Precision filtering device and method for finely processing condensation water from nuclear power station

A technology for fine treatment and precision filtration of condensate, which is applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of shortening unit start-up time, long unit start-up time, excessive sulfate in effluent, etc. The problem of exceeding the standard, improving the quality of the secondary circuit soda water, and the effect of improving the quality of soda water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

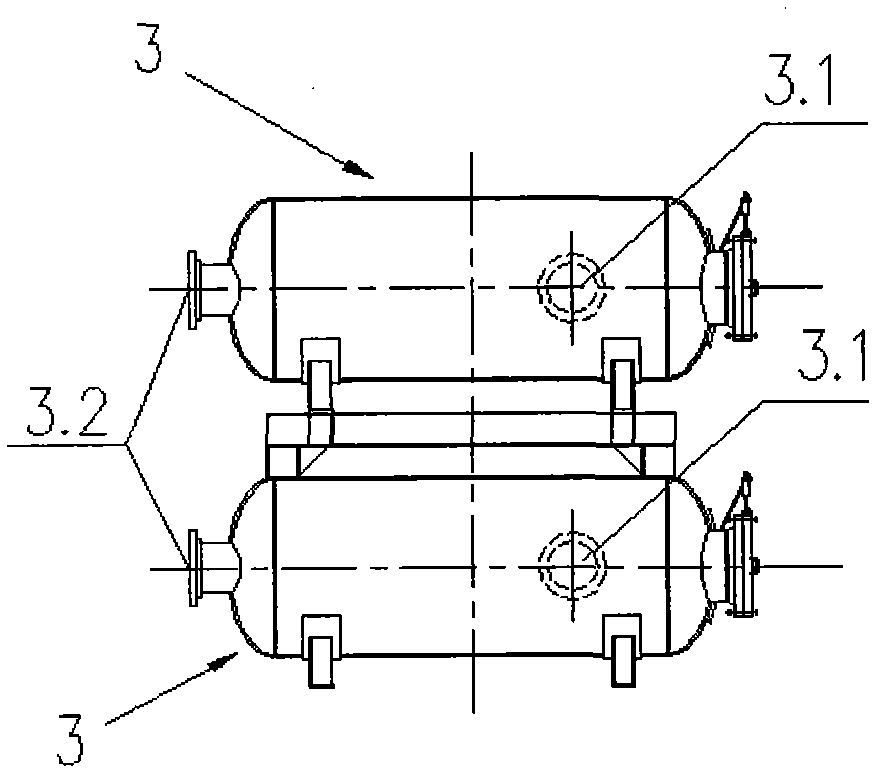

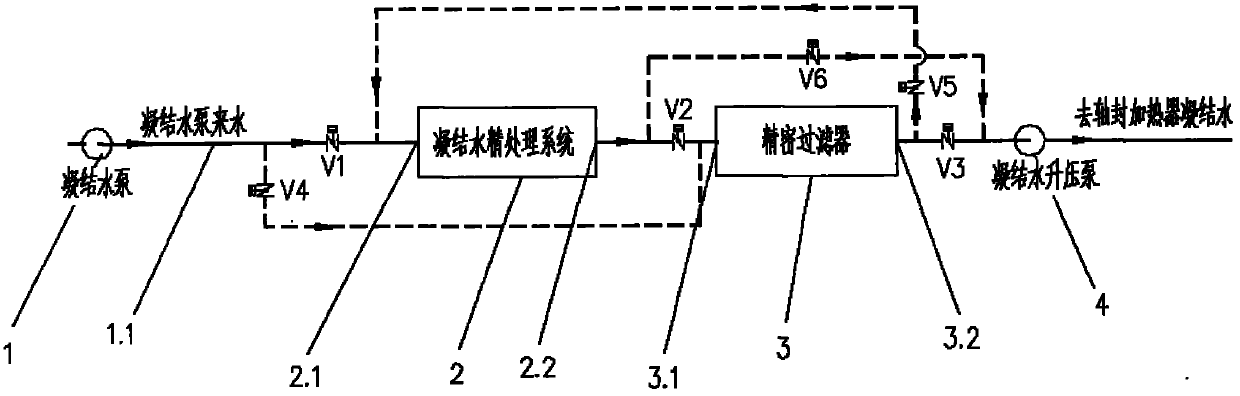

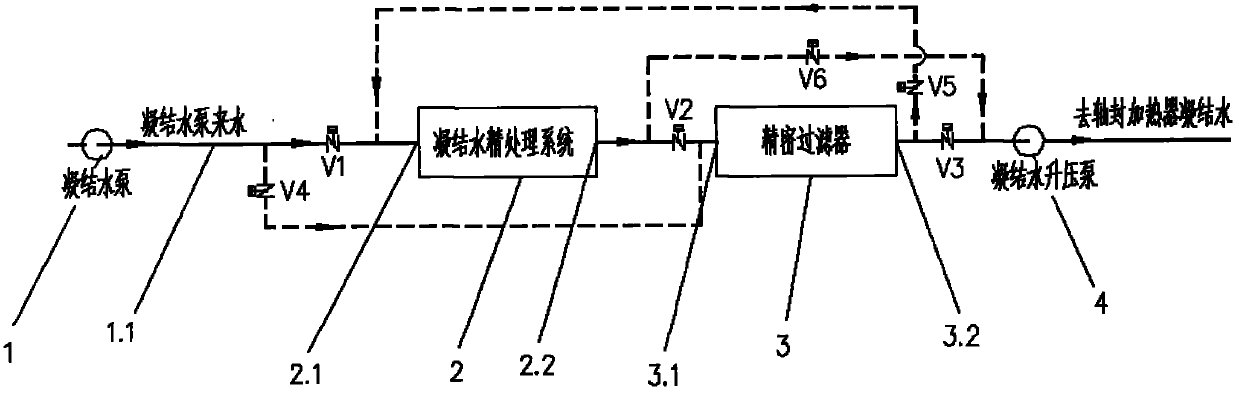

[0033] Such as figure 1 As shown, the precision filter device of a nuclear power plant condensate polishing system described in the embodiment of the present invention, wherein, this embodiment is illustrated by taking the AP1000 nuclear power plant as an example, and the condensate polishing system 2 is arranged between the condensate pump 1 and the condensate Between the booster pump 4, the precision filter device includes a precision filter 3 and valves. In this example, a precision filter 3 is provided behind the condensate polishing system 2, and the precision filter 3 is used as a front or rear position by switching the valve according to specific working conditions. When the nuclear power plant is in normal operation, through The valve is switched to operate after the precision filter 3, that is, the incoming water 1.1 of the condensate pump passes through the condensate polishing system 2 and the precision filter 3 to the condensate booster pump 4 in sequence ; When t...

Embodiment 2

[0052] see figure 1 , the embodiment of the present invention also provides a precision filtration method for a nuclear power plant condensate polishing system, the precision filter device is arranged between the condensate pump 1 and the condensate booster pump 4, and the precision filter device includes a precision filter 3 and the valve,

[0053] The precise filtration method includes receiving condensate pump incoming water 1.1,

[0054] When the nuclear power plant is in normal operation, the incoming water 1.1 of the condensate pump passes through the condensate polishing system 2 and the precision filter 3 to the condensate booster pump 4 in sequence;

[0055] When the nuclear power plant is started, the incoming water 1.1 of the condensate pump passes through the precision filter 3 and the condensate polishing system 2 to the condensate booster pump 4 in sequence.

[0056] In the method described in the embodiment of the present invention, the post-position and pre-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com