Patents

Literature

30results about How to "Stable furnace pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

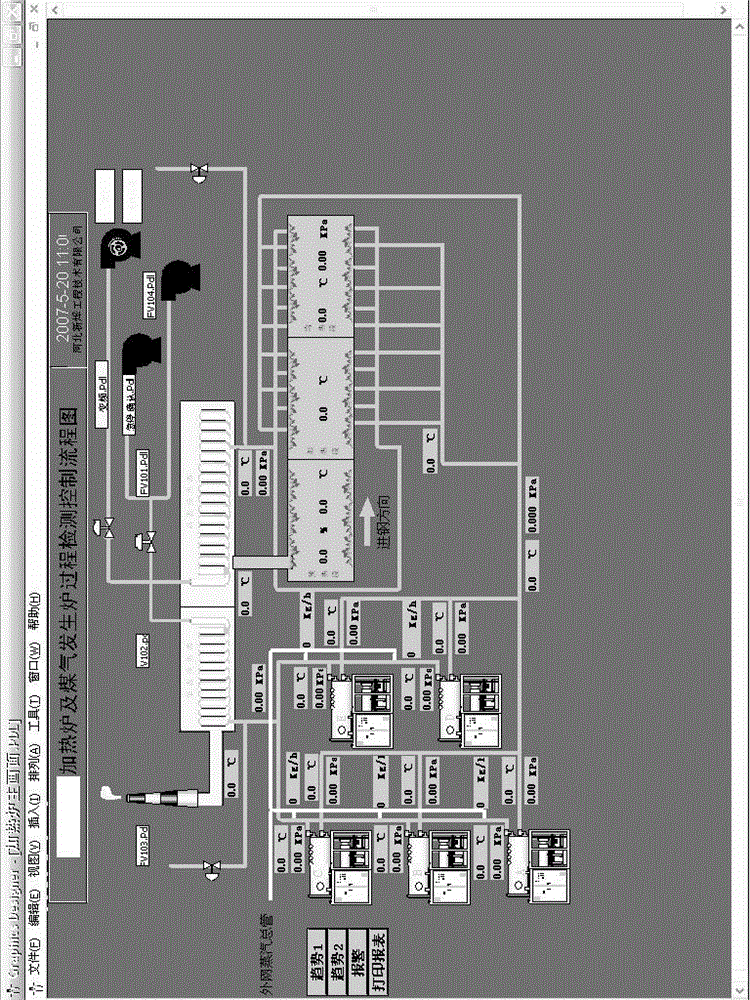

High-efficiency intelligentized heating furnace control method

ActiveCN102721288AGuaranteed reasonablenessRealize cross controlControl devices for furnacesFurnace temperatureThermodynamics

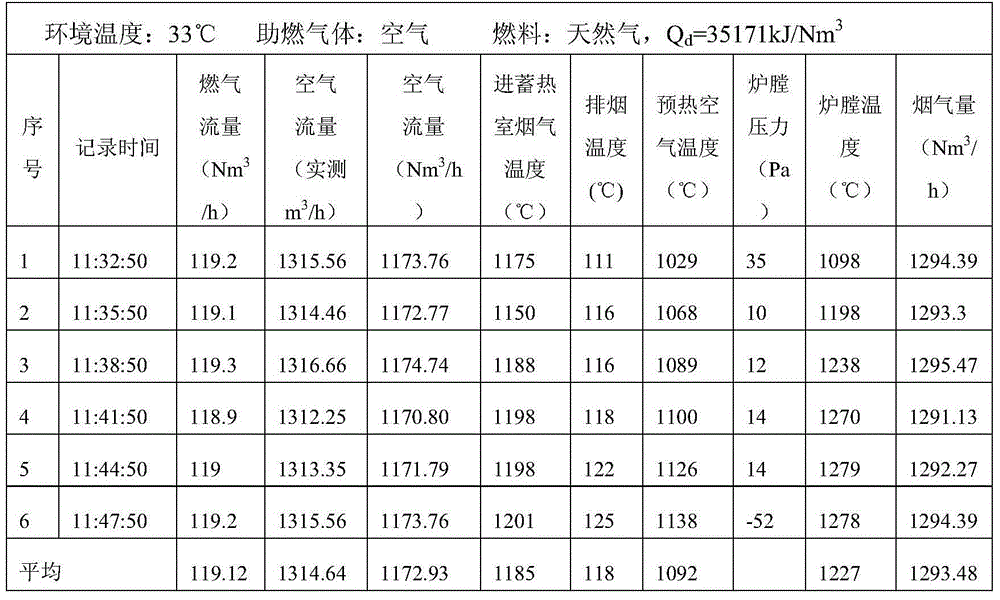

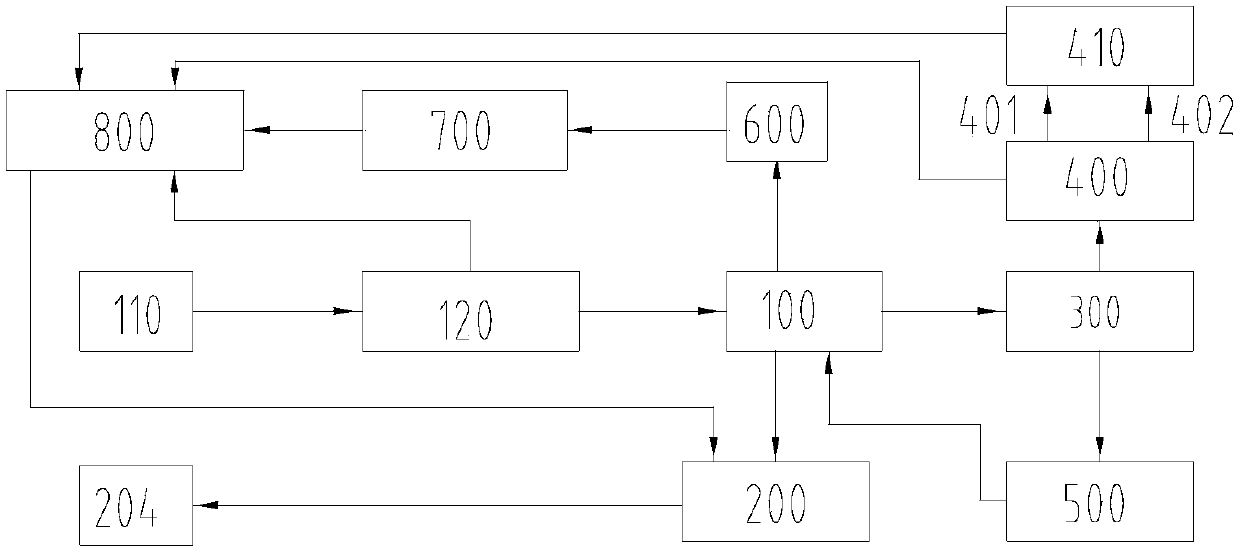

The invention relates to the technical field of heating furnaces of heat treatment equipment applied in the steel rolling industry, in particular to a high-efficiency intelligentized heating furnace control method. The method adopts a PLC (programmable logic controller) system for field control and an upper computer operating system communicating and connected with the PLC system to form an intelligent control system, and moreover, the intelligent control system is utilized to efficiently, scientifically and intelligently control a heat furnace. The method is characterized in that the intelligent control system controls and sets the heating furnace in the following six aspects: (1) furnace temperature control; (2) internal pressure control; (3) air-fuel ratio control; (4) safety protection system control; (5) adoption of an human-machine interface (HMI) on the intelligent control system; (6) history data recording. The method can reasonably control heating temperature, furnace temperature and furnace pressure at each stage in real time, increases the heating utilization rate, has an outstanding effect in saving energy and reducing consumption, increases the production efficiency, reduces the production cost, and prolongs the furnace service life.

Owner:HEBEI XINYE ENG TECH

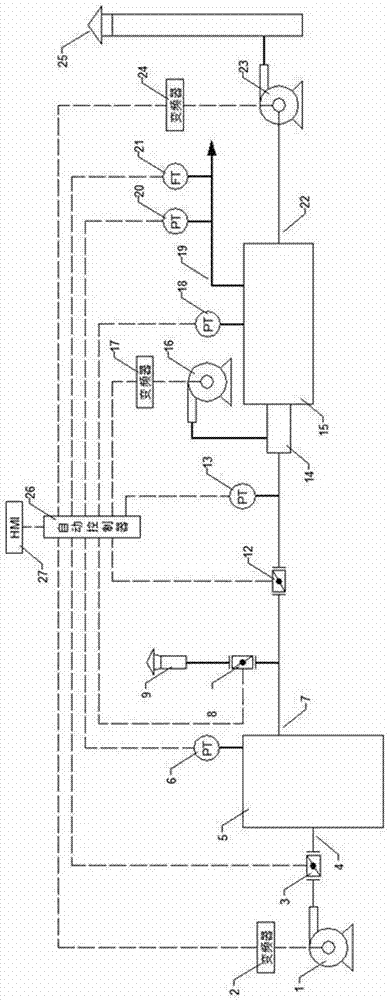

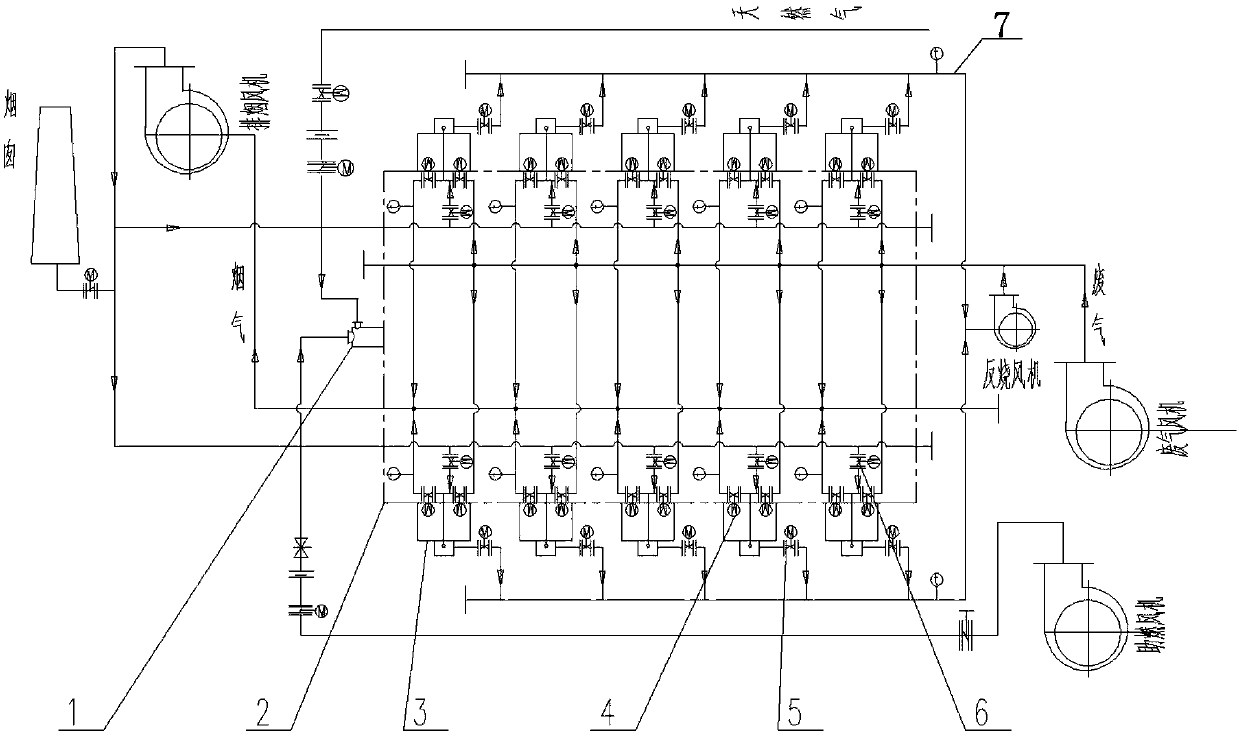

Optimized air-distribution control system for industrial furnace

InactiveCN101672482AEnsure combustion quality and furnace pressureEnsure stabilityAir supply regulationFlue gasIndustrial furnace

The invention discloses an optimized air-distribution control system for an industrial furnace. A combustor is connected with a fuel valve and an air valve connected with a hot air tube, a flue is connected with the inlet of a heat exchanger, and the outlet of the heat exchanger is connected with an induced draft fan set driven by an induced draft speed governor. A bypass valve is arranged betweena cold air tube and the hot air tube, and the cold air tube is connected with an air outlet of an air blower set driven by an air blast speed governor. An outlet of a sampling tube is connected withan flue gas oxygen concentration analyzer; a signal output end of the flue gas oxygen concentration analyzer is connected with a first signal input end of a controller, a second signal output end of the controller is connected with a control signal input end of the induced draft speed governor, a furnace pressure duct is connected with a pressure transmitter a signal output end of which is connected with the second signal input end of the controller, the first signal output end of the controller is connected with the control signal input end of the air blast speed governor, and a communicationport of the controller is connected with a human-computer interface. The invention controls the rotate speed of the induced draft fan set and the air blower set driven by the speed governors throughdetecting the pressure and flue gas oxygen concentration values in the furnace on line so that the furnace is in the optimized air-distribution state all the time.

Owner:夏学苏

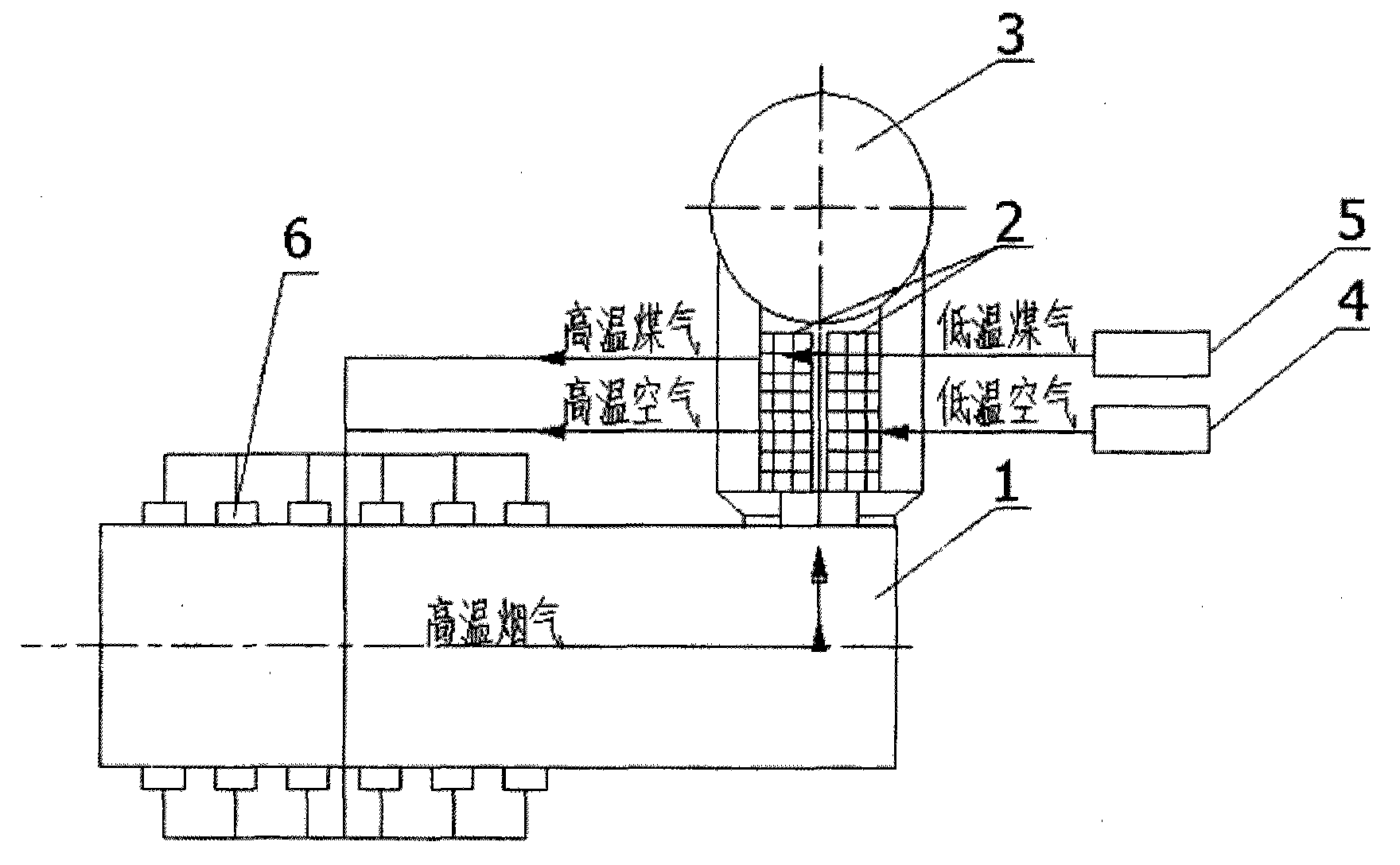

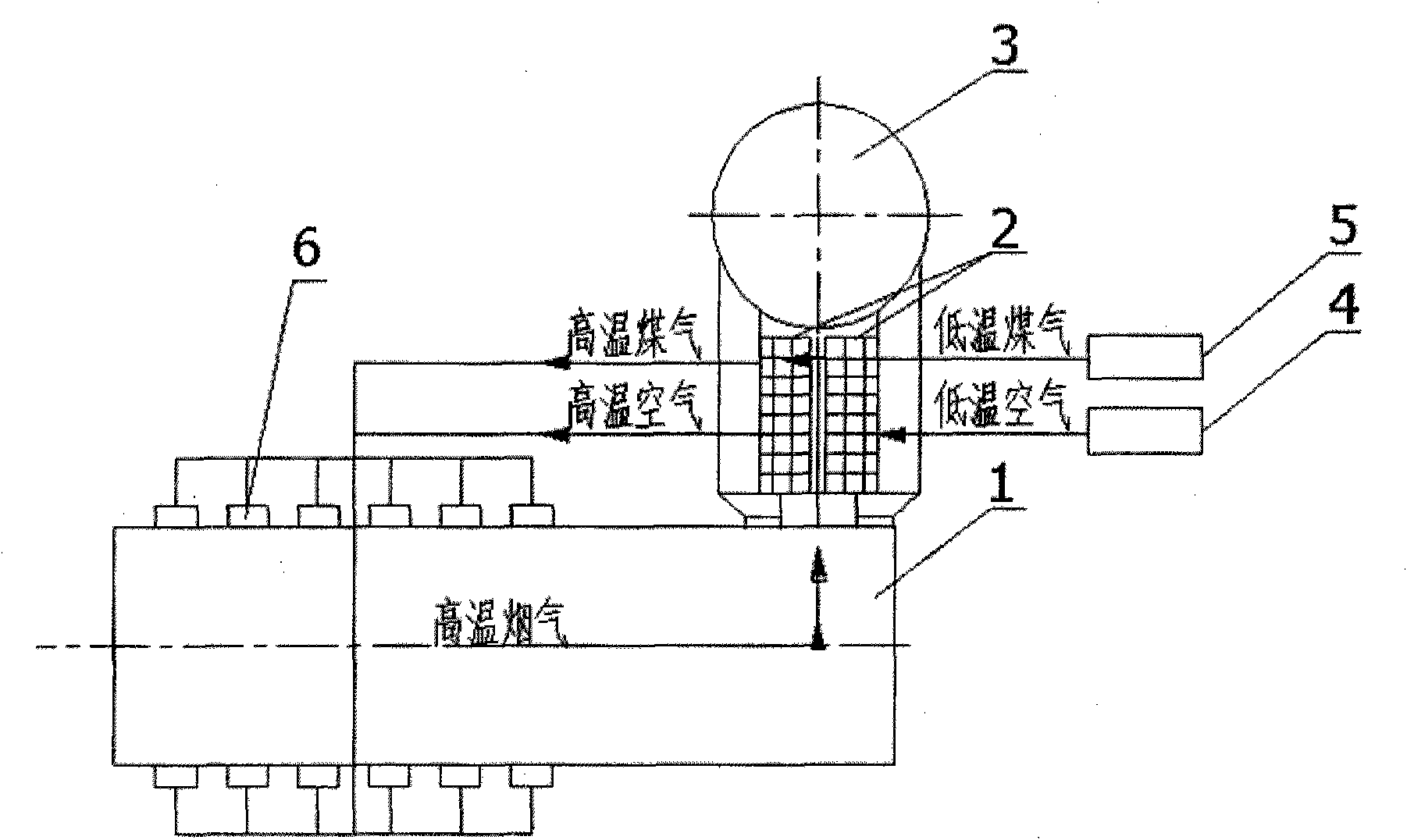

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

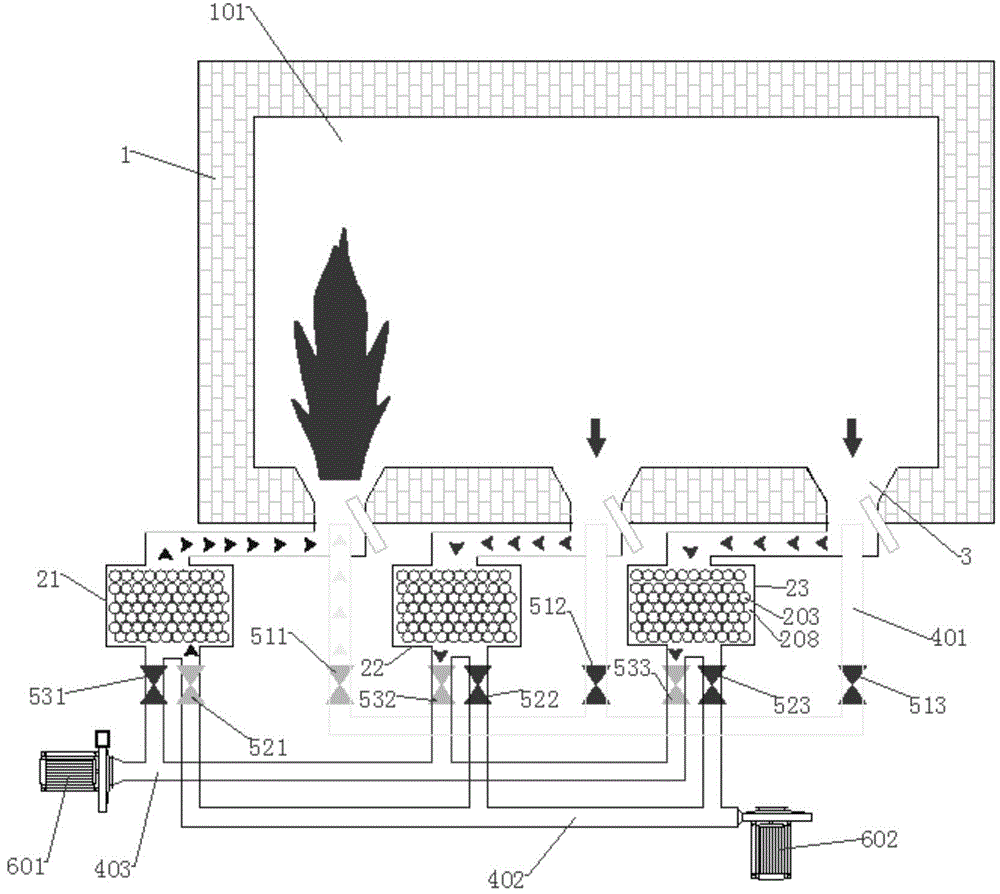

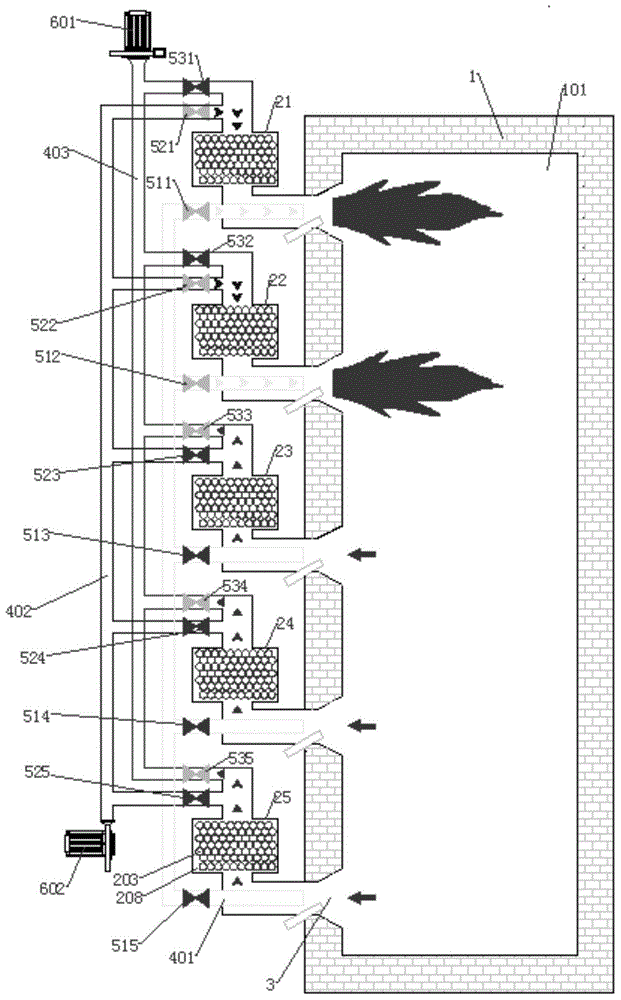

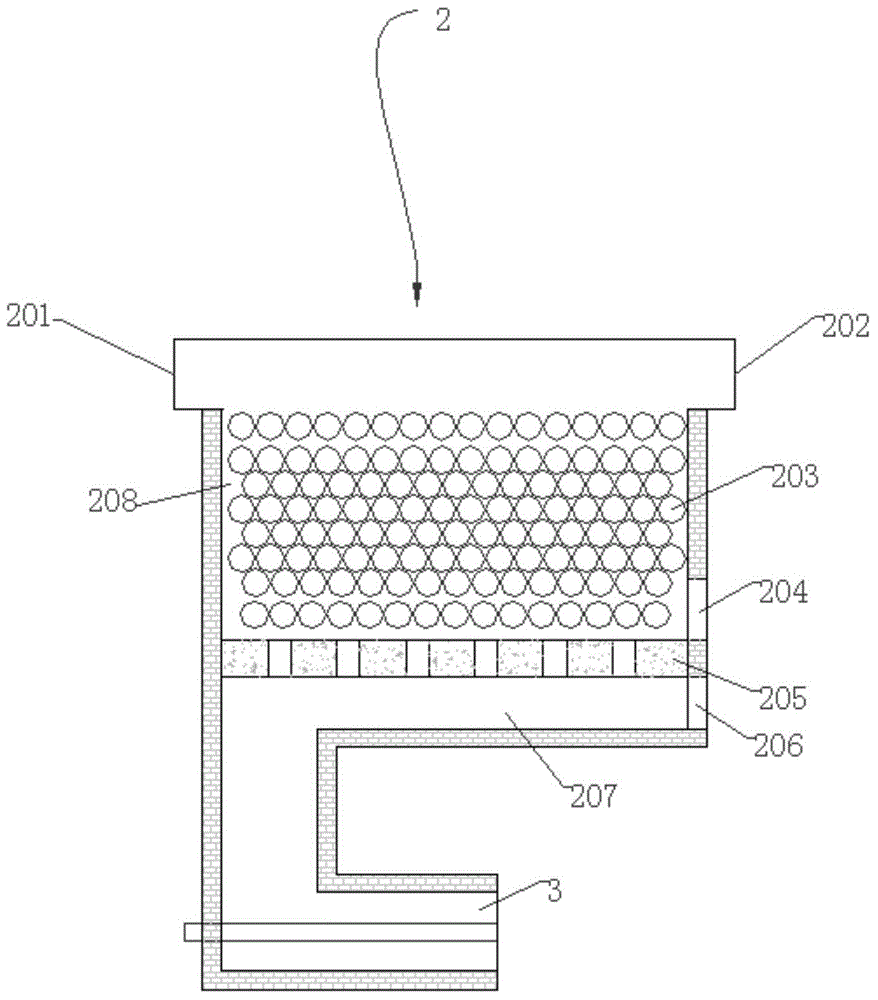

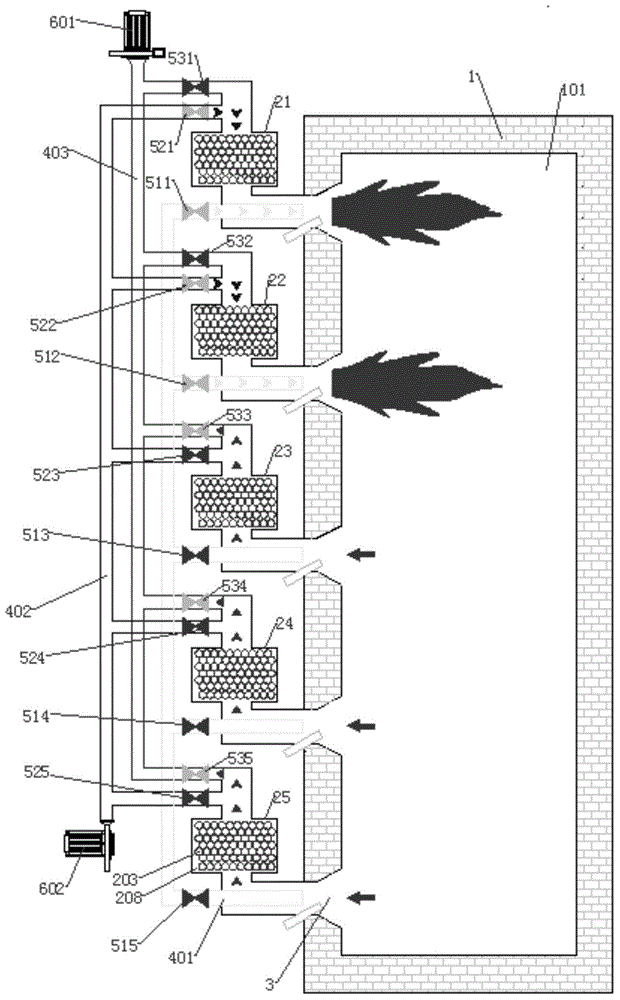

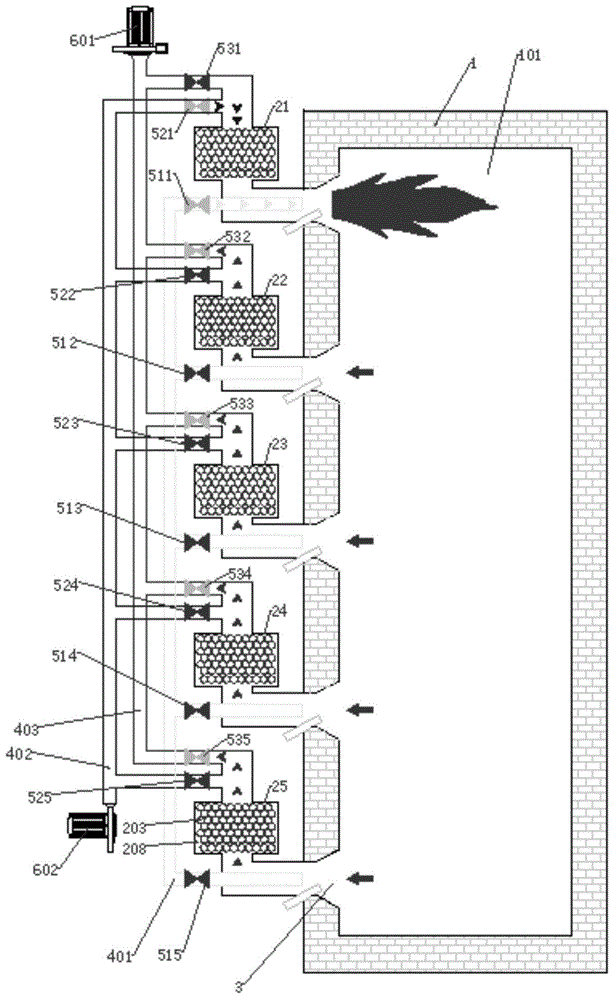

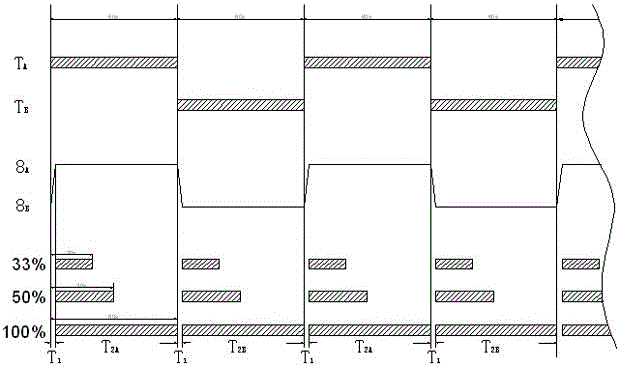

Progressive switchover heat storage type combustion device

InactiveCN104456569ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustor

The invention relates to a progressive switchover heat storage type combustion device. The progressive switchover heat storage type combustion device comprises at least five heat storage type combustors connected with a hearth and a controller capable of controlling the heat storage type combustors. The controller switches over the heat storage type combustors, so that the heat storage type combustors are alternately used for combustion or smoke exhaust, and the number of the heat storage type combustors used for smoke exhaust is made to be larger than that of the heat storage type combustors for combustion at any moment; in combustion production, when the controller switches over any heat storage type combustor, at least another heat storage type combustor maintains combustion work. Compared with the prior art, in the steering process of the device, the phenomena of detonation and furnace blast are effectively avoided, the safety performance is better, and the energy-saving effect is more obvious.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

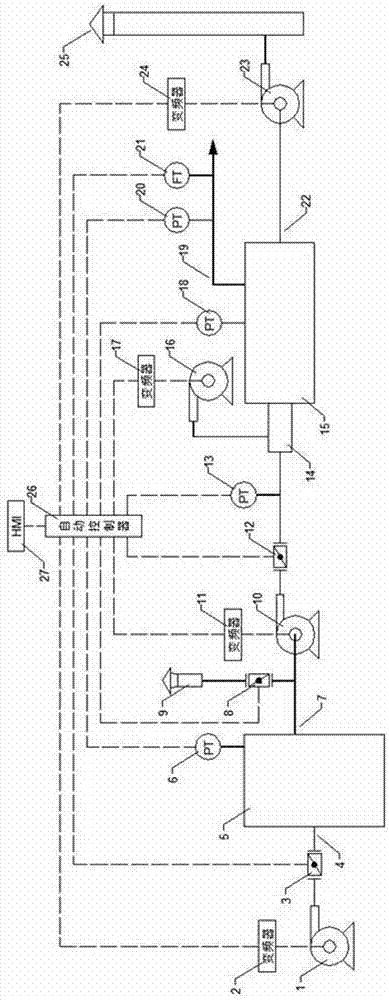

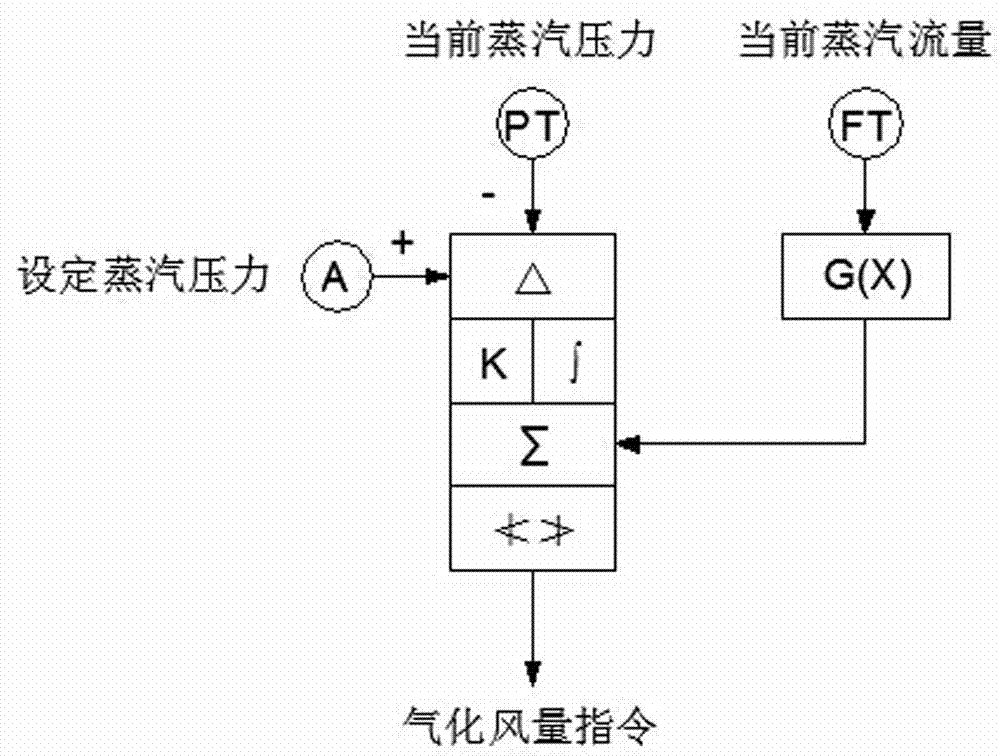

Automatic control method and system device for adjustment on load of biogas supplied for steam boiler

InactiveCN104501127AStable supplyRealize unified coordinated automatic controlBoiler controlSteam pressureAutomatic control

The invention relates to a biogas supplying system, in particular to a control method and a system device for adjustment on load of biogas supplied for a boiler. The running frequency of an active adjusting fan is controlled by an automatic controller, the active adjusting fan delivers a given amount of gasified air or a given amount of gas, the amount of steam generated by the steam boiler during combustion is controlled through the given amount of gasified air or the given amount of gas, steam pressure sensor signals and steam flow meter signals which serve as feedback signals enter the automatic controller, and a closed-cycle control loop is formed. The load of a biomass gasifier is changed stably, gas of a combustor of the boiler is combusted sufficiently and reasonably, the gas pressure of a hearth is stable, and steam is stably supplied within a set pressure range. By a control system, the problem that the existing fuel and gas boiler control method is not suitable for places at which the biogas is supplied for steam boilers is solved, the ability on matching between the biomass gasifier and the steam boiler is improved to a maximum degree, and the biomass gasifier and the steam boiler are unified and coordinated and are controlled automatically.

Owner:广东绿壳新能源有限公司

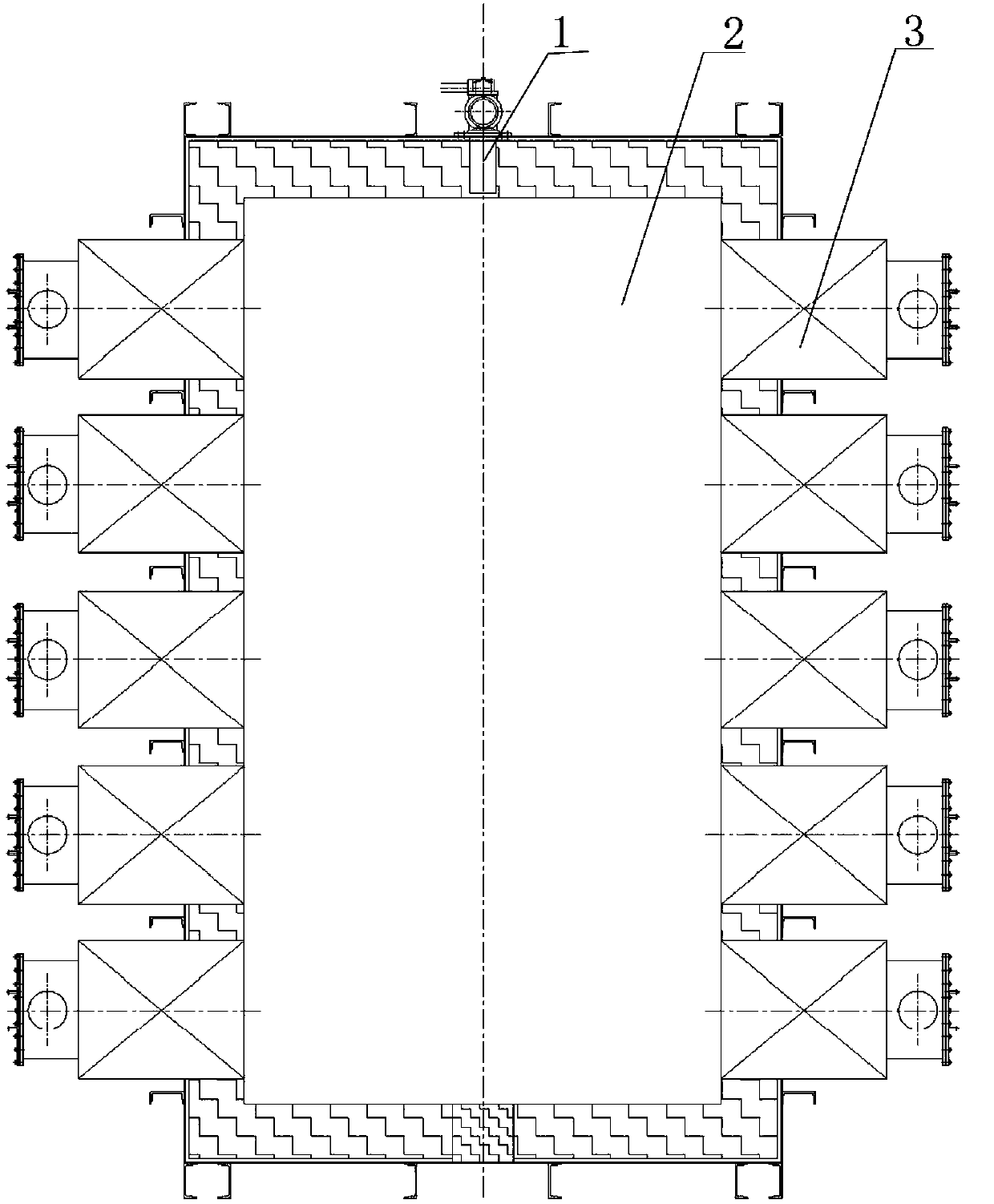

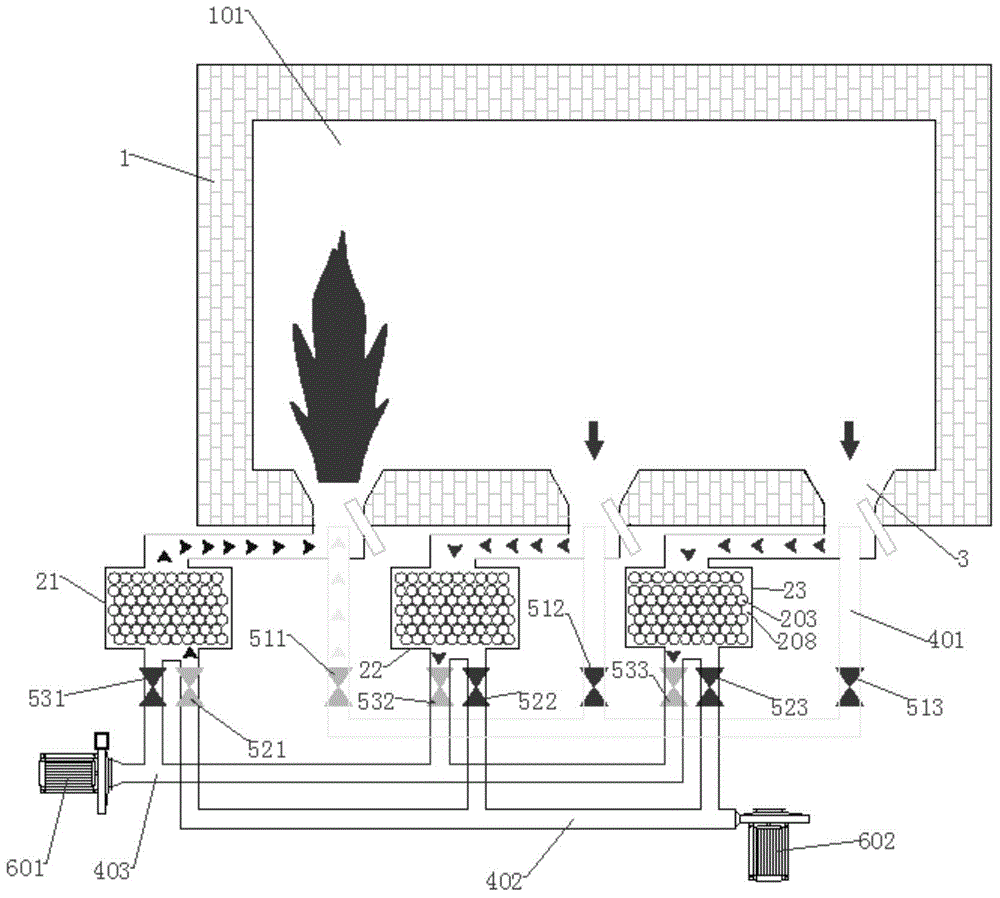

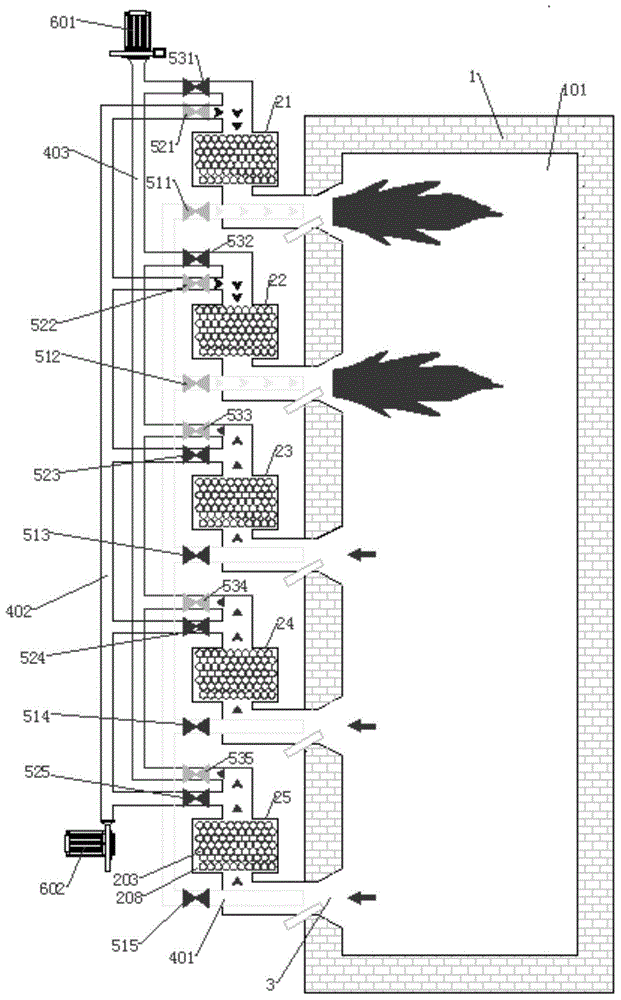

Carbon roasting furnace smoke pollutant heat storage incineration furnace and treatment method thereof

PendingCN108036665AConvenient to disperse and take turnsReduce cloggingHeat storage plantsIncinerator apparatusCombustion chamberSmoke Emission

The invention relates to the technical field of carbon roasting furnace smoke pollutant treatment, in particular to a carbon roasting furnace smoke pollutant heat storage incineration furnace and a treatment method thereof. The carbon roasting furnace smoke pollutant heat storage incineration furnace comprises a combustion chamber, heat storage chambers, a reversing system, a reverse burning system and a purging system; two sets of heat storage chambers are provided; each set of heat storage chambers comprises more than three heat storage chambers; the two sets of heat storage chambers are symmetrically arranged on the two sides of the incineration furnace; the heat storage chambers directly communicate with the combustion chamber; the two sets of heat storage chambers communicate by the reversing system; and the heat storage chambers communicate with an exhaust pipe through the reverse burning system. A heat storage technology is applied to the carbon roasting furnace smoke pollutanttreatment, and comprises heat storage, combustion oxygenolysis, combustion heat relief, purging and reverse burning; smooth incineration of carbon roasting furnace smoke pollutants can be guaranteed;the smoke emission accords with the air pollution release standard; the heat storage energy saving characteristic is achieved; the energy consumption is reduced; and the treatment cost is reduced.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

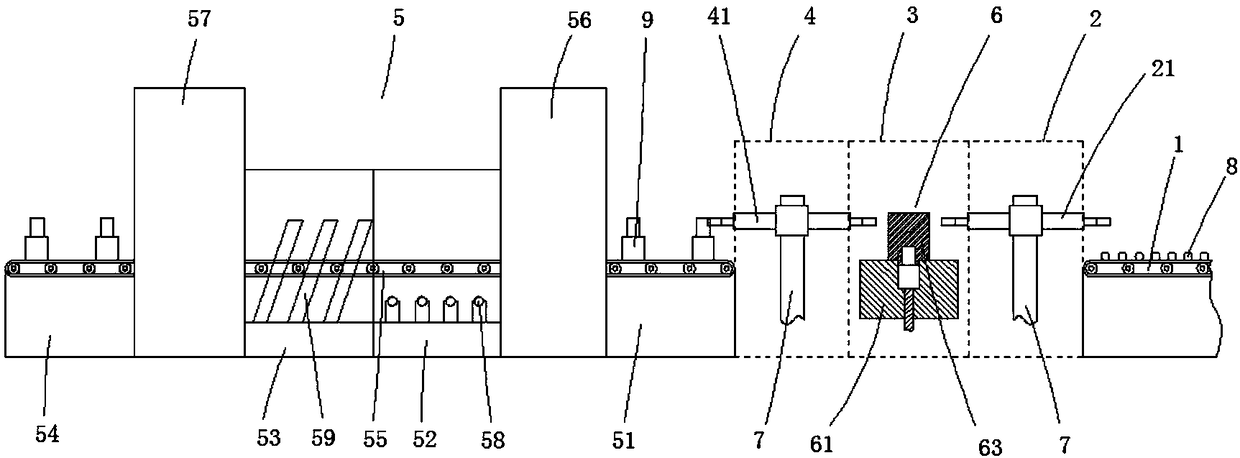

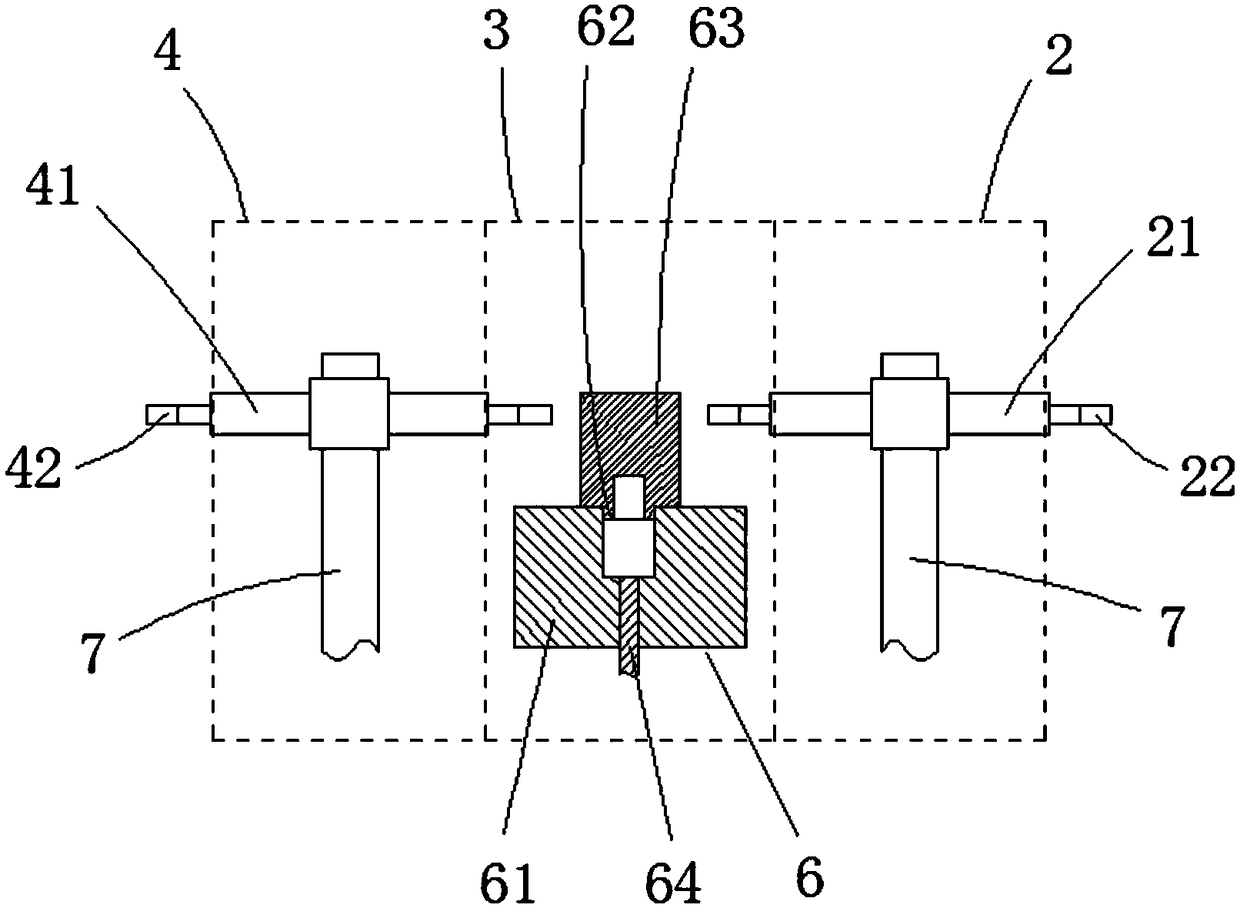

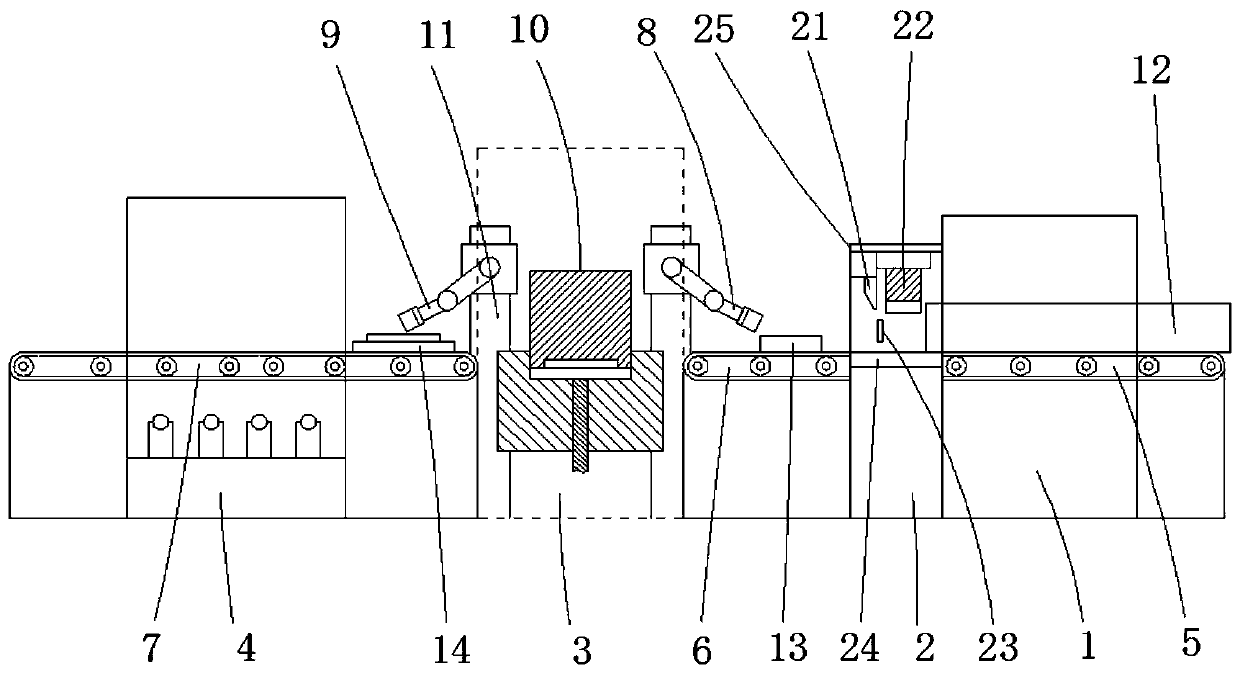

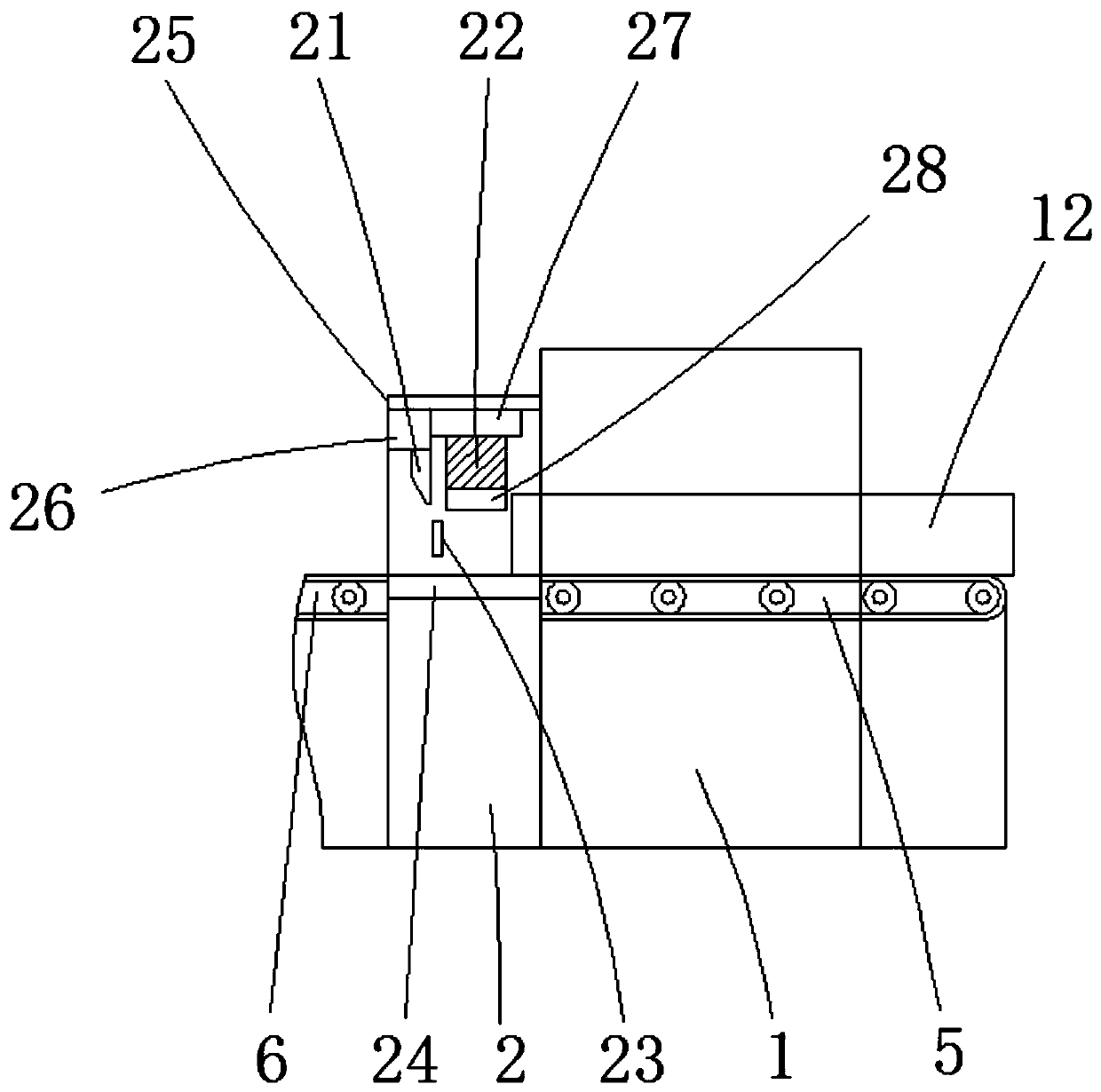

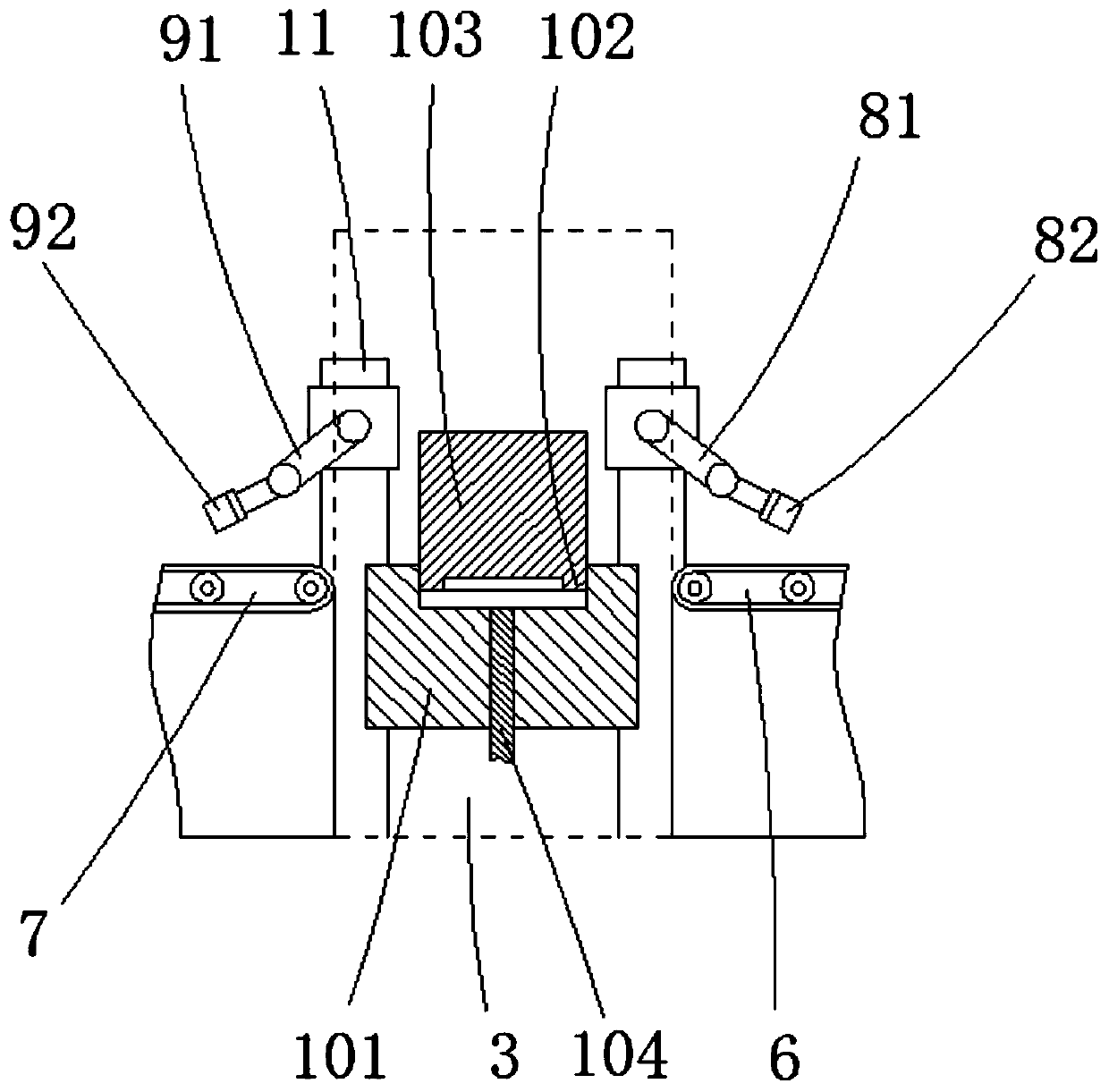

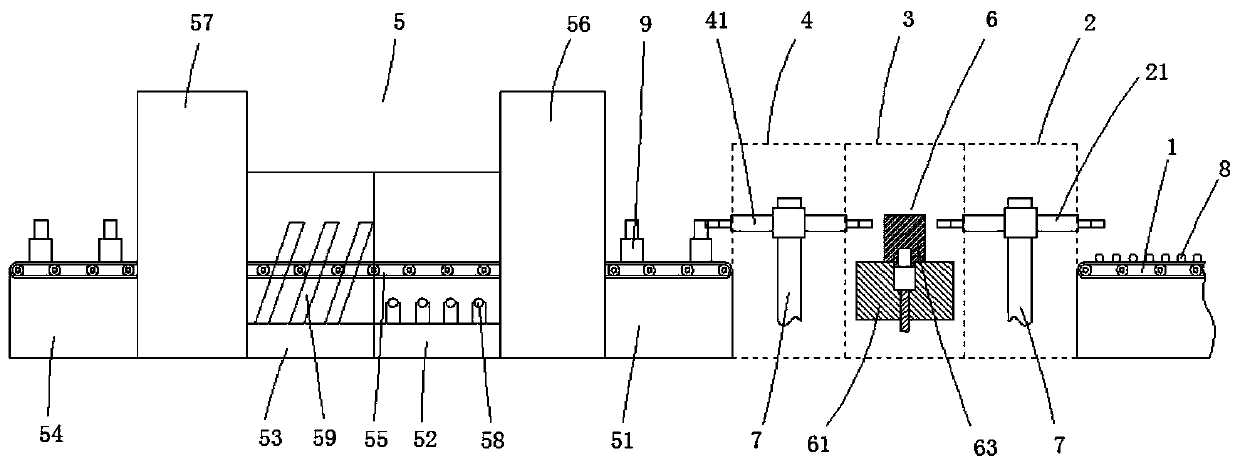

Closed forging device and production method for shaft products

ActiveCN108453205AReduce scrap rateIncrease productivityUpsetting pressesSwagging pressesEngineeringManipulator

The invention discloses a closed forging device for shaft products. The closed forging device comprises a feeding device, a first transferring manipulator, a forging and pressing device, a second transferring manipulator and a heat treatment device which are arranged in sequence. The forging and pressing device is provided with a closed forging mold. The closed forging mold comprises a lower moldbody and an upper mold body with a convex part at the lower end. The outer wall of the convex part is attached to the mold cavity of the lower mold body. The lower mold body is provided with an ejection rod. The first transferring manipulator and the second transferring manipulator are arranged on the base, rotatably connected with the base and separately connected with a rotation driving device.Shaft products are forged in a closed forging mode, so that flanges and leftovers are avoided, and the rejection rate is low; and integrated conveying, forging, pressing and heat treatment is achieved, so that production efficiency and product quality are improved; and materials are saved, and labor cost is reduced.

Owner:JIANGSU BAOJIE FORGING

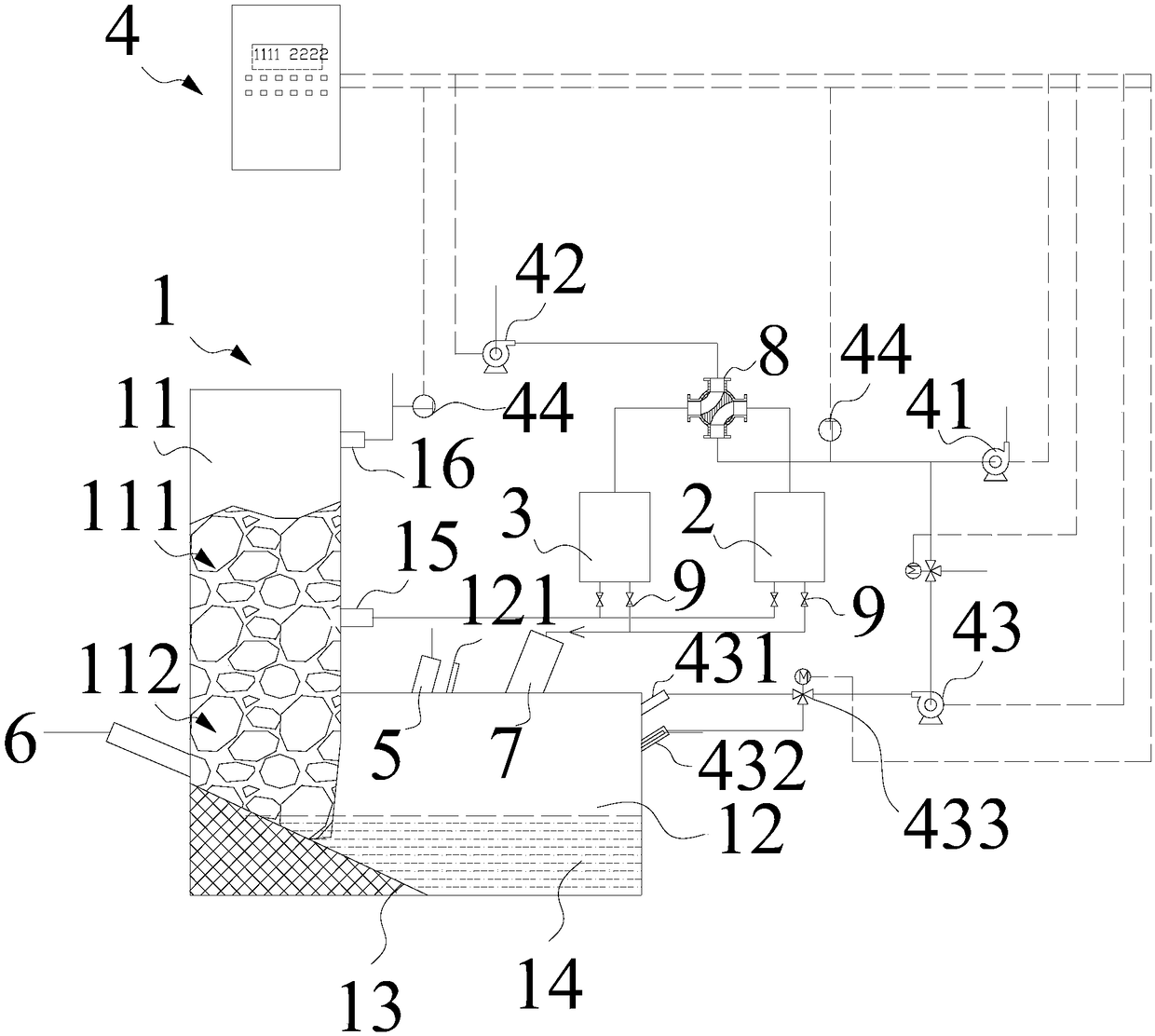

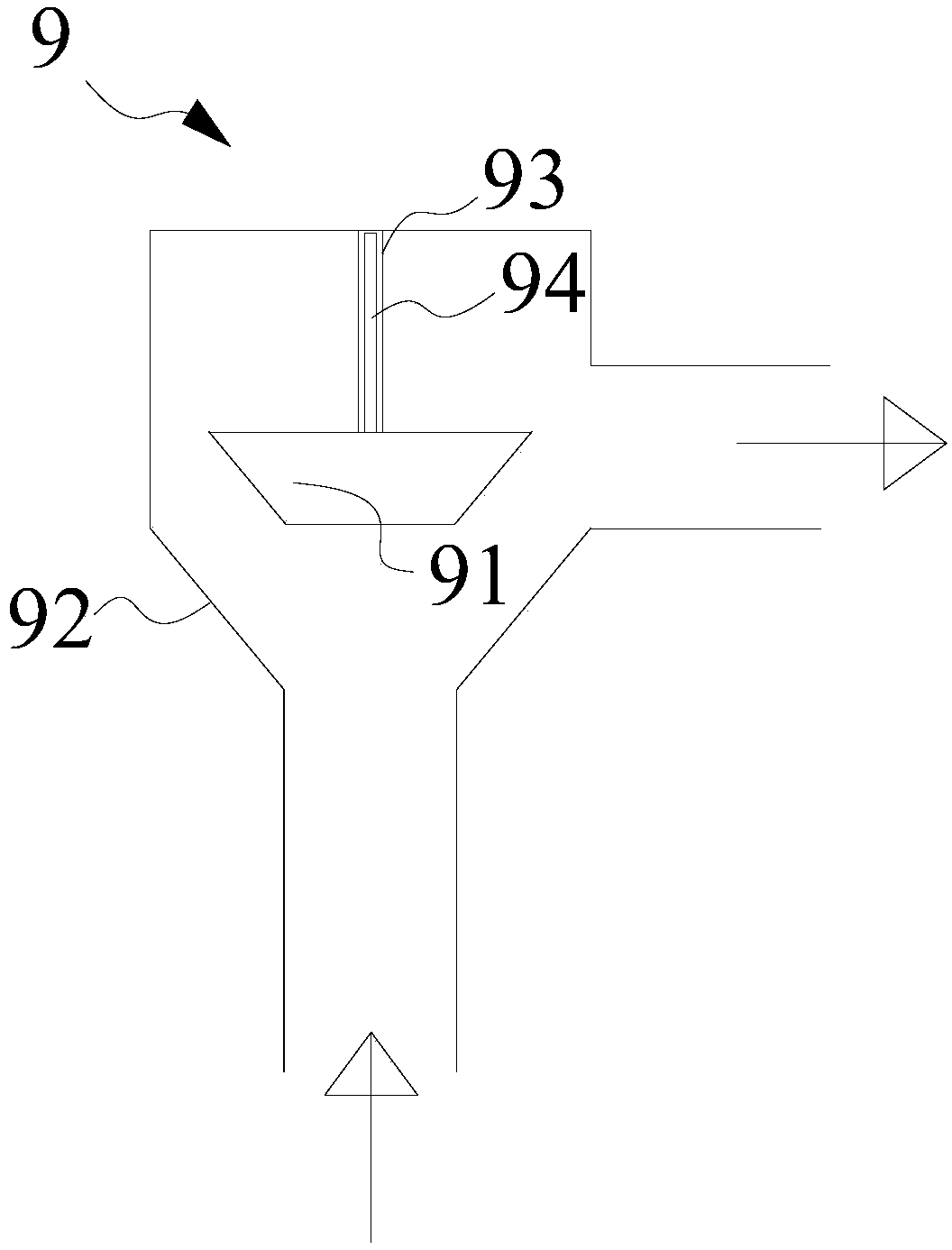

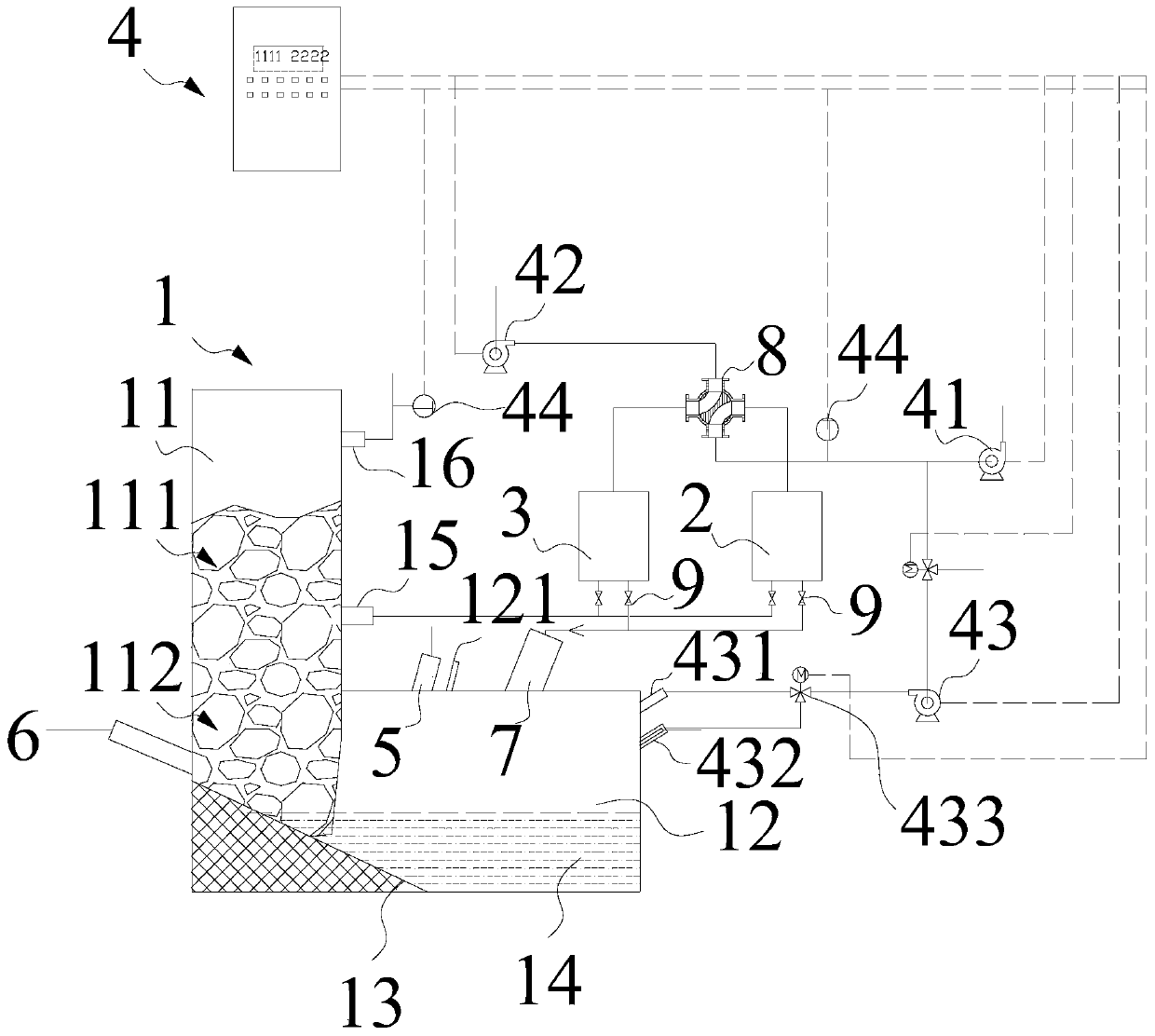

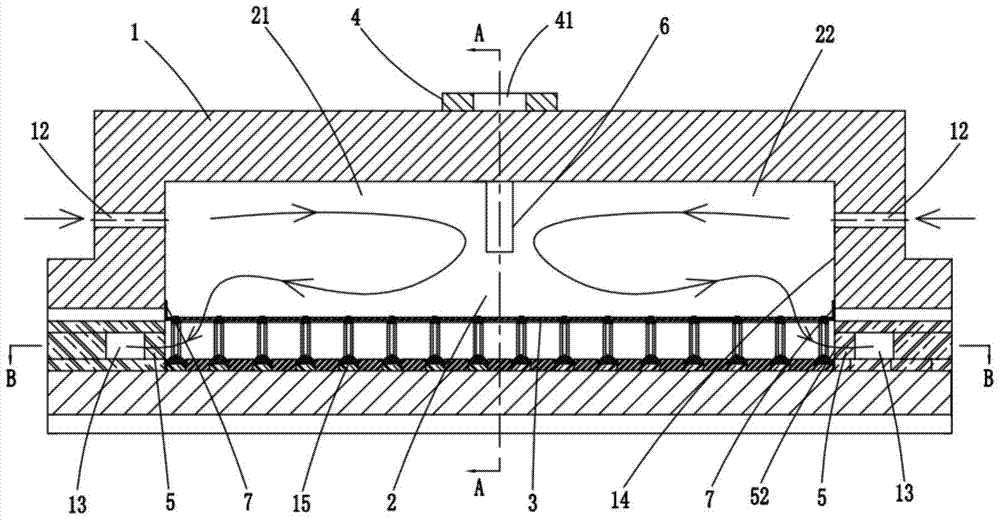

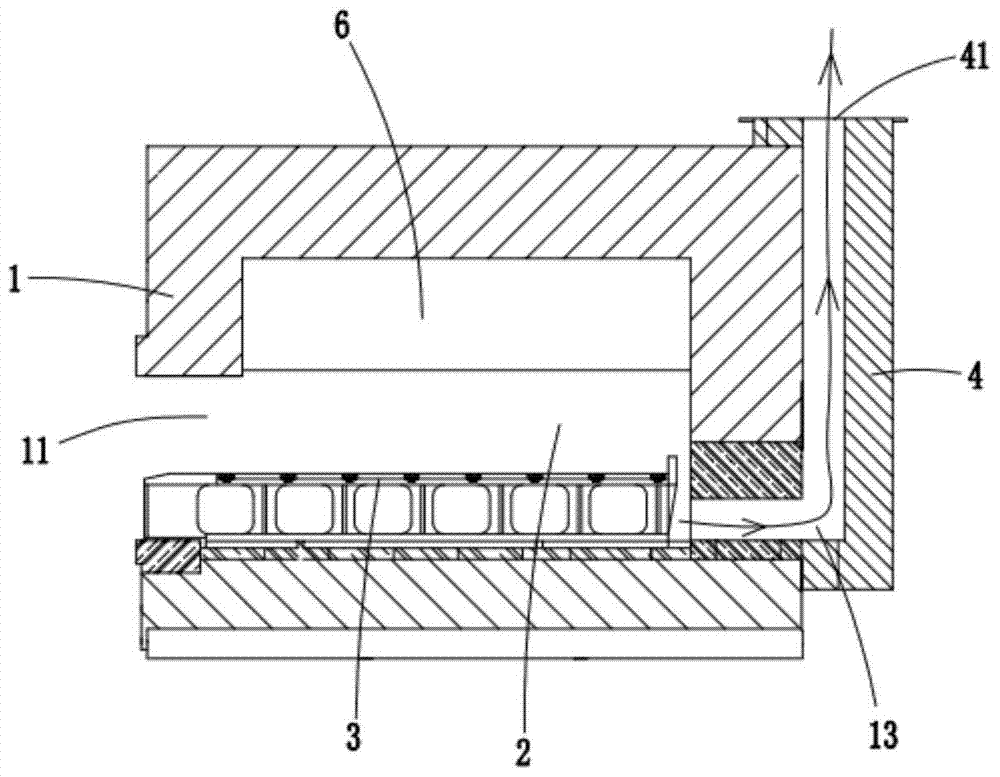

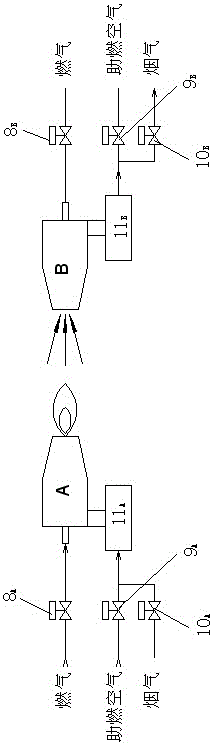

Energy-saving combustion and waste heat recovery system of quick aluminum melting furnace

ActiveCN108800957AImprove recycling efficiencyGuaranteed temperatureIncreasing energy efficiencyWaste heat treatmentCombustion systemWaste heat recovery unit

The invention provides an energy-saving combustion and waste heat recovery system of a quick aluminum melting furnace. The energy-saving combustion and waste heat recovery system of the quick aluminummelting furnace comprises a furnace body, a combustion system and a waste heat recovery system. The furnace body comprises a vertical melting furnace and a transverse holding furnace. The combustionsystem comprises a first fuel spray nozzle, an ignition nozzle and an air spray nozzle, wherein the air spray nozzle is used for guiding the preheated air into the holding furnace in the mode that thepreheated air serves as the combustion-supporting gas. The waste heat recovery system comprises a first heat storage chamber, a second heat storage chamber and a reversing device. The purposes that the heat storage chamber on one side stores the waste heat generated by combustion of the melting furnace, the heat storage chamber on the other side preheats the combustion-supporting gas of the holding furnace, and the operation is alternatively conducted according to the preset time cycle are achieved. The problems that in the prior art, a melting furnace and a holding furnace are low in waste heat recovery efficiency and high in the waste heat recovery difficulty, and due to the fact that the combustion temperature in the melting furnace is high, thermal power type NOX is prone to being generated when the air serves as the combustion-supporting gas are effectively solved, the overall energy consumption of the combustion system is reduced, the flue gas of the system is effectively balanced, and the waste heat recovery efficiency is improved.

Owner:HUATIAN ENG & TECH CORP MCC +1

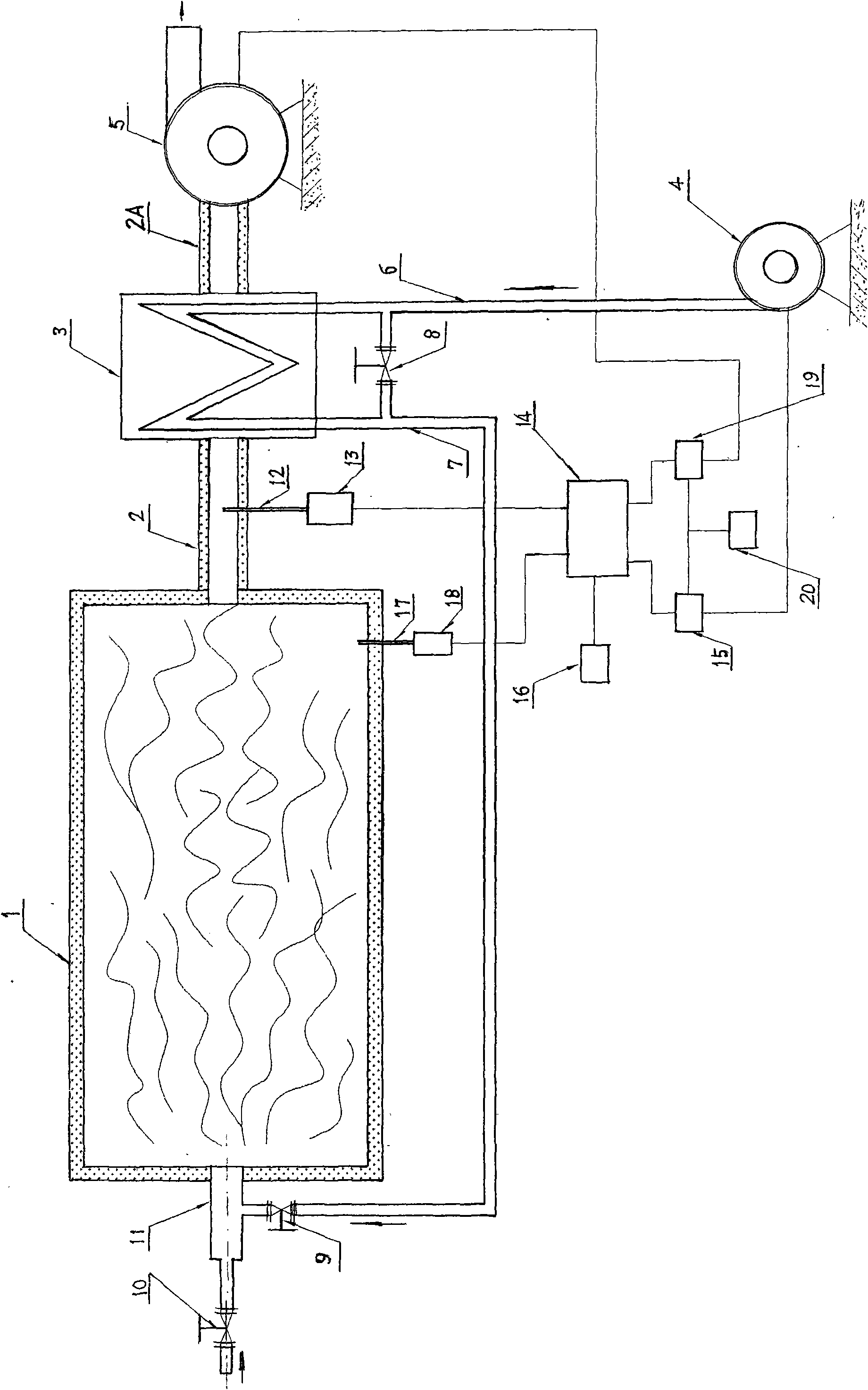

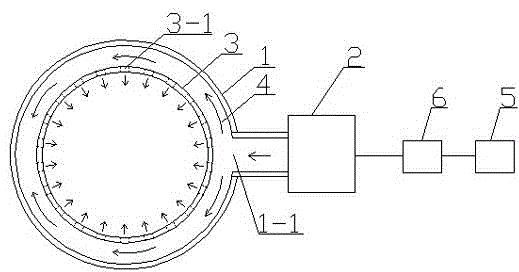

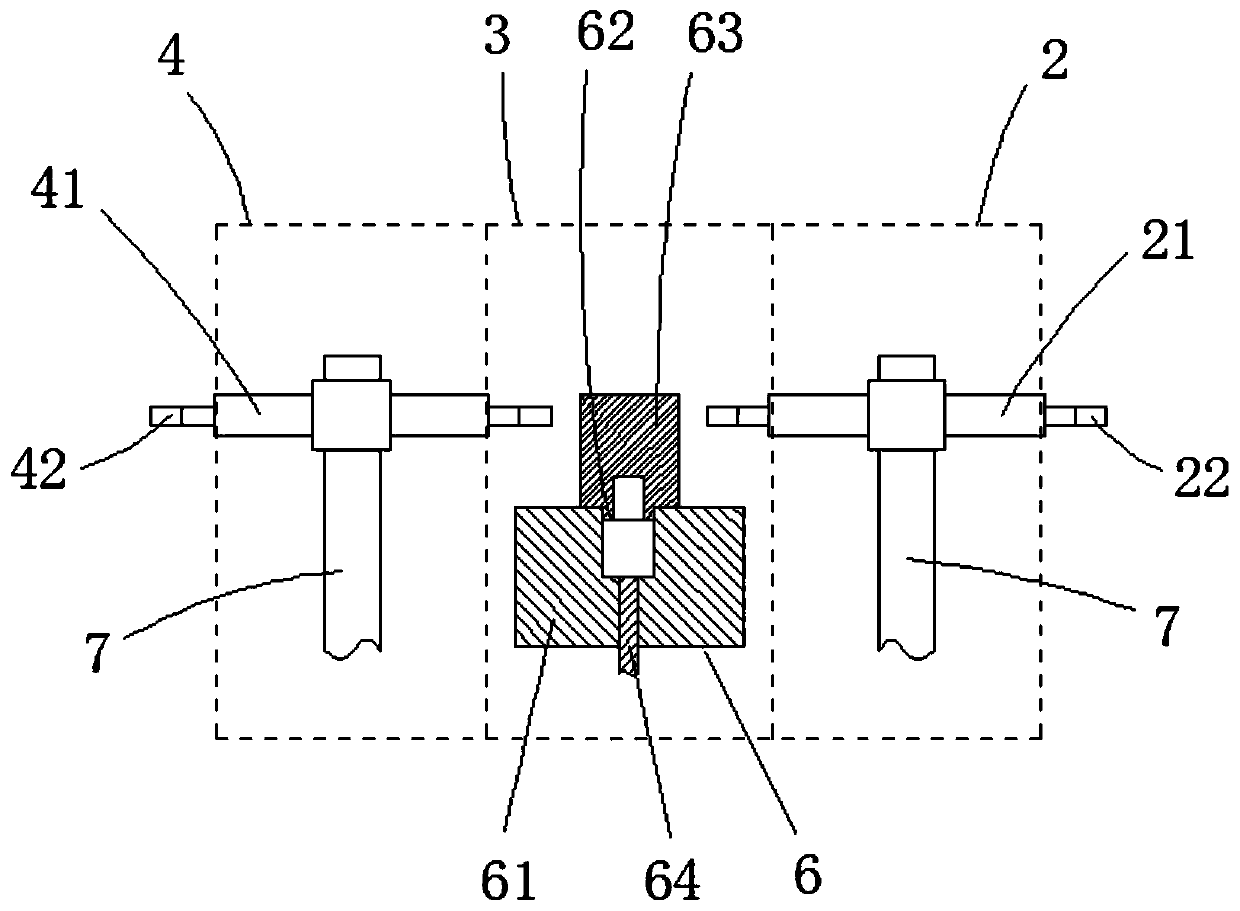

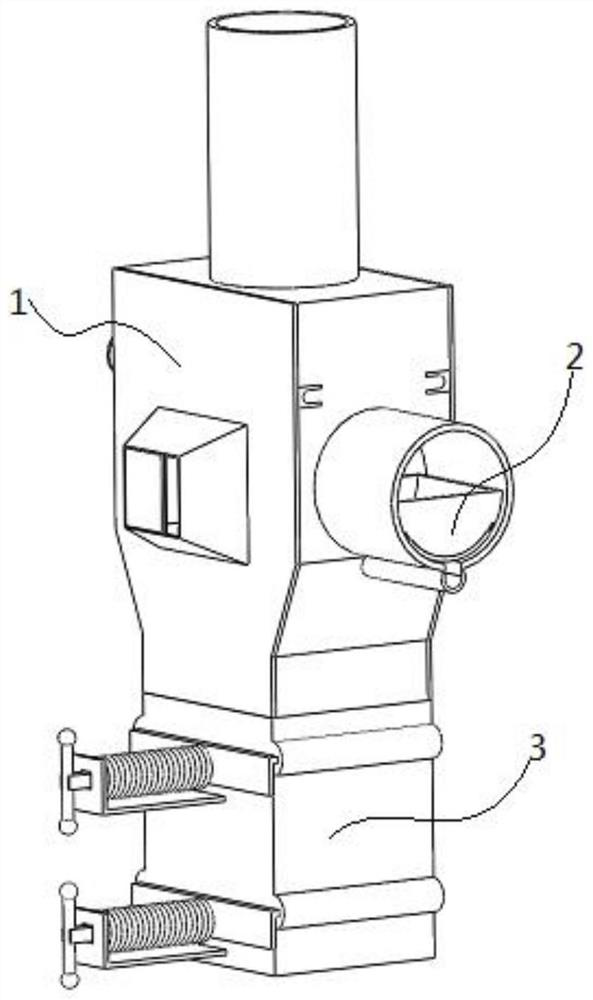

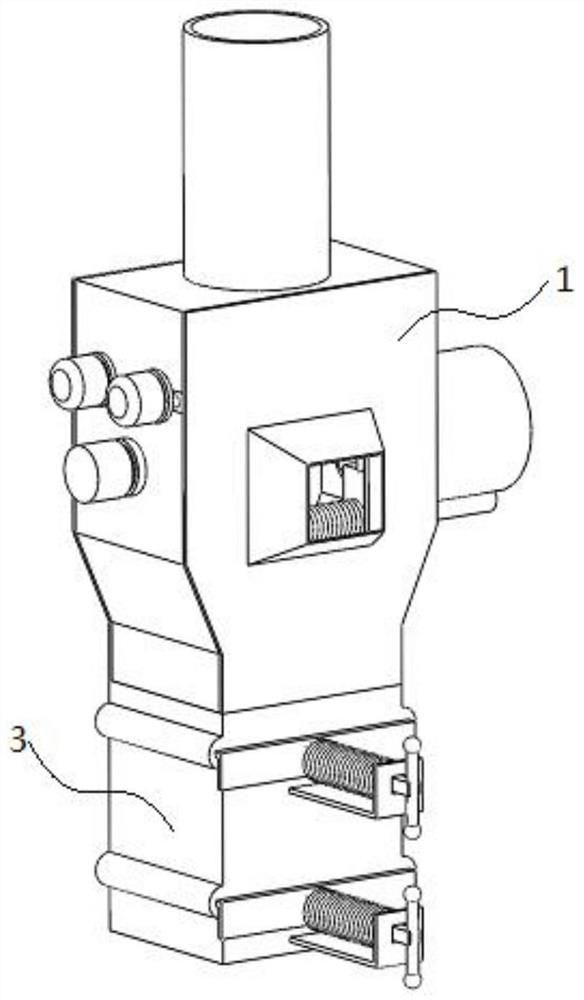

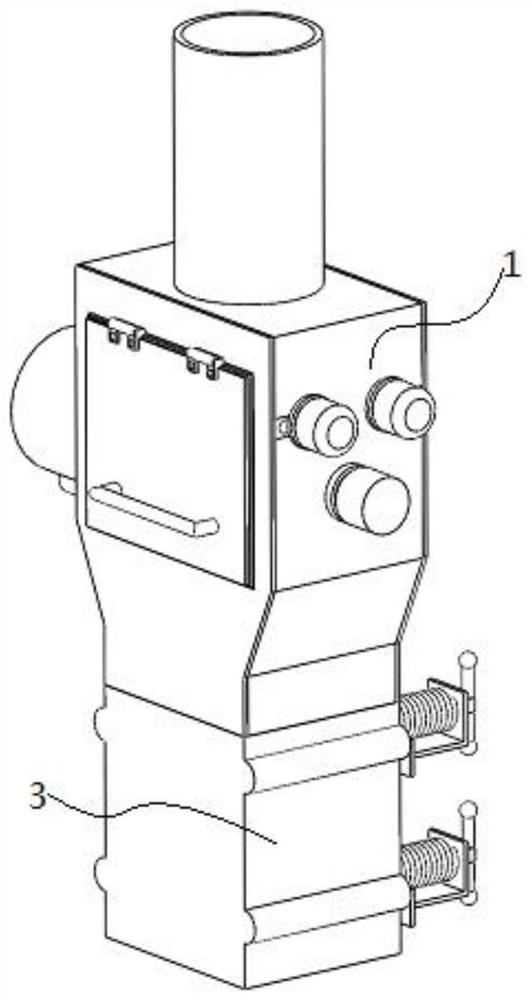

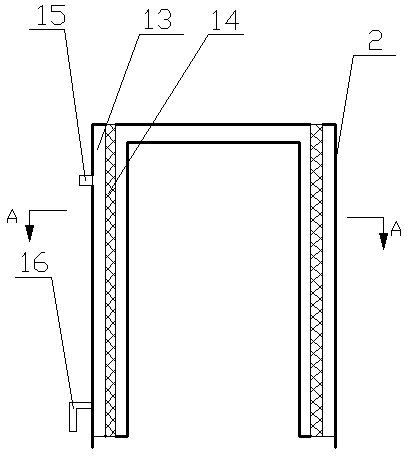

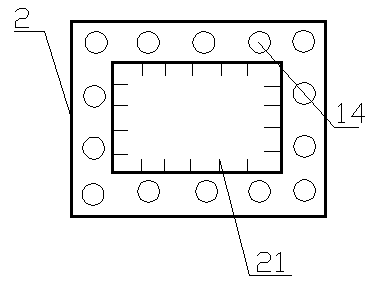

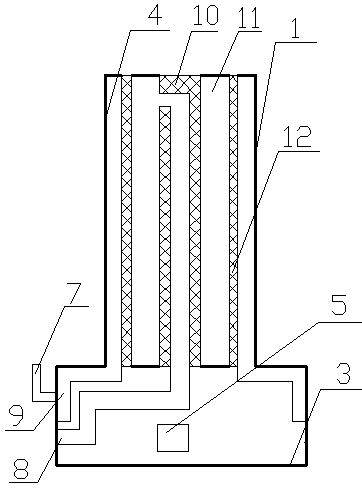

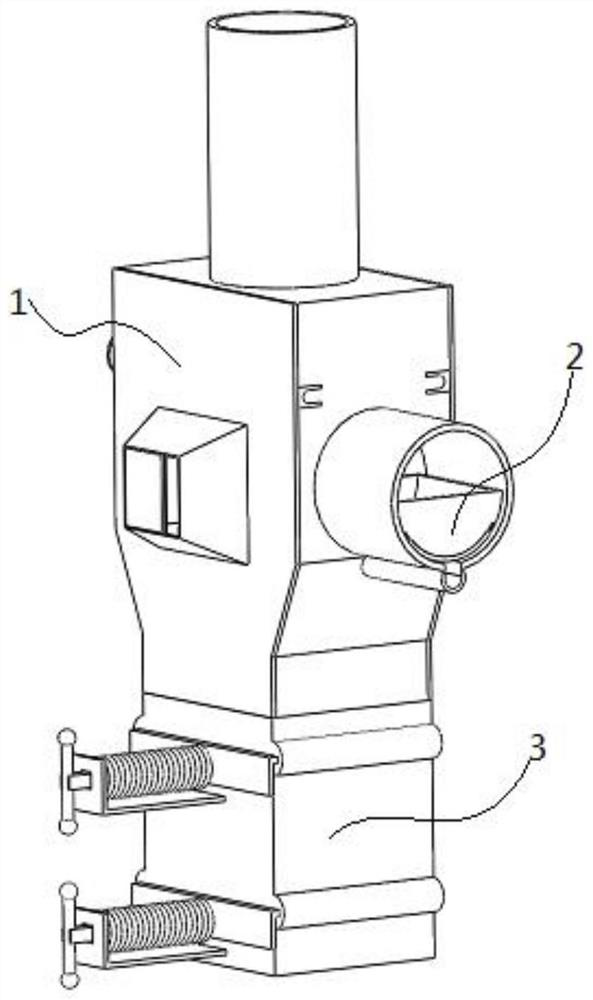

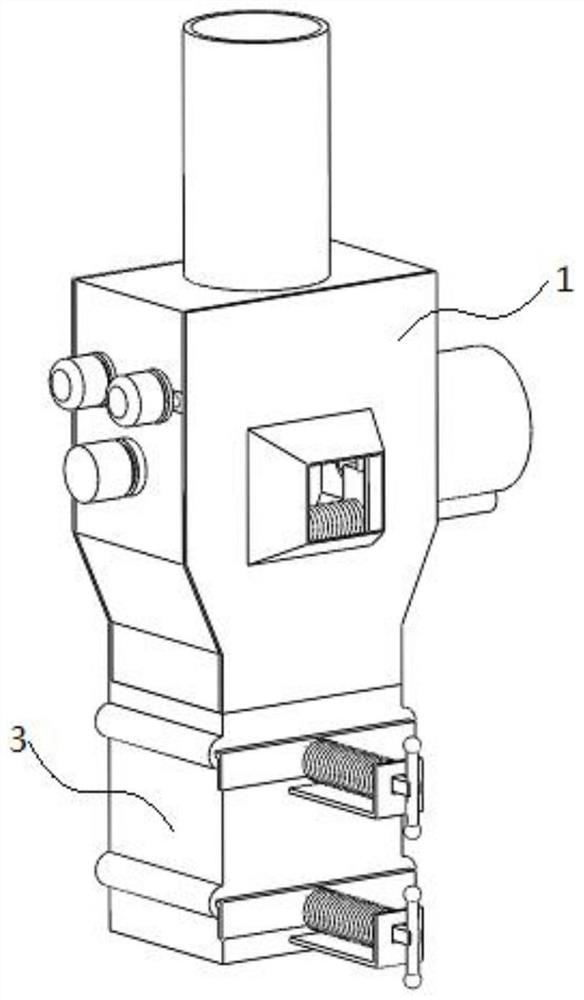

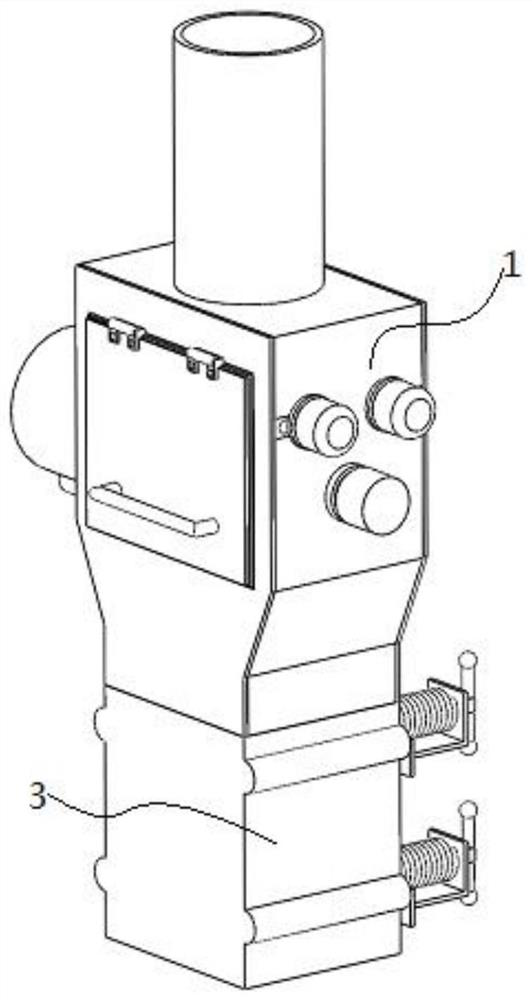

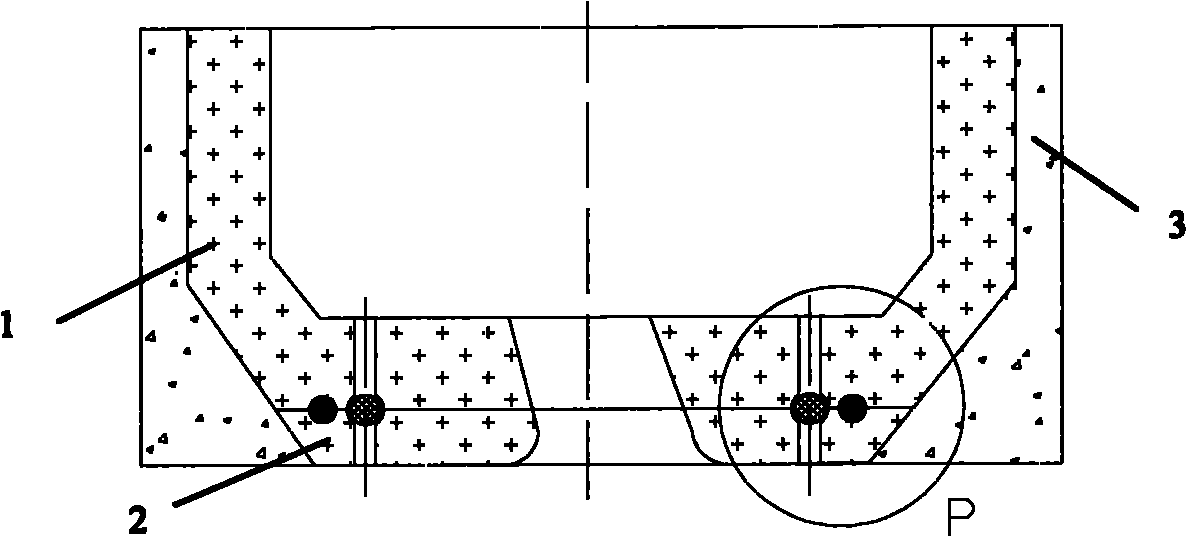

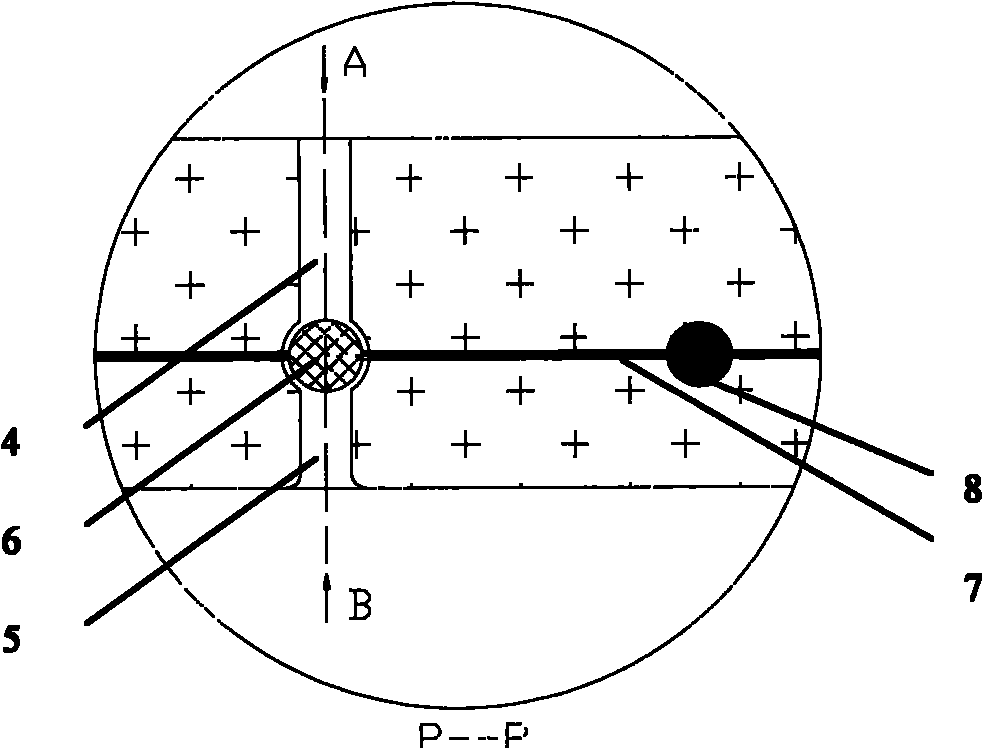

Automatic furnace-pressure control system for forging heating furnace

InactiveCN104911327AStable furnace pressureReduce energy consumptionFurnace typesHeat treatment process controlFrequency changerDetector

The invention provides an automatic furnace-pressure control system for a forging heating furnace. A pressure detector (2) is mounted in the furnace body of the forging heating furnace, a gas flowmeter (3) is mounted in a smoke exhaust duct of the forging heating furnace, the signal output end of the pressure detector (2) and the signal output end of the gas flowmeter (3) are in signal connection with a signal input end of a PLC controller (4), and the signal output end of the PLC controller (4) is in signal connection with a frequency converter (1-1) of a smoke exhaust fan. The automatic furnace-pressure control system for the forging heating furnace has the advantages that due to the adopted technical scheme, a control signal is transmitted to the frequency converter (1-1) of the smoke exhaust fan so that the frequency converter (1-1) regulates the rotating speed of the smoke exhaust to control the smoke exhaust amount, and therefore, the purposes of stabilizing the furnace pressure, saving the energy consumption, reducing the smoke exhaust temperature and reducing noise are achieved.

Owner:HUBEI WEISHIKANG MACHINERY MFG

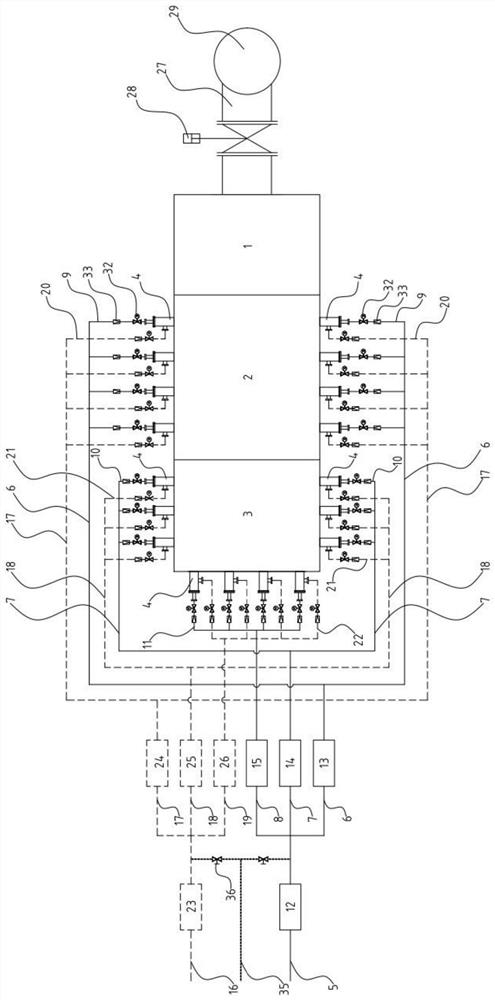

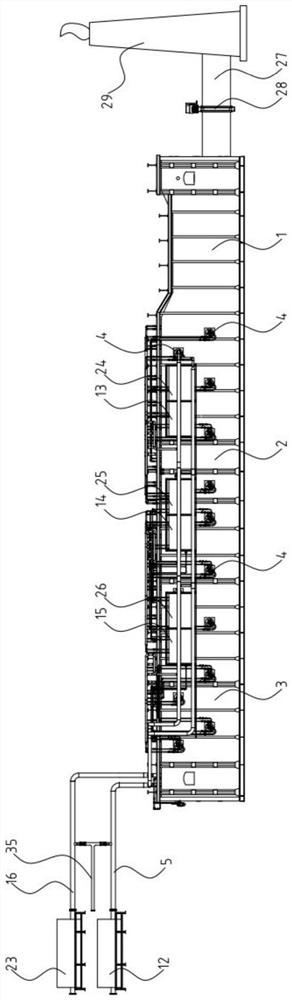

Oxy-fuel combustion system for steel rolling heating furnace

PendingCN114688868AImprove combustion efficiencyImprove heat transfer efficiencyFurnace typesHeat treatment furnacesCombustion systemTemperature control

The invention provides an oxygen-fuel combustion system for a steel rolling heating furnace. The oxygen-fuel combustion system comprises the heating furnace, a fuel system, a combustion-supporting system, a nitrogen purging system, a smoke exhaust system and a control system. The heating furnace comprises a preheating section, a heating section and a soaking section. Total-oxygen flameless combustors are arranged on the side walls of the upper heating area and the lower heating area of the heating section, and the total-oxygen flameless combustors are arranged in an up-and-down layered and left-and-right staggered mode. Total-oxygen flameless combustors are arranged on the side walls of the upper heating area and the lower heating area of the soaking section, and the total-oxygen flameless combustors are arranged in an up-and-down layered and left-and-right staggered mode. Total-oxygen flameless combustors are arranged on the end wall of the heating area on the upper portion of the soaking section and are horizontally arranged in a single-layer mode. The control system comprises a blank tracking system, an intelligent temperature control system, a hearth pressure control system, a linkage alarm protection system and a blank heat preservation rolling waiting system. The combustion efficiency and the heat transfer efficiency of the steel rolling heating furnace are improved, and the purposes of improving productivity, saving fuel, reducing emission and improving product quality are achieved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

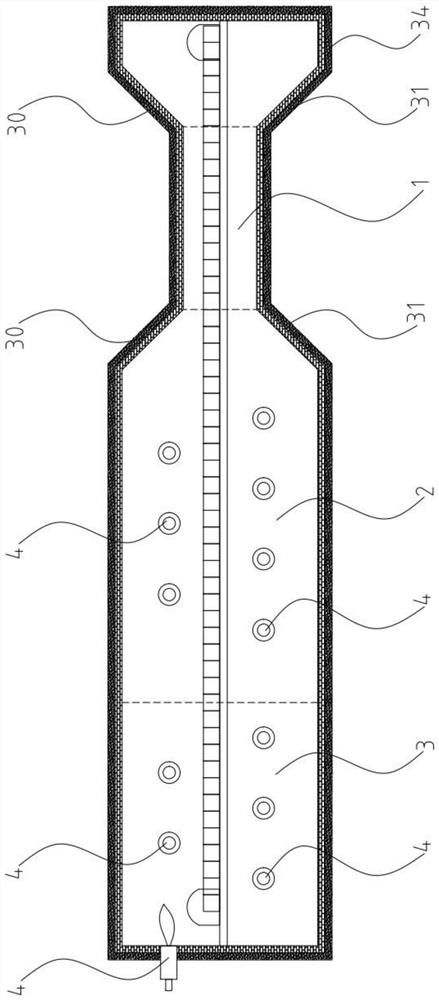

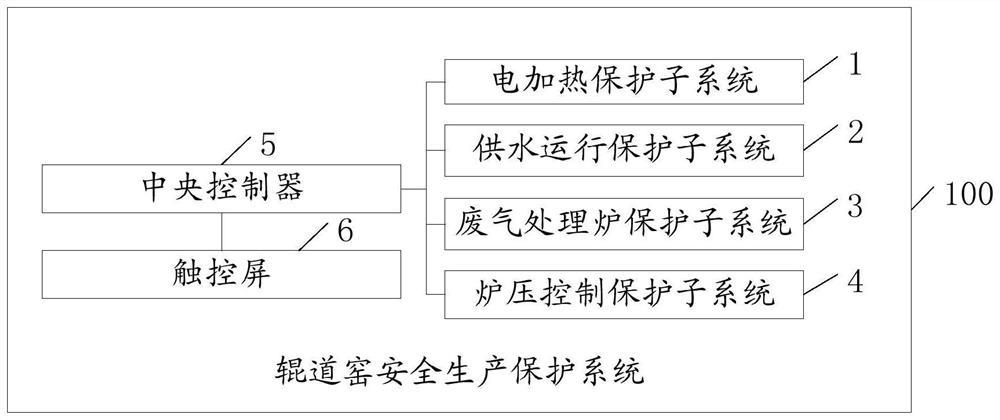

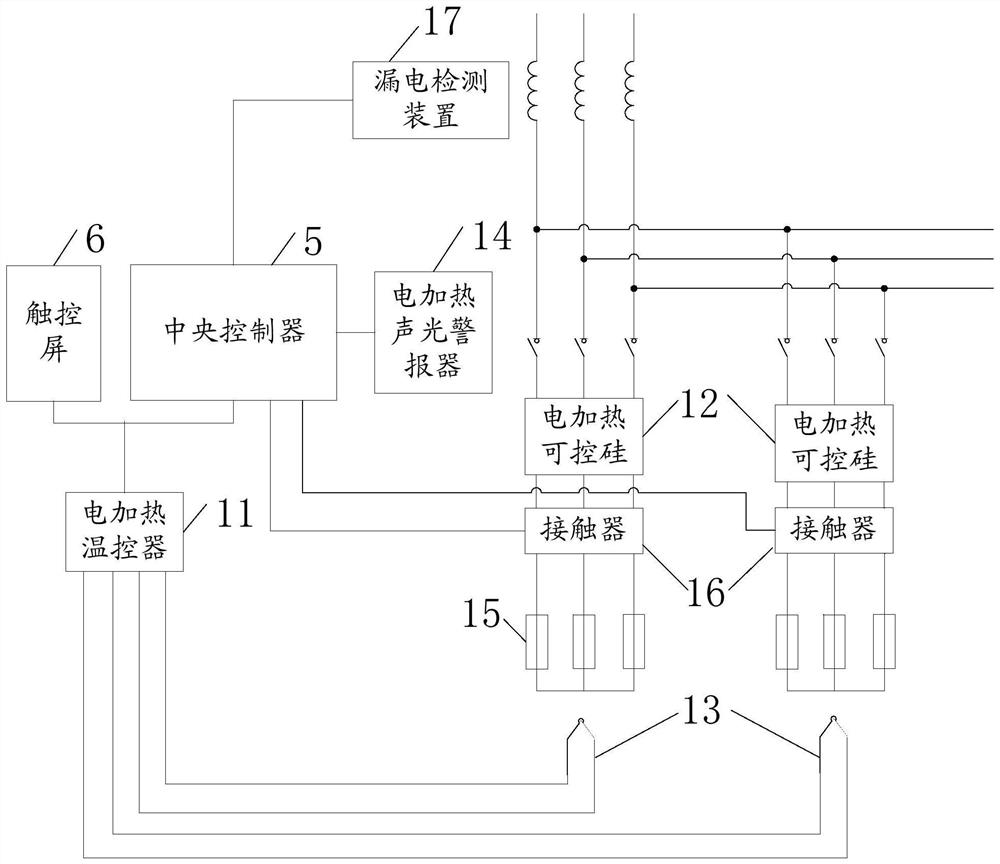

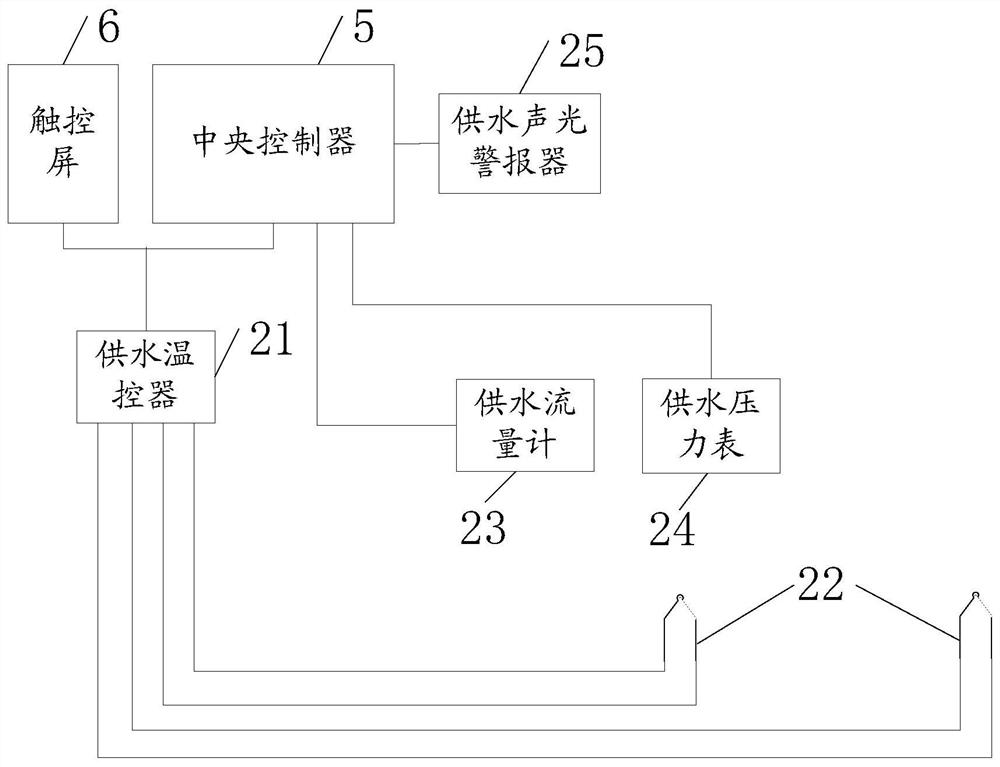

Roller kiln safety production protective system

PendingCN111998669AImprove securityImprove stabilityFurnace typesIncinerator apparatusExhaust fumesProcess engineering

The invention discloses a roller kiln safety production protective system. The roller kiln safety production protective system comprises the following subsystems, the electric heating protective subsystem which is used for detecting and transmitting the temperature of a thermocouple as well as the current and voltage of a heating element so as to drive a central control unit to judge the aging degree of the heating element, and outputting an alarm after receiving an alarm command, the water supply operation protective subsystem which is used for detecting and transmitting the water supply instantaneous flow rate and the water supply pressure value, and outputting an alarm after receiving an alarm command, the waste gas treatment furnace protective subsystem which is used for controlling atemperature control actuator through a waste gas temperature controller, detecting and transmitting the temperature of a waste gas thermocouple so as to driving the central control unit to conduct comparison treatment, and outputting an alarm after receiving an alarm command, and the furnace pressure control protective subsystem which is used for controlling a variable frequency fan through a furnace pressure temperature controller, detecting and transmitting the temperature detected by a furnace pressure thermocouple so as to control the central control unit to conduct comparison, and outputting an alarm after receiving an alarm command. By adopting the roller kiln safety production protective system, the safety and stability of roller kiln equipment can be improved.

Owner:FOSHAN TIANLU INTELLIGENT EQUIP TECH CO LTD

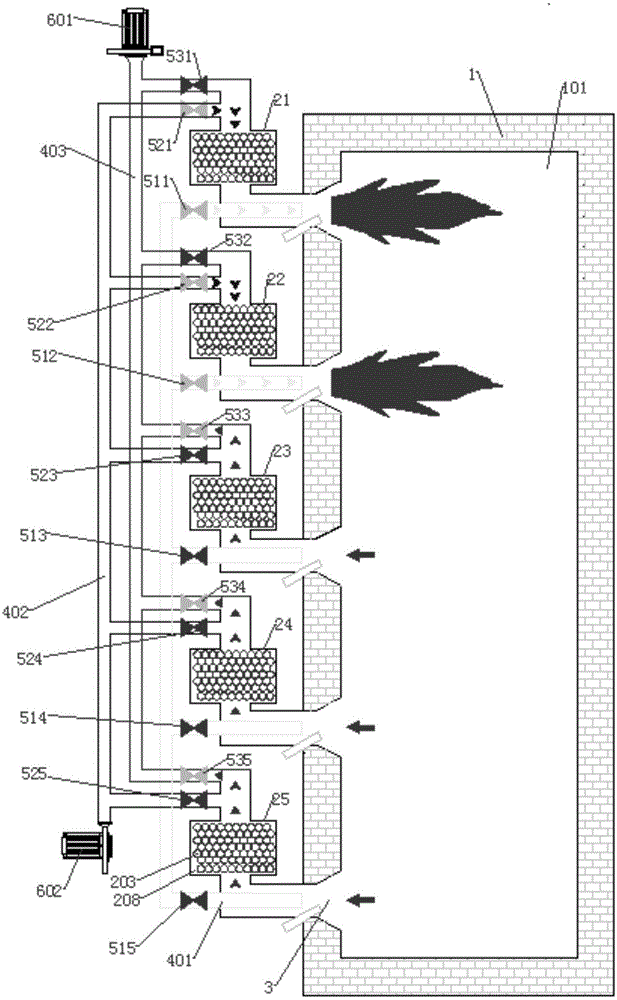

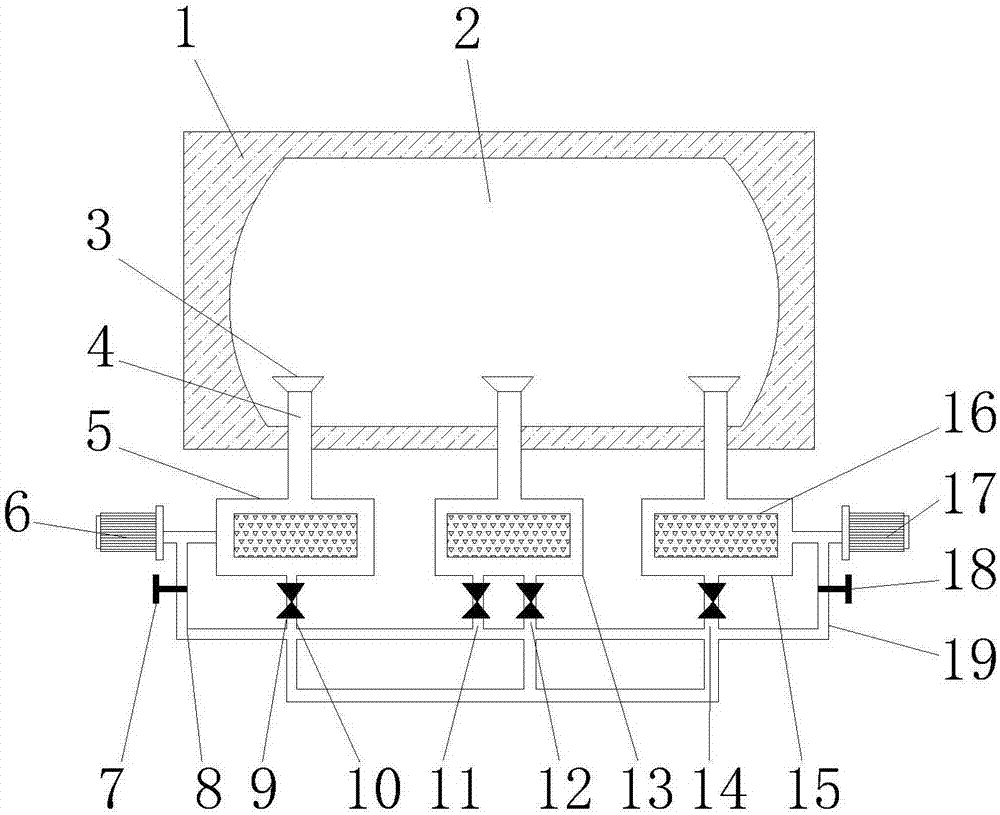

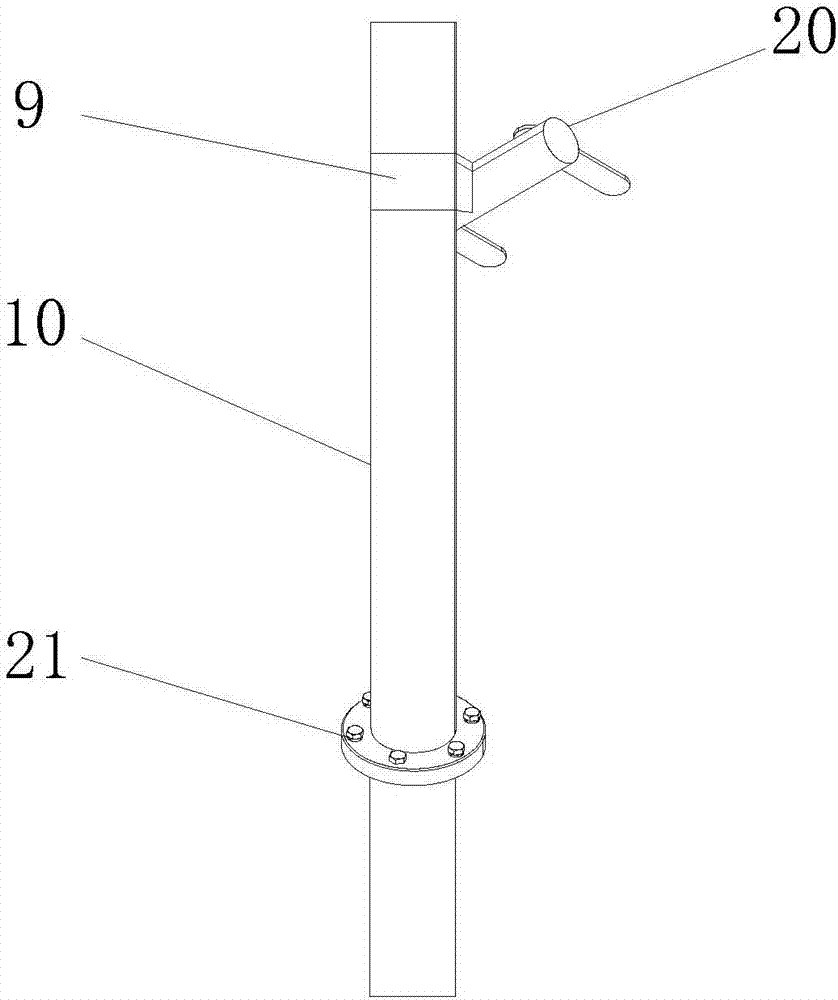

Premixed regenerative combustion device

InactiveCN107166974APrevent air leakageIncrease cooldownCombustion processEnergy industryFurnace temperatureCombustor

The invention discloses a premixed regenerative combustion device. The premixed regenerative combustion device comprises a furnace body, wherein a hearth is arranged in the furnace body; three branch pipes are arranged at the lower part of the hearth and sequentially connected with a first regenerative chamber, a second regenerative chamber and a third regenerative chamber from left to right; the first regenerative chamber is fixedly connected with an induced draft fan through a flue gas pipeline; a flue gas reversing valve is arranged in the flue gas pipeline; a first gas pipeline is mounted at the lower part of the first regenerative chamber; a gas valve is arranged in the first gas pipeline; a control wrench is mounted on the outer side of the gas valve; a second gas pipeline and a combustion-supporting gas pipeline are correspondingly arranged on the left side and the right side of the lower part of the second regenerative chamber; and a combustor is arranged in each of the first regenerative chamber, the second regenerative chamber and the third regenerative chamber. The premixed regenerative combustion device is smooth in smoke discharging, stable in furnace pressure, high in total flue gas waste heat recovery rate, and uniform in in-furnace temperature distribution, realizes high-temperature nitric oxide combustion and is more energy-saving, environment-friendly and safer.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

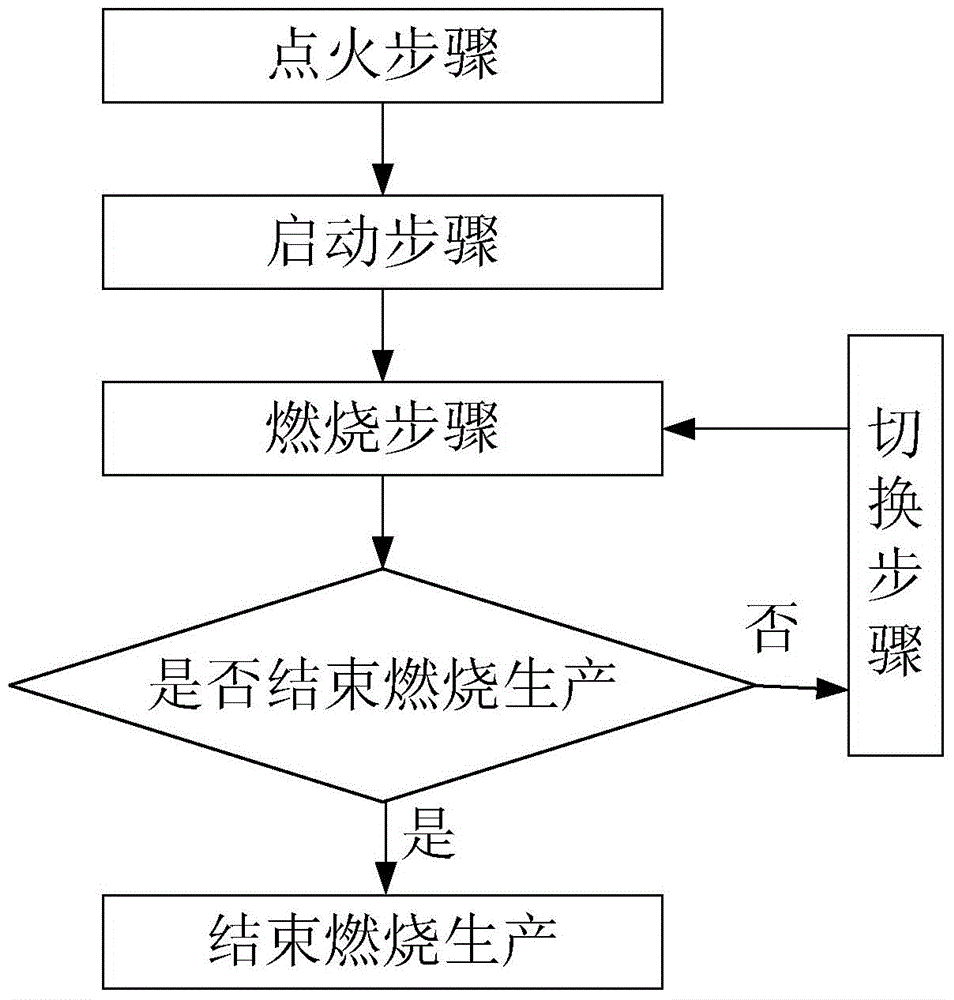

Control method of regenerative combustion equipment

ActiveCN104456616ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustion

The invention provides a control method of regenerative combustion equipment. The method includes an igniting step, a starting step, a combustion step and a switching step. The method overcomes the technical bias that the regenerative combustion equipment is controlled in pairs with a traditional method and achieves an unexpected energy-saving technical effect, and the phenomena that in an existing high-temperature air combustion technology, detonation and furnace explosion happen easily in the reversing process, and fuel waste is serious are effectively avoided.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

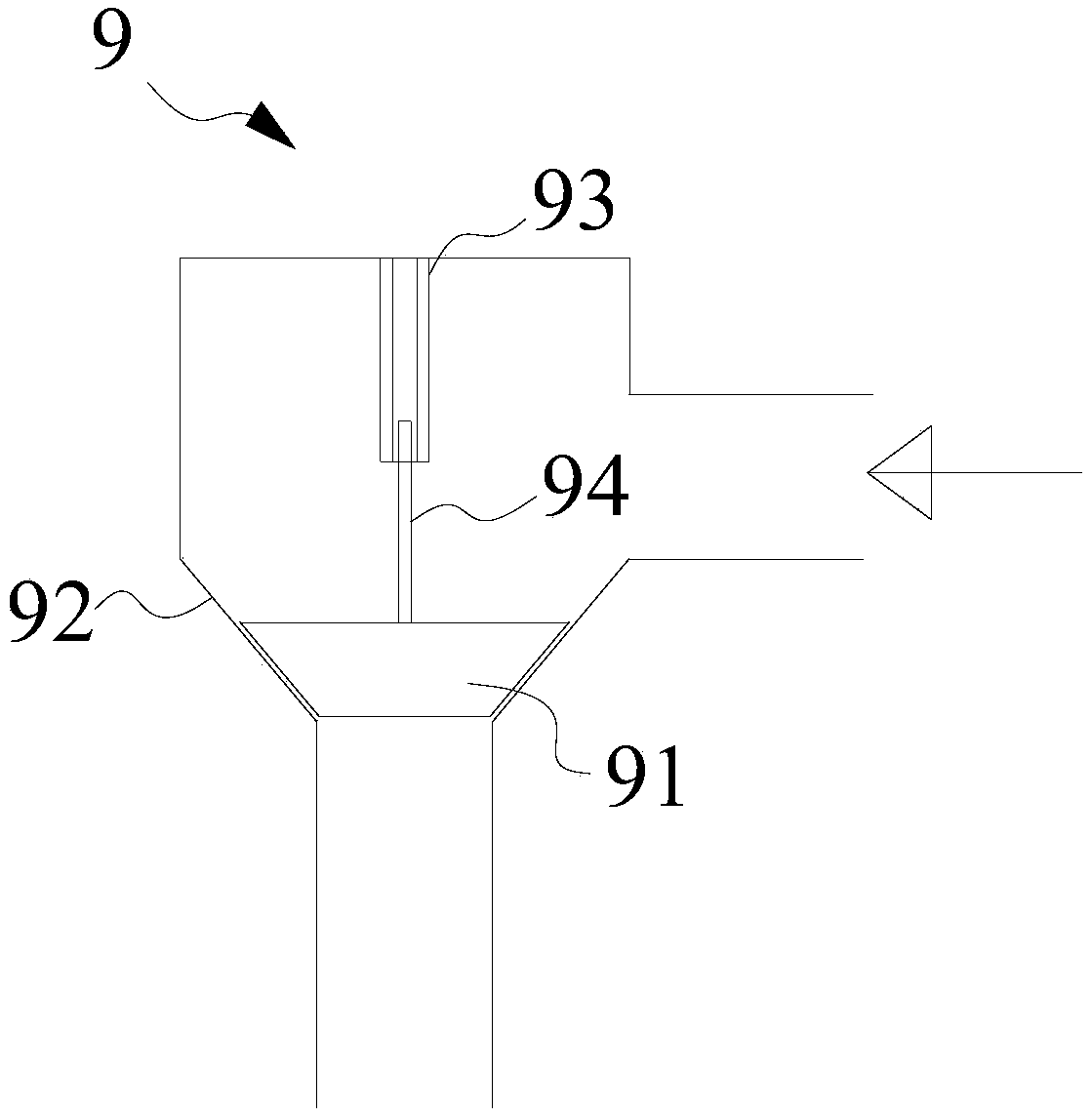

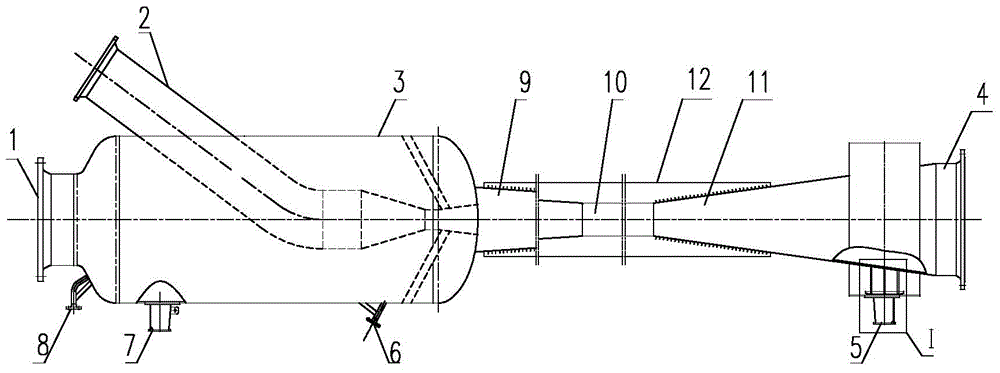

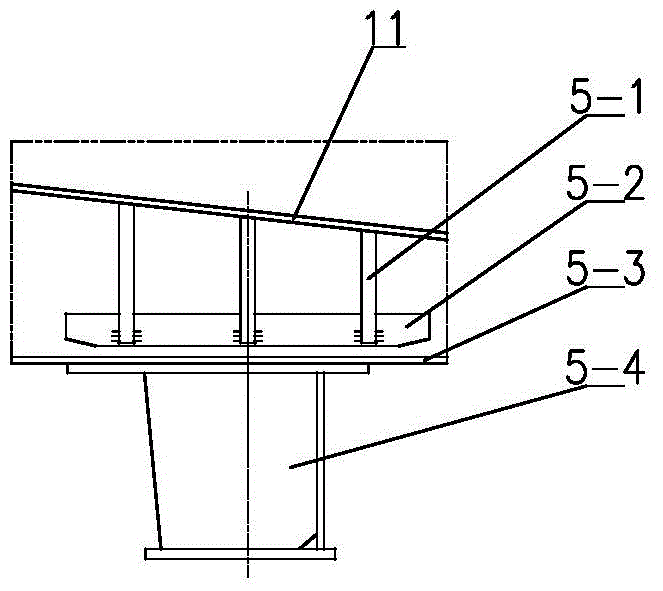

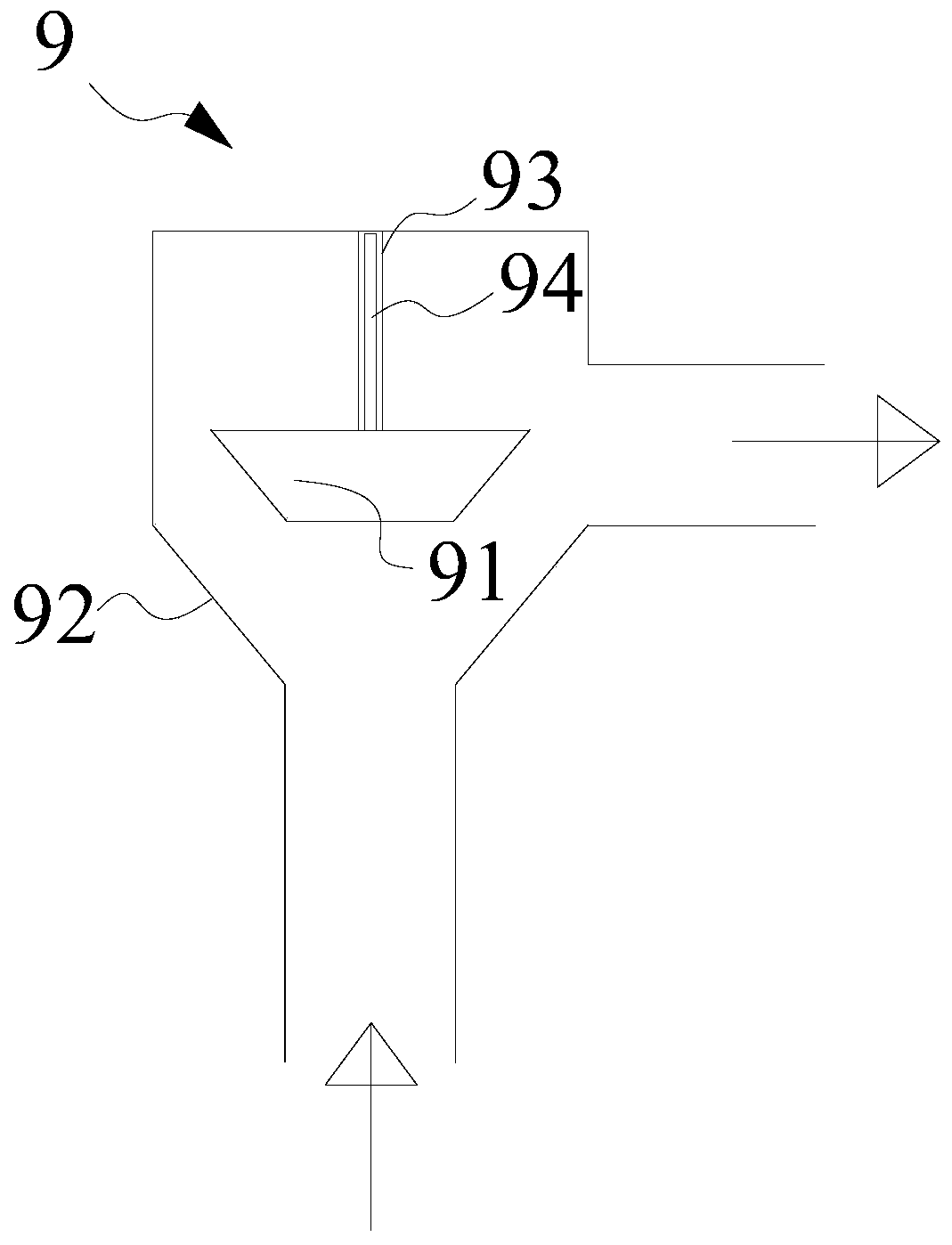

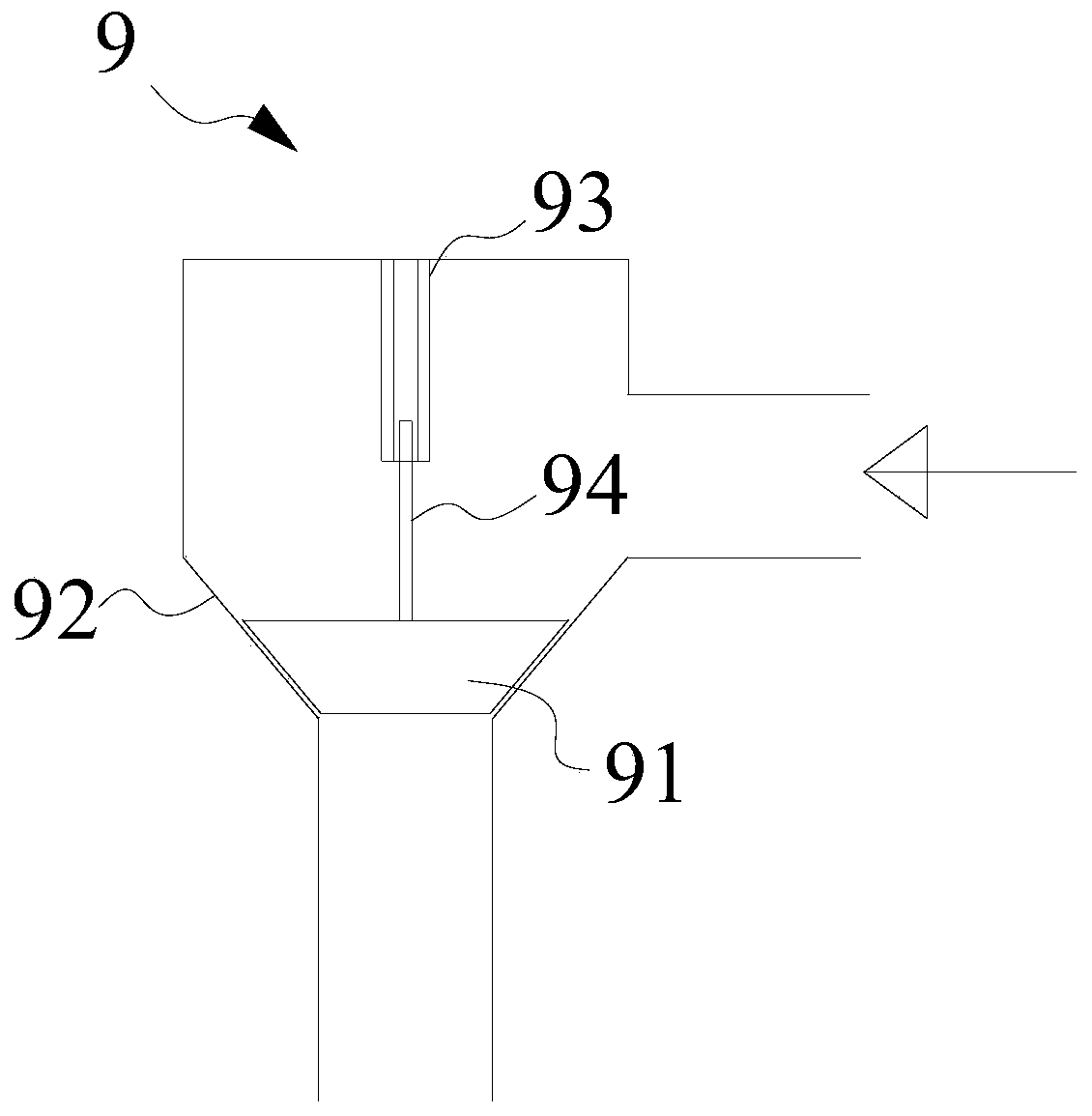

High temperature ejector

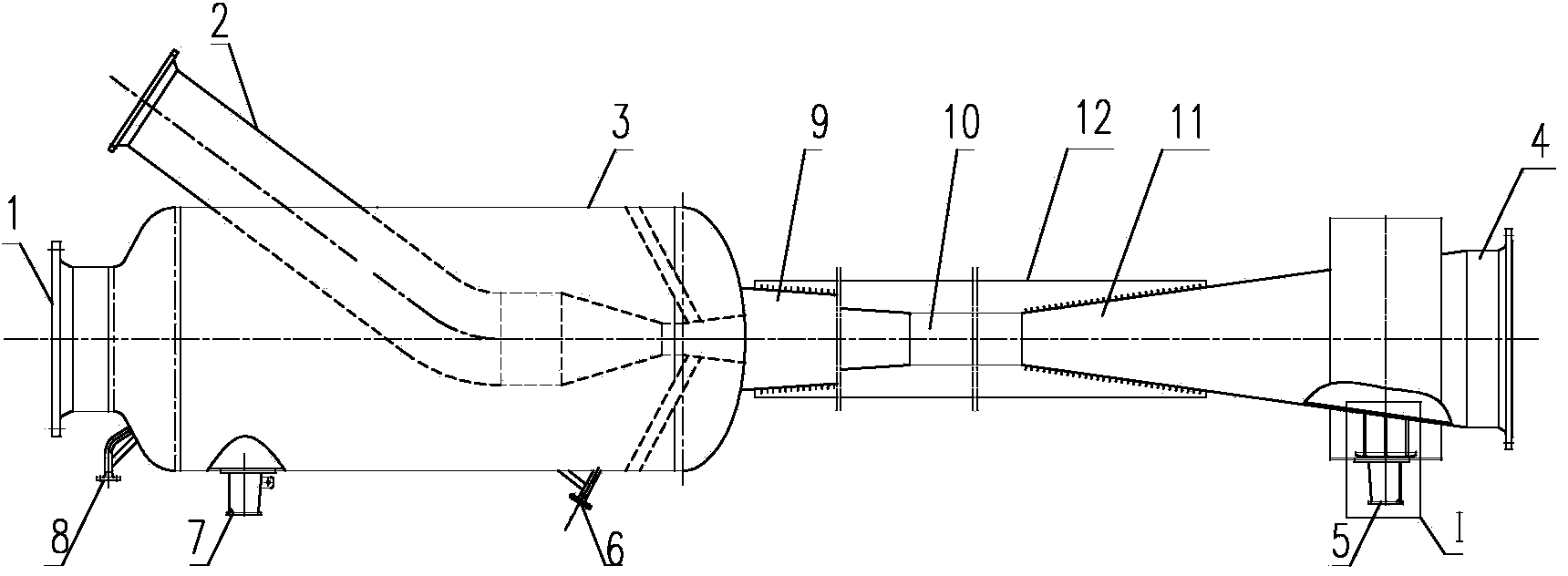

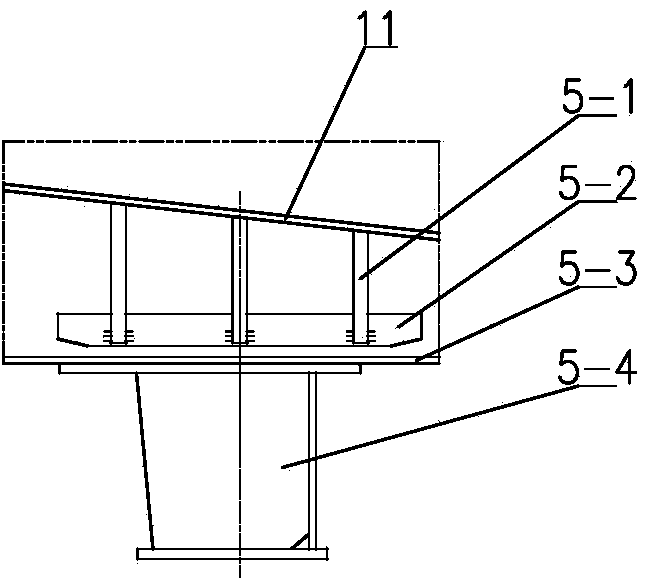

ActiveCN103638757BStable furnace pressureImprove work rateDispersed particle filtrationEngineeringNitrogen gas

The invention discloses a high temperature ejector. The high temperature ejector comprises an ejector shell, a first cone pipe section, an isometric pipe section and a second cone pipe section which are sequentially communicated with one another, wherein the diameter of the rear end of the first cone pipe section is less than that of the front end of the first cone pipe section; the diameter of the rear end of the second cone pipe section is greater than that of the front end of the second cone pipe section; the front end of the ejector shell is provided with a furnace gas suction inlet, and the rear end of the second cone pipe section is provided with a furnace gas exhaust hole; a power pressure inlet is inserted into the ejector shell from the outside of the ejector shell, and the outlet of the power pressure inlet is arranged on a communicating part of the ejector shell and the first cone pipe section; the outlets of first and second protective nitrogen gas input pipes outside the ejector shell are communicated with the ejector shell; the ejector shell is supported and fixed on a first fixed support, and the second cone pipe section is arranged on a sliding support in a supporting manner. The high temperature ejector provided by the invention has the advantages that the negative pressure purification of furnace gas is changed into positive pressure purification, the furnace pressure of a calcium carbide furnace is relatively stable, the operation rate of the calcium carbide furnace is improved, and the yield is increased.

Owner:CHINA TIANCHEN ENG +1

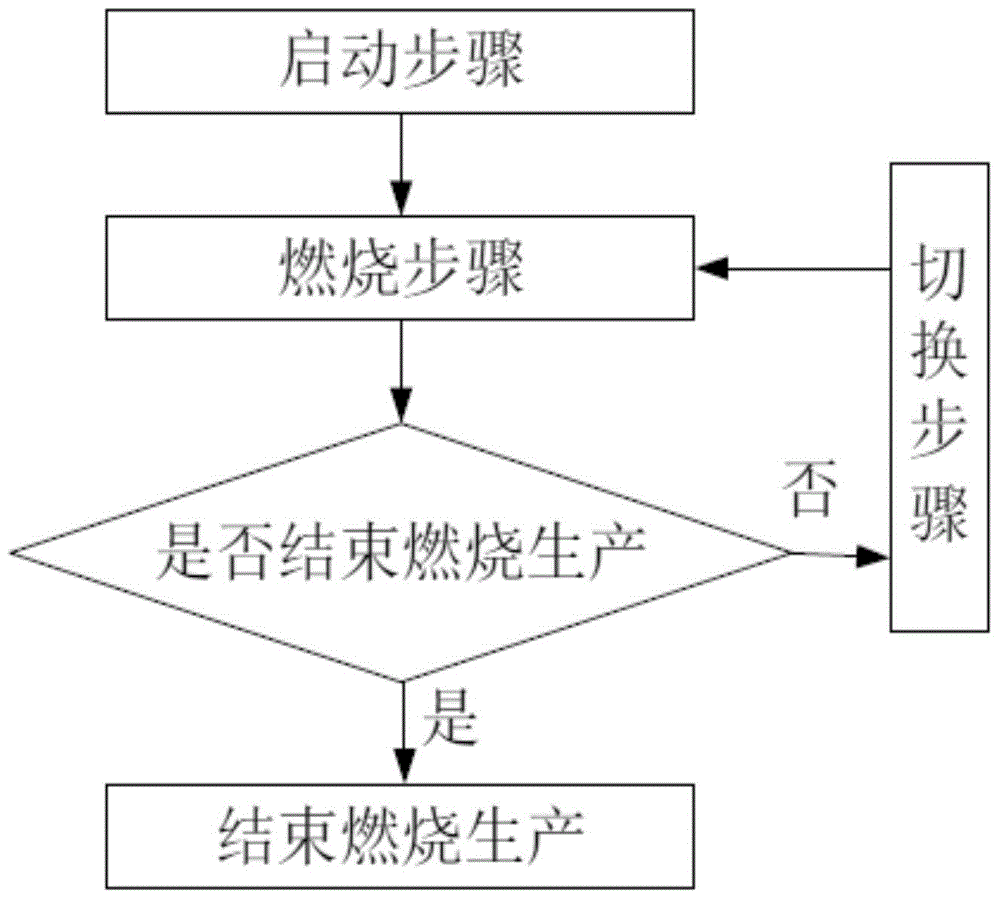

Control method of regenerative combustion device

ActiveCN104456617ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCoordination typePollutant emissions

The invention provides a control method of a regenerative combustion device. The method includes a starting step, a combustion step, a switching step and a circulation step. Compared with the prior art, the method has the outstanding technical effects of being smooth in smoke exhaust, stable in furnace pressure, small in temperature difference, good in heating quality, remarkable in energy-saving effect and little in pollutant discharge. Thus, the method belongs to an environment coordination type regenerative combustion technology.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

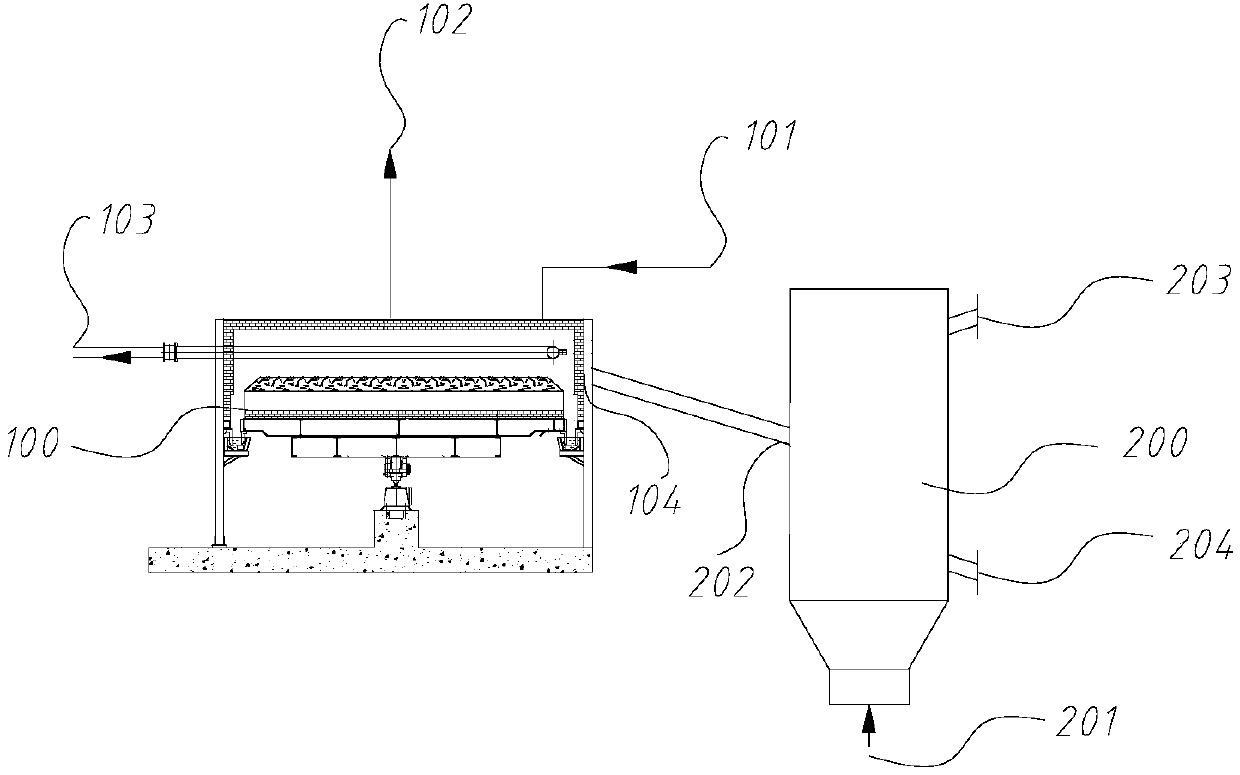

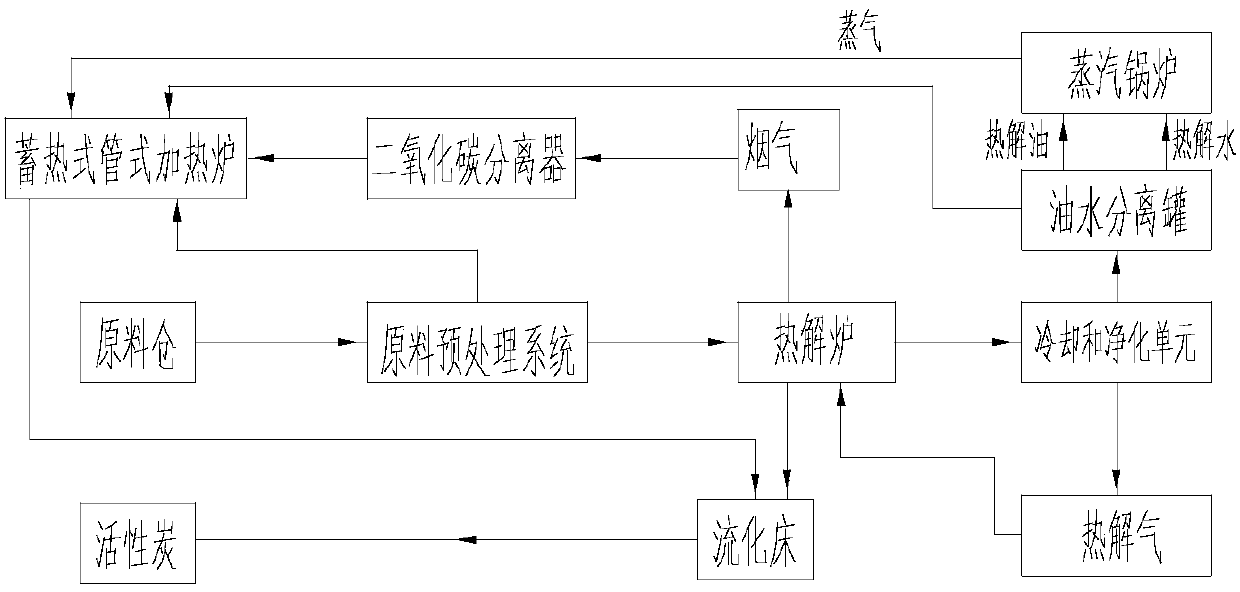

System and method for rotary pyrolysis treatment of domestic sludge

InactiveCN106698424AAvoid cloggingAvoid downtimeCarbon compoundsSludge treatment by pyrolysisCombustorFluidized bed

The invention relates to a system and method for rotary pyrolysis treatment of domestic sludge. The system comprises a sludge pyrolyzing furnace and a fluidized bed in sequential arrangement, wherein a reaction chamber, a tray and a burner are arranged in the sludge pyrolyzing furnace; the tray is rotatably arranged at the bottom of the reaction chamber; the burner is arranged above the tray in the reaction chamber; a pyrolysis raw material inlet and a pyrolysis oil gas outlet are formed in the top of the sludge pyrolyzing furnace; a pyrolysis carbon outlet is formed in the bottom of the sludge pyrolyzing furnace; and the fluidized bed is used for receiving and activating pyrolyzed carbon. The technical scheme of the invention avoids the problems of the original fluidized bed pyrolysis technology that lots of dust is generated by insufficient pyrolysis of pyrolysis raw materials, some solids being fluidized enter a pipeline and a dust removal system along with the pyrolysis gas and cause blocking and heavy dust and further lead to fault pause and maintenance; and in the invention, a relatively good pyrolysis effect and direct resource utilization can be realized while the cost is low.

Owner:SHENWU TECH GRP CO LTD

High temperature ejector

ActiveCN103638757AStable furnace pressureImprove work rateDispersed particle filtrationPositive pressureEngineering

The invention discloses a high temperature ejector. The high temperature ejector comprises an ejector shell, a first cone pipe section, an isometric pipe section and a second cone pipe section which are sequentially communicated with one another, wherein the diameter of the rear end of the first cone pipe section is less than that of the front end of the first cone pipe section; the diameter of the rear end of the second cone pipe section is greater than that of the front end of the second cone pipe section; the front end of the ejector shell is provided with a furnace gas suction inlet, and the rear end of the second cone pipe section is provided with a furnace gas exhaust hole; a power pressure inlet is inserted into the ejector shell from the outside of the ejector shell, and the outlet of the power pressure inlet is arranged on a communicating part of the ejector shell and the first cone pipe section; the outlets of first and second protective nitrogen gas input pipes outside the ejector shell are communicated with the ejector shell; the ejector shell is supported and fixed on a first fixed support, and the second cone pipe section is arranged on a sliding support in a supporting manner. The high temperature ejector provided by the invention has the advantages that the negative pressure purification of furnace gas is changed into positive pressure purification, the furnace pressure of a calcium carbide furnace is relatively stable, the operation rate of the calcium carbide furnace is improved, and the yield is increased.

Owner:CHINA TIANCHEN ENG +1

Energy-saving combustion and waste heat recovery system for fast melting aluminum furnace

ActiveCN108800957BImprove recycling efficiencyGuaranteed temperatureIncreasing energy efficiencyWaste heat treatmentCombustion systemTime cycles

The invention provides an energy-saving combustion and waste heat recovery system of a quick aluminum melting furnace. The energy-saving combustion and waste heat recovery system of the quick aluminummelting furnace comprises a furnace body, a combustion system and a waste heat recovery system. The furnace body comprises a vertical melting furnace and a transverse holding furnace. The combustionsystem comprises a first fuel spray nozzle, an ignition nozzle and an air spray nozzle, wherein the air spray nozzle is used for guiding the preheated air into the holding furnace in the mode that thepreheated air serves as the combustion-supporting gas. The waste heat recovery system comprises a first heat storage chamber, a second heat storage chamber and a reversing device. The purposes that the heat storage chamber on one side stores the waste heat generated by combustion of the melting furnace, the heat storage chamber on the other side preheats the combustion-supporting gas of the holding furnace, and the operation is alternatively conducted according to the preset time cycle are achieved. The problems that in the prior art, a melting furnace and a holding furnace are low in waste heat recovery efficiency and high in the waste heat recovery difficulty, and due to the fact that the combustion temperature in the melting furnace is high, thermal power type NOX is prone to being generated when the air serves as the combustion-supporting gas are effectively solved, the overall energy consumption of the combustion system is reduced, the flue gas of the system is effectively balanced, and the waste heat recovery efficiency is improved.

Owner:HUATIAN ENG & TECH CORP MCC +1

A rapid forging and hot cutting production system and its working method

ActiveCN108262433BGuaranteed temperatureIncrease productivityForging/hammering/pressing machinesHandling devicesThermal insulationEngineering

Owner:JIANGSU BAOJIE FORGING

A box type gas heat treatment furnace

ActiveCN105004191BIntegrity guaranteedReduce lossesCharge supportsWaste heat treatmentMetallurgyFlue gas

Owner:海盐凯鑫五金有限公司

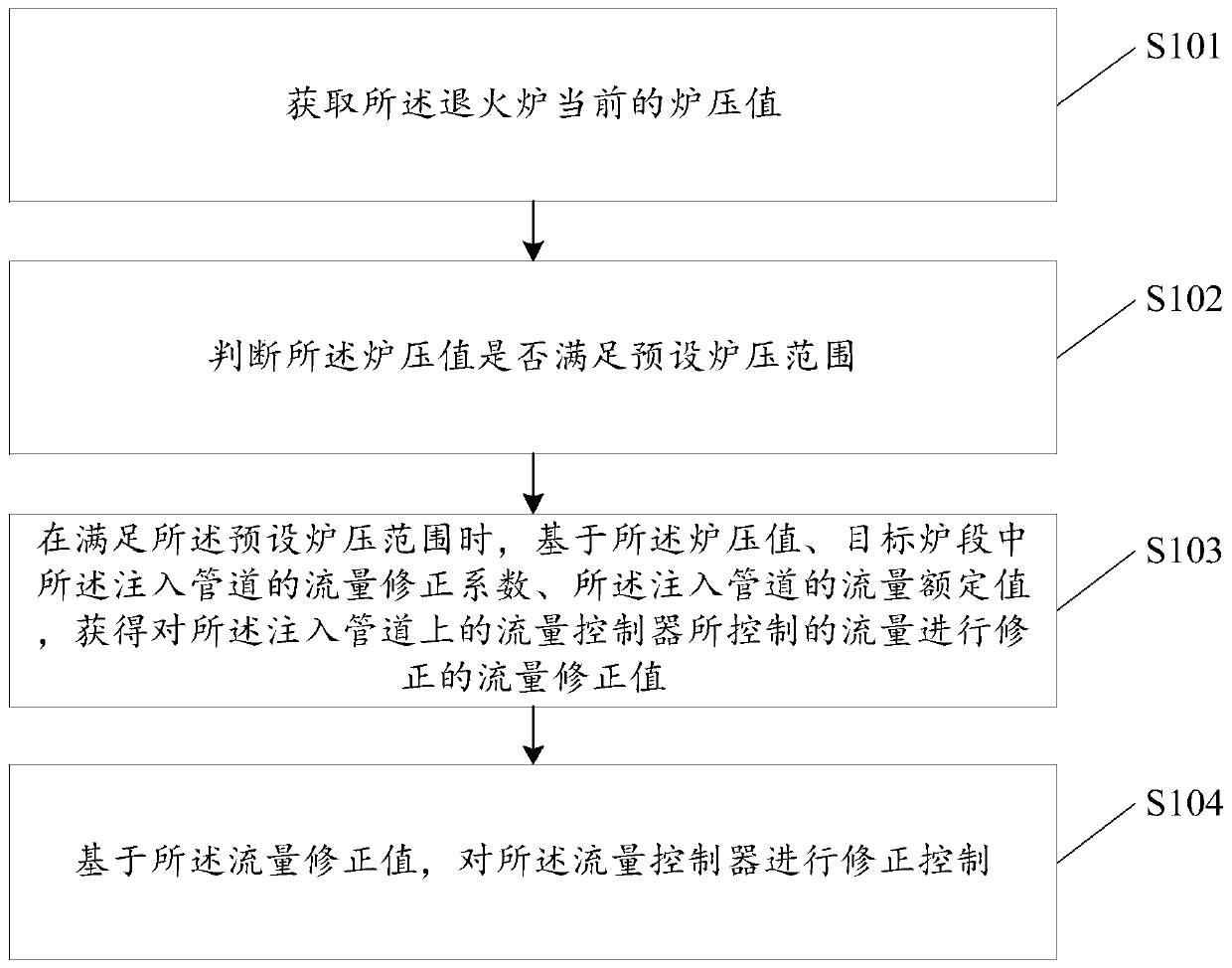

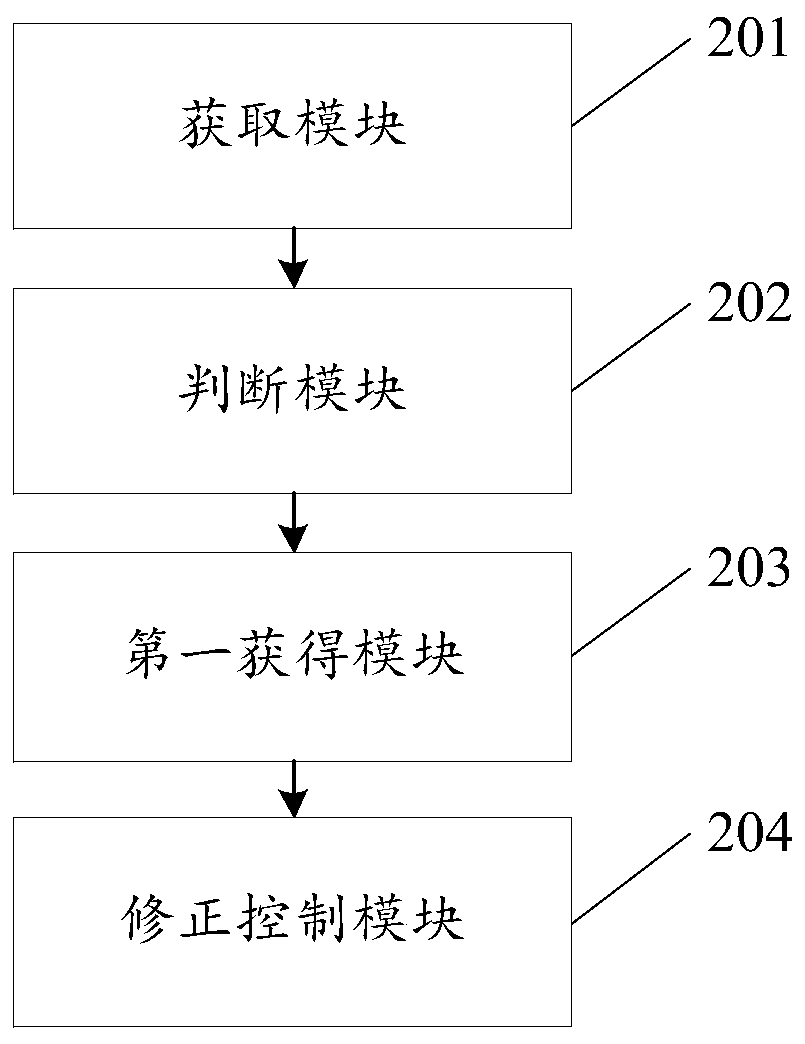

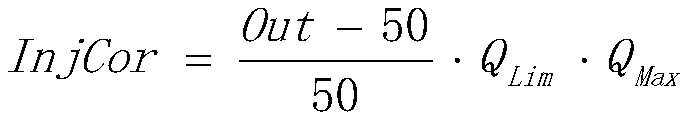

Furnace pressure control method and device for annealing furnace

InactiveCN110607434AStable furnace pressureQuality assuranceFurnace typesHeat treatment process controlStrip steelStreamflow

The invention relates to a furnace pressure control method and device for an annealing furnace. The furnace pressure control method is applied to each furnace section of the annealing furnace, an injecting pipeline for injecting protection gas is arranged at each furnace section, and a flow controller is arranged on each injecting pipeline. The furnace pressure control method comprises the following steps that the current furnace pressure value of the annealing furnace is obtained, whether the furnace pressure value meets the pre-set furnace pressure range is judged, when the pre-set furnace pressure range is met, based on the furnace pressure value, the flow correction coefficient of the injecting pipeline in a target furnace section and the flow rating of the corresponding injecting pipeline, and the flow correction value for correcting the flow controlled by the flow controller on the corresponding injecting pipeline is obtained; and based on the flow correction value, correcting control is conducted on the corresponding flow controller, so that the furnace pressure of the annealing furnace is stabilized, and the quality of strip steel in the annealing furnace is ensured.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A closed forging equipment for shaft products and its production method

ActiveCN108453205BReduce scrap rateIncrease productivityUpsetting pressesSwagging pressesManipulatorIndustrial engineering

The invention discloses a closed forging device for shaft products. The closed forging device comprises a feeding device, a first transferring manipulator, a forging and pressing device, a second transferring manipulator and a heat treatment device which are arranged in sequence. The forging and pressing device is provided with a closed forging mold. The closed forging mold comprises a lower moldbody and an upper mold body with a convex part at the lower end. The outer wall of the convex part is attached to the mold cavity of the lower mold body. The lower mold body is provided with an ejection rod. The first transferring manipulator and the second transferring manipulator are arranged on the base, rotatably connected with the base and separately connected with a rotation driving device.Shaft products are forged in a closed forging mode, so that flanges and leftovers are avoided, and the rejection rate is low; and integrated conveying, forging, pressing and heat treatment is achieved, so that production efficiency and product quality are improved; and materials are saved, and labor cost is reduced.

Owner:JIANGSU BAOJIE FORGING

A device for stabilizing furnace pressure in a tft liquid crystal glass furnace

ActiveCN112794627BStable furnace pressureSpeed up the fallGlass furnace apparatusPressure stabilizationThermodynamics

The invention discloses a furnace pressure stabilizing device for a TFT liquid crystal glass kiln, which comprises a steel flue assembly, and a condensate cleaning assembly is arranged on the inside of the condensate nozzle of the steel flue assembly, and the bottom of the steel flue assembly is fixed. A condensate falling pipe assembly is installed. When there is condensate on the top of the inlet pipe of the steel flue, open the upper flap valve and close the lower flap valve to ensure that the entire steel flue is still in a sealed state, thereby ensuring the stability of the furnace pressure. Through the second The rotation of a drive motor and the cooperation of the internal thread translation block and the translation screw realize the telescopic translation of the semicircular condensate receiving tray in the steel flue inlet pipe. When cleaning the condensate, the semicircular condensate receiving tray extends into the steel fume In the entrance pipe of the channel, through the rotation of the second drive motor and the cooperation of the scraper rotation rod and the hexagonal guide rod, the condensate scraper can be scraped and rotated in the semicircular condensate receiving tray, and the scraped condensate will fall on the semicircular shape. In the condensate receiving tray.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

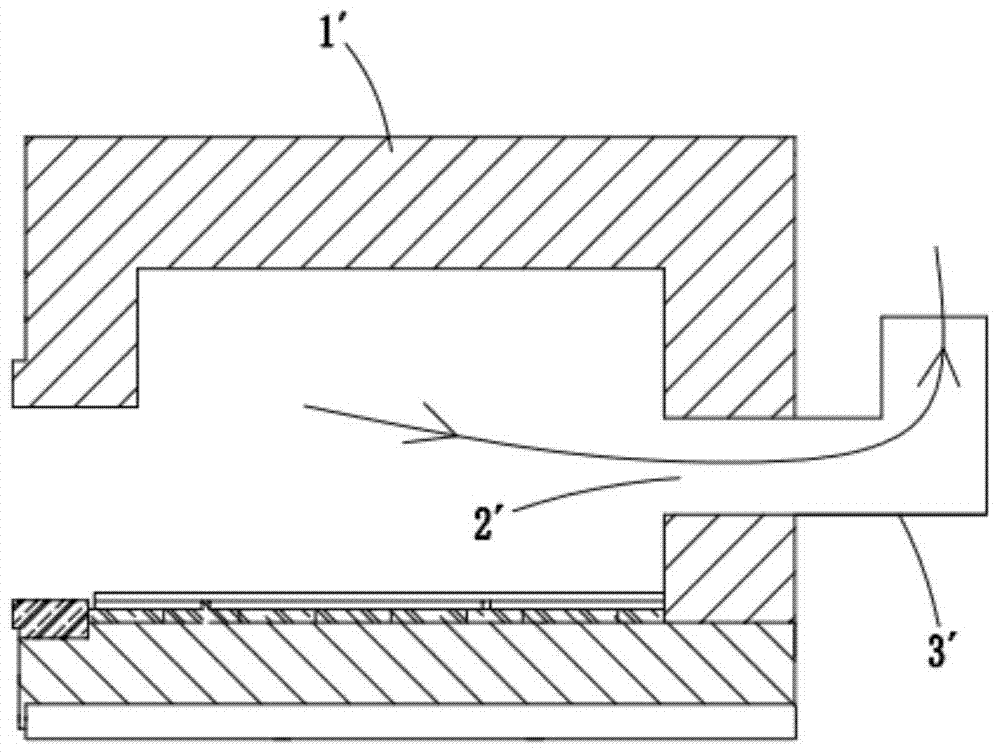

Efficient energy-saving boiler

InactiveCN103574890AIncrease profitIncrease heat absorption areaWater heatersManufacturing technologyEngineering

The invention relates to an efficient energy-saving boiler, and relates to the technical field of boiler manufacture. The efficient energy-saving boiler comprises a hot water boiler and a waste heat recovery furnace. The hot water boiler comprises an enlarged hearth and a hot water furnace barrel which are connected with each other and which form a T-shaped structure. The waste heat recovery furnace is in a T-shaped structure and is provided with an annular water chamber. The opening end of the waste heat recovery furnace is sleeved on the hot water furnace barrel of the hot water boiler, and the periphery of the opening end of the waste heat recovery furnace is flexibly connected to the periphery of the connection of the hot water furnace barrel and the enlarged hearth in a sealed manner. The efficient energy-saving boiler has the advantages of simplicity of cleaning, convenience, high heat energy utilization rate and the like.

Owner:陈和龙

Furnace pressure stabilizing device for TFT liquid crystal glass kiln

ActiveCN112794627AStable furnace pressureSpeed up the fallGlass furnace apparatusElectric machineLiquid crystal

The invention discloses a TFT liquid crystal glass kiln furnace pressure stabilizing device which comprises a steel flue assembly, a condensate cleaning assembly is arranged in a condensate pipe opening of the steel flue assembly in a telescopic mode, a condensate falling pipeline assembly is fixedly arranged at the bottom of the steel flue assembly, and when condensate exists on the top of the steel flue inlet pipe, an upper gate valve is opened, a lower gate valve is closed, it is ensured that the whole steel flue is still in a closed state, and thus it is ensured that the furnace pressure is stable, telescopic translation of the semicircular condensate receiving disc in the steel flue inlet pipe is achieved through rotation of the first driving motor and cooperation of the internal thread translation block and the translation screw rod, and when the condensate is cleaned, the semi-circular condensate receiving disc extends into an inlet pipe of the steel flue, the condensate scraper rotates in the semi-circular condensate receiving disc in a scraping mode through rotation of the second driving motor and cooperation of the scraper rotating rod and the hexagonal guide rod, and scraped condensate falls into the semi-circular condensate receiving disc.

Owner:彩虹(合肥)液晶玻璃有限公司

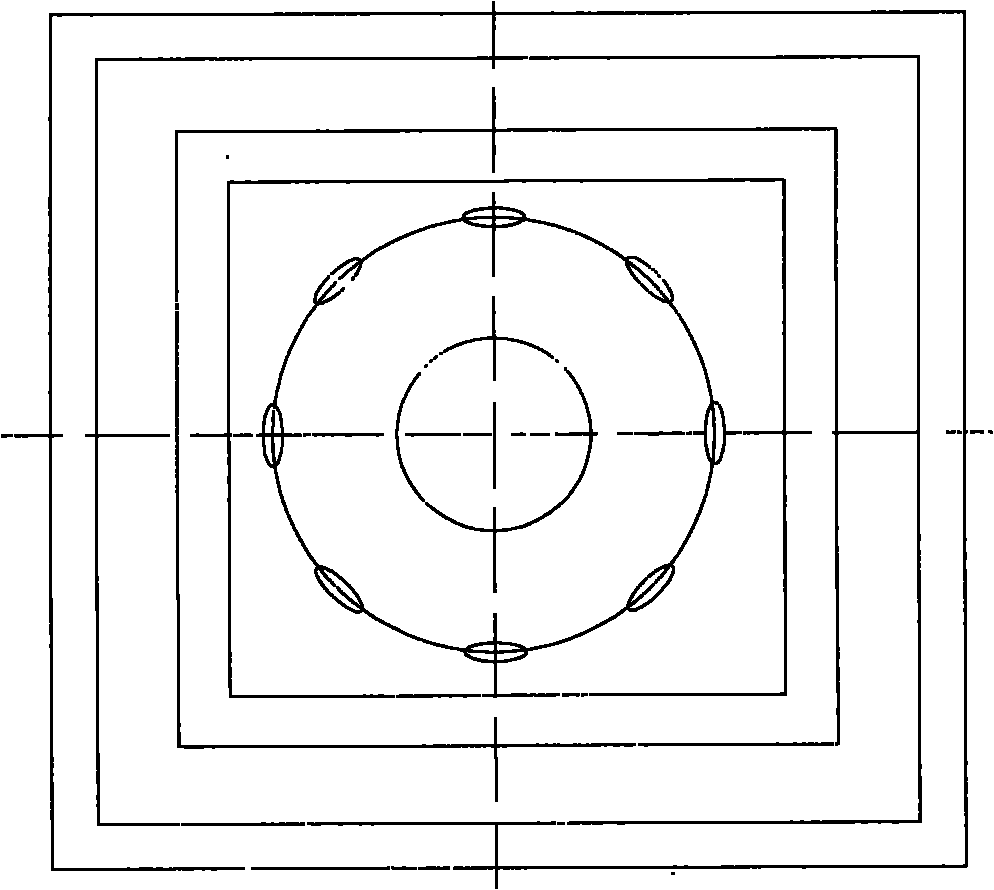

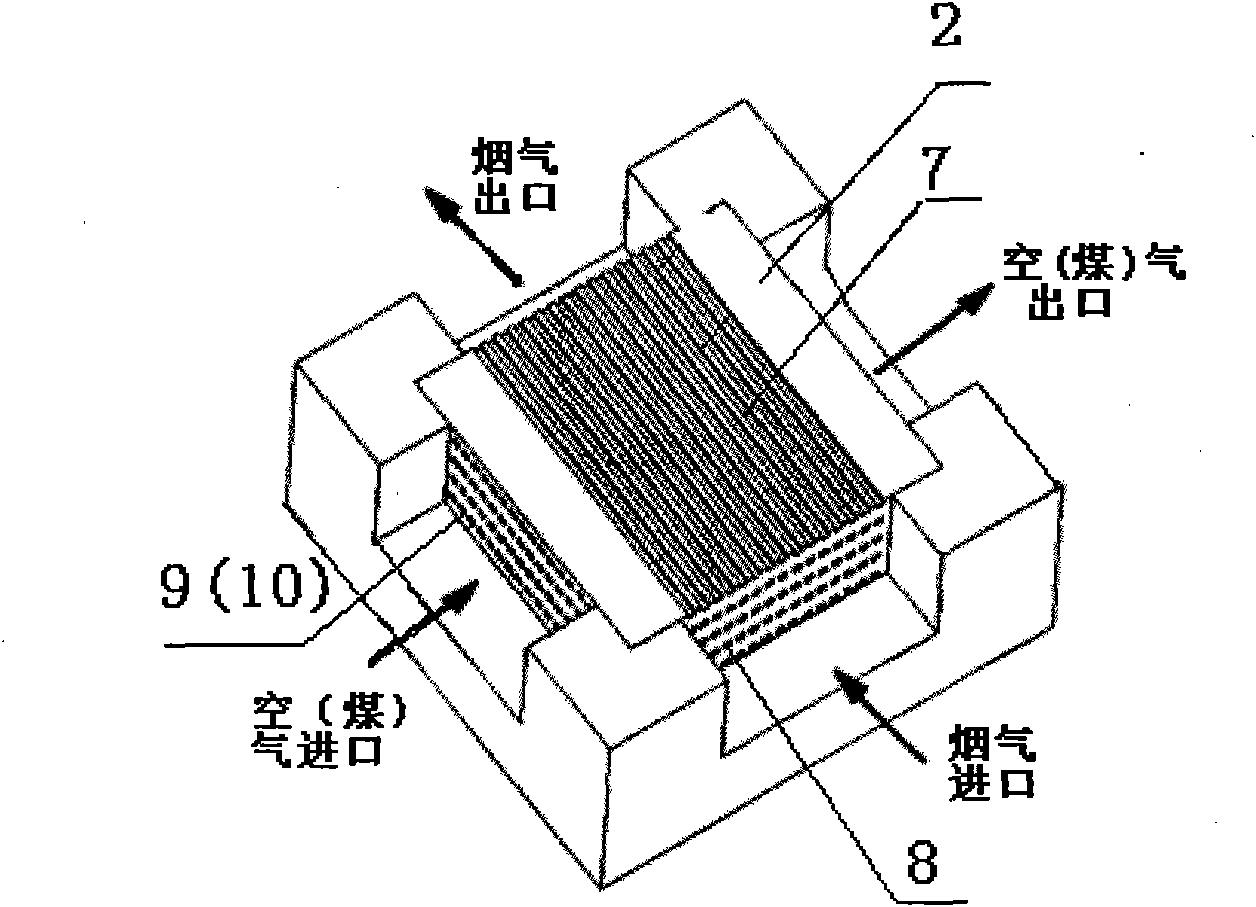

Device for improving smoke discharge capability of heat-accumulation-type stove kiln

ActiveCN102269528BIncrease flue gas volumeImprove recycling efficiencyWaste heat treatmentElectricityBrick

The invention provides a device for improving smoke discharge capability of a heat-accumulation-type stove kiln. The device is characterized in that a heat-accumulation-type nozzle brick is divided into an upper semi part, a lower semi part and an outer sleeve; the upper semi part and the lower semi part of the nozzle brick are fixed together through the outer sleeve, and are provided with unidirectional auxiliary channels with corresponding axes; the cross section of the channel at the upper semi part of the nozzle brick is elliptic; the cross section of the channel at the lower semi part of the nozzle brick is round; a spherical space is arranged at the joint part of the upper semi part and the lower semi part of the nozzle brick of the auxiliary channel, and occupies half of the upper semi part of the nozzle brick and half of the lower semi part of the nozzle brick; and a fire-resistant ball is put in the spherical space. According to the invention, under the condition that the invariable normal nozzle orifice area and flow rate of smoke are ensued, the smoke discharge area is increased, the smoke exhaust capability is improved, the smoke rate flowing through a heat accumulation chamber is increased, the stove pressure stability is ensured, and the recycling and utilization efficiency of smoke sensible heat is improved; and simultaneously the problem that electricity energy is wasted by adopting an ultra large draught fan is solved.

Owner:ANGANG STEEL CO LTD

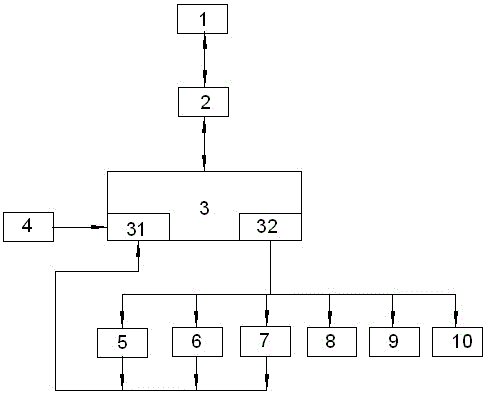

A regenerative combustion control system and its control method

ActiveCN104456618BFurnace pressure fluctuations are reducedTurn off the smoke extraction functionControl devices for furnacesCombustion regulationTemperature controlCombustor

The invention discloses a heat accumulating type combustion control system and a control method. The heat accumulating type combustion control system comprises an upper industrial personal computer, a lower computer, a combustion fan regulating switch, a smoke exhaust fan regulating switch, a burner front valve, a sensor group and an igniter. Configuration software is installed in the upper industrial personal computer. The upper industrial personal computer is connected with the lower computer. The burner front valve comprises a burner front gas switch, a burner front combustion air switch and a burner front smoke exhaust switch. The lower computer is connected with the combustion fan regulating switch, the smoke exhaust fan regulating switch, the burner front valve, the sensor group and the igniter. The lower computer detects the working states of the sensor group and the igniter and transmits the working states to the upper computer; the upper computer conducts comprehensive processing according to the working states of the sensor group and the igniter and the configuration software and sends an instruction to the lower computer; the lower computer controls a heat accumulating combustor. The invention further discloses the control method of the combustion control system. The heat accumulating type combustion control system is uniform in exhaust gas temperature, good in temperature control accuracy and low in energy consumption.

Owner:CHINA UNITED ENG

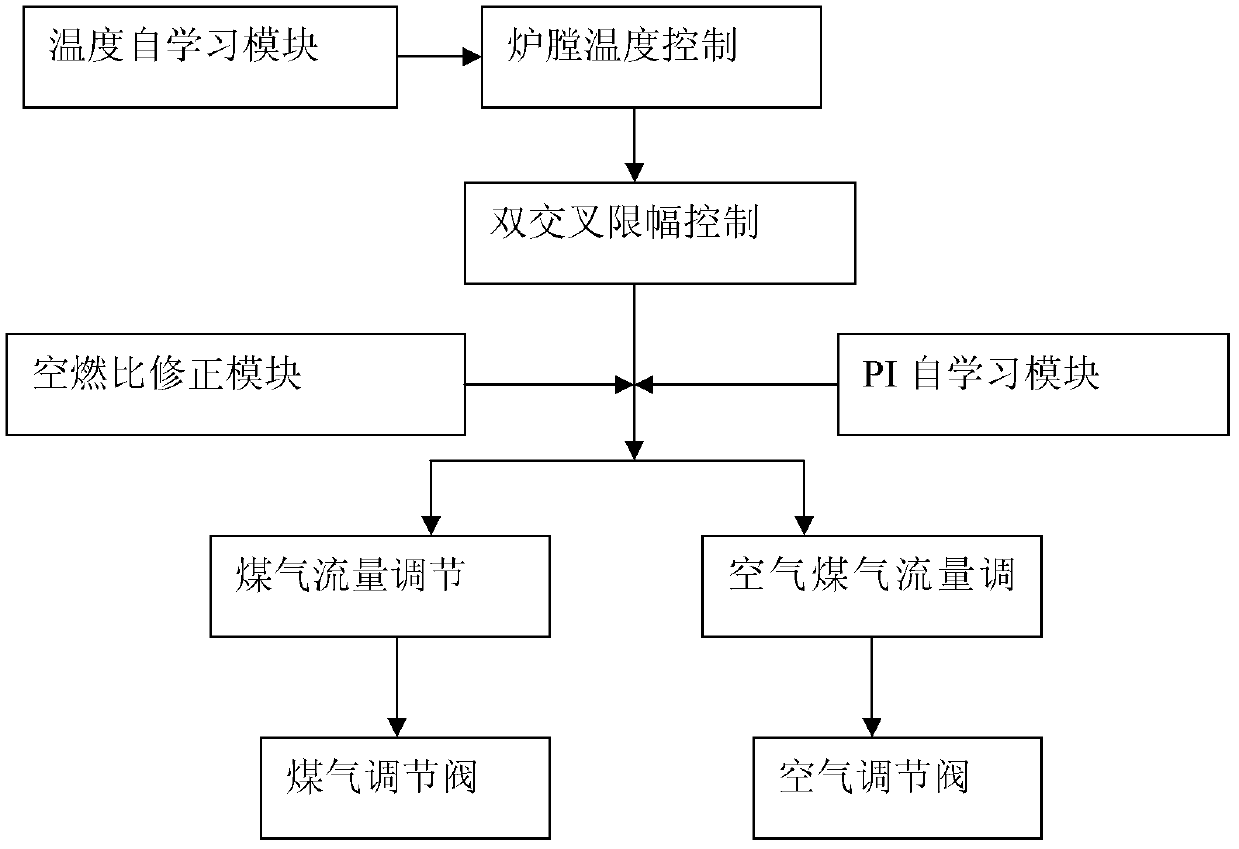

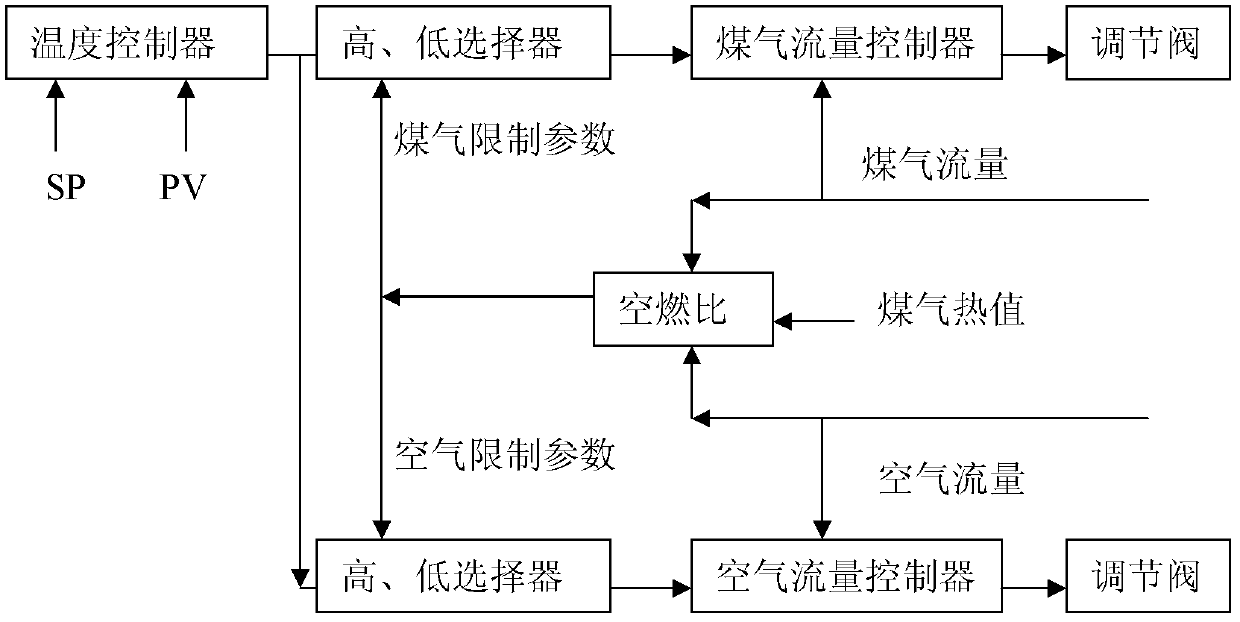

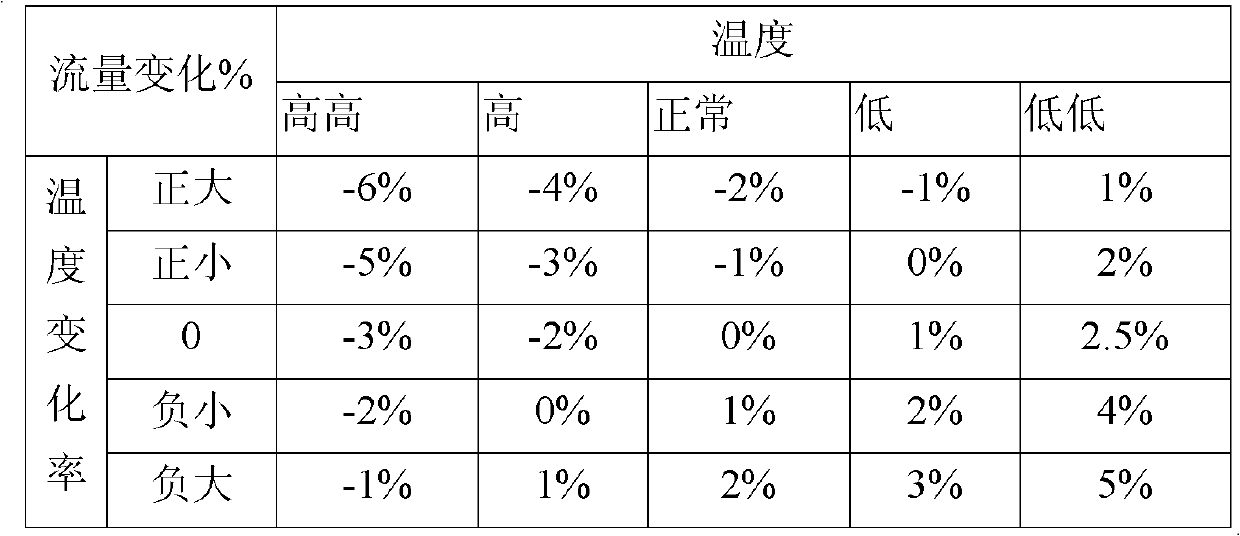

Automatic intelligent double cross limiting range combustion control method for heating furnace

ActiveCN102364252BHigh precisionMeet the rolling rhythmFuel supply regulationAutomatic controlFuzzy control system

The invention discloses an automatic intelligent double cross limiting range combustion control method for a heating furnace, and belongs to the technical field of heating furnace combustion control. By combining temperature self-learning, fuzzy control and PI parameter self-learning, the intelligent double cross limiting range control in the combustion process of the heating furnace is realized,the problem of control accuracy of the combustion of the heating furnace is effectively solved, and a hot rolling production requirement is well met. The method has the advantages that: gas and air flow rates are reasonably, accurately and quickly regulated and controlled, the regulating function of a regulating valve is effectively realized, and the temperature of a hearth of the heating furnaceis reasonably and accurately controlled.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

High-efficiency intelligentized heating furnace control method

ActiveCN102721288BReduce energy consumptionReduce oxidation burnControl devices for furnacesFurnace temperatureThermodynamics

The invention relates to the technical field of heating furnaces of heat treatment equipment applied in the steel rolling industry, in particular to a high-efficiency intelligentized heating furnace control method. The method adopts a PLC (programmable logic controller) system for field control and an upper computer operating system communicating and connected with the PLC system to form an intelligent control system, and moreover, the intelligent control system is utilized to efficiently, scientifically and intelligently control a heat furnace. The method is characterized in that the intelligent control system controls and sets the heating furnace in the following six aspects: (1) furnace temperature control; (2) internal pressure control; (3) air-fuel ratio control; (4) safety protection system control; (5) adoption of an human-machine interface (HMI) on the intelligent control system; (6) history data recording. The method can reasonably control heating temperature, furnace temperature and furnace pressure at each stage in real time, increases the heating utilization rate, has an outstanding effect in saving energy and reducing consumption, increases the production efficiency, reduces the production cost, and prolongs the furnace service life.

Owner:HEBEI XINYE ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com