Marine domestic sewage treatment process and vacuum discharge and treatment system

A technology of domestic sewage and treatment system, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Can not meet the standard and other problems, to achieve the effect of saving space and water, water quality and water load change ability, stable treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

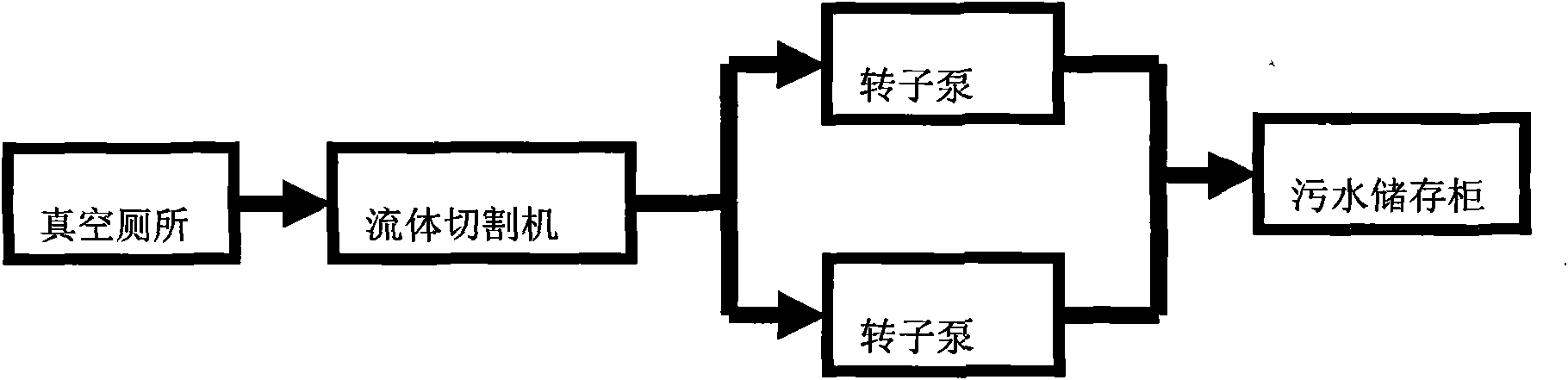

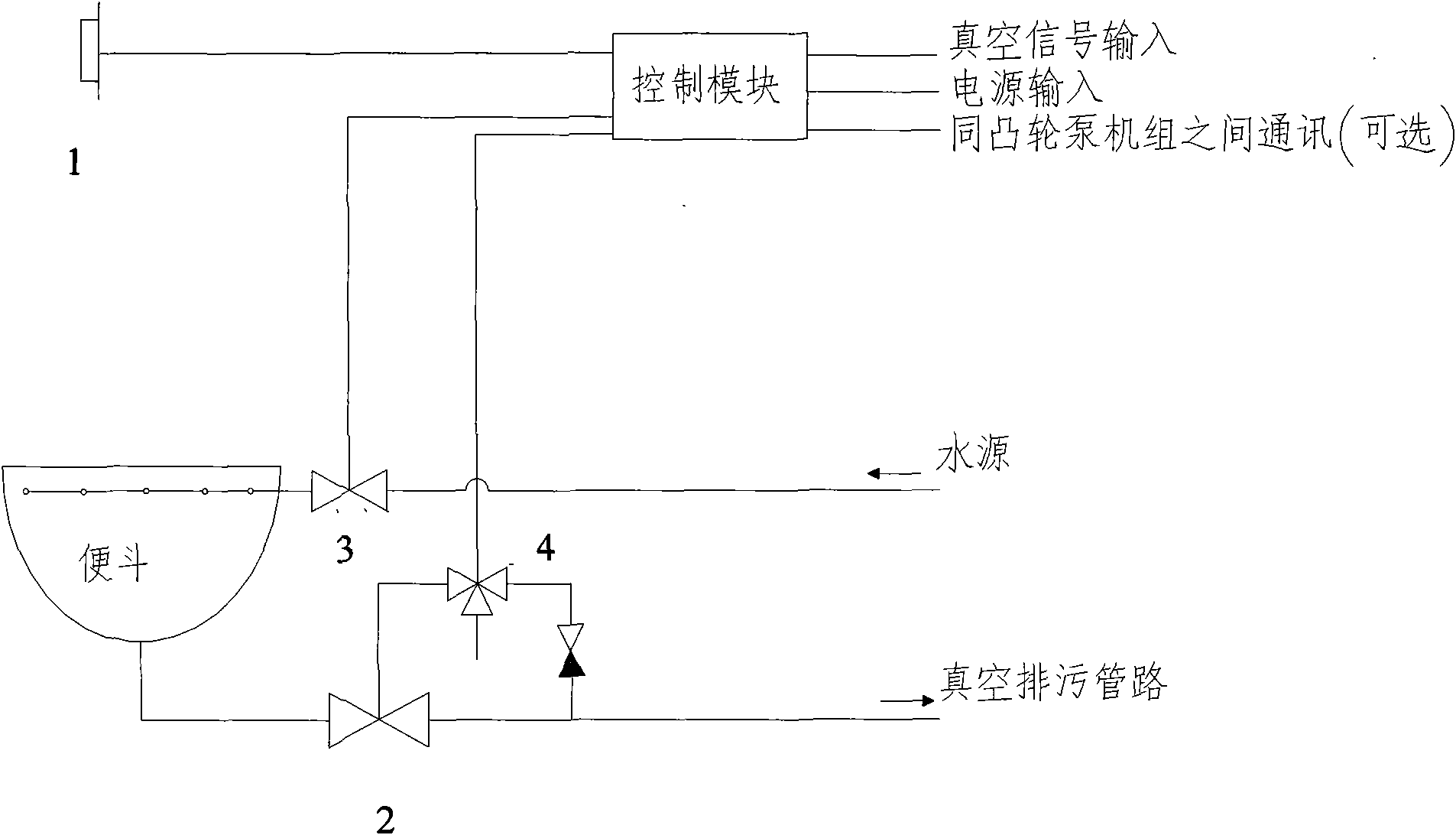

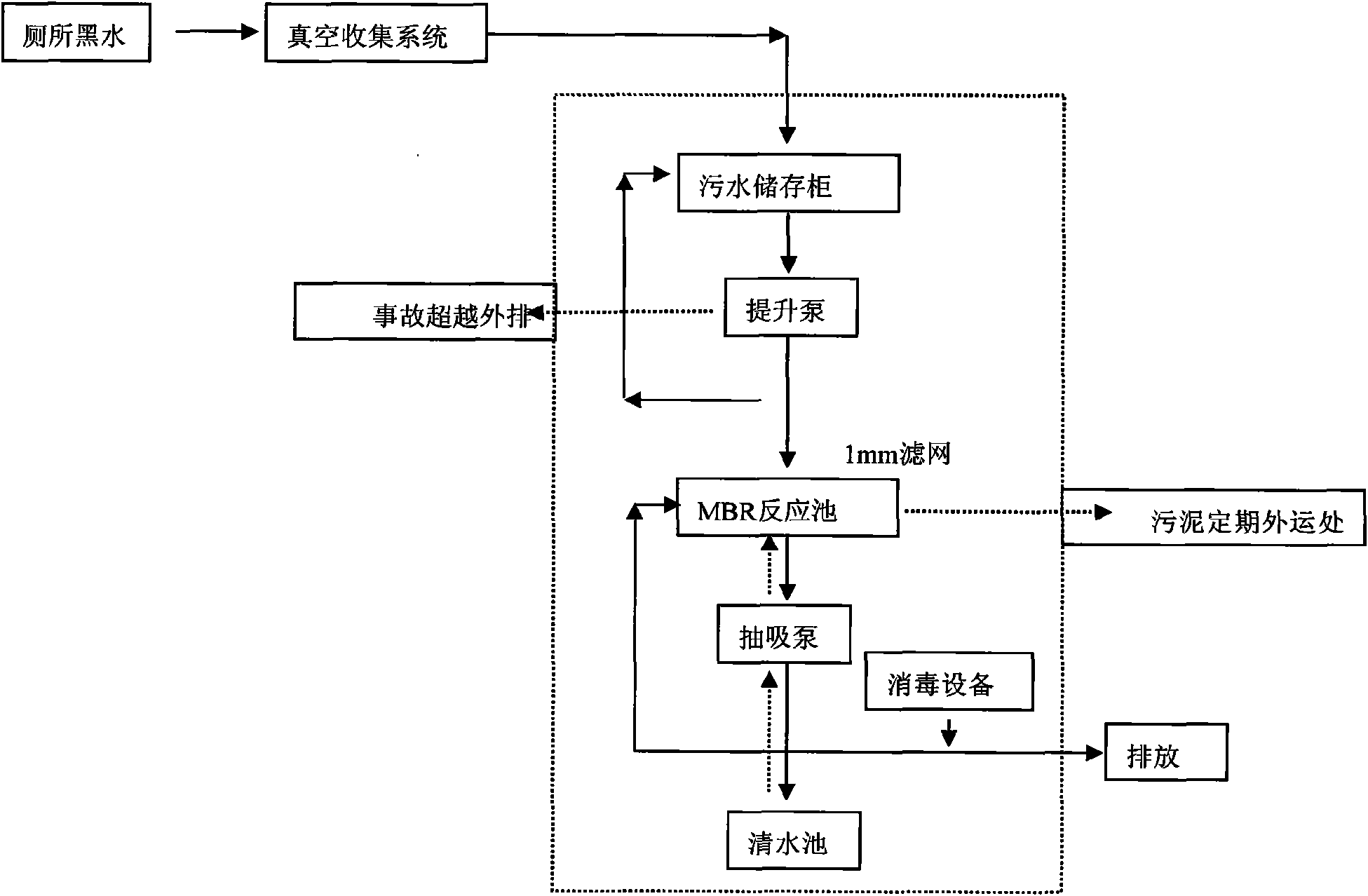

[0025] Such as figure 1 As shown, the vacuum discharge and treatment system for marine sewage includes a vacuum collection device and a sewage treatment device. The vacuum collection device is composed of a vacuum toilet, an intermediate collection device, a fluid cutting machine, a rotor pump unit, and a vacuum sewage pipeline. Completely closed collection and discharge system; vacuum toilet includes main components such as bedpan, discharge valve, water valve, flushing switch and control device; intermediate collection device includes collection box, liquid level switch, discharge valve and control unit, and the collection box is made of stainless steel , with a volume of 5L, installed in the interlayer of the bathroom or under the washstand, used to collect sewage discharged from gravity outlets such as wash basins. After the sewage (gray wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com