Foamed acid washing technological method for horizontal well

A process method, foam acid technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as poor residual acid flowback effect, acid liquid leakage, secondary pollution, etc., and achieve improvement Poor cleaning effect, improved pickling effect, enhanced flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Example: The length of the horizontal section of a horizontal well is 178m, the permeability of the reservoir is 539mD, the porosity is 26%, the reservoir temperature is 88°C, the well depth is 2100m, and the screen tube completion method is adopted. The well is a newly drilled horizontal well , due to serious mud loss, the newly commissioned production is very low, and the liquid production volume is 2.1m 3 / d, the water content is 56.7%, and the foam pickling process is used to remove drilling pollution. The specific implementation plan is as follows:

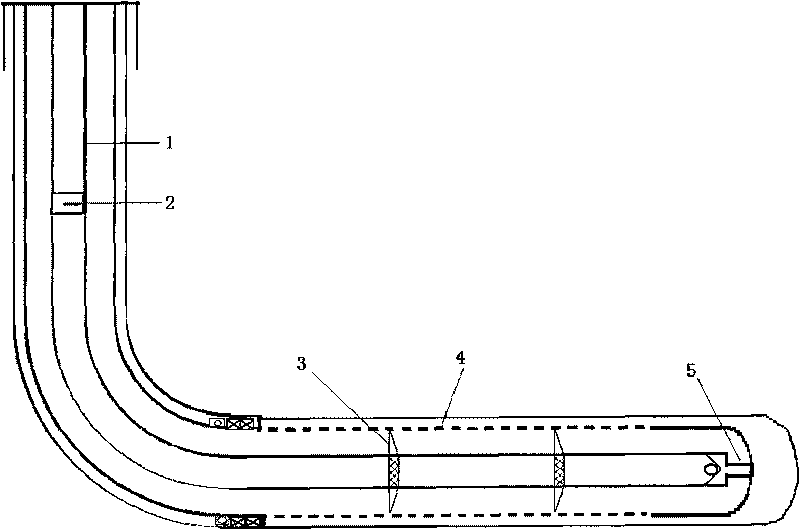

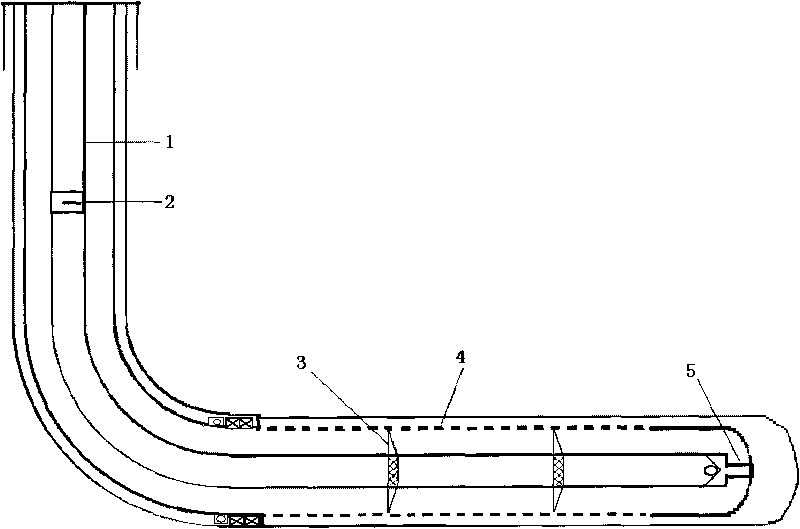

[0017] The tubing is lowered to the bottom of the reservoir, and the pickling string is as follows: figure 1 As shown, open the outlet of the tubing and inject a killing fluid composed of sewage + 1.5% ammonium chloride into the annulus of the oil set to replace the liquid in the well. The density of the killing fluid is 1.05g / cm 3 , stop injecting the killing fluid until the wellbore is full of killing fluid, and cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com