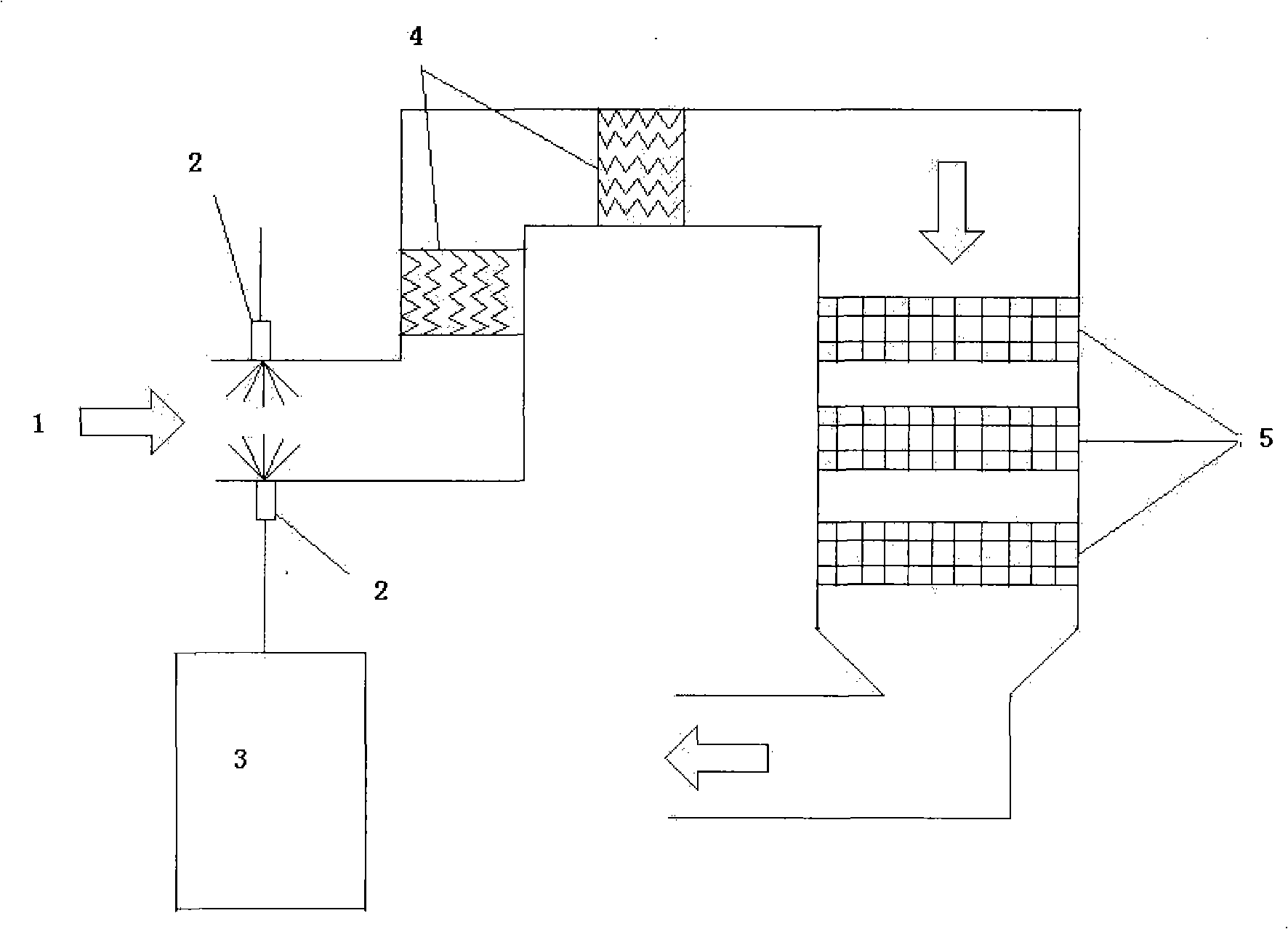

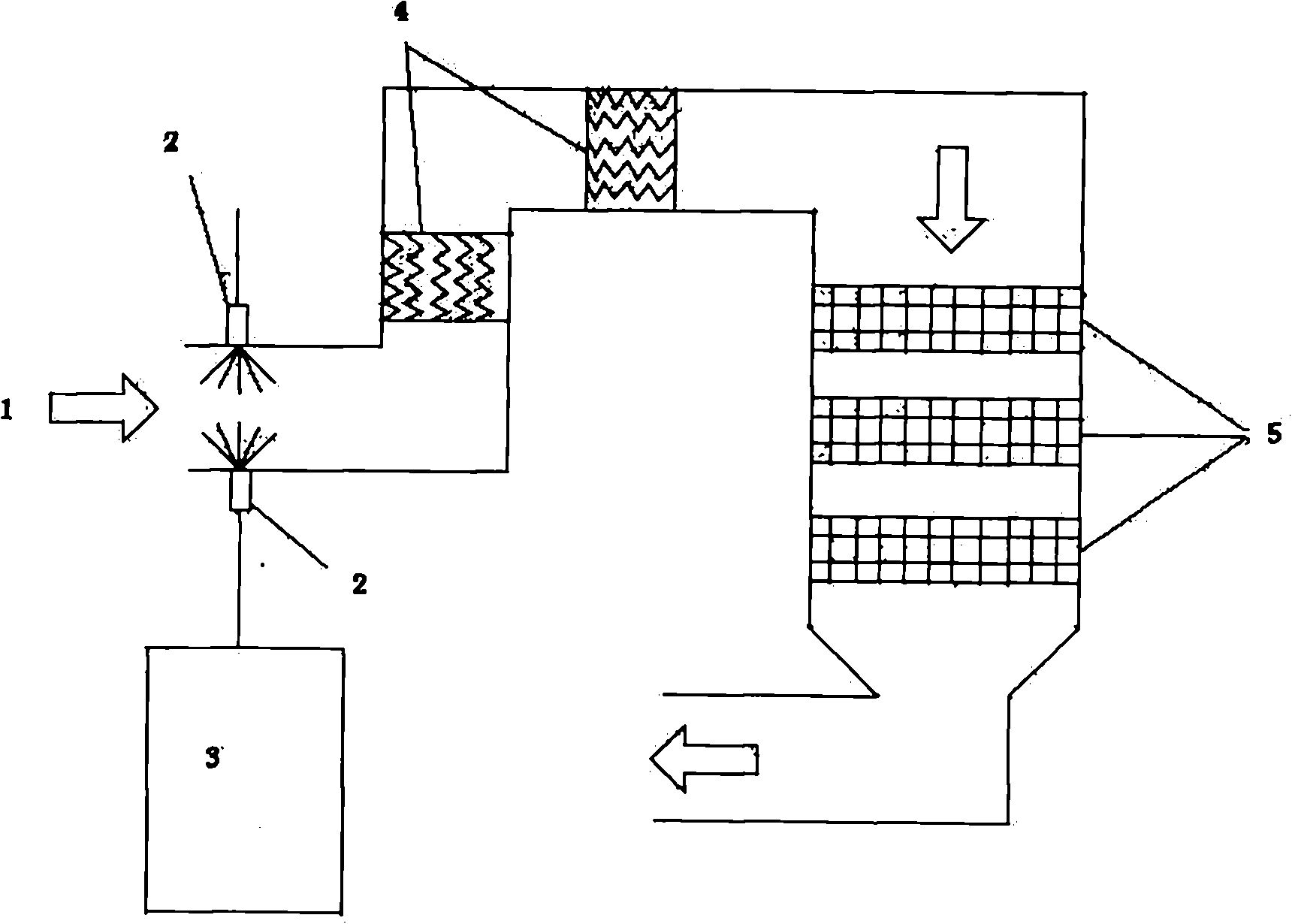

[0019] refer to figure 1 , the present invention includes multiple groups of spray guns 2 for spraying urea solution arranged at the front inlet flue of the SCR reactor, and a mixer 4 and a catalyst 5 arranged in sequence along the flue gas flow direction. Each spray gun 2 is arranged on the flue wall or in the flue cavity, and each spray gun 2 is connected with a solution tank 3 containing urea through a metering distributor. The number of mixers 4 is one or more, and a certain distance should be kept between two or more mixers 4 .

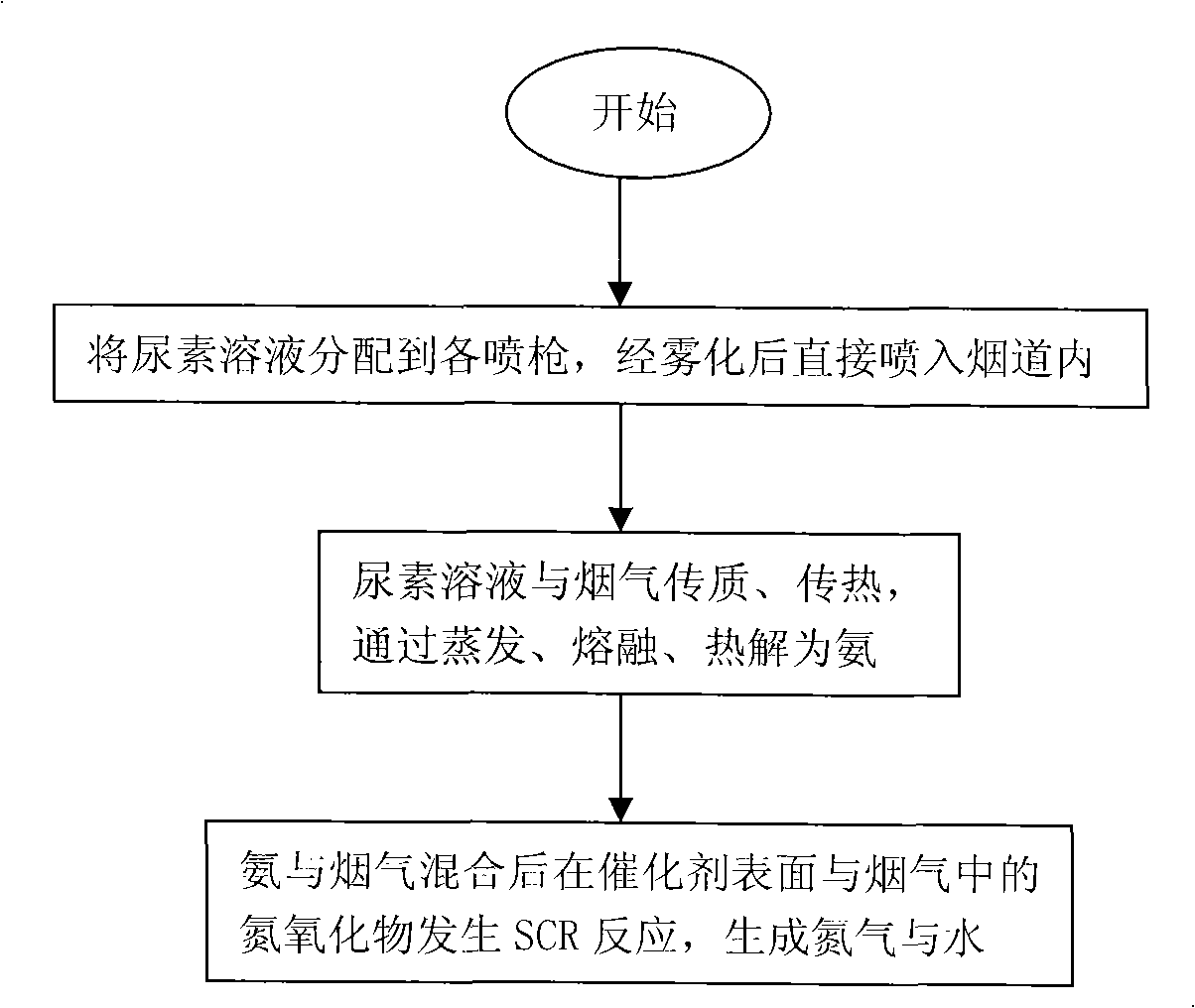

[0020] see figure 2 , the method step when the device of the present invention denitrates is:

[0021] 1) Arrange a certain number of spray guns 2 on the flue wall or in the flue cavity in front of the SCR reactor, where the temperature of the flue gas 1 is above 250°C. According to the mol ratio of 1:10~10:1 in the urea solution and the nitrogen oxides in the flue gas, the urea solution of 5%-70% concentration in the solution tank 3 is deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com