Closed forging device and production method for shaft products

A production method, closed forging technology, applied in the direction of mechanical equipment, metal processing equipment, swage presses, etc., can solve the problems of increasing tool cost and labor cost, difficulty in grasping the accurate drawing length, low forging pass rate, etc. , to achieve good sealing effect and temperature control effect, high degree of automation and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

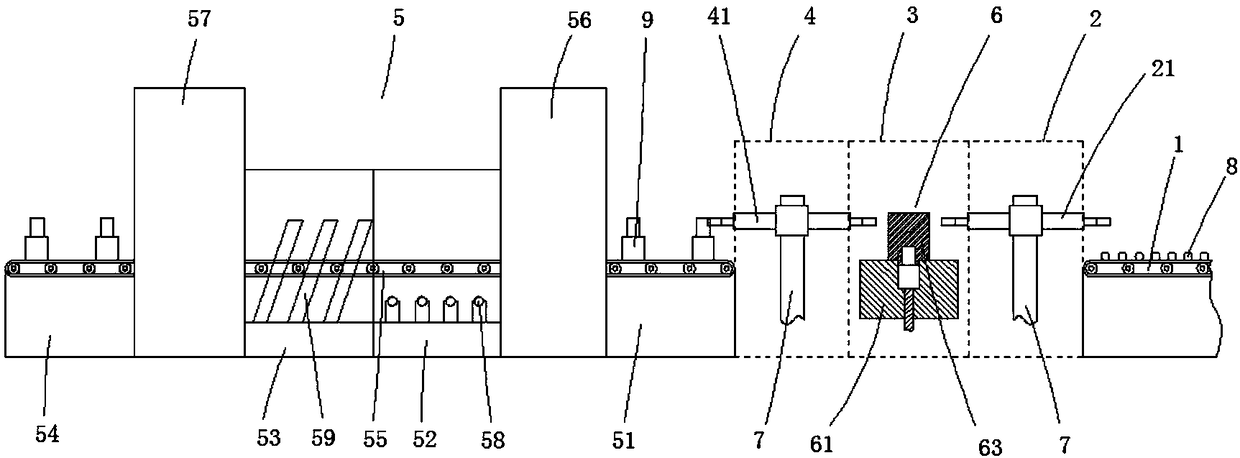

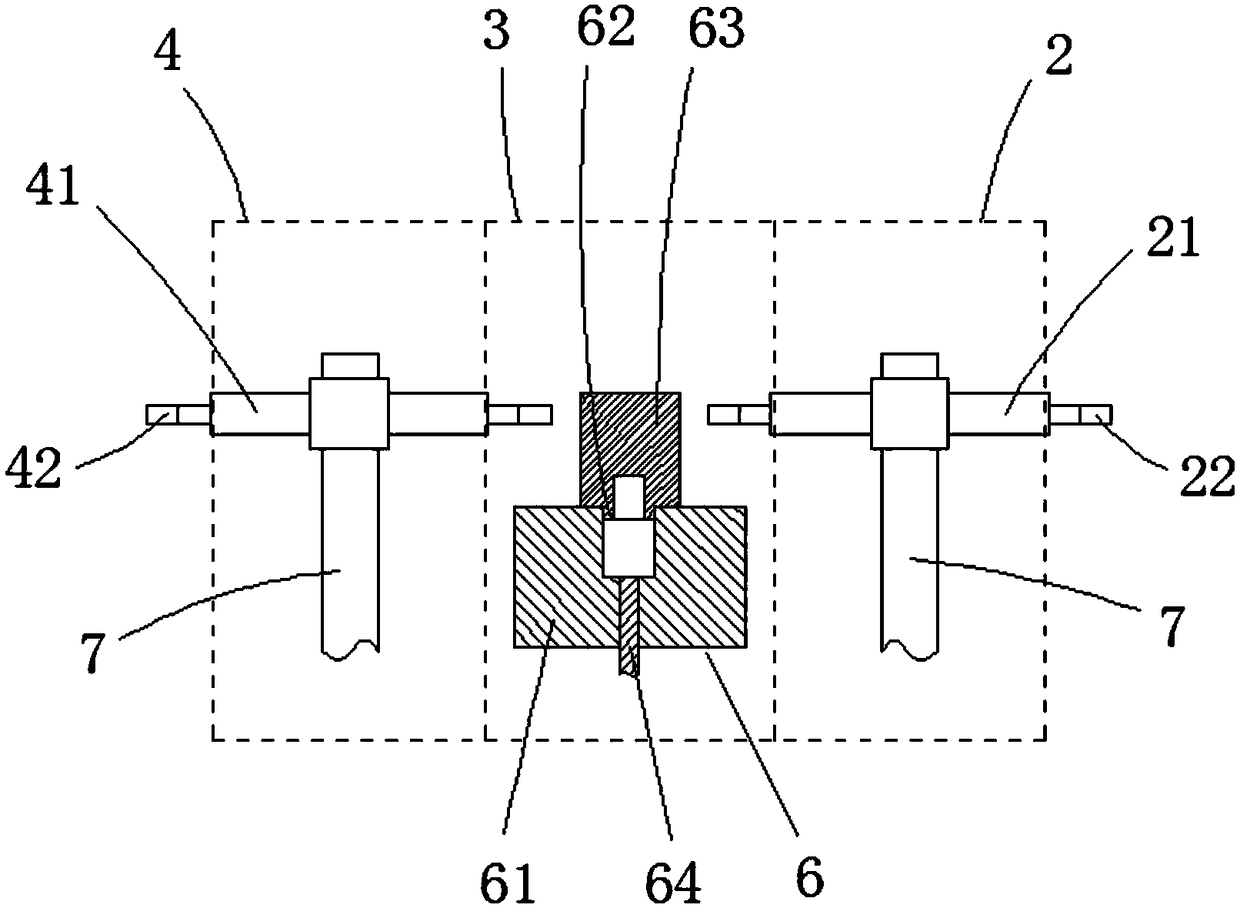

[0025] A closed forging equipment for shaft products of the present invention, such as figure 1 and figure 2 As shown, it includes a feeding device 1, a first feeding manipulator 2, a forging device 3, a second feeding manipulator 4 and a heat treatment device 5 arranged in sequence; the forging device 3 is provided with a closed forging die 6, and the closed The forging die 6 includes a lower die 61 and an upper die 63 with a convex portion 62 at the lower end, the outer wall of the convex portion 62 is attached to the cavity wall of the lower die 61, and the lower die 61 is provided with a push rod 64; A material transport manipulator 2 and a second material transport manipulator 4 are all arranged on the base 7, and are rotatably connected with the vertical base 7, and the first material transport manipulator 2 and the second material transport manipulator 4 are respectively connected with rotating drive unit.

[0026] The heat treatment equipment 5 described in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com