Fluidized discharge ventilation system for grain steel silos

A technology of ventilation system and silo, applied in fruit hanging device, botanical equipment and method, gardening, etc., can solve the problems of increasing storage cost, increasing civil engineering cost, reducing the capacity of single silo, etc., so as to reduce civil engineering cost and reduce Storage cost, the effect of reducing the height of the base platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

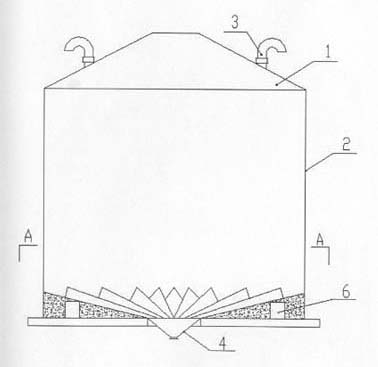

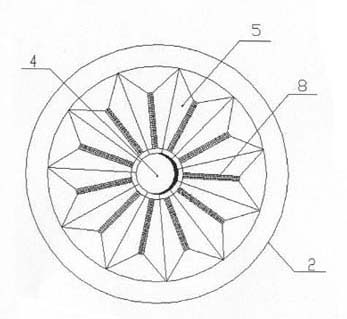

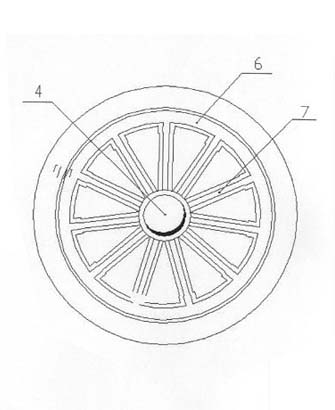

[0017] Such as Figure 1-3 As shown, the steel silo fluidization discharge ventilation system according to the present invention includes a steel silo body surrounded by a silo roof 1, a silo wall 2 and a silo bottom, and the silo roof is provided with ventilation holes 3, so that The bottom of the silo is a conical surface structure with a low center and high surroundings. A discharge port 4 is provided at the center of the silo bottom, and a V-shaped trough 5 inclined upward is evenly arranged along the discharge port 4 toward the wall 2 of the silo. The lower part of the warehouse body is provided with an annular air channel 6 connected to the external air source along the inner side of the warehouse wall 2, and a branch air channel 7 connected with the annular air channel 6 is opened below the V-shaped flow groove 5 , the branch air duct 7 communicates with the chamber cavity through the sieve plate 8 arranged at the bottom of the V-shaped flow groove 5, and a damper is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com