Production method of citric acid gypsum

A technology of citric acid gypsum and production method, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of difficulty in removing citric acid, increase the difficulty of removing citric acid, etc., and achieve the effect of wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

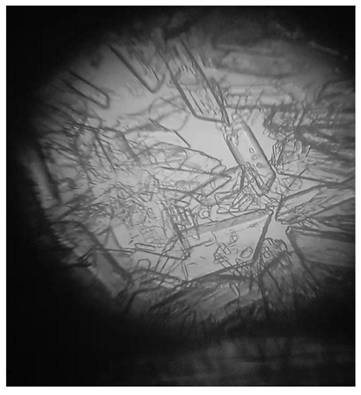

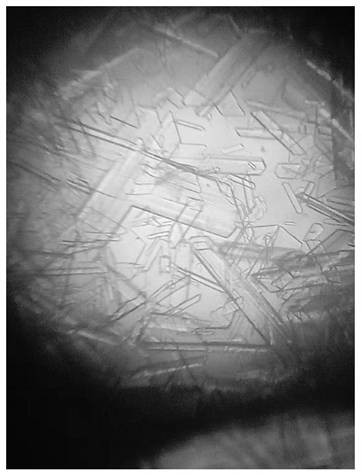

Image

Examples

Embodiment 1

[0039] A kind of citrate gypsum production method, comprises the following steps:

[0040] (1) Calcium hydrogen citrate and sulfuric acid are simultaneously passed into the reactor for continuous acidolysis, and the feeding speed of calcium hydrogen citrate is 40m 3 / h, the feed rate of sulfuric acid is 3.5m 3 / h, the reaction time is 5h, the reaction temperature is 88-89°C, and the citric acid gypsum raw material mixed with citric acid is prepared;

[0041] (2) Add the citric acid gypsum raw material obtained in step (1) into water to adjust the slurry, then add sulfuric acid to control the pH to 2.1, wherein the mass ratio of the citric acid gypsum raw material to water is 7:13, and filter to obtain thick citric acid gypsum;

[0042] (3) The crude citric acid gypsum obtained in step (2) is air-dried in an instant at 500°C; the feeding speed of the crude citric acid gypsum is 65m / s;

[0043] (4) Utilize the steam calcination machine to steam calcine for 40 minutes, and when...

Embodiment 2

[0045] A kind of citrate gypsum production method, comprises the following steps:

[0046] (1) Calcium hydrogen citrate and sulfuric acid are simultaneously passed into the reactor for continuous acidolysis, and the feeding speed of calcium hydrogen citrate is 40m 3 / h, the feed rate of sulfuric acid is 4m 3 / h, the reaction time is 6h, the reaction temperature is 88-89°C, and the citric acid gypsum raw material mixed with citric acid is prepared;

[0047] (2) adding the citric acid gypsum raw material obtained in step (1) into water to adjust slurry, then adding sulfuric acid, controlling the pH to be 2.3, wherein the mass ratio of citric acid gypsum raw material and water is 7:13, and filtering to obtain thick citric acid gypsum;

[0048] (3) The crude citric acid gypsum obtained in step (2) is air-dried instantaneously at 600°C; the feeding speed of the crude citric acid gypsum is 75m / s;

[0049] (4) Utilize the steam calcination machine to steam calcine for 50 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com