Desulfurizing tower spraying, condensing, amplifying, dedusting and demisting integrated device

A desulfurization tower, spray cooling technology, applied in combined devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of chimney gypsum rain, unavoidable carrying a large amount of fine dust and gypsum droplets, and low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

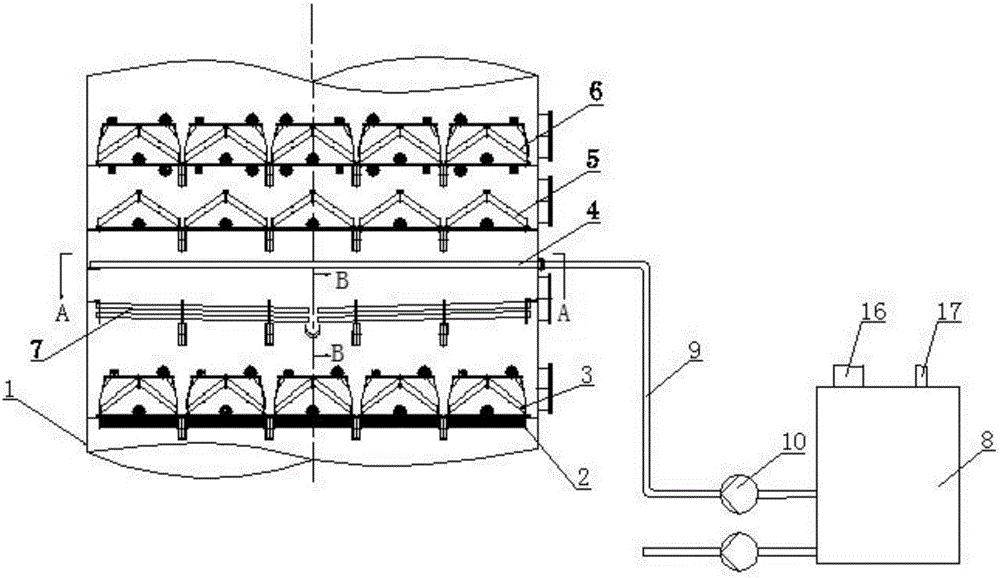

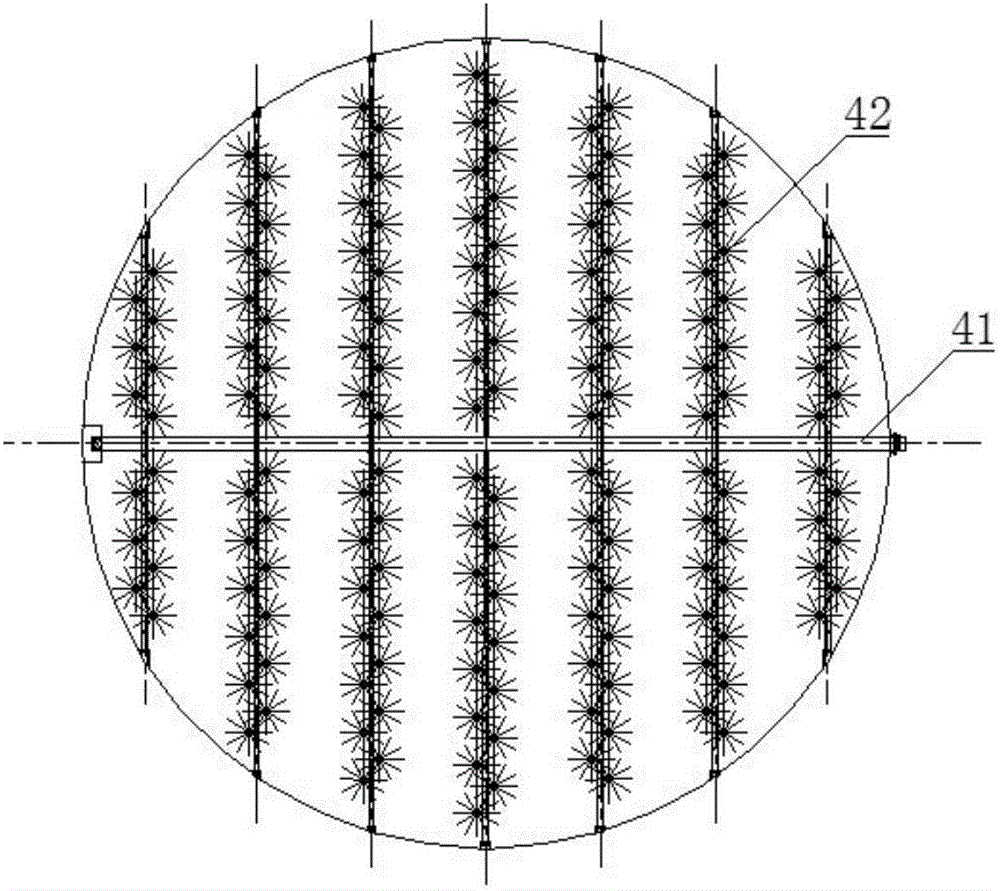

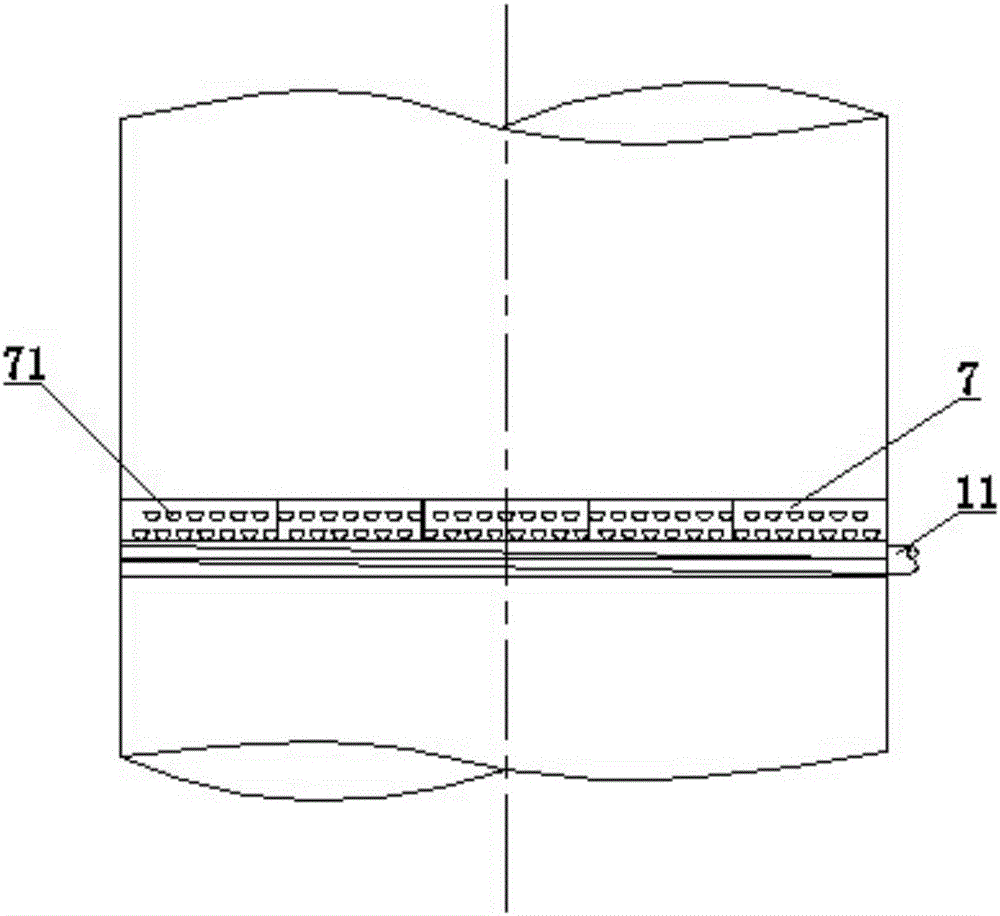

[0017] refer to figure 1 , the desulfurization tower spray condensation amplification dust removal and fog removal integrated device includes a desulfurization tower 1, a demister and a spray cooling system, and the demister is sequentially arranged from bottom to top Tubular demister 2, the first The first stage ridge type mist eliminator 3, the second stage fine ridge type mist eliminator 5 and the third stage fine ridge type mist eliminator 6, the first stage ridge type mist eliminator 3 is next to the tube type mist eliminator 2; The spray cooling system includes a cooling water spray layer 4, a liquid collector grid 7 and a cooling water tank 8, the cooling water spray layer 4 is above the liquid collector grid 7, and the liquid collector grid 7 is in the first On the top of the primary ridge type mist eliminator 3, the cooling water spray layer 4 is connected to the cooling water tank 8 through the water supply pipe 9, the water supply pump 10 is arranged on the water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com