Dust collection polar plate of wet-type electric dust collector

A technology of wet electrostatic precipitator and dust collection plate, applied in the direction of electrode structure, electrode cleaning, external electrostatic separator, etc., can solve the problems of increasing the amount of spraying water, decreasing the purification efficiency, increasing the amount of waste water and occupying land, etc. Achieve the effect of ensuring purification efficiency, reducing flushing water volume, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

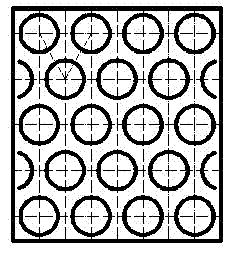

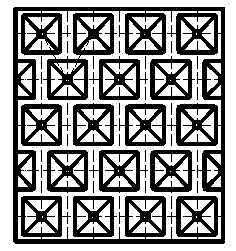

[0024] A dust-collecting pole plate of a wet electrostatic precipitator, the surface of the dust-collecting pole plate is in a regular concave-convex shape, and the concave parts form dimples; the dimples are arranged in rows on the pole plate surface, evenly arranged, and the centers of the two rows of dimples are arranged alternately, The dimples are arranged in a triangular shape, and the dimples are smoothly connected.

[0025] according to figure 1 , 2 According to the requirements indicated, the dust collection plate is processed into a concave-convex shape, the three-dimensional shape of the dimple is a spherical crown, and the surface is circular; the diameter of the dimple is 25-40mm, and the depth of the dimple is 5-8-mm. The dimples are arranged in a triangular shape, and the dimple diameter and dimple depth can be adjusted and changed according to the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circular diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com