Integrated mine water purification system

A purification system and mine water technology, applied in mining wastewater treatment, multi-stage water treatment, chemical instruments and methods, etc., can solve the problems of high treatment cost, high energy consumption, complicated treatment process, etc., and achieve low energy consumption of influent water , Save power consumption, save flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

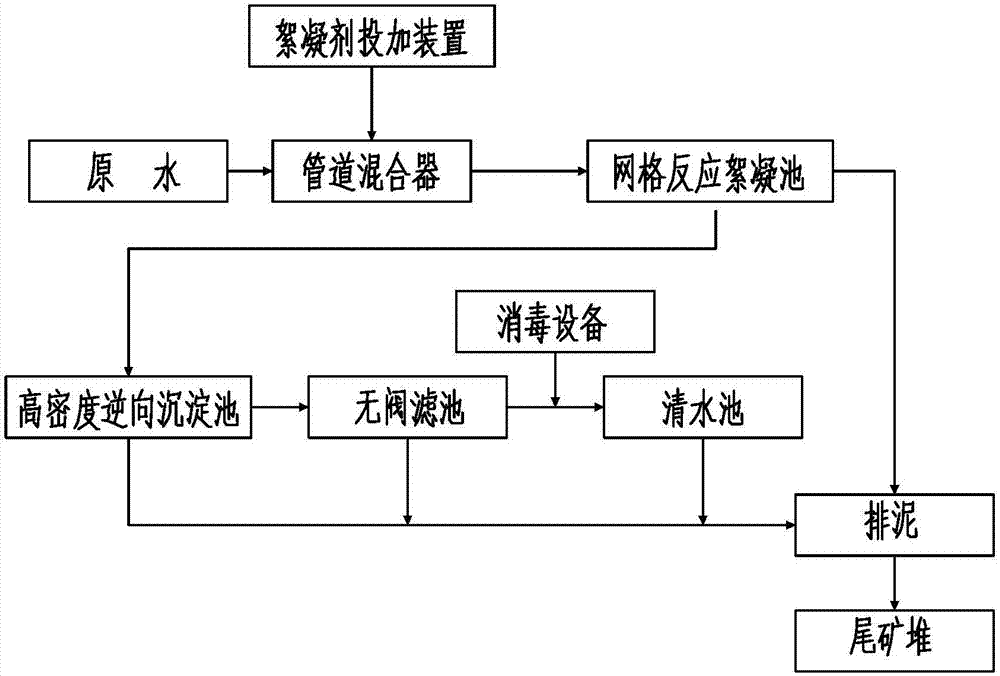

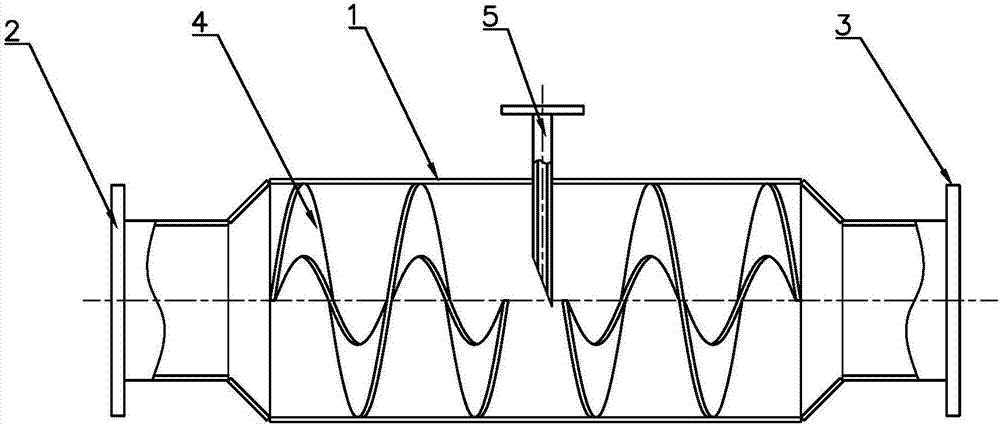

[0031] Such as figure 1 As shown, an integrated mine water purification system of the present invention, the system includes a pipeline mixer connected sequentially from front to back, a grid reaction flocculation tank, a high-density reverse sedimentation tank, a valveless filter tank and a clear water tank;

[0032] The system includes the following process steps:

[0033] S1: Mine wastewater enters the pipeline mixer, contacts and mixes with the composite flocculant added to the pipeline mixer, the residence time is 5-8s, and the flow rate is 0.7-1.0m / h;

[0034] S2: Mine wastewater flows into the grid reaction flocculation tank by itself after passing through the pipeline mixer. Under the action of the grid and eddy current in the network reaction flocculation tank, it fully reacts with the flocculant, the residence time is 8-15min, and the flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com