Coal-charging and coke-discharging flue gas integration dust-removal process for side coal-charging coke oven

A technology for flue gas and coke oven, which is applied to the field of integrated dedusting technology of coal charging and coke discharging flue gas from side-loading coal coke ovens, which can solve the problem that the fume collection ability of coal charging and coking discharging is reduced, the active powder cannot be fully utilized, and the tar adsorption It can prevent tar from sticking, save civil construction costs, and improve the adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

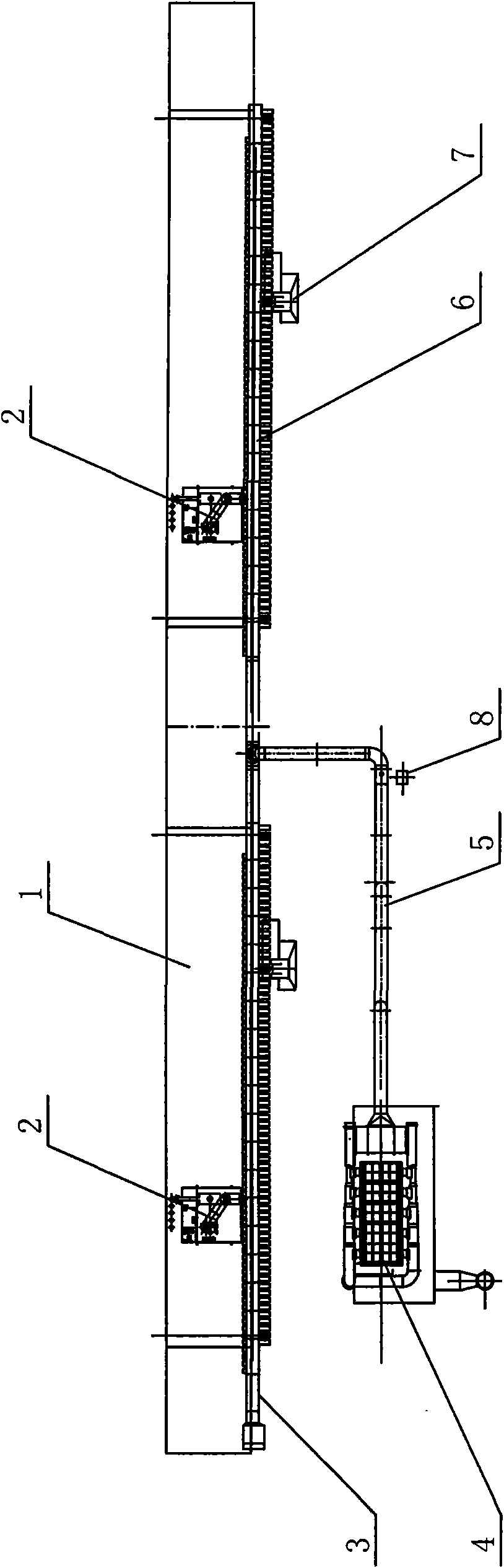

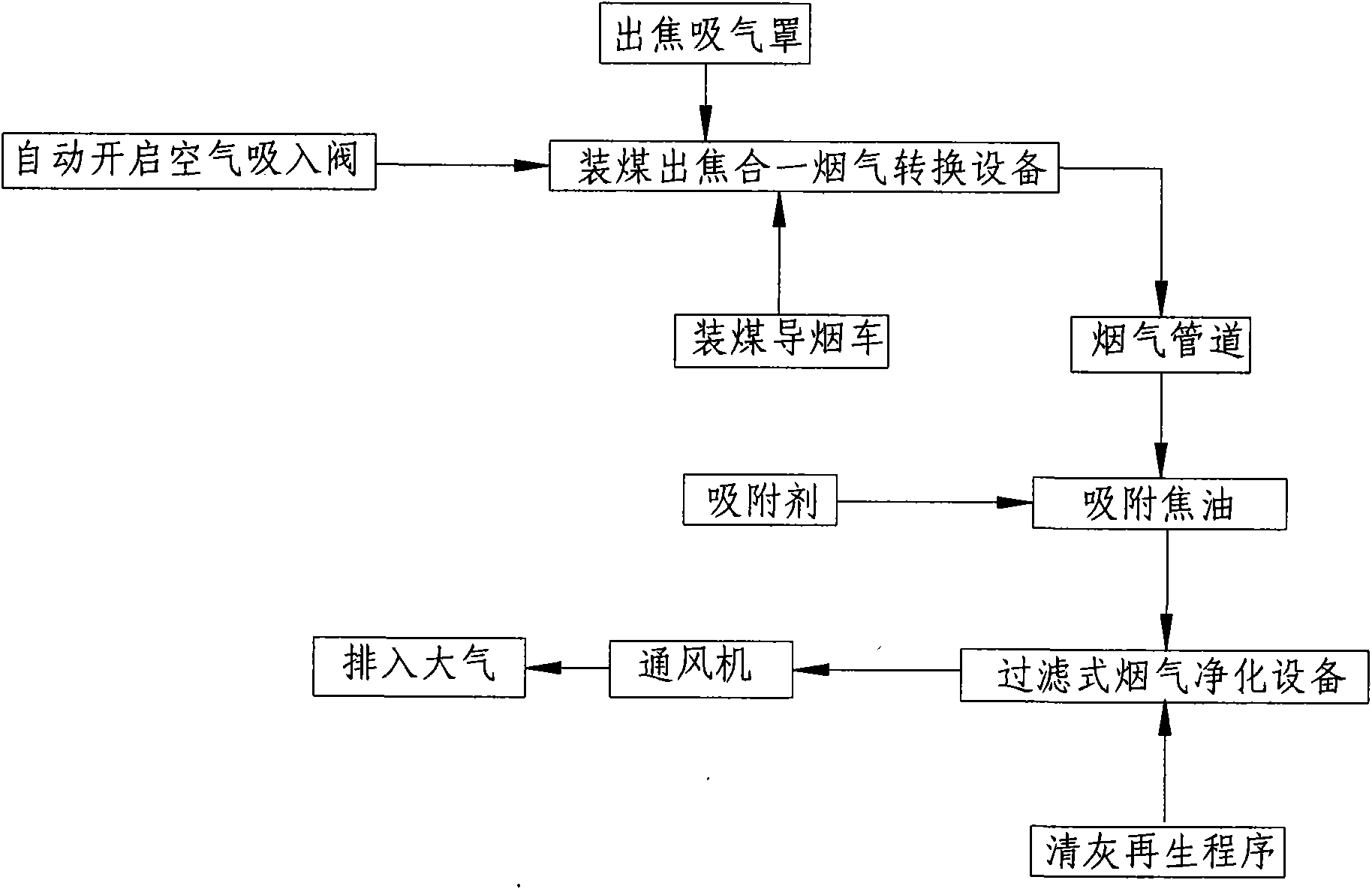

[0023] Such as figure 1 , figure 2 As shown, the process of the present invention adopts a set of system to remove dust and purify the flue gas generated when the coke oven 1 is charged with coal and the flue gas generated when the coke oven 1 is discharged. The furnace column of the coke oven 1 is provided with a two-way interface valve 6, on both sides of the two-way interface valve 6 can be connected with the exhaust port of the coke arrester hood 7 and the exhaust port of the coal-charging and smoke-guiding vehicle 2 respectively, and the end of the two-way interface valve 6 Set to automatically open the air suction valve 3. Two-way interface valves 6 are each 2-3 tons, and a total of two two-way interface valves 6 is fixed on the upper end of the furnace column of a coke oven 1. A focal side operating platform bracket, the load bearing capacity of the operating platform bracket is much greater than 3 tons. In the process of the present invention, the bracket of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com