Multi-bucket vibratory discharge silo and layered discharge method thereof

A technology of discharging cylinder and vibrating motor, which is applied in the direction of container, packaging, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

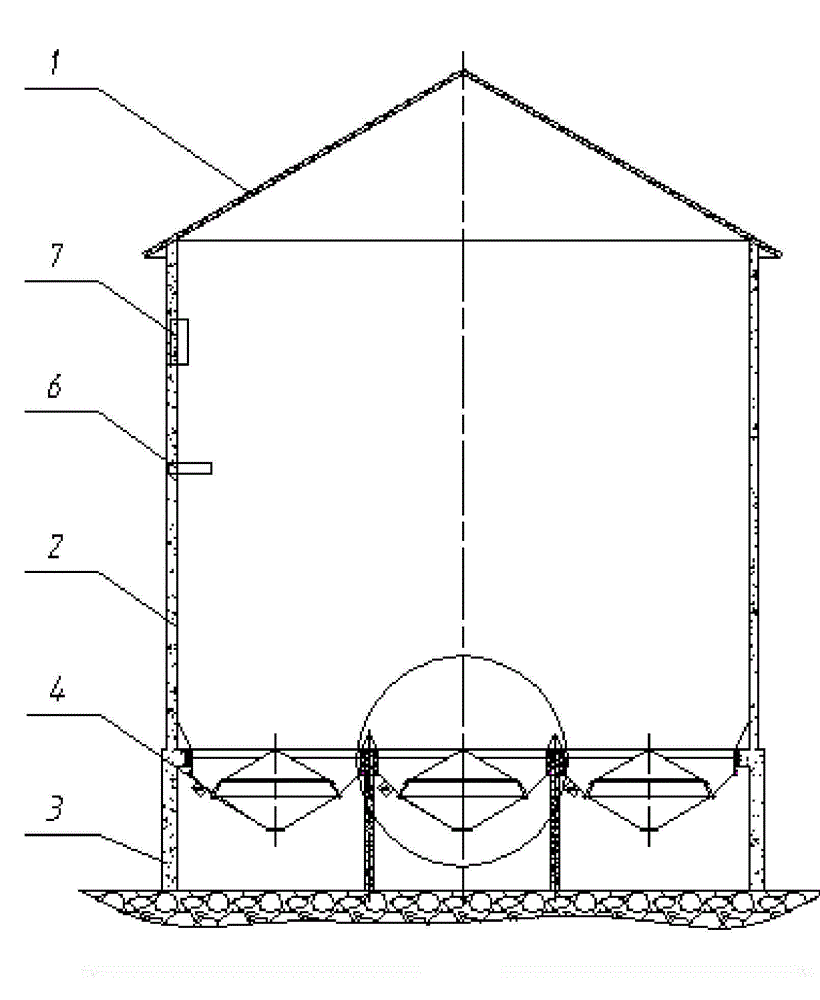

[0034] A multi-bucket vibrating discharge silo, which consists of a bin top 1, a bin bottom 3, a bin body 2 connecting the bin top and the bin bottom, a group of vibrating buckets 4 distributed on the bin bottom, the The upper part of the vibrating bucket is fixed on the bottom of the warehouse, and the vibrating motor 5 of the vibrating bucket is connected to the vibration discharge console.

Embodiment 2

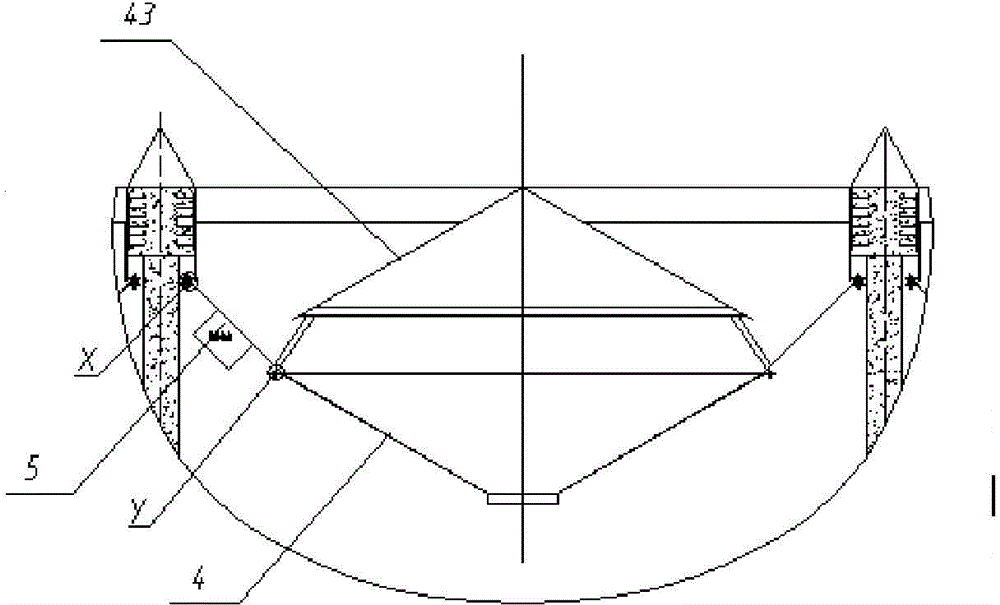

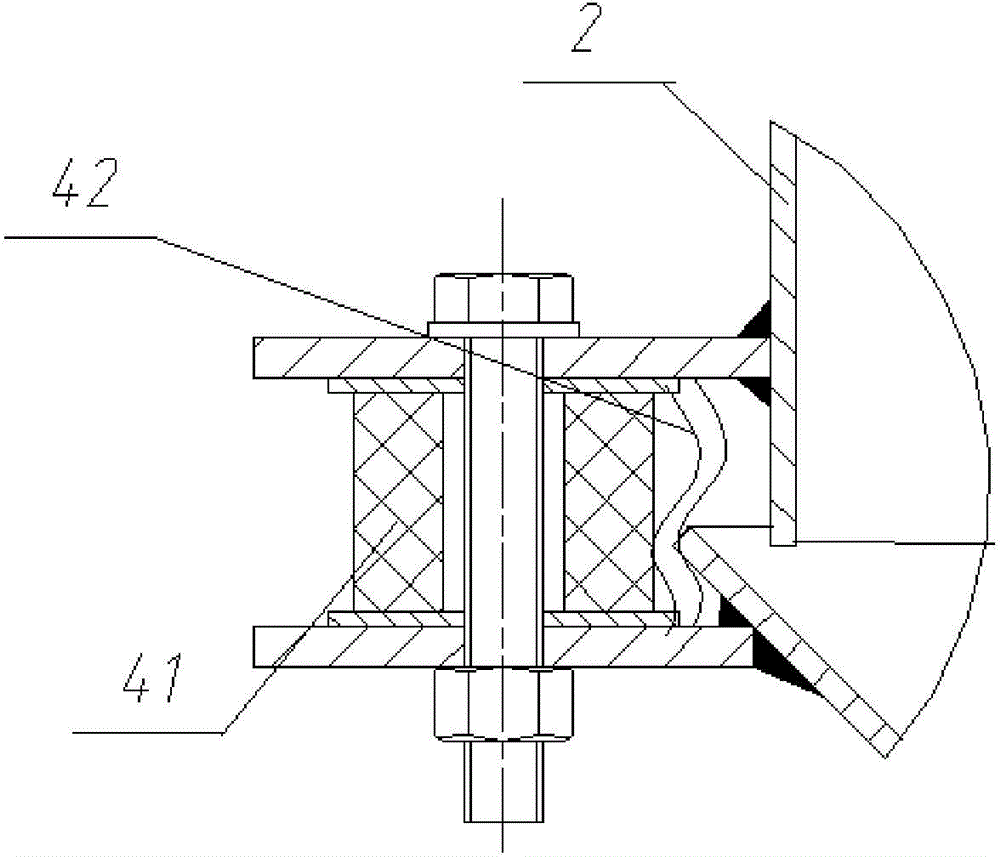

[0036] In the multi-bucket vibrating discharge silo, a rubber or dry molecular shock absorber 41 and a soft connection device 42 in the transition section are sandwiched between the upper part of the vibrating bucket and the lower part, and the vibrating bucket The sum of the area of the upper mouth is greater than 30% of the area of the bottom of the warehouse. The shape of the upper mouth of the vibrating bucket depends on the section. The room type warehouse is rectangular, and the position of the silo is circular. connected to reduce the intermediate beam.

Embodiment 3

[0038] The multi-bucket vibrating discharge silo has a decompression cone 43 on the vibrating bucket to reduce the pressure on the vibrating bucket due to the weight of the upper height. The vibrating bucket is conical and can be conical or polygonal. The number of vibrating buckets described above is 4 to 20, which are arranged in a ring direction or vertically and horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com