Bentonite cat litter and preparation method thereof

A technology of bentonite and bentonite powder, applied in animal houses, applications, animal husbandry, etc., can solve the problems of not being reused, not paying too much attention to sterilization and deodorization in the cat living room, etc., achieving no secondary pollution, long-lasting antibacterial The effect of bactericidal ability and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

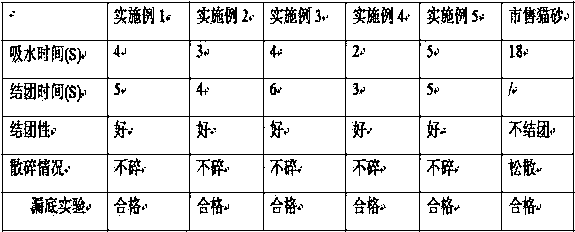

Examples

Embodiment 1

[0028] Bentonite modification: get 78 parts of bentonite powder and 120 parts of ultrapure water to prepare bentonite suspension, stir evenly on a magnetic stirrer, then take anhydrous sodium carbonate and add it to the bentonite suspension to prepare a 20% slurry. Put the slurry into a water bath for heating and stirring reaction, the heating temperature is 76°C, the stirring speed is 20r / min, the stirring time is 85min, centrifuged and washed, dried and then roasted at a high temperature, the roasting temperature is 250°C, put into a ball mill after roasting Grinding and crushing to obtain modified bentonite powder.

[0029] Preparation of composite materials: take modified bentonite powder and place it in a reaction kettle, add 45 parts of tourmaline powder, nano-TiO 2 42 parts of hydroxyapatite powder, 35 parts of hydroxyapatite powder, 25 parts of bamboo charcoal powder, add 53 parts of glycerol, stir and mix evenly, raise the temperature to 270°C for oil bath reaction fo...

Embodiment 2

[0034] Bentonite modification: get 70 parts of bentonite powder and 150 parts of ultrapure water to prepare bentonite suspension, stir evenly on a magnetic stirrer, then take anhydrous sodium carbonate and add it to the bentonite suspension to prepare a 20% slurry. Put the slurry into a water bath for heating and stirring reaction. The heating temperature is 78°C, the stirring speed is 25r / min, and the stirring time is 60min. Then, it is washed by centrifugation. After drying, it is roasted at a high temperature at 200°C. After roasting, put it into a ball mill Grinding and crushing to obtain modified bentonite powder.

[0035] Preparation of composite materials: take modified bentonite powder and place it in a reaction kettle, add 35 parts of tourmaline powder, nano-TiO 2 45 parts of hydroxyapatite powder, 38 parts of hydroxyapatite powder, 24 parts of bamboo charcoal powder, add 51 parts of glycerol, stir and mix evenly, raise the temperature to 300 ° C for 2.0 h in an oil b...

Embodiment 3

[0040] Bentonite modification: take 80 parts of bentonite powder and 125 parts of ultrapure water to prepare bentonite suspension, stir evenly on a magnetic stirrer, then take anhydrous sodium carbonate and add it to the bentonite suspension to prepare a 20% slurry. Put the slurry into a water bath for heating and stirring reaction. The heating temperature is 79°C, the stirring speed is 35r / min, and the stirring time is 90min. Then, it is washed by centrifugation. After drying, it is roasted at a high temperature at 280°C. After roasting, put it into a ball mill Grinding and crushing to obtain modified bentonite powder.

[0041] Preparation of composite materials: take modified bentonite powder and place it in a reaction kettle, add 38 parts of tourmaline powder, nano-TiO 2 35 parts of hydroxyapatite powder, 42 parts of hydroxyapatite powder, 22 parts of bamboo charcoal powder, add 50 parts of glycerol, stir and mix evenly, raise the temperature to 250°C for oil bath reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com