Energy absorption box for vehicle

An energy-absorbing box and vehicle technology, applied in bumpers and other directions, can solve the problems of long length, low strength and structural energy-absorbing efficiency, and large occupation, achieve structural optimization, increase the layout of cabin parts and passenger space, shorten the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

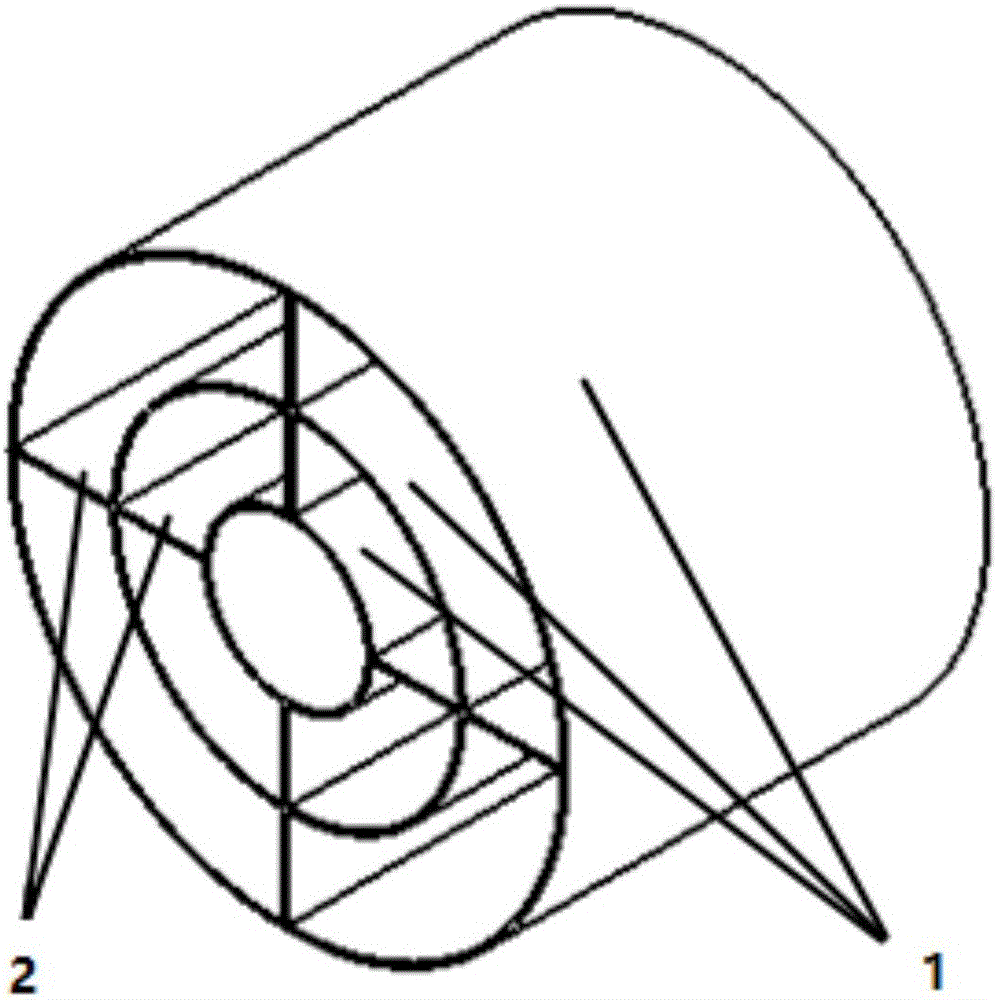

[0026] Such as figure 2 and 3 As shown, a vehicle energy-absorbing box provided by a preferred embodiment of the present invention includes a plurality of hollow shells 1 nested together, and two adjacent hollow shells 1 are connected by energy-absorbing ribs 2 . The number of layers of the hollow shell 1 and the number of energy-absorbing ribs 2 can be determined according to the energy-absorbing requirements of the developed vehicle model. In addition, the energy-absorbing ribs 2 are provided with a first deformation induction groove 3, and the first deformation induction groove 3 is along the The radial extension of the hollow housing 1 is provided. The energy-absorbing box of the present invention is provided with a plurality of nested hollow shells 1, and two adjacent hollow shells 1 are connected together by energy-absorbing ribs 2, and the energy-absorbing box can be made into an integral part, two separate The body part (two parts separated along the axis of symmetr...

Embodiment 2

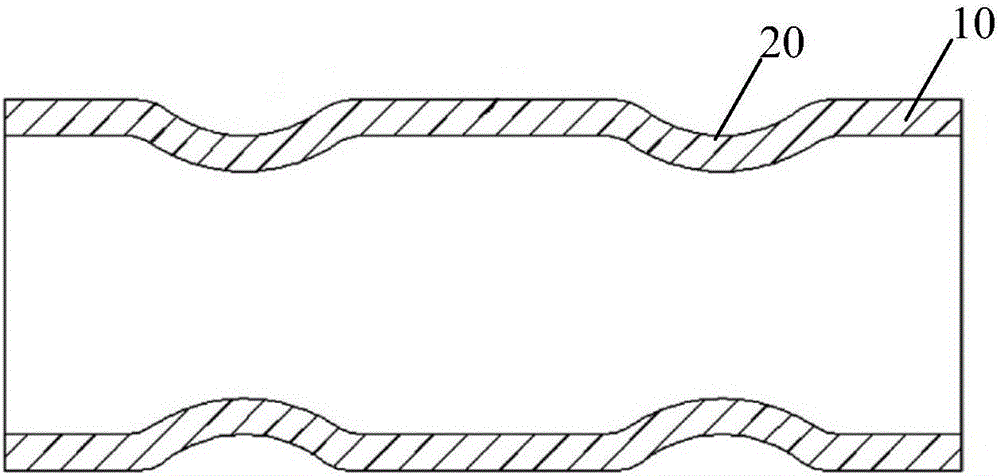

[0032] Such as Figure 4 As shown, the vehicle crash box of this embodiment is an improvement on the basis of Embodiment 1. The only difference between the two is that in order to better guide the deformation of the crash box when a collision occurs, the hollow shell of this embodiment The body 1 is provided with a second deformation inducing groove 4 , and the second deformation inducing groove 4 is annular arranged along the circumferential direction of the hollow shell 1 . Furthermore, there are a plurality of second deformation inducing grooves 4 distributed at intervals along the axial direction of the hollow casing 1 .

[0033] The second deformation inducing groove 4 can be a square groove or an arc groove or a groove body of other shapes, which can be set according to specific conditions.

[0034] In order to ensure the strength of the hollow shell 1 , the depth of the second deformation inducing groove 4 should not be greater than one third of the thickness of the ho...

Embodiment 3

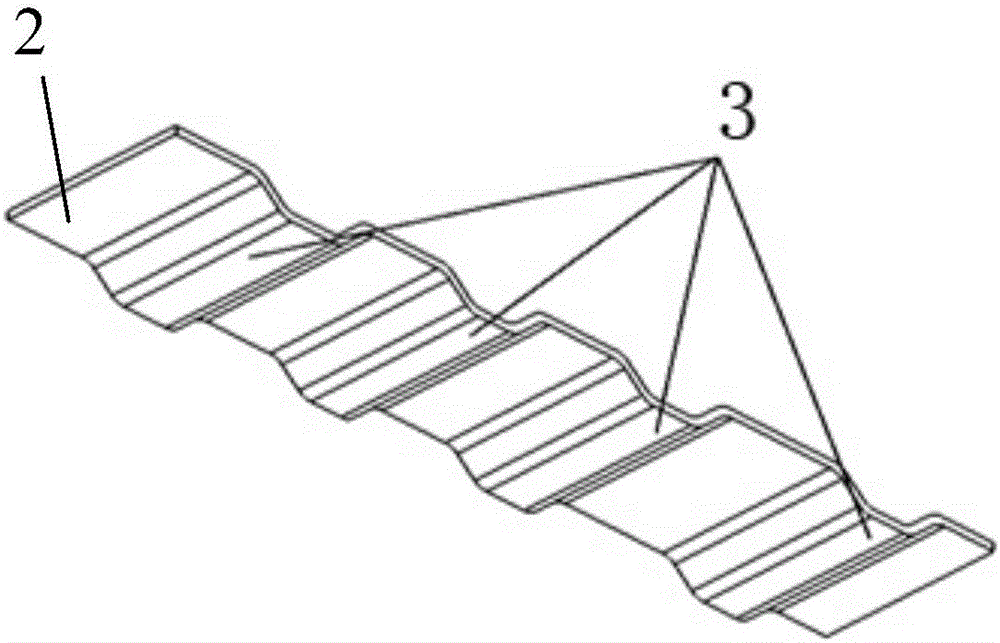

[0036] Such as Figure 5 As shown, the only difference between the energy-absorbing box for vehicles of this embodiment and Embodiment 1 is that the hollow shell 1 of this embodiment is a hollow polyhedron, which can be a hollow tetrahedron, a hollow hexahedron, a hollow octahedron or other polygonal cross-sections. Hollow polyhedron, the present embodiment takes hollow tetrahedron as an example. In addition, the multiple hollow polyhedrons have the same structure and are nested and arranged parallel to each other.

[0037] In this embodiment, the structure connected by energy-absorbing ribs 2 between two adjacent hollow polyhedrons has the following modes:

[0038] Such as Figure 5 and Figure 6 As shown, the corner regions of two adjacent hollow polyhedrons are connected by energy-absorbing ribs 2, specifically, one end of the energy-absorbing ribs 2 is connected to the two connection surfaces of the hollow shell 1, and the other end of the energy-absorbing ribs 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com