Patents

Literature

234results about How to "Layout improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

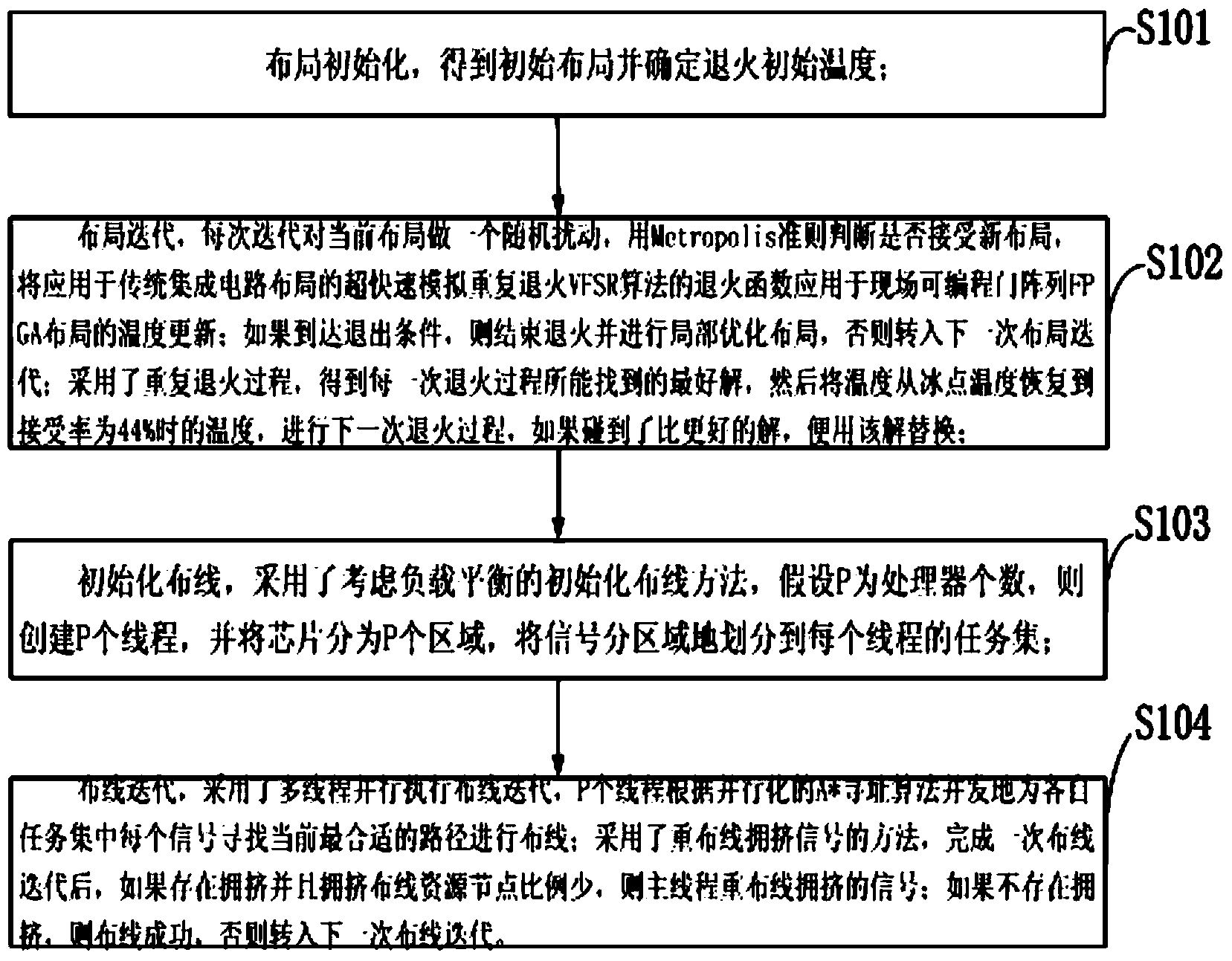

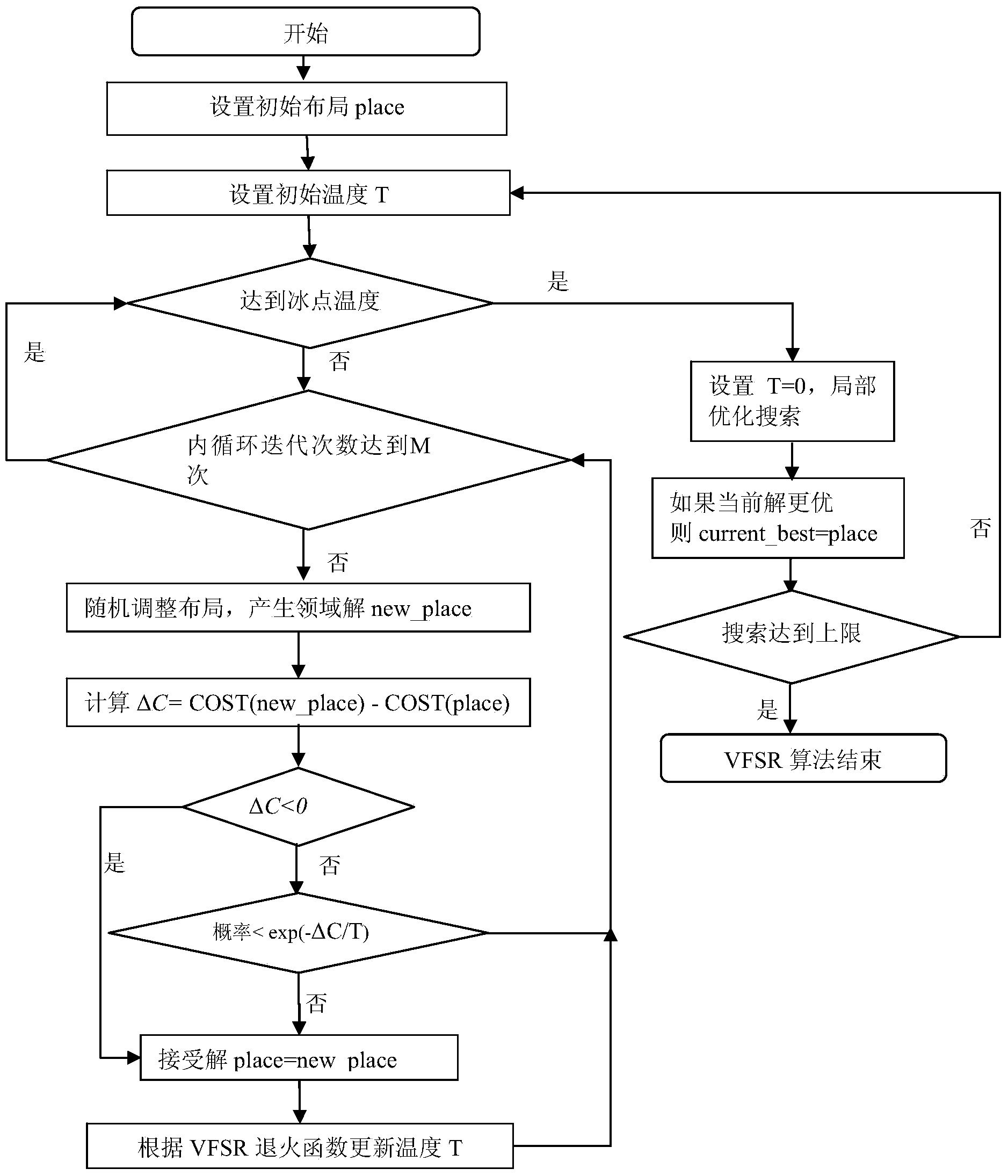

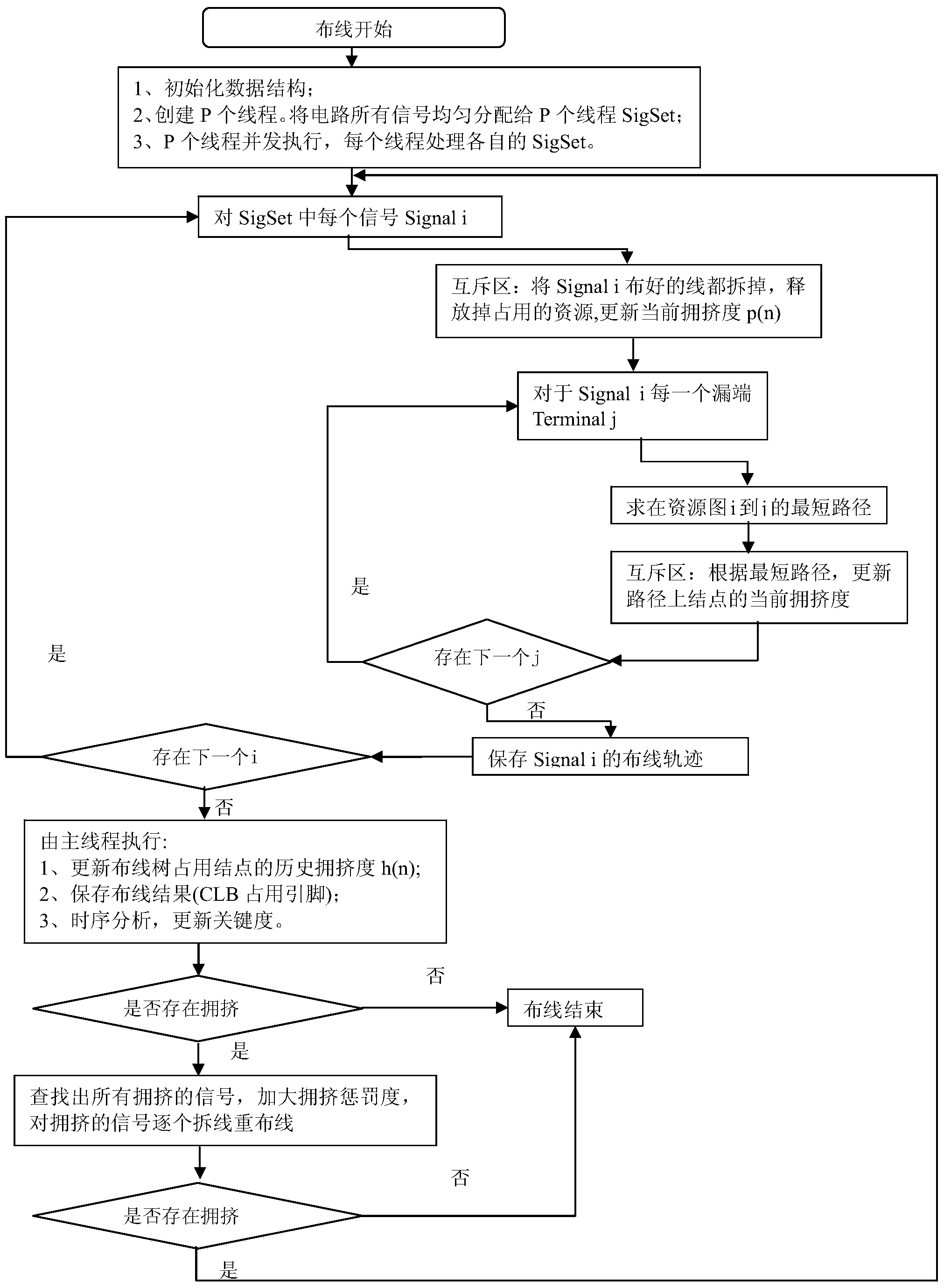

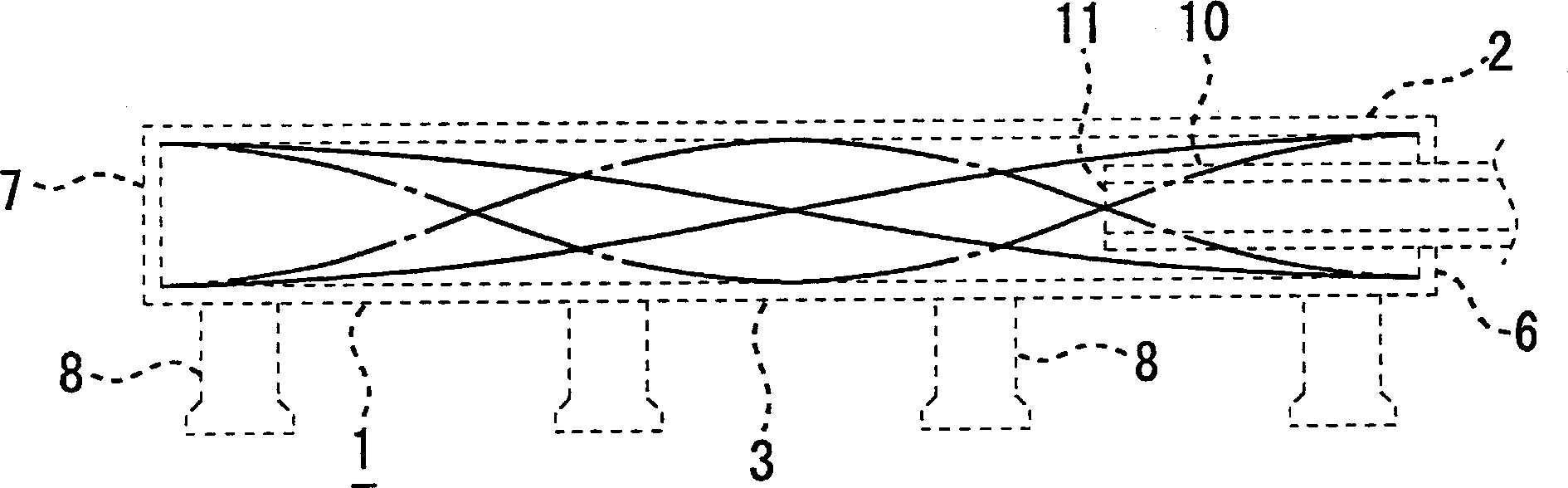

Method for implementing quick locating and wiring of field programmable gate array (FPGA)

ActiveCN103886137ALayout improvementShorten the convergence processSpecial data processing applicationsPerformance indexField-programmable gate array

The invention discloses a method for implementing quick locating and wiring of a field programmable gate array (FPGA). The method includes: applying annealing function to temperature updating of the FPGA; adopting repeated annealing processes to acquire current_best, the best solution which can be found out in each annealing process, and performing the next annealing process; adopting an initialized wiring method taking load balance into consideration, assuming P to be the number of processors, establishing P threads, dividing a chip into P areas, and dividing signals into task sets of the threads in areas; adopting multi-thread and executing wiring iteration, and the P threads concomitantly looking for most suitable paths currently for the signals in the task sets according to a parallelized A* addressing algorithm; adopting a heavy wiring crowded signal method to complete the one-time wiring iteration. By the method, the wiring process is quickened, and locating and wiring is obviously quickened under the condition that two important performance indexes of delay and thread length of a final circuit are basically remained unchanged.

Owner:XIDIAN UNIV

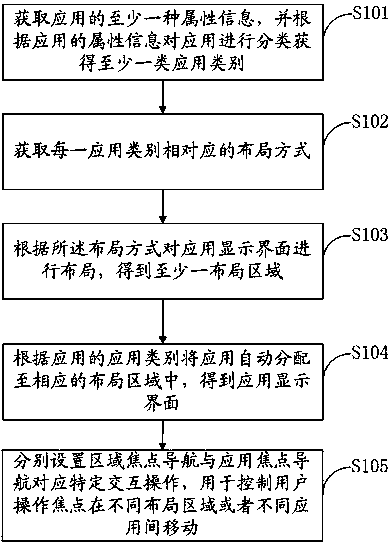

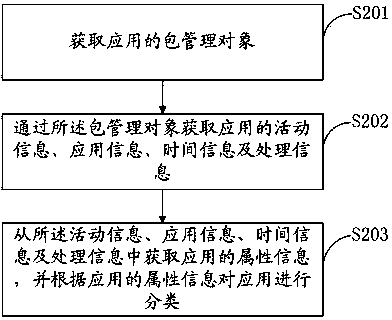

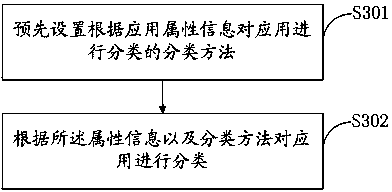

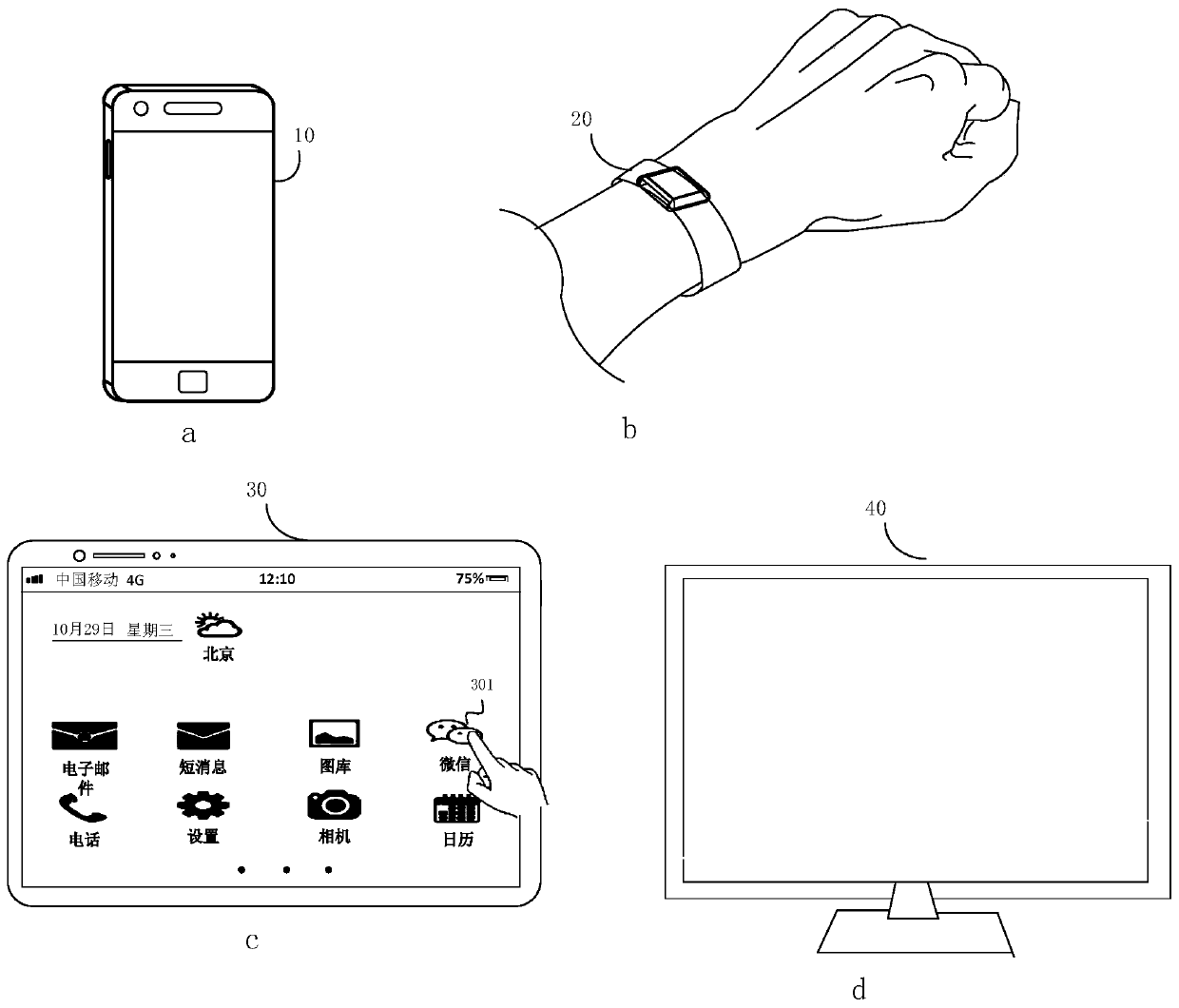

Method and system for managing layout of application according to attribute information of application

ActiveCN103513978AImprove comfortLayout improvementSpecific program execution arrangementsTerminal equipmentSoftware engineering

The invention discloses a method and system for managing the layout of application according to the attribute information of the application. The application is classified according to the attribute information of the application, an application display interface is adjusted, the application is classified and displayed by users according to requirements of the users, and therefore the users can conveniently look up the application and use the application, and the comfort degree and the layout effect of the application display interface are improved. According to the method and system, the overall structure of launcher does not need to be modified, and therefore the complex degree that the application is located by the users is relieved, and efficiency is improved. Furthermore, due to the adoption of the method and system, the application display interface can be modified to be suitable for UI interfaces of equipment, except mobile phones, like intelligent televisions, and terminal equipment has the new function of adjusting the application display interface. The method and system are simple and practical.

Owner:TCL CORPORATION

Integrated cabinet arrangement local area network system

InactiveCN101645816AImprove work and study environmentGood coolingDigital data processing detailsData switching by path configurationComputer casePeripheral

Owner:闫文斌

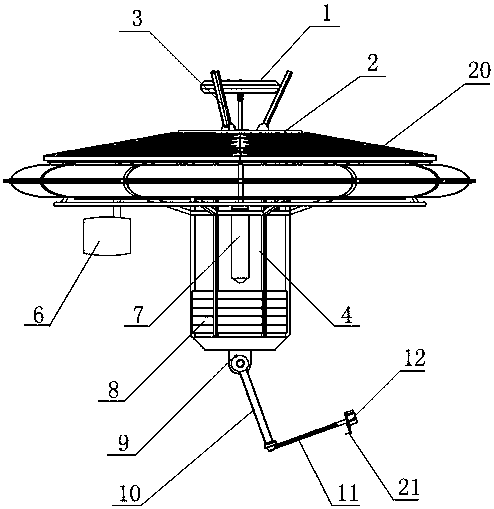

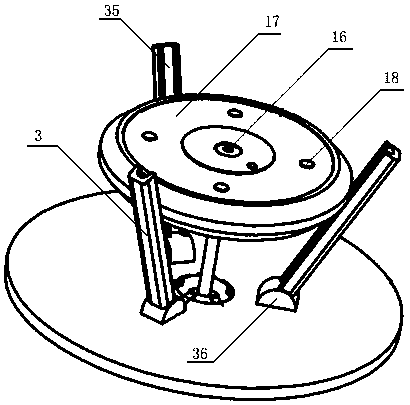

Multifunctional submerging and floating device with unmanned aerial vehicle taking-off and landing platform

PendingCN107672751AImprove battery lifePrecision landingHull interior subdivisionBatteries circuit arrangementsOcean bottomHigh pressure

The invention discloses a multifunctional submerging and floating device with an unmanned aerial vehicle taking-off and landing platform. The multifunctional submerging and floating device comprises afloating cabin, the unmanned aerial vehicle taking-off and landing platform, a high-pressure submersible pump, a balance weight cabin and a power drive device. Solar cell panels are arranged, so thatsolar energy serves as an energy source. The multifunctional submerging and floating device is provided with an energy storage device, and an unmanned aerial vehicle, all types of instruments and equipment carried on the multifunctional submerging and floating device and submarine electronic equipment can be charged. Through the maneuverability of the power drive device, the position of the multifunctional submerging and floating device can be adjusted or the multifunctional submerging and floating device can slowly move to the designated position. The multifunctional submerging and floatingdevice is simple in structure, flexible in loading and transporting and quick to arrange; and on the base of the platform, the functions of exploration, receiving, storage, launching, object transit shipment and the like can be expanded as well, and the device is extended to be the universal type multifunctional submerging and floating device which can process all types of information and integrate multiple functions.

Owner:余拓

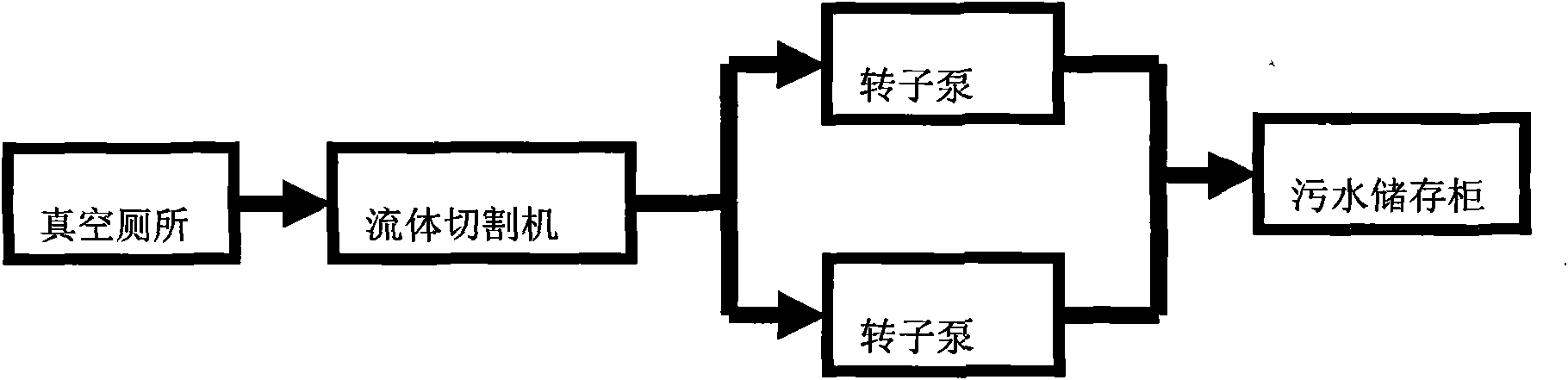

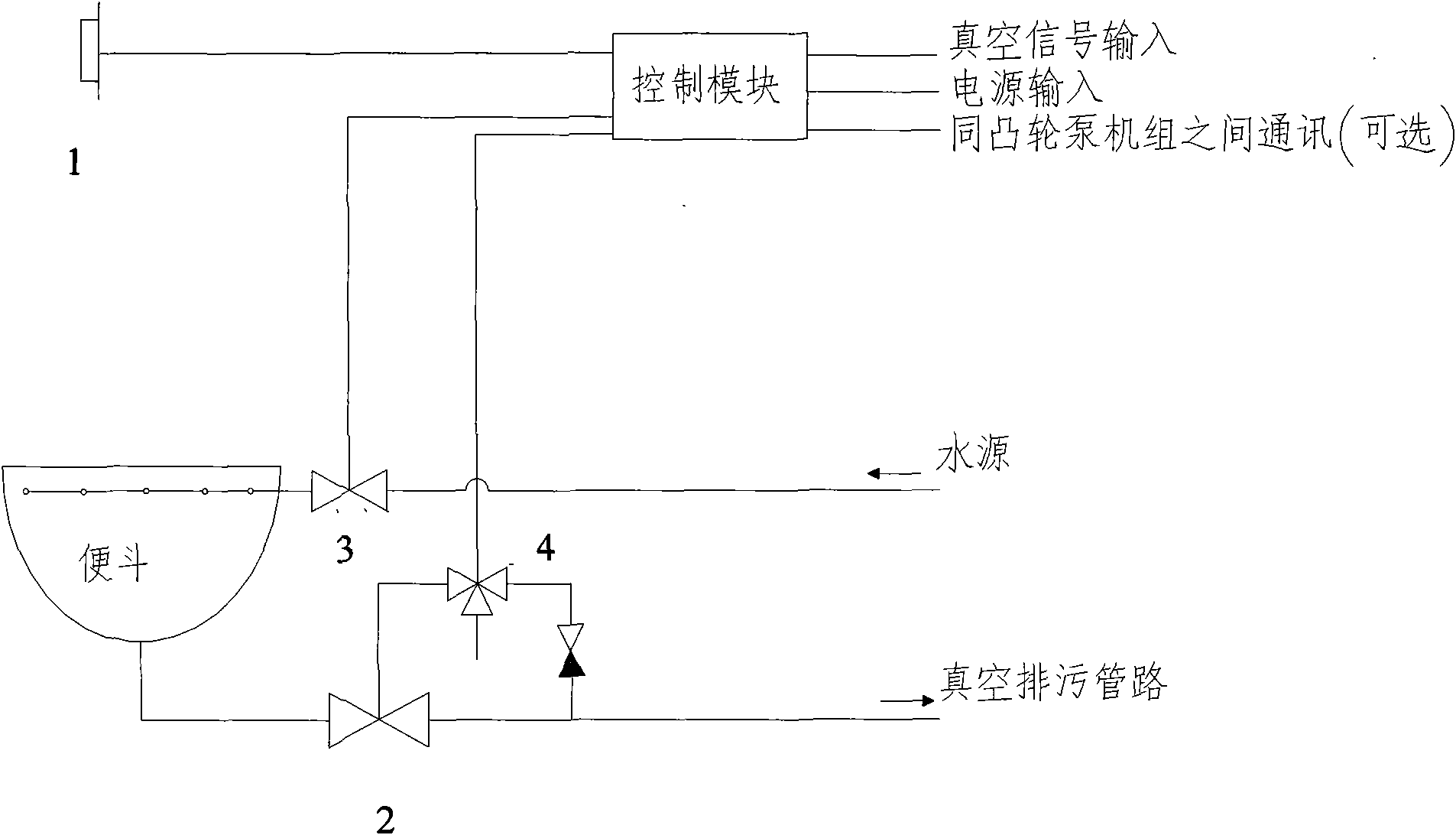

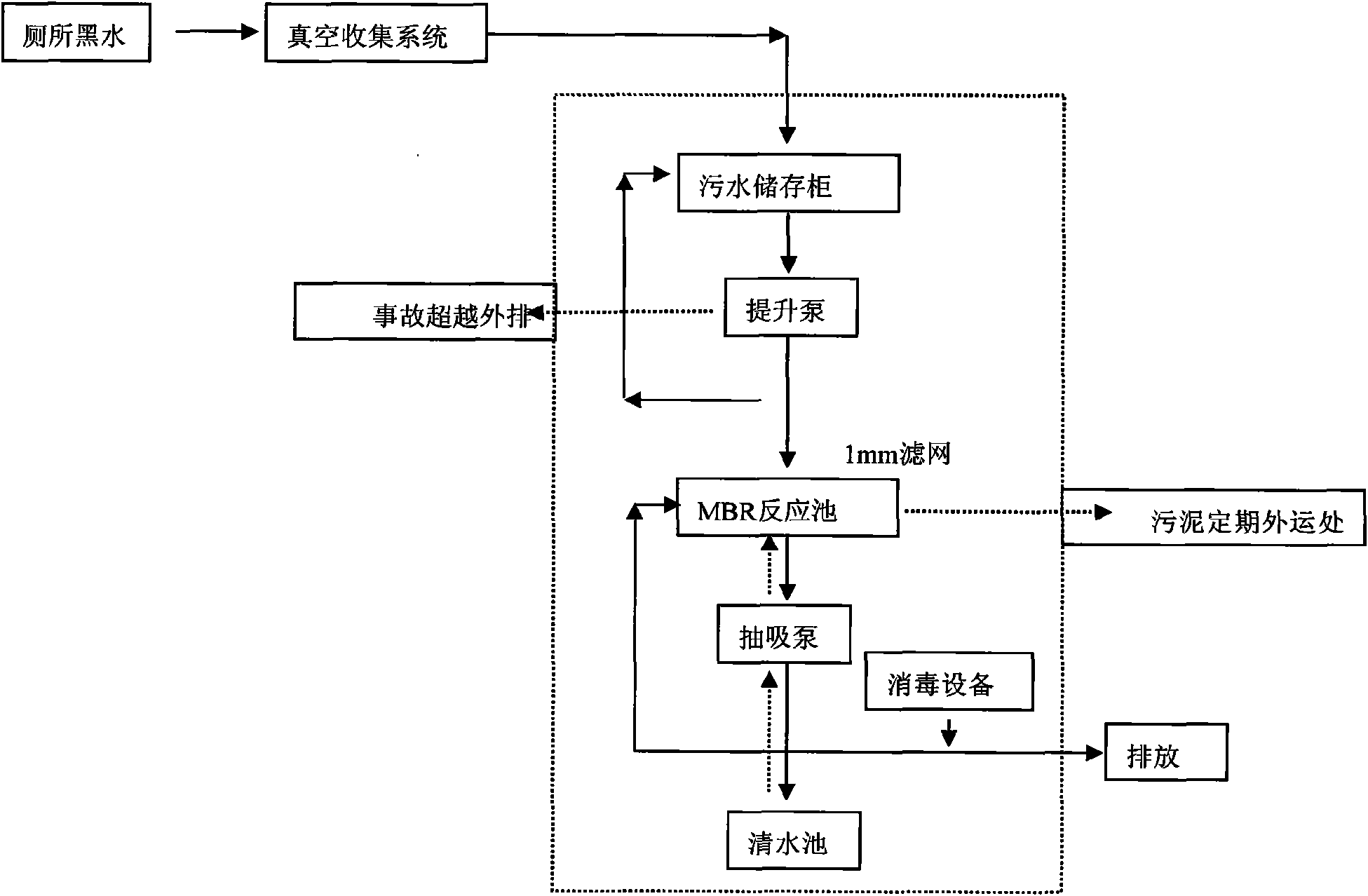

Marine domestic sewage treatment process and vacuum discharge and treatment system

ActiveCN101618927AReduce the amount of flushing waterSmall diameterAuxillariesWater/sewage treatment bu osmosis/dialysisCollection systemWater quality

The invention discloses a marine domestic sewage treatment process belonging to the technical field of sewage treatment and discharge. The marine domestic sewage treatment process comprises the following steps: (1) collecting sewage by a vacuum collection system, and achieving the discharge and transport by utilizing the pressure difference inside and outside the system; (2) crushing and thinning large granular suspended matters by a crushing pump, filtering by a grid and then conveying into a sewage tank; (3) conveying to a fur collector by the pump to remove furs and small granular suspended matters; and (4) degrading by aerobic bio-degradable bacteria, filtering by multiple groups of hollow micropore membrane reactors, then discharging into a sterilizing device, and finally discharging to the outside. The invention further discloses a marine domestic sewage vacuum discharge and treatment system. The invention has simple treatment process, not only saves space and water, has compact arrangement, safety and sanitation as well as easy maintenance, but also decreases the influence of the swing of a marine body on the water quality, and has high pollutant degradation efficiency and directly-reused discharged water.

Owner:SHENZHEN JINRUN IND

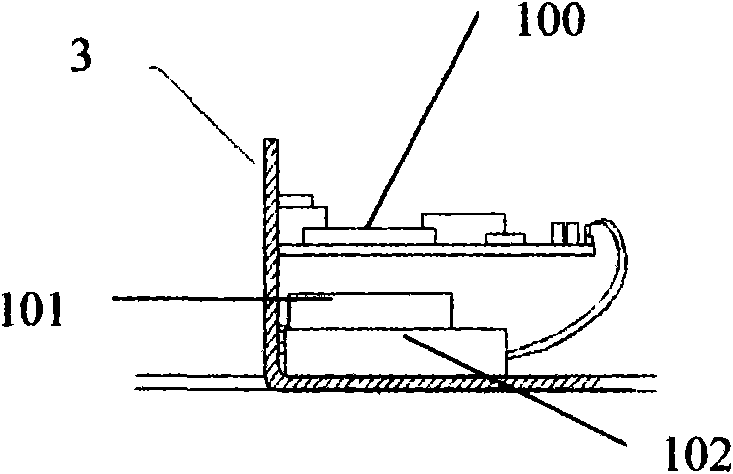

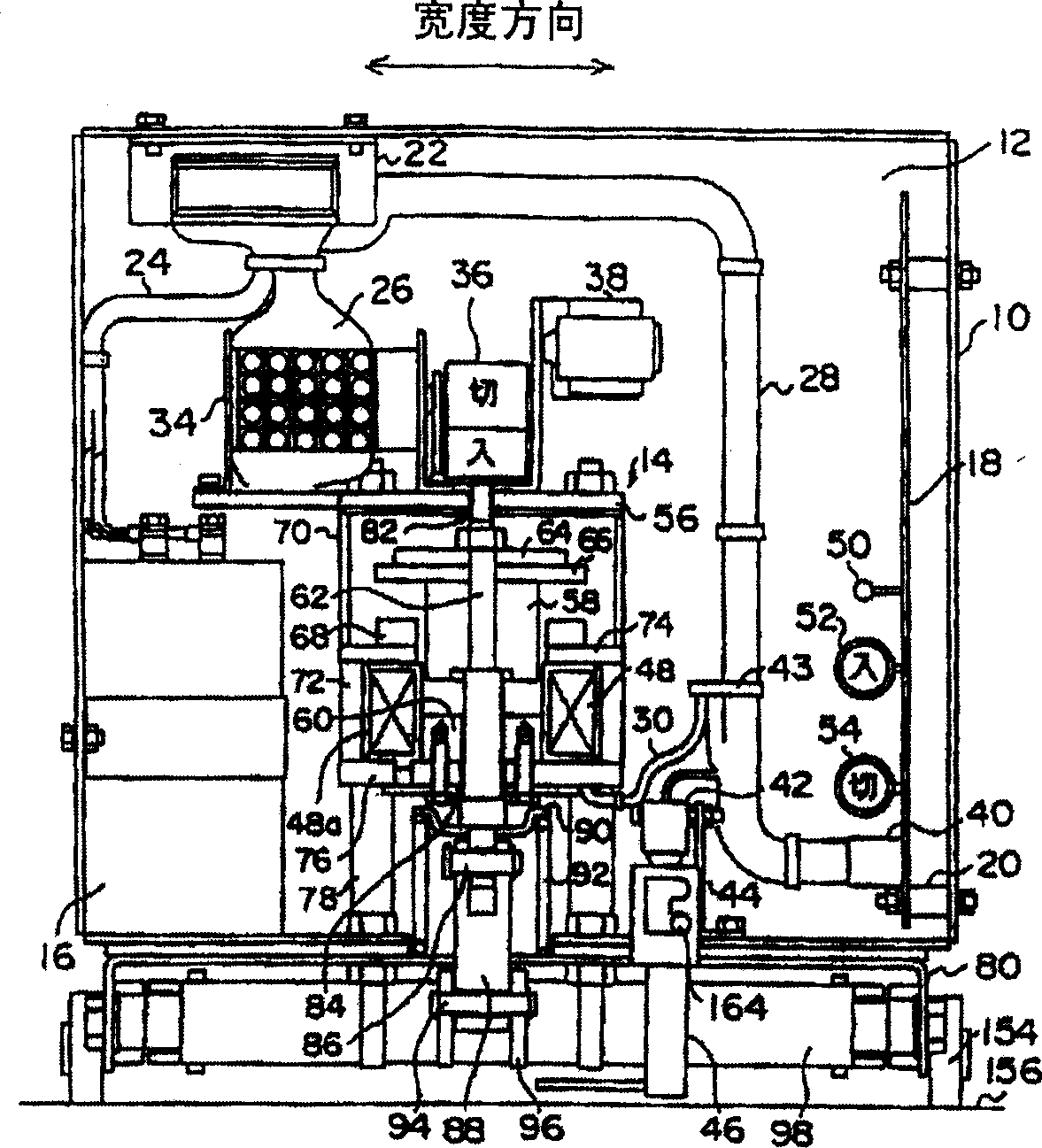

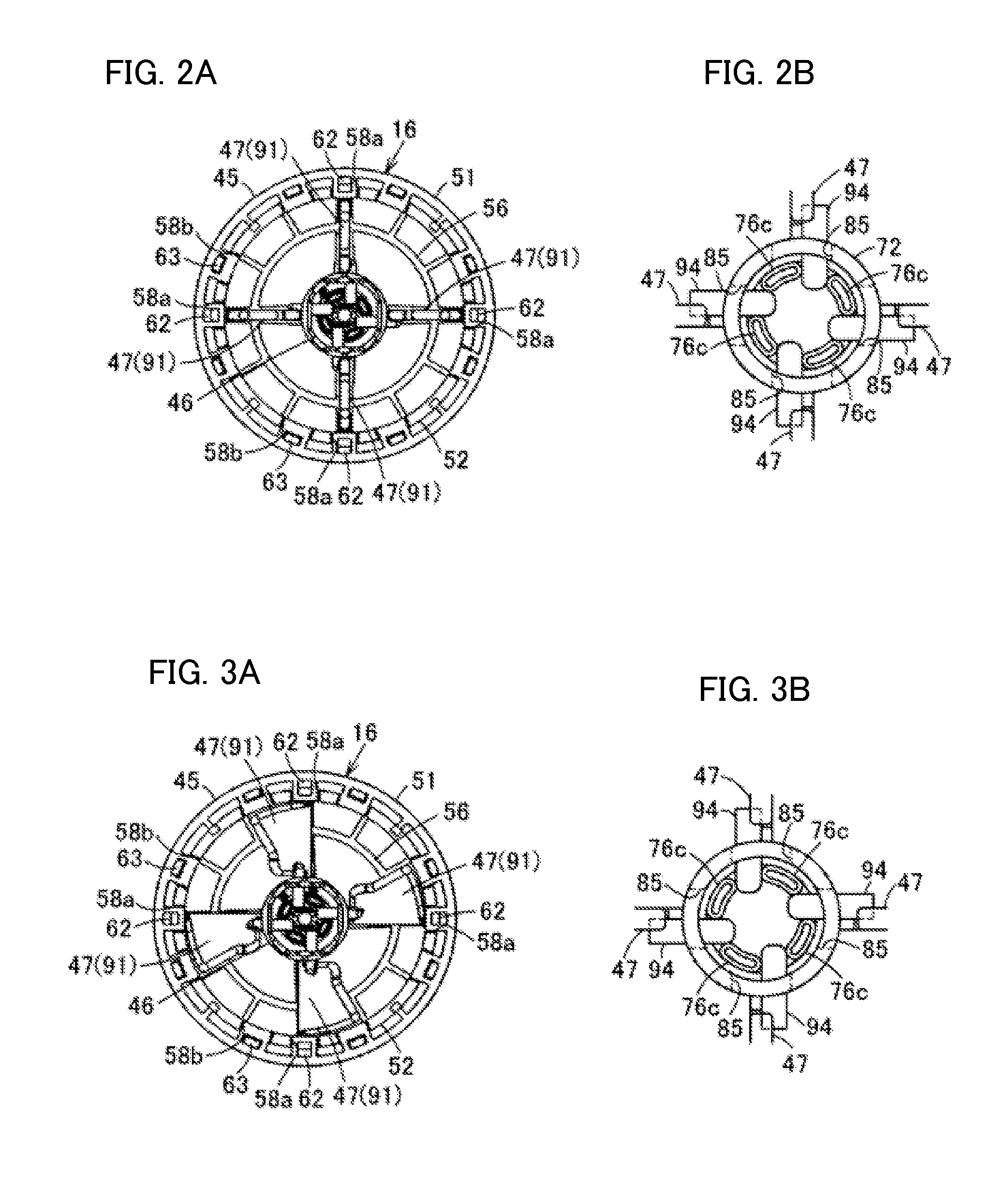

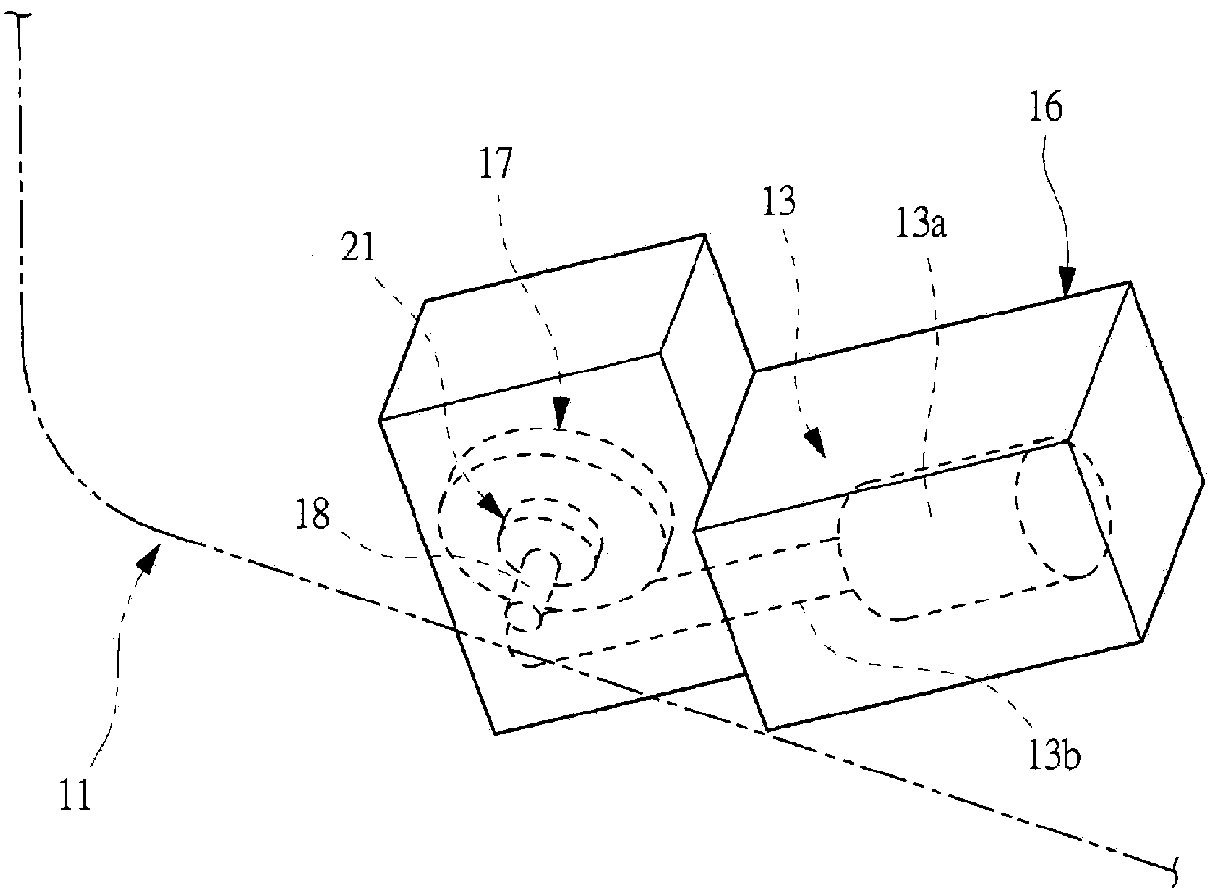

Solenoid operator and solenoid-operated switching device and control device for electromagnet

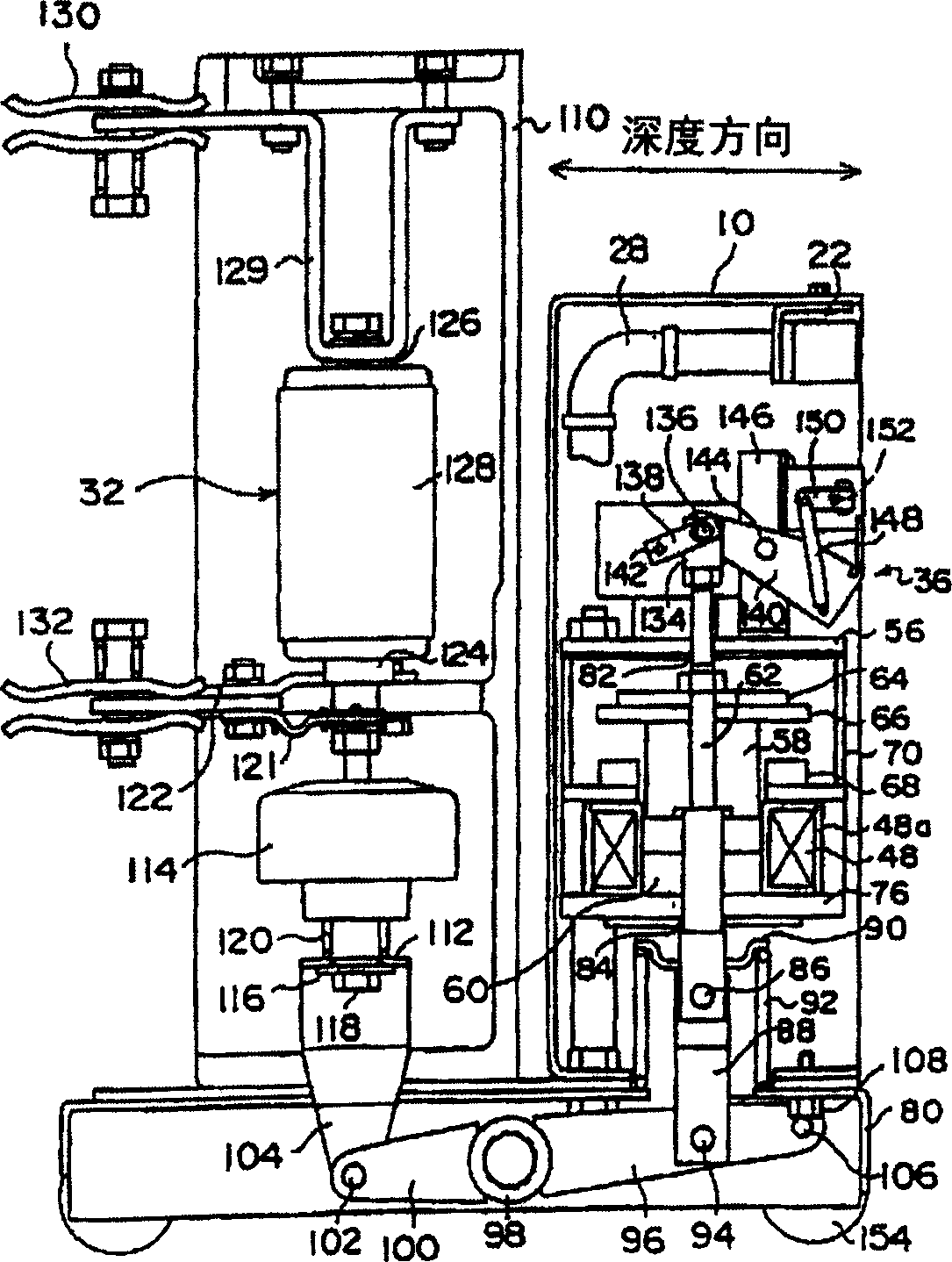

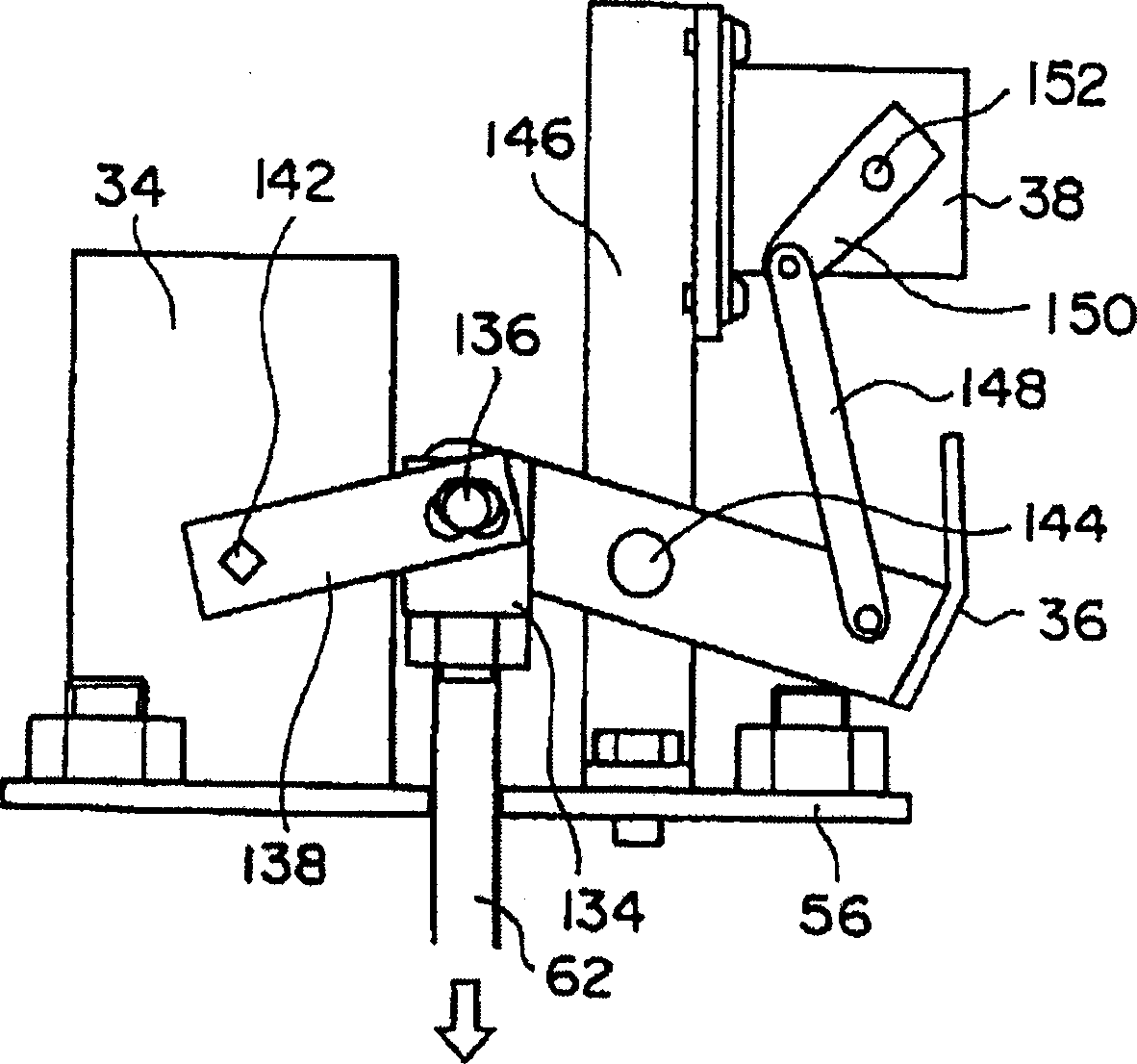

ActiveCN1728307AEasy to operateLayout improvementSwitchgear detailsSwitch power arrangementsEngineeringElectrical and Electronics engineering

The invention relates to an electromagnetic operating device and an electromagnetic operating type switching device and an electromagnet control device, in particular to the electromagnetic operating device capable of operating the switches like a breaker through an electromagnetic force and the electromagnetic operating type switching device and the electromagnet control device for driving an electromagnet which serves as the driving source of a drive switch. The designing structure of the invention capable of improving the operationability is that: the electromagnet (14) is arranged in the lower center position of a casing (10); a capacitor (16) and a control circuit board (18) are respectively arranged on the two sides of the electromagnet (14); an auxiliary contact (34), a display panel (36) and a counter (38) are arranged on the upper part of the electromagnet (14); the auxiliary contact (34), the display panel (36) and the counter (38) are further assembled on a board (56), thereby integrating with the electromagnet into a whole; thus, the capacitor (16) and the control circuit board (18) can be pulled out from the front.

Owner:HITACHI IND EQUIP SYST CO LTD

Wind direction adjuster

ActiveUS20150336445A1Downsize coupling structureSuppress manufacturing costAir-treating devicesVehicle heating/cooling devicesEngineeringActuator

A wind direction adjuster is disclosed in which an inner-side turning axis provided to a louver main body in a protruding manner is axially supported by an inner-side axial support hole provided in a spacer fixed to a bearing portion provided to a housing portion. Moreover, an actuator axis provided to the louver main body in a protruding manner at a position spaced from the inner-side turning axis is inserted into an operation opening provided to the spacer. In addition, a louver moves forward or rearward by pushing the actuator axis by a projecting portion in association with turning of a knob turnable with respect to the bearing portion and the spacer. The louvers can be moved in conjunction with each other with a simple configuration.

Owner:NIHON PLAST CO LTD

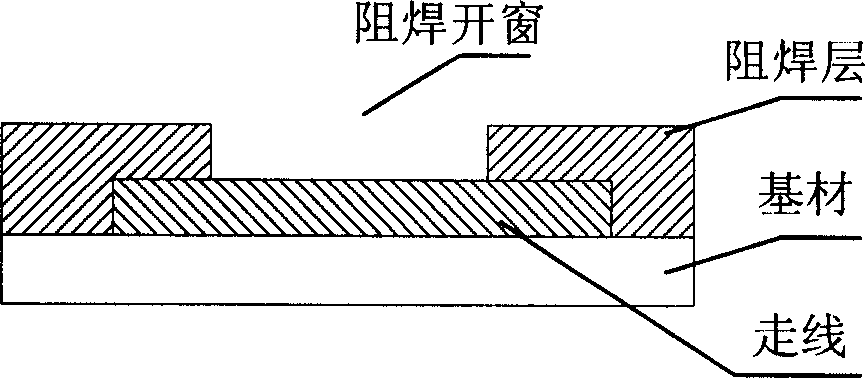

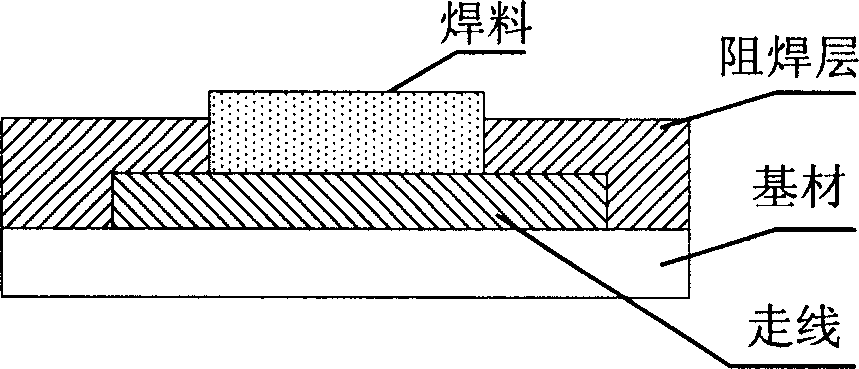

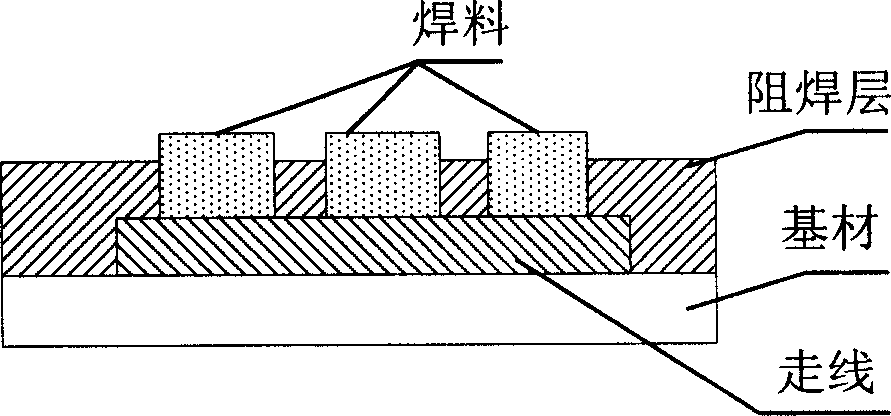

A printed circuit board and production method thereof

InactiveCN1838857ASimple designEasy to implementPrinted circuit assemblingElectrical connection printed elementsPrinted circuit board

The invention relates to a printed circuit board and relative producing method, for improving the current-carrying ability of circuit. Said circuit board comprises: routing and the welding-resistance layer covering said routing. Wherein, the welding-resistance layer comprises at least on welding-resistance window along the length of one routing; said window is filled with solder which is electrically combined with said routing; said routings are distributed on two surfaces of said circuit board and the windows are arranged on two surfaces too; and when there is one routing and several said windows, the windows are parallel arranged, and the length of window is the same with the length of routing. The producing method comprises: arranging at least one welding-resistance window along the length of at least one routing; filling solder into said window to electrically combine the routing.

Owner:HUAWEI TECH CO LTD

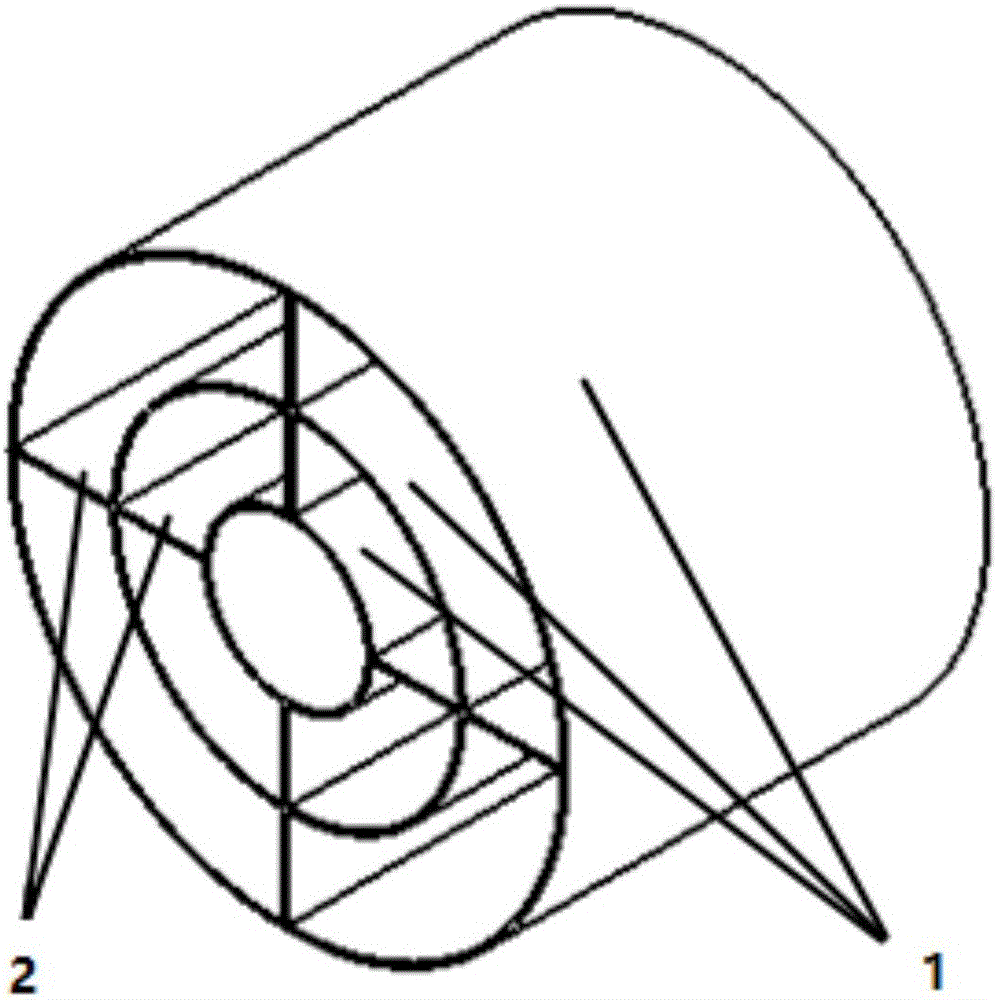

Brushless motor and wiper apparatus

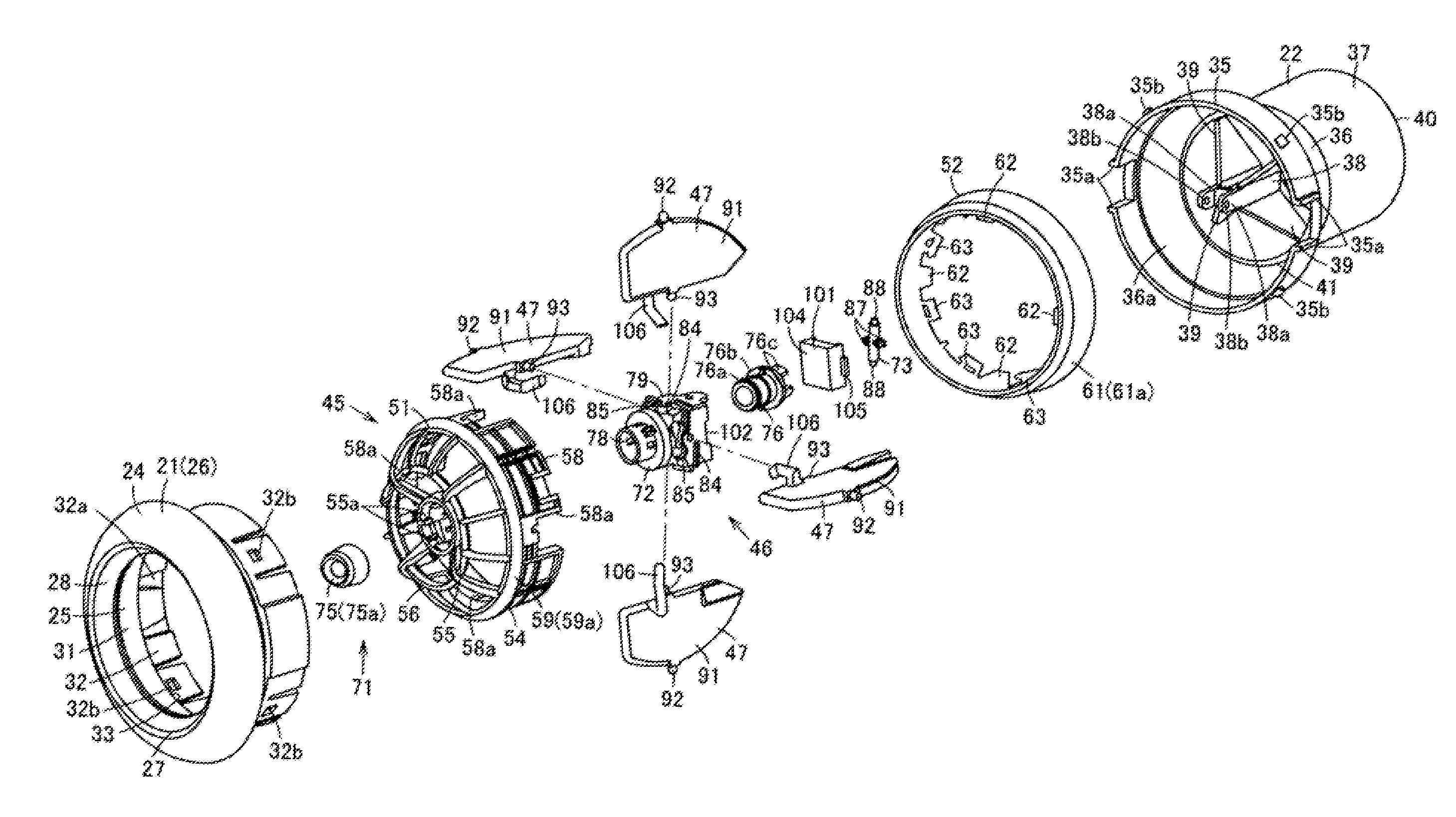

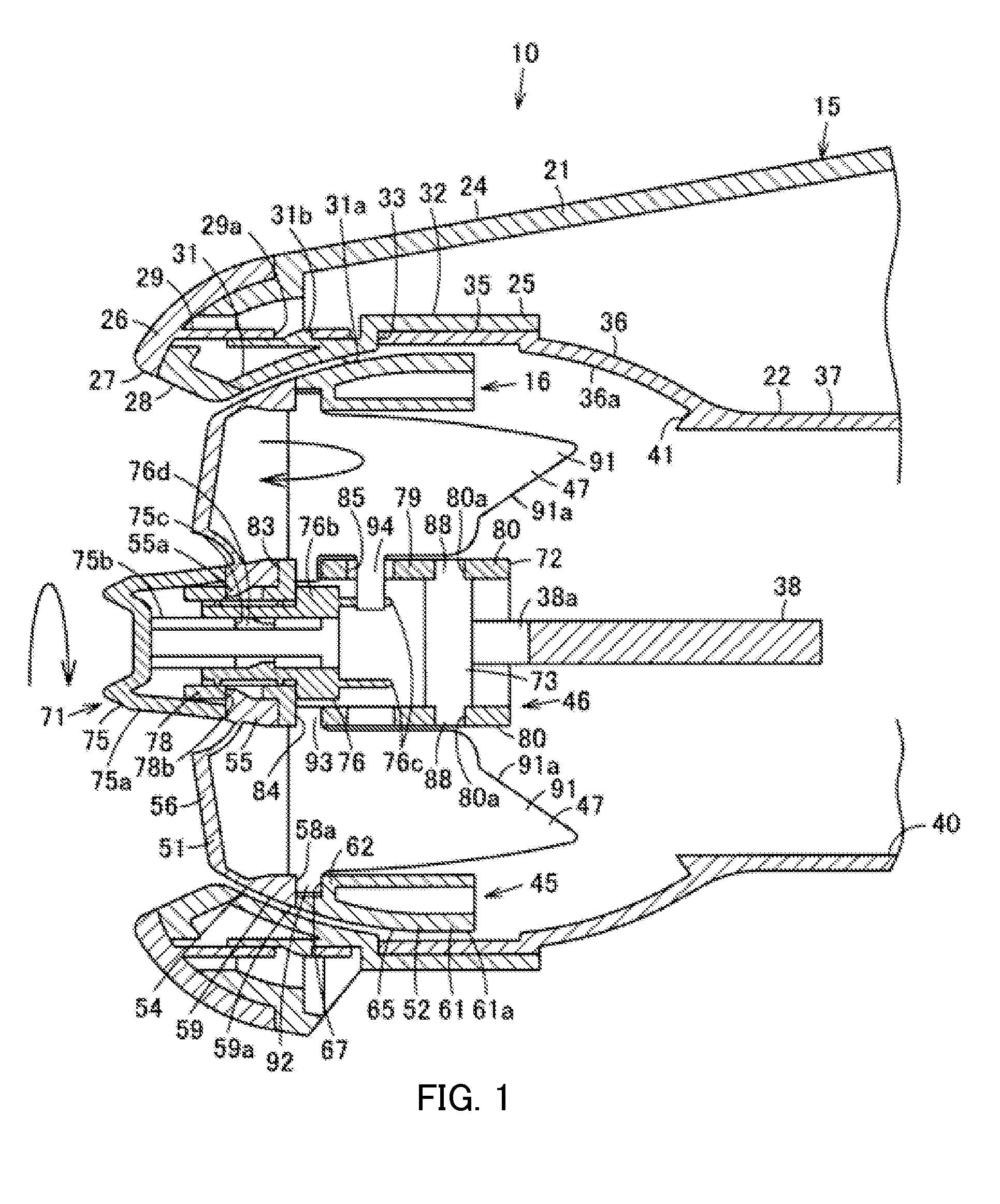

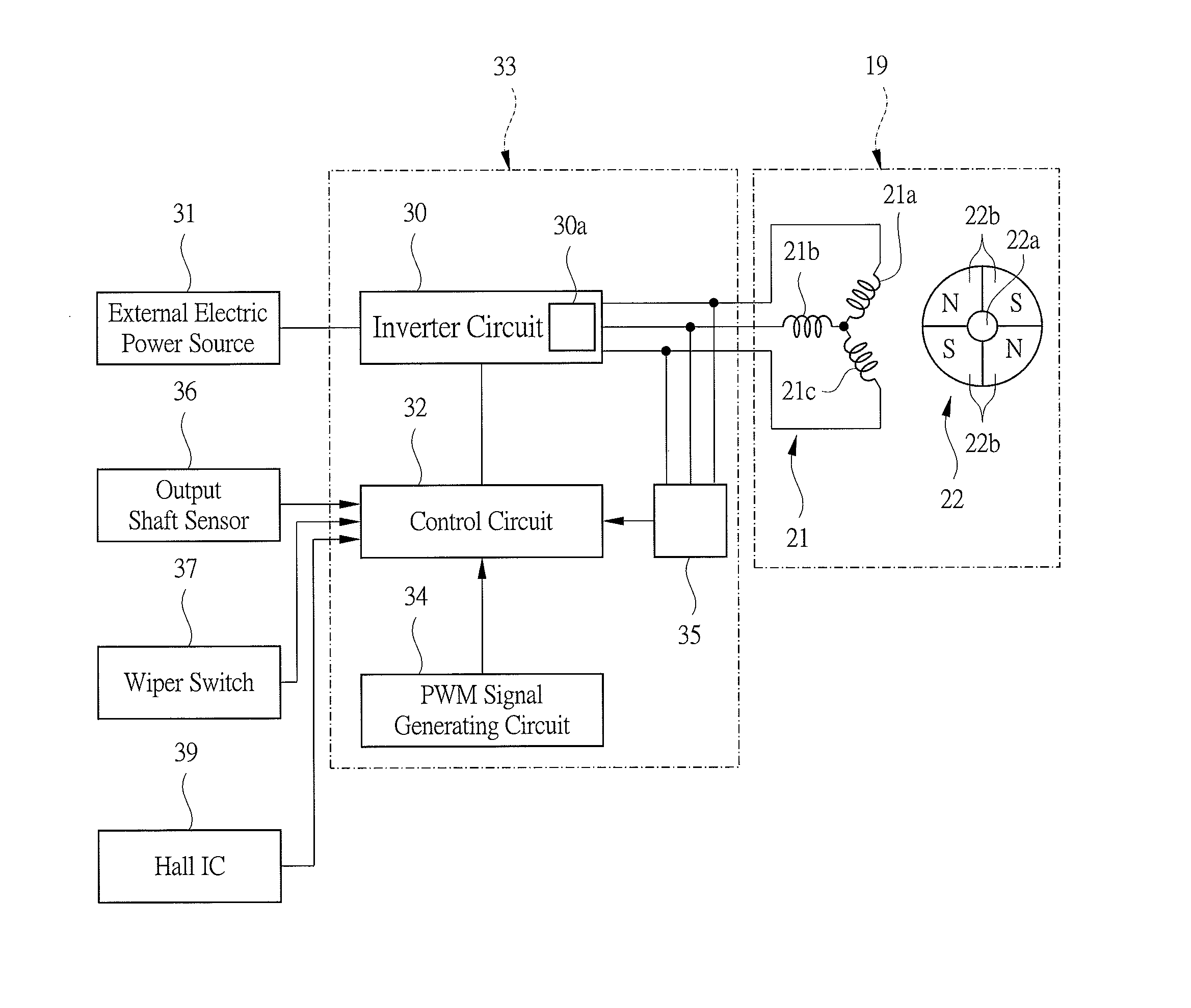

ActiveUS20150082575A1Small sizeLayout improvementSynchronous motors startersSingle motor speed/torque controlBrushless motorsSupply current

A brushless motor comprises: a stator 21 having armature coils 21a, 21b, and 21c; a rotor 22 which is rotated by a revolving magnetic field; and a switching element 30a, wherein the brushless motor has a rotation number control unit 33 which switches between low-speed and high-speed mode, wherein in the low-speed mode, the rotation number control unit 33 supplies current to the armature coils 21a, 21b, and 21c at predetermined energization timing and controls a duty ratio to control the rotation number of the rotor 22, and in the high-speed mode, the rotation number control unit 33 supplies current to the armature coils 21a, 21b, and 21c at energization timing advanced from the energization timing for the low-speed mode, thereby performing field weakening control of weakening the revolving magnetic field from that of the low-speed mode to control the rotation number of the rotor 22.

Owner:MITSUBA CORP

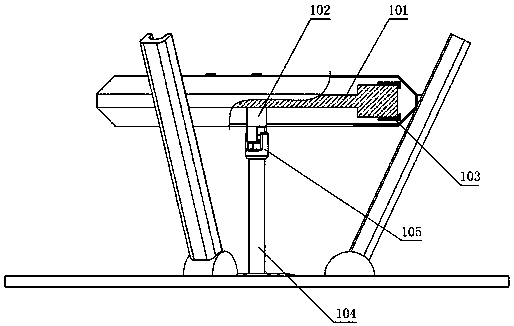

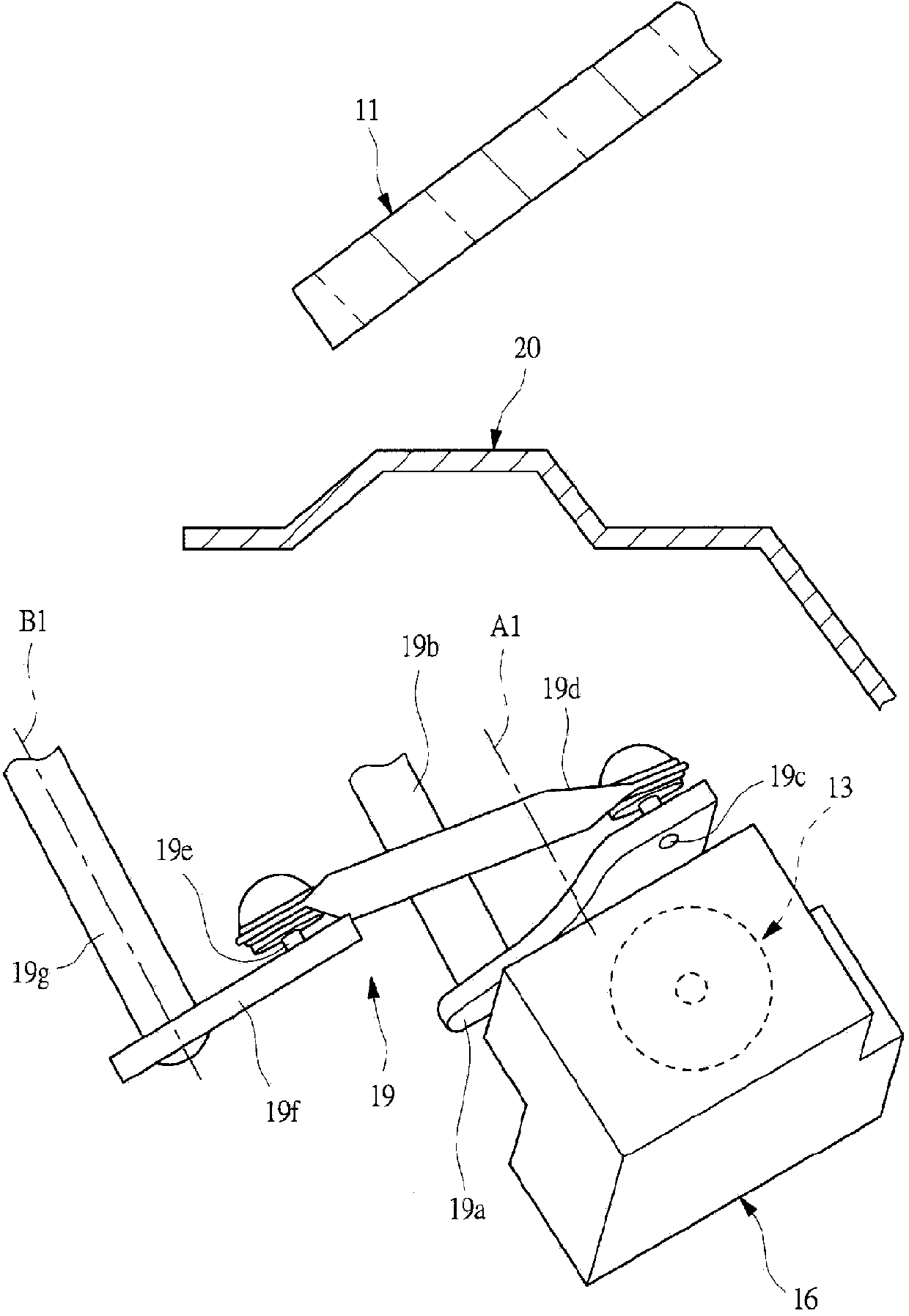

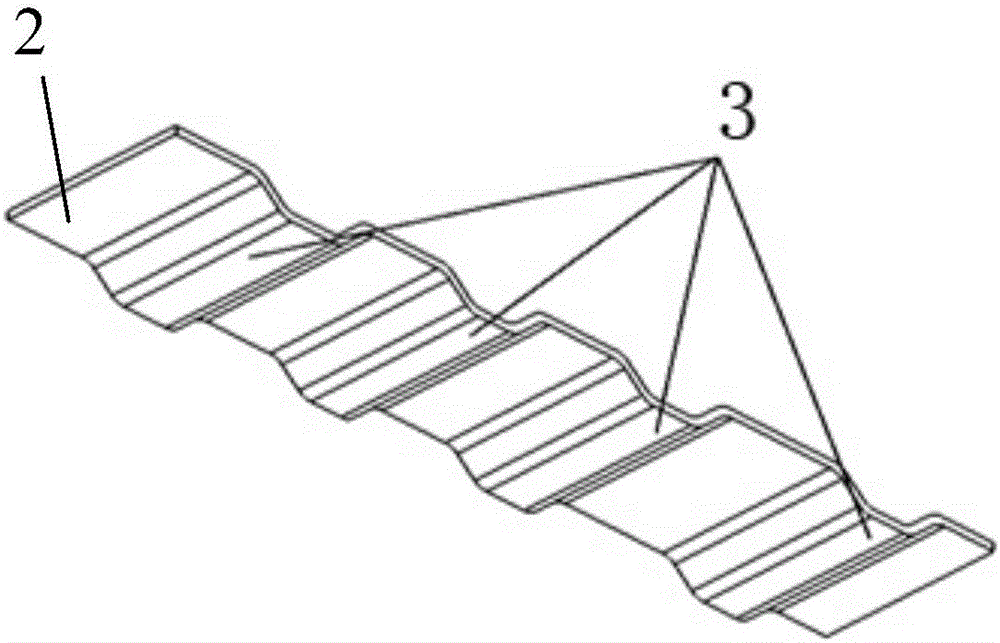

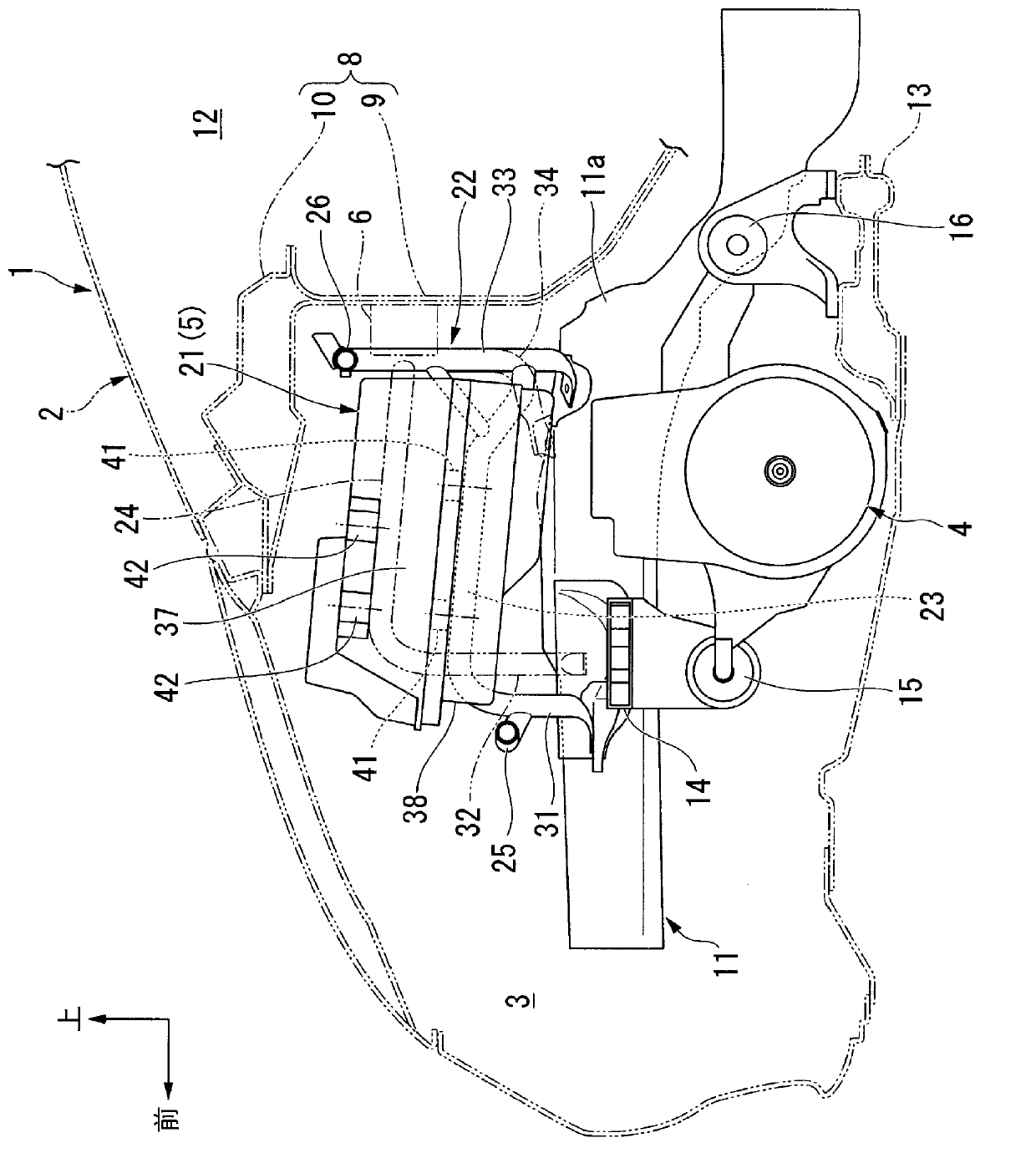

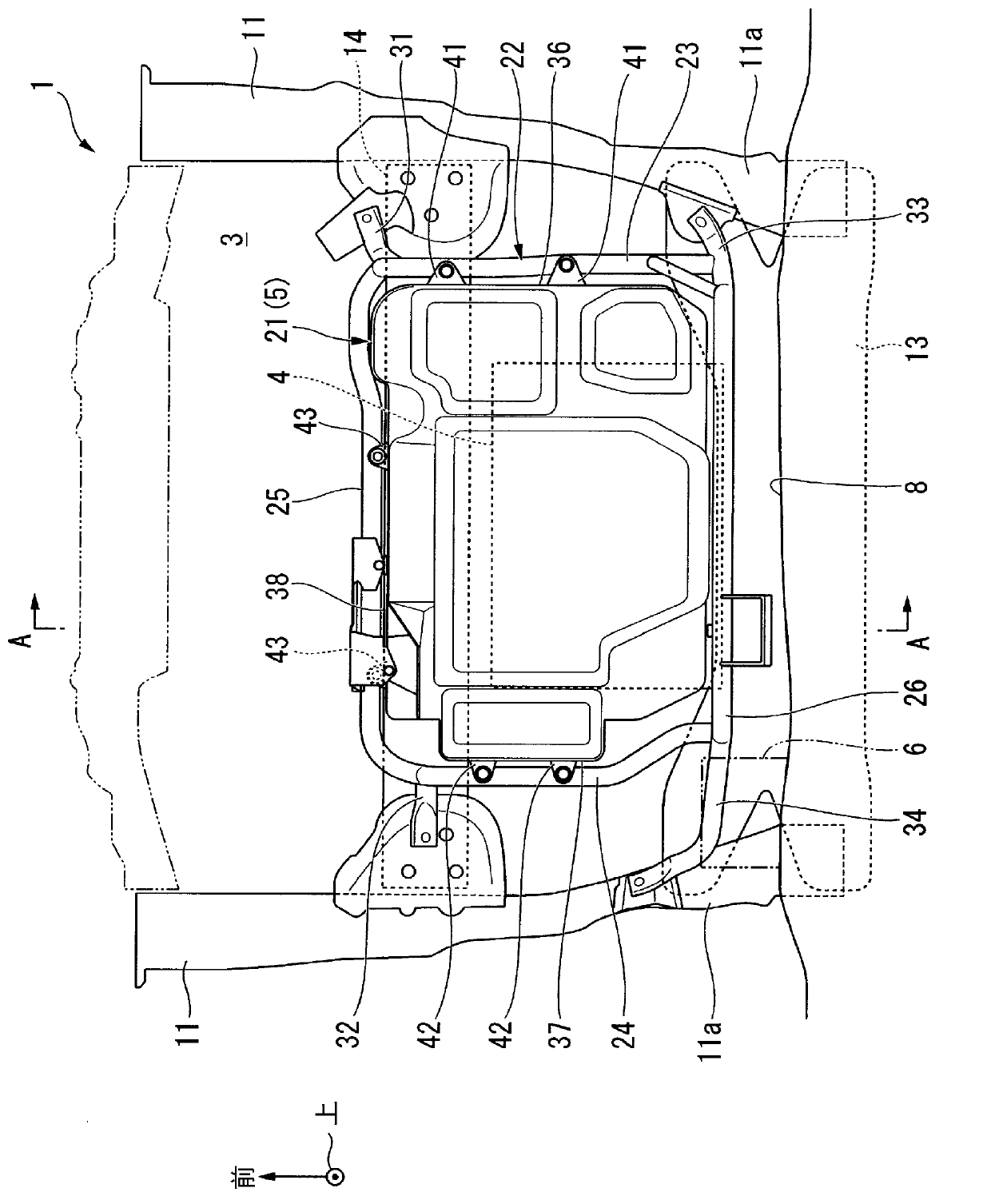

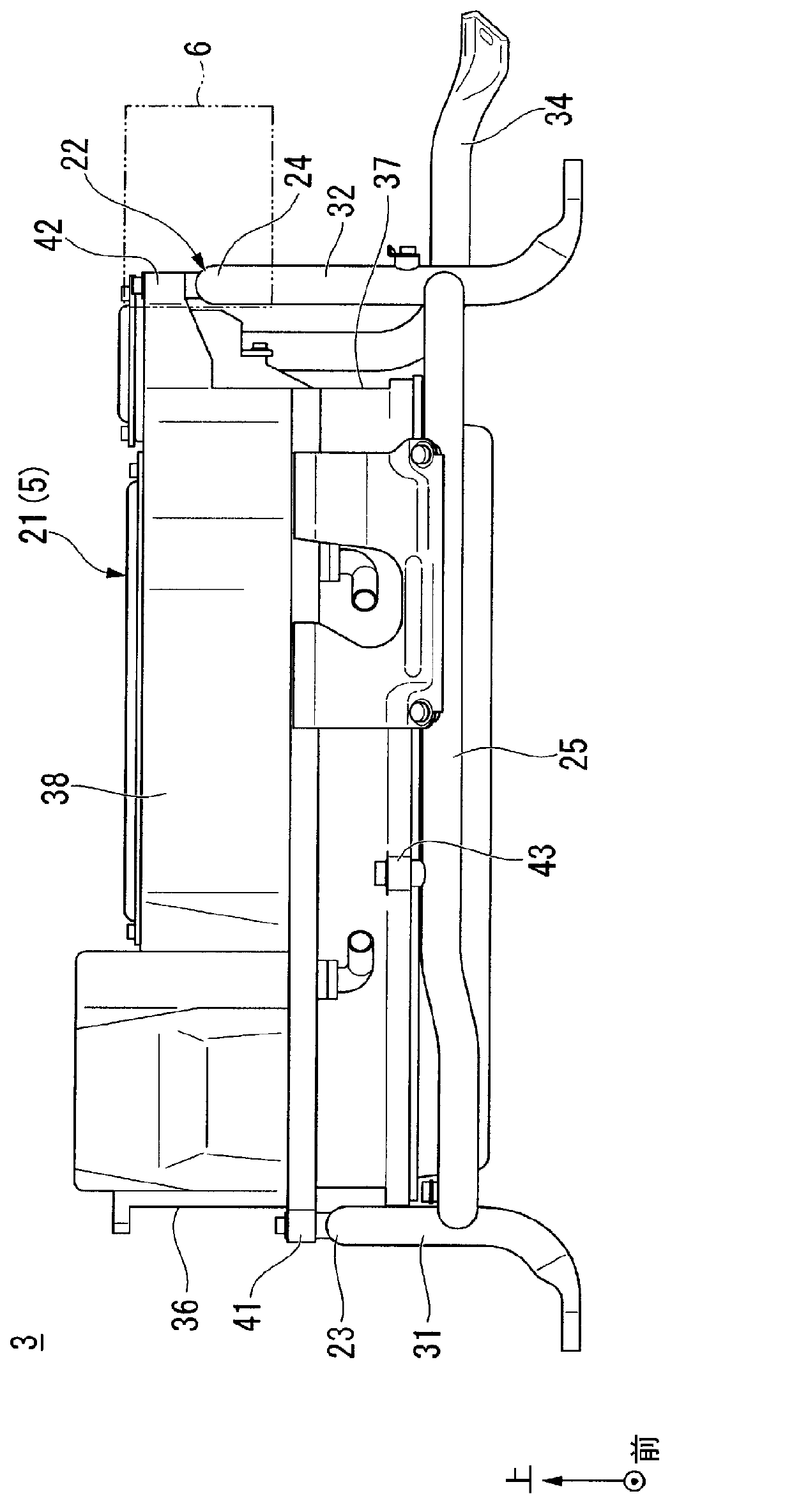

Wiper device

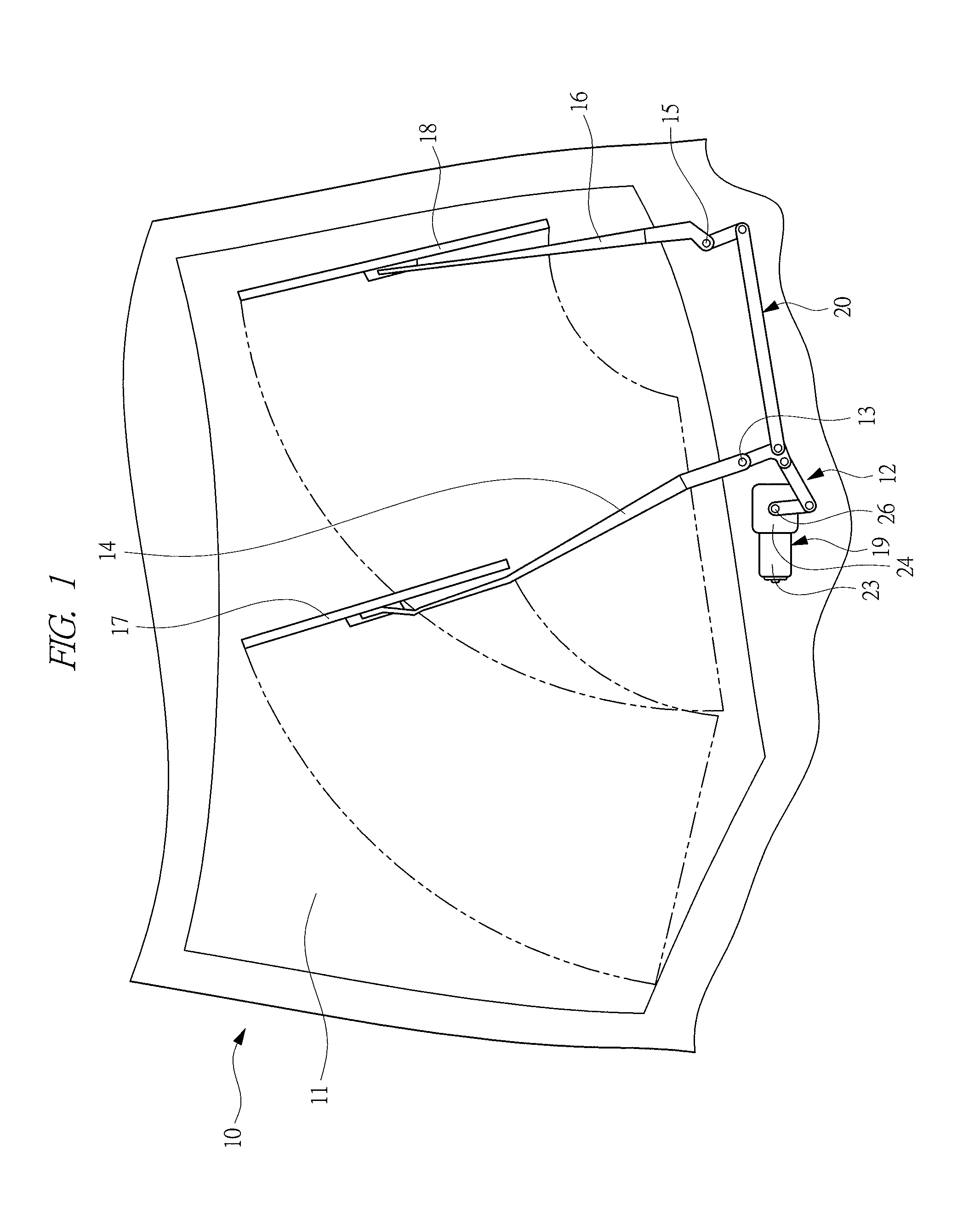

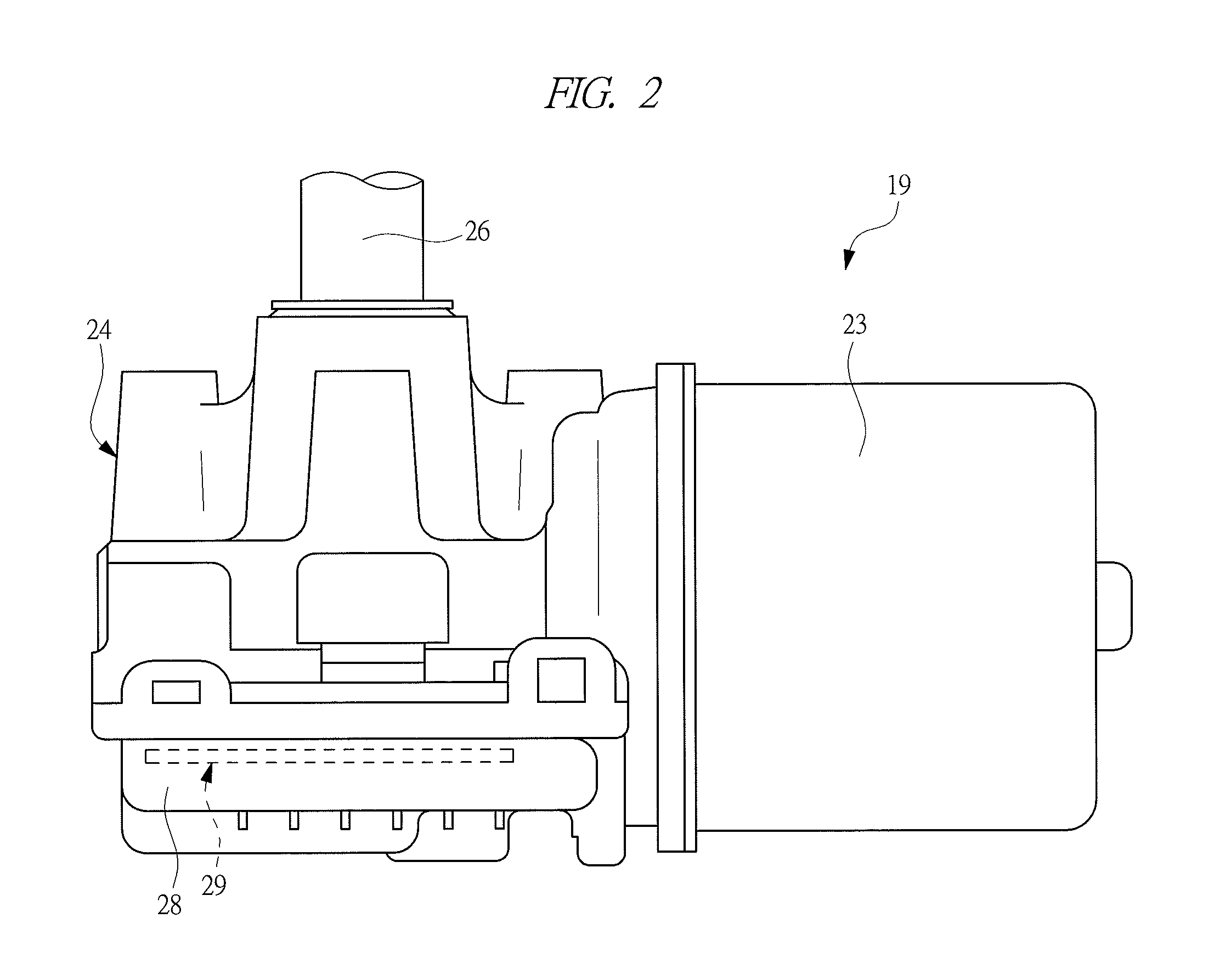

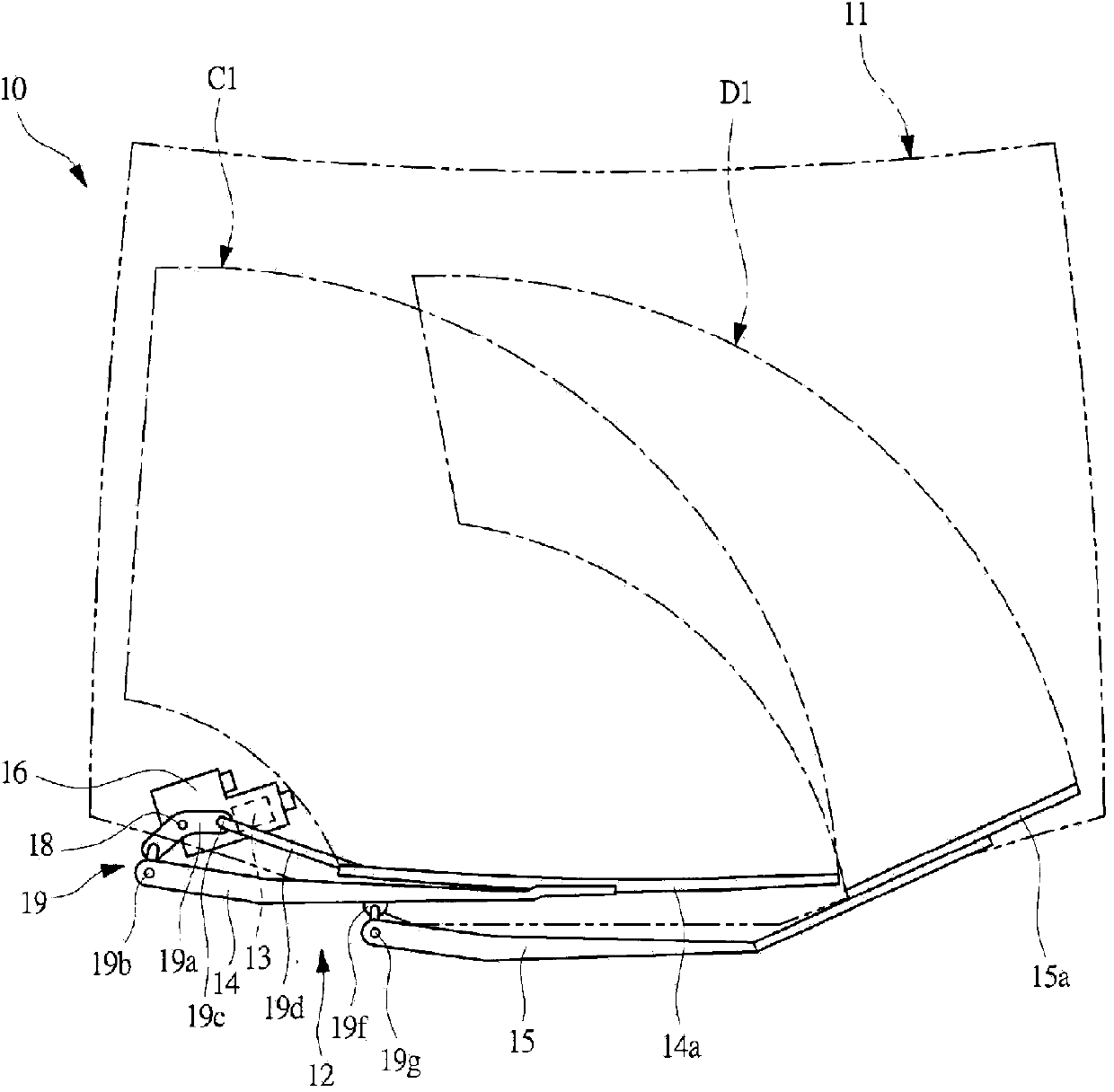

InactiveCN103796883ALayout improvementMeet miniaturization requirementsVehicle cleaningTransmitted powerElectric machine

This wiper device has the following: a wiper arm (14) that swings about a rotating shaft (18); and a wiper motor (13) that produces the power to be transmitted to the rotating shaft (18). The wiper device is also provided with a power-transmission mechanism (19) that transmits power from the rotating shaft (18) to the wiper arm (14). Said power-transmission mechanism (19) is provided with the following: a linking member (19a) affixed to the rotating shaft (18); and a support shaft (19b) that supports the wiper arm (14) and is affixed to a point on the linking member (19a) offset from the rotating shaft (18). The support shaft (19b) is provided such that the coupling between the support shaft (19b) and the wiper arm (14) is located forwards of the front edge of the windshield (11). At least part of the wiper motor (13) is disposed in a region corresponding to the projection of the windshield (11). The wiper motor is thus disposed as far rearwards as possible in the vehicle with minimal increase in the number of components.

Owner:MITSUBA CORP

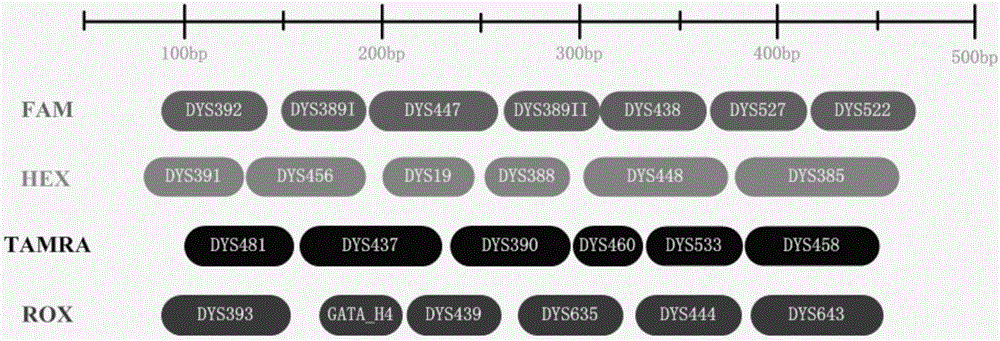

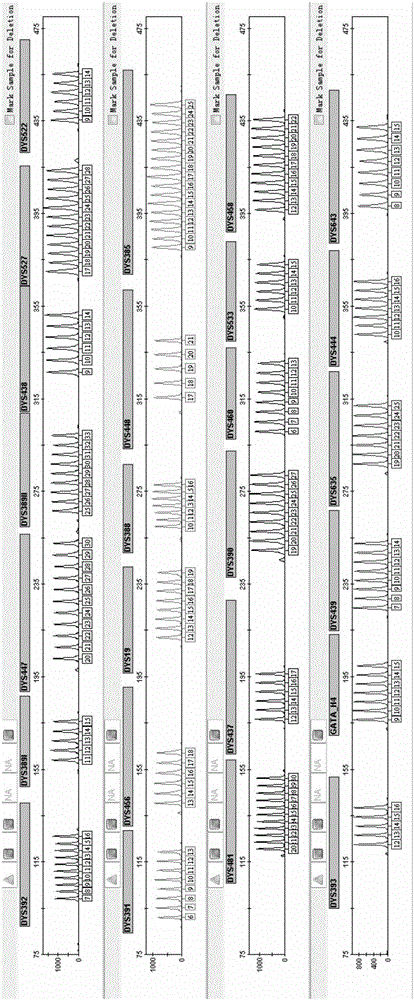

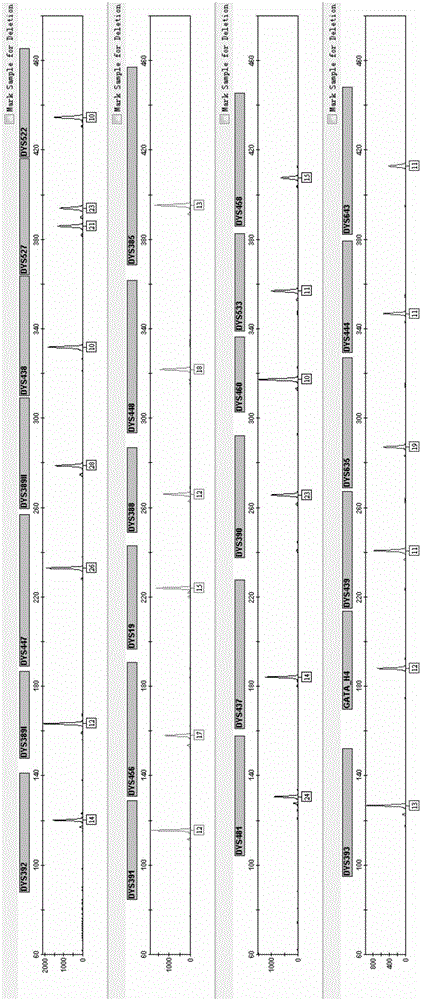

Fluorescent mark multi-amplification kit of 27 STR loci of human Y-chromosome and application of kit

ActiveCN105177146AReduce mutual interferenceHigh amplification specificity and high amplification sensitivityMicrobiological testing/measurementDNA/RNA fragmentationFluorescenceY-Chromosome Genes

The invention discloses a fluorescent mark multi-amplification kit of 27 STR loci of a human Y-chromosome and an application of the kit. The 27 low-mutation-rate STR loci on the Y chromosome can be amplified for multiple times in a single reaction. According to the fluorescent mark multi-amplification kit of the 27 STR loci of the human Y-chromosome and the application of the kit, a unique locus distribution mode and a specific primer sequence are designed, the 27 loci are divided into four groups, and different fluorescent marks are marked for each group. The multi-amplification system is one of the Y-STR kits which can detect the maximum number of the loci on the market, and the contained loci are all low-mutation-rate Y-STR loci, so that the kit is more suitable for checking of a male family. The multi-amplification system is good in primer specificity, wide in temperature tolerance range and high in check-material adaptability.

Owner:AGCU SCIENTECH

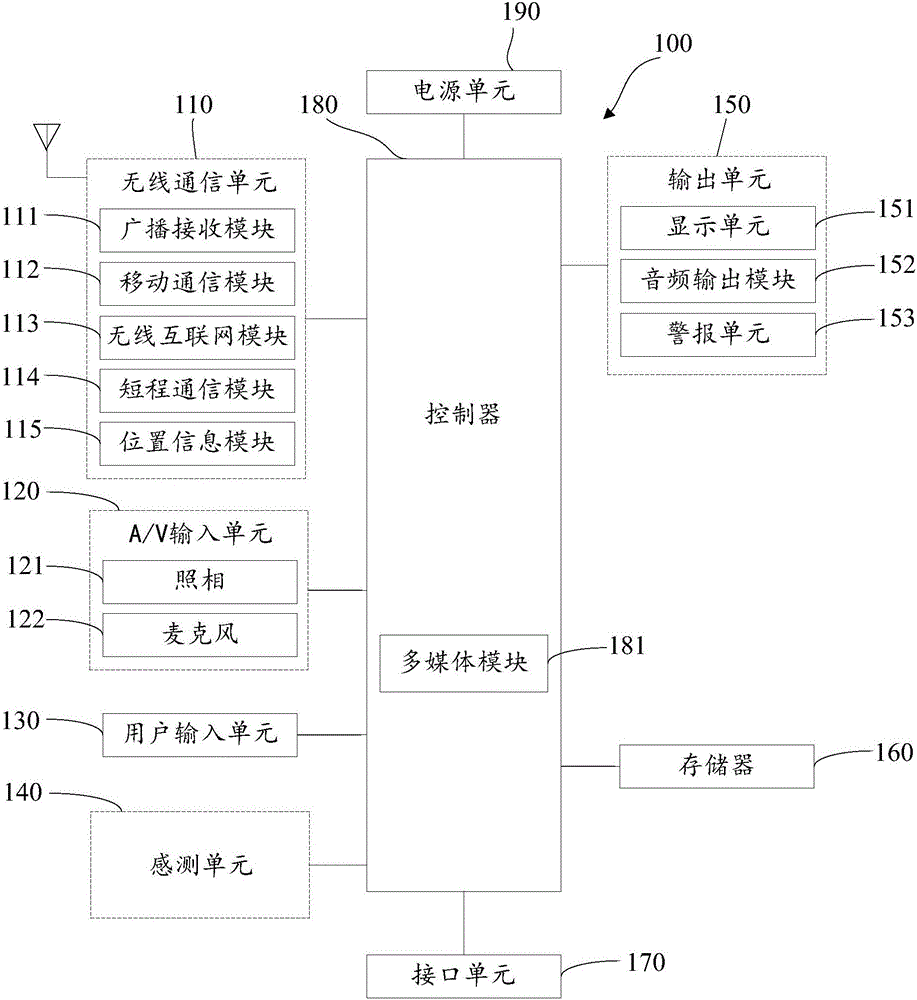

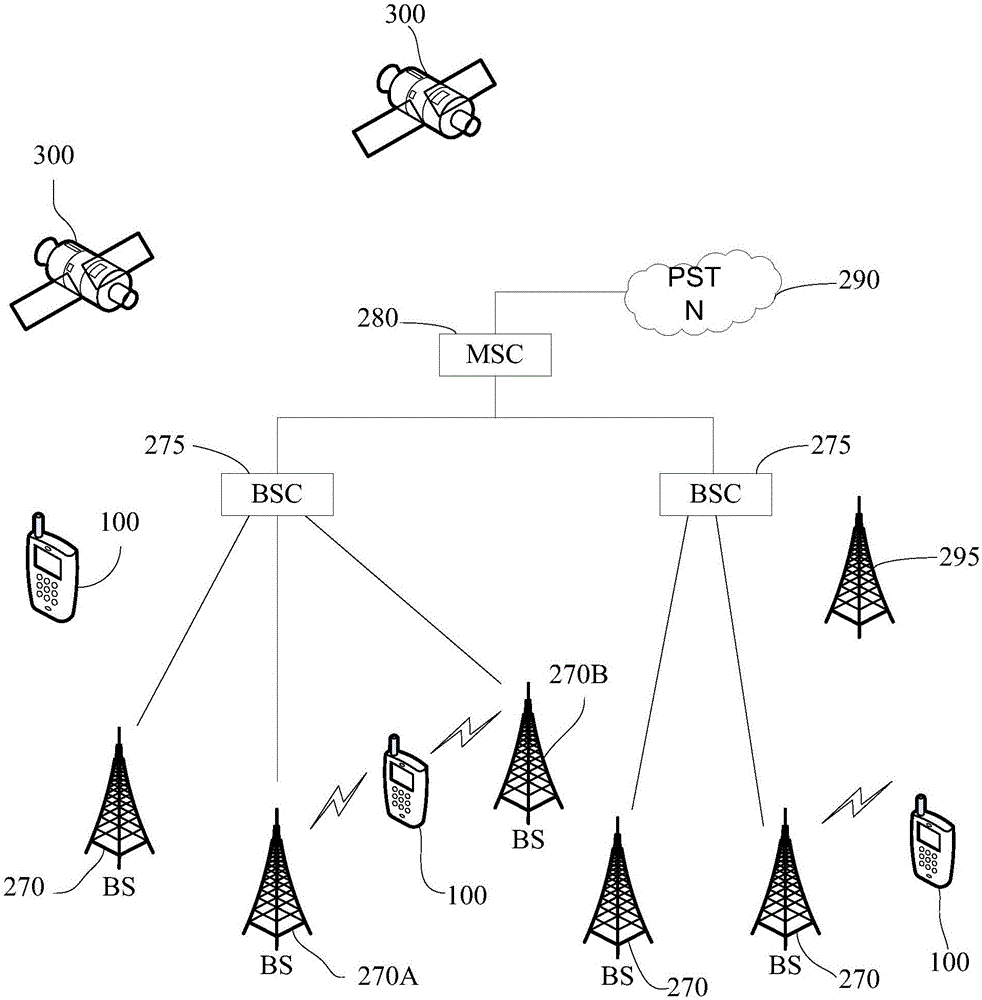

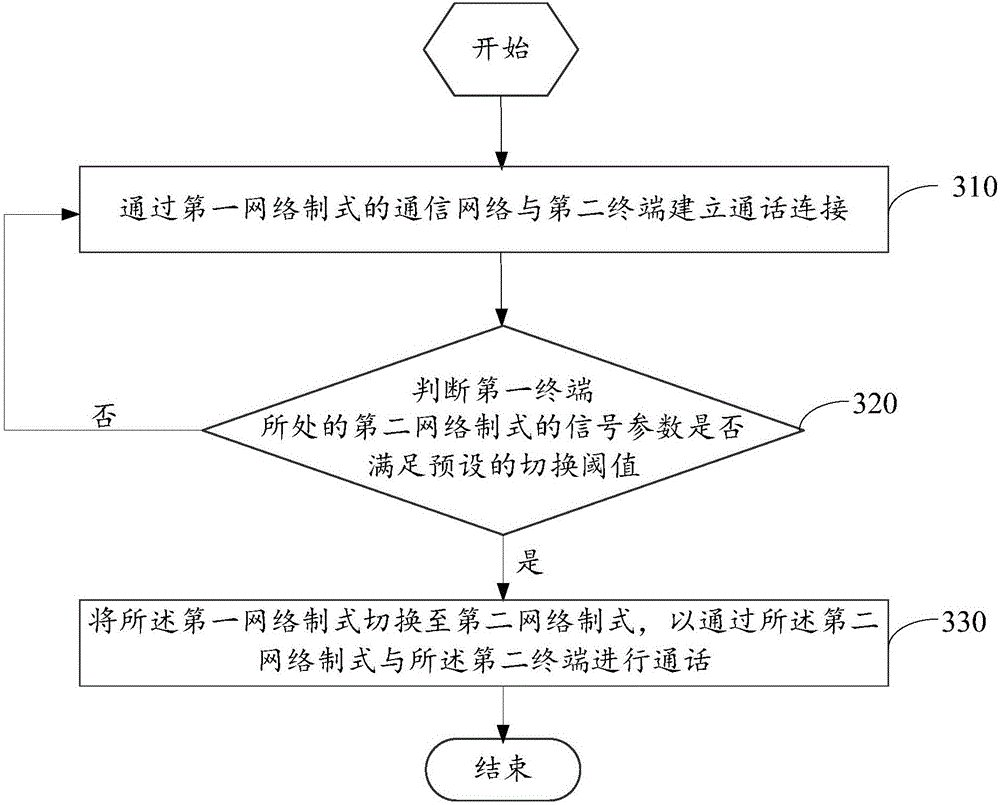

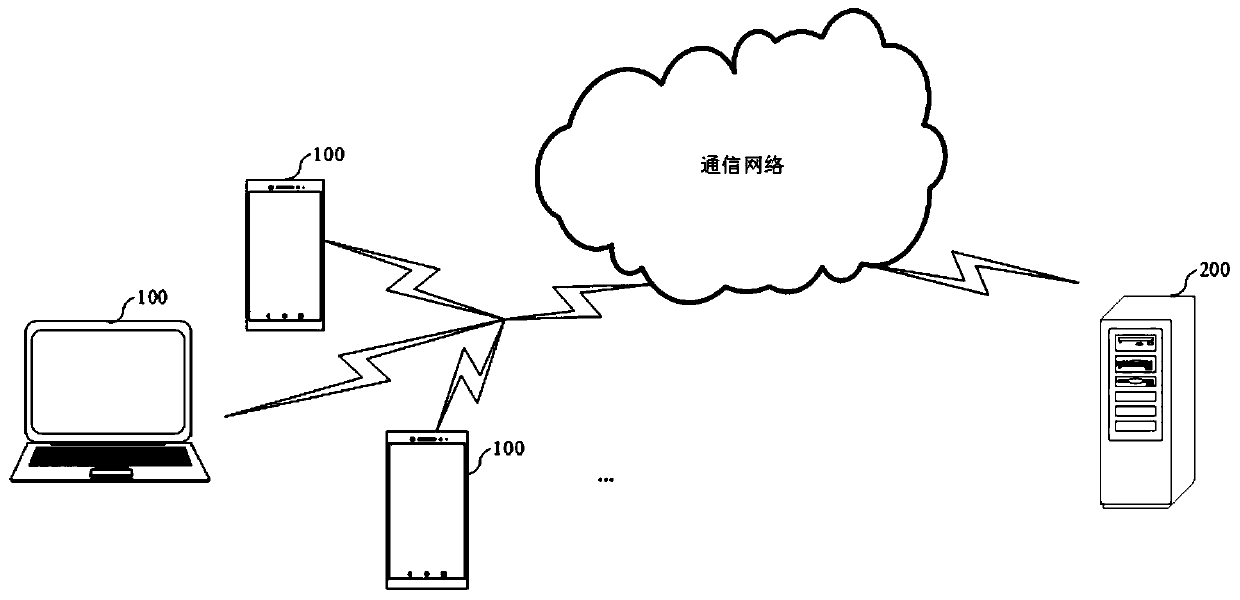

Method and device for switching network types in conversation process

InactiveCN106376040AGood serviceImprove call experienceWireless communicationNetwork communicationSignal parameter

The invention discloses a method and device for switching network types in a conversation process, and belongs to the technical field of communications. The method comprises the following steps: establishing the conversation connection with a second terminal through a communication network of the first network type; judging whether a signal parameter of the second network type of the first terminal satisfies a preset switching threshold value; if the signal parameter of the second network type of the first terminal satisfies the preset switching threshold value, switching the network communication of the first network type to the second network type, thereby performing conversation with the second terminal through the communication network of the second network type. Through the adoption of the method and device for switching the network types in the conversation process, the conversation can be performed after the network is immediately switched to the network with higher priority when the switching condition is satisfied, the higher RAT technology hybrid networking can be distributed, the conversation is preferentially resided on the network with higher priority to acquire better service, and the conversation experience is improved.

Owner:NUBIA TECHNOLOGY CO LTD

Energy absorption box for vehicle

The invention relates to the technical field of vehicle collision safety and discloses an energy absorption box for a vehicle. The energy absorption box for the vehicle comprises a plurality of hollow shells nested jointly. Every two adjacent hollow shells are connected through energy absorption ribs so that an integral structure or a split structure can be achieved. The energy absorption ribs are provided with first deformation inducing slots which are formed by extending in the radial direction of the hollow shells. The energy absorption box for the vehicle is provided with the multiple nested hollow shells, every two adjacent hollow shells are connected together through the energy absorption ribs, the energy absorption ribs are provided with the first deformation inducing slots, and when a collision happens, the first deformation inducing slots guide collapse deformation of the hollow shells and the energy absorption ribs, so that energy is absorbed. By means of the energy absorption box for the vehicle, the problems that an energy absorption box is low in strength and energy absorption efficiency and is bent under crush are solved effectively, and the safety is improved in case of a head-on collision of the vehicle. Meanwhile, the structural optimizing of the energy absorption box is achieved, the length of the energy absorption box is reduced, the layout space of cabin components and the riding space of passengers are expanded, and good economic benefits and social benefits are achieved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

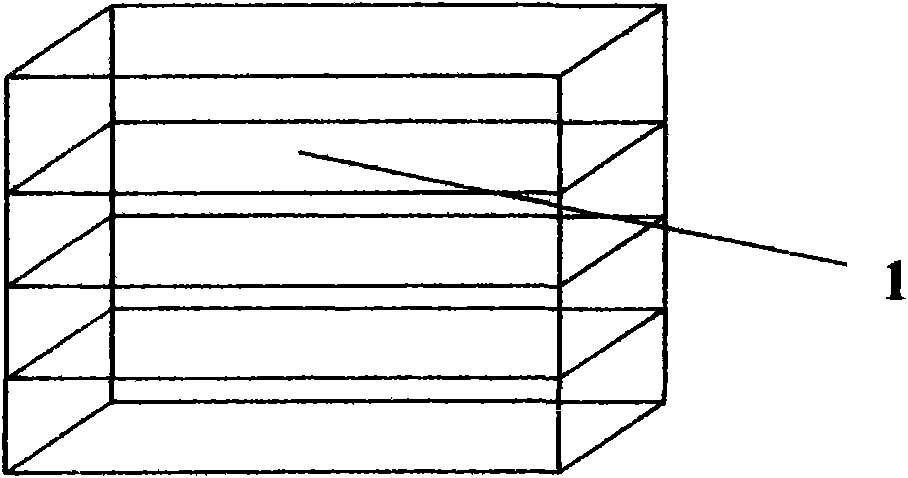

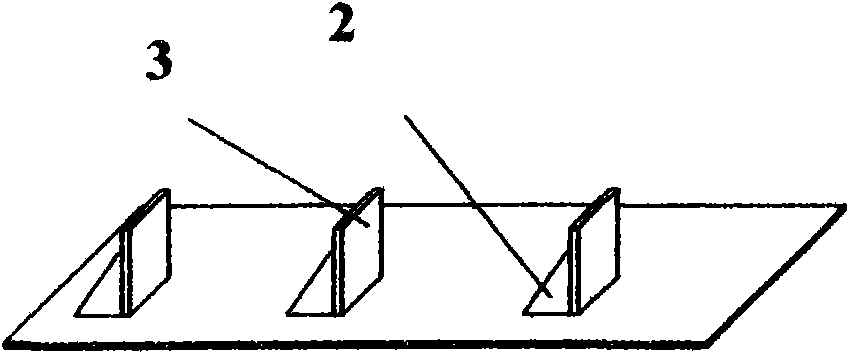

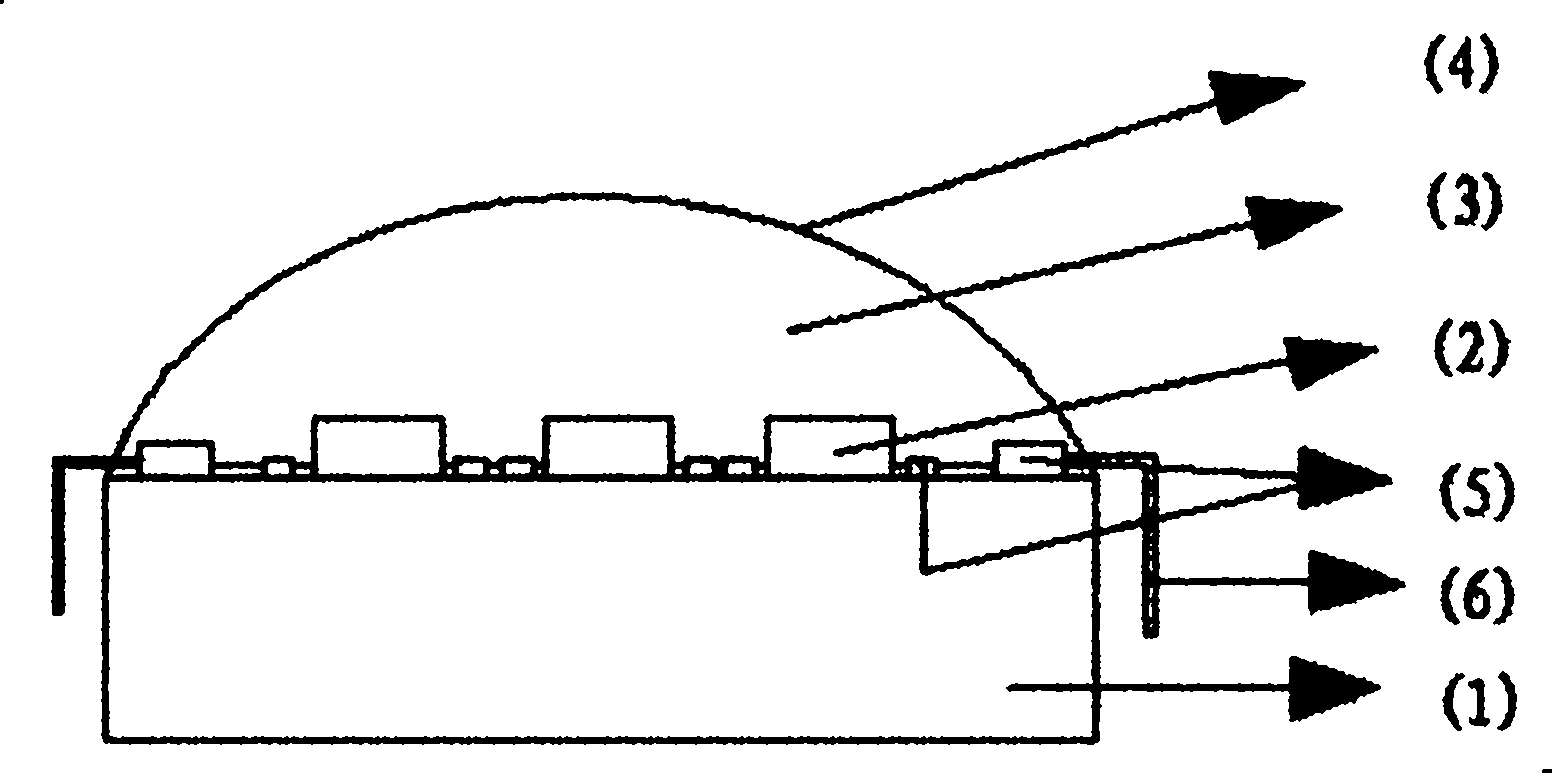

Radiating device integrating radiating plate and electrode and manufacturing method thereof

InactiveCN102110762AFlexible arrangementLayout improvementSemiconductor devicesFluorescenceMicrometer

The invention discloses a radiating device integrating a radiating plate and an electrode and a manufacturing method thereof. The radiating device comprises the radiating plate (1), a light-emitting diode (LED) chip (2) fixed onto the radiating plate (1), a fluorescent powder layer (3) coated on the radiating plate (1) and totally covering the LED chip (2), a silica gel sealing layer (4) coated on the fluorescent powder layer (3), an electrode pin (5) integrated on the radiating plate and an electrode lead (6) leaded from the electrode pin (5), wherein the silica gel sealing layer (4) is madeby mixing silica gel and nanometer or silica and micrometer particles. In the radiating device provided by the invention, the radiating plate is directly connected with the electrode pin, thereby improving the radiating efficiency of the chip and solving the problem of short service life of the device due to radiation problem; moreover, due to the elimination of bracket, the production cost is reduced and the invention is more favorable for commercial production.

Owner:SHAANXI UNIV OF SCI & TECH

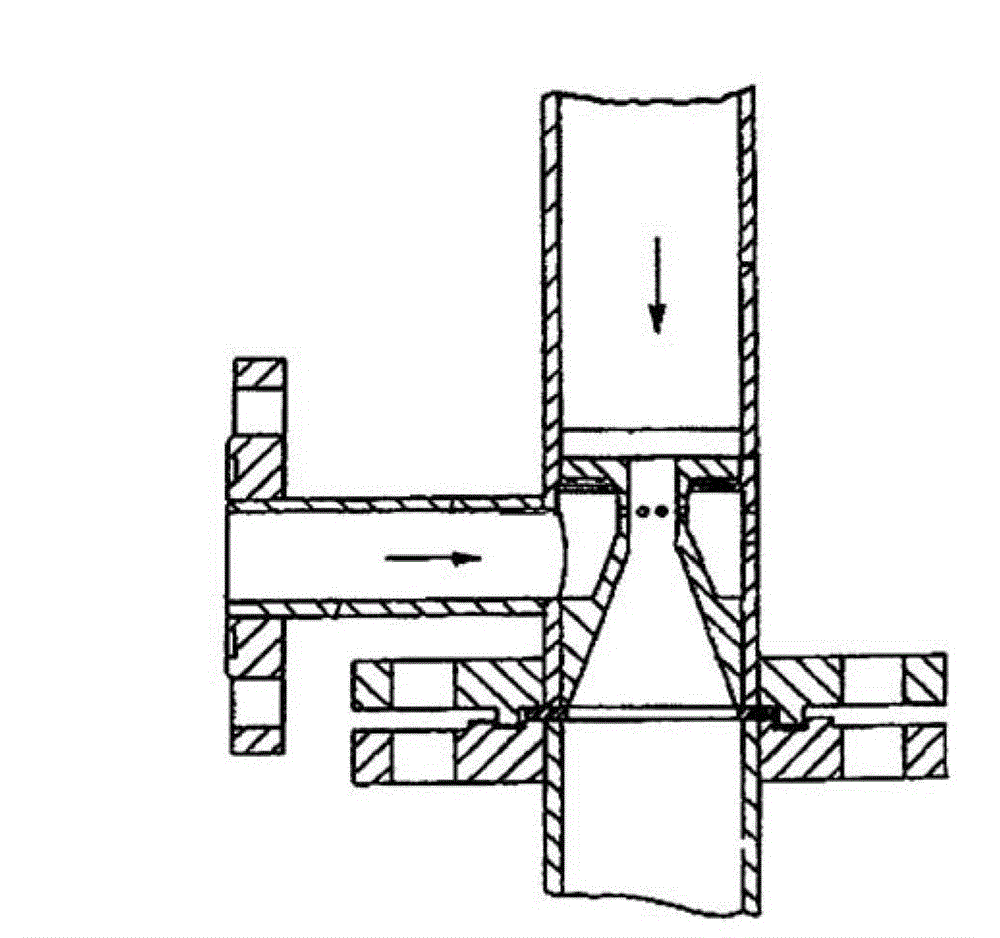

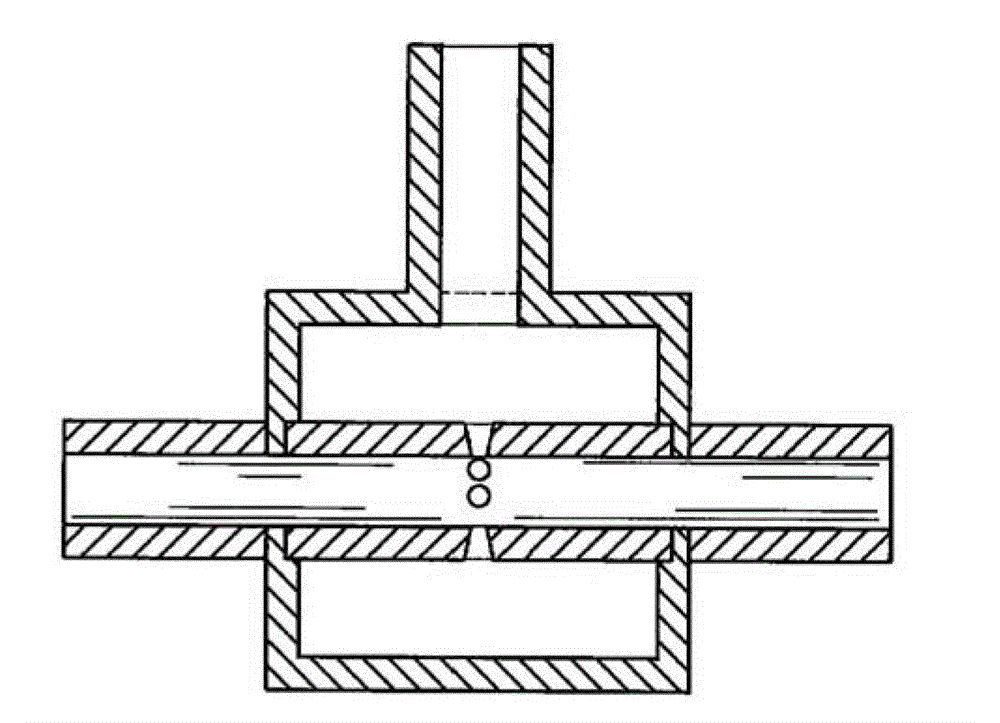

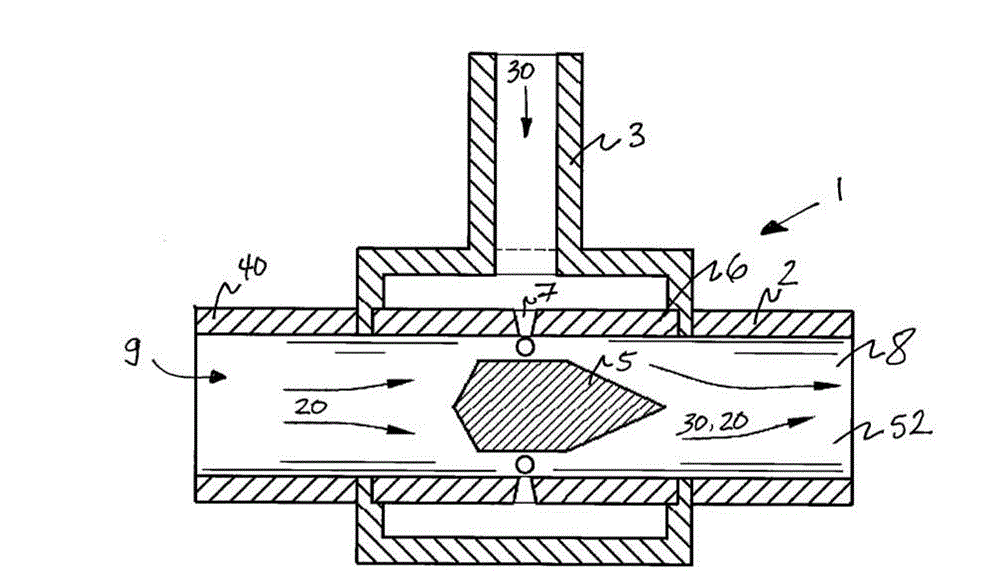

Reactive static mixer

InactiveCN102802773AImprove uniformityLayout improvementIsocyanic acid derivatives preparationOrganic compound preparationChemical reactionEngineering

This disclosure relates to a static phosgene mixer, and more generally, to an apparatus for mixing of fluid components such as phosgene and amine during an highly reactive, chemical reaction that is vulnerable to the creation of undesired by-products, and equipment fouling. A guide element ( 5 ) is disposed in the static mixer ( 1 ) to divert the incoming flow of phosgene around the guide element and create an annular mixing passage in the static mixer. This allows for the use of an increased external radius of the effective phosgene flow while maintaining phosgene velocity by creating a blockage of the flow. The same flow, when transformed from a circular configuration to an annular configuration has an increased external radius, and a greater quantity of MDA jets can be placed along the increased radius, thus increasing the overall homogeneity of the mixture. Further, the cross -sectional area of the annular passage section of phosgene defined around the guide element controls the velocity of phosgene which facilitates the mixing of MDA injected through the jets into the phosgene.

Owner:DOW GLOBAL TECH LLC

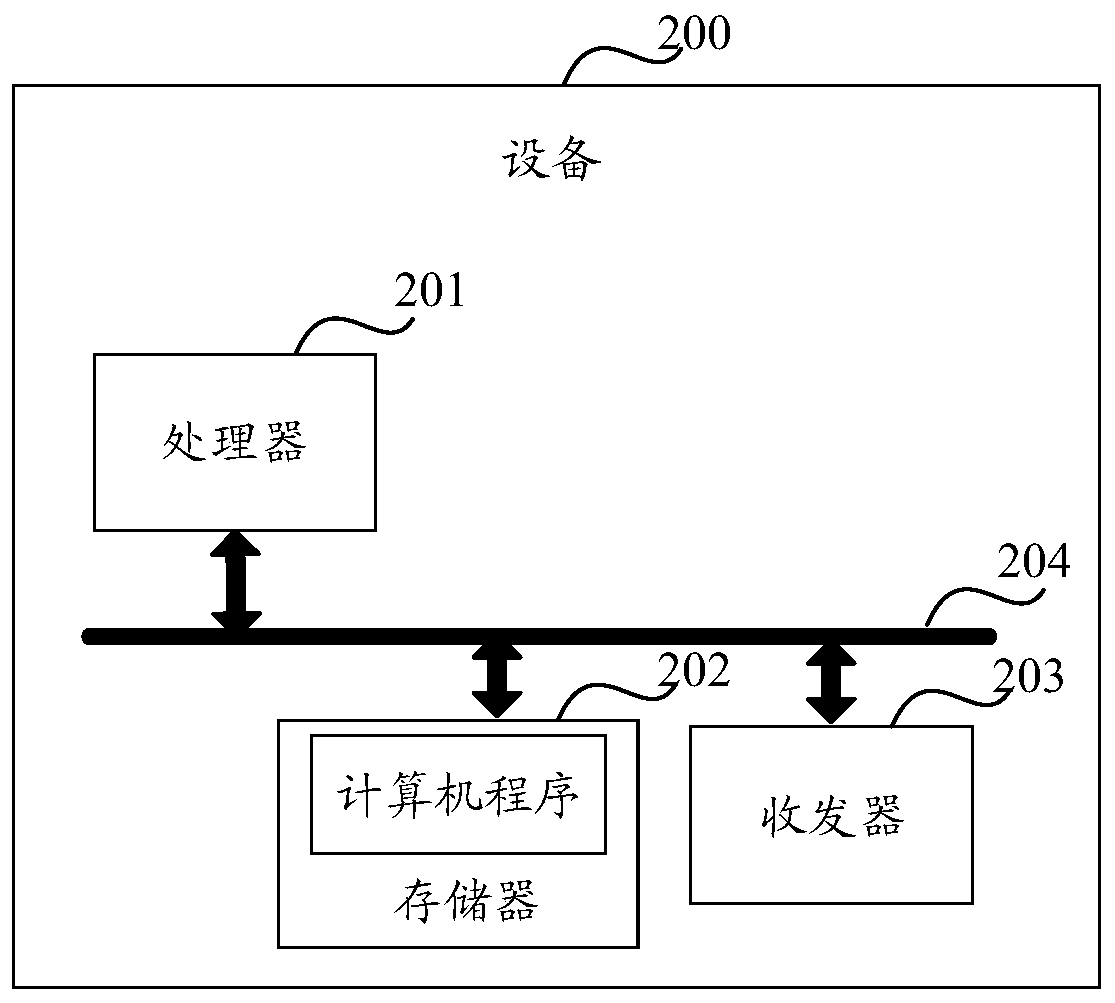

Interface generation method and equipment

PendingCN110554816AQuick buildAutomatically adjust the layoutInput/output for user-computer interactionStatic indicating devicesTerminal equipmentSoftware engineering

The embodiment of the invention provides an interface generation method and equipment. The method is applied to equipment with a development function. The method for automatically adjusting the layoutof the visual elements in the to-be-generated interface and quickly generating the interface can be provided, and the method comprises the following steps: firstly, acquiring the visual elements of areference interface by equipment, acquiring configuration information of a display screen of target terminal equipment, and then determining visual focuses of the visual elements according to attribute information of the visual elements. The equipment determines an interface layout template corresponding to the configuration information according to the configuration information of the display screen. Finally, the equipment adjusts the layout of the visual elements in the to-be-generated interface according to the visual focus and the interface layout template, and generates the interface.

Owner:HUAWEI TECH CO LTD

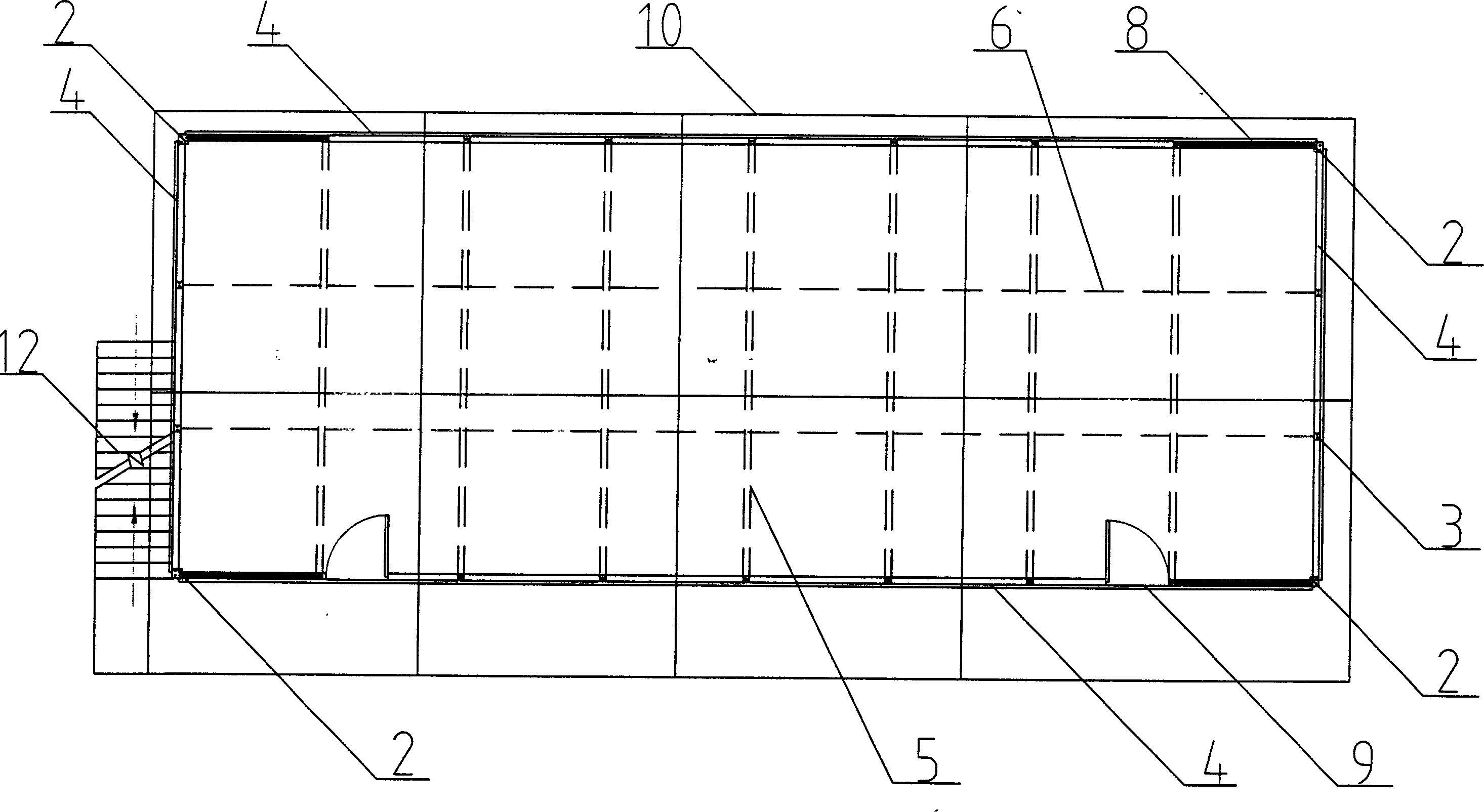

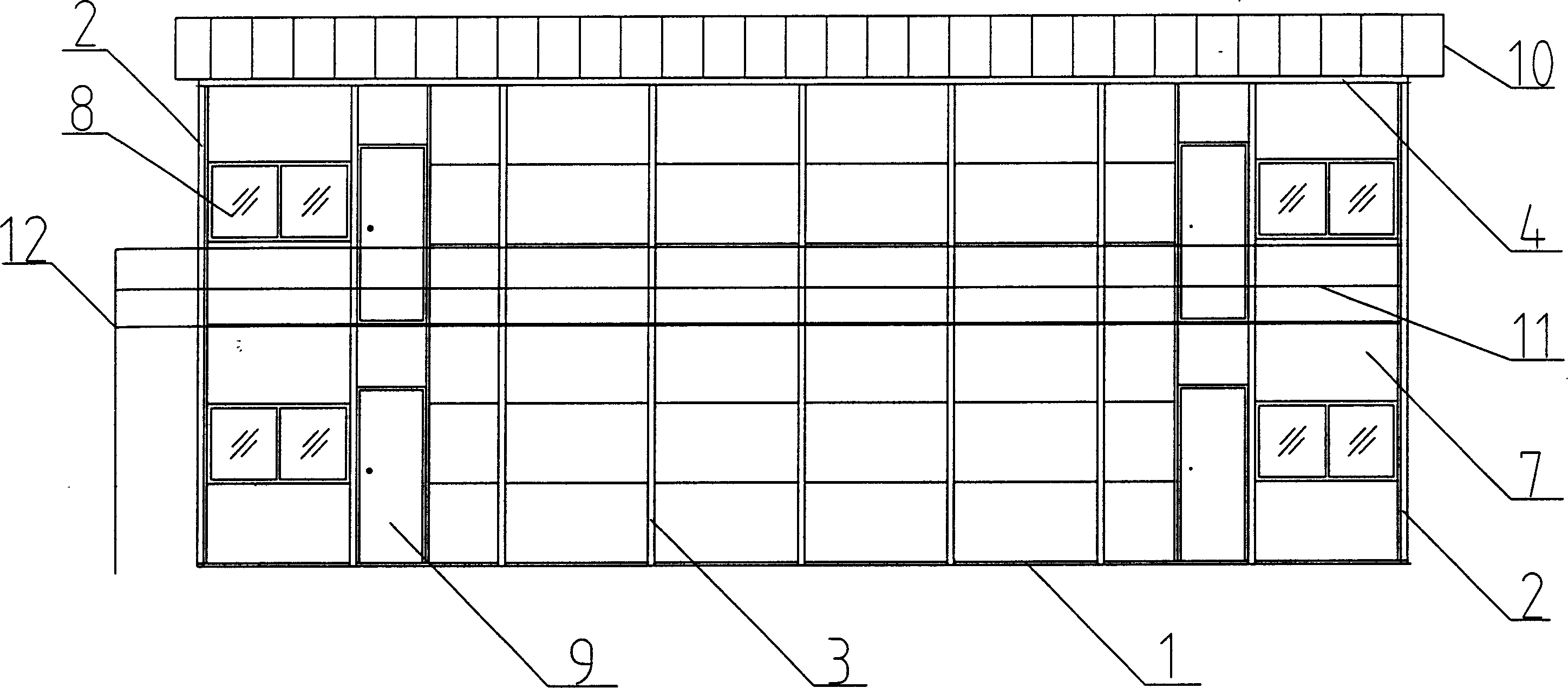

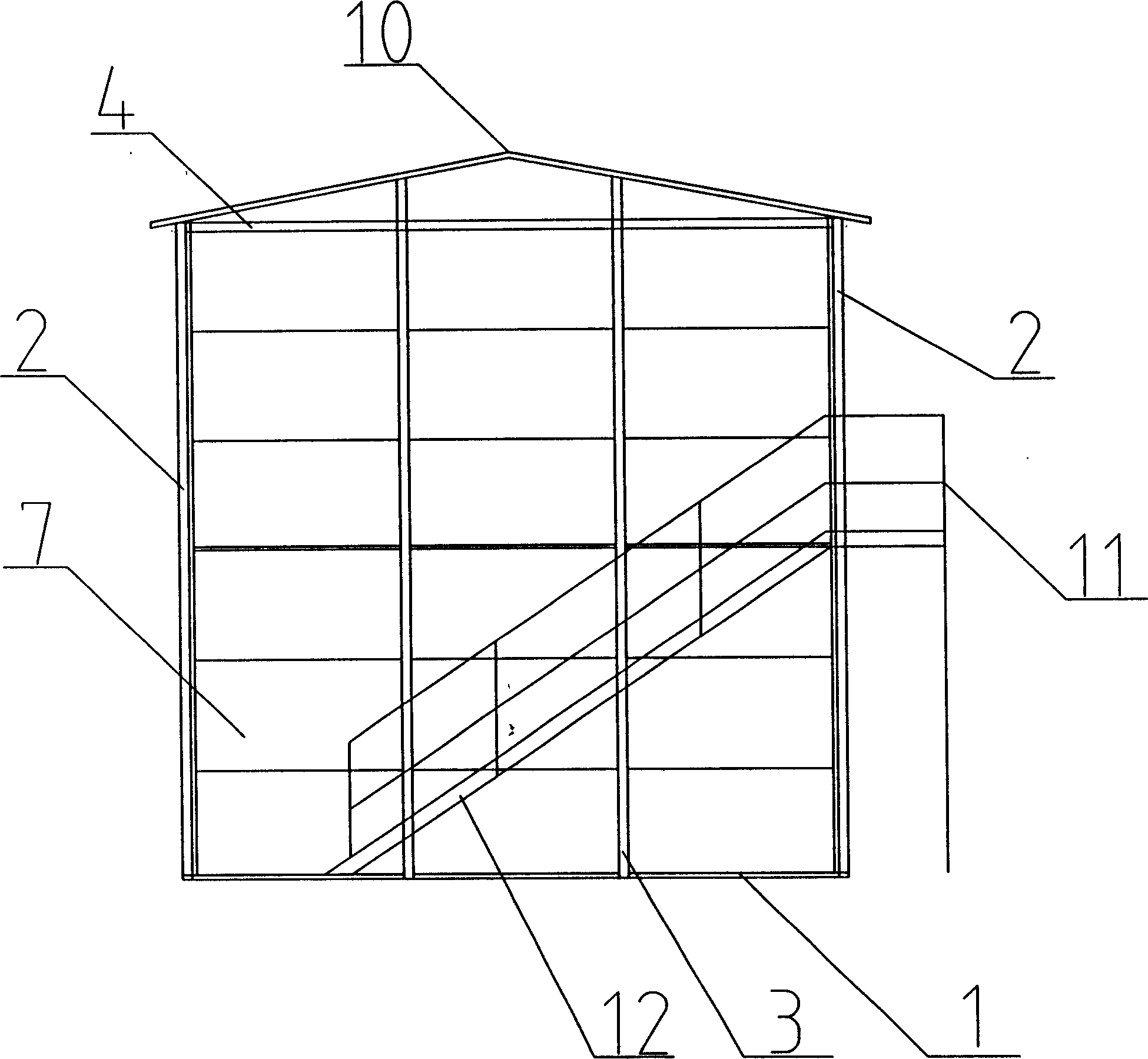

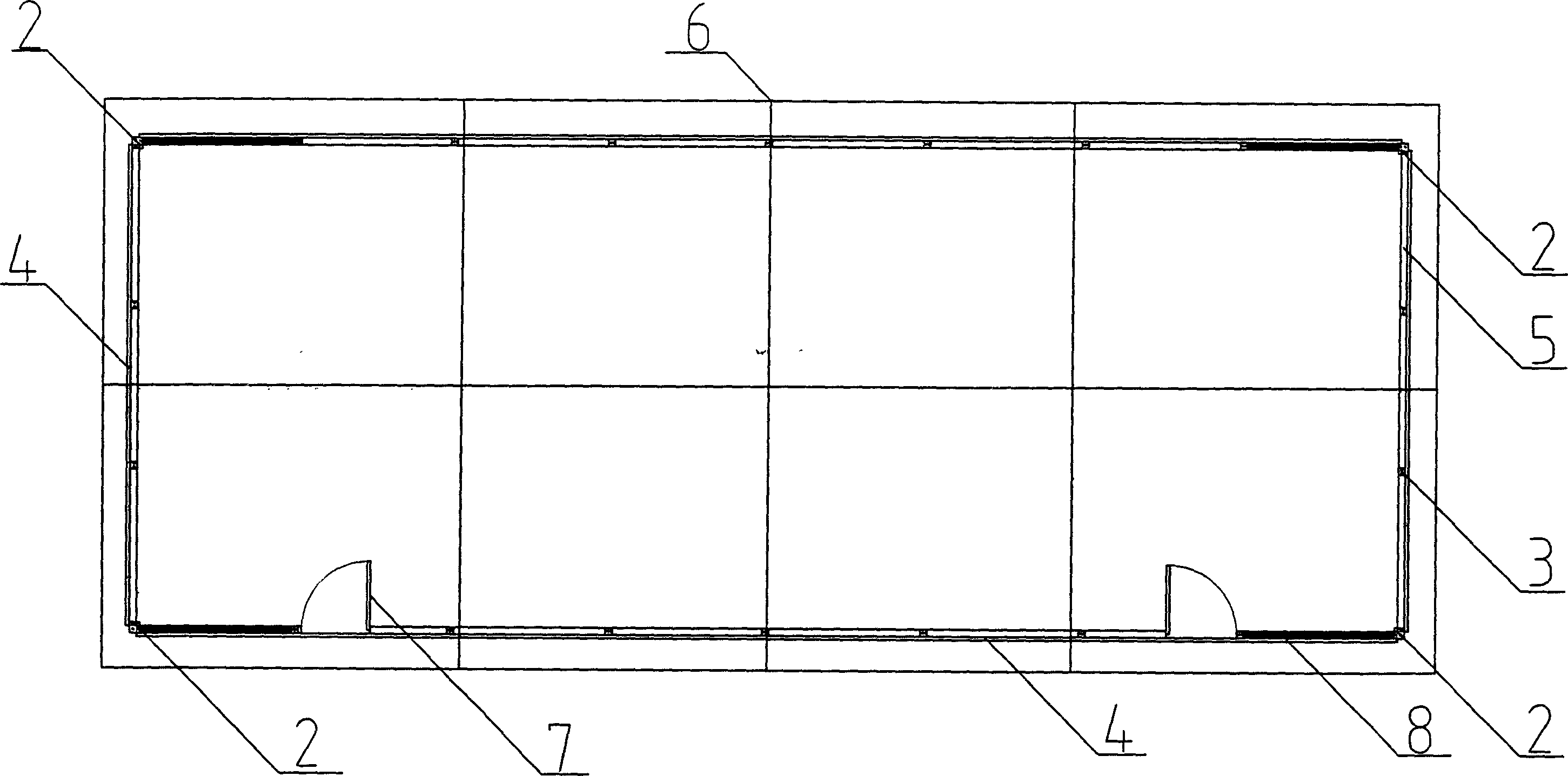

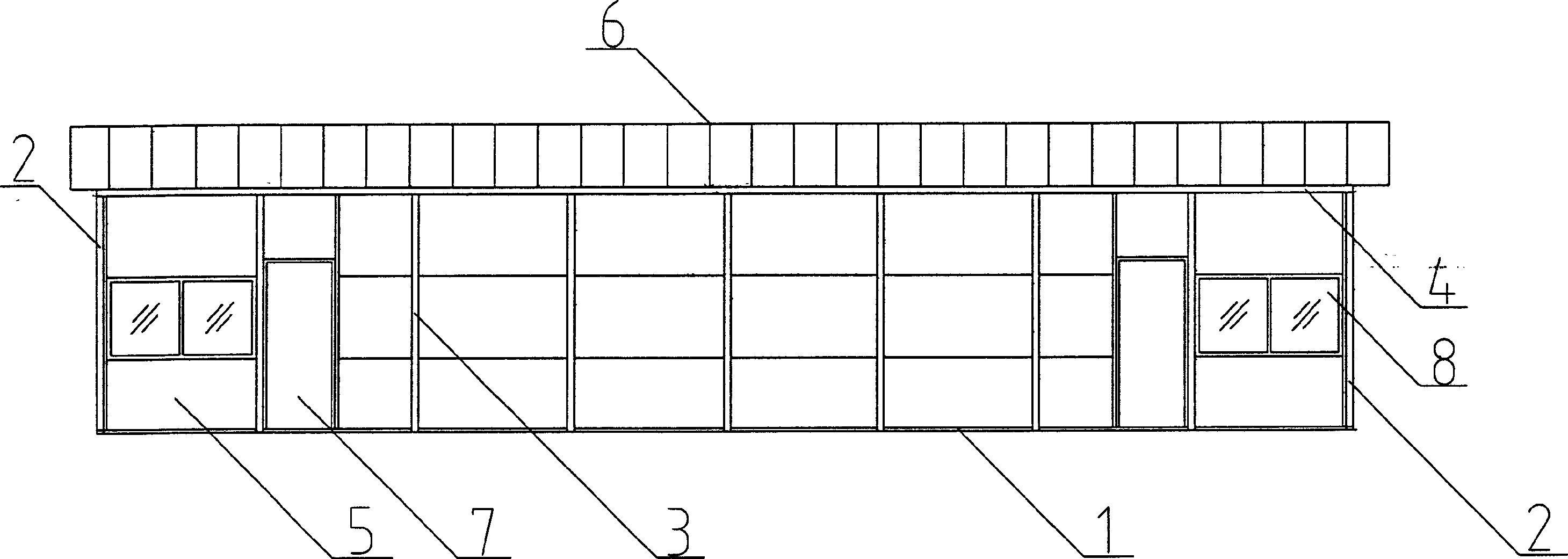

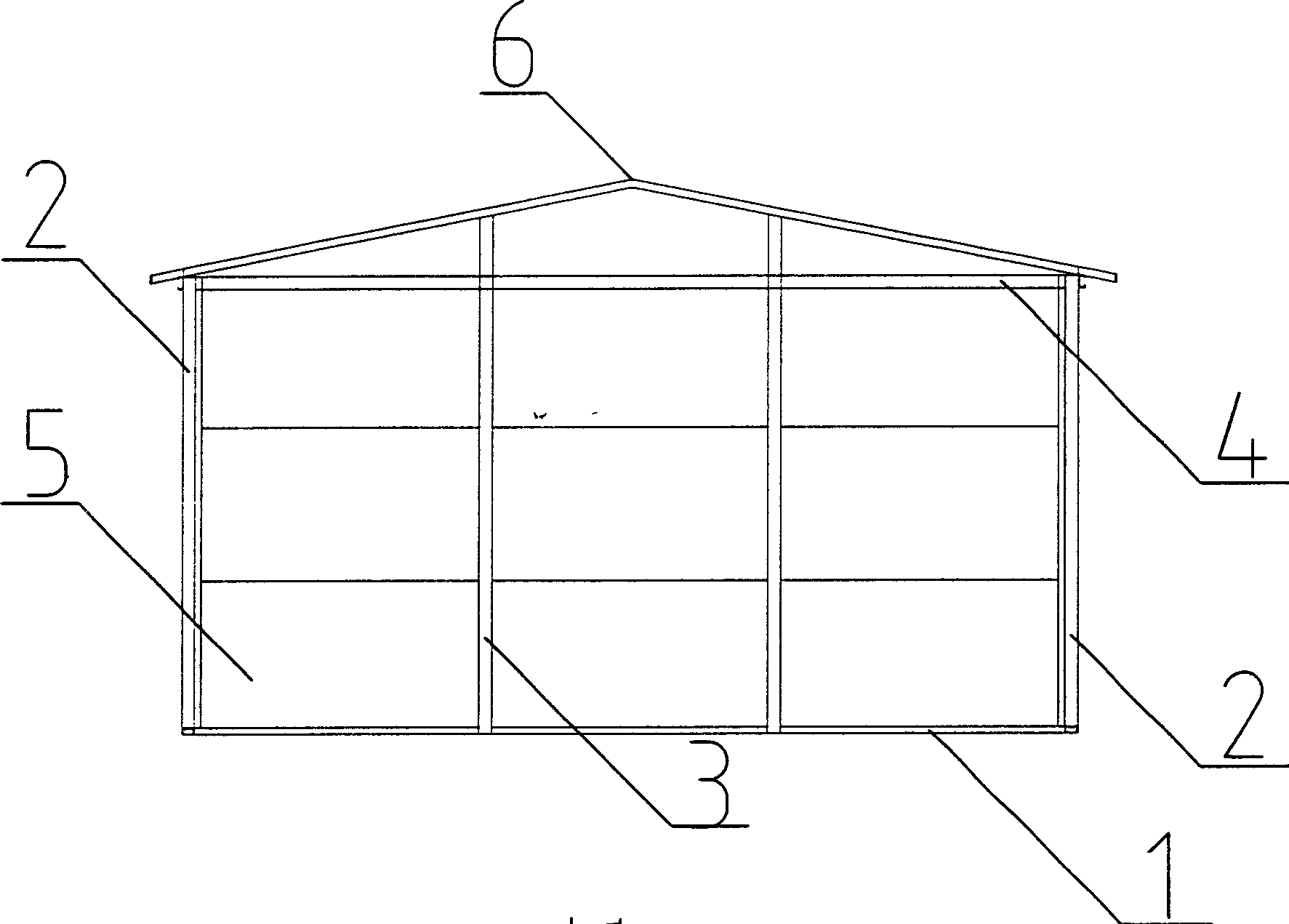

Building structure and installing method for two-layer movable panel house

The present invention provides a building structure of two-floor mobile plate home whose member materials can be used for several times and circularly reused and can be made up by adopting industrial production mode and its installation method. It includes four ground beams, four corner uprights, uprights, trimmer beams, purlines, four ring beams, sandwich panels, windows, doors, roof, corridor and stairs, and its installation method has eight steps, said eight steps are provided by said invention specification.

Owner:广东耀达房屋科技股份有限公司

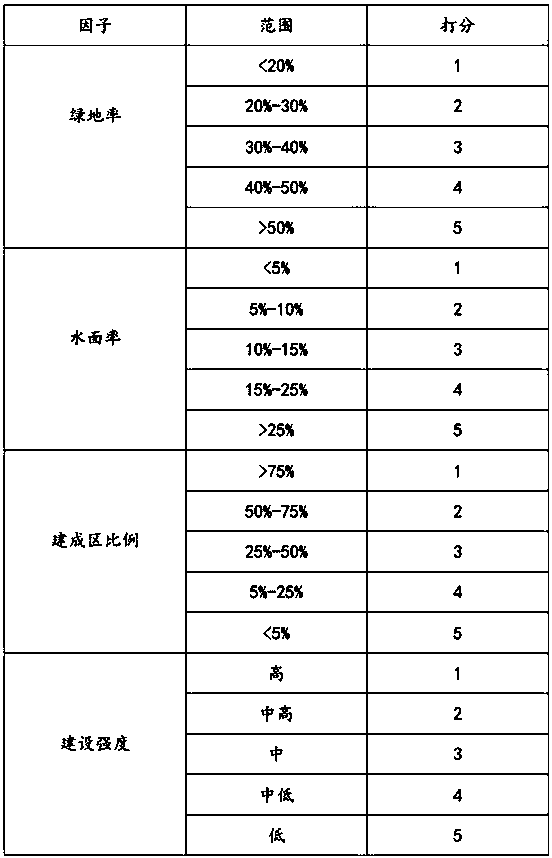

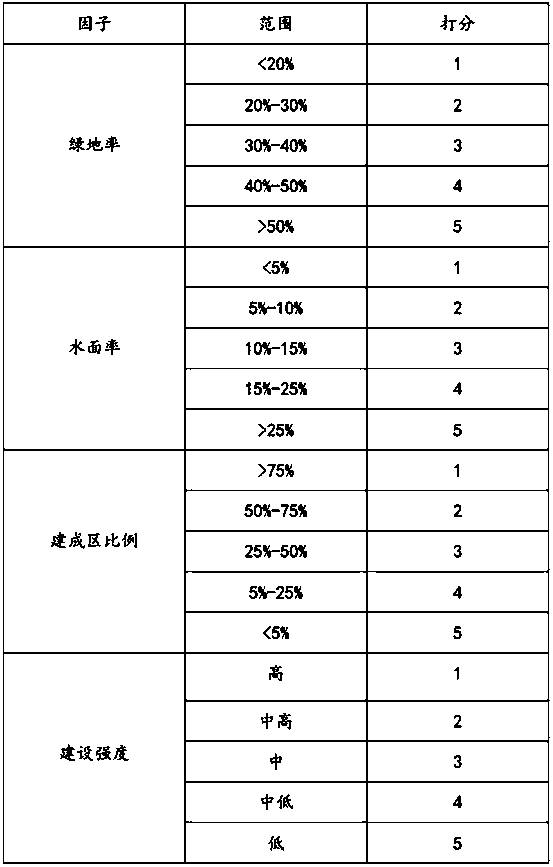

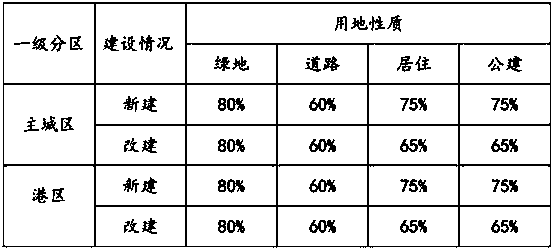

Evaluation method for regulation and storage capacity of sponge city

ActiveCN108510196AAccelerate the acquisition rateLayout improvementResourcesRainfall runoffDecomposition

The invention discloses an evaluation method for the regulation and storage capacity of a sponge city, and relates to a low-influence development evaluation method for the sponge city. The method aimsto solve the problem that an existing rain low-influence development planning method can not conveniently obtain a comprehensive high-quality sponge city rain facility distribution scheme. The technical scheme of the method has the key point that the annual runoff total quantity control rate of a planning area is decomposed to each land parcel through first-level decomposition, second-level decomposition, third-level decomposition and fourth-level decomposition; after a design rainfall and comprehensive rainfall runoff coefficient corresponding to each land parcel is determined, total regulation and storage capacity required by the land parcel can be calculated; and according to the total regulation and storage capacity required by the land parcel, the rain facility distribution of the sponge city can be conveniently planned. The evaluation method has the advantage of being convenient in obtaining the comprehensive high-quality sponge city rain facility distribution scheme.

Owner:苏州规划设计研究院股份有限公司

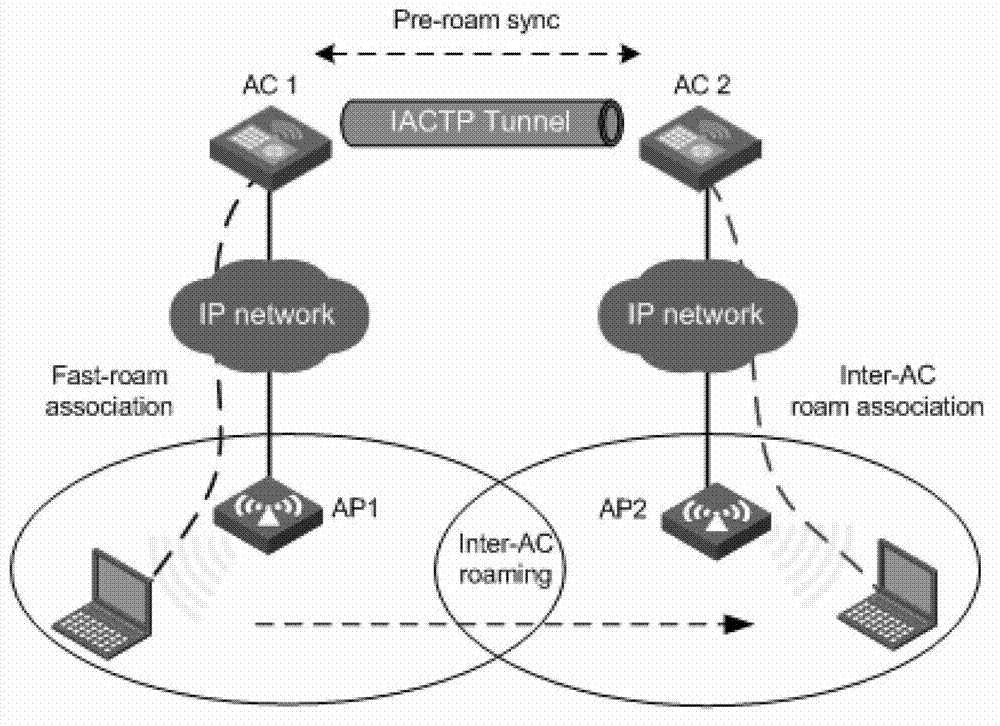

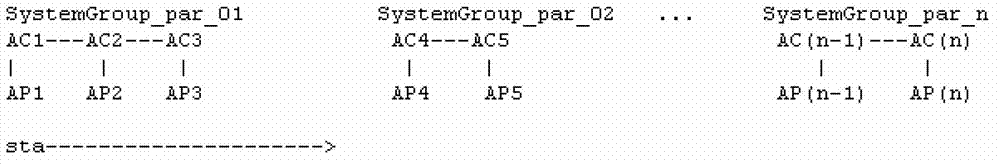

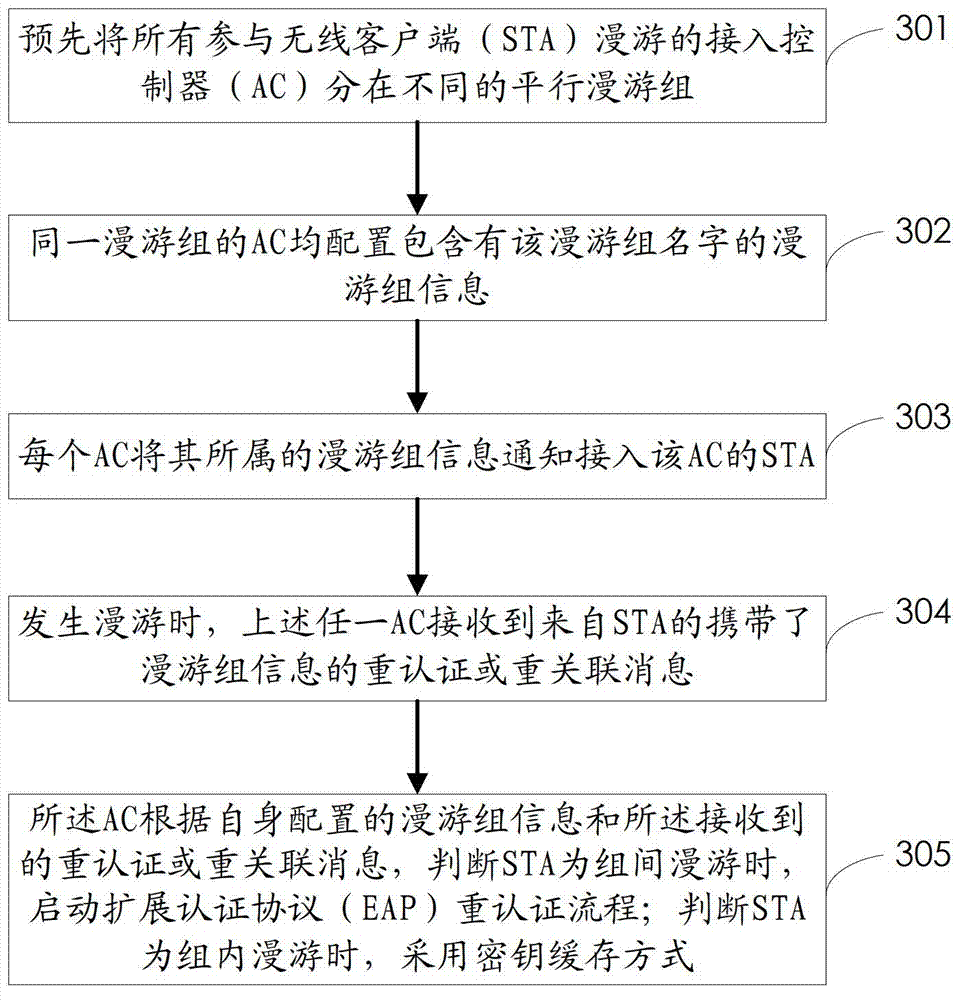

A wireless roaming method and an access controller

ActiveCN103596161AExpand the scope ofAbility to improve layoutTransmissionSecurity arrangementProtocol for Carrying Authentication for Network AccessClient-side

The application discloses a wireless roaming method comprising that all access controllers ACs participating in wireless client STA roaming are distributed in different parallel roaming groups; that the ACs in a same roaming group are all equipped with roaming group information containing the name of the roaming group; that each AC notifies the STA accessed to the AC of the roaming group information; that any above AC receives a authentication or re-associate message carrying the roaming group information from the STA when a roaming occurs; that the AC starts an expand authentication protocol EAP authentication flow when determining the STA is in an intergroup roaming according to the configured roaming group information and the received authentication or re-associate message; and that the AC uses a key cache manner if determining the STA is in-group roaming. The application also discloses an access controller AC. The wireless roaming method may achieve fast roaming among any multiple ACs and fast roaming spanning network segments, and may enhance the performance of the AC device.

Owner:NEW H3C TECH CO LTD

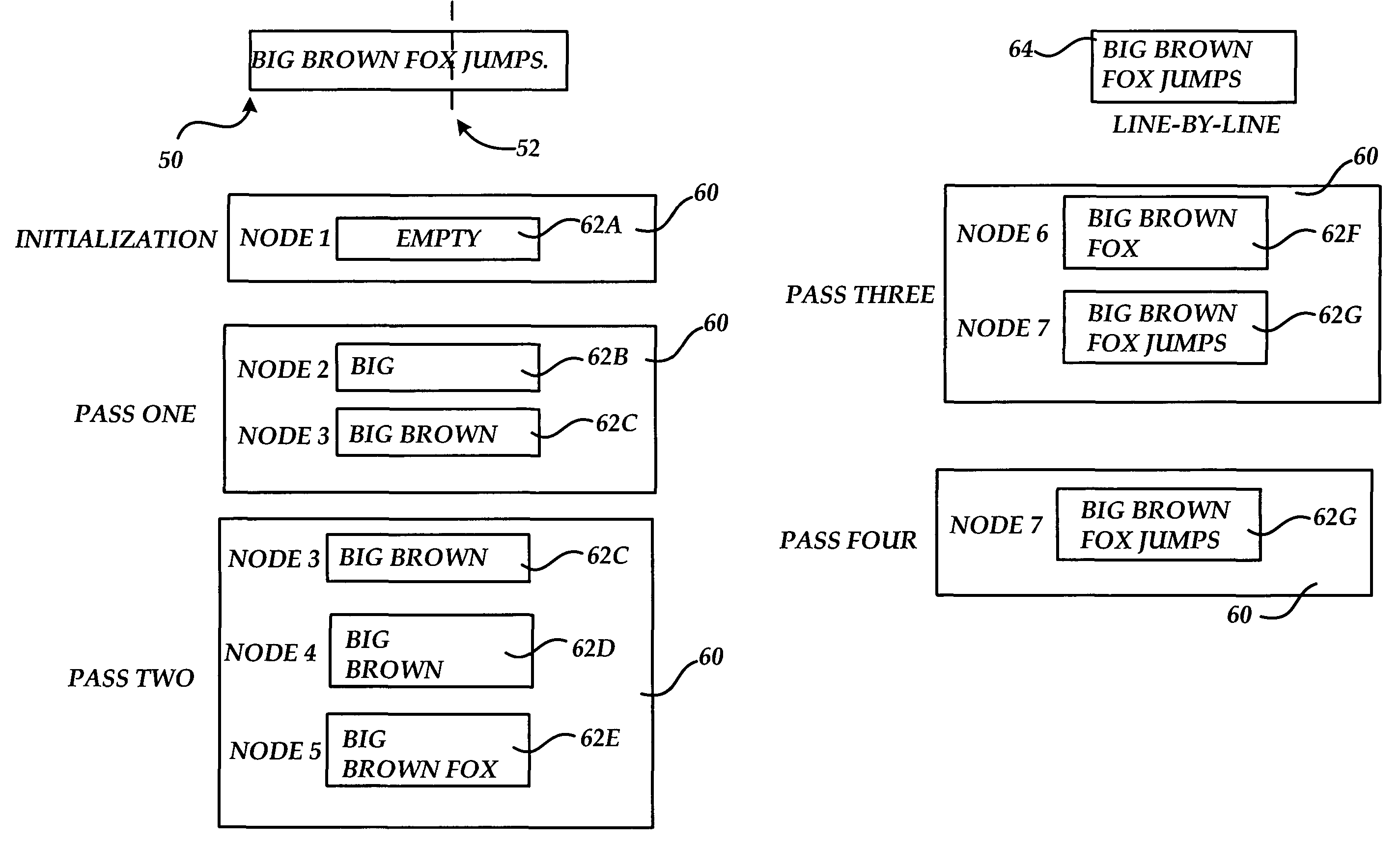

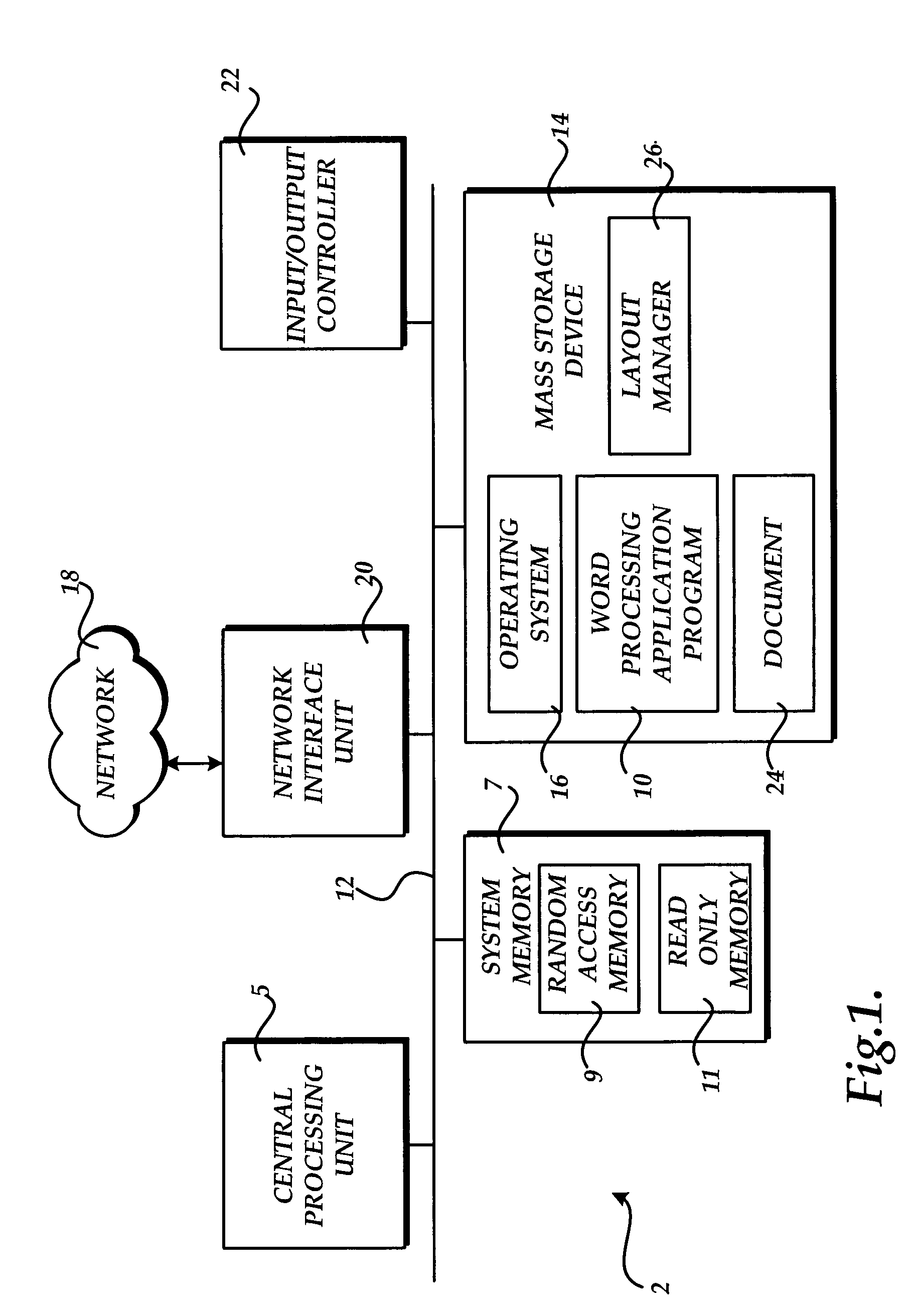

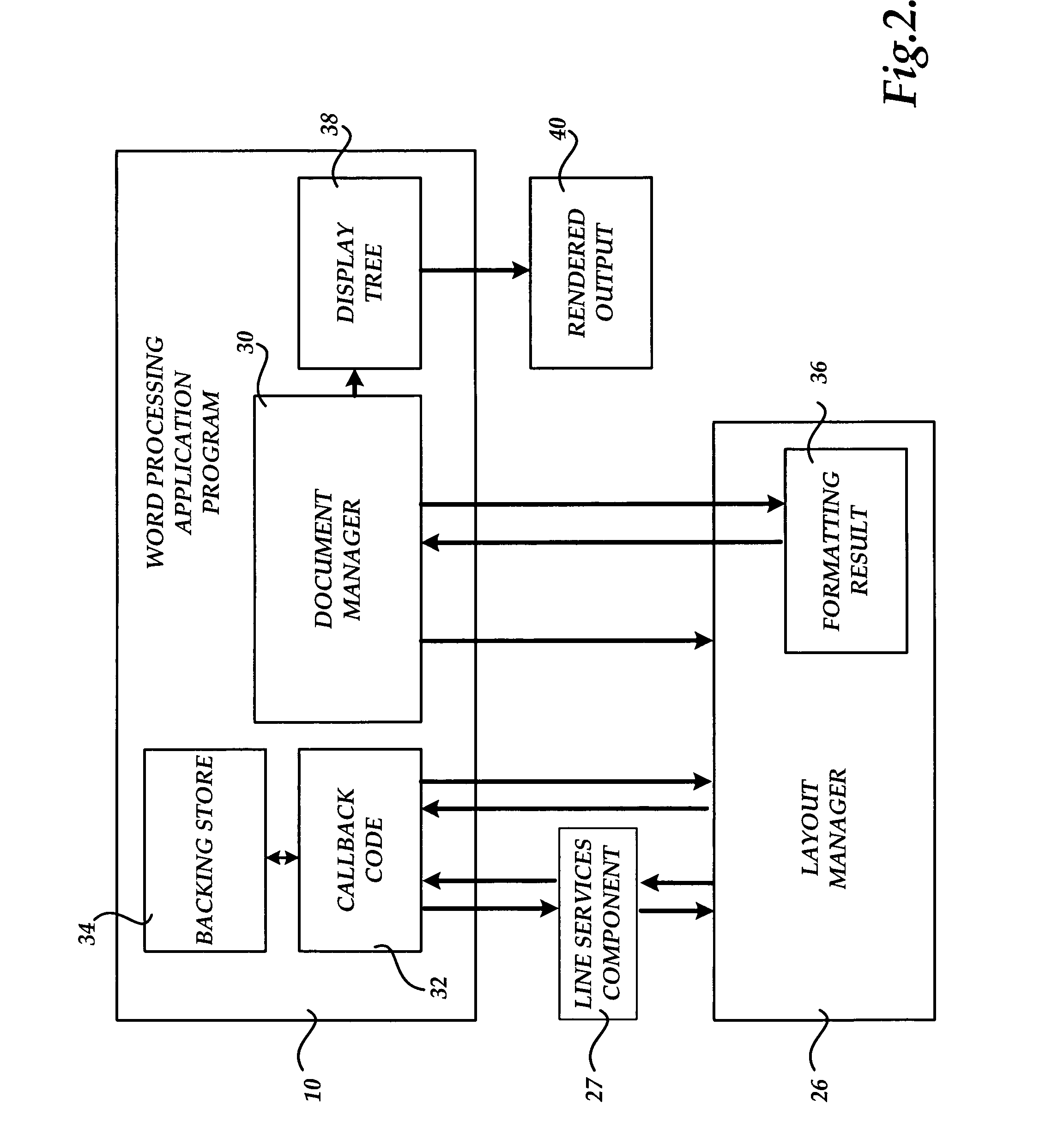

Method and computer readable medium for optimized paragraph layout

InactiveUS7770111B2Quality improvementHigh penaltyNatural language data processingSpecial data processing applicationsParallel computingParagraph

A method and computer-readable medium are provided for optimized paragraph layout. According to the method, a line-by-line paragraph layout is generated determine a maximum penalty for a paragraph. One or more layout nodes may be generated that include data representing a possible layout of the paragraph to a point within a backing store and identifying any changes to a geometry of the page caused by the layout of the paragraph defined by the layout node. A penalty is also calculated for each of the layout nodes. Each layout node that has a penalty less than the maximum penalty calculated during the line-by-line formatting processing is added to the node pool. This process repeats until only a single layout node remains in the node pool that represents the entire paragraph of text.

Owner:MICROSOFT TECH LICENSING LLC

Building structure and installing method for two-layer movable panel house

InactiveCN1584233AStable qualityLow costBuilding constructionsDwelling buildingWall plateEngineering

The present invention provides a building structure of one-flour mobile phone home whose member materials can be used for several times and circularly reused and can be made up by adopting industrial production mode and its installation method. Its structure includes four ground beams, four corner uprights, several uprights, four ring beams, several sandwich panels, one roof, several doors and several windows. The installation method of said building structure includes seven steps, said seven steps are provided by said invention specification.

Owner:广东耀达房屋科技股份有限公司

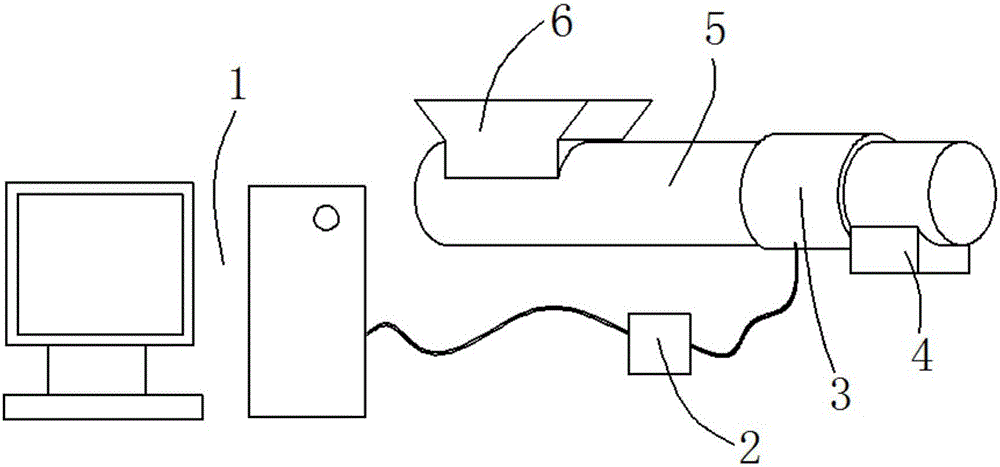

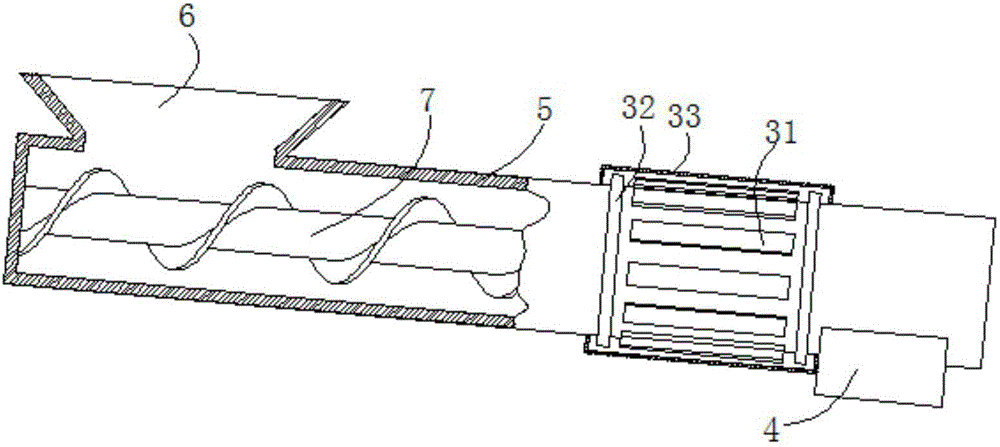

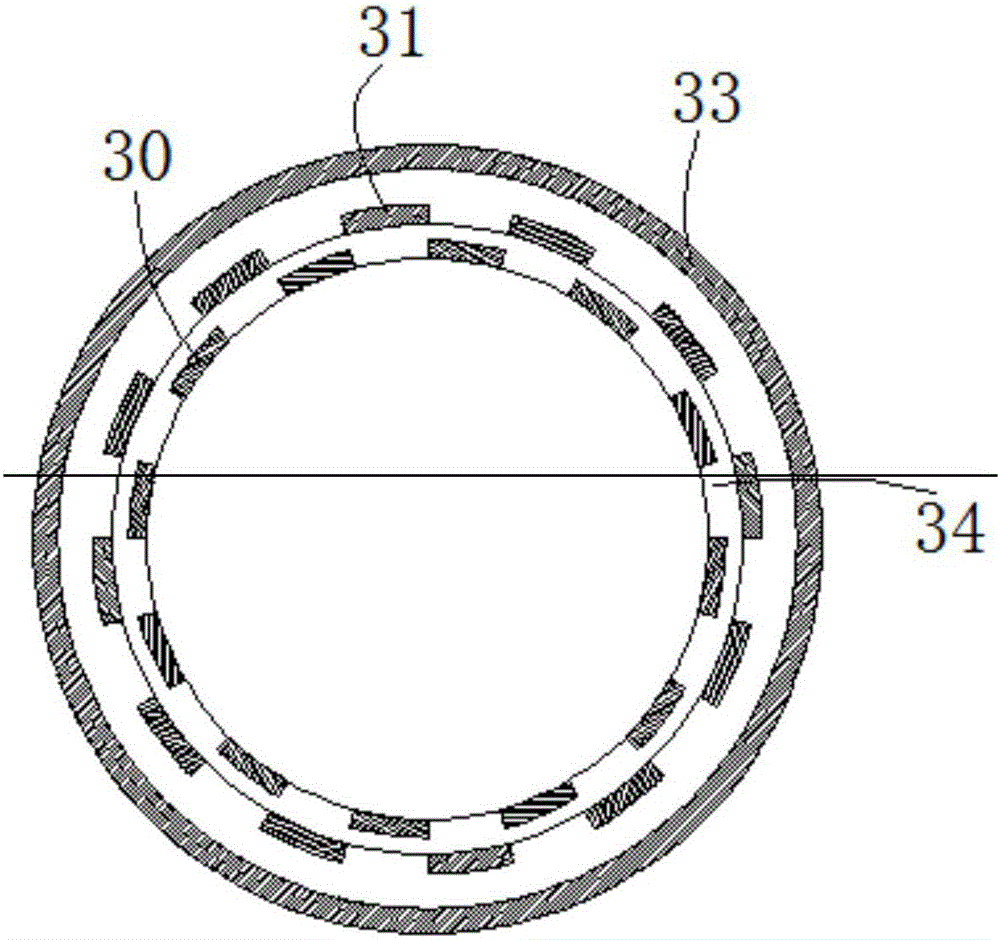

Apparatus for detecting concentration of powder in spiral conveying tube of bilayer electrode array

ActiveCN105973775AEasy to detectReliable isolationParticle suspension analysisLow-k dielectricElectrode array

The invention provides an apparatus for detecting the concentration of powder in the spiral conveying tube of a bilayer electrode array. The apparatus comprises a bilayer electrode array sensor, a data acquisition and control system and an image reconstruction computer, the bilayer electrode array sensor is arranged in a position close to a material outlet outside the spiral conveying tube, and is formed by a special circular tube with a low dielectric constant, the outer wall of the special circular tube is pasted with an electrode array, an electrode array is embedded to the inner wall of the special circular tube, and the two ends of the inner electrode array and the outer electrode array are respectively provided with two annular shielding electrodes. The arrangement mode of bilayer electrodes makes adjacent electrodes be isolated through the special circular tube to replace a spacing between original adjacent electrodes, so isolation is reliable, and arrangement is compact, thereby more or larger electrodes can be arranged by fully utilizing the perimeter of the spiral conveying tube in order to obtain more measurement data for carrying out capacitance chromatography imaging, or the detected capacitance is sensitive and reliable, and the quality and the resolution of a reconstructed image are improved. The circular tube directly sleeves outside the measured pipeline in the measurement process, so the detection is convenient.

Owner:JIANGSU UNIV

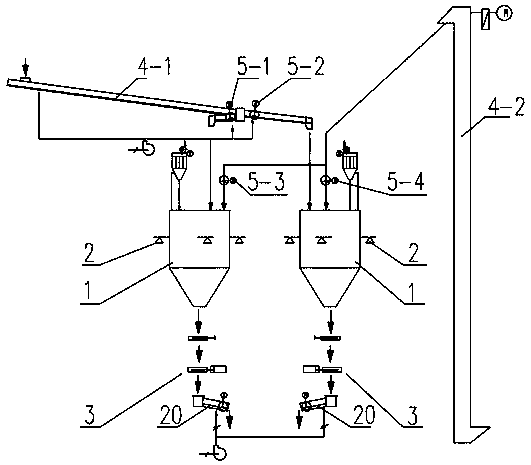

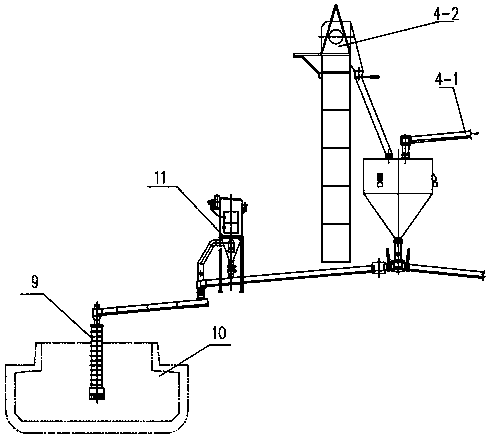

Dynamic-static interaction metering system and metering method

PendingCN111517127ALayout improvementHigh trafficConveyorsControl devices for conveyorsControl systemControl engineering

The invention firstly provides a dynamic and static interaction metering system. The system comprises two or more metering bins, feeding equipment and a control system, wherein each metering bin is provided with a weight sensor, and a bin bottom valve is arranged below each metering bin and used for controlling materials in the metering bin to be unloaded or loaded; and the feeding equipment is configured to be the feeding equipment with two paths. The invention further provides a metering method of the dynamic and static interaction metering system. According to the dynamic and static interaction metering system and the metering method, the metering functions of ship unloading and ship loading are integrated, and the system and the method can be suitable for material ship loading and unloading of large ship loaders and ship unloaders. The metering system is large in layout, large in flow, stable, reliable, higher in adaptability, lower in cost and higher in efficiency; and the weightis not obtained by weighing and peeling by the weight sensor at a time, but is obtained by respectively weighing between the full bin and the empty bin of the metering bin, so that the precision is higher.

Owner:杭州奥拓机电股份有限公司

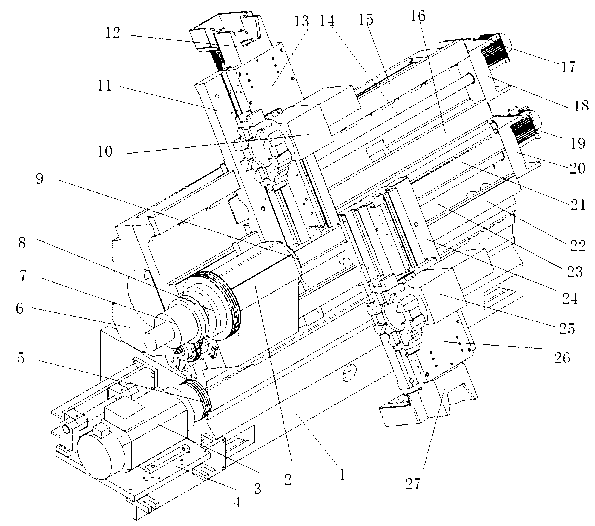

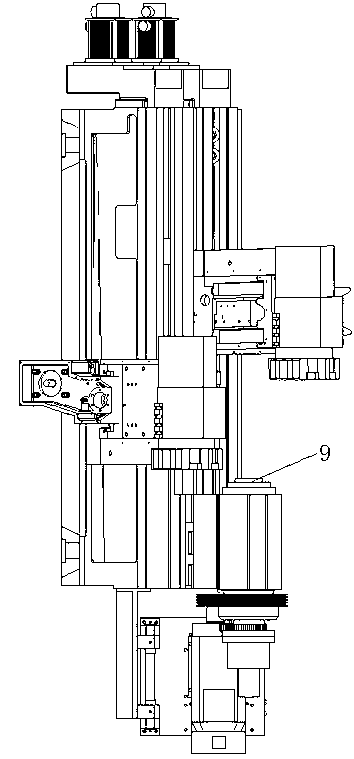

Double-disk-type-knife-rest single main shaft numerically-controlled lathe

ActiveCN103170651AReasonable arrangementFast processingFeeding apparatusTurning machinesEngineeringMechanical engineering

The invention discloses a double-disk-type-knife-rest single main shaft numerically-controlled lathe. The double-disk-type-knife-rest single main shaft numerically-controlled lathe comprises a base, a main shaft box, a main shaft motor, a motor bottom plate, a belt wheel, a lathe body, an angling cylinder, a main shaft assembly, a main shaft, an upper knife rest, an upper lathe saddle, an upper belt wheel box, an upper lathe saddle sliding board, an upper Z-direction lead screw, a first upper guide rail, a second upper guide rail, an upper servo motor, an upper Z-direction belt wheel box, a lower servo motor, a lower Z-direction belt wheel box, a first lower guide rail, a second lower guide rail, a lower Z-direction lead screw, a lower lathe saddle, a lower knife rest, a lower lathe saddle sliding board and a lower belt wheel box, wherein the upper lathe saddle and the lower lathe saddle are vertically arranged in a paralleled mode. According to the double-disk-type-knife-rest single main shaft numerically-controlled lathe, the upper knife rest and the lower knife rest are arranged reasonably and not interfered mutually, compared with a non-parallel-double-knife-rest lathe, the stroke of each knife rest is larger; a plurality of tools can be placed in the upper knife rest and the lower knife rest respectively, several faces of parts can be machined at the same time, machining speed is high, and production efficiency is high; and the use of multiple knife rests enables machining of the several faces of the parts to be finished under the condition of one-time clamping, and therefore machining accuracy and uniformity are improved.

Owner:ZHEJIANG JINTANG MACHINE TOOL

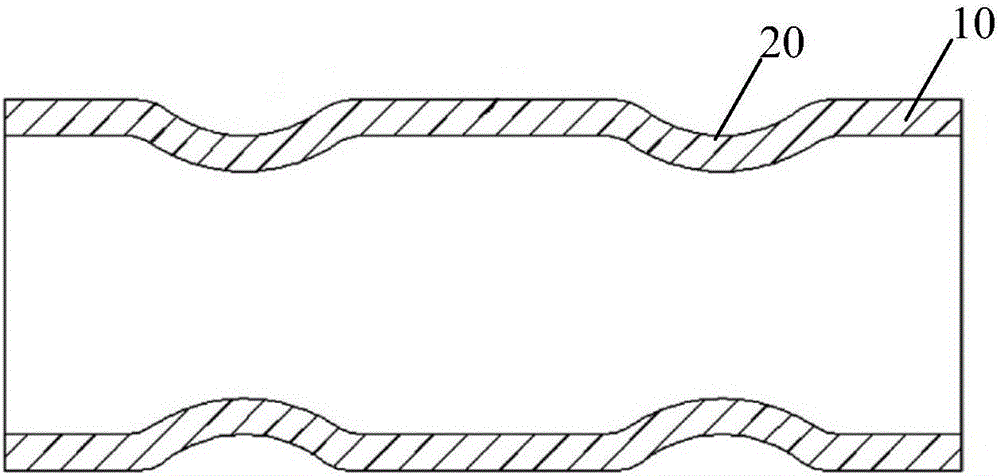

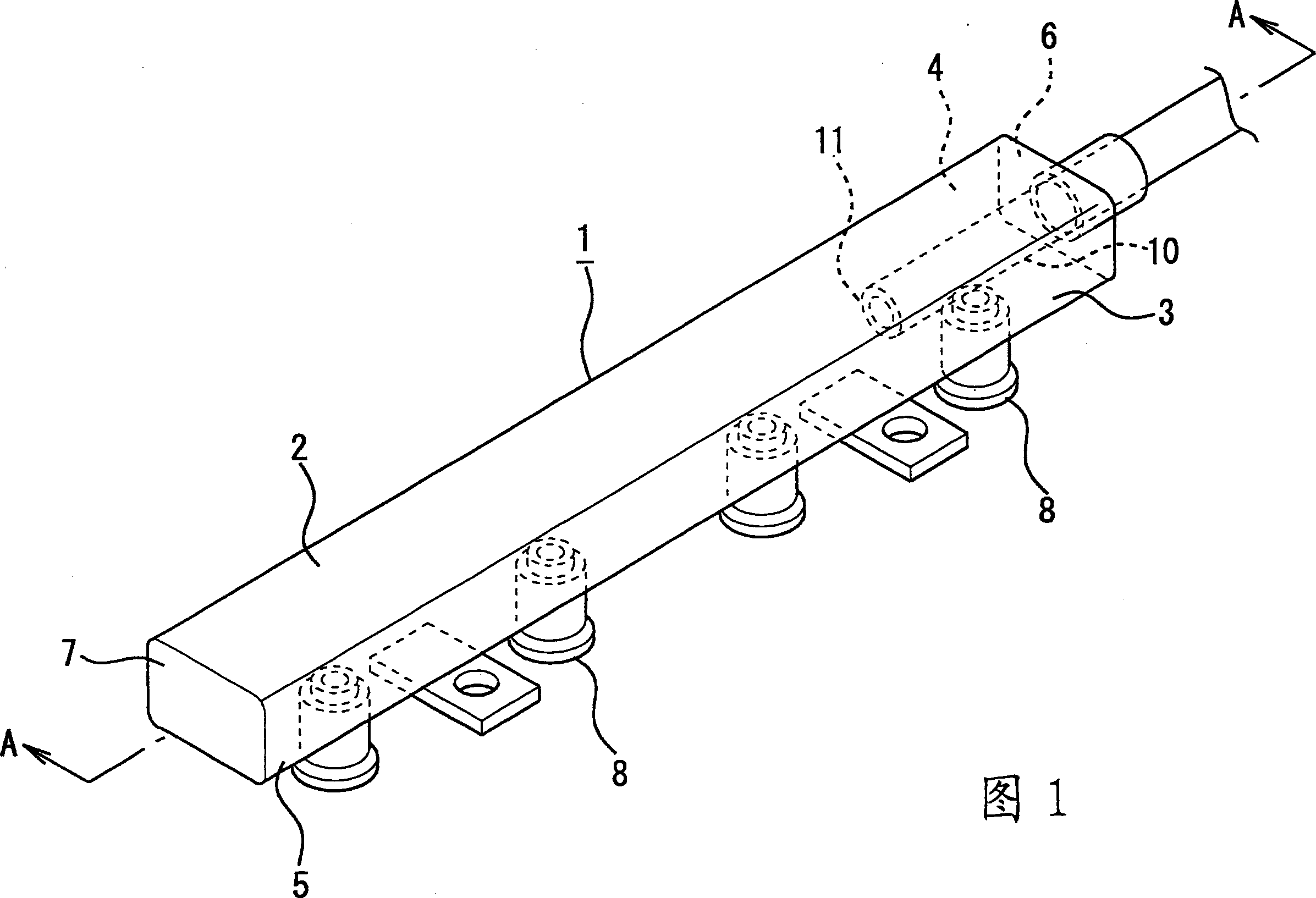

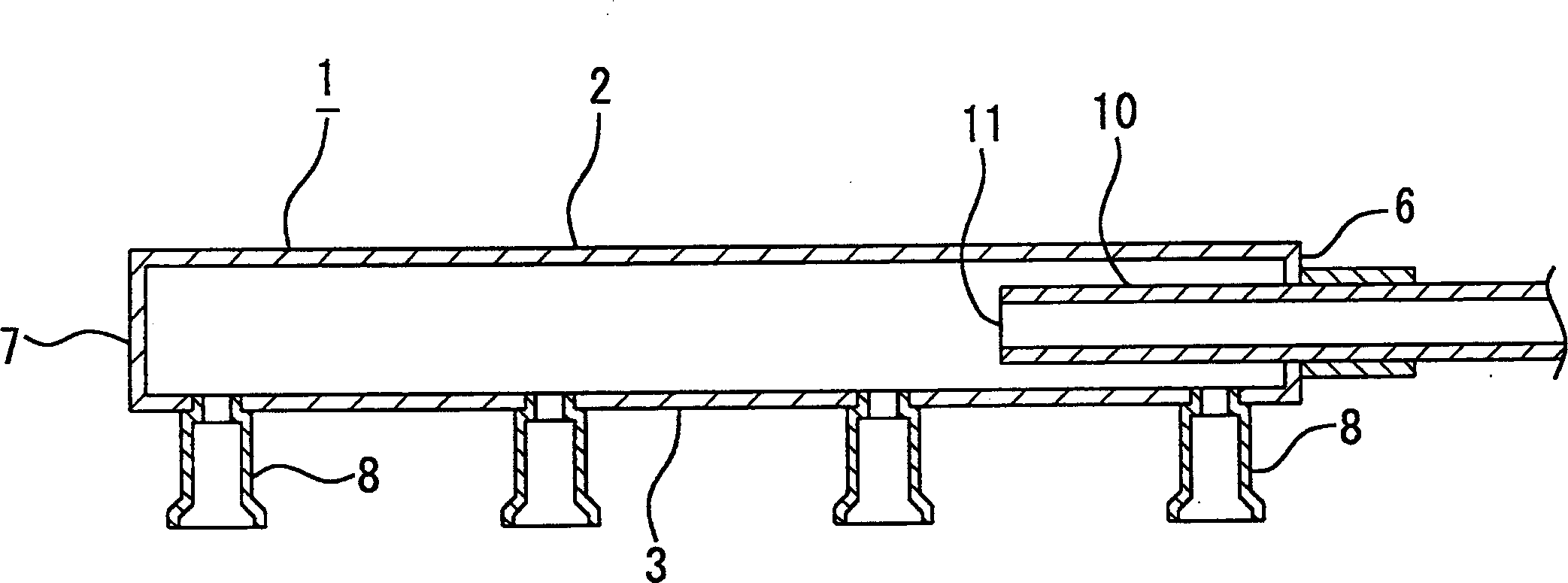

Fuel delivery pipe

InactiveCN1824941ASuppresses low frequency componentsLayout improvementPositive displacement pump componentsLow pressure fuel injectionManufacturing cost reductionFuel tank

The objective of the invention is to provide a fuel delivery pipe having high installation layout performance, and reducing manufacturing cost, while restraining propagation of a standing wave primary mode and a standing wave secondary mode, by connecting a fuel introducing pipe in the longitudinal direction to the inside from one end part of a fuel delivery body for forming a flexible absorbing wall surface on a wall surface. This fuel delivery pipe forms the flexible absorbing wall surface on the wall surface, has an injection nozzle, connects the fuel introducing pipe 10 to the one end part of the returnless type fuel delivery body 1 without a return circuit to a fuel tank, and connects this fuel introducing pipe 10 to the fuel tank via an underfloor pipe. When the total length in the longitudinal direction inside of the fuel delivery body 1 is set to 100, the fuel introducing pipe 10 is inserted inside the fuel delivery body 1 up to a position of 15 to 35 or 65 to 85, and is connected and fixed to the fuel delivery body 1.

Owner:USUI CO LTD

Electric vehicle

InactiveCN103101452AEnsure displacementInhibition of Interfering SituationsSpeed controllerElectric energy managementElectric carsEngineering

The invention provides an electric vehicle, which, on the basis of realizing low cost and light weight, can inhibit interference of a power control unit or a PCU mounting frame and other parts disposed in a motor chamber, thereby protecting the power control unit. The PCU mounting frame (22) surrounds a PCU (5) from the periphery, and the PCU mounting frame (22) is provided with a front part supporting leg part (32) connecting a front supporting frame (25) and a left side supporting frame (24), a back part supporting leg part (34) connecting the left side supporting frame (24) and a back supporting frame, the back part supporting leg part (34) is in an offset configuration to an internal side along a left-right direction relative to the front part supporting leg part (32) in a mode of getting away from a travel simulator (6) in a left-right direction, and is at the back part of a front end part of the travel simulator (6).

Owner:HONDA MOTOR CO LTD

Artificial rockery making process

InactiveCN1453151ALayout improvementReduce layoutDecorative surface effectsThree-dimensional effectsRoof gardenGypsum

The technological process of making rockery includes making soft inner rubber mold on true rock; making hard outer gypsum mold on the inner mold; setting the inner mold into the outer mold; filling cement into the inner mold to form artificial rock in different shapes; and combining and stacking the artificial rocks in the designed shape to form the rockery. The rockery is vivid, light, low in cost and easy to construct, and may be set in various places, such as underground car park, roof garden, square, park, etc.

Owner:纳志祥

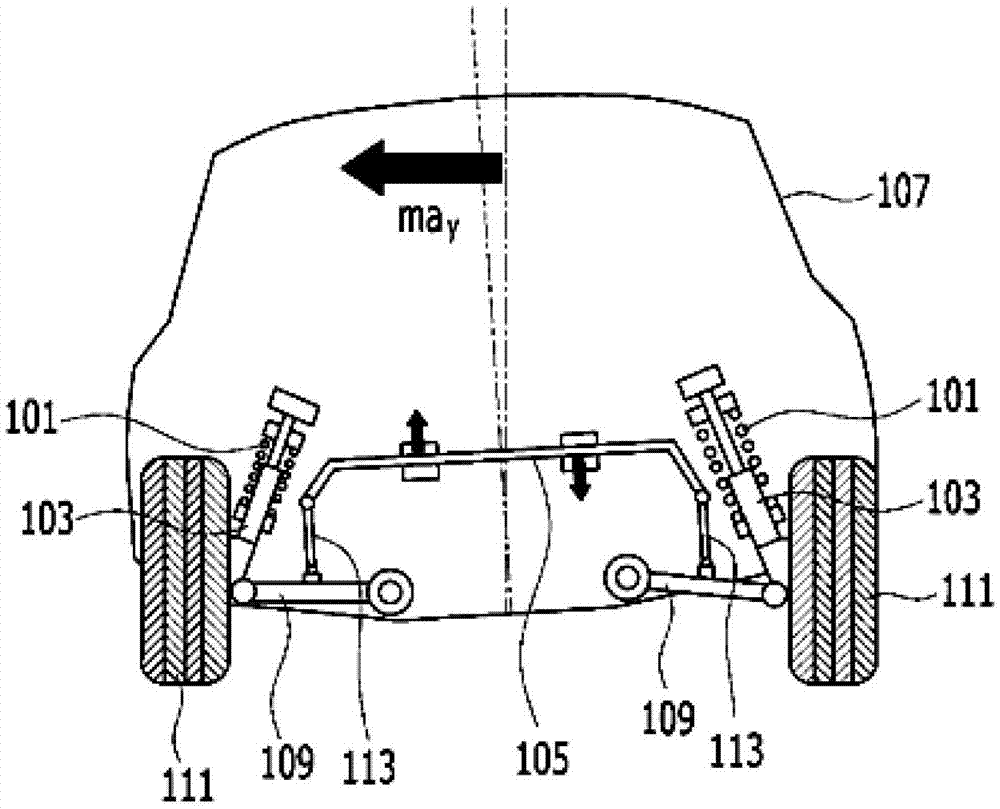

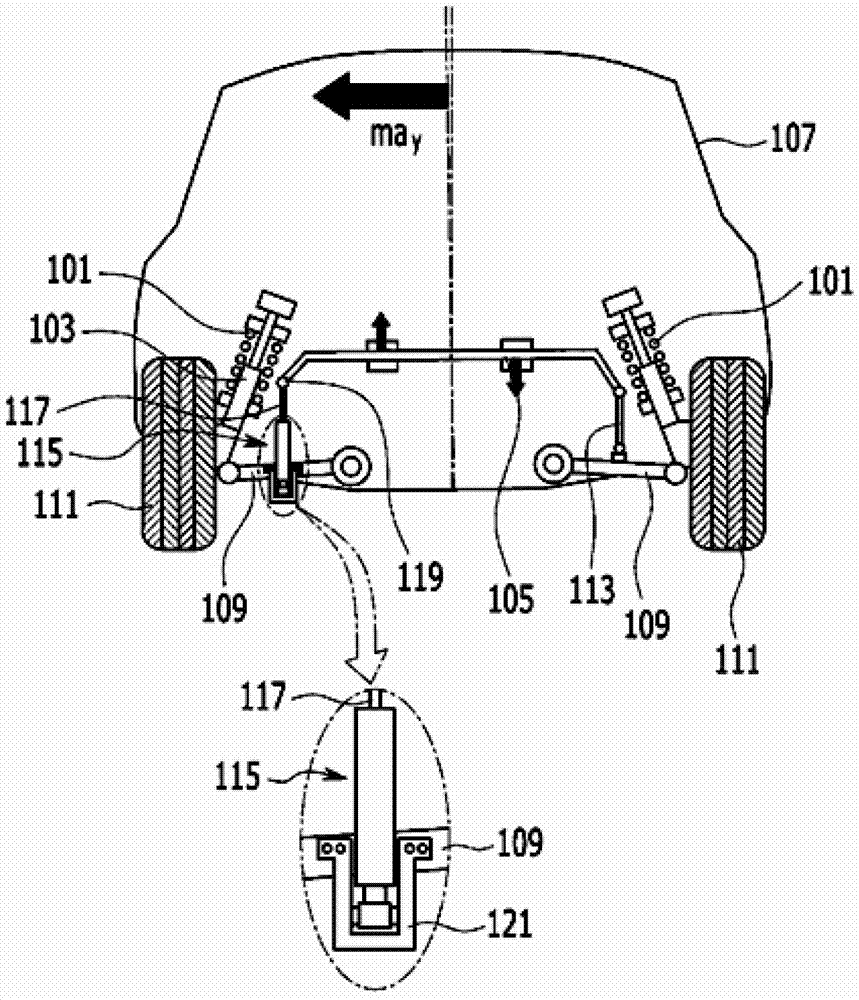

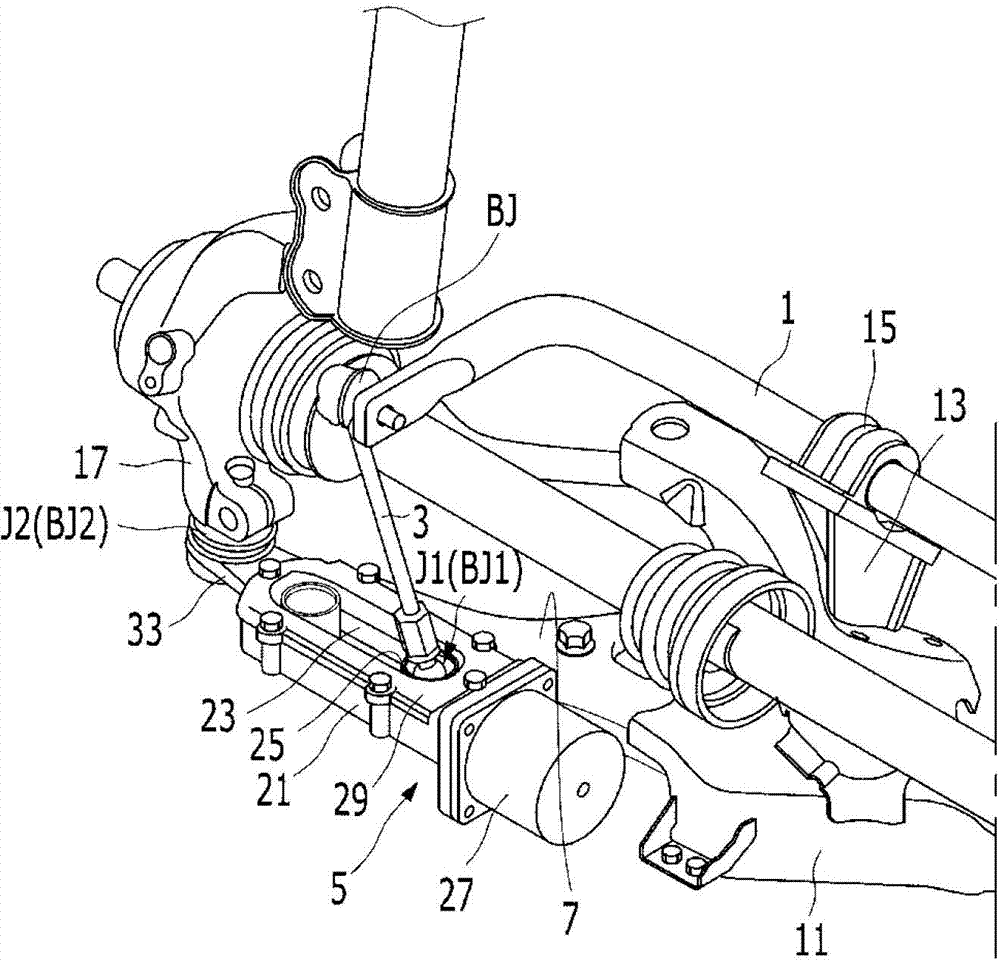

Active roll control system

ActiveCN103158474AFriction minimizationImprove operational efficiencyInterconnection systemsResilient suspensionsControl systemEngineering

Owner:HYUNDAI MOTOR CO LTD

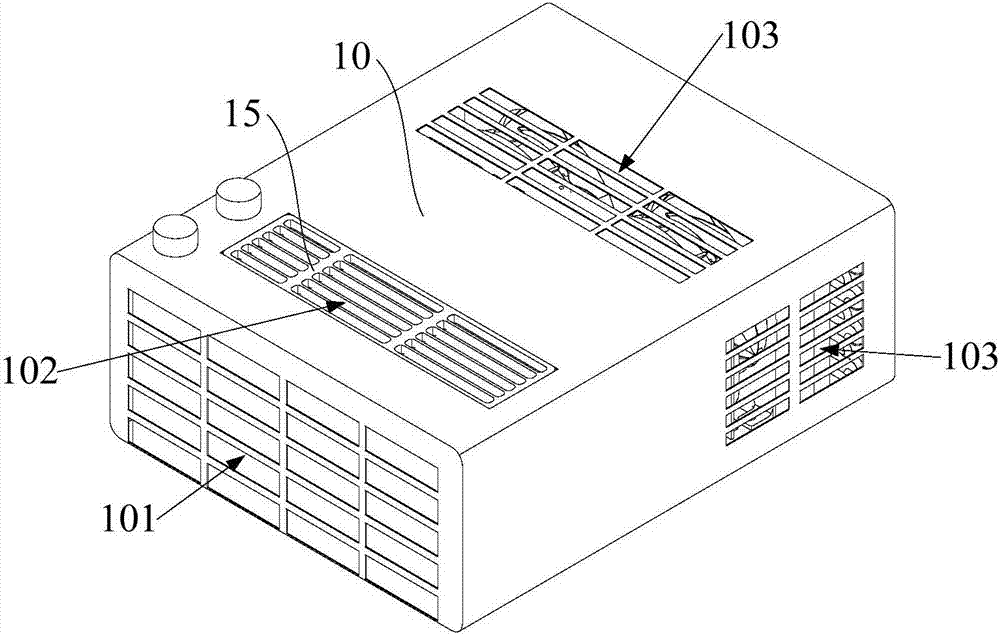

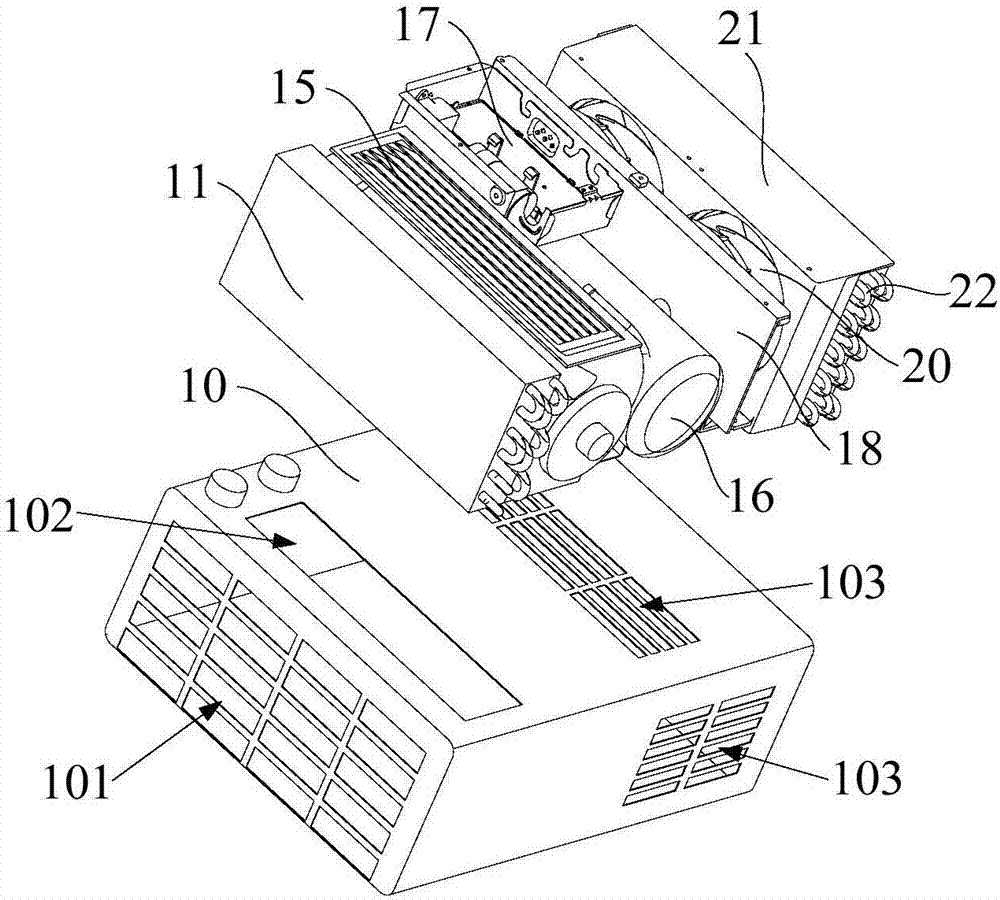

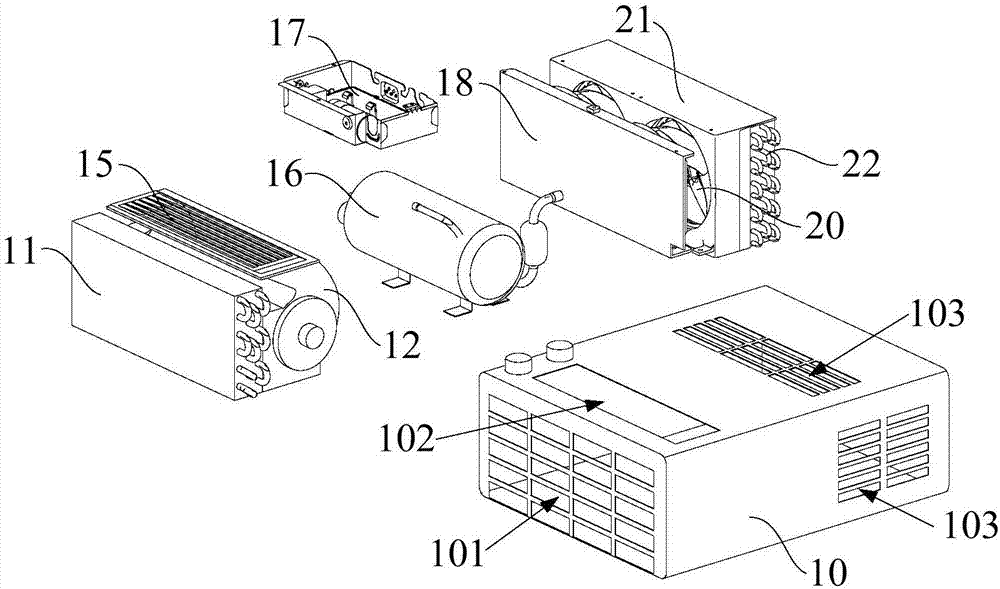

Window-type air conditioner

InactiveCN107255315ACompact structureReduce volumeSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringIndoor air

The invention discloses a window-type air conditioner. The window-type air conditioner comprises a machine shell, an indoor heat exchanger, an indoor air driving device, a horizontal compressor, an outdoor air driving device, an outdoor heat exchanger and an electronic control box, wherein the indoor heat exchanger, the indoor air driving device, the horizontal compressor, the outdoor air driving device and the outdoor heat exchanger are arranged in the machine shell in sequence, the electronic control box is located on the upper portion of the horizontal compressor, the shaft axis of the horizontal compressor is parallel to the length directions of the indoor heat exchanger and the outdoor heat exchanger. According to the technical scheme, through the reasonable placement of all parts in the machine shell, the window-type air conditioner is compact in structure and small in size, specifically, the compressor is placed in a horizontal mode and is placed between the indoor heat exchanger and the outdoor heat exchanger, the shaft axis of the horizontal compressor is parallel to the length directions of the indoor heat exchanger and the outdoor heat exchanger, the whole height of the window-type air conditioner is reduced effectively, the window-type air conditioner is compact in structure and small in size, the adaptive window kind of the window-type air conditioner is increased, and storage and transport are convenient.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

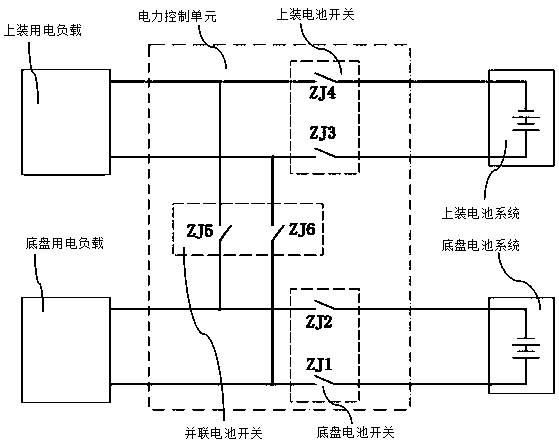

Multi-power battery system structure of pure electric special vehicle

InactiveCN107901744ALayout improvementImprove powerElectric propulsion mountingPower batteryElectricity

The invention discloses a multi-power battery system structure of a pure electric special vehicle. The multi-power battery system structure comprises a chassis battery system, an upper part battery system, a chassis, an upper part, a power control unit, a chassis electricity load and an upper part electricity load. When the vehicle works normally, the chassis battery system supplies power to the chassis electricity load, and the upper part battery system supplies power to the upper part electricity load. When the upper part battery system runs out, the chassis battery system can supply power to the upper part electricity load through deploying of the power control unit. When the chassis battery system runs out, the upper part battery system can supply power to the chassis through deployingof the power control unit. In addition, through deploying of the power control unit, the two sets of battery systems can work coordinately, and meanwhile supply power to the upper part or the chassisand charge each other. According to the multi-power battery system structure, based on the chassis battery system, the upper part battery system is additionally arranged, the matching flexibility ofthe vehicle battery energy is increased, and the reliability of the vehicle battery system is improved.

Owner:北京华田汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com