Patents

Literature

37results about How to "Avoid hedging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

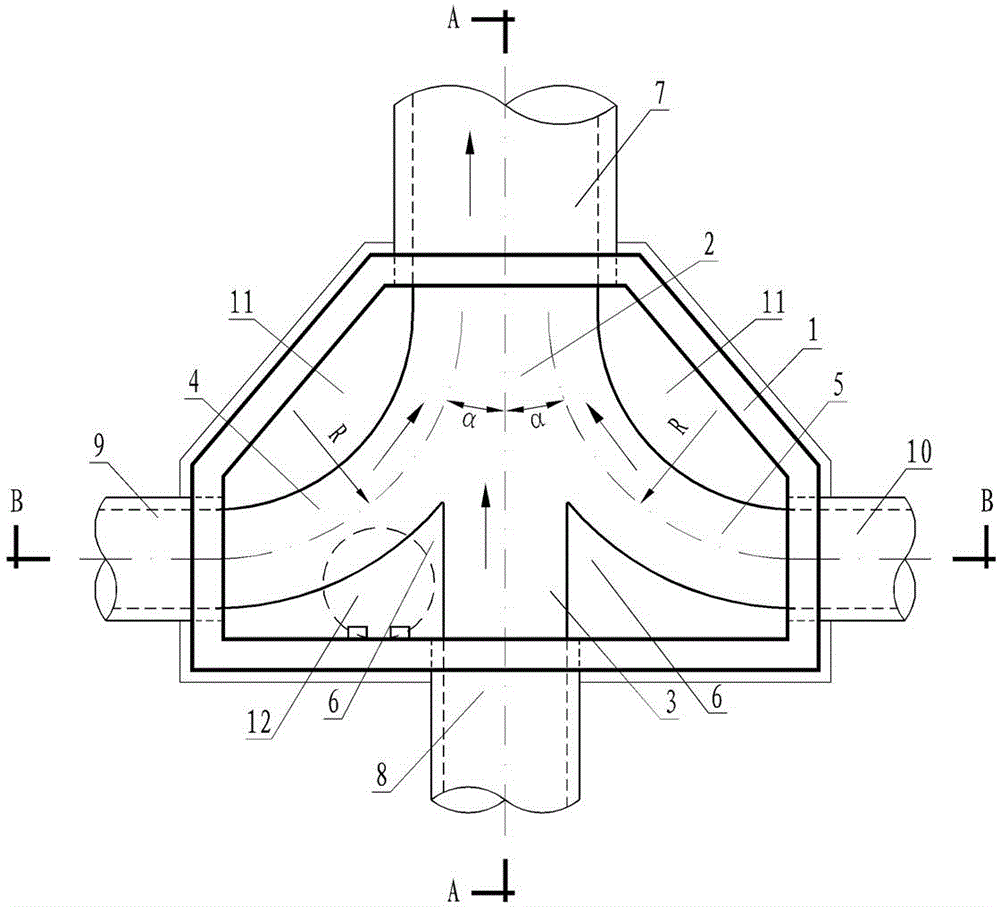

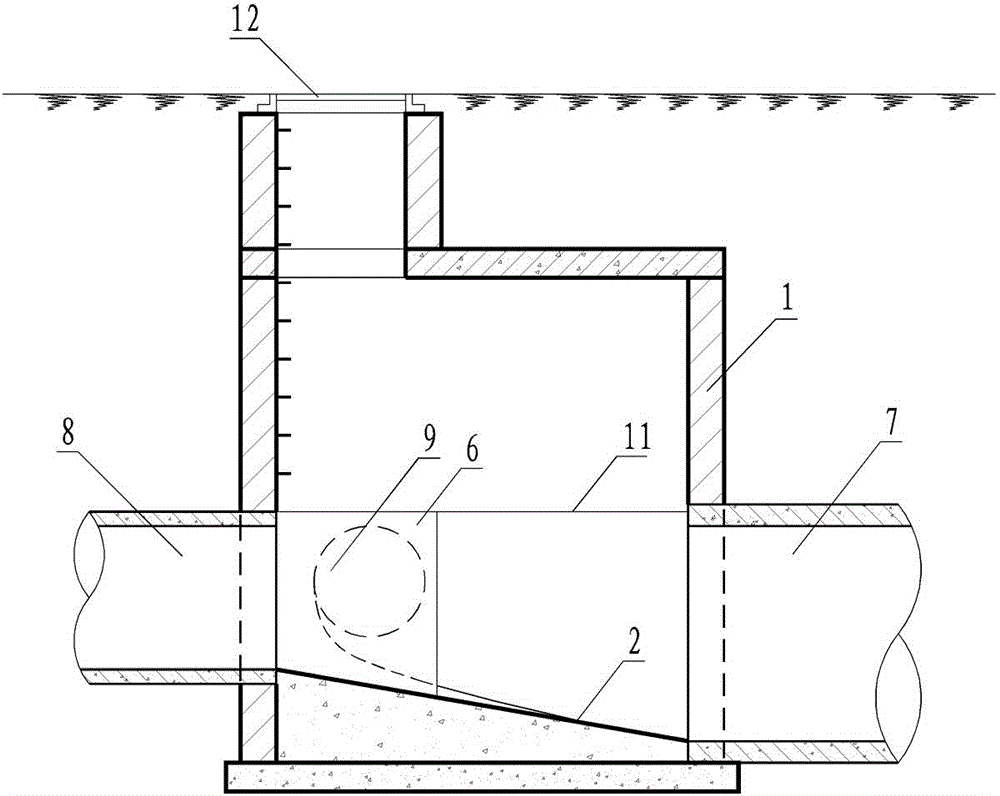

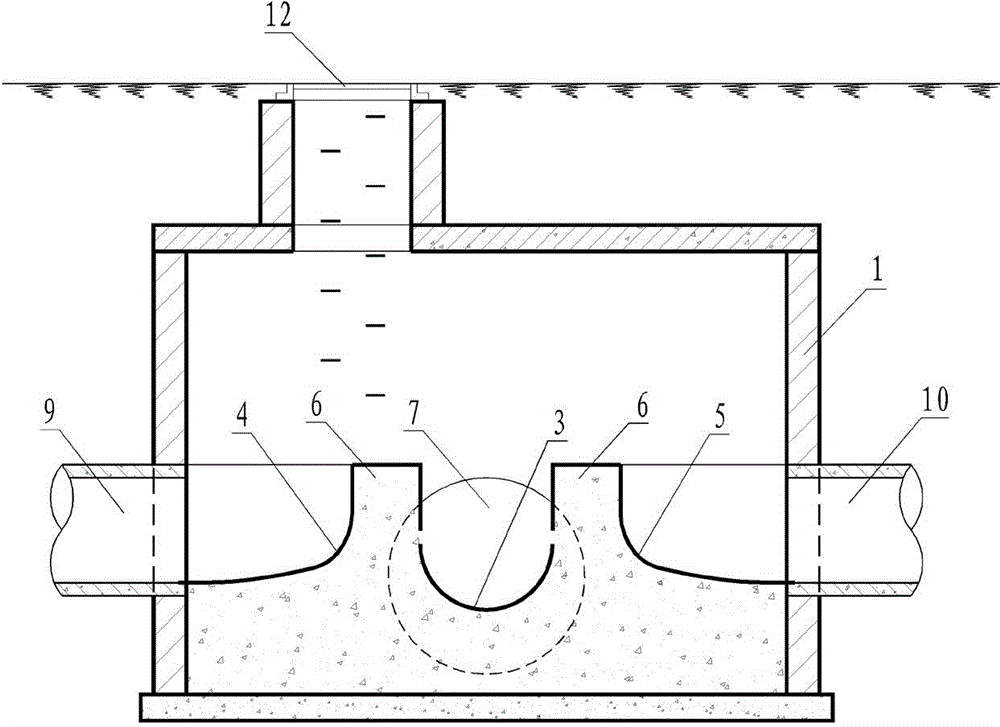

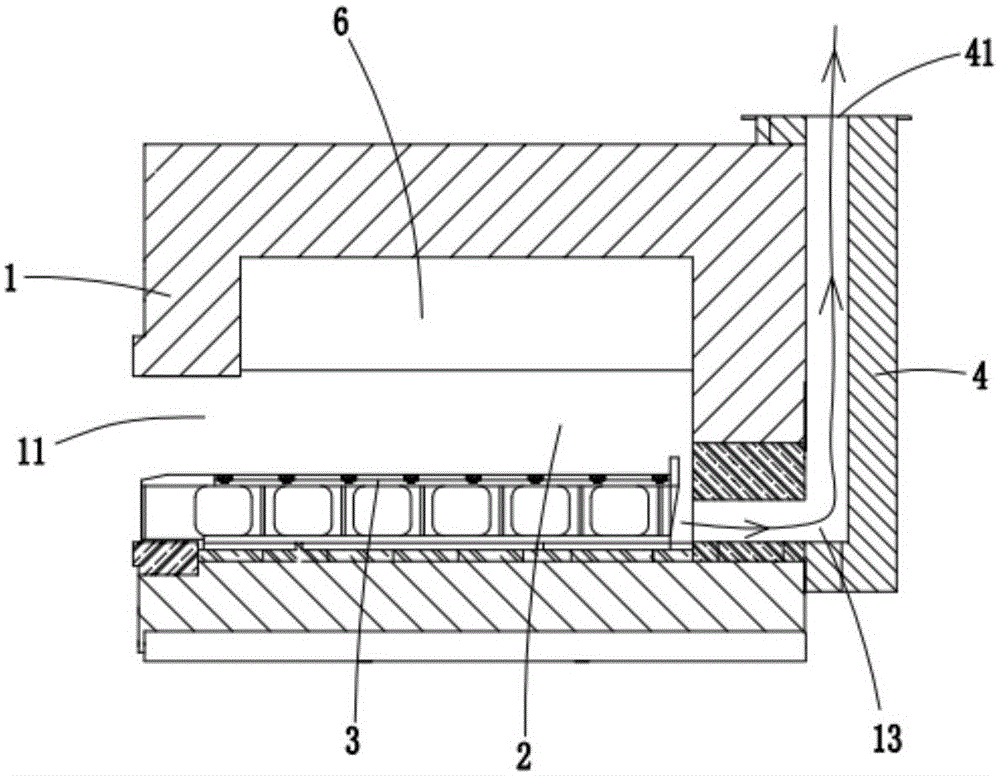

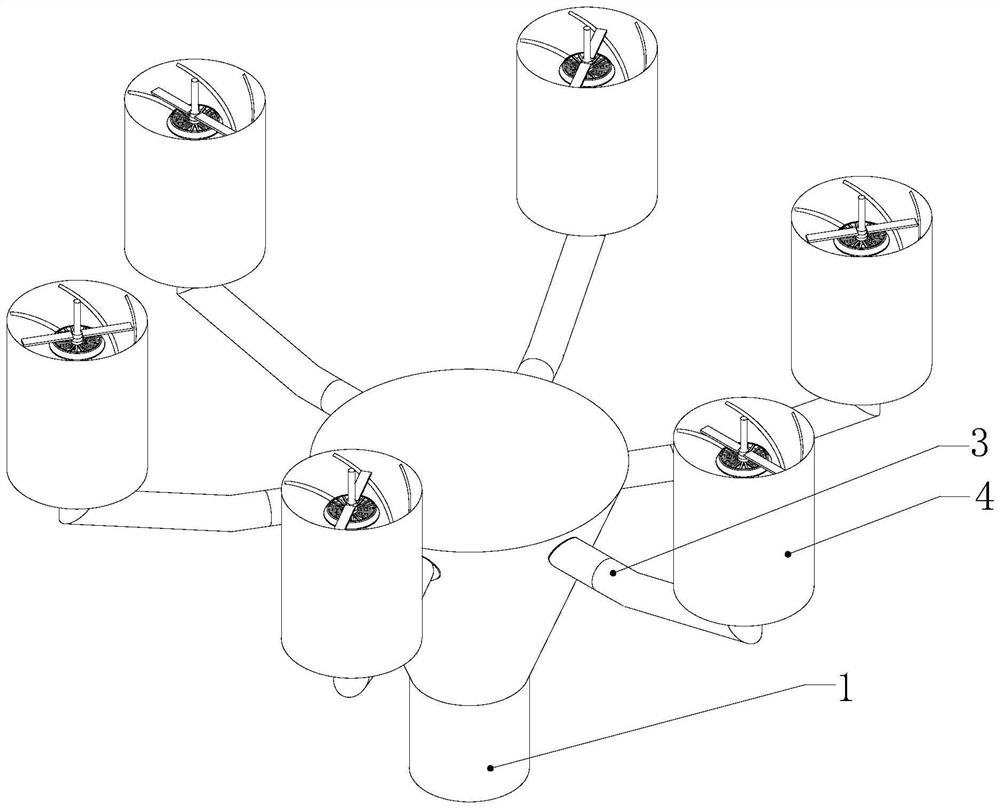

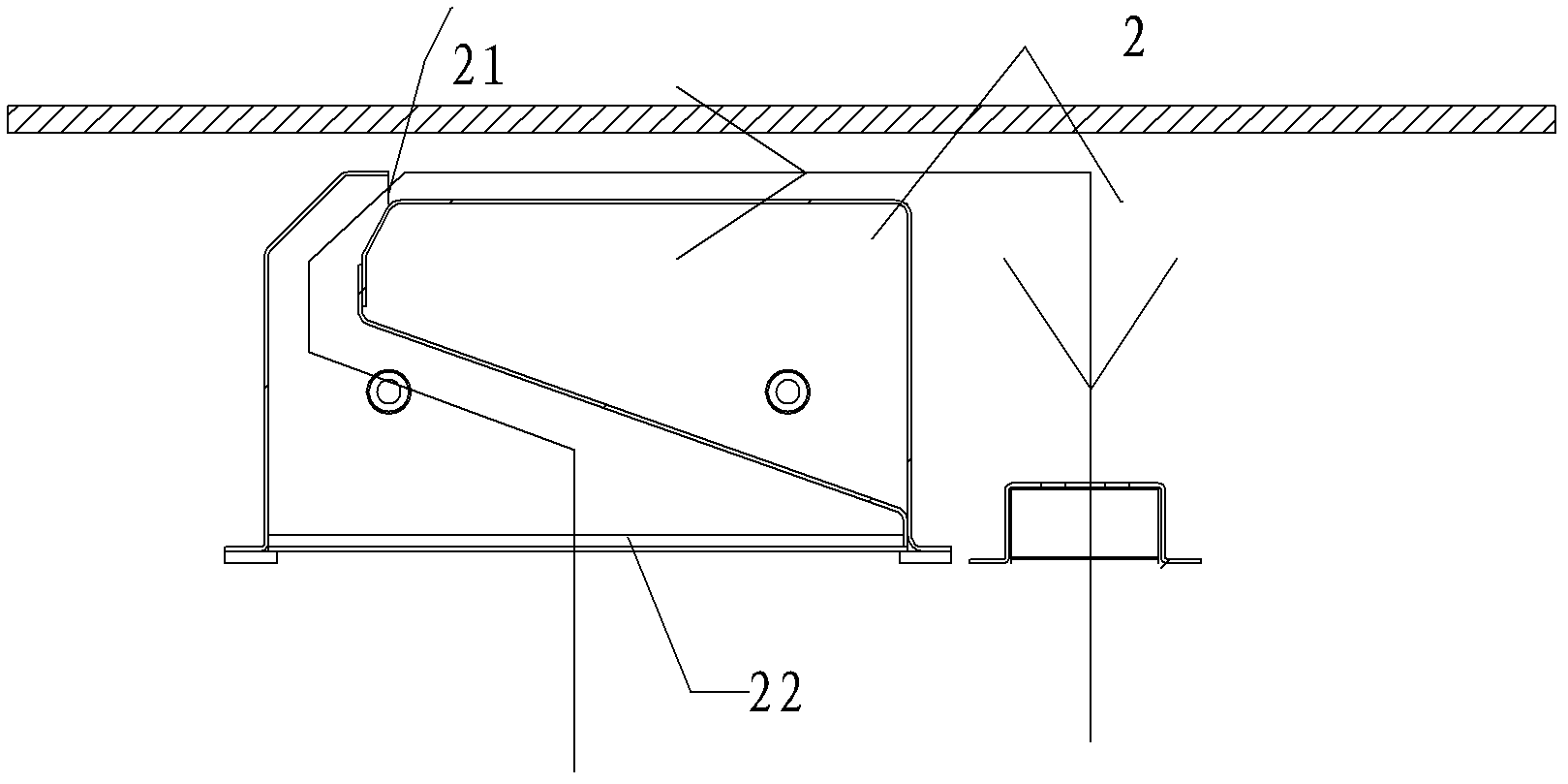

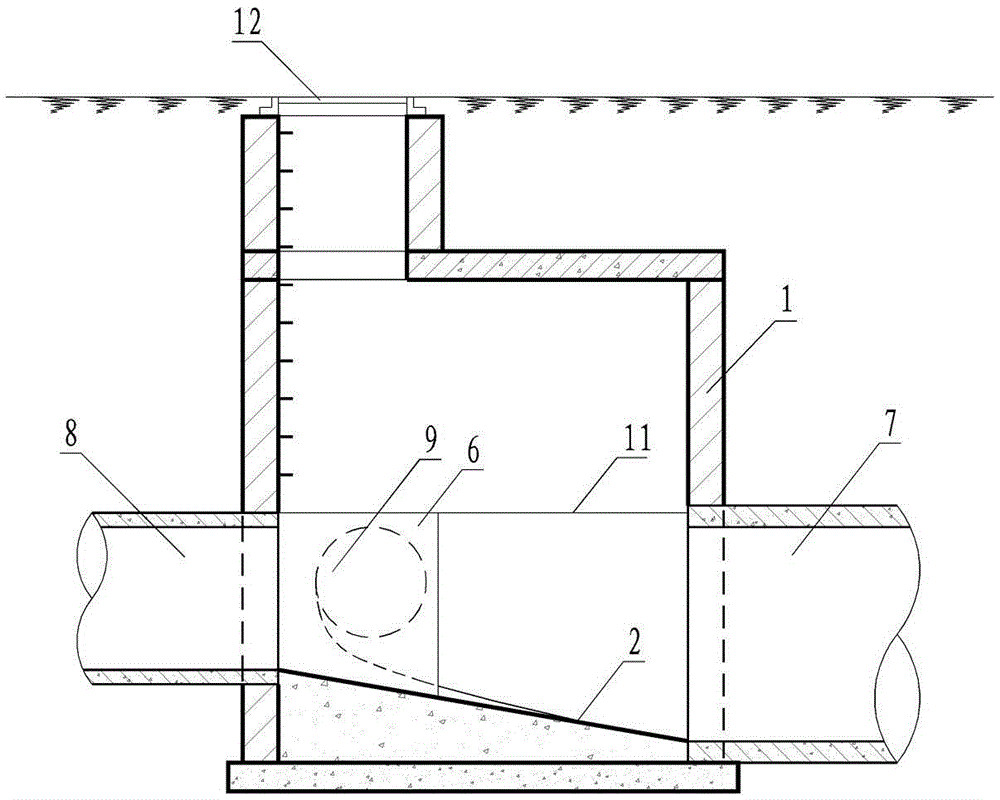

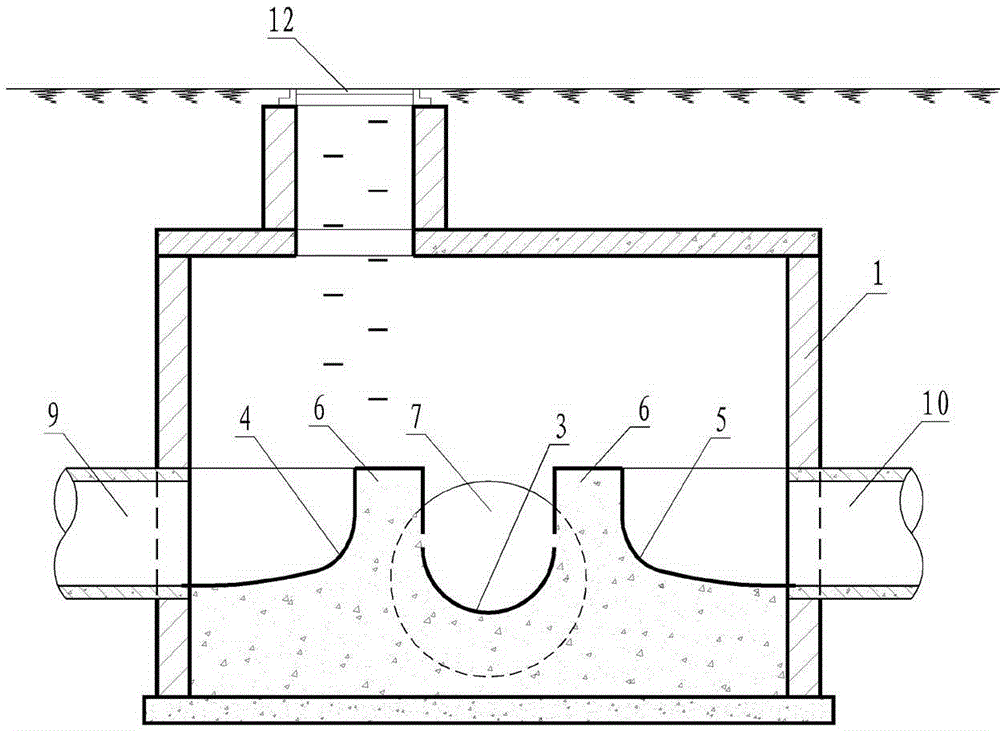

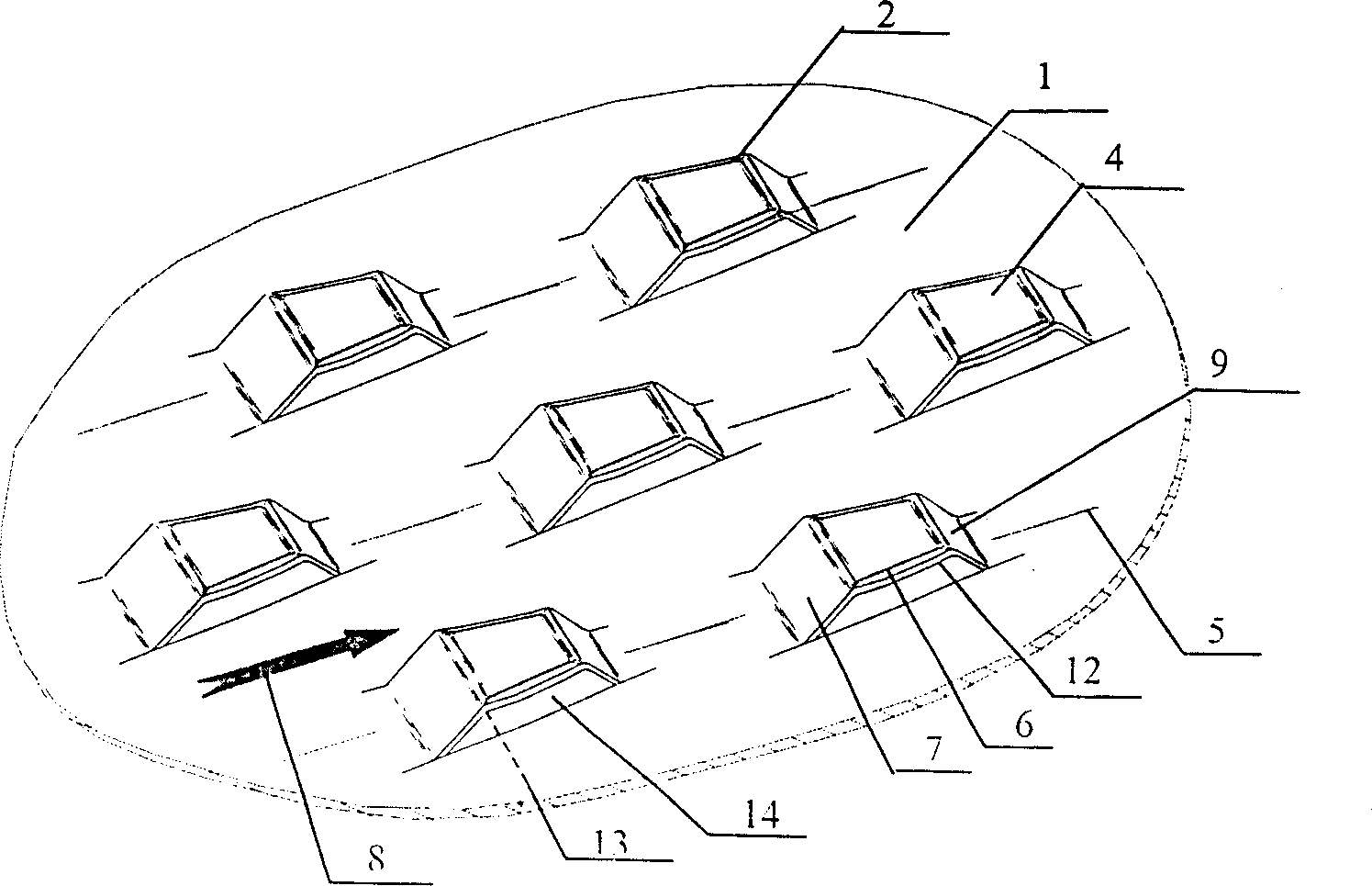

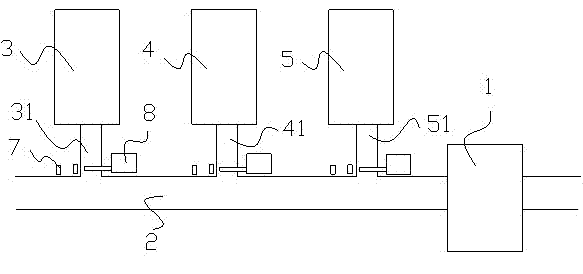

Water drainage cross inspection well preventing water face-to-face flushing

ActiveCN104018569AGive full play to drainage efficiencyReduce waterloggingSewerage structuresPipeflowWater flow

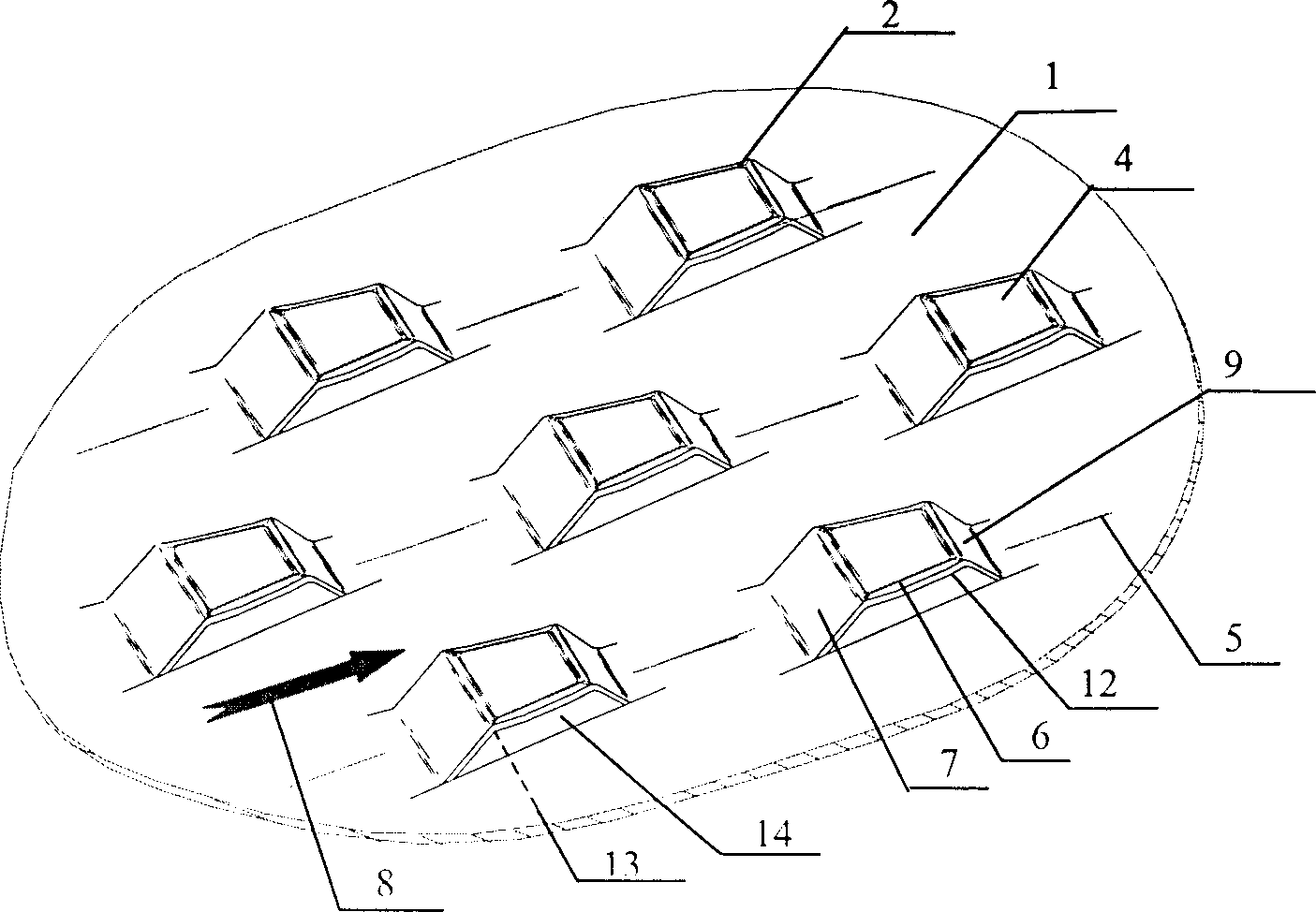

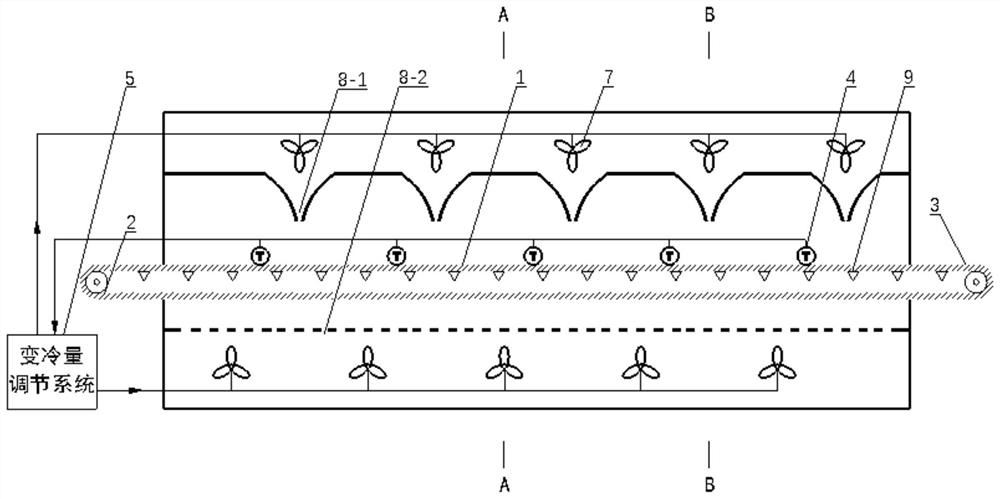

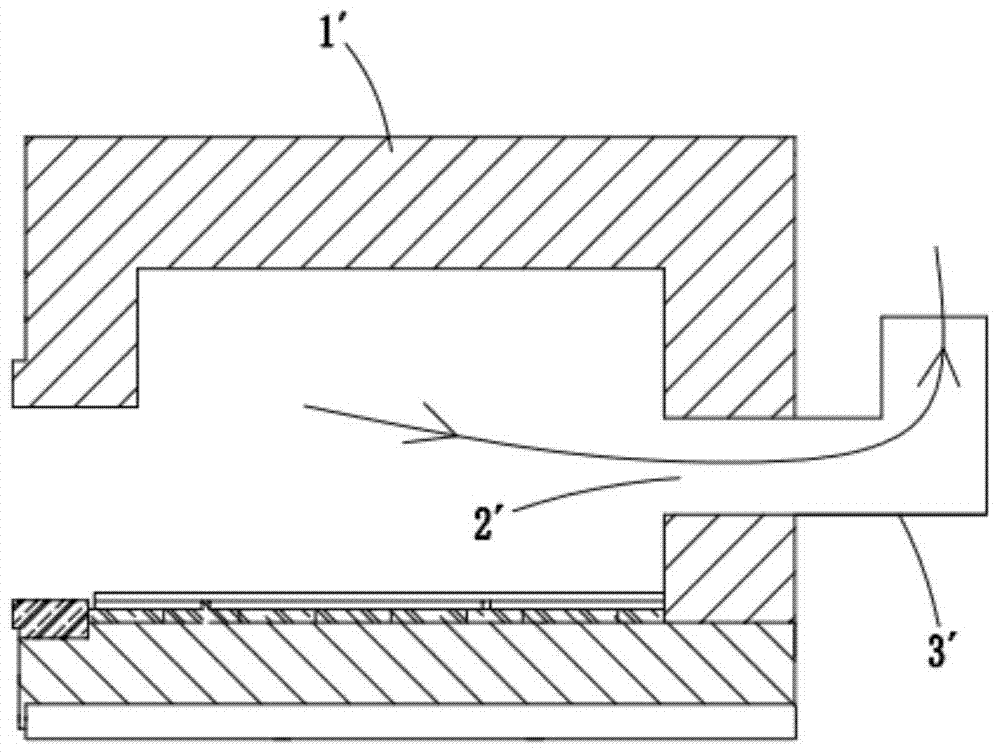

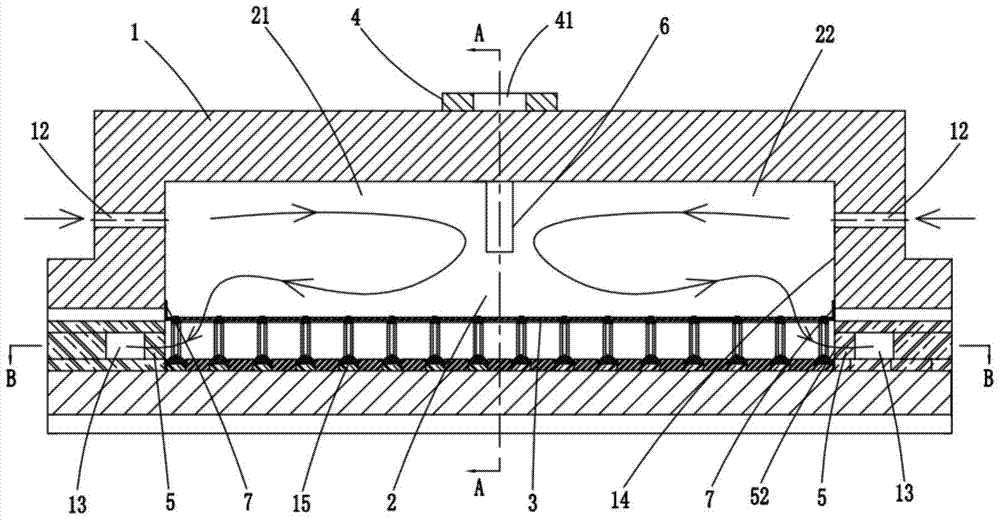

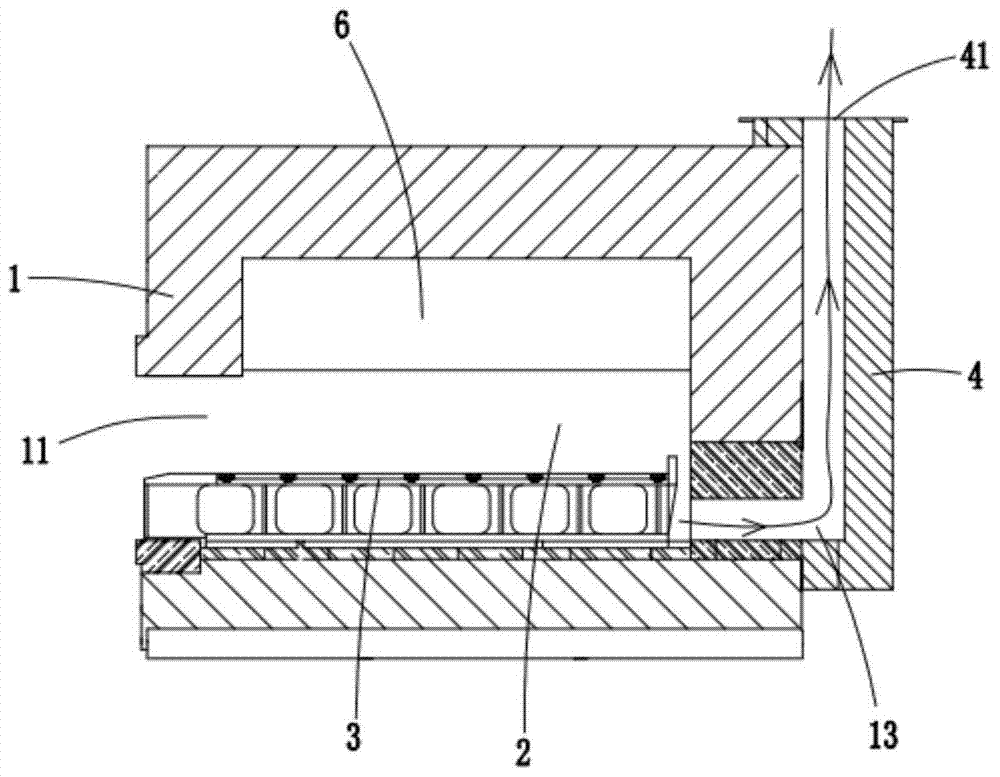

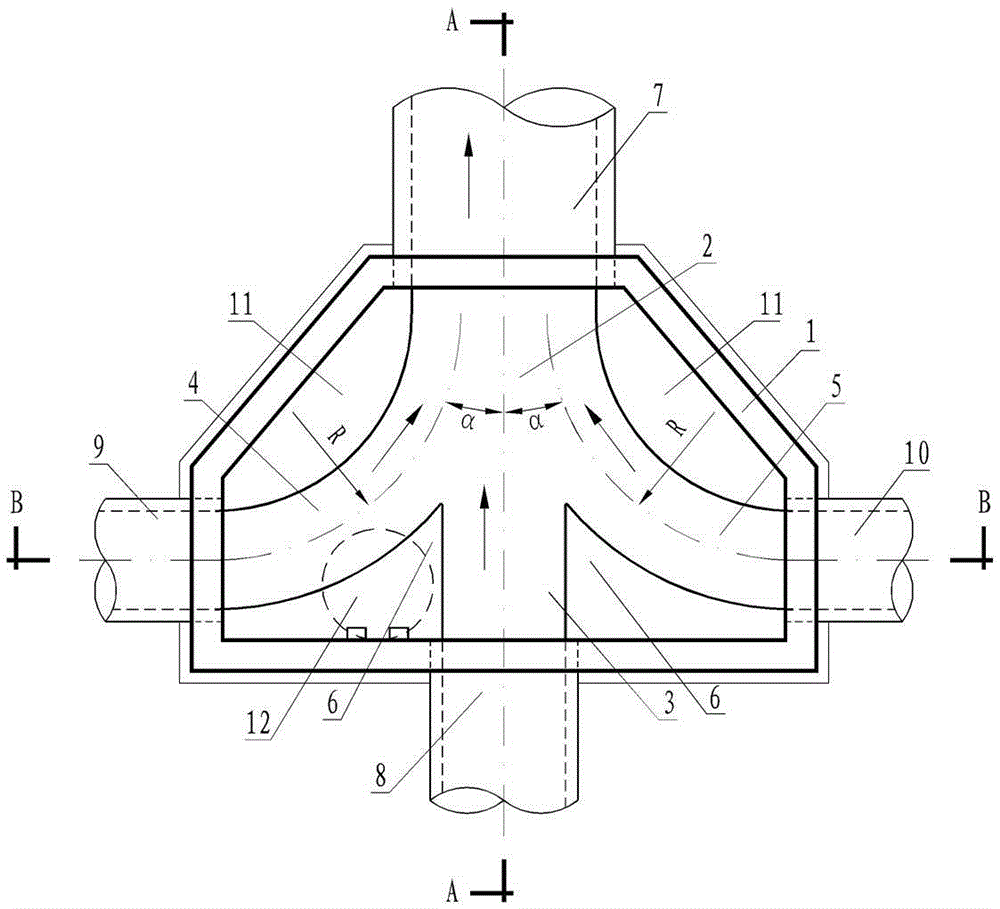

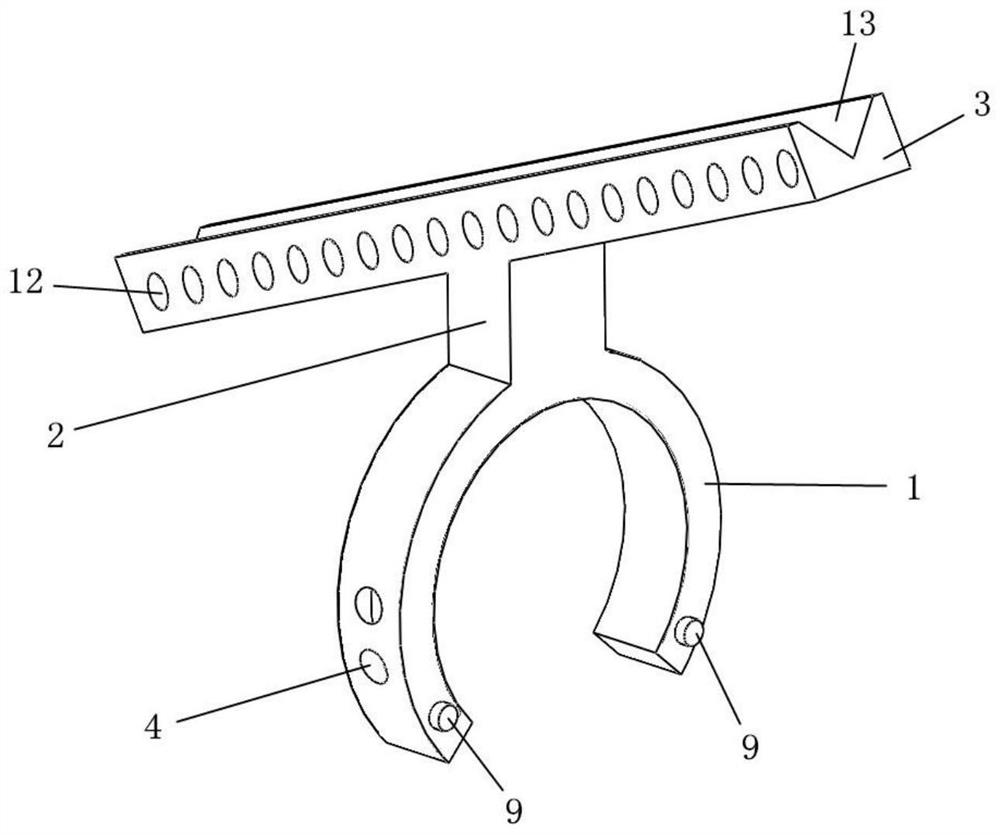

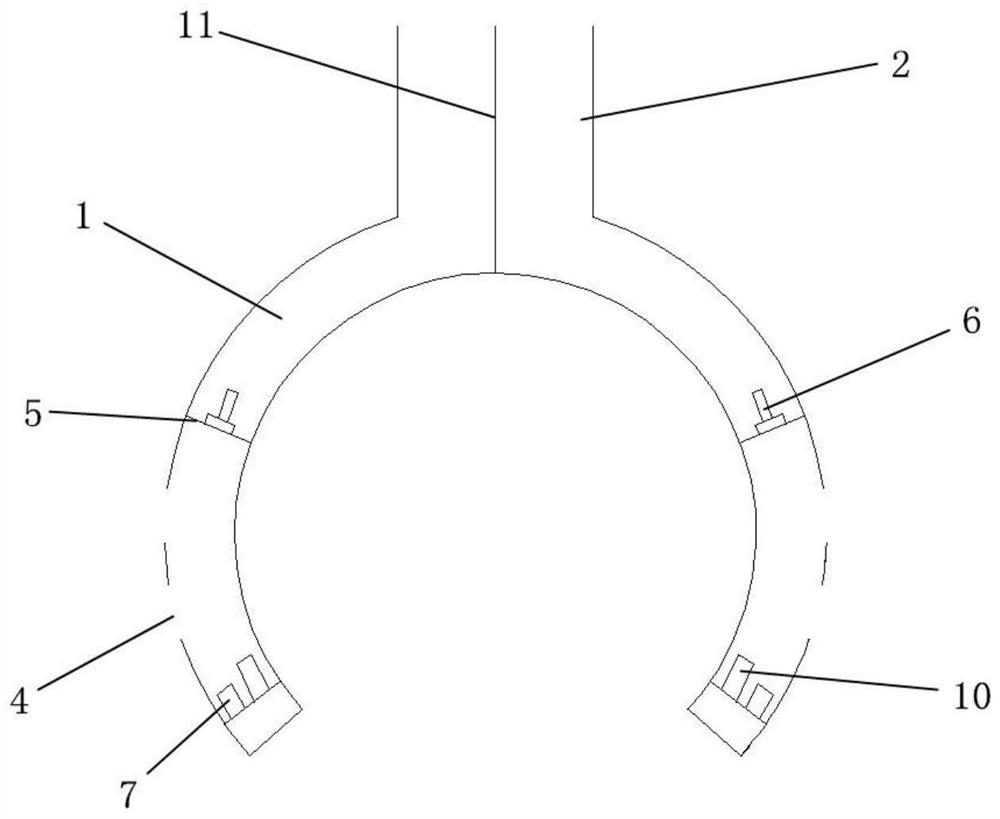

The invention discloses a water drainage cross inspection well preventing water face-to-face flushing, belongs to the field of water drainage projects and particularly relates to a rainwater and sewage convergence water drainage structure. The well is an intersection inspection well applicable to a rainwater or sewage pipeline. Branch pipes on the two sides of a water drainage pipeline are connected into the inspection well through sluices with large cornering radius, the sluices of the branch pipes on the two sides are spaced from a sluice of an upstream pipeline, and the included angle of afflux of the three sluices is small. The inspection well can prevent face-to-face flushing of water entering the inspection well, reduce turbulence flow to stabilize the water and bring the water drainage efficiency of the intersection inspection well into full play, thereby reducing the frequency of waterlogging of urban roads.

Owner:洛阳城市建设勘察设计院有限公司 +1

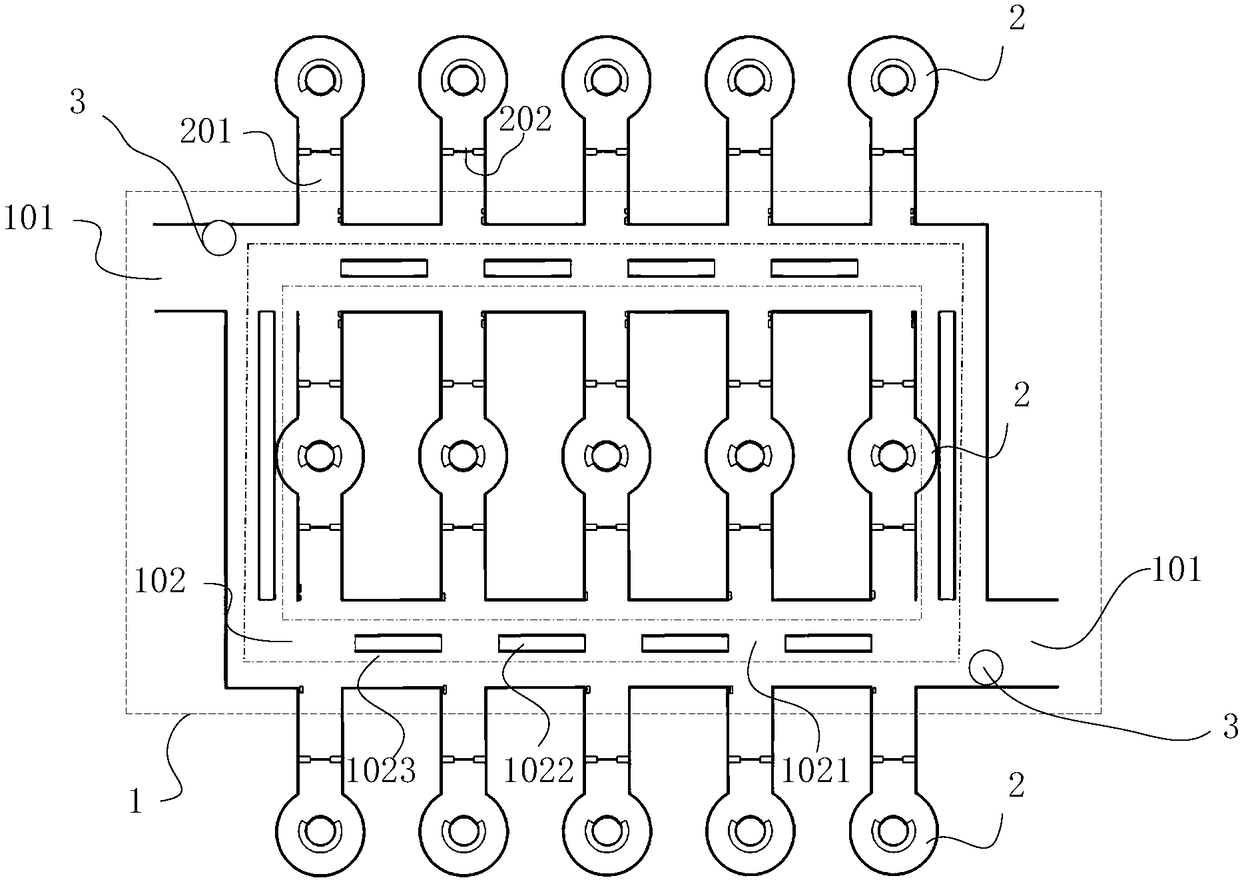

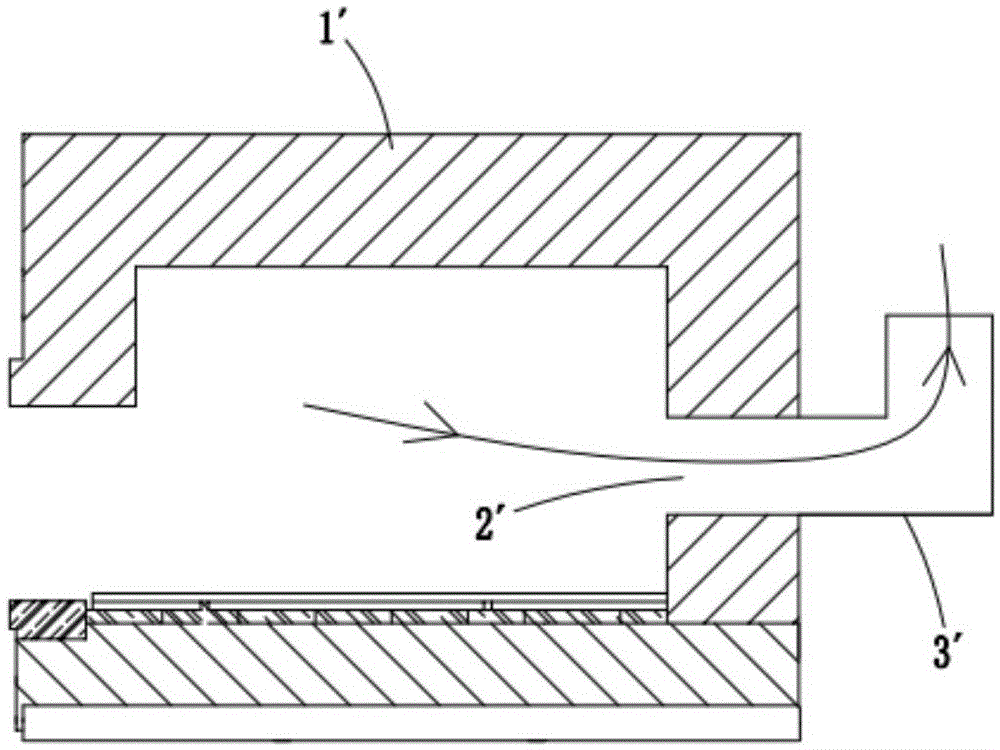

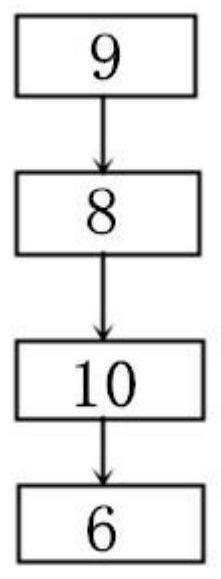

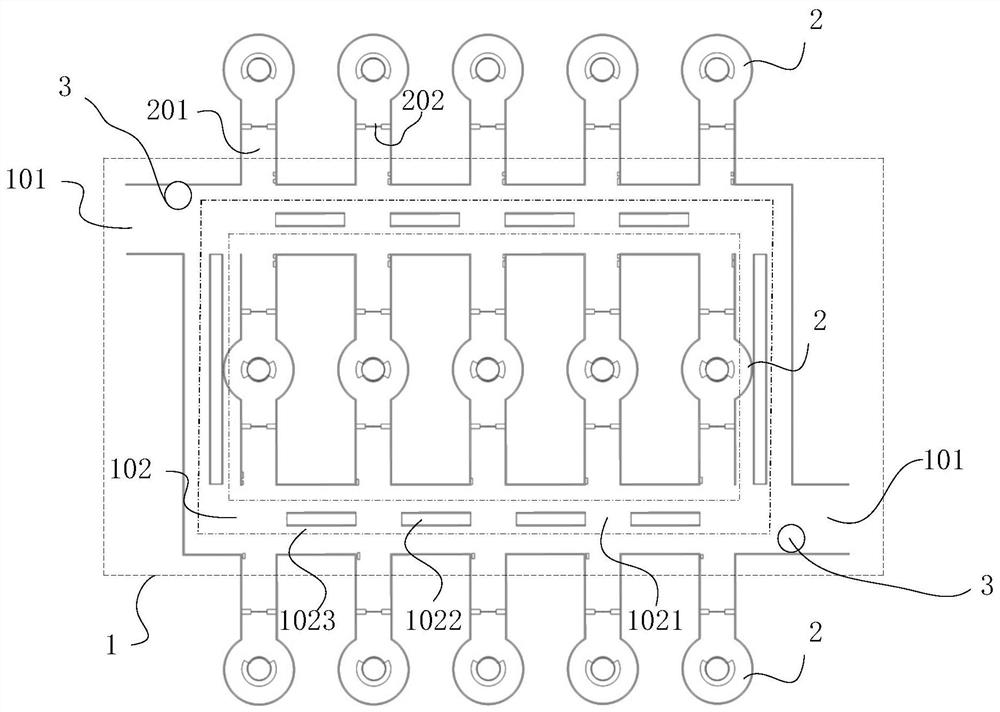

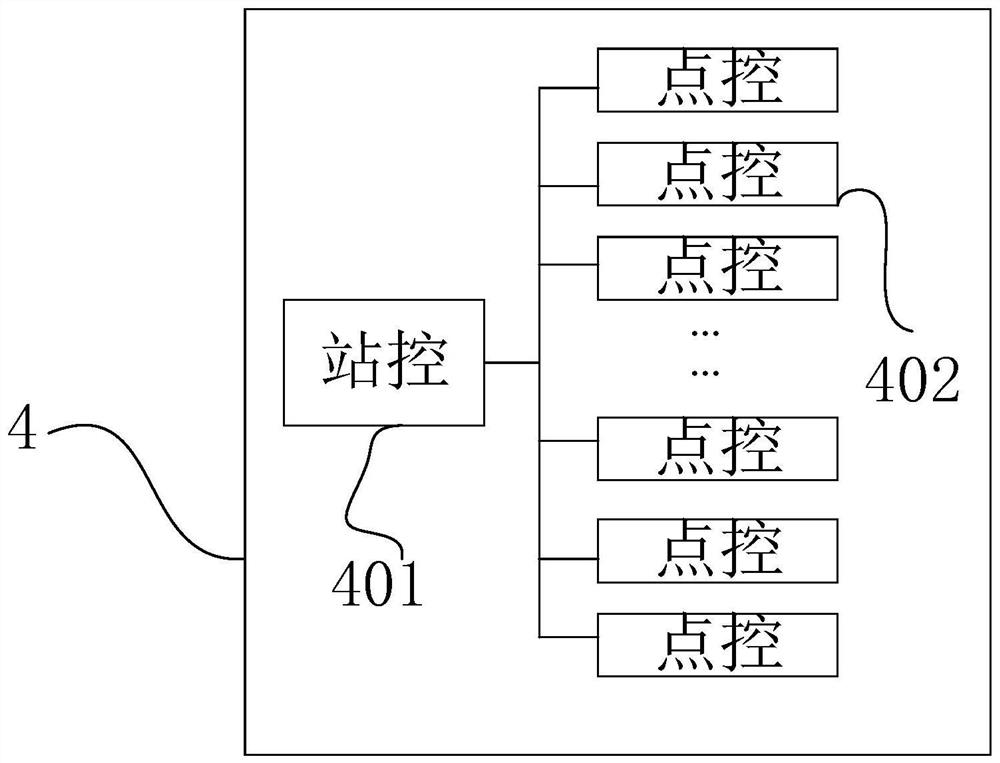

Ride allocation system and method

ActiveCN109118415AImprove the efficiency of ride allocationAvoid delays in arriving at the pick-up areaData processing applicationsControl systemComputer terminal

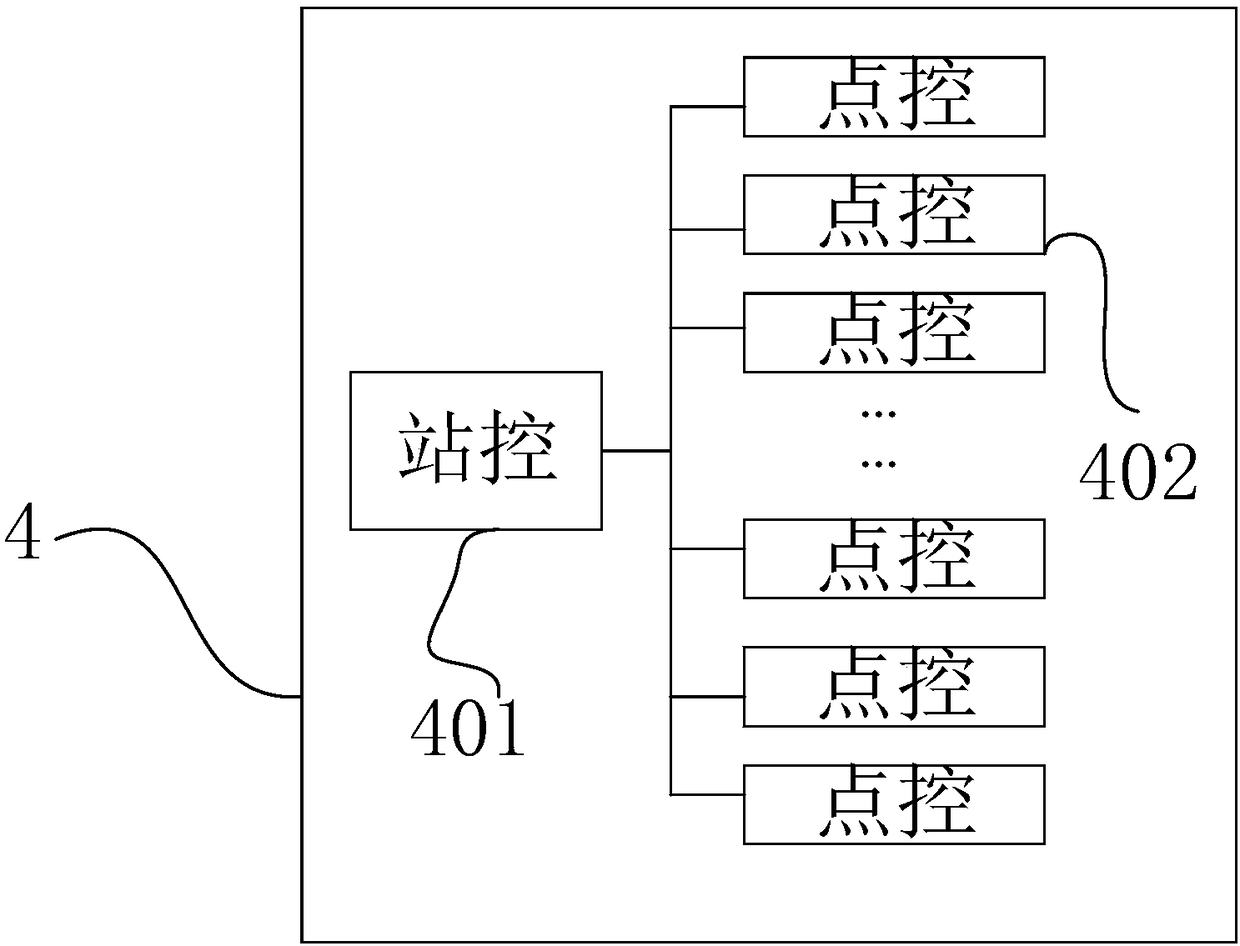

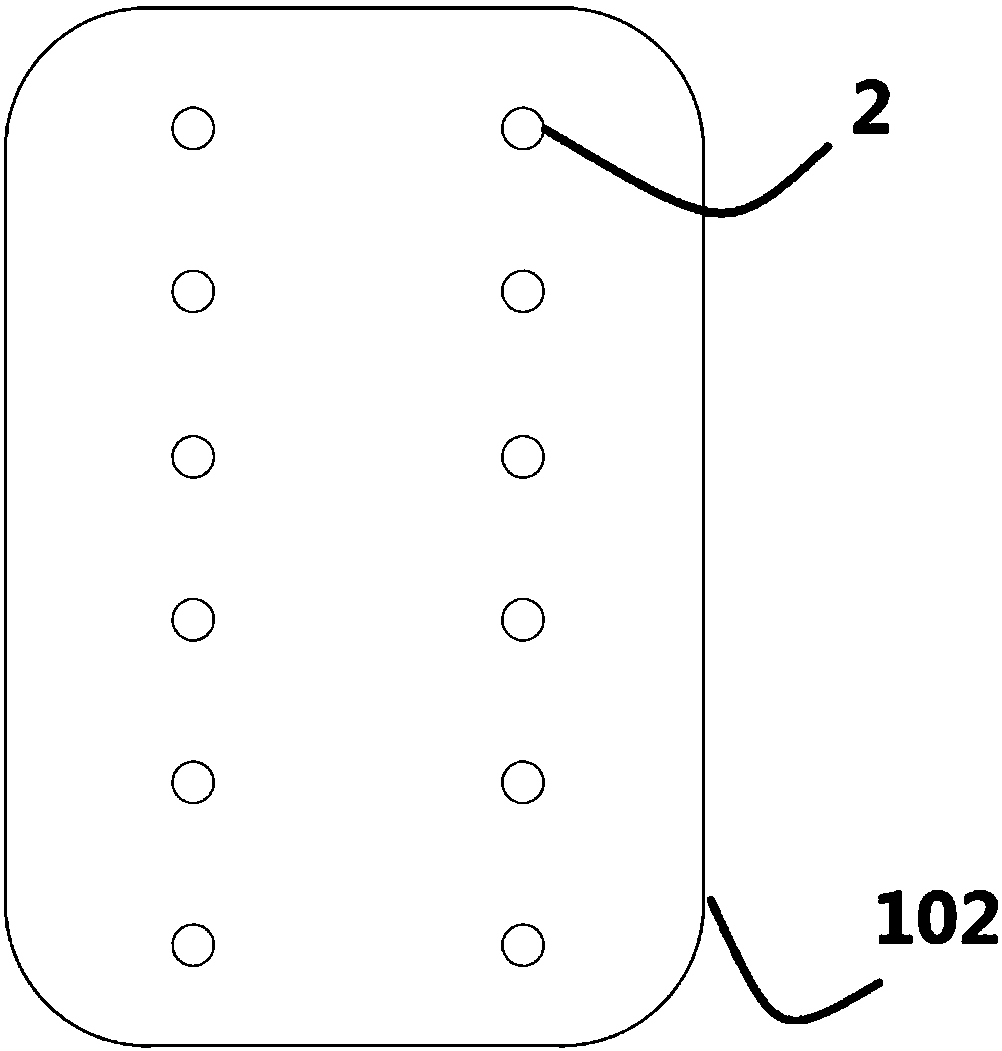

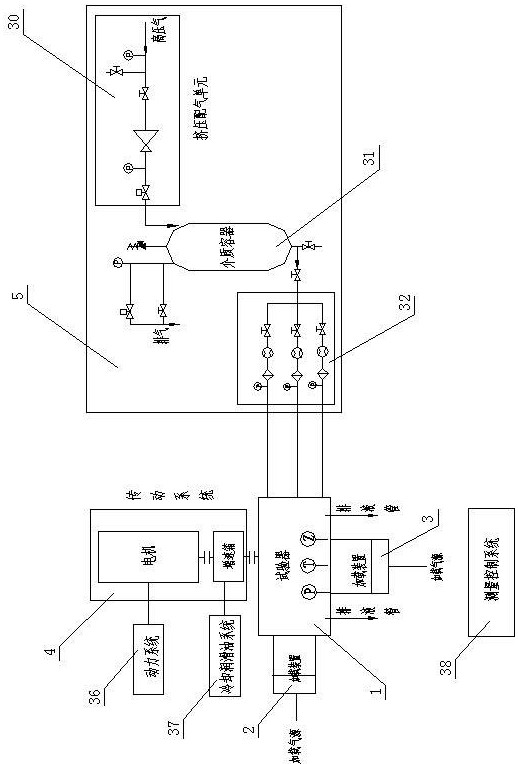

The invention discloses a ride allocation system and method. The system includes a passenger allocation area, a plurality of pick-up areas, a station control system, a plurality of identity terminals,and at least one first induction device. The passenger allocation area includes at least one allocation area entrance, and the passenger allocation area communicates with an entrance of each of the pick-up areas; the identity terminals record passenger information, the first induction device is disposed on the allocation area entrance, and the first induction device is used for collecting the passenger information of each of the identity terminals entering the allocation area entrance, and sends the passenger information to the station control system; and the station control system is used for obtaining vehicle information in each of the pick-up areas, is further used for match each of the identity terminals to one of the pick-up areas according to the passenger information and the vehicle information, and guides each of the identity terminals to matched entrances of the pick-up areas. The invention can achieve fast passenger-vehicle matching and passenger matching riding in a same destination or a similar destination during the time of multi-person and multi-vehicle, thereby improving the riding allocation efficiency.

Owner:SHANGHAI DIJIE TECH CO LTD

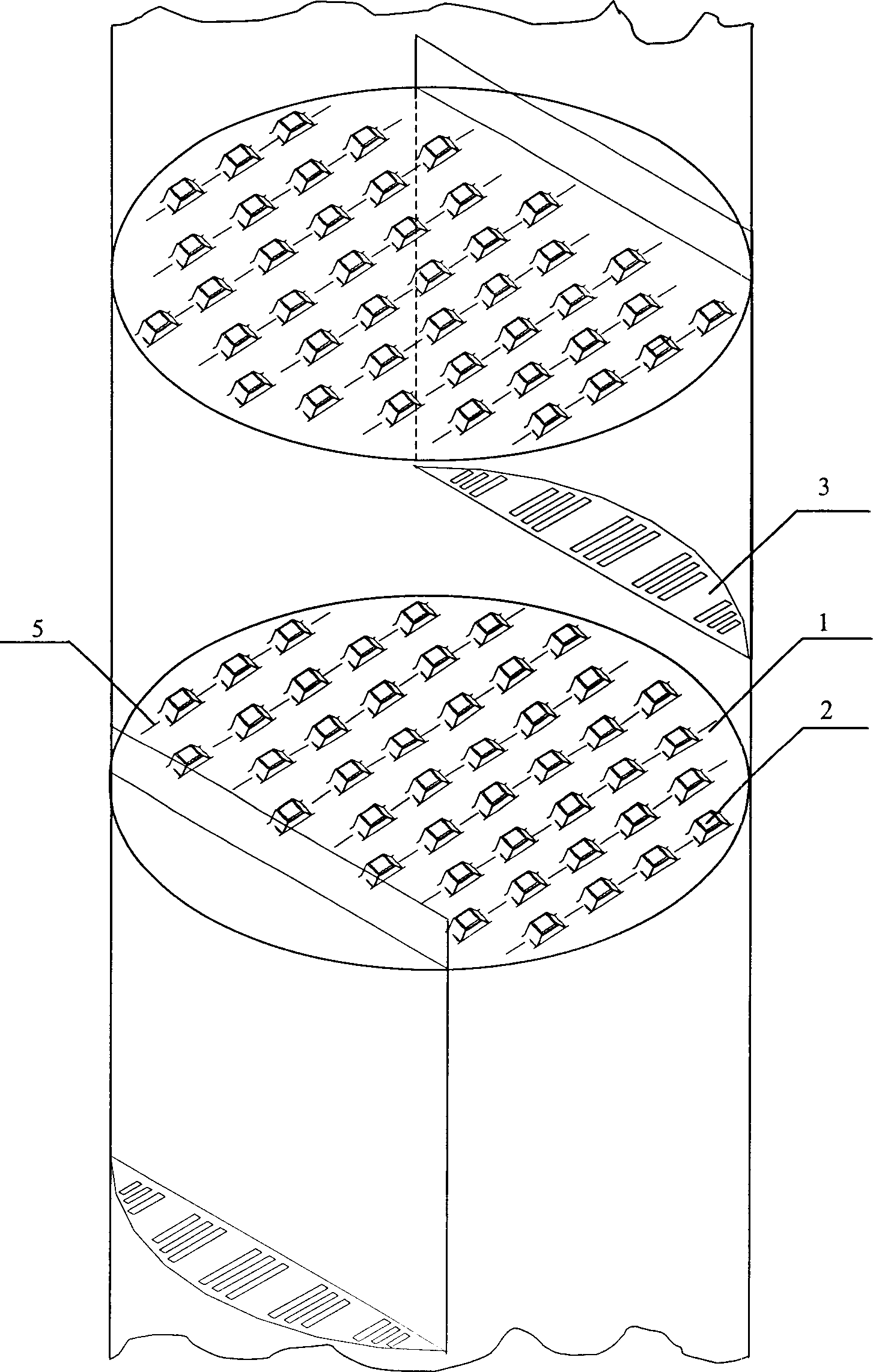

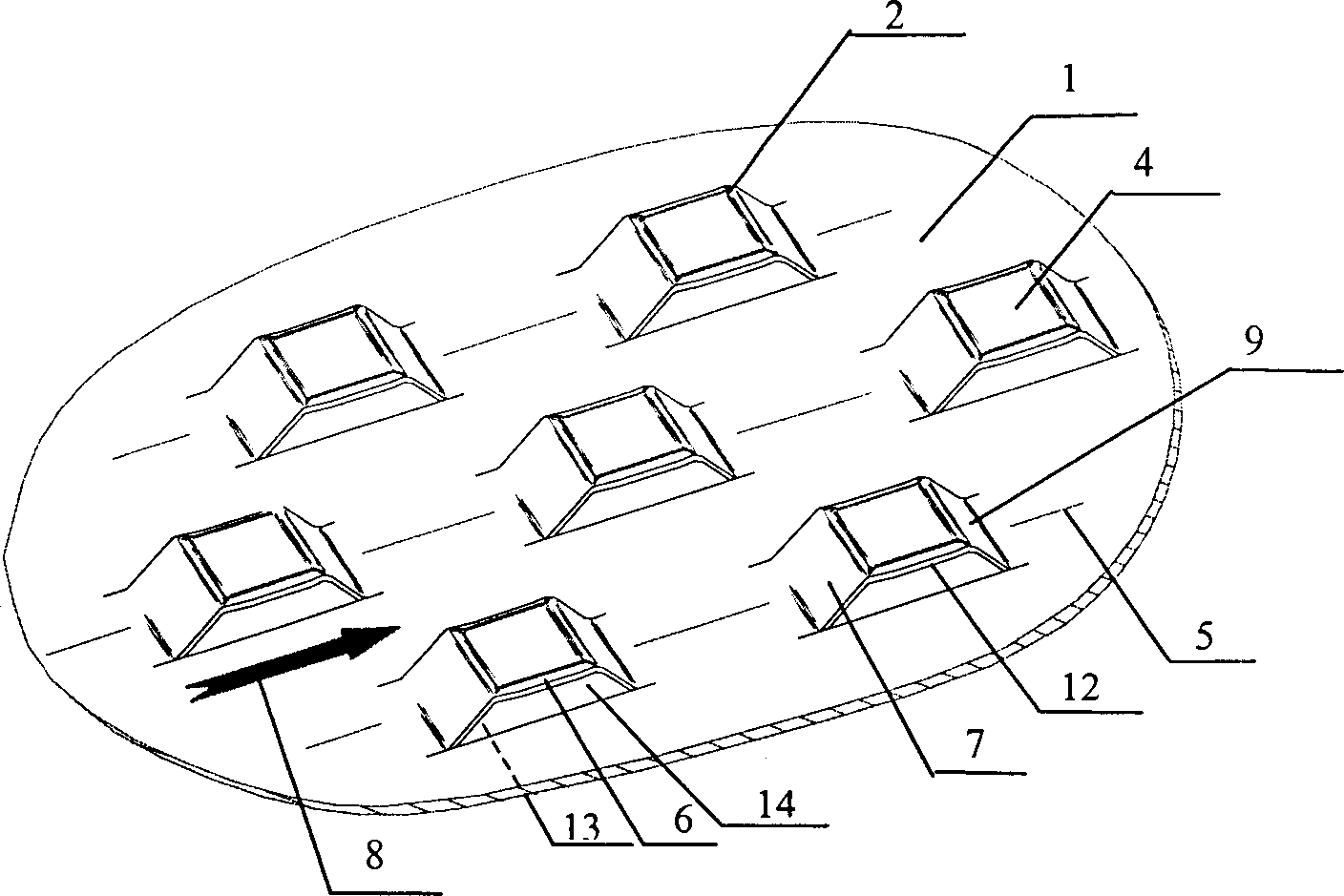

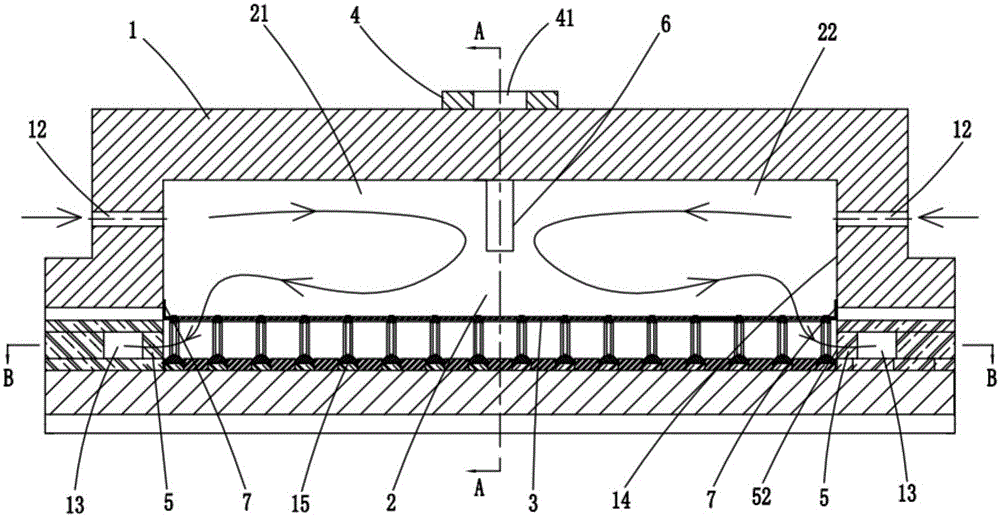

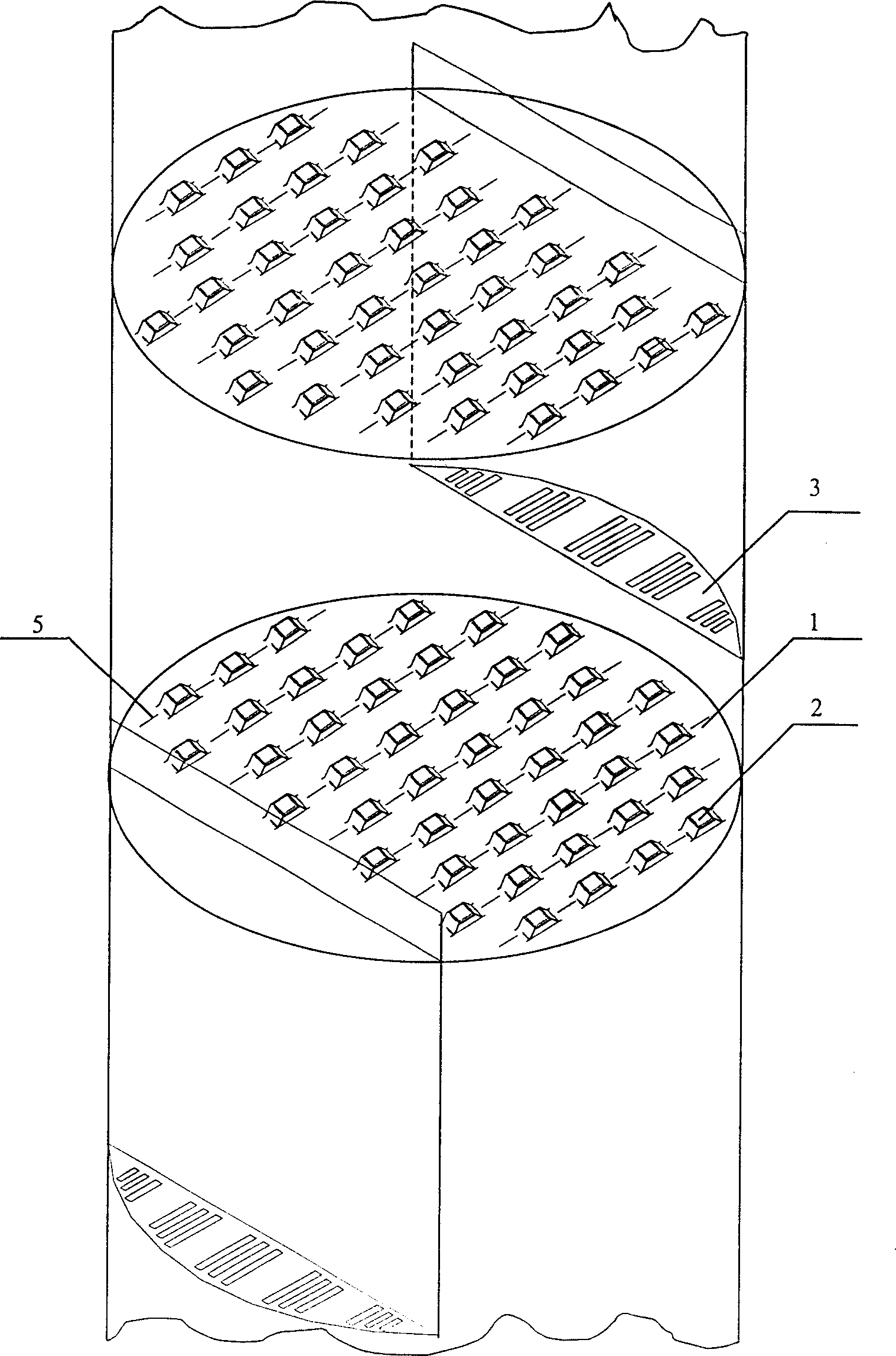

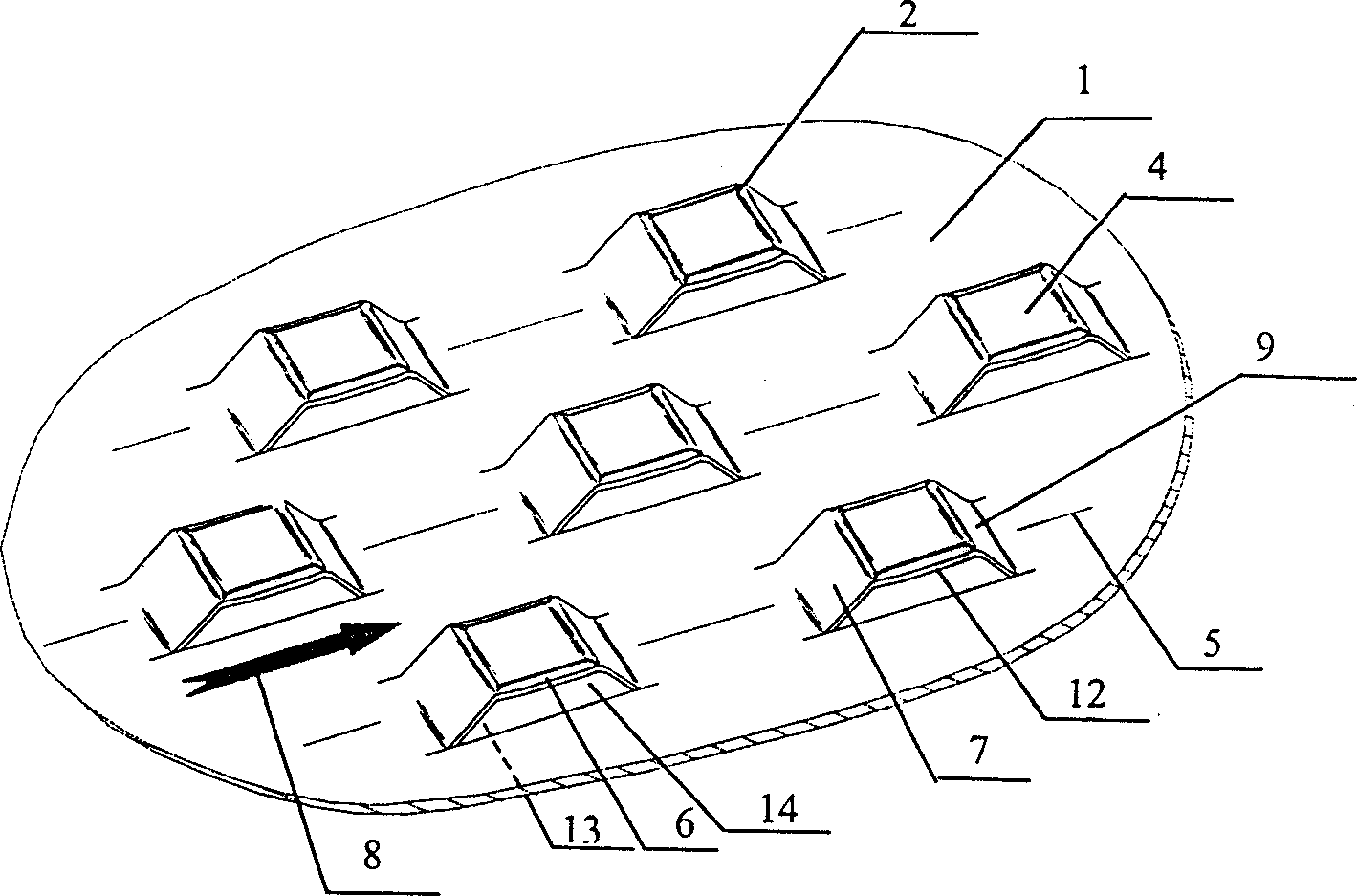

Efficient large-flux fixed valve tray

The present invention relates to a high-effective large-flux fixed valve tower tray. It is formed from column plate, fixed valve and down-pipe. The fixed valve is formed by directly stamping the column plate self-body, and said fixed valve is composed of valve surface of fixed valve and valve leg of fixed valve, the valve surface is connected with column plate by means of valve leg of fixed valve, and the valve surface of the fixed valve has a downward bent folded edge. Said invented structure can raise treatment capacity of tower tray and its operation elasticity, at the same time the gas-liquid contact on the plate can be intensified so as to raise column plate mass transfer efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

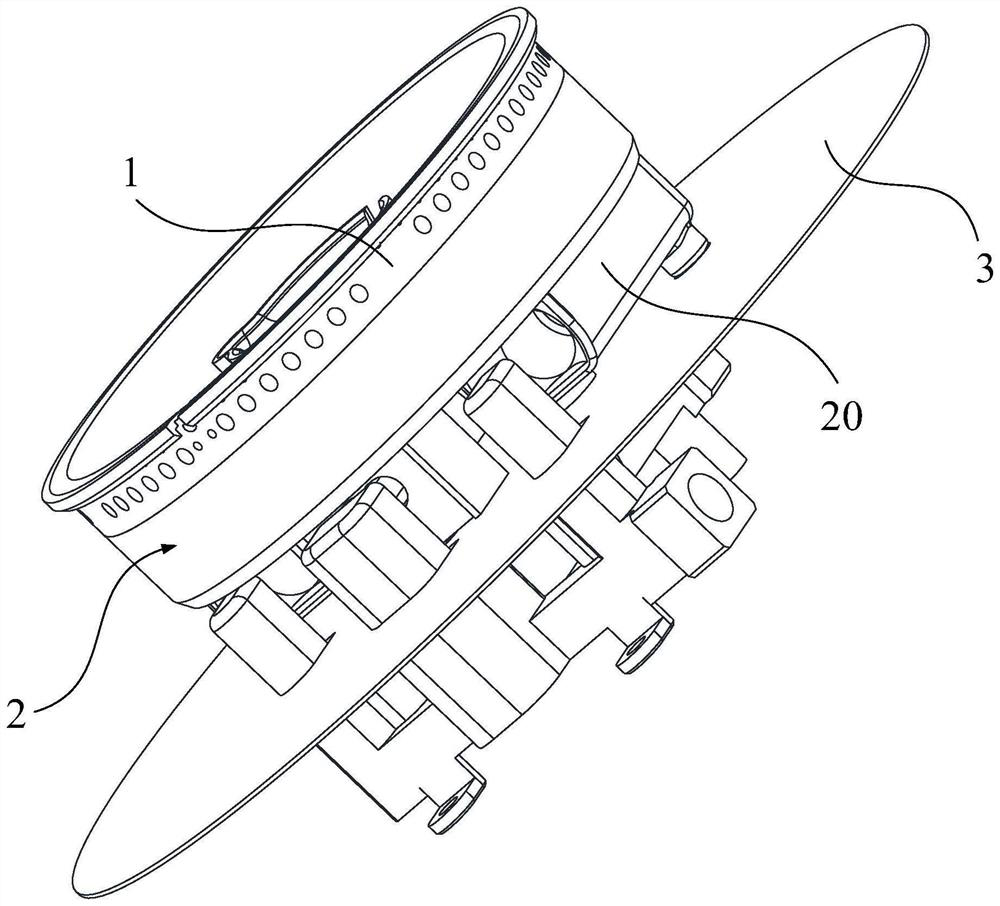

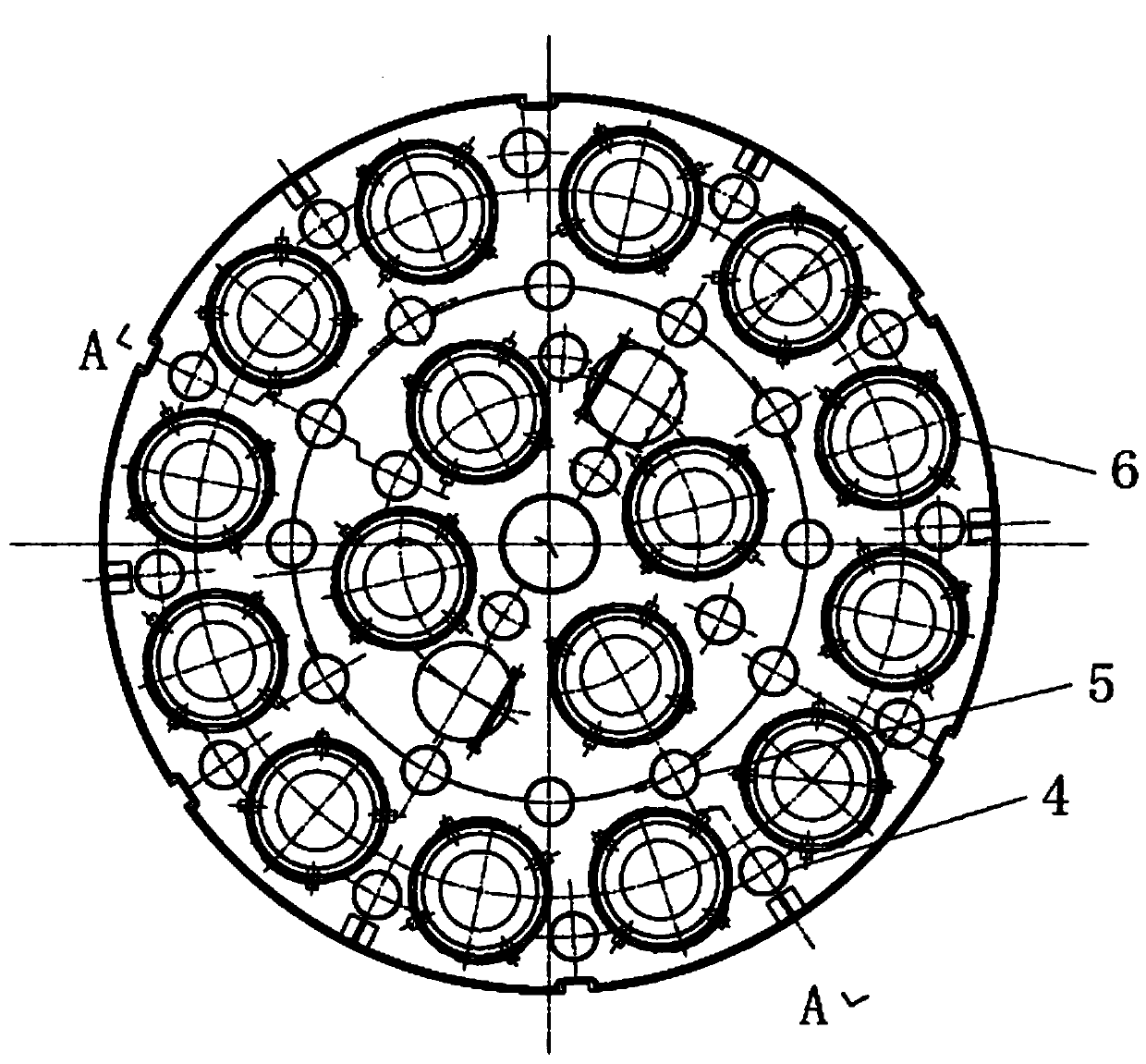

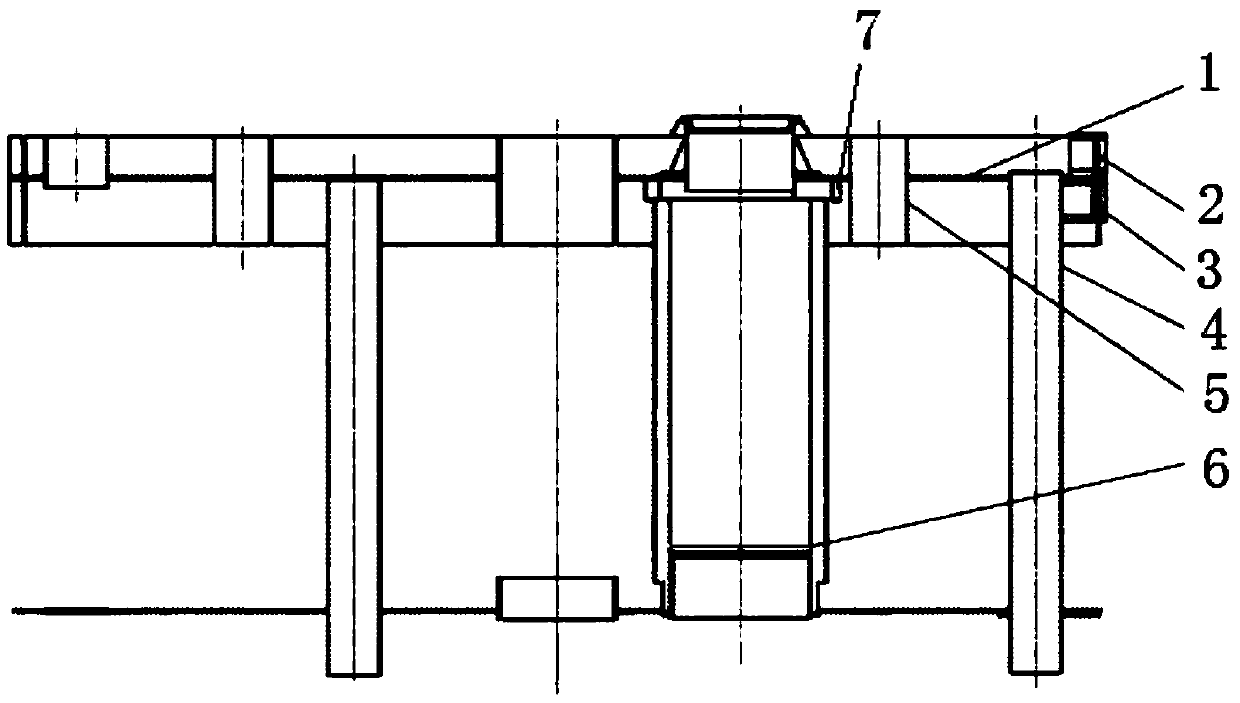

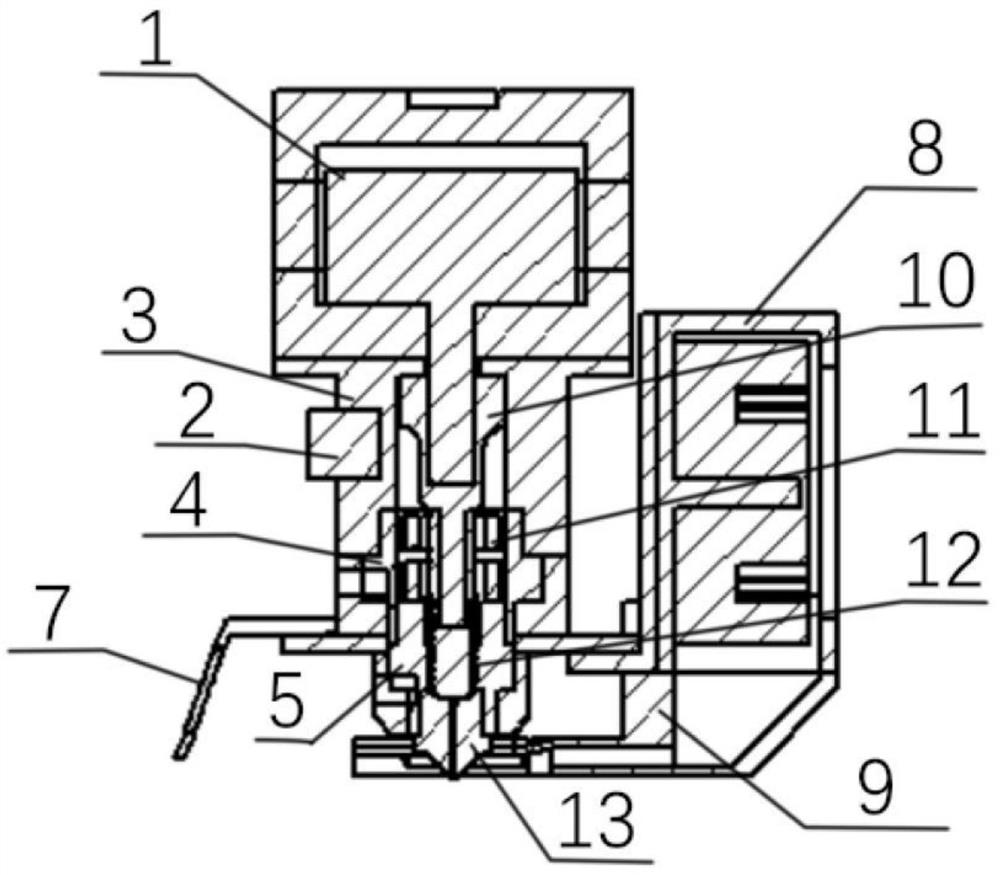

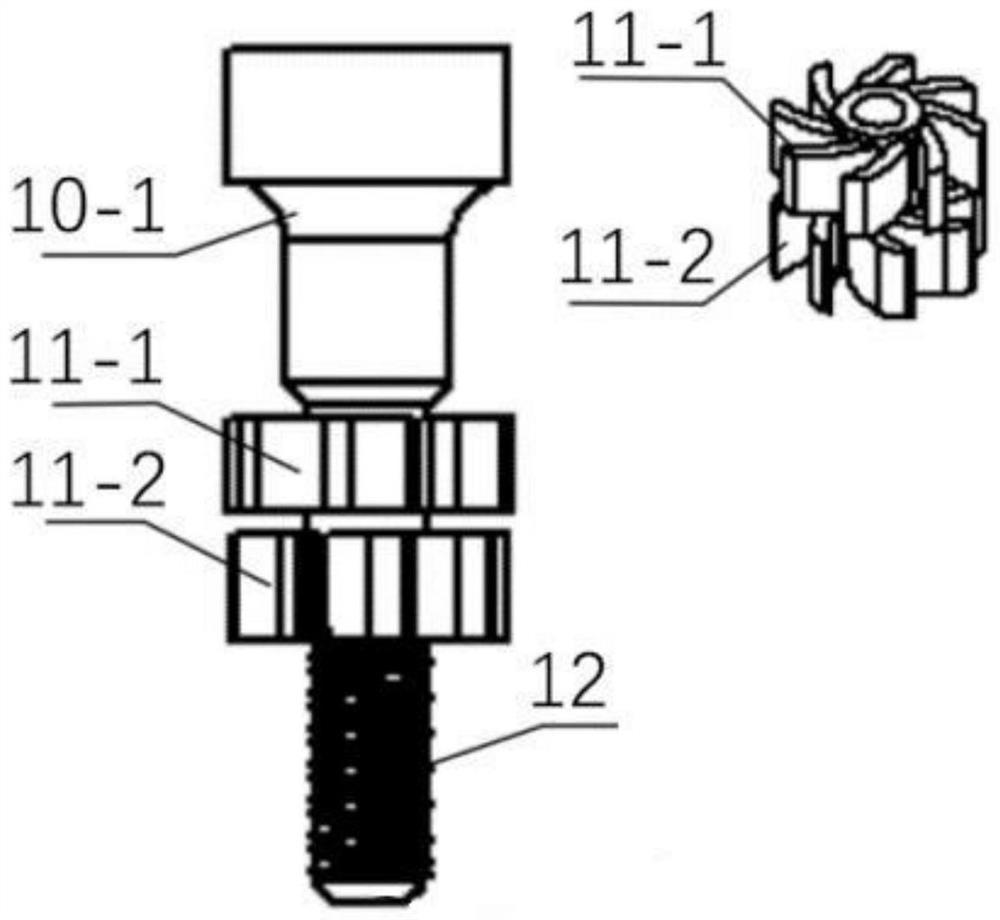

Rolling bearing test table and test method

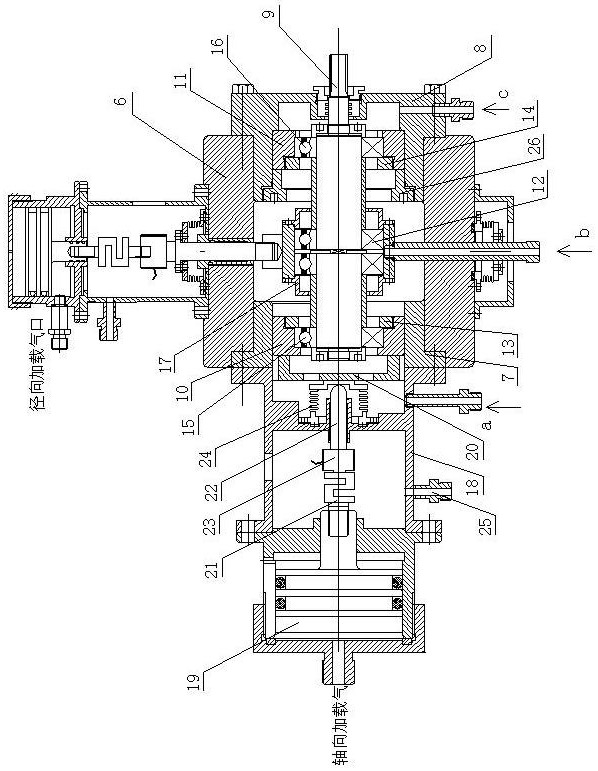

PendingCN111721533AReasonable structural designReduce damage rateMachine bearings testingRolling-element bearingEngineering

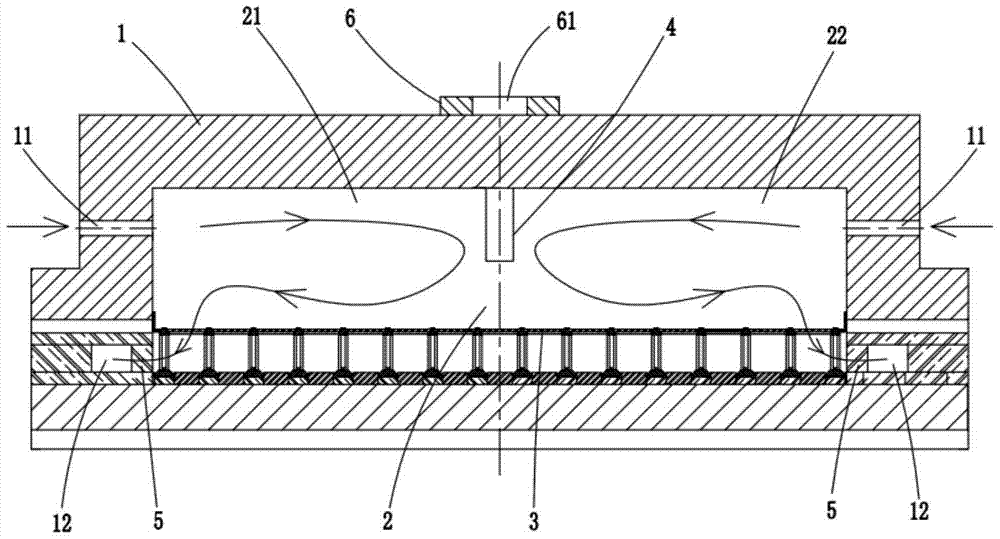

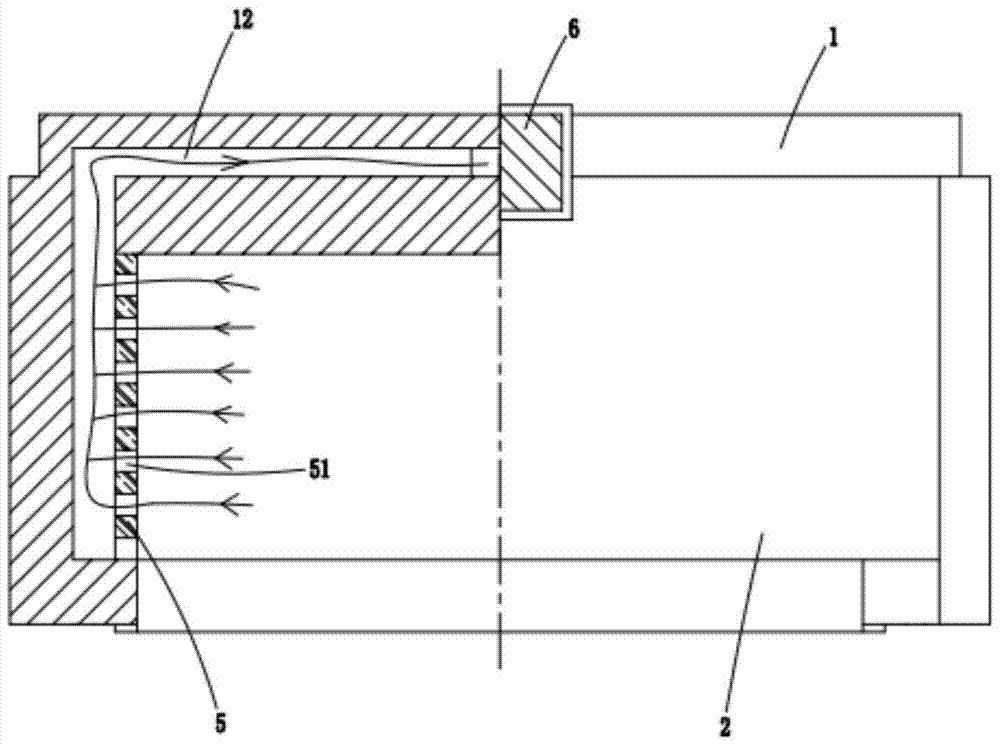

The invention discloses a rolling bearing test table and a test method, and belongs to a bearing test device and method. According to the rolling bearing test table, middle sleeves are installed at the two ends of a tester shell, a main shaft is installed in the shell in the axial direction in a penetrating mode, a radial bearing loading device and an axial bearing loading device are arranged on the shell, a front-end tested bearing sleeve and a rear-end tested bearing sleeve are installed at the front end and the rear end of the main shaft respectively, a process bearing is installed in the middle of the main shaft, the two ends of the process bearing sleeve are sleeved with medium isolation rings respectively, a medium supply system is connected with a pipeline thereof, and a transmission system and the main shaft are in transmission connection. According to the invention, the rolling bearing test table is reasonable in structure, the process bearing and the tested bearing on the tester main shaft are the same in stress and cooling medium working conditions, and two bearings can be tested at a time, so that the efficiency is improved, and the test cost is saved; the locking sleeve can effectively prevent the bearing sleeve and the tester shell from rotating relatively; and the medium isolation ring is arranged at the process bearing, so that the hedging of medium discharged by the two bearings is effectively prevented, and the damage rate of the bearings in the test process is reduced.

Owner:BEIJING STARTECH

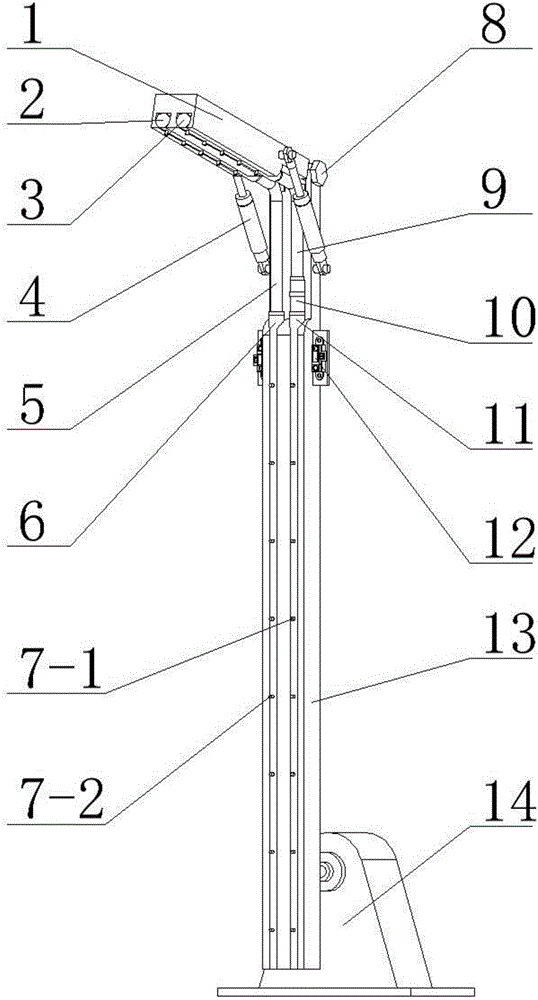

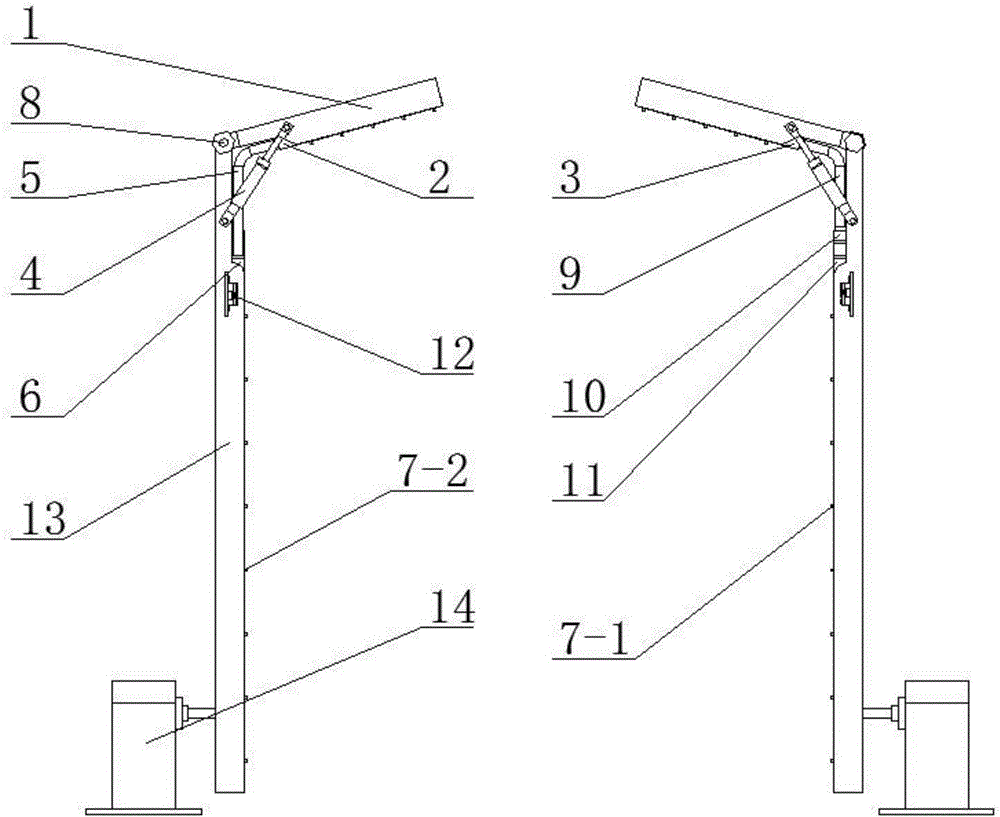

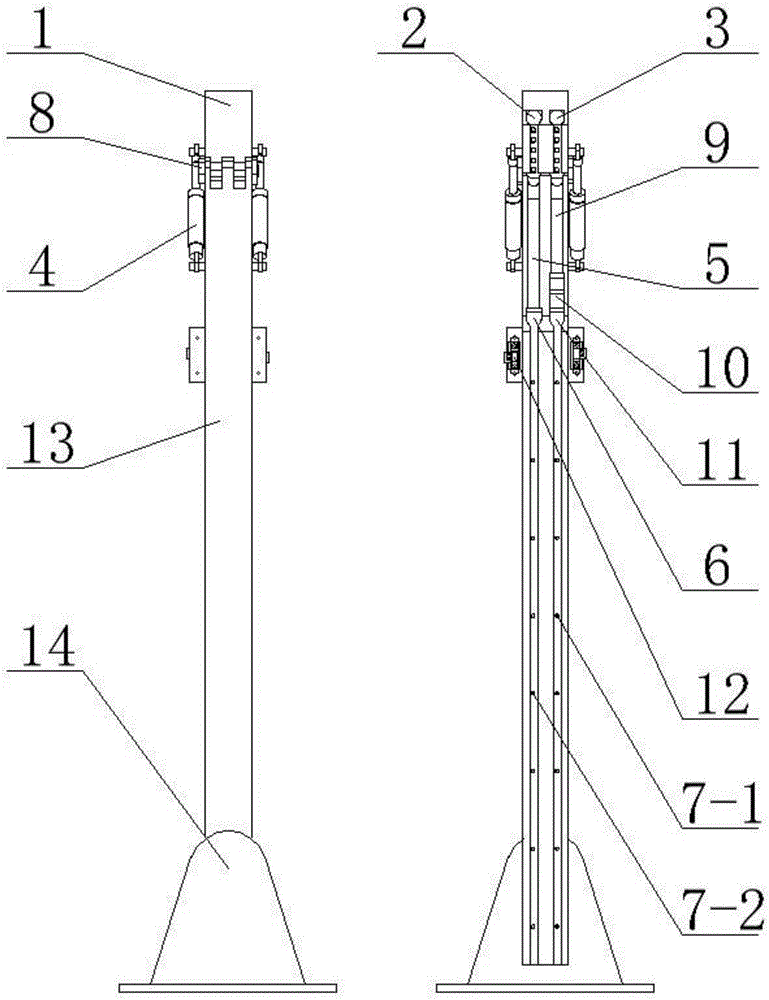

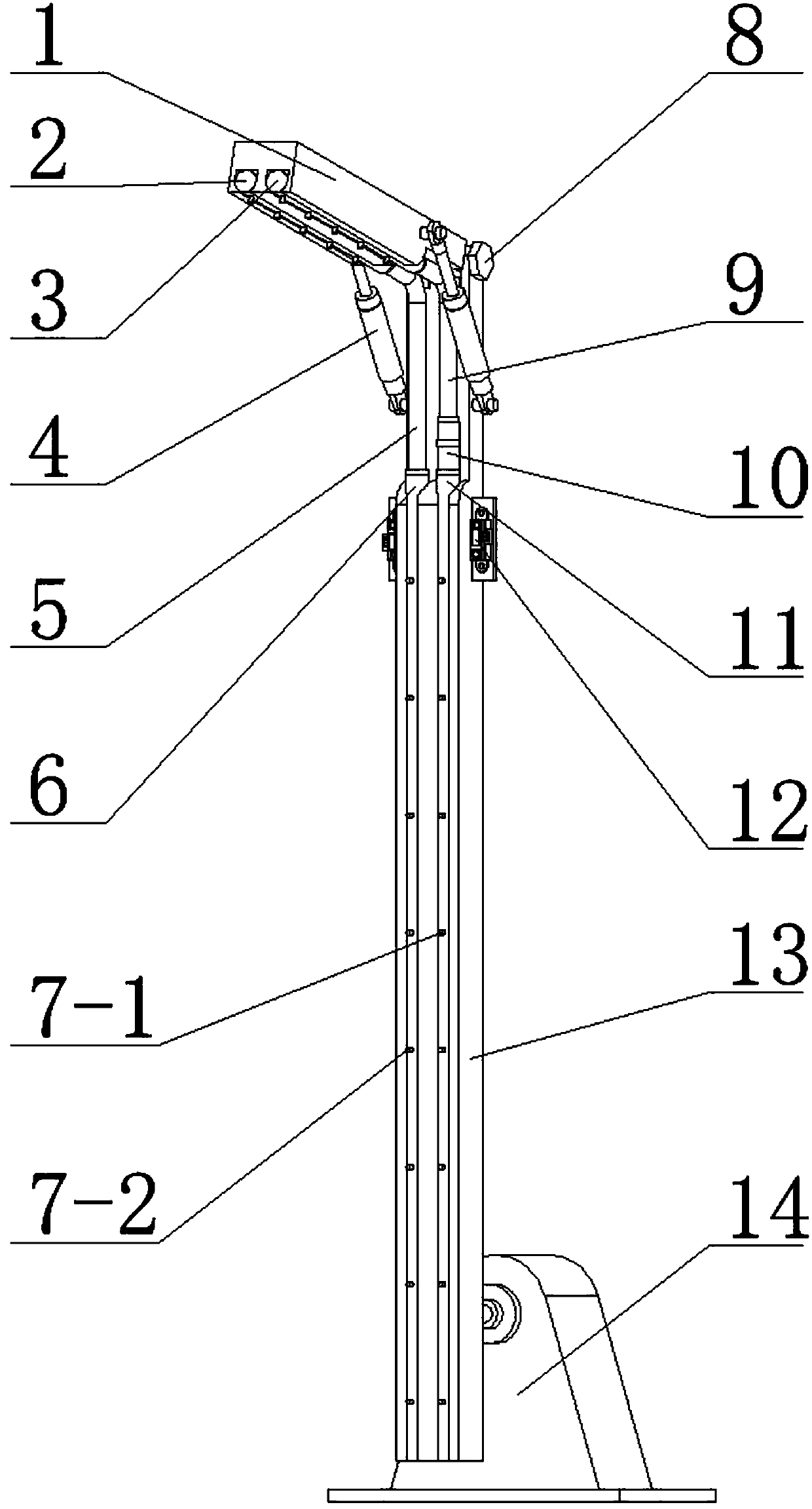

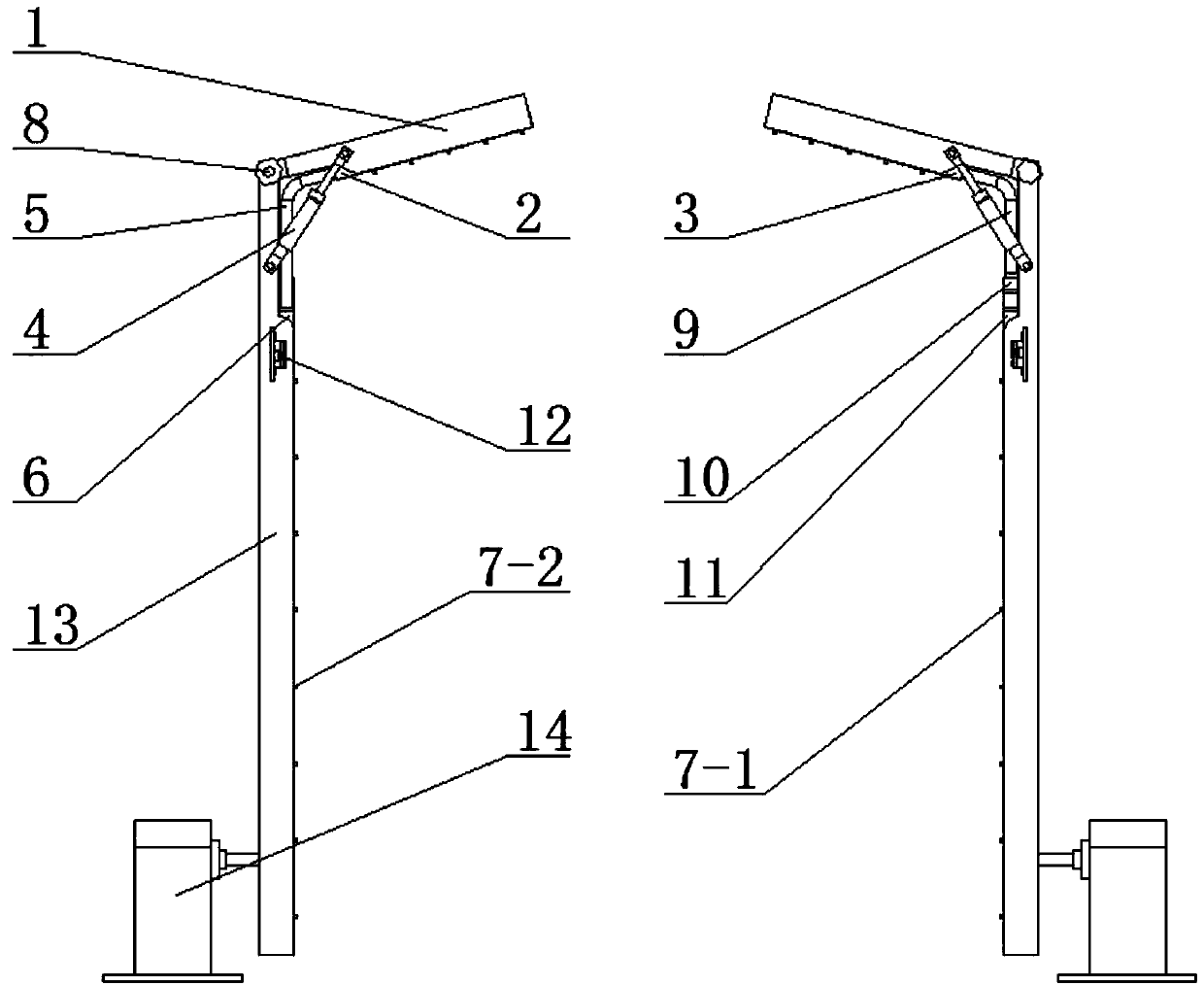

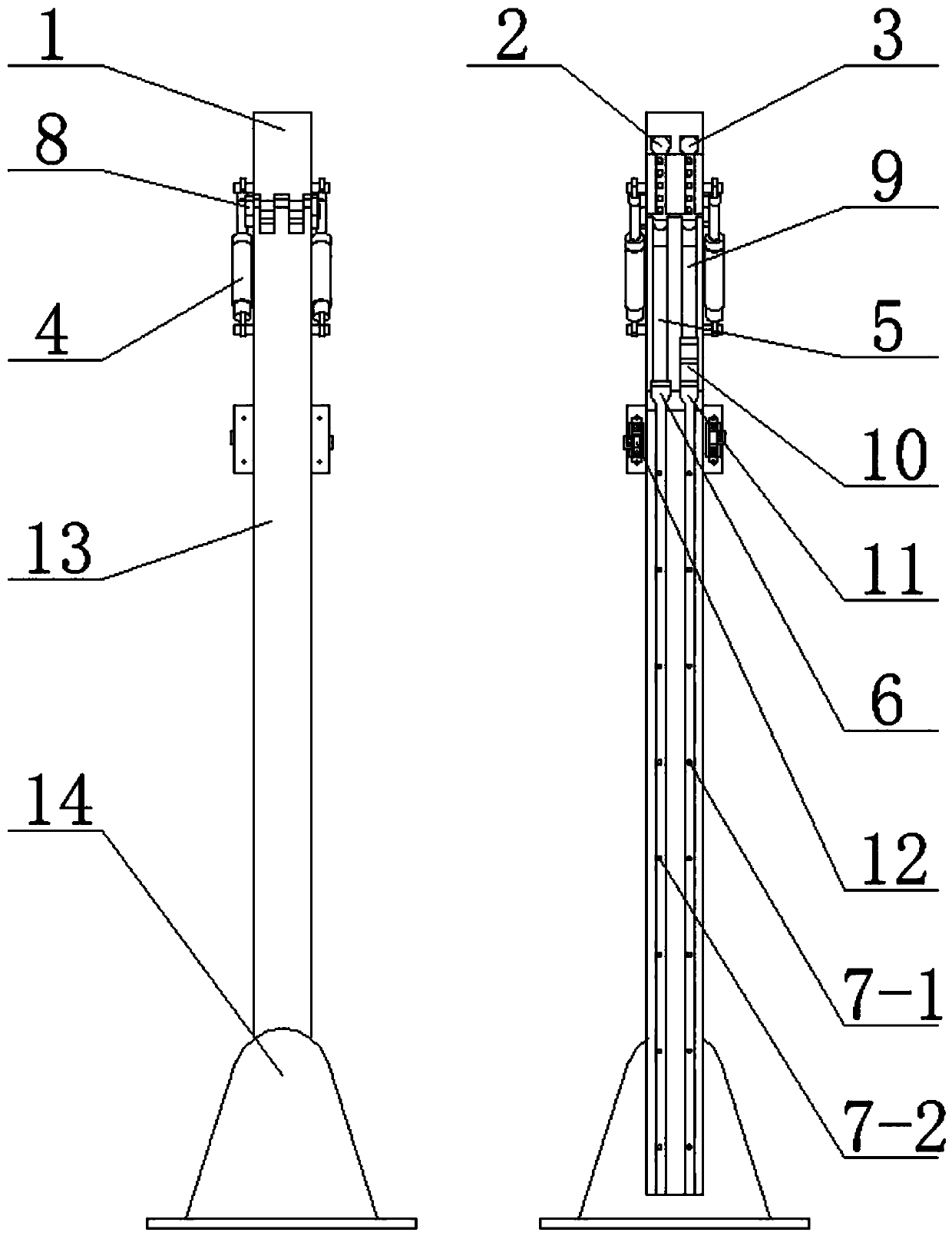

Automatic car washing machine

InactiveCN105882614AAchieve cleaningAvoid hittingCleaning apparatus for vehicle exteriorsWater savingSmall footprint

The invention belongs to a car washing device, and particularly discloses a simple water-saving type automatic car washing machine. The car washing machine comprises support portions in pair, water spraying portions in pair, detergent spraying portions in pair and movement control portions in pair. The water spraying portions and the detergent spraying portions are in parallel arrangement. The upper ends of the water spraying portions are fixed to the upper ends of the support portions. The lower ends of the water spraying portions are fixed to the lower ends of the support portions. Telescopic rods in the movement control portions are connected with cylindrical protrusions on the support portions in a rotatable mode. Motor bases in the movement control portions are fixedly connected with the lower ends of the support portions. The automatic car washing machine has the advantages of simple structure, low component quantity, simplicity in production, convenience in demounting and mounting, small occupied area, high working efficiency, energy conservation, water saving and the like.

Owner:JILIN UNIV

Electroplating device

The invention relates to an electroplating device. The electroplating device comprises an electroplating bath, a delivery mechanism and multiple groups of jet flow components arranged in the electroplating bath, wherein each jet flow component comprises two jet flow pipes vertically arranged side by side; a gap for passing of a circuit board is left between the two jet flow pipes; at least one row of injection hole sets distributed in the axial direction of each jet flow pipe is arranged at the inner side of the jet flow pipe; the rows of injection hole sets of the two jet flow pipes are arranged opposite to each other; each injection hole set comprises a plurality of injection holes; and the injection holes of the injection hole sets positioned in the opposite rows are arranged in the axial direction of the jet flow pipe in a staggered manner. The injection hole is of a hole-like structure, so that the circuit board can not be scratched; when the injection holes of the opposite rows are staggered, opposite injection of the injection holes of the two rows can be avoided, thus improving the hole debubbling effect; and impact forces of electroplating solutions injected by the injection holes of the two opposite rows on the circuit board are the same, so that circuit board swing and jet flow pipe collision can be effectively avoided, and the jet flow pipe can be prevented from scratching the circuit board.

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

Box-type fuel gas thermal treatment furnace

The invention relates to a box-type fuel gas thermal treatment furnace. The box-type fuel gas thermal treatment furnace comprises a furnace shell and a furnace hearth. The furnace shell is a rectangular box body. The furnace shell is provided with a material inlet and a material outlet. The furnace hearth is internally provided with a storage rack. The furnace shell is provided with a high-temperature flue gas inlet. The furnace shell is internally provided with an annular flue gas channel. The left side and the right side of the flue gas channel are communicated with the furnace hearth. A vertical flue communicated with the flue gas channel is arranged on the outer portion of the furnace shell. The storage rack is arranged below the high-temperature flue gas inlet and communicated with the flue gas channel. The two ends of the storage rack are in airtight connection with the inner wall of the furnace shell. According to the box-type fuel gas thermal treatment furnace, a plurality of flue gas exhaust pipelines arranged on a traditional thermal treatment furnace are omitted, the flue gas channel is directly and additionally arranged in the furnace shell, and the vertical flue communicated with the flue gas channel is arranged on the outer portion of the furnace shell, so that flue gas subjected to heat exchange in the furnace hearth enters the flue gas channel and centralized and output through the vertical flue; pipeline configuration is simplified, the production cost is lowered, circulation pressure of the flue gas in the furnace is uniform, the thermal utilization rate is high, and heat loss is less.

Owner:海盐凯鑫五金有限公司

Air knife assembly and drying device

ActiveCN106369985AShorten the installation distanceSmall sizeDrying gas arrangementsDrying machines with progressive movementsAir knifeElectrical and Electronics engineering

The invention relates to an air knife assembly and a drying device. The air knife assembly comprises two vertical air pipes arranged side by side. A gap is reserved between the two air pipes, and a circuit board can pass through the gap. The inner side of each air pipe is provided with at least one line of air hole groups which are distributed in the axial direction of the air pipe. Each line of air hole groups of each air pipe are arranged on the inner side. Each air hole group comprises multiple air holes. The air holes of the lines of air hole groups on the inner sides of the air pipes are arranged alternately in the axial direction of the air pipes. The air holes are of hole-shaped structures in the air pipes, so that the circuit board cannot scrape against protruding objects, and the installation distance between the air pipes is shortened; when the air holes of the lines on the inner sides are arranged alternately, the two lines of air holes are protected against opposite impact, and therefore the air drying effect on the holes is improved; and air sprayed by the air holes of the two lines on the inner sides apply the same impact force on the circuit board, the circuit board can smoothly pass through the gap of the air knife assembly, the circuit board can be effectively prevented from swinging and colliding with the air pipes, and the air pipes are prevented from scraping against the circuit board.

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

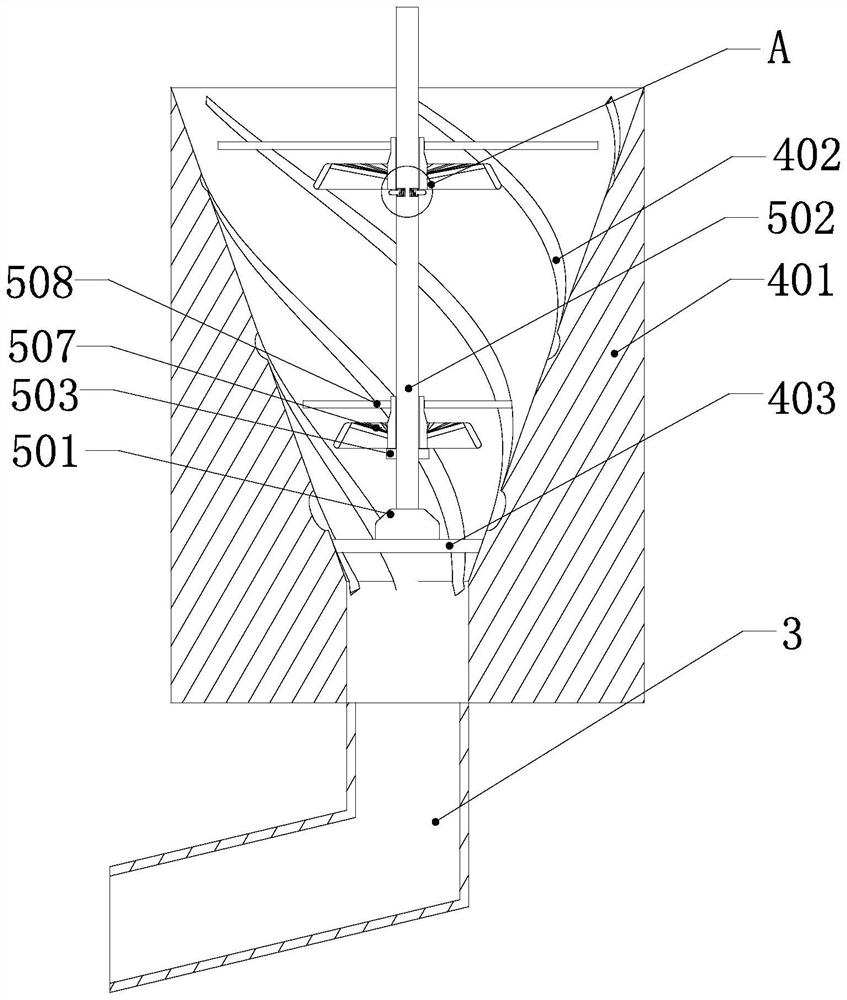

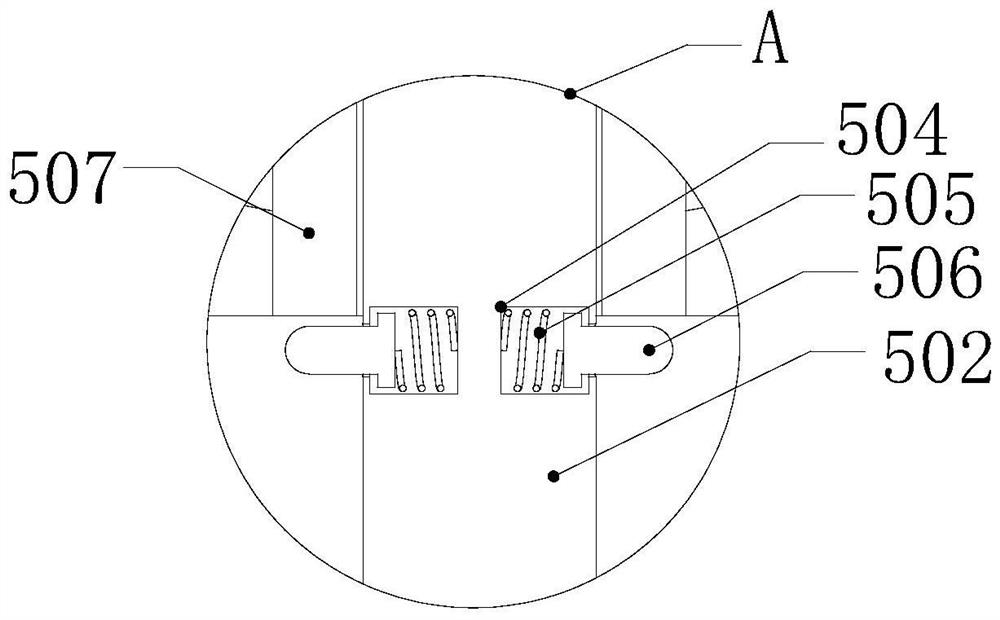

Spiral water flow pollution discharge mechanism

PendingCN114562007AAvoid blockageSave energySewer cleaningSustainable biological treatmentSludgeWater flow

The invention relates to the field of water flow pollution discharge, in particular to a spiral water flow pollution discharge mechanism which comprises a flow collecting barrel, a flow collecting hole, a connecting pipe, a pollution discharge mechanism and an anti-blocking mechanism. According to the spiral water flow sewage discharge mechanism, the conical structure of the sewage discharge cylinder is matched with the spiral groove, water flow and water pressure of sewage during drainage can be used as a power source, rotation of the mounting ring seat and the fan-shaped blades can be accelerated and driven, vortex and inward rolling force are formed, sludge and sundries in a pipeline are smashed, and the sundries adhering to the inner wall of the pipeline are washed away; the device has the advantages of being simple in structure, convenient to use, capable of avoiding blocking, capable of saving energy, capable of avoiding opposite flushing of multiple strands of sewage through the arrangement of the inclined confluence holes, capable of enabling the confluence sewage to be accelerated to form vortex under the cooperation of the conical structure of the inner wall of the confluence barrel, capable of effectively accelerating the water flow speed and improving the sewage discharging efficiency, and capable of saving energy. And through the cooperation of the mounting baffle ring, the two movable bolts and the two springs, the two mounting ring seats can be quickly supported and positioned.

Owner:XIAMEN LIYUAN ENVIRONMENTAL TECH

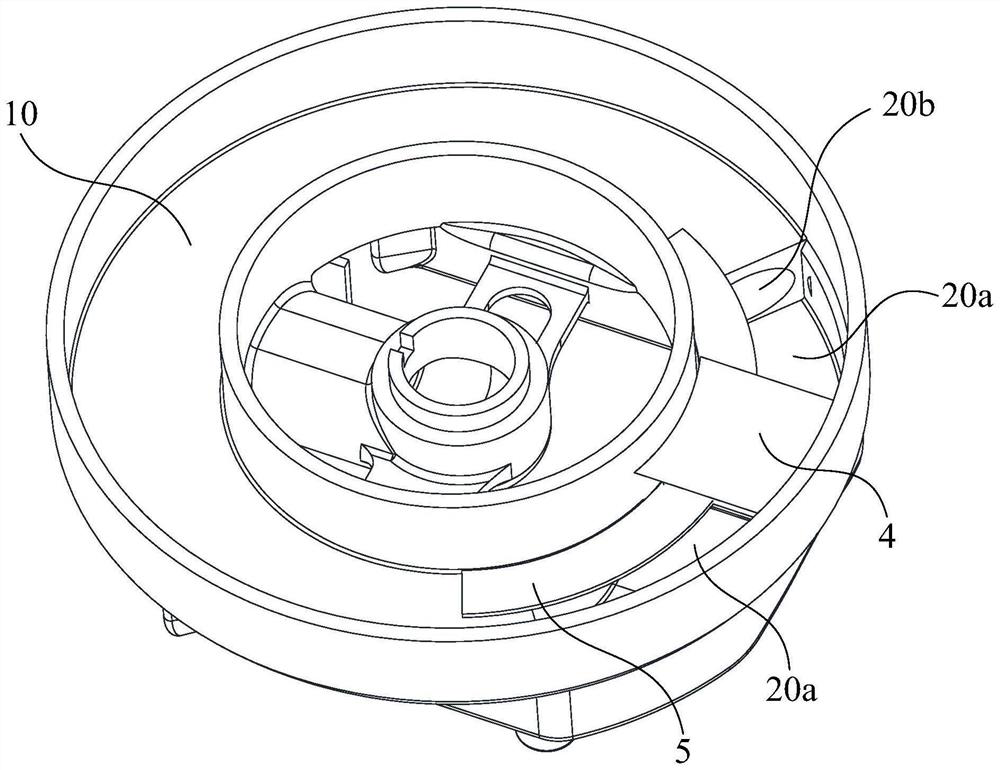

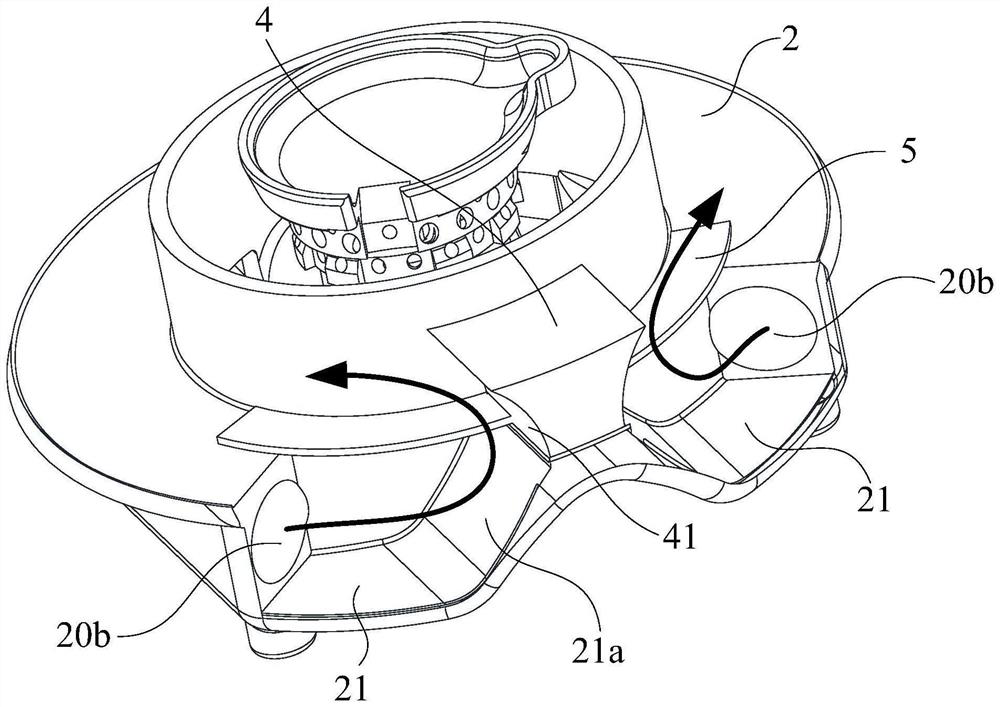

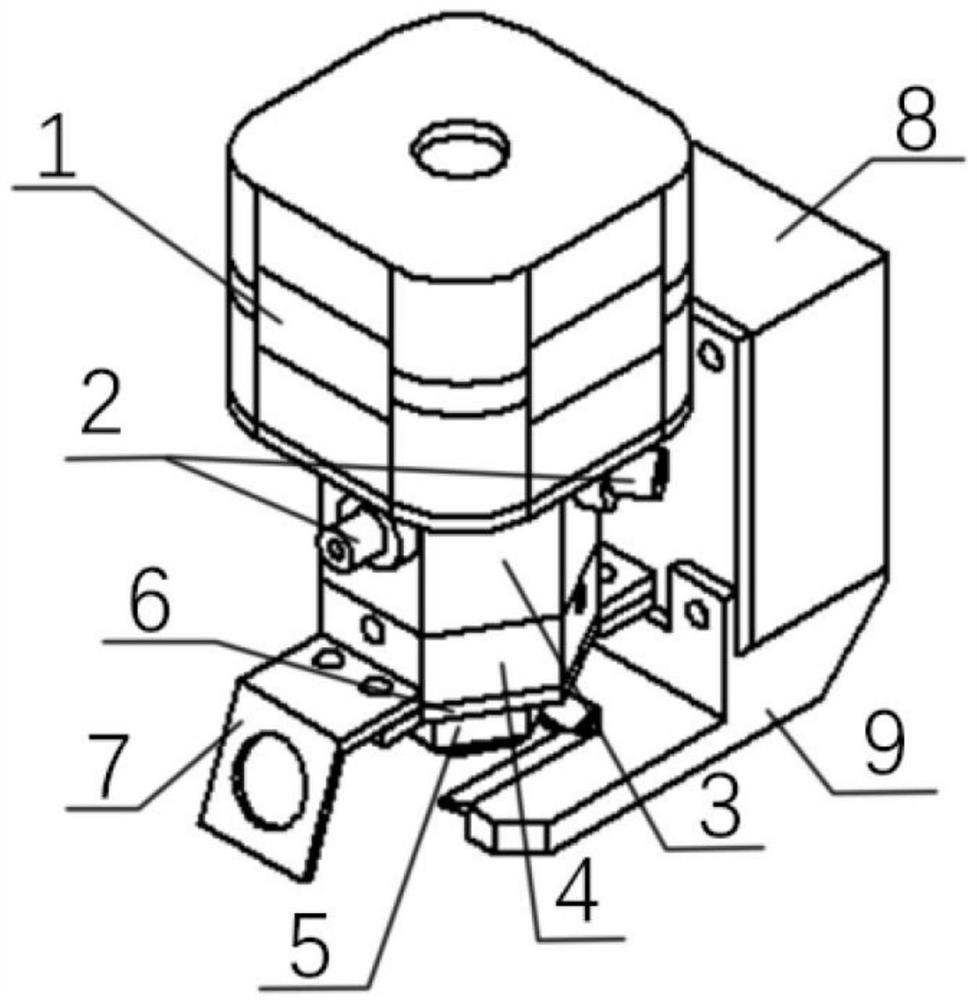

cooktop burner

ActiveCN111947149BRandom combinationStable and even flowDomestic stoves or rangesGaseous fuel burnerThermodynamicsCombustor

The invention provides a cooker burner, which includes an outer ring fire cover, two outer ring injection pipes and a flow guide block, the gas outlet ends of the two outer ring injection pipes are arranged oppositely, and both are connected to the outer ring fire cover In the inner outer ring gas mixing chamber, the guide block is arranged between the two gas outlet ends, and has guide surfaces facing the two gas outlet ends respectively, and the guide surface can change the gas flow direction of the two gas outlet ends to a direction away from each other flow. The cooker burner provided by the present invention is provided with a guide block between the two gas outlet ends, so that the two opposite guide surfaces of the guide block are used to change the flow direction of the gas flowing out of the gas outlet end, so that each of them flows in a direction away from each other. Ensure that the gas flow in the outer ring gas mixing chamber and the gas at each fire hole are relatively stable and even, avoid the gas at the two gas outlets from hedging, solve the problem of flame separation and tempering in the fire hole caused by gas hedging, and avoid The large loss of fuel-air mixture energy caused by hedging reduces the problem of ejection capability.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Water jet cutter assembly and washing device

PendingCN106376181AShorten the installation distanceSmall sizePrinted circuit liquid treatmentEngineeringWater jet cutter

The invention relates to a water jet cutter assembly and a washing device. The water jet cutter assembly comprises two spray pipes vertically arranged side by side, wherein a gap for a circuit board to pass through is reserved between the two spray pipes; at least one column of spray holes distributed along the axial direction of each spray pipe are formed in the inner side of each spray pipe; the columns of spray holes of the two spray pipes are arranged oppositely; each group of spray holes comprises a plurality of spray holes; and the spray holes positioned in the opposite columns of spray holes are formed in the axial directions of the spray pipes in a staggered manner. The spray holes are of porous structures on the spray pipes, the circuit board cannot rub protruding objects, and the mounting distance between the spray pipes is decreased; when the spray holes in the opposite columns are staggered, the spray holes in the two columns are prevented from rushing oppositely, and the washing effect for the holes is improved; the impact forces of washing fluids sprayed by the two opposite columns of spray holes for the circuit board are the same, the circuit board can smoothly pass through the gap between the spray pipes, circuit board swinging and collision with the spray pipes can be effectively avoided, and the circuit board is avoided from being scratched by the spray pipes.

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

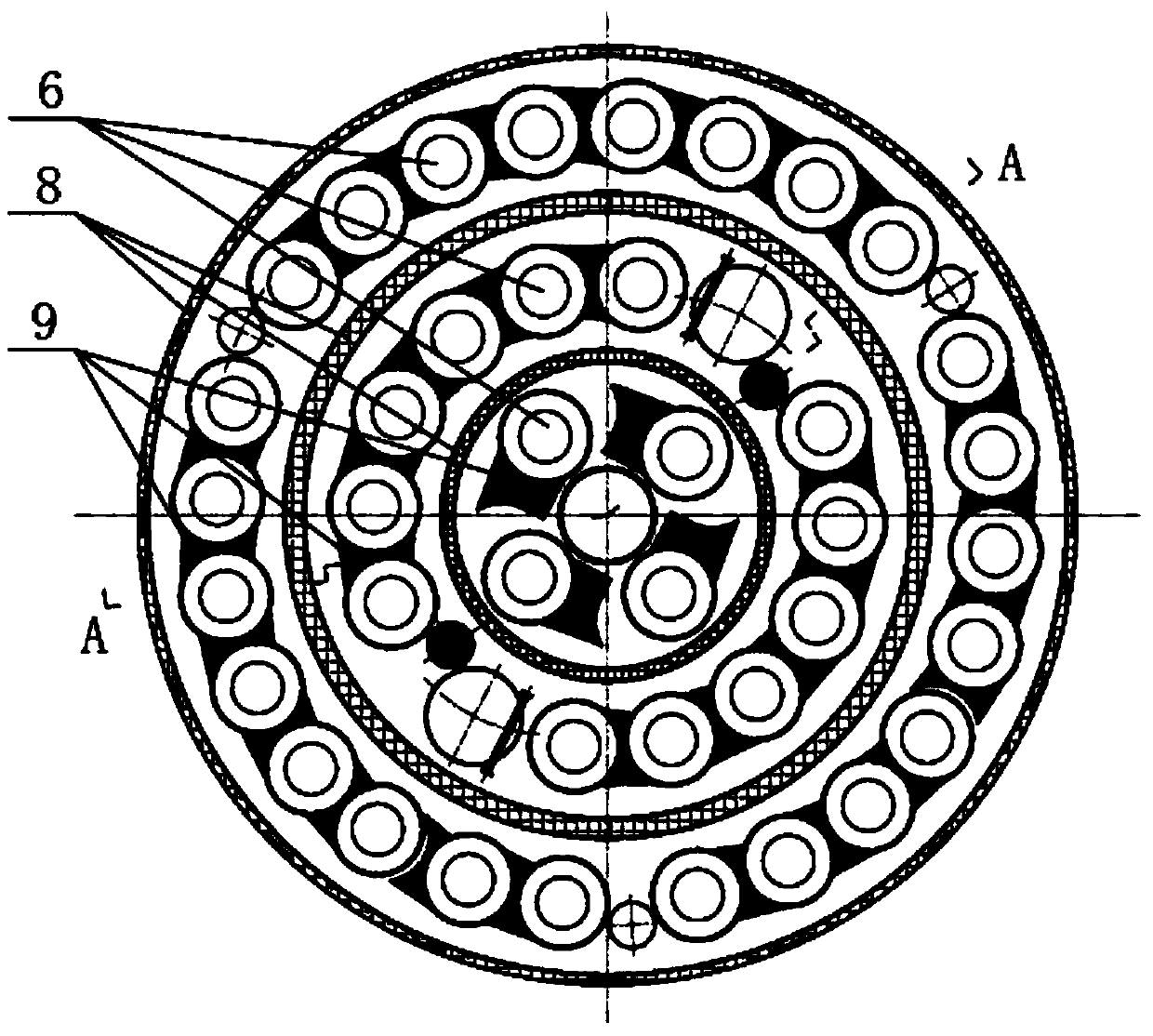

A steam-water separator component exhaust structure specially used for nuclear power plant steam generators

ActiveCN106914108BSave spaceIncrease the circulation areaDispersed particle separationEngineeringNuclear power plant

The invention discloses a steam-water separator component exhaust structure specially used for steam generators in nuclear power plants. The steam-water separators are combined to form several concentric ring structures with different diameters, and the adjacent steam-water separation in each ring structure There are exhaust steam passages between the devices, and the exhaust steam passages pass through the upper deck. This invention increases the steam circulation area of the exhaust structure of the steam-water separator under the condition that the diameter of the upper cylinder of the steam generator remains unchanged, saves the space of the upper cylinder of the steam generator, ensures the exhaust capacity of the exhaust structure of the steam-water separator, and satisfies The steam exhaust requirements of small-diameter steam-water separator components create conditions for the application of compact and efficient small-diameter steam-water separators, and avoid the steam in the steam-water mixture from being opposed to the tangential drainage of the steam-water separator, thereby ensuring that the steam-water separator and even the dryer The separation efficiency is high, and dry saturated steam with qualified quality is obtained.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

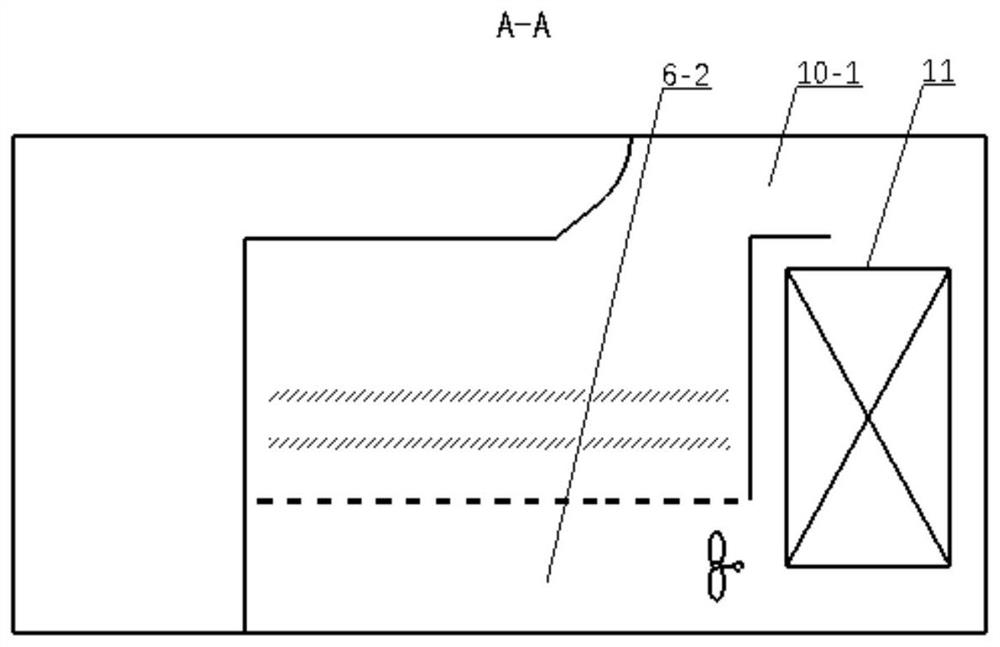

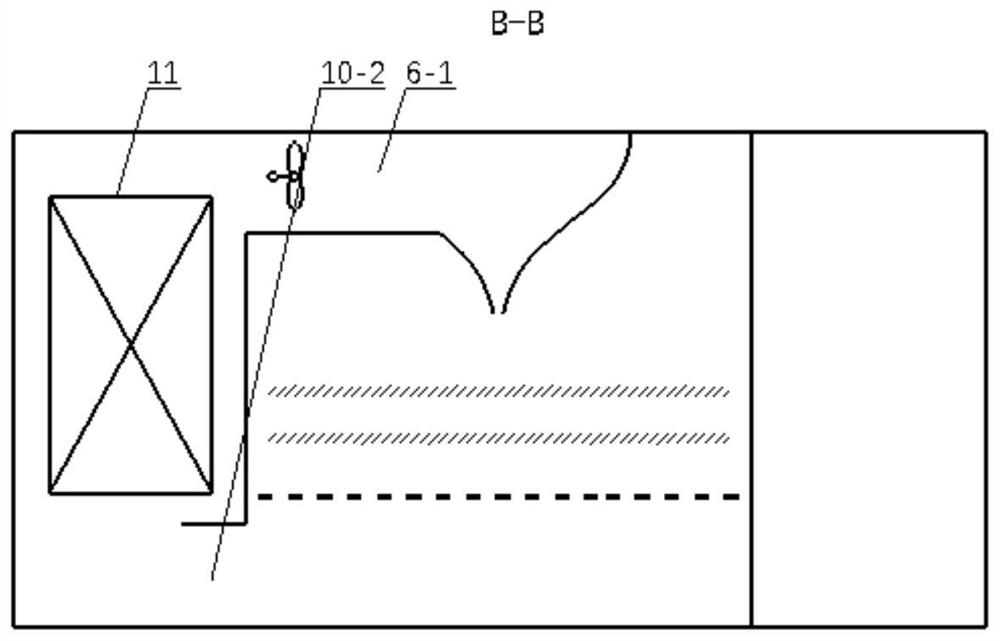

Alternate air supply tunnel type freezing device

The invention discloses an alternate air supply tunnel type freezing device. The alternate air supply tunnel type freezing device comprises a built-in freezing tunnel and a variable-speed surroundingtype conveying belt, and cold air supply ducts, air supply fans and air supply outlets are arranged on the upper side and the lower side of the conveying belt in the freezing tunnel. The alternate airsupply tunnel type freezing device is characterized in that an arch-shaped lower jet flow air supply slit is formed in the upper side of each air supply outlet, an upper blowing floating air supply pore plate is formed in the lower side of each air supply outlet, meanwhile, the positions of an upper air opening and an lower air opening are staggered front and back in the conveying direction, theairflow hedging phenomenon is avoided, and up-down alternate air supply and synchronous freezing are achieved. The alternate air supply tunnel type freezing device is reasonable in structure and highin freezing efficiency, equipment energy consumption is reduced while the material freezing quality is guaranteed, and the device has wide market prospects.

Owner:XI AN JIAOTONG UNIV

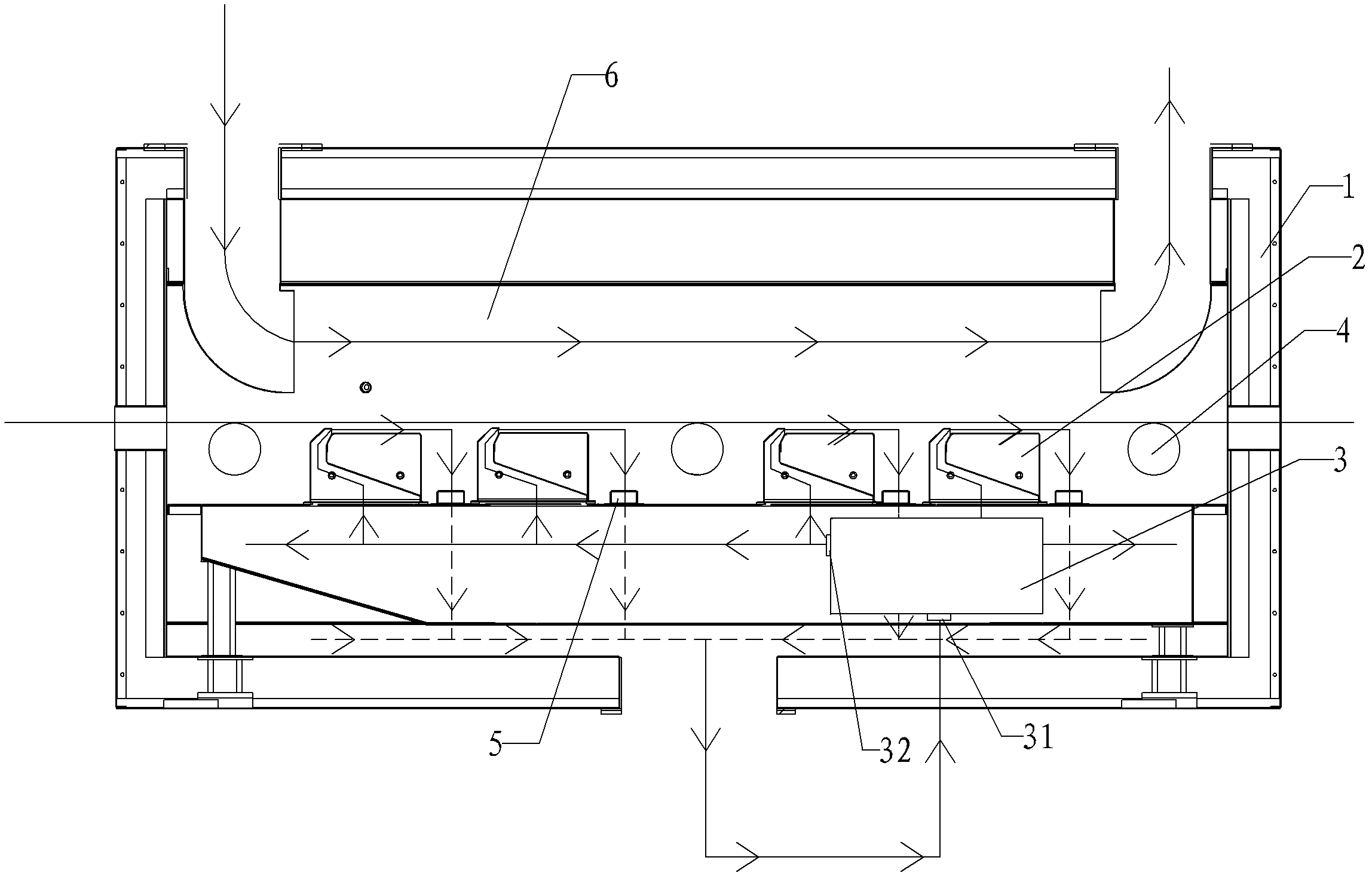

Drying channel of coating machine

Owner:SHENZHEN HAONENG TECH

Efficient gas type stepping furnace

ActiveCN105063314AImprove heating efficiencyEven flowFurnace typesHeat treatment furnacesEngineeringHeating efficiency

The invention relates to an efficient gas type stepping furnace. The efficient gas type stepping furnace comprises a furnace shell and a hearth. The furnace shell is a rectangular box type body. A material inlet and a material outlet are formed in the furnace shell. A material storage frame used for containing workpieces is arranged in the hearth. The left side and the right side of the furnace shell are each provided with a high-temperature smoke inlet communicated with the hearth. A diversion plate dividing the hearth into a left side area and a right side area is vertically arranged in the hearth. The shape of the diversion plate is matched with the shape of the inner portion of the furnace shell. The top end of the diversion plate is connected with the top of the furnace shell in a sealed manner. The bottom end of the diversion plate is located on the material storage frame. By forming the two high-temperature smoke inlets in the left side and the right side of the furnace shell and through the combination with the diversion plate dividing the hearth into the left area and the right area which are symmetrical, it is ensured that smoke flowing in the hearth is uniform and temperatures of all positions in the hearth are consistent while the heating efficiency is improved, and the temperature field stability is improved.

Owner:嘉兴三喜新材料有限公司

An automatic car washing machine

InactiveCN105882614BAchieve cleaningAvoid hittingCleaning apparatus for vehicle exteriorsWater savingEngineering

The invention belongs to a car washing device, and particularly discloses a simple water-saving type automatic car washing machine. The car washing machine comprises support portions in pair, water spraying portions in pair, detergent spraying portions in pair and movement control portions in pair. The water spraying portions and the detergent spraying portions are in parallel arrangement. The upper ends of the water spraying portions are fixed to the upper ends of the support portions. The lower ends of the water spraying portions are fixed to the lower ends of the support portions. Telescopic rods in the movement control portions are connected with cylindrical protrusions on the support portions in a rotatable mode. Motor bases in the movement control portions are fixedly connected with the lower ends of the support portions. The automatic car washing machine has the advantages of simple structure, low component quantity, simplicity in production, convenience in demounting and mounting, small occupied area, high working efficiency, energy conservation, water saving and the like.

Owner:JILIN UNIV

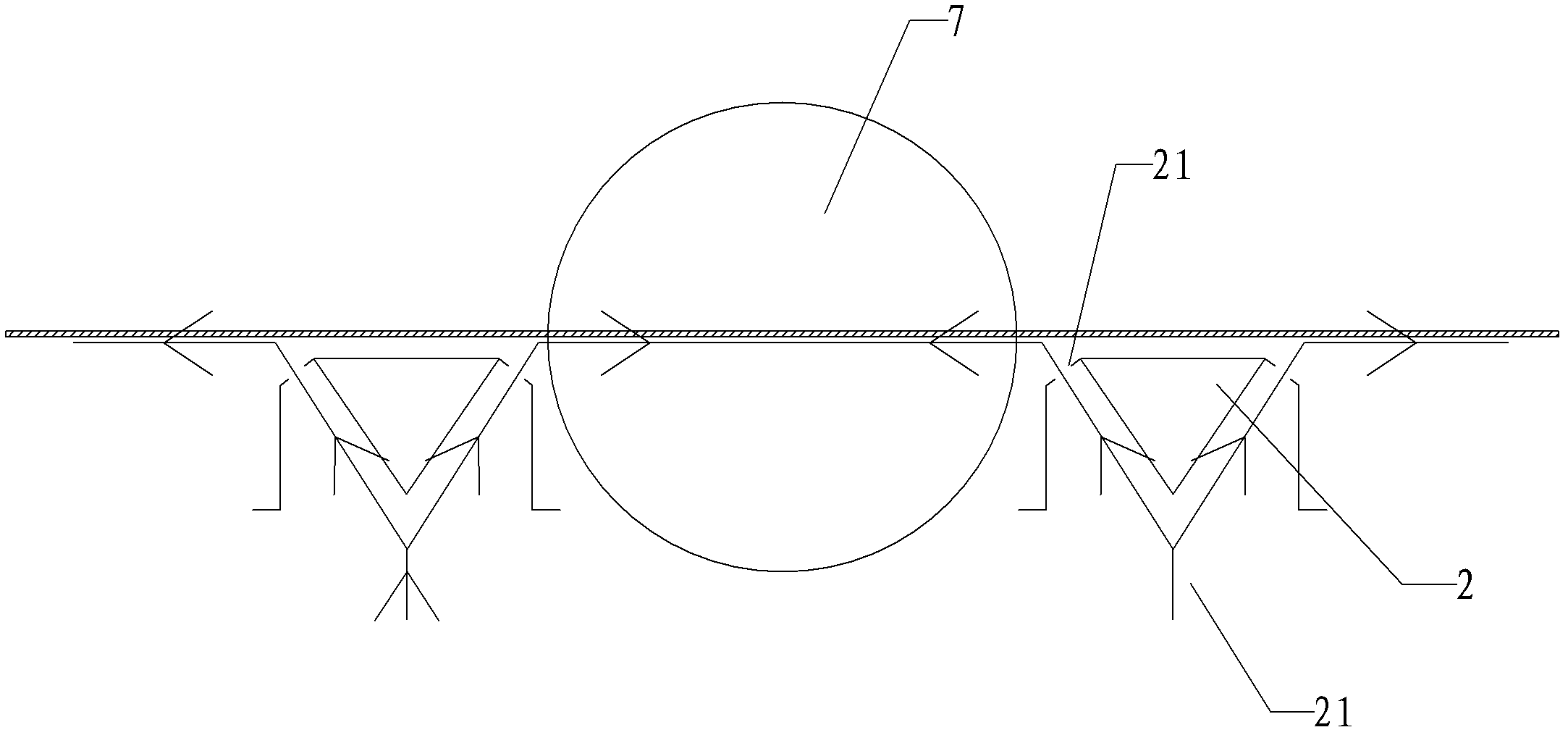

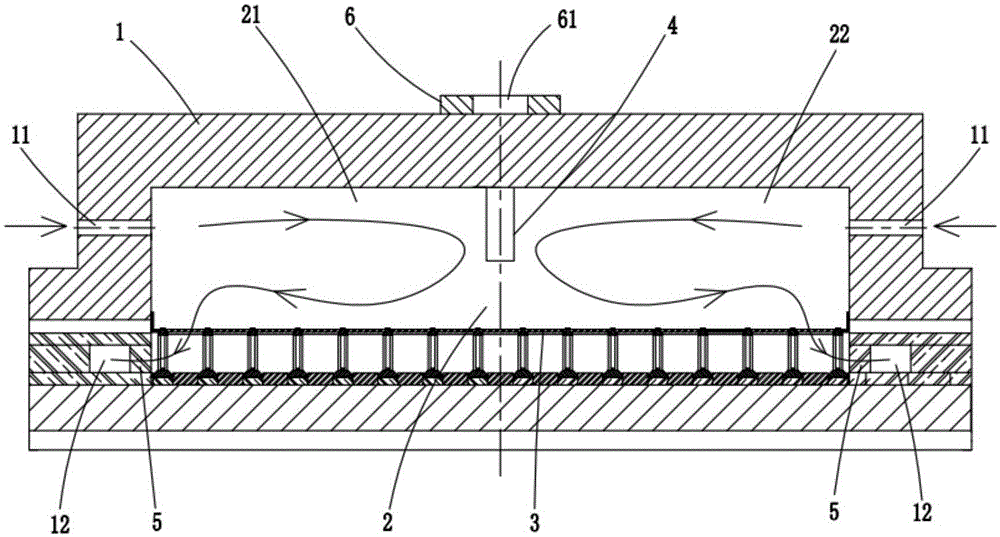

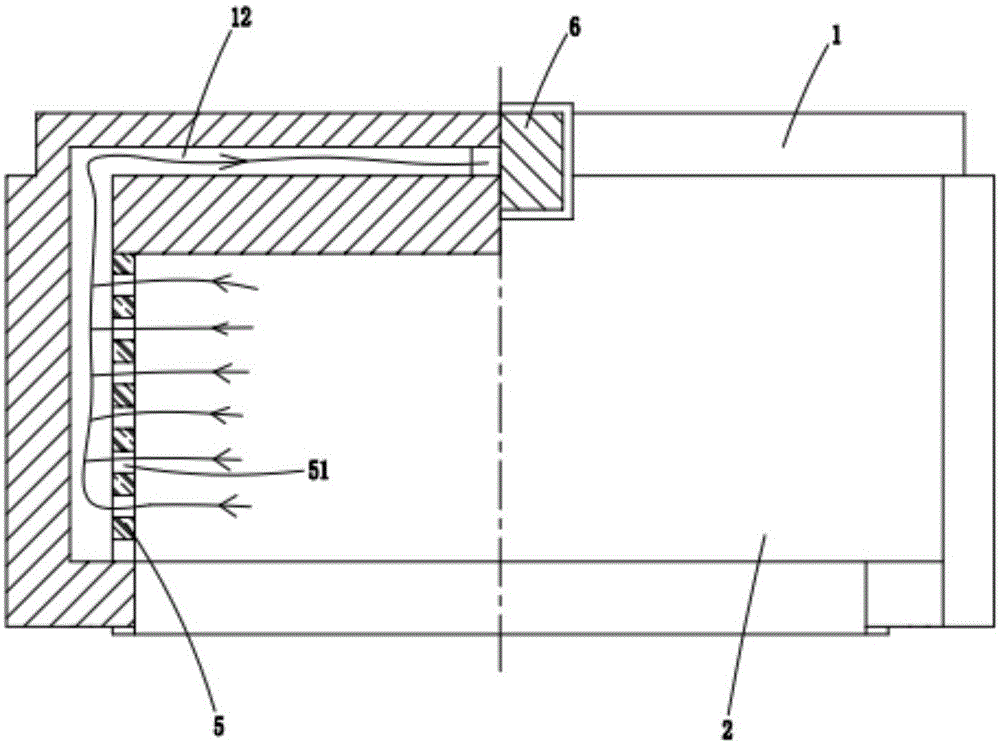

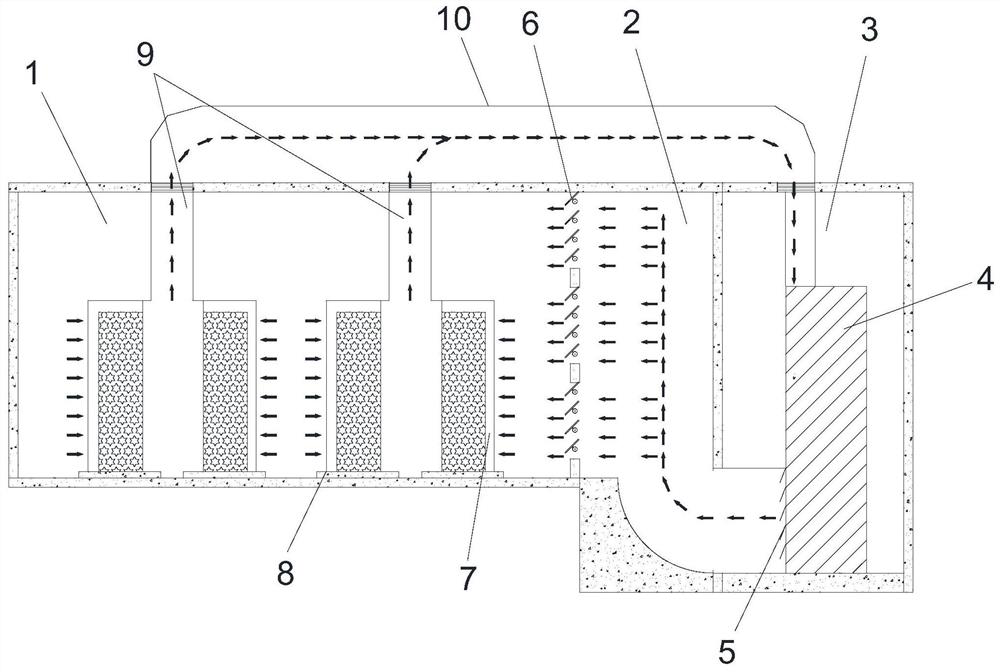

Diffuse side air supply system

ActiveCN111447808BImprove cooling effectReduce construction costsCooling/ventilation/heating modificationsCold airEngineering

The invention discloses a diffuse lateral air supply system, which comprises a data machine room (1), an air supply channel (2), a precision air conditioner room (3), and a precision air conditioner (4) in the precision air conditioner room arranged sequentially in the machine room ), the air supply outlet (5) of the air conditioner room connecting the air supply duct and the precision air conditioner room, the air supply louvers (6) connecting the air supply duct and the data room, the cold aisle (7) on the data cabinet (8), and the The data cabinet, the hot passage (9) connecting the data cabinet and the circulation pipe (10), and the circulation pipe connecting the precision air-conditioning room; the hot air enters the precision air-conditioning room through the circulation pipe through the hot passage, and is cooled into cold air by the precision air conditioner, The cold air enters the data cabinet through the air supply outlet of the air conditioner room, the air supply channel, the air supply louvers and the cold aisle in order to dissipate heat for the data set. The invention can achieve the purpose of heat exchange through lateral air supply, reduce the energy consumption of air supply, eliminate the need for an integral overhead machine room, and reduce construction costs.

Owner:上海上证数据服务有限责任公司

A box type gas heat treatment furnace

ActiveCN105004191BIntegrity guaranteedReduce lossesCharge supportsWaste heat treatmentMetallurgyFlue gas

Owner:海盐凯鑫五金有限公司

Drainage four-way inspection well to prevent water flow hedging

ActiveCN104018569BGive full play to drainage efficiencyReduce waterloggingSewerage structuresPipeflowWater flow

The invention discloses a water drainage cross inspection well preventing water face-to-face flushing, belongs to the field of water drainage projects and particularly relates to a rainwater and sewage convergence water drainage structure. The well is an intersection inspection well applicable to a rainwater or sewage pipeline. Branch pipes on the two sides of a water drainage pipeline are connected into the inspection well through sluices with large cornering radius, the sluices of the branch pipes on the two sides are spaced from a sluice of an upstream pipeline, and the included angle of afflux of the three sluices is small. The inspection well can prevent face-to-face flushing of water entering the inspection well, reduce turbulence flow to stabilize the water and bring the water drainage efficiency of the intersection inspection well into full play, thereby reducing the frequency of waterlogging of urban roads.

Owner:洛阳城市建设勘察设计院有限公司 +1

Efficient large-flux fixed valve tray

The present invention relates to a high-effective large-flux fixed valve tower tray. It is formed from column plate, fixed valve and down-pipe. The fixed valve is formed by directly stamping the column plate self-body, and said fixed valve is composed of valve surface of fixed valve and valve leg of fixed valve, the valve surface is connected with column plate by means of valve leg of fixed valve, and the valve surface of the fixed valve has a downward bent folded edge. Said invented structure can raise treatment capacity of tower tray and its operation elasticity, at the same time the gas-liquid contact on the plate can be intensified so as to raise column plate mass transfer efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

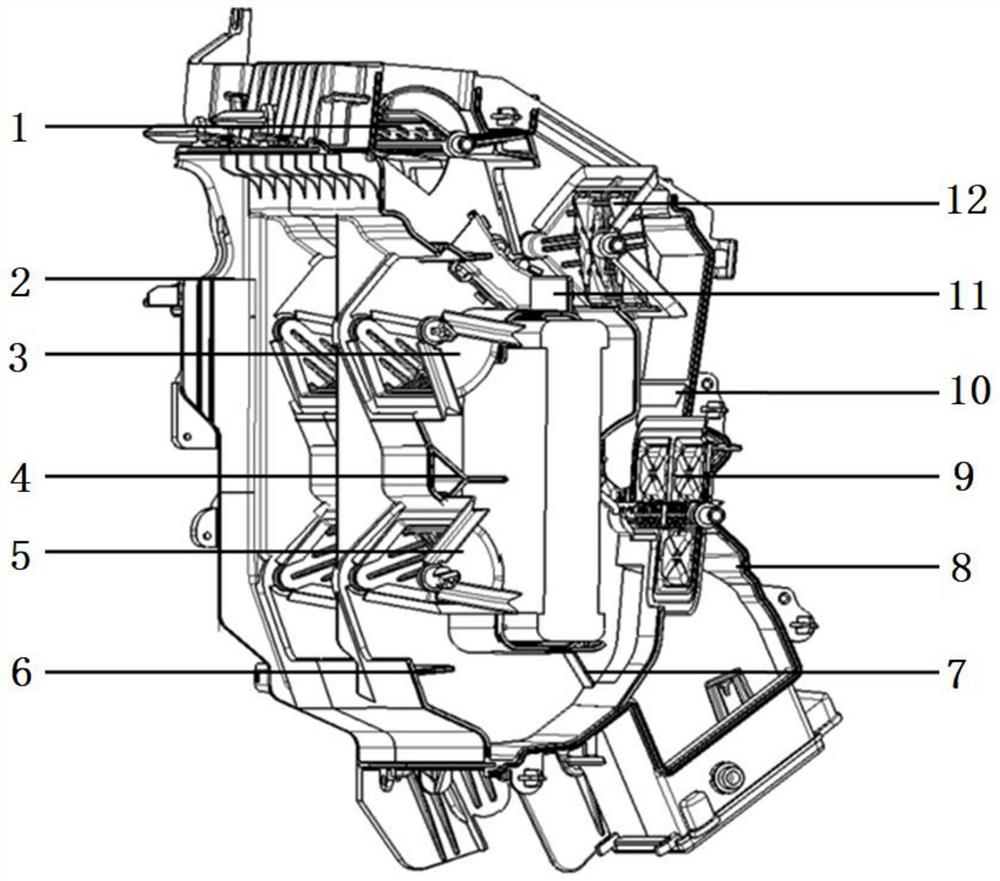

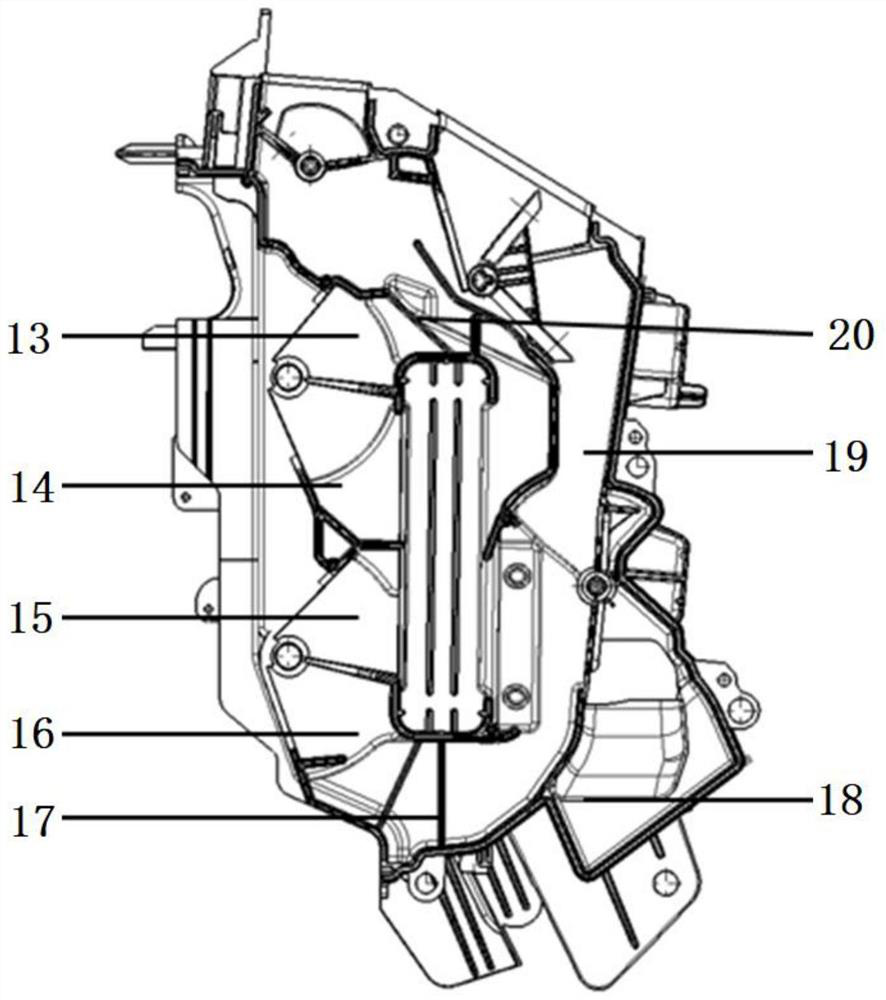

Automobile air conditioning system temperature control curve optimization structure

PendingCN112248755AReach a reasonable temperature differenceReduce the cross-sectional areaAir-treating devicesVehicle heating/cooling devicesHot runnerTemperature control

The invention belongs to the field of automobiles, and relates to an automobile air conditioning system temperature control curve optimization structure which comprises a middle shell, a left shell and a right shell, and a face blowing air door, a foot blowing air door and a defrosting air door which are used for controlling face blowing, foot blowing and defrosting respectively are arranged in acavity formed by the middle shell, the left shell and the right shell. The structure further comprises an air mixing door which comprises an upper mixing air door and a lower mixing air door which areindependently arranged; the upper mixing air door comprises an upper-layer cold runner and an upper-layer hot runner, and the lower mixing air door comprises a lower-layer hot runner and a lower-layer cold runner. According to the invention, the linearity can be better optimized, the temperature can be orderly and quantitatively increased, the jittering condition is avoided, the temperature difference between the upper, lower, left, right, front and back parts can be better changed, the temperature difference required by different parts of passengers is effectively met, the comfort of a passenger compartment is better controlled, and vehicle models with more modes can be efficiently met.

Owner:SOUTH AIR INT

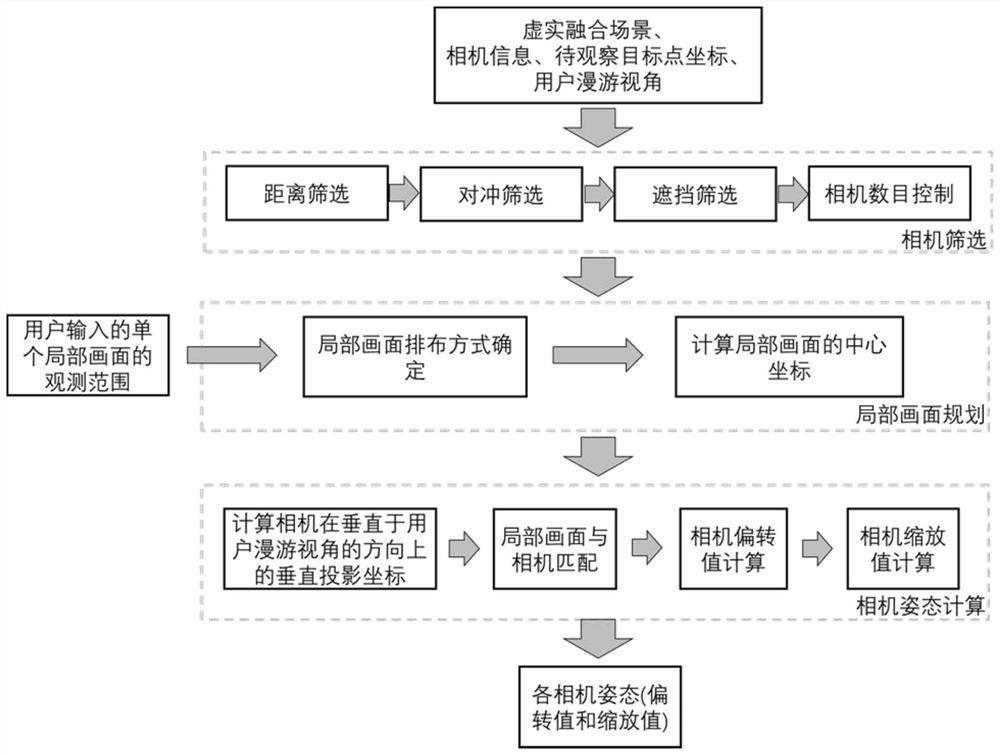

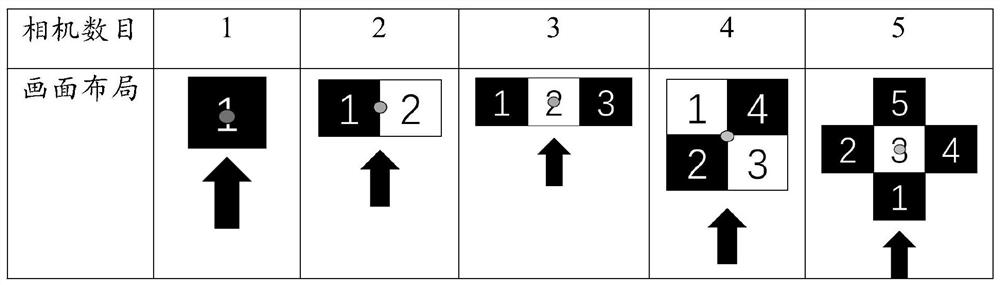

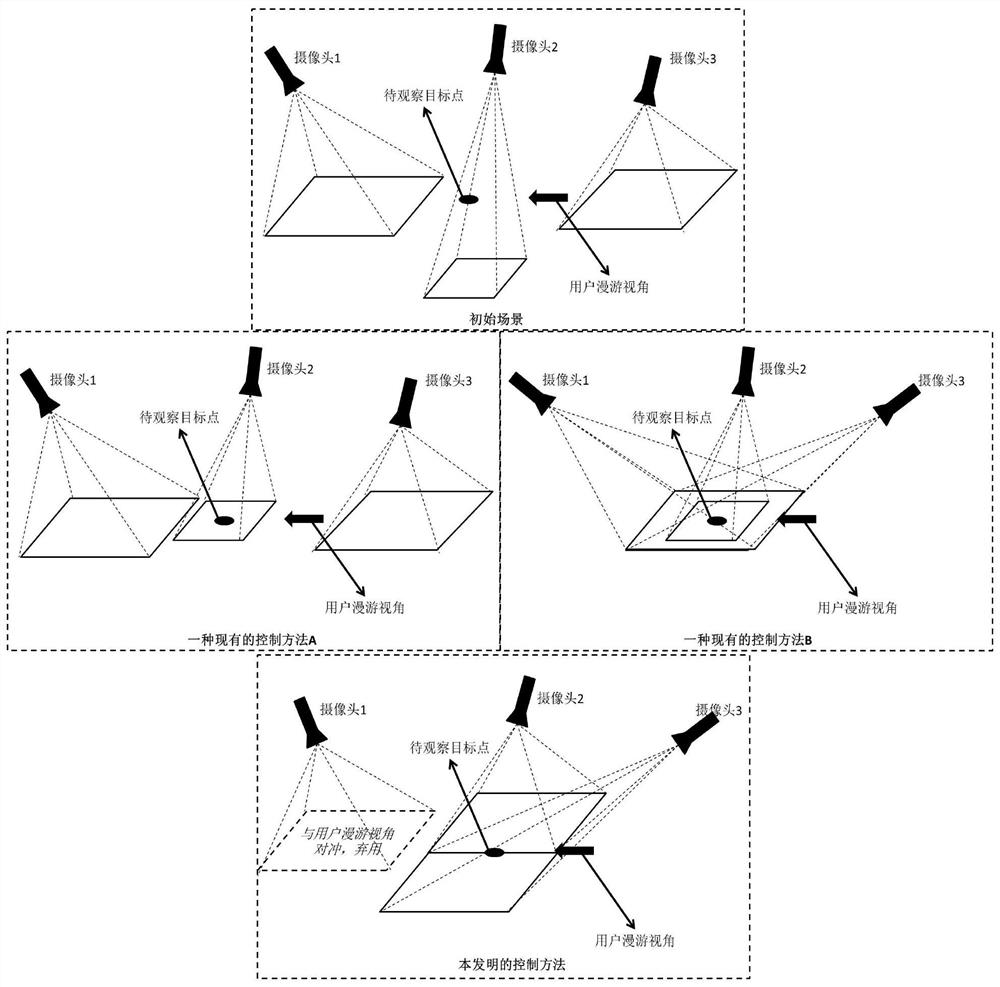

A joint control system and method for multiple ptz cameras in a virtual-real fusion scene

ActiveCN109963120BIncrease profitCompletely preventTelevision system detailsColor television detailsComputer graphics (images)Radiology

The present invention proposes a joint control system and method for multiple PTZ cameras in a virtual-real fusion scene, including camera screening, local picture planning and camera attitude calculation. The present invention can provide the joint control function of multiple PTZ cameras for the virtual-real fusion video scene, improve the utilization rate of multiple cameras, expand the picture capture range of the scene, optimize the camera monitoring area, thereby improving the viewing experience of users.

Owner:北京大视景科技有限公司

A high-efficiency gas-fired walking furnace

ActiveCN105063314BChange the circulation trackAvoid hedgingFurnace typesHeat treatment furnacesMetallurgyFlue gas

The invention relates to a high-efficiency gas-fired walking furnace, which includes a furnace shell and a furnace. The furnace shell is a rectangular box-shaped body. The furnace shell is provided with a material inlet and a material outlet, and the furnace is provided with a storage rack for placing workpieces. , the left and right sides of the furnace shell are respectively provided with high-temperature flue gas inlets communicating with the furnace; the furnace is vertically provided with a deflector that divides it into a left area and a right area. The inner shape of the furnace shell is suitable, the top end is airtightly connected with the top of the furnace shell, and the bottom end is located above the storage rack. In the present invention, two high-temperature flue gas inlets are arranged on the left and right sides of the furnace shell, combined with a deflector that divides the furnace into two symmetrical areas on the left and right, so as to improve the heating efficiency and ensure that the flue gas in the furnace flows evenly. The temperature is consistent everywhere, improving the stability of the temperature field.

Owner:嘉兴三喜新材料有限公司

head-mounted air umbrella

ActiveCN108433277BAvoid hedgingGuaranteed rain protectionWalking sticksUmbrellasEngineeringMechanical engineering

The invention discloses a head-mounted air umbrella, which comprises a head-mounted frame, an airflow conduction block, a fan and a PLC controller; Hollow structure, the outer surface of the head-mounted frame is provided with an air intake hole, the control box and the power supply are arranged inside the described head-mounted frame, the airflow conduction block is connected with the head-mounted frame through a connecting block, and the airflow conduction block is lower than the horizontal plane It is arranged at an inclination, and both sides of the airflow conduction block are provided with exhaust holes, the fan is located in the head-mounted frame and connected to the head-mounted frame through a backing plate, the fan is electrically connected to the power supply, and the PLC controller Located in the control box and electrically connected to the power supply. The invention provides a head-mounted air umbrella, which has good rain-shielding effect, simple operation and strong practicability.

Owner:临沂高新区金蓝领劳务有限公司

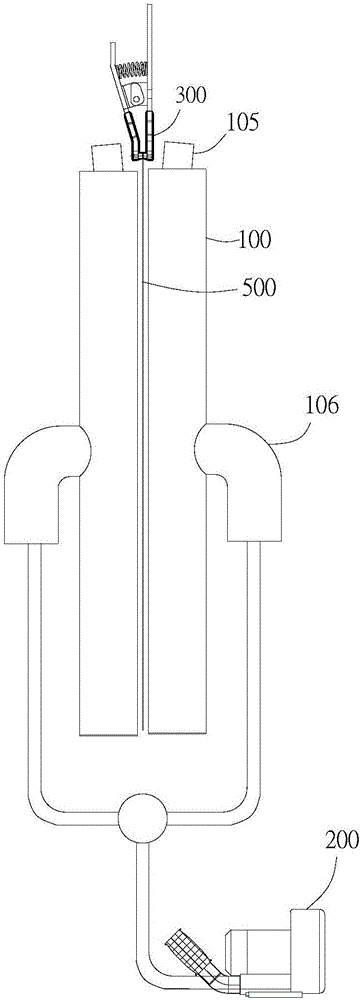

An electroplating device

The invention relates to an electroplating device. The electroplating device comprises an electroplating bath, a delivery mechanism and multiple groups of jet flow components arranged in the electroplating bath, wherein each jet flow component comprises two jet flow pipes vertically arranged side by side; a gap for passing of a circuit board is left between the two jet flow pipes; at least one row of injection hole sets distributed in the axial direction of each jet flow pipe is arranged at the inner side of the jet flow pipe; the rows of injection hole sets of the two jet flow pipes are arranged opposite to each other; each injection hole set comprises a plurality of injection holes; and the injection holes of the injection hole sets positioned in the opposite rows are arranged in the axial direction of the jet flow pipe in a staggered manner. The injection hole is of a hole-like structure, so that the circuit board can not be scratched; when the injection holes of the opposite rows are staggered, opposite injection of the injection holes of the two rows can be avoided, thus improving the hole debubbling effect; and impact forces of electroplating solutions injected by the injection holes of the two opposite rows on the circuit board are the same, so that circuit board swing and jet flow pipe collision can be effectively avoided, and the jet flow pipe can be prevented from scratching the circuit board.

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

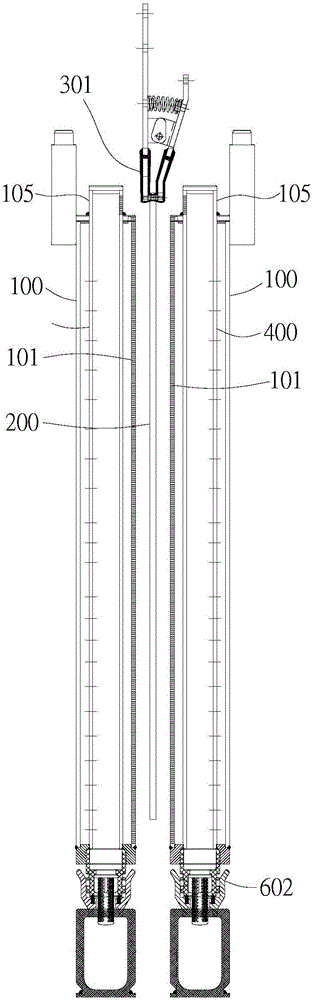

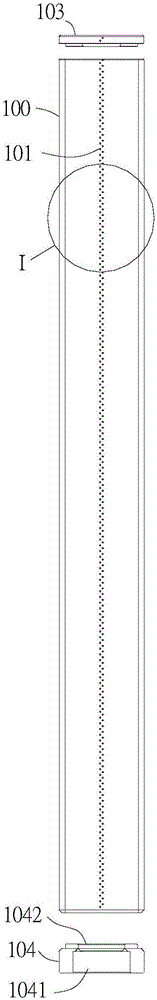

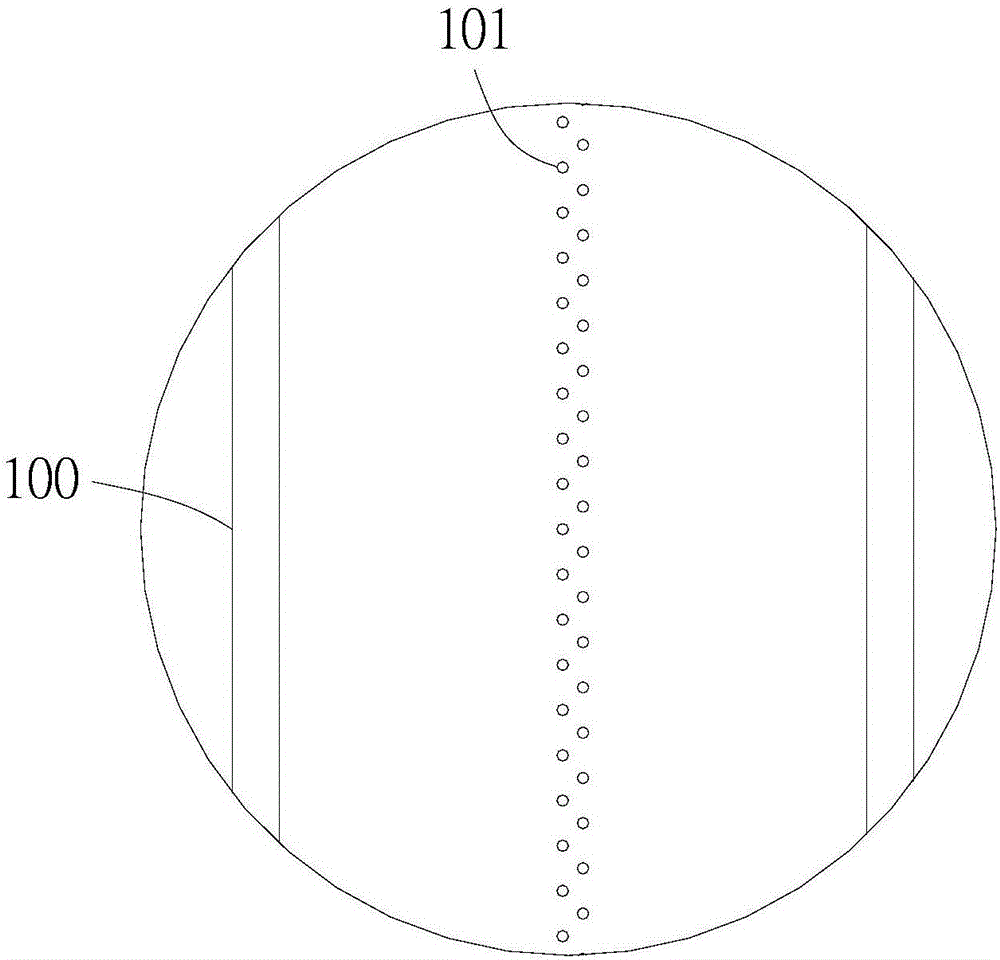

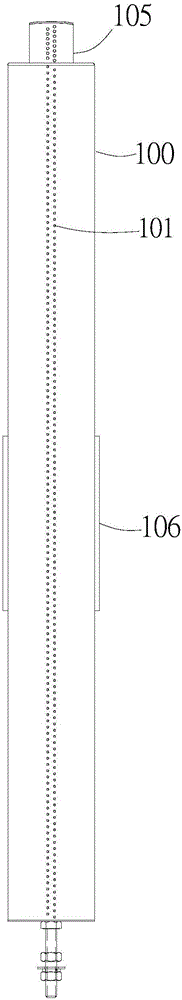

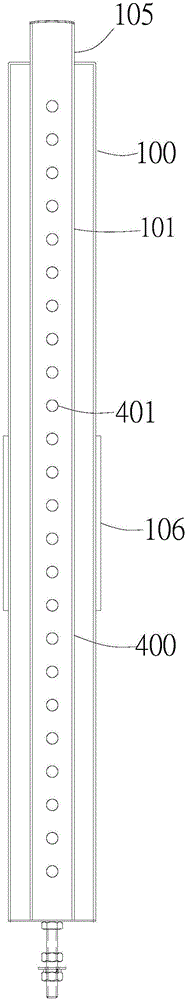

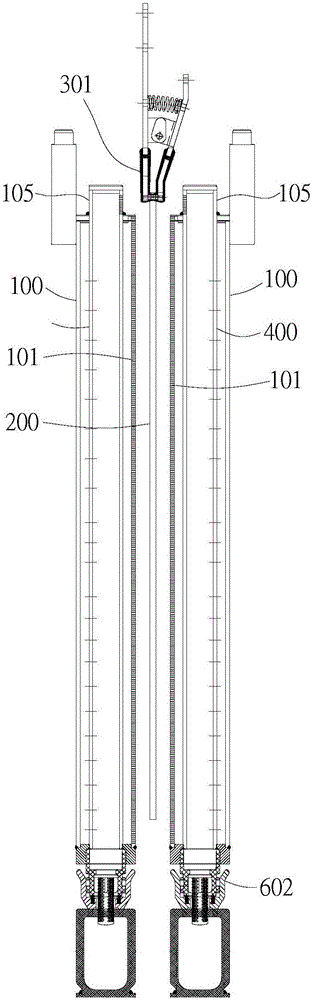

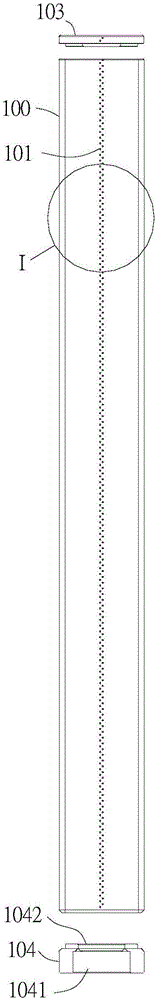

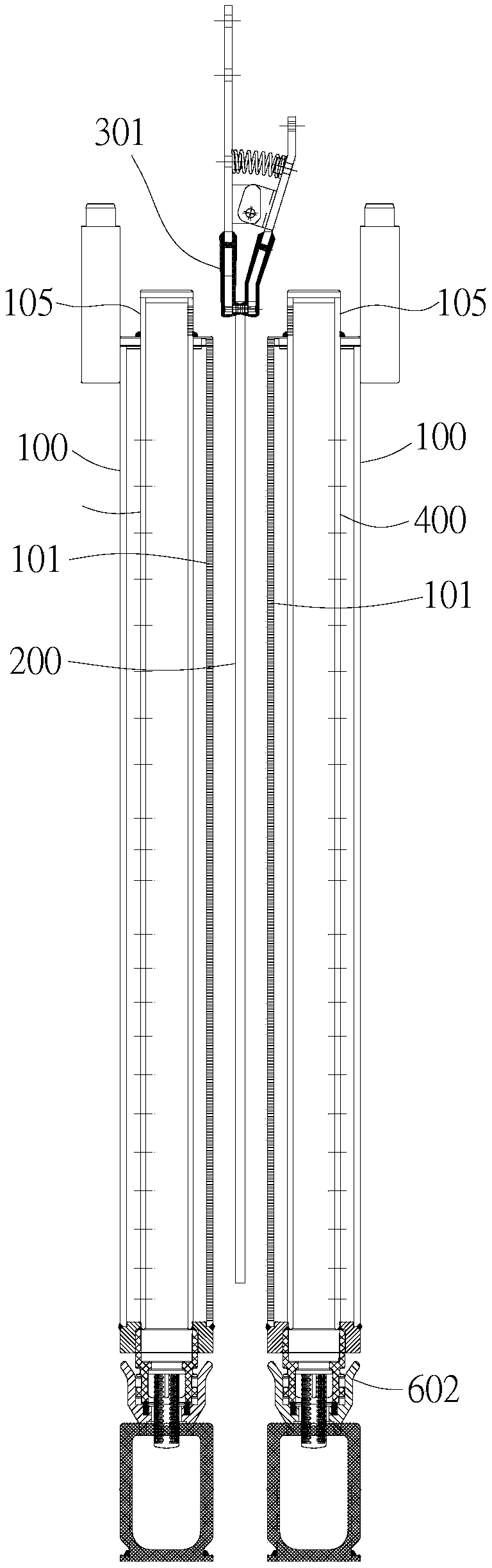

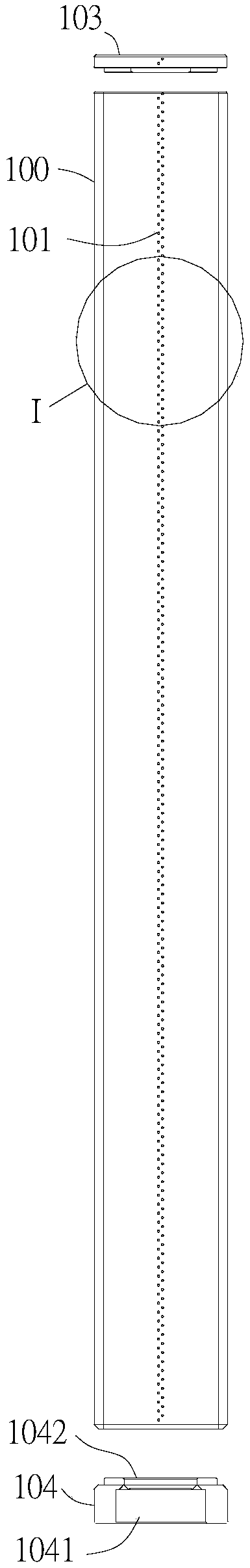

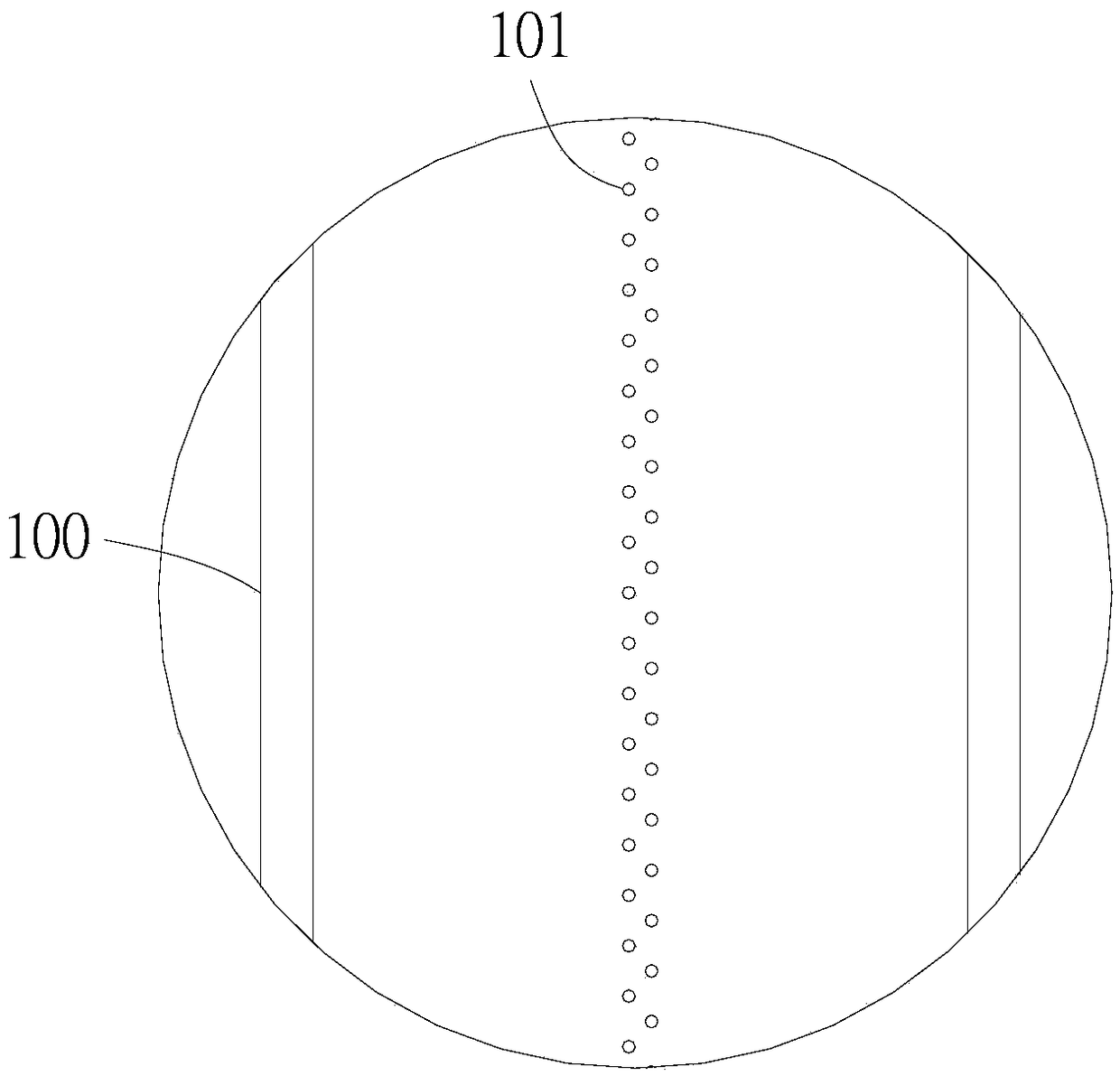

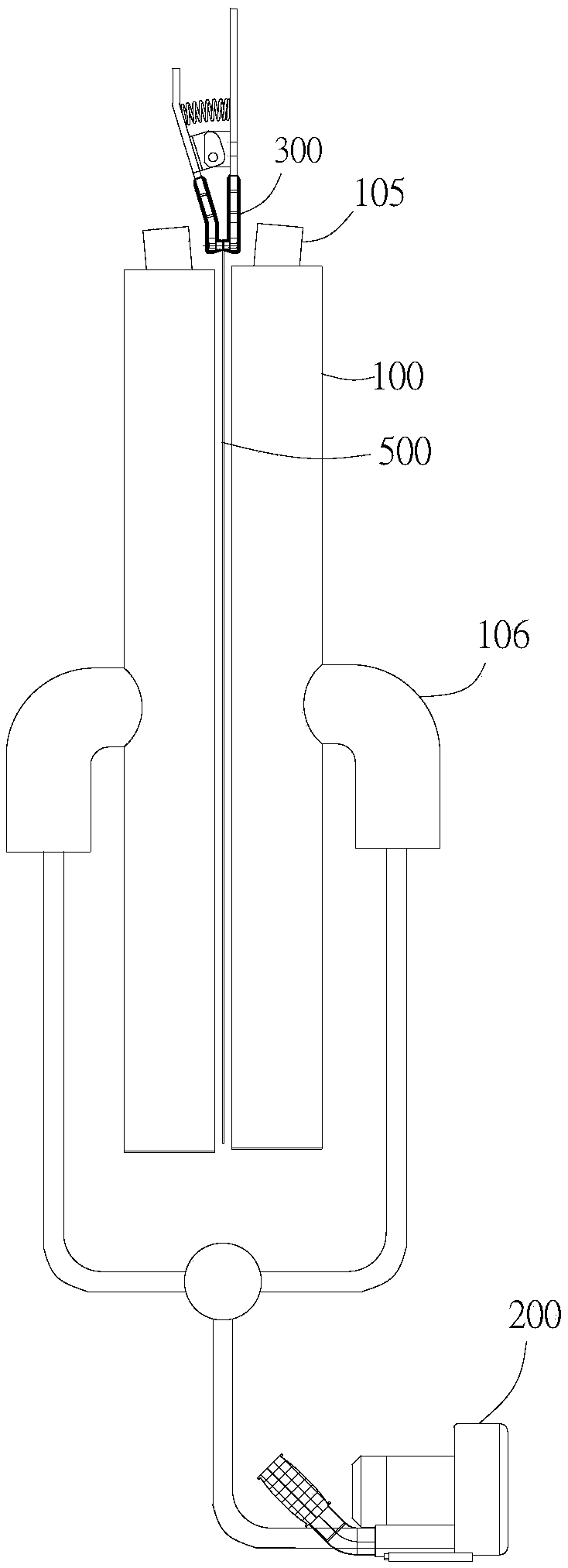

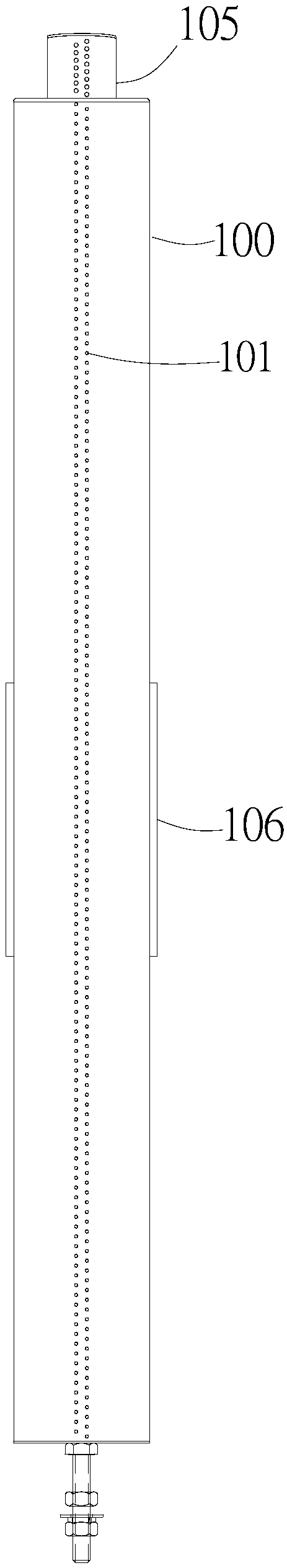

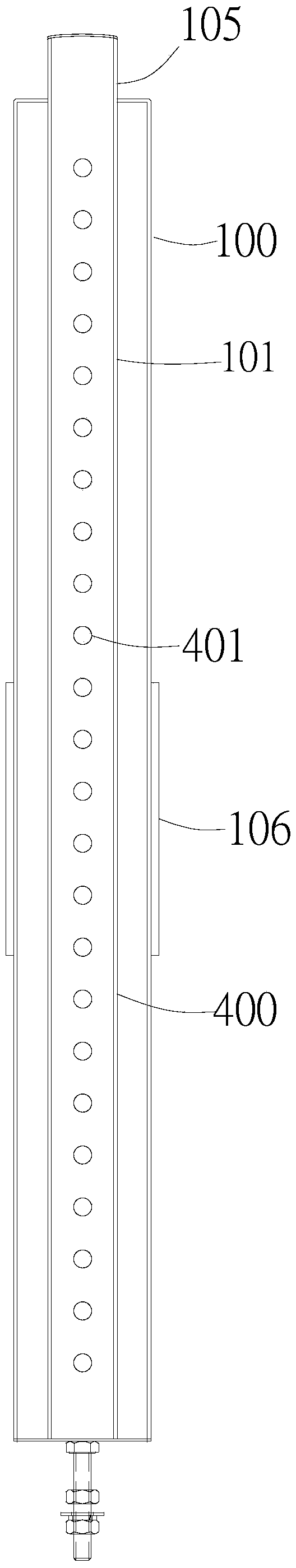

A kind of air knife assembly and drying device

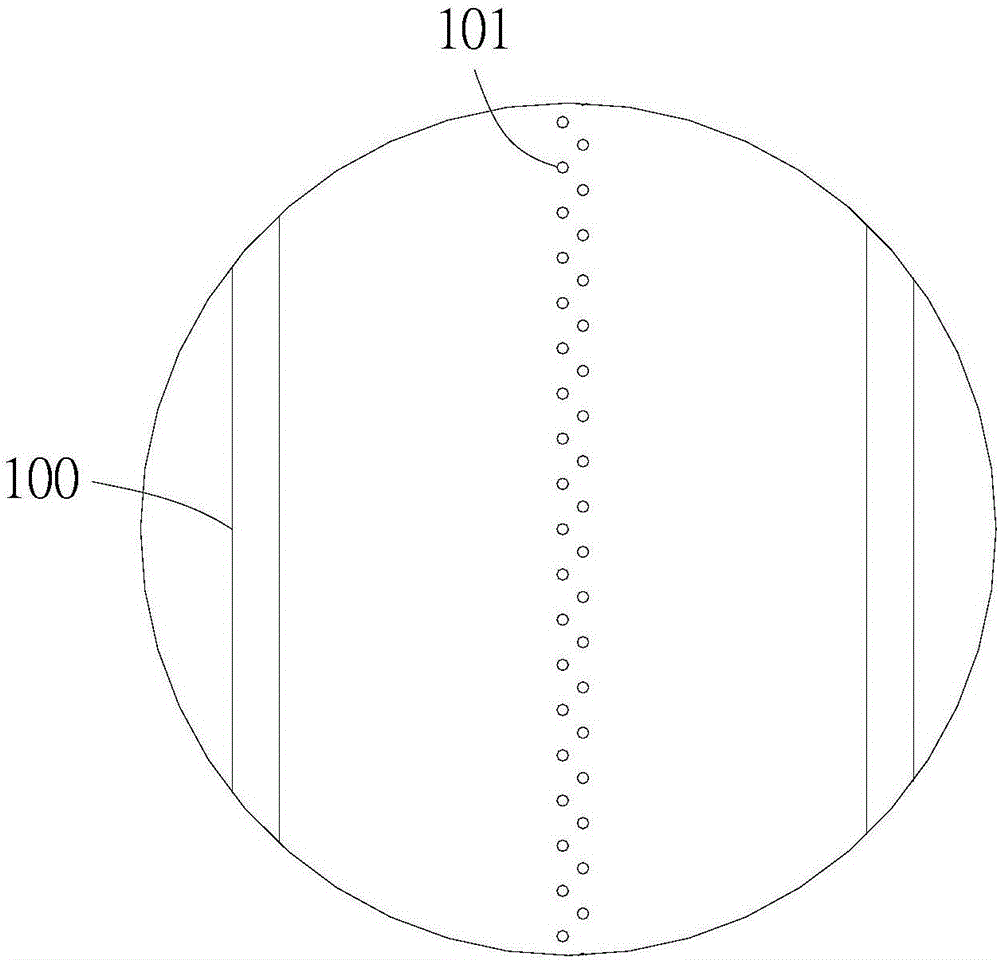

ActiveCN106369985BShorten the installation distanceSmall sizeDrying gas arrangementsDrying machines with progressive movementsAir knifePhysics

Provided are an air knife assembly and a drying device, wherein the air knife assembly comprises two vertical and side-by-side air ducts (100); a gap is provided between the two air ducts (100) for allowing a circuit board (500) to pass through therefrom; at least one row of vent hole group distributed axially along the air ducts (100) is provided along an inner side of each air duct (100); each row of vent hole group of the two air ducts (100) is oppositely arranged; each vent hole group comprises a plurality of vent holes (101); and the vent holes (101) of the vent hole group located in the inner row are each alternately arranged along the axial direction of the air duct (100).

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

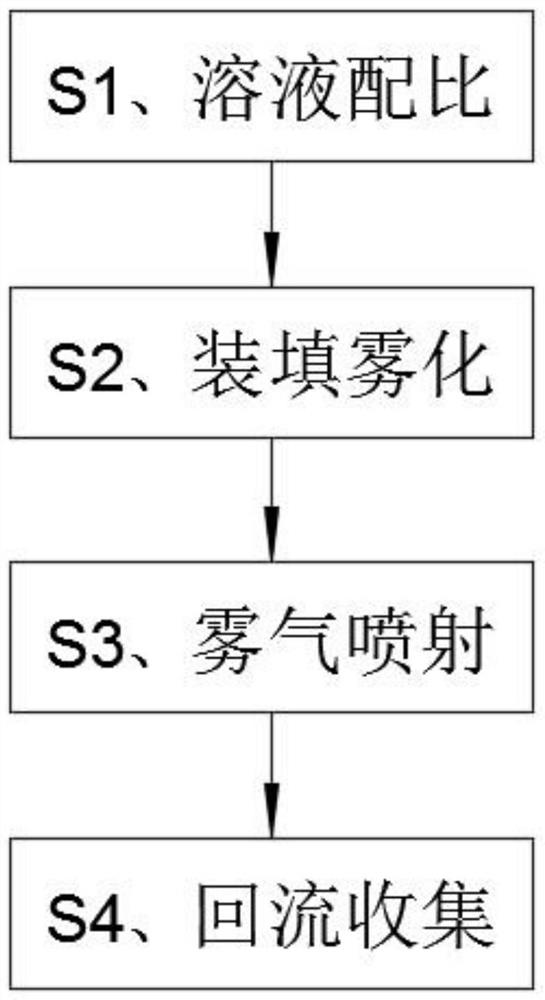

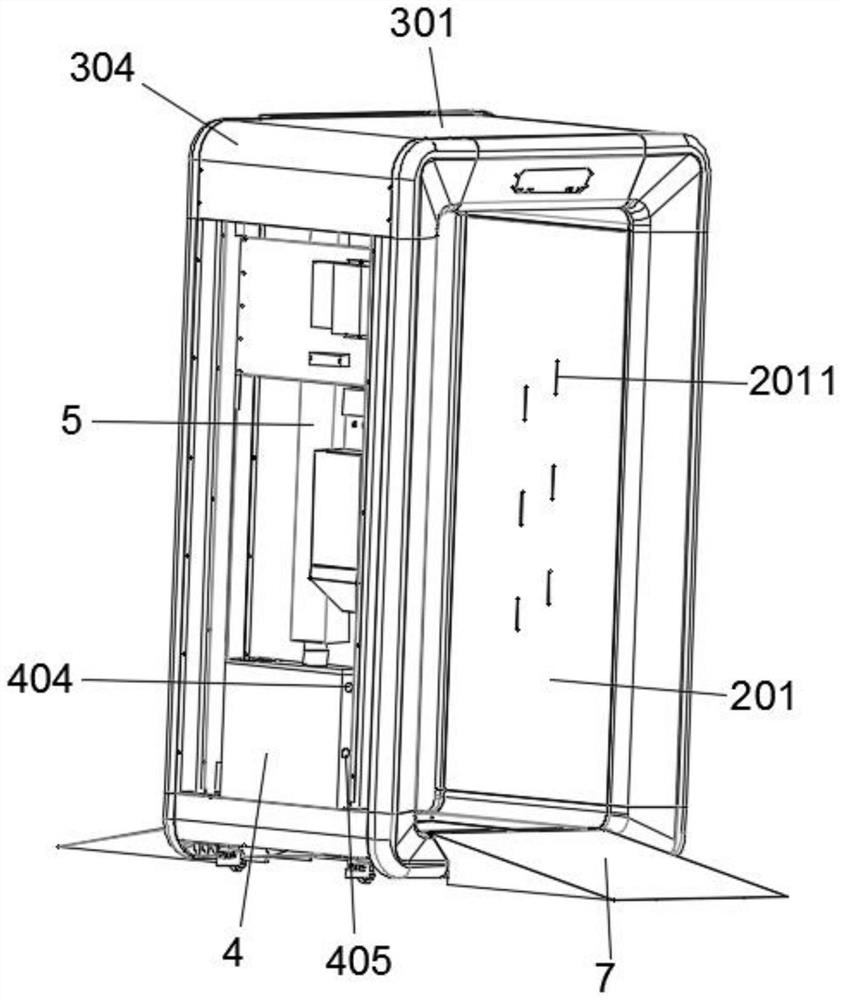

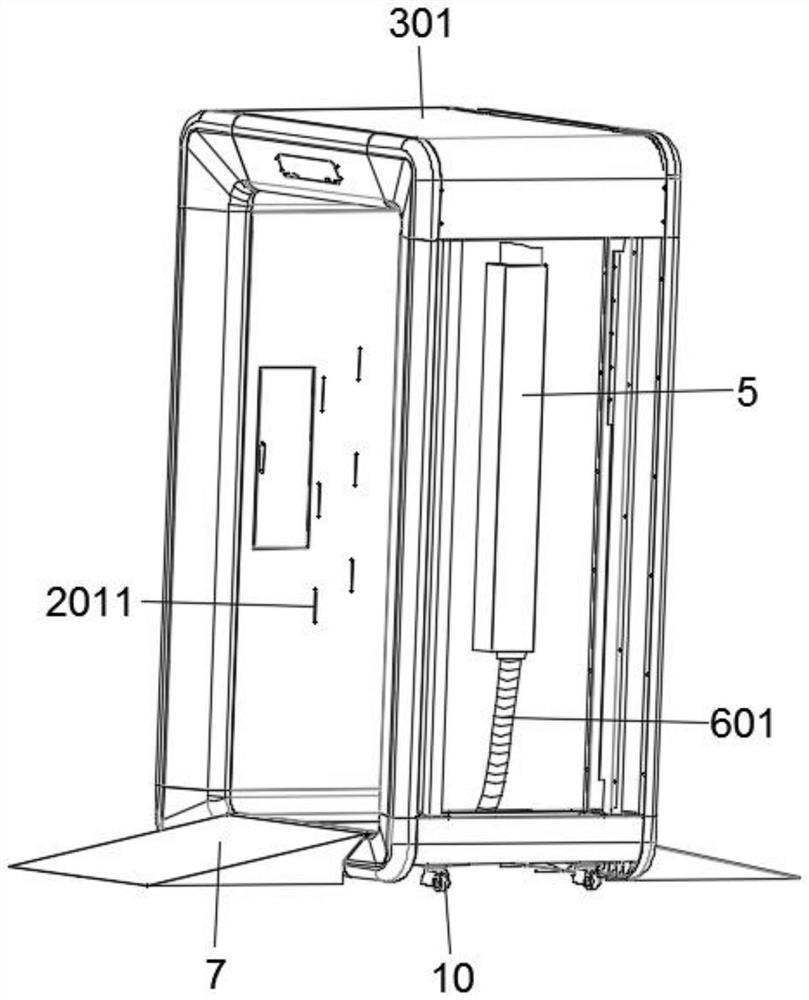

AES disinfection channel spraying method

PendingCN114225083AEfficient and stable spray efficiencyImprove the effect of disinfection protectionLavatory sanitoryChemicalsWater flowEnvironmental engineering

The invention relates to the technical field of disinfection protection, and discloses an AES disinfection channel spraying method, which comprises the following steps: S1, solution proportioning: mixing an AES new material and water according to a ratio of 1: 99, and stirring for 30 s to prepare a disinfection solution; the disinfection solution is added into a liquid storage area of a water tank in a dust collection channel through a water inlet hole, the solution in the liquid storage area is pumped into an atomization area through a water pump and a water pipe, and mist is discharged out of the water tank from a mist outlet pipe under the pressure action of a fan after the solution is atomized by an atomizer; s3, mist spraying, wherein mist sequentially penetrates through a left mist guide box body, a communicating pipe, a transverse pipe and a right mist guide box body under the action of air pressure; and S4, backflow collection: then the water flows back to a liquid storage area of the water tank through a corrugated water pipe and a backflow hole. A reciprocating circulating spraying operation is formed, and the whole spraying process does not need human interference and can be continuously carried out, so that the high spraying efficiency is ensured, and the disinfection and protection effects are improved.

Owner:安徽同净枫翎新材料科技有限公司 +1

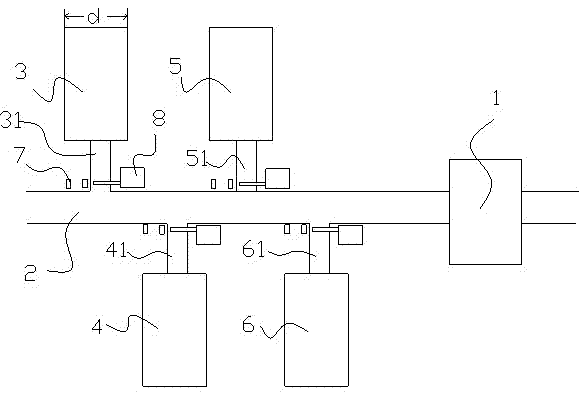

Device with multiple packing machines sharing pipe sticking machine

The invention provides a device with multiple packing machines sharing a pipe sticking machine. By means of the device, the production area and the production machinery cost can be reduced. The device comprises a conveying belt connected with the pipe sticking machine, discharging passages of the multiple packing machines are connected onto the conveying belt at intervals, a sensor for detecting whether a place enough for holding a packing box exists at each connection position is arranged at each of the connection positions of the discharging passages and the conveying belt, and stopping units controlled by sensor signals are arranged on the discharging passages of the packing machines. According to the device, the discharging passages of the multiple packing machines share the pipe sticking machine, so that the pipe sticking machine investment cost is reduced; when product positions are hedged, the sensors send signals to the stopping units which suspend discharging of the discharging passages of the packing machines to the hedged positions, so that hedging is prevented; the sensors send signals to the stopping units after detecting the passing of the hedged positions, and the stopping units open the discharging passages, so that the continuity of products sent to the pipe sticking machine is guaranteed, and the production efficiency is improved.

Owner:广东远东食品包装机械有限公司

A multi-input and one-out 3D printing color mixing nozzle that can be equipped with a camera

ActiveCN112318874BImprove uniformityWell mixedIncreasing energy efficiency3D object support structuresHeat conservationMechanical engineering

The invention discloses a multi-input and one-out 3D printing color mixing nozzle which can be equipped with a camera, which includes a main cavity, a stirring mechanism, a nozzle, a fan and a camera. The main cavity includes a preheating cavity, a heating cavity and a The heat preservation chamber is provided with a plurality of feeding ports on the preheating chamber, each feeding port is arranged on an outer wall of the preheating chamber and penetrates inwardly, the side wall of the heating chamber is provided with a first heater, and the side wall of the heat preservation chamber is provided with There is a second heater, the stirring mechanism includes a stirring motor, a guide rod, a mixer and a booster rod, the guide rod is fixed on the output shaft of the stirring motor, the mixer is fixed in the middle of the guide rod, and the booster rod is fixed on the guide rod The nozzle is installed at the bottom of the flow rod and the bottom of the booster rod, the fan is installed outside the main cavity and blows air to the nozzle, the camera is installed outside the main cavity and the lens faces the nozzle, so that the feeding, mixing and extrusion processes are relatively independent, improving the The uniformity of the extruded material in terms of viscosity, thickness, color, etc.

Owner:WUHAN UNIV OF SCI & TECH

Ride allocation system and method

ActiveCN109118415BImprove the efficiency of ride allocationAvoid delays in arriving at the pick-up areaData processing applicationsControl systemTransport engineering

The invention discloses a passenger allocation system and method. The system includes a passenger allocation area, several boarding areas, a station control system, several identity terminals and at least one first sensing device. The passenger allocation area includes at least one allocation area entrance, and passengers The allocation area is connected to the entrance of each boarding area; the identity terminal records passenger information, and the entrance of the allocation area is provided with a first sensing device, which is used to collect passengers in each identity terminal entering the entrance of the allocation area information, and send passenger information to the station control system; the station control system is used to obtain vehicle information in each boarding area, and the station control system is also used to match each identity terminal to a boarding station according to passenger information and vehicle information zone and direct each ID terminal to the matching pick-up zone entrance. The invention can realize rapid passenger-vehicle matching when there are multiple people and multiple vehicles, and passengers with the same destination or similar destinations can be paired to ride, thereby improving the efficiency of ride allocation.

Owner:SHANGHAI DIJIE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com