Patents

Literature

140results about How to "Improve waste heat recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

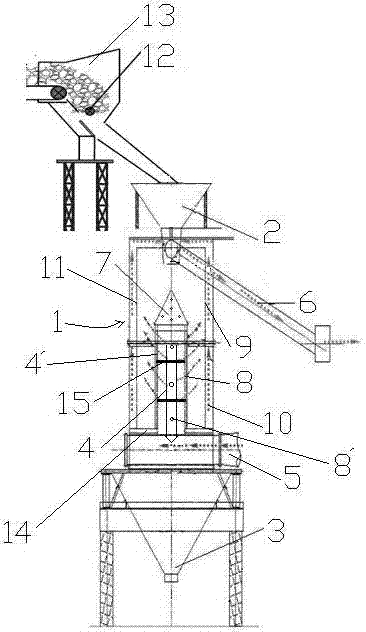

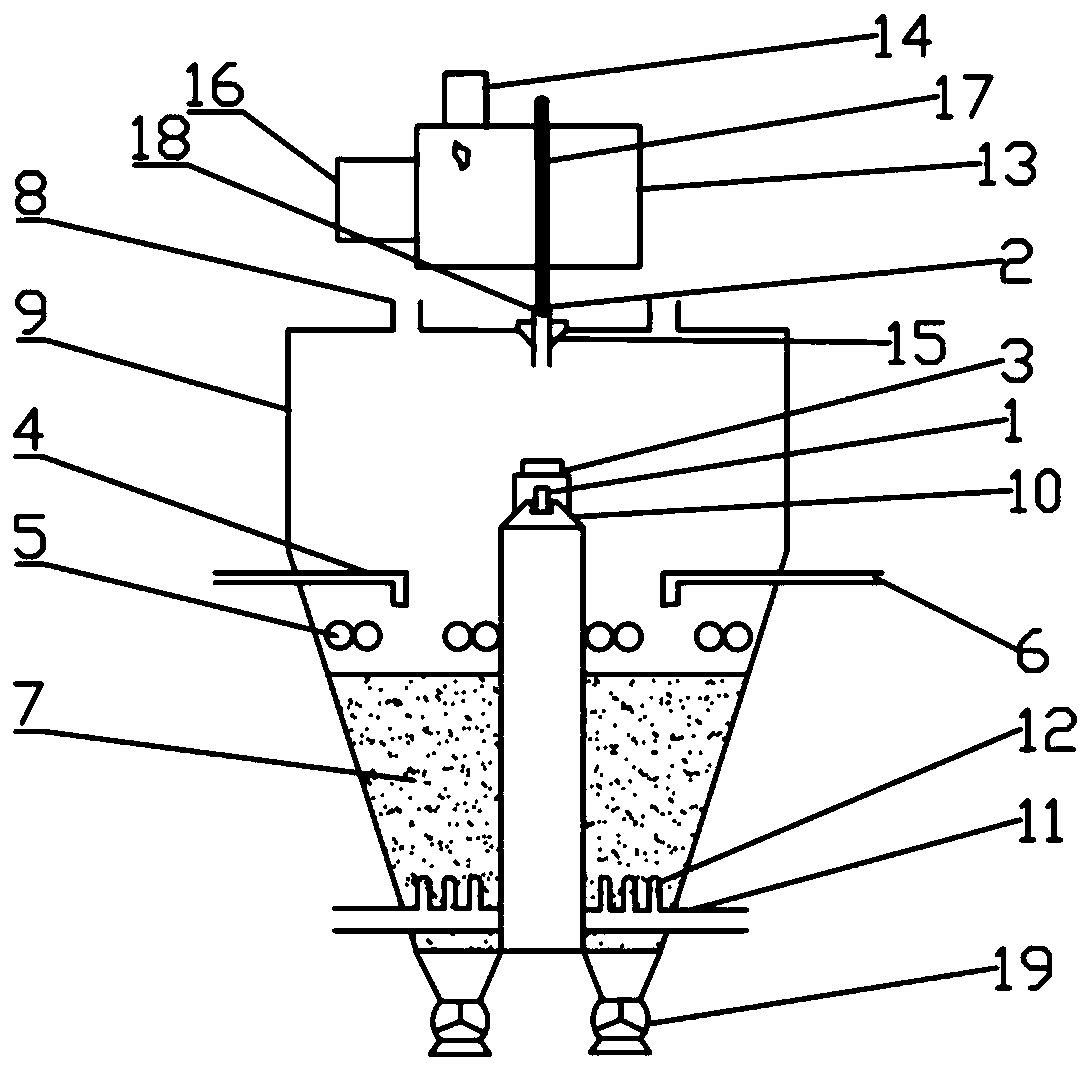

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

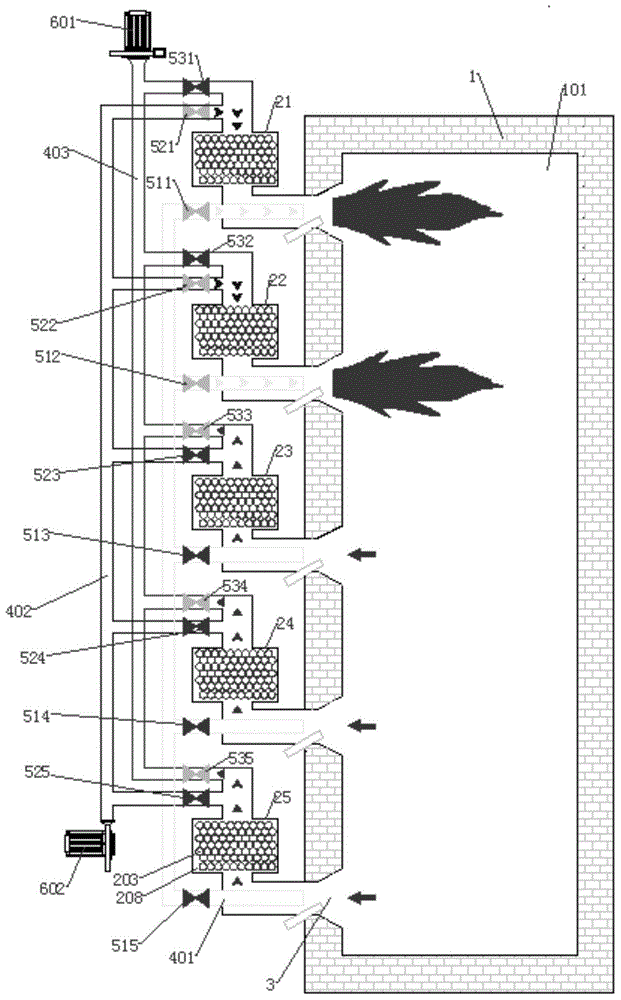

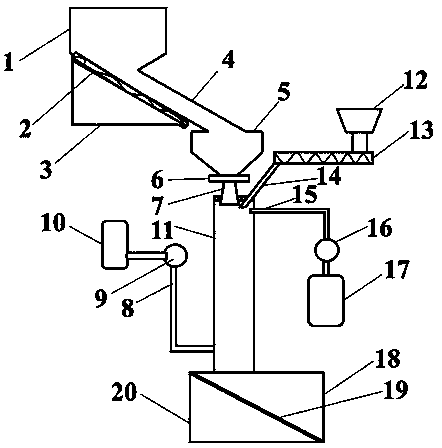

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

Gas waste heat recovery device for coal-fired boiler

InactiveCN102200288AIncrease the flue gas velocityGood cleaning effectCombustion technology mitigationSolid removalFlueProcess engineering

The invention discloses a gas waste heat recovery device for a coal-fired boiler. The recovery device comprises a gas box, a cooling box and a plurality of heat exchange pipes, wherein the cooling box is arranged on the gas box; the heat exchange pipes pass through a separation layer of the gas box and the cooling box; a sonic dust cleaner is arranged in the gas box; a plurality of gas flues which are separated by the separation layer are arranged in sections of the gas box, in which the heat exchange pipes are arranged; and an inlet of each gas flue is provided with a gas flue valve. Compared with the prior art, the gas waste heat recovery device for the coal-fired boiler has the advantage of solving the problem that accumulated dust of the gas box is difficult to clean and remove.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

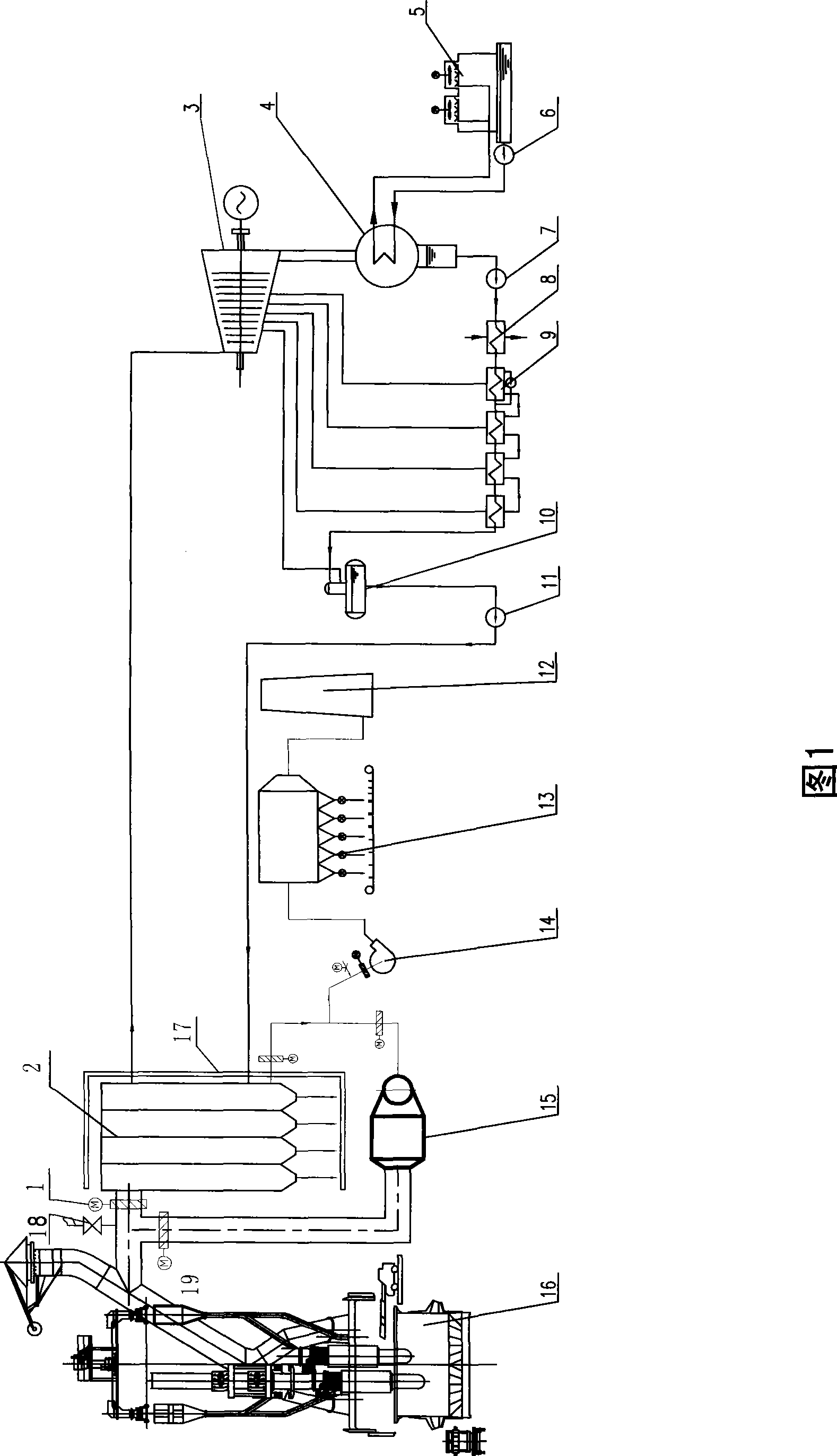

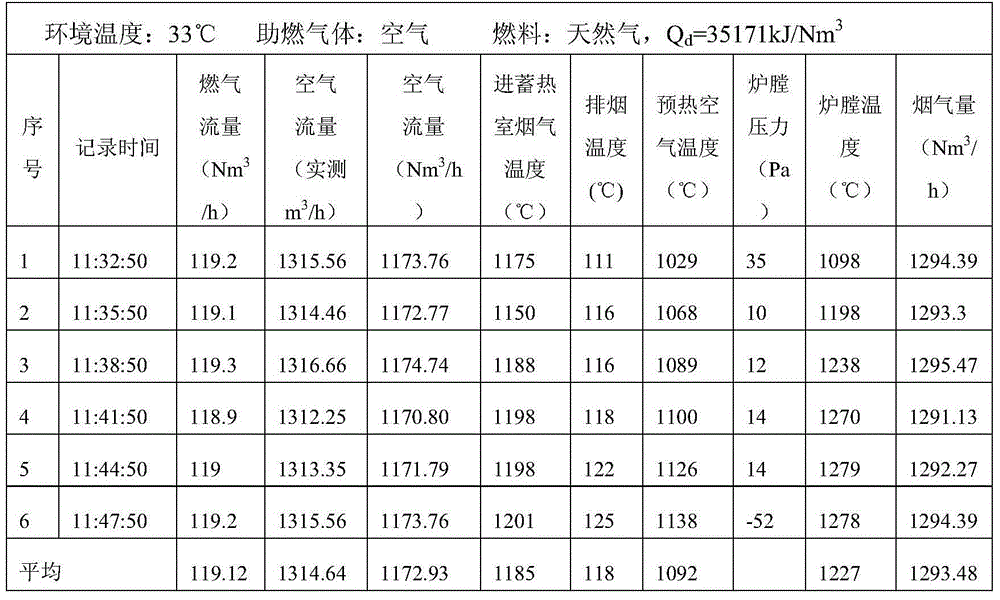

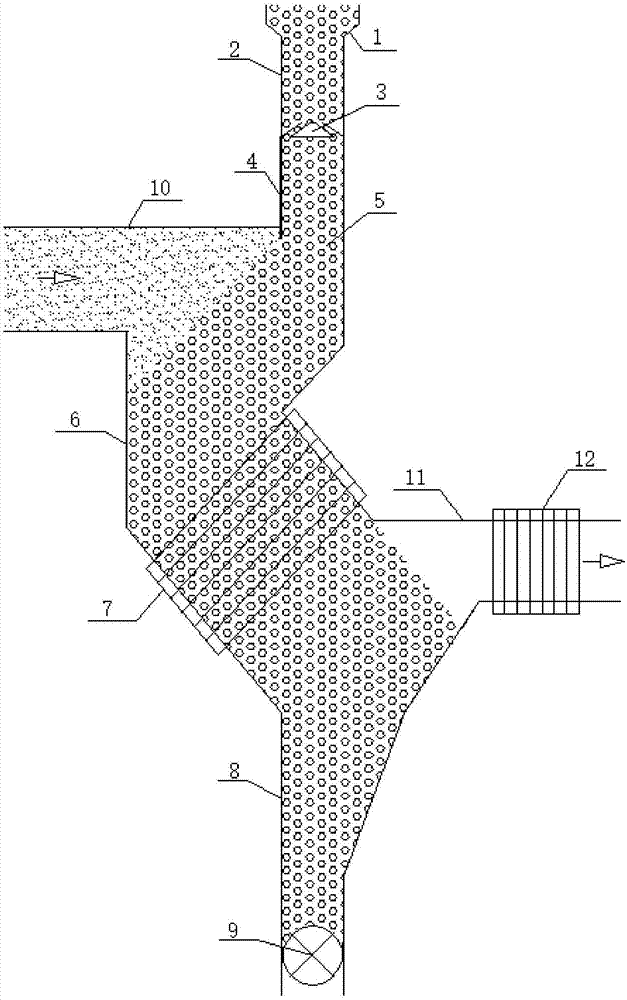

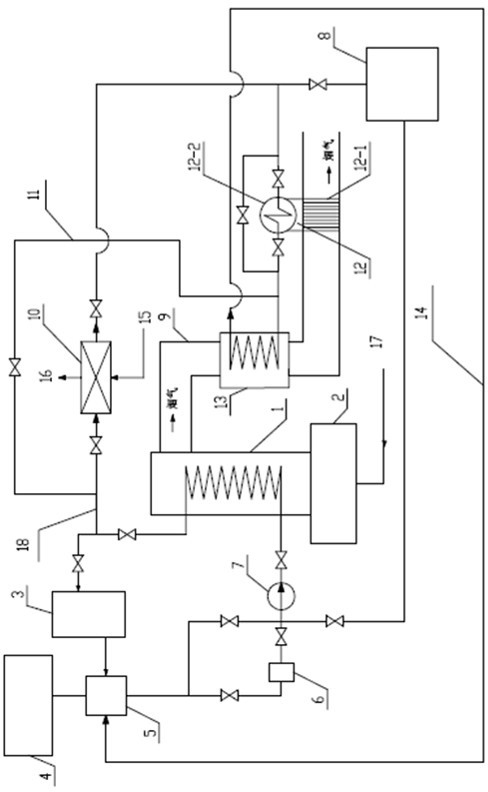

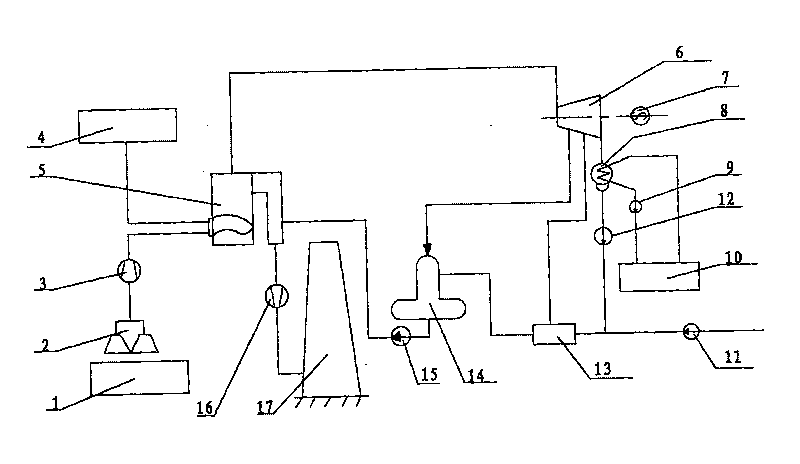

Silicon smelting electric furnace waste heat power generation process flow and configuration

ActiveCN101392992AEfficient extractionIncrease waste heatEnergy industryIncreasing energy efficiencyCooling towerAtmospheric air

The invention provides silicon smelting electric furnace waste heat power generating equipment, which consists of a valve 1, a waste heat boiler 2, a turbo generator 3, a vapor condenser 4, a cooling tower 5, a circulating water pump 6, a condensing water pump 7, a vapor seal heater 8, a low-pressure heater 9, a deaerator 10, a feed water pump 11, a chimney 12, a bag dust collector 13, an induced draft fan 14, a air cooler 15, a steel ball collection conveying distribution lifting device 17, a mixing cold air valve 18 and a by-pass valve 19, wherein waste flue gas discharged by a silicon smelting electric furnace 16 is introduced into the waste heat boiler to release partial heat; and when the temperature of the waste flue gas is reduced to nearly 180 DEG C, the waste flue gas enters the bag dust collector through the induced draft fan, and finally is discharged to atmosphere through the chimney. The desalted water enters the waste heat boiler through the feed water pump, vapor generated by the waste heat boiler enters the turbo generator; and after the vapor does work, the vapor enters the vapor condenser to be condensed into water, and the water enters the deaerator through a condensate removal pump, and the deoxidized water enters the waste heat boiler through the feed water pump. The silicon smelting electric furnace waste heat power generating equipment has the advantages of good energy saving effect, little investment and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

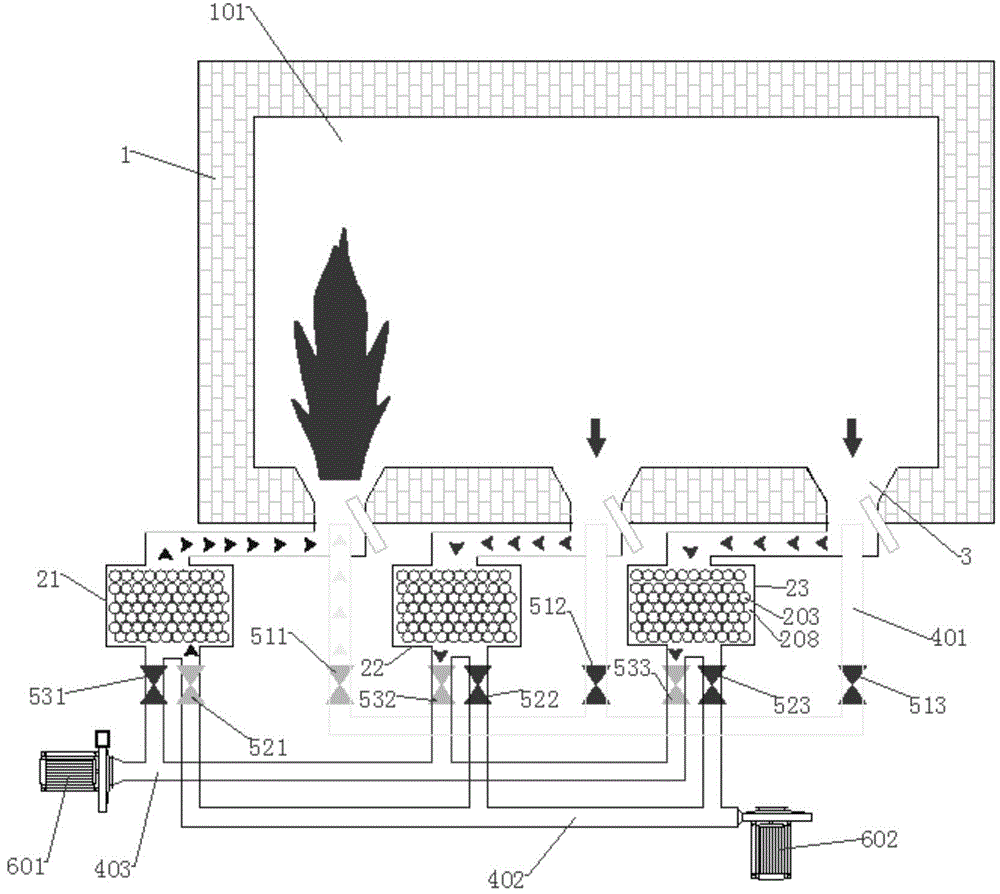

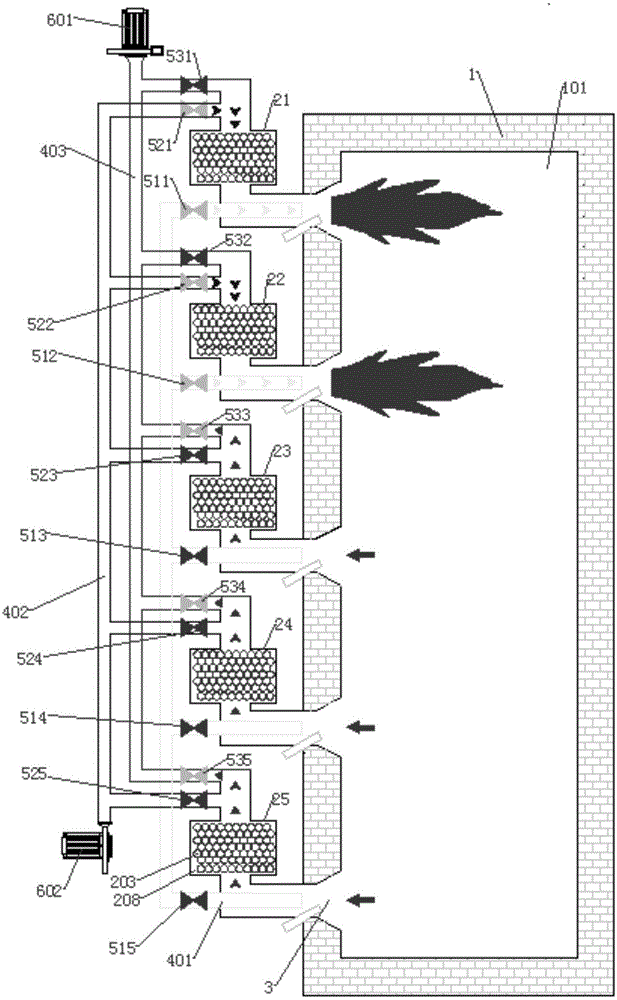

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

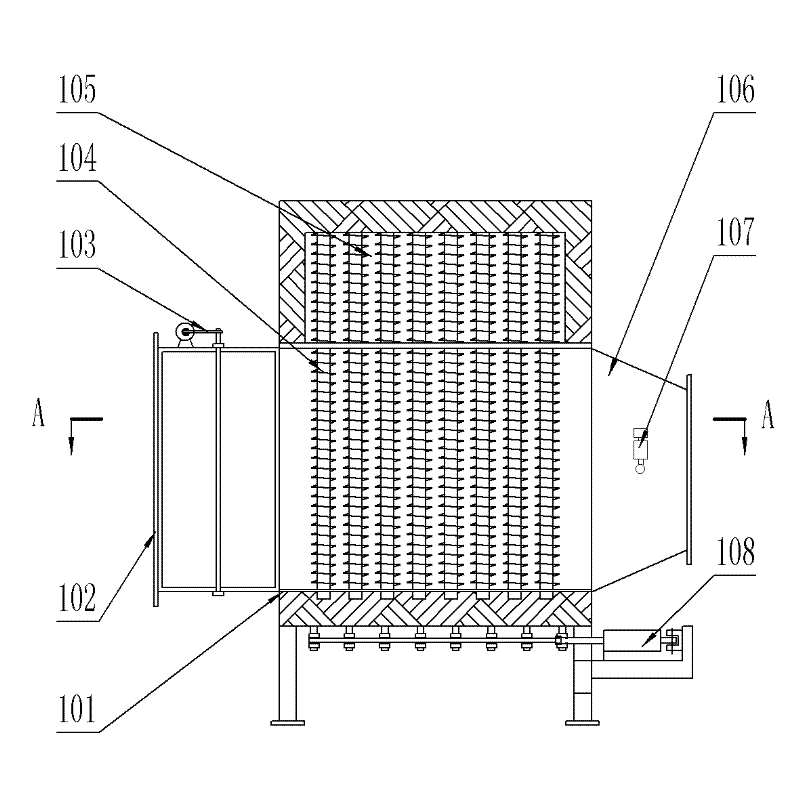

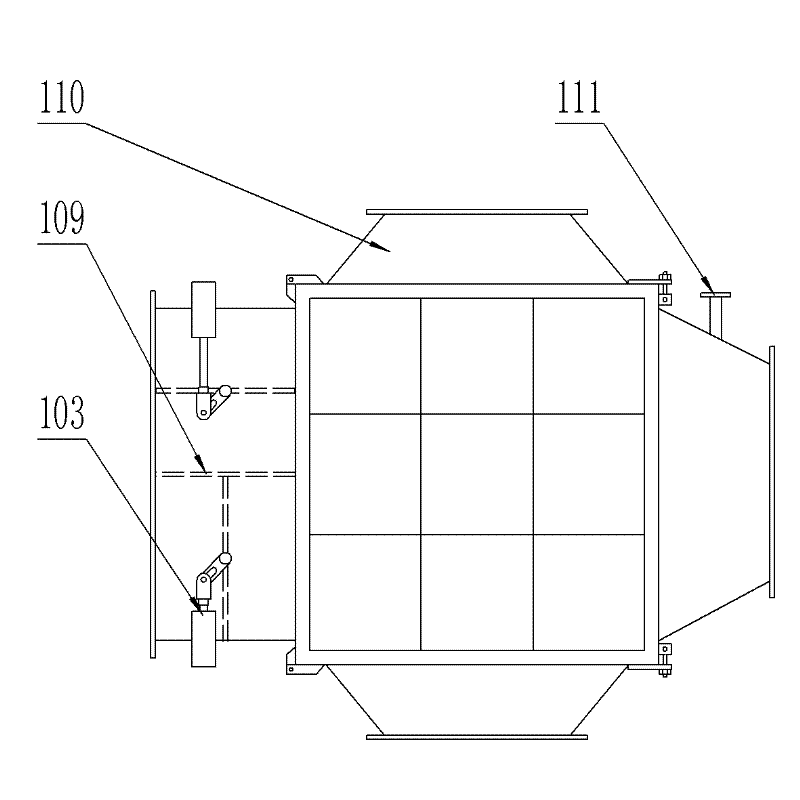

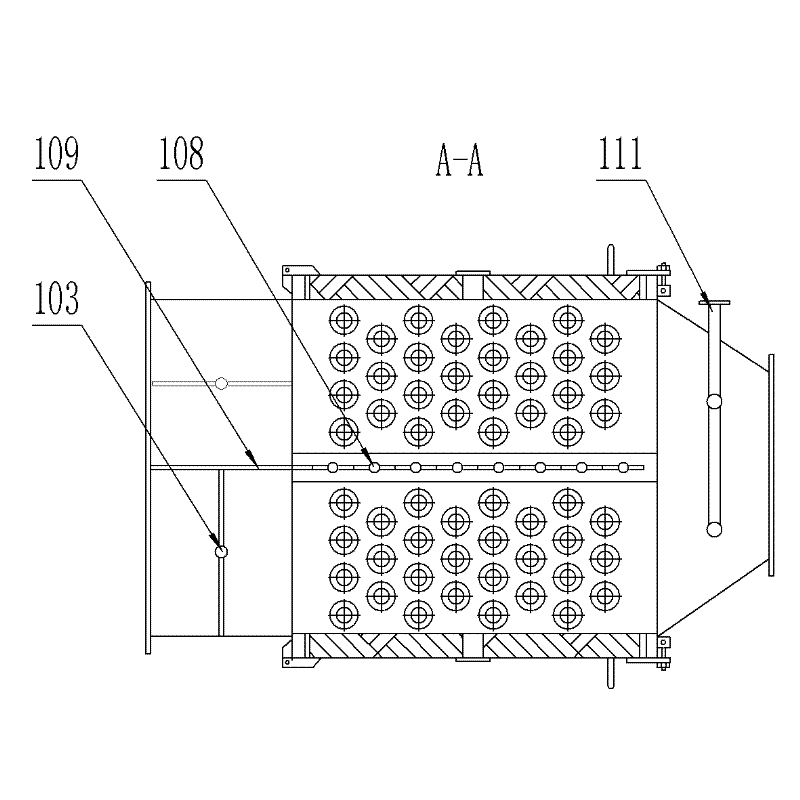

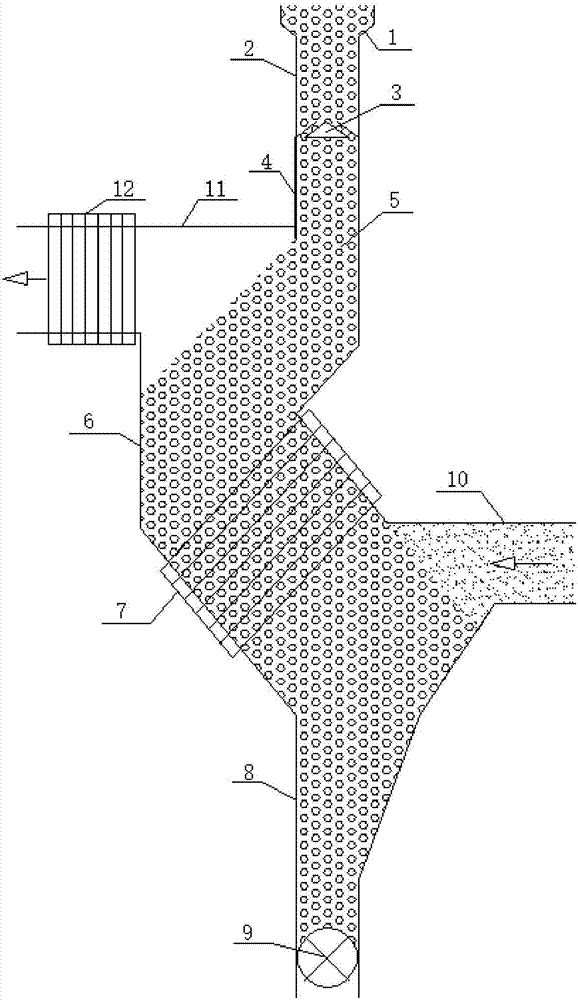

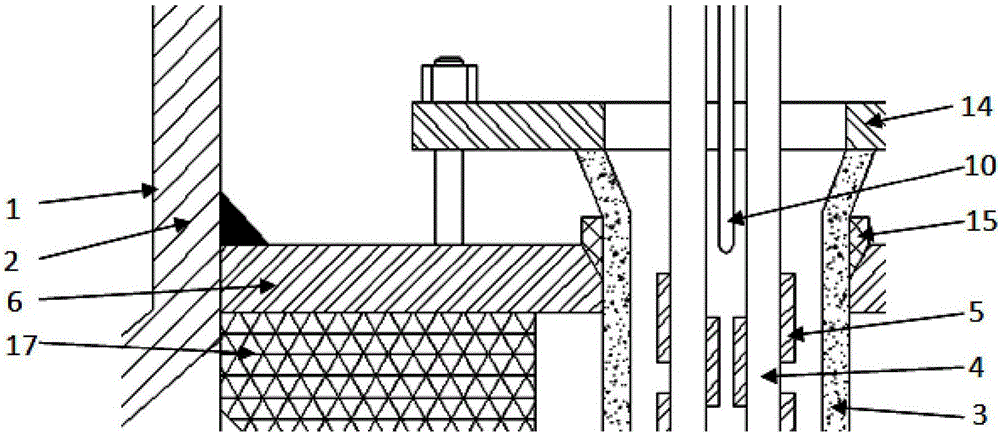

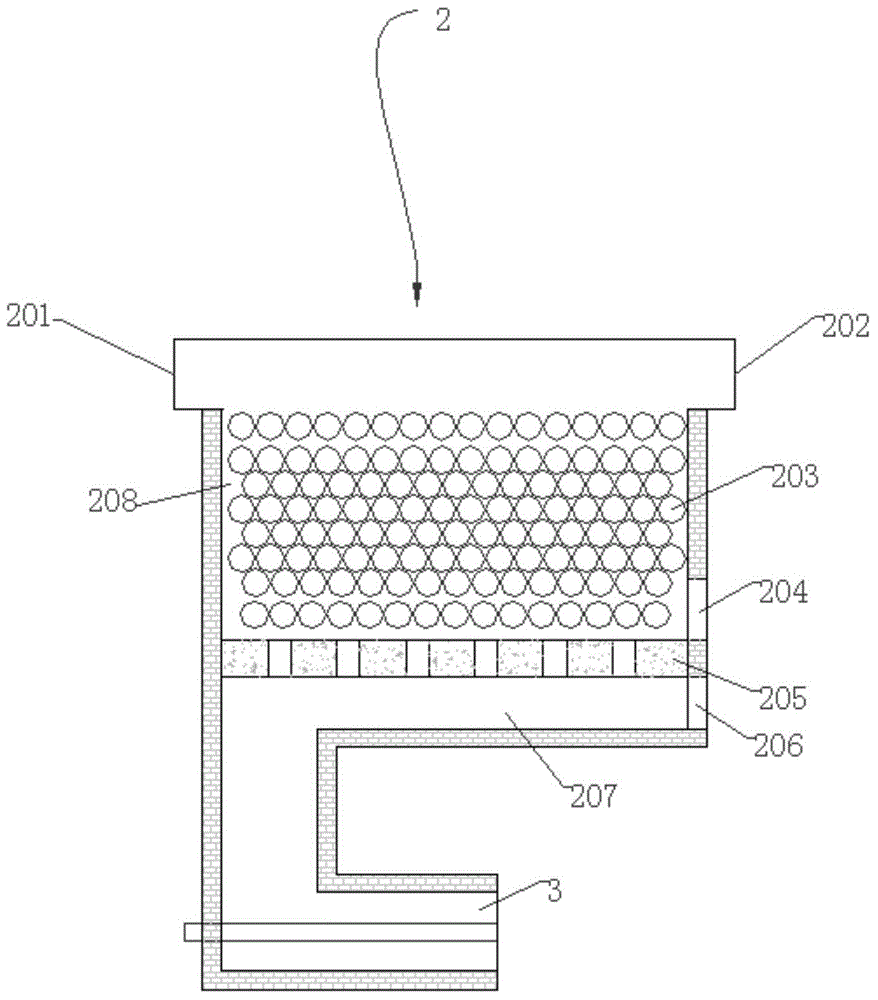

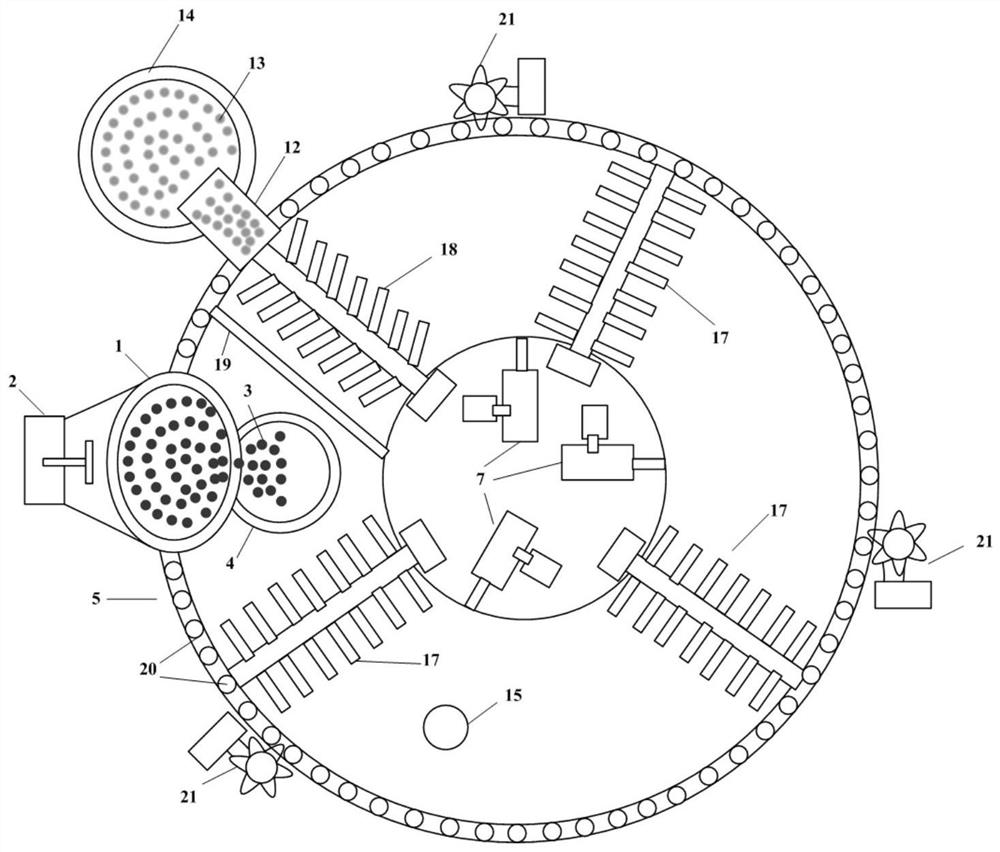

High-temperature dust-containing flue gas moving particle bed purification and waste heat recovery system

InactiveCN107511009AAdjustable thicknessSimple structureGas treatmentRecuperative heat exchangersWaste heat recovery unitInlet channel

The invention provides a high-temperature dust-containing flue gas moving particle bed purification and waste heat recovery system, belongs to the technical field of dust-containing gas filtering, purification and waste heat recovery, and aims to improve purification and waste heat recovery effects. The system comprises a filtering channel, a feeding channel, a discharging channel, a flue gas inlet channel, a flue gas outlet channel, a primary heat exchanger and / or a secondary heat exchanger, wherein the feeding channel is connected with the upper end of the filtering channel, the discharging channel is connected with the lower end of the filtering channel, the primary heat exchanger is arranged inside the filtering channel, the secondary heat exchanger is arranged inside the flue gas outlet channel, and the flue gas inlet channel and the flue gas outlet channel are respectively connected with the upper and lower ends of the filtering channel. The system provided by the invention has the advantages of simple structure, convenient operation, adjustable particle layer thickness, no components such as blocking nets / baffles / pore plates, wide range of suitable temperature, high filtering efficiency, low filtration pressure drop, high waste heat recovery rate and capability of continuously and stably running.

Owner:UNIV OF SCI & TECH BEIJING

Waste heat recovering device for conduction oil furnace

InactiveCN102538203AEfficient recyclingAvoid Low Temperature CorrosionFluid heatersThermal fluidsEconomizer

The invention relates to a waste heat recovering device for a conduction oil furnace. The conduction oil furnace includes a furnace body, a heating source, a high-temperature end conduction oil circulation loop and a flue; the waste heat recovering device includes an inner circulating pipeline, a thermoregulator, a phase change heat exchanger and a coal economizer; the phase change heat exchangerincludes an evaporator and a condenser that are connected through a pipeline to form a phase change working medium circulation loop; the evaporator and the coal economizer are arranged in the flue; the condenser is arranged outside the flue; a conduction oil inlet end or a conduction oil outlet end of the furnace body is sequentially connected with the thermoregulator, the condenser and a conduction oil inlet end of the coal economizer through the inner circulating pipeline; and a conduction oil outlet end of the coal economizer is connected to the high-temperature end conduction oil circulation loop. According to the invention, the conduction oil furnace can economically operate with high heat efficiency, the problem that the waste heat of the conduction oil furnace is difficult to recover is solved, and the purposes of energy saving and consumption reducing are achieved.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

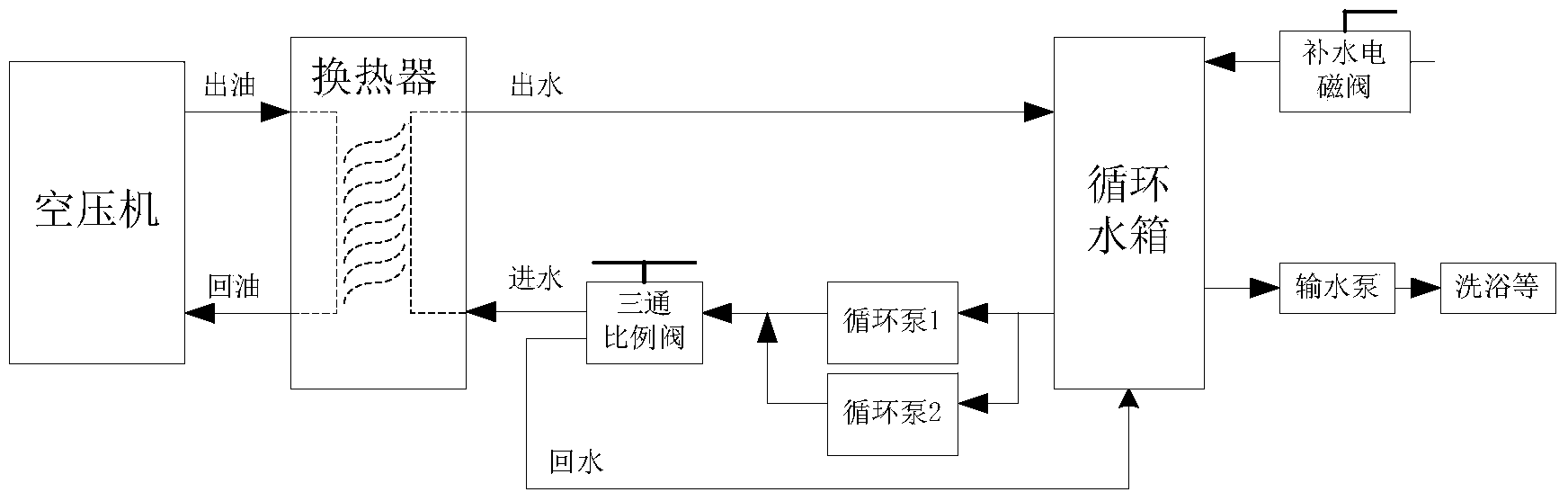

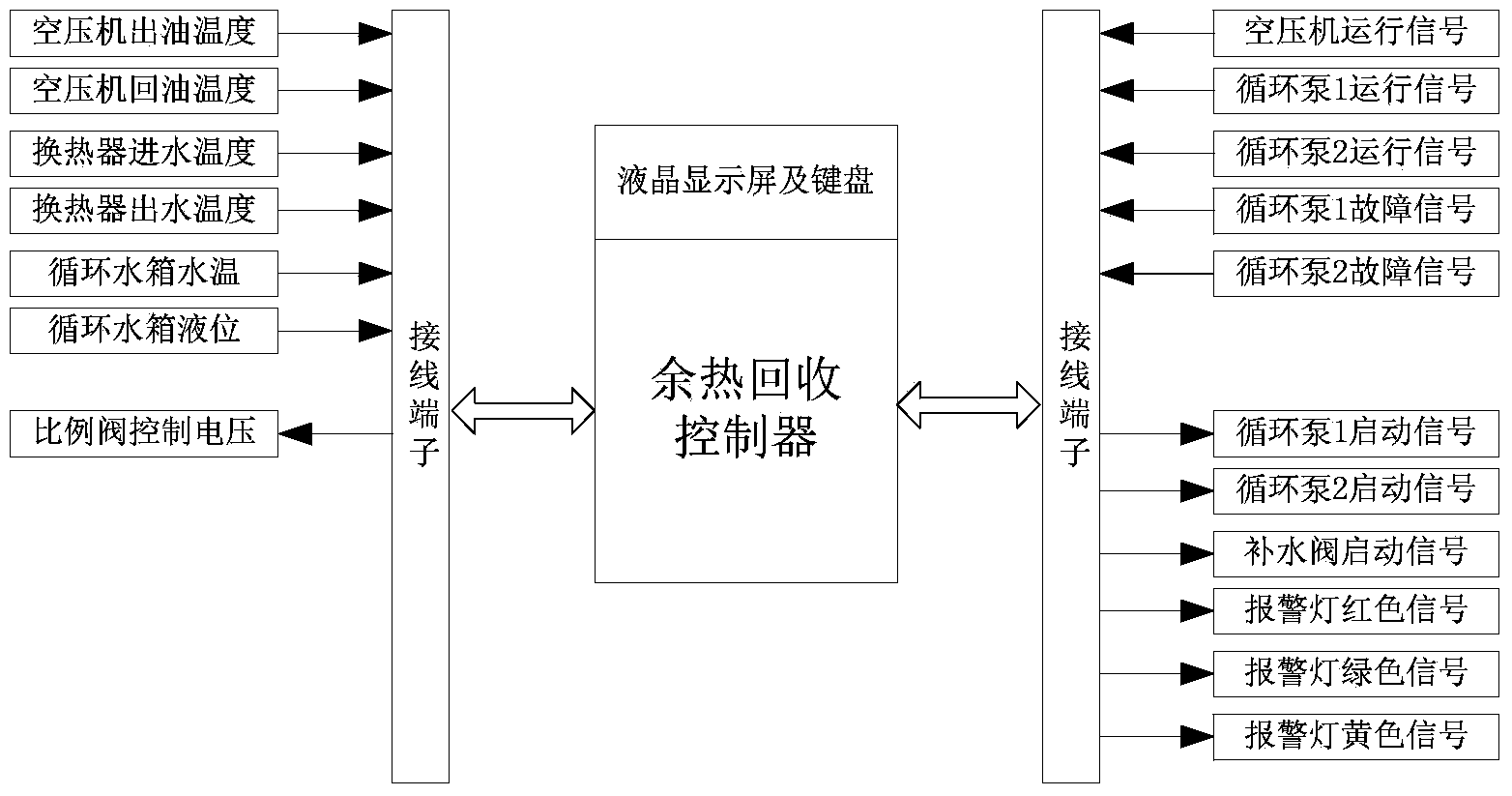

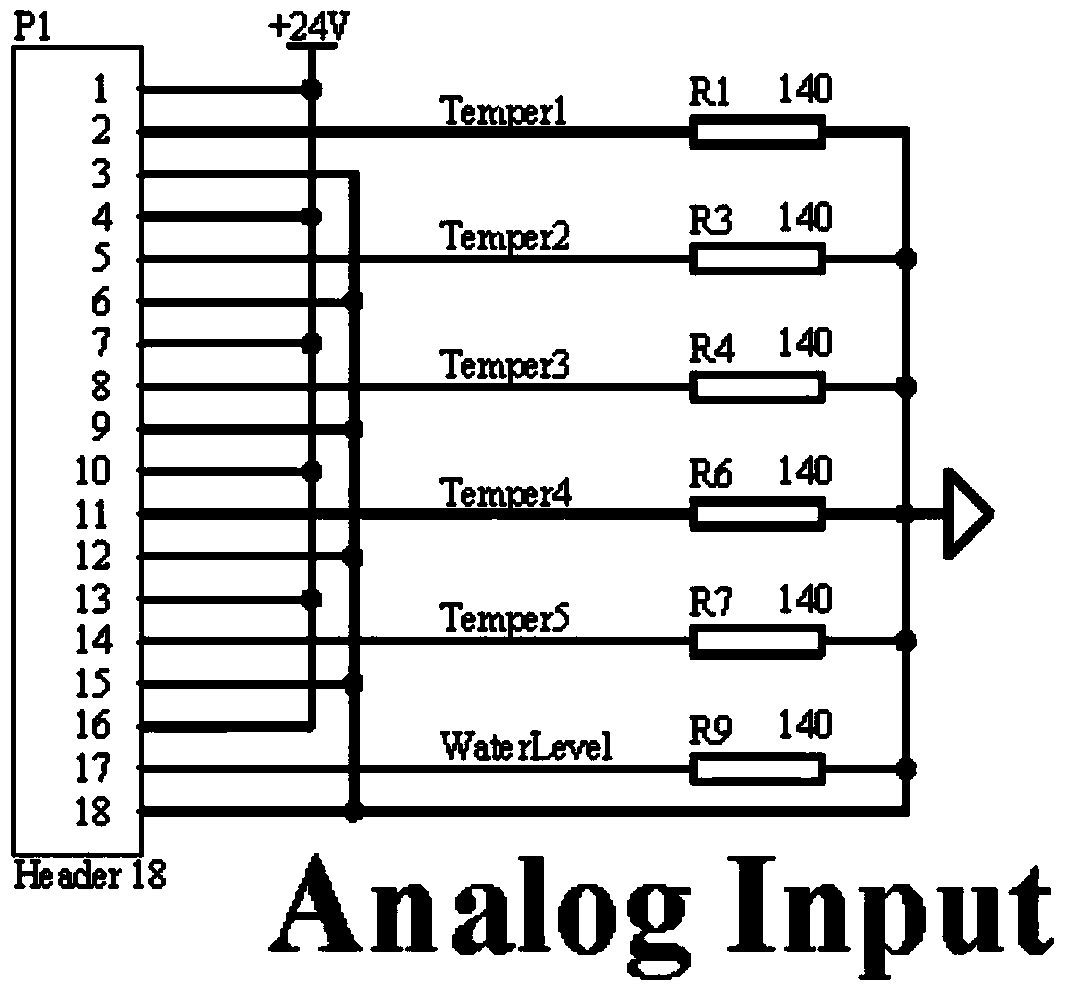

Air compressor waste heat recycling control system based on C8051 microprocessor

InactiveCN103883505APrecise control of return oil temperatureImprove waste heat recovery ratePositive displacement pump componentsPump controlControl systemCirculator pump

The invention discloses an air compressor waste heat recycling control system based on a C8051 microprocessor. The air compressor waste heat recycling control system comprises a circulating water tank, a heat exchanger, a three-way proportional valve and temperature sensors. The circulating water tank is provided with a water outlet, a water inlet, a hot water output opening and water adding opening. The heat exchanger is provided with an oil return pipe and an oil outlet pipe which are connected to an air compressor and used for recycling the heat generated by the air compressor. The heat exchanger is further provided with a water outlet pipe and a water inlet pipe which are connected to the water inlet and the water outlet of the circulating water tank and used for heating the water in the circulating water tank. The three-way proportional valve is provided with two outlets and one inlet, wherein the inlet is connected to the water outlet of the circulating water tank through a circulating pump, one outlet is connected with the water inlet pipe inlet of the heat exchanger, and the other outlet is connected to the circulating water tank. The temperature sensors are respectively disposed in the oil outlet pipe, the oil return pipe, the water outlet pipe, the water inlet pipe and the circulating water tank. The air compressor waste heat recycling control system has the advantages that the C8051 microprocessor is used as a core processor for waste heat recycling control, integral control is achieved, a control module is integrated with a liquid crystal display module and a keyboard module, and the system is compact in structure, low in cost and good in reliability.

Owner:SHANGHAI JIYI ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD

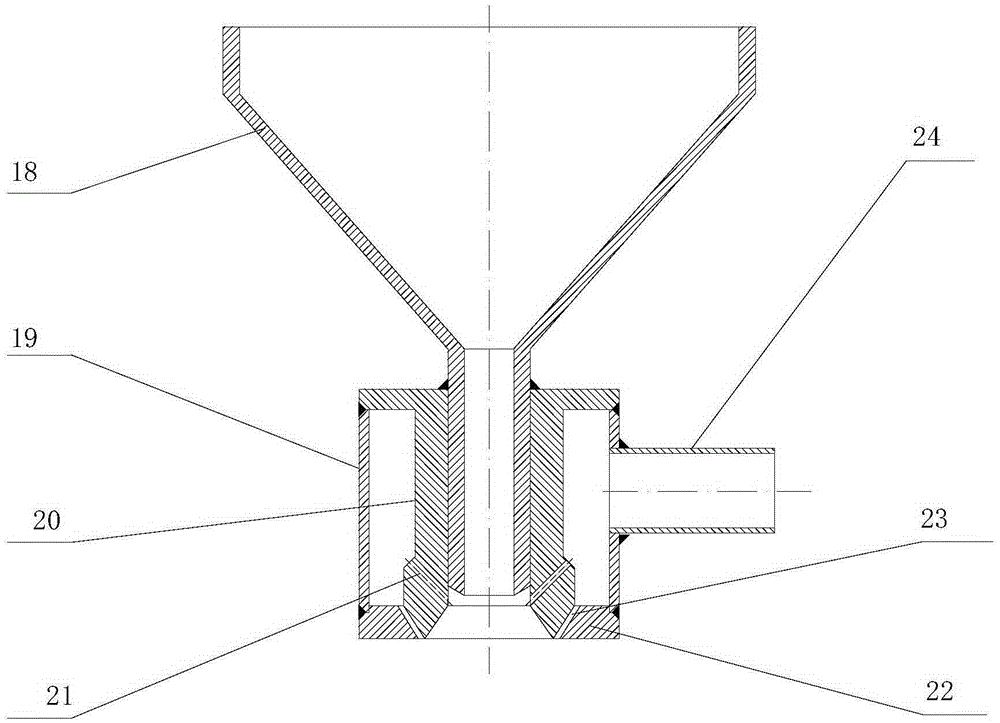

Device and method for waste heat recovery of high-temperature molten slag by means of two-step method

ActiveCN105277004AReduce energy consumptionReduce spacingEnergy industryIncreasing energy efficiencySuperheated steamQuenching

The invention provides a device for waste heat recovery of high-temperature molten slag by means of a two-step method. The device comprises a jet pelletizer, a pelletizing barrel and a granulating pit. The lower end of the pelletizing barrel is inserted in the granulating pit, and a liquid level difference is formed due to the difference of inner pressure and outer pressure of the lower end of the pelletizing barrel. The upper end of the pelletizing barrel is connected with a discharging opening of the jet pelletizer. The pelletizing barrel is communicated with a heat exchanger flue, an evaporator is arranged in the heat exchanger flue and connected with a steam bag through a condensation liquid descending pipe and a steam ascending pipe. Waste heat recovery is achieved by means of the two-step method, saturated steam jet pelletizing are firstly carried out on the high-temperature molten slag to form slag particles, superheated steam is generated, and high-grade waste heat is recovered; and water quenching is carried out before the slag particles are solidified, water granulated slag with the high glass phase content is obtained, and low-grade waste heat is recovered. The process is simple, the molten slag waste heat recovery rate is high, energy consumption is reduced, a few of devices are needed, and the size is small. The device can be widely applied to waste heat recovery of blast furnace slag, phosphorus slag and other high-temperature molten slag.

Owner:NANJING SHENGNUO HEAT PIPE

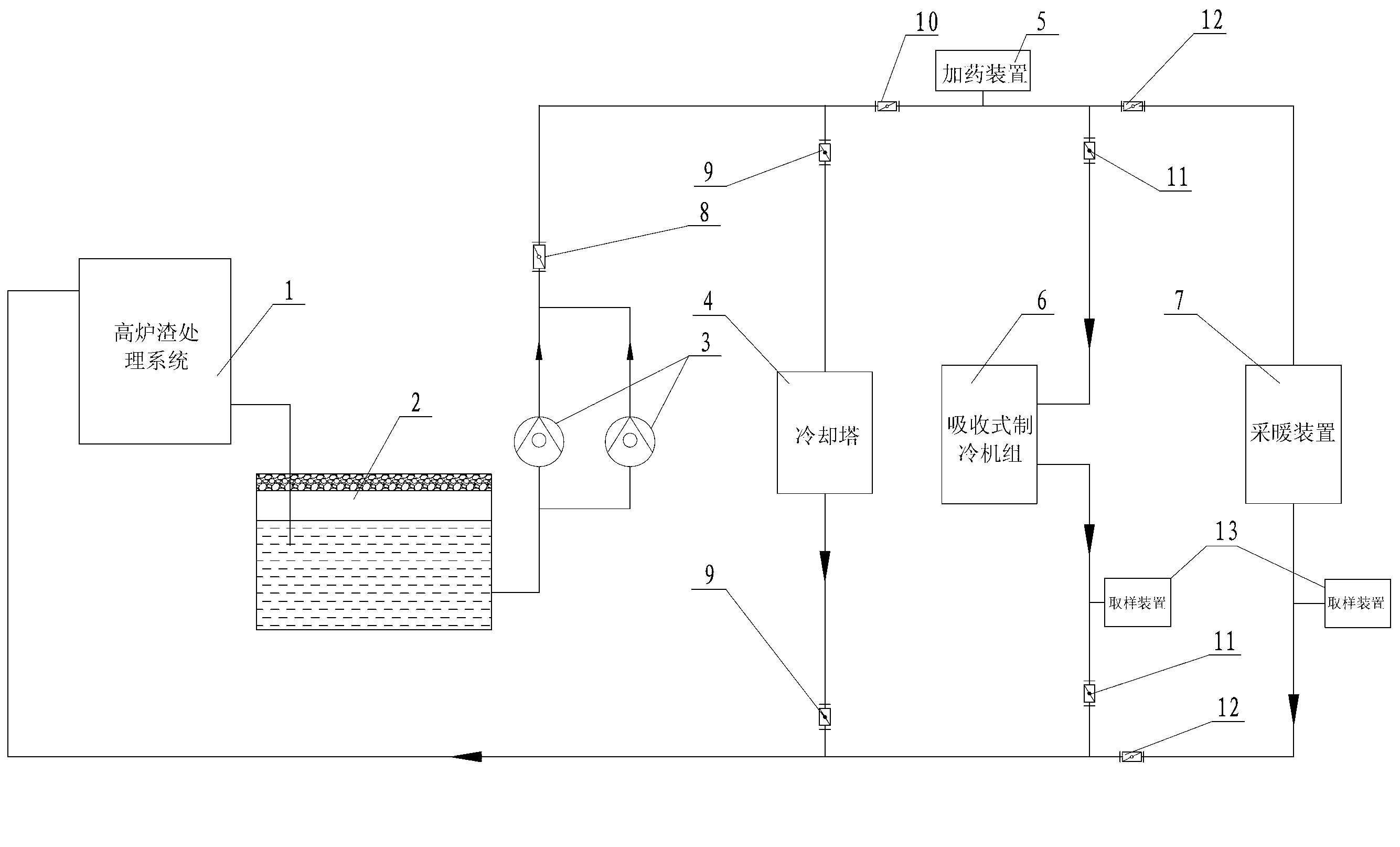

Method and system suitable for recovering waste heat of blast furnace slag flushing water

InactiveCN103060496AFix seasonalityImprove waste heat recovery rateIncreasing energy efficiencyRecycling and recovery technologiesCooling towerSlag

The invention relates to a method and a system suitable for recovering waste heat of blast furnace slag flushing water. The method comprises the following steps of: S1, filtering the high-temperature blast furnace slag flushing water and then storing in a hot water tank; S2, performing pressure delivery on the hot water; S3, delivering the hot water to an absorption refrigerating unit or a heating device or a cooling tower; and S4, delivering the water flowing out of the absorption refrigerating unit or the heating device or the cooling tower to a blast furnace slag treatment system to flush slag. The system comprises the blast furnace slag treatment system, the hot water tank and a circulating pump which are connected sequentially, and the cooling tower, the absorption refrigerating unit and the heating device which are connected in parallel. By adopting the method and the system, the low-temperature waste heat in the blast furnace slag flushing water can be fully utilized, so that the aims of energy conservation and environmental friendliness are fulfilled, the seasonal problem of the slag flushing water waste heat recovery is solved, and the recovery rate of the waste heat of the high-temperature slag flushing water is improved.

Owner:WISDRI ENG & RES INC LTD

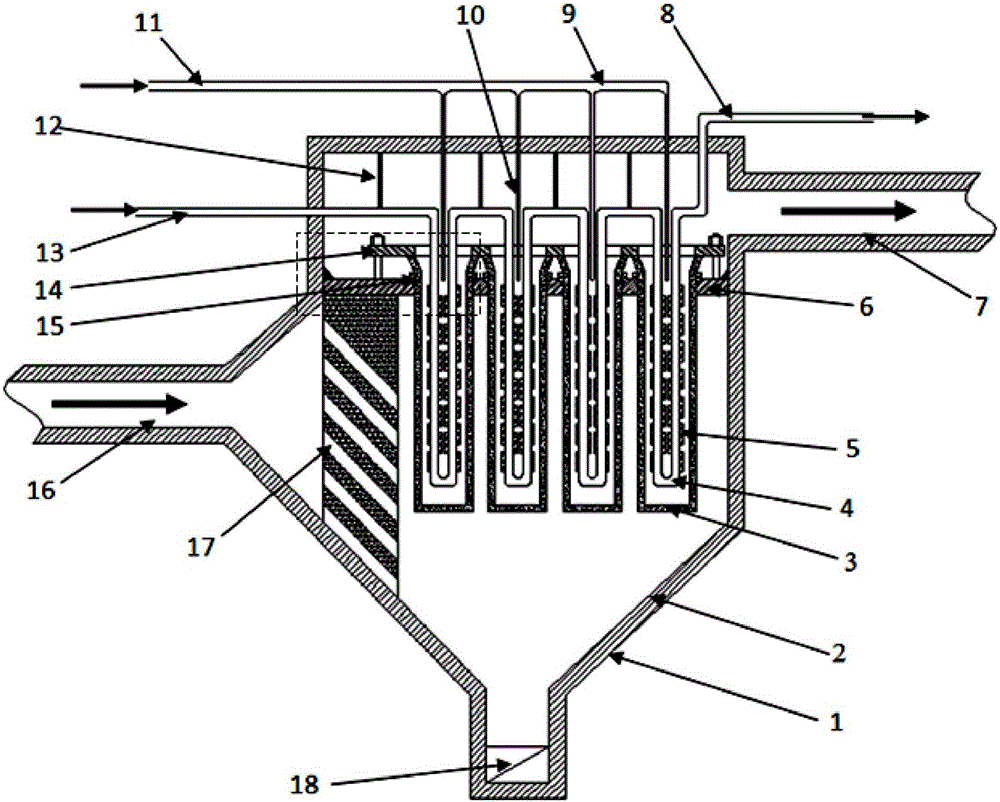

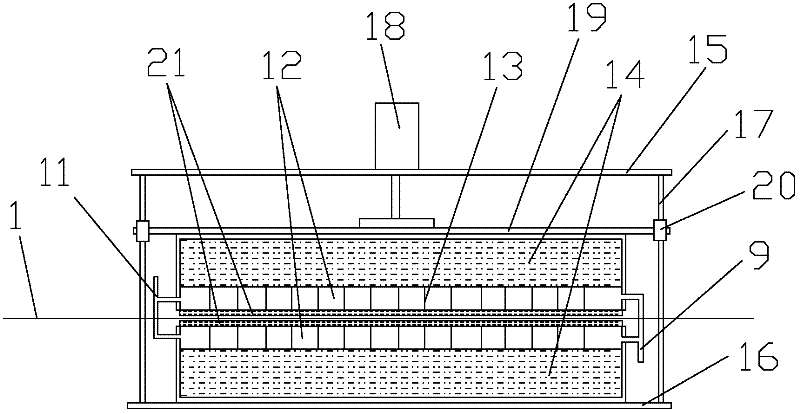

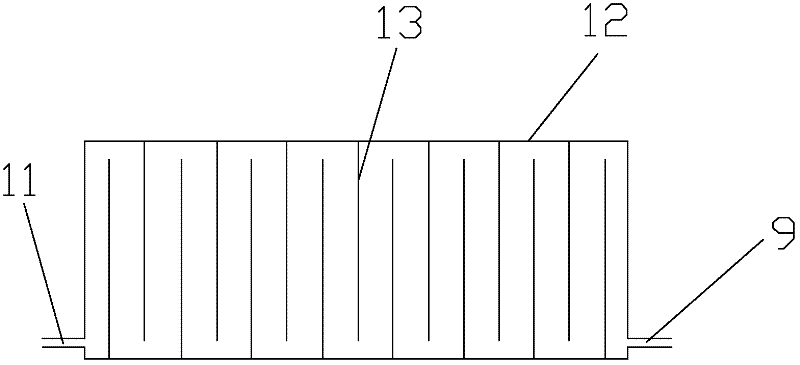

Smoke purification and heat exchange integration device

ActiveCN106482533AReduce the temperatureImprove waste heat recovery rateEnergy industryIncreasing energy efficiencyKilnFilter element

The invention discloses a smoke purification and heat exchange integration device, belongs to the technical field of smoke afterheat recovery devices, and is designed for solving such problems as low smoke afterheat recovery rate and bad damage of the smoke temperature fluctuation to filter elements in a traditional device. The smoke purification and heat exchange integration device comprises a shell, a tubesheet for dividing the shell into a dust collecting chamber and a smoke purifying chamber, a ceramic filter film pipe inserted in the tubesheet, a heat exchange pipe positioned in the ceramic filter film pipe, and a heat storage wall for storing smoke or releasing heat; a smoke inlet and a smoke outlet are respectively formed in two sides of the shell; the smoke inlet is communicated with the dust collecting chamber; the smoke outlet is communicated with the smoke purifying chamber; and the heat storage wall is positioned in the dust collecting chamber near the smoke inlet. The smoke purification and heat exchange integration device is suitable for dust removal and heat exchange of high-temperature smoke of an intermittent industrial kiln, can efficiently recover smoke afterheat, and reduces the heat vibration damage of the smoke temperature fluctuation to the filter elements.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

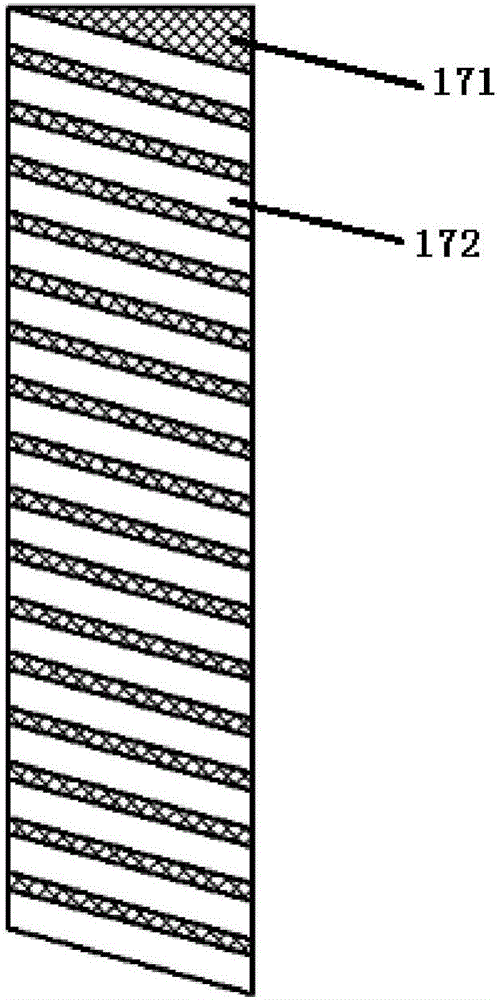

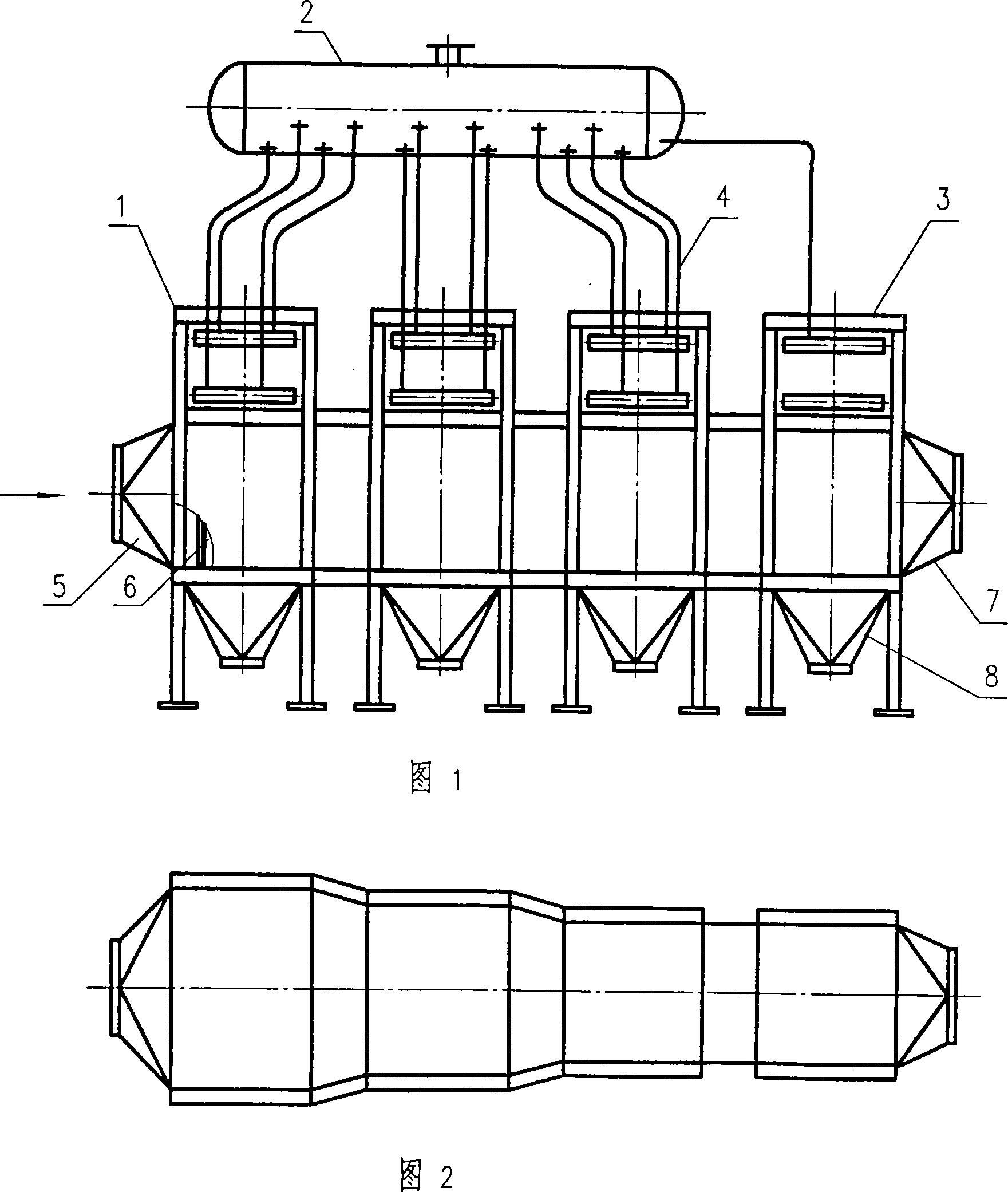

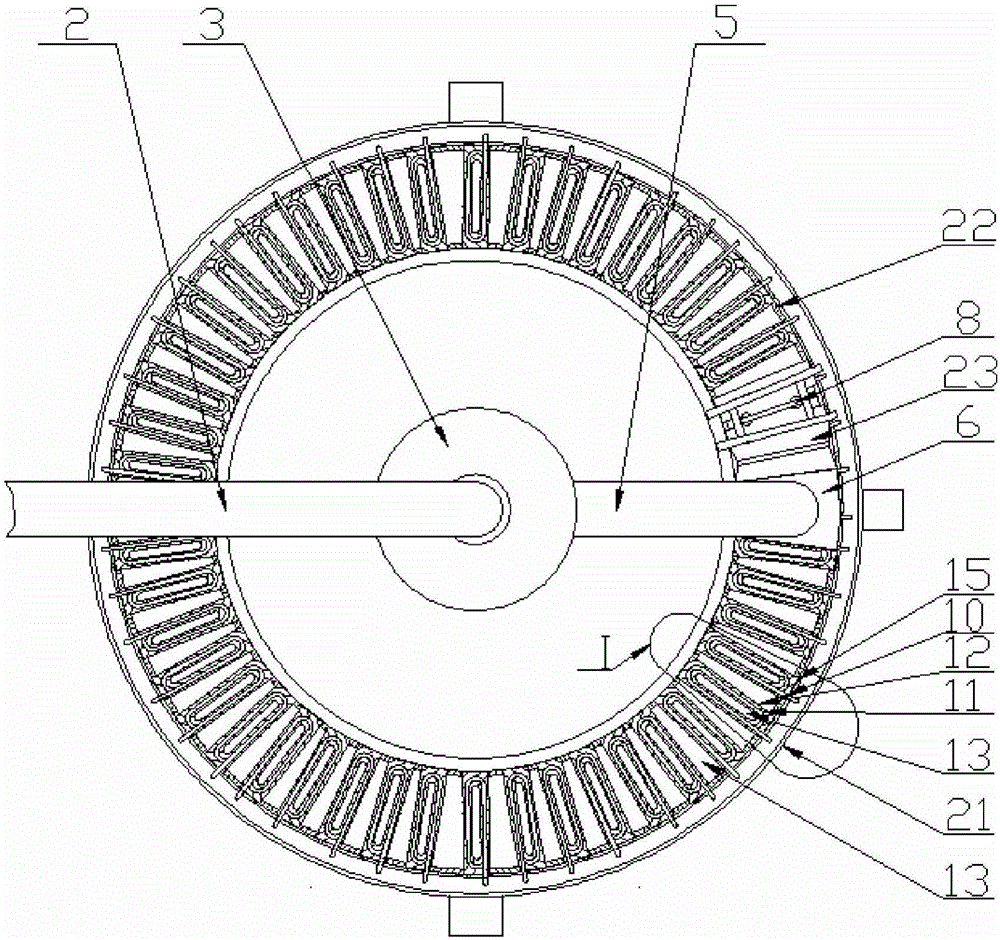

Revolving furnace, electric stove steel-smelting high-temperature gas cooling down heat-recovering steam producing energy conservation system device

InactiveCN101118053AImprove qualityGreat tasteSteam generation using hot heat carriersHeat transfer efficiencyEngineering

The present invention relates to a steel-making high temperature gas cooling waste heat recycling steam producing energy saving system device for a converter and an electric oven. The present invention is characterized in that the device comprises a plurality of steam generators (1) which are connected in series and whose the gas circulating section is decreased in cascade type, an inlet interface (5) is arranged at one end of the steam generator (1), an outlet interface (7) is arranged at the other end, a heat transfer element (6) is arranged inside the steam generator (1), and the steam generator (1) is connected with a steam drum through each steam-water connecting pipe (4). The steam generator system waste heat steam producing energy saving device which is arranged in a high temperature chimney neck makes the gas temperature in the chimney neck decrease from 1000 degrees centigrade to 180 degrees centigrade to discharge, meeting the purposes of waste heat reuse and energy conservation. The present invention has the advantages that heat transfer efficiency is improved, each part of the process is independently arranged dispersedly, the equipment cubage is small, the disassembly is convenient, and the routine maintenance and the servicing and repair are convenient.

Owner:NANJING SHENGNUO HEAT PIPE

Heat energy exchange device capable of saving energy of water heater

PendingCN110017718AImprove waste heat recovery rateRaise the water temperatureFluid heatersHeat recovery systemsWater flowEngineering

The invention relates to a heat energy exchange device capable of saving energy of a water heater. The device comprises an upper cover, a heat exchange plate module, a heat exchange tube module and abase, the top surface of the upper cover is provided with a water inlet, the bottom surface close to the base is provided with a water outlet, the heat exchange plate module is arranged below the water inlet of the upper cover and connected with the heat exchange tube module to form a closed communication water path, and is placed inside the base together, shower hot water flowing in through the water inlet of the upper cover firstly touches the heat exchange plate module, so that normal-temperature water preheated by the heat exchange tube module in the shower hot water can be guided to a water inlet of the water heater immediately after obtaining the heat exchange of highest-temperature heat energy, and therefore the energy consumption of the water heater can be greatly saved.

Owner:蔡应麟 +1

Progressive switchover heat storage type combustion device

InactiveCN104456569ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustor

The invention relates to a progressive switchover heat storage type combustion device. The progressive switchover heat storage type combustion device comprises at least five heat storage type combustors connected with a hearth and a controller capable of controlling the heat storage type combustors. The controller switches over the heat storage type combustors, so that the heat storage type combustors are alternately used for combustion or smoke exhaust, and the number of the heat storage type combustors used for smoke exhaust is made to be larger than that of the heat storage type combustors for combustion at any moment; in combustion production, when the controller switches over any heat storage type combustor, at least another heat storage type combustor maintains combustion work. Compared with the prior art, in the steering process of the device, the phenomena of detonation and furnace blast are effectively avoided, the safety performance is better, and the energy-saving effect is more obvious.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

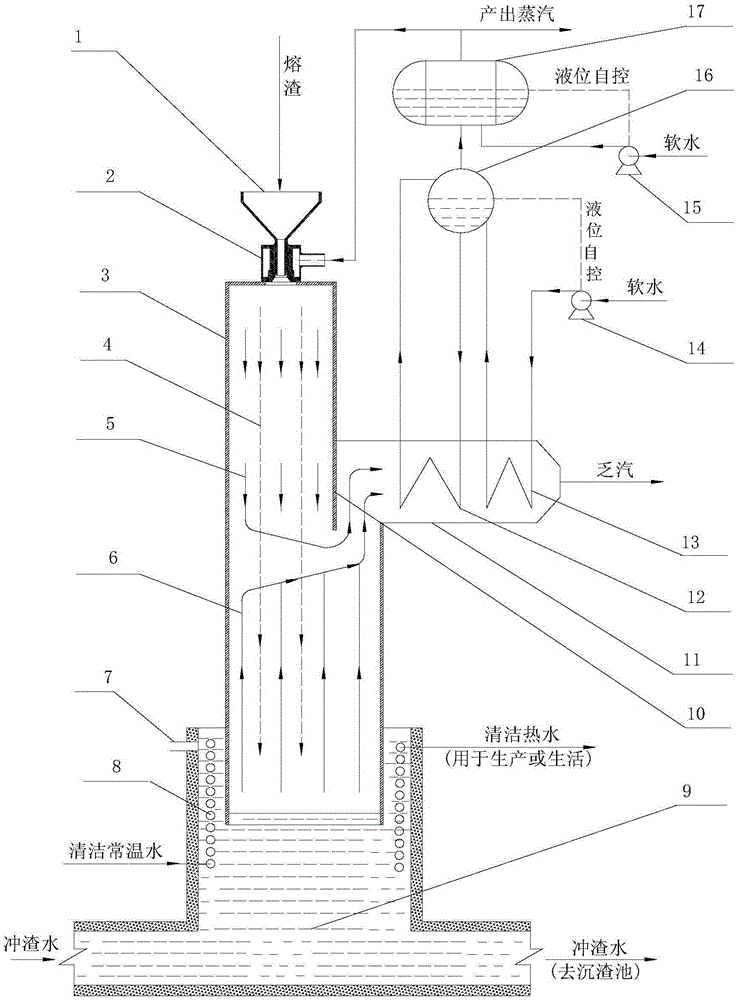

Melting slag waste heat recovery system

ActiveCN106676214ASimple structureCompact layoutIncreasing energy efficiencyWaste heat treatmentWaste heat recovery unitSlag

The invention discloses a melting slag waste heat recovery system. The melting slag waste heat recovery system comprises a melting slag feeding system, a melting slag heat exchanging device and a vapor-water system. The melting slag heat exchanging device is composed of at least one heat exchanging unit. Each exchanging unit adopts one of four structures, specifically, a melting slag injector is arranged at the output end of the melting slag feeding system, and the melting slag injector is arranged above an upper material opening; the melting slag heat exchanging device and the melting slag heat exchanging system are of moving type structures or static type structures according to practical requirements; when the vapor-water system is matched with the melting slag heat exchanging device of the static type structure, the vapor-water system is composed of a water inlet pipe connector, a water inlet pipe, a water outlet pipe connector and a water outlet pipe; and when the vapor-water system is matched with the melting slag heat exchanging device of the moving type structure, the vapor-water system is composed of the water inlet pipe connector, the water inlet pipe, the water outlet pipe connector, the water outlet pipe and a pressure resistant deformable pipe or a rotating joint. The melting slag waste heat recovery system has the advantages of simple and reasonable in structure, compact in arrangement, small in occupied area, low in investment, high in waste heat recovery rate and the like.

Owner:徐州企润食品有限公司

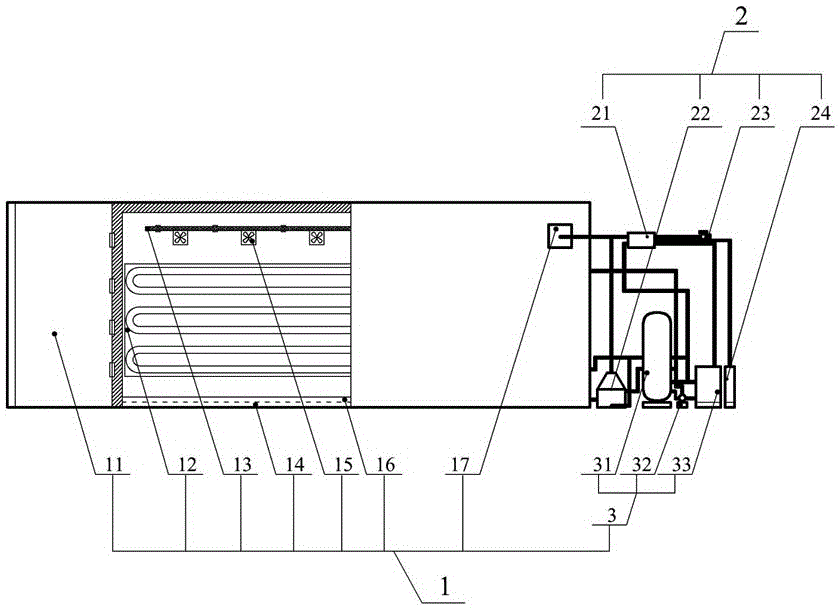

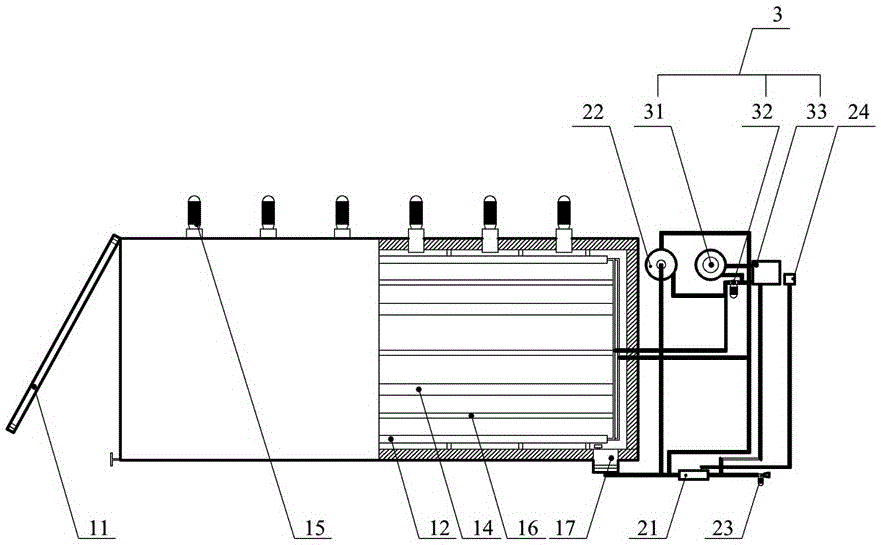

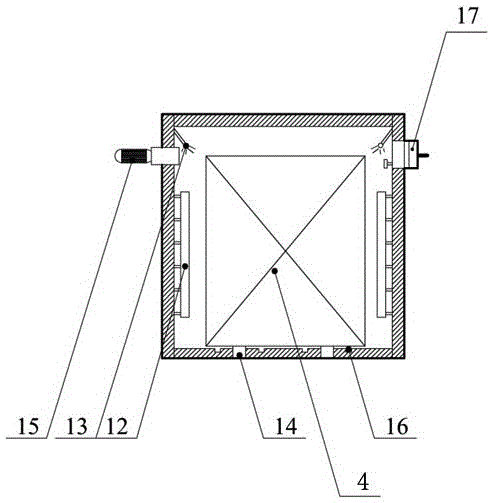

Camphorwood vaporization water vapor drying and essential oil and waste heat recycling device and using method

PendingCN107525356AHumidity parametric controlHigh control precisionDrying gas arrangementsEssential-oils/perfumesHigh humidityWater vapor

The invention discloses a camphorwood vaporization water vapor drying and essential oil and waste heat recycling device and a using method. The camphorwood vaporization water vapor drying and essential oil and waste heat recycling device comprises a high-temperature drying chamber, an essential oil and waste heat recycling assembly and a heat source assembly. A drying chamber door is arranged at the front end of the high-temperature drying chamber. Cooling fin assemblies and steam-injection assemblies are arranged in the high-temperature drying chamber. Bottom rails and condensed water recycling channels are formed in the bottom of the high-temperature drying chamber. A fan assembly is arranged on the upper portion of one side of the high-temperature drying chamber, and a micro-pressure self-discharging assembly extending to the outside is arranged on the upper portion of the other side of the high-temperature drying chamber. The essential oil and waste heat recycling assembly is connected with the condensed water recycling channels and the micro-pressure self-discharging assembly. The heat source assembly is connected with the essential oil and waste heat recycling assembly and the cooling fin assemblies. The using method comprises the following steps that S1, camphorwood is put in the drying chamber; S2, high-humidity preheating is conducted; S3, drying is conducted, and essential oil and waste heat are recycled; S4, cooling treatment is conducted; S5, high-humidity balance treatment is conducted; and S6, the camphorwood is taken out of the drying chamber. The camphorwood vaporization water vapor drying and essential oil and waste heat recycling device and the using method have the advantages that the drying period is short, emission of waste gas is avoided, and the camphorwood essential oil and the drying waste heat can be recycled.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

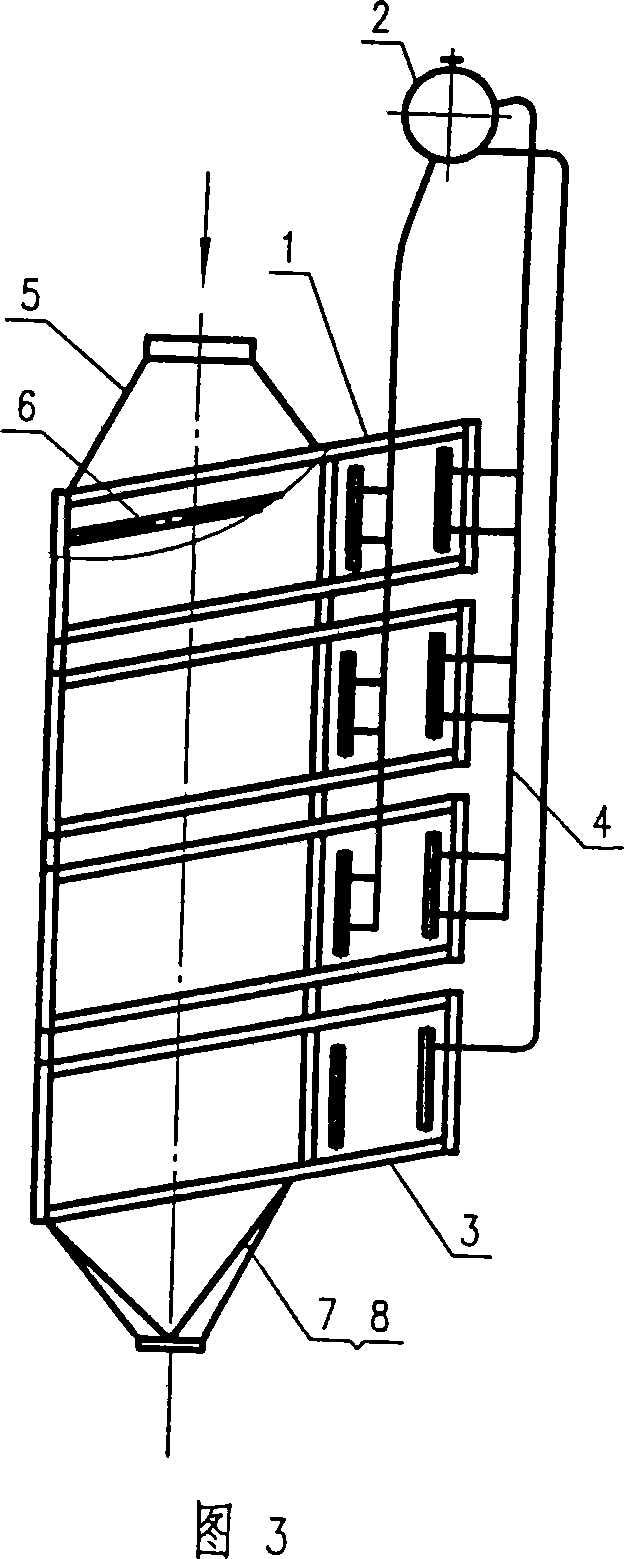

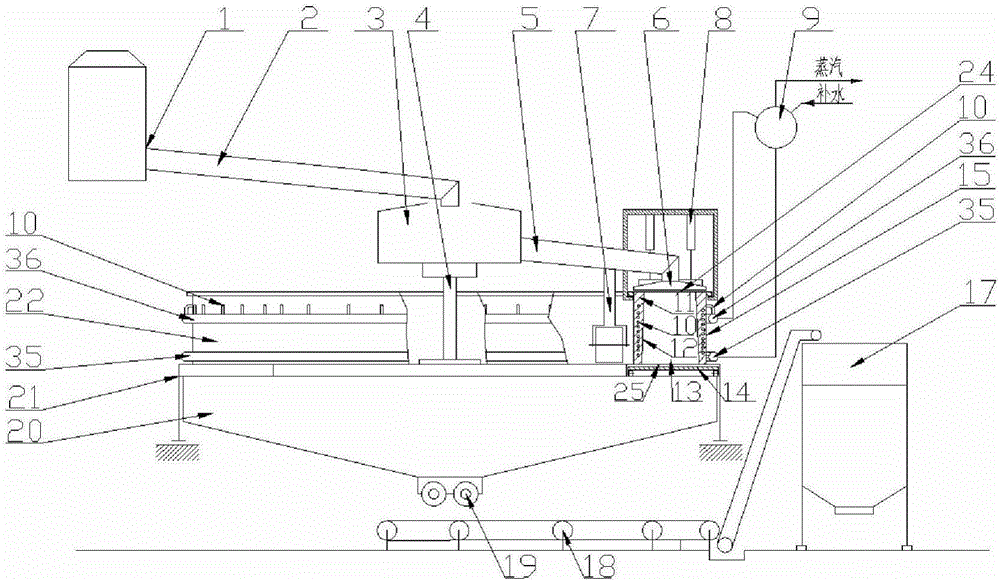

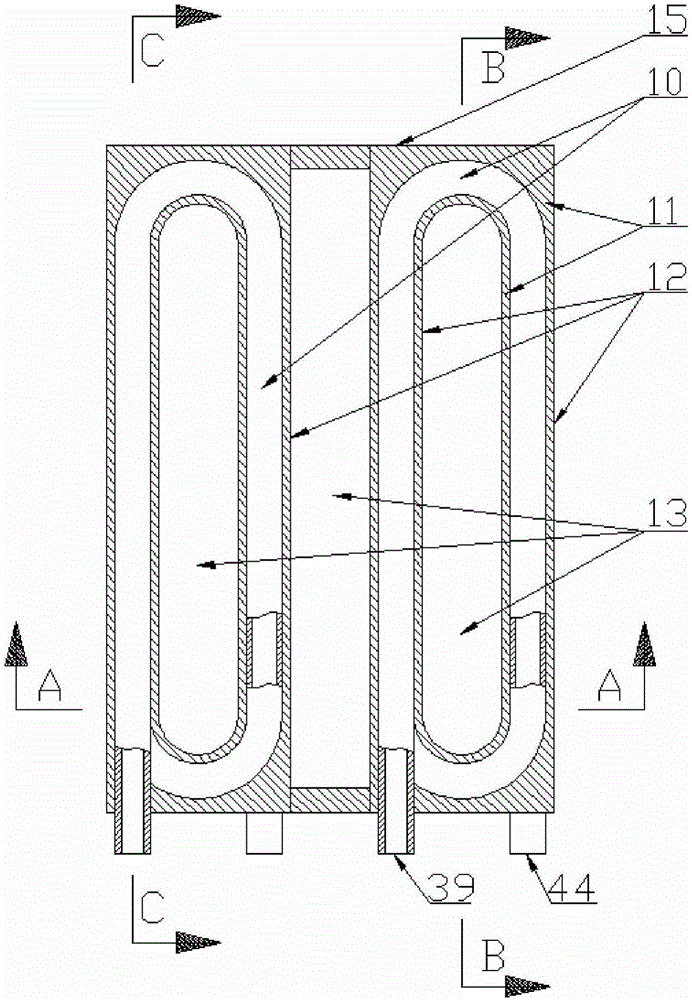

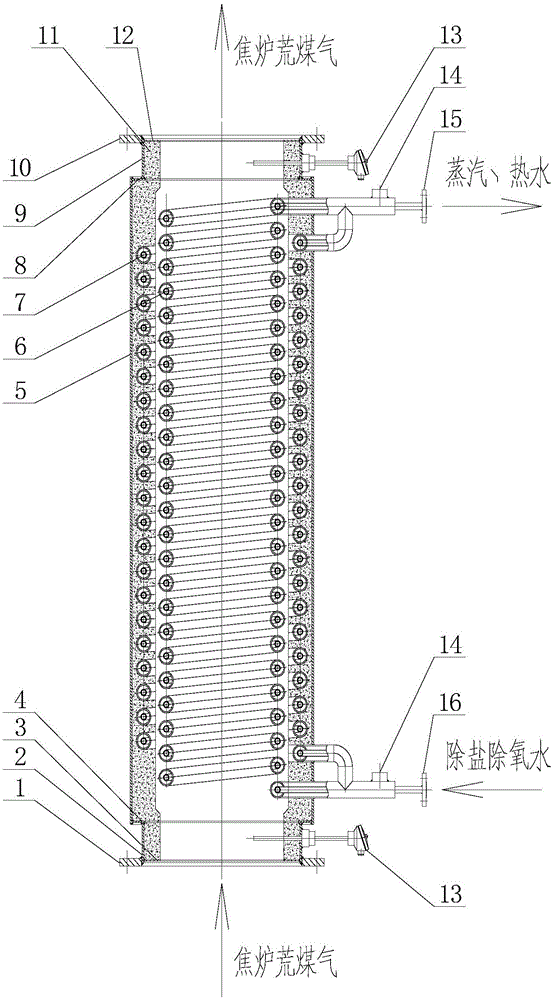

Cokery raw gas riser pipe high-efficiency waste heat recovery device

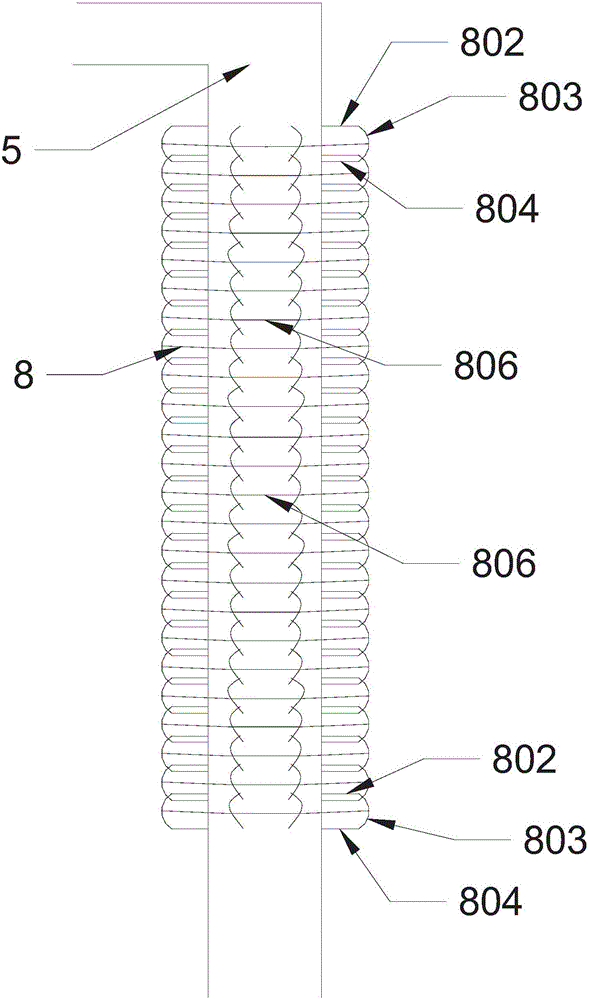

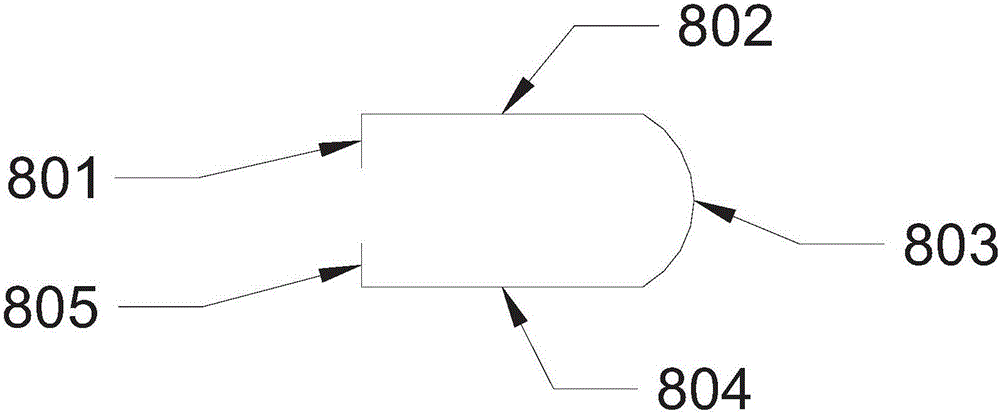

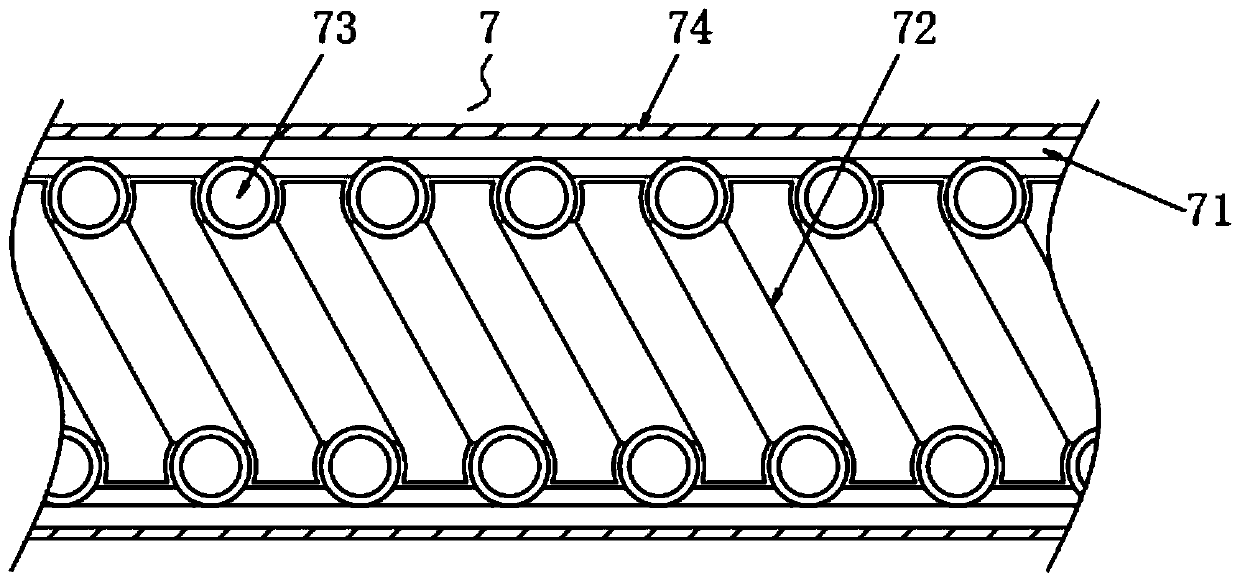

ActiveCN106190189ASimple structureEasy to useRecuperative heat exchangersEnergy inputWaste heat recovery unitEngineering

The invention relates to a cokery raw gas riser pipe high-efficiency waste heat recovery device which comprises an outer pipe, an upper connecting pipe, a lower connecting pipe, an upper flange and a lower flange, wherein a heat insulating material is respectively annularly arranged on the inner walls of the upper connecting pipe, outer pipe and lower connecting pipe; a plurality of outer annular heat exchange tubes are arranged in the heat insulating material from top to bottom; an inner heat exchange tube is arranged on the inner ring of the outer heat exchange tubes in the outer tube body; the orifice on one end of the outer heat exchange tube and the orifice on one end of the inner heat exchange tube are merged and connected to an outlet pipe; the orifice on the other end of the outer heat exchange tube and the orifice on the other end of the inner heat exchange tube are merged and connected to an inlet pipe; and the inlet pipe and outlet pipe are respectively provided with a remote pressure monitoring alarm device port. The device is simple in structure; the inner heat exchange tube is added to increase the heat exchange area and enhance the waste heat recovery rate, so that the overall waste heat recovery efficiency is greatly enhanced; and the remote pressure monitoring alarm device port is added to prevent the cokery accidents caused by leakage of the heat exchange tube.

Owner:无锡金龙石化冶金设备制造有限公司

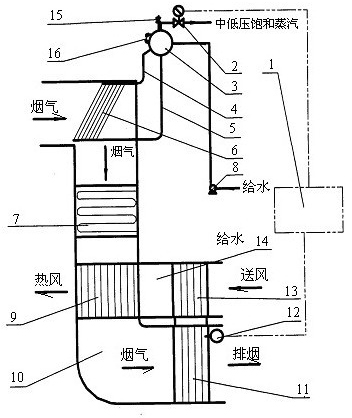

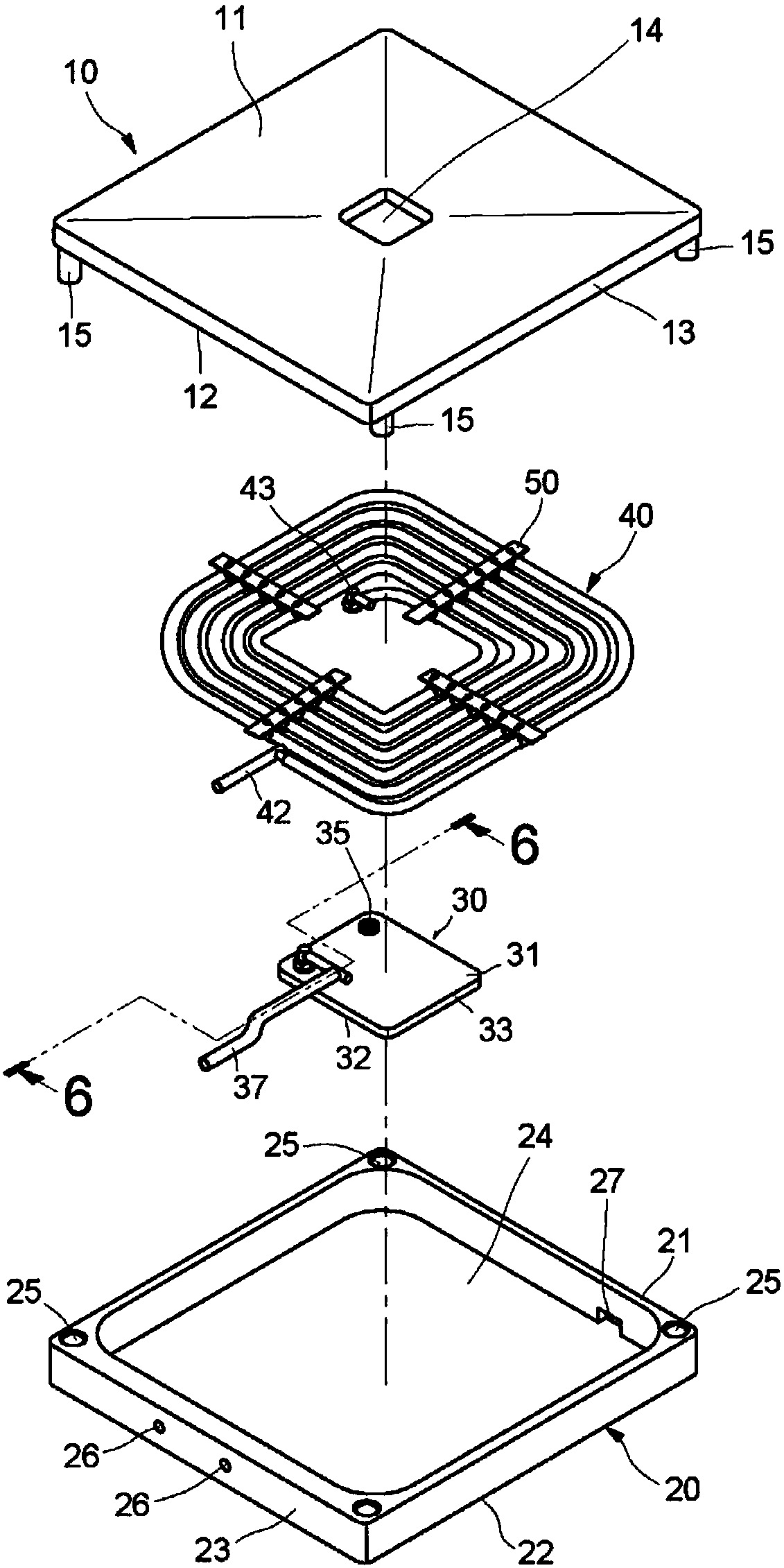

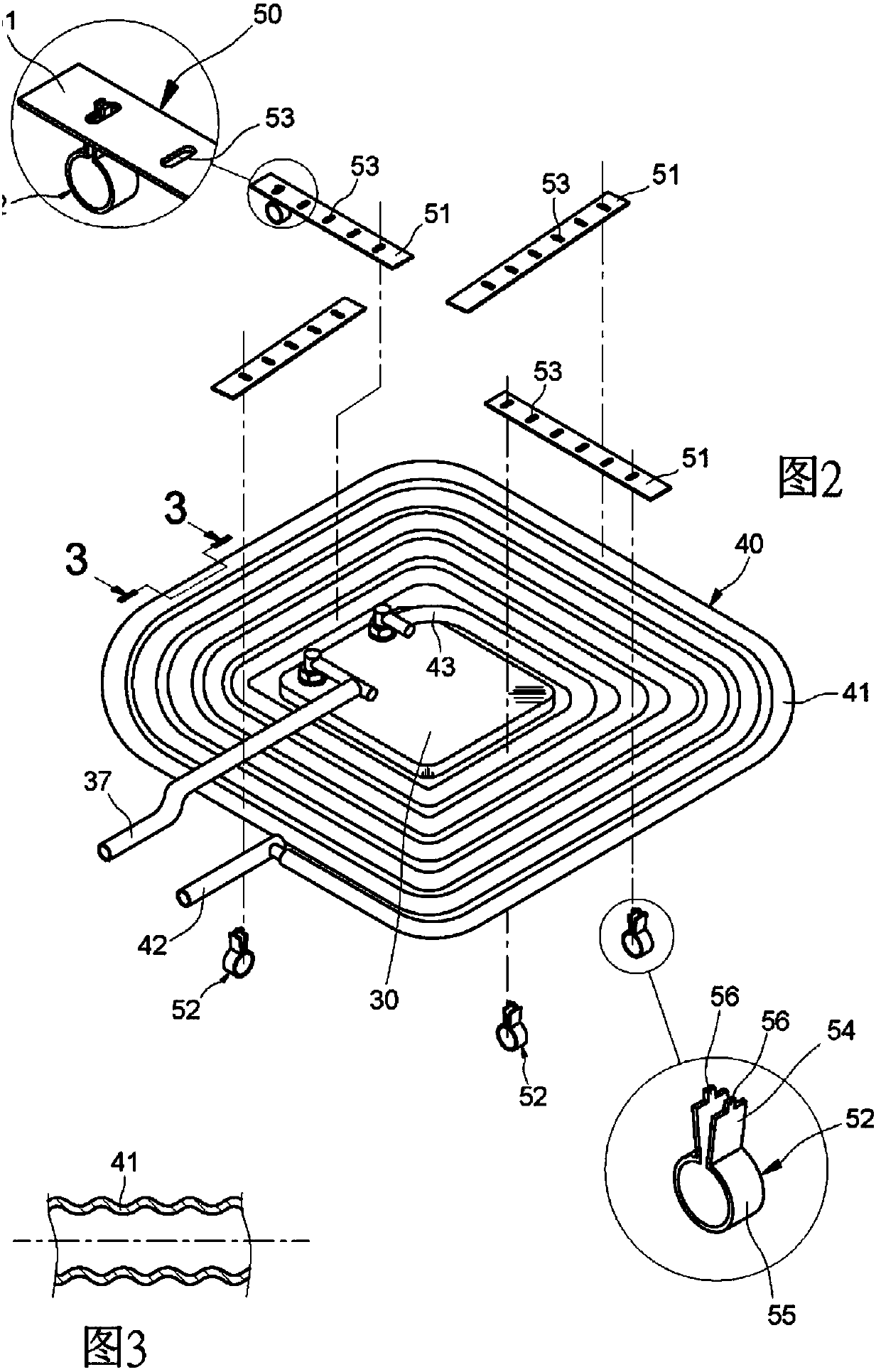

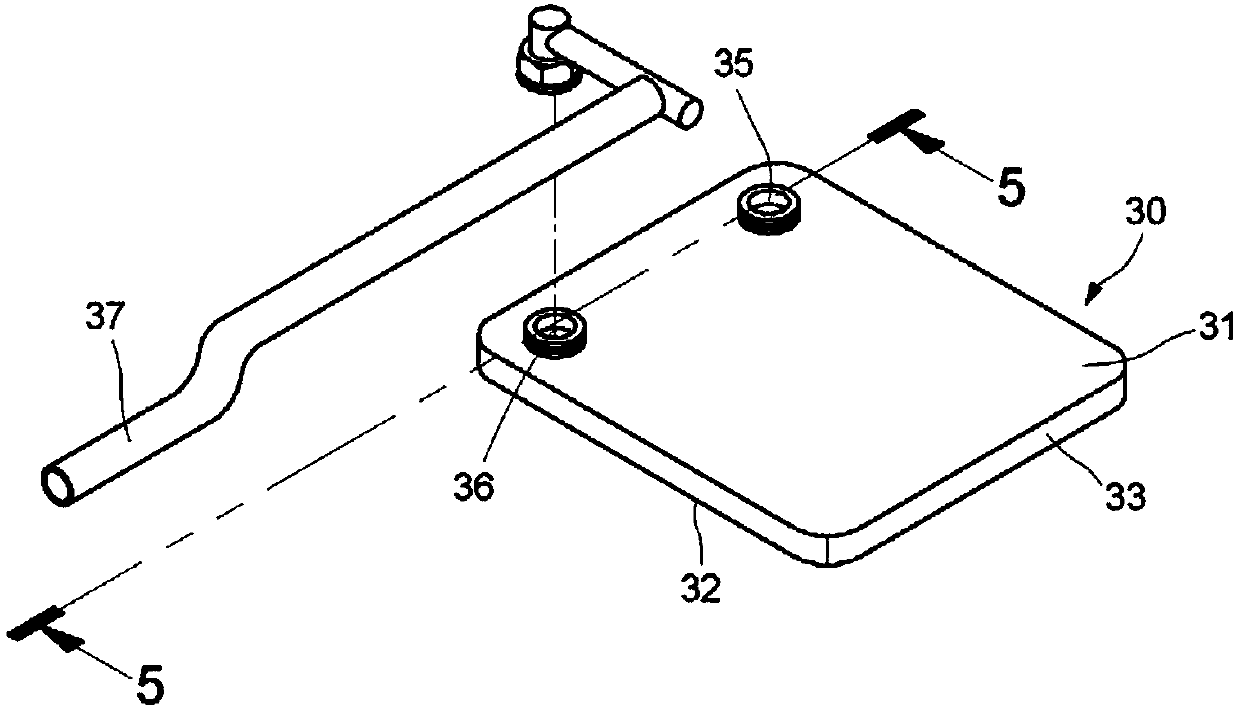

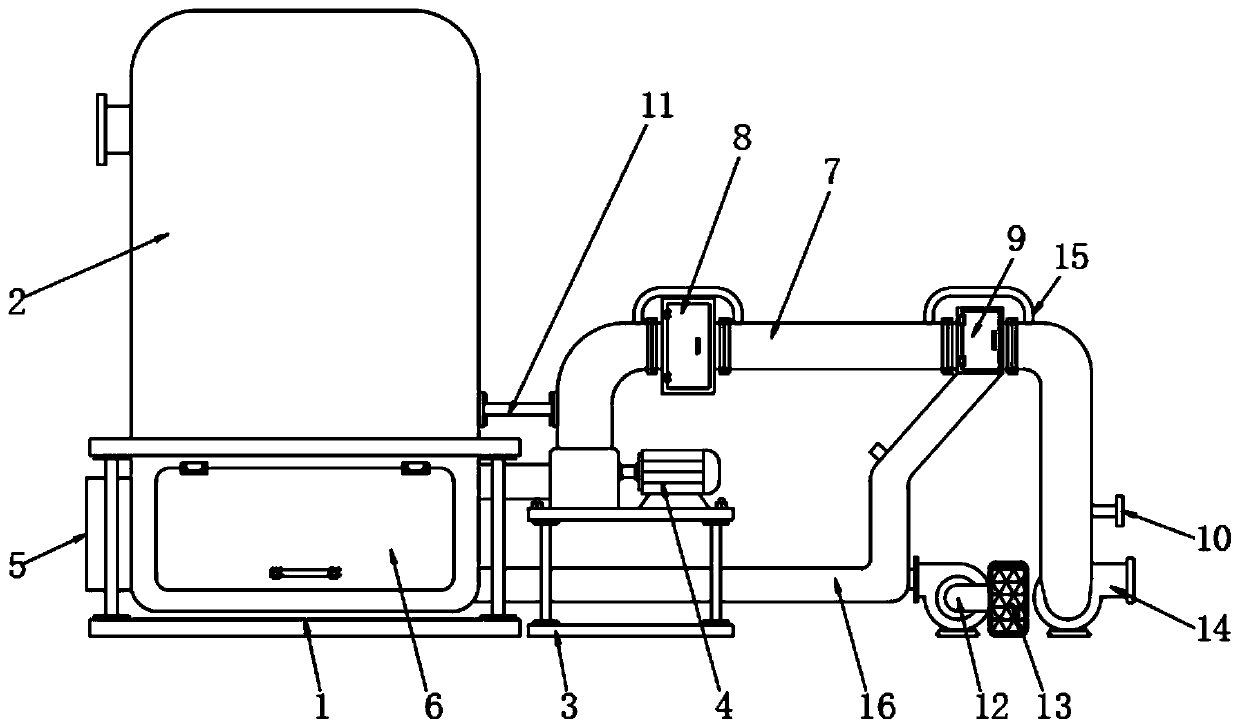

Boiler afterheat recovery system with vertical low-resistance cooling system

ActiveCN106224932AAvoid cloggingIncrease contact heat transfer areaEnergy industryIncreasing energy efficiencyHigh densityEngineering

The invention discloses a boiler afterheat recovery system with a vertical low-resistance cooling system. The boiler afterheat recovery system comprises a boiler, afterheat recovery equipment, a smoke treatment device and a steam tank; the afterheat recovery equipment includes a heat exchange module, a first heat exchange pipe, a second heat exchange pipe and a heat exchange water tank; a first circulating pump is arranged between the heat exchange module and the first heat exchange pipe; the heat exchange module, the first heat exchange pipe and the first circulating pump form a refrigerant circulating loop; a first induced draft fan is arranged between a cyclone dust remover and the second heat exchange pipe; an intake pipe of the cyclone dust remover is communicated with a smoke outlet of the boiler; an exhaust pipe of the cyclone dust remover is communicated with an intake port of the second heat exchange pipe through the first induced draft fan; an exhaust port of the second heat exchange pipe is connected with the smoke treatment device by a second induced draft fan; multiple layers and multiple rows of high-density linear bent heat exchange pieces are arranged on the surface of the middle part of the second heat exchange pipe; the smoke treatment device comprises a filter chamber; a spraying device is arranged on the middle inner wall; and a settling pool is arranged at the lower end. The boiler afterheat recovery system is better in heat exchange effect, higher in afterheat recovery rate and more environment-friendly.

Owner:SUZHOU BSE AIR CONDITIONER

Boiler discharge flue waste heat recovery device and boiler discharge flue waste heat recovery method

PendingCN111006236AReduce flow rateHigh recovery rateLighting and heating apparatusCombustion technology mitigationFlueProcess engineering

The invention discloses a boiler discharge flue waste heat recovery device and a boiler discharge flue waste heat recovery method. The device comprises a first mounting frame and a second mounting frame, wherein the first mounting frame and the second mounting frame are arranged side by side, a boiler is fixedly connected to the interior of the first mounting frame, the upper surface of the secondmounting frame is fixedly connected with a first fan, a material inlet pipe is fixedly connected to the bottom of the side surface of the boiler, a rotating door is hinged to the bottom end of the front surface of the boiler through a hinge, the gas inlet of a first fan is fixedly connected with the boiler, and the gas outlet of the first fan is fixedly connected with a waste heat recovery pipe.The invention relates to the technical field of boiler equipment. According to the invention, heat in flue gas is recovered through the waste heat recovery pipe, the flow speed of the flue gas in thepipeline can be reduced through the speed reduction box, and the flue gas can rotate in the pipeline through the spiral groove, so that the contact area and the contact time of the flue gas and the pipeline can be increased.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

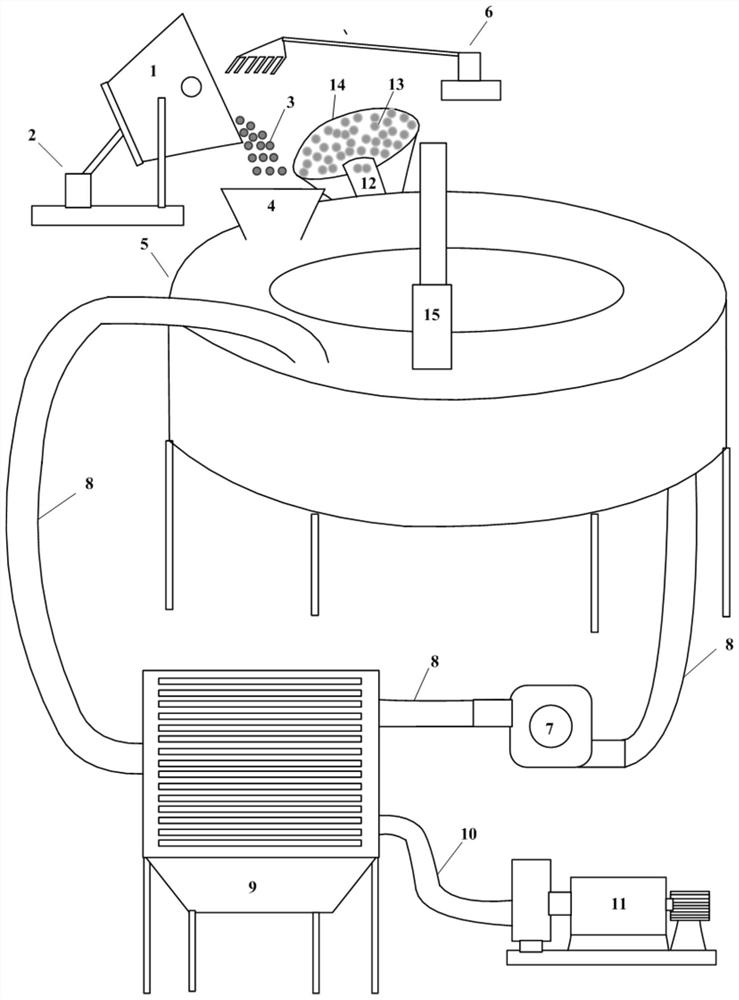

Device for preparing hydrogen-rich gas by gasifying biomass under catalysis of high-temperature metallurgical slag particles and method

ActiveCN104192799ASimple structureEasy to implement and useHydrogenEnergy inputChemical energyMetallurgical slag

The invention relates to a device for preparing hydrogen-rich gas by gasifying a biomass under the catalysis of high-temperature metallurgical slag particles and a method. The device comprises a downer reactor, a high-temperature slag particle storage chamber, a spiral biomass raw material feeder, a separator, a steam generator and a hydrogen-rich gas collector, wherein the high-temperature slag particle storage chamber and the spiral biomass raw material feeder are located above the downer reactor and are communicated with the top of the downer reactor; the separator is located below the downer reactor and is communicated with the bottom of the downer reactor; and the steam generator and the hydrogen-rich gas collector are located at two sides of the downer reactor and are respectively communicated with the downer reactor. The method in which the device is applied comprises the steps of respectively adding high-temperature metallurgical slag particles, biomass raw materials and steam into the downer reactor through a rotary molten slag granulating device, the spiral biomass raw material feeder and the steam generator; carrying out gasification reaction on the biomass raw materials under the catalysis of the high-temperature metallurgical slag particles to generate hydrogen-rich gas; and storing the hydrogen-rich gas into the hydrogen-rich gas collector. By using the method, waste heat of metallurgical slag is recycled in a chemical energy way, so that the recovery rate of the waste heat is relatively high, and the problems of low waste heat recovery rate and low recovery quality of a dry-method metallurgical slag treatment process are solved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

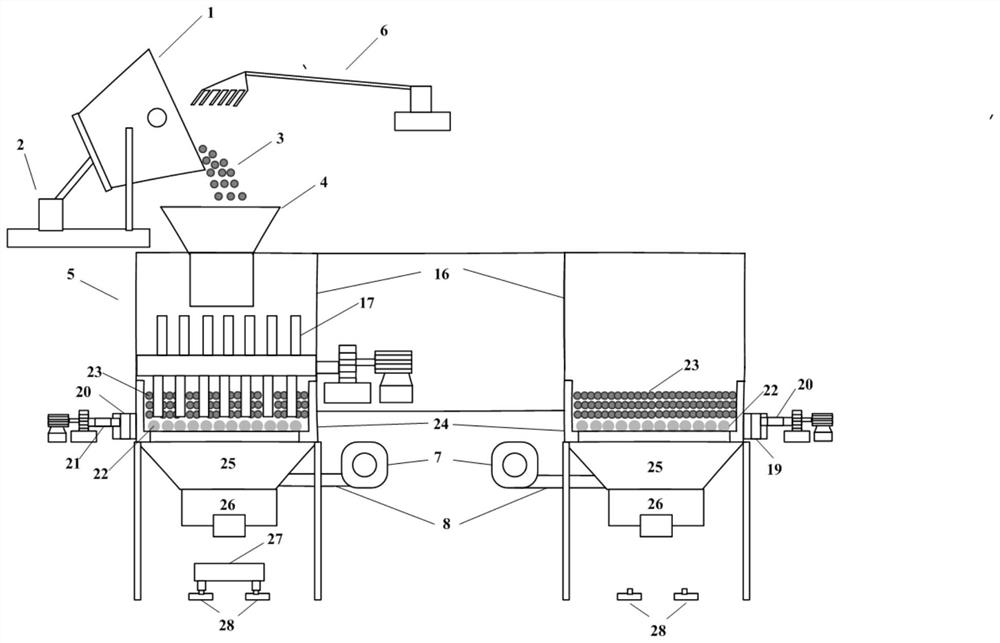

High-temperature steel slag rotating bed crushing waste heat recovery device and method

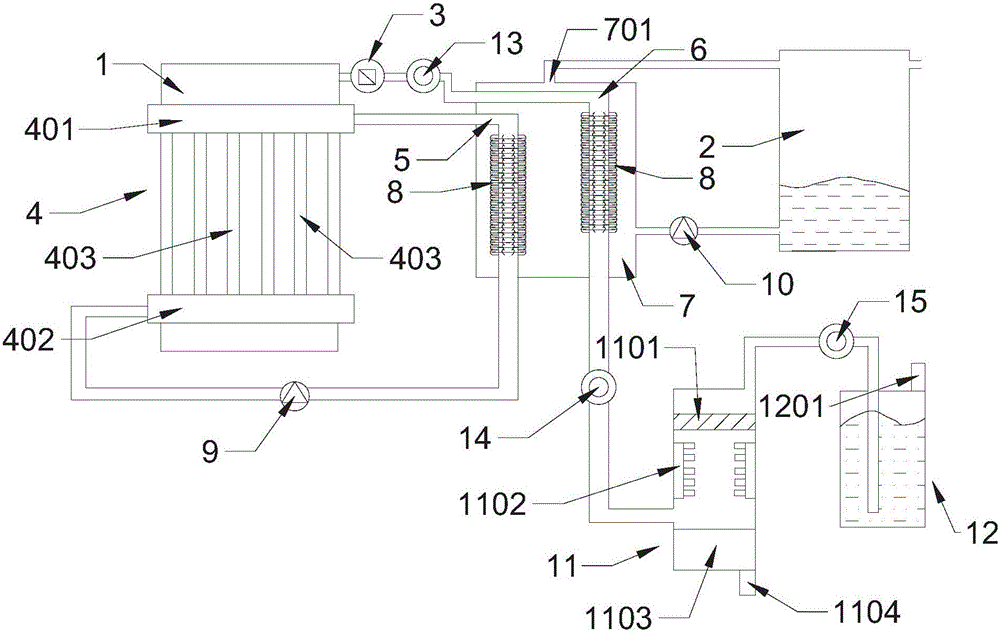

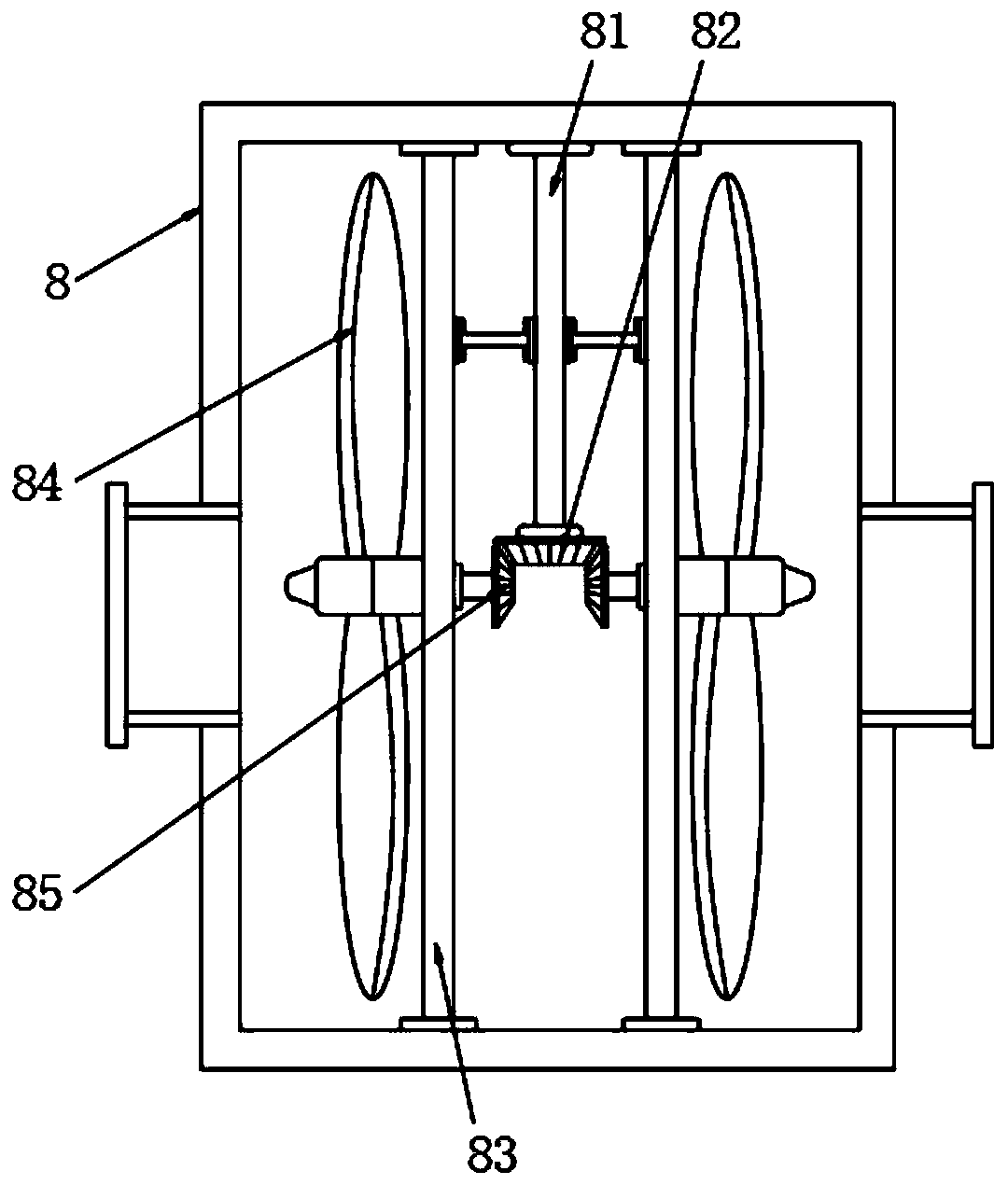

PendingCN113061673AImprove processing efficiencyImprove crushing effectRecycling and recovery technologiesProcess efficiency improvementLiquid slagDust control

The invention provides a high-temperature steel slag rotating bed crushing waste heat recovery device and method. The high-temperature steel slag rotating bed crushing waste heat recovery device comprises a liquid slag tank (1), a slag pouring machine (2), a rotating bed (5), a slag pulling machine (6), a circulating fan (7), an air pipe (8), a heat exchanger (9), a steam pipe (10), a power generator (11) and a solid slag tank (14), wherein the liquid slag tank (1) is arranged on the slag pouring machine (2) in a pouring mode, and the slag pulling machine (6) is arranged above the rotating bed (5); and the circulating fan (7) is connected with the rotating bed (5) and the heat exchanger (9) through the air pipe (8), the heat exchanger (9) is connected with the power generator (11) through the steam pipe (10), the rotating bed (5) is rotationally arranged between the slag pouring machine (2) and the circulating fan (7), and steel slag is cooled and discharged through the rotating bed (5). The device and method greatly solve the problem about discharge in the steel slag treatment process, greatly reduce the investment of public and auxiliary facilities such as water and dust removal, effectively reduce the steel slag production and operation cost, and improve the system income.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

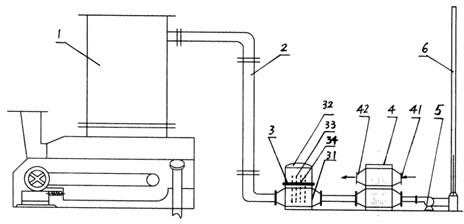

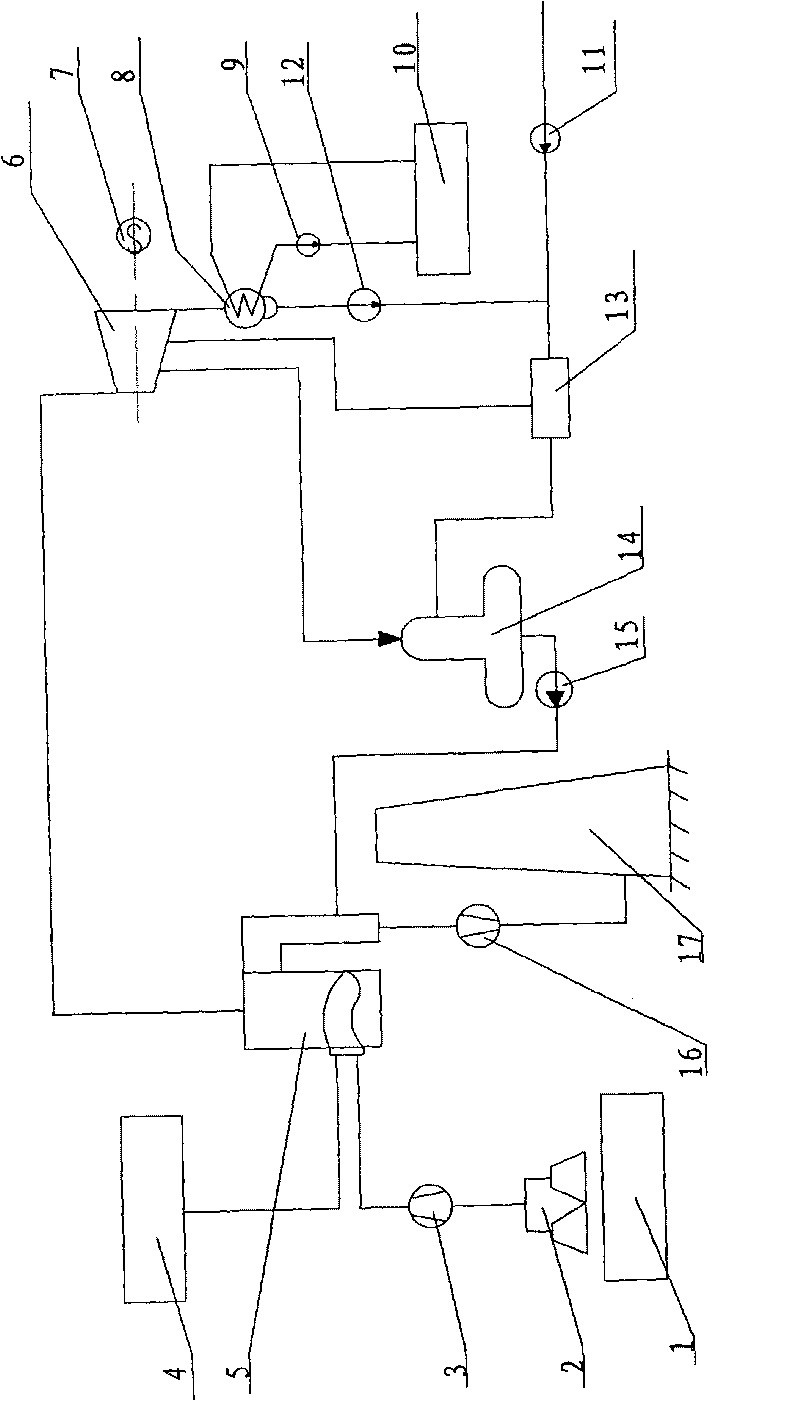

Sintering ore cooling waste gas full combustion-supporting generating set

InactiveCN101699038AImprove waste heat recovery rateSave land resourcesSteam engine plantsCombustion chamberWater supply

The invention relates to a method for reclaiming sintering ore cooling waste gas low-temperature waste heat, in particular to a sintering ore cooling waste gas full combustion-supporting generating set, which comprises a fuel supply system forming a conventional fuel boiler generating system, a generating boiler, a steam turbine, a generator, a condenser, a circulating water pump, a cooling tower, a water supplementing pump, a condensed water pump, a low-pressure heater, a deaerator, a water supply pump, a draft fan and a chimney, and also comprises a sintering ore cooling waste gas collector and a waste gas pressurizer, wherein the waste gas collector is placed above a sintering machine of which a water gas output pipe is connected with a combustion chamber of the generating boiler, and the water gas output pipe is provided with the waste gas pressurizer. The device has the advantages that: the reclaiming rate of the waste heat of the sintering ore cooling waste gas is greatly improved, the waste heat grade of the sintering ore cooling waste gas is greatly improved, the basic Rankine cycle efficiency of the generating system is greatly improved, the vast disposable investment and precious land resources are saved, the running expense of the generating system is greatly reduced, and the management fee of the generating system is greatly reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

System for deeply recovering smoke waste heat through absorbing type heat pump and two-stage heat exchanger

InactiveCN109974062ATake advantage ofImprove waste heat recovery rateGas treatmentRecuperative heat exchangersPlate heat exchangerRecuperator

The invention provides a system for deeply recovering smoke waste heat through an absorbing type heat pump and a two-stage heat exchanger, and belongs to the technical field of recovering and utilizing of smoke waste heat of boilers of thermal power plants. The system comprises a smoke channel, a waste heat recovering tower, the absorbing type heat pump and a heat exchanger; smoke in a reverse flowing type spraying tower is in direct contact with low-temperature spraying water and exchanges heat with the low-temperature spraying water; after temperature increases, the spraying circulating water transfers heat to the cold end of the absorbing type heat pump through a two-stage plate type heat exchanger; heat recovered by the heat pump from the cold is used for heating returned by a primarynet of the hot end under the driving of a driving heat source; and water recovered by a heat supply network is heated to reach the temperature as requirement and then is returned to the heat supply network. Compared with the prior art, the system has the advantages that the absorbing type heat pump is combined with the heat exchanger to recover smoke waste heat, and the smoke exhausting temperature can be decreased to be 20-30 DEG C, and thus the sensible heat and the potential heat in the smoke can be fully utilized; the waste heat recovery rate is high; the system efficiency is improved; andmeanwhile, the system is high in economy, efficiency and environmental protection performance.

Owner:DALIAN UNIV OF TECH

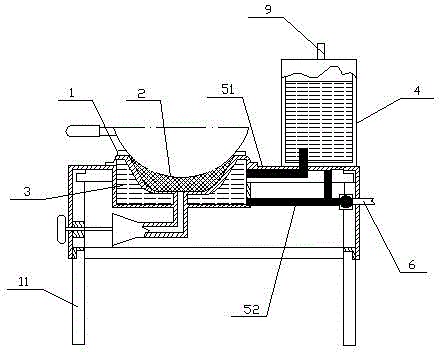

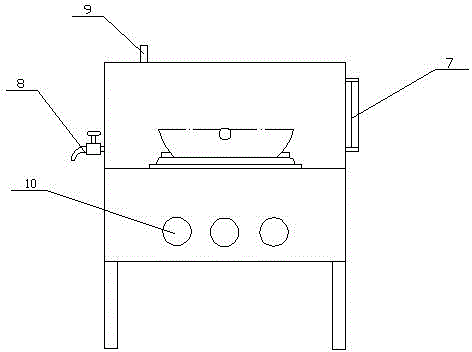

Heat-collecting and energy-saving gas stove

InactiveCN104566546AIncrease useSimple structureLighting and heating apparatusWater heating stoves/rangesEngineeringWater circulation

The invention discloses a heat-collecting and energy-saving gas stove. The gas stove comprises a stove body, wherein the stove body is internally provided with a burner, the stove body is internally provided with an airtight water cavity surrounding the burner, and the airtight water cavity is connected with a hot water collecting tank by virtue of a circulation pipeline; the hot water collecting tank is provided with a water drain valve and a safety valve, a hot water circulation cavity communicated with the airtight water cavity and the hot water collecting tank is externally connected with a water adding opening. When the gas stove is ignited, the upper part of the gas stove is used for heating foods, side flame and radiant heat are absorbed by water in the airtight water cavity, the heated water and the water in the hot water collecting tank are circulated until the water is boiled. The gas stove is simple in structure, convenient in use and high in waste heat recovery rate; not only can the energy be saved, but also the purpose of the gas stove is increased.

Owner:KUNSHAN FULING ENERGY USE

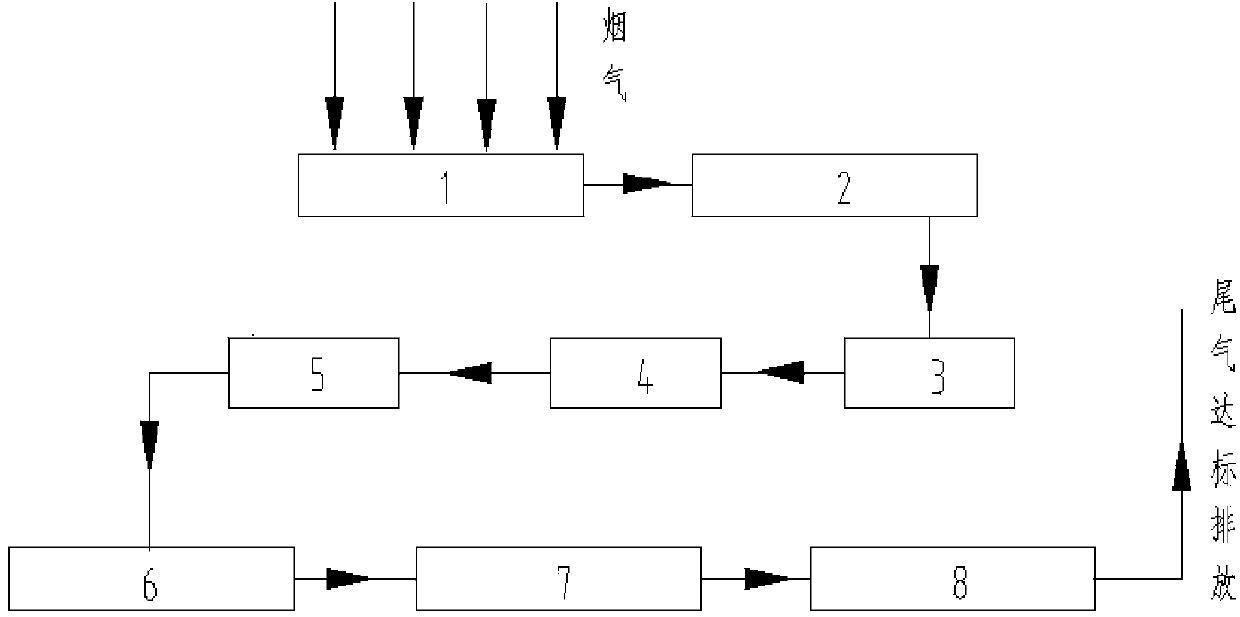

Method of recovering flue gas waste heat and dust in nonferrous metal smelting

ActiveCN103471405AHigh temperature resistance hasLow densityEnergy industryWaste heat treatmentCounter flowFiltration

The invention relates to a method of recovering flue gas waste heat and dust in nonferrous metal smelting and belongs to a method of waste heat utilization and waste gas treatment. A waste heat recovery device and a dust recovery device are formed by connecting a counter flow heat exchange waste heat boiler A, a silicon nitride porous ceramic filter, a counter flow heat exchange waste heat boiler B, a counter flow heat exchange waste heat boiler medium preheater, a plate type passage gas counter flow heat exchanger, a bag filter, and a draught fan through a pipeline or pipes; flue gas subjected to waste heat and dust recovery is subjected to sulfur recovery in a desulfurization shop, and the tail gas can be discharged standardly. The method includes the steps of primary waste heat recovery, filtration, dedusting and purification of high temperature flue gas, secondary waste heat recovery, tertiary waste heat recovery, quaternary waste heat recovery, low temperature filtration and dedusting, sulfur recovery, and emission of tail gas under national standard. The method has the advantages that waste heat recovery is efficient, dust recovery is complete, process control is simple, and recovery cost is low.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

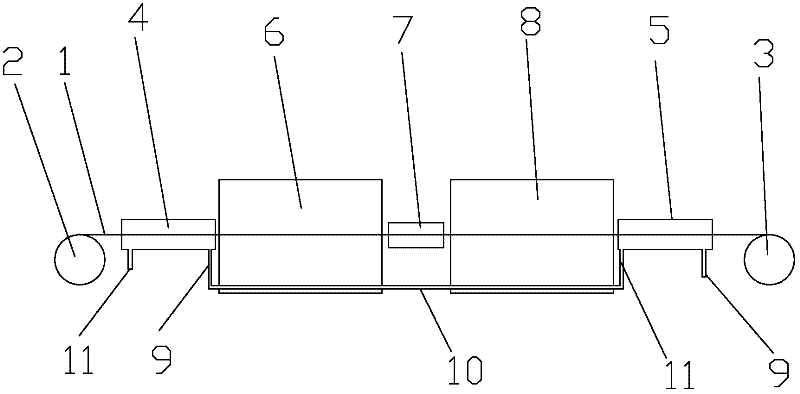

Device for recovering waste heat in heat treatment tempering process of steel strip

InactiveCN102517434AImprove waste heat recovery rateSimple structureFurnace typesIncreasing energy efficiencyHeating furnaceQuenching

The invention provides a device for recovering waste heat in the heat treatment tempering process of a steel strip. The device comprises an unwinding wheel, a winding wheel and the steel strip for connecting the unwinding wheel and the winding wheel, wherein a heating furnace, a quenching device and a tempering furnace which are used for performing heat treatment on the steel strip are arranged between the unwinding wheel and the winding wheel in turn; a waste heat absorption heat exchanger for vaporizing inlet water to form vapor is arranged on the steel strip between the tempering furnace and the winding wheel; a waste heat release heat exchanger for liquefying the vapor to form outlet water is arranged on the steel strip between the unwinding wheel and the heating furnace; and the waste heat absorption heat exchanger conveys the vapor to the waste heat release heat exchanger through a vapor conveying pipe. The device is high in waste heat recovery rate and has a simple structure.

Owner:ZHEJIANG BAINAI STEEL STRIP

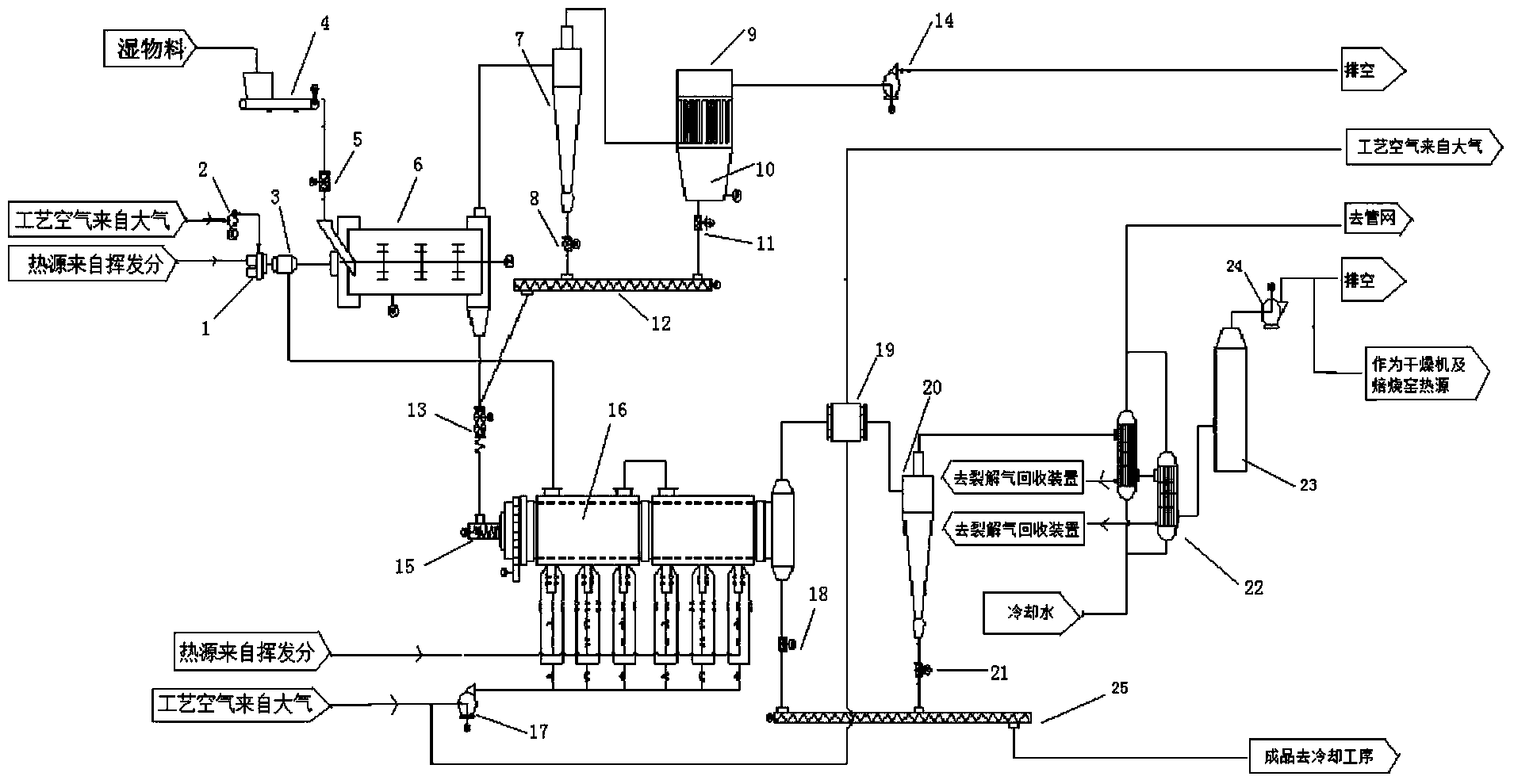

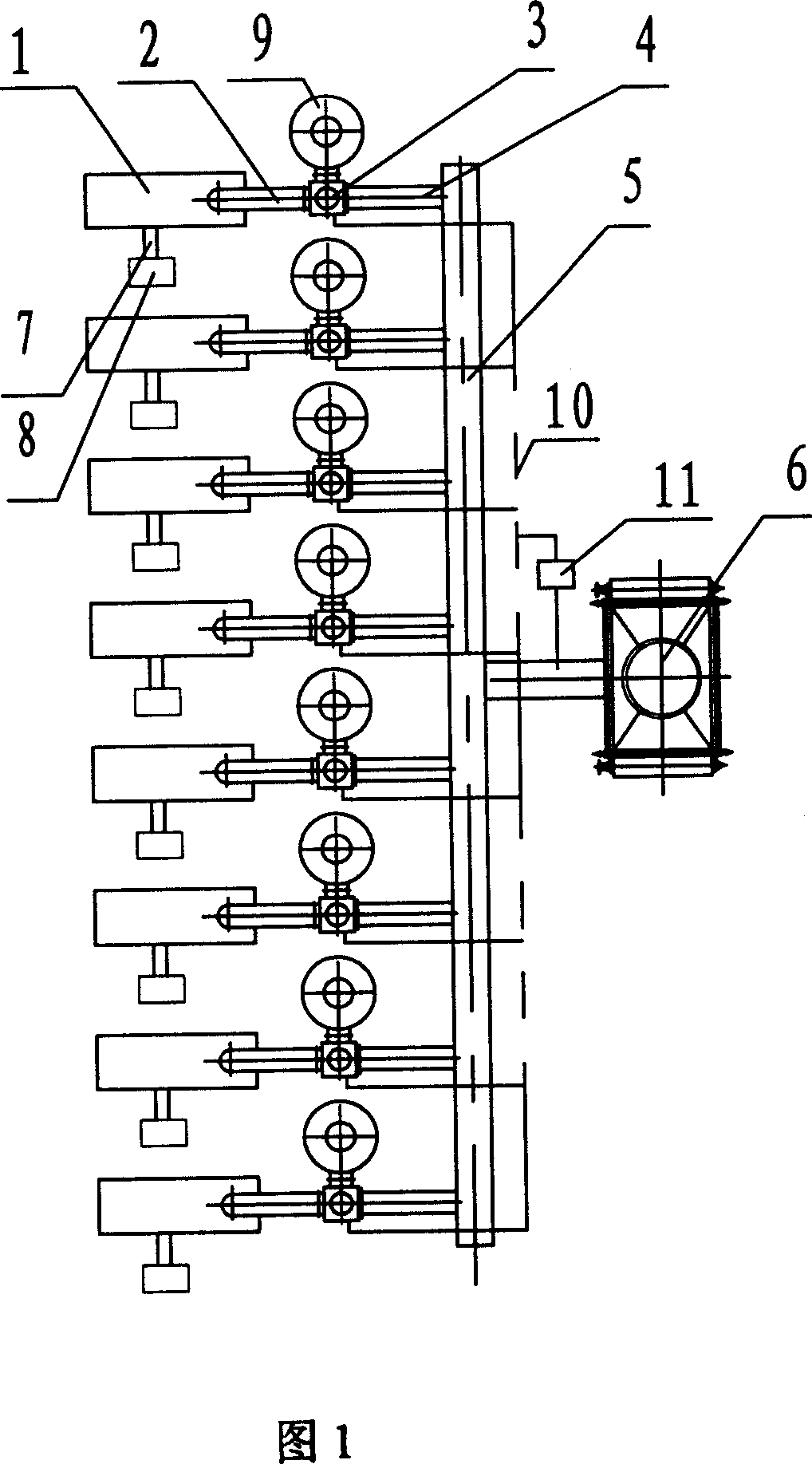

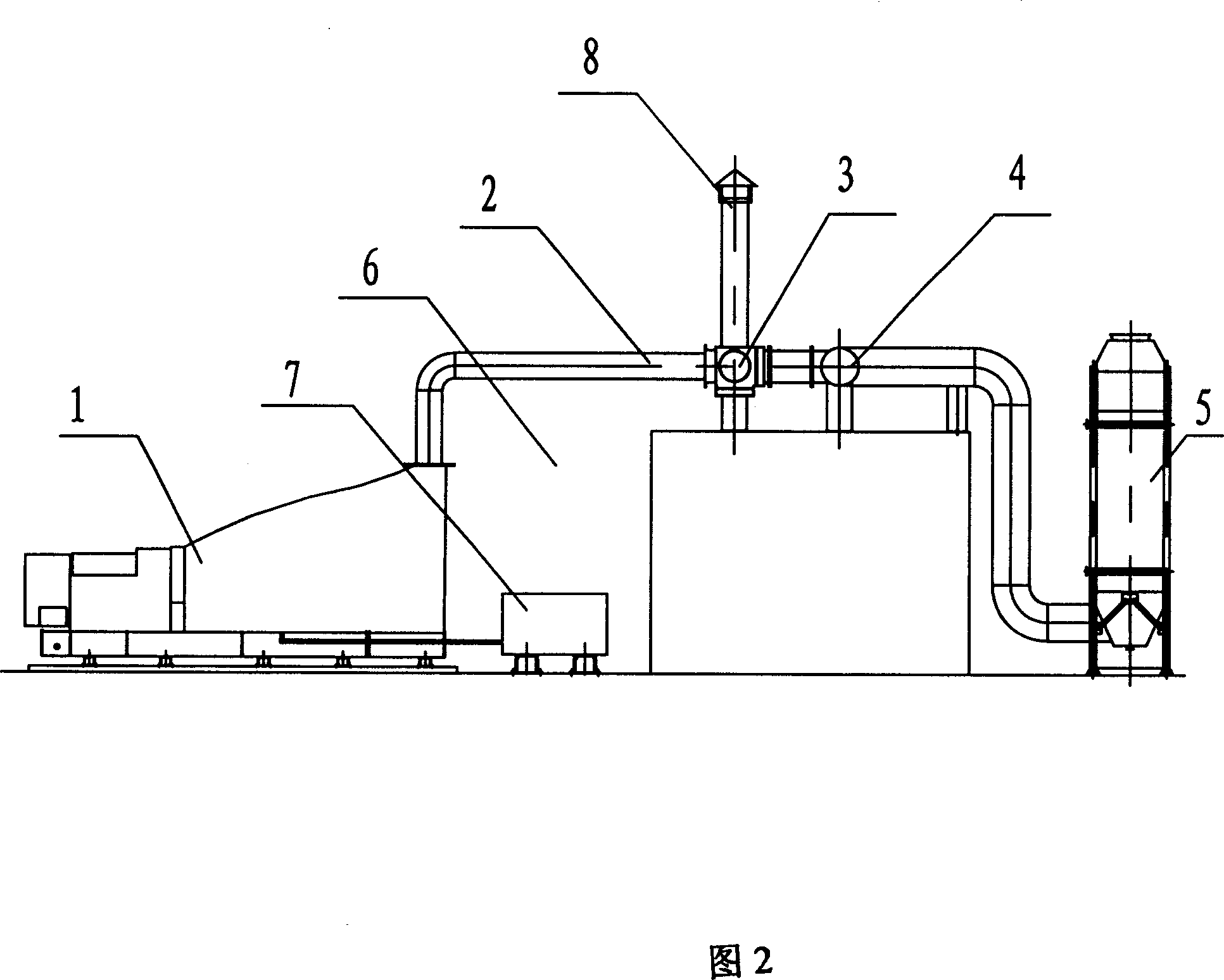

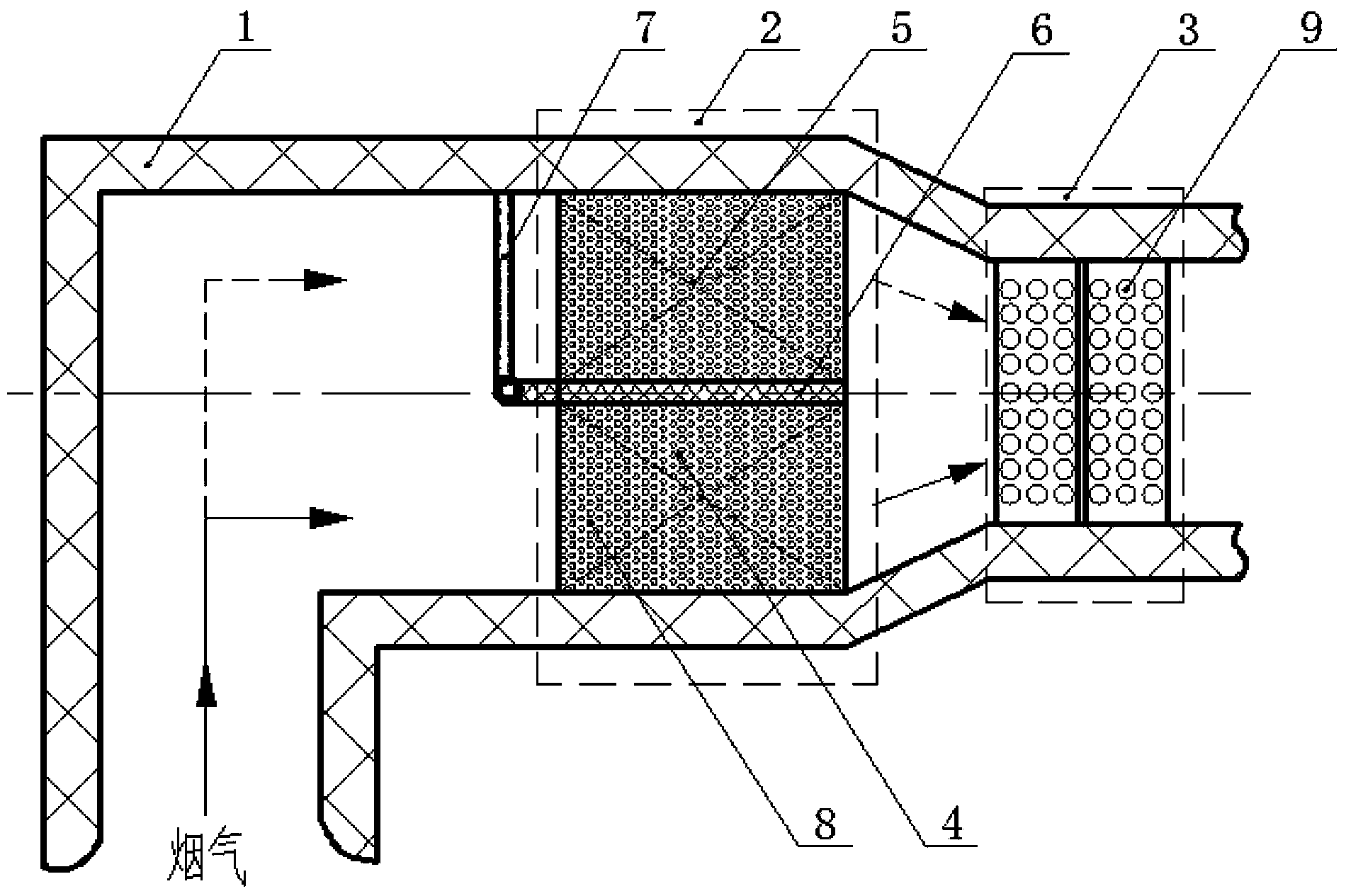

Oil sand calcining device and an oil sand calcining process

ActiveCN103450919AGuaranteed uptimeImprove thermal efficiencyLiquid hydrocarbon mixture productionAir preheaterAutomatic control

The invention discloses an oil sand calcining device and an oil sand calcining process. The oil sand calcining device comprises a rotary dryer, a cyclone dust collector I, a cyclone dust collector II, a bag-type dust collector, a spiral conveyer I, a spiral conveyer II, a drying induced fan, a combustor, a combustor combustion fan, a hot-blast furnace, a feeding machine, a calcining kiln, a combustion fan, an air preheater, a shell and tube condenser, an absorbing tower and a system induced fan. A system which adopts the process has the advantages of continuity in operation, stability in operation, high heat efficiency and convenience for operation, can realize the automatic control, is suitable for larger-scale production, is reduced in occupied area and low in investment and operation and maintenance cost and successfully solves the problem of wall adhesion of oil sand. According to the oil sand calcining device and the oil sand calcining process disclosed by the invention, a calcined product is more incompact and can meet the requirements of building materials; the waste heat recovery rate of the system is greatly increased, and the energy is saved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP +1

Hot conflux main pipe residual heat reclamation and utilization system using gas medium as hot source

ActiveCN101078534ACompact structureSmall footprintInternal combustion piston enginesExhaust apparatusWaste heat recovery unitSmall footprint

The invention relates to a thermal confluence bus-piping waste heat recovery and utilization system, whose thermal source is air medium. It is characterized in that at least two thermal air sources are connected with the channel of thermal air source respectively; each channel of thermal air source is connected one way of three-way wind door; another channel of three-way wind door is connected with the bus pipe of thermal confluence by connecting pipes; the bus pipe of thermal confluence is connected with the waste heat recovery device; the third way of three-way wind door is connected with by-pass channel; the protection device of generating device of thermal air source can be assigned on the channel of thermal air channel directly; the control equipment of thermal confluence is connected with the generating device of thermal air source, the three-way wind door and controlling and measuring component on the waste heat recovery and utilization device by control circuit. The merit of invention is that multiple thermal air sources are combined to enter into a waste heat recovery and utilization device so that waste recovery is realized easily and it is provided with high recovery efficiency, compact structure, small occupied area, easy assignment, easy running and maintenance and few spare parts.

Owner:SHANGHAI EAGLE NEW TECH ENG

Phase change-dividing-wall-type combined heat exchange system and method for flue gas of heating furnace

InactiveCN103438743AImprove waste heat recovery efficiencyImprove waste heat recovery rateCombustion processHeat storage plantsEngineeringHigh heat

Owner:ANGANG STEEL CO LTD

Liquid slag dry granulating and waste heat recovery device with slag wool crushing function and operation method of device

ActiveCN111020073AAvoid reunionAvoid cloggingRecycling and recovery technologiesLiquid slagReciprocating motion

The invention discloses a liquid slag dry granulating and waste heat recovery device with a slag wool crushing function and an operation method of the device. The device comprises a granulating bin, agranulating system, a slag wool crushing device and a moving bed. A temperature measuring device and a slag falling pipe are arranged on the top wall of the granulating bin. The granulating system isarranged in the granulating bin and comprises a rotating cup, the rotating cup is located under the slag falling pipe, and a partition wall is arranged on the lower portion of the rotating cup. A shear crusher doing reciprocating motion is arranged on the partition wall. The position of the moving bed is lower than the position of the shear crusher. The moving bed comprises a rake and a crusher.The rake and the crusher are arranged in the granulating bin, the rake can do reciprocating motion, and the position of the crusher is lower than the position of the rake. A bulk material accumulationportion is arranged at the bottom of the granulating bin. A cooling air pipeline is arranged at the bottom of the granulating bin. According to the liquid slag dry granulating and waste heat recoverydevice, slag wool generated in the granulating process can be crushed efficiently, accidents can be reduced, and the waste heat recovery rate can be improved.

Owner:XI AN JIAOTONG UNIV

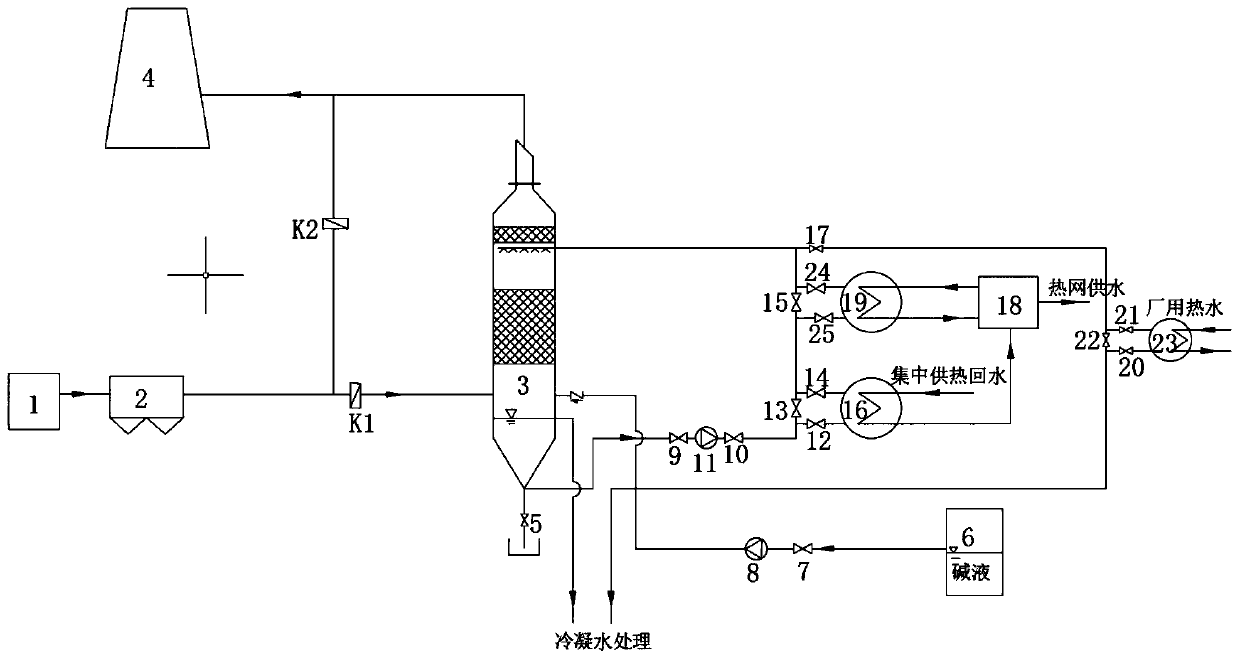

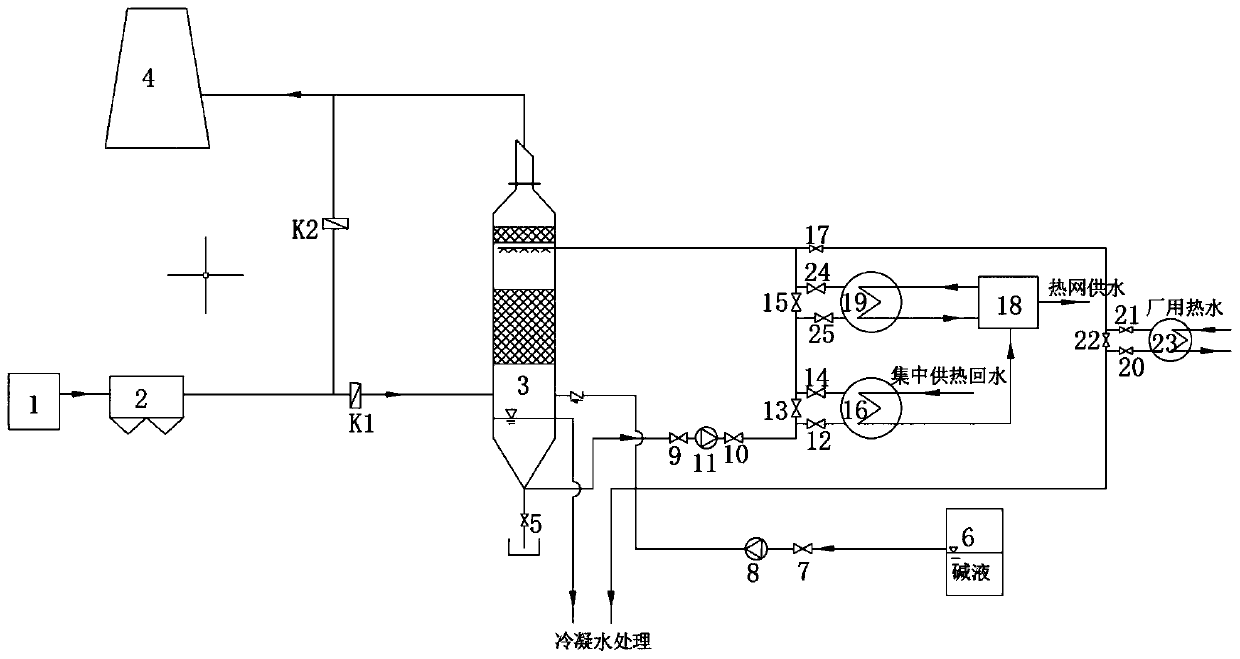

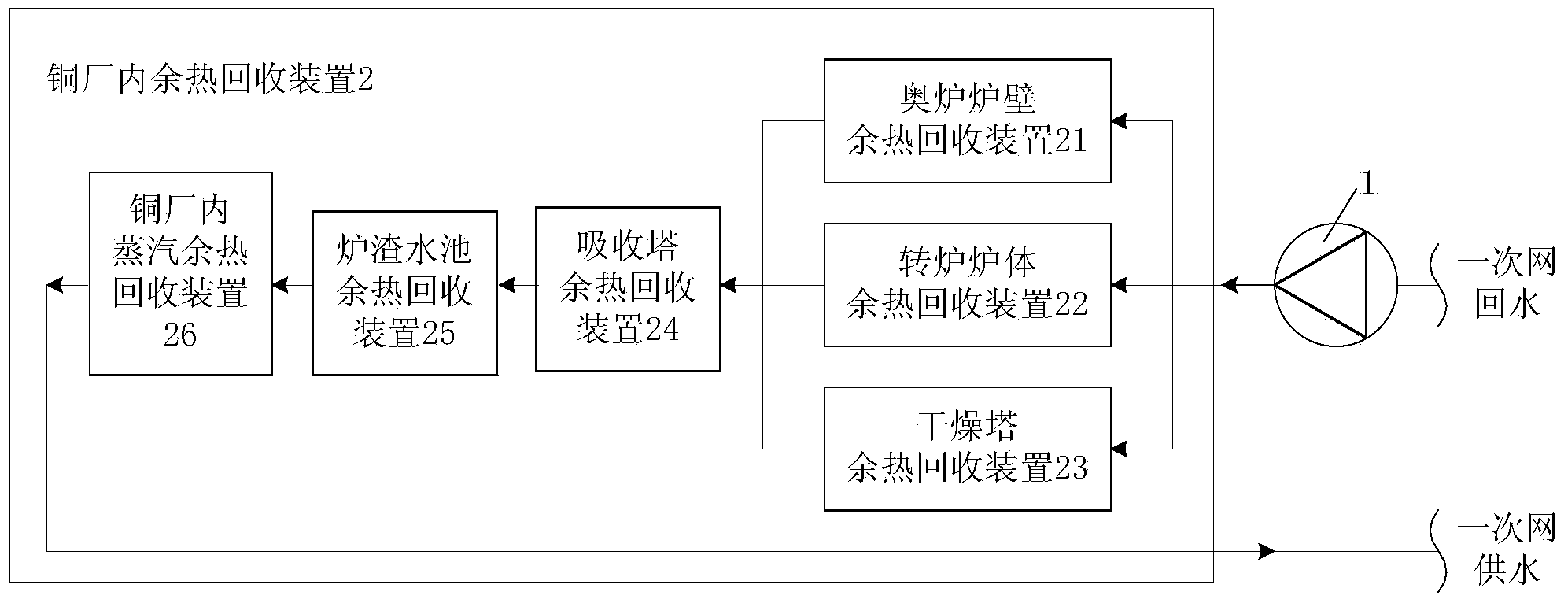

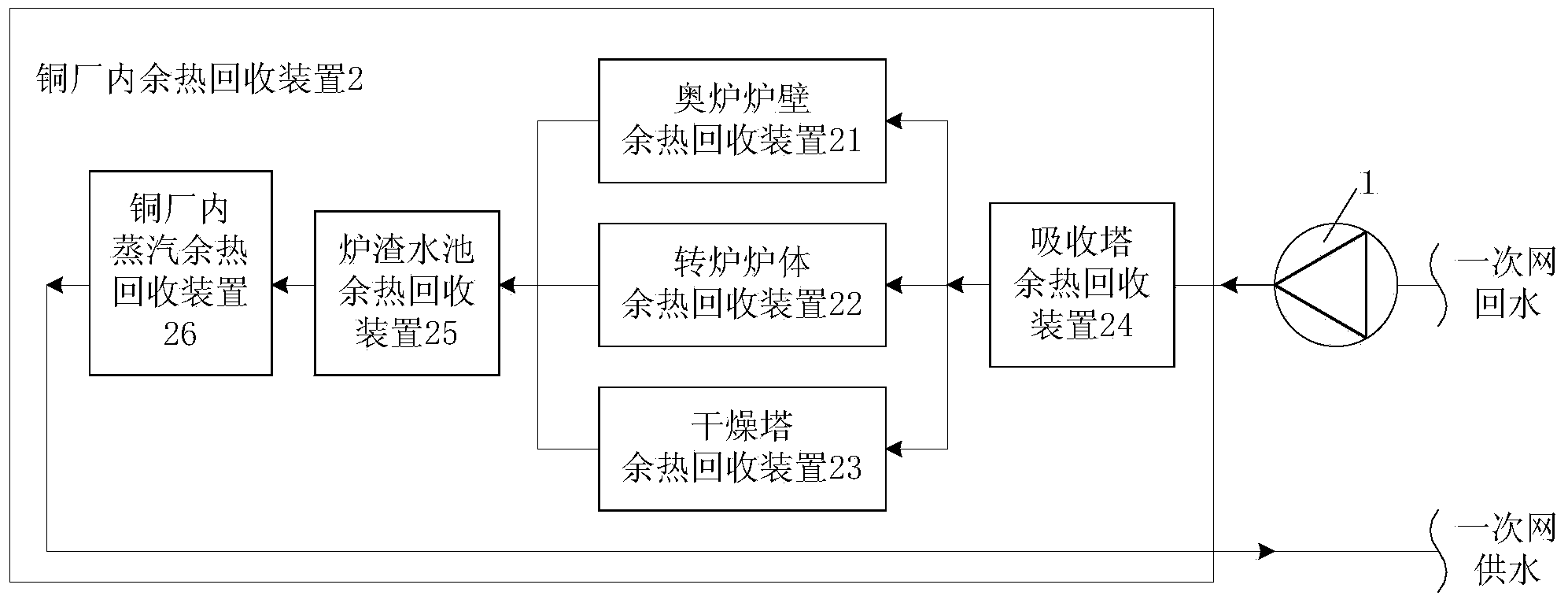

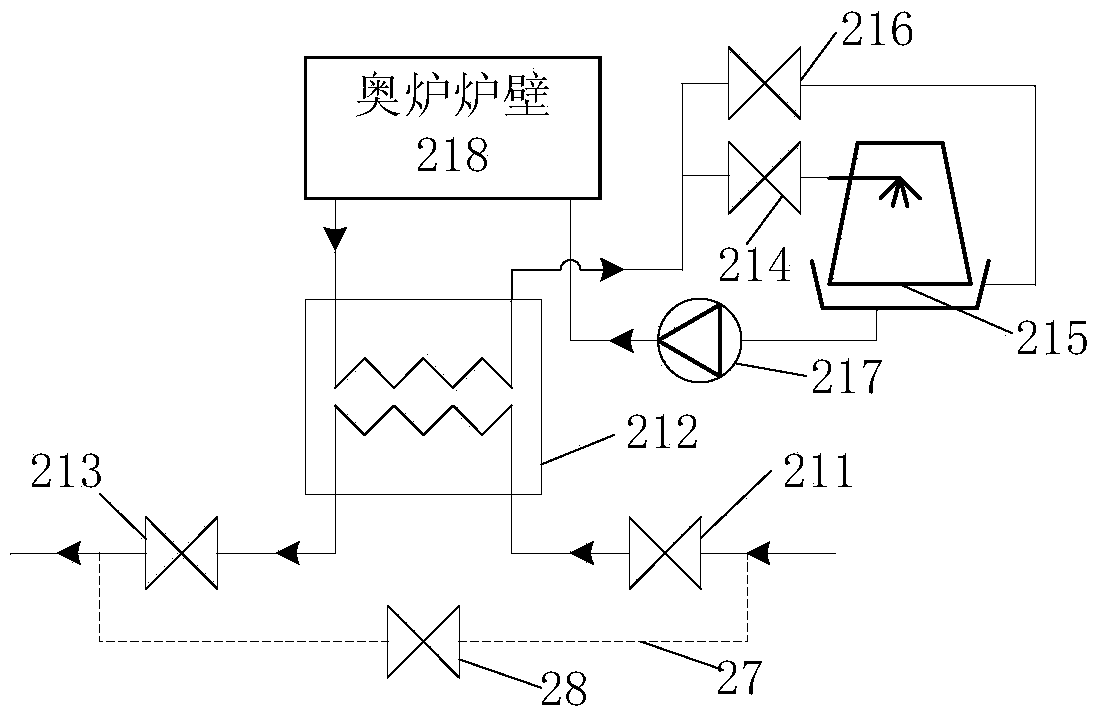

Copper plant low-grade waste heat recovery system for urban central heating

ActiveCN103868132AImprove waste heat recovery rateEase the shortageEnergy efficient heating/coolingEnergy industryWaste heat recovery unitSlag

The invention relates to a copper plant low-grade waste heat recovery system for urban central heating. The copper plant low-grade waste heat recovery system is characterized by comprising a primary network circulating pump and a copper plant waste heat recovery device, wherein primary network return water from a primary pipe network flows into the copper plant waste heat recovery device through the primary network circulating pump, the copper plant waste heat recovery device collects waste heat in a copper plant, the waste heat is used for heating the primary network return water, and after the temperature rises, the primary network return water is supplied to a user in the form of primary network water supply; the copper plant waste heat recovery device comprises an austenitic furnace wall waste heat recovery device, a converter body waste heat recovery device, a drying tower waste heat recovery device, an absorption tower waste heat recovery device, a slag pool waste heat recovery device and a copper plant steam waste heat recovery device, wherein the austenitic furnace wall waste heat recovery device, the converter body waste heat recovery device and the drying tower waste heat recovery device are arranged in parallel, and the absorption tower waste heat recovery device, the slag pool waste heat recovery device and the copper plant steam waste heat recovery device are connected in series with the three waste heat recovery devices which are connected in parallel. The copper plant low-grade waste heat recovery system can be widely applied to recovery of low-grade waste heat in the copper plant.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com