Patents

Literature

59results about How to "Reduce the amount of flushing water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Revolving drum type micro-filter and sewage treatment method

InactiveCN104436809ASimple and compact structureSmall footprintWater/sewage treatmentMoving filtering element filtersTreatment effectSmall footprint

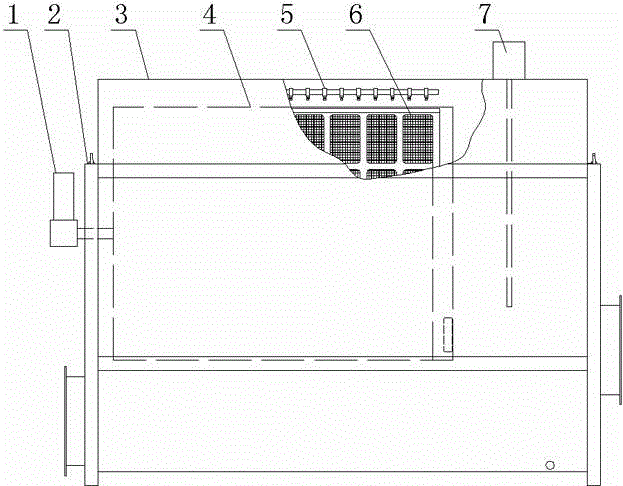

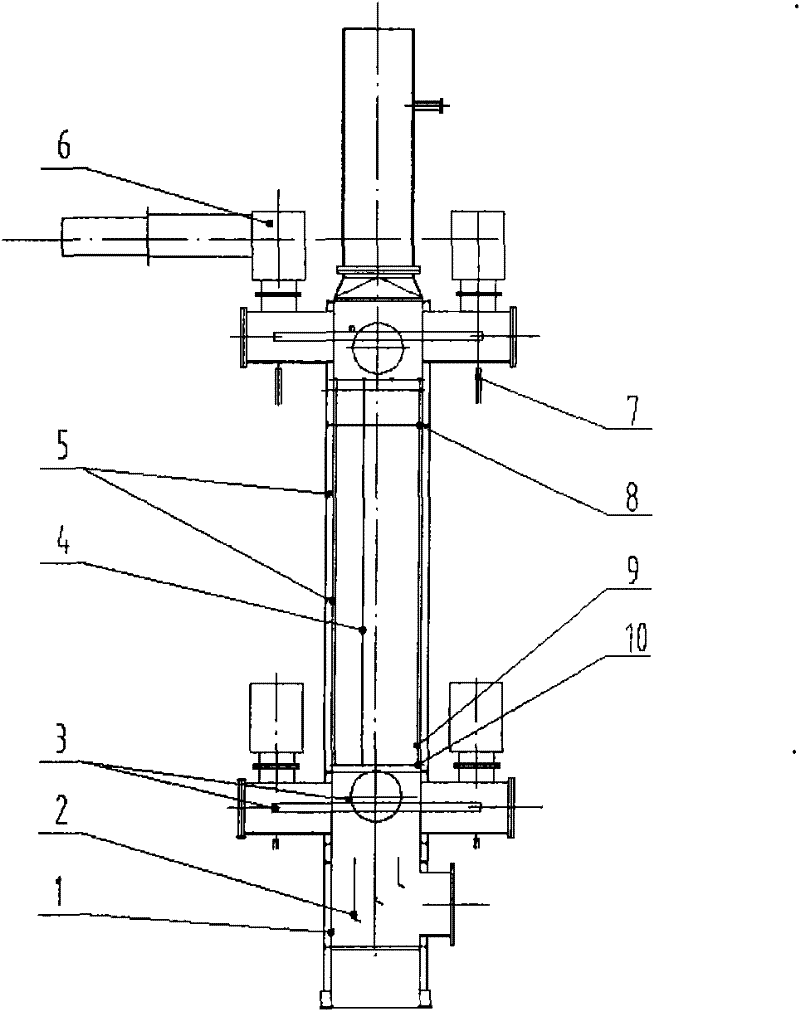

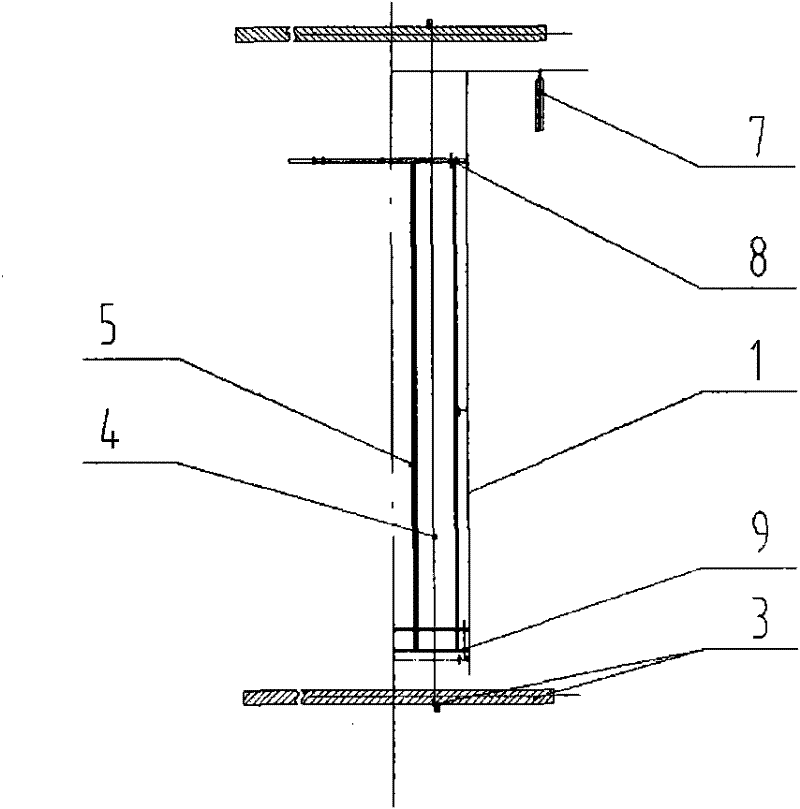

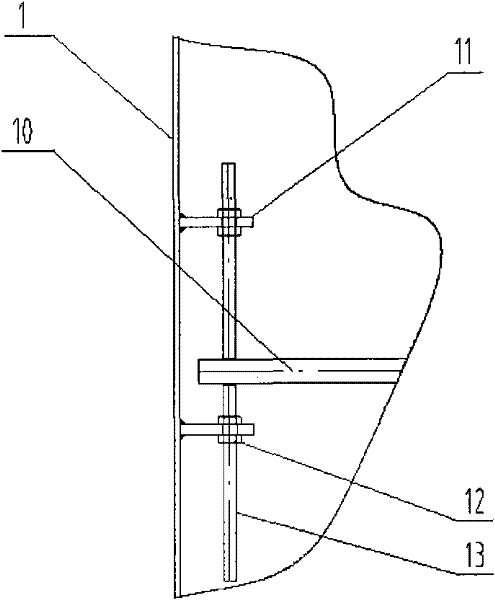

The invention relates to a revolving drum type micro-filter. The revolving drum type micro-filter comprises a driving device (1), a box body (2), a housing (3), a revolving drum (4), a flushing device (5), a micro filtering net (6) and a dirt discharging groove (9). According to the method for processing sewage, sewage can flow into the hollow revolving drum, due to the action of gravity, the liquid flows towards the outer side of the filtering net from the inner side of the filtering net, and suspended matter in the water is intercepted on the inner side of the stainless steel filtering net; the revolving drum revolves slowly, a flushing water pump of the flushing device extracts the filtered water to conduct back flushing on the filtering net, the flushing water is used for flushing the filtering net from the outer side of the filtering net to the inner side of the filtering net through a nozzle of the flushing device located on the top of the revolving drum, and particulate matter which is flushed away is collected through the dirt discharging groove and is discharged out of the micro-filter through a sewage pipe. The micro-filter is simple and small in structure, small in occupied area, good in treatment effect, convenient to maintain, low in unit treatment cost and more environmentally friendly compared with other filtering devices.

Owner:江阴天汇环保设备有限公司

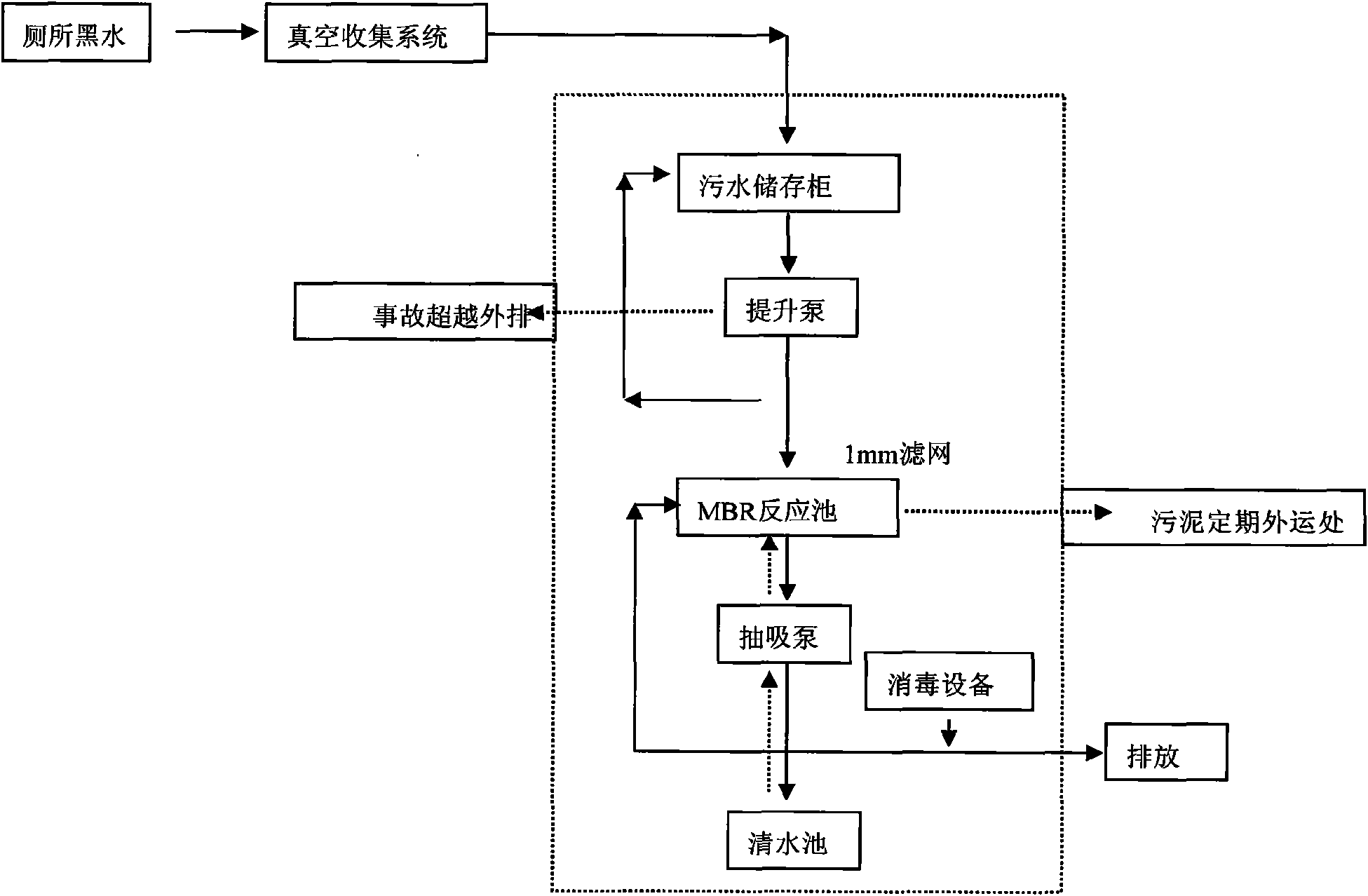

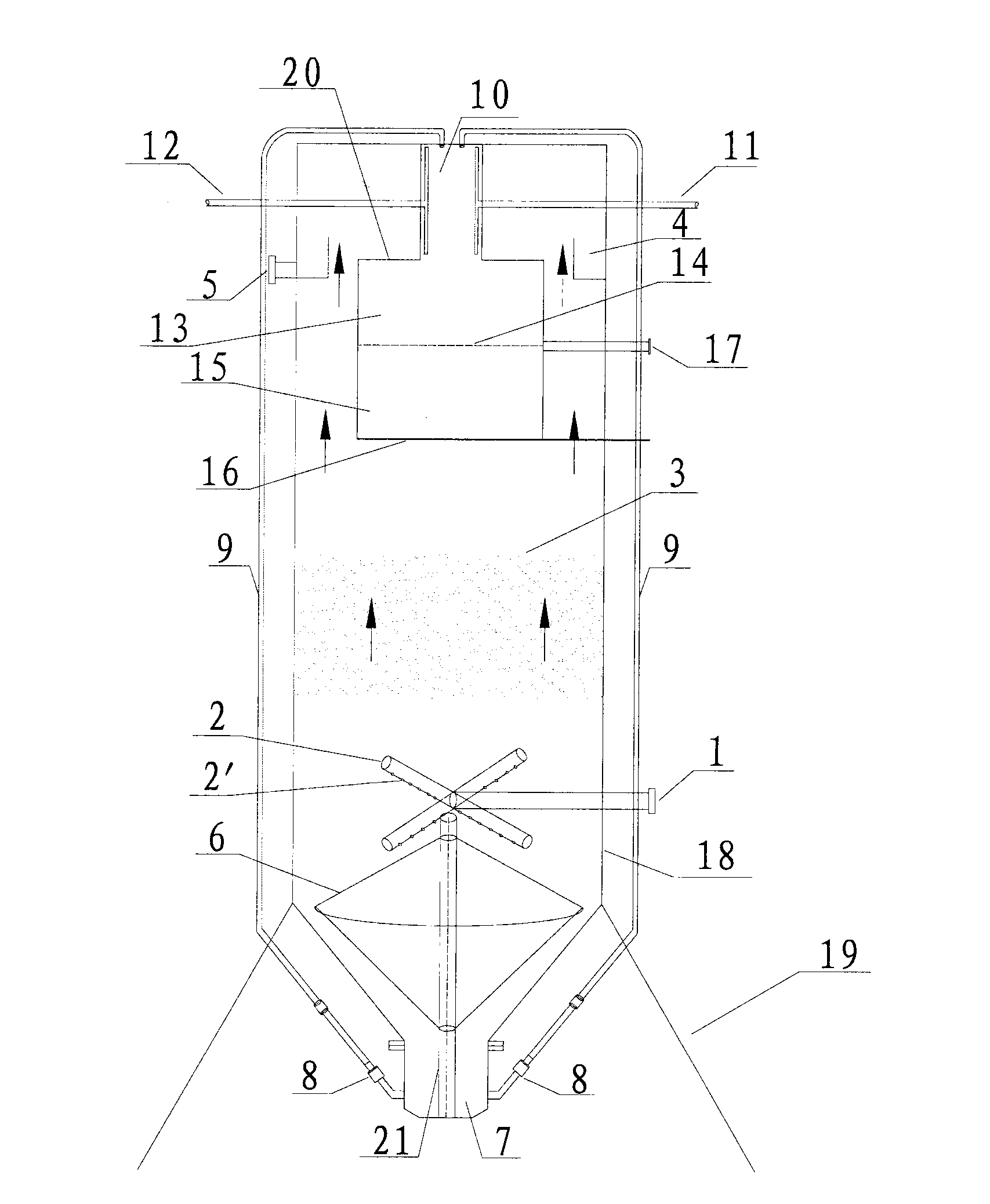

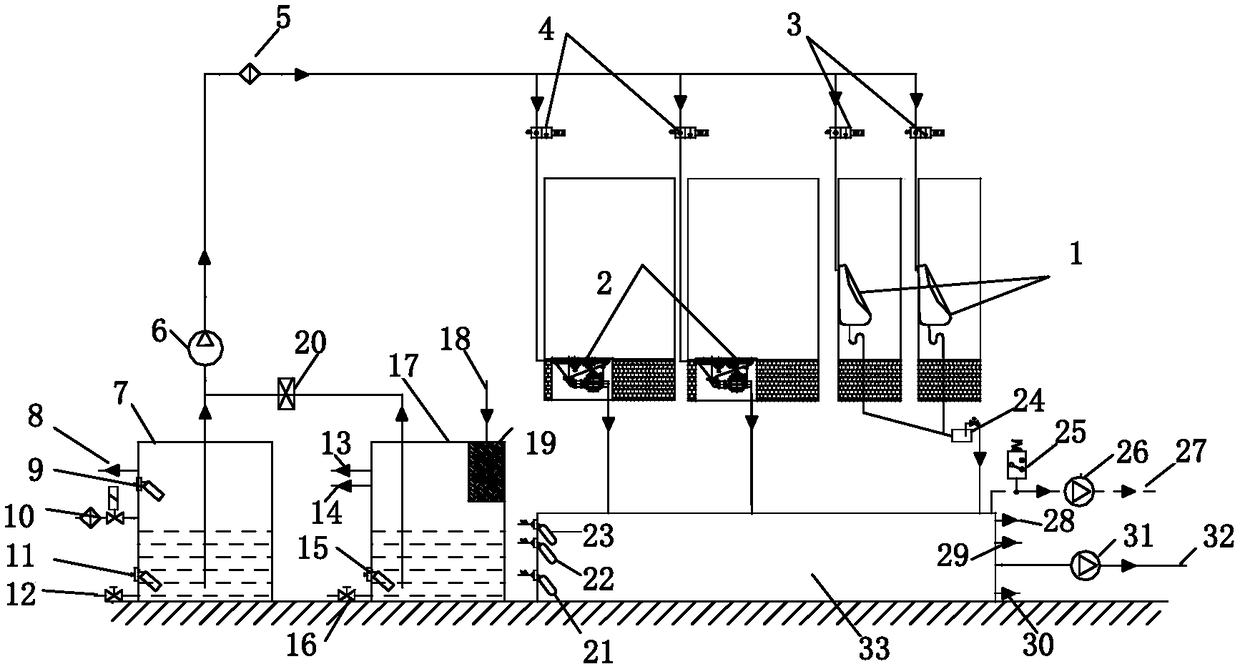

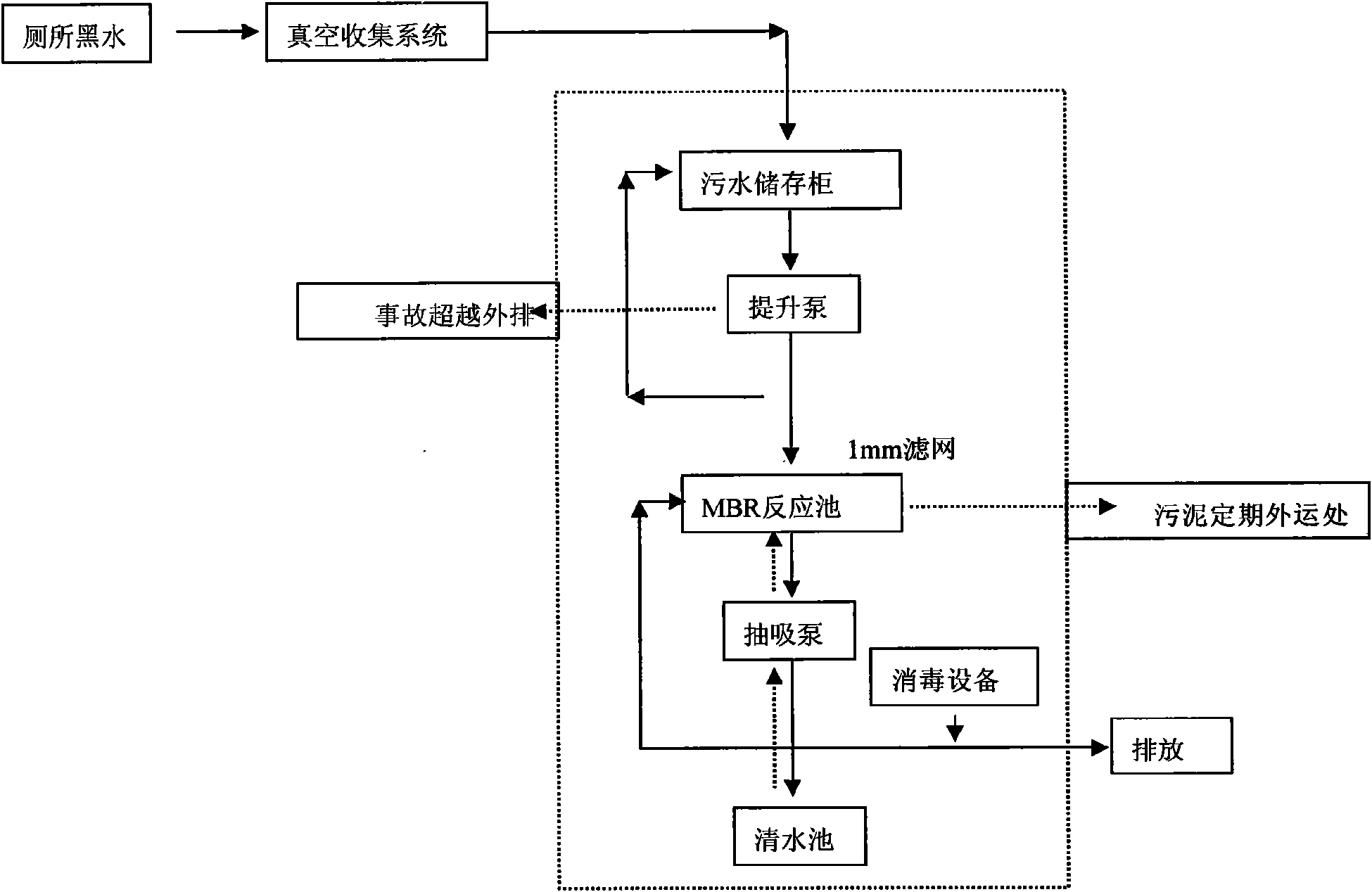

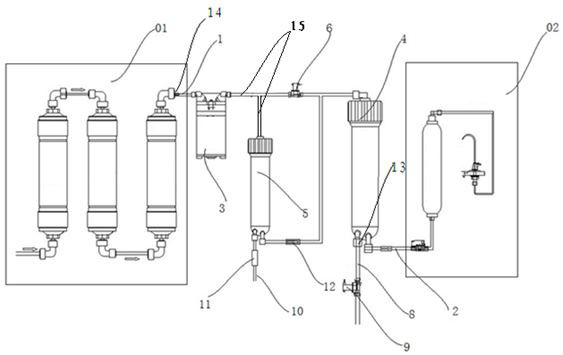

Marine domestic sewage treatment process and vacuum discharge and treatment system

ActiveCN101618927AReduce the amount of flushing waterSmall diameterAuxillariesWater/sewage treatment bu osmosis/dialysisCollection systemWater quality

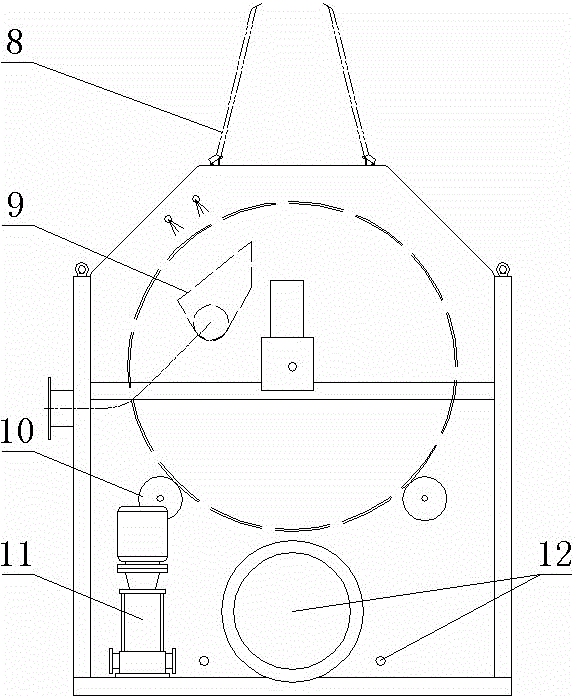

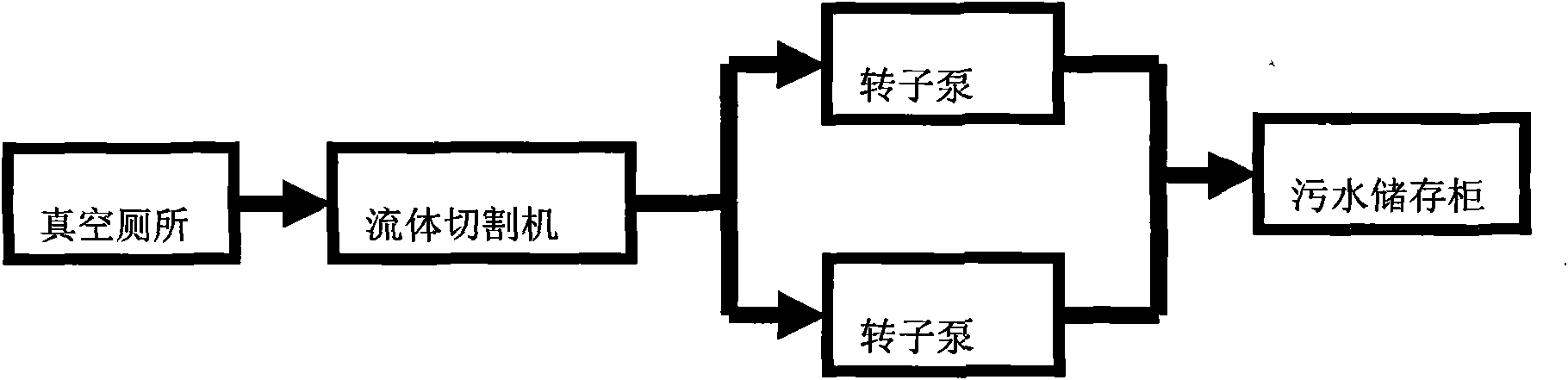

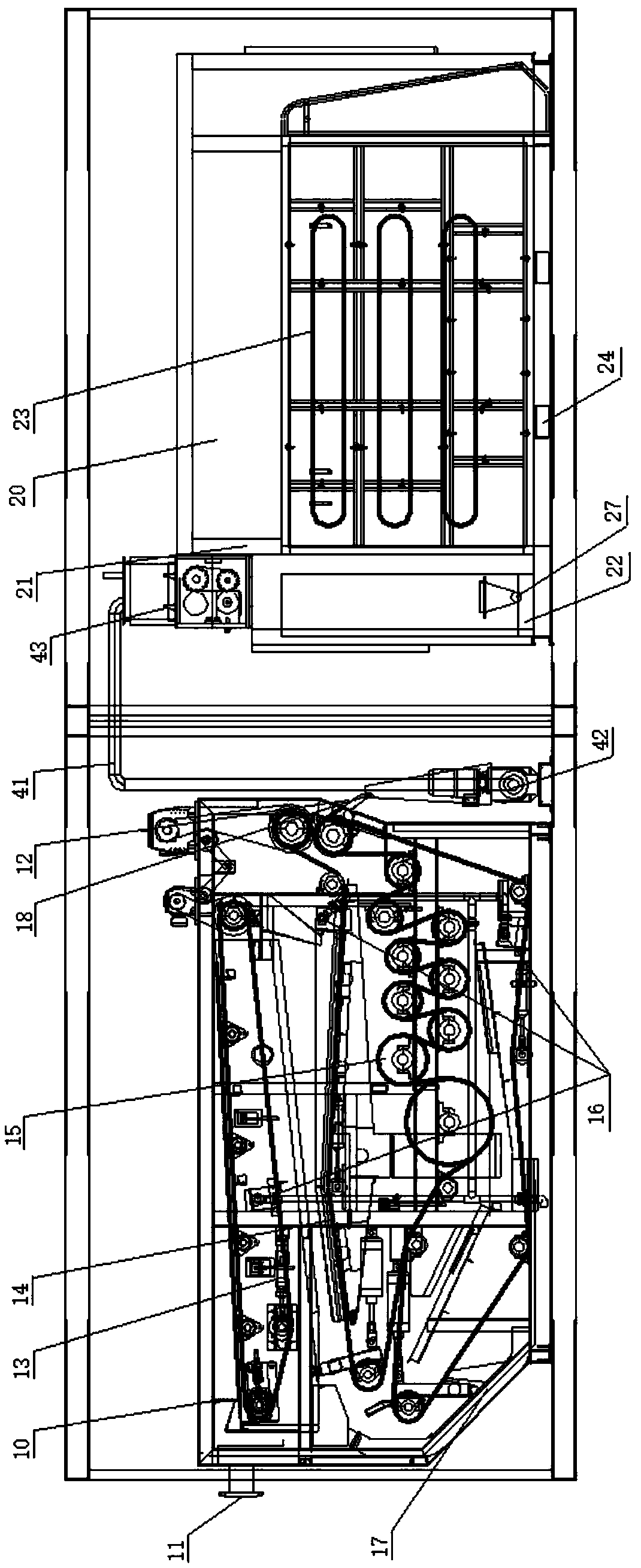

The invention discloses a marine domestic sewage treatment process belonging to the technical field of sewage treatment and discharge. The marine domestic sewage treatment process comprises the following steps: (1) collecting sewage by a vacuum collection system, and achieving the discharge and transport by utilizing the pressure difference inside and outside the system; (2) crushing and thinning large granular suspended matters by a crushing pump, filtering by a grid and then conveying into a sewage tank; (3) conveying to a fur collector by the pump to remove furs and small granular suspended matters; and (4) degrading by aerobic bio-degradable bacteria, filtering by multiple groups of hollow micropore membrane reactors, then discharging into a sterilizing device, and finally discharging to the outside. The invention further discloses a marine domestic sewage vacuum discharge and treatment system. The invention has simple treatment process, not only saves space and water, has compact arrangement, safety and sanitation as well as easy maintenance, but also decreases the influence of the swing of a marine body on the water quality, and has high pollutant degradation efficiency and directly-reused discharged water.

Owner:SHENZHEN JINRUN IND

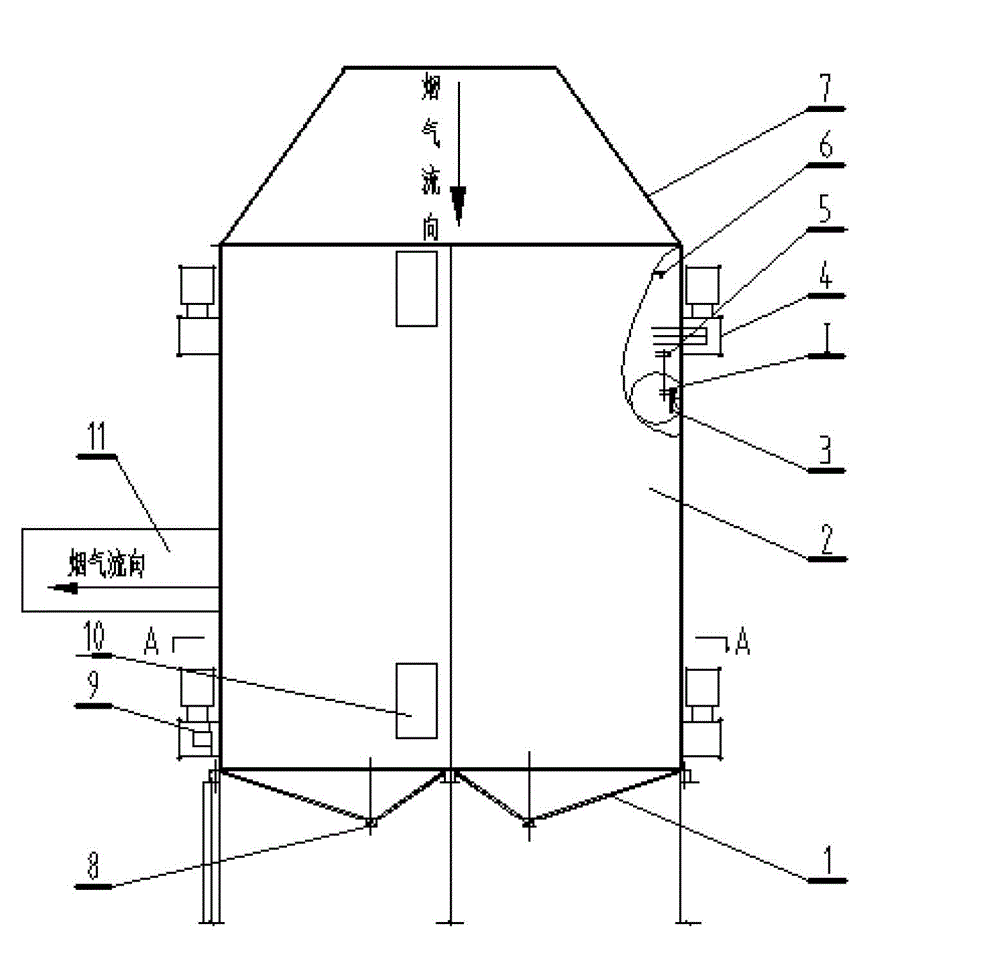

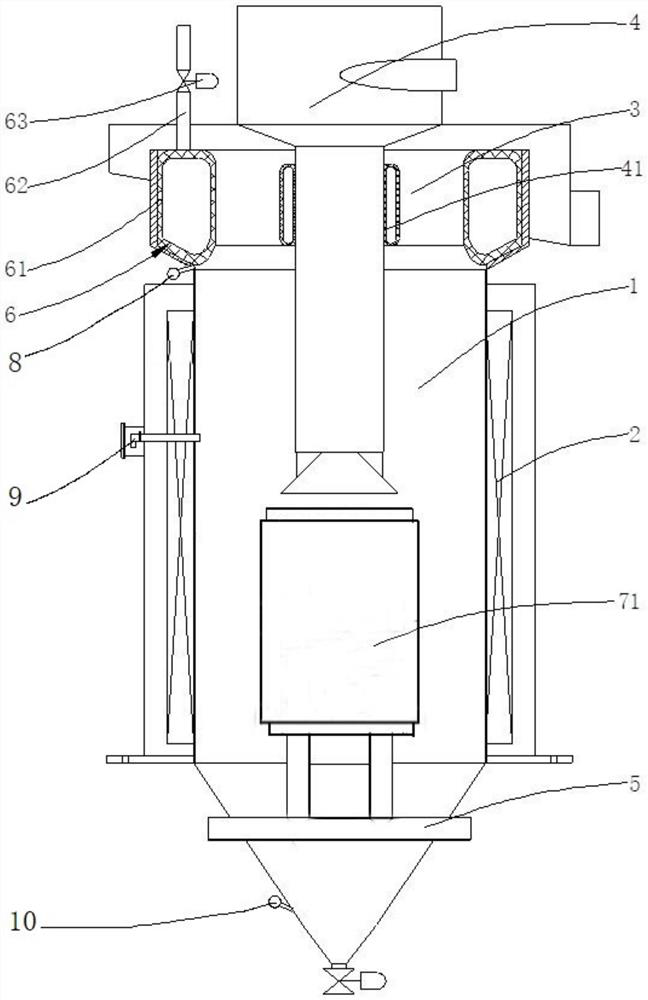

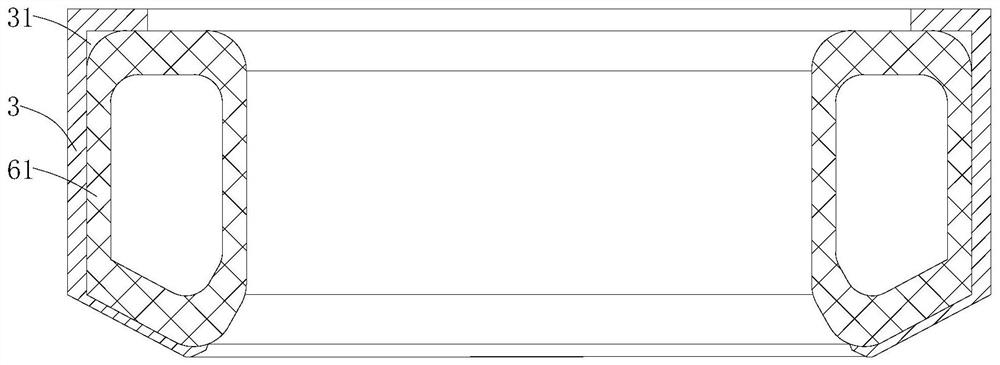

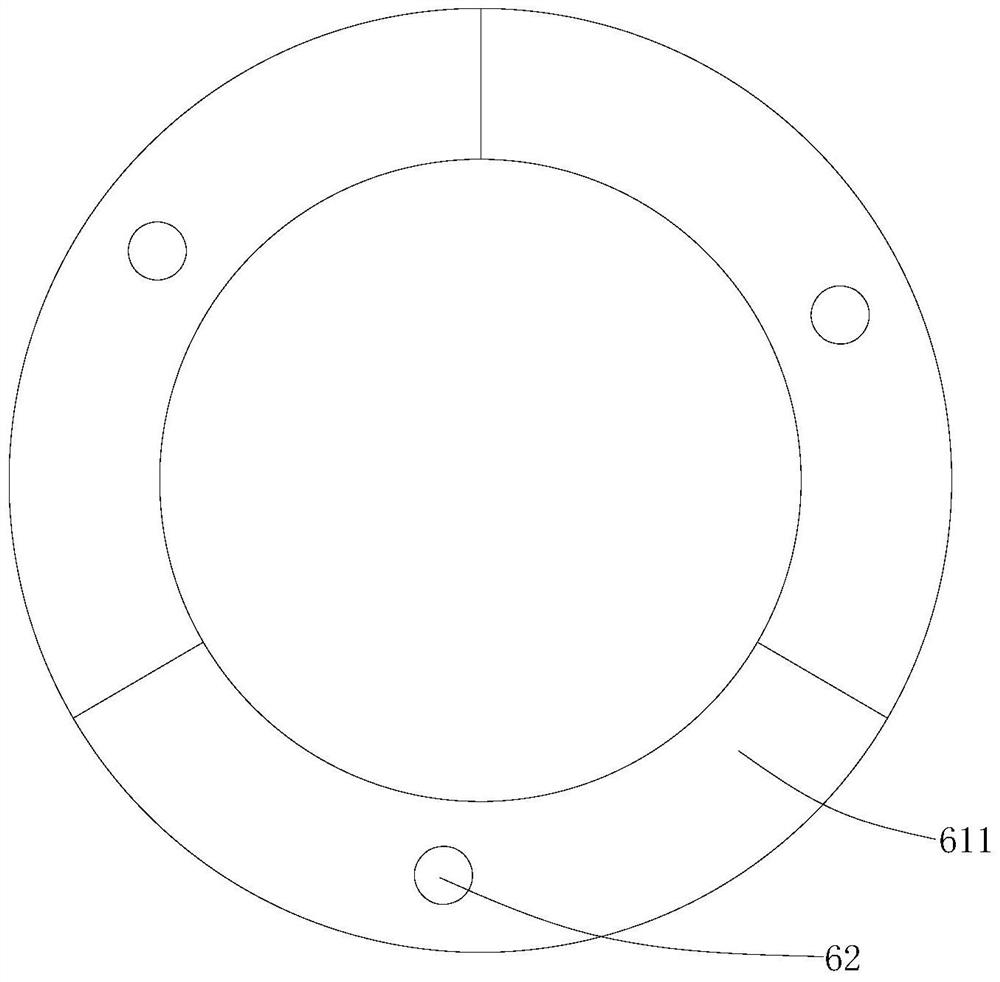

Advanced dust-removing and demisting device

ActiveCN104368215AGood dedusting and demisting effectNo risk of fouling and cloggingCombination devicesFlue gasEngineering

The invention discloses an advanced dust-removing and demisting device, and particularly relates to a dust-removing and demisting device which is suitable for saturated flue gas containing a great deal of fog drops. The advanced dust-removing and demisting device has a main working principle as follows: collision among fog drop liquid particles and between fog drop liquid particles and dust particles can be realized during high-speed motion of flue gas based on the characteristic that the flue gas contains a great deal of fog drops and liquid drops, so that larger particles are formed by agglomeration and then settle; the fog drop liquid particles and the dust solid particles are in full contact with a liquid-containing layer in the device, and then separation is realized by liquid trap; the fog drop liquid particles and the dust solid particles rotate at high speed along with the flue gas, centrifugal separation is realized by virtue of the density difference between the fog drop liquid particles and the flue gas as well as between the dust particles and the flue gas, and then the fog drop liquid particles and the dust solid particles are thrown onto the surface of the inner wall of the device and are removed after contacting a liquid film layer attached onto the wall surface of the device. The advanced dust-removing and demisting device has the advantages that efficient dust removing and demisting can be realized under the conditions of low running cost and investment cost; the device is simple and reliable in structure and free of a risk of blocking, and is also portable and safe.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

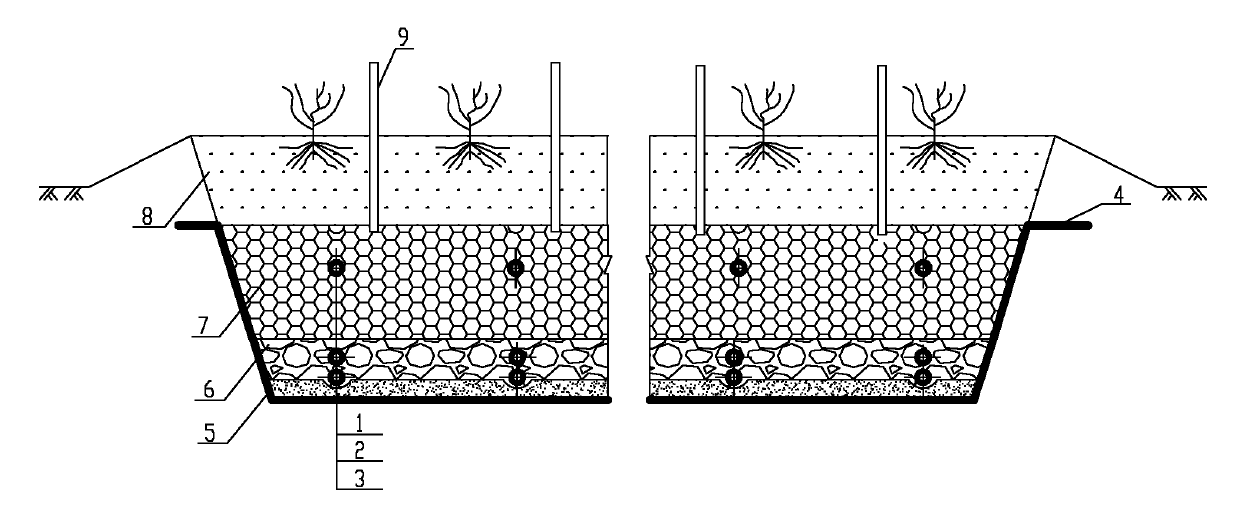

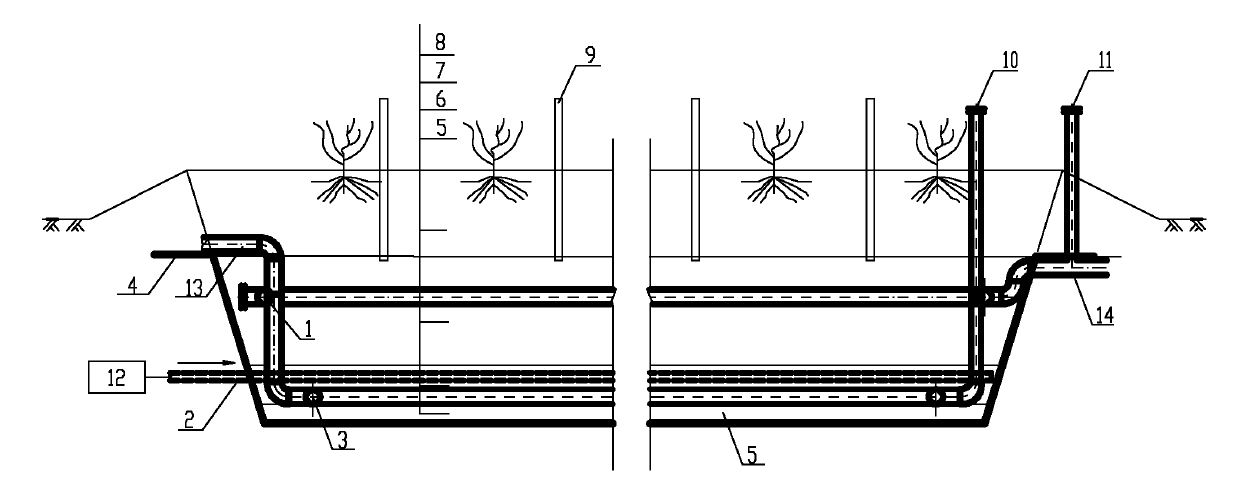

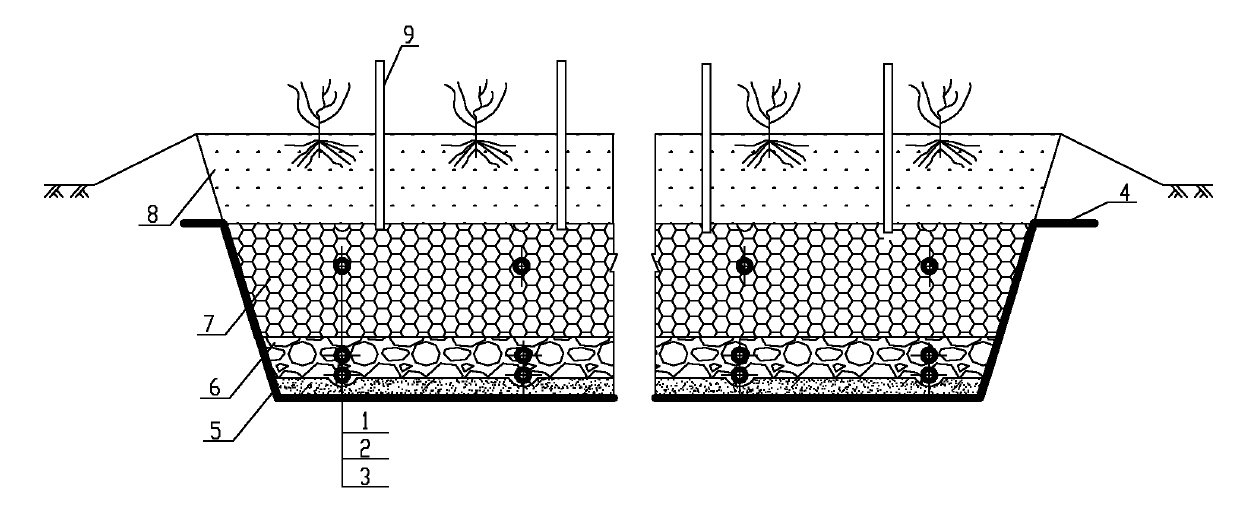

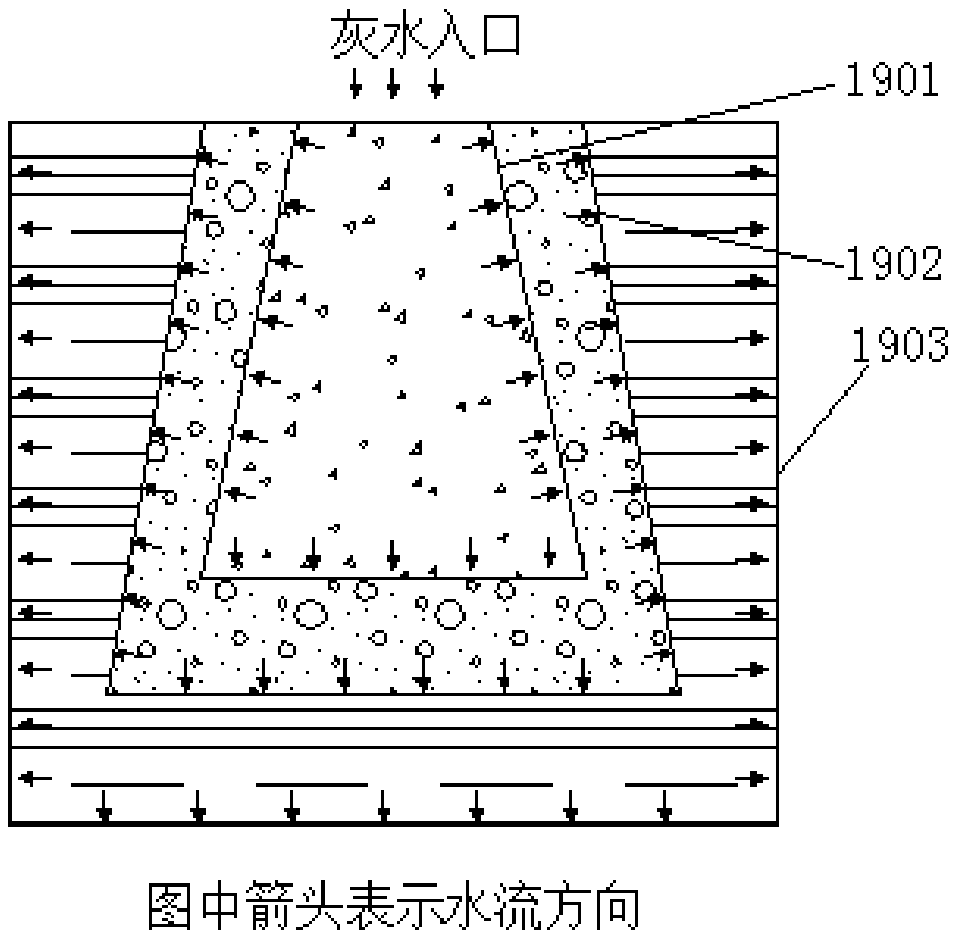

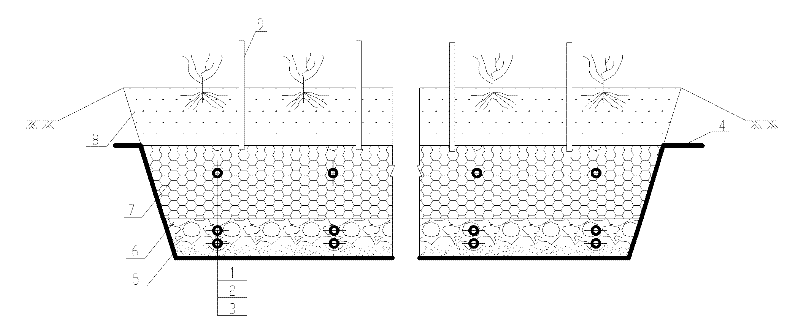

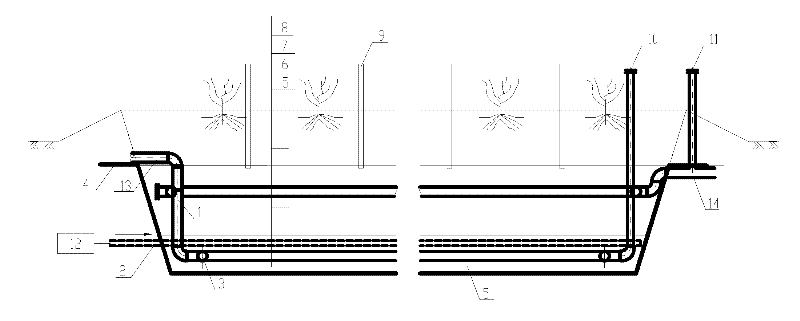

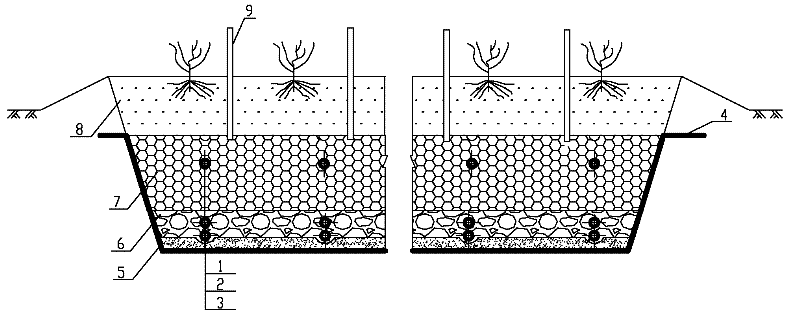

Sewage aerobic land treatment system

ActiveCN102001743ARelieve blockageRealize the function of removing ammonia nitrogenTreatment using aerobic processesEnergy based wastewater treatmentAeration systemPipeflow

The invention discloses a sewage aerobic land treatment system. The system comprises a groove body formed by digging under the ground, wherein impermeable membranes are laid at the periphery and at the bottom of the groove body; and a sand layer, a water distribution layer, a packing and water collecting layer and a soil layer are formed in turn from bottom to top. The sewage aerobic land treatment system is characterized by also comprising a blast aeration system consisting of a blast blower, an air diffusion device and a connecting pipeline, wherein the air diffusion device is positioned below the water surface of the land treatment system and connected with the blast blower through a pipeline; pretreated sewage enters the land treatment system; and air is pressurized by the blast blower and diffused into sewage of the system in the form of small air bubbles through the air diffusion device. Therefore, the aims of charging oxygen into the sewage and stirring are fulfilled, good reoxygenation effect, high mass transfer efficiency, quick bio-membrane updating and high treatment efficiency are achieved, and the problem of blockage of the land treatment system in the operating process is solved effectively.

Owner:QINGDAO LIGONG NEW ENVIRONMENTAL TECH DEV

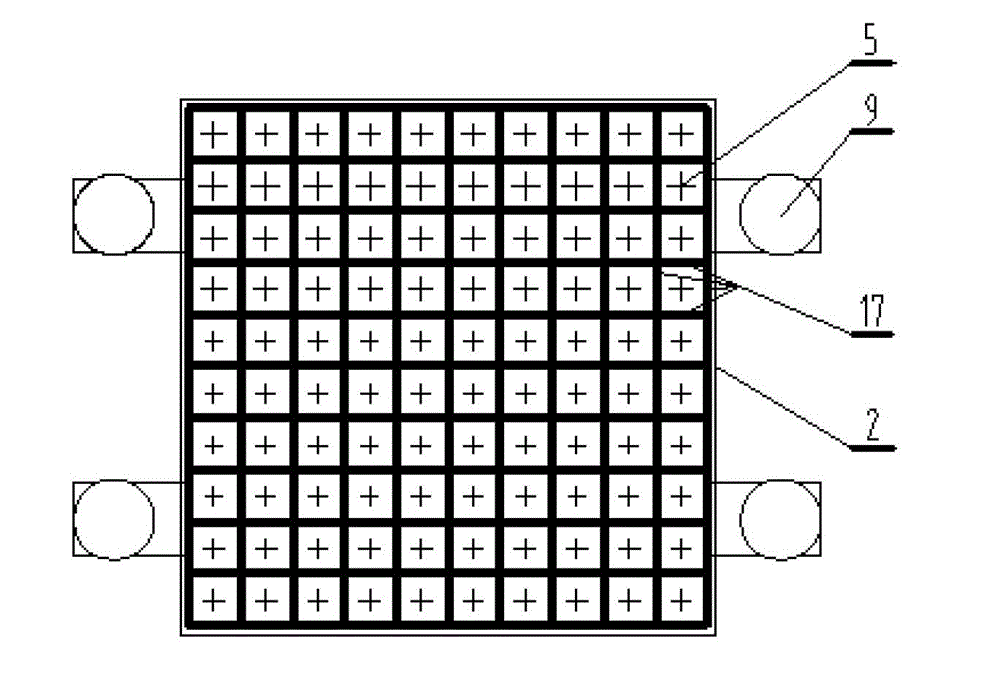

Rigid anode plate surface water film arrangement technology and device

ActiveCN102941158AStable removalEfficient removalExternal electric electrostatic seperatorElectrode constructionsParticulatesEngineering

The invention relates to a solid anode plate surface water film arrangement technology and device for an electrostatic dust collector. The device comprises clamp plate fastening bolts, suspension clamp plates, water distribution pipes, guide vanes, anode plate fastening bolts, anode plates, lower plate part positioning steel plates, lower plate part fixing shafts, and positioning steel plate fastening bolts. The surfaces of the anode plates are subjected to pretreatment of coating by a hydrophilization agent, and the upper parts of the anode plates are connected with the water distributed pipes through suspension clamps and are twisted to form the 45-degree guide vanes; corrugated guide trenches with widths of 5mm-8mm are formed in the front ends of the anode plates; stainless steel pipes are crossed and welded to form a gridding water distribution pipe net, water distribution holes are formed in the lower ends of the water distribution pipes and are connected with an external process water tank, and the quantity of water intake is controlled by a PLC (programmable logic controller); the vertical anode plates with the same width form an electrostatic field channel; upper and lower crossbeams of discharge electrodes are suspended by upper and lower insulating boxes respectively and are insulated from a casing; and ash hoppers are arranged below the anode plates. According to the invention, particulate matters settled on the surfaces of the anode plates can be cleaned away thoroughly in a water-film ash cleaning manner, and thus the smoke emission can reach the standard.

Owner:SHANDONG UNIV +1

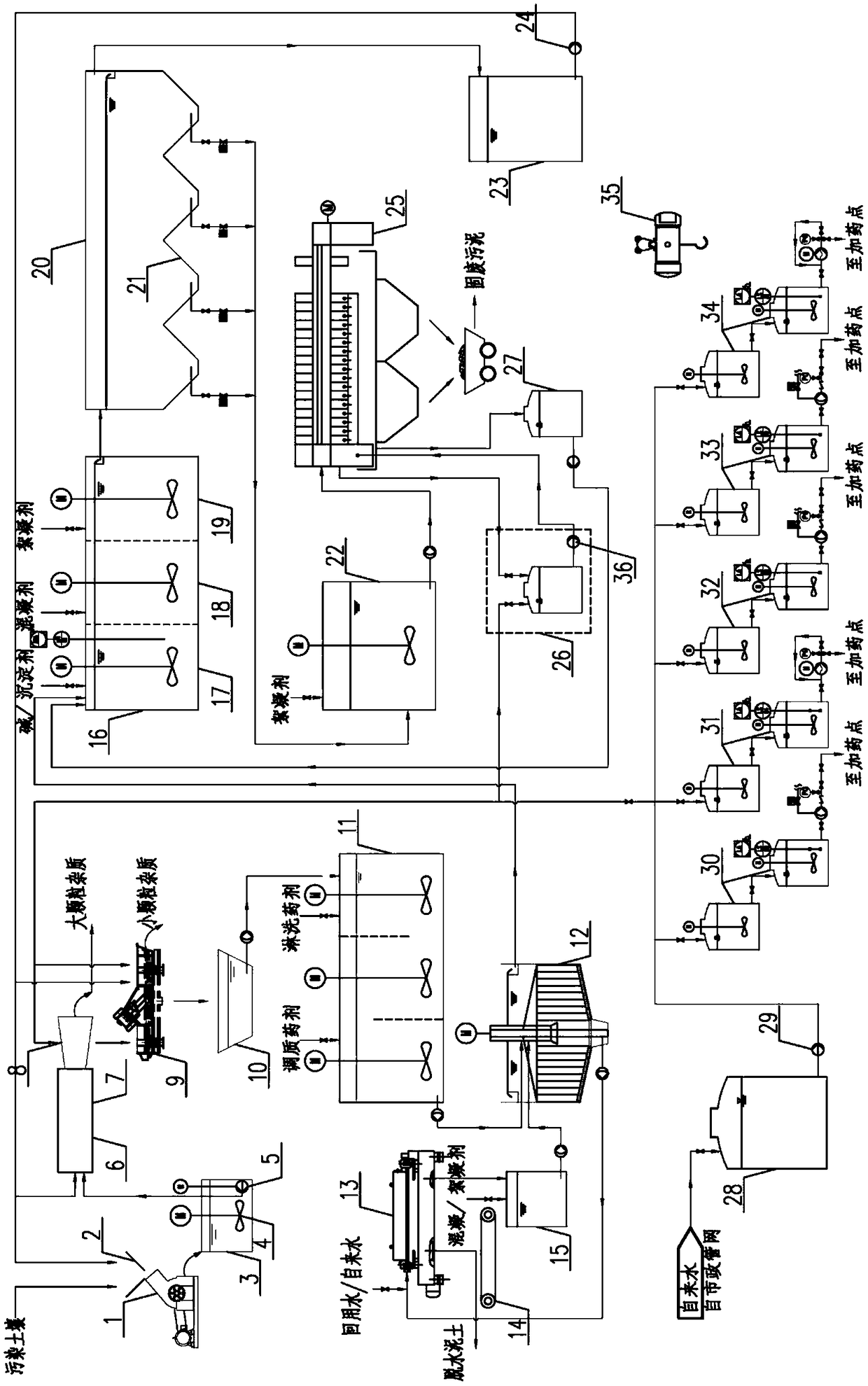

Ex-situ leaching remediation device suitable for remediation of cohesive soil pollution and remediation method

PendingCN109500074AImprove reuse rateImprove repair effectSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeSlurry

The invention relates to an ex-situ leaching remediation device suitable for remediation of cohesive soil pollution and a remediation method. The ex-situ leaching remediation device comprises a soil particle size grading and pulping unit, a leaching and dewatering unit, a wastewater treatment unit, a sludge treatment unit, an auxiliary constant pressure water supply unit and an auxiliary medicament allocation unit, wherein the soil particle size grading and pulping unit is composed of a wet crusher, a slurry collecting tank, a roller mud decomposing machine, a wet vibrating screen, a liquid collecting tank and the like, and the leaching and dewatering unit is composed of a leaching tank, a slurry concentration basin, a centrifugal dehydrator and the like; and the wastewater treatment unitis composed of a wastewater reaction combination tank, a wastewater sedimentation tank and the like, and the sludge treatment unit is composed of a sludge storage basin, a filter press and the like. The remediation method comprises the steps of crushing, pulping, screening, leaching, concentration, dehydration, and matching steps of wastewater treatment, sludge treatment, water supply, dosing andthe like. The ex-situ leaching remediation device and the remediation method are mainly suitable for the remediation of various heavy metal, organic or compound polluted soils including cohesive soils, and have the advantages of wide application range, stable remediation effect, simple operation and running, high wastewater recycling rate and the like.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES +1

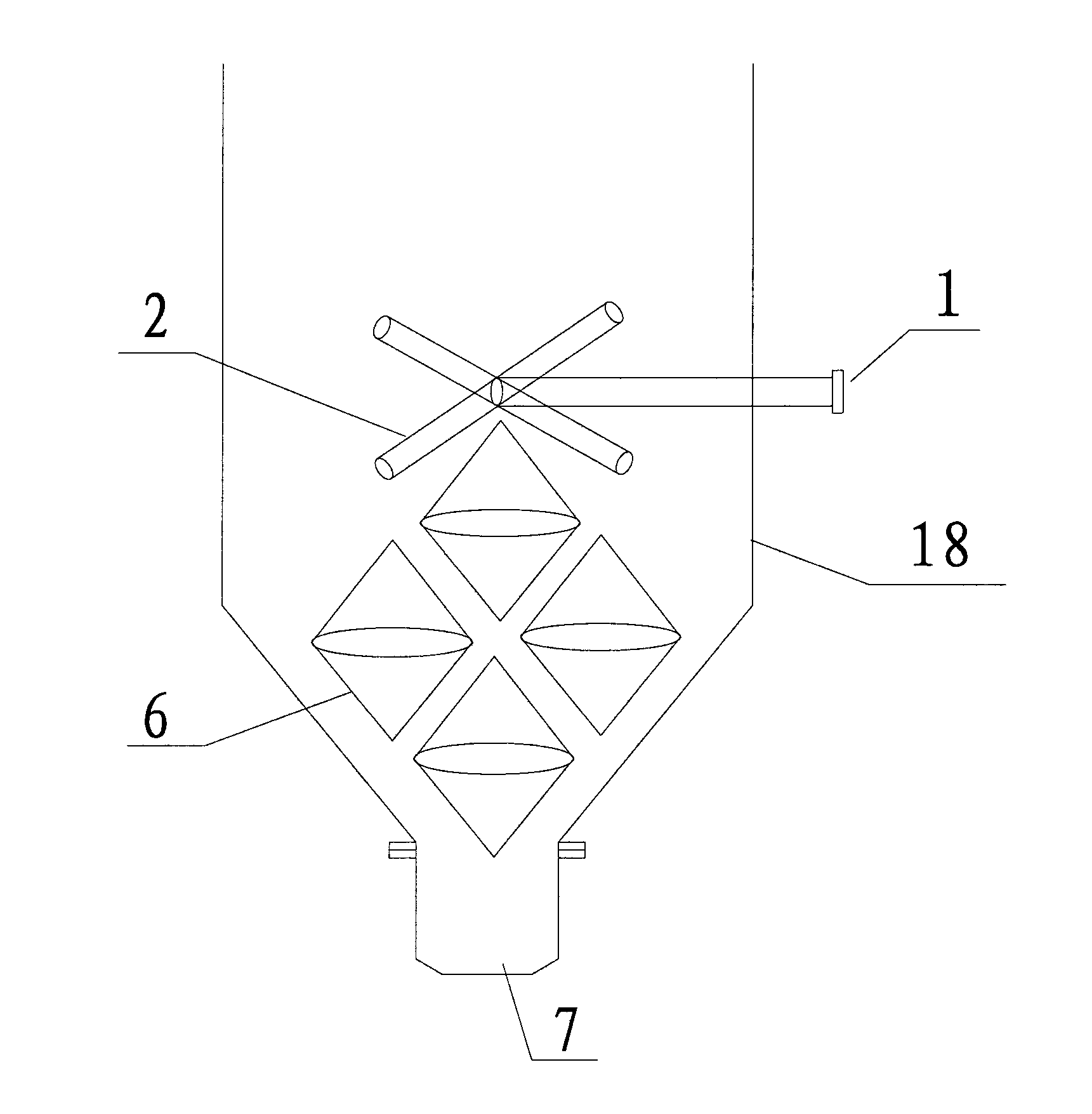

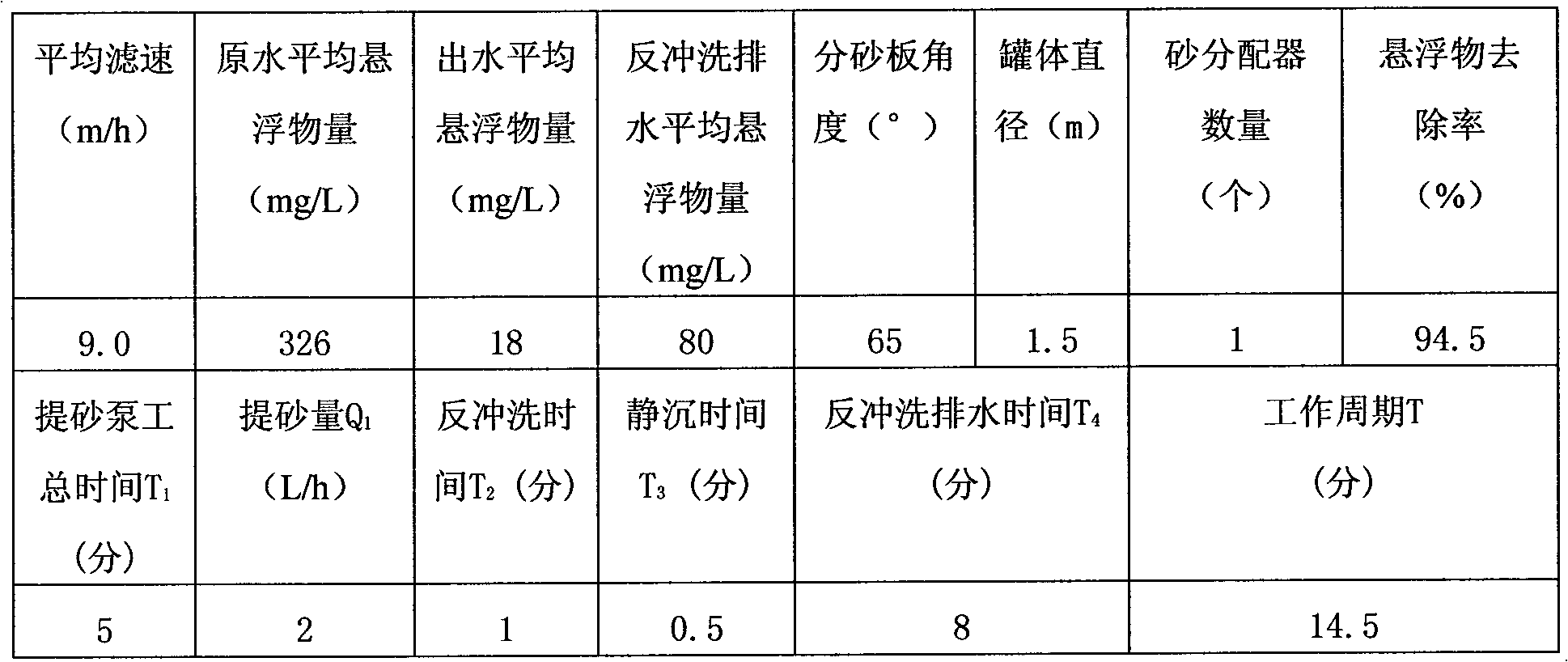

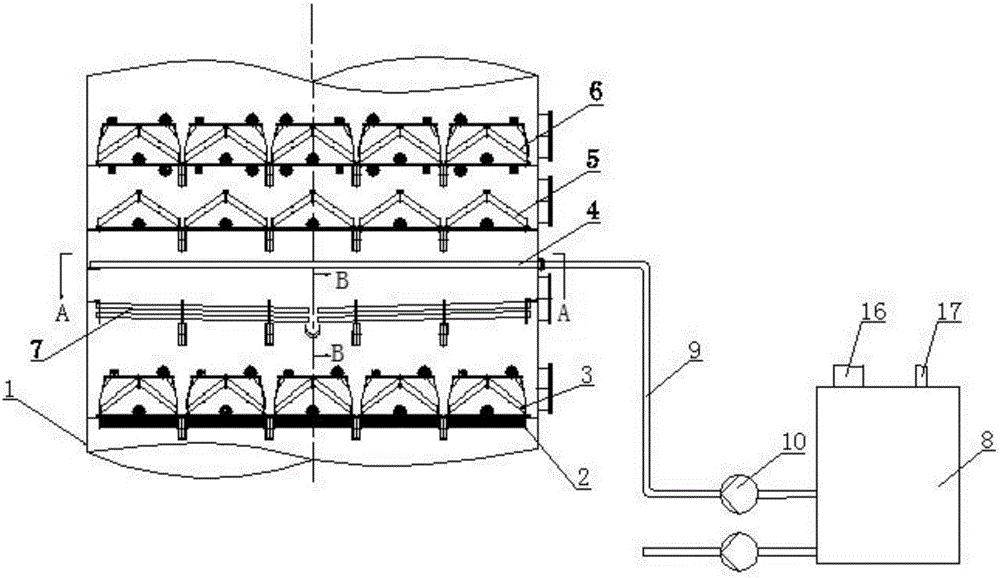

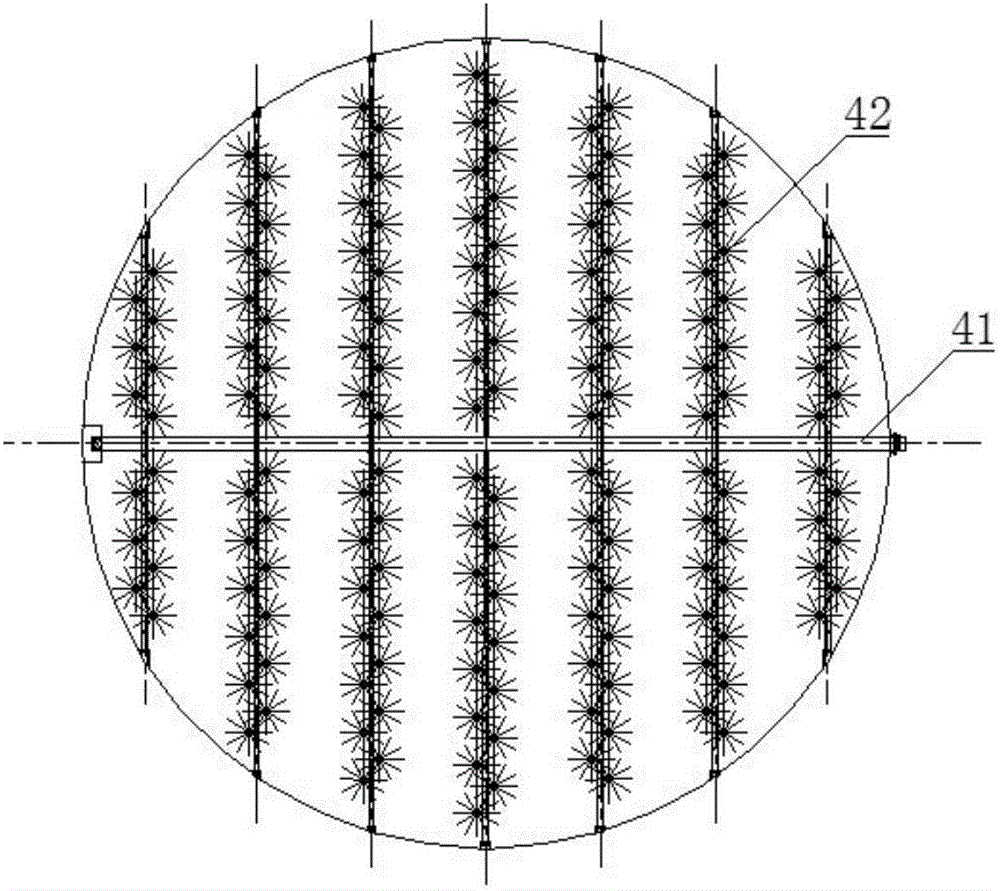

Water treatment method and device for synchronously realizing filtering and back washing

InactiveCN102847352AImprove pollution interception effectImprove work efficiencyLoose filtering material filtersGravity filtersWater dischargeWastewater

The invention discloses a water treatment device and method for synchronously realizing filtering and back washing. A filtering tank is installed on a supporting support, and the device is characterized in that the lower part of the filtering tank is connected with a water inlet tube and a water distribution device; a sand distribution device is arranged below the water distribution device; filter materials are placed in the filtering tank; a water outlet groove and a water discharge tube are arranged on the upper part of the filtering tank; a sand storage hopper is arranged at the bottom of the filtering tank; the sand storage hopper is externally connected with a sand transportation tube and a sand extraction pump; a back washing chamber is installed on the upper part of the filtering tank; the sand transportation tube is connected with the back washing chamber; sand-water separation is carried out on back washing water and inlet gas, clean sand enters a sand cleaning chamber and falls down a filter material layer; and separated back washing sewage is discharged out of the filtering tank from a back washing tube. A mode that waste water flows upwards is adopted, the filter material with the maximum sewage cutting amount in the filtering tank is located on the lower part of the whole filtering layer, sand in a lower layer falls down, replacement and changing are convenient through sand lifting, filtering and back washing can be synchronously operated, continuous operation of a filtering device is achieved, filtering layer sewage cutting capacity and work efficiency are improved, and the energy consumption and cost are reduced.

Owner:HUBEI ZHONGBI ENVIRONMENTAL PROTECTION TECHCO

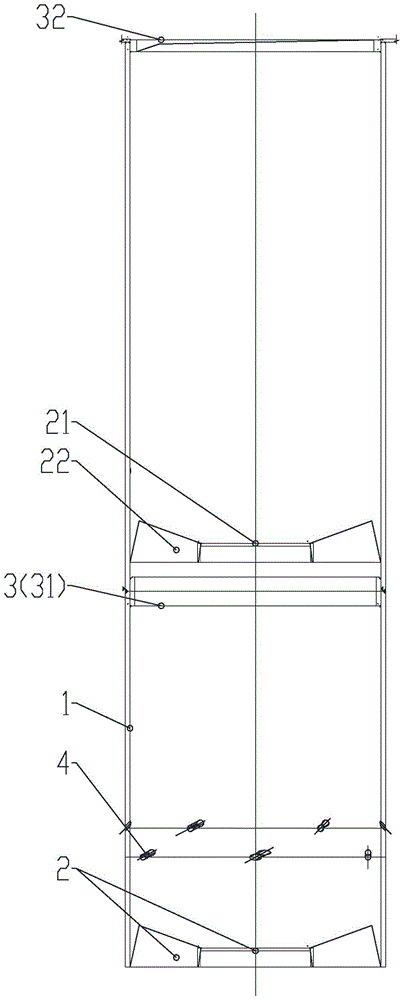

Desulfurizing tower spraying, condensing, amplifying, dedusting and demisting integrated device

InactiveCN106422633ASolve difficult-to-remove problemsLarge particle sizeCombination devicesTowerSpray cooling

A desulfurizing tower spraying, condensing, amplifying, dedusting and demisting integrated device comprises a desulfurizing tower, a demister and a spray cooling system. The device is technically characterized in that the demister is composed of a tubular demister, a first-stage weir-type demister, a second-stage thin-weir-type demister and a third-stage fine-weir-type demister which are sequentially arranged from bottom to top, the spray cooling system comprises a cooling water spray layer, a liquid collection tube grid and a cooling water tank, the cooling water spray layer is arranged between the second-stage fine-weir-type demister and the first-stage weir-type demister, the liquid collection tube grid is positioned between the cooling water spray layer and the first-stage weir-type demister, the cooling water spray layer is connected with the cooling water tank through a water supply pipe, a water supply pump is arranged on the water supply pipe, the top of the liquid collection tube grid is open, and the liquid collection tube grid is connected with the cooling water tank. By the device, synergistic dedusting capacity of the desulfurizing tower can be improved effectively, system flushing water amount can be reduced, gypsum carrying amount of smoke at an outlet of the desulfurizing tower can be lowered substantially, so that gypsum rain of a chimney is eliminated thoroughly.

Owner:哈尔滨电气环保有限公司

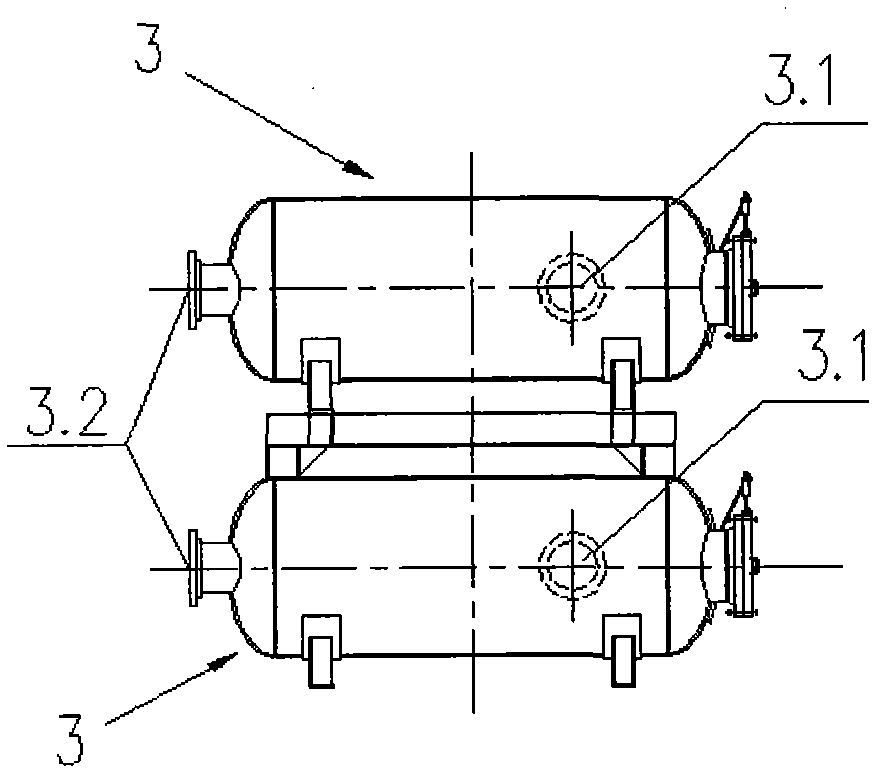

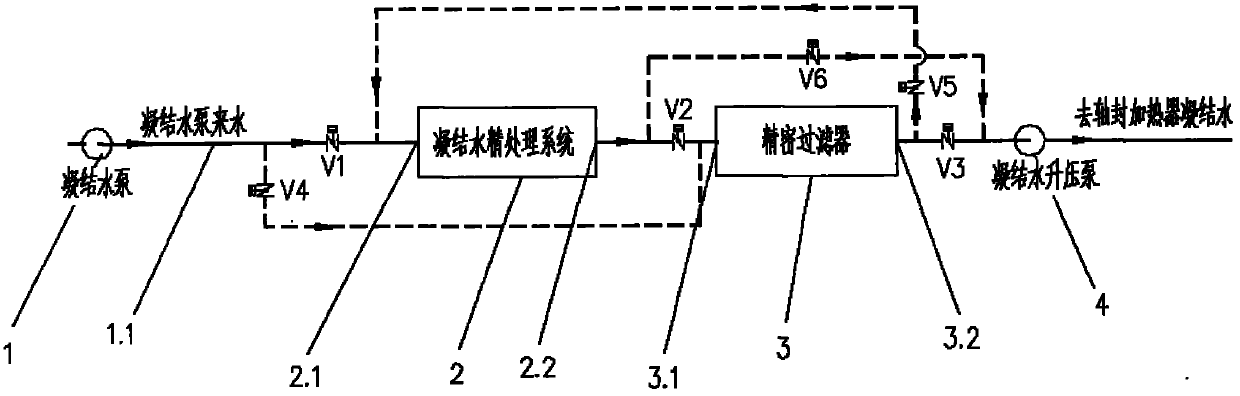

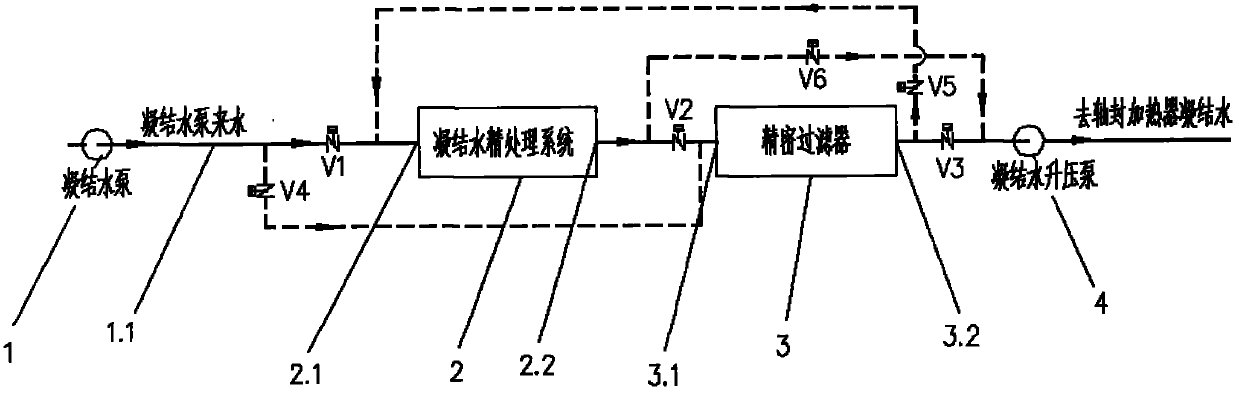

Precision filtering device and method for finely processing condensation water from nuclear power station

ActiveCN101947398AGuaranteed uptimeAvoid it happening againFiltration separationStart timeNuclear power

The invention discloses precision filtering device and method for finely processing condensation water from a nuclear power station, relating to the field of nuclear power stations, wherein the precision filtering device is arranged between a condensation water pump and a condensation water booster pump; the precision filtering device comprises a precision filter and a valve; when the nuclear power station runs, water from the condensation water pump passes through a condensation water fine processing system and the precision filter in sequence and finally goes to the condensation water booster pump; and when the nuclear power station is started, water from the condensation water pump passes through the precision filter and the condensation water fine processing system in sequence and finally goes to the condensation water booster pump. A rear precision filter and a front precision filter in the embodiment are the same equipment and are switched by the valve to achieve use in front during starting or use at rear during the normal running, the steam-water quality of the secondary circuit of the nuclear power station is not only improved, the safe and high-level running of the nuclear power station is effectively ensured, but also the start time of the unit is greatly shortened, and the washing water amount at the starting of the unit is reduced.

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD

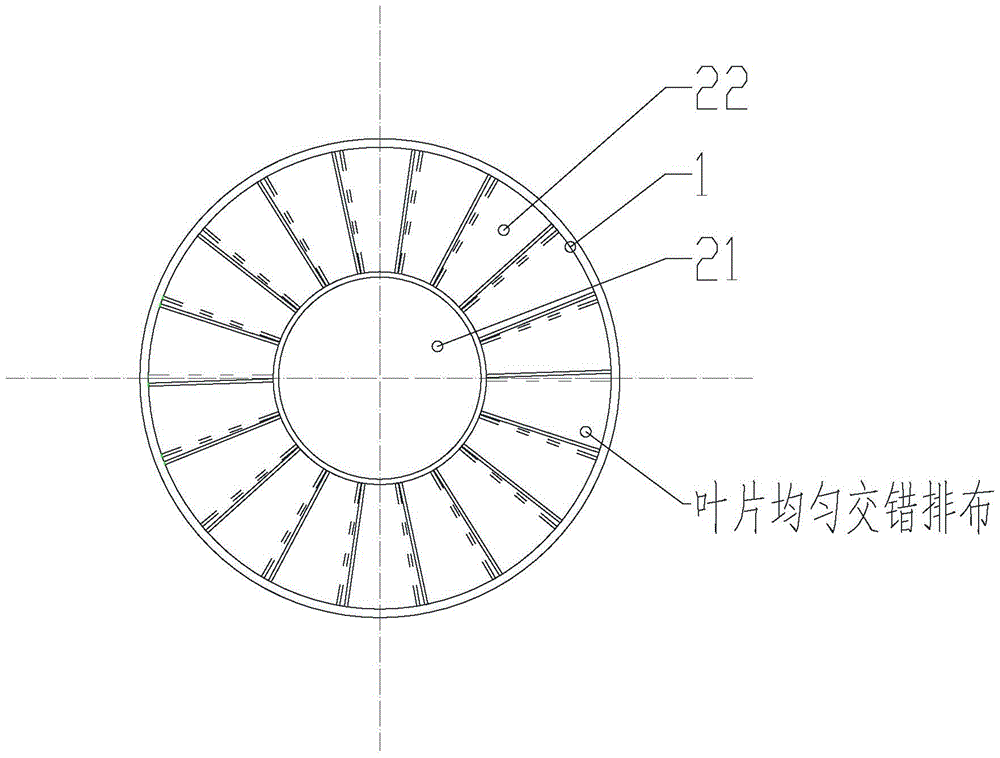

Dust collection polar plate of wet-type electric dust collector

ActiveCN103878066AReduce the amount of flushing waterSmall footprintExternal electric electrostatic seperatorElectrode constructionsThree dimensional shapeElectrostatic precipitator

The invention relates to a dust collection polar plate of a wet-type electric dust collector. The surface of the dust collection polar plate is in a convex-concave shape, a slot is formed on one concave part, the slots are arranged in rows on the surface of the polar plate and uniformly distributed, the centers of the two rows of slots are arranged in a staggered manner, the slots are distributed in a triangular shape, and are smoothly connected with each other, and the three-dimensional shape of each slot is a spherical crown body or a pyramid body. The concave-convex dust collection polar plate has a function of transversely buffering and uniformly distributing the water flow, the flow direction of the water flow can be controlled in a guiding manner, a uniform water membrane can be formed on the entire surface of the polar plate, the rinsing water amount of the polar plate is reduced, and the water consumption can be reduced; the length of the polar plate can be increased from 6m to 8m to 8m to 13m, and the occupied area of the equipment can be reduced; the formation of channeling on the polar plate can be avoided, the running stability of the equipment can be improved, and the purification efficiency can be guaranteed.

Owner:中钢集团天澄环保科技股份有限公司

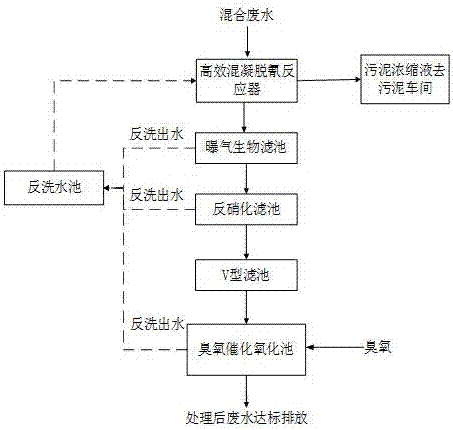

Method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of industrial park

InactiveCN107010782ASimple processSmall footprintWater treatment parameter controlTreatment using aerobic processesCyanideCatalytic oxidation

The invention relates to a method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of an industrial park. The method comprises the following steps: wastewater enters a high-efficiency coagulated decyanation reactor to remove total cyanogen in the wastewater removed from the coagulated decyanation reaction; effluent from the coagulating reaction enters an aeration biofilter, ammonia and nitrogen in the wastewater is oxidized into nitrate nitrogen or nitrite nitrogen, and partial organic matters are oxidized and removed; effluent from the aeration biofilter flows into a denitrification filter tank, and nitrate nitrogen and nitrite nitrogen in the wastewater are denitrified into nitrogen and removed; effluent from the denitrification filter tank is filtered in a V-shaped filter tank and then enters an ozone catalytic oxidation tank, and insoluble organic matters are oxidized into small-molecular organic matters or mineralized in the presence of a catalyst. The method can be used for oxidizing and degrading organic matters while removing total cyanogen and total nitrogen in the wastewater to ensure that treated effluent can be emitted in standard, thus having an excellent market prospect.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL TECH RES INST CO LTD

Small rapid filter equipped with air and water backwash system and filtering and backwashing technology thereof

ActiveCN104623935AImprove washing effectExtend the filter cycleLoose filtering material filtersGravity filtersFiltrationFilter material

The invention discloses a small rapid filter equipped with an air and water backwash system. The small rapid filter comprises a filter body and is characterized in that the filter body is provided with a filter material layer, and the bottom of the filter material layer is provided with air and water distribution pipes which are also used as water collecting devices and water and air distribution devices for air and water backwashing; and the top and side wall of each water and air distribution pipe are provided with backwashing air holes, and each pipe bottom is provided with backwashing water holes. From the bottom to the top, the bottom of the filter is respectively provided with a lower supporting layer, water and air distribution pipes, an upper supporting layer and a filter material layer. One side of the filter is communicated with an intake canal, and the other side is communicated with the a water and air distribution chamber through the water and air distribution pipes; one end of the intake canal is provided with a water inlet pipe, and the other end is provided with a backwashing drainage pipe; and one end of the water and air distribution chamber is provided with a backwashing air pipe and a backwashing water pipe, and the other end is provided with a water outlet pipe. In operation, the fast filter reaches a filtration rate of 8 m / h, filtration period of 24-48 h, and water treatment amount of 700 m<3> / d. According to water supply demand, multi-group fast filters can be arranged for parallel operation, and the capacity expanding is convenient with basically no building work amount.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

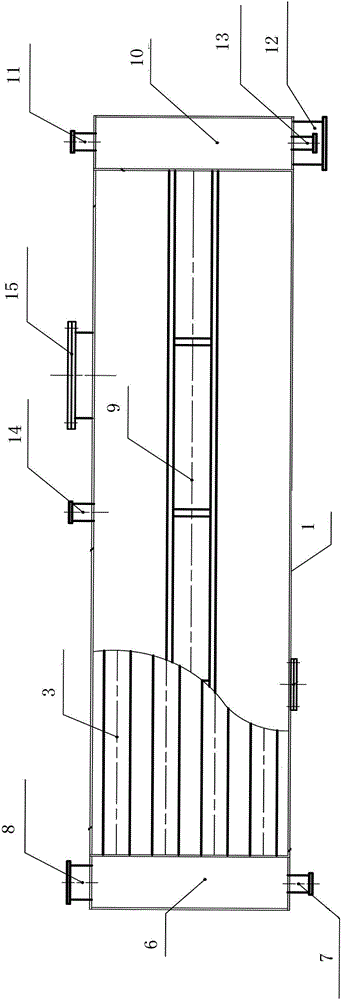

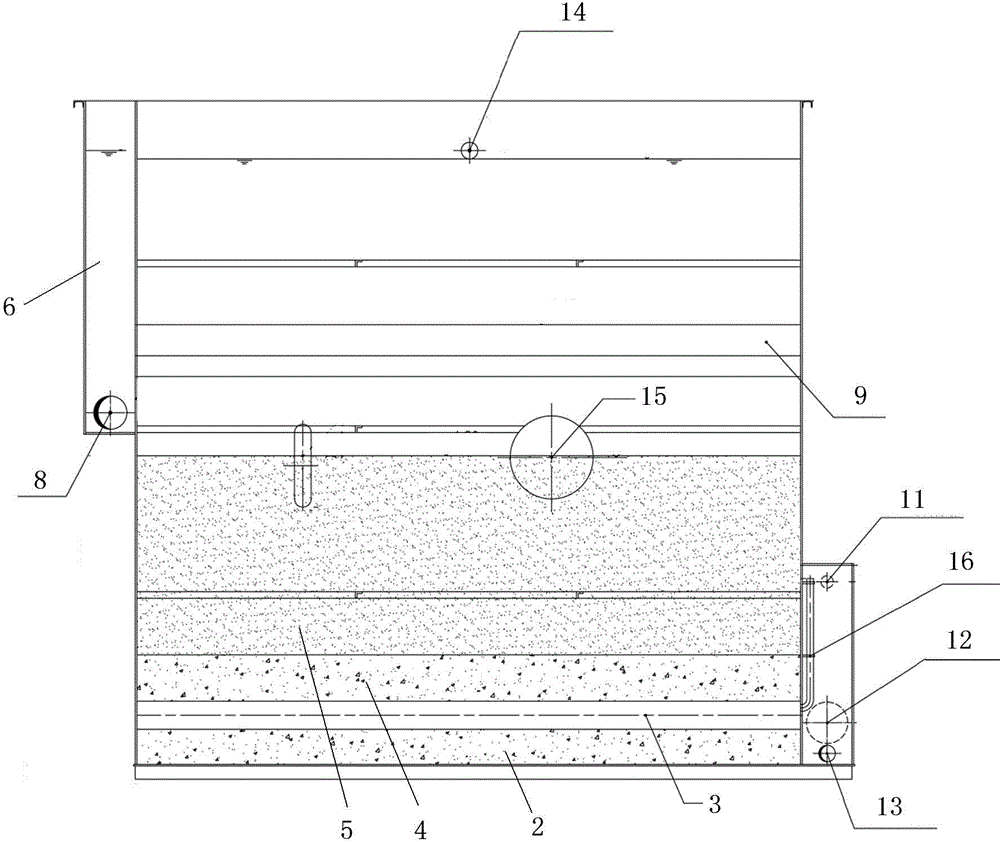

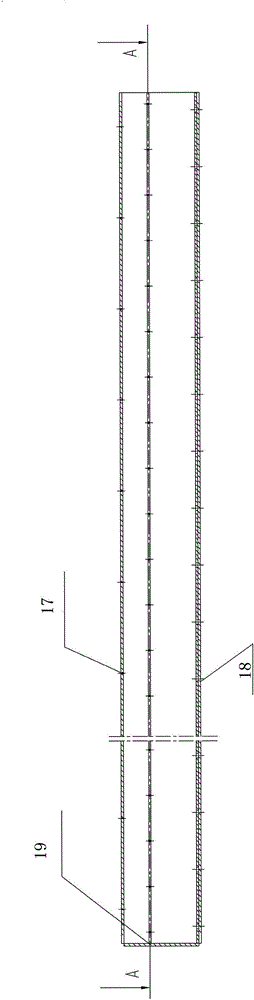

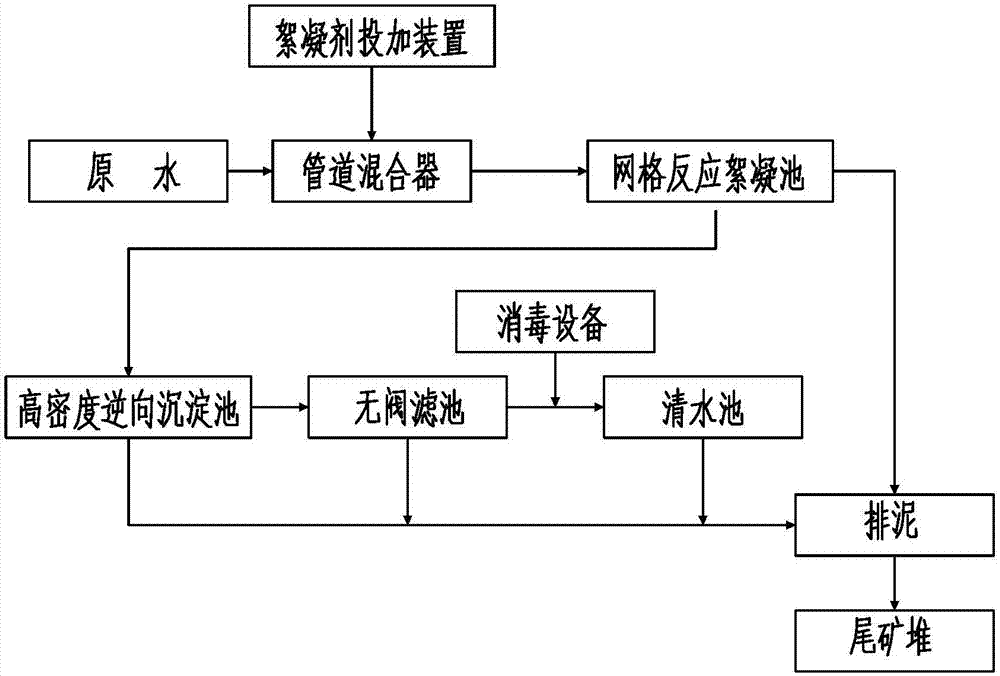

Integrated mine water purification system

PendingCN106865822AReduce consumptionReduce energy consumptionWaste water treatment from quariesSpecific water treatment objectivesMicroorganismRinse water

The invention discloses an integrated mine water purification system which comprises a pipeline mixer, a grid reaction flocculation tank, a high-density reverse sedimentation tank, a valveless filter tank and a clear water tank which sequentially communicate from front to back; mine wastewater sequentially enters the pipeline mixer and the grid reaction flocculation tank, silt, suspended matters and heavy metal ions are removed and then the treated water automatically enters the high-density reverse sedimentation tank, suspended matters in the purified water A are removed, and then the treated water automatically enters the valveless filter tank, and after micro suspended matters and microorganisms are removed, the treated water automatically enters the clean water tank. The integrated mine water purification system is energy-saved and has small water inlet energy consumption and saves the washing water amount, is high in efficiency, higher in volume utilization rate, smaller in occupied area, reasonable in structure and convenient to operate and manage.

Owner:SOUTHWEST JIAOTONG UNIV +1

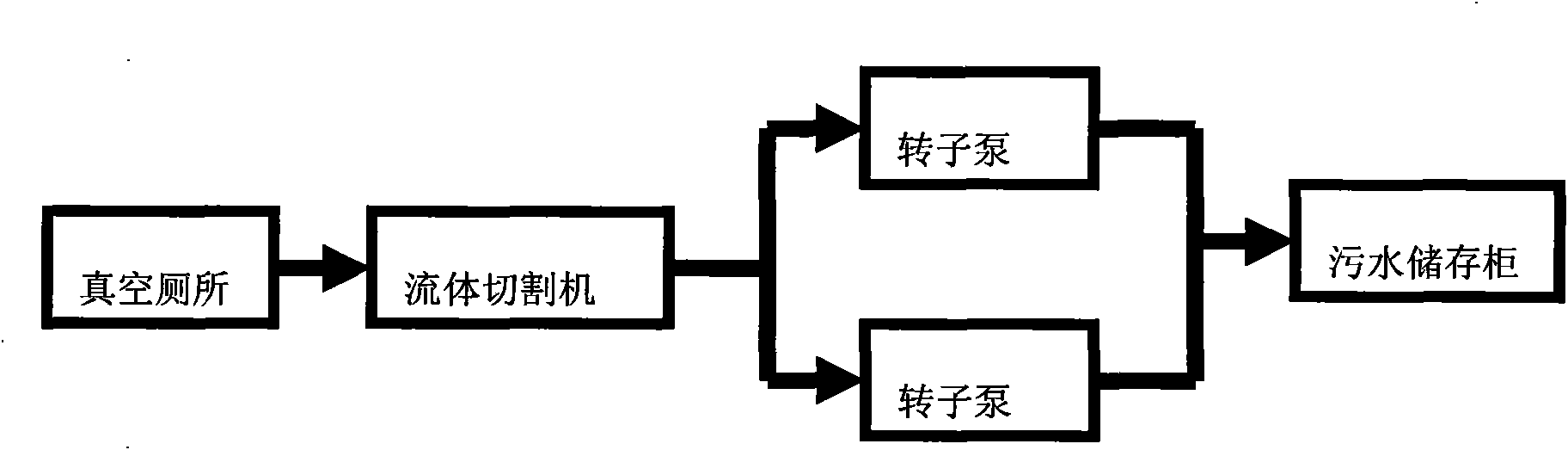

Vacuum water-saving public toilet

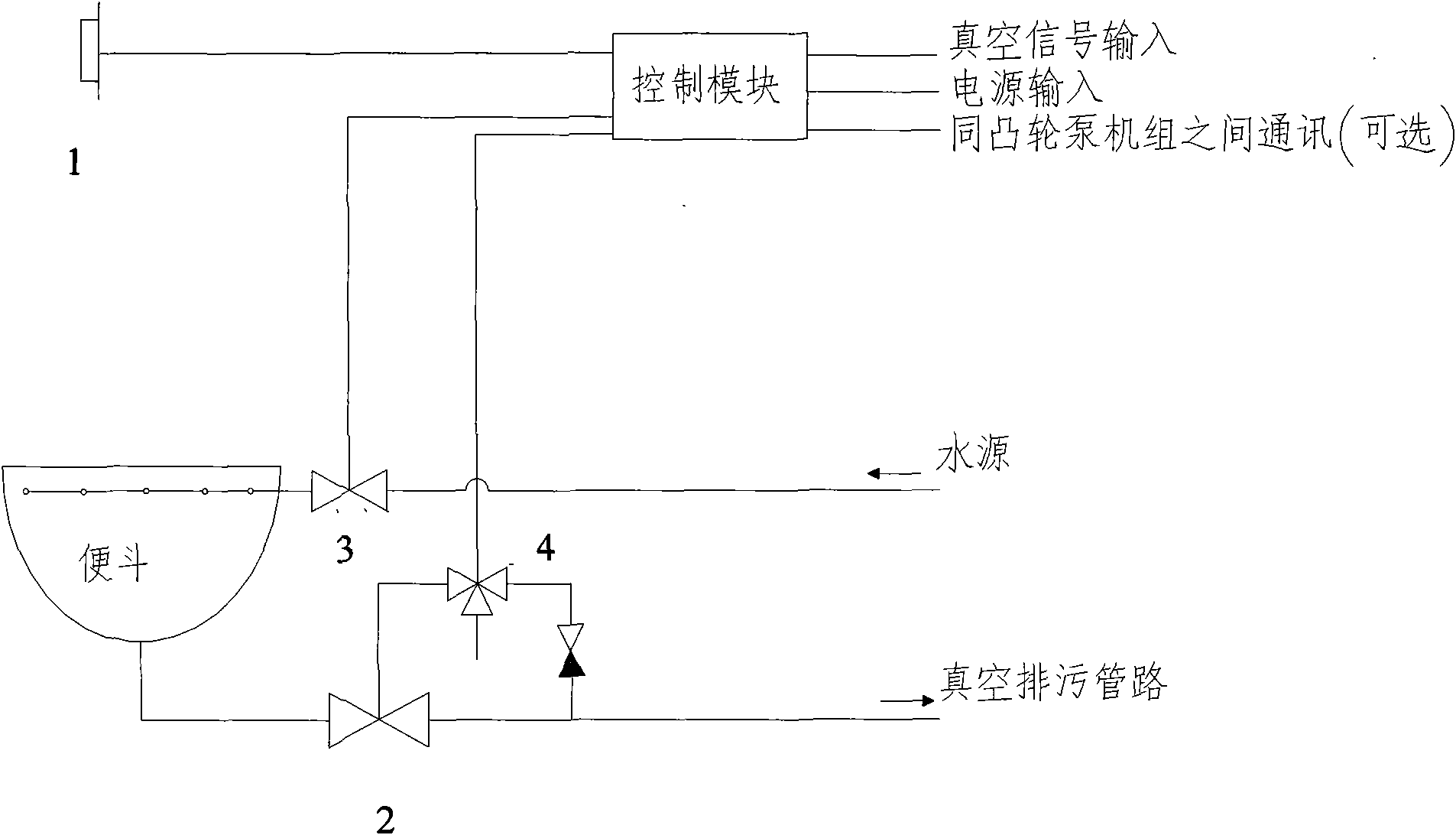

PendingCN108867789AIncrease profitPrevent overflowLavatory sanitorySewage drainingWater savingWastewater

The invention discloses a vacuum water-saving public toilet, comprising a vacuum toilet, a urinal, a clean water tank, a gray water tank, an intermediate tank and a vacuum sewage tank, wherein the gray water tank is configured to receive water drained from a wash basin and treat the drained water for flushing the vacuum toilet and the urinal; the clean water tank is configured to provide hand washing water, and to provide clean water for flushing the vacuum toilet and the urinal when the water in the gray water tank is insufficient; the intermediate tank is configured to receive and temporarily store sewage from the urinal, and discharge the sewage to the vacuum sewage tank when a certain amount of sewage is accumulated; the vacuum sewage tank is configured to have a certain degree of vacuum and suck sewage in the vacuum toilet and the intermediate tank in vacuum. The vacuum water-saving public toilet can reduce the water consumption of public toilets, improve the utilization rate of waste water, avoid the overflow of odor in the sewage tank, and effectively improve the toilet environment.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

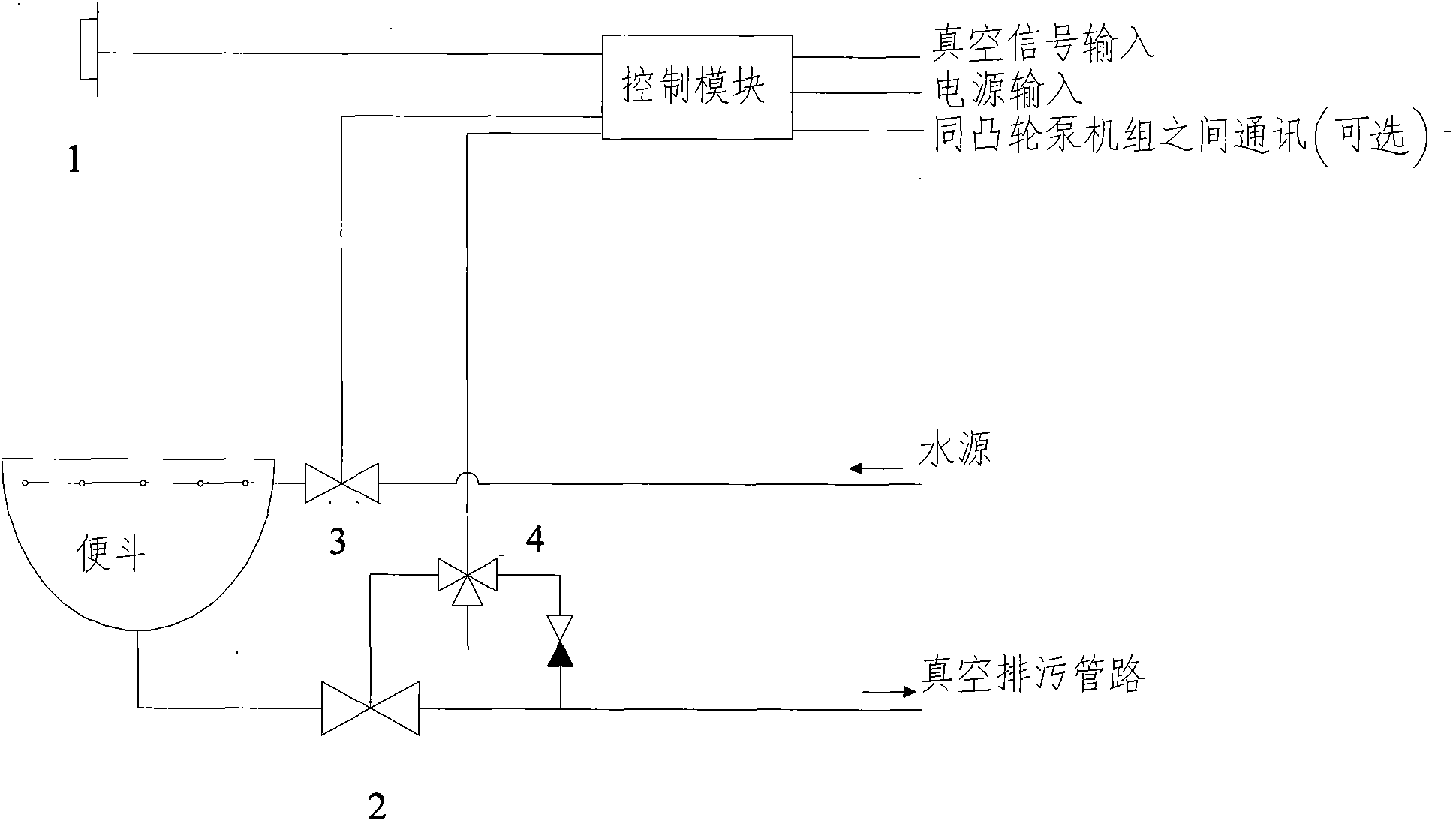

Sewage vacuum discharge and treatment system for marines

ActiveCN101618928AReduce the amount of flushing waterSmall diameterAuxillariesMultistage water/sewage treatmentWater qualitySewage

The invention discloses a sewage vacuum discharge and treatment system for marines, belonging to the technical field of sewage treatment and discharge devices and comprising a sewage vacuum collection device and a sewage treatment device, wherein the sewage vacuum collection device is closely communicated with the sewage treatment device by a rotor pump assembly and a vacuum discharge pipeline; the sewage treatment is sequentially connected with a crushing pump for collecting and crushing large granular impurities, a grid for filtering suspended matters and impurities, a tank for collecting sewage, a fur collector for removing furs and small granular suspended matters, a bio-membrane reactor and a sterilizing device. The invention adopts a modularized design on the whole, combines flexibly according to the space of the marine body, is particularly suitable for the reconstruction and the improvement of the domestic sewage treatment device for marines, not only saves space and water, has compact arrangement, safety and sanitation as well as easy maintenance, but also decreases the influence of the swing of a marine body on the water quality and has high pollutant degradation efficiency and directly-reused discharged water.

Owner:SHENZHEN JINRUN IND

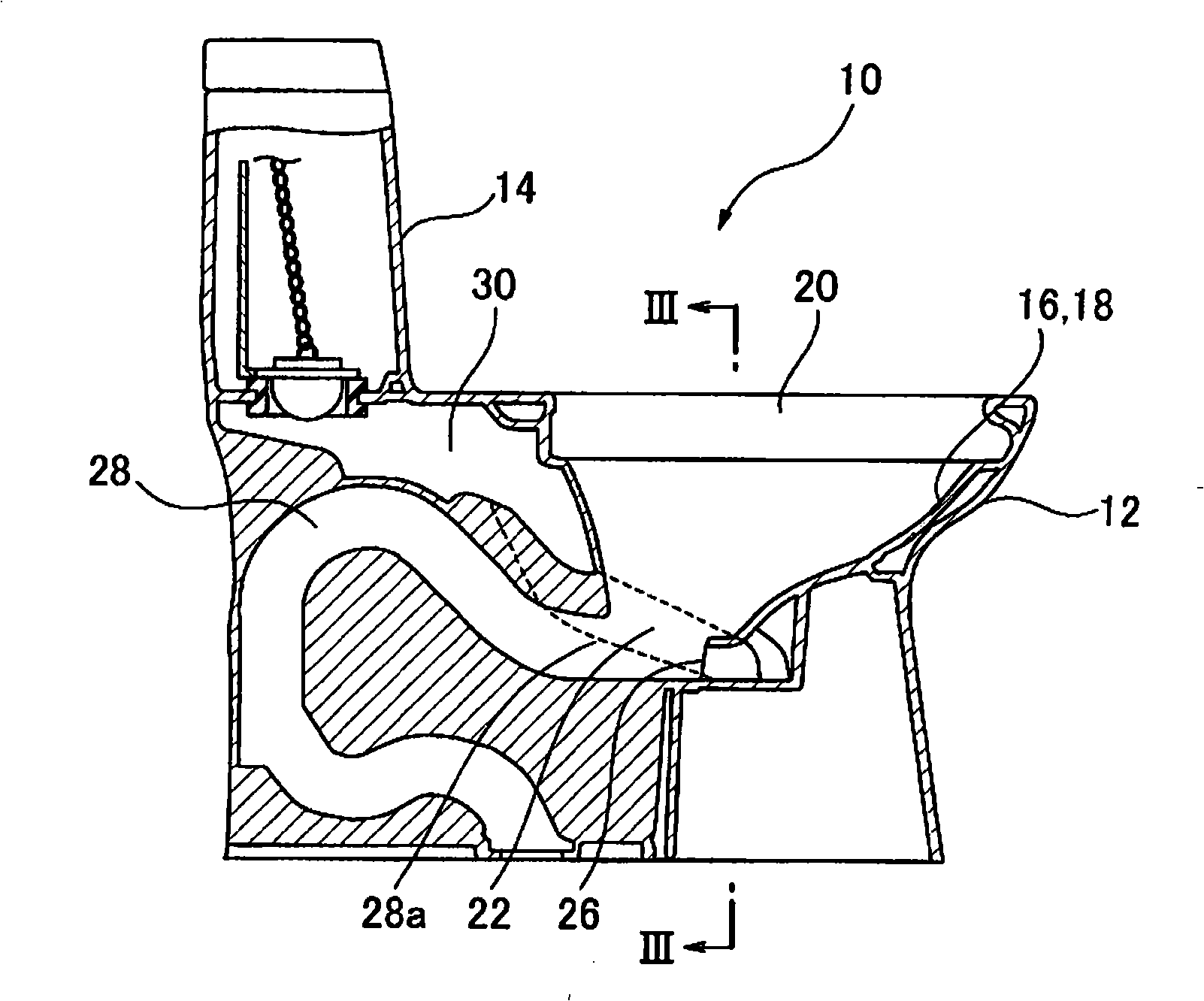

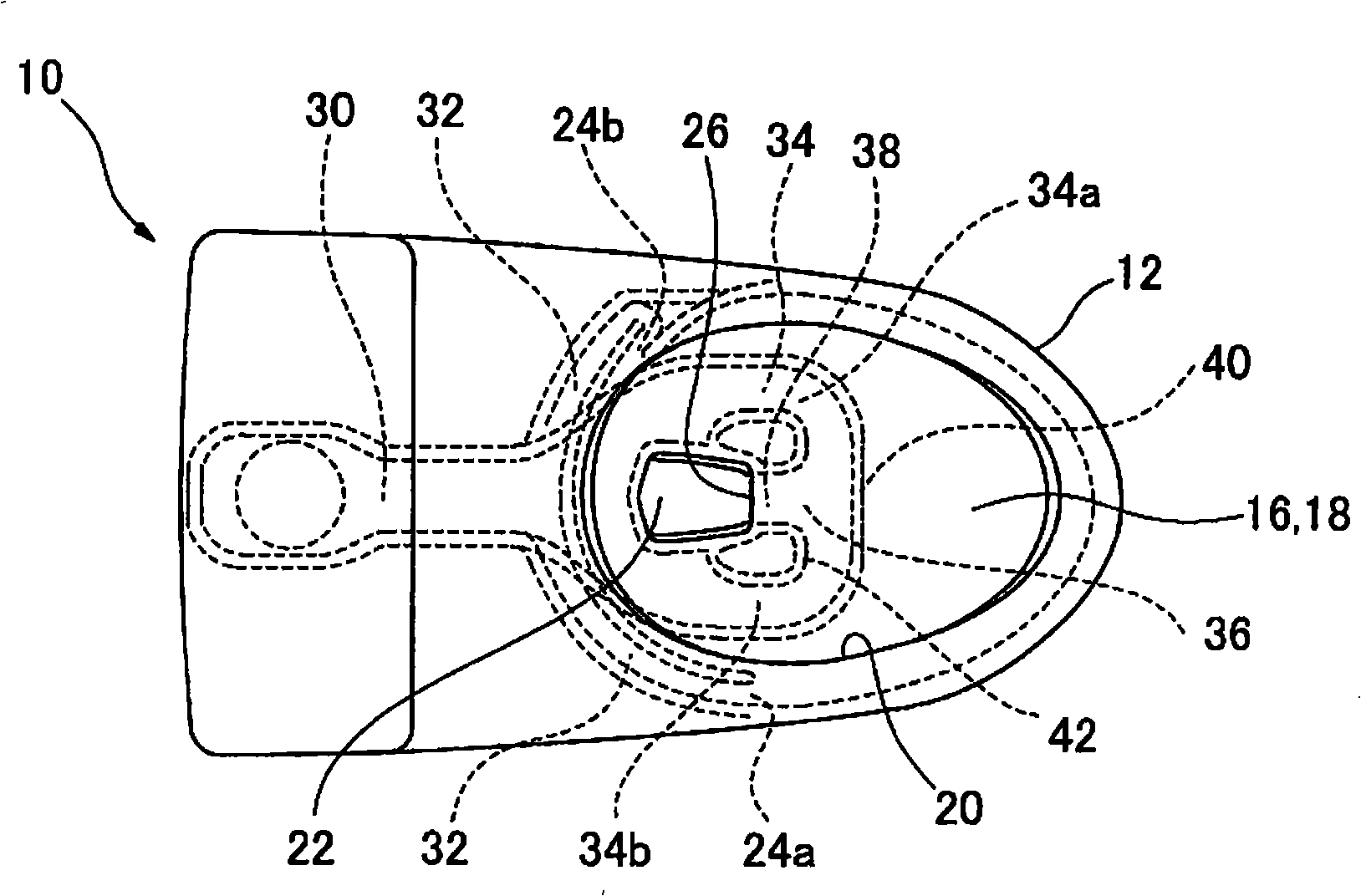

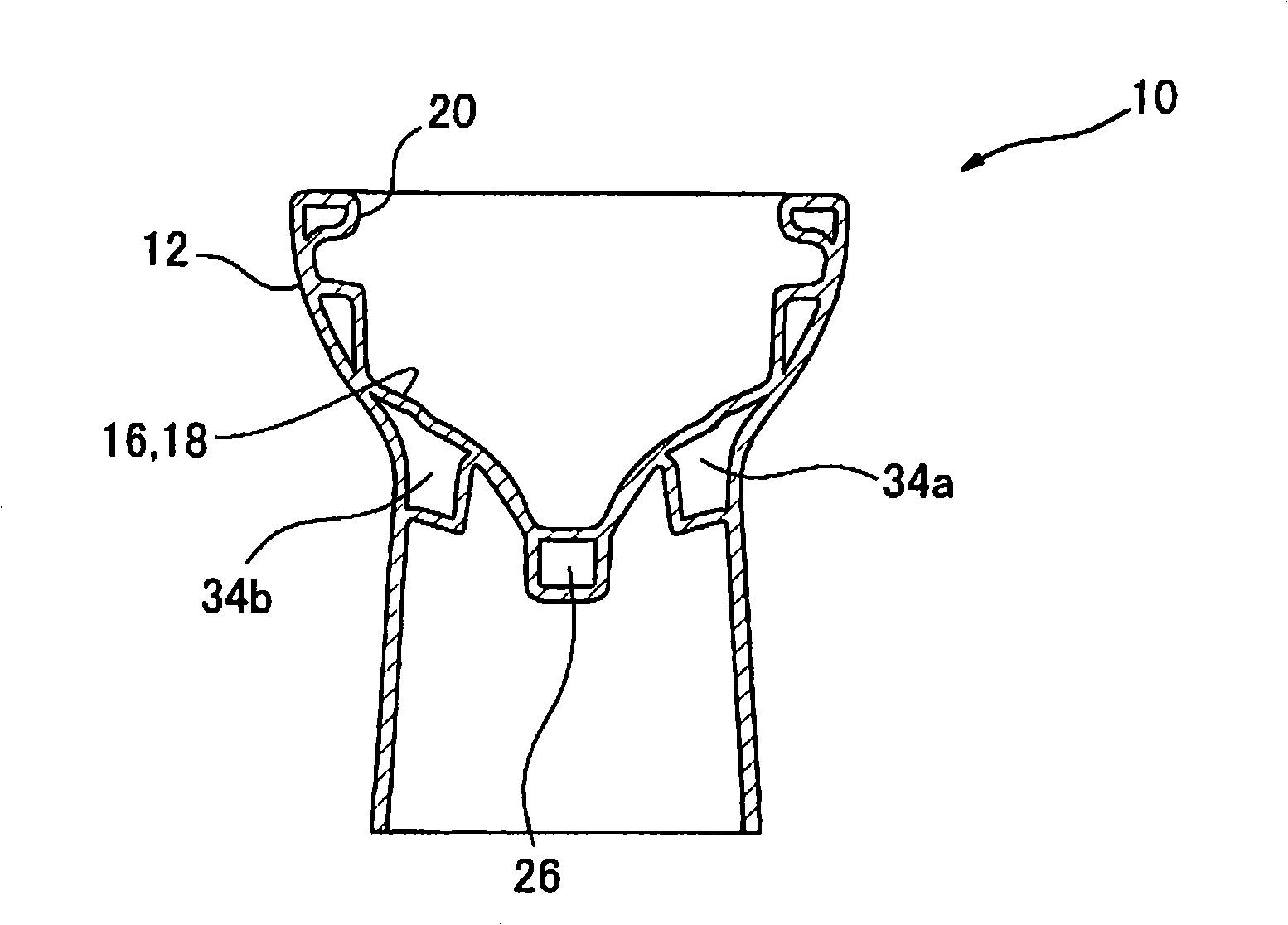

Siphon jet w.c.pan

ActiveCN101298785AProduce siphon effectReduce the amount of flushing waterUrinalsWater closetsSiphonWater channel

A siphon jet toilet for supplying flush water in a storage tank by using the head pressure thereof is disclosed. The siphon jet toilet has a toilet main unit furnished with a bowl portion, a rim water spout, a drain trap passage for expelling waste using siphon action, a jet water spout opening formed at a position opposite the inlet of the drain trap passage, a rim water channel for supplying flush water to the rim water spout opening, and a jet water channel for supplying flush water to the jet water channel. The jet water channel includes a plurality of branched water conduits, a merging portion for causing flush water from the plurality of branched water conduits to merge and swirl toward the jet water spout opening and a flow aligner for aligning the flow of flush water merged in the merging portion.; The merging portion including an outer wall portion formed in essentially a straight line so that flush waters in the outer region of the swirl collide head-on and an inner wall portion on which a bent portion is formed so that flush water in the inner region of the swirl flows smoothly toward the jet water spout opening.

Owner:TOTO LTD

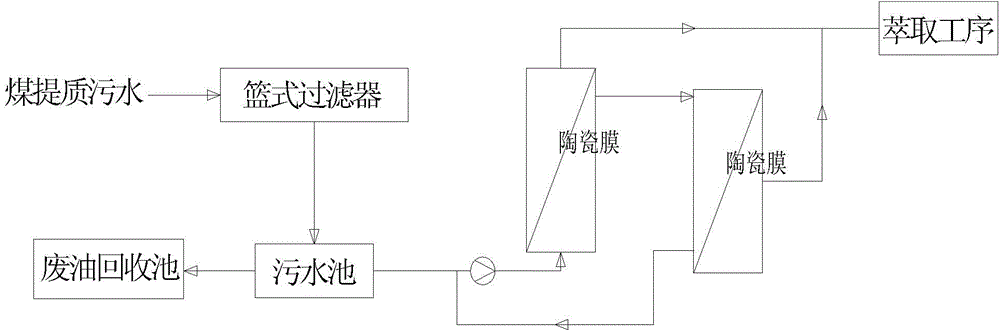

Oil removal process for quality improving sewage of coal

InactiveCN104528974AImprove washing effectIncrease water flowWater contaminantsTreatment involving filtrationWastewaterCeramic membrane

The invention discloses an oil removal process for quality improving sewage of coal. The process comprises the following steps: a, filtering quality improving sewage of coal to remove large particle pollutants; filtering and feeding into a sewage pool; b, pumping sewage in the sewage pool by using a material feeding pump into a #1 ceramic membrane filter to be filtered; and c, feeding sewage discharged from a drain outlet of the #1 ceramic membrane filter into a #2 ceramic membrane filter to be filtered, returning sewage discharged from the drain outlet of the #2 ceramic membrane filter directly back to the inlet of the material feeding pump, and feeding wastewater discharged from the water outlets of the #1 ceramic membrane filter and the #2 ceramic membrane filter into the next step. By using the process disclosed by the invention for removing oil from quality improving sewage of coal, the oil ratio of effluent is less than 20mg / L, so that the requirement of a subsequent extraction and biochemical system on the oil ratio is satisfied. The oil removal process for quality improving sewage of coal disclosed by the invention is simple, rapid, efficient and energy-saving, the cleaning period reaches 6-8 days, and the process is worth popularizing and applying.

Owner:CHENGDU HOT NEW ENERGY TECH

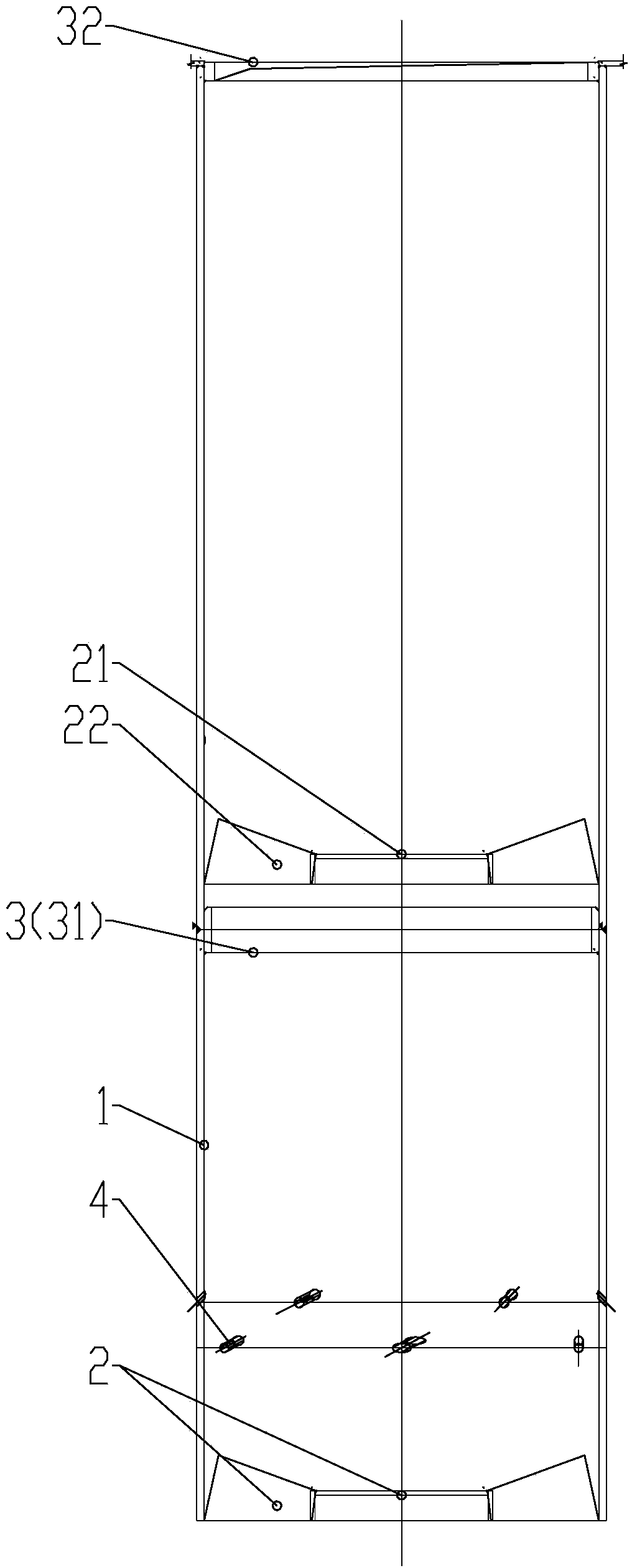

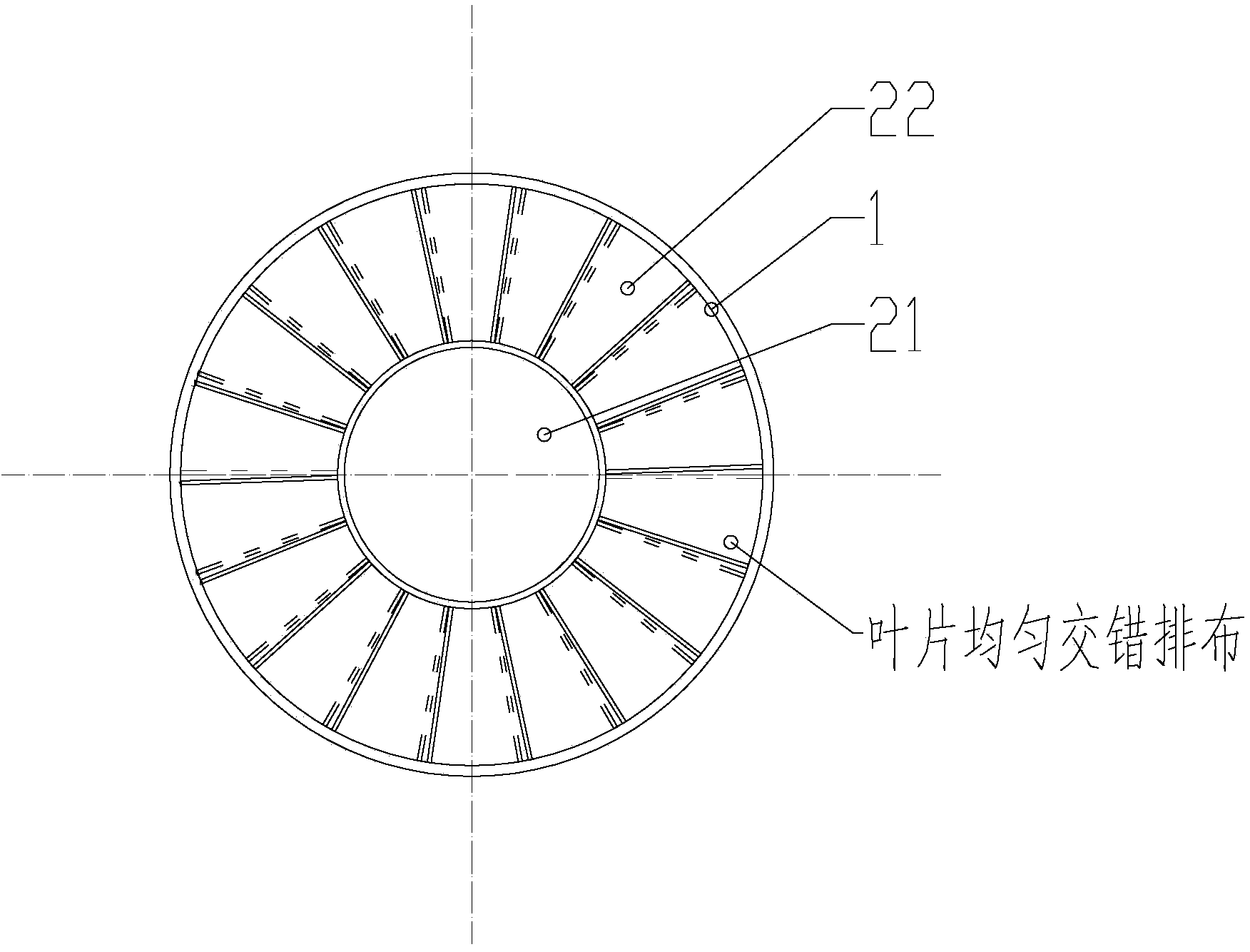

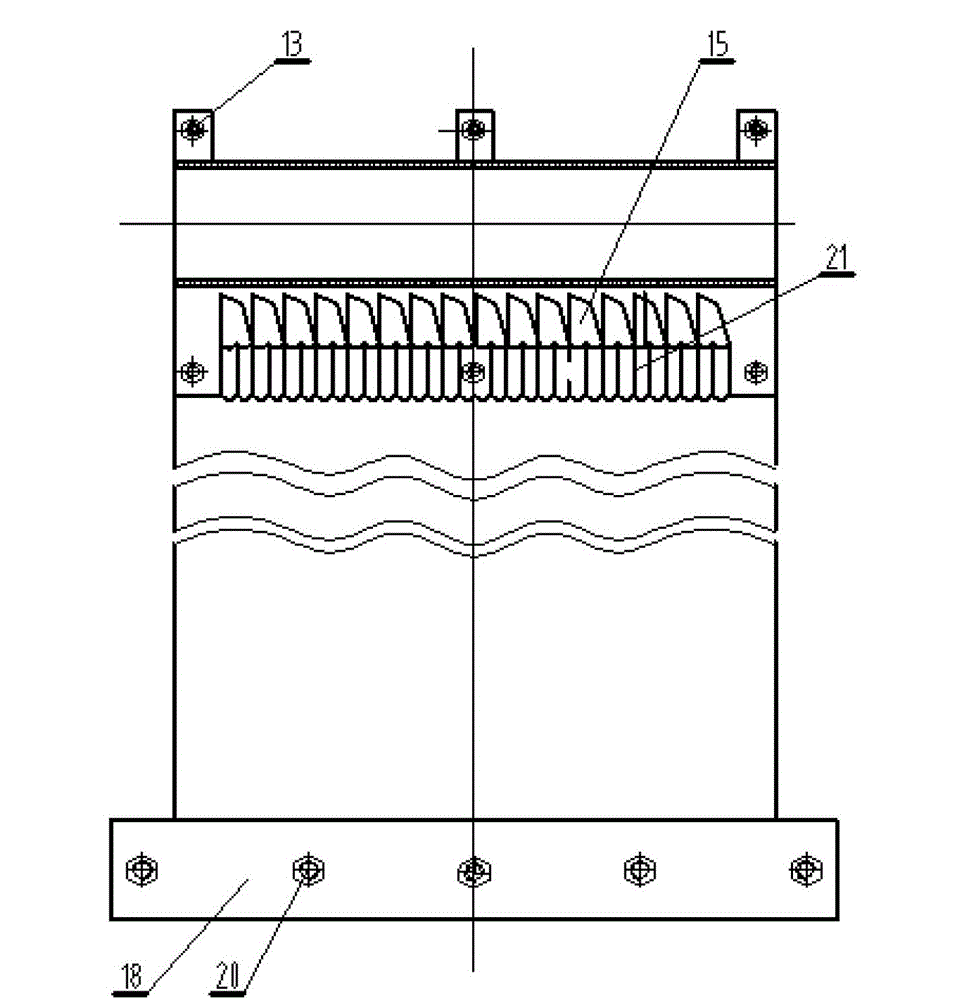

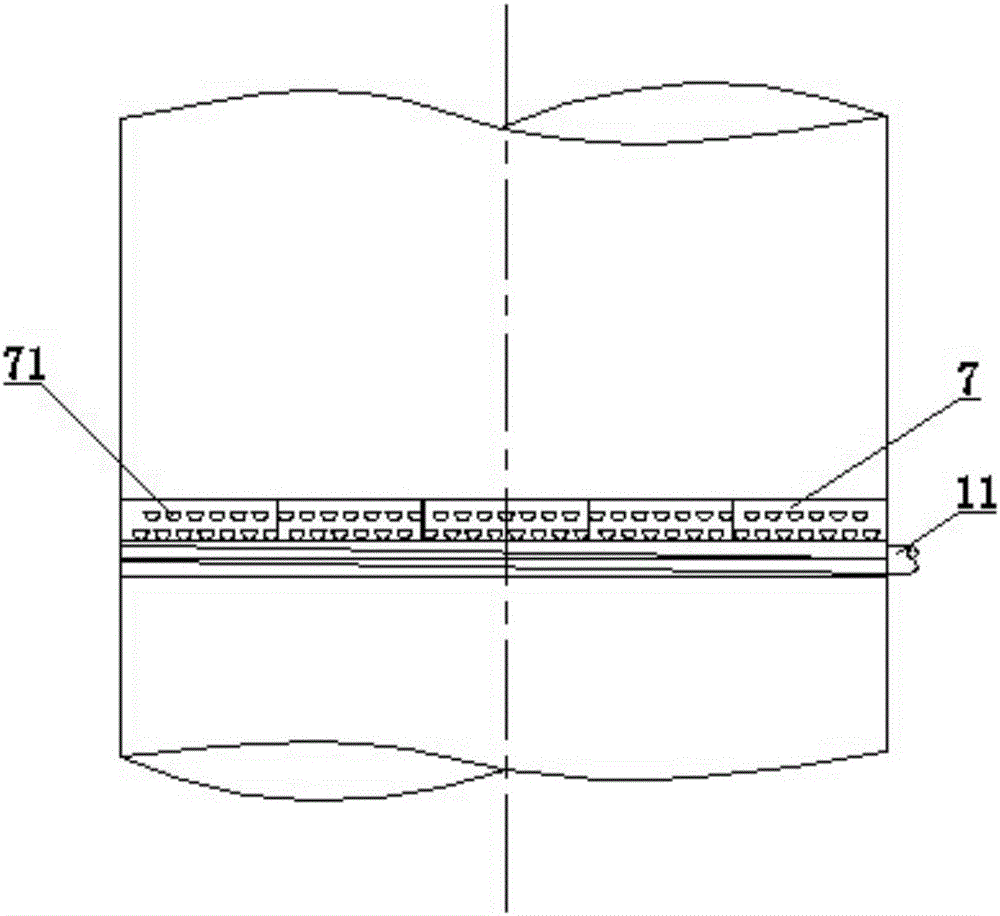

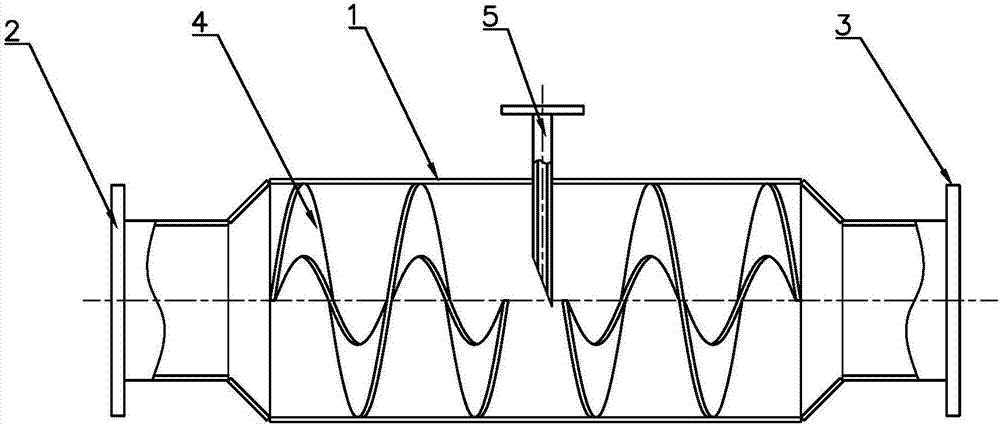

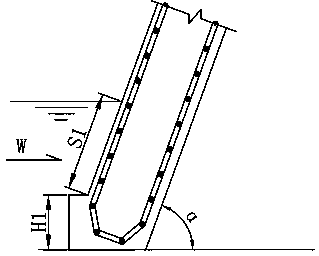

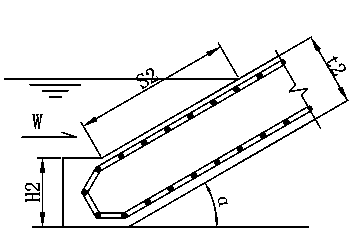

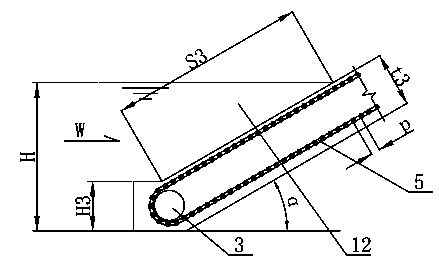

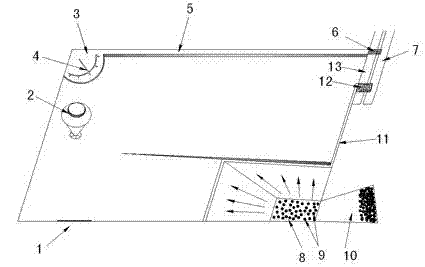

Thin type ultra-fine rotating grating trash remover

ActiveCN103866747ASolve the main problems of rotary grid cleaning machineReduce thicknessWater cleaningGratingFiltration

The invention discloses a thin type ultra-fine rotating grating trash remover. A machine frame is arranged in a water channel in an inclined mode. Filter plates are arranged between a left chain and a right chain. A driving motor drives a main chain wheel to drive the filter plates to rotate along rails through the left chain and the right chain so that sewage can be lifted to the upper portion of a machine frame from the upstream face of the water channel and slag can fall. The width of the filter plates is at least two times the length of each chain link of the chains. According to the thin type ultra-fine rotating grating trash remover, displacement, in the front and back direction, generated when the links rotate is compensated for through open grooves, and therefore the main problem of applying the narrow-spacing chains to the rotating grating trash remover is solved. The diameter of the chain wheel corresponding to the narrow-spacing chains can be greatly reduced, the thickness of the trash remover is obviously reduced, manufacturing cost is directly reduced, the height of a baffle at the bottom of the water channel is reduced, the effective filtration area of the trash remover is enlarged, and filter efficiency is higher.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

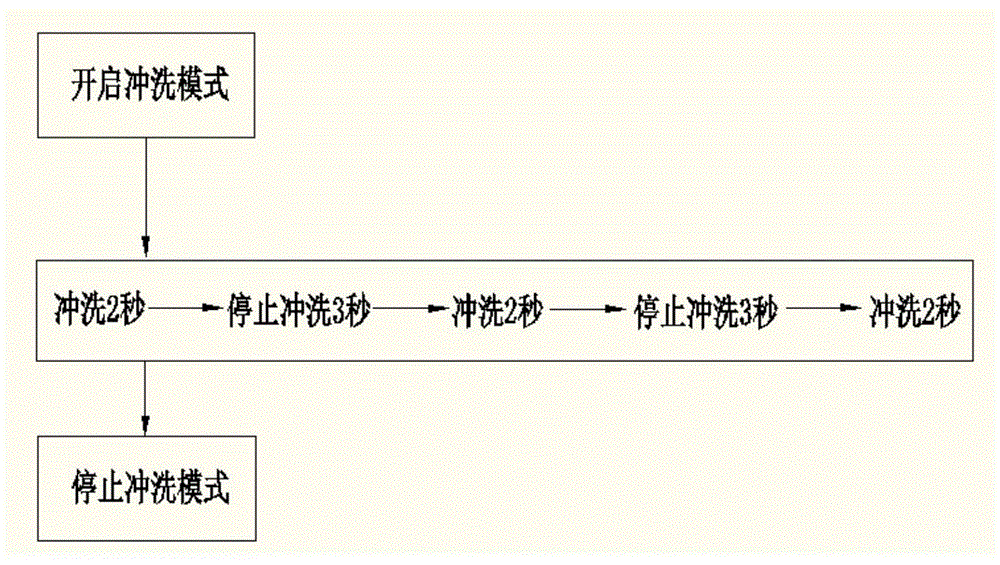

Pulse washing method of reverse osmosis membrane of water purifier

InactiveCN104607050AIncrease water pressureImprove work efficiencySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater filterReverse osmosis

The invention discloses a pulse washing method of a reverse osmosis membrane of a water purifier, and relates to the technical field of water purifiers, domestic drinking machines and commercial drinking machines. The pulse washing method comprises the following steps: when an electric control plate of the water purifier receives a washing reverse osmosis membrane instruction from the water purifier, controlling a washing electromagnetic valve to wash the reverse osmosis membrane in an interval working mode through the electric control plate, namely washing for a certain time, stopping washing, washing again, stopping washing, and repeating the operation until the accumulated washing time reaches a set value. As the washing operation is implemented in an interval manner in the method, the water pressure to the reverse osmosis membrane is increased within each small section of the washing time, the washing water amount and the washing time are reduced on premise that an original washing effect is maintained, the resource is saved, the use cost is lowered, and the working efficiency is improved.

Owner:GUANGDONG AIWO TECH

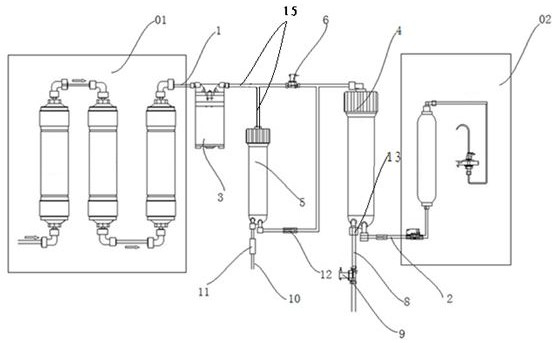

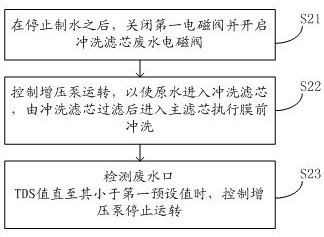

Water purification system control method and water purification system

PendingCN111974218ASolve high technical problemsLower the TDS valueWater treatment parameter controlReverse osmosisWater productionWastewater

The invention discloses a water purification system control method and a water purification system. A flushing filter element is connected in parallel on a pipeline between a water outlet of a boosterpump and a water inlet of a main filter element, and a first electromagnetic valve is mounted on the pipeline between the water outlet of the booster pump and the water inlet of the main filter element; after water production is stopped, the first electromagnetic valve is closed, a flushing filter element wastewater electromagnetic valve is started, the booster pump operates, water ends the flushing filter element, and then enters a main filter element to flush in front of a membrane of the main filter element after being filtered by the flushing filter element, thereby reducing a TDS value of the wastewater on the front side of the membrane of the main filter element; and meanwhile, the TDS value of a wastewater opening of the main filter element is acquired through a first detection device mounted at the wastewater opening of the main filter element, flushing is stopped when the TDS value of the wastewater opening is smaller than a first preset value, the inner side and the outer side of the membrane of the main filter element are soaked in pure water with the low TDS value, the technical problem that the TDS of a first cup of water is particularly high is solved, and crystallization of waterway system key components is avoided.

Owner:QINGDAO HAIER STRAUSS WATER EQUIP CO LTD +1

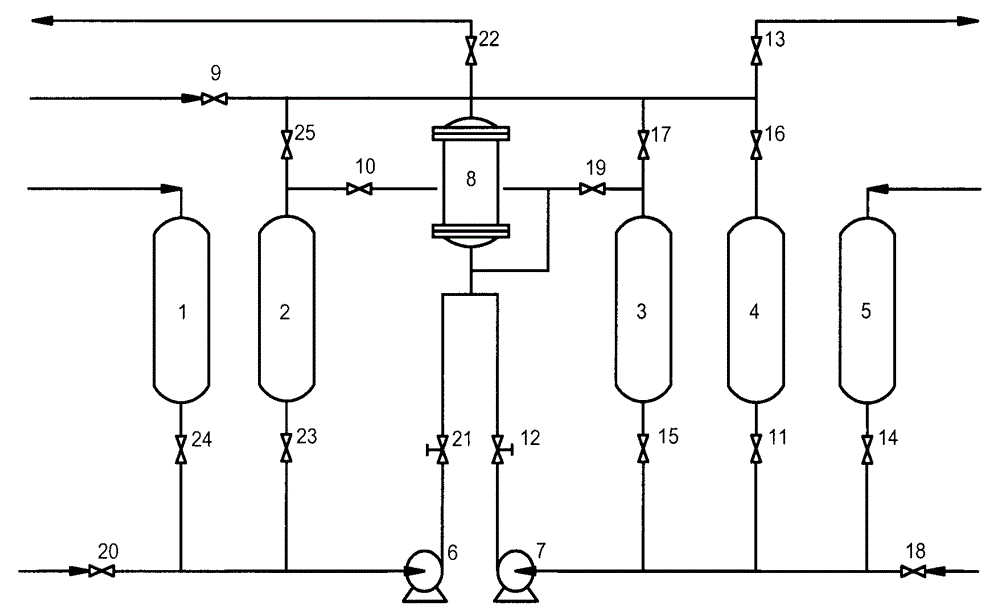

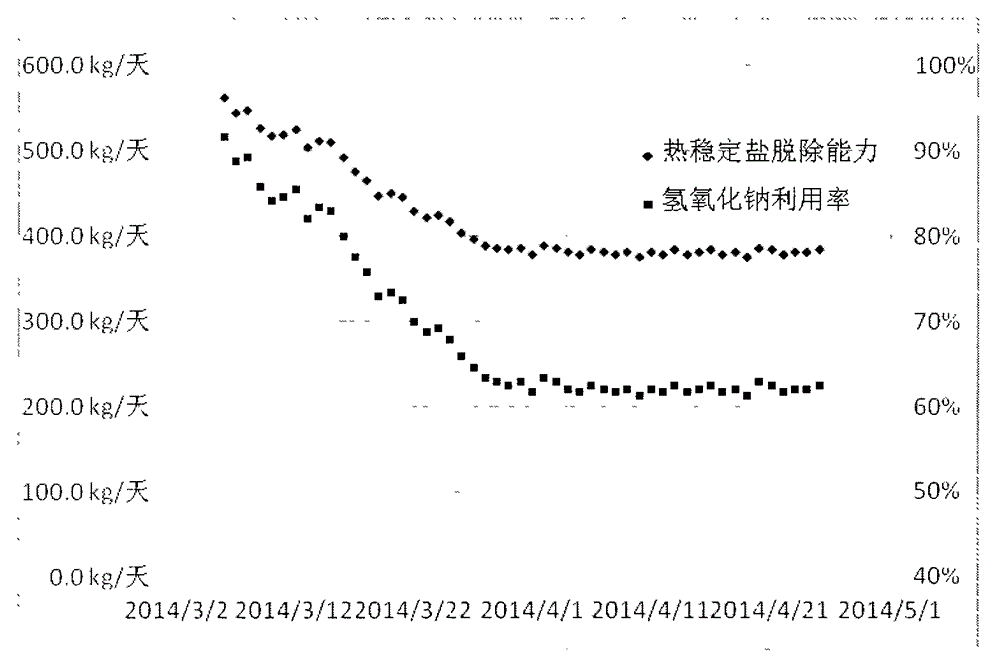

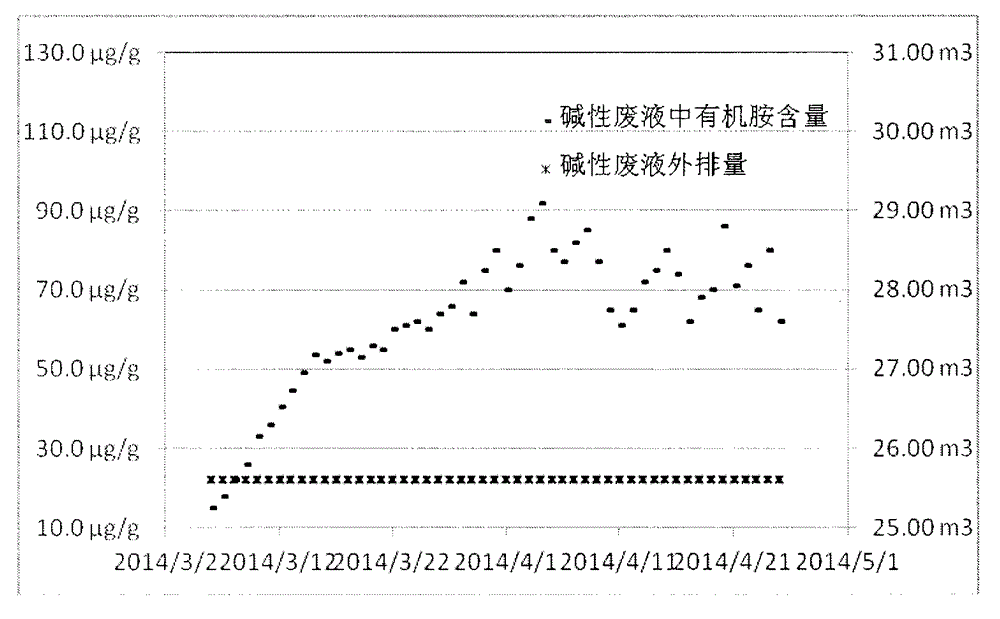

Resin bed thermal stabilization salt removing method

ActiveCN105366766AReduce dosageIncrease profitIon-exchanger regenerationWater/sewage treatment by ion-exchangeWater rinsingRinse water

The invention discloses a resin bed thermal stabilization salt removing technology to overcome the defects that regenerant consumption is large, washing water consumption is large and drained waste liquid amount is large in the prior art. The method comprises the steps of resin bed purging and emptying (through purging amine), resin bed preregeneration, resin bed regeneration, alkali recovery, recycle washing after regeneration, deep washing after regeneration, resin bed purging and emptying (through purging alkali), thermal stabilization salt removal, amine-containing water washing, lateral line extraction and washing and amine recovery. By the adoption of the technology, the good resin exchange, regeneration and washing effects can be obtained through a small amount of washing water and regeneration agent, so that according to the resin bed device, the consumption of the regeneration agent and salt removing water is reduced, and the drained waste liquid amount is greatly reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Sewage aerobic land treatment system

ActiveCN102001743BRelieve blockageRealize the function of removing ammonia nitrogenTreatment using aerobic processesEnergy based wastewater treatmentAeration systemSewage

The invention discloses a sewage aerobic land treatment system. The system comprises a groove body formed by digging under the ground, wherein impermeable membranes are laid at the periphery and at the bottom of the groove body; and a sand layer, a water distribution layer, a packing and water collecting layer and a soil layer are formed in turn from bottom to top. The sewage aerobic land treatment system is characterized by also comprising a blast aeration system consisting of a blast blower, an air diffusion device and a connecting pipeline, wherein the air diffusion device is positioned below the water surface of the land treatment system and connected with the blast blower through a pipeline; pretreated sewage enters the land treatment system; and air is pressurized by the blast blower and diffused into sewage of the system in the form of small air bubbles through the air diffusion device. Therefore, the aims of charging oxygen into the sewage and stirring are fulfilled, good reoxygenation effect, high mass transfer efficiency, quick bio-membrane updating and high treatment efficiency are achieved, and the problem of blockage of the land treatment system in the operating process is solved effectively.

Owner:QINGDAO LIGONG NEW ENVIRONMENTAL TECH DEV

A deep dust and mist removal device

ActiveCN104368215BGood dedusting and demisting effectNo risk of fouling and cloggingCombination devicesFlue gasEngineering

The invention discloses an advanced dust-removing and demisting device, and particularly relates to a dust-removing and demisting device which is suitable for saturated flue gas containing a great deal of fog drops. The advanced dust-removing and demisting device has a main working principle as follows: collision among fog drop liquid particles and between fog drop liquid particles and dust particles can be realized during high-speed motion of flue gas based on the characteristic that the flue gas contains a great deal of fog drops and liquid drops, so that larger particles are formed by agglomeration and then settle; the fog drop liquid particles and the dust solid particles are in full contact with a liquid-containing layer in the device, and then separation is realized by liquid trap; the fog drop liquid particles and the dust solid particles rotate at high speed along with the flue gas, centrifugal separation is realized by virtue of the density difference between the fog drop liquid particles and the flue gas as well as between the dust particles and the flue gas, and then the fog drop liquid particles and the dust solid particles are thrown onto the surface of the inner wall of the device and are removed after contacting a liquid film layer attached onto the wall surface of the device. The advanced dust-removing and demisting device has the advantages that efficient dust removing and demisting can be realized under the conditions of low running cost and investment cost; the device is simple and reliable in structure and free of a risk of blocking, and is also portable and safe.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Elutriation Magnetic Separator

ActiveCN111632753BReduce section sizeRaise the gradeMagnetic separationWet separationParticulatesMagnetic separator

The invention provides an elutriating magnetic separator, belonging to the technical field of mineral separation, comprising a sorting cylinder, an overflow device, a feeder and a water supply structure, the outer wall of the sorting cylinder is provided with a magnetic structure; the overflow device is located on On the sorting tube, and communicated with the sorting tube, it is used to discharge tailings. There is a movable or deformable first adjustable balance structure on the inside of the overflow and / or outside the feeder, which is used to change the size of the overflow. The size of the overflow surface; the feeder is arranged above the overflow device; the water supply structure is located below the sorting cylinder and communicates with the sorting cylinder; the elutriation magnetic separator provided by the invention can be selected according to the characteristics of the minerals, Properly adjust the size of the adjustable balance structure, change the size of the overflow surface of the overflow tank, so as to change the rising water velocity in the overflow tank, thereby changing the buoyancy of the solid particles with different particle sizes and densities in the overflow tank slurry, to achieve the best The separation effect is good, the concentrate grade is improved, the recovery rate is increased, and the amount of flushing water at the bottom can be reduced to save water.

Owner:石家庄金垦科技有限公司

Pig house capable of respectively collecting pig manure and pig urine and wash water

The invention relates to a pig house capable of respectively collecting pig manure, pig urine and wash water. The pig house capable of respectively collecting the pig manure, the pig urine and the wash water comprises a pig house body, an automatic feeding device and a drinker, and is characterized in that a urine drainage ditch and a sewage drainage ditch are arranged on an outer side of the pig house body, wherein the sewage drainage ditch is arranged on an outer side of the urine drainage ditch. An excrement drainage platform is arranged on a corner of the pig house body, and an excrement accumulation pool is arranged outside a wall opposite to a side of the excrement drain platform. A urine drainage shallow ditch is arranged around the excrement drain platform, and the urine drainage shallow ditch is directly drained to the urine drainage ditch by a urine drainage guide pipe penetrating the wall or drained to the sewage drainage ditch by the urine drainage guide pipe penetrating the wall through see-saw type transfer bridge groove after the urine drainage shallow ditch is connected with a urine discharge ditch in abutted mode along the direction of the wall or a fence. A water drainage shallow ditch is arranged around the drinker and drained to the sewage drainage ditch by a water drainage guide pipe penetrating the wall and crossing the urine discharge ditch after the water drainage shallow ditch is connected with a water drainage ditch in abutted mode along the wall or the fence.

Owner:JIANGSU ACAD OF AGRI SCI

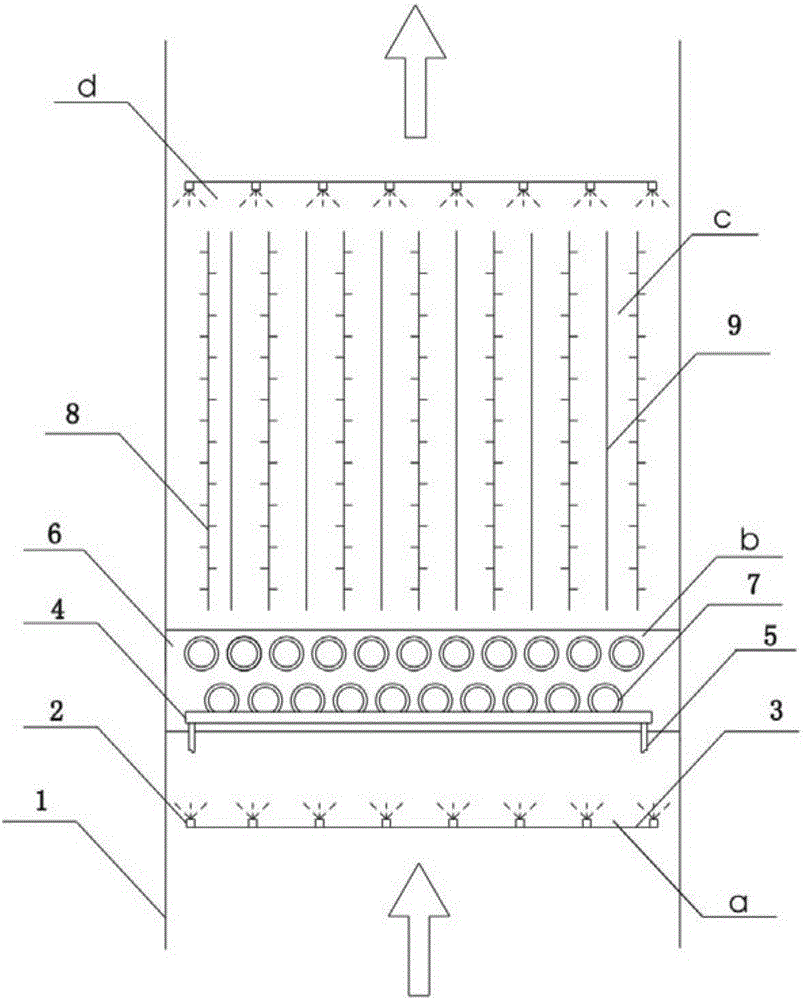

High-efficiency coupling dust remover applicable to desulfurization dust-removing absorption tower and dust removing method thereof

ActiveCN105797526AAvoid affecting operational efficiencyHumidification reductionCombination devicesGas treatmentParticulatesFlue gas

The invention discloses a high-efficiency coupling dust remover applicable to a desulfurization dust-removing absorption tower and a dust removing method thereof. The high-efficiency coupling dust remover comprises an impact dust-removing area, an electric-field dust-removing area and a washing and spraying layer, wherein the impact dust-removing area comprises two or more rows of round pipe layers which are arranged in parallel from top to bottom, and each two adjacent upper and lower rows of round pipe layers are arranged in a staggering manner; the electric-field dust-removing area comprises an anode plate for collecting dust and a cathode line for discharging; the washing and spraying layer is arranged above the electric-field dust-removing area; flue gas flows through the impact dust-removing area, the electric-field dust-removing area and the washing and spraying layer in sequence. The dust removing method comprises the following steps: carrying out impact treatment on flue gas to be treated entering from a flue-gas inlet; carrying out electric-field force adsorption treatment on the flue gas after impact treatment; and carrying out intermittent or continuous spraying cleaning on the anode plate and the cathode line. The high-efficiency coupling dust remover disclosed by the invention has the advantages that high-efficiency and stable operation of the dust remover can be effectively guaranteed, the efficiency of removing fine particles in the flue gas can be improved and thus the requirement on ultraclean emission of particles is met.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

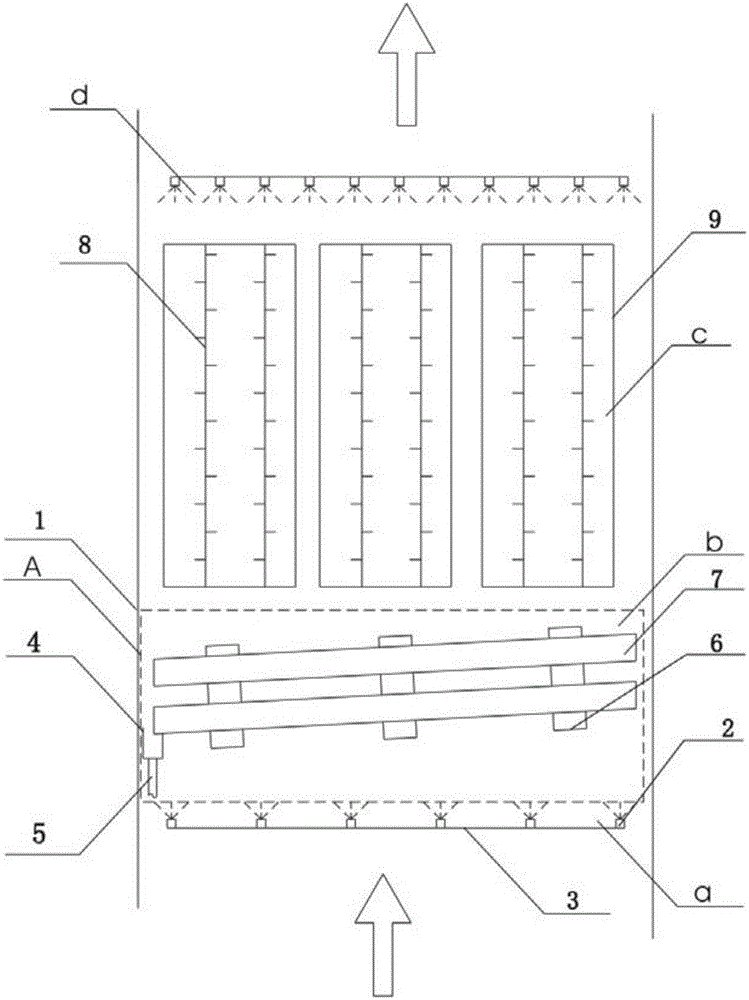

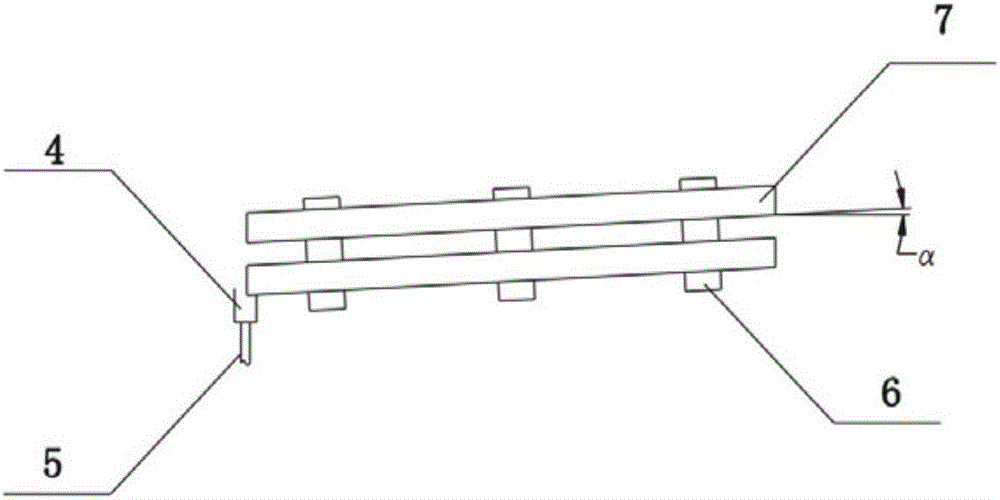

Device and process for homogenizing fabric dust collecting electrode surface water film

ActiveCN101670313BUniform thicknessLow flushing water requirementDispersed particle filtrationExternal electric electrostatic seperatorFiberEngineering

The invention relates to a device and a process for homogenizing a fabric dust collecting electrode surface water film for a wet electrostatic dust collector / demister. The device comprises a shell, a guide vane, a discharge electrode fixing device, a discharge electrode, a dust collecting electrode square tube, an insulated case, a support device, a film distributing device, a dust collecting electrode length adjusting device and a homogenizing rod; the water distribution amount is adjusted by an adjusting valve, the thickness of the collecting electrode surface water film is controlled by a PLC; water flows into the upper part of a fabric collecting electrode through a water distribution hole to form an initial water film and then downwards spreads to the bottom in a corrugated shape; a wall-cooling wall surface formed by the water film contacts with a flue gas counterflow to generate friction lift force to be mutually coupled with flue gas condensed water and capillary characteristics of fiber fabrics, thereby promoting the rapid formation of the water film with uniform thickness; in the process of precipitating water condensation nuclei in the flue gas, micro fine particulate matters are condensed and the particle size is increased; and a grey cake layer formed by the micro fine particulate matters on the surface of the fabrics is fractured and shed in a flaky shape. The device has the outstanding effects of dust removal, demisting, energy saving and consumption reduction.

Owner:SHANDONG UNIV

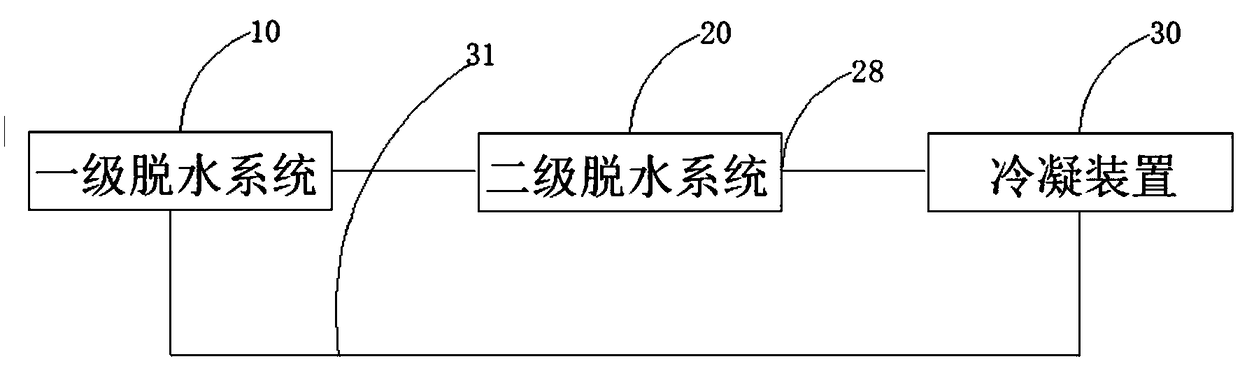

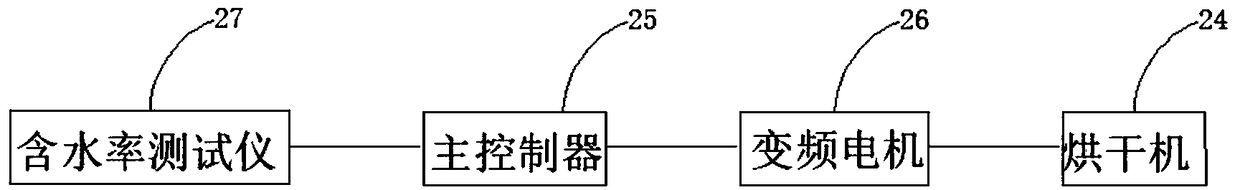

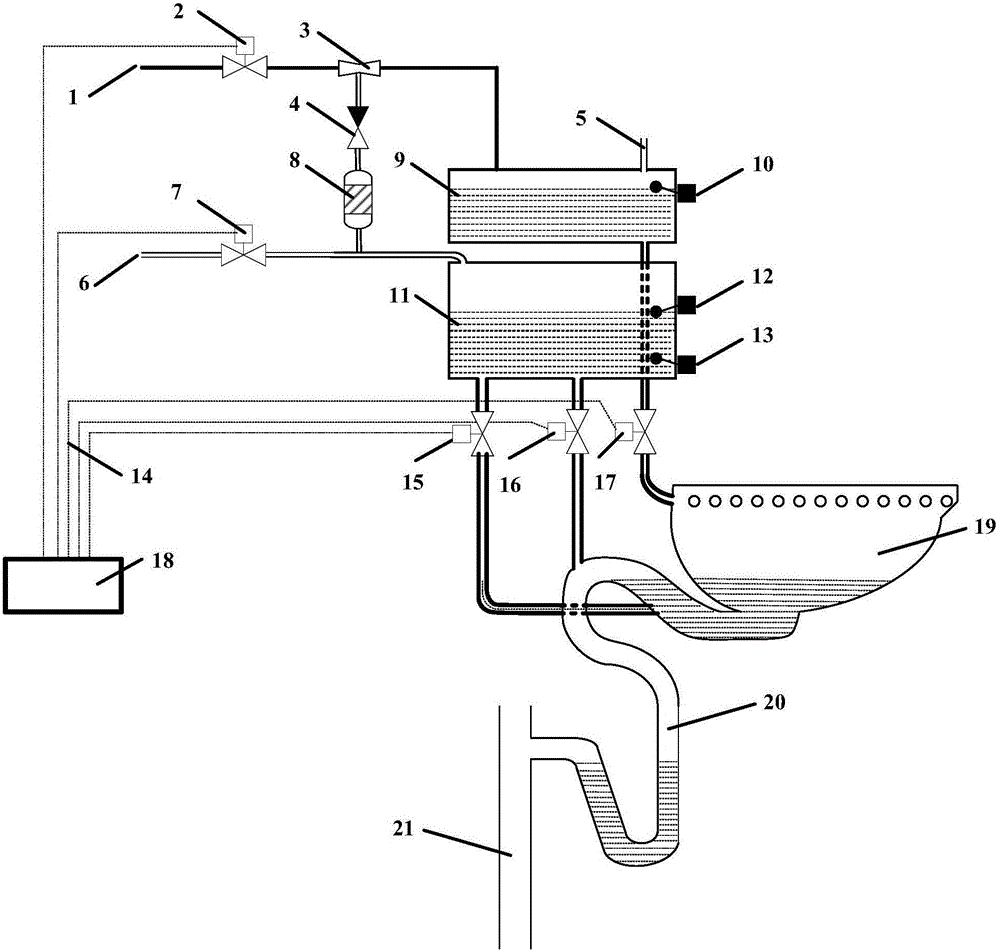

Efficient energy-saving sludge deep dewatering device

InactiveCN109293191AAvoid cloggingReduce the amount of flushing waterSludge treatment by de-watering/drying/thickeningPulp and paper industryWater vapor condensation

The invention belongs to the technical field of sludge dewatering, and provides an efficient energy-saving sludge deep dewatering device. The device comprises a first-stage dewatering system for extrusion dehydration, a second-stage dewatering system for drying and dehydration and a condensing device. The first-stage dewatering system and the second-stage dewatering system are arranged side by side. Two sides of the first-stage dewatering system are provided with a first feeding inlet and a first discharge outlet. The top of the second-stage dewatering system is provided with a second feedinginlet and the bottom is provided with a second discharge outlet. The first discharge outlet is connected to the second feeding inlet through a sludge transfer pipe. A sludge lifting pump is arranged in the sludge transfer pipe. The bottom of the second-stage dewatering system is provided with a condensed water outlet, the condensed water outlet is connected to a condensing unit through a condensing pipe. The condensing unit is connected to the first-stage dewatering system. The device can condense and collect water steam produced by the second-stage dewatering system, feed the water into the first-stage dewatering system to backwash a first-stage filter belt so that holes of a first-stage filter belt of the first-stage dewatering system are not blocked through sludge during the process ofextruding the sludge. The pores of the grade filter belt.

Owner:YANGZHOU MAOYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Toilet flushing system with injection pump

InactiveCN106049631AReduce the amount of flushing waterFlushing devicesLavatory sanitoryWater useSiphon

The invention discloses a toilet flushing system with an injection pump. The toilet flushing system comprises a flushing water system and a water saving system, wherein the flushing water system comprises a tap water control solenoid valve, the injection pump, a liquid level measurement float switch and a flushing water control solenoid valve, and the water saving system comprises the injection pump, an air control solenoid valve, a high-liquid-level measurement float switch, a low-liquid-level measurement float switch, a water sucking control solenoid valve and a siphon water release control solenoid valve. According to the toilet flushing system, the injection pump is added, so that part of pressure energy of the tap water is recycled, and the part of energy is used for recycling part of water for urine flushing of the toilet; during the faces flushing, the recycled water is drained into a drain pipeline of the toilet earlier than the flushing water of the toilet, siphon force is generated for sucking dirt such as feces, and then the water with the amount being equal to that of the water used for flushing urine is released for flushing the toilet to be clean. Compared with the existing water-saving toilet, the toilet flushing system provided by the invention has the advantage that the amount of the water for flushing the feces is reduced by one half.

Owner:DALIAN MARITIME UNIVERSITY

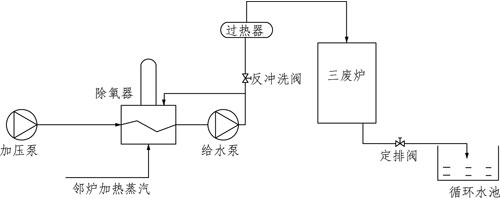

Steady-pressure energy-saving backwashing method for heating surface of three-waste furnace

PendingCN114812264AImprove heat transfer efficiencyReduce the number of starts and stopsLiquid degasificationBoiler controlWater dischargeSuperheater

The invention relates to a three-waste furnace heating surface pressure-stabilizing and energy-saving backwashing method which comprises the following steps: a, feeding washing water to a water tank of a deaerator to a high water level, controlling the water temperature to be 90-100 DEG C, and enabling the washing water to be ammoniated desalted water with the pH value of 8.8-9.3; b, entering the three-waste furnace from a backwash valve of the superheater, controlling the flow rate, closing a water feeding pump after a steam pocket is full of water, and standing bubbles for 1-1.5 hours; c, opening a fixed discharging valve, starting a water feeding pump to feed water for flushing, discharging water after flushing to a circulating water pool for recycling, and supplementing water to a water tank of the deaerator for heating; d, repeating the steps b and c until the conductivity and the sodium content of the water discharged by the fixed discharge valve are the same as those of the flushing water; and stopping the water feeding pump and the pressure pump, and closing the backwashing valve and the fixed discharge valve to finish backwashing. All heating surfaces of the three-waste furnace are flushed at one time and are not corroded, so that the heat exchange efficiency of the heating surfaces is improved; the start-stop frequency of the pump is reduced, stable-pressure operation is achieved, the steam consumption and the flushing water amount are reduced, and the flushing efficiency is improved.

Owner:甘肃银光聚银化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com