Oil sand calcining device and an oil sand calcining process

A roasting device and oil sand technology, which is applied in the field of building materials and energy, can solve the problems of high experimental requirements and high operating costs, and achieve the effects of improving waste heat recovery rate, low investment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

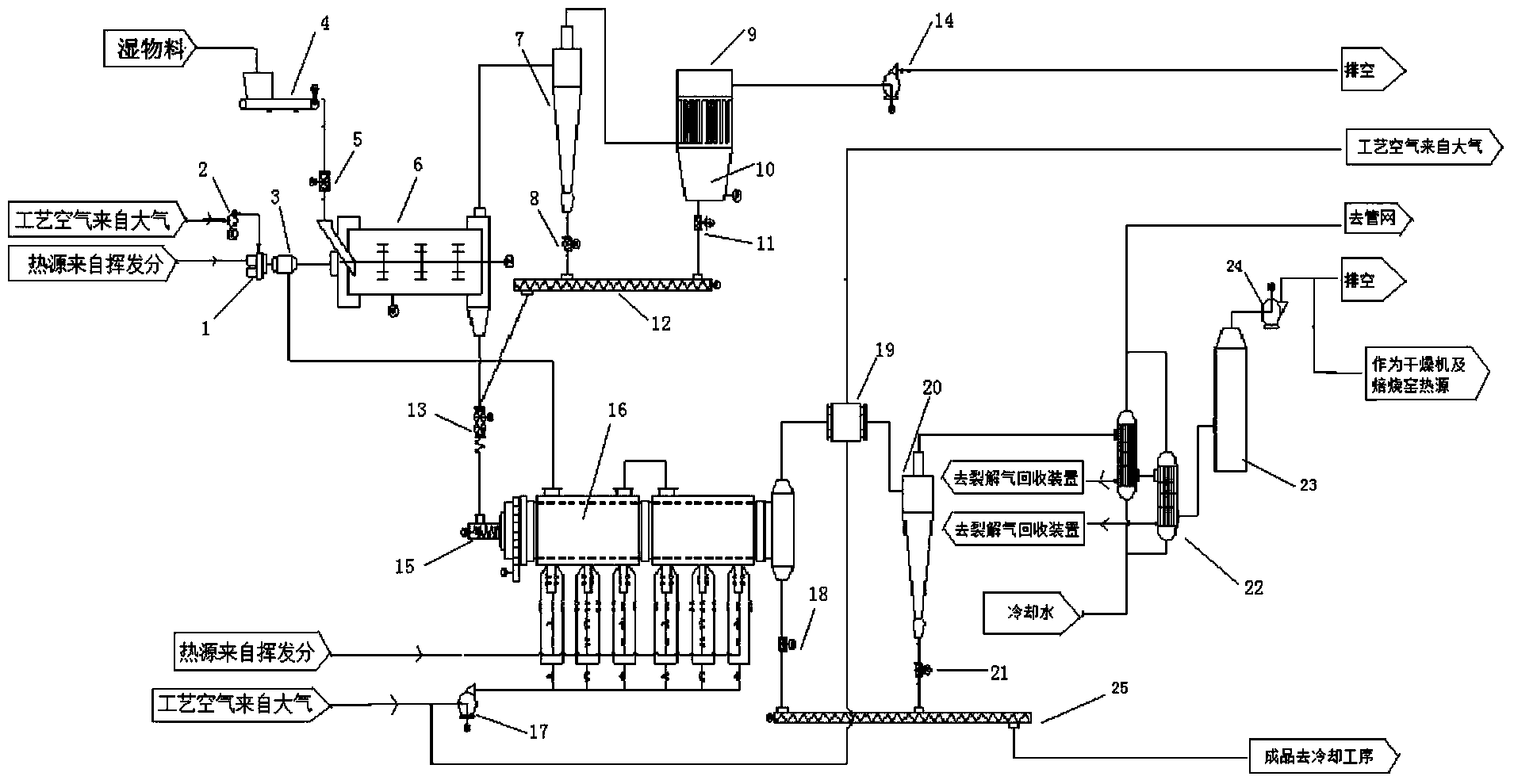

[0028] Such as figure 1 As shown, an oil sand roasting device includes: rotary dryer 6, cyclone dust collector 1 7, cyclone dust collector 2 20, bag filter 9, screw conveyor 1 12, screw conveyor 2 25, drying induced draft fan 14 , burner 1, burner combustion-supporting fan 2, hot blast stove 3, feeder 15, roasting kiln 16, combustion-supporting fan 17, air preheater 19, cyclone lower closing air device one 8, cyclone lower closing air device two 21, Self-cleaning air locker 13, finished product air locker 18, shell and tube condenser 22, absorption tower 23 and system induced draft fan 24.

[0029] The tail gas outlet port of the rotary dryer 6 is sequentially connected with the cyclone dust collector-7, the bag filter 9 and the drying induced draft fan 14, and the material outlet port of the rotary dryer 6 is connected with the self-cleaning air shuto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com