Thin type ultra-fine rotating grating trash remover

A technology of rotary grille and cleaning machine, which is applied in the cleaning of open water, water conservancy projects, construction, etc. It can solve the problems of thick equipment, unstable operation, and reduced water flow, so as to achieve thinner thickness and longer service life. Longer, the effect of reducing the amount of flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

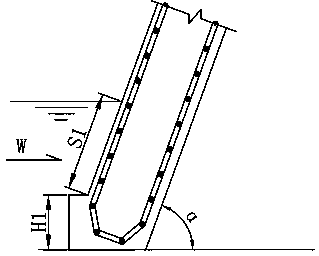

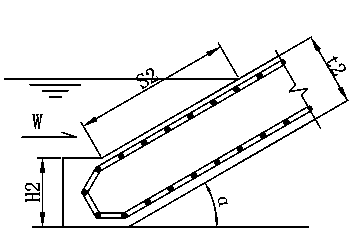

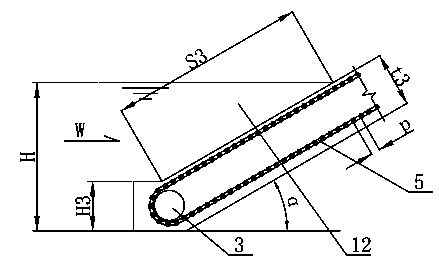

[0034] like image 3 As shown, the thin-type ultra-fine rotary grid cleaning machine of the present invention is installed in the water channel 12 of the lower water surface H with a small inclination angle α=20-60 degrees, and the present invention adopts sprocket chains with small pitches to manufacture , National standard chains of 28A-48A can be used. In this embodiment, standard chain links 5 with a pitch p of 50.8mm are used, and the diameter of the sprocket 3 is 290mm, so the thickness t3 of the equipment can be reduced to 360mm. Due to the thinning of the equipment, the height H3 of the water retaining plate 13 at the bottom of the canal can be effectively reduced, thereby ensuring a larger filtration area S3 under the installation condition of a small angle.

[0035] like Figure 4 to Figure 6 As shown, the frame 1 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com