Multi-power battery system structure of pure electric special vehicle

A battery system and special vehicle technology, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of limited space for chassis layout and low power of pure electric special vehicles, and achieve the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] See attached picture.

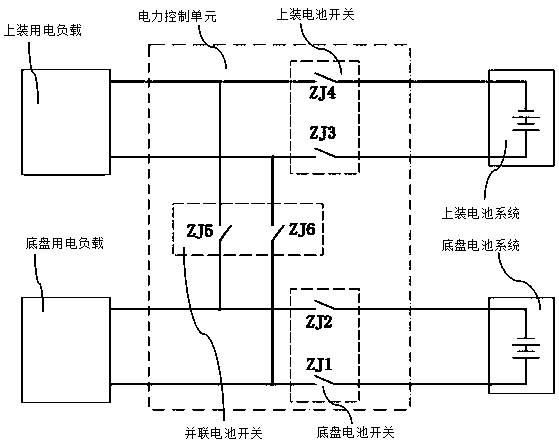

[0015] figure 1 is a schematic diagram of the electrical architecture. It can be seen from the figure that the power control unit can complete the following working modes.

[0016] 1. The bodywork battery supplies power to the bodywork load, and the chassis battery supplies power to the chassis load;

[0017] When the vehicle is running and working normally, relays ZJ1, ZJ2, ZJ3 and ZJ4 are closed, relays ZJ5 and ZJ6 are disconnected, the bodywork battery system supplies power to the bodywork load, and the chassis battery system supplies power to the chassis.

[0018] 2. The bodywork battery supplies power to the chassis load, and the chassis battery supplies power to the bodywork load;

[0019] When the vehicle bodywork battery system is out of power and the bodywork still needs to work, close ZJ1, ZJ2, ZJ5, ZJ6 relays to realize the chassis battery system supplying power to the bodywork load. When the vehicle chassis battery system is dead a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com