A box type gas heat treatment furnace

A heat treatment furnace and gas technology, applied in the direction of waste heat treatment, furnace, furnace components, etc., can solve the problems of difficult maintenance, intricate flue layout design, high production cost, etc., to improve the stability of the temperature field, simplify the pipeline layout and Internal flue design, the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

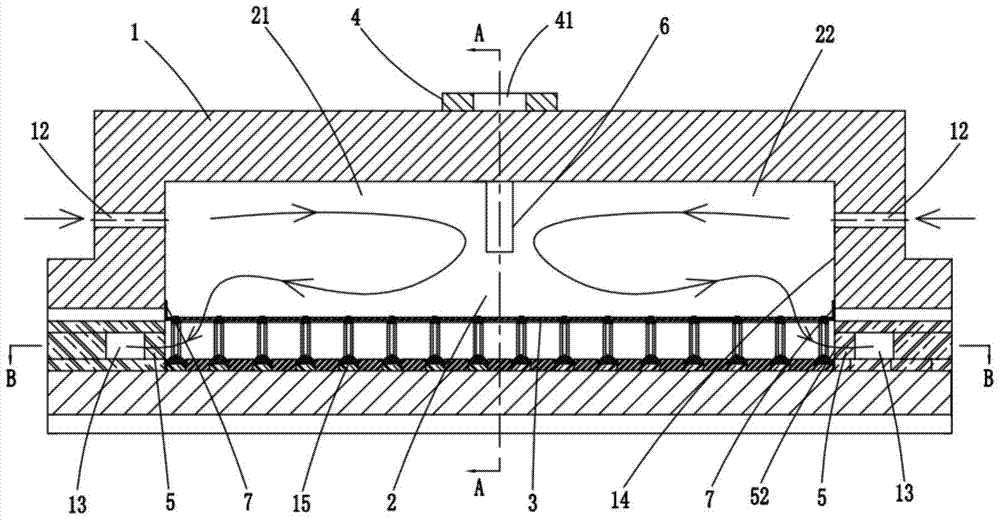

[0041] Such as figure 2 As shown, the present invention provides a box-type gas heat treatment furnace, including a furnace shell 1 and a furnace 2. The furnace shell 1 is a rectangular box-shaped body, which is made of welded steel and steel plates, and has the required rigidity and Intensity, the feed end of the furnace shell 1 is provided with a material inlet 11, and the discharge end is provided with a material outlet. According to the product heat treatment process requirements, the size of the furnace 2 is designed to be 4500mm×2650mm×600mm, and the heating volume is around the furnace shell 1. There are high-temperature flue gas inlets 12 connected to the burner nozzles on the upper parts of both sides, and the high-temperature flue gas inlets 12 are all connected to the furnace 2 to improve heating efficiency.

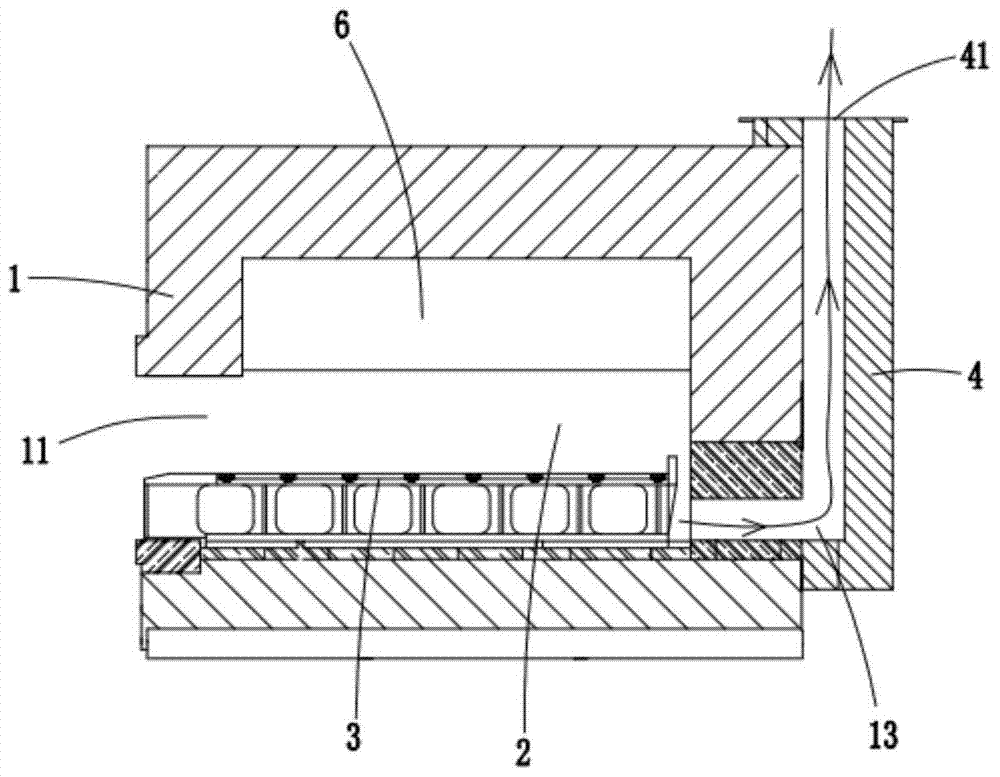

[0042] image 3 As shown, the interior of the furnace shell 1 is provided with an annular flue gas passage 13, the left and right sides of the flue gas pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com