Patents

Literature

500results about How to "Enhanced flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

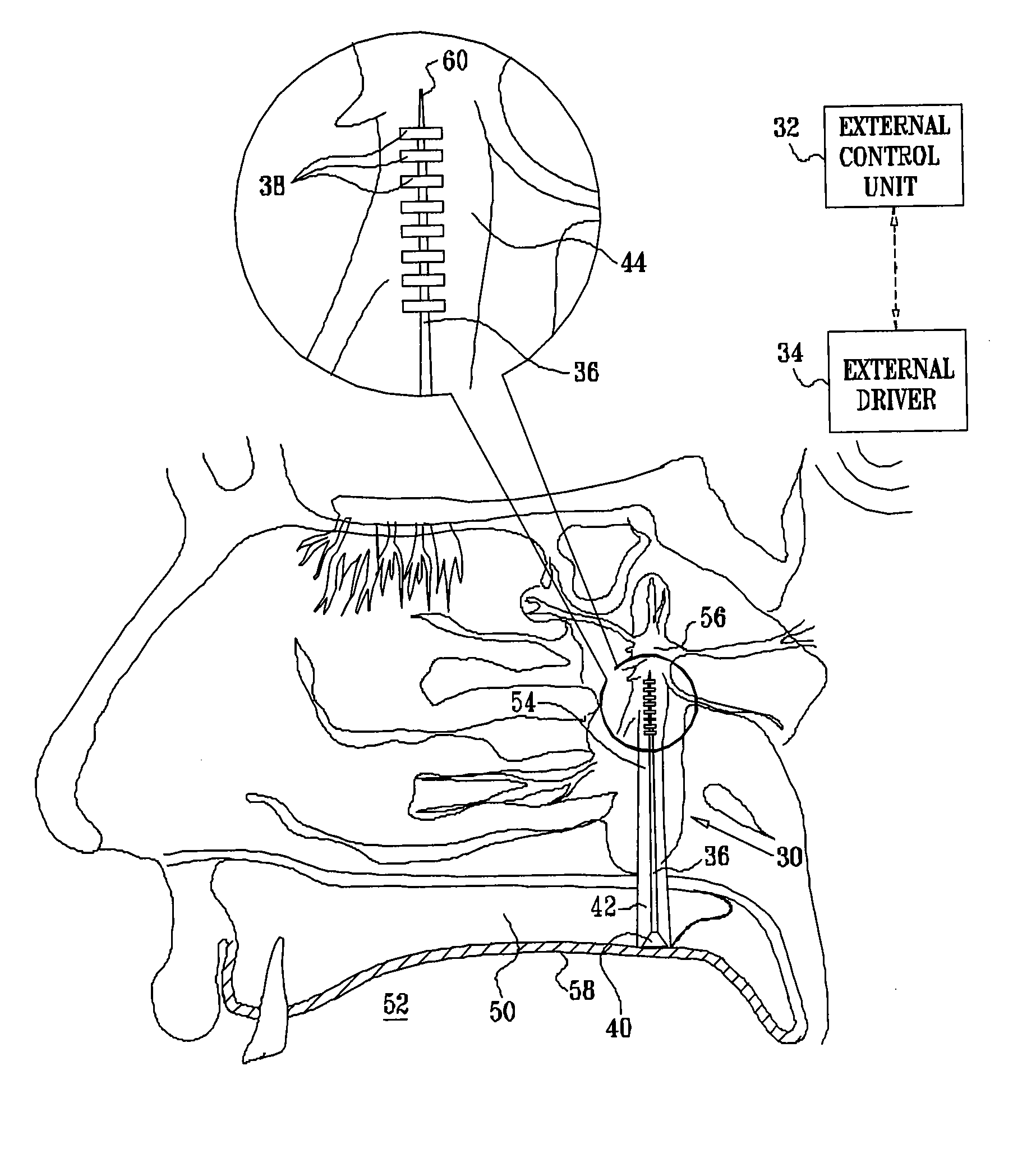

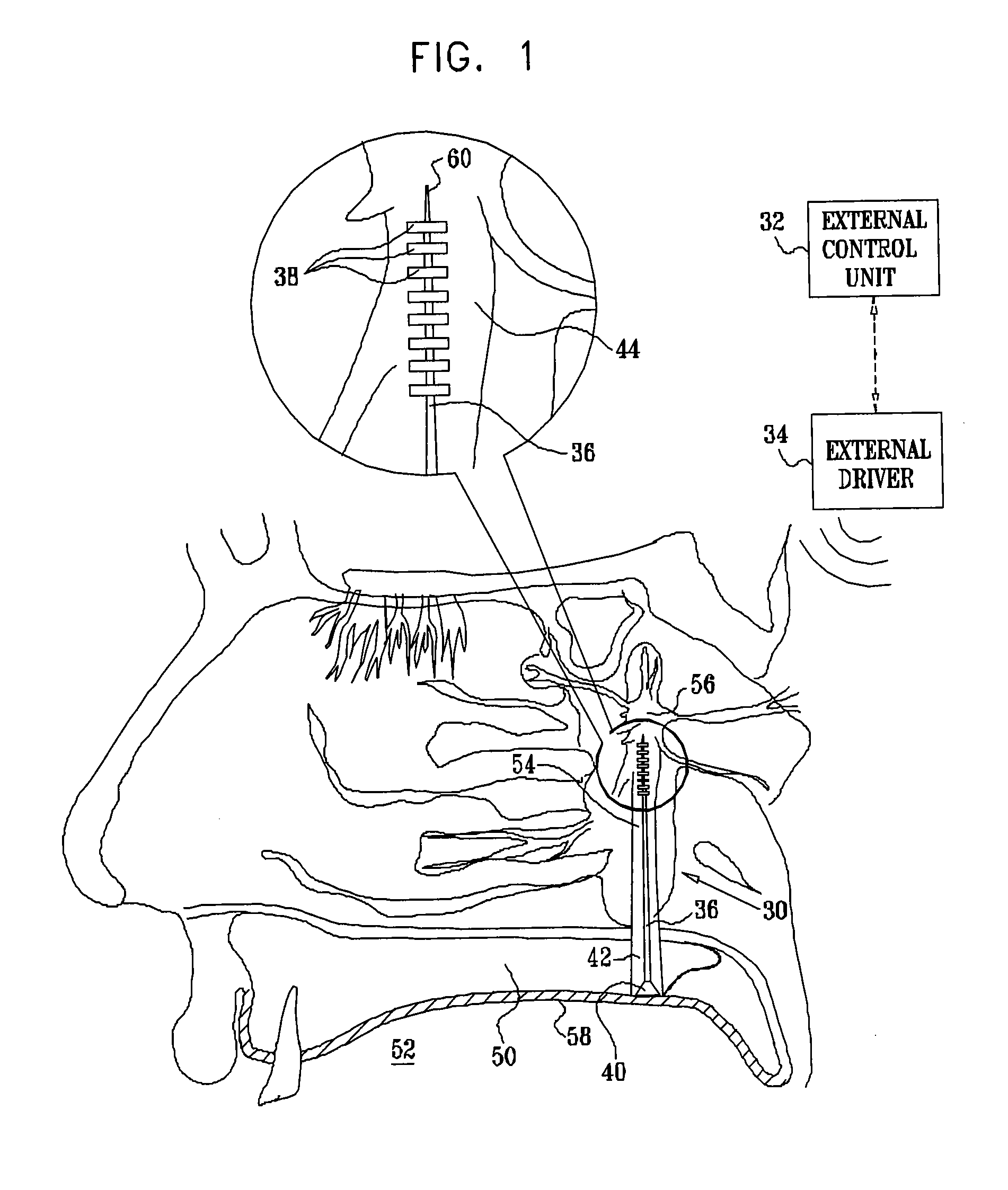

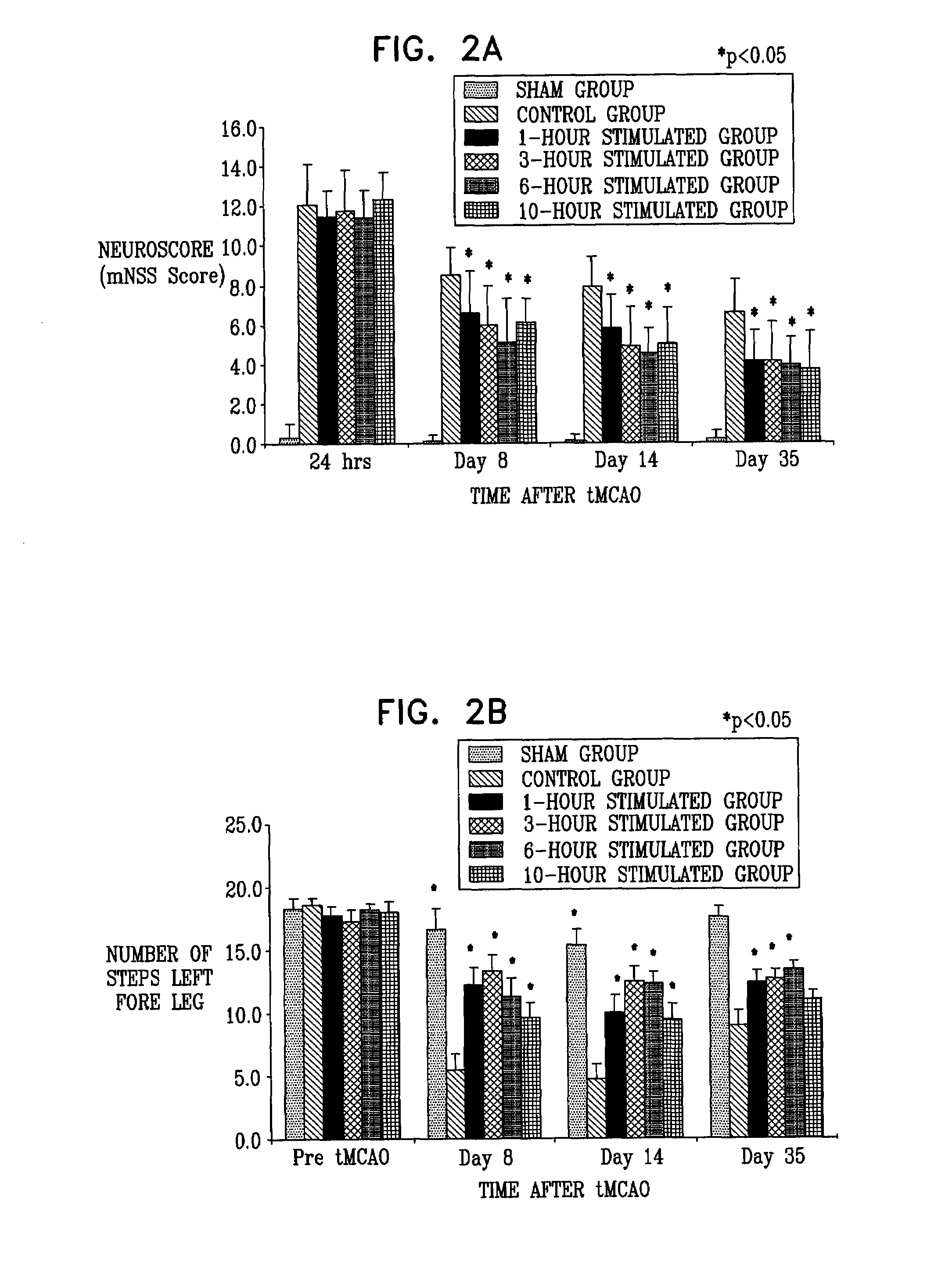

Spg stimulation for enhancing neurogenesis and brain metabolism

InactiveUS20090210026A1Promote recoveryIncrease blood perfusionElectrotherapyArtificial respirationDeep petrosal nerveNeurogenesis

A method is provided, including identifying an electrical stimulation protocol as being suitable for augmenting genesis of one or more cell populations in at least one brain region of the subject. The cell genesis is augmented by applying the identified stimulation protocol to an SPG, a greater palatine nerve, a branch of the greater palatine nerve, a lesser palatine nerve, a sphenopalatine nerve, a communicating branch between a maxillary nerve and an SPG, an otic ganglion, an afferent fiber going into the otic ganglion, an efferent fiber going out of the otic ganglion, an infraorbital nerve, a vidian nerve, a greater superficial petrosal nerve, a lesser deep petrosal nerve, a maxillary nerve, a branch of the maxillary nerve, a nasopalatine nerve, a peripheral site that provides direct or indirect afferent innervation to the SPG, or a peripheral site that is directly or indirectly efferently innervated by the SPG.

Owner:BRAINSGATE LTD

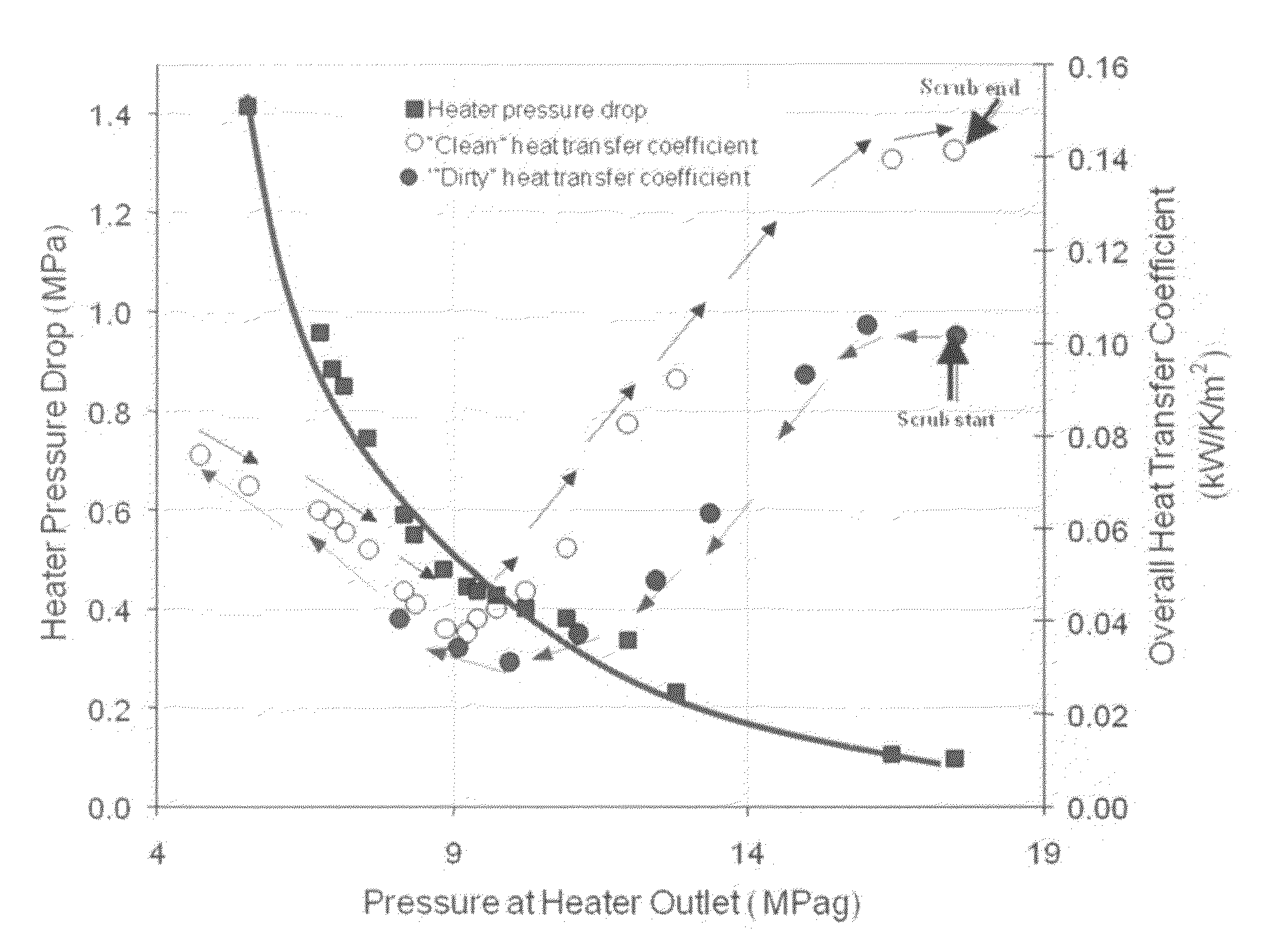

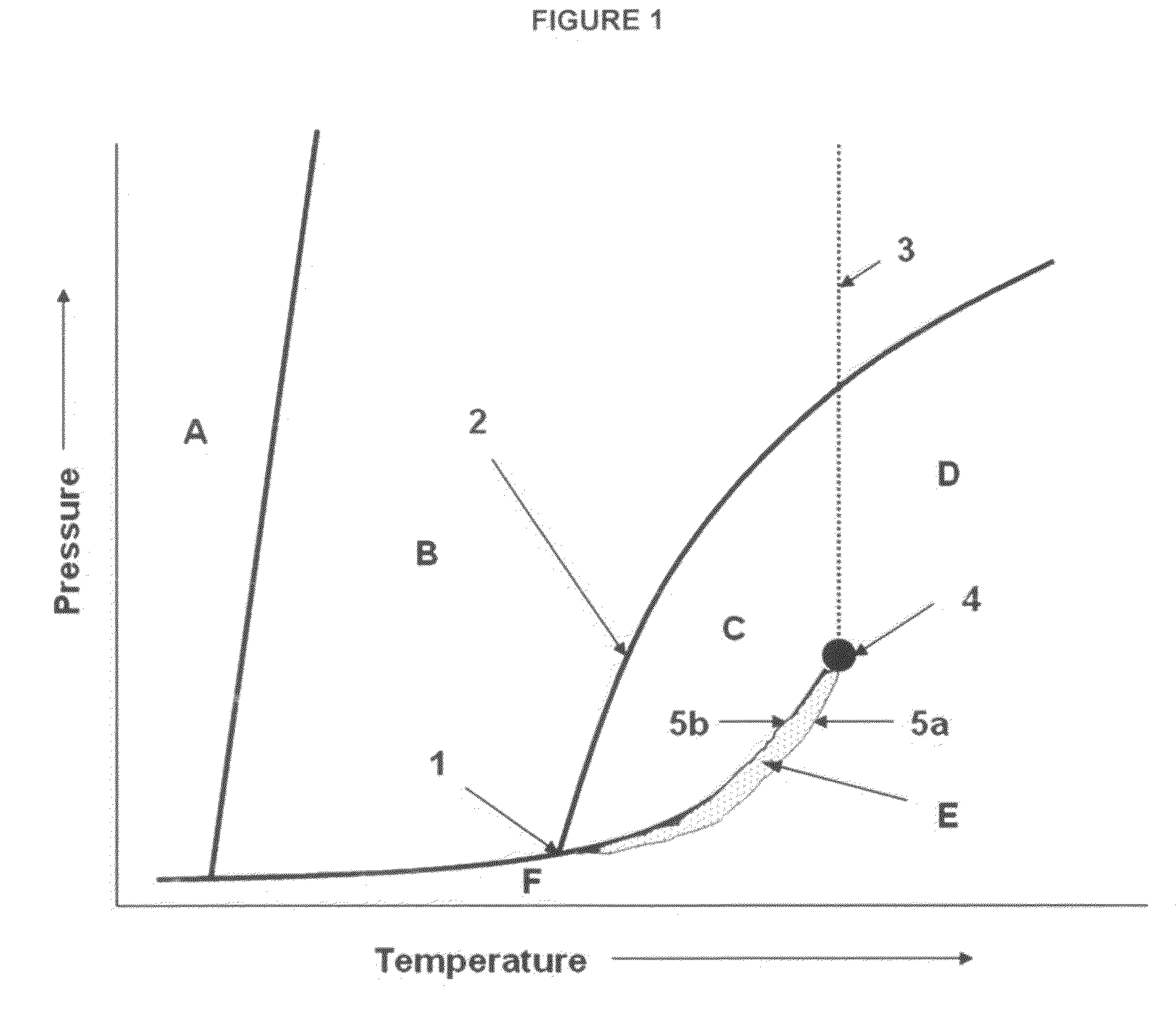

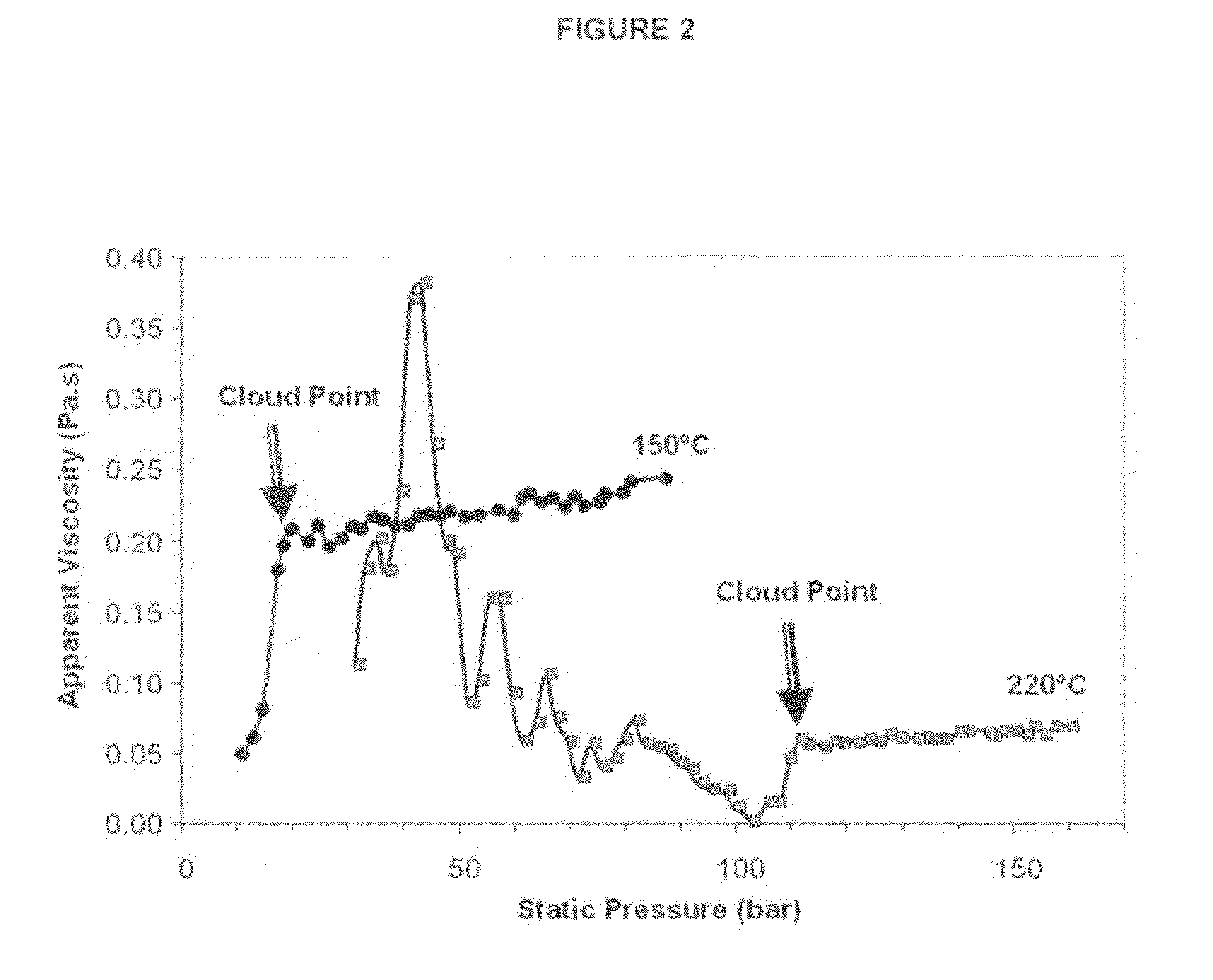

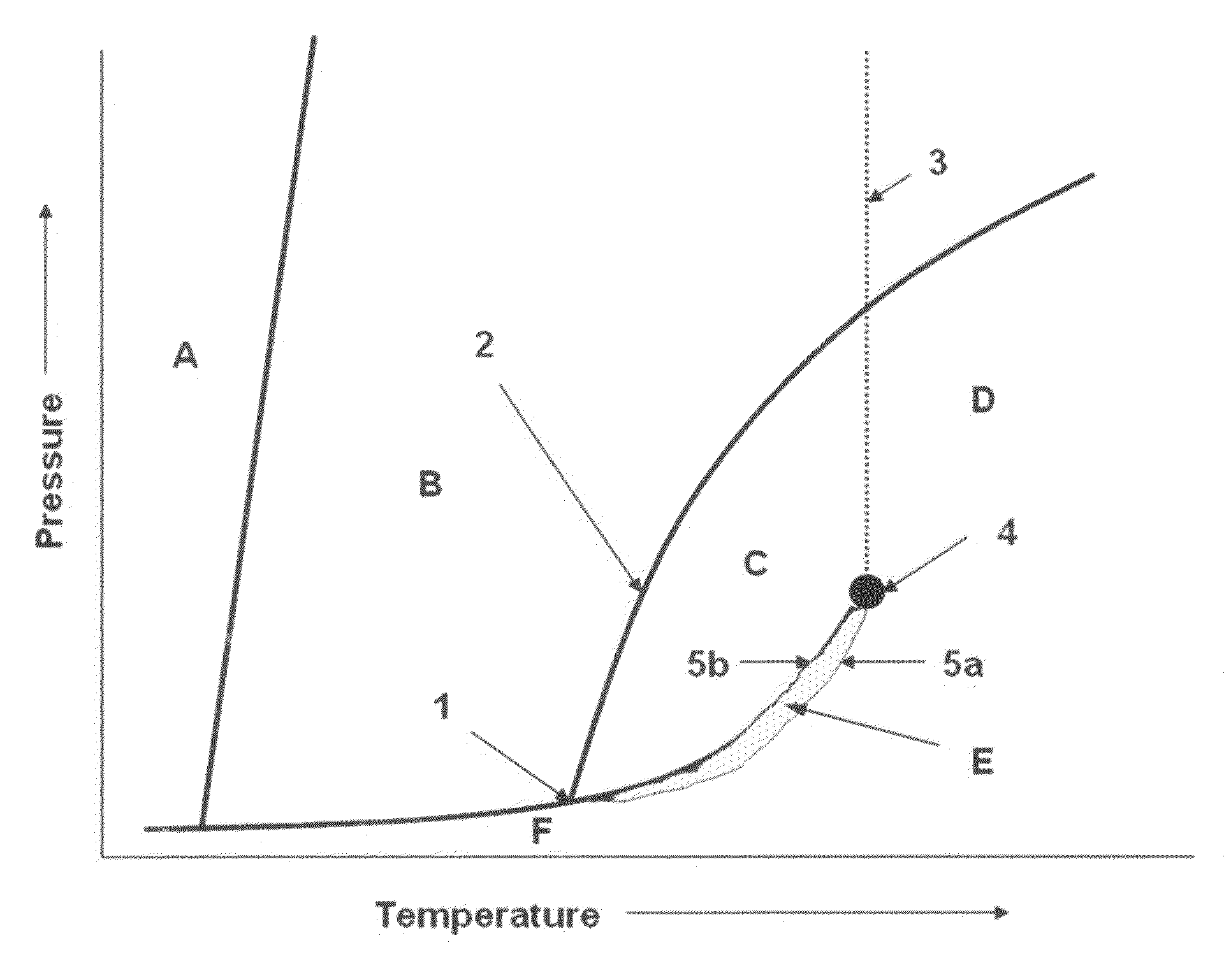

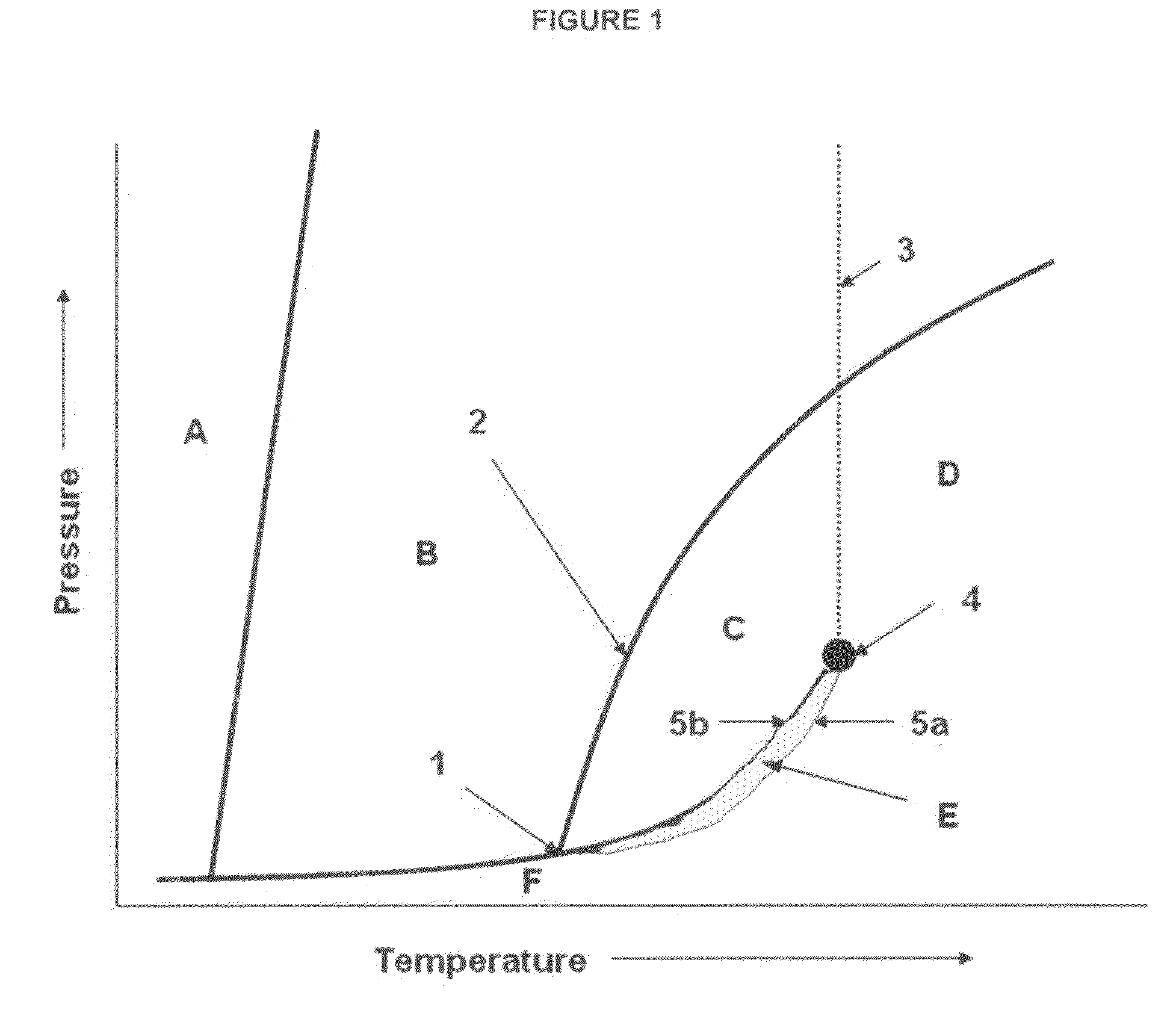

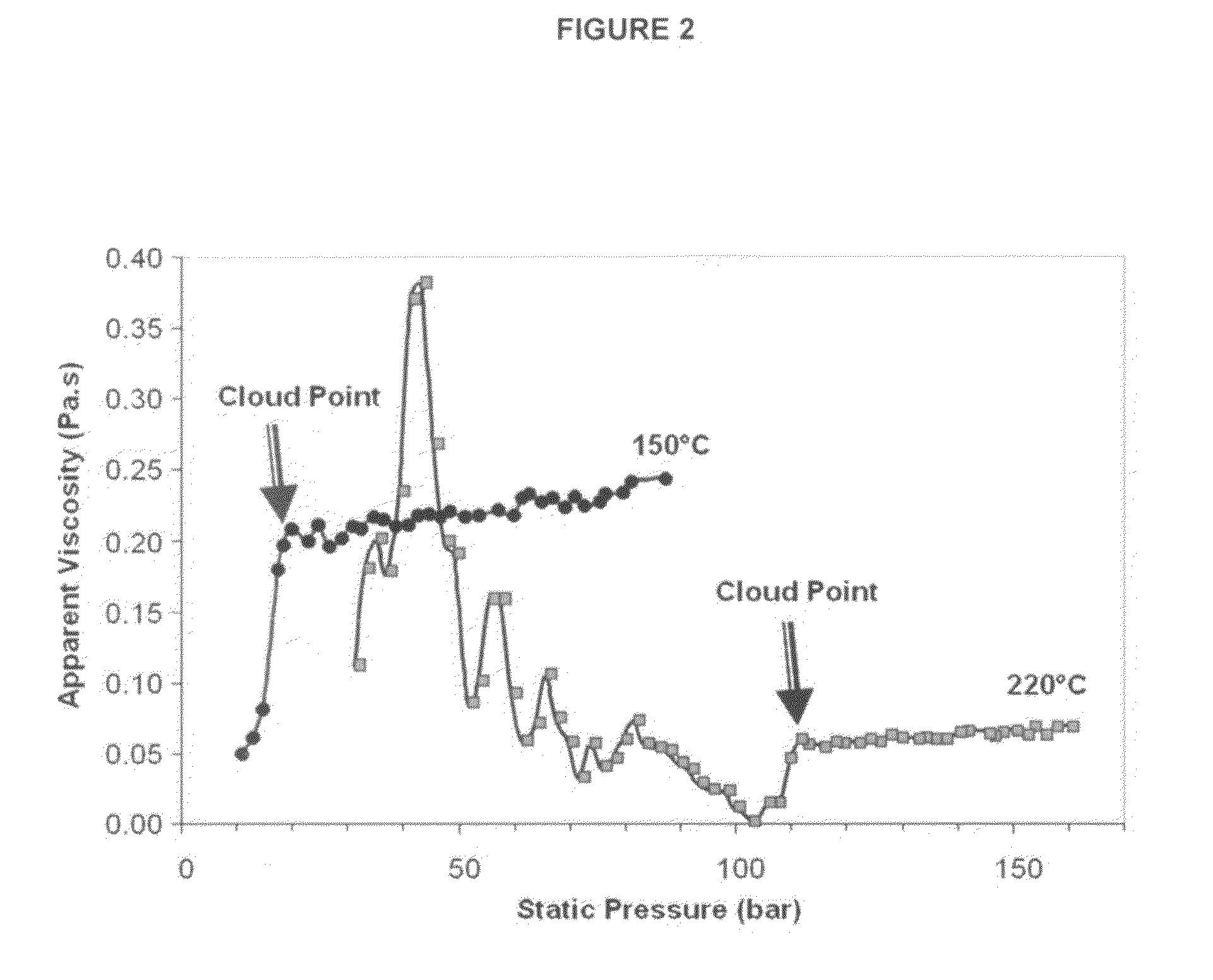

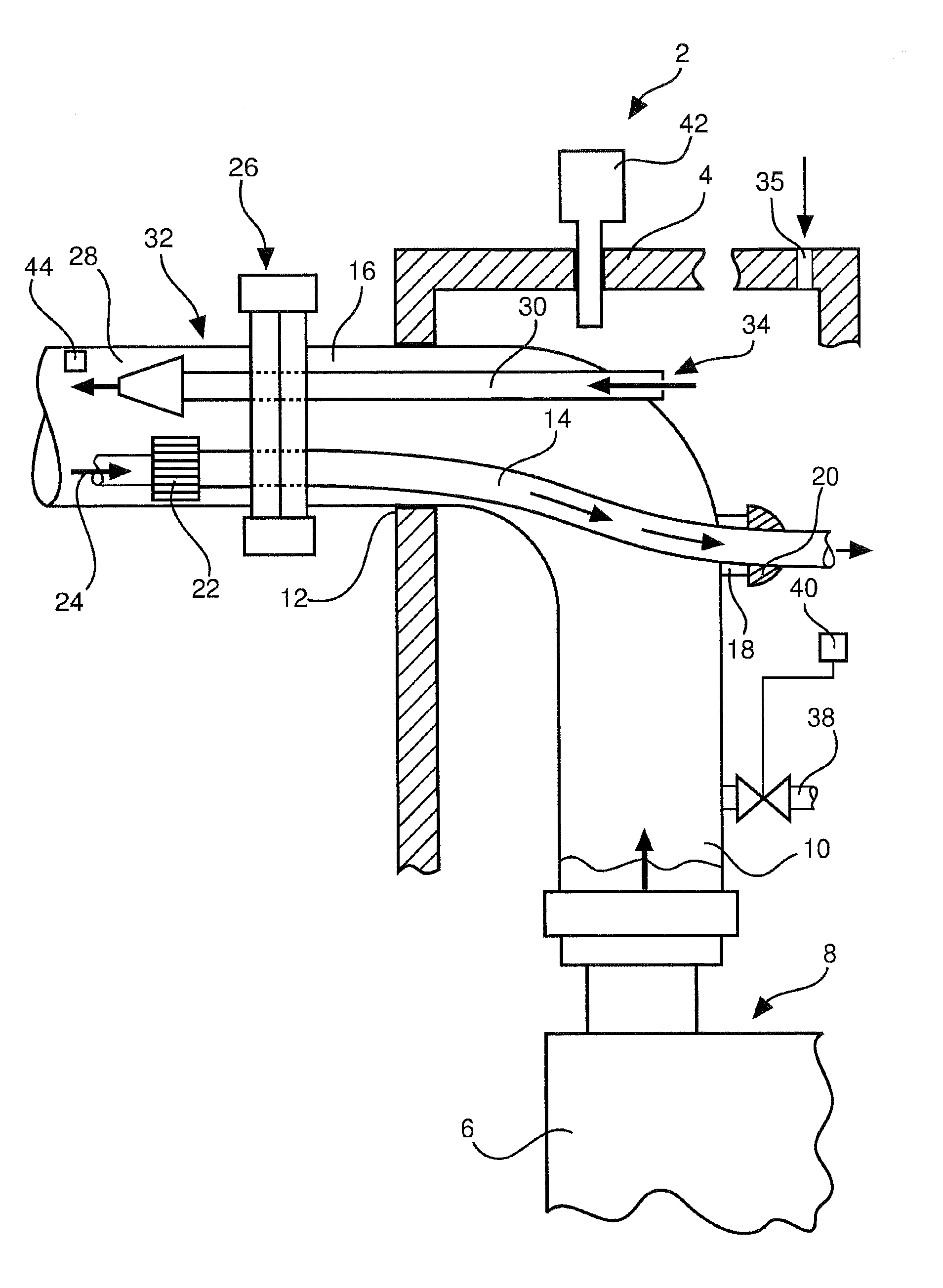

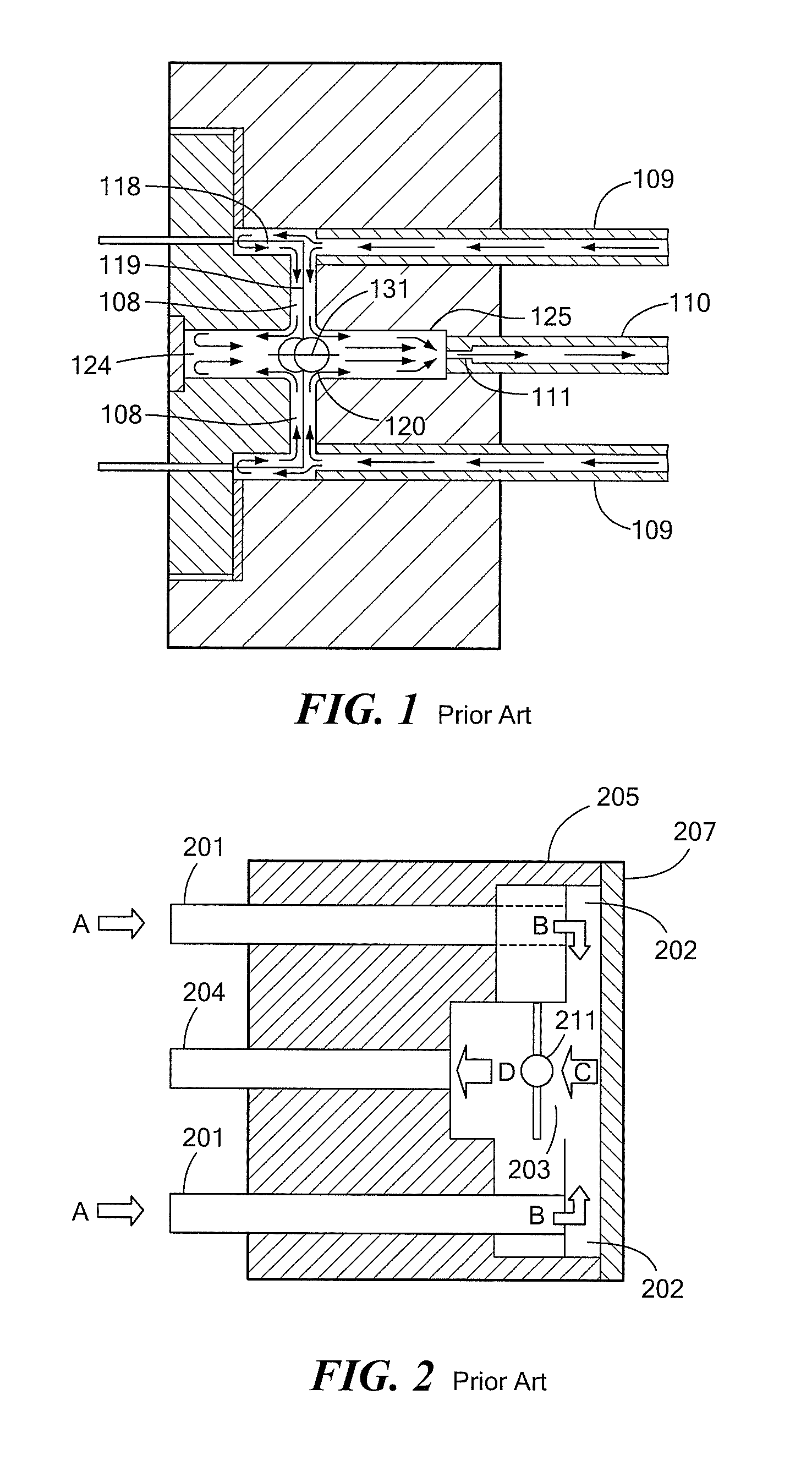

High temperature process for solution polymerization

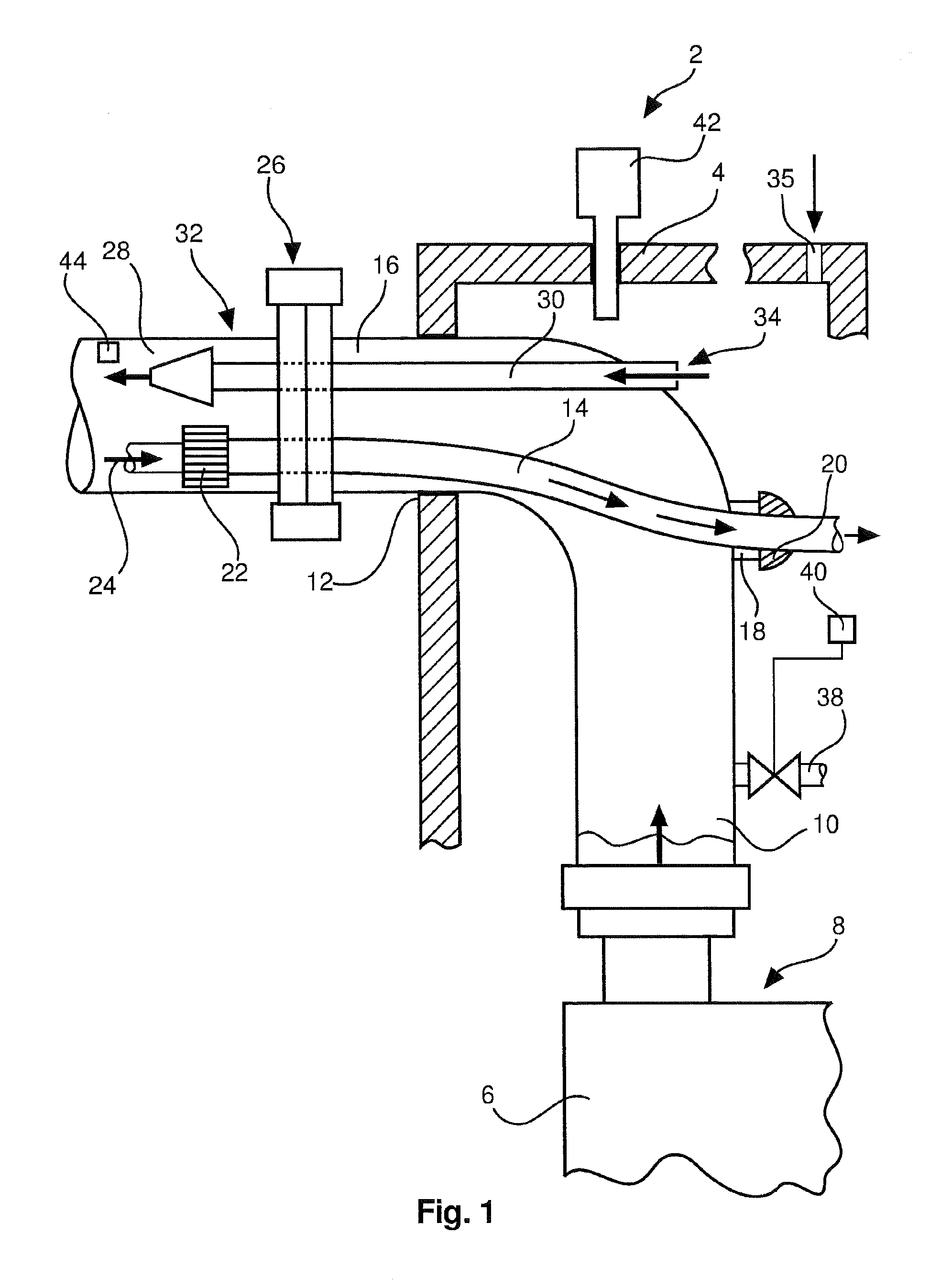

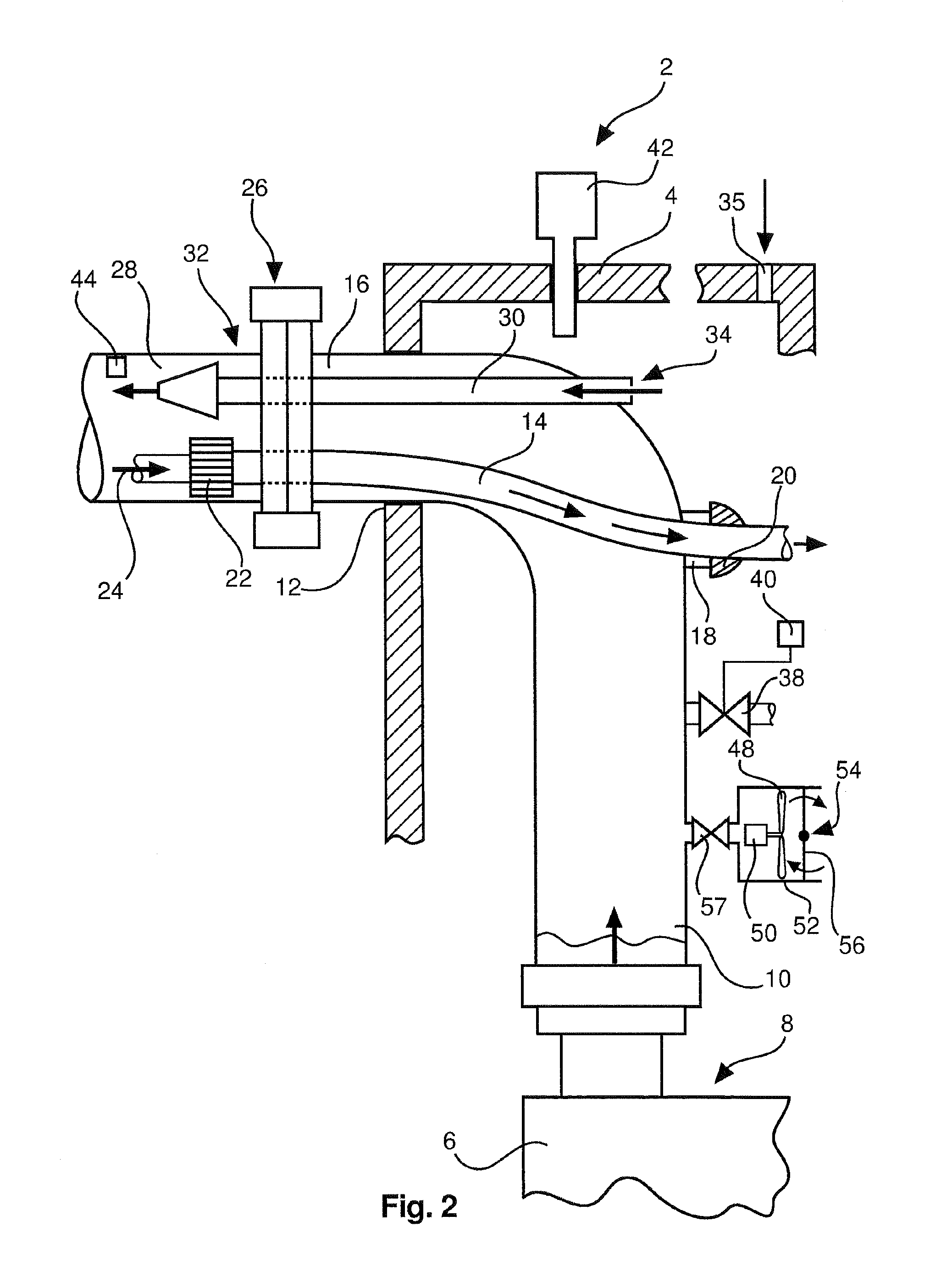

ActiveUS7650930B2Avoid accumulationIncrease forceHollow article cleaningVapor condensationPlate heat exchangerEmulsion polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

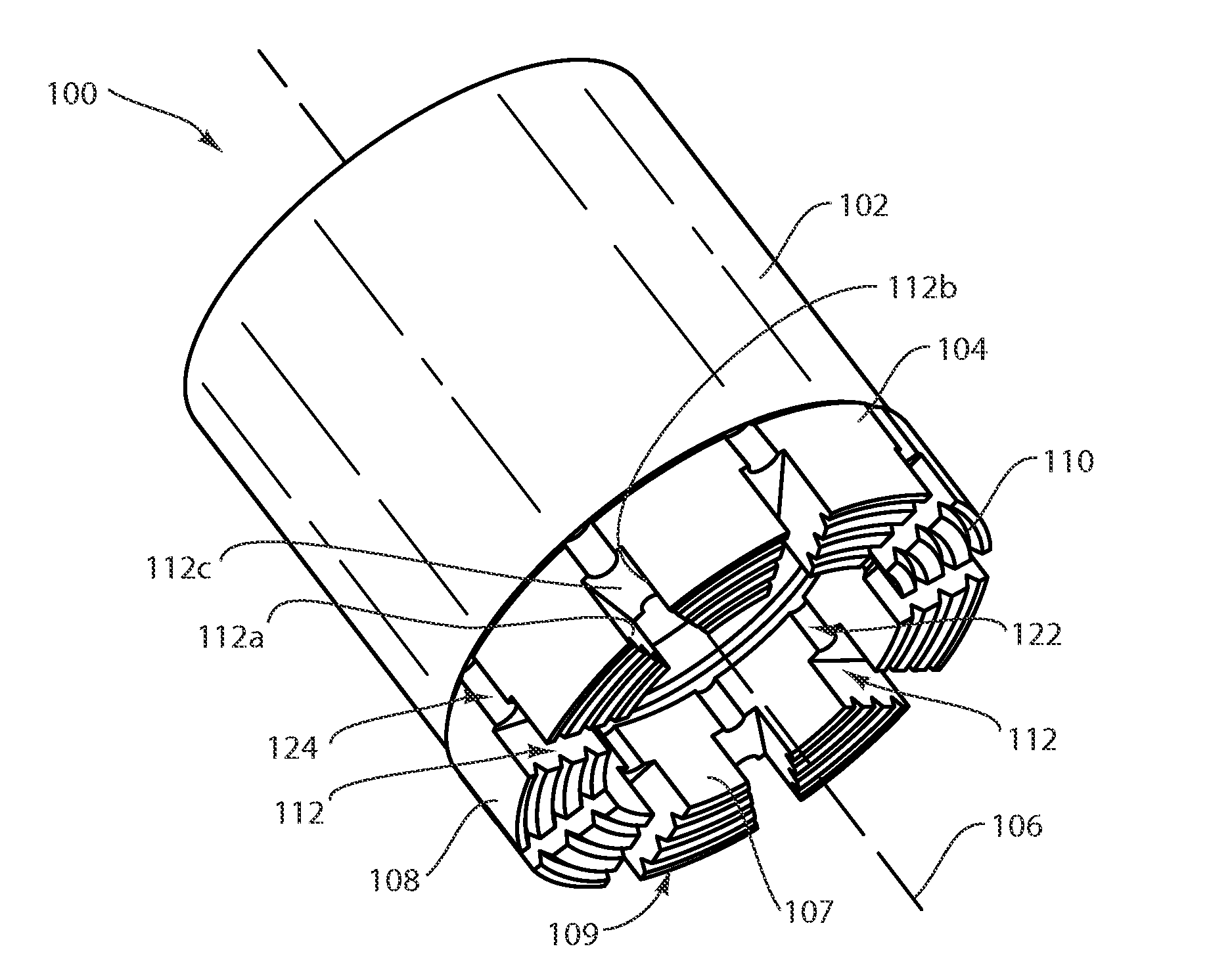

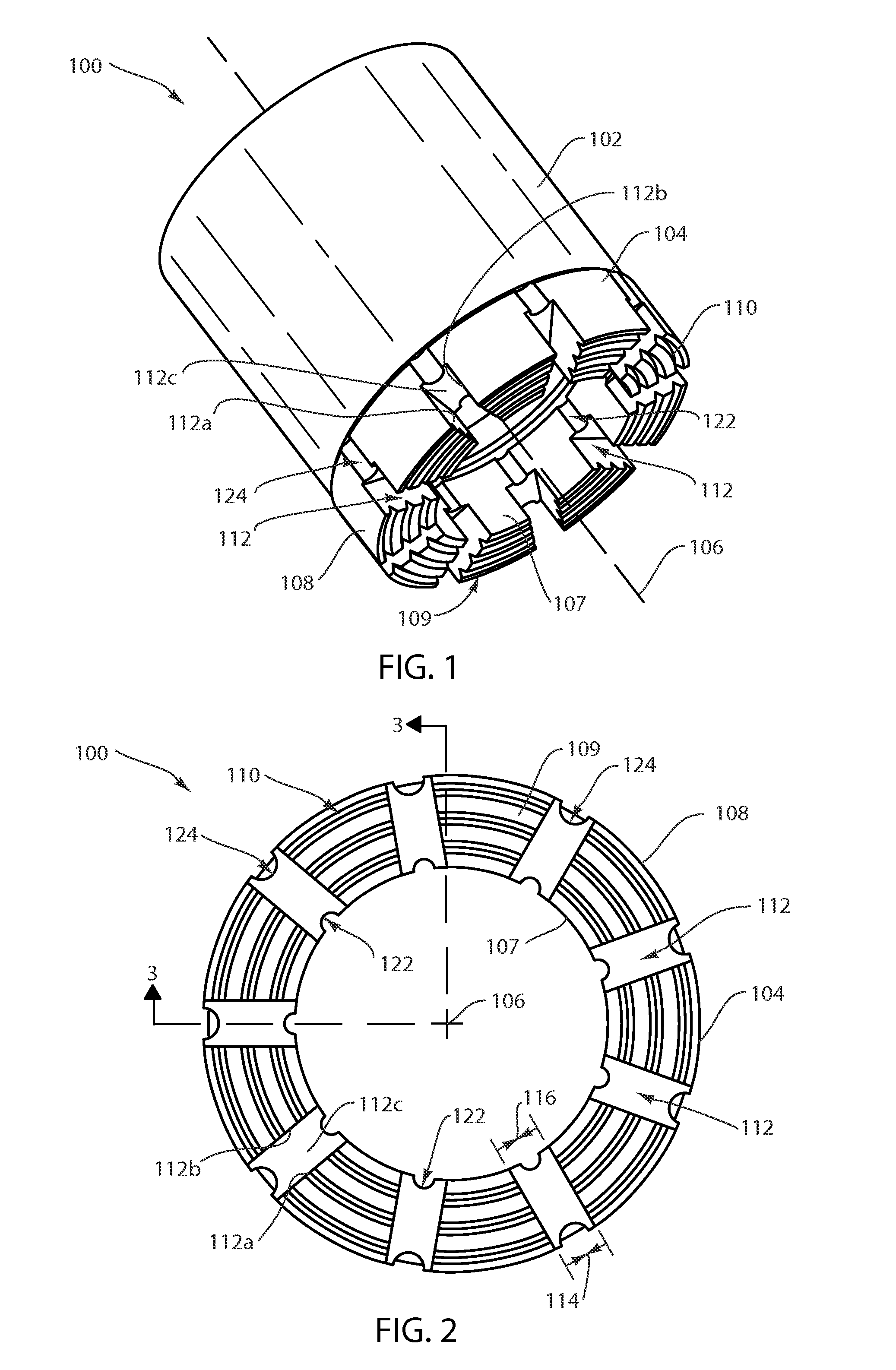

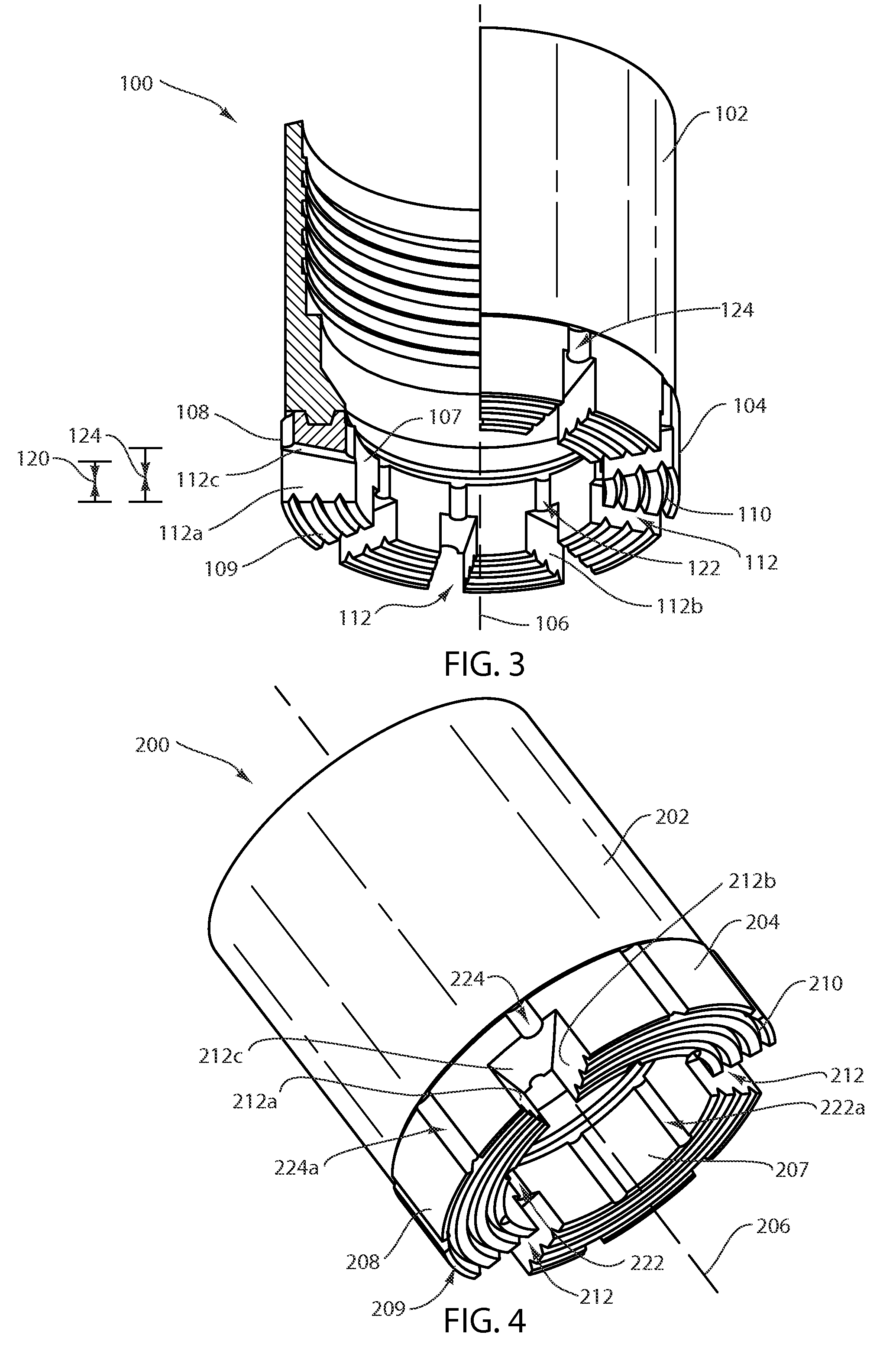

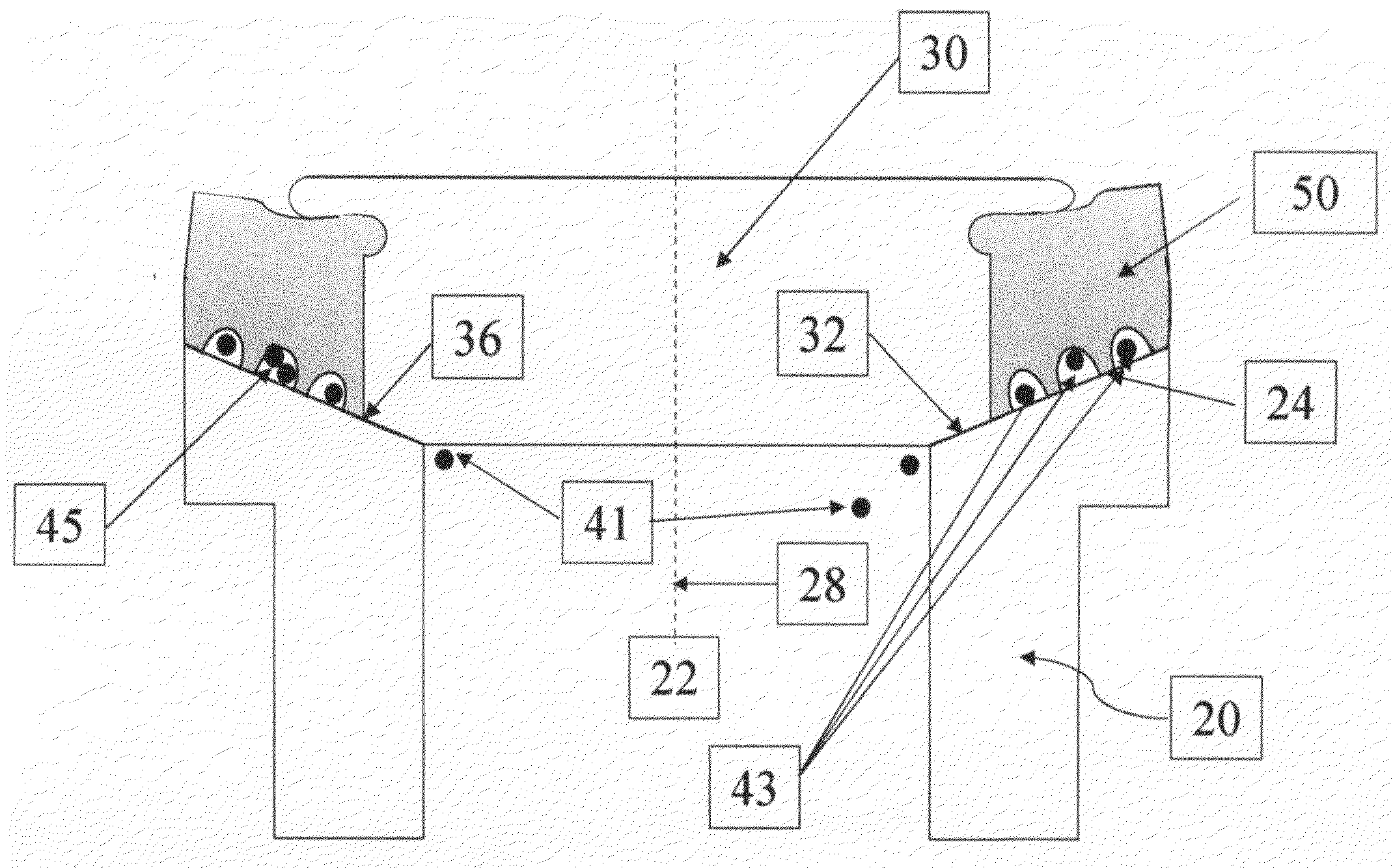

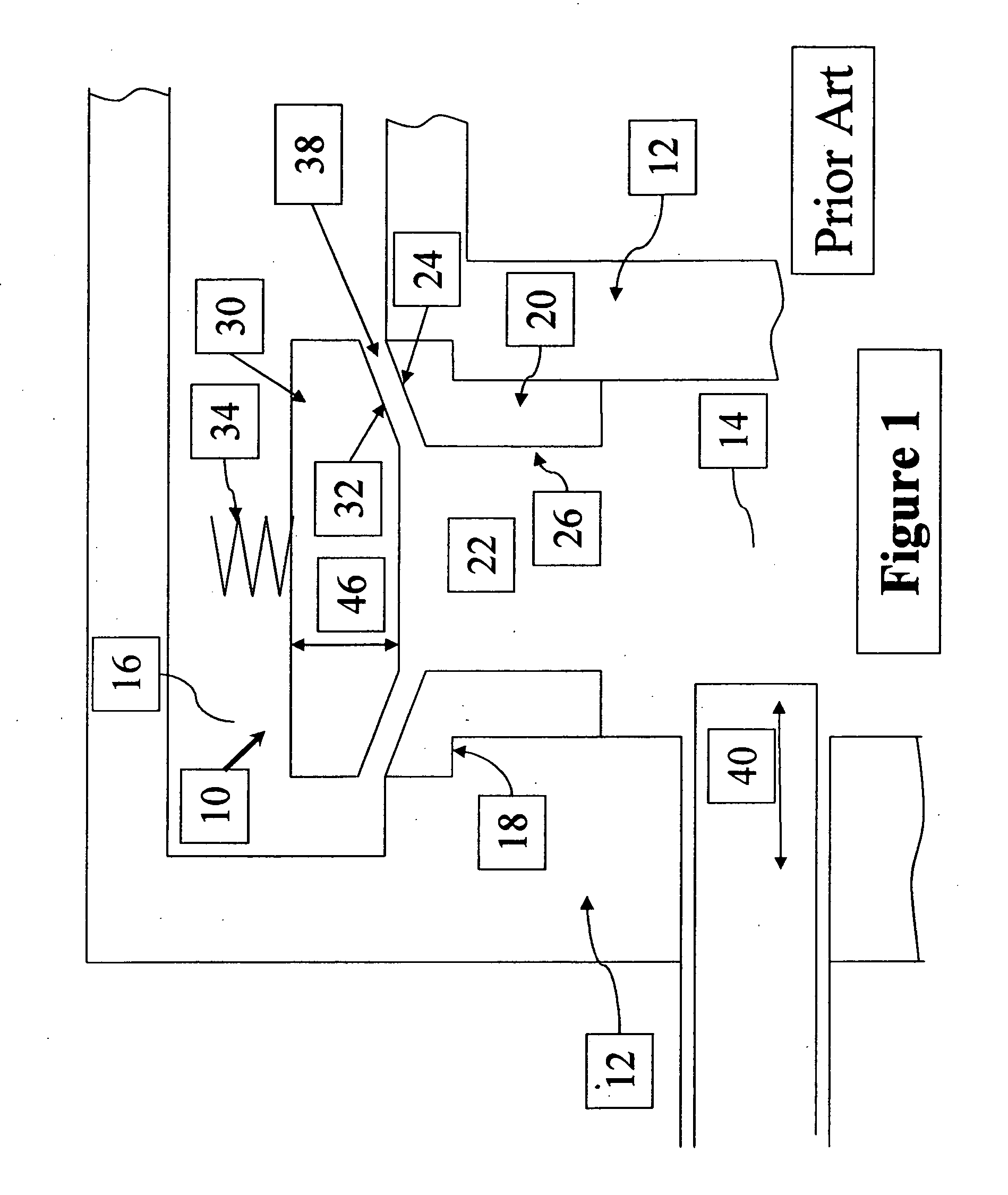

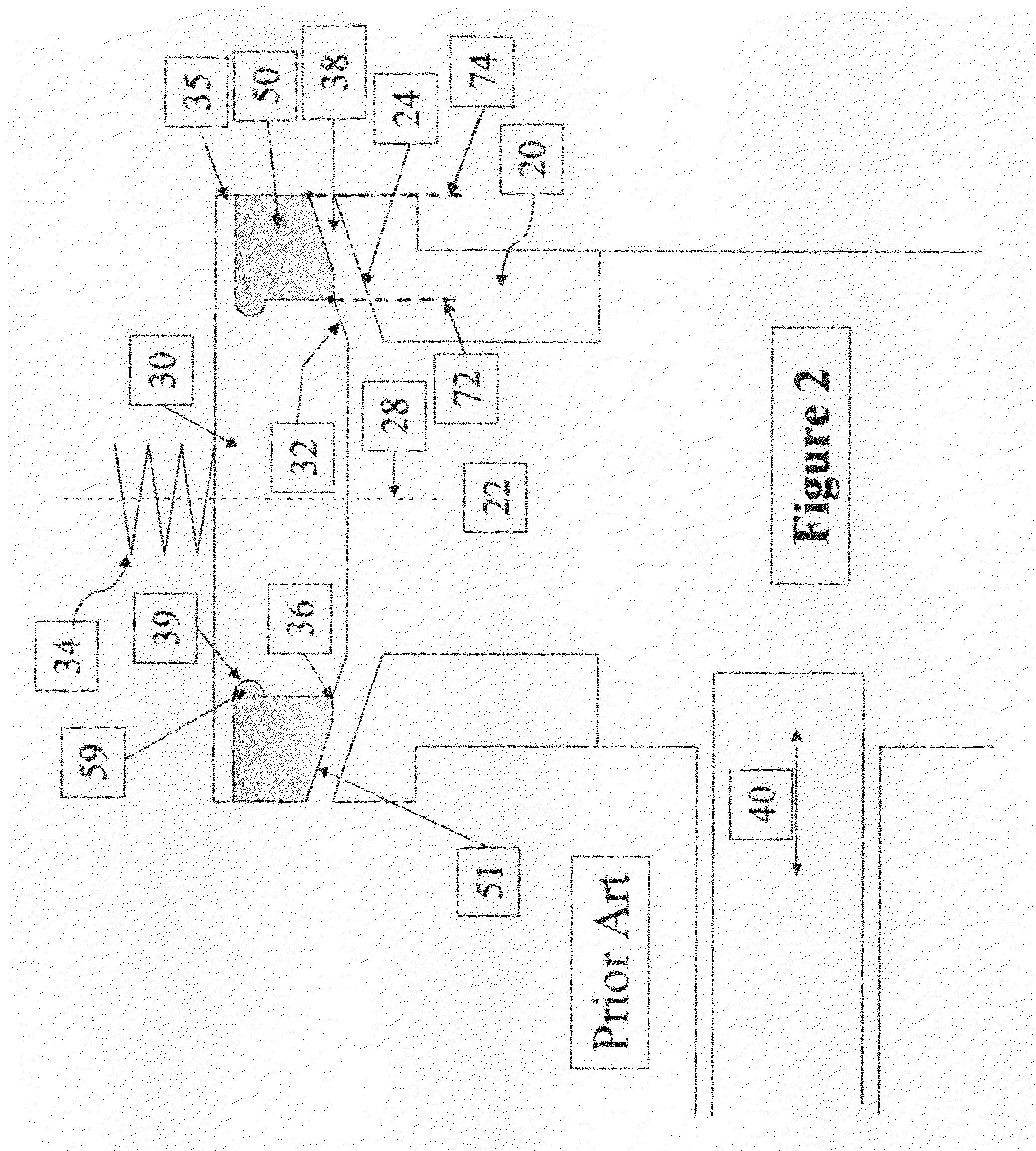

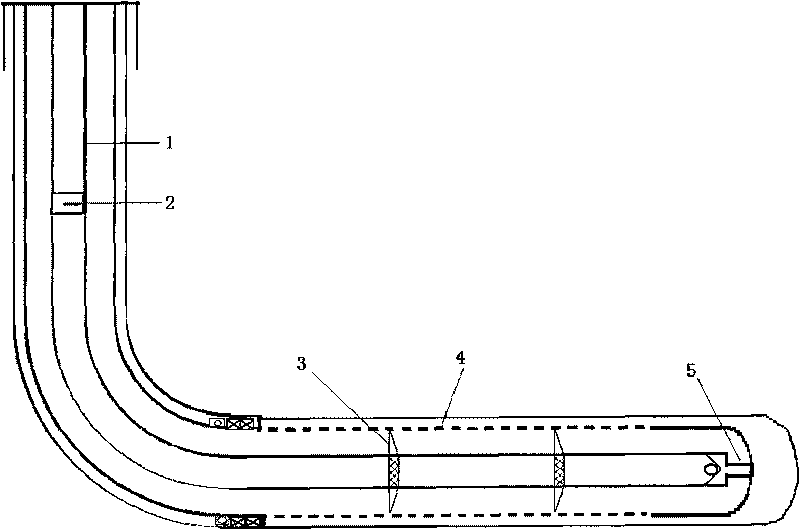

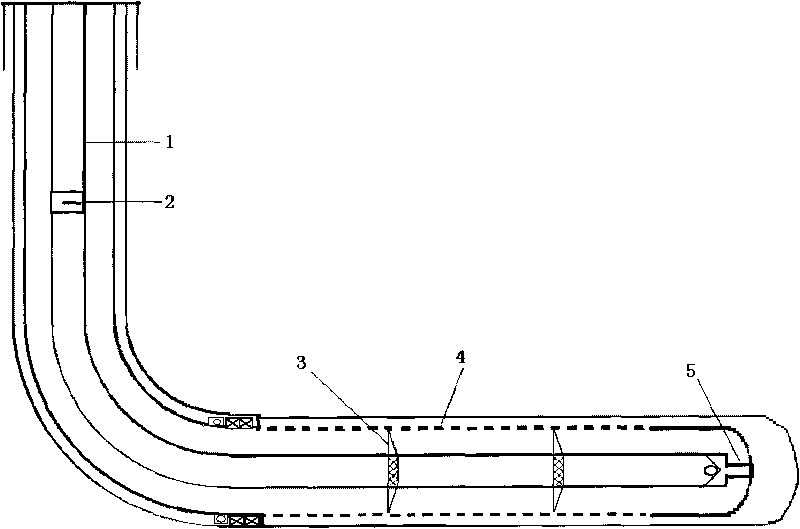

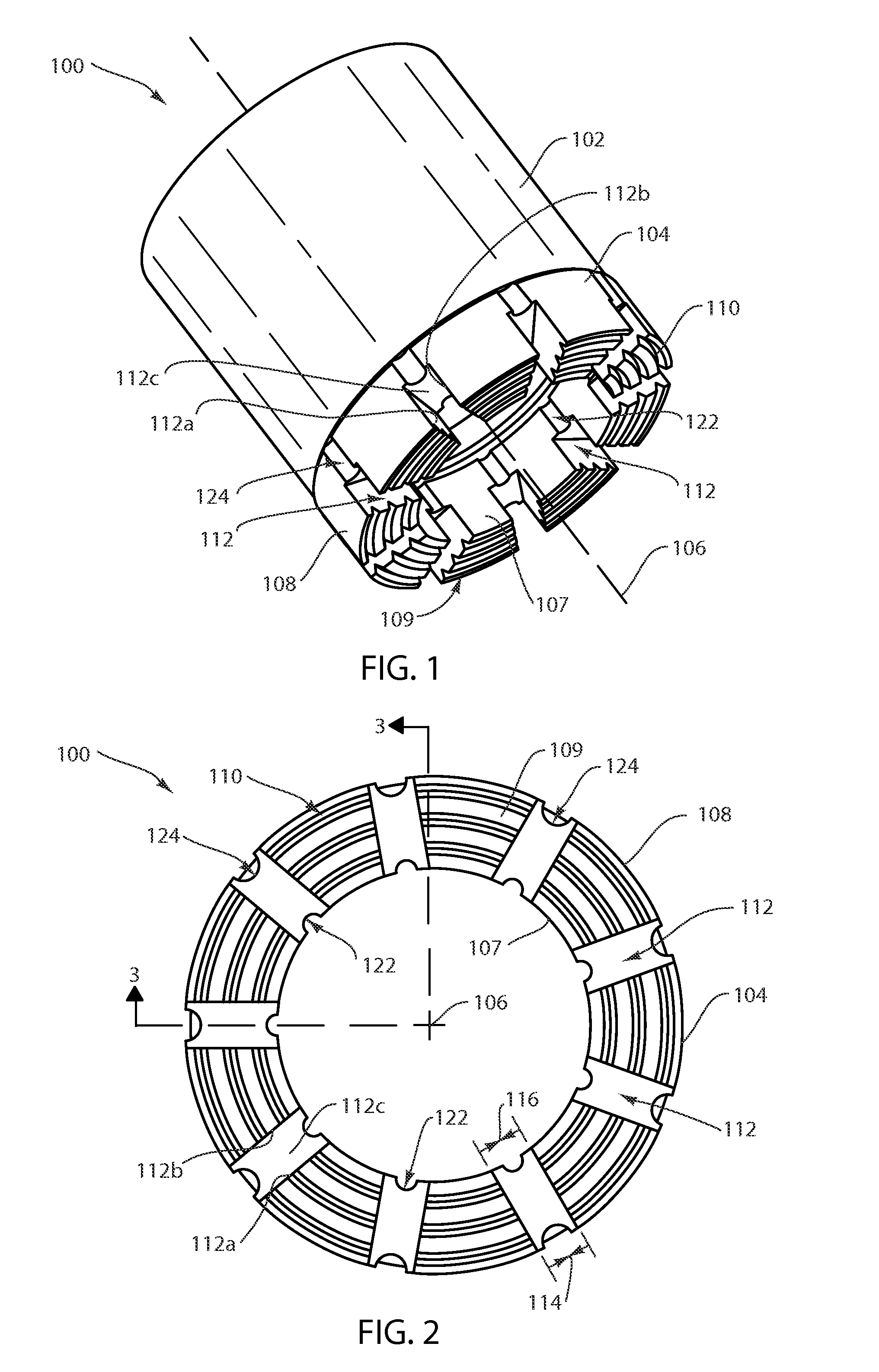

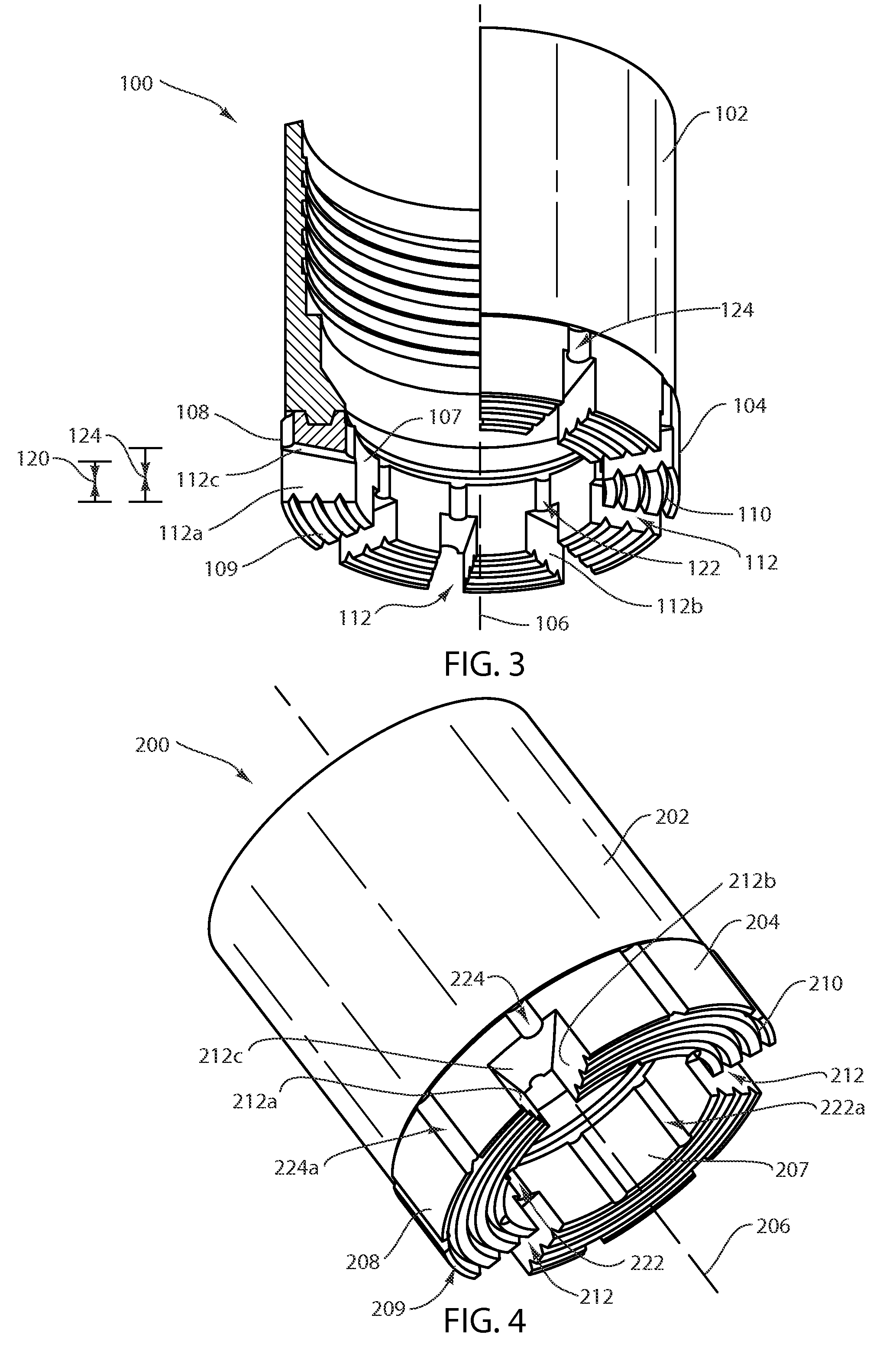

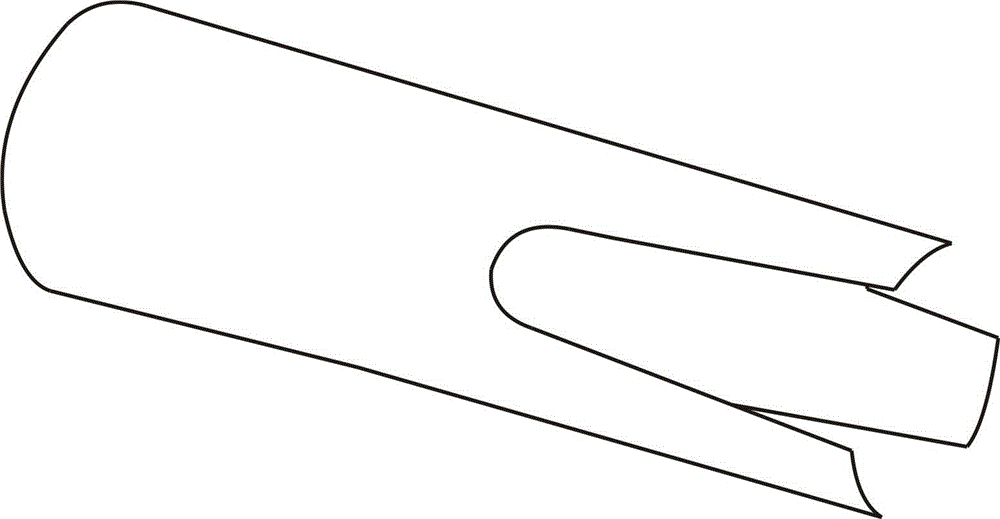

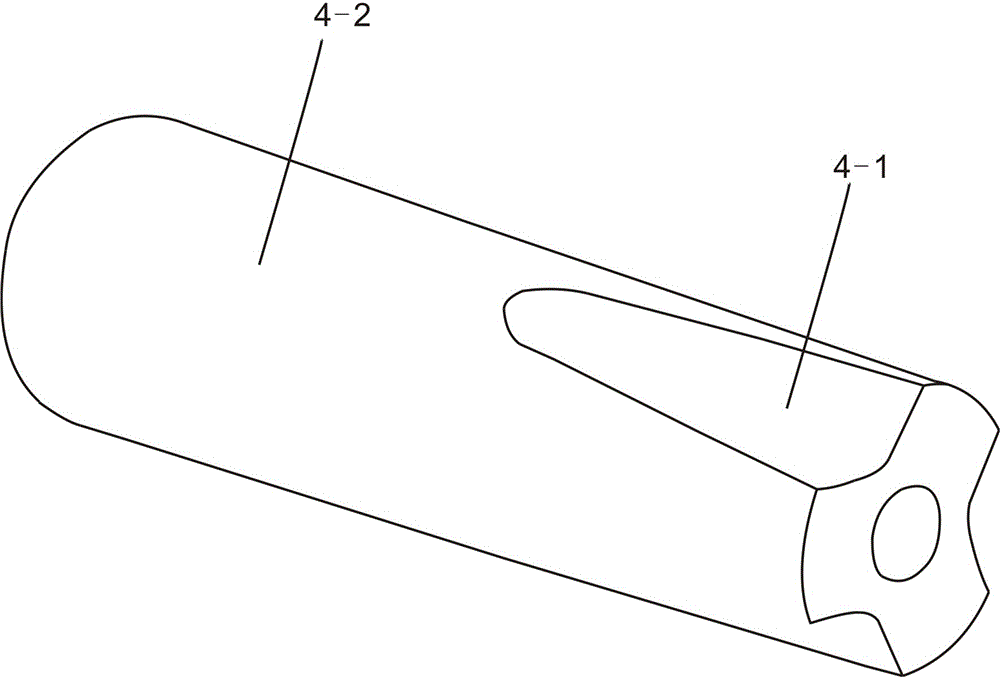

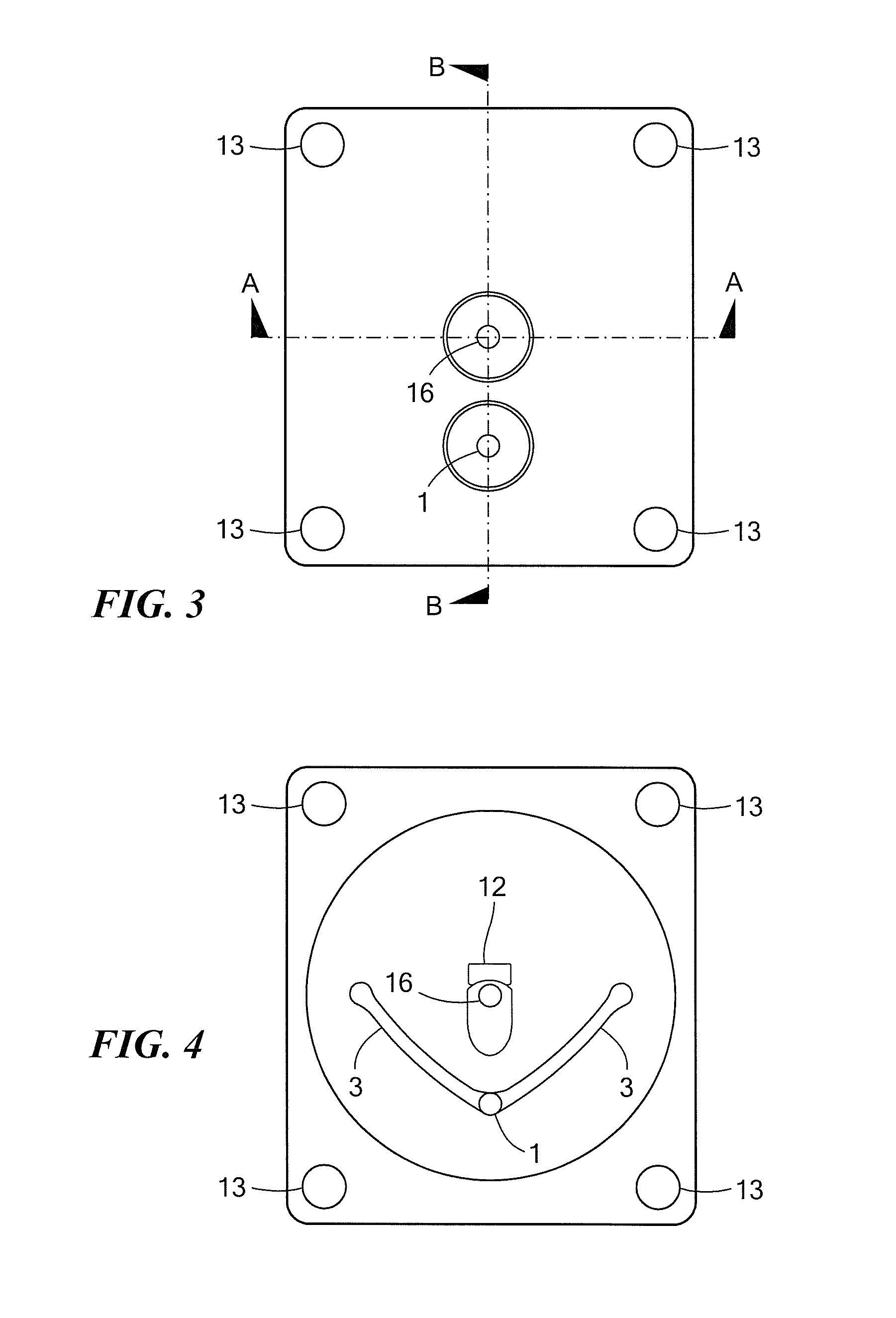

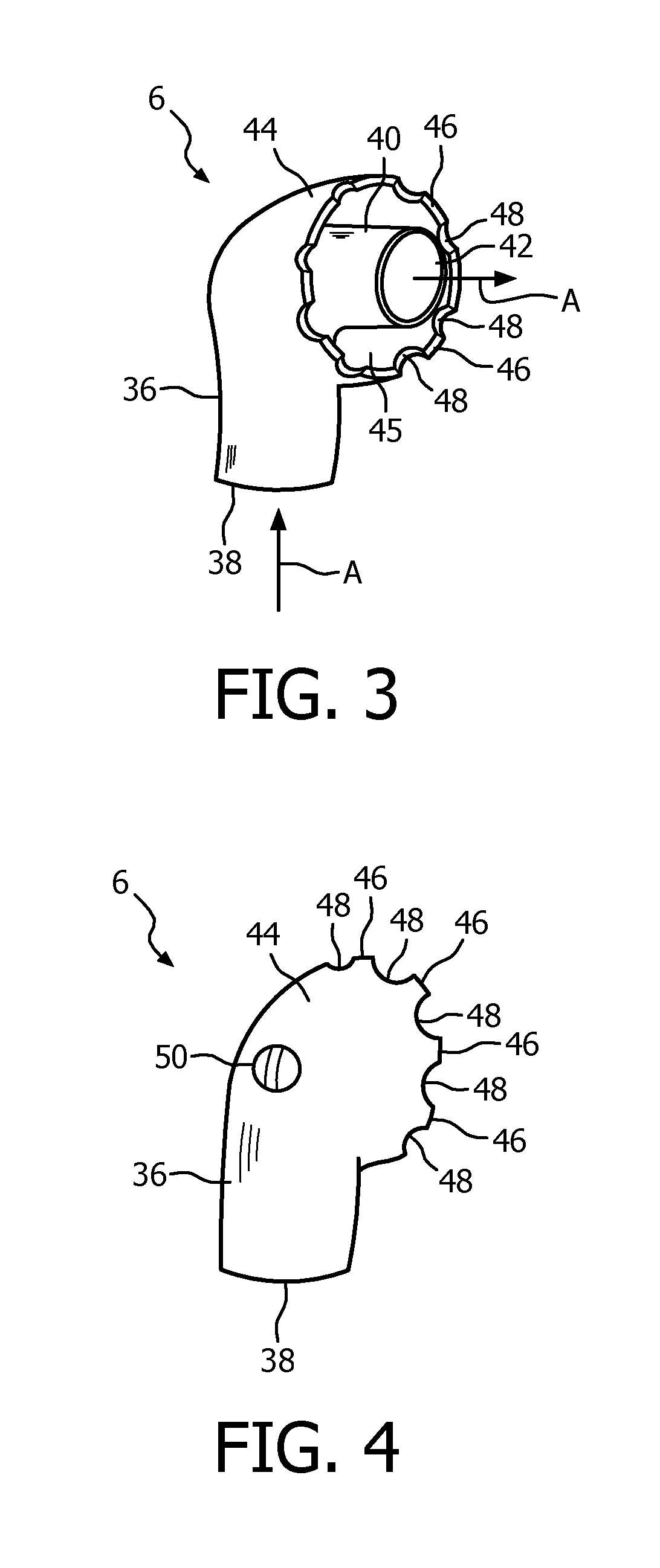

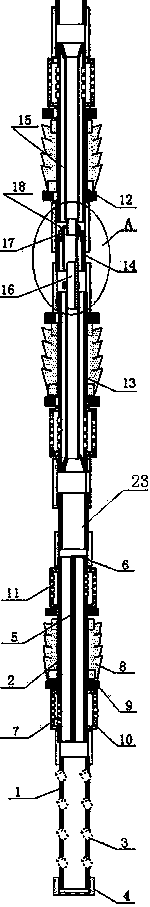

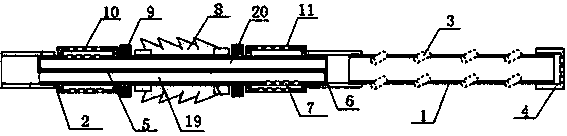

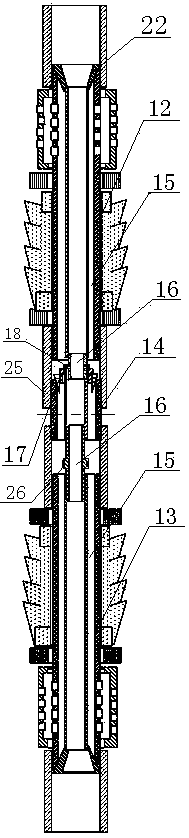

Drill bits with axially-tapered waterways

ActiveUS20100089660A1High trafficEnhanced flushingDrill bitsMetal-working drilling toolsWell drillingEngineering

Implementations of the present invention include drilling tools having axially-tapered waterways that can increase flushing and bit life, while also decreasing clogging. According to some implementations of the present invention, the waterways can be radially tapered in addition to being axially tapered. The axially-tapered waterways can include notches extending into the cutting face of the drilling tools and / or slots enclosed within the crown of the drilling tools. Implementations of the present invention also include drilling systems including drilling tools having axially-tapered waterways, and methods of forming drilling tools having axially-tapered waterways.

Owner:LONGYEAR TM

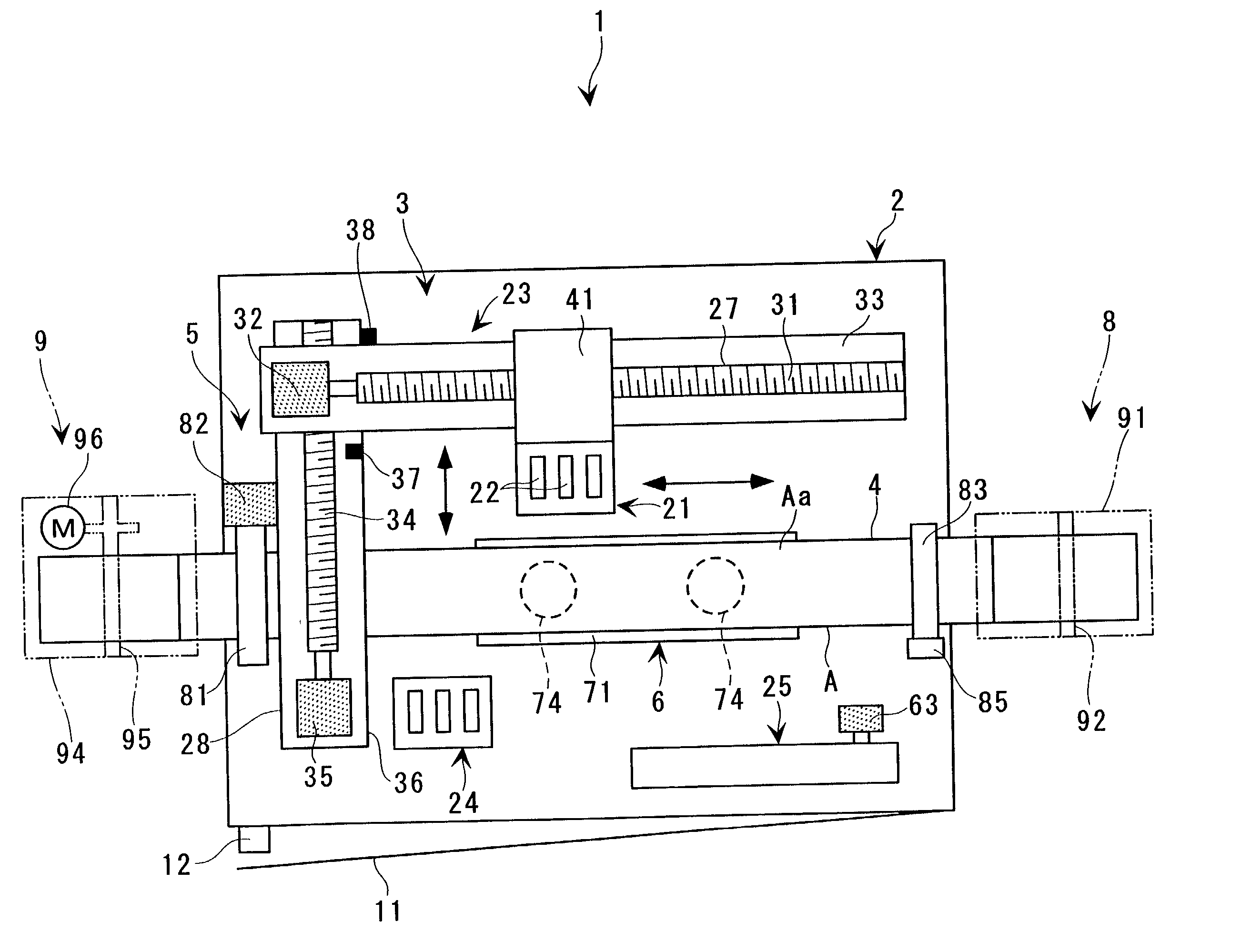

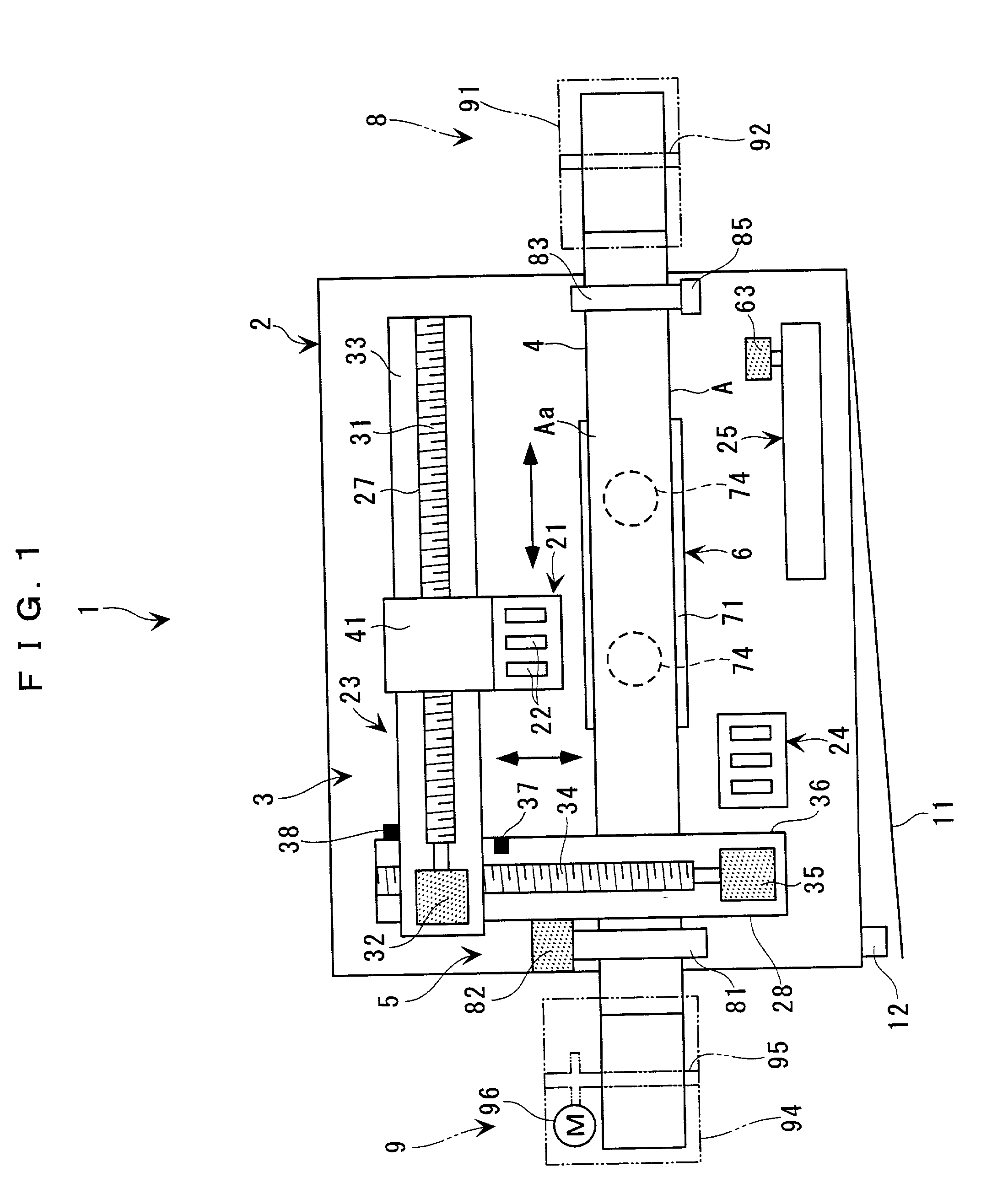

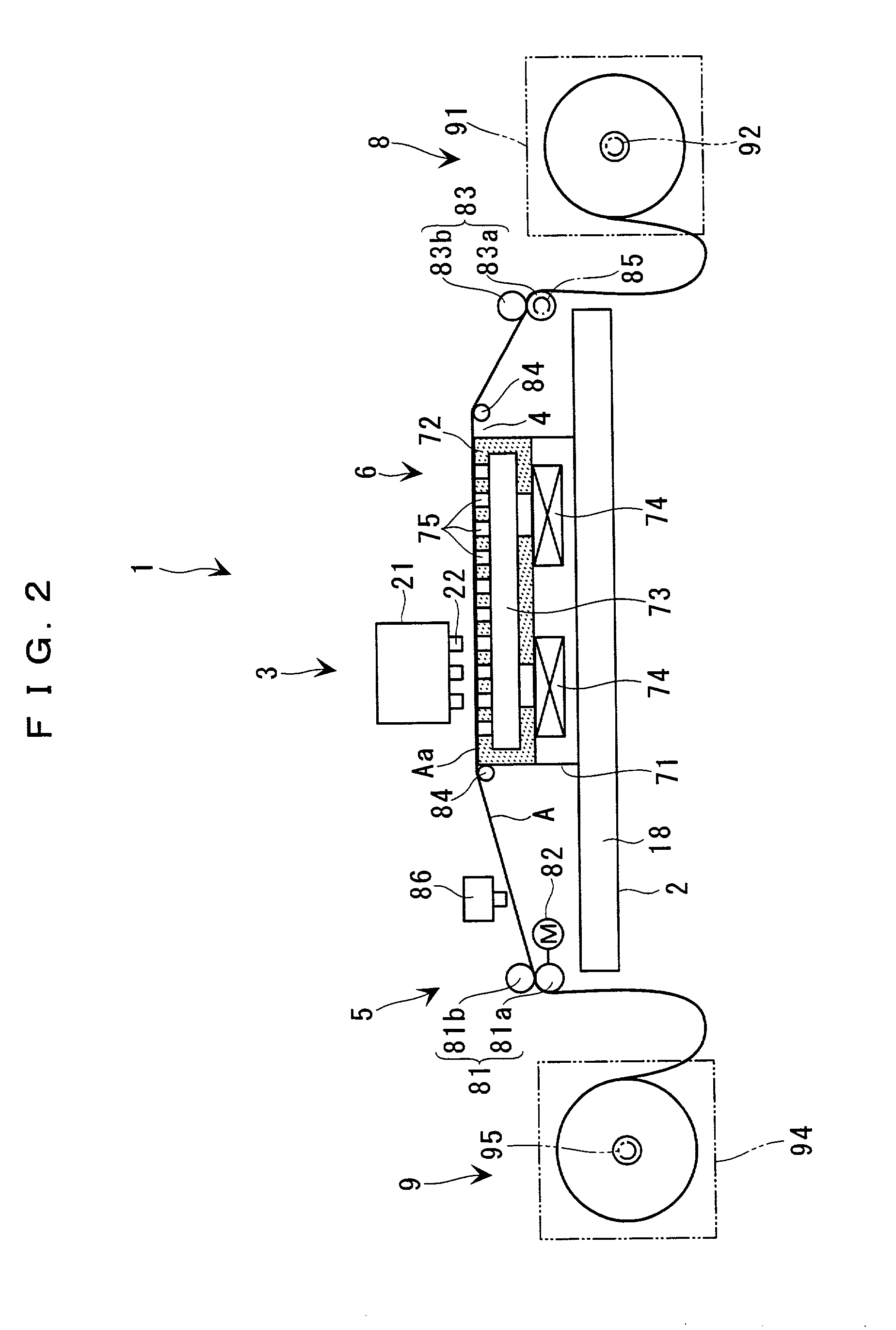

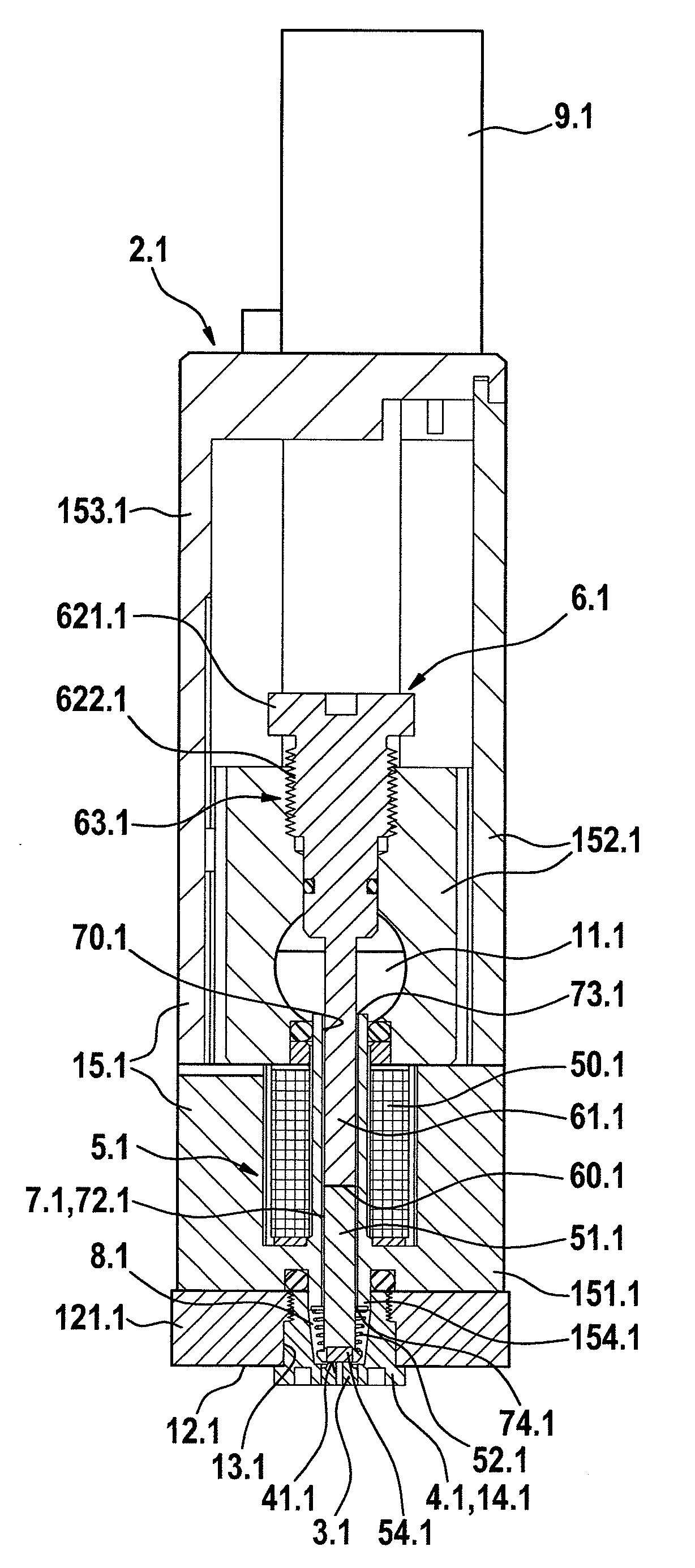

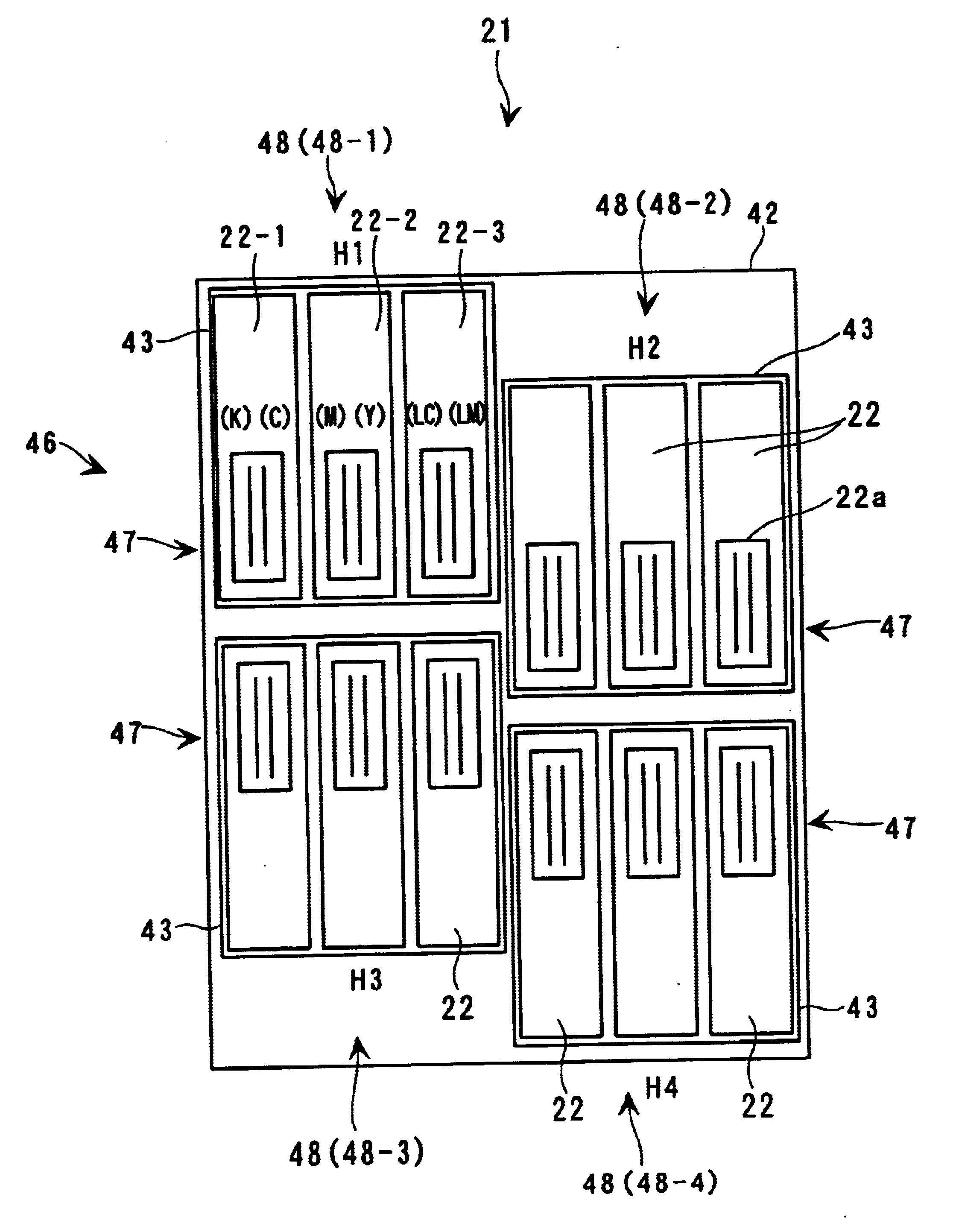

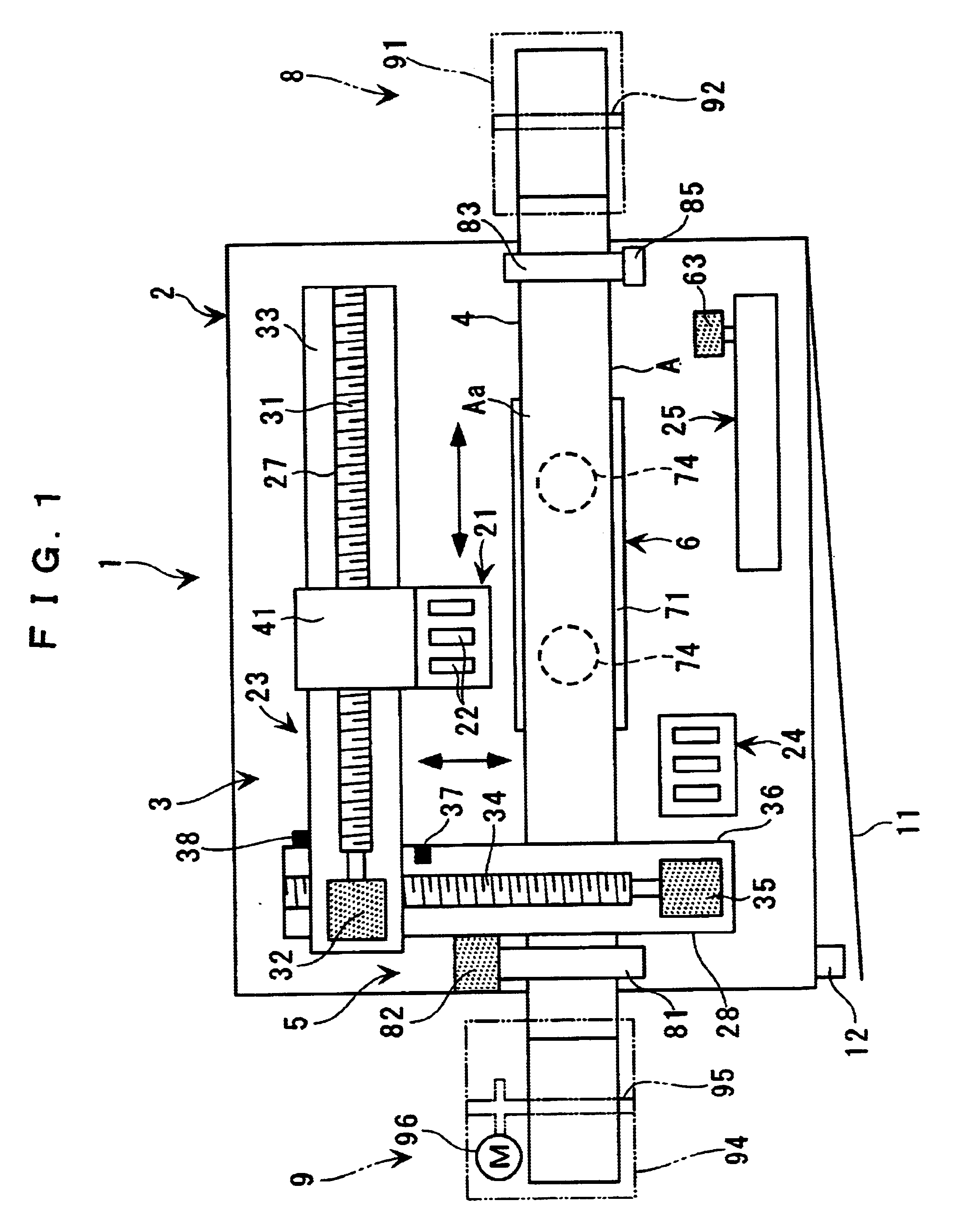

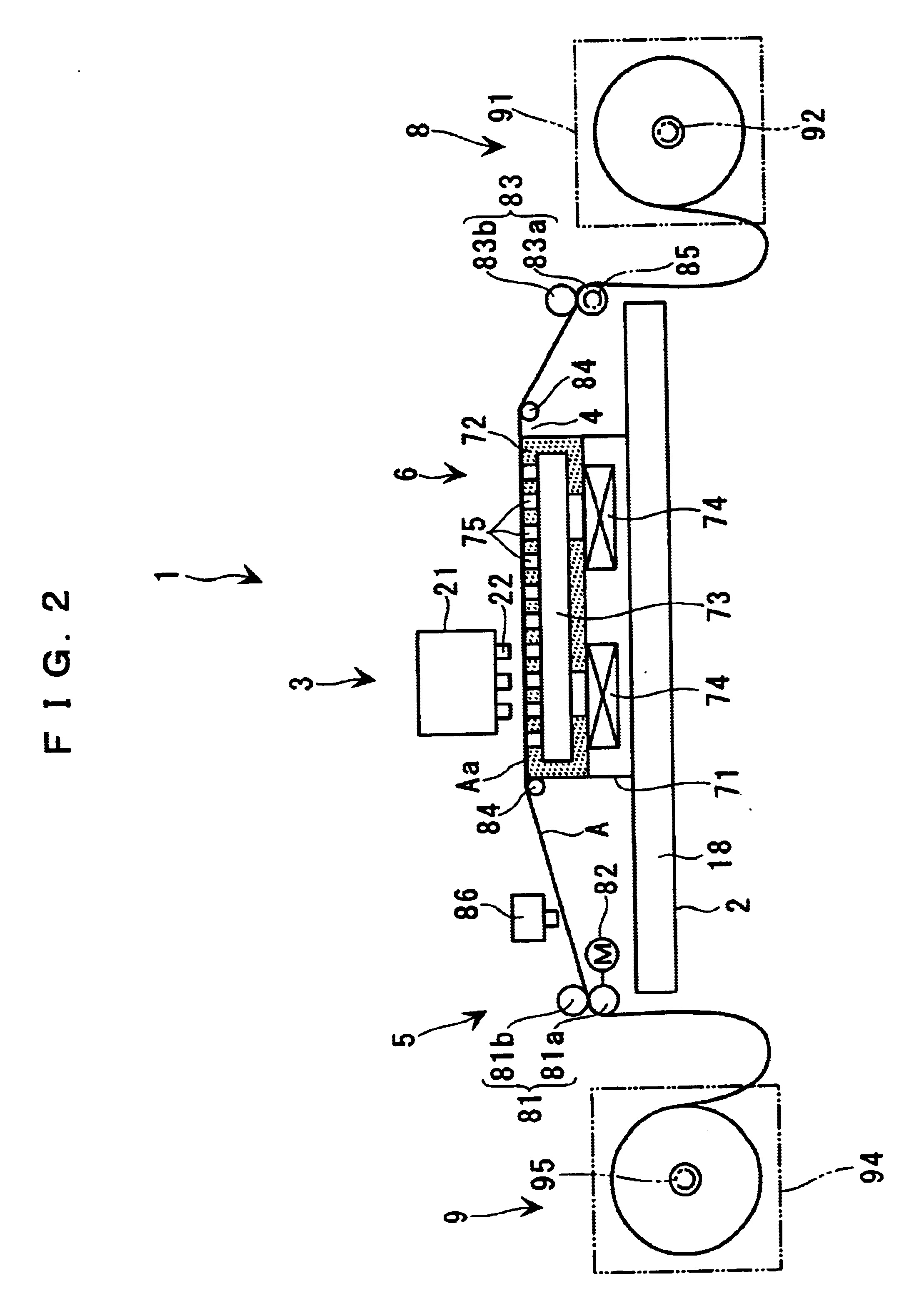

Ink jet head unit and ink jet printing apparatus incorporating the same

There are provided an ink jet head unit which is capable of incorporating a large number of ink jet heads with ease and precision, and an ink jet printing apparatus incorporating the ink jet head unit. The ink jet head unit performs printing color printing by using a plurality of ink nozzle arrays each for use in printing one line, the plurality of ink nozzle arrays corresponding to a plurality of basic colors. A plurality of head groups are each formed by a plurality of ink jet heads, and have the plurality of ink nozzle arrays arranged therein such that the plurality of ink nozzle arrays are divided among the plurality of head groups. A plurality of sub-carriages have respective ones of the plurality of head groups mounted thereon. A unitizing carriage has the plurality of sub-carriages mounted thereon.

Owner:SEIKO EPSON CORP

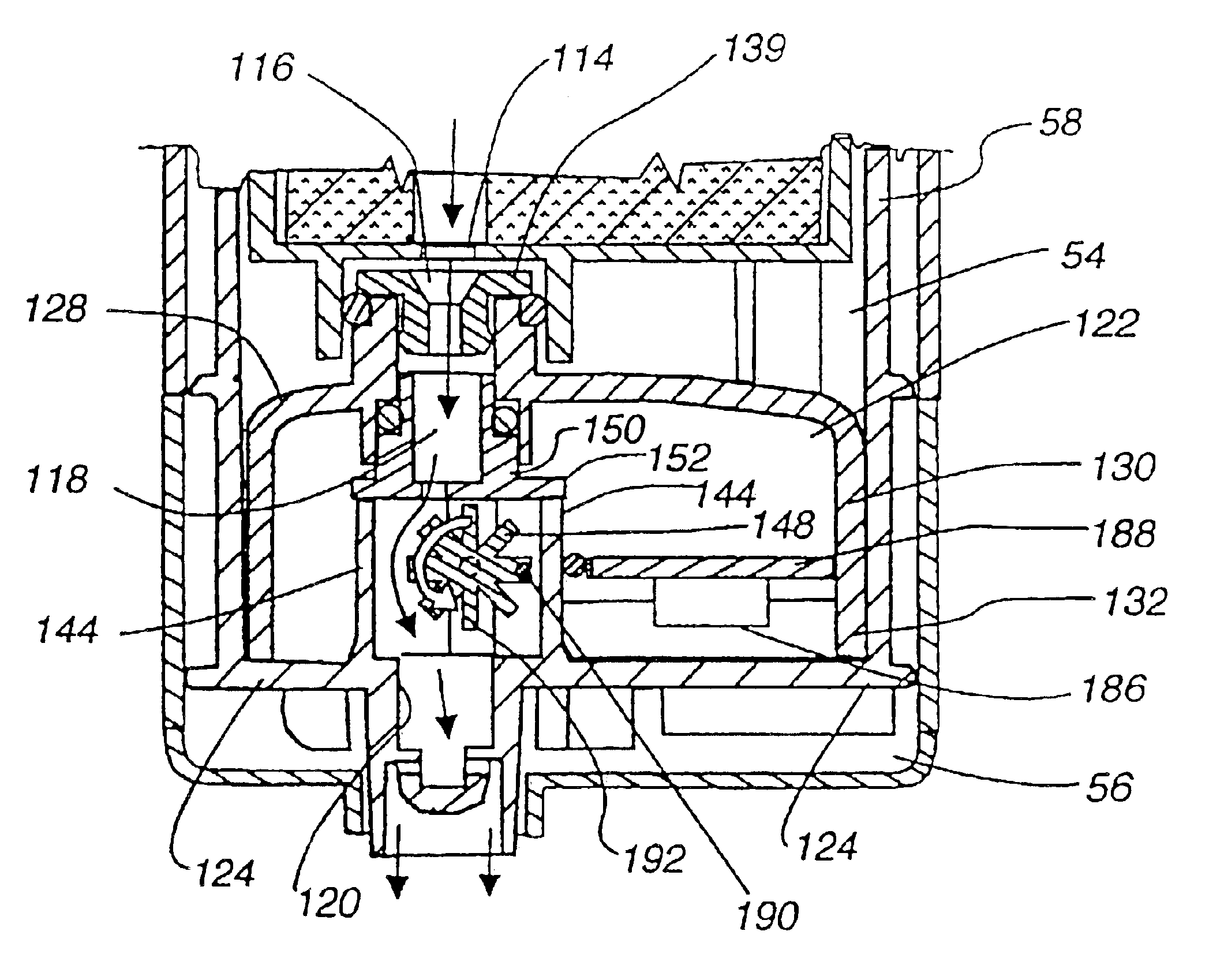

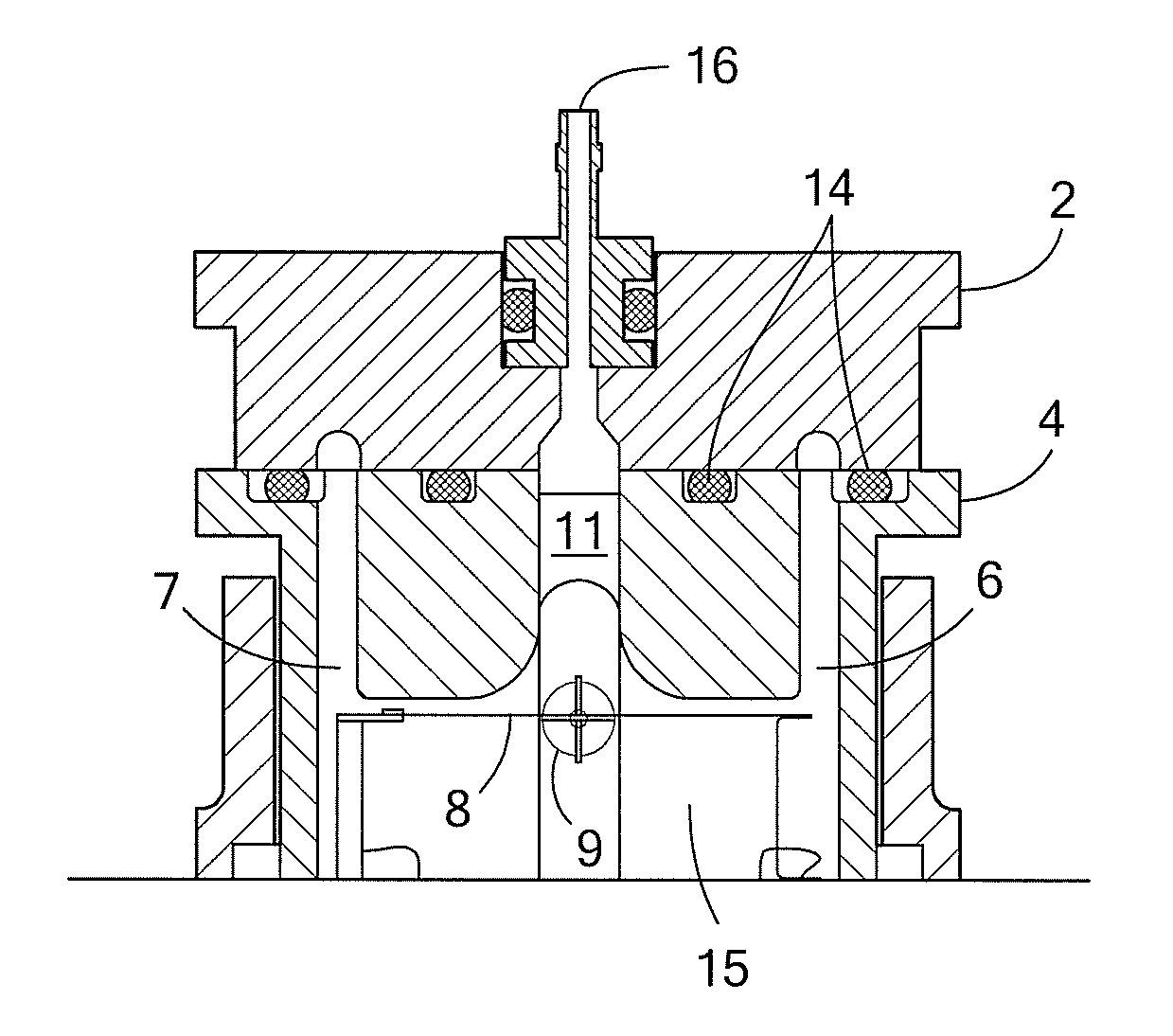

Valve apparatus

InactiveUS20090314979A1Reduces percentage deformationReduce distortionPositive displacement pump componentsCheck valvesSolid particleEngineering

A valve apparatus that has a longitudinal axis therethrough comprises a valve seat member, a valve closure member, a fluid flow path, and a resilient valve insert member. The valve seat member comprises a hollow bore and a first frustoconical contact surface that has an inner perimeter and an outer perimeter. The valve closure member comprises a valve body and a second frustoconical contact surface that is adapted to seal against the first frustoconical contact surface in a strike face area. The valve closure member is movable along the longitudinal axis of the valve apparatus. The fluid flow path extends through the bore of the valve seat member and between the valve seat member and the valve closure member. This fluid flow path is closed when the second frustoconical contact surface is sealed against the first frustoconical contact surface. The resilient insert member is attached to the valve closure member. It has an inner perimeter and an outer perimeter, the inner perimeter being adjacent to the strike face area on the second frustoconical surface. The resilient insert member is offset and adapted to contact the first frustoconical contact surface and form a hydraulic seal therewith at the inner perimeter of the insert member, before the first frustoconical contact surface comes in contact with the second frustoconical surface as the valve closes. The offset of the insert member is greater at its outer perimeter than at its inner perimeter, and is greater at its outer perimeter than the diameter of the largest particle in any fluid to be pumped. The insert is deformable but substantially non-compressible and comprises a particle retaining means to accommodate solid particles that are trapped between the insert and the valve seat member when the valve closes. The particle retaining means has at least one cavity (void space) that is in fluid contact with the flow path for fluids between the valve seat member and valve closure member when the valve is open. The cavity has an opening in fluid contact with the flow path for fluids when the valve is open and is large enough to accommodate one or more solid particles within the interior of the cavity. The volume of the cavity contracts as the valve closes, whereby solid particles are screened from the fluid and retained within the cavity, and whereby clear fluid is forced out of the cavity into the flow path and directed inwardly toward the bore of the valve seat member through the gap between the first and second frustoconical contact surfaces.

Owner:MCINTIRE WILLIAM RAY

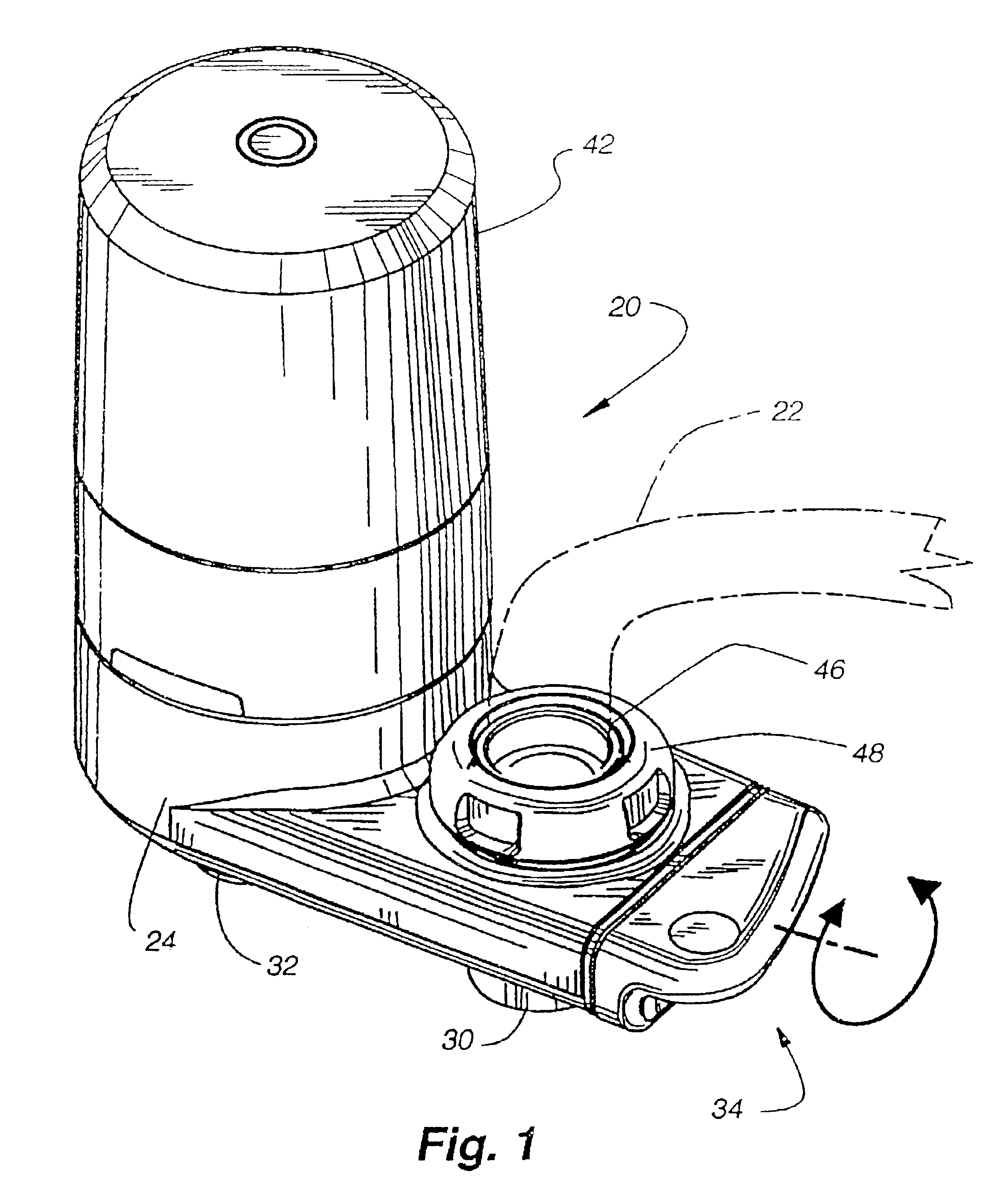

Water treatment device with volumetric and time monitoring features

InactiveUS6926821B2Less palatableEnhanced flushingTreatment involving filtrationCartridge filtersMicrocontrollerOutput device

A totalization meter system for a water treatment device, the device having an inlet aperture and an outlet aperture, and a channel for channeling water between the inlet and outlet apertures. A flow reactive device is positioned in the channel and is exposed to the flowing water, and a signal generating member is positioned on the flow reactive device. A switch is positioned proximately to the flow reactive device, and is sensitive to the proximity of the signal generating member. The switch is able to communicate electric signals indicative of the motion of the signal generating member. A resettable processor having a performance threshold programmed therein and an output device is included. The microcontroller is in electrical communication with the switch for receiving electrical signals from the switch. The switch is capable of sensing the characteristics of the flow reactive device and communicates electrical signals representative of the characteristics to the microcontroller. The microcontroller interprets the signals as a first performance data. The microcontroller compares the first performance data against the respective performance threshold in the microcontroller to determine if the performance threshold has been surpassed, and if surpassed actuates the output device.

Owner:INSTAPURE BRANDS

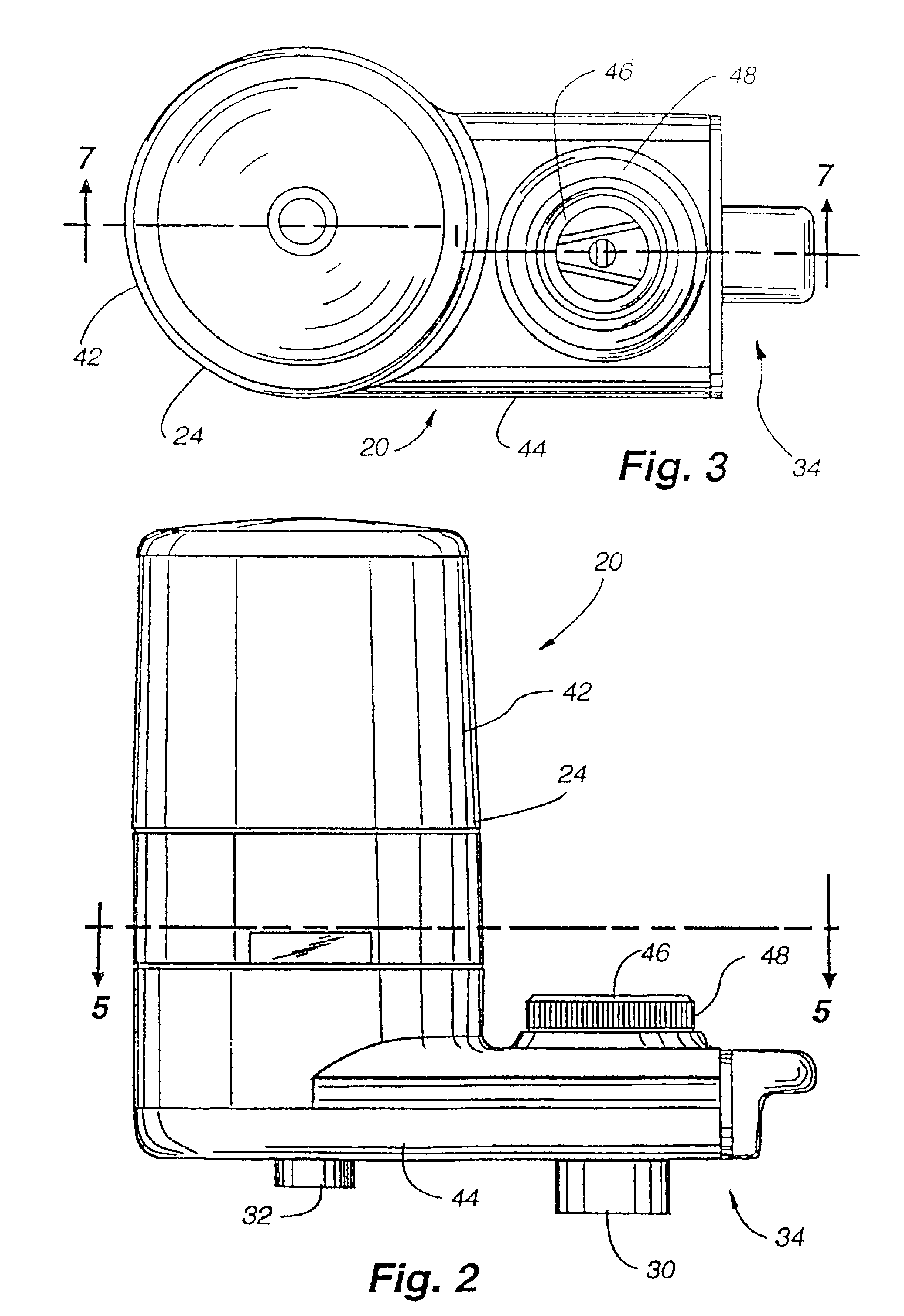

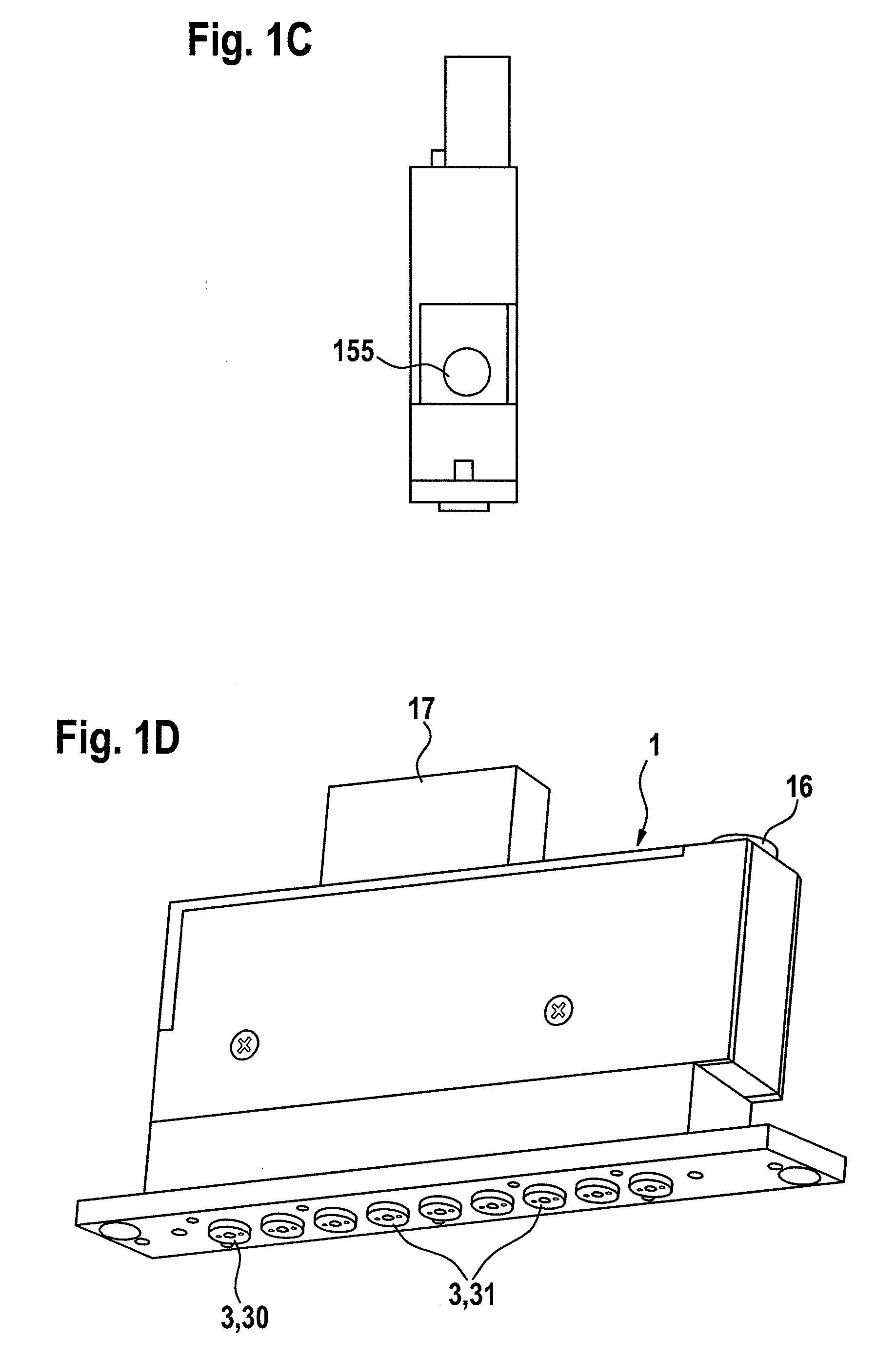

Valve device of an application device for applying fluid to a substrate, and applicator

ActiveUS20100170918A1Easy maintenanceEnhanced flushingLiquid surface applicatorsOperating means/releasing devices for valvesEngineeringElectromagnetic valve

A valve device of an application device for applying fluid to a substrate comprises a valve body, a valve housing with inner chamber and valve seat, a supply fluid chamber, an electromagnetic valve actuating device with valve piston and an adjusting piston. The valve nozzle is detachably mounted on the nozzle side of the valve device. The valve device has a nozzle plate which closes the valve body at the bottom on the nozzle side, with mounting opening for the valve piston. The valve housing is designed in the form of a nozzle orifice which is a closure member that can be fitted on the mounting opening from below and removed. The valve nozzle forms part of the valve housing. The valve piston is exposed through the mounting opening of the nozzle plate for removal and fitting when the closure member is removed. The valve device is provided with at least one rectilinear fluid duct that connects the supply fluid chamber to the valve seat. The valve piston and part of the adjusting piston together form a wall of the straight fluid duct which, when the nozzle orifice closure member is removed, is exposed for cleaning through the mounting opening. An application device comprises the valve devices arranged in a row.

Owner:J ZIMMER MASCHENBAU GES

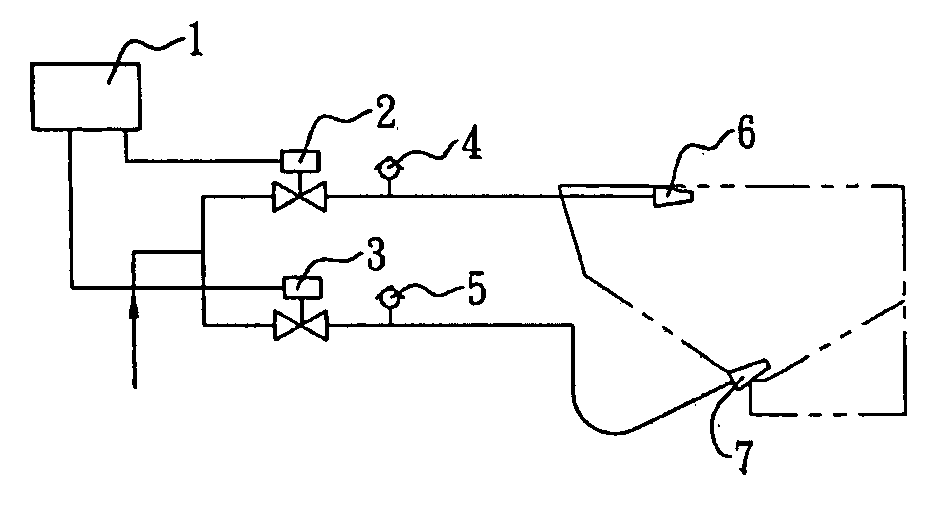

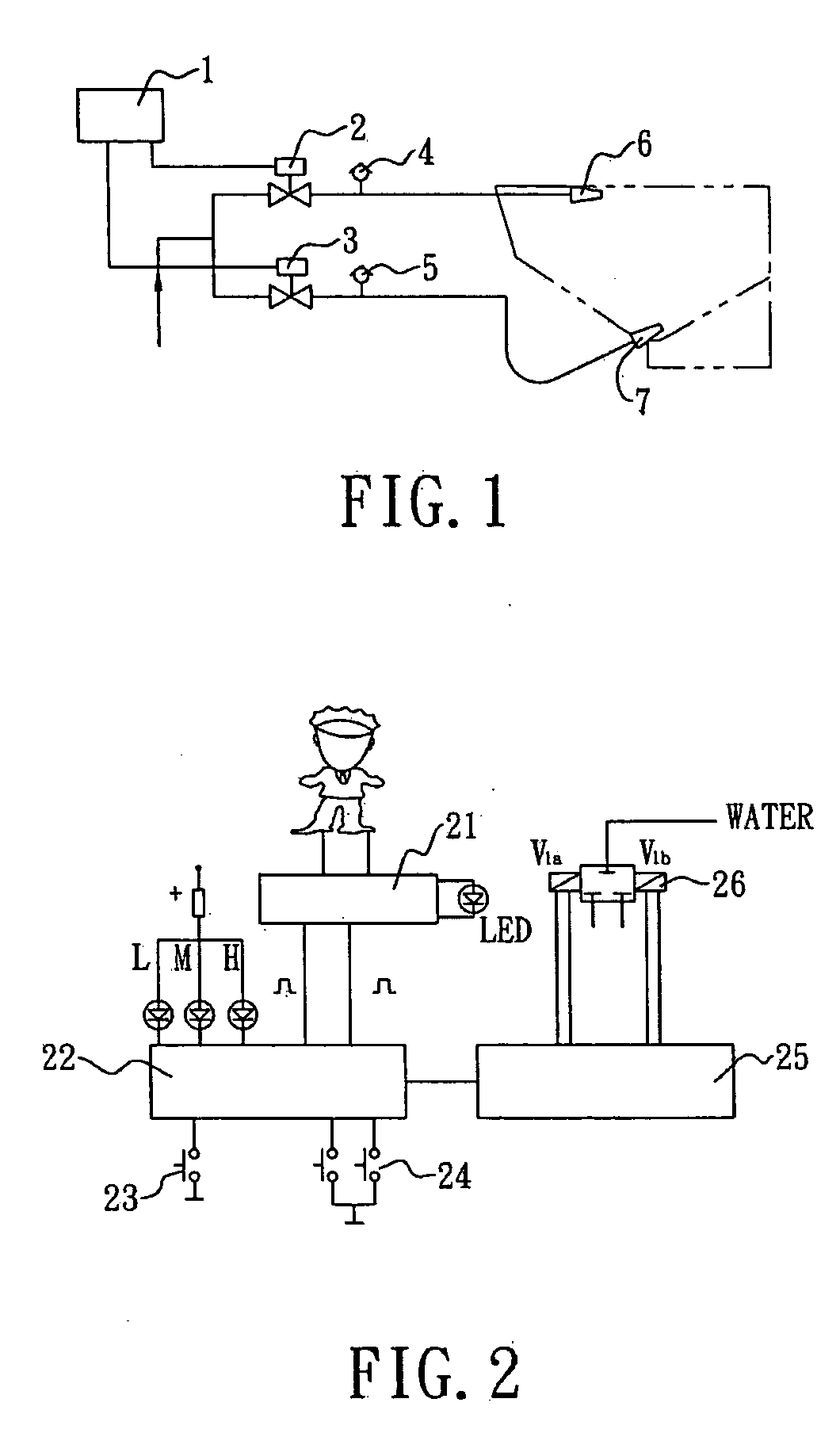

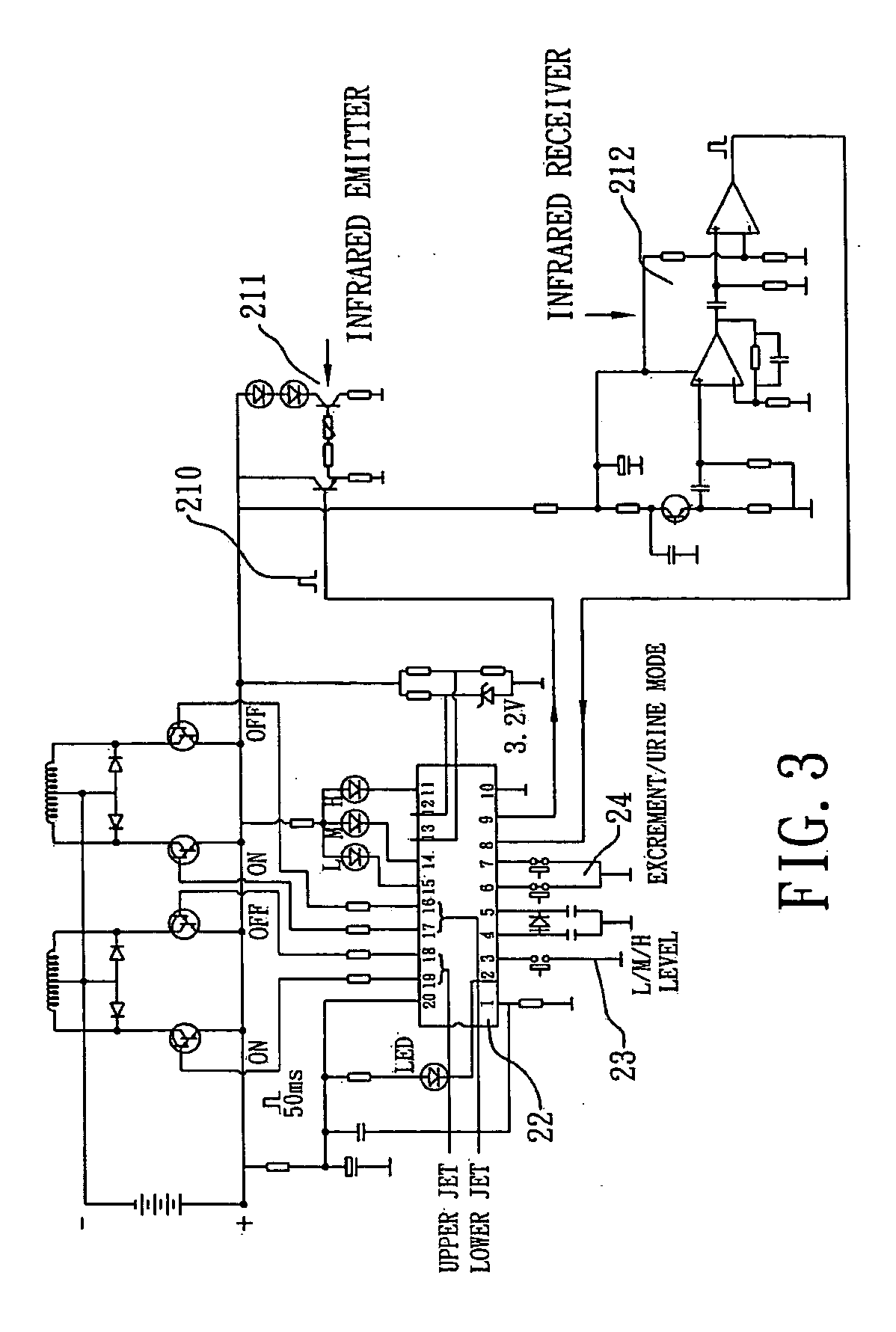

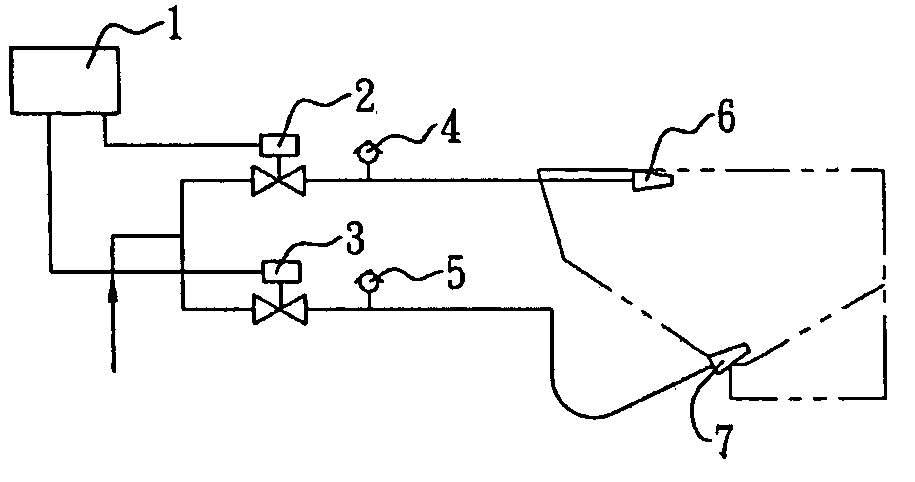

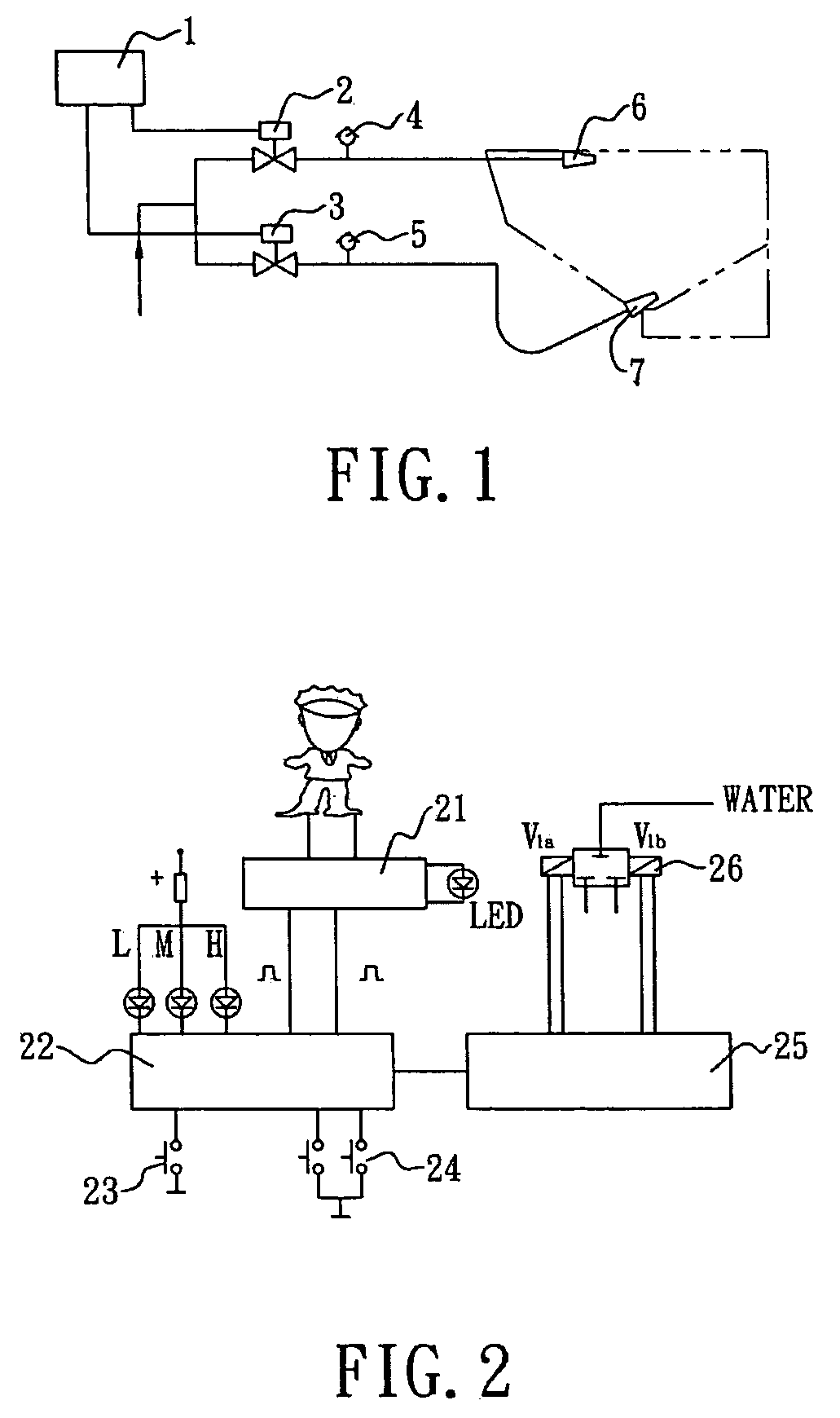

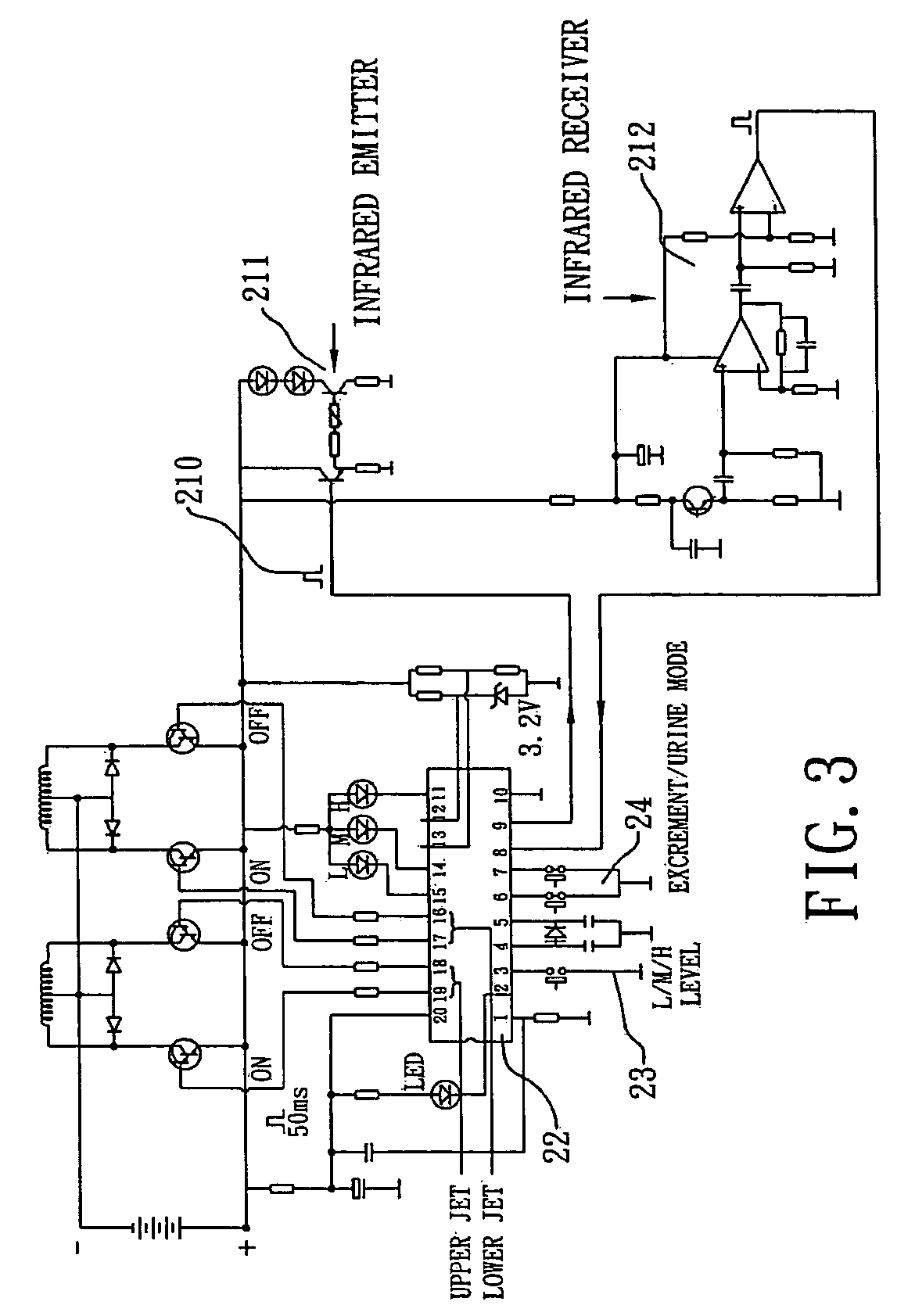

Infrared sensor flushing control method and plumbing fixture flushing system

The present invention includes an infrared sensor flushing control method and the plumbing fixture flushing system. The realization of flushing with two different jets is achieved by using the infrared sensor and MCU to control the electromagnetic-controlled valves. The MCU preinstalled with three different solid waste flushing procedures and one liquid waste flushing procedure, providing the water-saving consumption according to the requirements of each individual and the automatic discrimination of the usage. The integrated design also accomplishes the purpose of convenient installation and space saving.

Owner:LING LIGONG

Ink jet head unit and ink jet printing apparatus incorporating the same

There are provided an ink jet head unit which is capable of incorporating a large number of ink jet heads with ease and precision, and an ink jet printing apparatus incorporating the ink jet head unit. The ink jet head unit performs printing color printing by using a plurality of ink nozzle arrays each for use in printing one line, the plurality of ink nozzle arrays corresponding to a plurality of basic colors. A plurality of head groups are each formed by a plurality of ink jet heads, and have the plurality of ink nozzle arrays arranged therein such that the plurality of ink nozzle arrays are divided among the plurality of head groups. A plurality of sub-carriages have respective ones of the plurality of head groups mounted thereon. A unitizing carriage has the plurality of sub-carriages mounted thereon.

Owner:SEIKO EPSON CORP

Foamed acid washing technological method for horizontal well

ActiveCN101718184AIncrease productionEnhanced flushingCleaning apparatusDrilling compositionCarrying capacityWell drilling

The invention provides a foamed acid washing technological method for a horizontal well. With two packers at a horizontal well segment installed and foamed acid washing liquid poured from an annulus, the acid liquid flows outside a sieve tube, thereby enhancing the flushing and unclogging effects on mud cakes of a drilling well. With the temporary clogging effect of foam on a high permeability position and the low density characteristic of the foam used, the acid liquid leakage can be effectively reduced; and at the same time, with the high carrying capacity of foamed liquid and the expansion energy of nitrogen gas used, acidized solid particles and residual acid can flow back, thereby avoiding the secondary sedimentation damage, solving the problems of acid liquid leakage and incomplete residual acid backflow in the conventional acid washing process, and effectively improving the acid washing effect. In the technological method, the reaction between the foamed acid washing liquid and the mud cakes of the drilling well is carried out in two steps: firstly, displacing the foamed acid washing liquid to the horizontal well segment, and shutting the well for reaction; and then, displacing the unreacted foamed acid washing liquid to the horizontal well segment, inversely squeezing the foamed acid washing liquid into the stratum, and shutting the well for reaction. The invention is especially suitable for relieving the well drilling damage of a low-pressure leakage horizontal well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

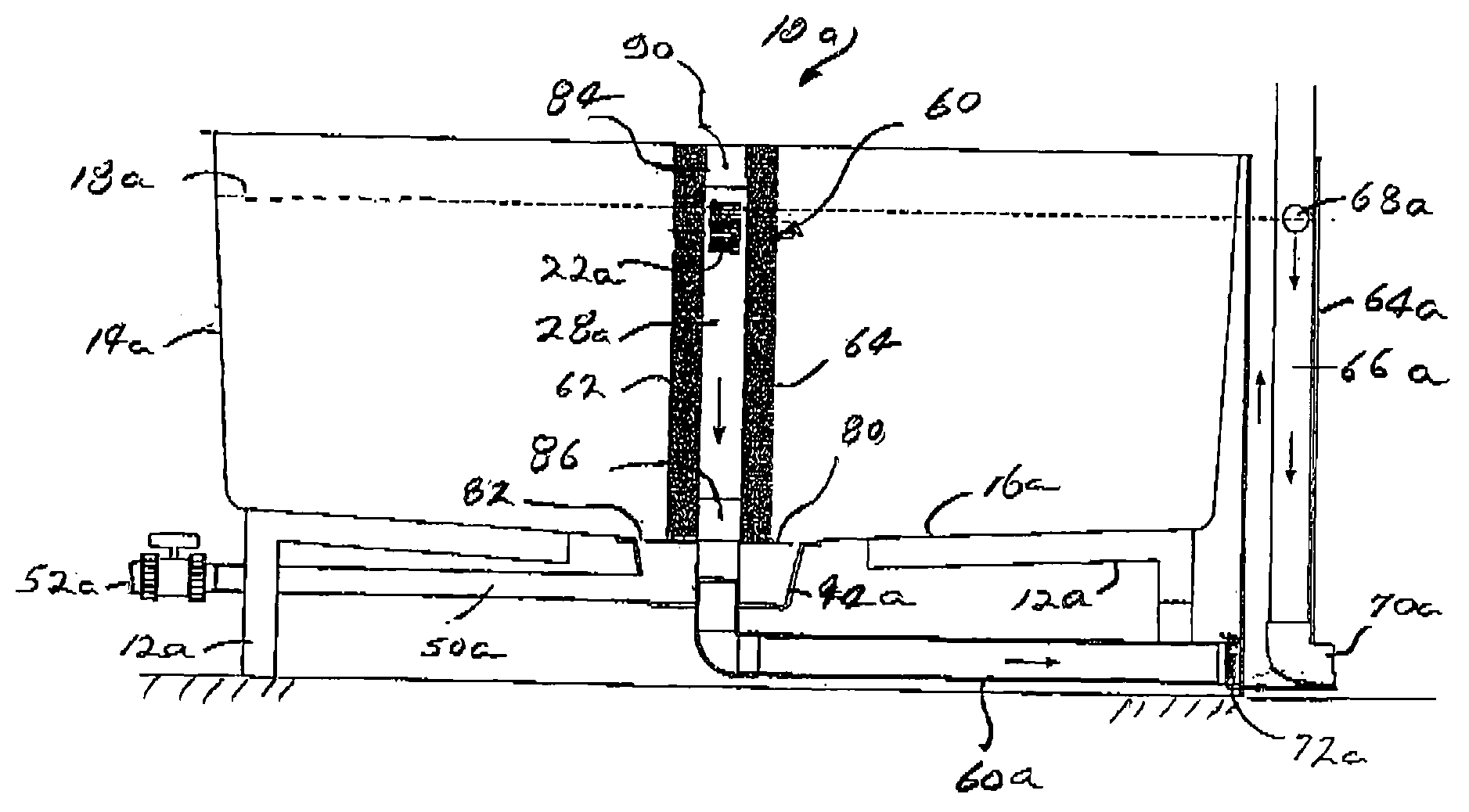

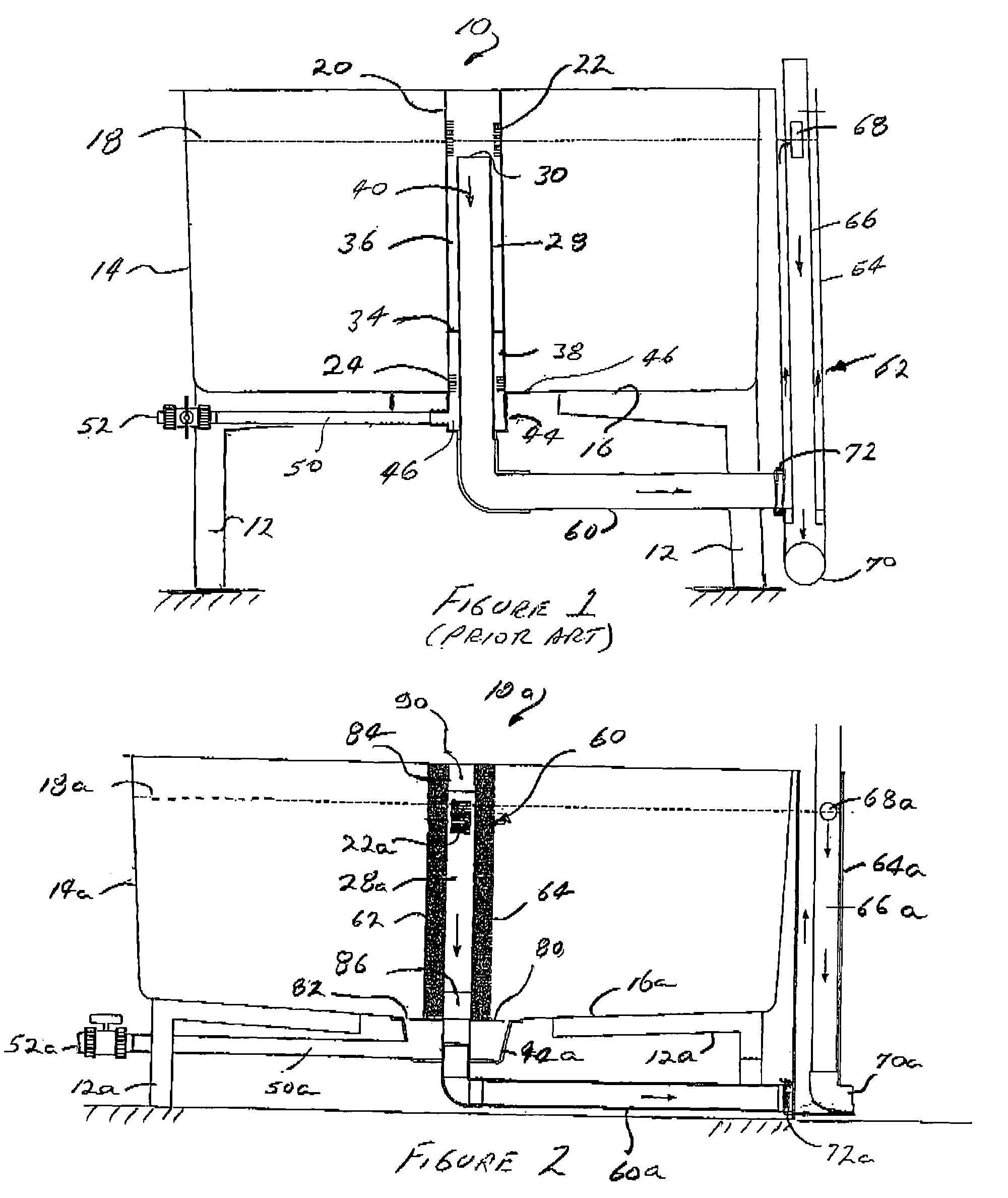

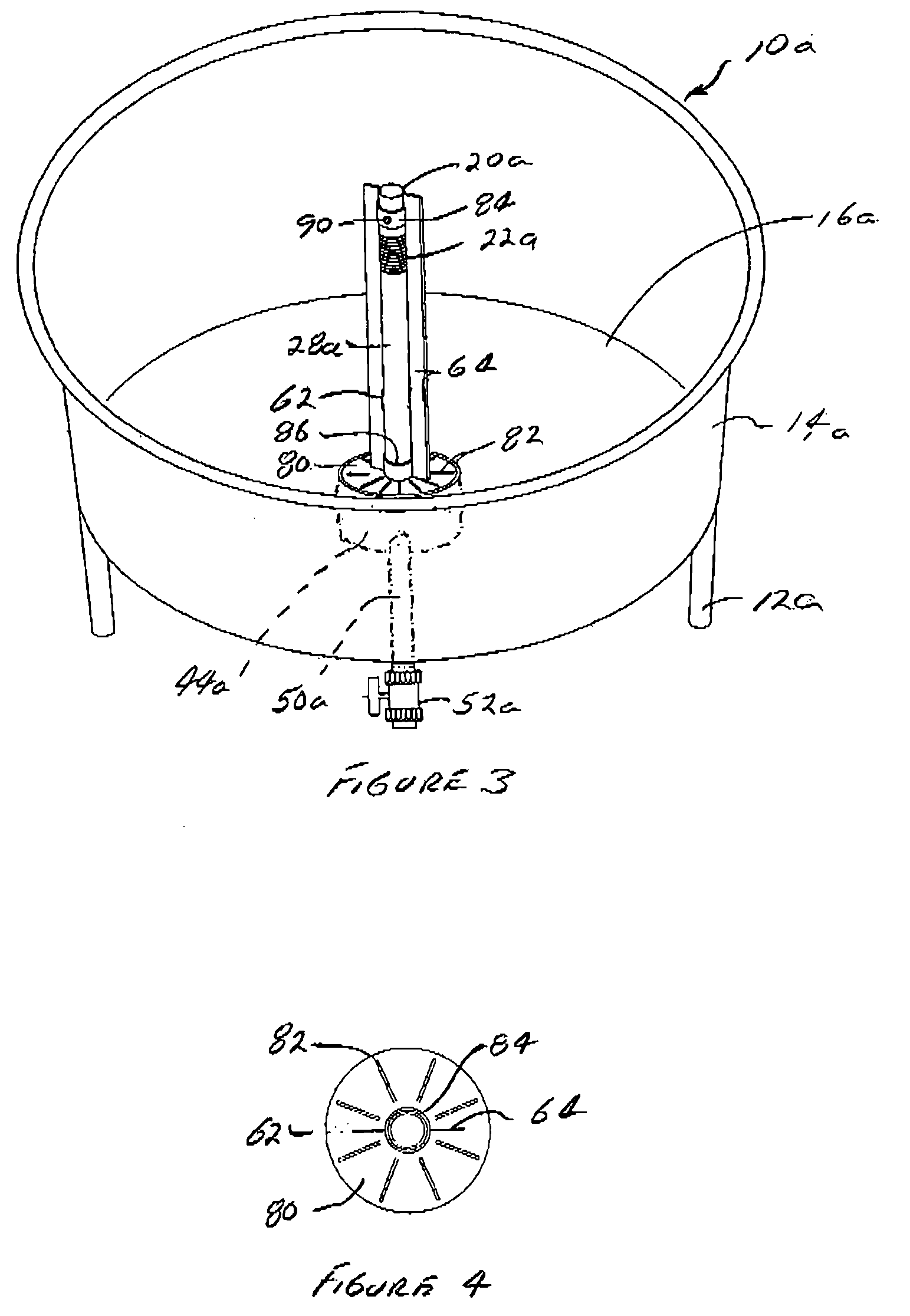

Anti-vortex double drain system

InactiveUS20090206044A1Increase solid storage capacityEnhance flushingWater/sewage treatment by centrifugal separationReversed direction vortexSolid waste collectionLiquid waste

Enhancements to the Double Drain technology used for separation of settle-able solid wastes previously developed. Anti-vortex fins are added to the central clarified effluent water manifold to minimize re-suspension of settled solids. A further aspect includes the addition of a slotted horizontal cover plate to a solid waste collection sump below the tank floor. These additions significantly increase the effectiveness of the Double Drain system for separation of settle-able solid waste from fish culture water. The enhanced Double Drain Tank design with the anti-vortex feature could also be used in non-fish culture applications to enhance the separation of settle-able solids from any liquid waste water flow.

Owner:VAN TOEVER J WAYNE

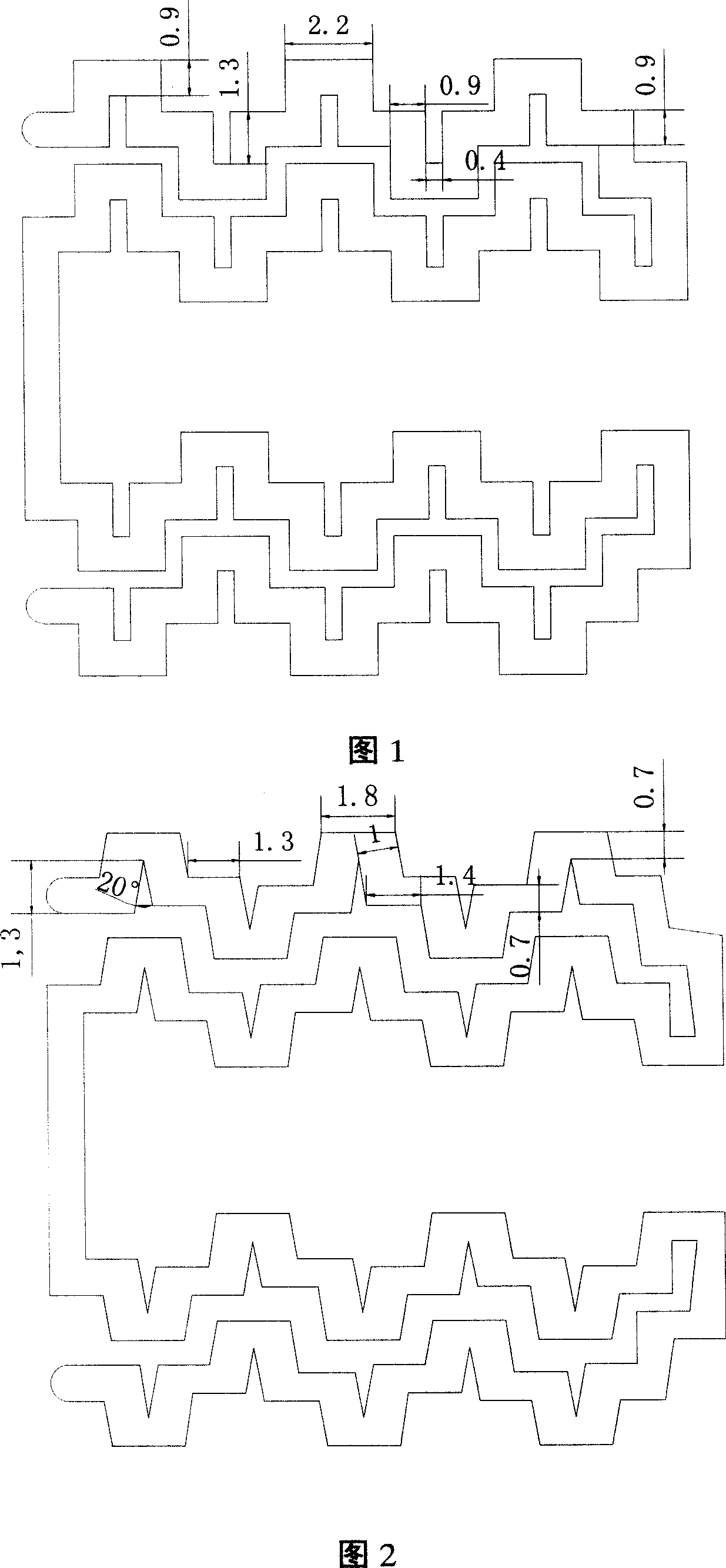

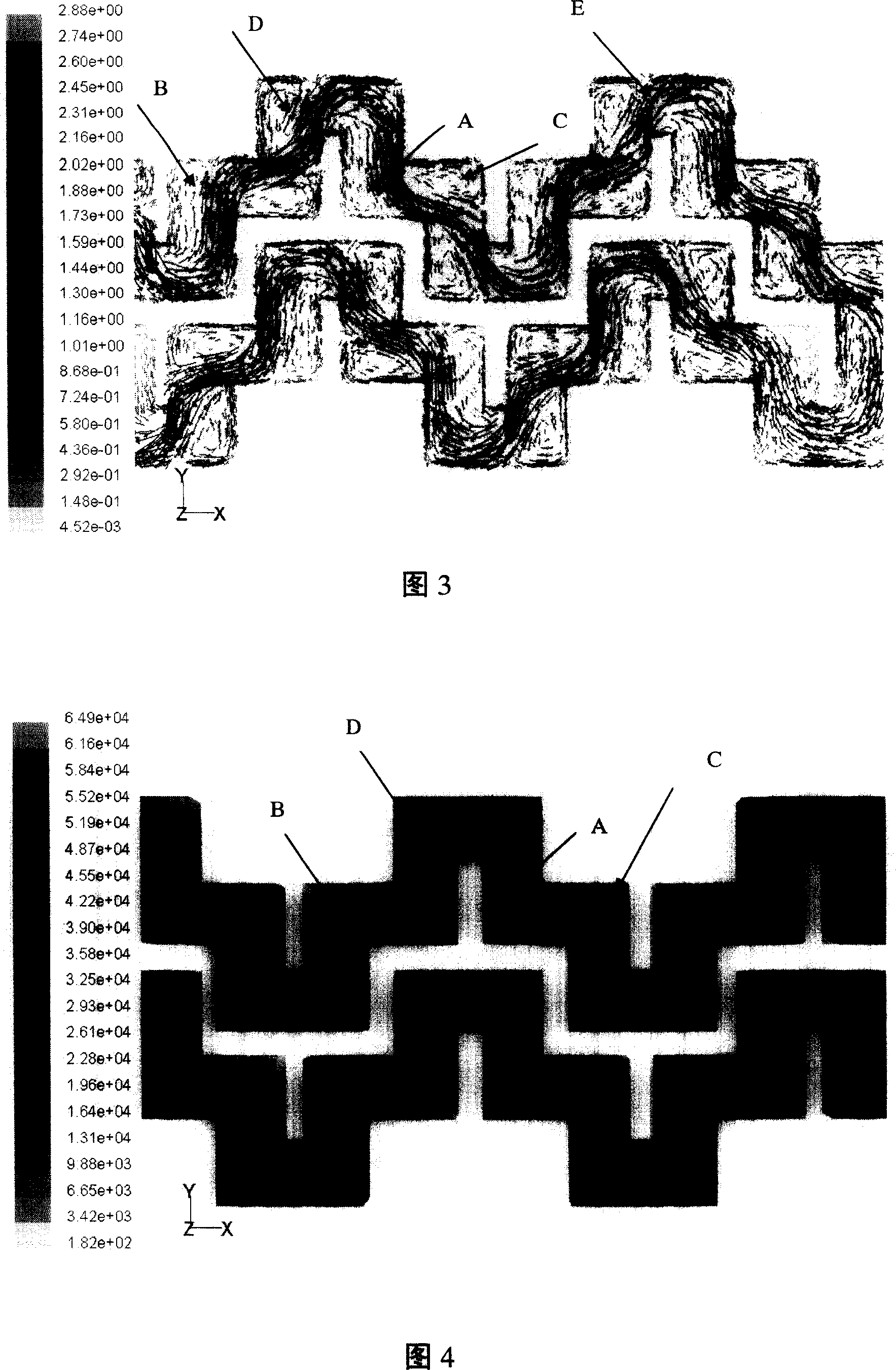

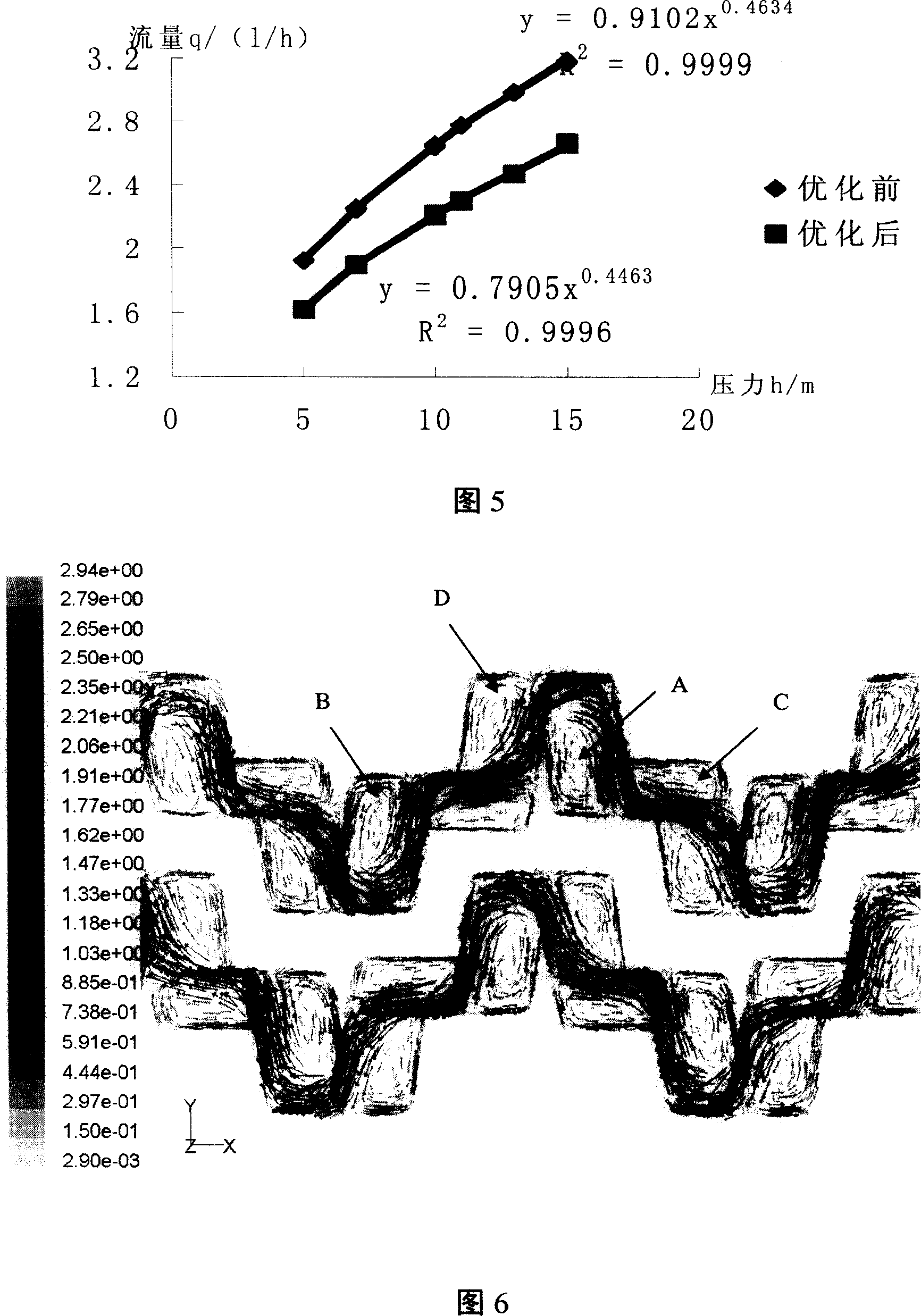

Antiplugging drip irrigation irrigator design method

InactiveCN101021881AReduce fluidity indexEnhanced flushingClimate change adaptationWatering devicesJet flowDrip irrigation

This invention provides a designing method for anti-jam drop-fill douches including: 1, setting up a structure model of the runner of a douche to divide it into lattices and design the border condition of the computed regions, 2, applying CFD evaluator to compute the runner of the drop head, 3, getting the velocity of flow field and eddy distribution parameter and determining the position of low flow rate regions in the head runner and the decision factor for pressure energy dissipation, 4, finishing borders of the runner structure and changing the tooth structure to reduce brush of the tooth tine place and the back surface to the runner borders to strengthen the eddy structure of the flow field, 5, computing repeatedly and balancing flow field parameters in the front and back runners to decide the anti-jam ability of the douche and testing the flow-pressure relation of the douche to guarantee its water power performance.

Owner:内蒙古兆通管道系统有限公司

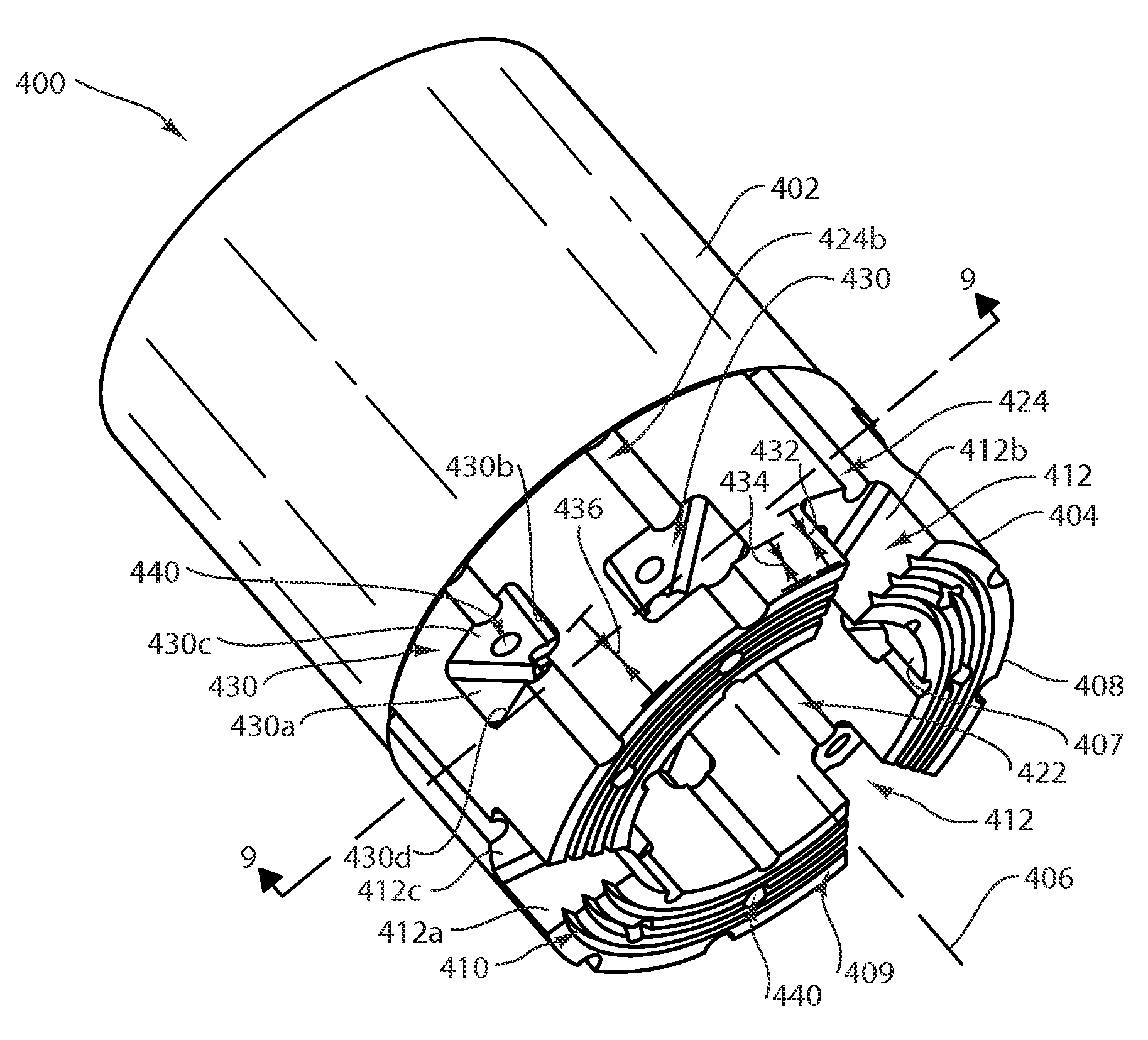

Drill bits with axially-tapered waterways

ActiveUS8459381B2High trafficEnhanced flushingDrill bitsMetal-working drilling toolsWell drillingDrilling system

Implementations of the present invention include drilling tools having axially-tapered waterways that can increase flushing and bit life, while also decreasing clogging. According to some implementations of the present invention, the waterways can be radially tapered in addition to being axially tapered. The axially-tapered waterways can include notches extending into the cutting face of the drilling tools and / or slots enclosed within the crown of the drilling tools. Implementations of the present invention also include drilling systems including drilling tools having axially-tapered waterways, and methods of forming drilling tools having axially-tapered waterways.

Owner:LONGYEAR TM

High temperature process for solution polymerization

ActiveUS20090062495A1Avoid accumulationEliminate depositsHollow article cleaningVapor condensationPositive pressureSolution polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

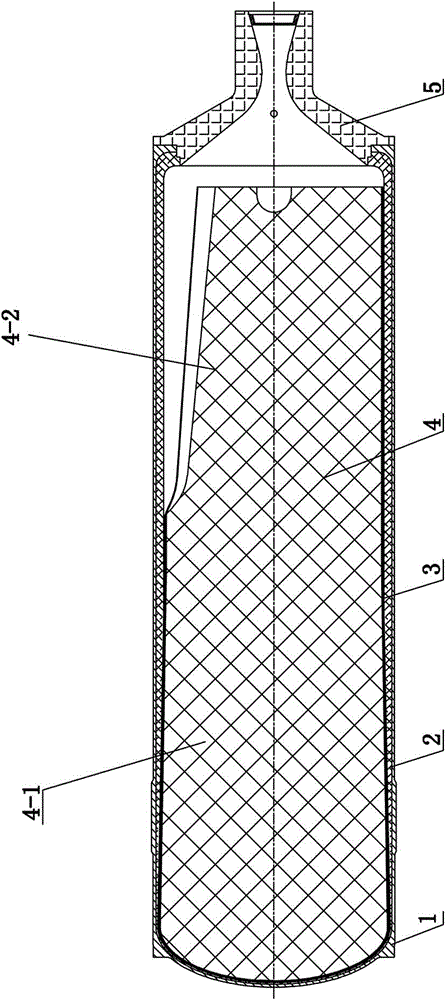

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Environment-friendly stemming and preparation method thereof

The invention provides an environment-friendly stemming and a preparation method thereof. The environment-friendly stemming is prepared from, by mass, 15-40% of aluminum containing aggregates, 2-15% of coke, 1-5% of graphite, 10-25% of silicon carbide, 5-20% of ferro-silicon nitride, 5-20% of aluminum containing fine powder, 5-15% of clay, 2-8 parts of sericite, 2-6% of high-temperature pitch, 2-15% of an expanding agent and a binding agent accounting for the total mass of the other materials by 15-30%, wherein thermoplastic phenolic resin serves as the binding agent. The environment-friendly stemming and the preparation method thereof have advantages that toxic gases are avoided, a furnace front operation environment is improved, environmental friendliness, low raw material consumption, high hardening speed and short sintering time are realized, opening performance and slag iron erosion resistance of the anhydrous stemming are improved, resistance of the anhydrous stemming to flushing and abrasion of high-temperature molten iron is enhanced, and quality stability of the anhydrous stemming is improved.

Owner:ZHENGZHOU SAIWO TECH CO LTD

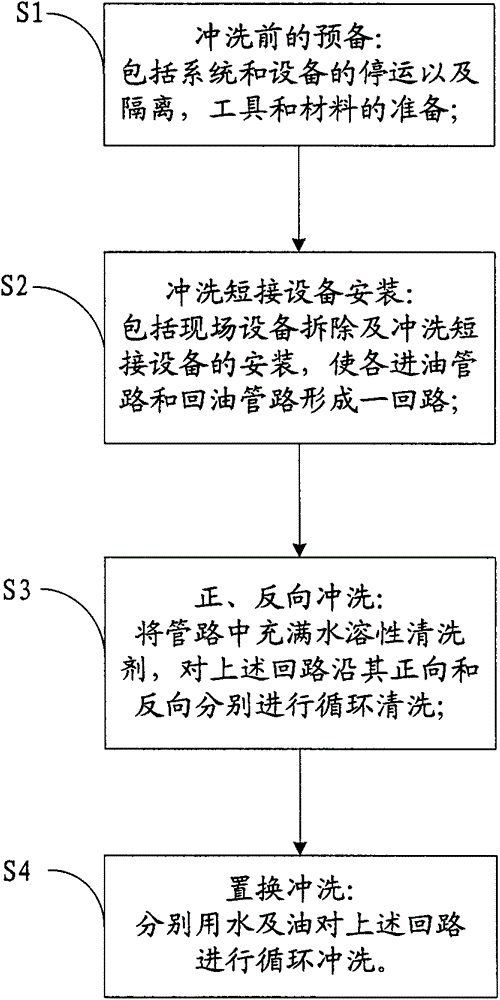

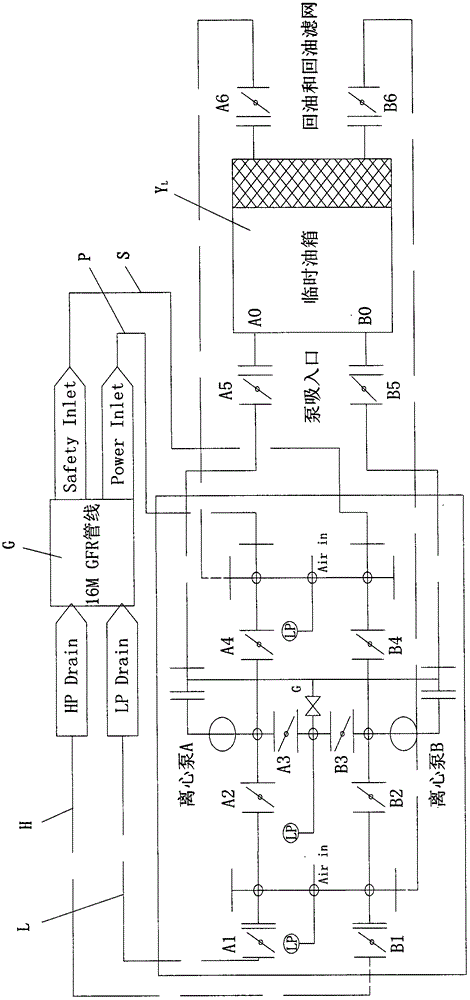

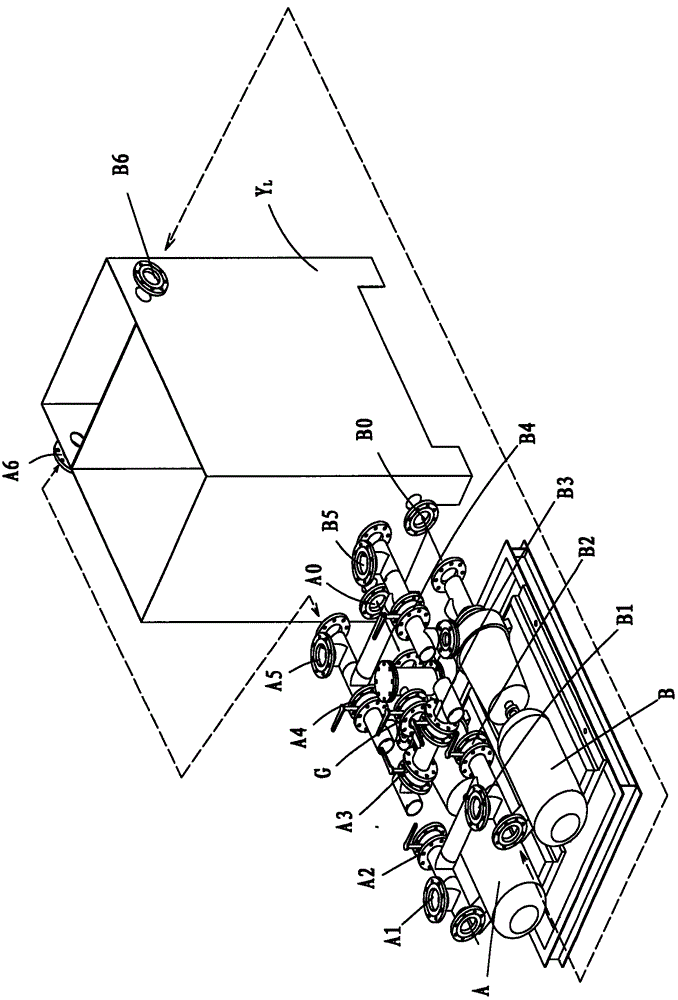

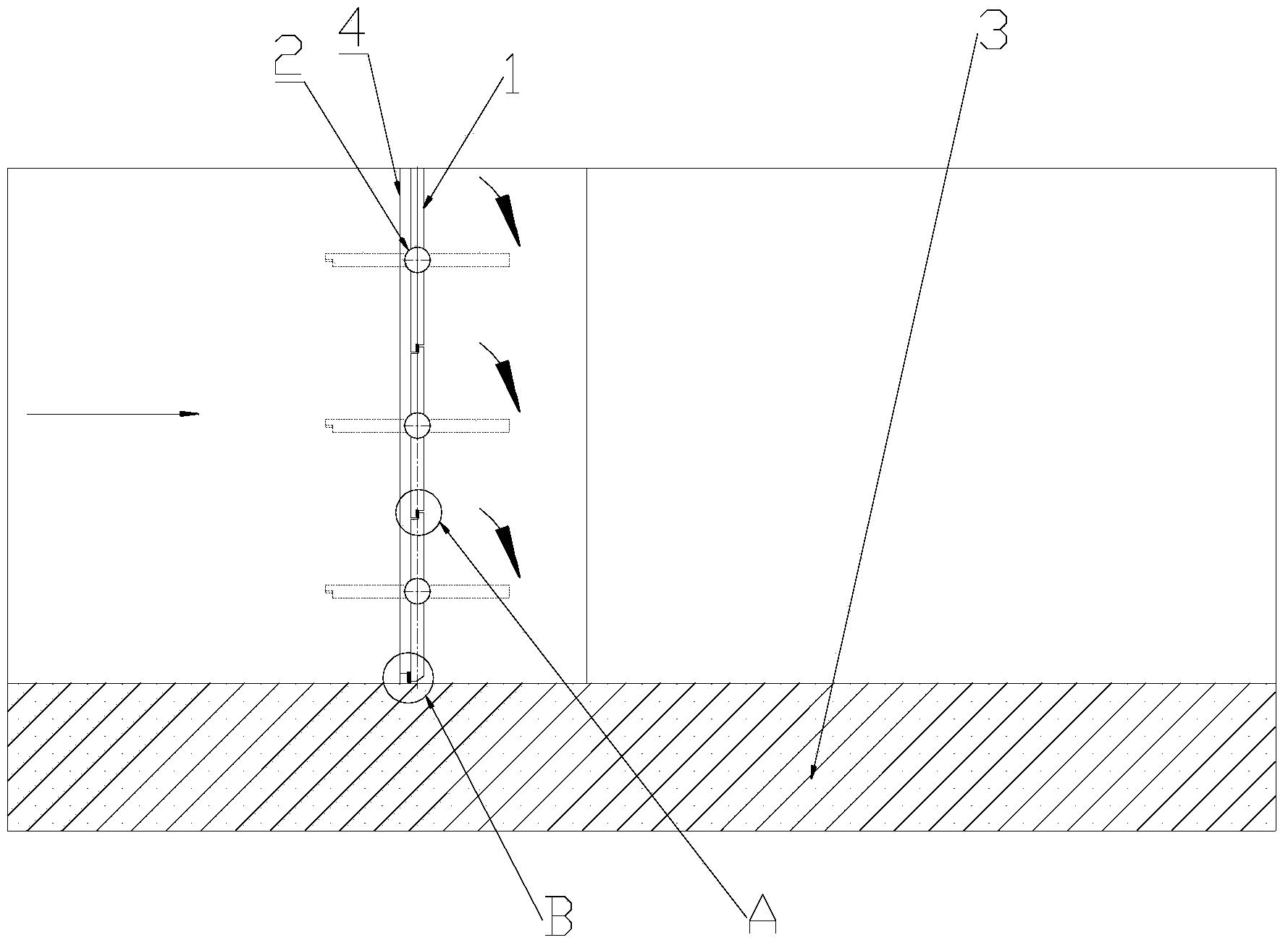

Method for washing oil adjusting system of steam turbine at nuclear power station

ActiveCN104415951AEasy temperature controlLess corrosiveHollow article cleaningNuclear powerWater soluble

The invention provides a method for washing an oil adjusting system of a steam turbine at a nuclear power station. The method comprises the following steps: preparation before washing: stopping and isolating the system and device, preparing the tools and materials; installation of washing short circuit device: disassembling the on-site device and installing the washing short circuit device, forming a loop by each oil changing line and oil return line; forward and backward washing: filling the lines with water soluble cleaning agent, respectively performing the circular washing to the loop along the forward direction and the backward direction; replacement washing: performing the circular washing to the loop by using the water and oil respectively. Because the external mass-flow washing short circuit device is used, and each oil charging line and the oil return line of the oil adjusting system of the steam turbine are connected totally to form one loop, the washing effect is obvious specifically, and the washing time is reduced greatly. Otherwise, the water circulation and oil replacement are respectively used for circularly washing the loop after washing, the replacement process is simplified, the cost is saved, and the operation efficiency of the steam turbine set is further improved.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

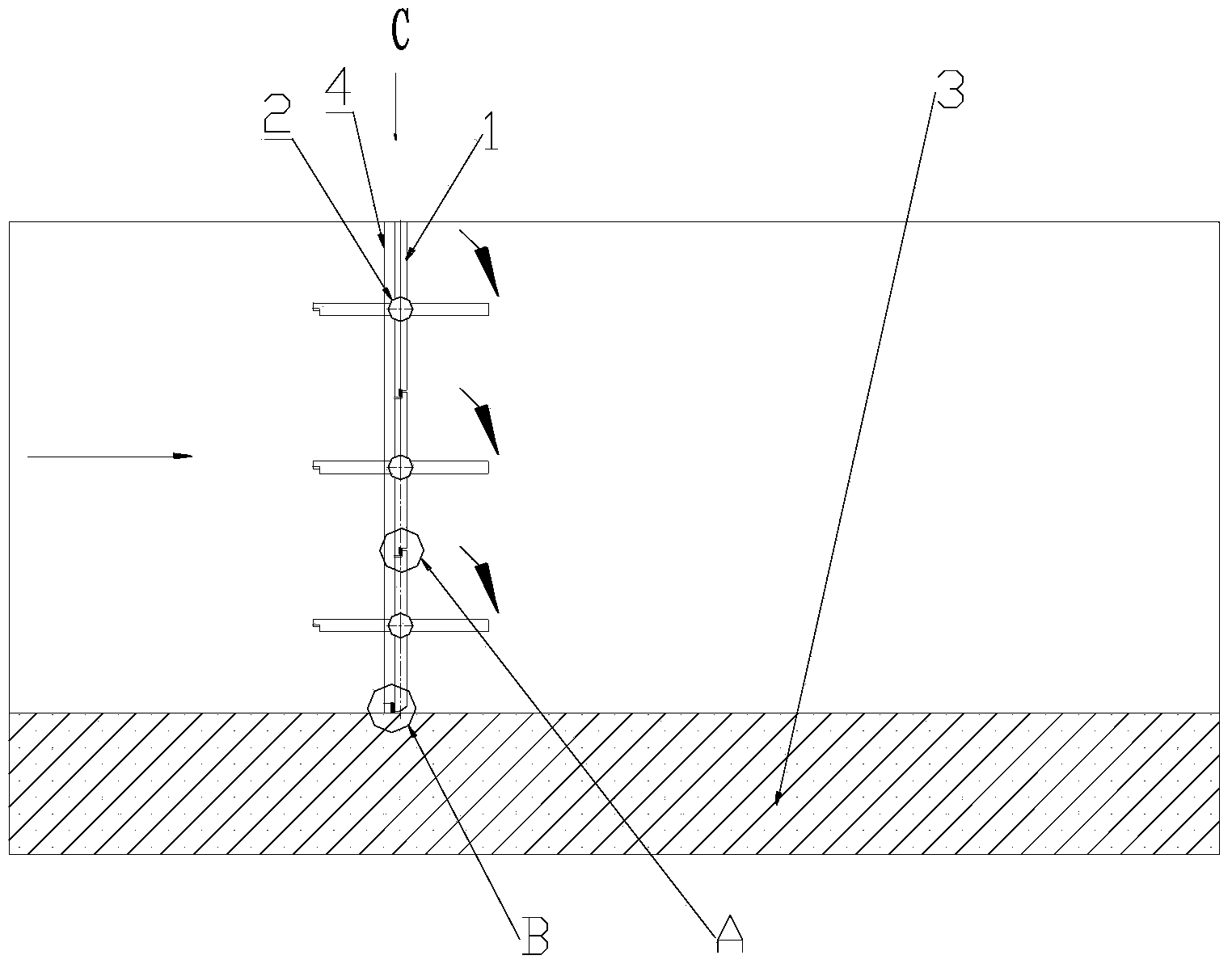

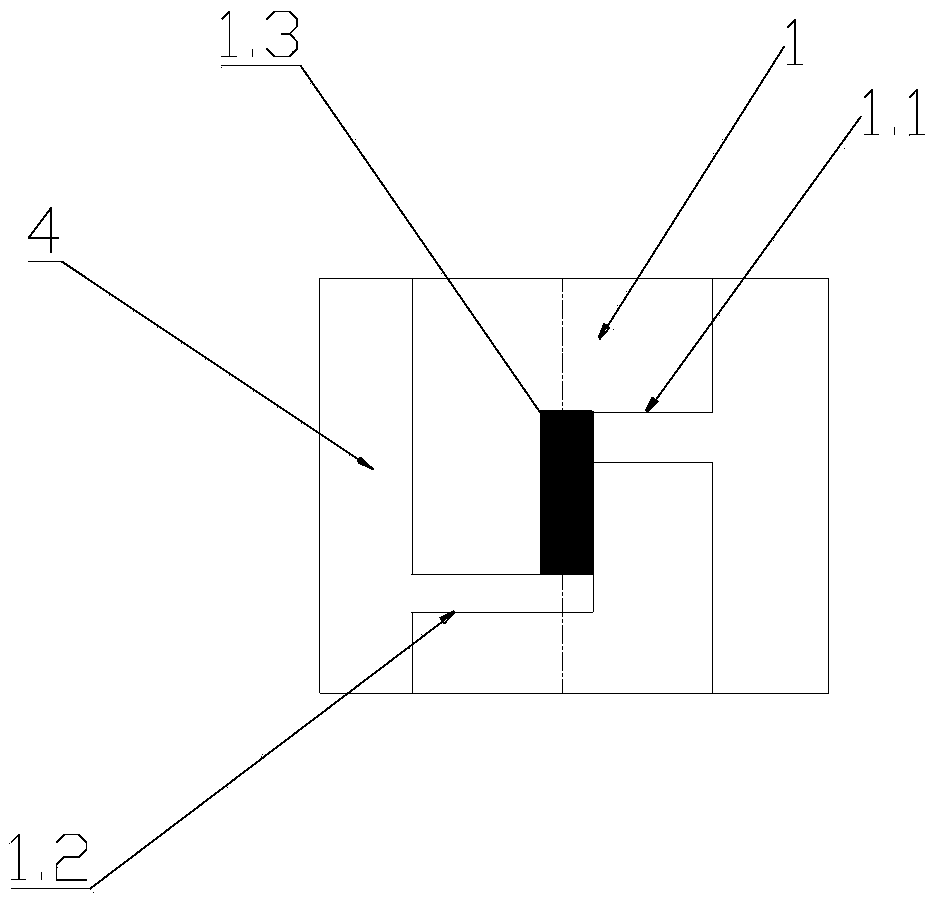

Multistage middle shaft rapid flushing gate

ActiveCN103850225AReduce stressReduce size requirementsBarrages/weirsArtificial water canalsOpen waterWater discharge

The invention discloses a multistage middle shaft rapid flushing gate which comprises a plurality of weir plates arranged on a vertical face. The middle part of each weir plate is correspondingly connected with one rotating shaft; the end parts of the rotating shafts are connected with the output end of a driving device; first sealing structures are arranged between the adjacent weir plates; the bottom of the bottommost weir plate is provided with a second sealing structure. The multistage middle shaft rapid flushing gate disclosed by the invention is arranged at an open water gap; the rotating shafts are driven to rotate by the driving device so as to drive the weir plates corresponding to the rotating shafts to rotate; when each weir plate is in a horizontal state, a pipe culvert has the maximum water discharge; when each weir plate rotates to a vertical state, the adjacent weir plates are abutted and are limited by a transverse baffle to form an integrated combined weir plate so as to form the flushing gate for stopping water flow, i.e. the multistage middle shaft rapid flushing gate has an intercepting effect.

Owner:WUHAN SHENGYU DRAINING SYST

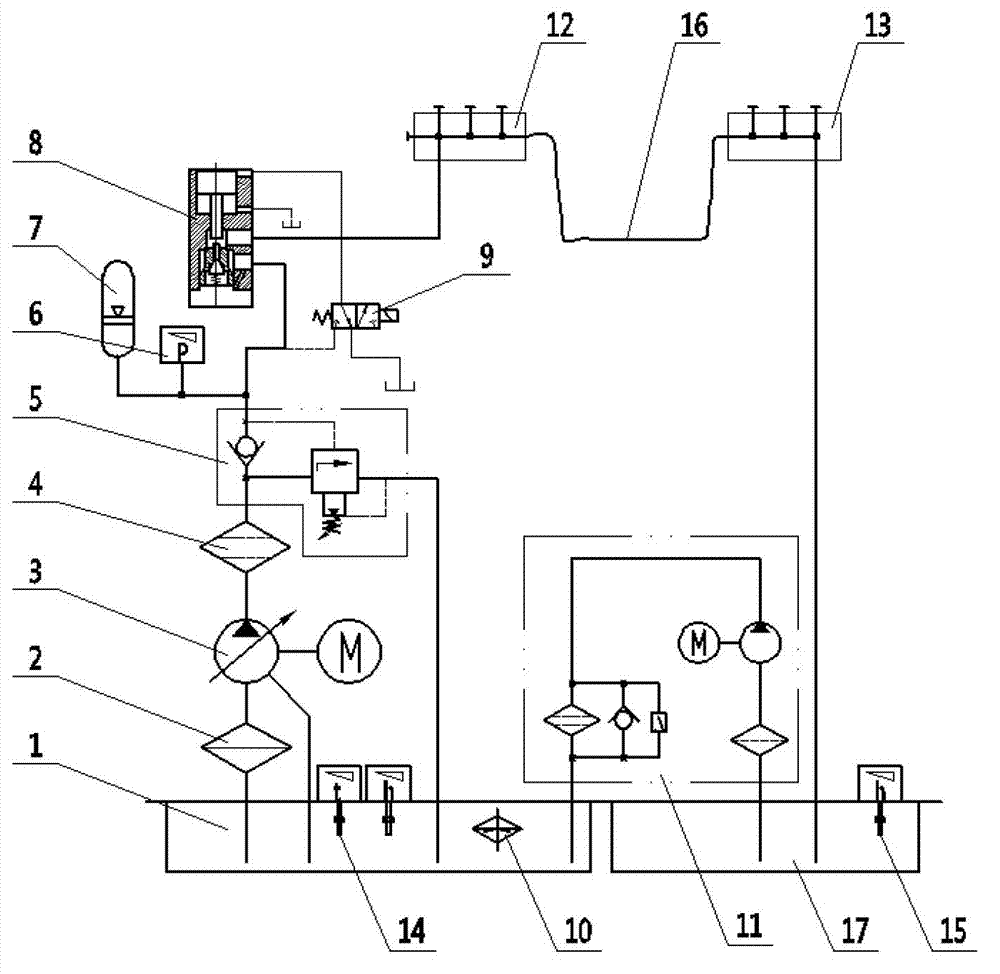

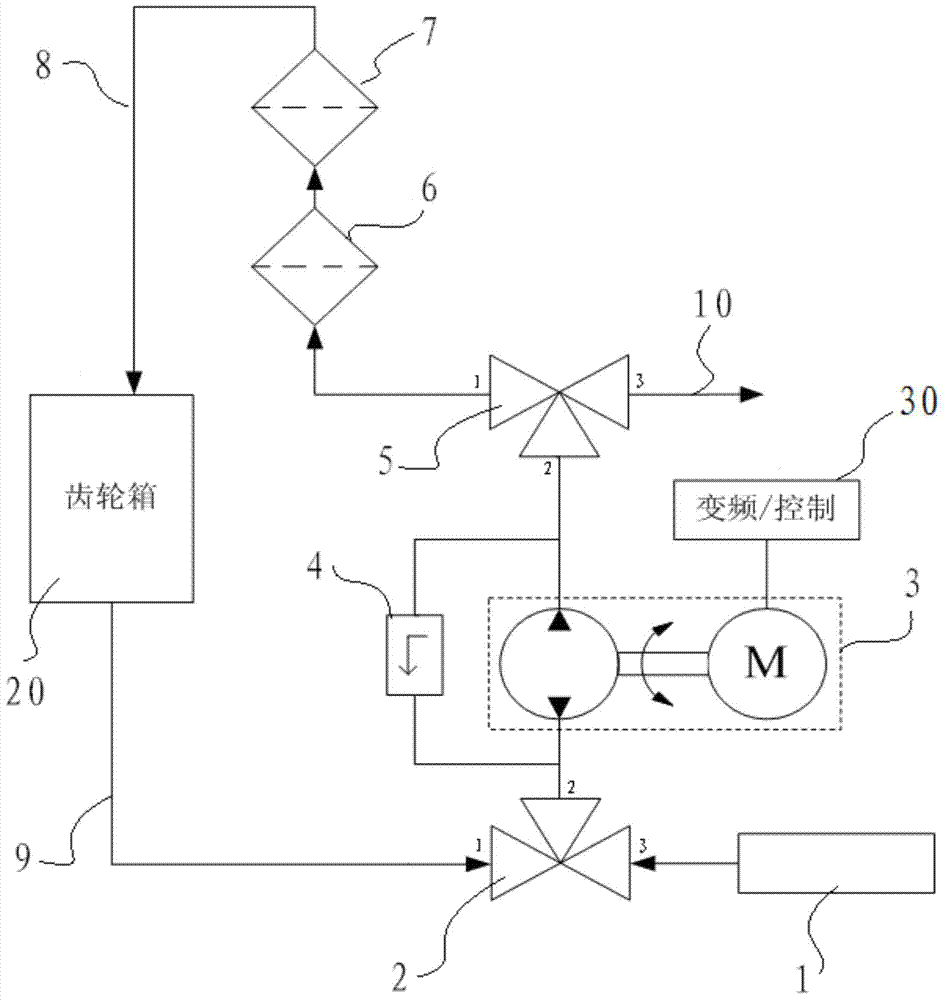

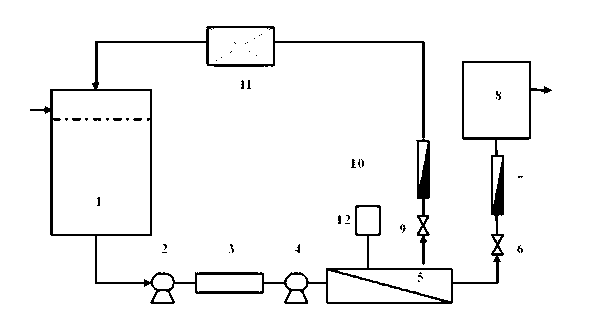

High-pressure pulsed turbulent flow pipeline flushing system

ActiveCN102962232AShorten cleaning timeImprove flushing efficiencyHollow article cleaningFluid-pressure actuator componentsConstant powerHigh pressure

The invention discloses a high-pressure pulsed turbulent flow pipeline flushing system. The high-pressure pulsed turbulent flow pipeline flushing system is characterized in that: the system comprises a main oil tank and an auxiliary oil tank, a heater is arranged in the main oil tank, and an oil pump motor assembly, a pressure sensor, a pilot-operated check valve and a flushed pipeline are sequentially connected between the main oil tank and the auxiliary oil tank; the other end of the oil pump motor assembly communicates with the main oil tank, electromagnetic valves for controlling the opening and closing of the pilot-operated check valve are arranged on both ends of the pilot-operated check valve, a temperature sensor is arranged on the main oil tank as well, and a filter pump assembly is connected between the main oil tank and the auxiliary oil tank as well. By adopting an energy accumulator, a constant-power variable pump and an instantly opening valve bank, the system can provide high-pressure, ultrahigh-flow flushing oil in a short time according to the requirements of pipeline varieties, consequently, violently turbulent oil is produced in the pipeline, and oil molecules irregularly and violently move up and down to clean the pipeline in a drilling manner.

Owner:WUHAN HUAYE AUTOMATION MACHINERY

Fuel Cell System, Use Of A Fuel Cell System And Aircraft With A Fuel Cell System

ActiveUS20130288160A1Blocking to ariseEnhanced flushingPower installationsReactant parameters controlFuel cellsAirplane

A fuel cell system includes a fuel cell having a housing that encases the fuel cell, a supply line for a fuel cell fuel, and an exhaust gas line for fuel-cell exhaust gas. In this arrangement the supply line extends in the exhaust gas line, and the exhaust gas line encases the supply line while forming a space. Any leakage in the supply line thus results in the fuel being flushed out by means of the exhaust gases flowing in the exhaust gas line so that higher system reliability and a reduction in costs can be achieved.

Owner:AIRBUS OPERATIONS GMBH

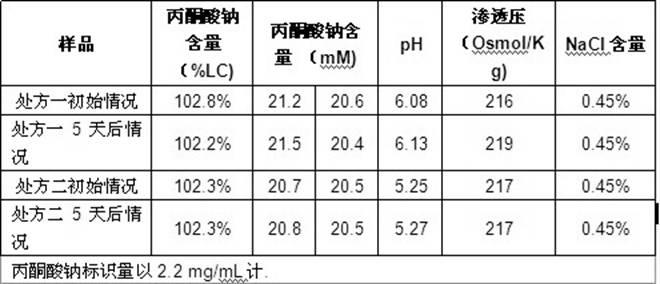

Sodium pyruvate nasal spray and preparation method thereof

ActiveCN102657611AGood antibacterial effectLess irritatingAerosol deliveryPharmaceutical non-active ingredientsNasal passageNasal passages

The present invention relates to a nasal spray containing sodium pyruvate and a preparation method thereof, belonging to the field of medical technology, being characterized in that: the nasal spray containing sodium pyruvate comprises the following components: sodium pyruvate, pyruvic acid, an isoosmotic adjusting agent, a preservative and water. Because the sodium pyruvate is capable of alleviating nasal obstruction and inflammation caused by rhinitis, a medical fluid provided in the invention can be made into a nasal spray medical fluid which is capable of entering nasal cavities by adopting a portable spraying device. The nasal spray medical fluid is particularly suitable for cleaning and removing harmful pollutants in nasal passages, paranasal sinuses and mucosal cilia and is capable of being used in nursing after a nasal cavity operation, relieving rhinostegnosis and reducing respiratory tract irritation and risks of infection. By adding the pyruvic acid to form a buffer solution, tingling caused by using the flushing fluid to wash the cavities can be reduced, and inflammation is alleviated. Allergic symptoms can be prevented or gradually alleviated for the people of special professional who often use the product provided in the invention to wash and care nasal cavities.

Owner:JIANG SU PHARMAMAXCORP +1

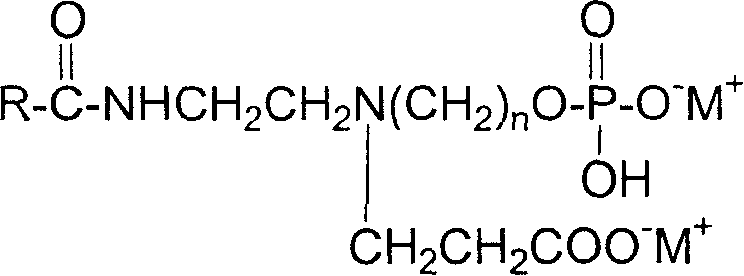

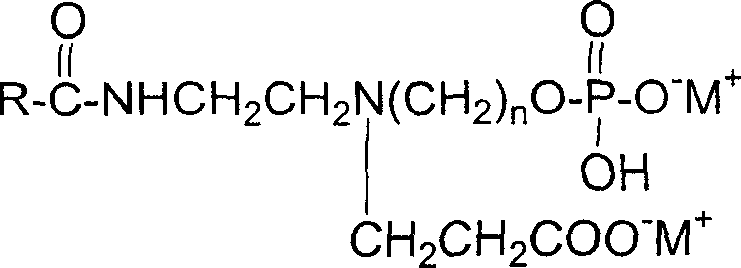

Imidazoline amophoteric surface active agent and its synthesis technology

InactiveCN1911938ALess irritatingExcellent cleaning and descaling performanceGroup 5/15 element organic compoundsPhosphateSURFACTANT BLEND

The present invention is amphoteric imidazoline surfactant in the structure as shown and its synthesis. The amphoteric imidazoline surfactant of the present invention contains phosphate ester radical and carboxyethyl radical and has improved product performance.

Owner:CHINA RES INST OF DAILY CHEM IND

Paramagnetic Gas Sensor Apparatus and Adjustment Method

ActiveUS20120203529A1Reduce dependenceThe solution result is accurateMagnetic property measurementsAnalogue computers for fluid flowMagnetic susceptibilityTime response

This present invention relates to a device for the measurement of the amount of oxygen in a gas mixture, or other gas with significantly different magnetic susceptibility than the background gas mixture, by the use of a suspended test body in a magnetic field that experiences force due to the magnetic susceptibility of the measurand gas. In order to enable a fast time response for the system with a change in oxygen concentration, a flow regime is presented which allows a fast sweep of the measurement volume combined with adjustable, balanced pressure drops via a flow balancing element (or elements) within the flow channels to independently minimise flow related uncertainties.

Owner:SERVOMEX GRP LTD

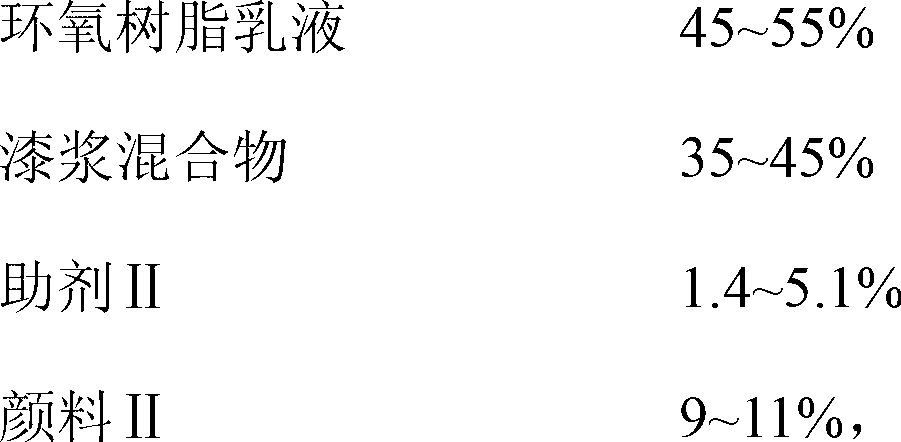

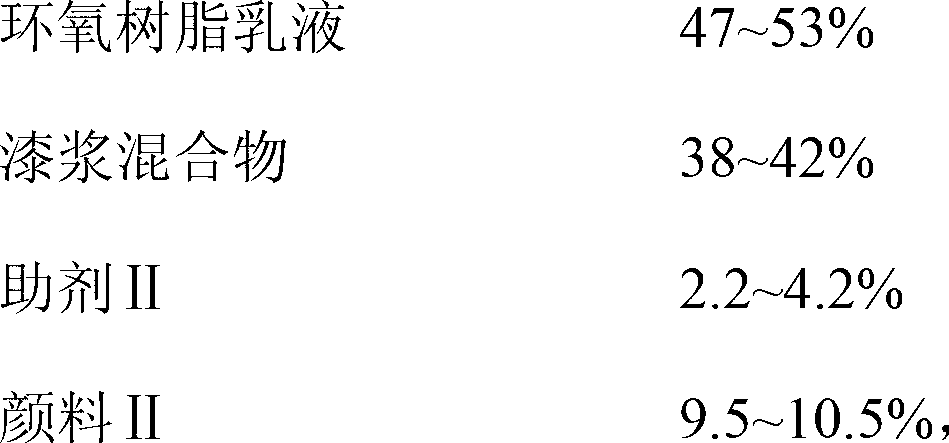

Waterborne epoxy conductive paint and preparation method thereof

ActiveCN102993903AImprove conductivityLow resistivityEpoxy resin coatingsElectrically-conductive paintsEpoxyEmulsion

The invention discloses a waterborne epoxy conductive paint. The waterborne epoxy conductive paint mainly comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 45%-55% of epoxy resin emulsion, 5%-45% of mill base mixture, 1.4%-5.1% of auxiliary agent II and 9%-11% of pigment II, and the sum of the components is 100%, wherein the mill base mixture comprises the following components in percentage by weight: 68%-73% of pigment I, 1.3%-4.6% of auxiliary agent I, 0.2%-0.6% of conductive agent and the balance of water; and the component B comprises a curing agent and an emulsifying agent. The waterborne epoxy conductive paint disclosed by the invention has the advantages of good conductibility, acid resistance, alkali resistance, heat resistance and chemical resistance, and can prevent the static accumulation inside an oil tank.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

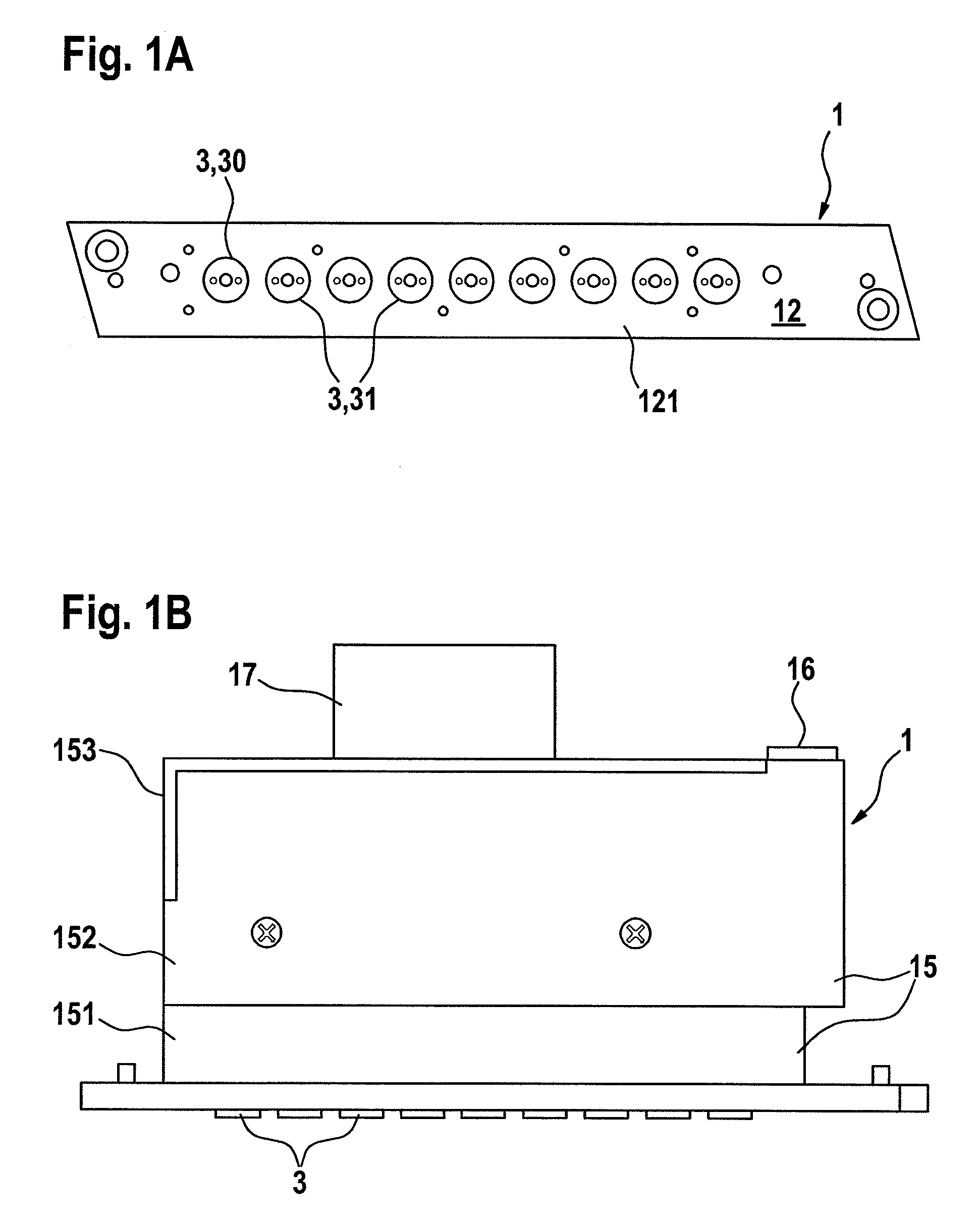

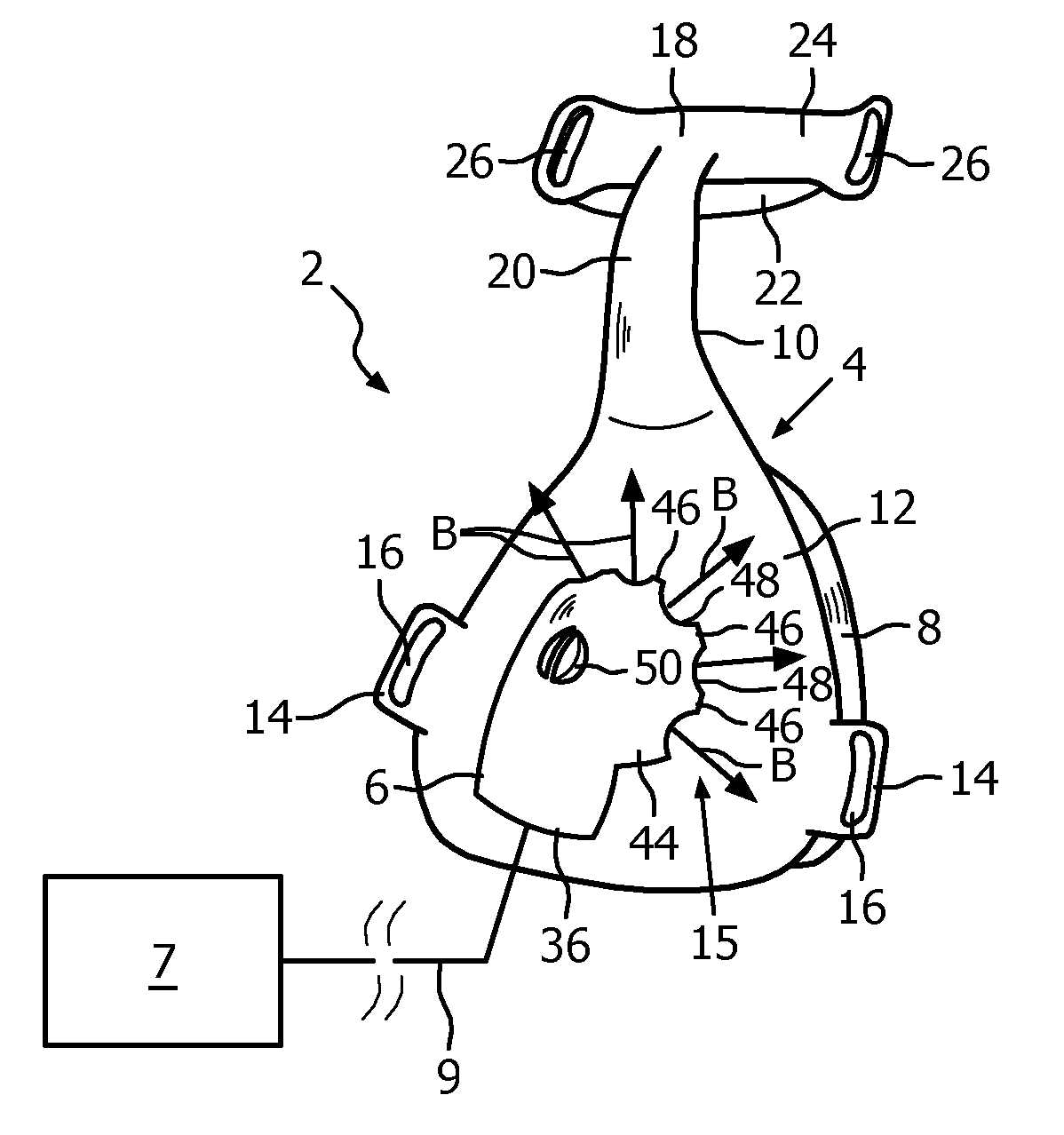

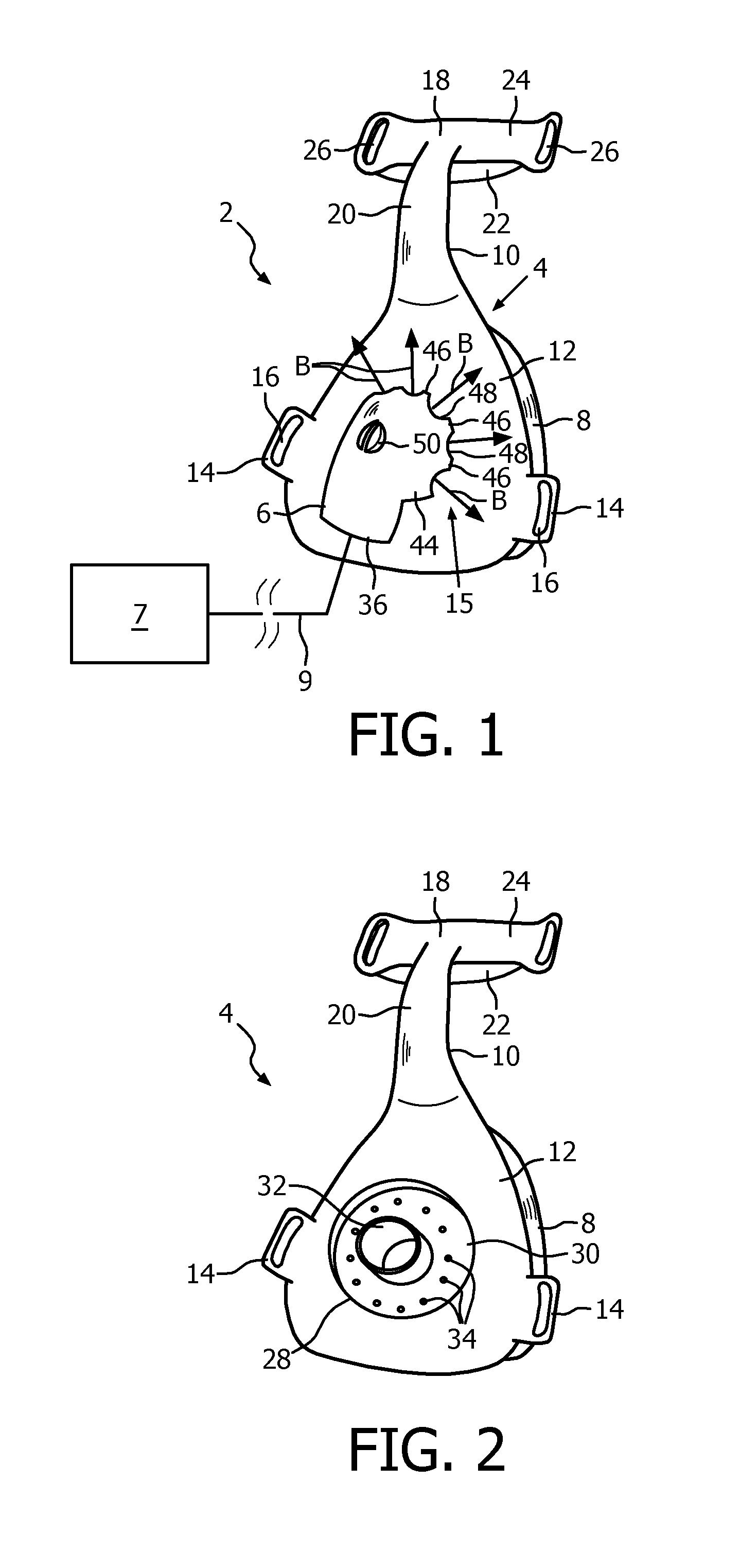

Exhaust gas assembly for a patient interface device

ActiveUS20130213401A1Overcomes shortcomingEnhanced flushingBreathing masksRespiratory masksCouplingBreathing gas

A patient interface device (2, 60, 160, 204) includes a cushion (8, 66, 210), a frame (10, 68, 162, 206) having a faceplate portion. The cushion is coupled to the frame. The faceplate portion has a main orifice and holes adjacent the main orifice. The device further includes a coupling conduit (6, 64, 164, 212) having an inlet end, an outlet end coupled to the inlet end, and a hood member having openings provided on an outer periphery thereof. The inlet end is structured to receive a flow of breathing gas. The outlet end is coupled to the main orifice to deliver the flow of breathing gas to the main conduit. The hood member surrounds the outlet end and is disposed over the holes such that exhalation gasses will through the holes and be captured by the hood member and directed through the openings.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Cleaning method of gearbox of wind-driven generator

The invention discloses a cleaning method of the gearbox of a wind-driven generator. The method comprises the steps of old oil discharging, washing, circulated washing, cleaning and circulated cleaning. According to the cleaning method of the gearbox of the wind-driven generator, firstly, No.32 oil with high liquidity and low viscosity serves as the washing oil to wash the inside of the gearbox at high pressure, and also, single-component surfactant and disperse additives can be added inside the washing oil to achieve better washing effects; secondly, the washing oil is circulated and filtered to eliminate particle residues at the bottom of the gearbox, oil residues on the walls, oil dirt and the like and further can deeply reach the dead ends inside the gearbox, where common cleaning manners cannot reach; thirdly, No.320 lubricating oil for normal operation of the gearbox serves as cleaning oil to washing the inside of the gearbox at high pressure, and then the cleaning oil is circulated and filtered to be fully fused with residue waste oil and diluted. Therefore, the waste oil residue rate can be greatly reduced, and further the cleaning effects can be greatly improved.

Owner:内蒙古中科凌胜科技有限公司

Infrared sensor flushing control method and plumbing fixture flushing system

An infrared sensor flushing control method and the plumbing fixture flushing system. The realization of flushing with two different jets is achieved by using the infrared sensor and MCU to control the electromagnetic-controlled valves. The MCU preinstalled with three different solid waste flushing procedures and one liquid waste flushing procedure, providing the water-saving consumption according to the requirements of each individual and the automatic discrimination of the usage. The integrated design also accomplishes the purpose of convenient installation and space saving.

Owner:LING LIGONG

Horizontal well leakage-proof rotational flow sand-washing device and sand-washing technology thereof

The invention relates to a horizontal well leakage-proof rotational flow sand-washing device and sand-washing technology thereof. When a horizontal well is subjected to sand washing, sand-washing liquor seriously leaks in a perforation section, and is poor in washing and carrying capabilities at a horizontal section. A horizontal well rotational flow sand-washing device and a horizontal well leakage-proof double-layer oil pipe insulating circulation mechanism are communicated by a common oil pipe, and both ends of the common oil pipe are communicated with the horizontal well rotational flow sand-washing device and the horizontal well leakage-proof double-layer oil pipe insulating circulation mechanism by an oil pipe coupling. The technology is characterized in that the horizontal well rotational flow sand-washing device, the horizontal well leakage-proof double-layer oil pipe insulating circulation mechanism and the common oil pipe are connected in sequence and enter a shaft of the horizontal well; a self-sealing preventor is mounted in a wellhead, and the sand washing liquor is pumped into an annular cavity;and whether the sand washing liquor circulates smoothly is checked, a sand washing pipe column is passed down while the sand washing liquor is pumped, and then the operation can be carried out according to routine sand washing work. The horizontal well leakage-proof rotational flow sand-washing device and the sand-washing technology thereof can prevent floor in sand-washing operation of the horizontal well from greatly leaking the sand-washing liquor, and improves working efficiency.

Owner:XIAN ZHONGFU KAIHONG GASOLINEEUM TECH +3

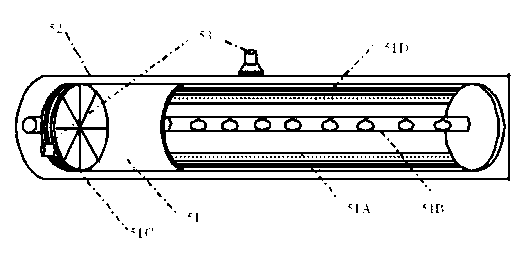

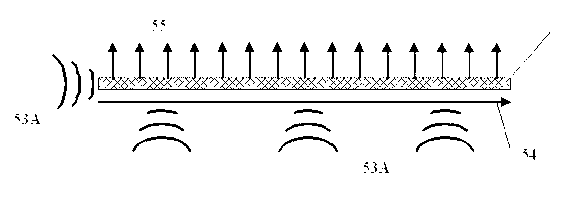

Ultrasound vibration type rolling type ultrafiltration membrane group device and ultrafiltration device thereof

InactiveCN103007759AEnhanced flushingIntensive ScrubUltrafiltrationHorizontal and verticalUF - Ultrafiltration

The invention relates to an ultrasound vibration type rolling type ultrafiltration membrane group device and an ultrafiltration device thereof. The ultrasound vibration type rolling type ultrafiltration membrane group device comprises a rolling type ultrafiltration membrane, a membrane shell and ultrasonic wave oscillators, wherein the rolling type ultrafiltration membrane is arranged in the membrane shell, the ultrasonic wave oscillators are arranged on an end socket and are arranged outside the membrane shell in horizontal and vertical directions, and the improvement of a membrane flux and deceleration of membrane pollution by the ultrasound vibration can be enhanced; and the rolling type ultrafiltration membrane comprises a ultrafiltration membrane group, a water collecting pipe, the end socket and a flow channel, and at least one ultrafiltration membrane group and the flow channel are successively overlaid so as to be rolled on the water collecting pipe and arranged in the membrane shell after being sleeved with the end socket. According to the ultrasound vibration type rolling type ultrafiltration membrane group device provided by the invention, the flux is large, the antifouling property is good, the service life is long, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com