Melting slag waste heat recovery system

A waste heat recovery system and molten slag technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve the requirements that the working life is difficult to meet the requirements of use, the bearing is difficult to bear, and the working life of the rotating cup is difficult to meet the requirements of use And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

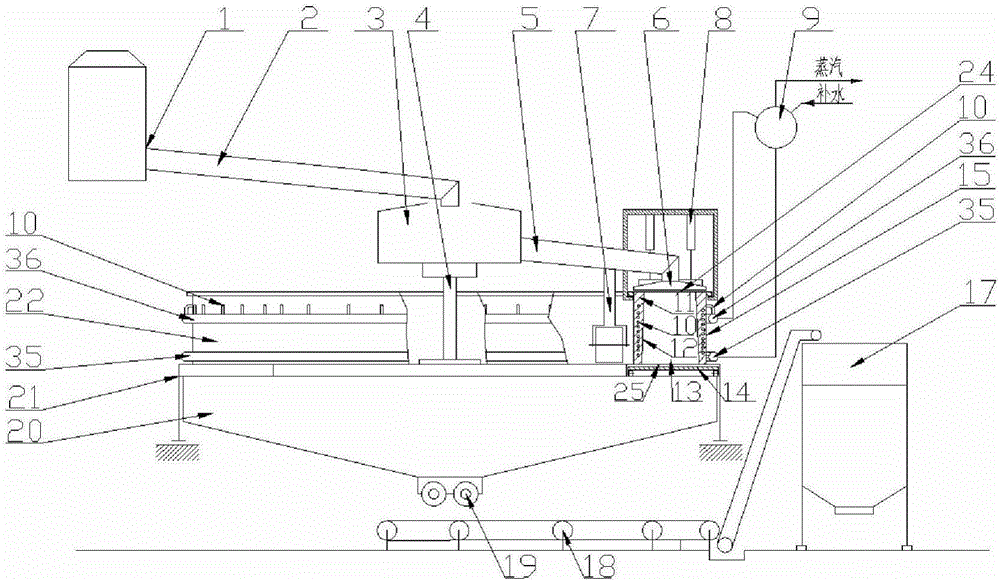

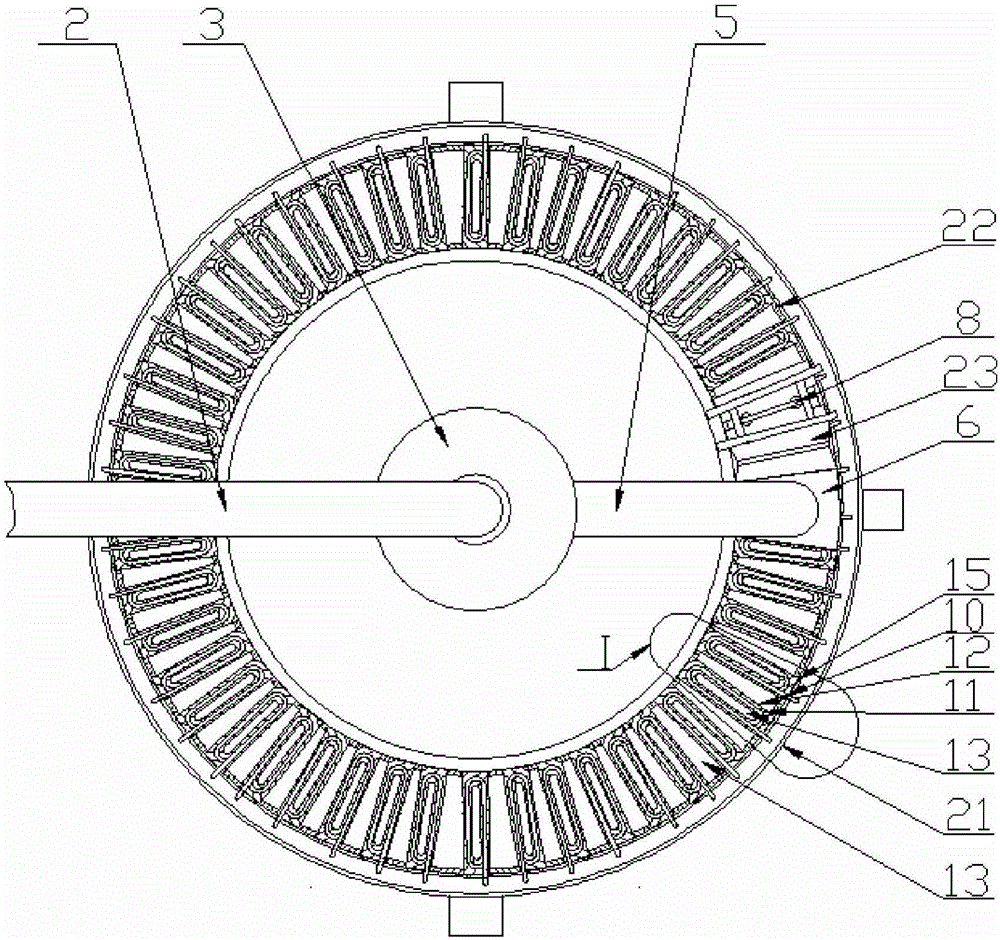

[0121] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0122] Reference attached Figure 1-36 :

[0123] The system includes a slag feeding system, a slag heat exchange device 22 and a steam water system;

[0124] The slag heat exchange device 22 is composed of at least one heat exchange unit 15;

[0125] The heat exchange unit 15 is selected from one of the following four structures:

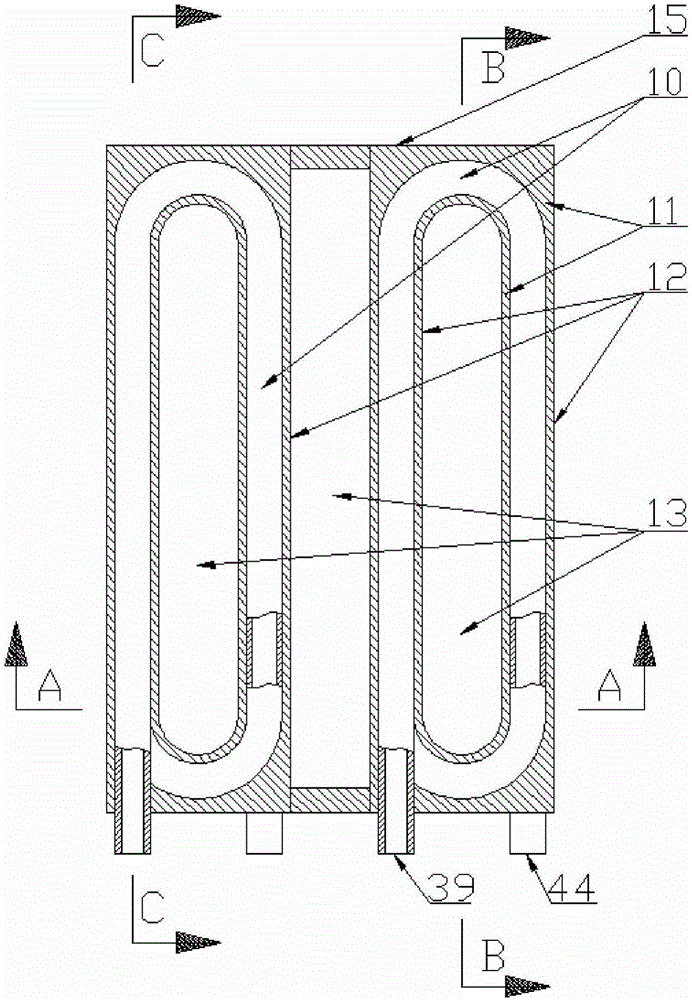

[0126] 151: A cylinder-shaped slag heat exchange chamber 13 surrounded by slag heat exchange plates 12 and slag baffles 14. The upper and lower parts of the slag heat exchange chamber 13 are the upper feed port 24 and the lower feed port 25, respectively. A slag baffle 14 is arranged below the feed port 25;

[0127] 152: An airtight cavity is formed by the pressure-bearing shell 42, the upper end plate 40 of the shell and the lower end plate 43 of the shell. The water inlet 44 and the water outlet 39 are arranged on the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com