Resin bed thermal stabilization salt removing method

A heat-stable salt and resin bed technology, applied in chemical instruments and methods, ion exchange regeneration, ion exchange water/sewage treatment, etc., can solve the problem of large waste liquid discharge, large consumption of regenerant, and large consumption of flushing water and other problems, to achieve the effect of less waste liquid discharge, less flushing water consumption and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

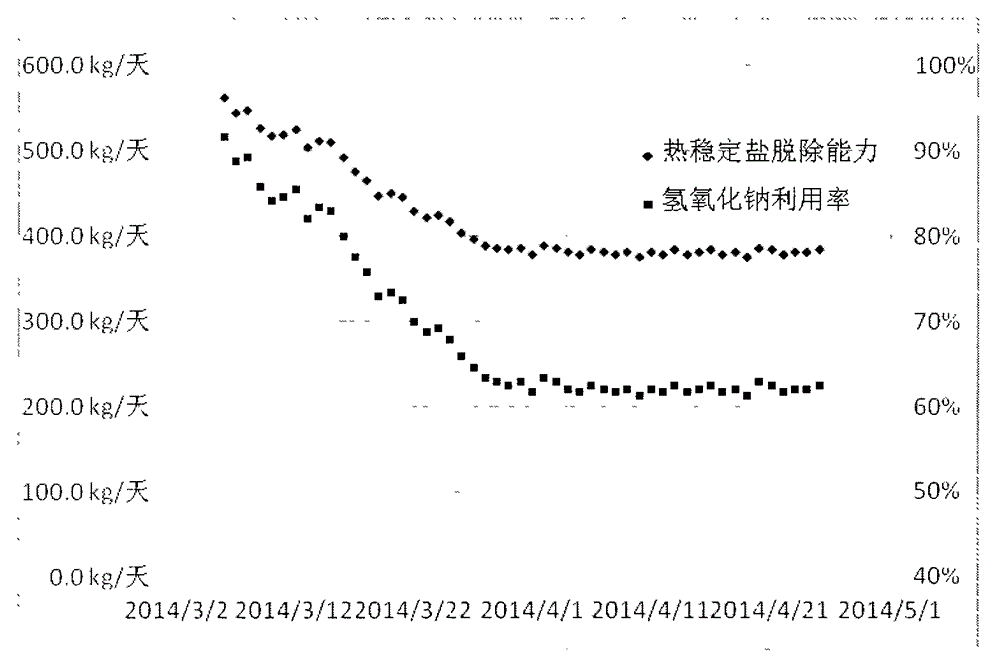

[0035] Renewable organic amine wet flue gas desulfurization device is equipped with a set of thermally stable salt removal device, and the designed resin loading capacity is 1m 3 , heat stable salt removal capacity not less than 300kgSO 4 2- / sky.

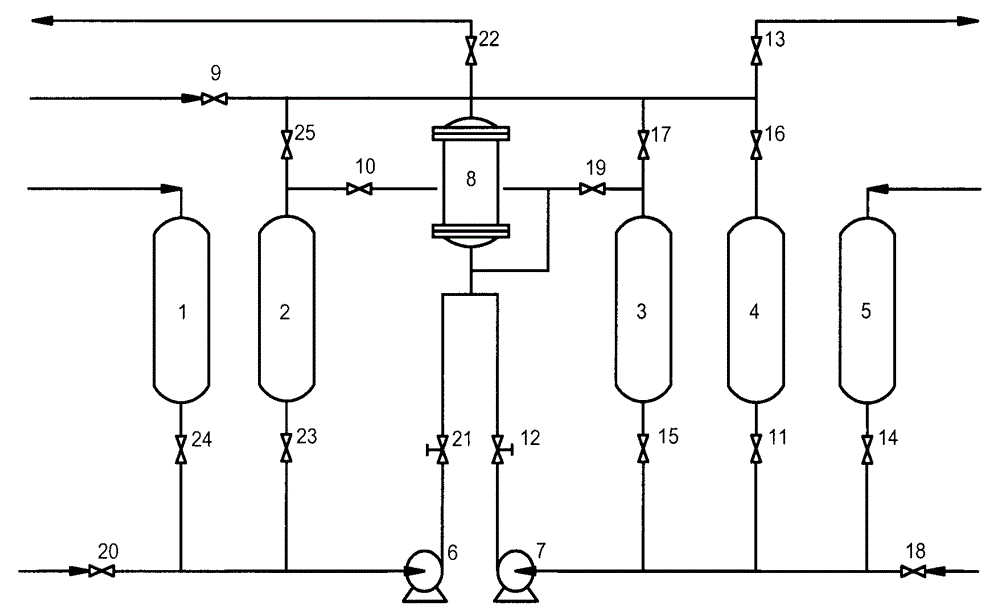

[0036] The heat-stable salt removal device control system adopts remote DCS automatic control, the exchange-regeneration cycle is 1 hour, and the operation is not less than 10 cycles per day. A description of the complete workflow per cycle of the thermally stable salt removal unit (see figure 1 )as follows:

[0037] 1) After the control program is started, the system checks itself. At this time, all the automatic control valves, that is, the first valve 9 to the seventeenth valve 25, are in the closed state, the amine liquid pump 6 and the lye pump 7 are in the closed state, and each material storage tank After the liquid level meets the conditions, enter the next step;

[0038] 2) Resin bed purging and emptying step (purge a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com