Rigid anode plate surface water film arrangement technology and device

A surface water film and anode plate technology, applied in the field of air pollution control, can solve the problems of equipment downtime flushing, spark discharge, water resource waste, etc., and achieve the effects of small flushing water, stable electric field, and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

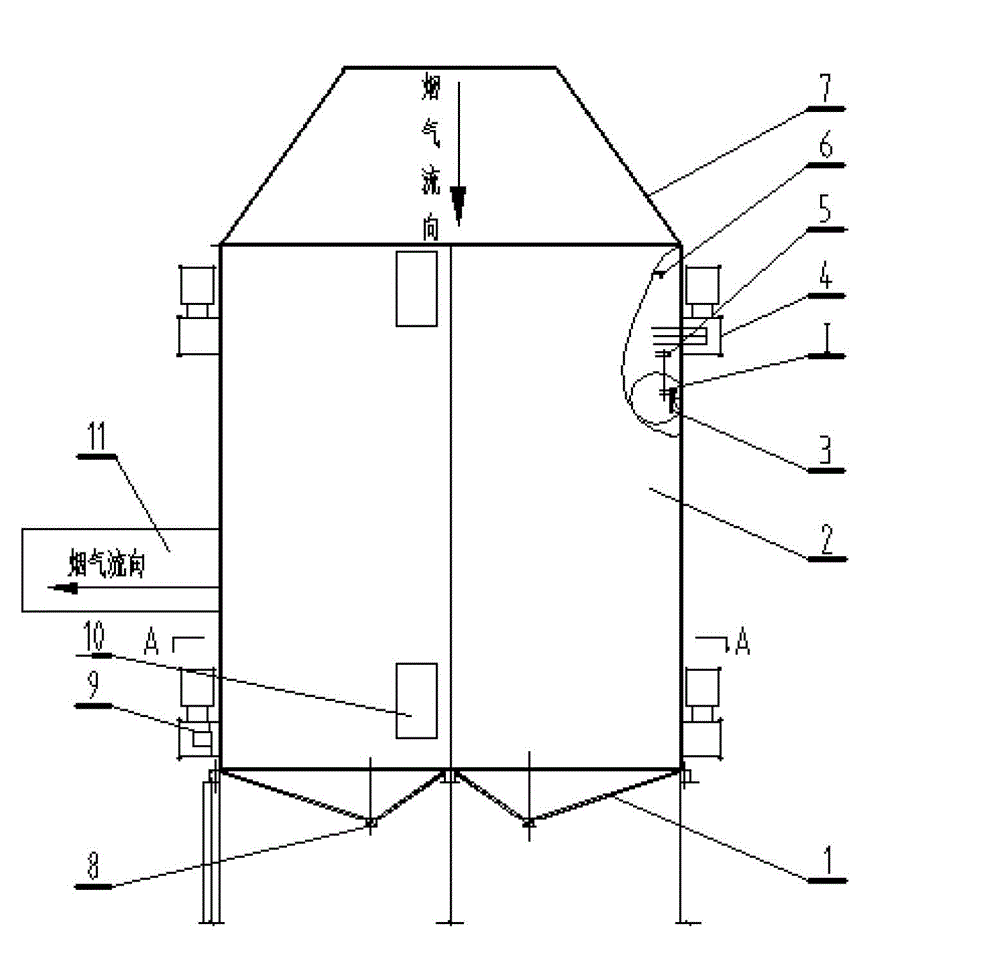

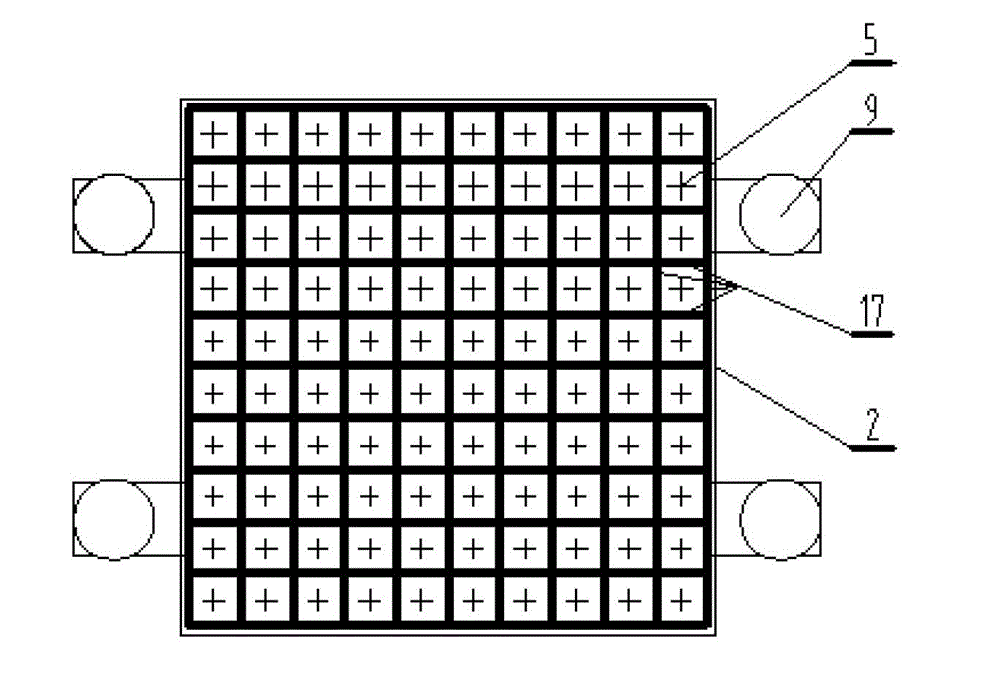

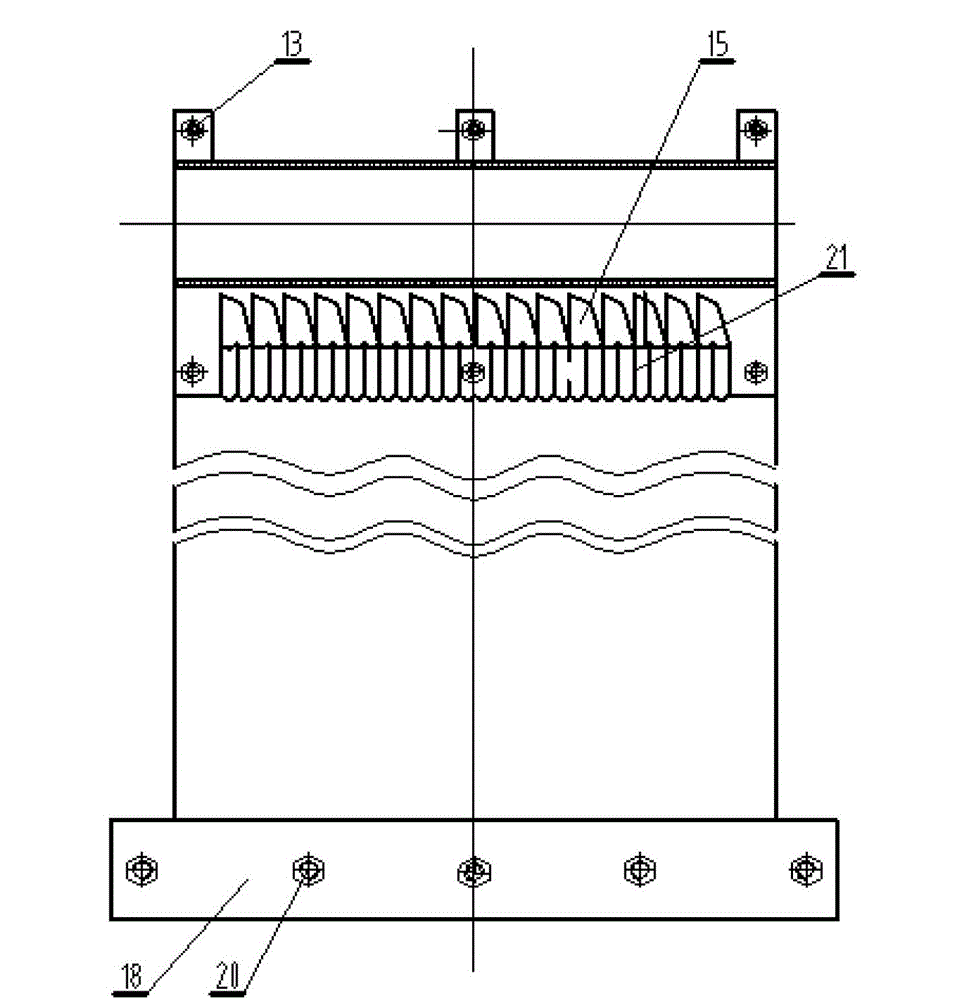

[0015] Combine below figure 1 , figure 2 , image 3 with Figure 4 A best embodiment of the present invention is presented.

[0016] The water film layout process and device on the surface of the rigid anode plate are through figure 1 , figure 2 , image 3 with Figure 4 The device shown is realized. The flue gas enters the casing 2 after being homogenized by the upper head 7. The flue gas first flows through the 6 spray pipe layers, passes through the cathode wire 5 suspended by the upper insulating box 4, and enters the splint fastening bolt 12, suspended The anode channel composed of the anode water film arrangement device 3 composed of the hanging splint 13, the water distribution pipe 14, and the anode plate fastening bolt 16, the bottom of the anode plate 17 is fastened by the positioning steel plate 18 at the lower part of the pole plate, the fixed shaft 19 at the lower part of the pole plate, and the positioning steel plate The bolts 20 are fixed, the anode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com