Patents

Literature

39 results about "Face flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

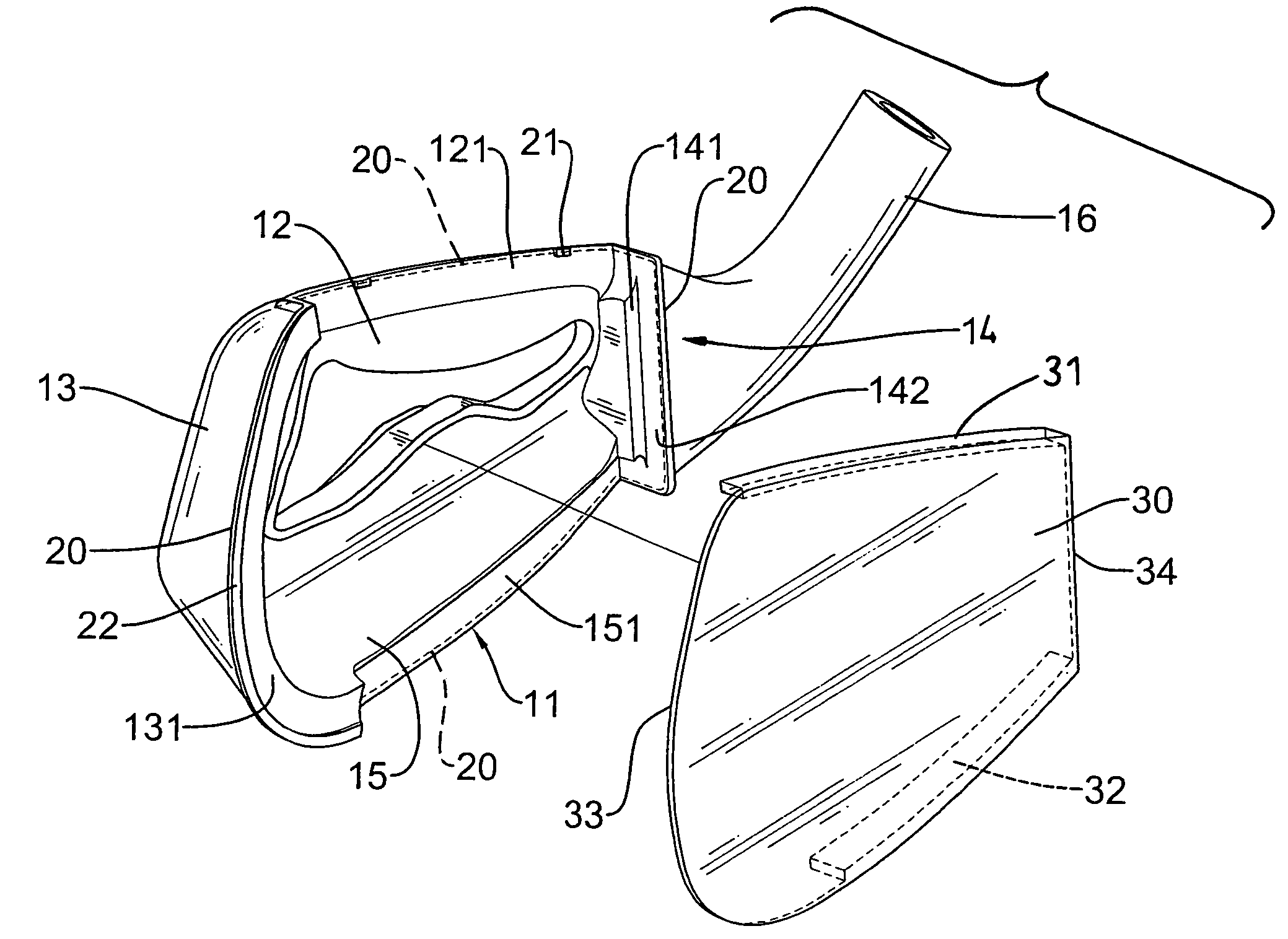

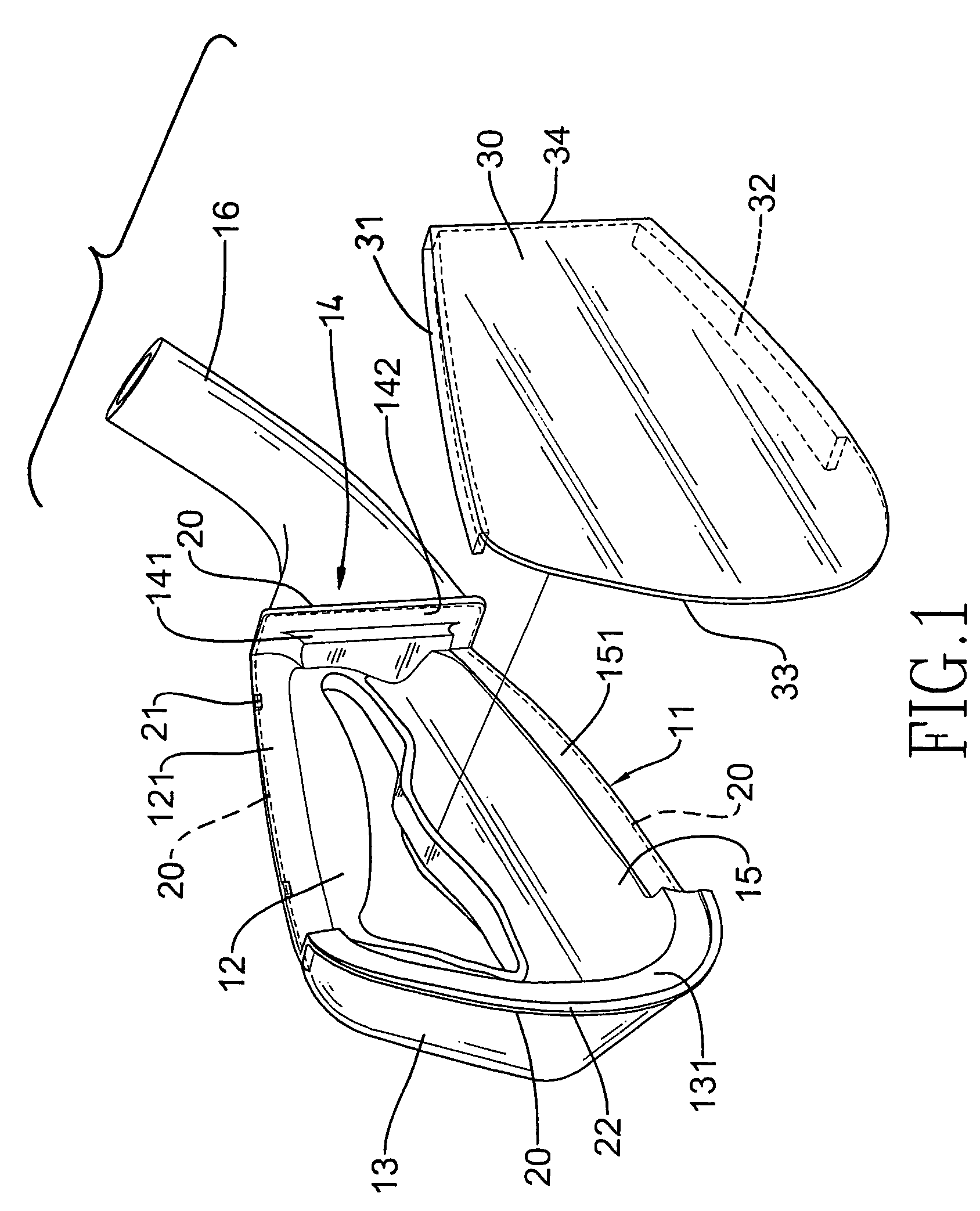

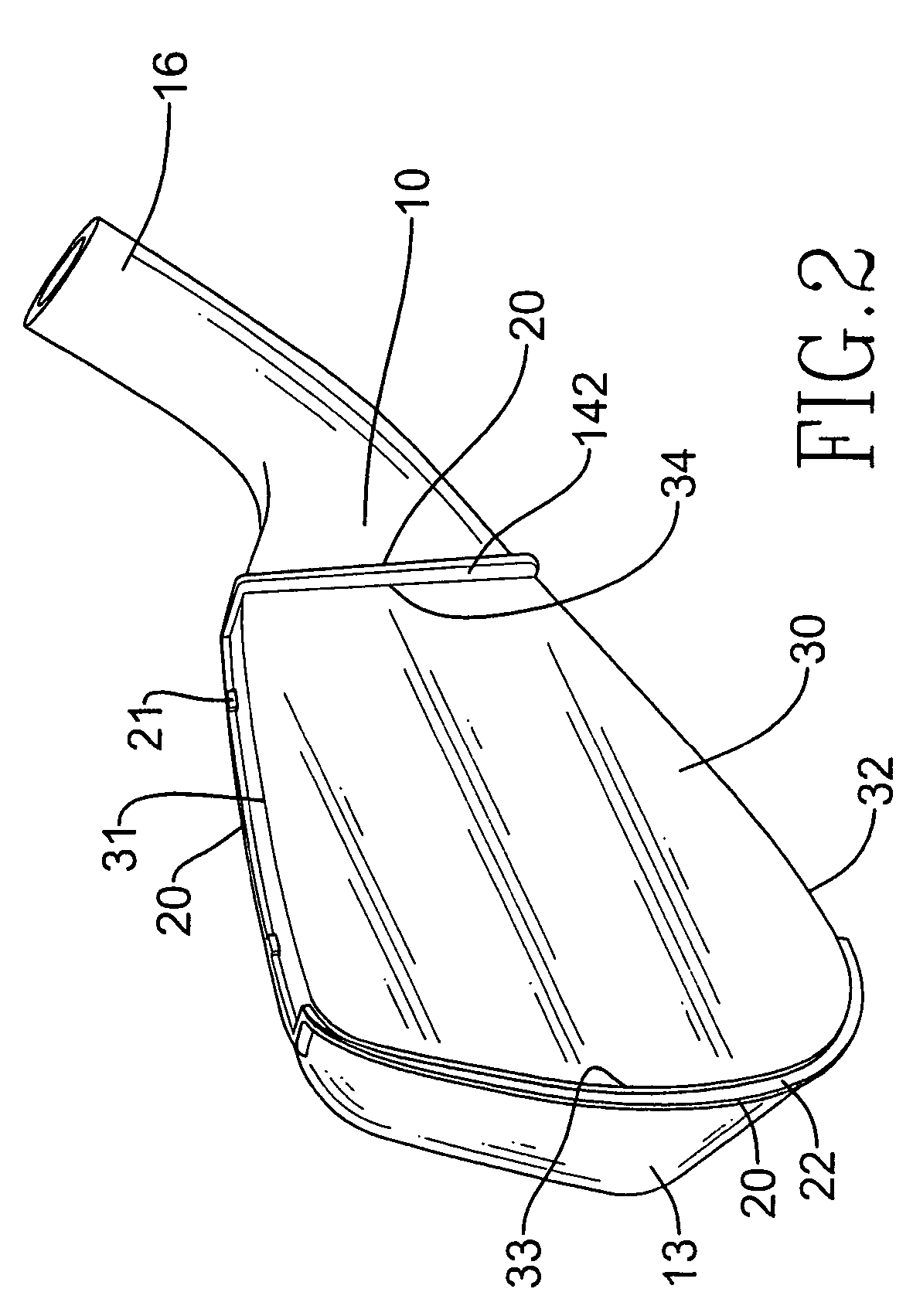

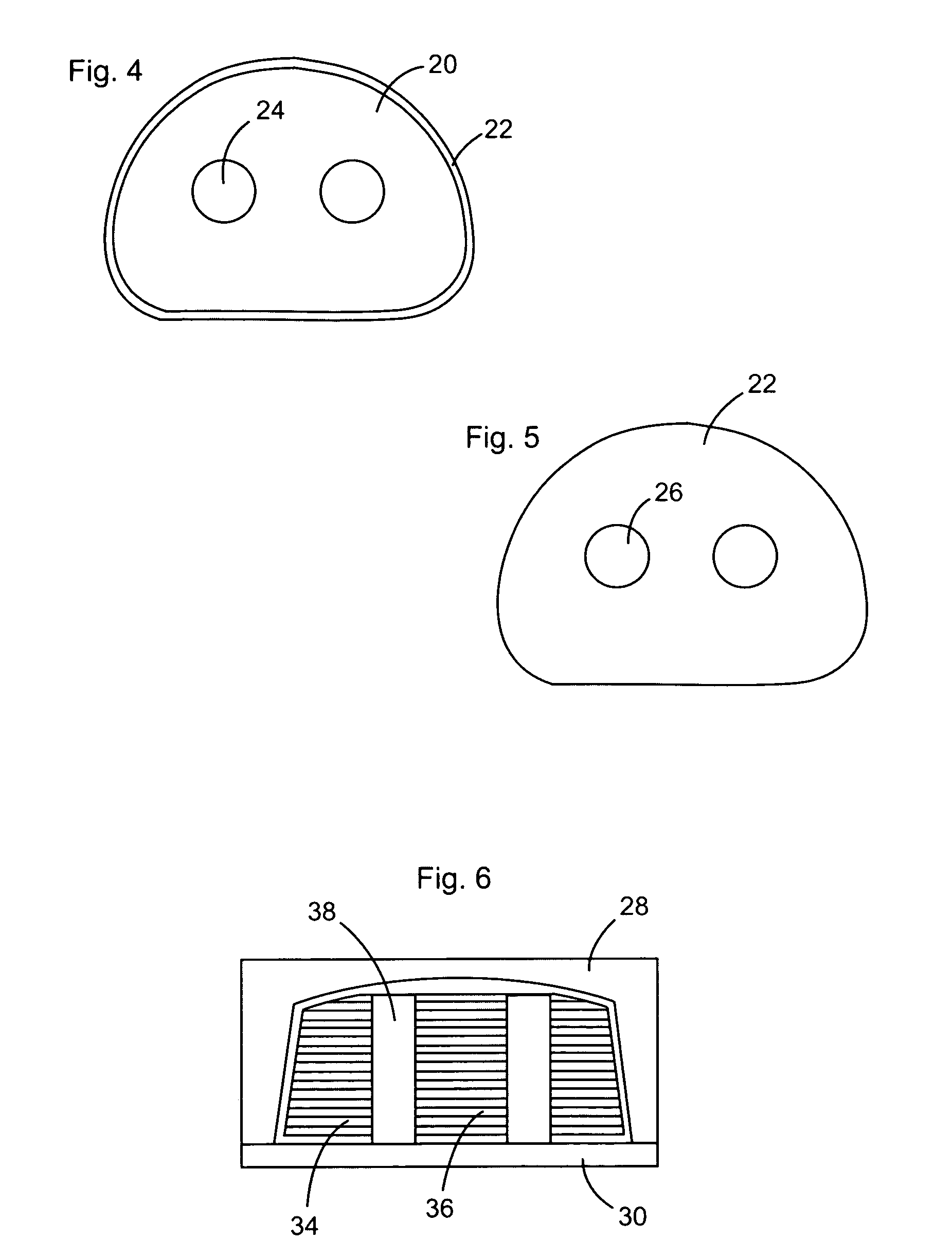

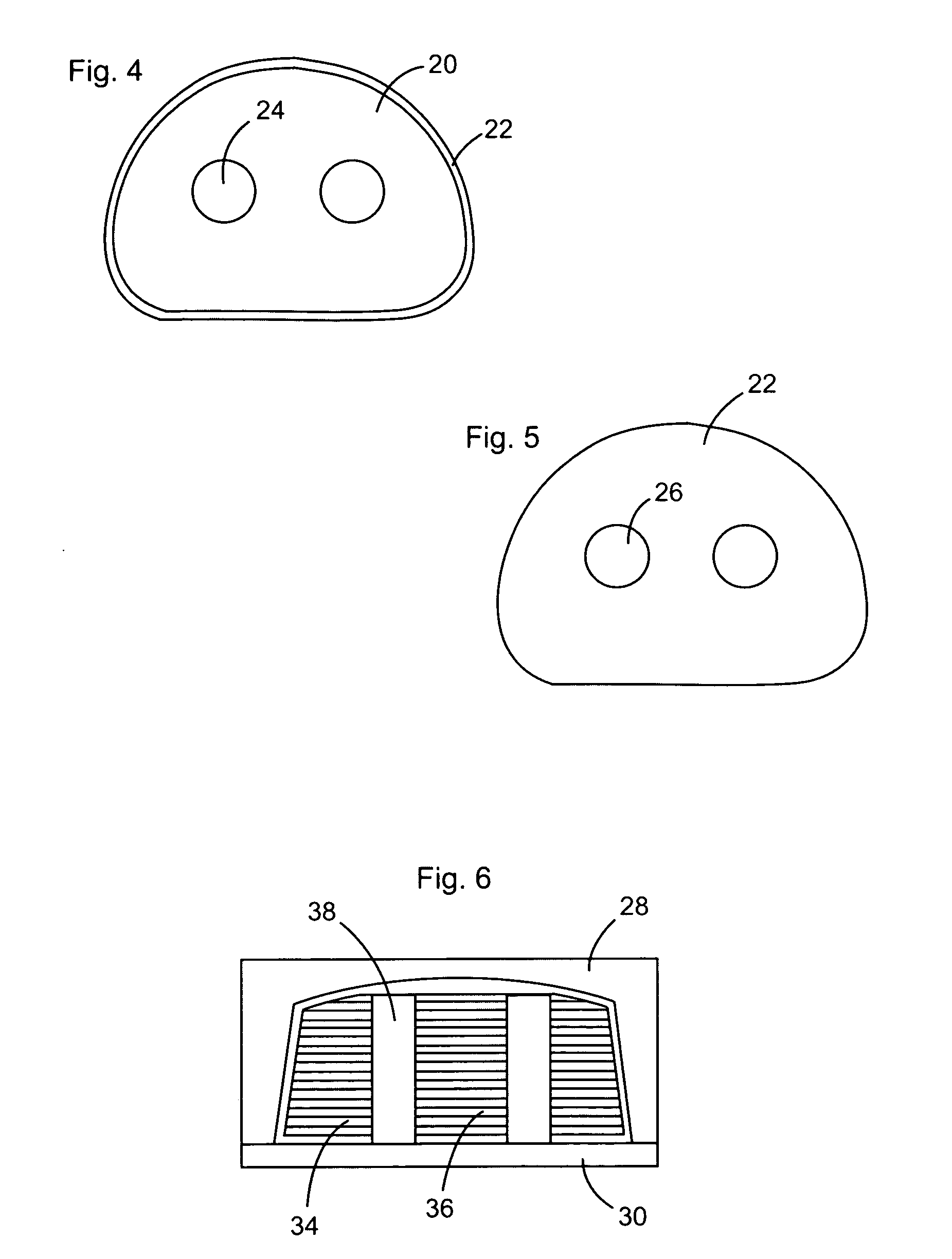

Positioning structure in a golf club head

InactiveUS7121958B2Optimize positioning structurePrecise dockingGolf clubsRacket sportsEngineeringFace flushing

A golf club head includes a head body having a recessed area defined in a central area of the head body and abutting faces formed along a periphery defining the recessed area. A soldering seam is formed on an outer periphery defining the recessed area and at least one positioning block is formed on one of the abutting faces and has a bottom face flush with a top face of the recessed area. A striking face is abutted to the abutting faces and the bottom face of the positioning block to allow the soldering seam to securely combine the head body and the striking face.

Owner:ADVANCED INT MILITIECH

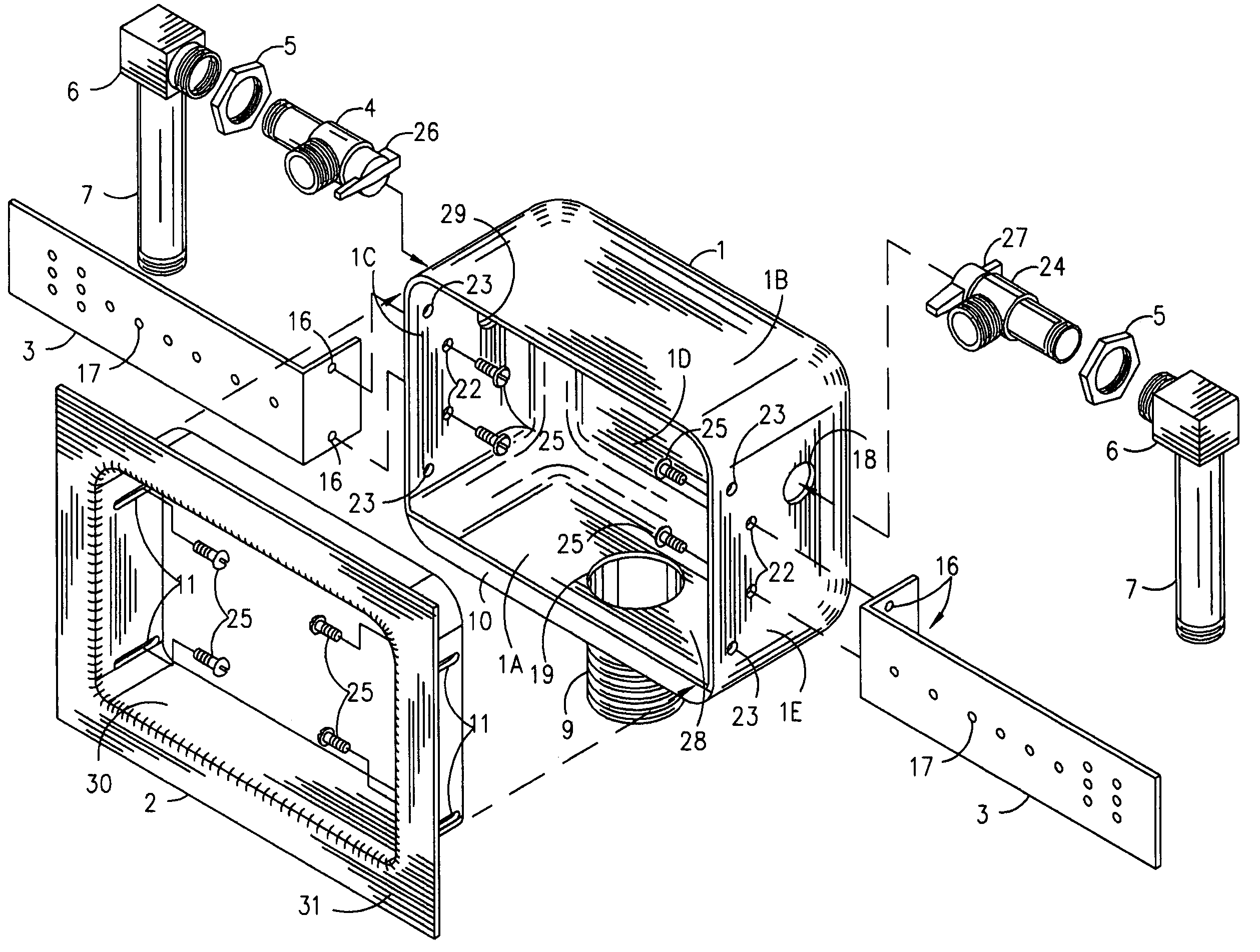

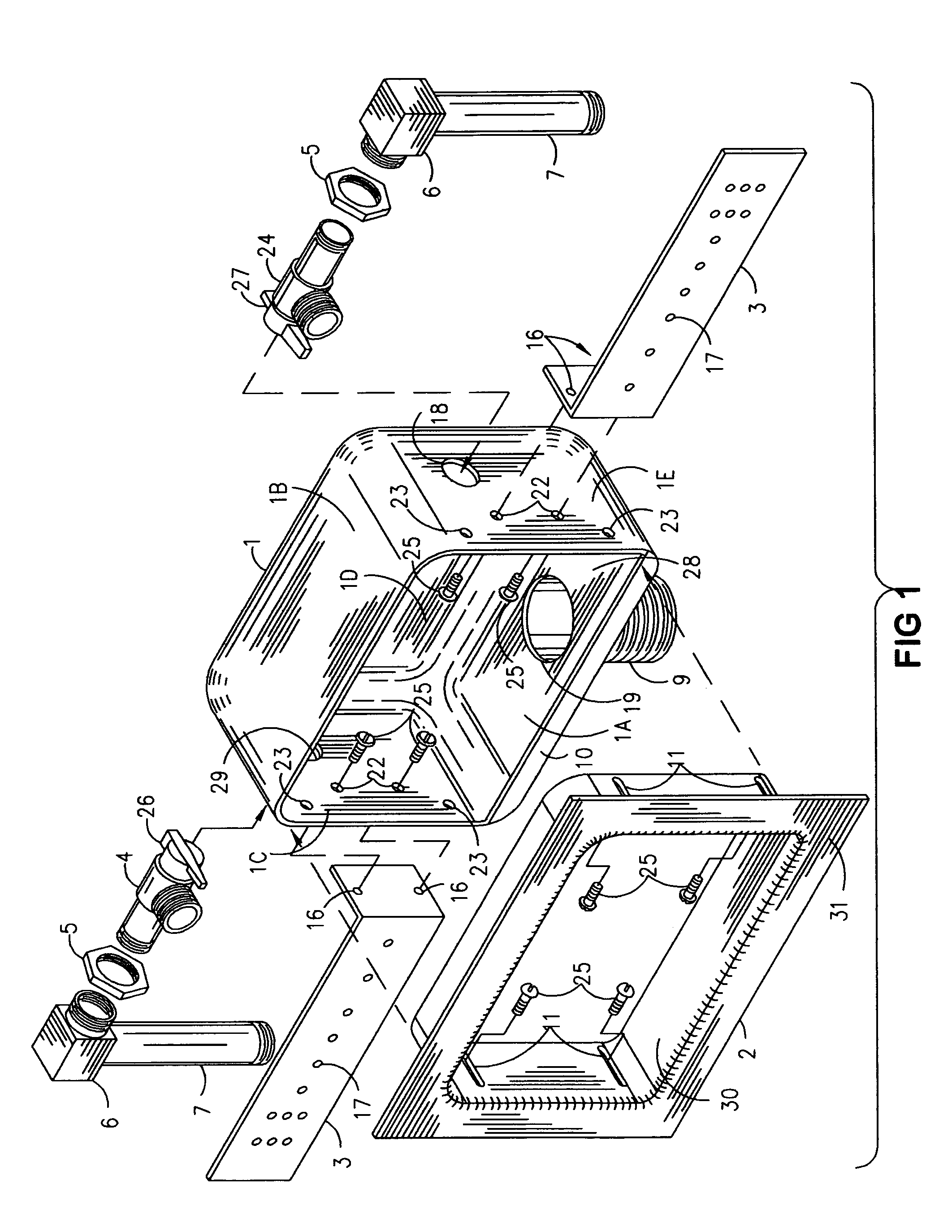

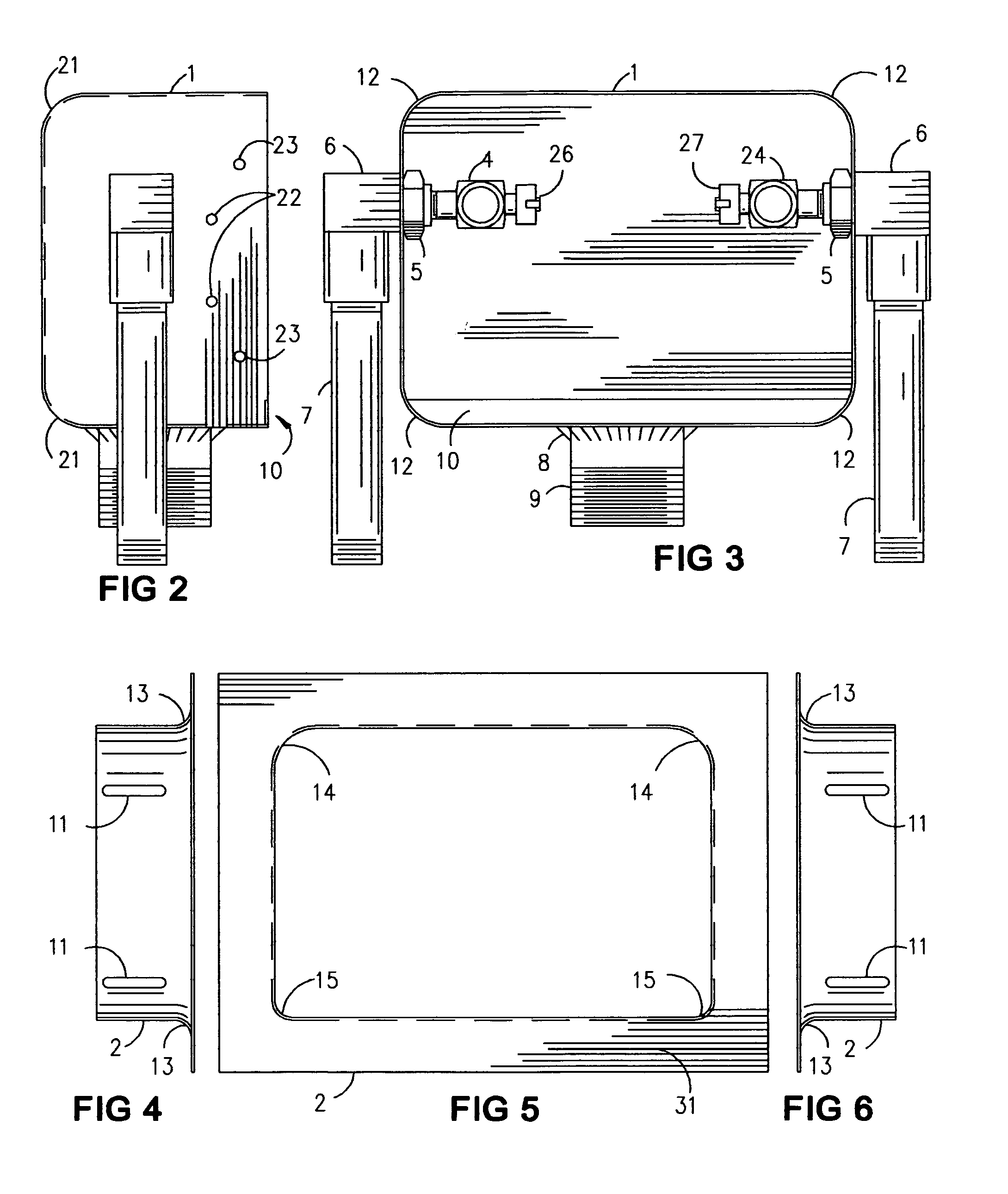

Prefabricated in-wall water service box

A prefabricated in-wall water service box with a five sided deep drawn stainless steel enclosure that has an open side with a reservoir lip and three closed sides integral with a top and bottom so that a reservoir is formed that is drained through a drain hole into a stainless steel nipple that is welded to the bottom and extends downwardly from the drain hole while hot and cold water control valves are mounted inside the enclosure through holes to a fittings located outside the enclosure at its two side walls. A trim bezel with a planar facing flush with a mounting wall is secured to the enclosure when it is mounted to two studs by two mounting brackets affixed to the two side walls by stainless steel screws. The hot and cold water control valves are ninety degree stainless steel ball valves while the brass hot and cold water fittings are a ninety degree elbow connected to an extension nipple that can accept a sweated copper connection, a compression fitting and a direct pipe thread connection while the side walls, the bottom and the top are joined with the back wall by four ninety degree radius turns.

Owner:GIBSON MICHAEL

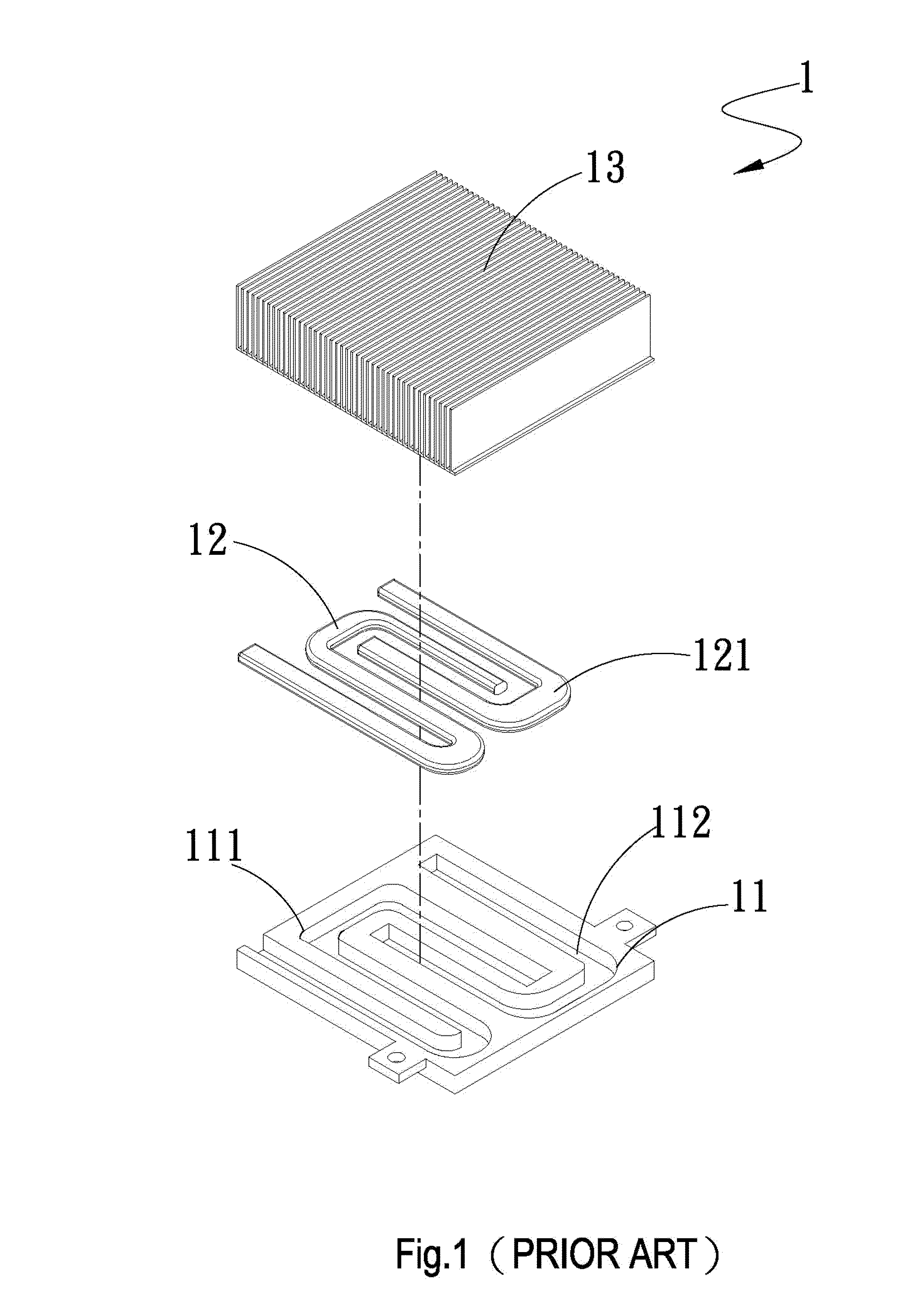

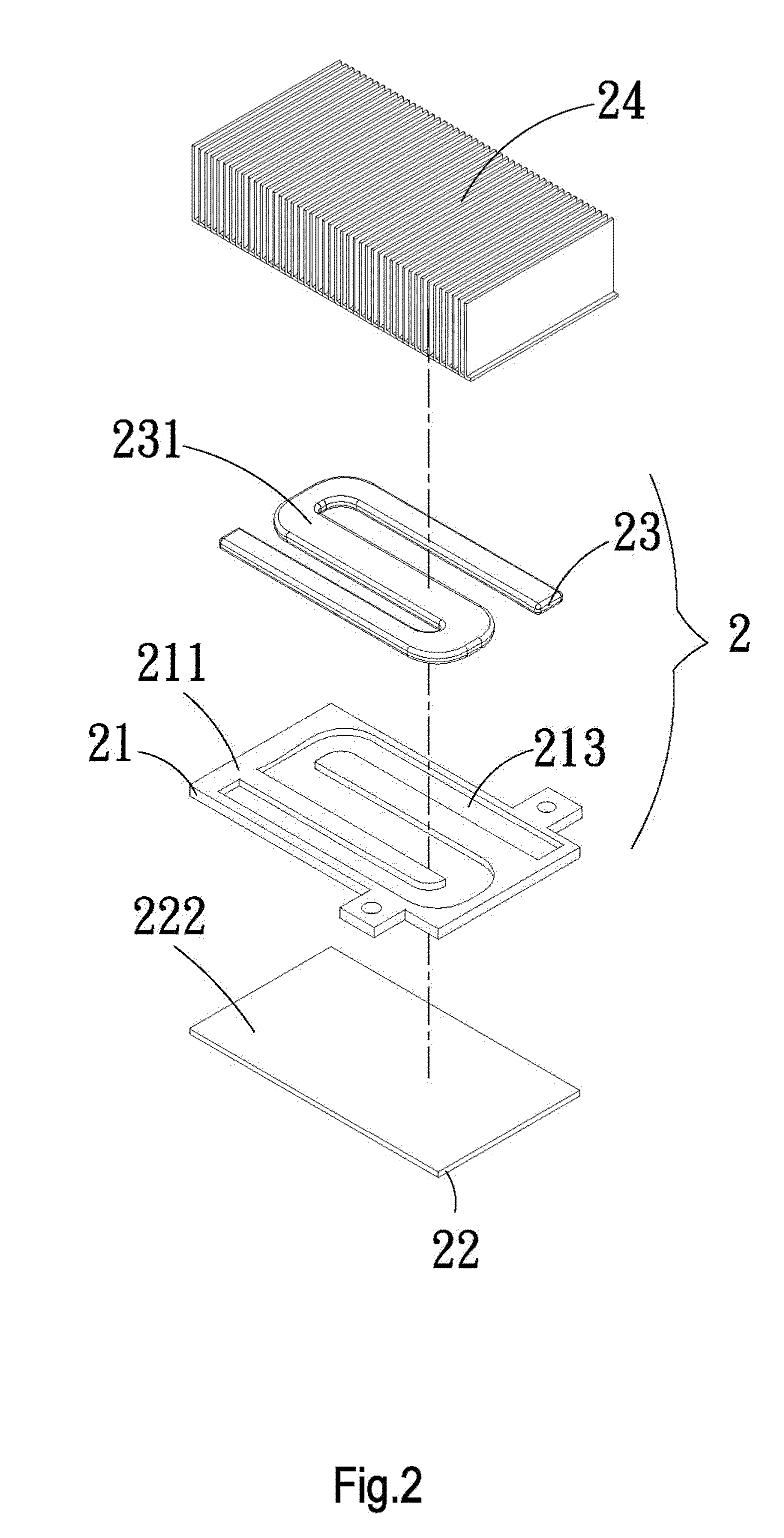

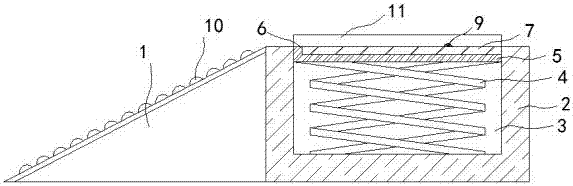

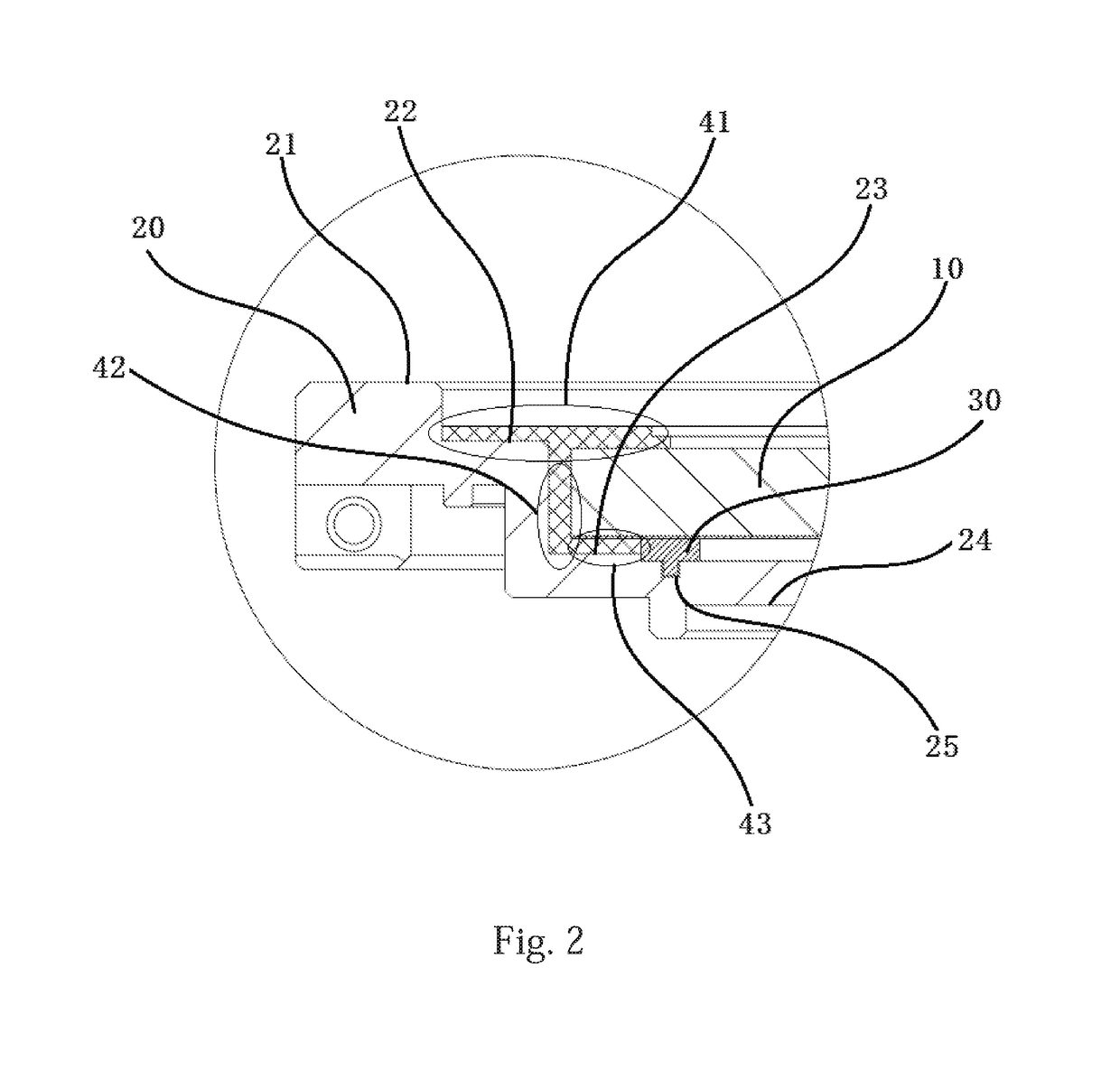

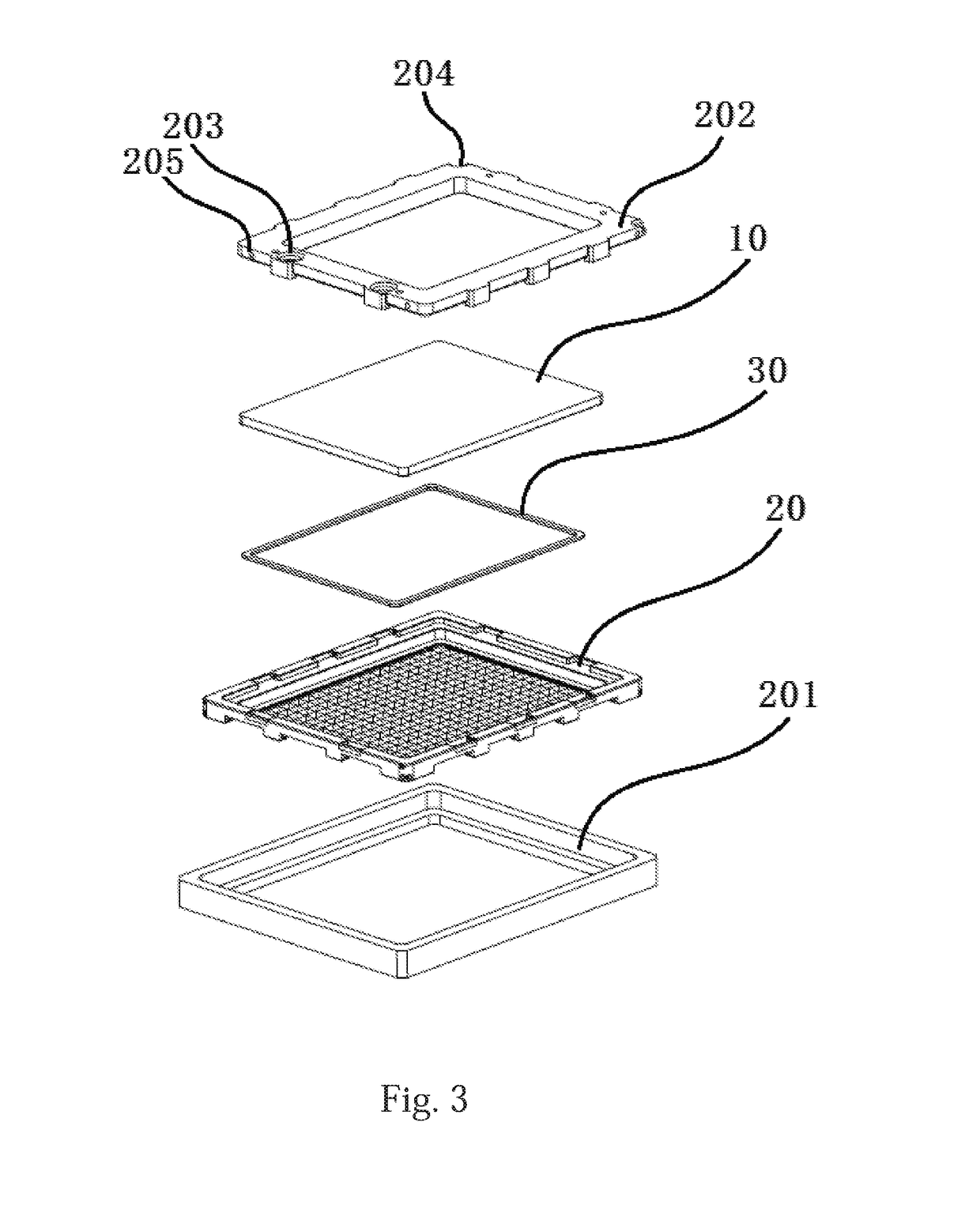

Heat-radiating base plate and heat sink using the same

InactiveUS20100126700A1Improve cooling effectReduce total usageSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

A heat-radiating base plate includes an aluminum-made upper base plate, a copper-made lower base plate, and a heat pipe unit. The upper base plate has a first face, an opposite second face, and a slotted pattern extended through the upper base plate in a thickness direction to communicate the first face with the second face. The heat pipe unit is set in the slotted pattern, and has a thickness equal to a depth of the slotted pattern. The heat pipe unit has a first and a second heat-conducting flat face flush with the first and the second face of the upper base plate, respectively. The second face and the second heat-conducting face are attached to the lower base plate, which has another flat face in contact with a heat-producing unit. A radiating fin assembly can be mounted to a top of the heat-radiating base plate to provide a heat sink.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

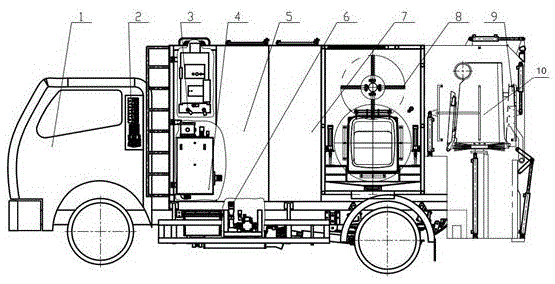

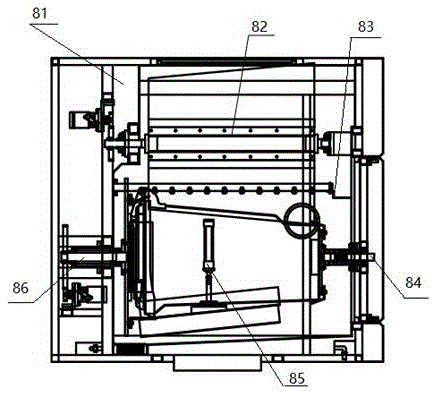

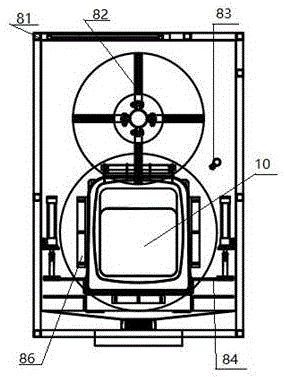

Vehicle special for cleaning garbage cans

ActiveCN105598107AShorten cleaning timeImprove cleaning efficiencyHollow article cleaningWater savingSprayer

The invention provides a device for cleaning the interiors and exteriors of garbage cans. The device comprises a closed box body, a turnover back door assembly, a turnover structure, a hydraulic device, an electric control device, at least one cleaning device and connecting parts relevant to the cleaning devices. The turnover back door assembly comprises a fixed seat clamping assembly, a movable seat clamping assembly and a left-and-right clamping oil cylinder. The cleaning devices comprise the outer cleaning devices and the inner cleaning devices, and the cleaning devices and the garbage cans are matched in number. The outer cleaning devices comprise sprayers installed on the tops, single-face cleaning pipelines, sprayers connected with the single-face cleaning pipelines, double-U-type three-face flushing pipelines, and sprayers connected with the double-U-type three-face flushing pipelines. The other ends of single-face cleaning moving oil cylinders are connected with the single-face cleaning pipelines and the sprayers connected with the single-face cleaning pipelines. Internal brushing and external flushing are combined, compared with an internal and external flushing scheme, more water is saved, compared with an internal and external brushing scheme, more space is saved, and the structure is more compact.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

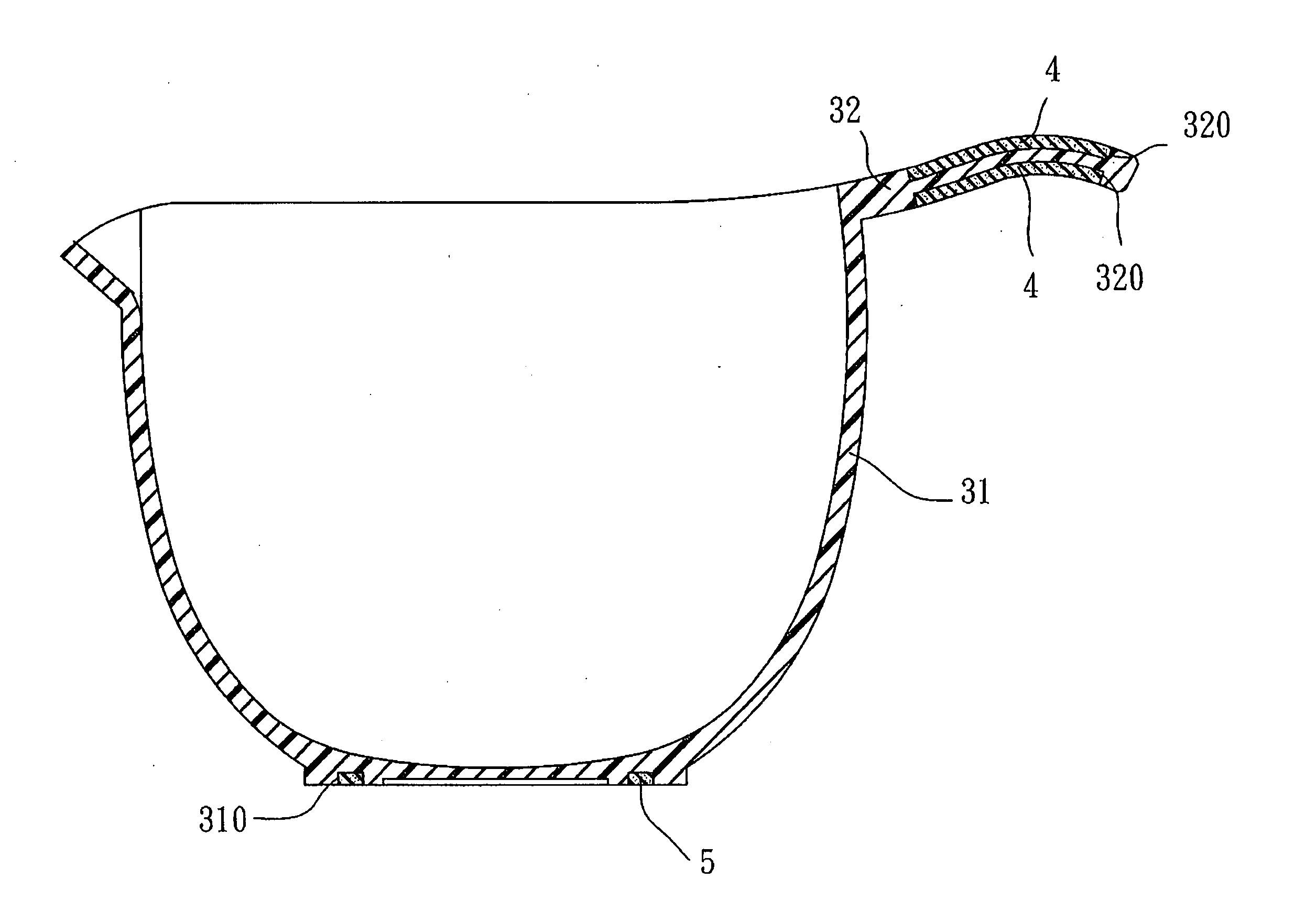

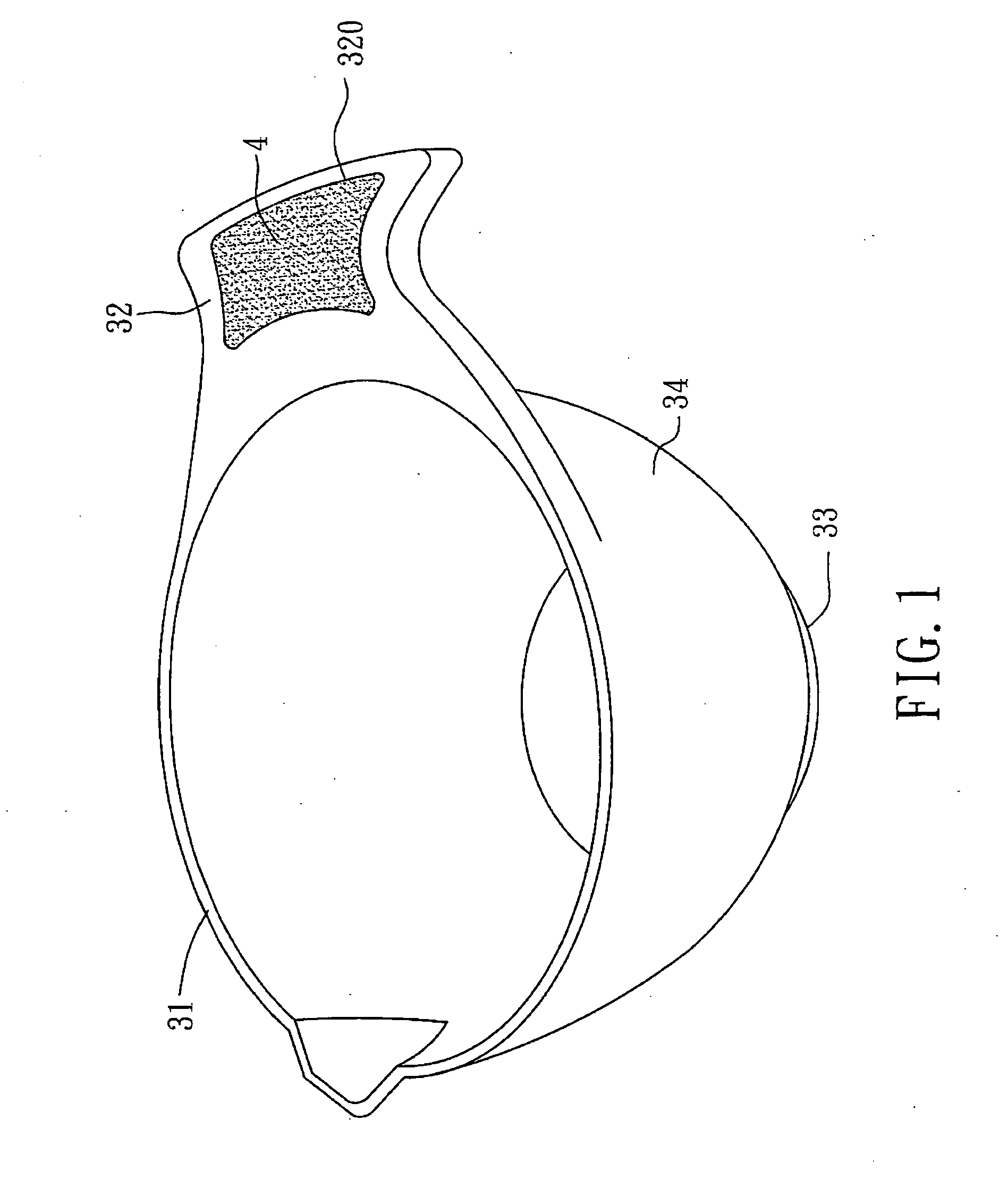

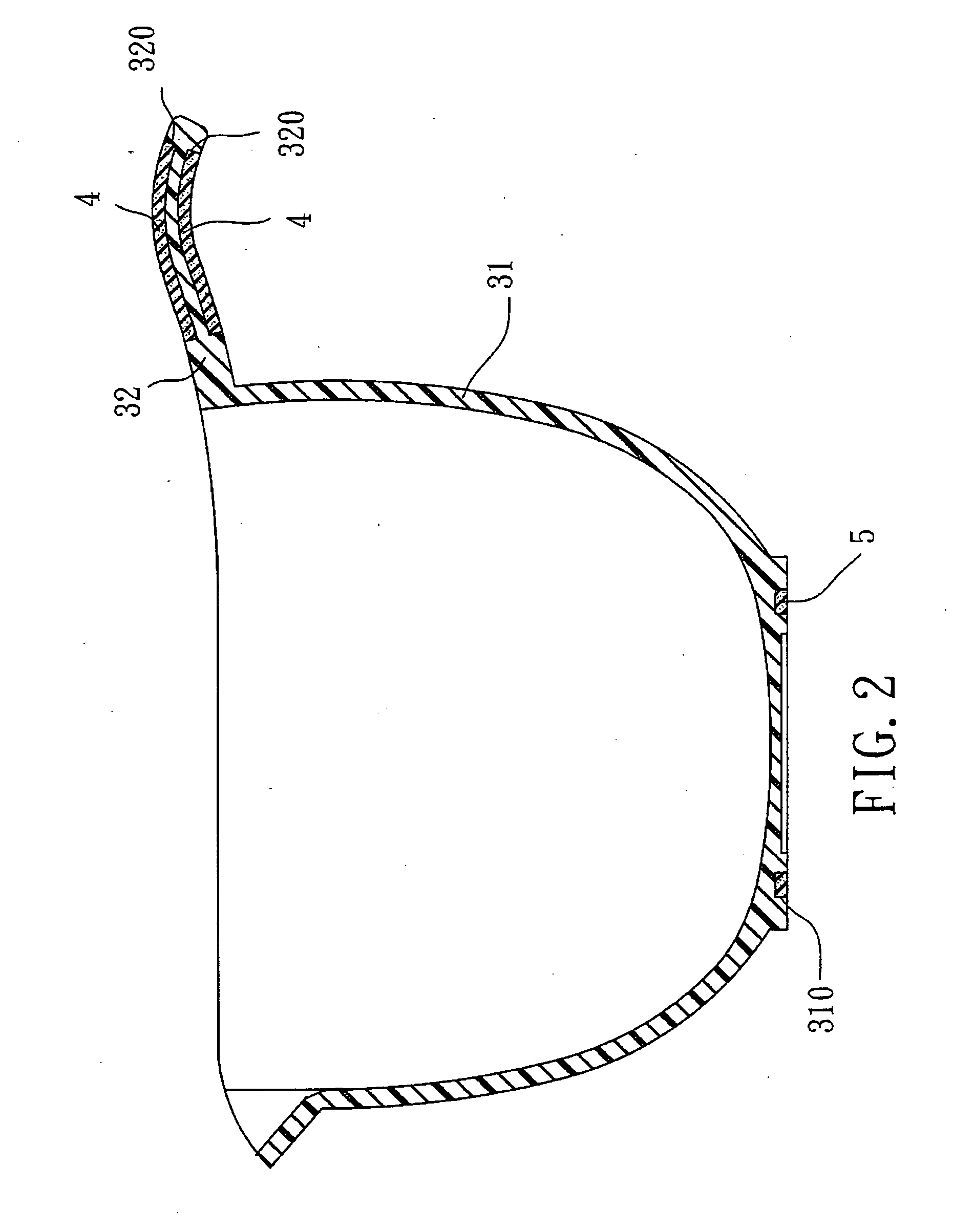

Container with anti-slip capability

A container with anti-slip capability includes: a container body having a bottom wall that has an outer surface and that is formed with a bottom groove indented inwardly from the outer surface; and a flexible anti-slip member that is mounted in the bottom groove and that has an outer end face flush with the outer surface of the bottom wall of the container body.

Owner:WU JUI LIANG

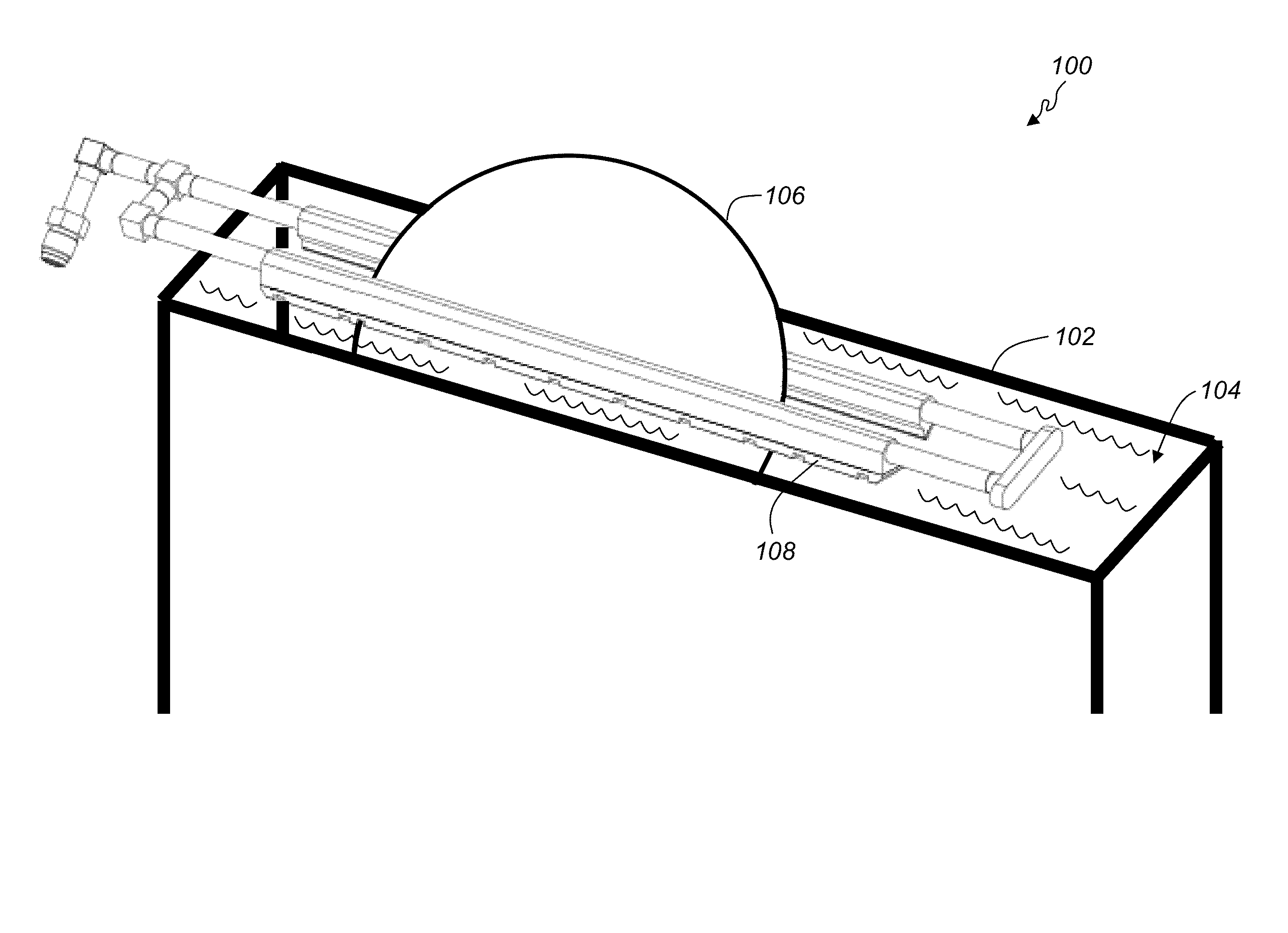

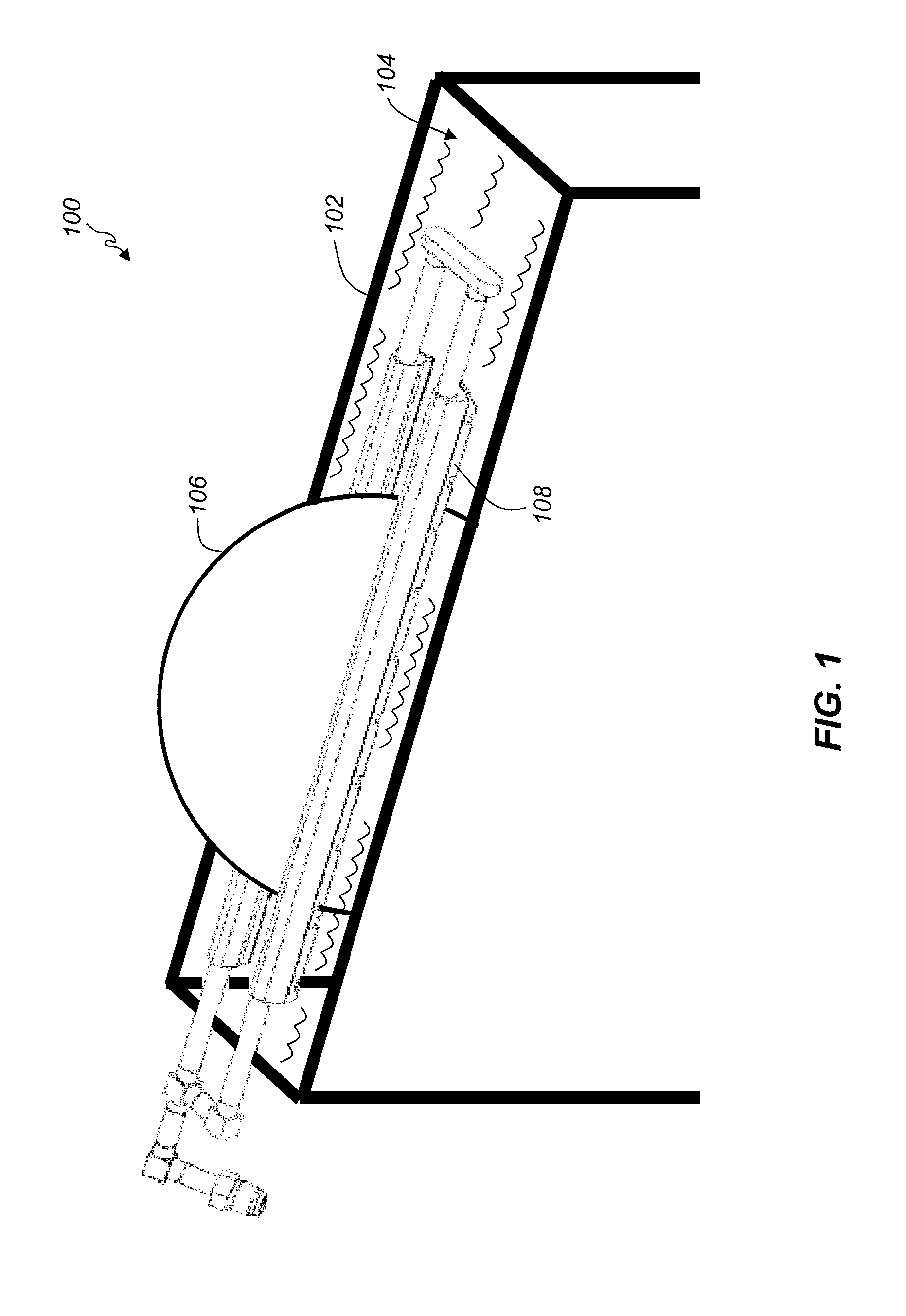

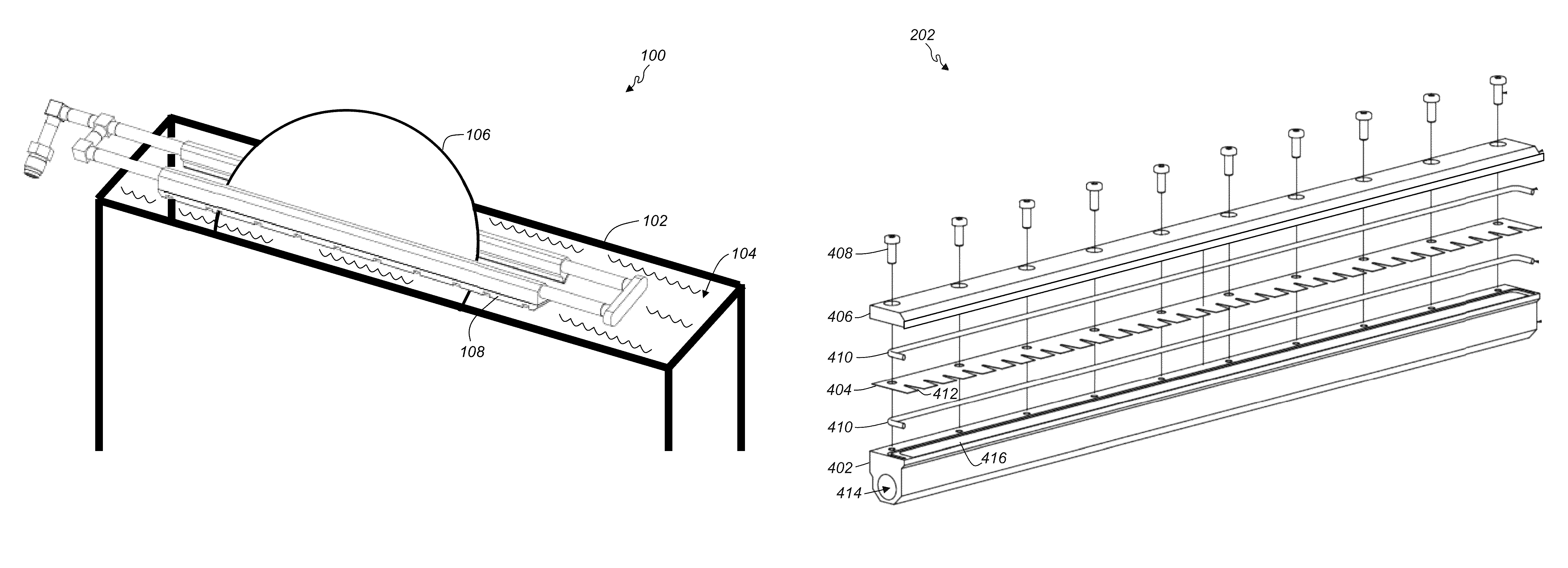

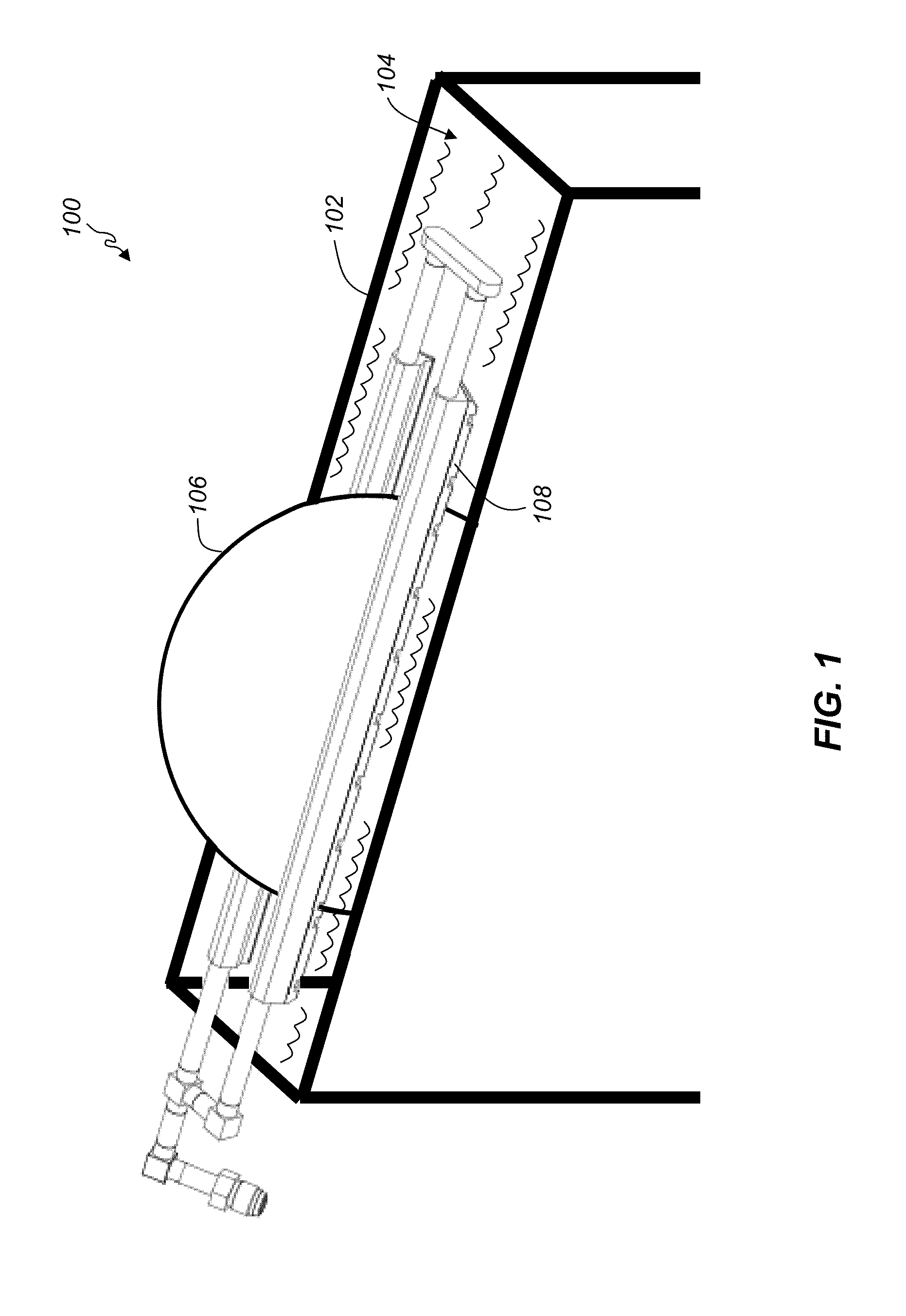

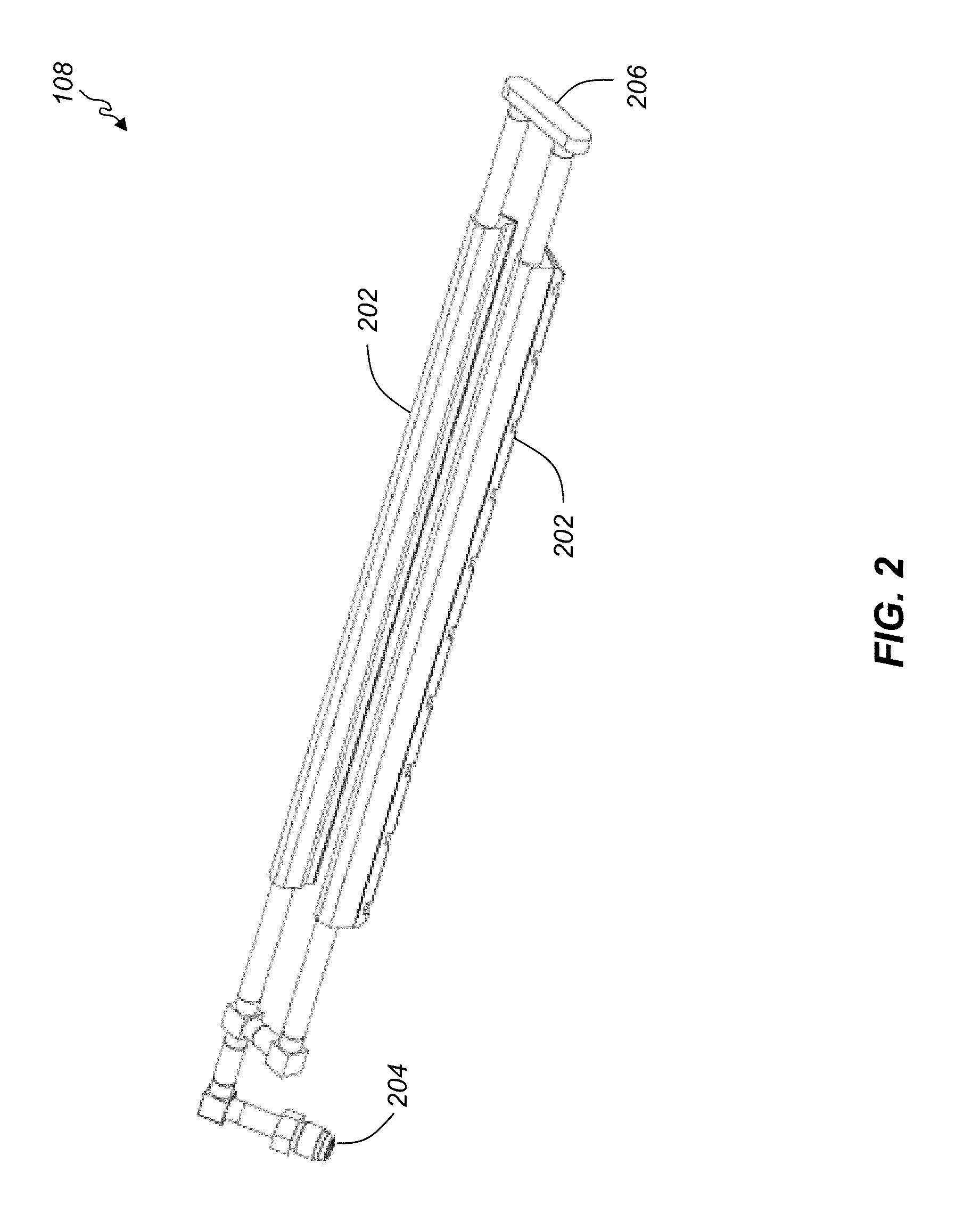

Methods and apparatus for marangoni substrate drying using a vapor knife manifold

ActiveUS20130283634A1Drying solid materials with heatDrying gas arrangementsEngineeringFace flushing

The present invention provides methods and apparatus for a Marangoni vapor knife assembly. The assembly includes a base having a channel extending longitudinally through the base and a plurality of passages extending laterally from the channel toward an outer face of the base; a top plate adapted to be removeably coupled to the base with an outer face flush with the outer face of the base; and a shim adapted to be disposed between the base and the top plate and further adapted to form a plurality of spray orifices in the assembly. Numerous additional features are disclosed.

Owner:APPLIED MATERIALS INC

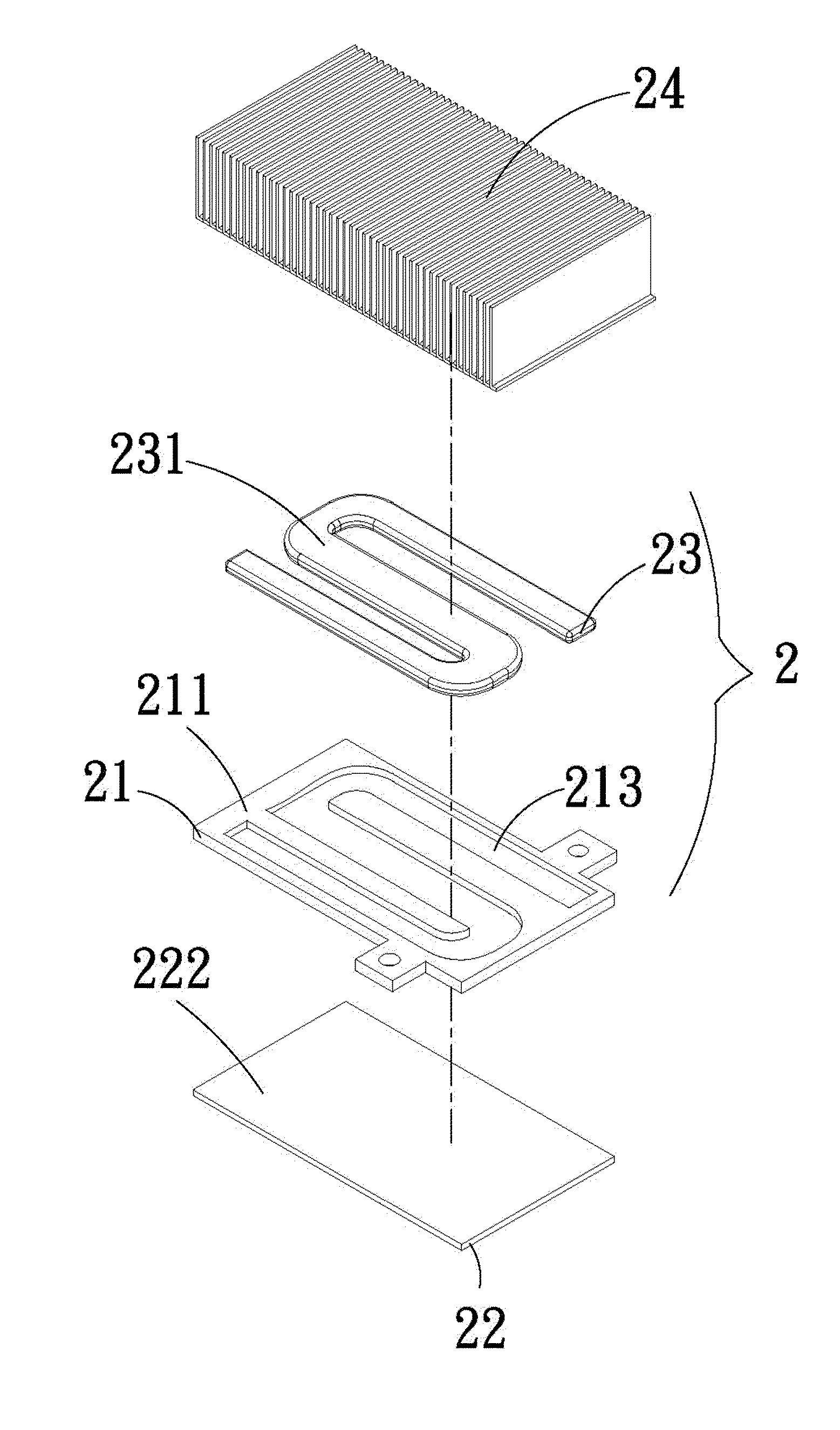

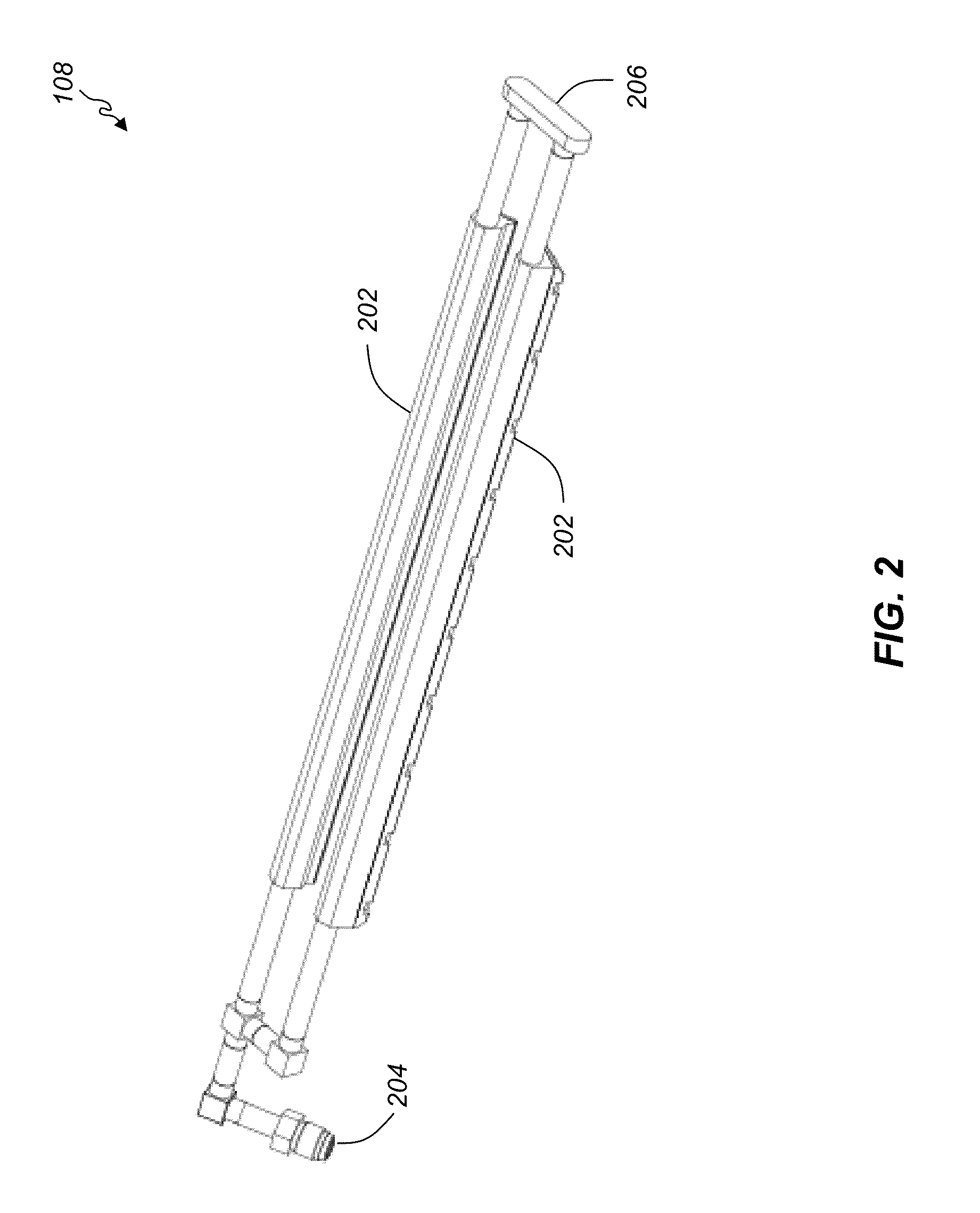

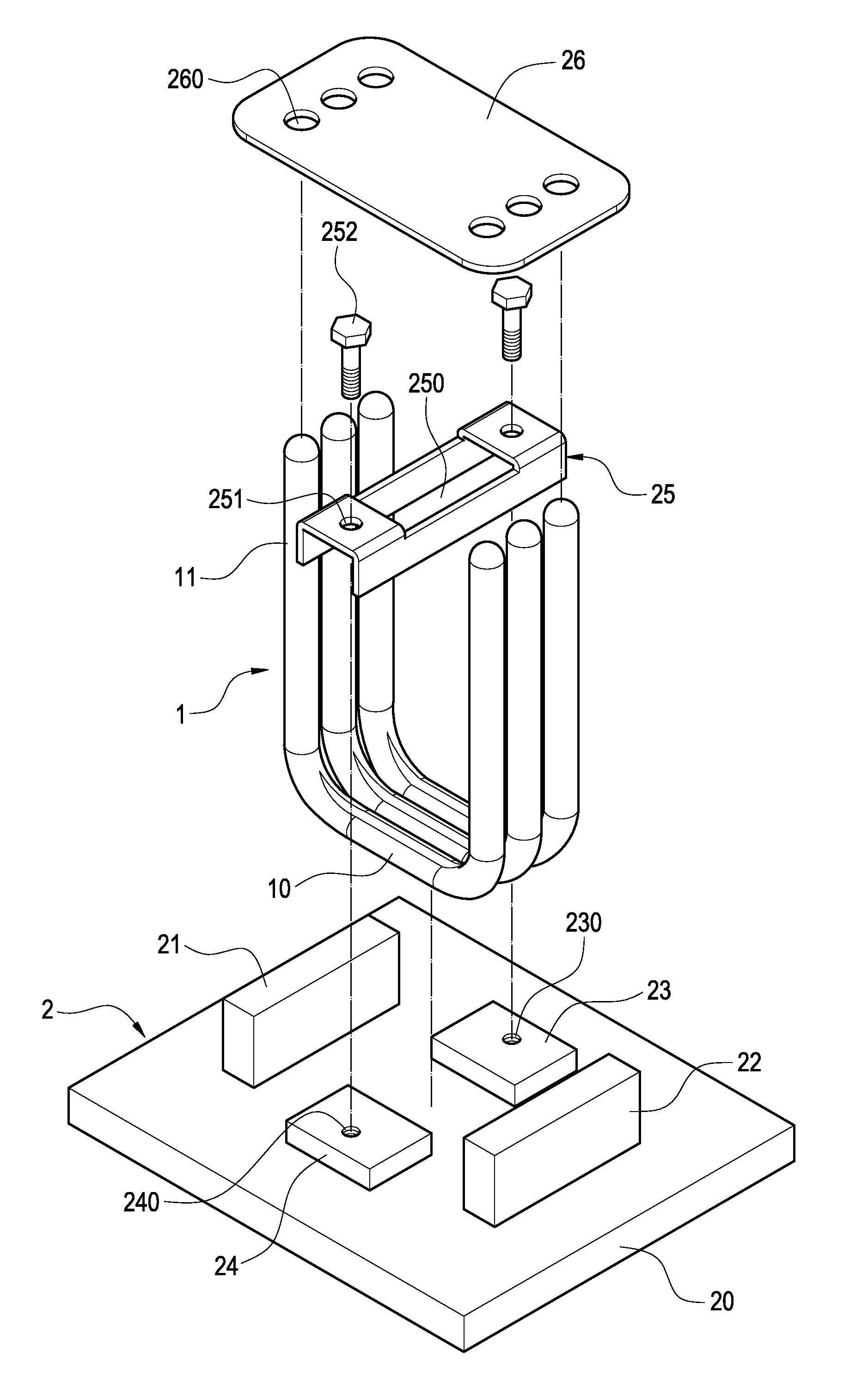

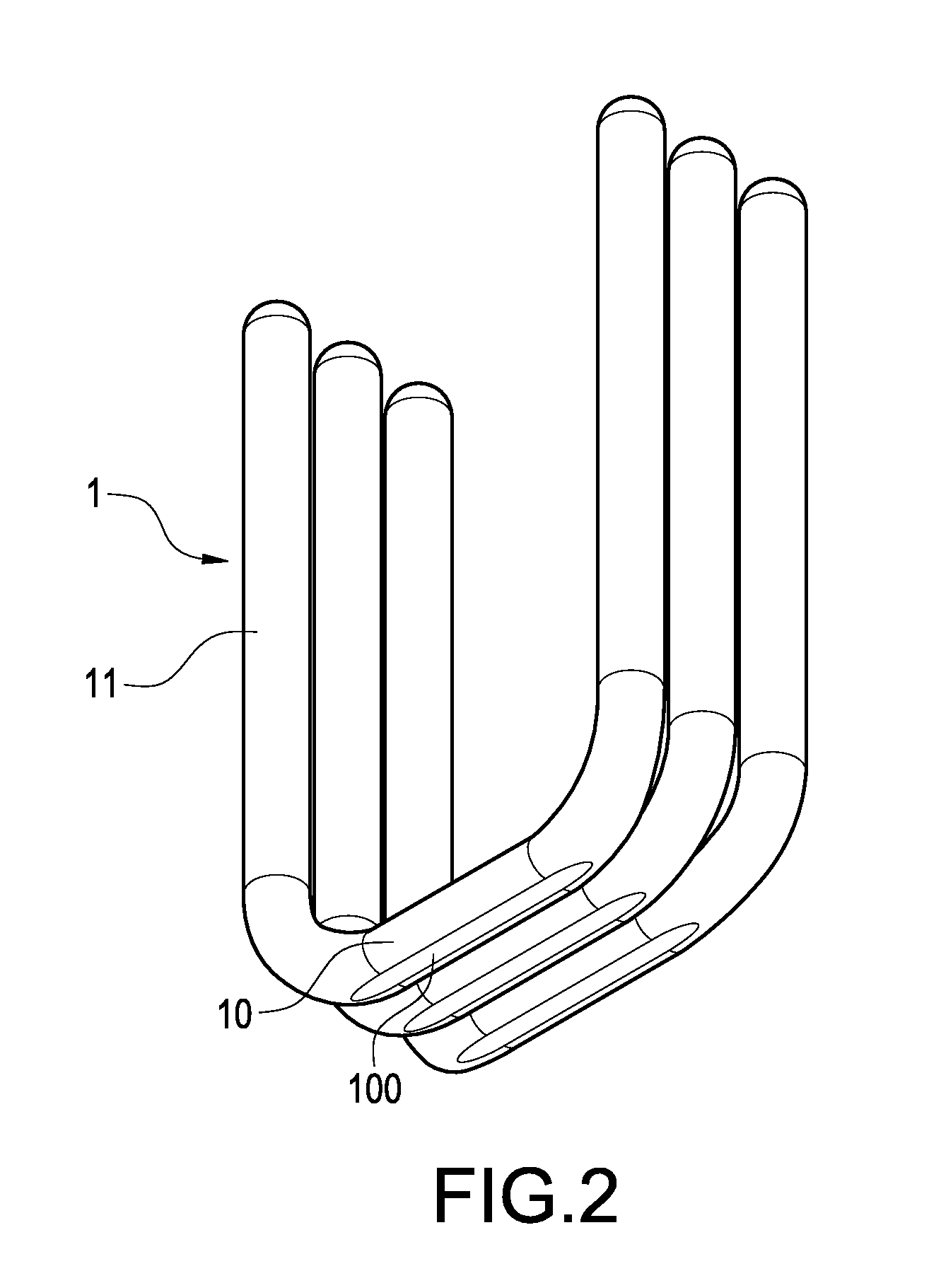

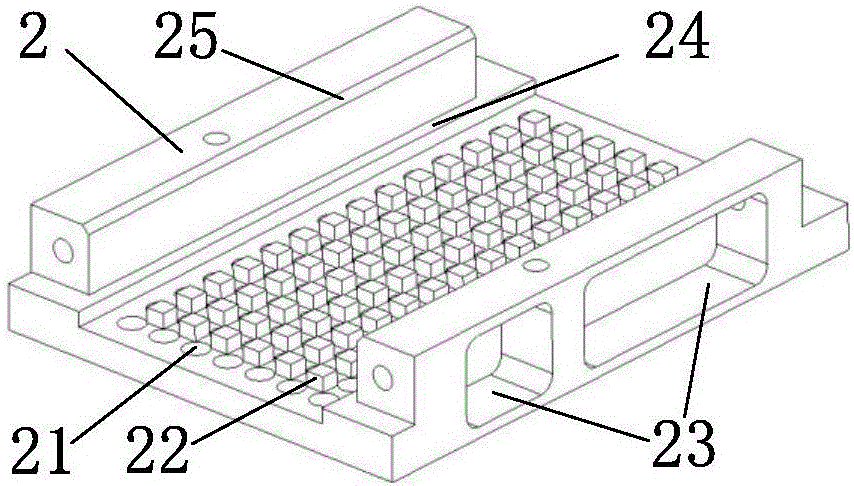

Manufacturing method, finished product and fixture of coplanar evaporators of multiple heat pipes

InactiveUS20110114293A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringFace flushing

In a manufacturing method, finished product and fixture of coplanar evaporators of multiple heat pipes, the method is first to provide a plurality of heat pipes, each of which has an evaporator formed a heated face thereon; then, the evaporators are moved closely to one another in a manner, such that their heated faces are disposed onto a flat face; next, the evaporators are limited from multiple directions; afterward, pressing the evaporators toward the flat face makes their heated faces flush therewith; finally, injecting a bonding media into the gaps among the heat faces of the evaporators bonds the heat faces together to form a fixedly coplanar configuration.

Owner:GOLDEN SUN NEWS TECHN +1

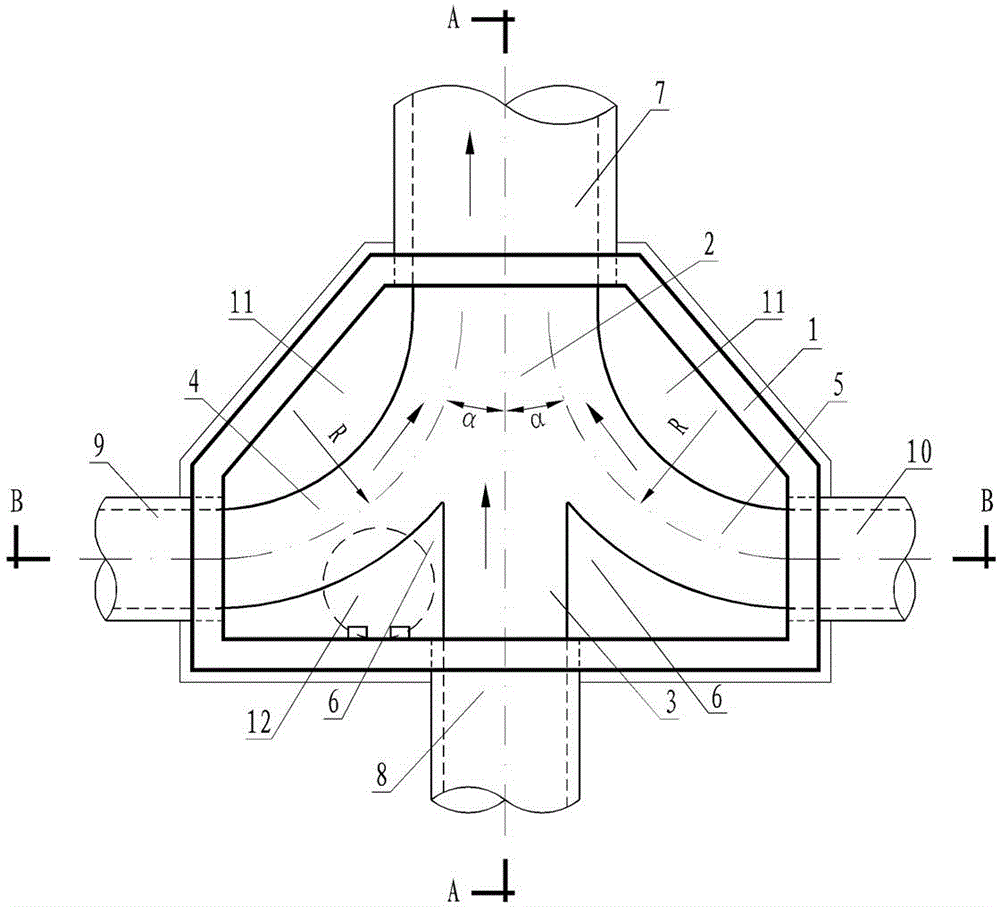

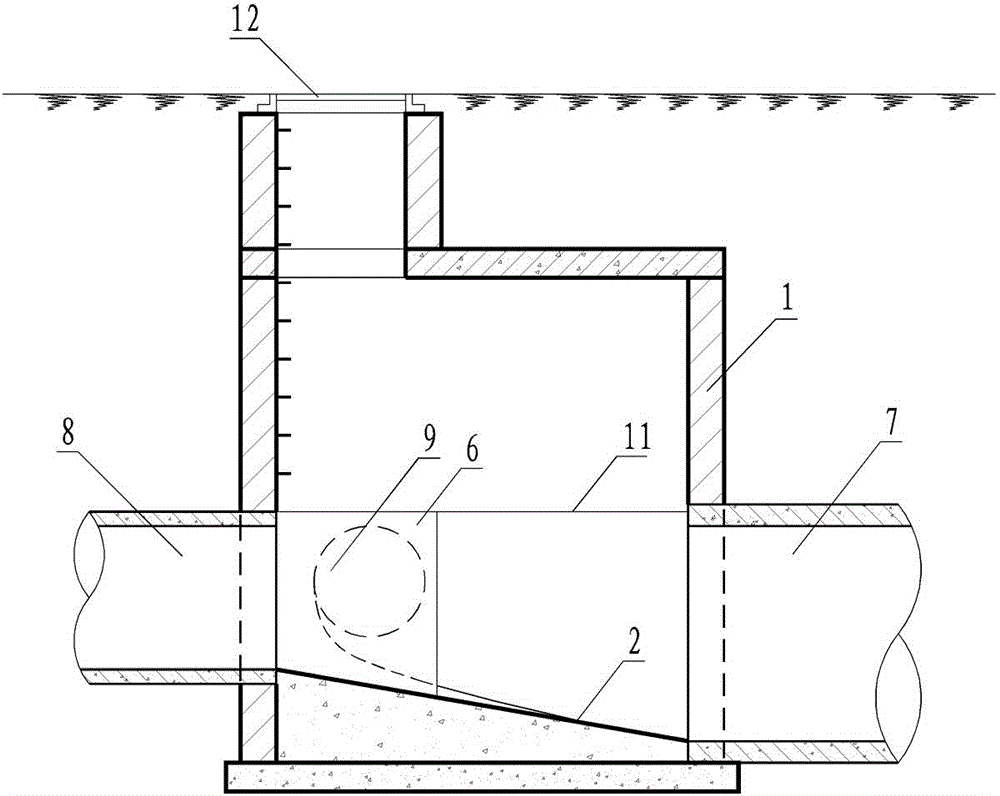

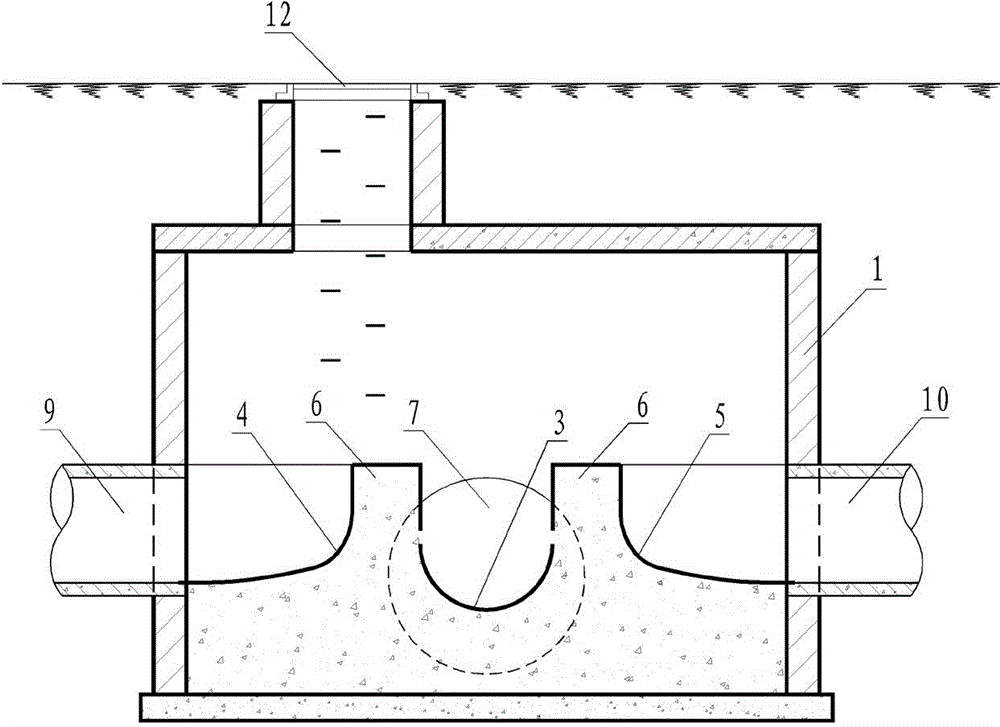

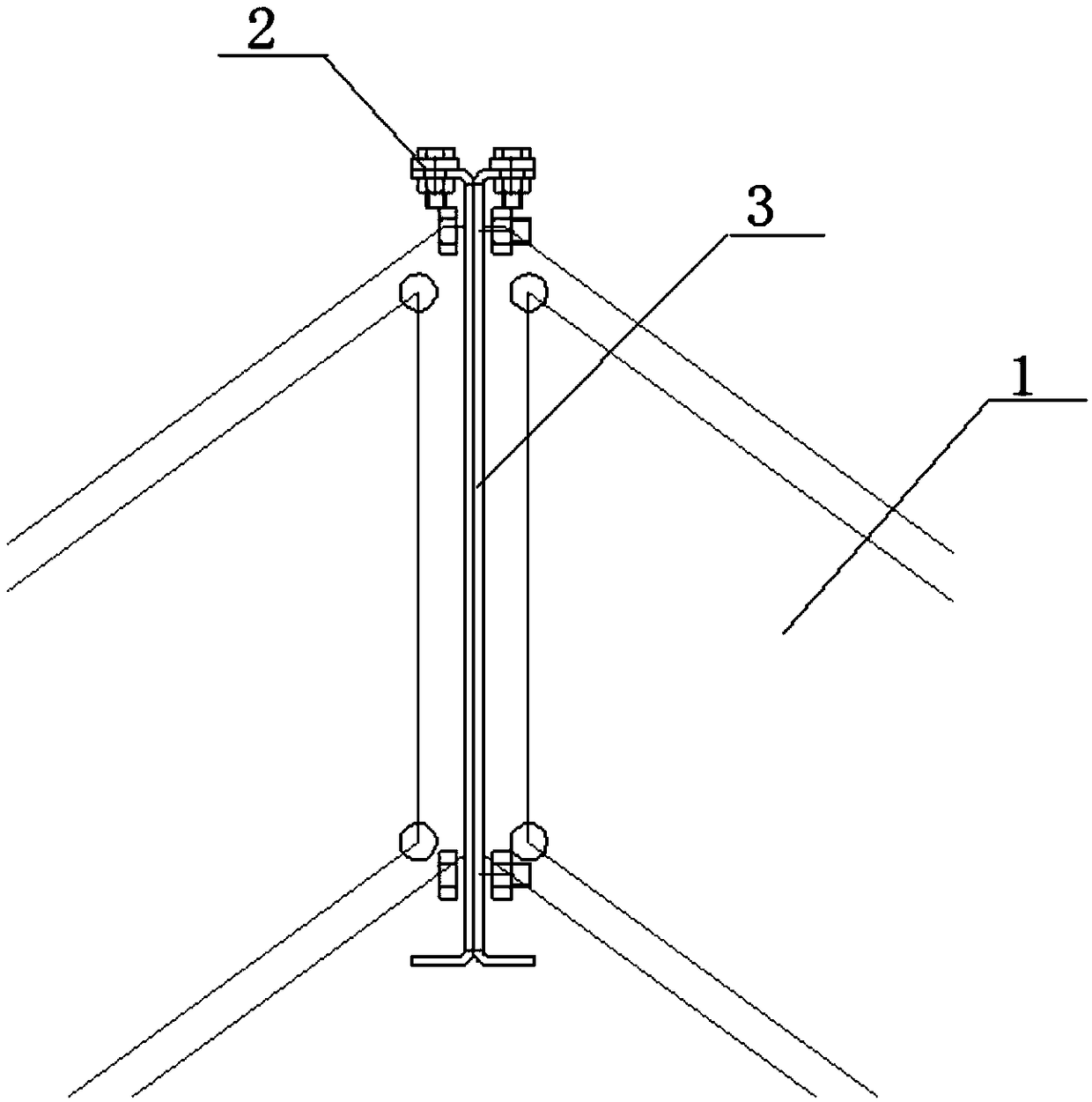

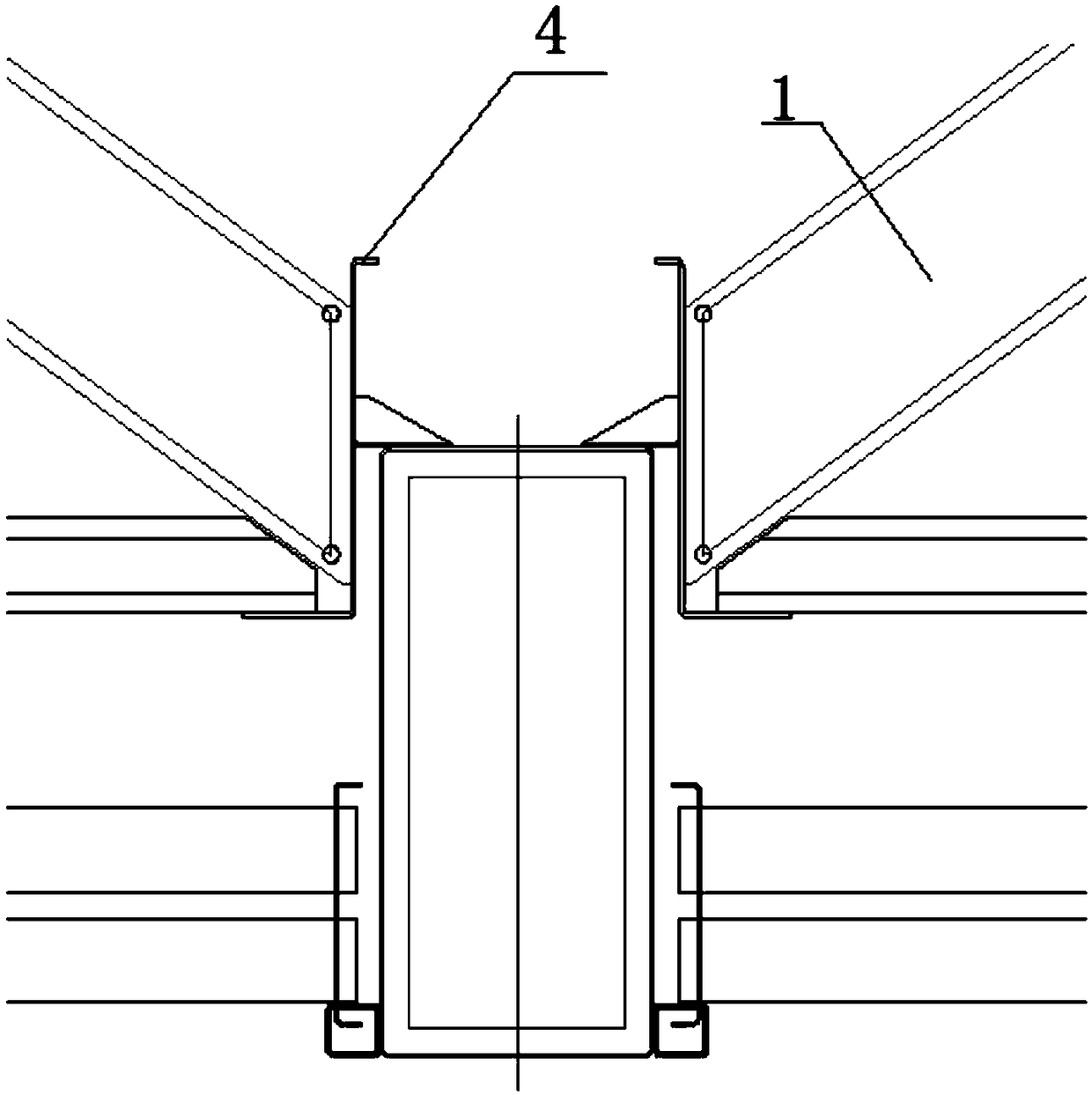

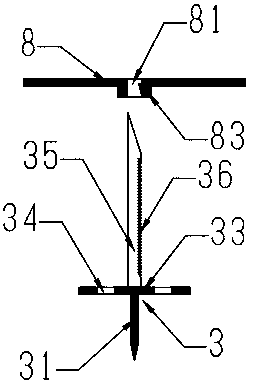

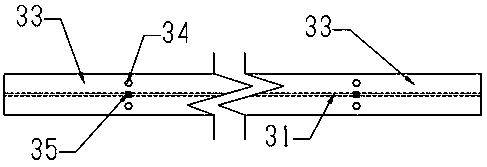

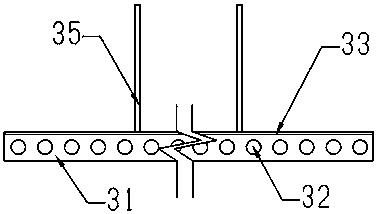

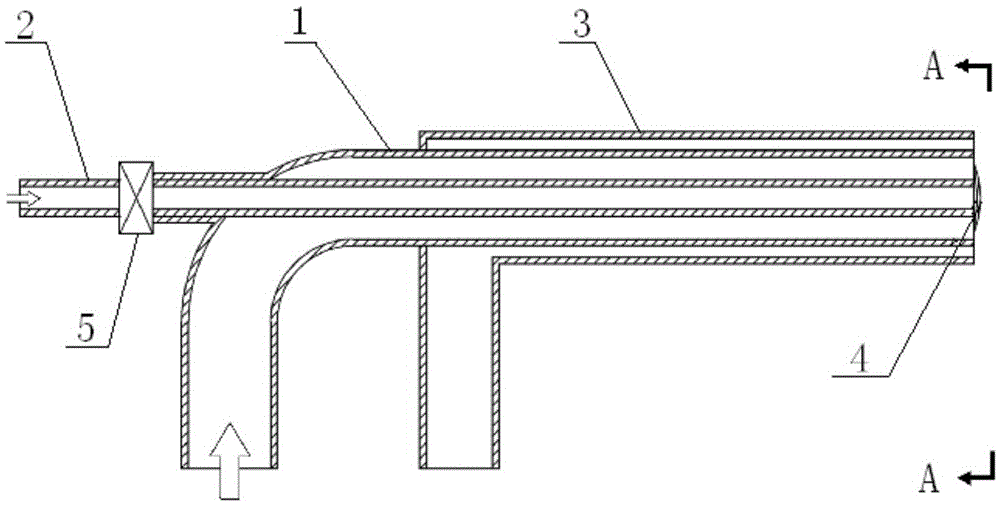

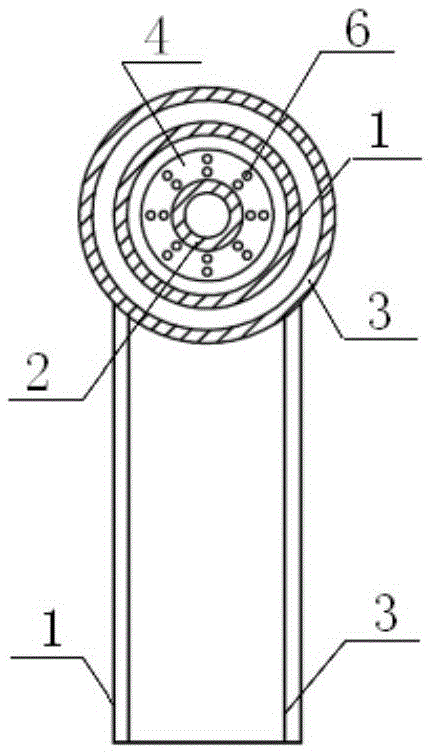

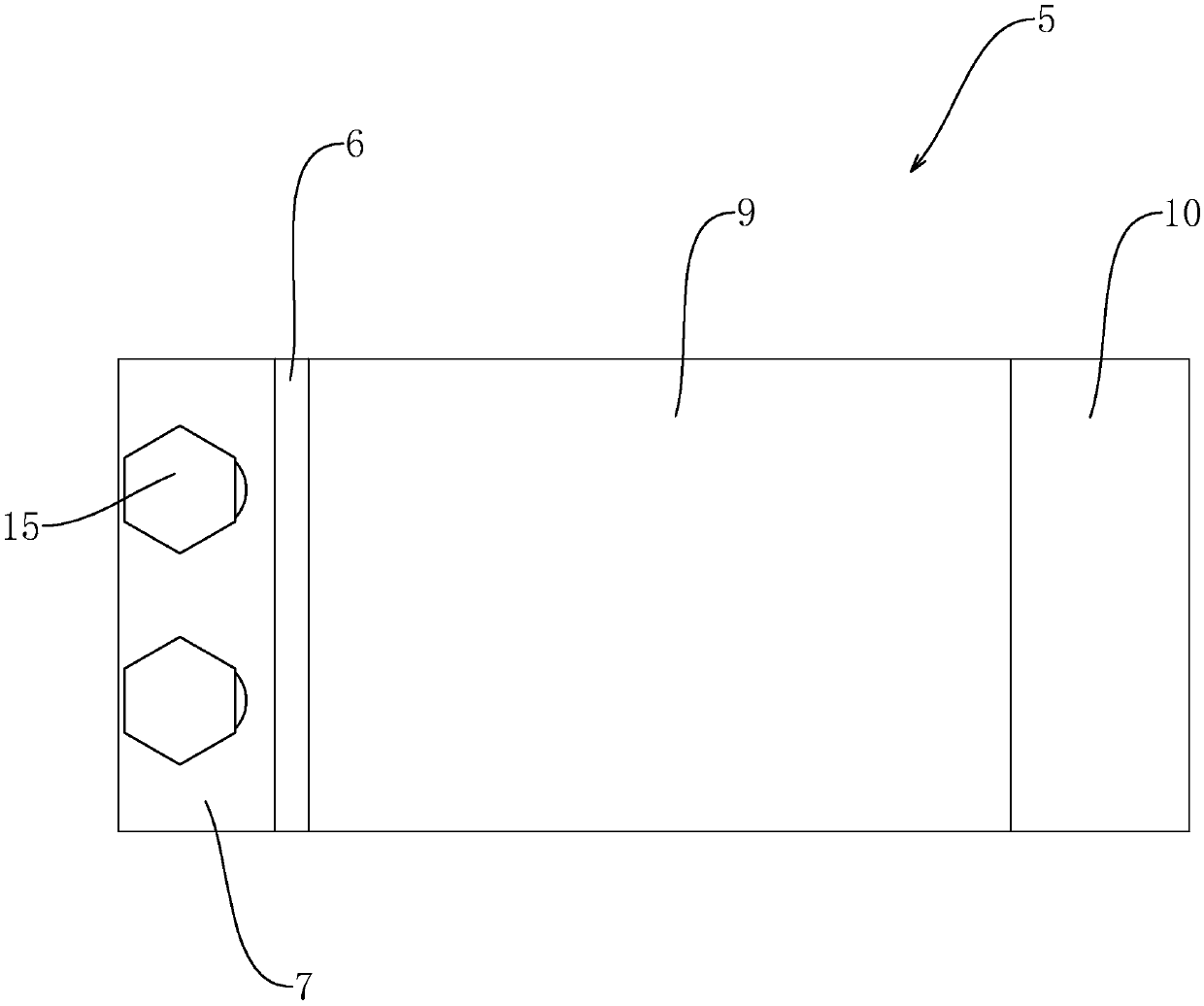

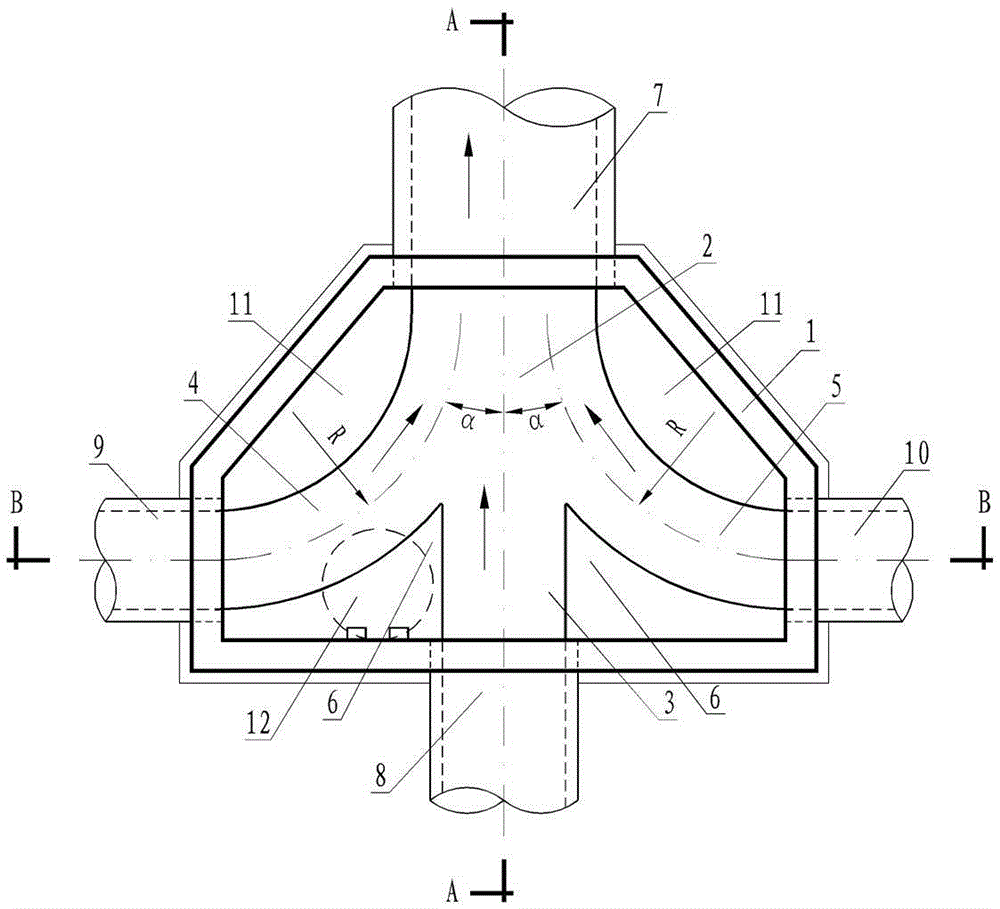

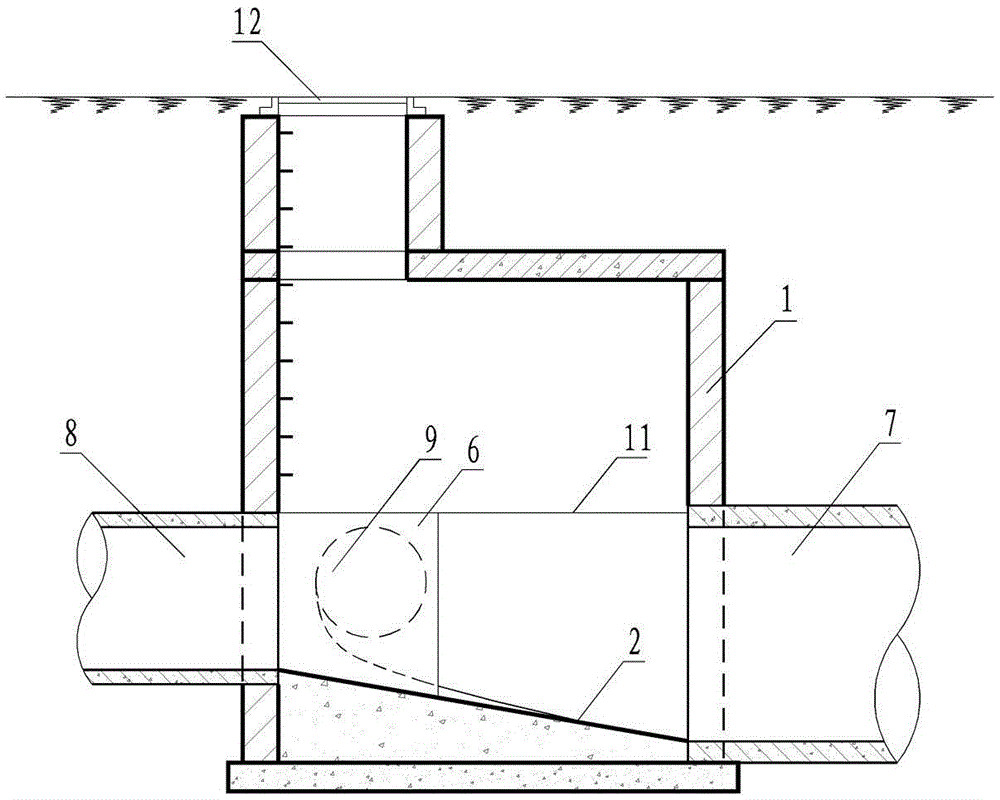

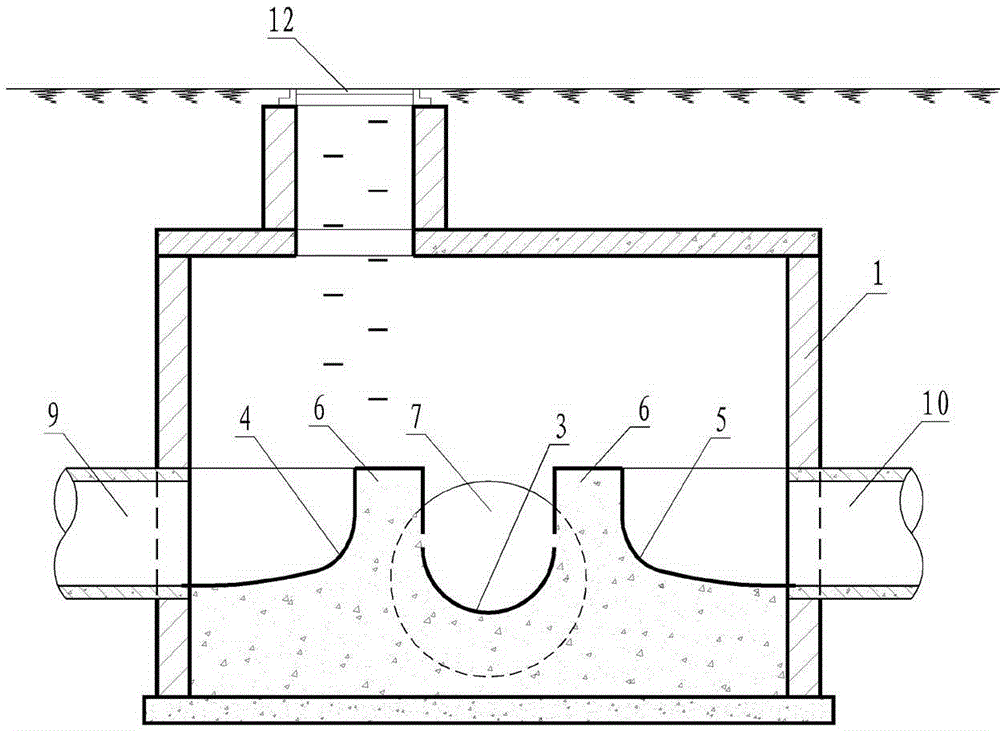

Water drainage cross inspection well preventing water face-to-face flushing

ActiveCN104018569AGive full play to drainage efficiencyReduce waterloggingSewerage structuresPipeflowWater flow

The invention discloses a water drainage cross inspection well preventing water face-to-face flushing, belongs to the field of water drainage projects and particularly relates to a rainwater and sewage convergence water drainage structure. The well is an intersection inspection well applicable to a rainwater or sewage pipeline. Branch pipes on the two sides of a water drainage pipeline are connected into the inspection well through sluices with large cornering radius, the sluices of the branch pipes on the two sides are spaced from a sluice of an upstream pipeline, and the included angle of afflux of the three sluices is small. The inspection well can prevent face-to-face flushing of water entering the inspection well, reduce turbulence flow to stabilize the water and bring the water drainage efficiency of the intersection inspection well into full play, thereby reducing the frequency of waterlogging of urban roads.

Owner:洛阳城市建设勘察设计院有限公司 +1

Methods and apparatus for marangoni substrate drying using a vapor knife manifold

ActiveUS8869422B2Drying using combination processesDrying solid materials with heatEngineeringFace flushing

The present invention provides methods and apparatus for a Marangoni vapor knife assembly. The assembly includes a base having a channel extending longitudinally through the base and a plurality of passages extending laterally from the channel toward an outer face of the base; a top plate adapted to be removeably coupled to the base with an outer face flush with the outer face of the base; and a shim adapted to be disposed between the base and the top plate and further adapted to form a plurality of spray orifices in the assembly. Numerous additional features are disclosed.

Owner:APPLIED MATERIALS INC

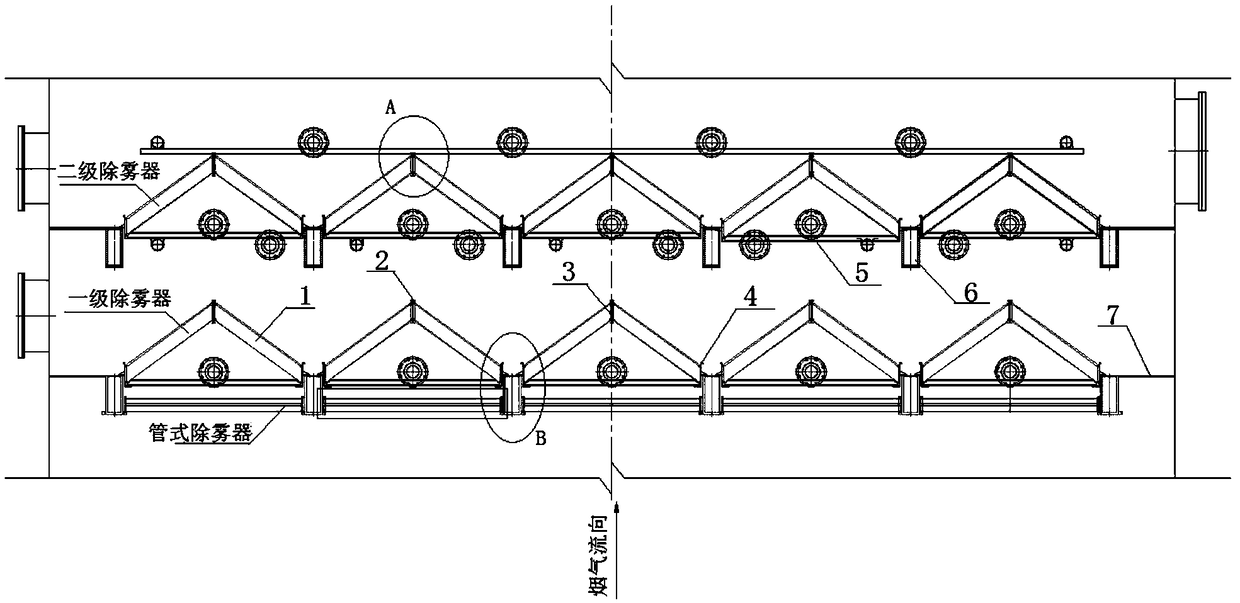

Alloy weir-type demister apparatus used for wet method flue gas desulphurization system

The invention discloses an alloy weir-type demister apparatus used for wet method flue gas desulphurization system. The alloy weir-type demister apparatus used for wet method flue gas desulphurizationsystem comprises a primary demister system, a secondary demister system and a flushing system, the primary demister system and the secondary demister system comprises several alloy weir-type demistercomponents, the alloy weir-type demister components are an independent unit structure, the alloy weir-type demister components comprises two alloy demister blades, a frame and a support block, the alloy demister blades are connected with the frame through a plugging mode to form a weir-type demister module, the weir-type demister module is erected on a support beam through the support block, theflushing system is arranged at an upper side and a lower side of the alloy weir-type demister components, and double-face flushing is formed on the demister components.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

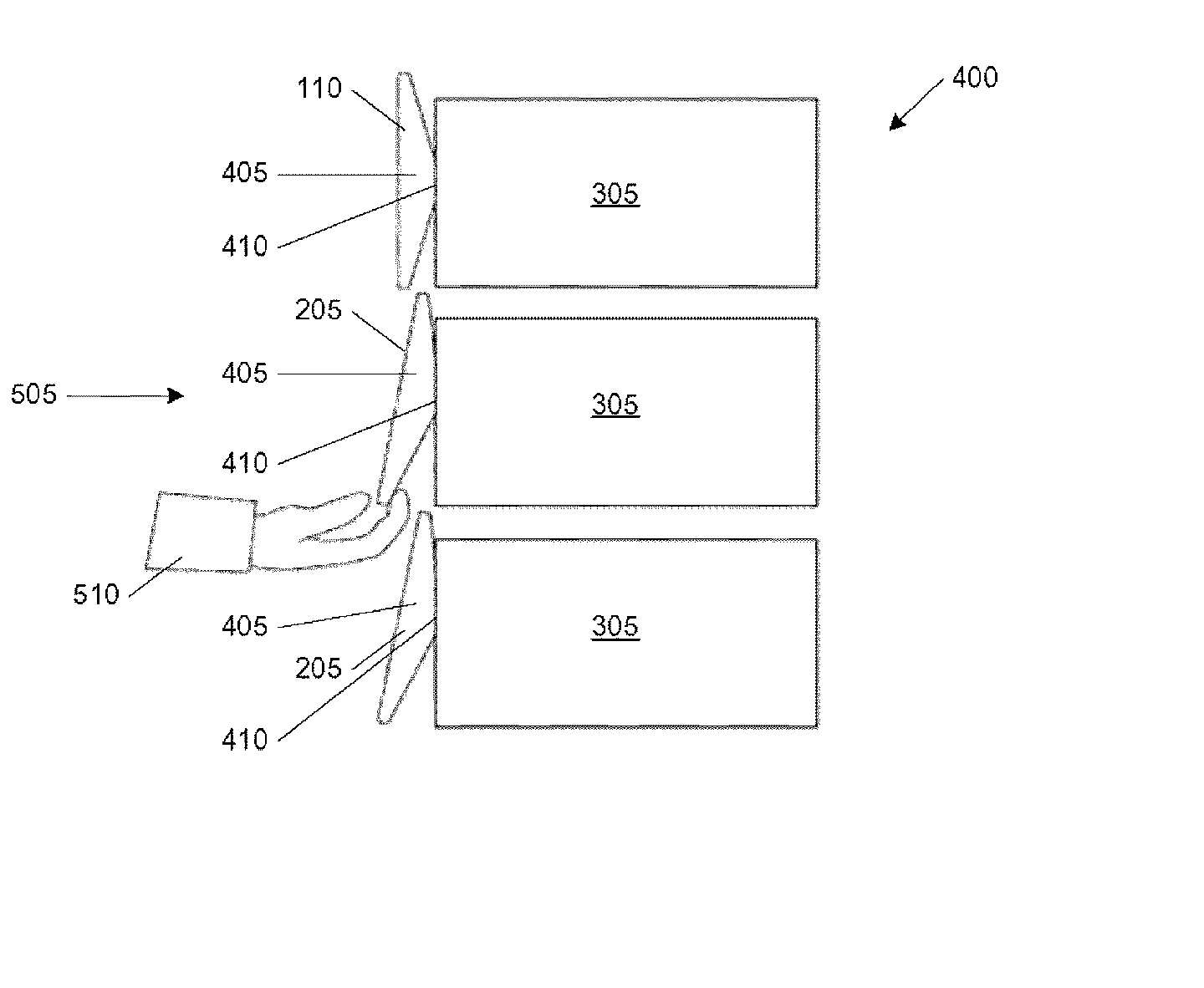

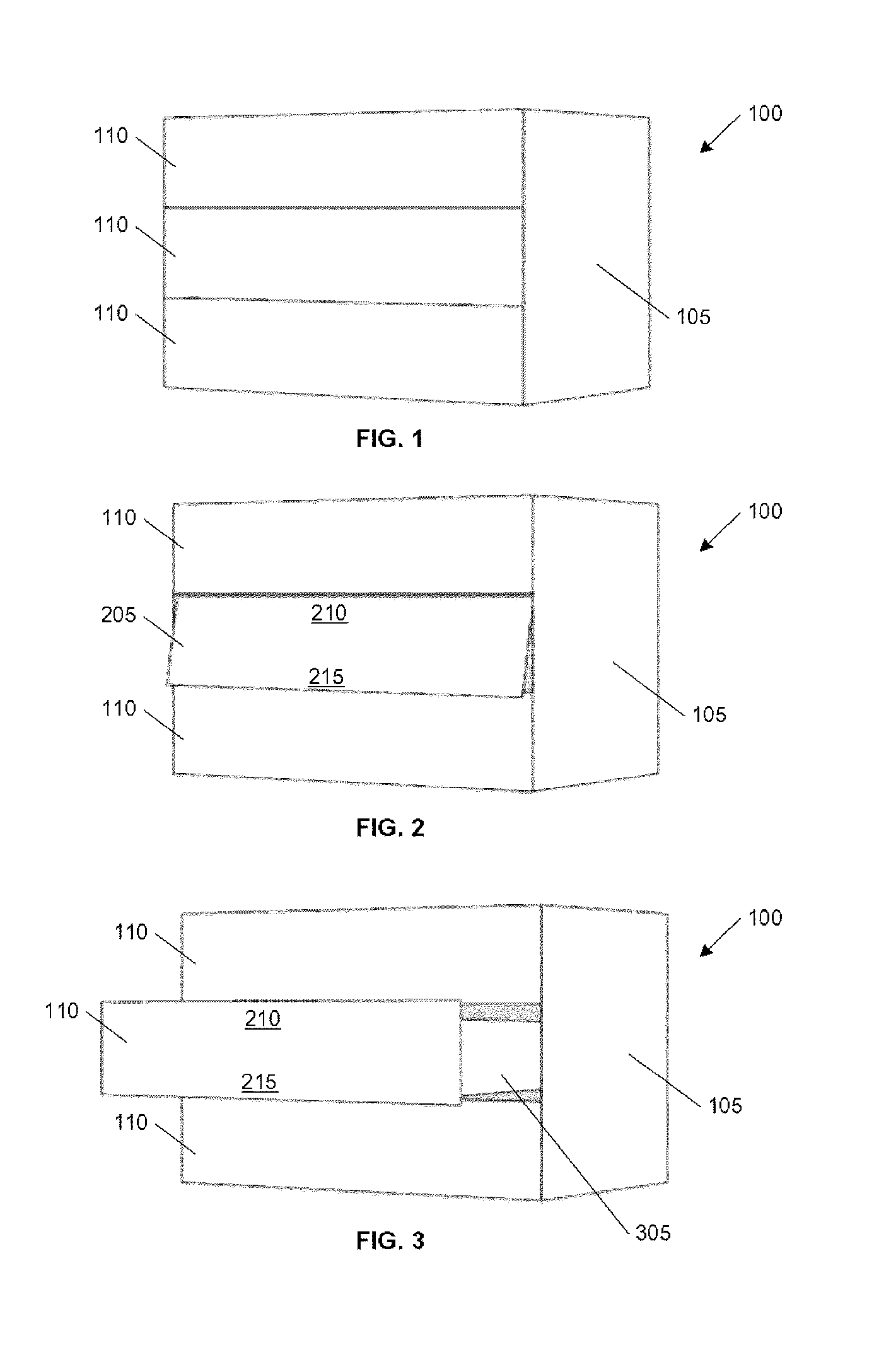

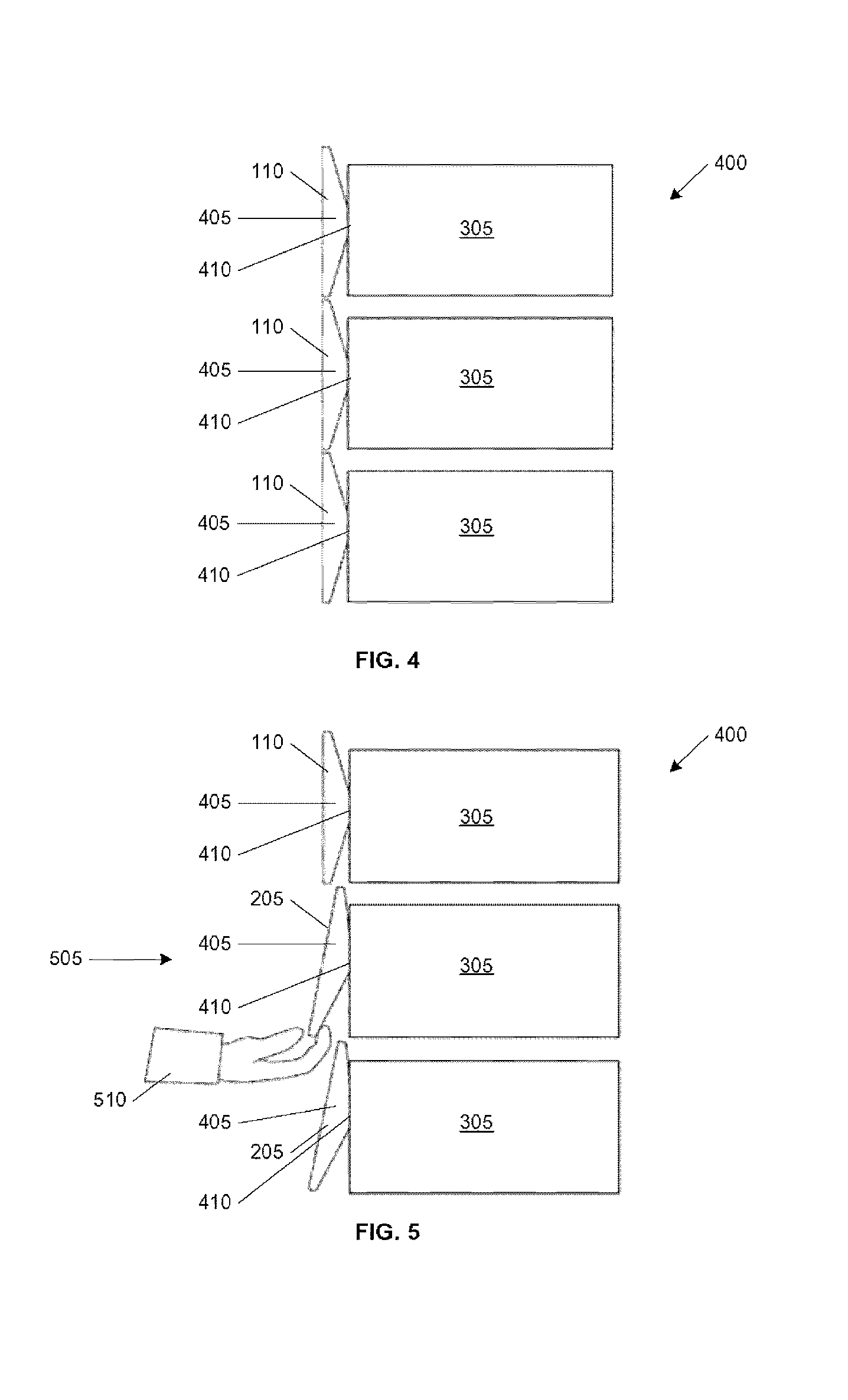

Pivoting Drawer Face

An apparatus, system, and method for providing an opening solution for drawers and similar enclosure systems that permit no visible external hardware or gripping elements / surfaces that may be easily used irrespective of a size or weight of the drawer or enclosure. An apparatus includes a housing including an exterior wall having a portion defining an opening; a drawer translatably mounted within the housing, the drawer moveable between a closed position wherein a storage space within the drawer is inaccessible from outside the housing, and an open position wherein the drawer extends out of the housing through the opening such that the storage space is accessible, the drawer including a drawer face moveably coupled to a drawer body including the storage space with the drawer face free of any externally accessible handle when the drawer is in the closed position, the drawer face having a perimeter conforming closely to a perimeter of the opening of the housing when the drawer is in the closed position, wherein the drawer face includes an edge exposing mode and an edge concealing mode with the edge concealing mode providing the drawer face flush with the portion of the exterior wall in the closed mode with no gripping surface to extend the drawer from the closed mode to the open and wherein the edge exposing mode pivoting the drawer face so it is not flush with the portion of the exterior wall and exposes an edge of the face in the closed mode for use in extending the drawer from the closed mode to the open mode.

Owner:CHEN DEREK

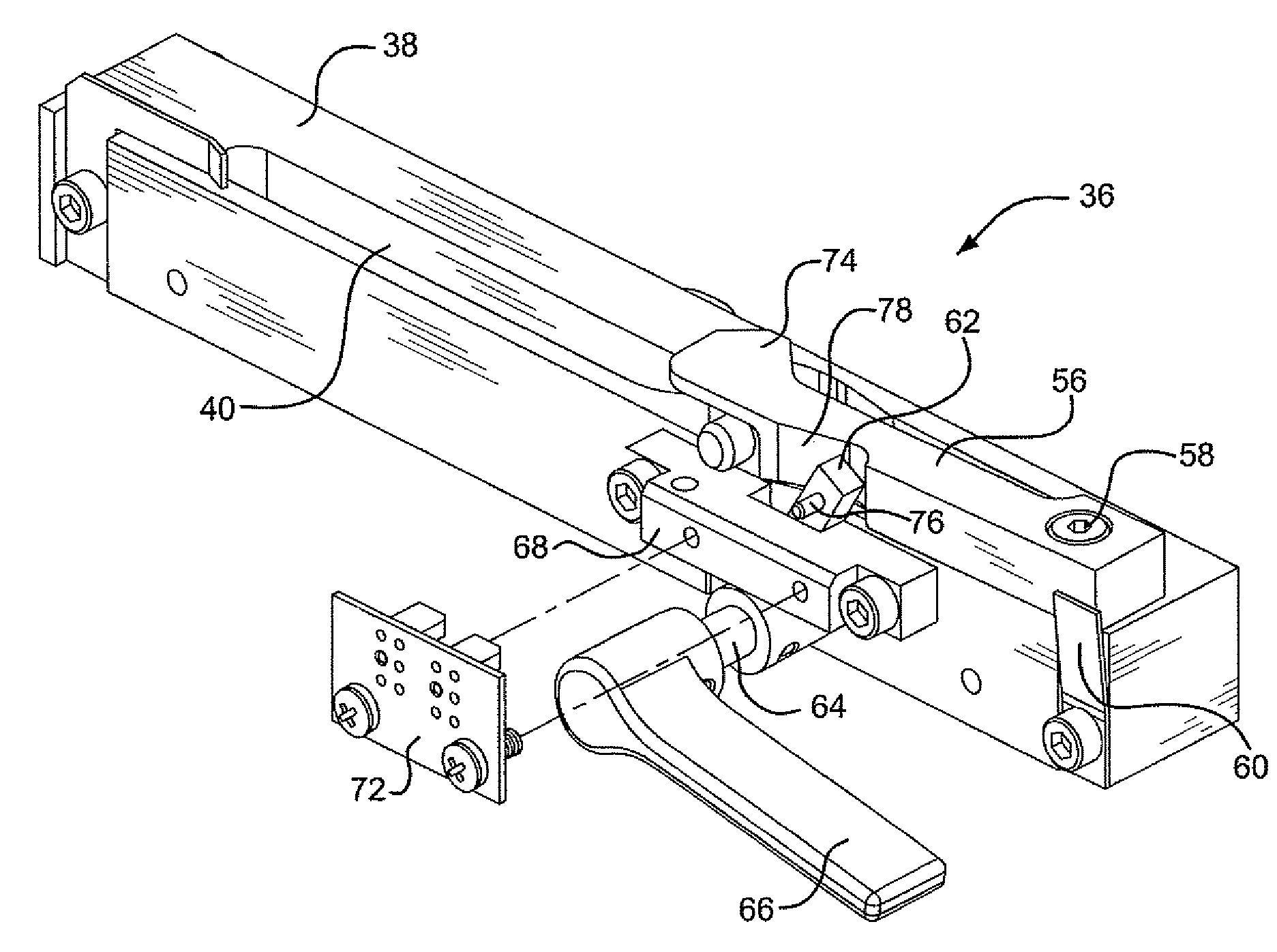

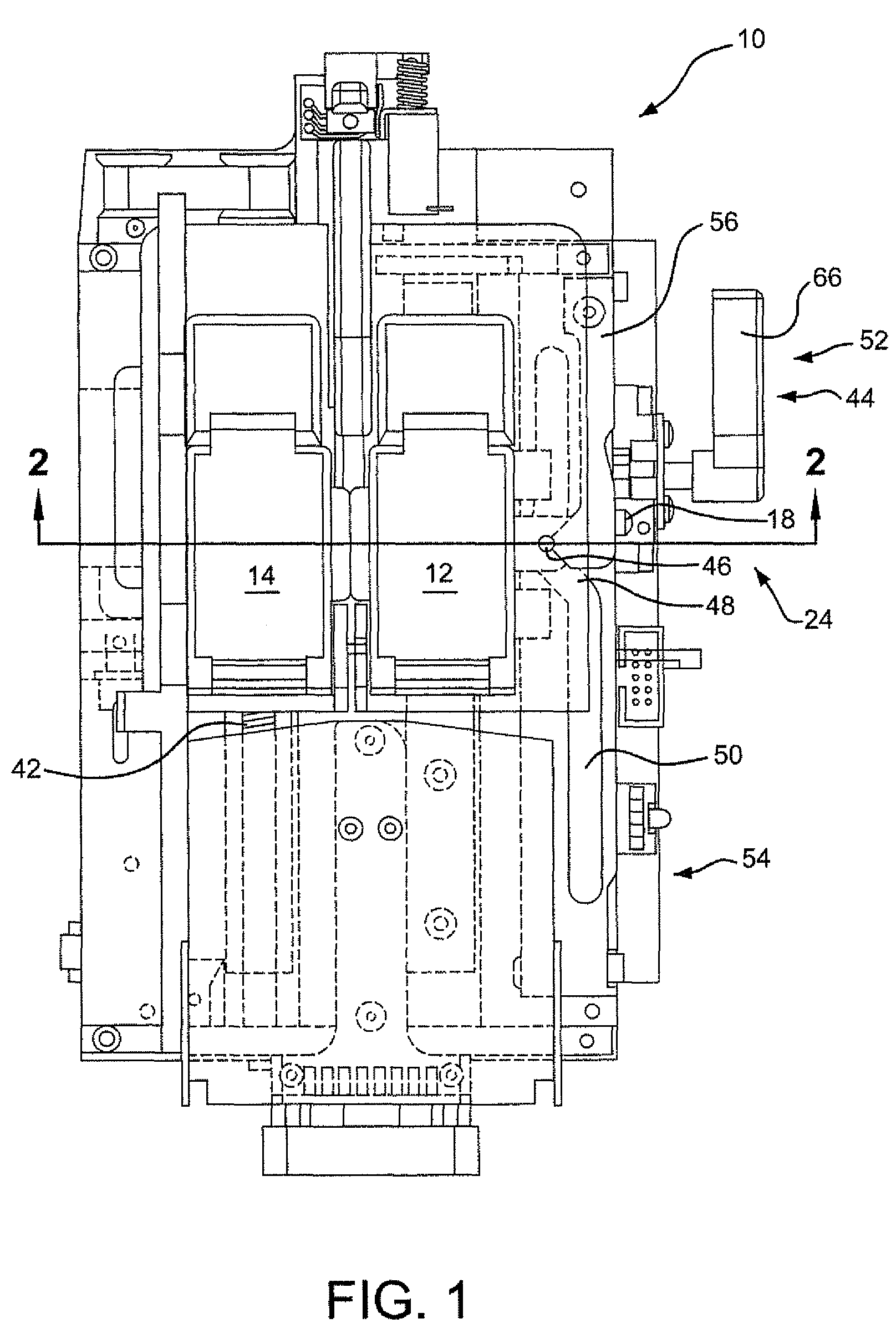

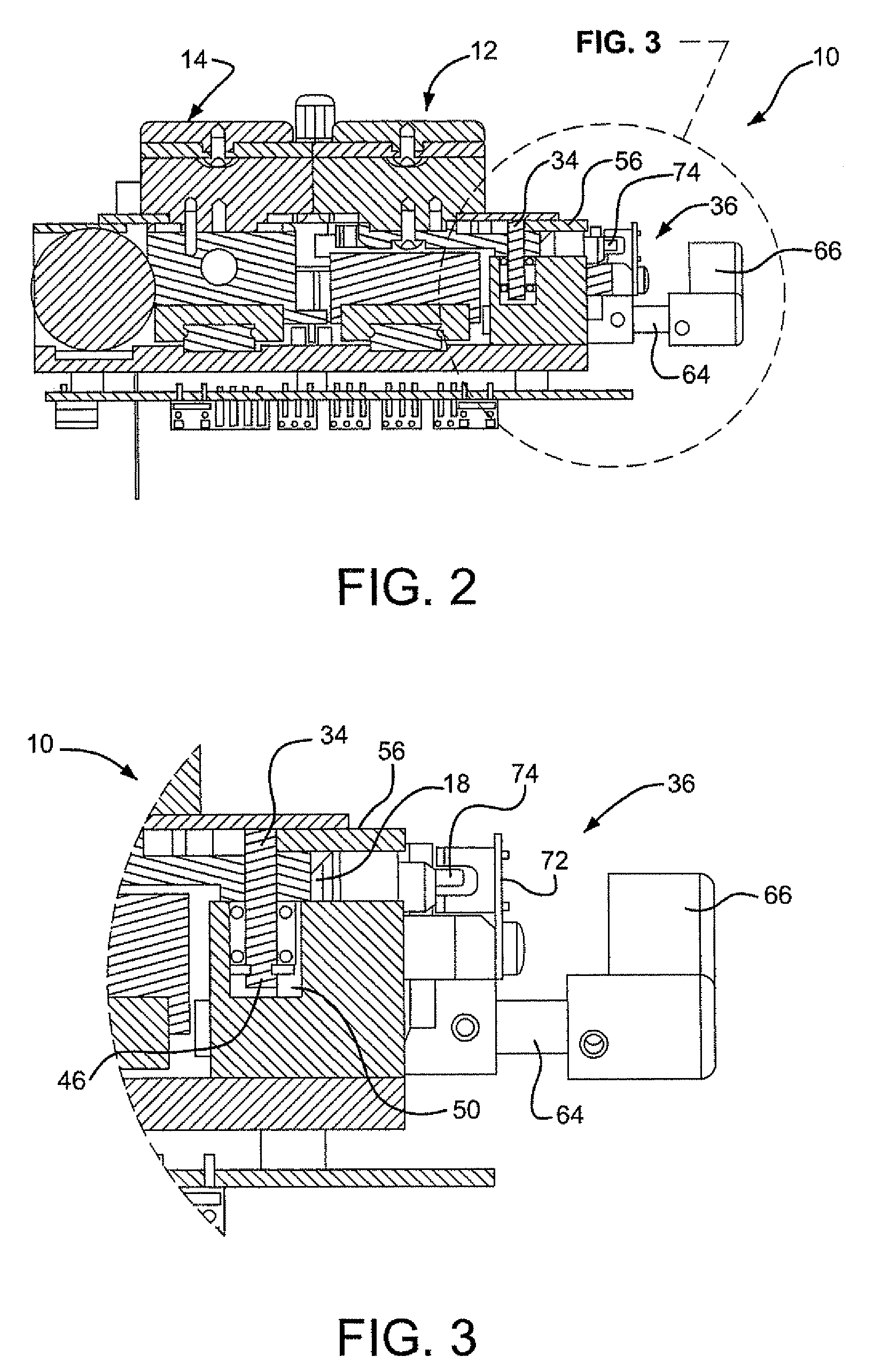

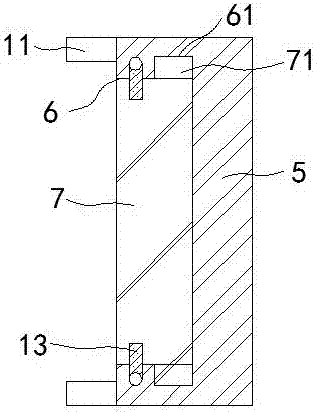

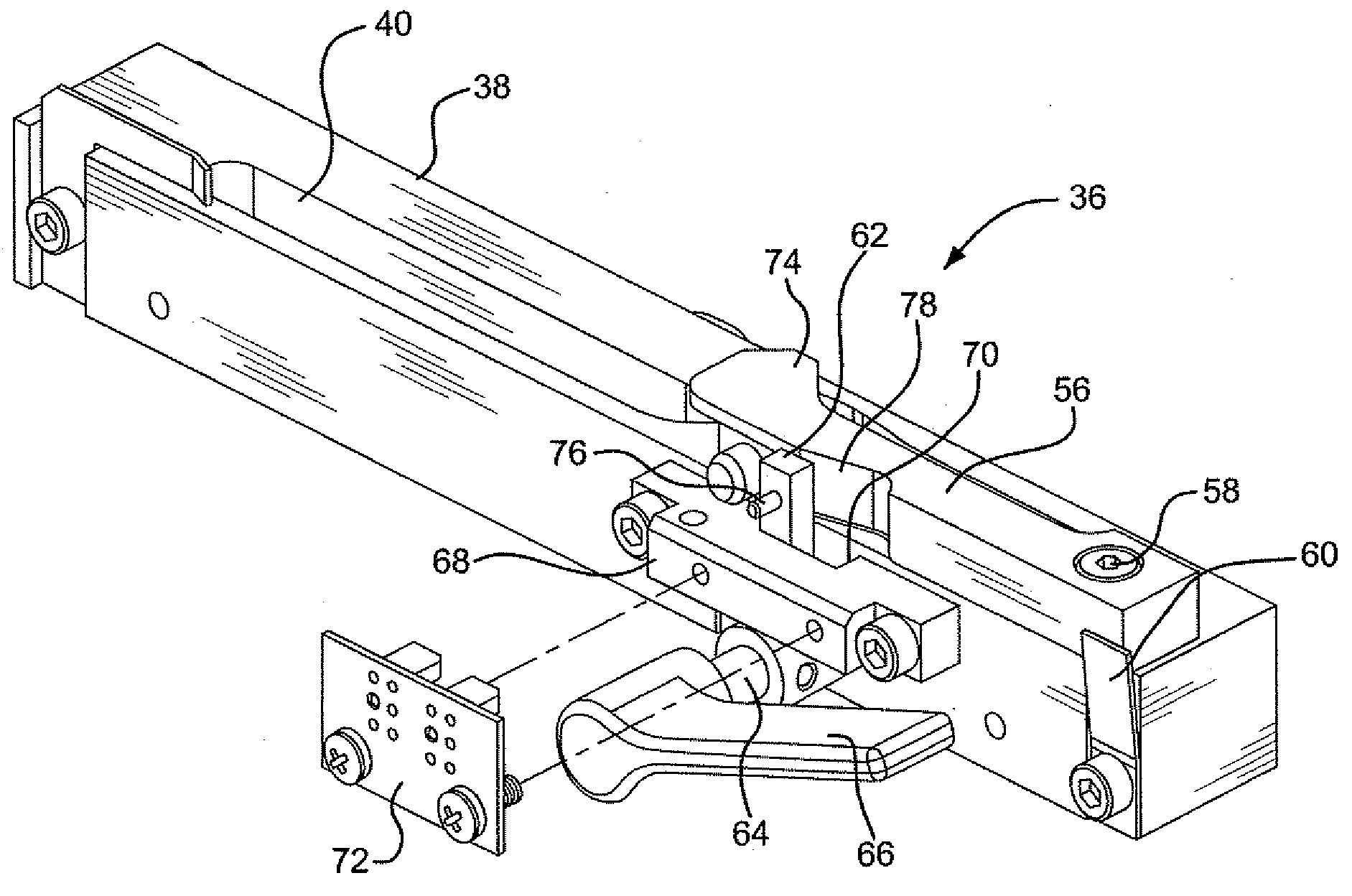

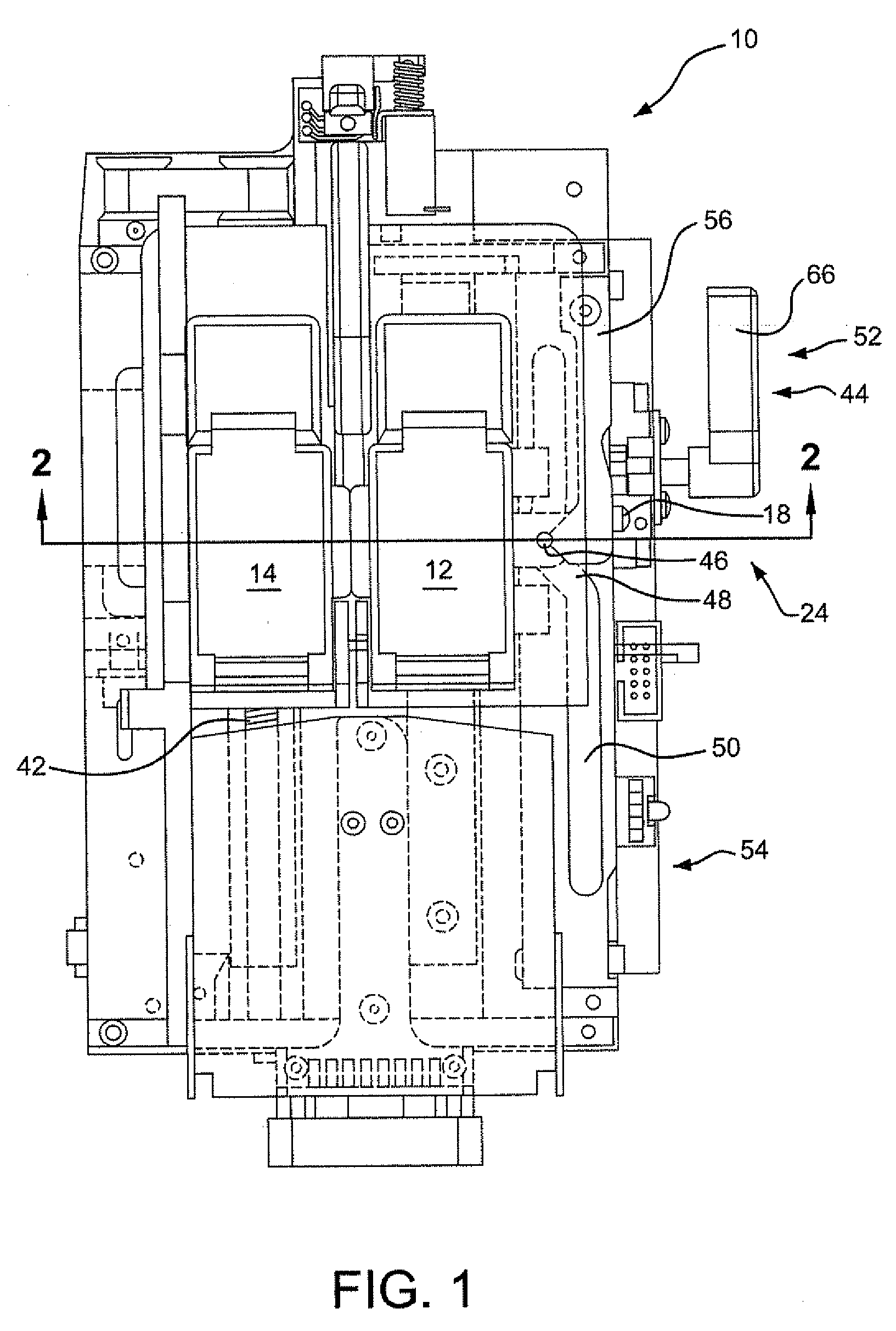

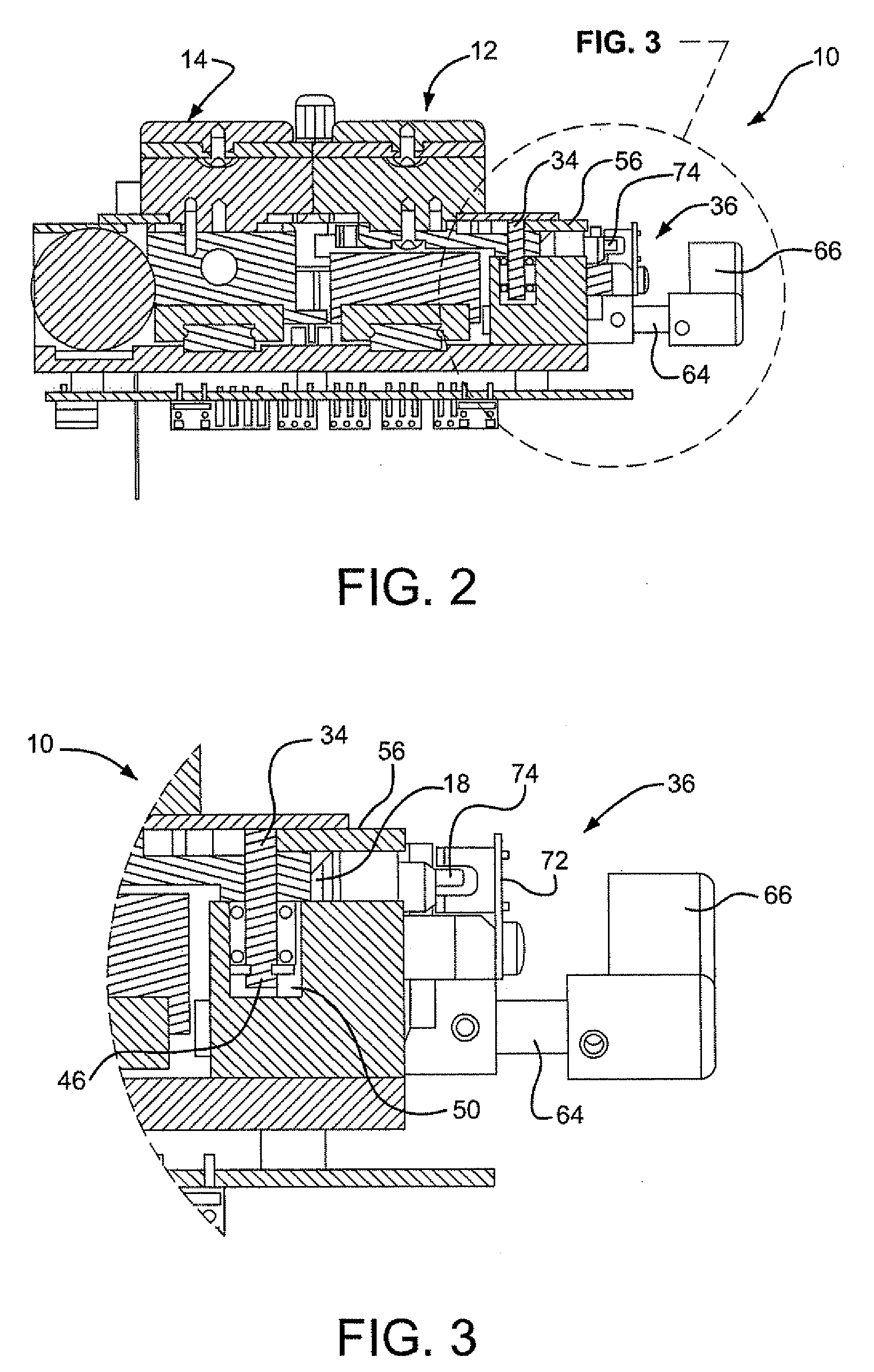

Clamp locking mechanism in device for welding plastic tubes

ActiveUS8066269B2Promote sportsWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

Owner:GENESIS BPS

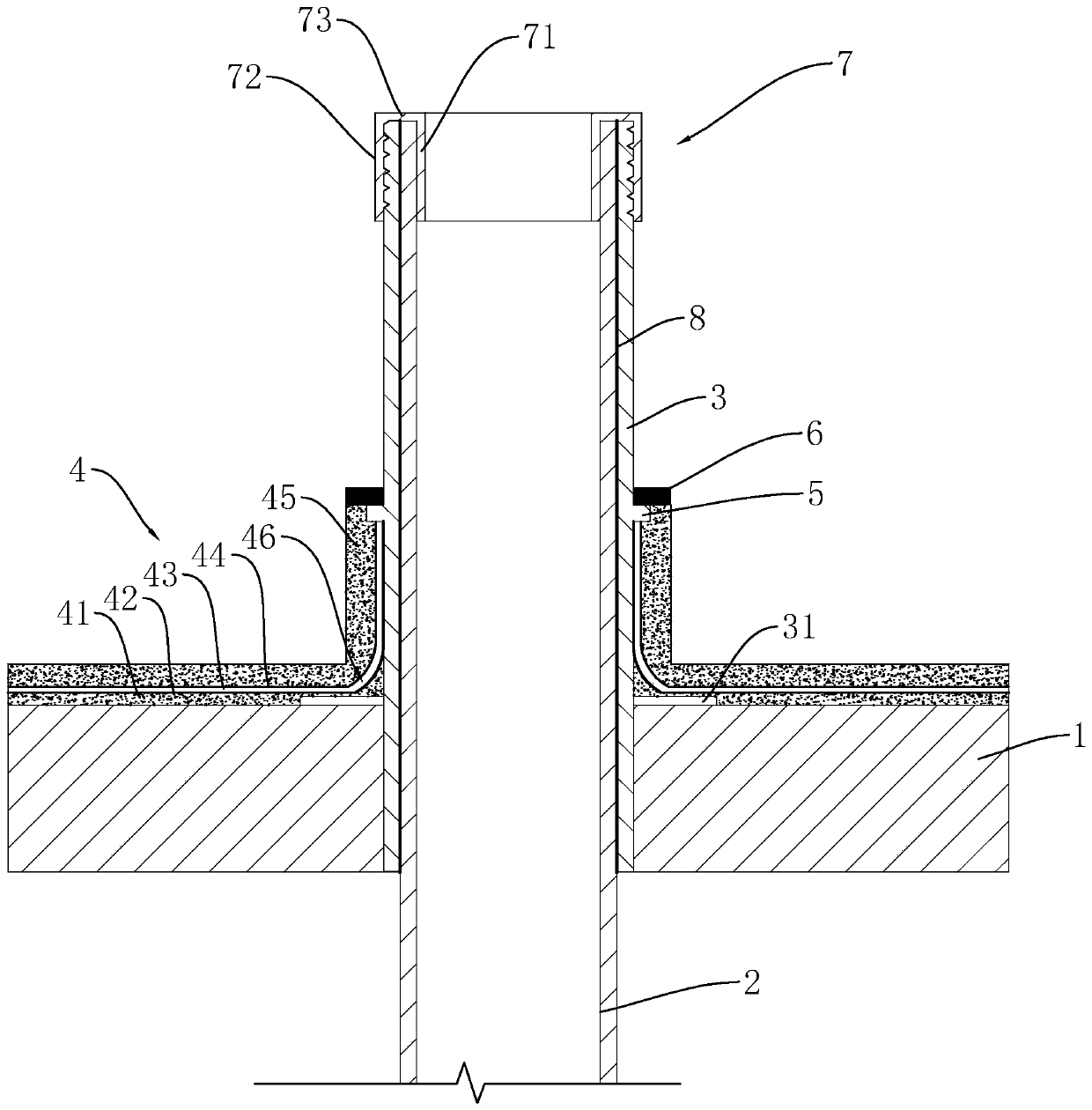

Roof outlet pipeline waterproof structure and construction method thereof

ActiveCN110397225AImprove waterproof performanceAvoid the problem of water seepageRoof coveringPipesArchitectural engineeringFace flushing

The invention relates to a roof outlet pipeline waterproof structure, and relates to the technical field of roof waterproofness. The structure comprises a pipeline protruding out of a roof, the pipeline is sleeved with a waterproof casing pipe, a flanging attached to the roof is fixedly arranged on the waterproof casing pipe, the waterproof casing pipe and the top of the pipeline are in seal connection through a connecting part, a waterproof layer is arranged outside the waterproof casing pipe, one end of the waterproof layer extends to the roof, the other end of the waterproof layer wraps thewaterproof casing pipe upwards, the waterproof layer sequentially comprises an inner bonding mortar layer, a waterproof coiled material, an outer bonding mortar layer, an alkali-resisting fiberglassgridding cloth and a concrete protection layer from inside to outside, the two ends of the concrete protection layer extend out of the waterproof coiled material and the alkali-resisting fiberglass gridding cloth, an annular protrusion with the top face flush with the top face of the concrete protection layer and inserted into the concrete protection layer is fixedly arranged on the outer side ofthe waterproof casing pipe, and a sealant is arranged on the annular protrusion and the top face of the concrete protection layer. The structure has the advantages of being convenient to mount and good in anti-seepage effect.

Owner:北京世纪金鳄建筑装饰有限公司

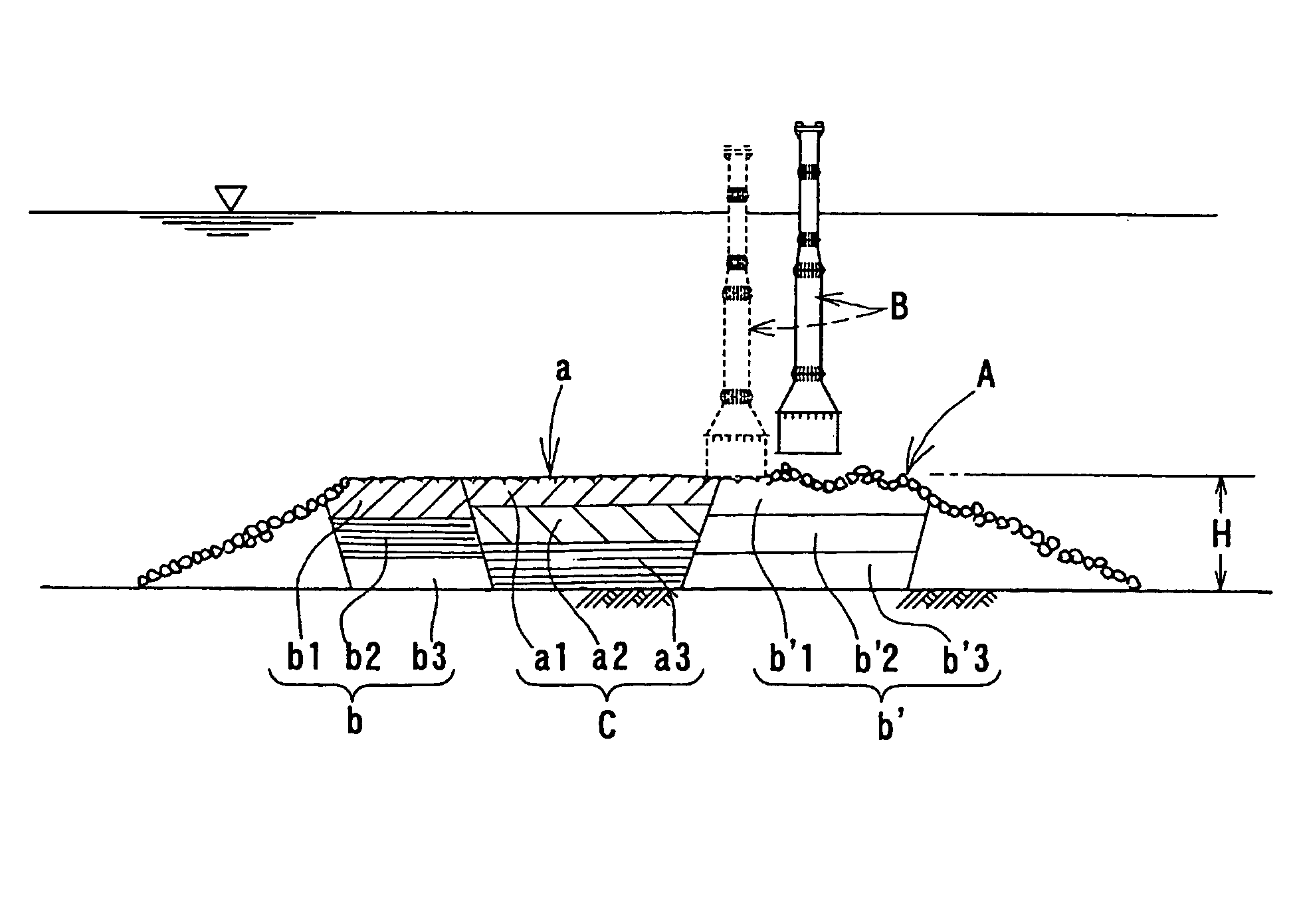

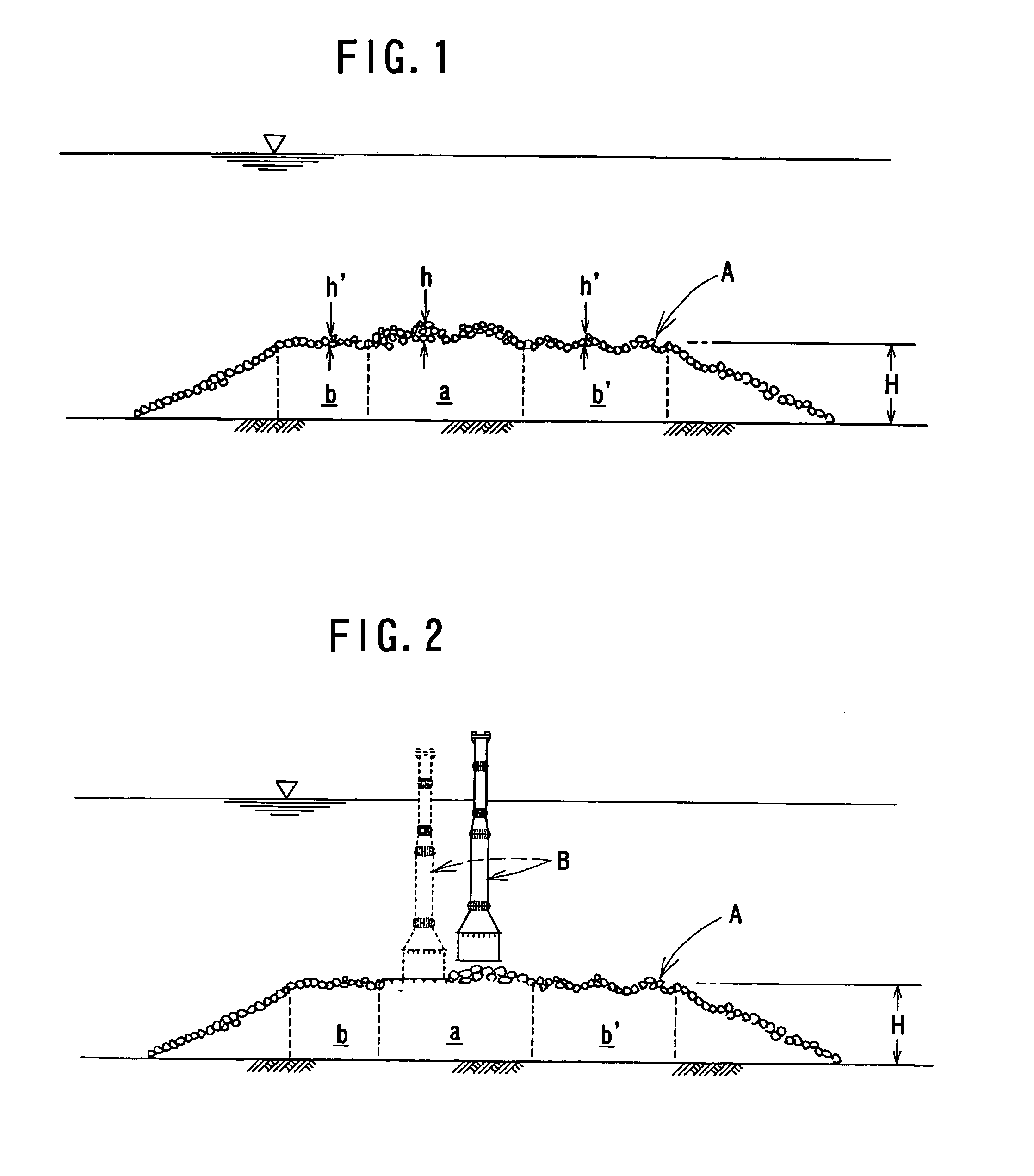

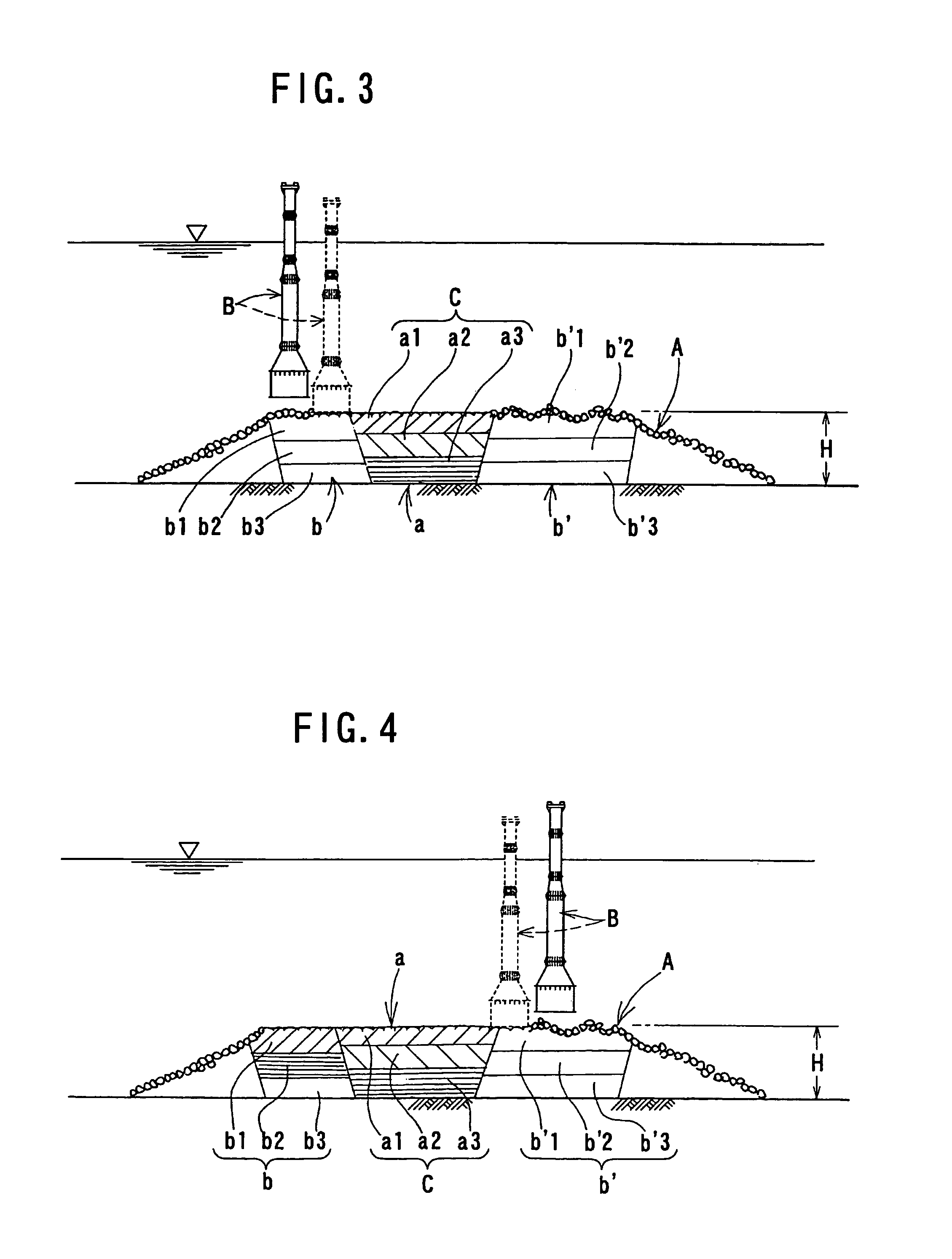

Underwater riprap foundation and consolidation smoothing method therefor

ActiveUS6997649B1Efficient constructionReduce the amount requiredMarine site engineeringCaissonsFree fallingLow load

An underwater riprap foundation which can be constructed efficiently using a reduced amount of ripraps and a consolidation smoothing method for efficient construction of the same are disclosed. The underwater riprap foundation includes a first region for supporting comparatively high load from a structure such as a caisson, and a second region positioned adjacent the first region for supporting comparatively low load from mulch blocks or the like. The first region is formed as a rigid riprap core wall body having a consolidation density higher than that in the second region. The first and second regions have top faces flush with each other. In construction, ripraps are thrown into water such that the extra-banking height in the first region is higher than in the second region, and free fall of a weight is repetitively carried out to the first and second regions to consolidate the ripraps.

Owner:SAITO KIYOSHI

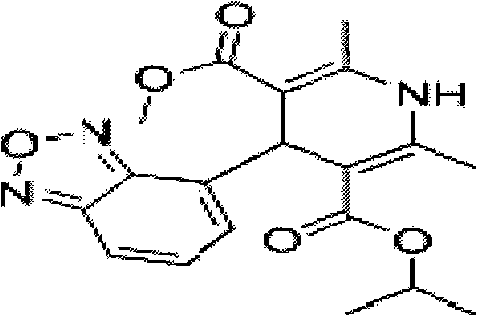

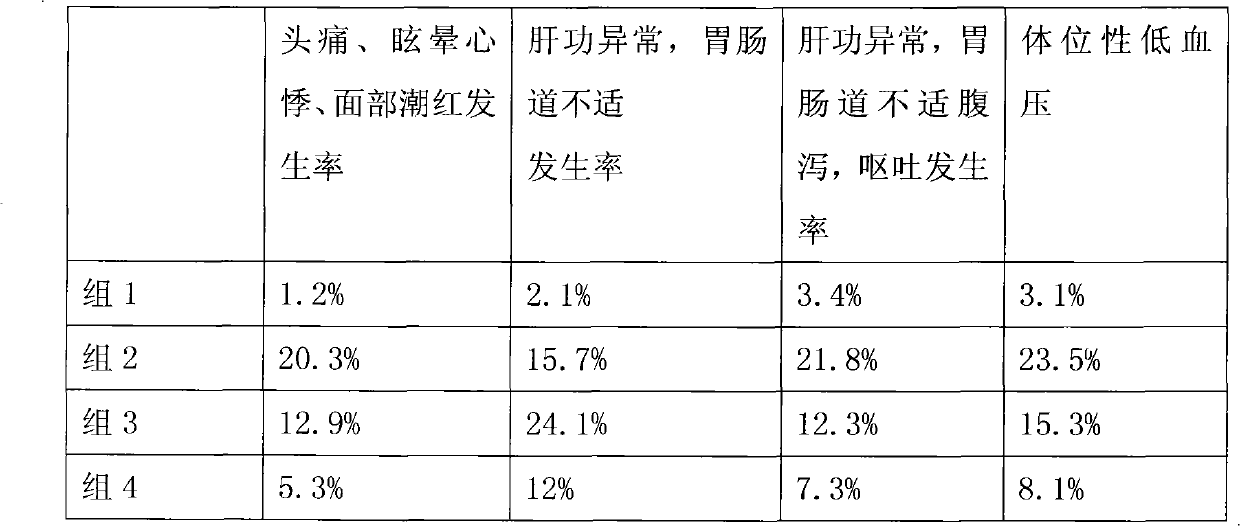

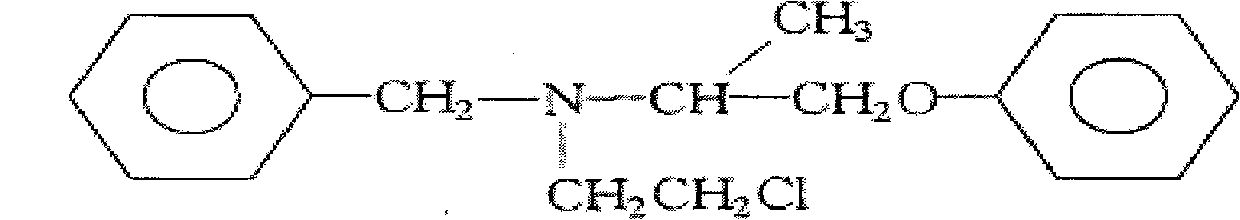

Ointment for treating high blood pressure and preparation method thereof

InactiveCN101947222AFast absorptionImprove bioavailabilityOrganic active ingredientsAerosol deliverySide effectMedicine

The invention relates to a western medicament ointment for treating high blood pressure and preparation method thereof, wherein the ointment contains 10 to 60 weight parts of reactive compounds including isradipine. The preparation method comprises the following steps of: 1) mixing base materials in percentage by weight, heating the mixture at 60 to 90 DEG C and stirring to dissolve the mixture; 2) grinding and sieving the reactive compounds, then adding the reactive compounds into the mixture obtained by the step 1) and stirring for 15 to 25 minutes, and lowering the temperature to 20 to 60 DEG C to obtain finished products. The ointment can be absorbed by human body through skin, and the synergy of active compounds can greatly improve the bioavailability of the ointment; moreover, the ointment has a great degree of security and a few side effects and avoids the symptoms including headache, vertigo, cardiopalmus and face flush basically.

Owner:北京水圣木科技有限责任公司

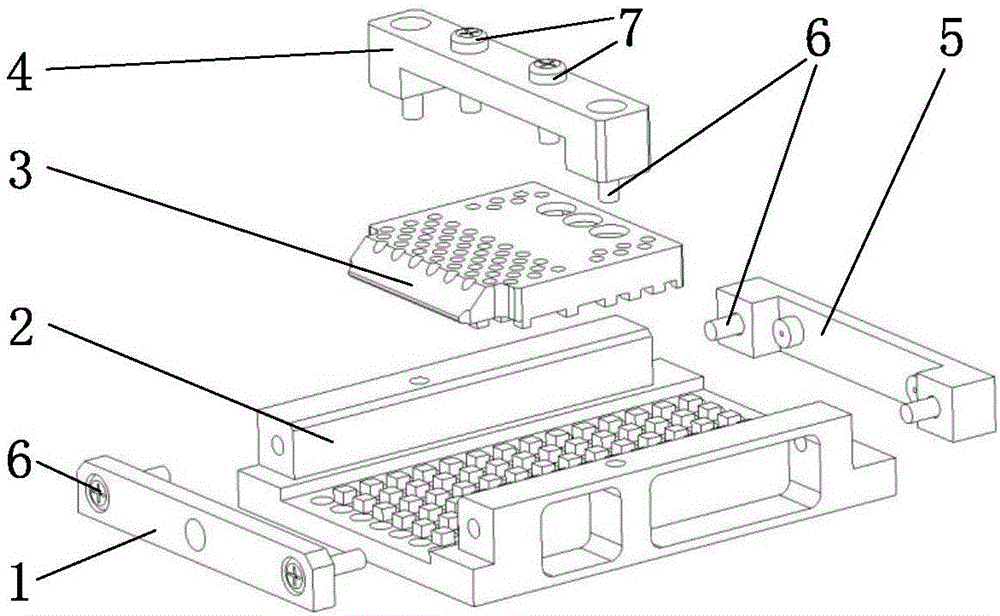

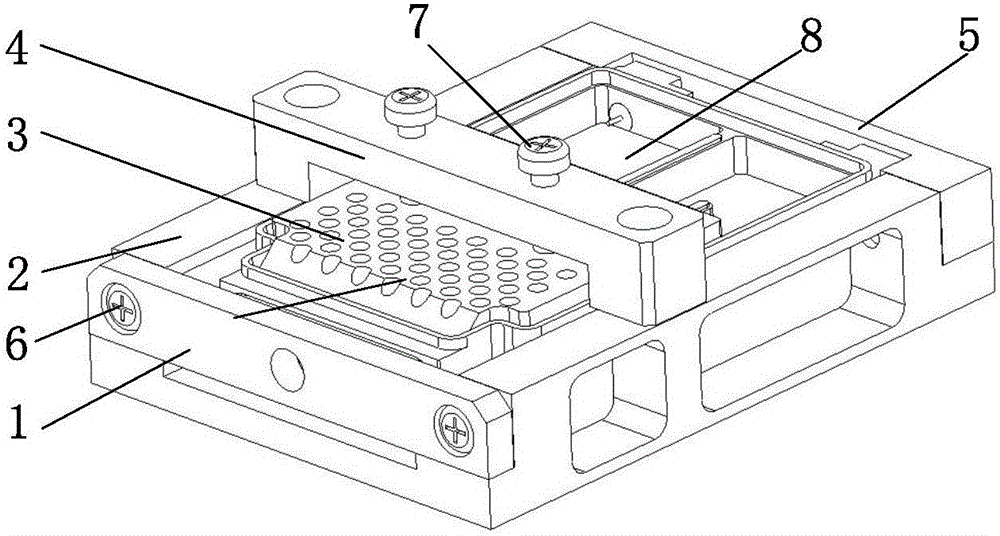

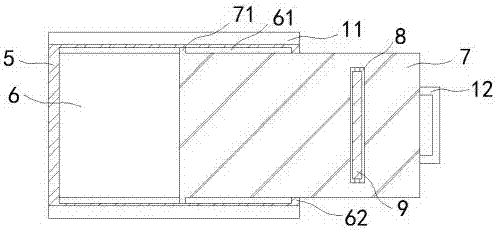

Microwave assembly welding device

ActiveCN106271327AImprove welding flatnessStrong penetrating powerWelding/cutting auxillary devicesAuxillary welding devicesMicrowave substrateEngineering

The invention discloses a microwave assembly welding device used for welding a microwave assembly comprising a box body, a microwave substrate, glass beads and a connector. The microwave assembly welding device comprises a base, a left pressing block, a right pressing block, an upper pressing block and a cross beam. The left pressing block is fixedly connected with the base and used for pressing the connector. The right pressing block is fixedly connected with the base and used for pressing the glass beads. The upper pressing block is put in the box and used for pressing the microwave substrate. The cross beam is fixedly connected with the base and used for pressing the upper pressing block. The base comprises a base bottom and guide pillars, wherein supporting bosses are arranged on the upper surface of the base bottom in an array mode, positioning faces flush with the upper surfaces of the supporting bosses are arranged on the two sides of the supporting bosses, the guide pillars are located on the positioning faces, and the inner sides of the guide pillars are of plane structures and are used for clamping the two sides of the microwave assembly. Pressurizing bosses arranged in an array mode and ventilation lightening holes which are adjacent to the pressurizing bosses and are arranged in an array mode are arranged on the lower surface of the upper pressing block. The microwave assembly welded with the microwave assembly welding device has the advantages that the welding flatness is high, the penetration rate and the welding efficiency are high, and the welding quality uniformity is good.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

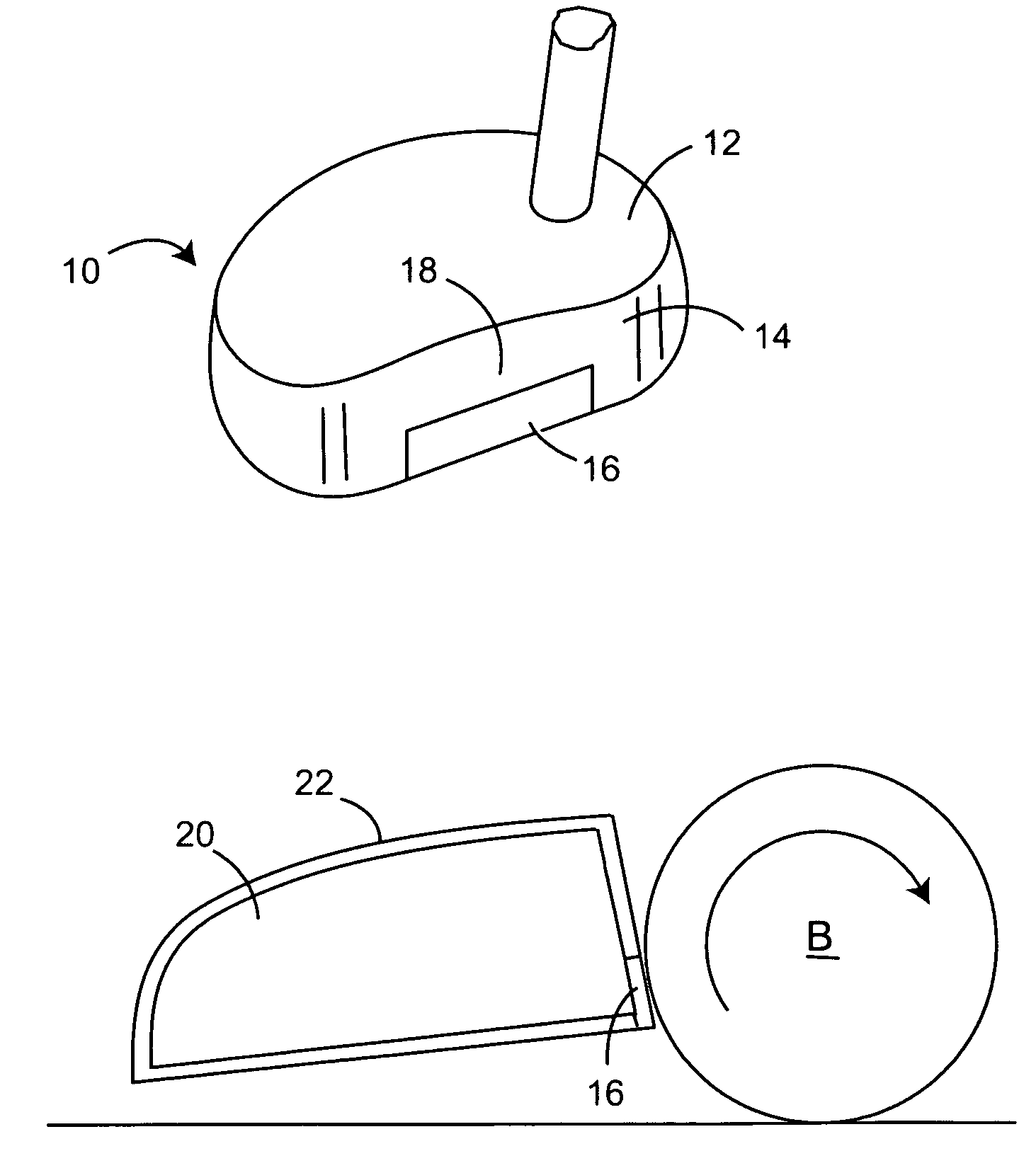

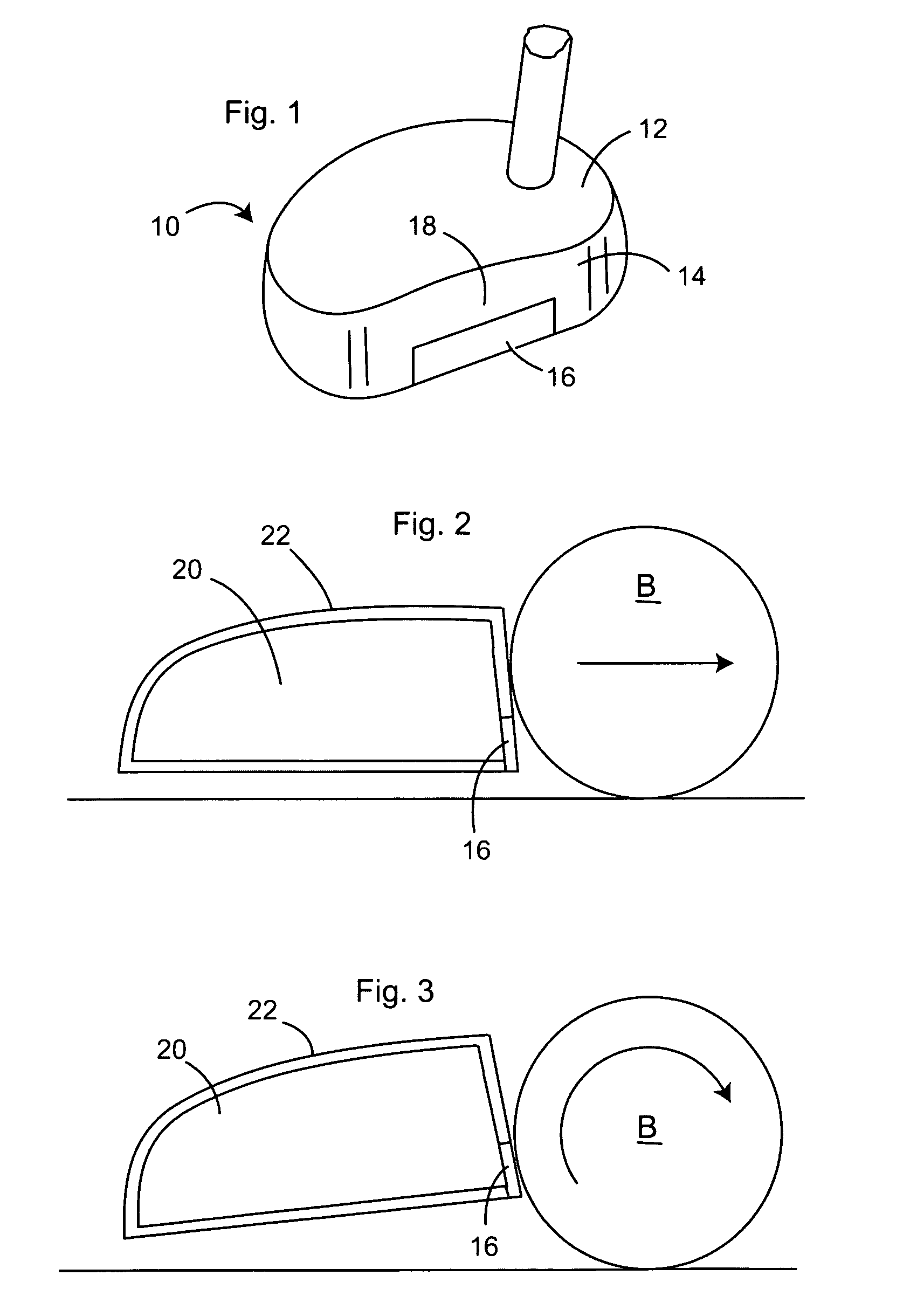

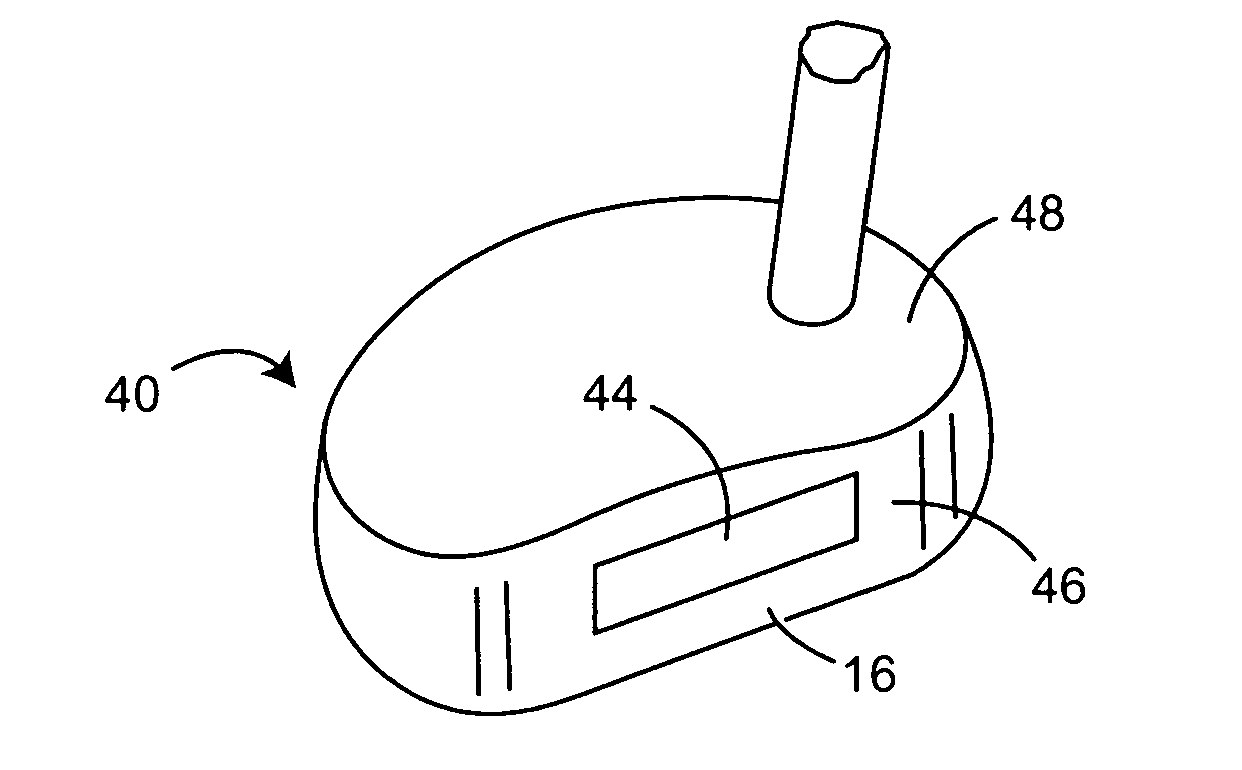

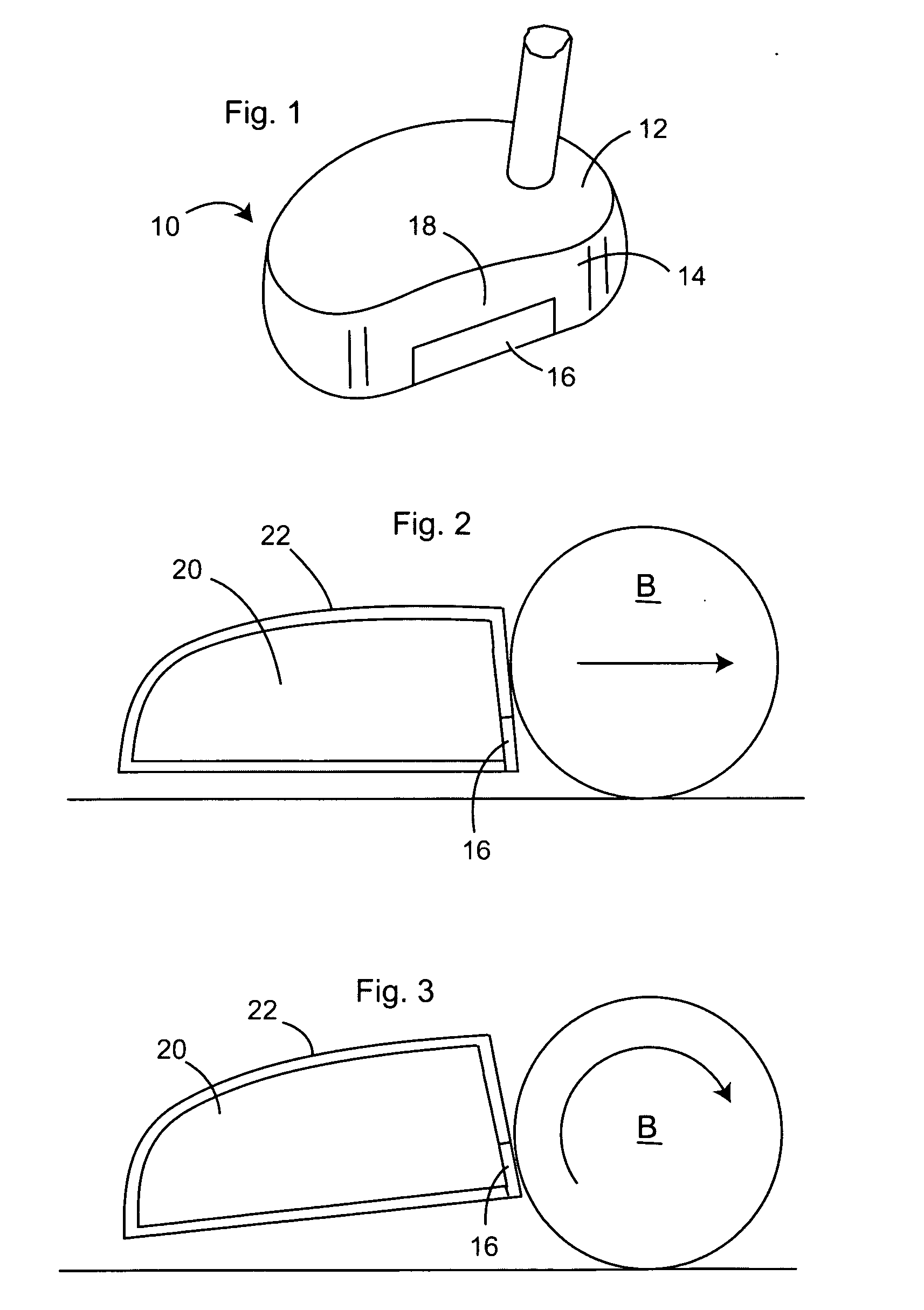

Golf club head

A golf club head having a front surface with a substantially planar face, a lower edge and a ball impact area, is constructed with a composite core of metal and plastic, with the core being enclosed in an injection molded plastic sheath. The core may be formed of layers of metal and plastic, or an injection molded plastic having metal particles dispersed therein. The metal to plastic weight ratio is preferably from about 90:10 to about 10:90. For putter heads, the head also includes a resilient section in the front surface having a face flush with the front surface, a lower edge aligned with the front surface lower edge, and an upper edge below the ball initial impact area. An exposed section of the non-resilient core may serve as the initial striking surface, while a front section of the resilient sheath may serve as the second ball striking surface.

Owner:PHOENIX TECHNOLOGIES LTD

Golf club head

A golf club head having a front surface with a substantially planar face, a lower edge and a ball impact area, is constructed with a composite core of metal and plastic, with the core being enclosed in an injection molded plastic sheath. The core may be formed of layers of metal and plastic, or an injection molded plastic having metal particles dispersed therein. The metal to plastic weight ratio is preferably from about 90:10 to about 10:90. For putter heads, the head also includes a resilient section in the front surface having a face flush with the front surface, a lower edge aligned with the front surface lower edge, and an upper edge below the ball initial impact area. An exposed section of the non-resilient core may serve as the initial striking surface, while a front section of the resilient sheath may serve as the second ball striking surface.

Owner:PHOENIX TECHNOLOGIES LTD

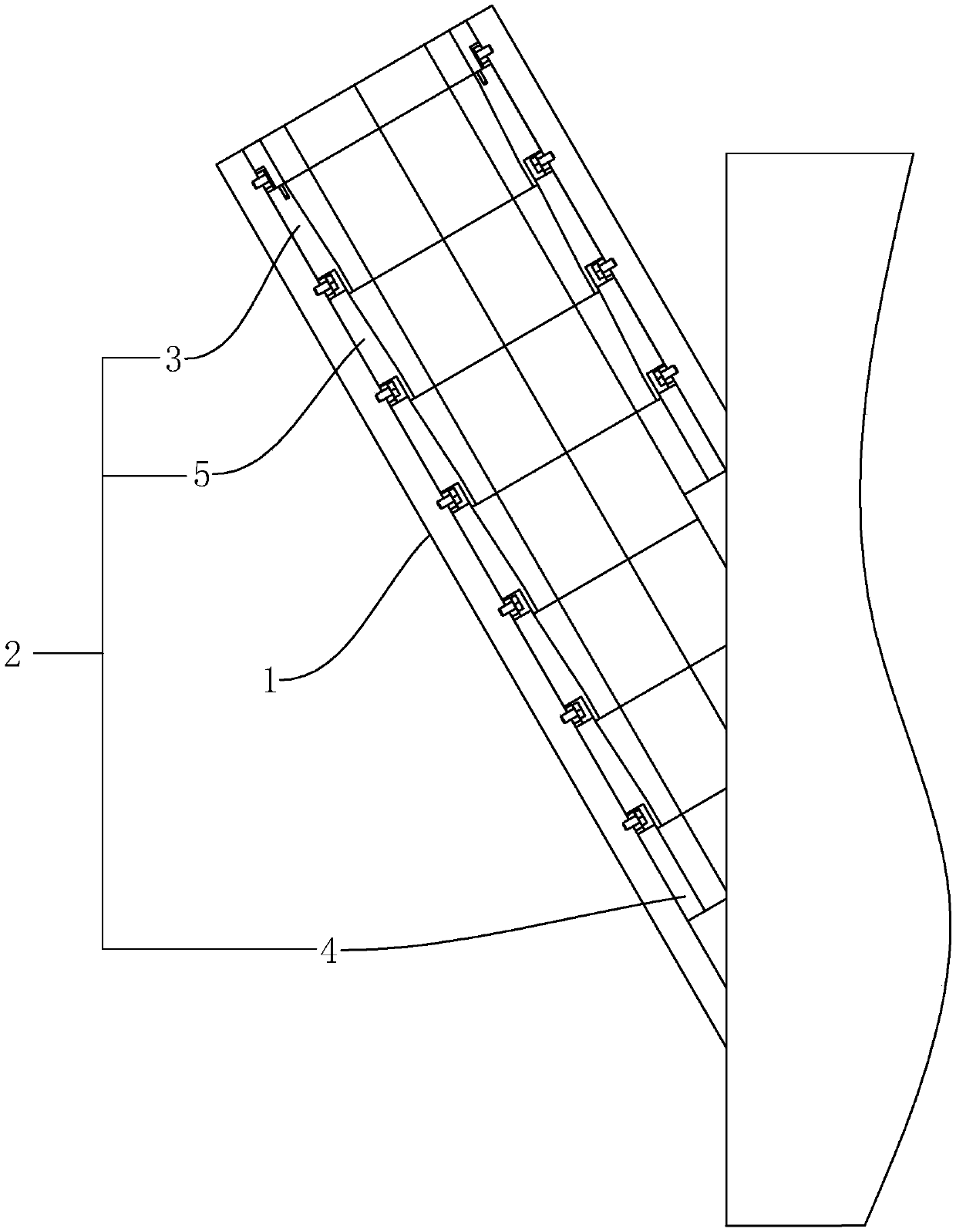

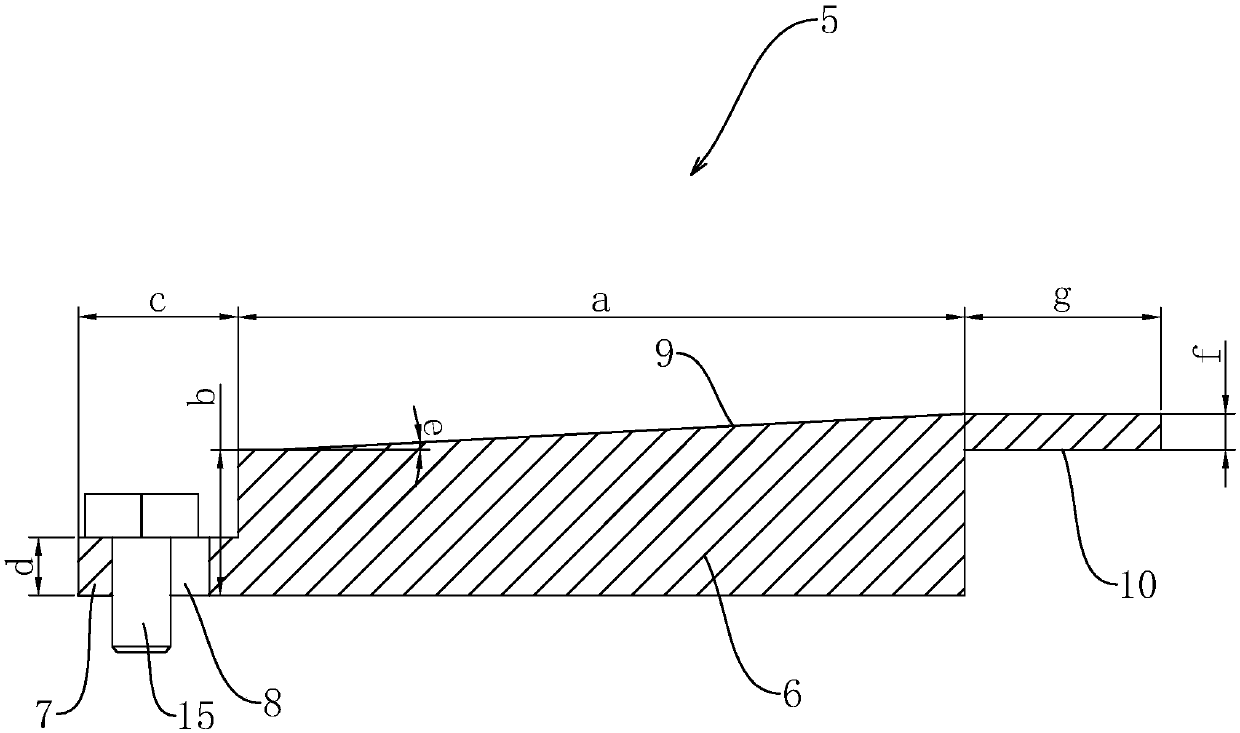

Heat insulation board anchoring part and external wall heat insulation system construction technology adopting same

The invention discloses a heat insulation board anchoring part and an external wall heat insulation system construction technology adopting the heat insulation board anchoring part. The anchoring partcomprises anchoring strips and a chuck detachably connected with each anchoring strip, and each anchoring strip comprises a wing plate as well as a unidirectional clamping belt and a web which are respectively arranged on the upper end face and the lower end face of the wing plate. The construction technology comprises the following steps: smearing a leveling layer on a wall body basement layer;pressing multiple anchoring strips into the leveling layer; fixing the anchoring strips by adopting steel nails; smearing a waterproof layer on the leveling layer; smearing a binding agent layer on the waterproof layer, and covering the unidirectional clamping belts of the anchoring strips with a heat insulation board, so that the heat insulation board is fixed; covering each unidirectional clamping belt with one chuck; smearing one anti-crack mortar layer with the outer end face flushed with the chucks on the heat insulation board, and pressing in glass fiber grid cloth. The heat insulation anchoring part and the external wall heat insulation system construction technology adopting the anchoring part have the advantages that the heat insulation board is firmly mounted, wall body heat insulation effect is good and construction period is short.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

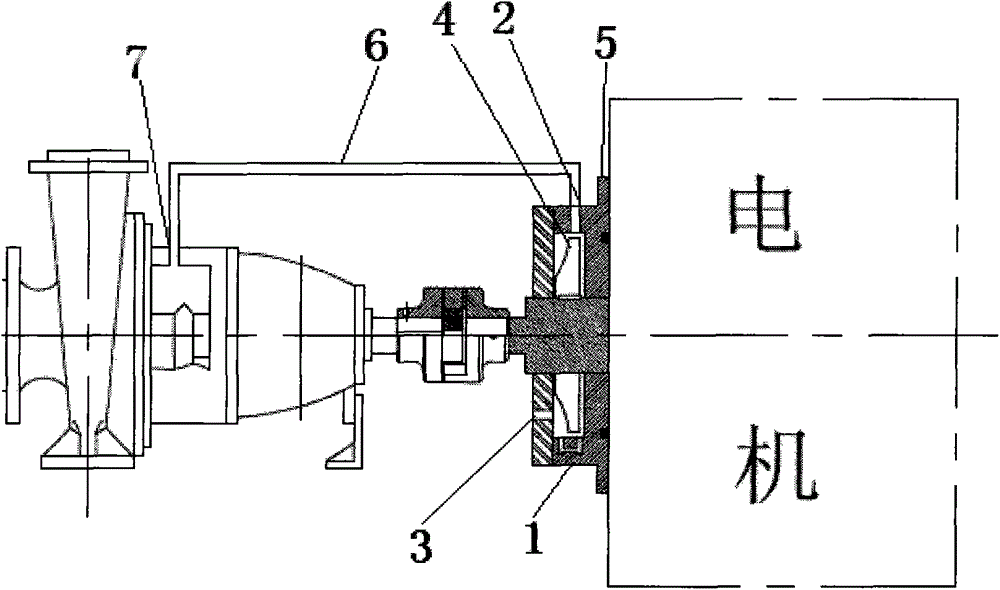

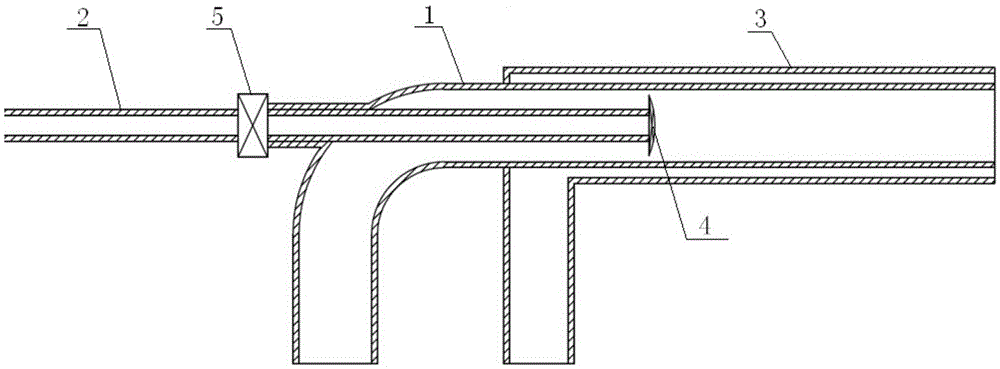

Mechanical sealing and flushing method and device of seafloor mud lifting pump

InactiveCN103334968ARealize pressurized flowAchieve flushingPump componentsPumpsImpellerOcean bottom

A mechanical sealing and flushing method and device of a seafloor mud lifting pump comprises a seawater pump, a pump outlet, a pump inlet, an impeller, an O-type ring and a seawater flushing pipe. The seawater pump is arranged in seawater and is coaxial with a motor, the pump outlet is formed in the seawater pump, the pump inlet is formed in a front end cover of the seawater pump, the impeller is arranged inside the seawater pump and is connected with a motor shaft through keys, the O-type ring is arranged between the seawater pump and the front end cover of the motor, and the seawater flushing pipe is connected with the pump outlet and a sealing and flushing opening. The seawater pump is immersed in the seawater, the pump inlet is directly communicated with the seawater, the seawater is boosted through the effect of the impeller inside the seawater pump, and seawater flowing and flushing to a sealing face are achieved. The mechanical sealing and flushing method and device of the seafloor mud lifting pump is simple in structure, sealing liquid does not need to be drawn from a sea surface to flush a circulation pipeline, the problem of sealing face flushing of the seafloor mud lifting pump of a seafloor mud lifting drilling well can be effectively solved, meanwhile, the mechanical sealing and flushing method and device of the seafloor mud lifting pump can be applied to ocean mining and other seafloor solid-liquid two-phase conveying pumps, and the demands for mechanical sealing and flushing of deep sea seafloor solid-liquid two-phase conveying pumps are met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Auxiliary device facilitating communication cabinet car loading and car loading method thereof

InactiveCN107200290AEffective cabinet loadingIncrease frictionLifting devicesEngineeringFace flushing

The invention discloses an auxiliary device for facilitating the loading of communication cabinets, which relates to the technical field of communication equipment, and includes an inclined platform. There is an electric lifting platform in the cavity, and a support plate is provided on the top of the electric lifting platform. There is a second installation cavity with an open structure on the upper side and the right side in the support plate. The moving plate is neat, and the moving plate is provided with a third installation cavity with an opening upward, and a roller is connected in rotation in the third installation cavity, and the roller protrudes from the moving plate and its axis is parallel to the right side of the moving plate; the invention also discloses A method for loading an auxiliary device that facilitates the loading of a communication cabinet; the invention can save time and labor for loading the communication cabinet into a vehicle compartment.

Owner:合肥展游软件开发有限公司

A gas flameless combustion device and combustion method with extremely low nitrogen oxide emissions

ActiveCN104132344BAchieve flameless combustionReduce manufacturing costGaseous fuel burnerNitrogen oxideFace flushing

The invention relates to a gas flameless combustion device and combustion method with extremely low emission of nitrogen oxides, which comprises: an L-shaped air nozzle, one section of the air nozzle is arranged horizontally, and the end of the horizontal section of the air nozzle It is the outlet of the nozzle, and a horizontal branch pipe is arranged at the bend of the L-shaped pipe; a central gas nozzle is a straight pipe, which extends into the horizontal section of the air nozzle in parallel after passing through the horizontal branch pipe. An annular gap is left between the pipe and the central gas nozzle to form an air channel; the central gas nozzle is connected to the horizontal branch pipe through a sealed joint; an outer gas nozzle is sleeved and sealed connected to the air nozzle On the outside of the horizontal section, a nozzle inlet is arranged on one side of the outer gas nozzle, and an annular gap is left between the outer gas nozzle and the air nozzle to form an outer gas passage; the horizontal section of the outer gas nozzle, the air nozzle and the The three central gas nozzles have a coaxial relationship, and the outlet of the outer gas nozzle is flush with the end face of the outlet of the air nozzle; the flame stabilizer is installed at the outlet end of the central gas nozzle.

Owner:PEKING UNIV

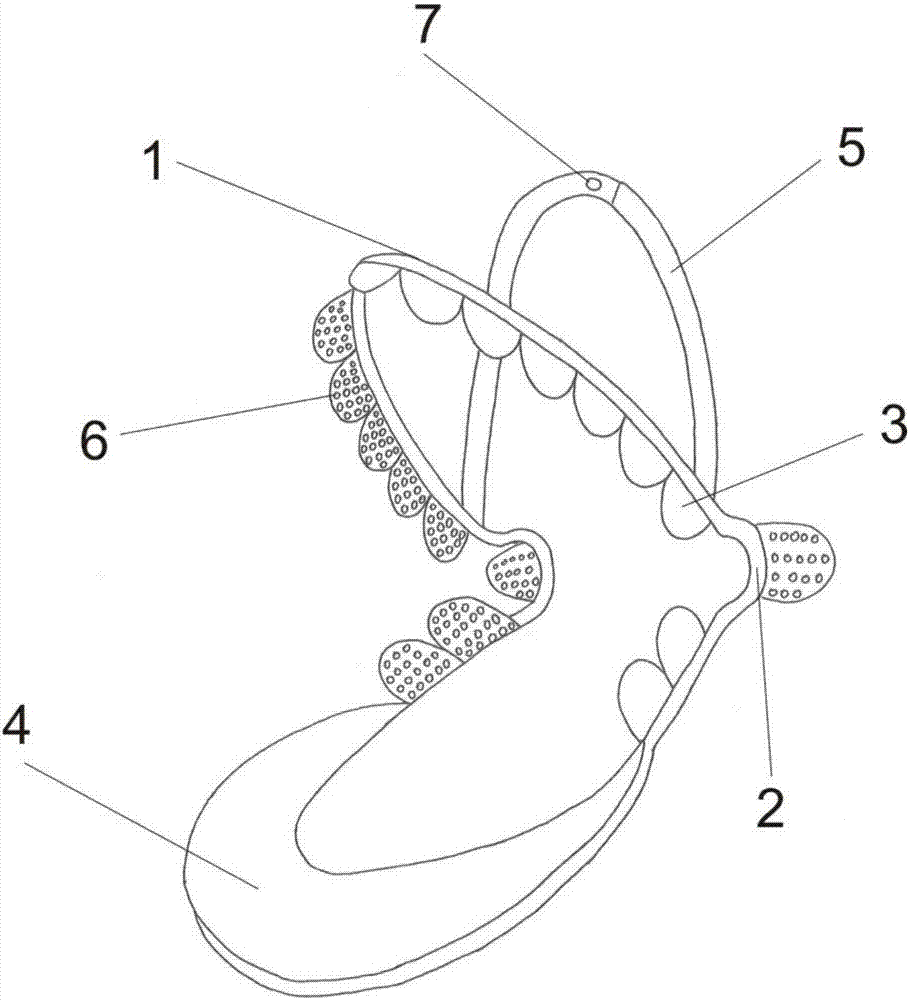

Face flushing fence and face flushing method

PendingCN107373993AHealthy and effective cleaning processSimple structureShaving accessoriesPaper towelEngineering

The invention discloses a face flushing fence. The face flushing fence comprises an enclosing ring, postotic fixing semi-rings are arranged on the enclosing ring, a bearing plate is arranged at the position, corresponding to the underjaw, of the enclosing ring, and an enclosing edge is arranged at the position, except the connecting position with the bearing plate, of the periphery of the enclosing ring. The invention further discloses a face flushing method, the face flushing fence is used in the method and worn on the face, hair is pushed after the enclosing ring, and the postotic fixing semi-rings are located after the ears to ensure that the face flushing fence does not slip off during face flushing; the face is wet with clean water and scrubbed and rubbed with a soap, or a toilet soap or facial cleanser; a movable water spray head is opened; the water spray head is aligned to the face and flushes the face from top to bottom multiple times until no dirt or face cleaning product residual exists on the face; the face flushing fence is taken down, and the face is naturally aired or wiped dry with a disinfected towel or tissue.

Owner:陈延

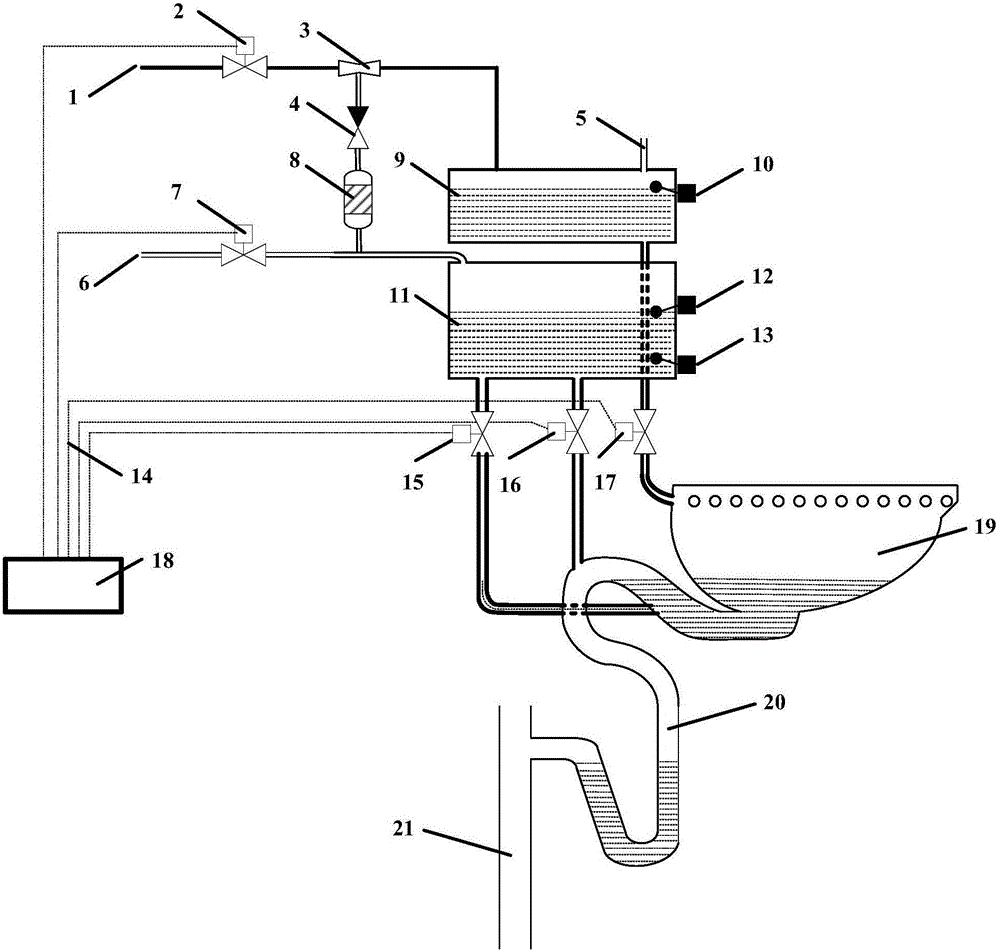

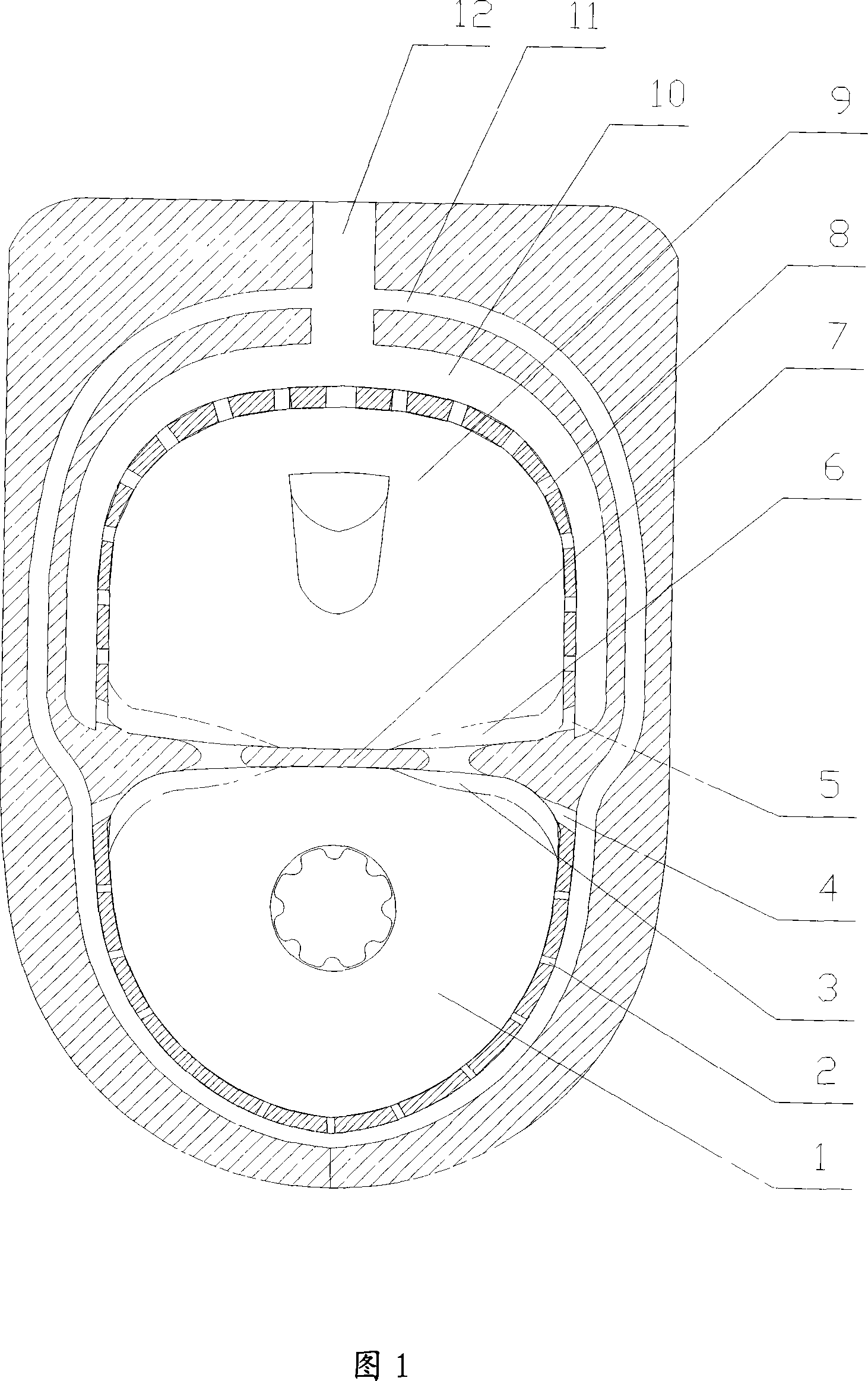

Toilet flushing system with injection pump

InactiveCN106049631AReduce the amount of flushing waterFlushing devicesLavatory sanitoryWater useSiphon

The invention discloses a toilet flushing system with an injection pump. The toilet flushing system comprises a flushing water system and a water saving system, wherein the flushing water system comprises a tap water control solenoid valve, the injection pump, a liquid level measurement float switch and a flushing water control solenoid valve, and the water saving system comprises the injection pump, an air control solenoid valve, a high-liquid-level measurement float switch, a low-liquid-level measurement float switch, a water sucking control solenoid valve and a siphon water release control solenoid valve. According to the toilet flushing system, the injection pump is added, so that part of pressure energy of the tap water is recycled, and the part of energy is used for recycling part of water for urine flushing of the toilet; during the faces flushing, the recycled water is drained into a drain pipeline of the toilet earlier than the flushing water of the toilet, siphon force is generated for sucking dirt such as feces, and then the water with the amount being equal to that of the water used for flushing urine is released for flushing the toilet to be clean. Compared with the existing water-saving toilet, the toilet flushing system provided by the invention has the advantage that the amount of the water for flushing the feces is reduced by one half.

Owner:DALIAN MARITIME UNIVERSITY

Headwater separating toilet

ActiveCN101117817AReduce in quantityReduce volumeWater closetsFlushing devicesInlet channelEngineering

The present invention relates to a source separation toilet chair, whose urinal is composed of a urinal and a faces urinal which are distributed at the front and the back. A urinal flushing channel around the urinal and a faces urinal flushing channel around the faces urinal are arranged at the upper position of the urinal, and a water inlet pipe is arranged at the back of the urinal. Openings communicating with the urinal flushing channel and the faces urinal flushing channel are arranged at a water inlet channel. Two openings are provided for communicating with the urinal flushing channel and arranged on the both sides of the water inlet channel. The opening connecting with the faces flushing channel at the water inlet channel is arranged at the front end of the water inlet channel, namely, the front end of the water inlet channel is connected with the faces flushing channel. One water inlet channel is connected with the urinal flushing channel and the faces flushing channel in the present invention to ensure the toilet chair look to be nice, reduce the volume and occupied the space, and can not damage the toilet chair and the appearance of the toilet by the complicated structure of the toilet chair, and the present invention can be made into for a toilet bowel and a squatting pan.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Clamp locking mechanism in device for welding plastic tubes

ActiveUS20100320669A1Promote sportsWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismFace flushing

A device for welding plastic tubes includes a laterally movable tube holder having tube holding areas and a laterally fixed tube holder having tube holding areas. Each tube holder includes clamping structure for clamping each tube placed in the respective tube holder areas and for creating a fluid free area. A spring mechanism urges the laterally movable tube holder toward the laterally fixed tube holder to maintain the clamp faces flush against each other. A clamp locking mechanism is provided to supplement the action of the spring mechanism by maintaining the clamp faces flush against each other during the loading of the tubes.

Owner:GENESIS BPS

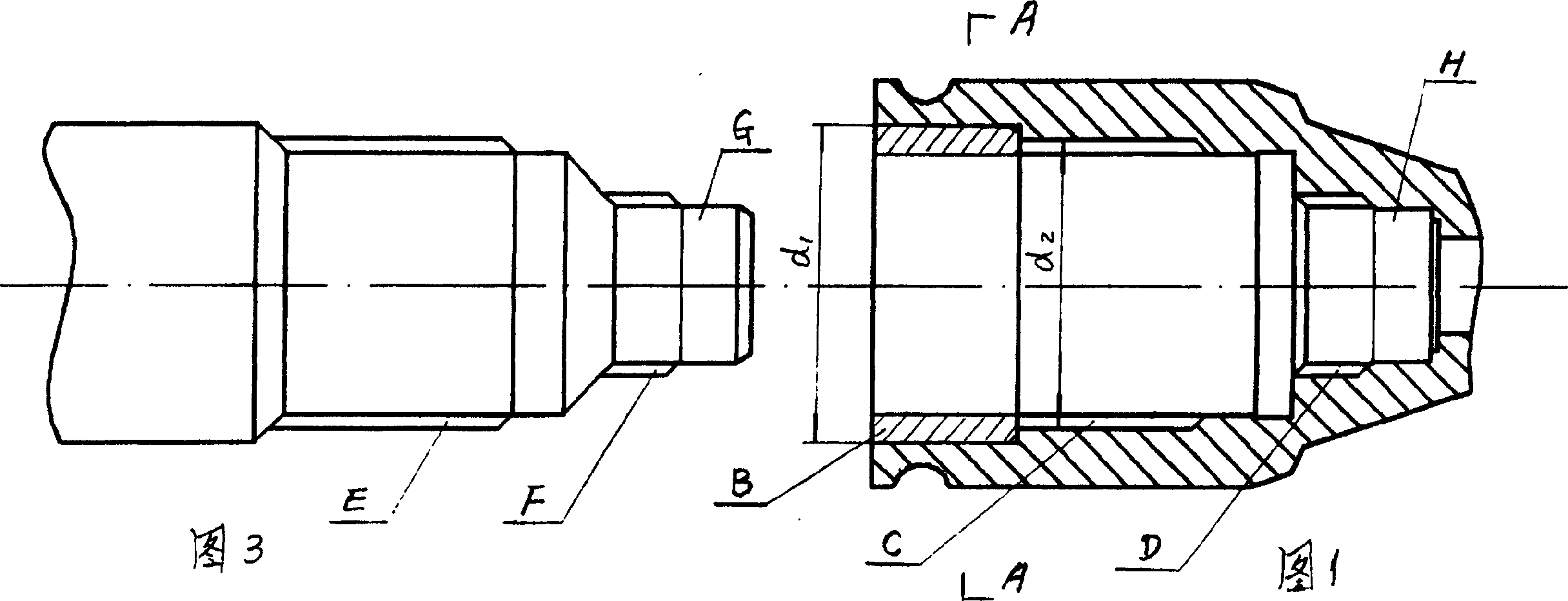

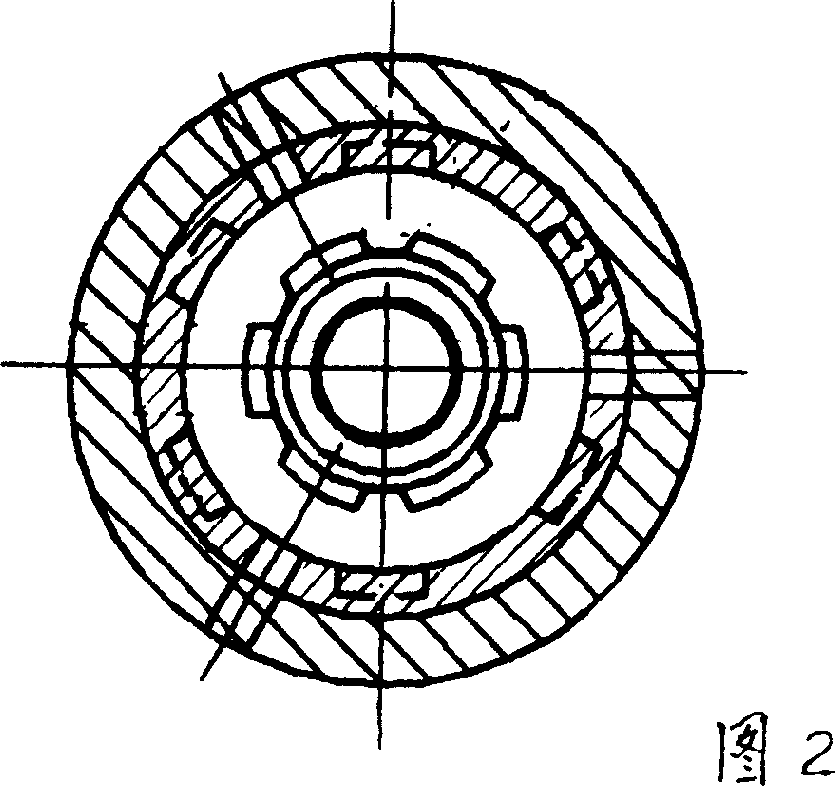

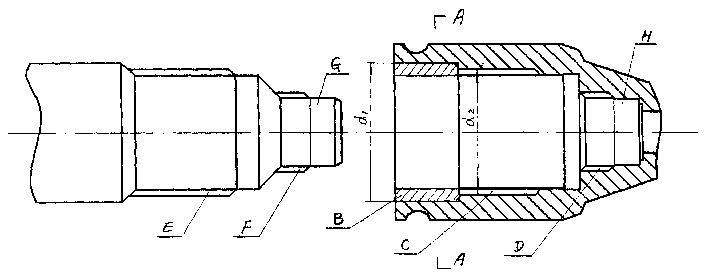

Once cold extrusion shaping method of automobile power steering gear jacketed screw and its multiple key and oil distributing groove

InactiveCN1174888CGuaranteed positioning accuracyGuaranteed dimensional accuracyMetal-working apparatusFluid steeringFace flushingOne shot

Owner:马福生

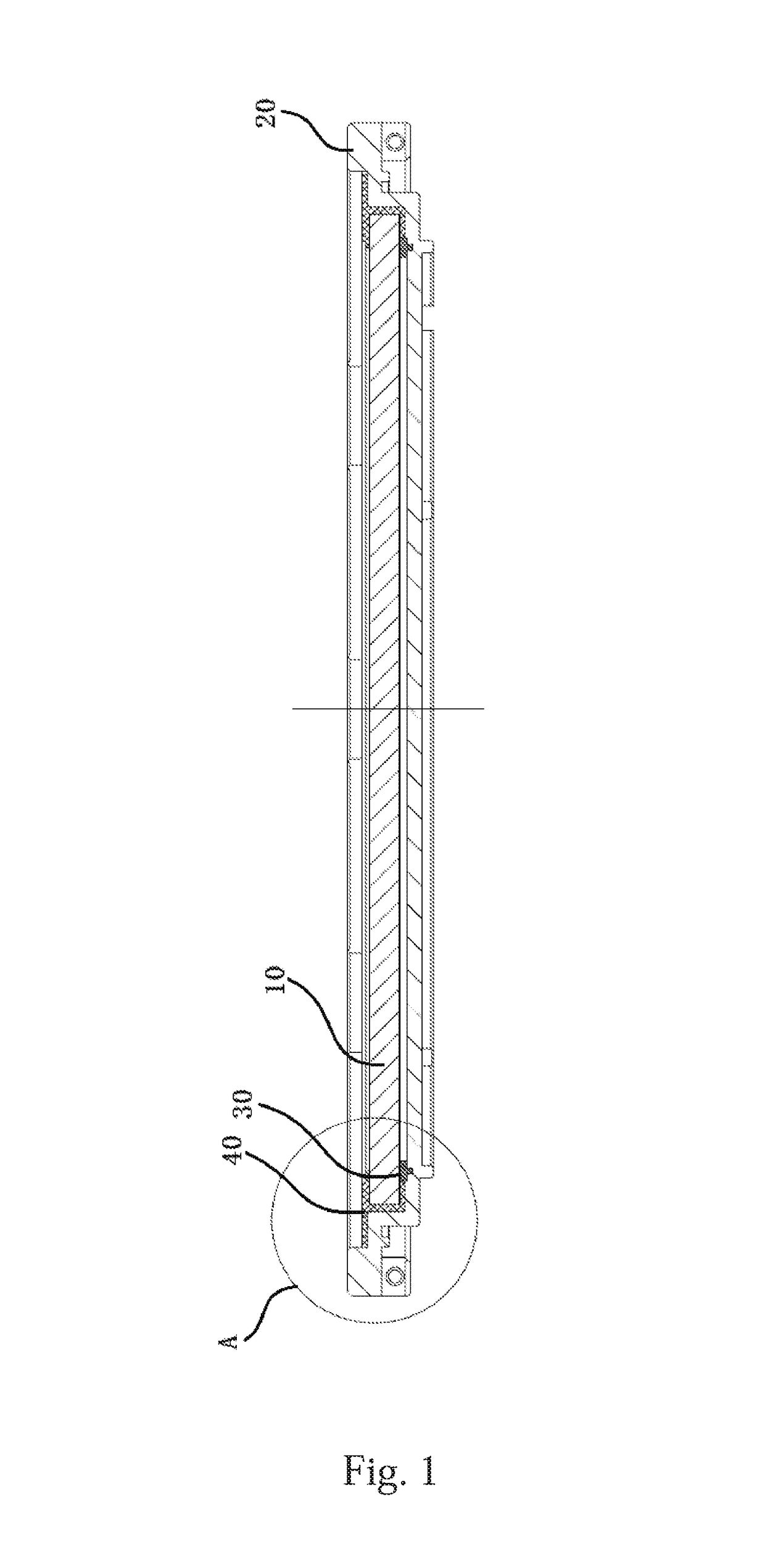

Packaging structure for waterproof LED lamp and method of making the same

InactiveUS20190086069A1Avoid flowLighting heating/cooling arrangementsProtective devices for lightingFace flushingEngineering

A packaging structure for a waterproof LED lamp contains: a transparent sheet, a grid casing, and a sealing ring, and a sealant. The grid casing includes a grille groove formed on a central portion thereof, a first fixing face exposing on a top of the grid casing, a second face formed below the first fixing face, and a third fixing face defined below the second fixing face flushing with the grille groove. Between the third fixing face and the grille groove is defined a retaining trench configured to retain the sealing ring, wherein the sealing ring has a T-shaped cross section. The transparent sheet is placed on the sealing ring and the sealant, and among the second fixing face, the sealing ring, and the transparent sheet is defined a gap in which the sealant is fed.

Owner:LI FENG

Feed device for circulating fluidized bed boiler

ActiveCN107975793BSmoothly fall intoFluidized bed combustionApparatus for fluidised bed combustionFluidized bedFace flushing

The invention discloses a feeding device of a circulating fluidized bed boiler. The feeding device comprises a concrete drainage pipe with an include angle with the horizontal plane, multiple columnsof steel plate assemblies used for guiding materials are arranged in the concrete drainage pipe, a gap is reserved between the adjacent steel plate assemblies, each steel plate assembly comprises multiple middle fixed steel plates, each middle fixed steel plate comprises a main plate with the lower side face attached to the inner wall of the concrete drainage pipe, the front ends of the main plates are provided with mounting plates thinner than the main plates, the mounting plates are provided with fastening bolts penetrating the mounting plates to be fixedly connected with the concrete drainage pipe, the rear ends of the main plates are provided with covering plates with the lower side faces flush with the upper side faces of the main plates, the length of the covering plates is larger than the length of the mounting plates, the middle fixed steel plates in the steel plate assemblies are mounted in the concrete drainage pipe, the covering plates of the adjacent middle fixed steel plates are attached to the upper side faces of the other main plates, and gaps are reserved between the mounting plates and the other main plates.

Owner:温州宏泽热电股份有限公司

Drainage four-way inspection well to prevent water flow hedging

ActiveCN104018569BGive full play to drainage efficiencyReduce waterloggingSewerage structuresPipeflowWater flow

The invention discloses a water drainage cross inspection well preventing water face-to-face flushing, belongs to the field of water drainage projects and particularly relates to a rainwater and sewage convergence water drainage structure. The well is an intersection inspection well applicable to a rainwater or sewage pipeline. Branch pipes on the two sides of a water drainage pipeline are connected into the inspection well through sluices with large cornering radius, the sluices of the branch pipes on the two sides are spaced from a sluice of an upstream pipeline, and the included angle of afflux of the three sluices is small. The inspection well can prevent face-to-face flushing of water entering the inspection well, reduce turbulence flow to stabilize the water and bring the water drainage efficiency of the intersection inspection well into full play, thereby reducing the frequency of waterlogging of urban roads.

Owner:洛阳城市建设勘察设计院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com