Oil removal process for quality improving sewage of coal

A technology for improving coal quality and sewage, applied in the field of coal chemical industry, can solve the problems of increasing the water consumption of backwashing, increasing the energy consumption of system operation, blocking heat exchangers, etc. The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

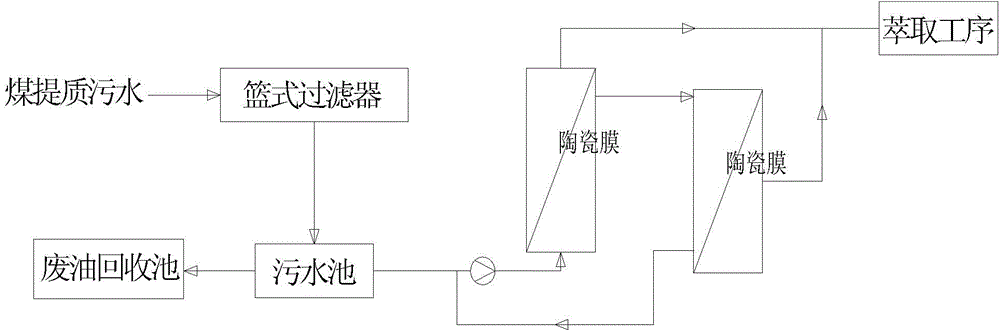

[0042] The coal upgrading sewage is treated by gravity degreasing treatment, filtered to remove large particle pollutants; after filtration, it is sent to the sewage pool to stand for more than 20 minutes, and then the oil on the surface of the sewage is discharged to the waste oil recovery pool.

[0043]Use the feed pump to send the sewage in the sewage pool into the No. 1 ceramic membrane filter (model HOTcCL-1; pore size 30 μm) for filtration; the concentrated water discharged from the sewage outlet of the No. 1 ceramic membrane filter is passed into the No. 2 ceramic membrane (model HOTcCL-2; pore size: 50μm) filter for filtration, the concentrated water discharged from the sewage outlet of the second ceramic membrane filter is directly returned to the inlet of the feed pump; the ceramic membrane of the first ceramic membrane filter and the second ceramic membrane filter is controlled The flow velocity on the surface of the membrane is about 4-5m / s.

[0044] The wastewater...

Embodiment 2

[0046] Similarly, the coal upgrading sewage is treated by gravity degreasing treatment, filtered to remove large particle pollutants; after filtration, it is sent to the sewage pool to stand for more than 20 minutes, and then the oil on the surface of the sewage is discharged to the waste oil recovery pool.

[0047] Use the feed pump to send the sewage in the sewage pool into the ceramic membrane filter (model HOTcCL-1; pore size: 30μm) for filtration; the concentrated water discharged from the sewage outlet of the ceramic membrane filter is passed into the sewage pool for circulation; control the ceramic membrane filter The membrane surface flow rate is about 4-5m / s; the wastewater discharged from the outlet of the ceramic membrane filter is sent to the extraction process for further treatment, and the oil content of the effluent is 15mg / L; when it is detected that the pressure difference between the inlet and outlet of the ceramic membrane filter reaches When it is between 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com