Dynamic-static interaction metering system and metering method

A metering system and metering method technology, applied in the field of metering systems, can solve the problems of low precision, calculation, and low precision, and achieve the effects of strong adaptability, large flow, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

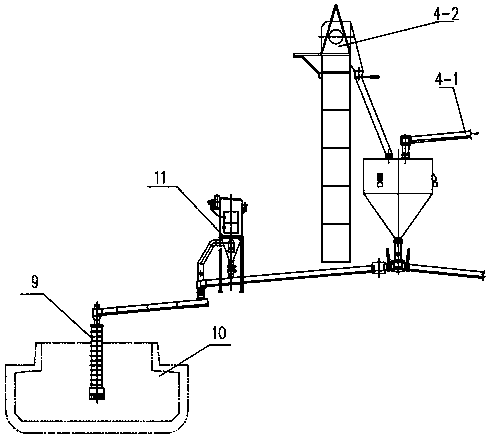

[0053] The invention discloses a dynamic and static interactive metering system, which is suitable for loading or unloading dry, loose, non-toxic and harmless powder or granular materials. The metering system is generally set on the ground of the wharf instead of inside the ship .

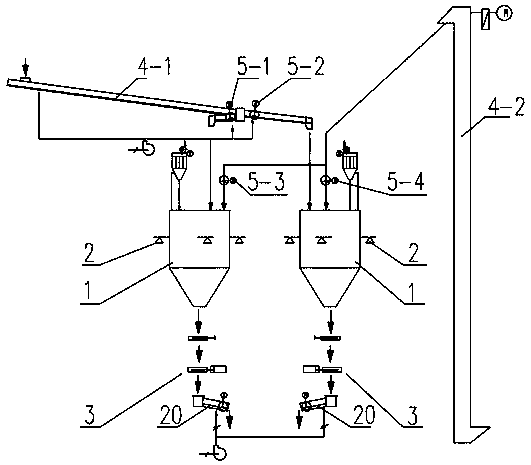

[0054] Such as figure 1 As shown, the present disclosure includes 2 and more than 2 measuring bins 1, figure 1 Shown in is two metering bins; the metering bin 1 is provided with a weight sensor 2, and the bottom of the metering bin 1 is provided with a valve 3 at the bottom of the bin; and

[0055] feeding equipment such as figure 1 and figure 2 As shown, there are two feeding methods. For the two feeding methods, the feeding equipment is configured as a two-way feeding equipment, and the two-way feeding equipment includes at least two or more metering bins for feeding The delivery end 4-1 of the chute and the delivery end 4-2 of the elevator for feeding at least two or more metering bins, the...

Embodiment 2

[0086] A metering method for a dynamic and static interactive metering system realized by the metering system disclosed in Embodiment 1, wherein it includes the following steps:

[0087] 1): preset

[0088] Select one or more metering bins that need to be weighed, set the preset value of the material weight in the selected one or more metering bins, and the feeding valve and bottom of the one or more metering bins The opening sequence of the valves;

[0089] Close the material delivery valve corresponding to the metering bin after the weight of the material in any metering bin reaches the preset value;

[0090] When setting the delivery of a single metering bin, after the weight of the material in the metering bin reaches the preset value, close the feeding valve and equipment corresponding to the metering bin, and set the opening time of the valve at the bottom of the bin, after unloading Circular feeding and unloading are carried out according to the opening times of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com