Preparation method of wet complexing iron desulfurizer

A complex iron method and complex iron technology are applied in the field of acid gas purification, which can solve the problems of slow reaction rate, high desulfurization cost, and poor desulfurization liquid stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

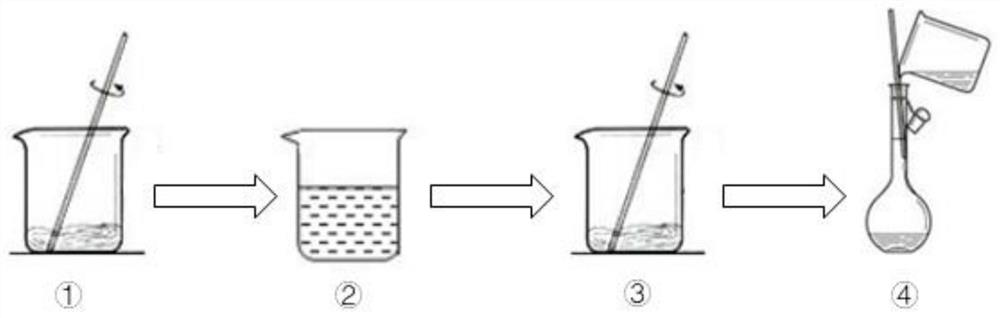

Embodiment 1

[0019] Take 100mL of deionized water, 97g of ferric chloride, and 2mL of sulfuric acid. First, slowly dissolve 97g of ferric chloride into 100mL of deionized water, and then keep stirring. The reaction is exothermic, so it must be dissolved slowly and kept stirring. After completely dissolving, let stand to room temperature. Then take by weighing 100 g of EDTA, 200 mL of ammonia water, and dissolve while stirring in the fume hood. After the EDTA is completely dissolved, the solution is clear. At this time, slowly add the ferric chloride solution in the EDTA ammonia solution, and constantly stir during the dissolution process to prevent precipitation. form. Finally, polyaspartic acid, glycerin, and sorbitol stabilizer are added into the solution, and the solution obtained after stirring to completely dissolve is a reddish-brown complex iron desulfurizer solution, which has strong desulfurization performance.

Embodiment 2

[0021] Take 100mL of deionized water, 97g of ferric chloride, and 2mL of sulfuric acid. First, slowly dissolve 97g of ferric chloride into 100mL of deionized water, and then keep stirring. The reaction is exothermic, so it must be dissolved slowly and kept stirring. After completely dissolving, let stand to room temperature. Then take by weighing 100 g of EDTA, 200 mL of ammonia water, and dissolve while stirring in the fume hood. After the EDTA is completely dissolved, the solution is clear. At this time, slowly add the ferric chloride solution in the EDTA ammonia solution, and constantly stir during the dissolution process to prevent precipitation. form. During the stirring process, polyaspartic acid, glycerin, and sorbitol stabilizer are added in batches, and the solution obtained after the stirring is completely dissolved is a reddish-brown complex iron desulfurization agent solution, which has strong desulfurization performance.

Embodiment 3

[0023] Take 100mL of deionized water, 97g of ferric chloride, and 2mL of sulfuric acid. First, slowly dissolve 97g of ferric chloride into 100mL of deionized water, and then keep stirring. The reaction is exothermic, so it must be dissolved slowly and kept stirring. In addition, add a part of stabilizer. After completely dissolving, let stand to room temperature. Then weigh 100 g of EDTA and 200 mL of ammonia water and dissolve them in the fume hood while stirring. Stir constantly to prevent the formation of a precipitate. During the stirring process, polyaspartic acid, glycerin, and sorbitol stabilizer are added in batches, and the solution obtained after the stirring is completely dissolved is a reddish-brown complex iron desulfurization agent solution, which has strong desulfurization performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com