A printed circuit board and production method thereof

A printed circuit board and circuit board technology, which is applied in the fields of printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., can solve the problems of high cost and limitation, and achieve the effects of convenience, shortening the manufacturing cycle, and ensuring the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

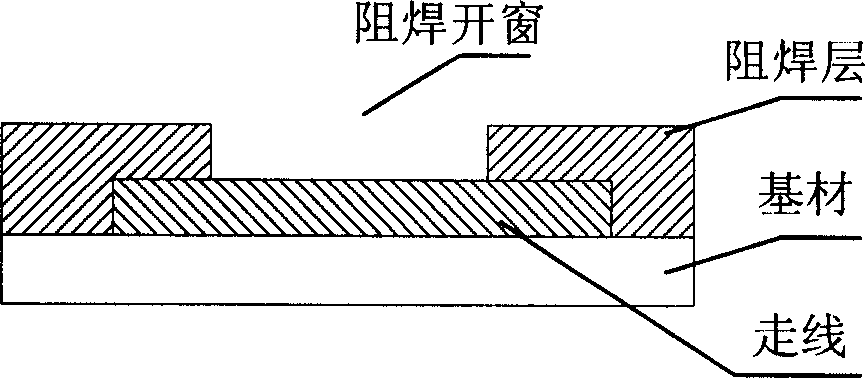

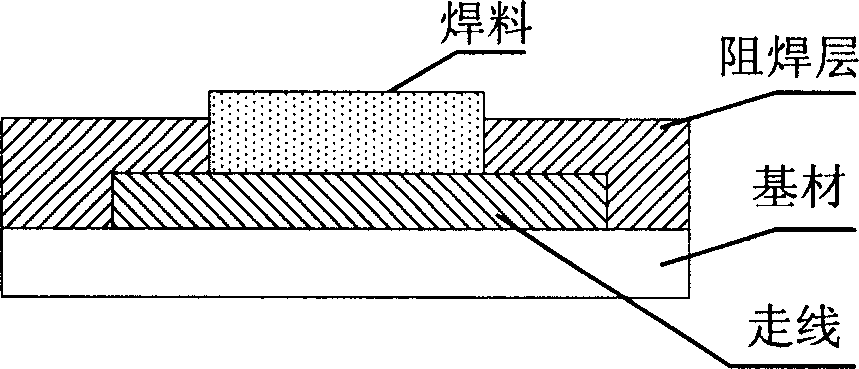

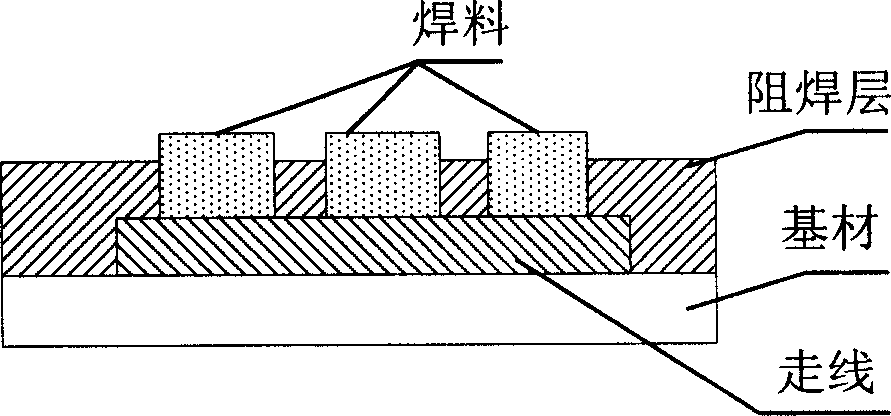

[0028] The structure of the PCB board of the present invention is as figure 1 As shown, in PCB design, for PCB traces that need to carry high current, design a solder mask window with a certain width above the trace, and then fill the solder mask window with solder when assembling devices on the PCB. When the solder melts and electrically bonds with the trace, as figure 2 As shown, it is equivalent to increasing the cross-sectional area of the wiring and improving the current carrying capacity of the wiring. According to the requirements of PCB structure, characteristics of solder and welding process, etc., the design of solder mask opening has the following characteristics:

[0029] 1. The shape and number of solder mask openings are not limited, and are determined by the number and shape of the traces carrying high current on the PCB;

[0030] 2. The direction of the solder mask opening is consistent with the direction of the trace, and it is distributed continuously al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com