Patents

Literature

227results about How to "Improve pickling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

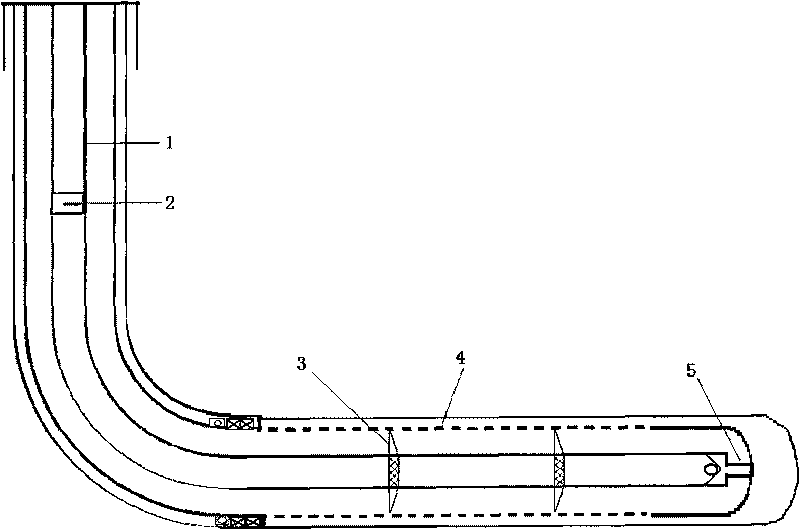

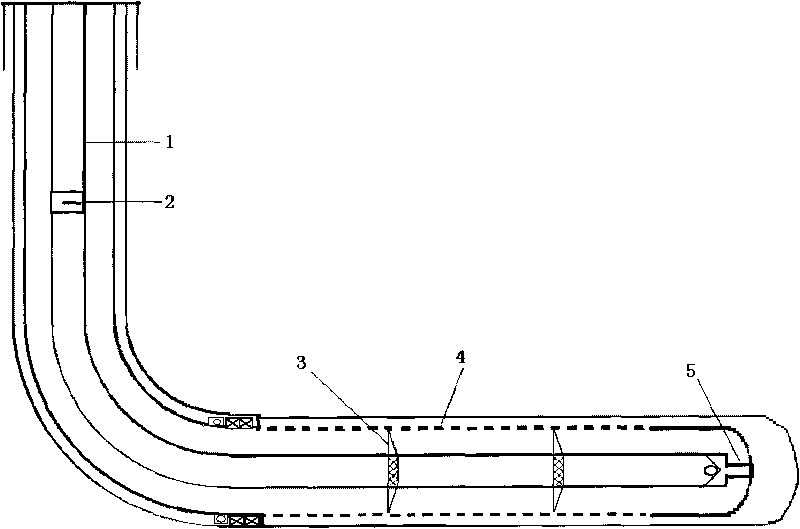

Foamed acid washing technological method for horizontal well

ActiveCN101718184AIncrease productionEnhanced flushingCleaning apparatusDrilling compositionCarrying capacityWell drilling

The invention provides a foamed acid washing technological method for a horizontal well. With two packers at a horizontal well segment installed and foamed acid washing liquid poured from an annulus, the acid liquid flows outside a sieve tube, thereby enhancing the flushing and unclogging effects on mud cakes of a drilling well. With the temporary clogging effect of foam on a high permeability position and the low density characteristic of the foam used, the acid liquid leakage can be effectively reduced; and at the same time, with the high carrying capacity of foamed liquid and the expansion energy of nitrogen gas used, acidized solid particles and residual acid can flow back, thereby avoiding the secondary sedimentation damage, solving the problems of acid liquid leakage and incomplete residual acid backflow in the conventional acid washing process, and effectively improving the acid washing effect. In the technological method, the reaction between the foamed acid washing liquid and the mud cakes of the drilling well is carried out in two steps: firstly, displacing the foamed acid washing liquid to the horizontal well segment, and shutting the well for reaction; and then, displacing the unreacted foamed acid washing liquid to the horizontal well segment, inversely squeezing the foamed acid washing liquid into the stratum, and shutting the well for reaction. The invention is especially suitable for relieving the well drilling damage of a low-pressure leakage horizontal well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

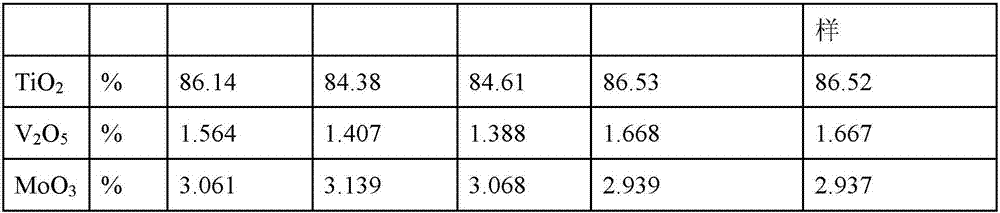

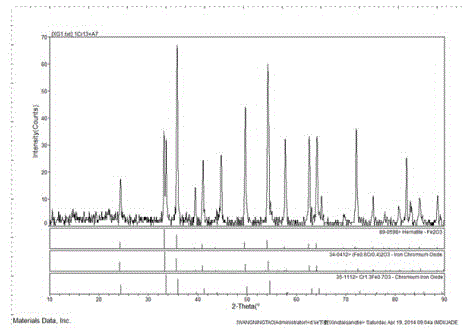

Method for regeneration of spent denitration catalyst

InactiveCN106902895AImprove pickling effectIncrease pickling speedDispersed particle separationCatalyst regeneration/reactivationPotassium hydroxideArsenic

The invention discloses a method for regeneration of a spent denitration catalyst, and relates to a composition for a cleaning solution and an application thereof, and an activity recovering method for a spent SCR catalyst. The invention is used for solving the technical problems in the prior art that a lost catalyst active component in a regeneration process cannot be selectively supplemented and an iron rust defect of a metal module framework cannot be effectively eliminated. The method comprises the following steps: one, dust cleaning; two, spraying; three, cleaning; four, re-cleaning; five, acidification; six, pre-drying; and seven, activity supplementing. Cleaning media of sodium hydroxide and potassium hydroxide can dissolve inactivated V2O5 and toxic element arsenic on the surface of the catalyst. While the method can selectively supplement the catalyst active component (TiO2), the iron rust removal rate of the metal module framework reaches 19% to 24%. The invention belongs to the field of spent denitration catalyst regeneration.

Owner:黑龙江丰迪环保科技有限公司

Chemical stainless steel polishing solution

The invention discloses a chemical stainless steel polishing solution which comprises the following components in content: 80mL / L to 120mL / L of 68% nitric acid, 50mL / L to 150mL / L of 40% hydrofluoric acid, 50mL / L to 120mL / L of 30% hydrogen peroxide, 50mL / L to 80mL / L of 85% phosphoric acid, 50mL / L to 80mL / L of 98% concentrated sulfuric acid, 10mL / L to 30mL / L of 95% ethanol, 5g / L to 15g / L of urea, 20g / L to 40g / L of a brightening agent, 0.5g / L to 2g / L of a fog inhibitor and 2g / L to 6g / L of a corrosion inhibitor. The chemical polishing solution is stable in polishing speed; a processed stainless steel workpiece is flat in surface, bright, free of dust, also stable in performance, capable of being stored for a long time and low in production cost; during polishing, irritant acidic gas is small in volatility.

Owner:HUBEI UNIV OF EDUCATION

Hydrochloric-acid acid washing liquid and acid washing method for 400-series stainless steel hot-rolled annealing wire

The invention relates to a hydrochloric-acid acid washing liquid and an acid washing method for a 400-series stainless steel hot-rolled annealing wire. The acid washing liquid comprises hydrochloric acid, nitric acid, a corrosion inhibitor, a surface active agent, an accelerant, a solution stabilizer and water. The acid washing liquid comprises the substances at a mass ratio as follows: 8wt%-22wt% of hydrochloric acid, 0.01wt%-10wt% of nitric acid, 0.01wt%-1wt% of the corrosion inhibitor, 0.05wt%-1wt% of the surface active agent, 0.05wt%-1wt% of the accelerant, 0.05wt%-1wt% of the solution stabilizer and the balance of water. The acid washing method comprises steps as follows: the acid washing liquid is injected to an acid washing tank, the whole coil of the hot-rolled wire after annealing is directly placed in the acid washing tank for acid washing, the acid washing temperature is in a range from 45 DEG C to 85 DEG C, and the acid washing time is 0.5-2 h. The treated wire rod surface is clean, white and bright, oxide scale residues are avoided, the acid washing process is stable, the surface is slightly frosted and suitable for wire drawing, and a follow-up passivation process can be omitted.

Owner:XINGTAI IRON & STEEL

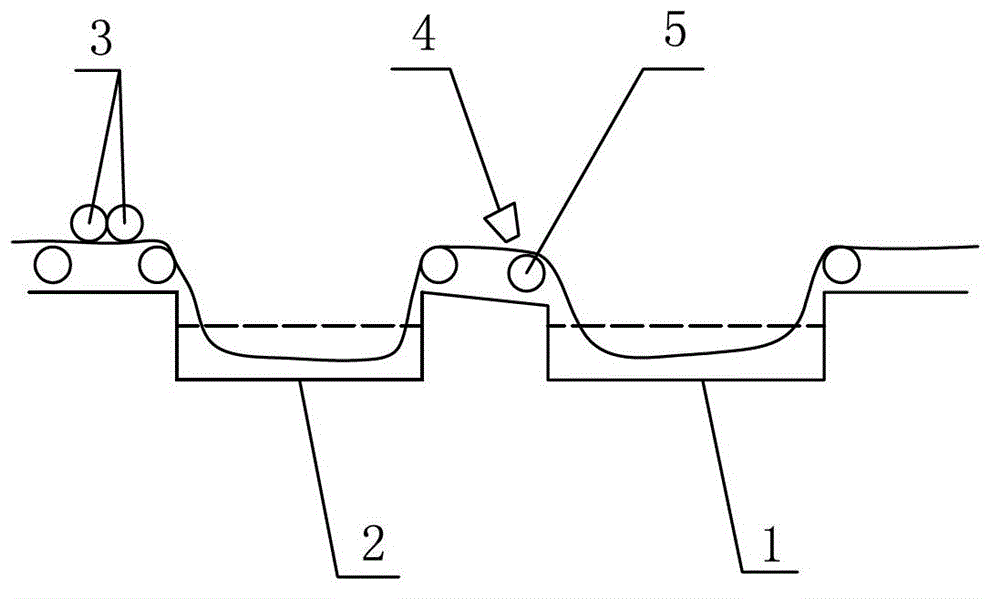

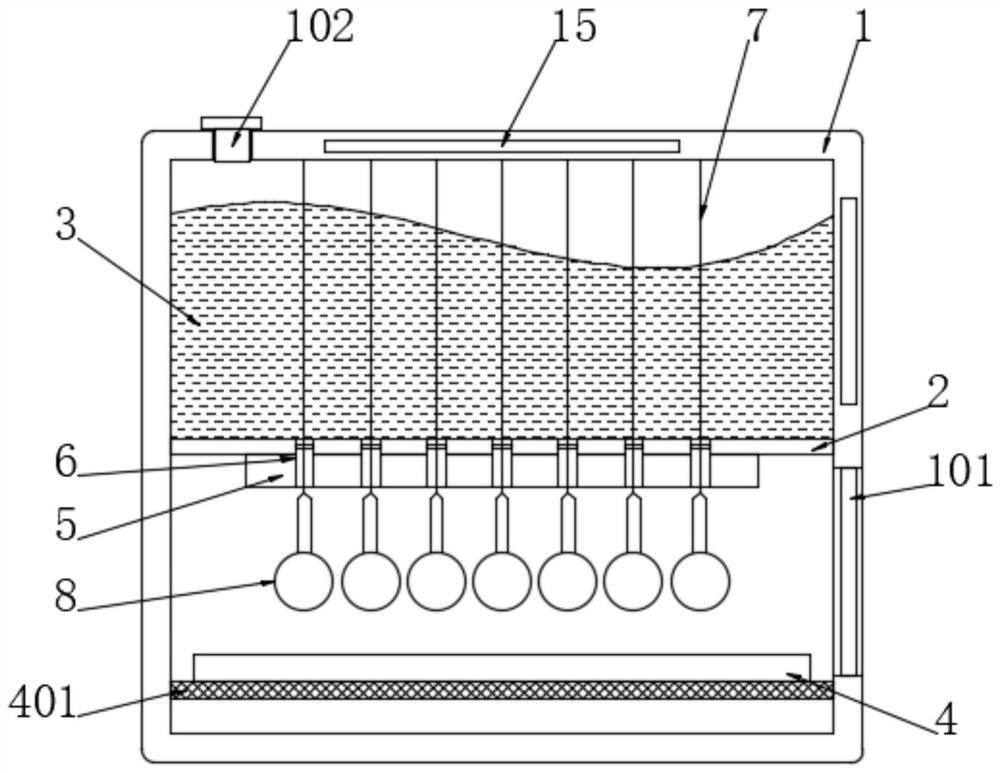

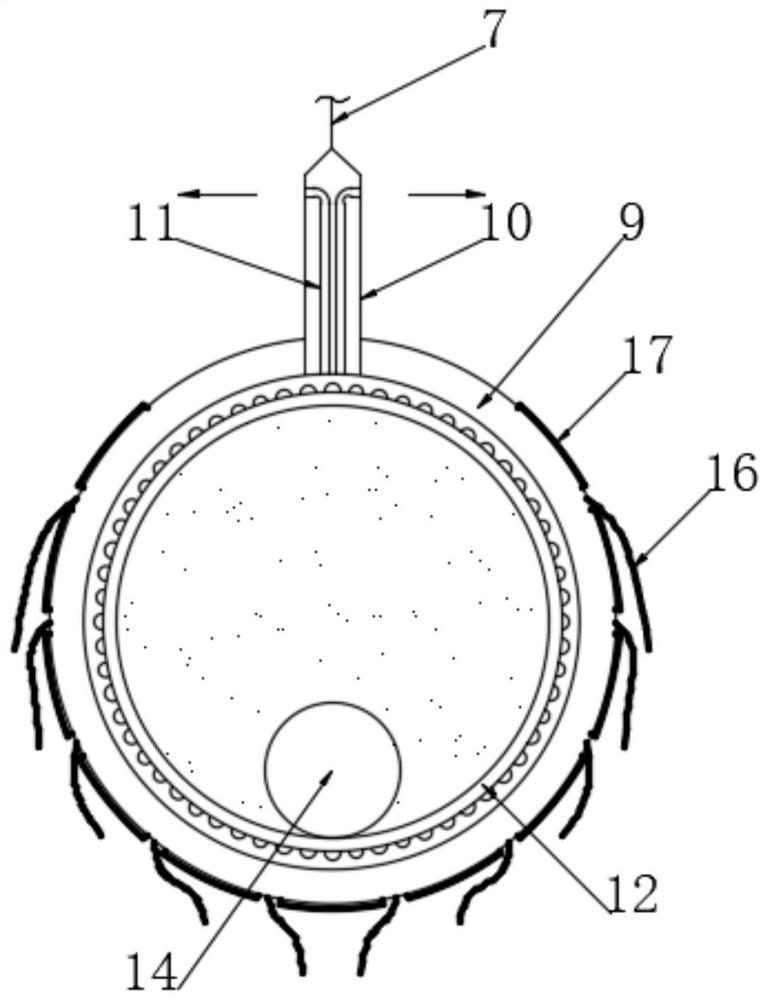

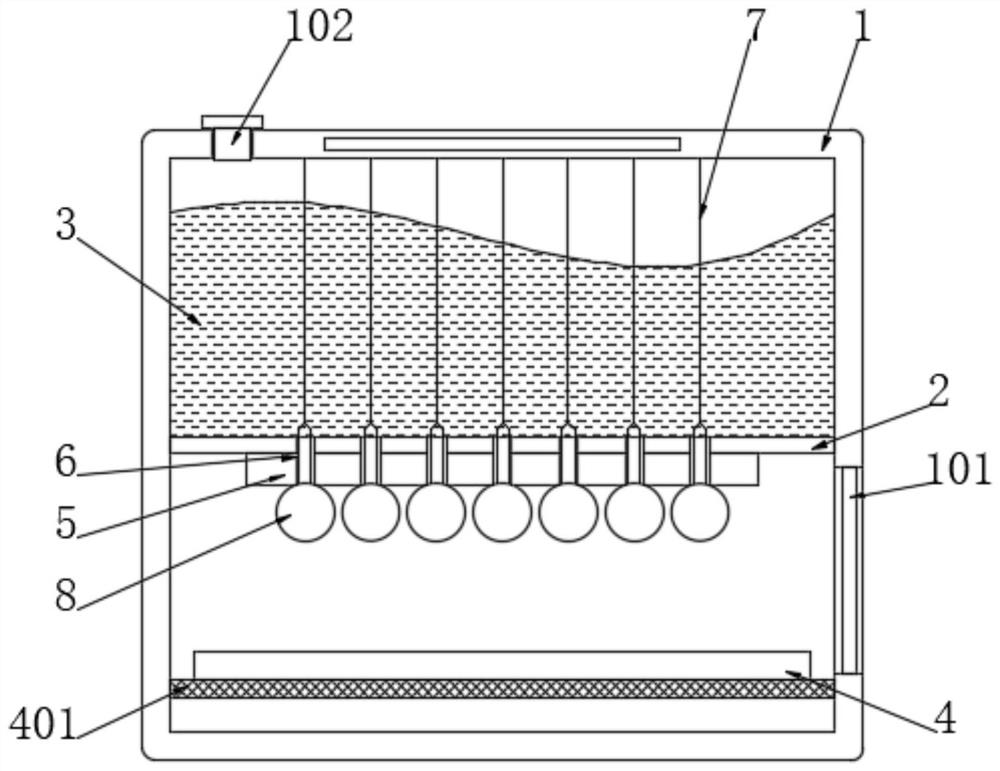

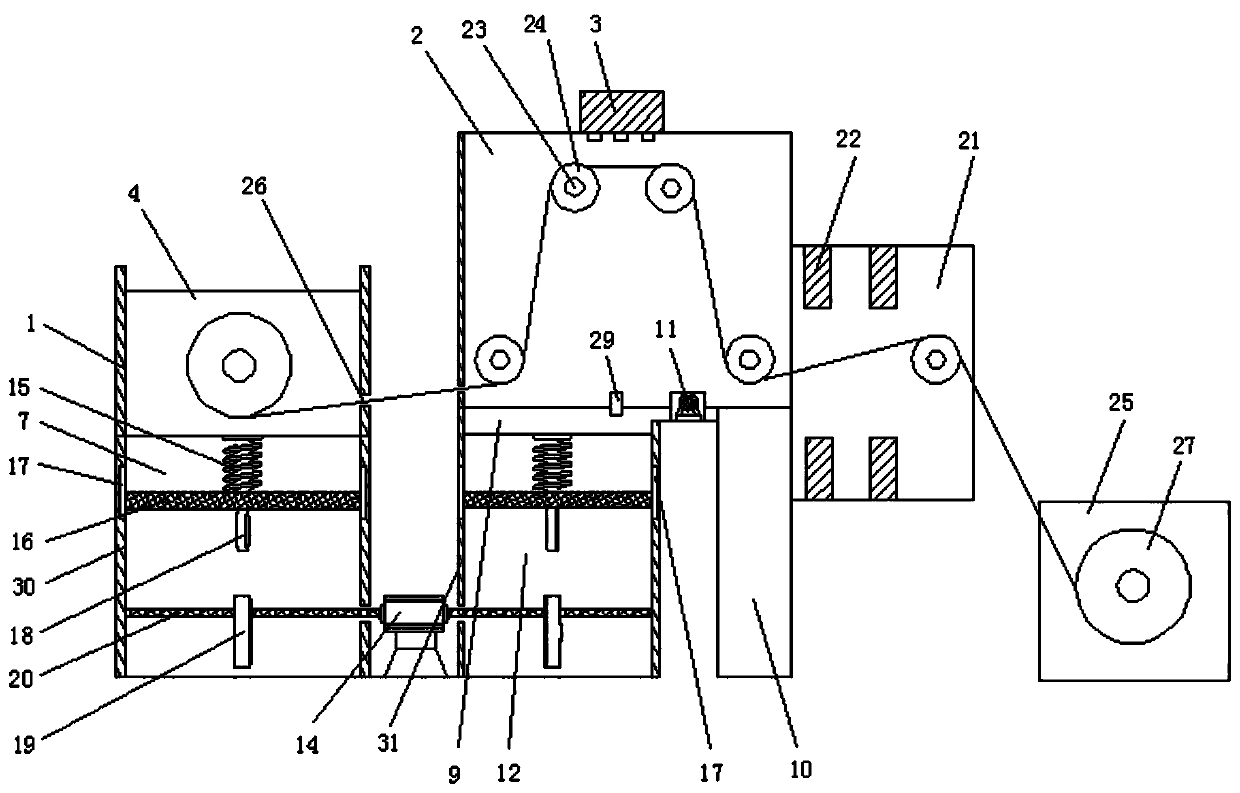

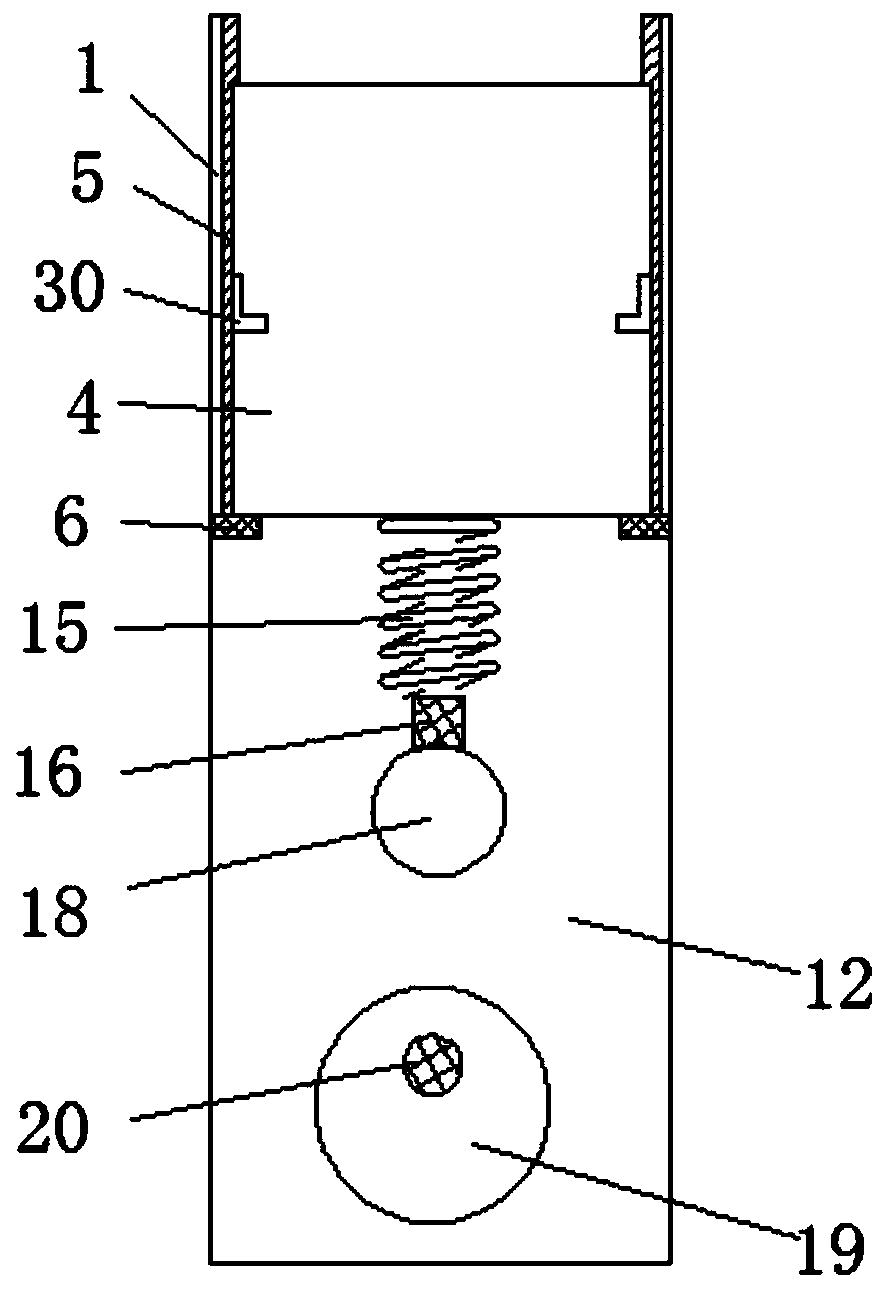

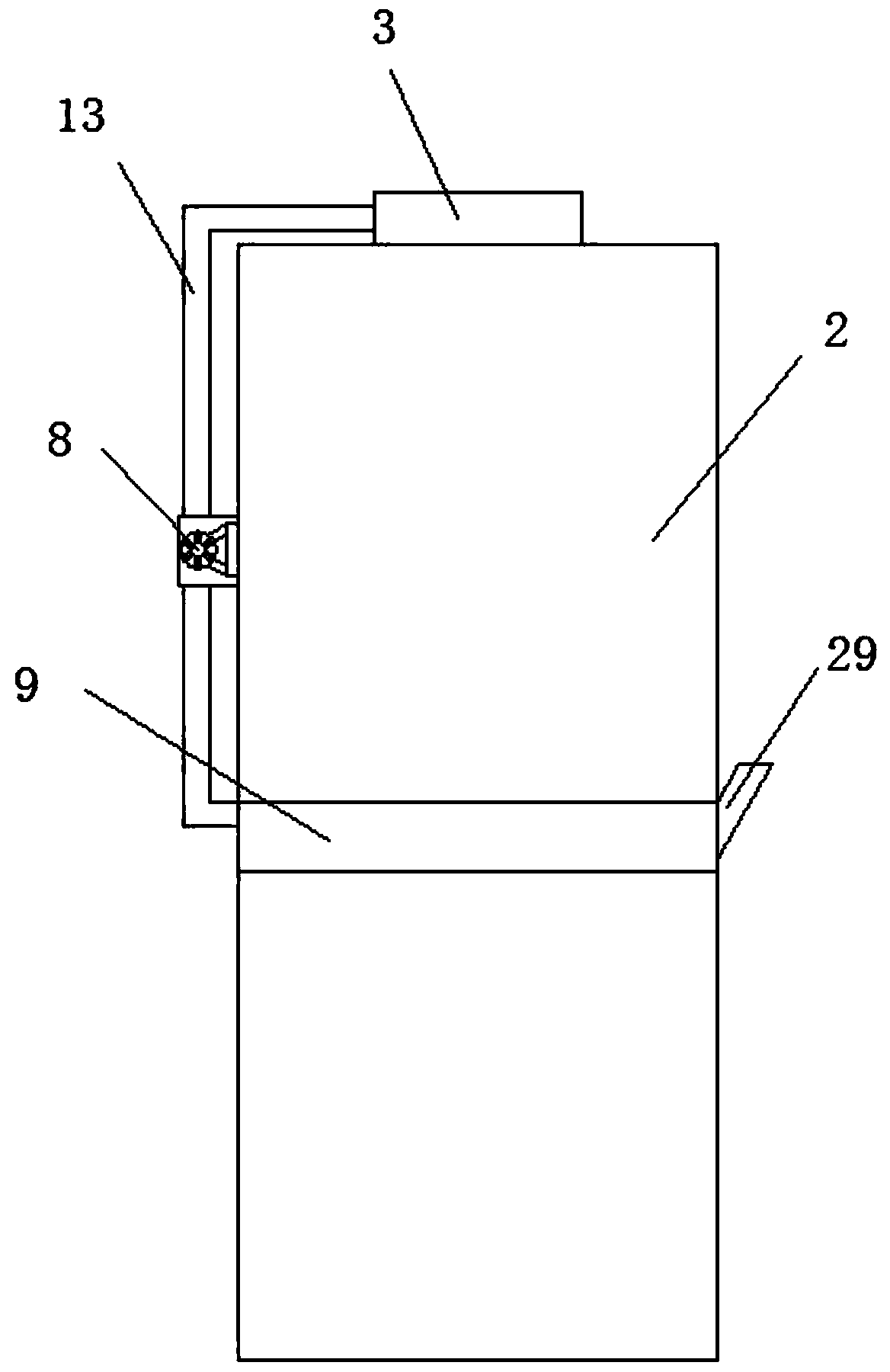

A high-efficiency, energy-saving and environment-friendly pickling device for hydraulic pipe fittings

A high-efficiency, energy-saving and environment-friendly pickling device for hydraulic pipe fittings, including a pickling tank with a raised middle and concave sides. The raised part in the middle of the pickling tank is provided with an acid-resistant bracket for placing the pickling pipe, and one side of the pickling tank is concave. There is a sediment frame in the tank, a steam heater is installed in the concave tank on the other side, a return pipe is provided between the concaves on both sides, and a float covering the pickling liquid surface is installed on the upper part of the pickling tank. There is a nozzle at one end of the pickling pipe, and the nozzle is fixed on the distributor. The distributor is connected to an acid-resistant pump through a quick joint, and is equipped with a device to control the on-off of the heater steam and the start-stop of the acid-resistant pump drive motor according to the temperature of the acid liquid. Electric control system. Utilizing the acid delivery pump to realize the circulating flow of the cleaning liquid effectively improves the uniformity of the acid concentration, and effectively improves the cleaning efficiency and cleaning quality; the structure is simple, the acid liquid can flow and circulate, the pickling efficiency is high, and the pickling effect is high. Good, energy saving and environmental protection.

Owner:徐州市全球通精密钢管有限公司

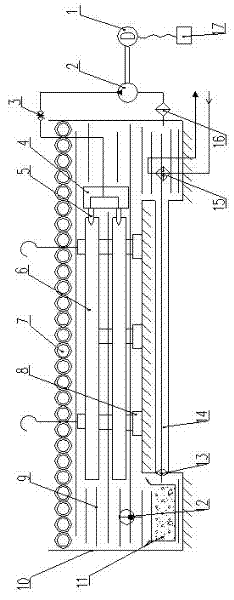

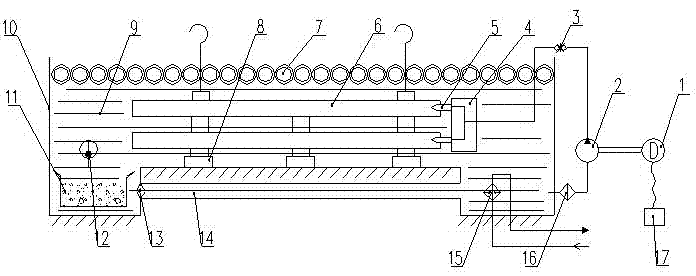

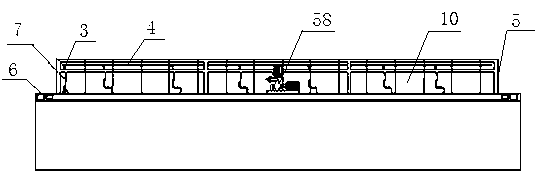

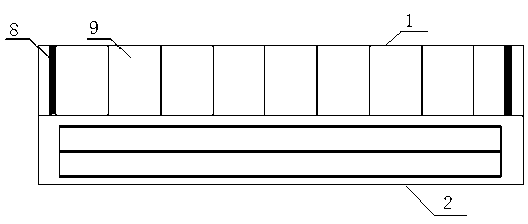

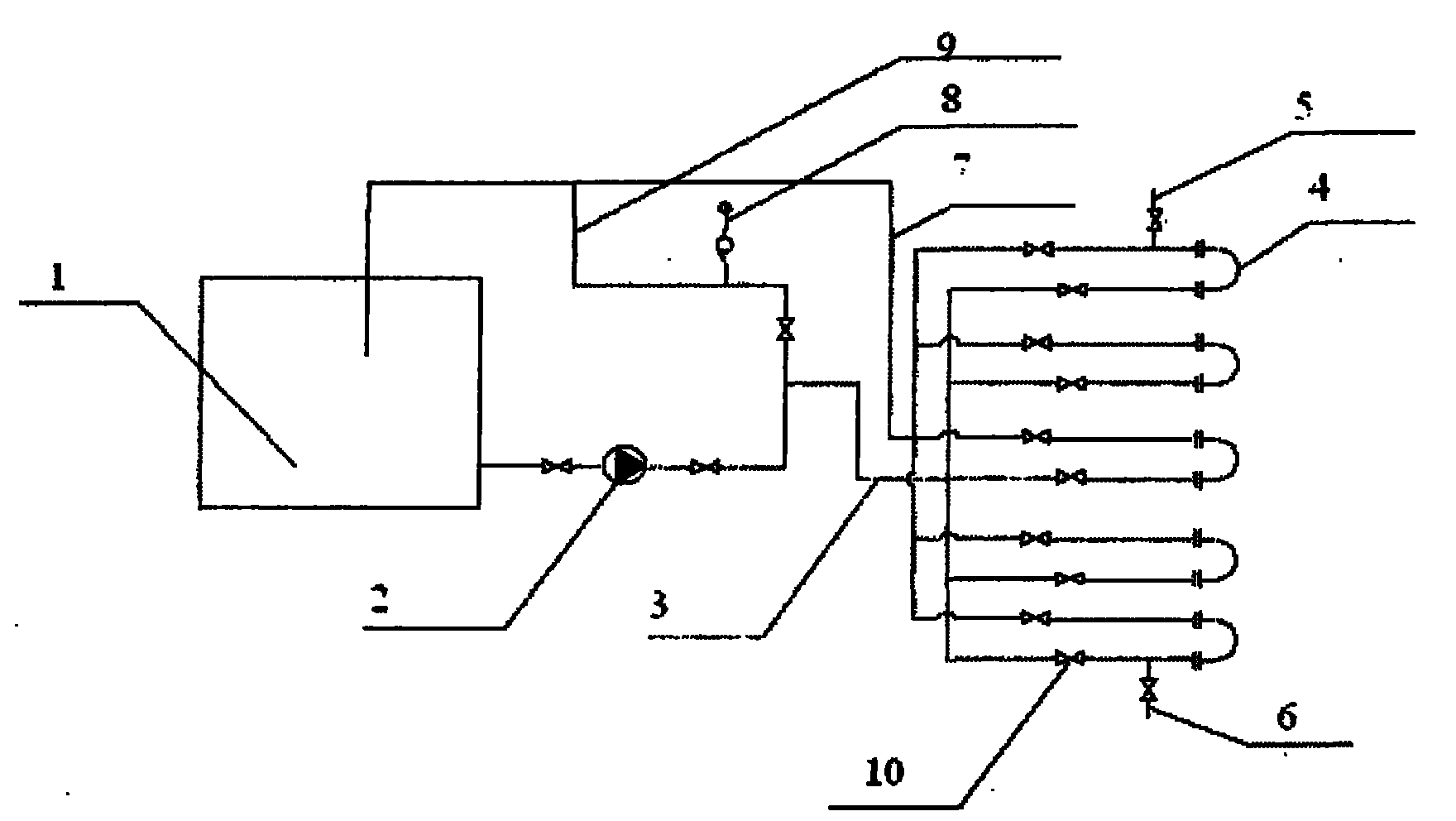

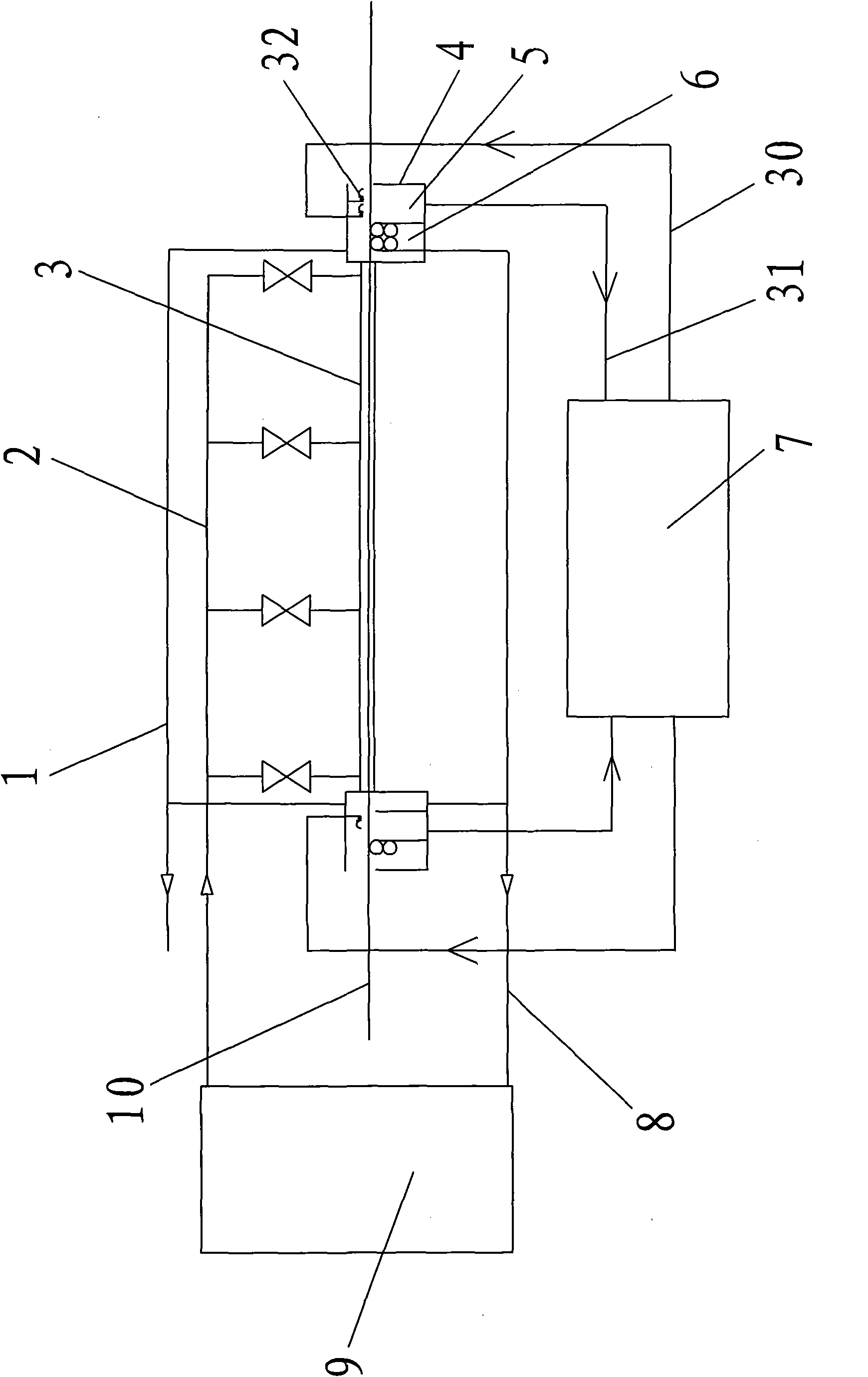

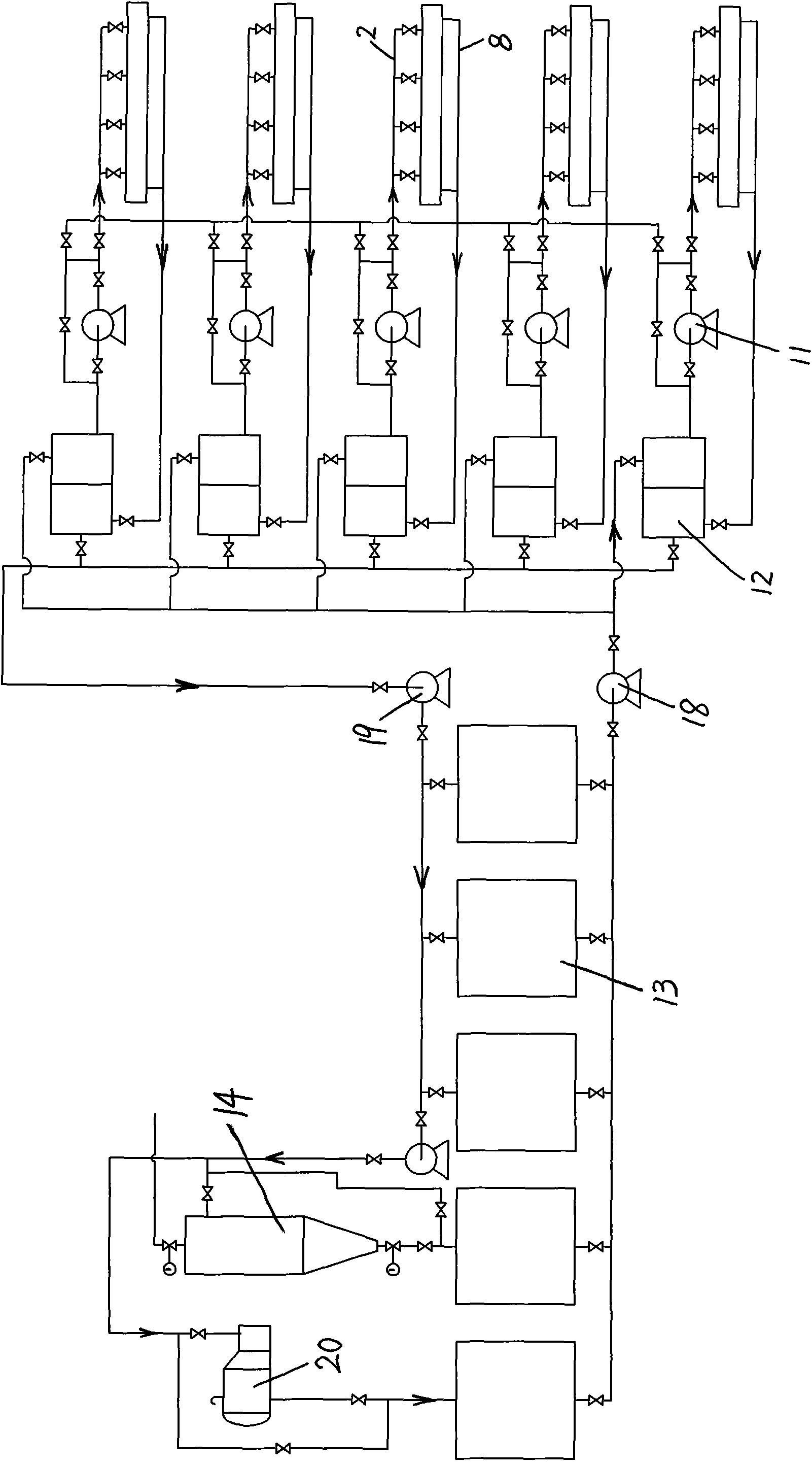

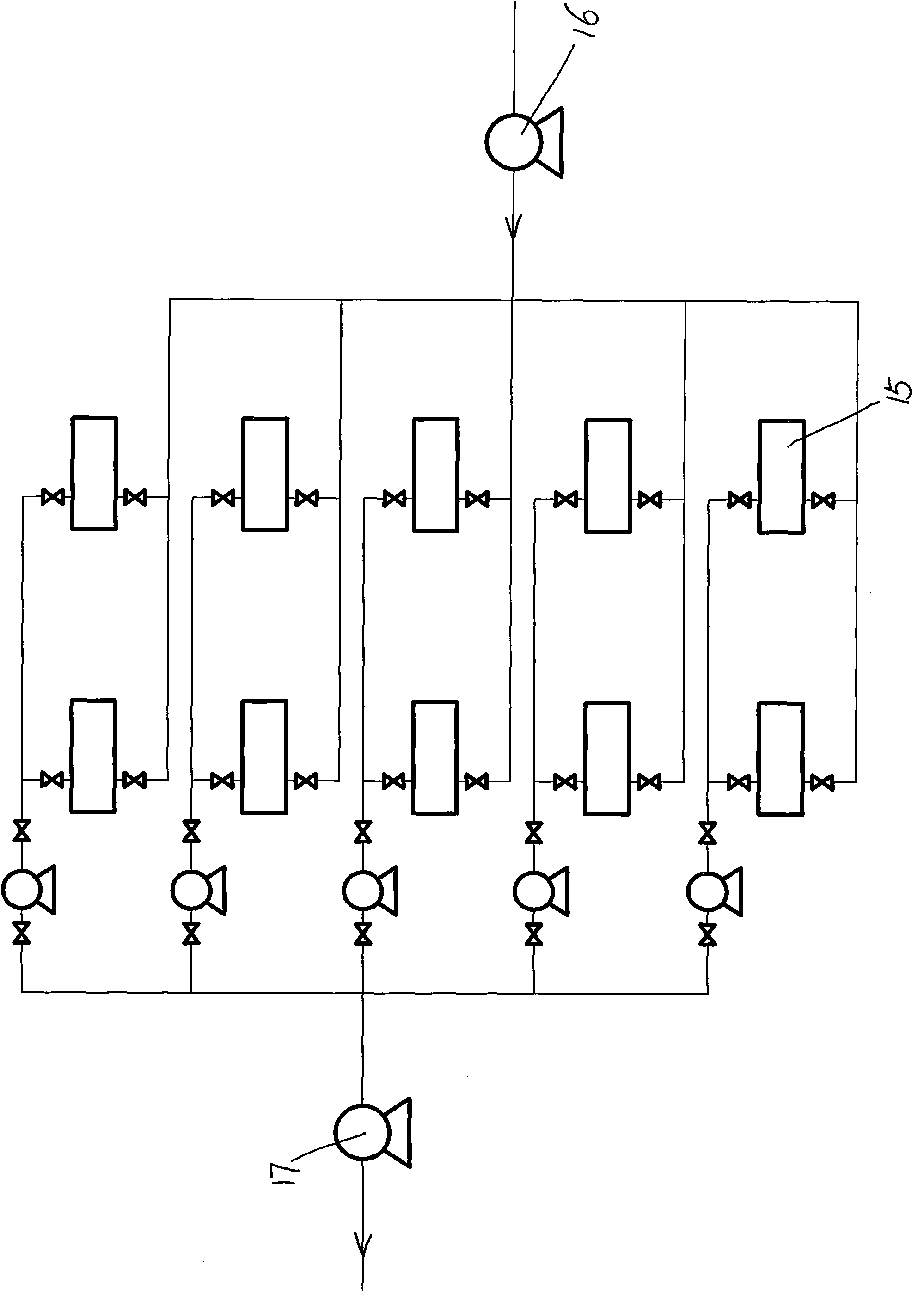

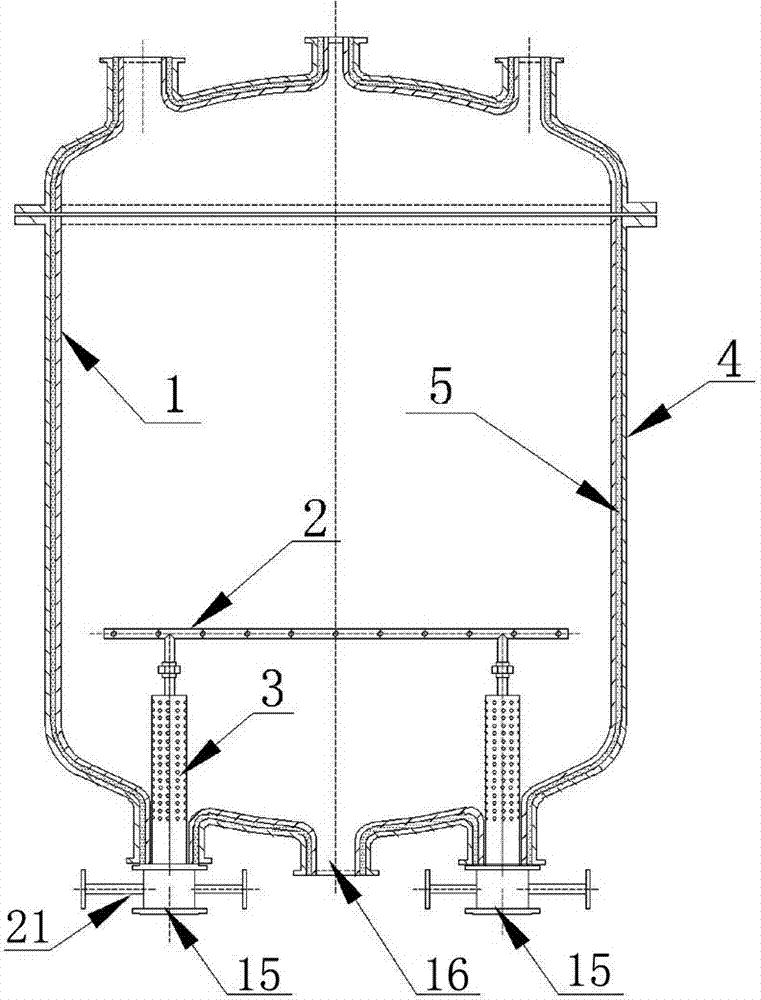

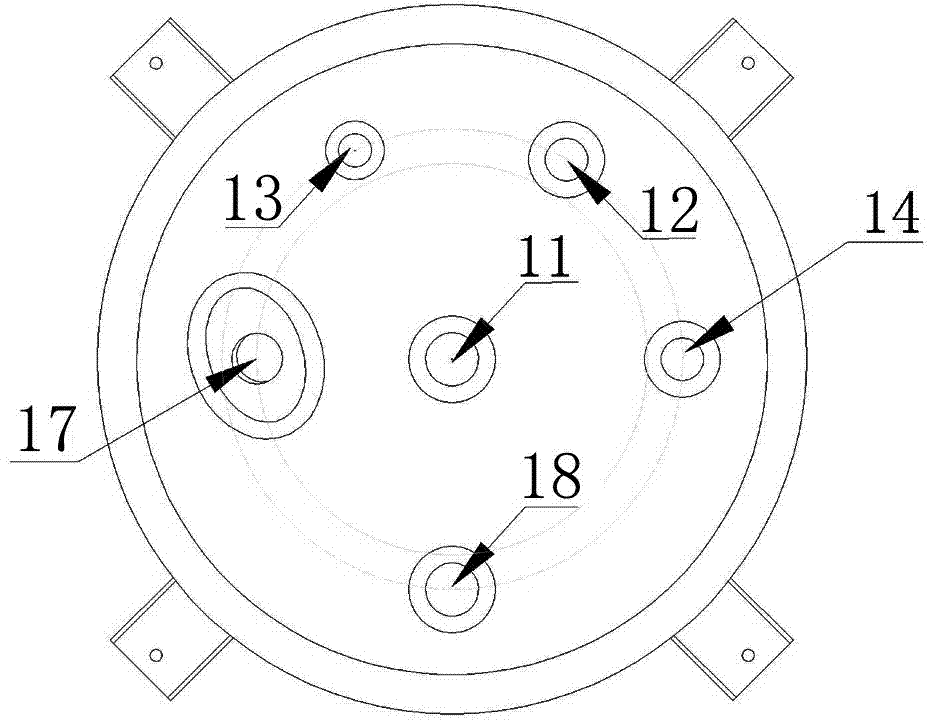

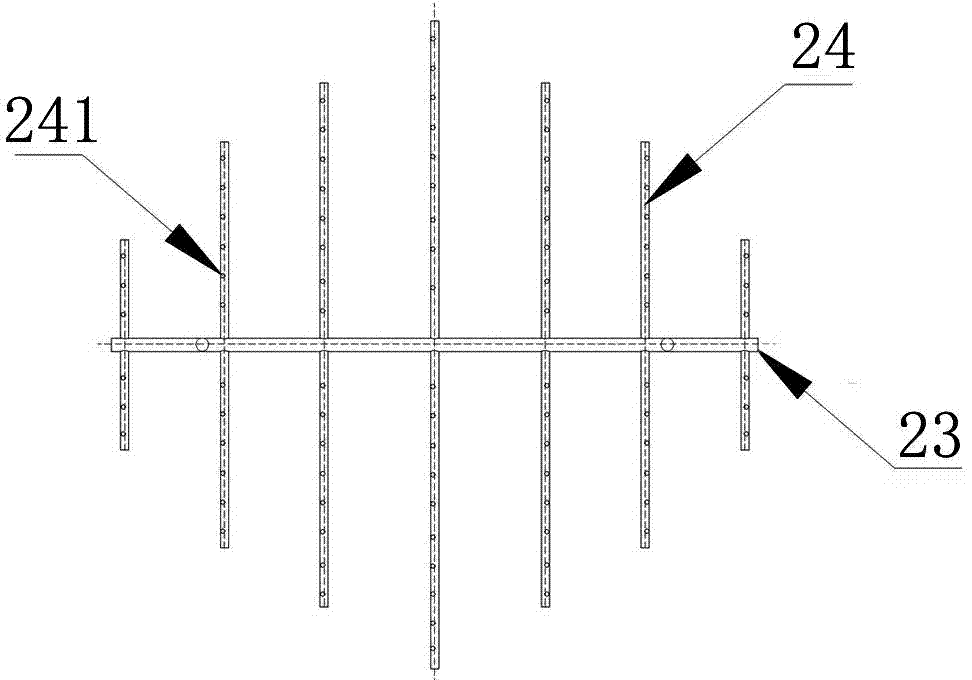

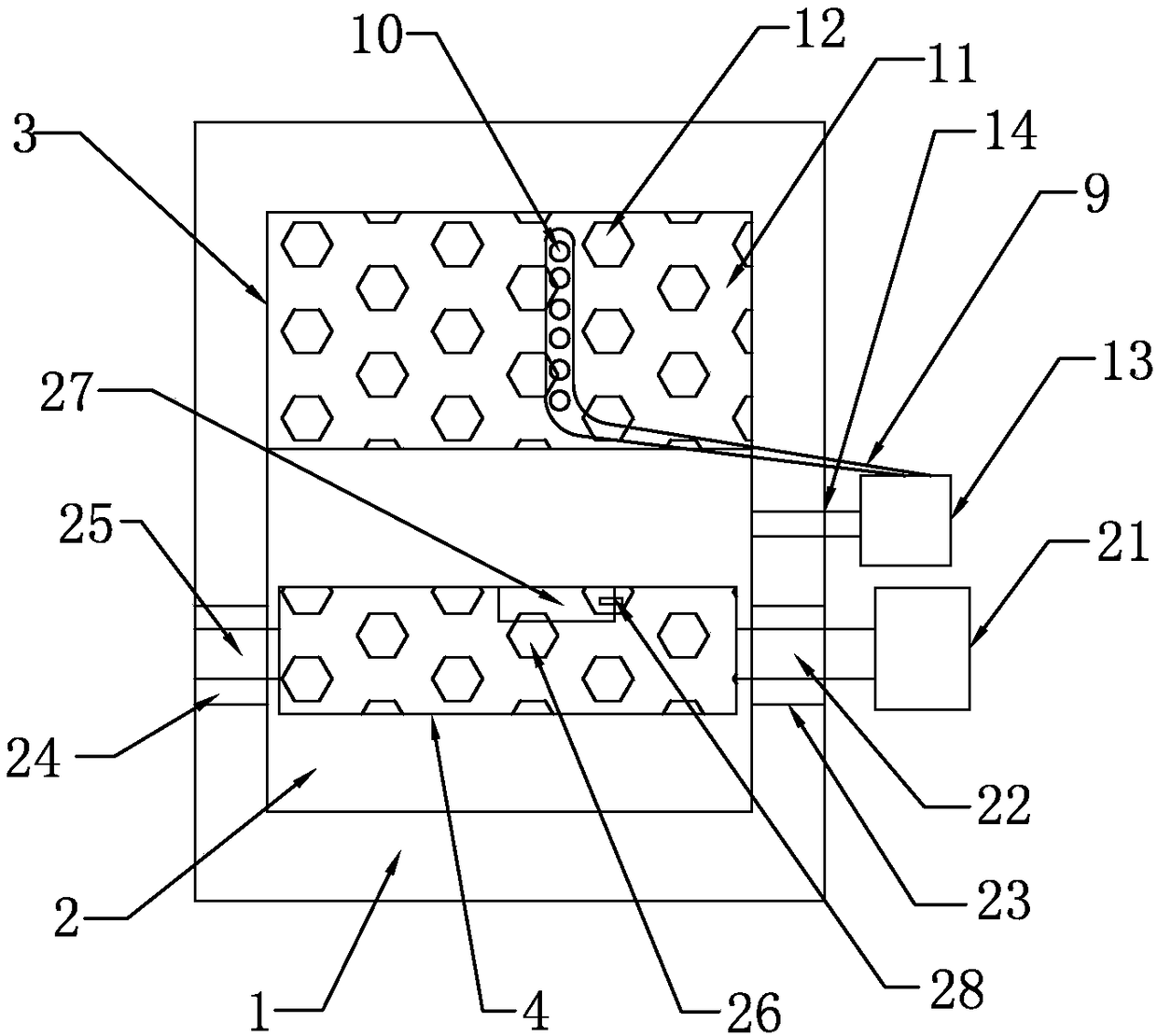

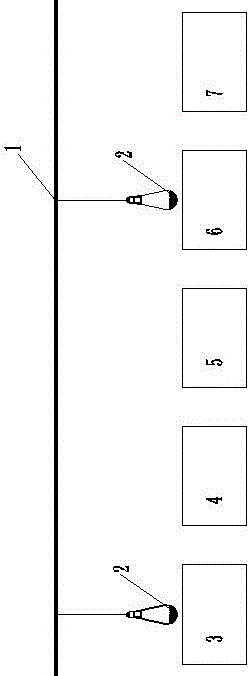

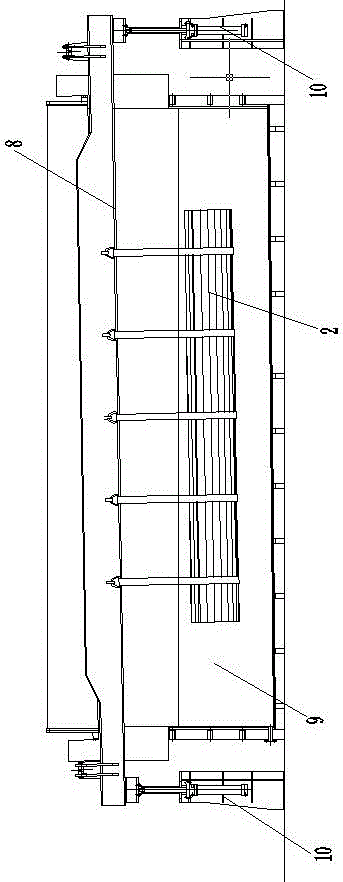

Cyclic acid pickling device and method of trough type pickling tank

The purpose of the invention is to provide a cyclic acid pickling device of a trough type pickling tank and a cyclic acid pickling method of a trough type pickling tank. Rusts and other impurities adhering to the inner and outer surfaces of a pipeline can be efficiently removed through the device and the method provided by the invention; the production cost is reduced and the discharge of waste acids is reduced because the acid pickling solution is cyclically filtered and used repeatedly; and therefore, actual use effects of energy conservation and emission reduction are achieved. According to the invention, the processes of soaking acid pickling, side spray forced cyclic acid pickling, cyclic acid pickling by injecting an acid into a pipeline and acid pickling by spraying outside the pipeline are adopted to performing multi-directional acid pickling on the pipeline, and the acid pickling effect on the pipelines which are deep in rusting degree, large in pollutant adsorption quantity, and multiply bent are especially obvious; simultaneously, a method of cyclically filtering and recycling the acid pickling solution and complete covering with soft plastics is adopted, so that the purposes of energy conservation and emission reduction are achieved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Pickling impurity removal method and equipment and method and system for purifying polysilicon

InactiveCN101671026AReduce contentOptimizing the pickling processSilicon compoundsGranularityMaterials science

The invention discloses a pickling impurity removal method for removing impurities after metallurgical silicon drawacharge and before melting purification. The method comprises the following steps: slowing down the cooling process of the drawacharge of the metallurgical silicon, smashing the cooled metallurgical silicon into silicon powder with certain granularity, and selecting a plurality of acids to carry out pickling operation on the silicon powder according to a certain sequence. The invention also discloses pickling impurity removal equipment, a metallurgical silicon purification methodand a metallurgical silicon purification system. In the invention, optimized cooling process and reasonable pickling sequence are adopted, and proper granularity and suitable temperature are selected,therefore, the pickling process flow is optimized to realize the optimal pickling effect, the content of Fe, Al, Ca, Mn, Ti, Ni and other metal impurities are effectively reduced, and the purification purpose is realized.

Owner:BAOTOU SHANSHENG NEW ENERGY

Stainless steel pipeline pickling method

The invention discloses a stainless steel pipeline pickling method. The method sequentially comprises steps of pickling, neutralizing and passivating. According to the method of the present invention, the steps of pickling, neutralizing and passivating are integrated, wherein the added acid solution is not required to discharge, the alkali solution is directly added to carry out the neutralizing, then the passivating agent is added, the waste liquid is discharged in one time, and the solutions required by the three steps are completed in the one pickling solution tank, such that the working procedure is saved, and the waste liquid is treated in one time, and the operation is convenient to performed; the weak acid is adopted, such that hydrogen ions and chloride ions are avoided in the pickling solution so as to protect the passivation film and reduce the environment pollution.

Owner:天津市耀新科技发展有限公司

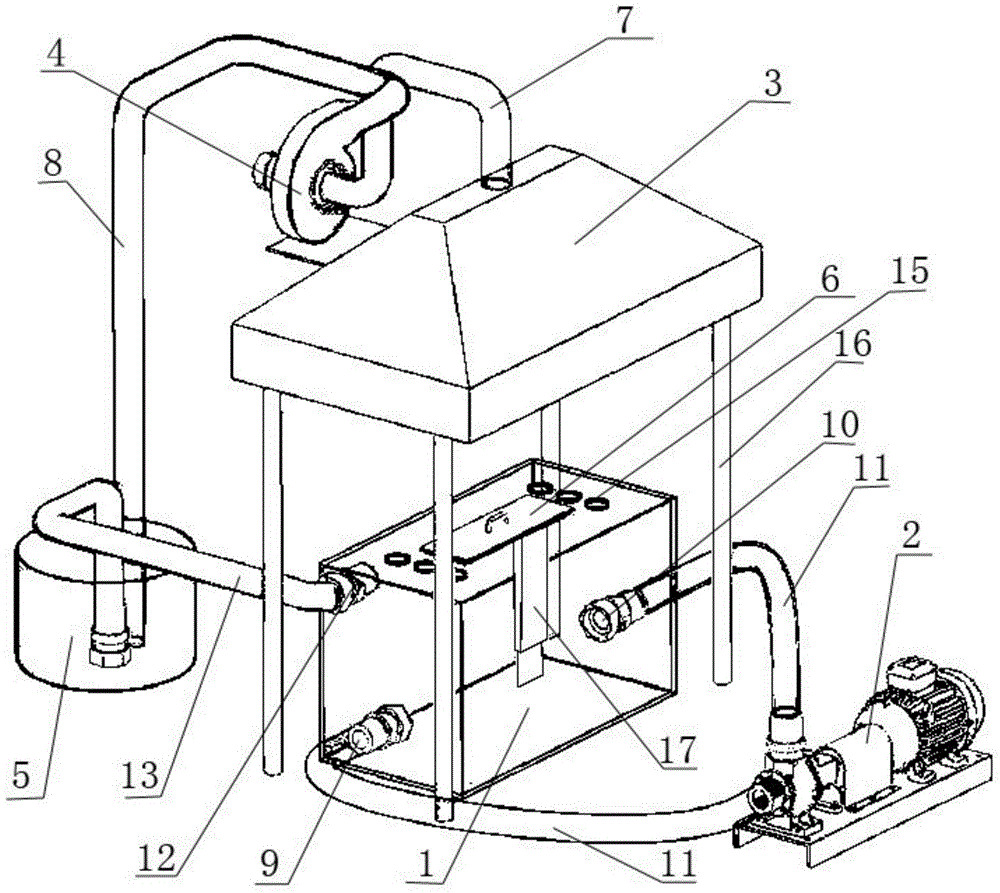

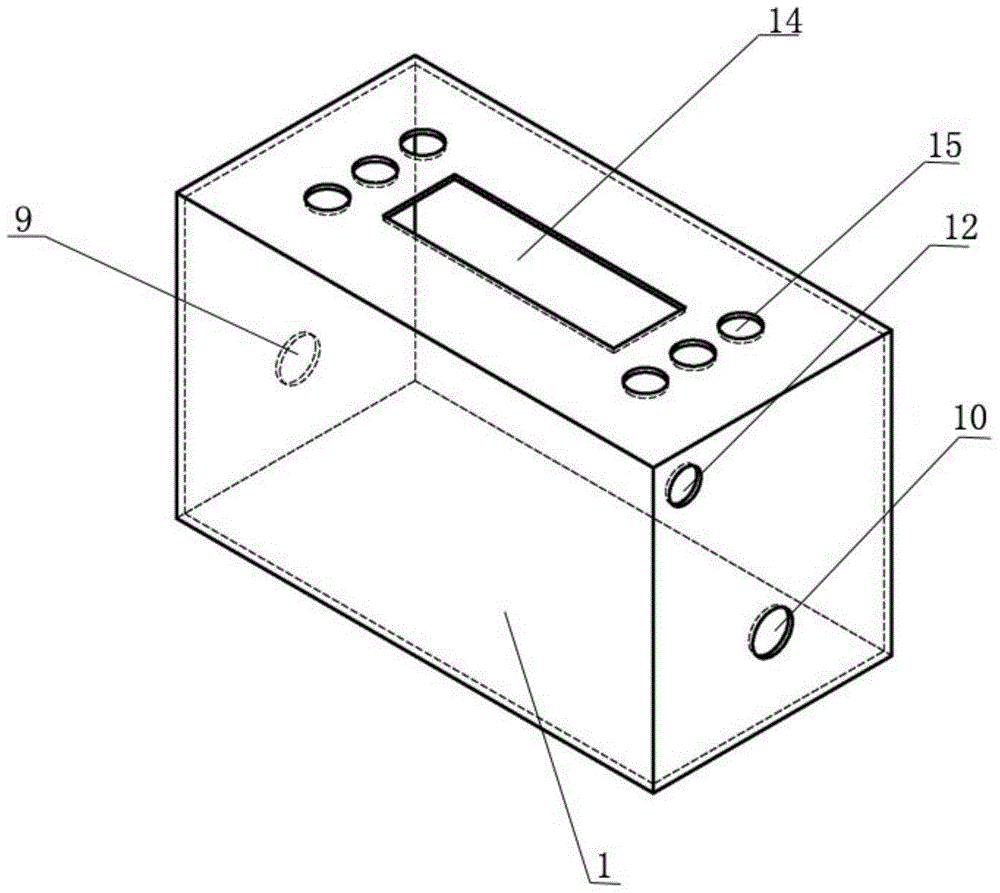

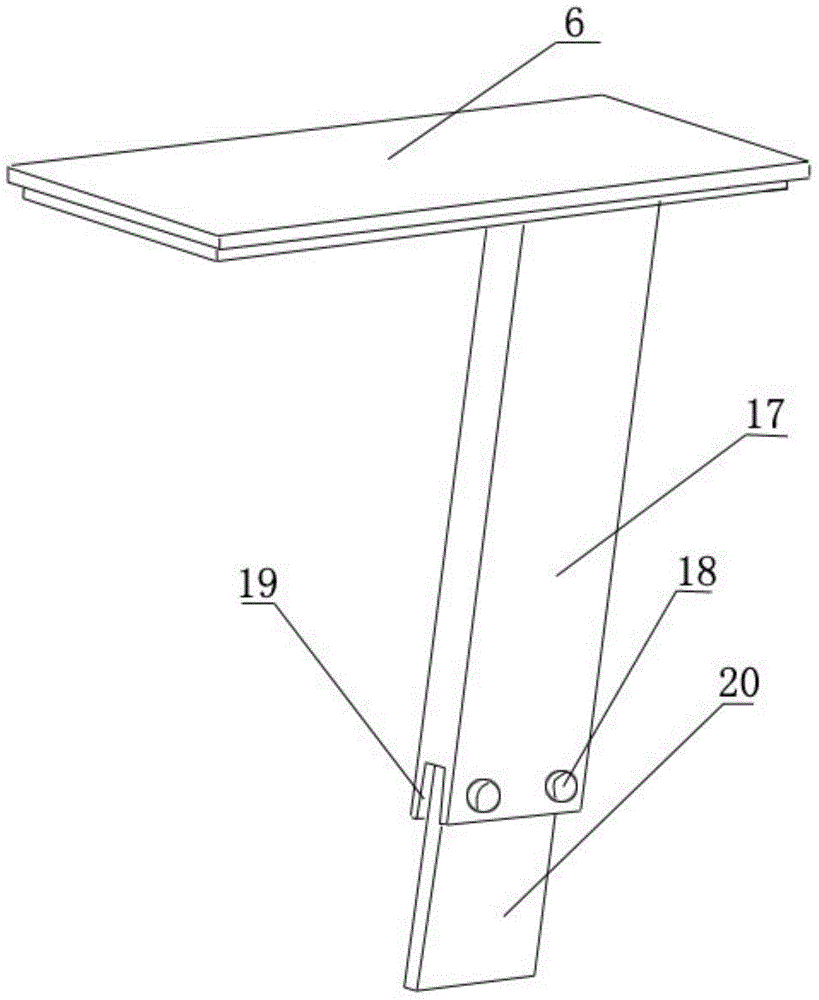

Acid pickling device for laboratory

The invention relates to an acid pickling device for a laboratory. The acid pickling device comprises a pickling bath, a fluoroplastic magnetic drive pump, an acid mist absorption cover, a suction fan, an acid mist collection vessel, a cover plate and a heating device inserted into the pickling bath, wherein the acid mist absorption cover is arranged above the pickling bath; a suction port and an air outlet of the suction fan are connected with a suction pipe and an air outlet pipe respectively; one end of the air suction pipe extends into the acid mist absorption cover to be communicated with the acid mist absorption cover; one end of the air outlet pipe is communicated with the acid mist collection vessel; an acid liquor draining hole and an acid liquor entering hole are symmetrically formed in two side walls of the pickling bath and connected with a suction port and a drain port of the fluoroplastic magnetic drive pump respectively through an acid liquor conveying pipe; an acid mist discharge port is further formed above one side wall of the pickling bath and is connected with an acid mist conveying pipe communicated with the acid mist collection vessel. The acid pickling device for the laboratory is compact in structure, high in acid pickling efficiency, good in energy saving and environmental protection property and suitable for acid pickling device in the laboratory, and cleaning acid liquor can flow circularly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

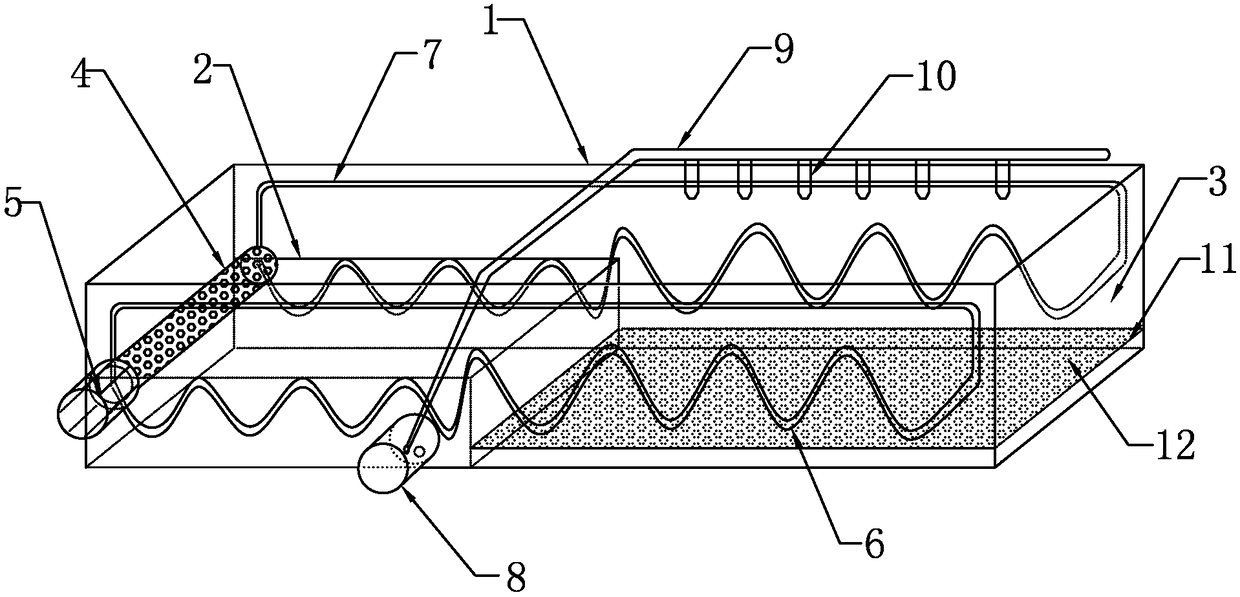

Environment-friendly steel wire pickling bath

The invention discloses an environment-friendly steel wire pickling bath which comprises a water circulating device and an acid liquor circulating device. The pickling bath consists of a plurality of horizontally arranged pickling pipelines, and the pickling pipelines consist of PE (Polyethylene) pipes. A UHMV-PE (Ultra High Melt Viscosity-Polyethylene) layer is arranged on the inner wall of each pickling pipeline, acid adding pipes are uniformly connected at intervals on the top faces of the pickling pipelines, and the acid adding pipes are communicated with the acid liquor circulating device. Both ends of each pickling pipeline are respectively connected with a liquor collecting tank, a steel wire drawing device is arranged in the liquor collecting tank, and a steel wires pass through the pickling pipelines and the steel wire drawing devices in the two liquor collecting tanks. An acid return tank and a water return tank are also arranged in the liquor collecting tank, the acid return tank is communicated with both ends of the pickling pipeline, and the bottom face of the acid return tank is connected with the acid liquor circulating device through an acid return pipe. A water spray device for spraying water to the surfaces of the steel wires is arranged above the water return tank, the water spray device is connected with the water circulating device through a water inlet pipe, and the bottom face of the water return tank is connected with the water circulating device through a water return pipe. The top faces of the two liquor collecting tanks are respectively connected with air exhaust pipes.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

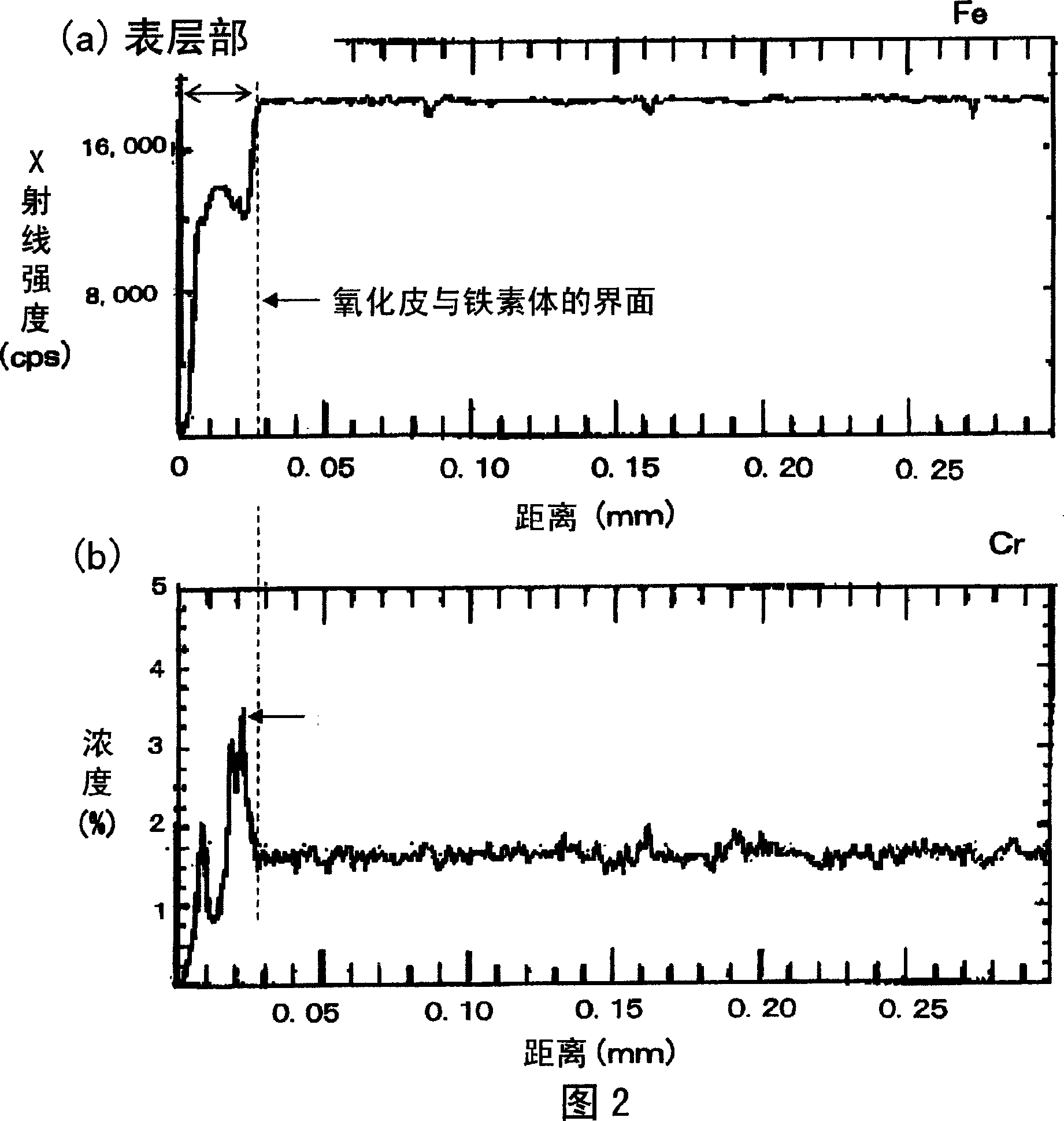

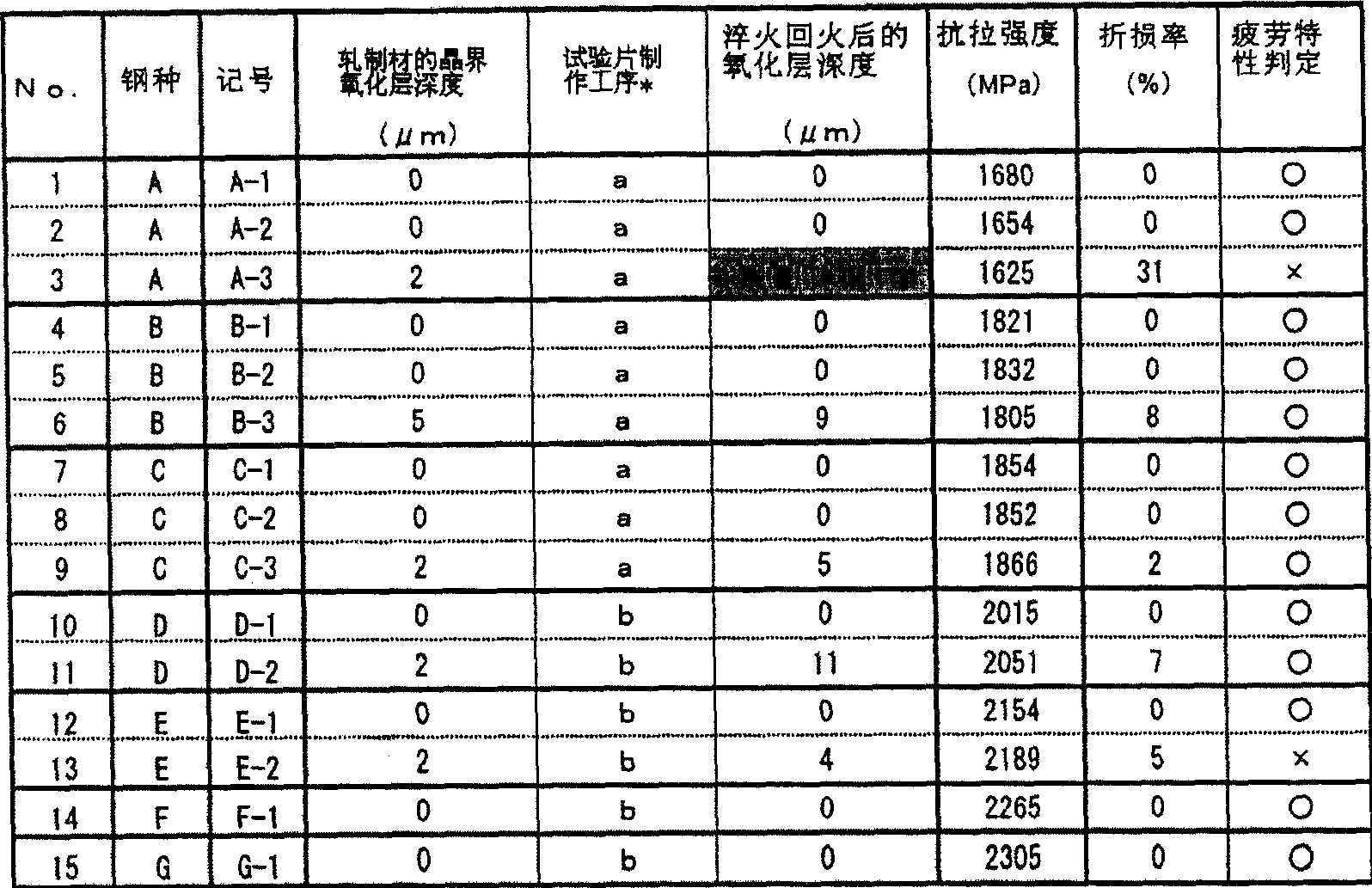

Steel wire material for spring with excellent acid rinsing property

The steel wire material for spring in accordance with the present invention comprises, on the percent by mass basis, C: 0.35 to 0.7%, Si: 1.4-2.5%, Mn: 0.05-1.0%, Cr: 0.5-1.9%, P: less than 0.02% (not including 0%), and S: less than 0.02% (not including 0%), wherein the concentration difference of Cr between on the surface and in the steel is less than 2.50%. Plenty of steel wire materials containing Si and Cr have excellent acid rinsing property even without additional alloy components containing necessary component such as Mo and the like.

Owner:KOBE STEEL LTD

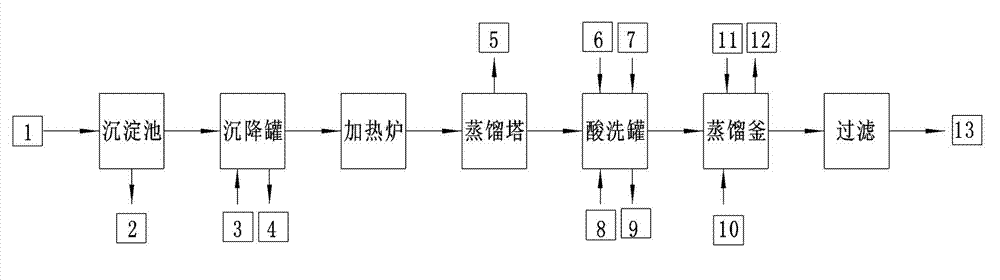

Regeneration process for waste lubricating oil

The invention discloses a regeneration process for waste lubricating oil. The process mainly comprises the procedures of deposition, distillation, pickling, adsorption with white clay and filtering and is characterized in that 2 to 4 parts by weight of No. 120 solvent naphtha is added into every 100 parts by weight of waste lubricating oil before pickling so as to realize dilution, then the procedures of pickling and adsorption with white clay are carried out and underpressure distillation is simultaneously carried out as adsorption with white clay is carried out so as to remove the No. 120 solvent naphtha through distillation. According to the invention, a diluent is added into waste lubricating oil for dilution to reduce viscosity of lubricating oil, which enables refining temperature to drop to an appropriate range, usage amount of sulfuric acid to be effectively reduced, pickling effects to be improved, usage amount of white clay to be reduced at the same time, regeneration cost to be substantially decreased and refining quality to be enhanced; and the diluent can be recycled, thereby effectively saving resources and further reducing pollution to the environment.

Owner:XINJIANG KUITUN NEW PETROCHEM

Stainless steel pickling passivator and preparation method thereof

InactiveCN107012472AAvoid harmGood for healthMetallic material coating processesFatty alcoholMaterials science

The invention discloses a stainless steel pickling passivator and a preparation method thereof. The stainless steel pickling passivator comprises citric acid, hydrochloric acid, formic acid, fatty alcohol-polyoxyethylene ether, polyethyleneimine, epoxy octyl stearate, thiosemicarbazide, epoxy chloropropane, hydrogen peroxide, a penetrating agent, a corrosion inhibitor, a thickening agent, an inorganic filler and a viscosity modifier. The preparation method comprises the steps of firstly adding part of raw materials such as the fatty alcohol-polyoxyethylene ether and the like into the hydrochloric acid sequentially, and uniformly stirring the raw materials to obtain a mixed solution I; then sequentially adding part of the raw materials such as the hydrogen peroxide into mixed acid liquor of the citric acid and the formic acid, and uniformly stirring the raw materials to obtain a mixed solution II; then mixing the mixed solution I and the mixed solution II, and adding the inorganic filler into the mixture; and finally adding the penetrating agent, the corrosion inhibitor, the thickening agent and the viscosity modifier sequentially into the mixture, and uniformly mixing the mixture to obtain the finished product. According to the stainless steel pickling passivator and the preparation method thereof, the stainless steel pickling passivator is good in passivation effect, not prone to damage the surface of stainless steel, environment-friendly and simple to prepare and does not cause harm to human bodies and environment.

Owner:合肥协耀玻璃制品有限公司

Acid pickling method

The invention relates to an acid pickling method belonging to the field of steel plate acid pickling methods. The acid pickling method comprises the step of uncoiling a steel plate and is characterized by also comprising the following steps of: (1) scale breading; (2) primary acid pickling; (3) spray acid pickling; (4) neutralizing; and (5) drying. When the method is used, a metal sheet enters an acid pickling machine through a feeding device, and the spray acid pickling of an acid spray nozzle is additionally provided on the basis of the original acid pickling, so that the acid pickling effect is improved. The acid spray nozzle is communicated with an acid pickling tank, an acid liquid in the acid pickling tank can be returned to the acid pickling tank, so that the utilization efficiency can be increased, the acid pickling cost can be reduced, and the acid pickling quality can be improved. Through optimized design, the acid pickling method is good in acid pickling effect, capable of reducing acid pickling cost and increasing the production efficiency of the acid pickling machine.

Owner:山东全通精密薄板有限公司

Activated carbon pickler

ActiveCN103480601AAchieving stirringPickling fullyCarbon compoundsCleaning using liquidsActivated carbonPulp and paper industry

The invention discloses an activated carbon pickler. The activated carbon pickler comprises a cylinder body, a steam heating pipe and a filter cylinder. A feeing port, an acid feeding port, a water inlet and an exhaust port are formed in the top of the cylinder body. A drainage port and a discharging port are formed in the bottom of the cylinder body. The steam heating pipe is located in the lower portion inside the cylinder body. The filter cylinder is arranged in the cylinder body and connected with the drainage port. A steam inlet of the steam heating pipe is led out via the inner space of the filter cylinder. By the adoption of the activated carbon pickler, a carbon bed layer in the cylinder body can be stirred, the damage, caused by manual stirring, to activated carbon is avoided, pickling of the activated carbon of the carbon bed layer can be thorough, and therefore the pickling efficiency and the pickling effect are improved. The activated carbon pickler has the advantages of being simple in structure, convenient to use, and low in degree of abrasion of the activated carbon. When the type of the activated carbon is changed, a user only needs to replace the filter cylinder and a filter screen.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

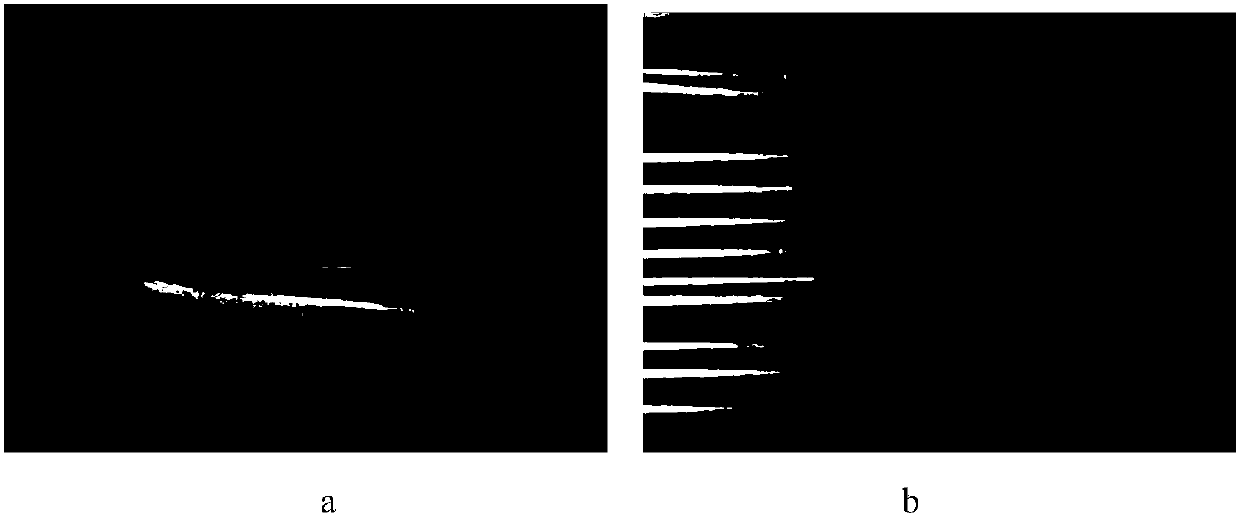

Seamless steel pipe continuous pickling device and method

The invention relates to a seamless steel pipe continuous pickling device. An immersing tank and a spray-washing tank are arranged in a pickling tank, a first guide groove and a second guide groove which are closed are oppositely formed on the inner walls of two sides of the pickling tank, a pickling tank is arranged between the first guide groove and the second guide groove and used for putting apipe blank in for pickling, the pipe blank is added into the pickling tank which is immersed in the immersing tank, pickling liquid is arranged inside the immersing tank, the pickling tank is drivento rotate itself and move along the first guide groove and the second guide groove through a driving component connected on one side of the pickling tank, and the pickling tank is driven by the driving component to enter the spray-washing tank; a water extraction component is arranged on one side of the immersing tank, a water outgoing end of the water extraction component is connected with a liquid outgoing pipe, one end of the liquid outgoing pipe is arranged above the spray-washing tan, an atomizing nozzle is connected on the liquid outgoing pipe, and the pickling liquid is sprayed onto thepipe blank through the atomizing nozzle to flush and continuously pickle the pipe blank. The seamless steel pipe continuous pickling device is good in pickling effect and high in efficiency.

Owner:ZHEJIANG JINHANG STEEL PIPE TECH

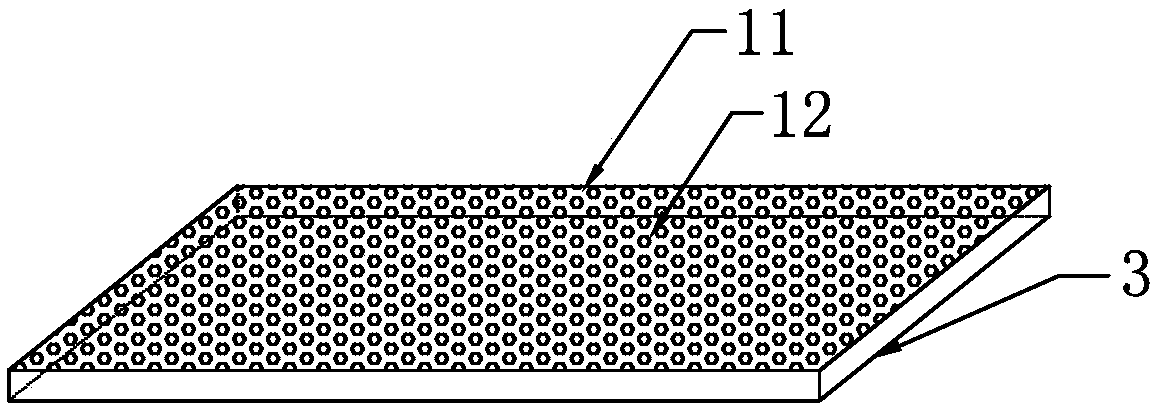

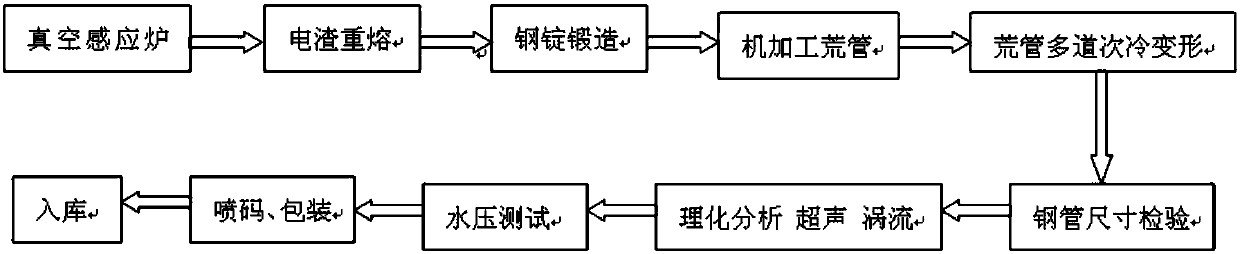

Processing technology for corrosion-resistant stainless steel seamless steel tube

The invention relates to a processing technology for a steel tube, particularly relates to a processing technology for a corrosion-resistant stainless steel seamless steel tube, and belongs to the technical field of tube processing. The processing technology for the corrosion-resistant stainless steel seamless steel tube comprises the following steps: (1) tube blank smelting, (2) tube blank forging, (3) machining of a pierced billet, and (4) steel tube deforming. A tube blank is subjected to repeated chambering and cold rolling treatment, and is processed by a multi-pass small deformation; andaccording to the final cold drawing procedure, processing of the seamless steel tube is finished by cold drawing, oil removal, annealing, straightening, fixed cutting, acid pickling and inspection toobtain the product. In a cold rolling process, the processing deformation of the seamless steel tube does not exceed 55%; in a chamfering process, the processing deformation of the seamless steel tube does not exceed 10%; in a cold drawing process, the processing deformation of the seamless steel tube does not exceed 15%; and an annealing process in the chamfering, cold rolling and cold drawing processes meets the conditions of solution annealing at the temperature of 1,052-1,093 DEG C and rapid cooling or water cooling.

Owner:BAOFENG STEEL GRP

Chemical pickling solution for removing surface oxide layer of high-temperature alloys containing elements Cr and Al and application of chemical pickling solution

The invention relates to a chemical pickling solution for removing surface oxide layers of high-temperature alloys containing elements Cr and Al and application of the chemical pickling solution and belongs to the process field of removal of oxide layers of high-temperature alloys by using a chemical method. The pickling solution is prepared from the following components: 300-400g / L of hydrochloric acid, 400-450g / L of nitric acid and 100-150g / L of hydrogen peroxide and the balance of water. Aiming at the high-temperature alloy work-pieces of which the nickel base, iron base and cobalt base contain Cr and Al, the surface oxide layers are removed through the synergism of hydrochloric acid, nitric acid and hydrogen peroxide in specific concentration, the action mechanisms of above components are as follows: hydrochloric acid and nitric acid are used as base reactants to react with the surface oxide of a high-temperature alloy, and the hydrogen peroxide is used as a catalyst to accelerate the generation of the reaction. The chemical pickling solution provided by the invention is obvious in pickling effect and high in efficiency, the treated high-temperature alloy has a bright and uniform surface; the pickling solution is low in heat release in the matching process, no inflammable, sensitizing and explosive reactant is generated, and the security is high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Stainless steel acid pickling passivation paste and preparing method thereof

InactiveCN106917095AAvoid harmGood for healthMetallic material coating processesAcetic anhydridePhosphoric acid

The invention discloses stainless steel acid pickling passivation paste and a preparing method thereof. The stainless steel acid pickling passivation paste comprises the ingredients including nitrous acid, phosphoric acid, oxalic acid, alkyl alcohol polyoxyethylene ether, sodium citrate, acetic anhydride, potassium pyrophosphate, disodium hydrogen phosphate, benzotriazole, glycerol, gel, a corrosion inhibitor, a penetrating agent, a thickening agent, a viscosity modifier and an inorganic filler. Parts of raw materials like the acetic anhydride are firstly added into the phosphoric acid to be mixed to obtain mixed liquor I; then parts of raw materials like glycerol are sequentially added into mixed acid liquor of the nitrous acid and the oxalic acid to be mixed to obtain mixed liquor II; the mixed liquor I and the mixed liquor II are mixed, and the inorganic filler is added into a mixture; and finally the penetrating agent, the corrosion inhibitor, the thickening agent, the viscosity modifier and the gel are sequentially added while stirring is carried out, and the finished product is obtained after even stirring is carried out. The stainless steel acid pickling passivation paste is good in passivation effect, damage to the stainless steel surface is not prone to occurrence, the stainless steel acid pickling passivation paste is environment-friendly and simple in preparation, and harms on human bodies and damage to the environment can be avoided.

Owner:合肥协耀玻璃制品有限公司

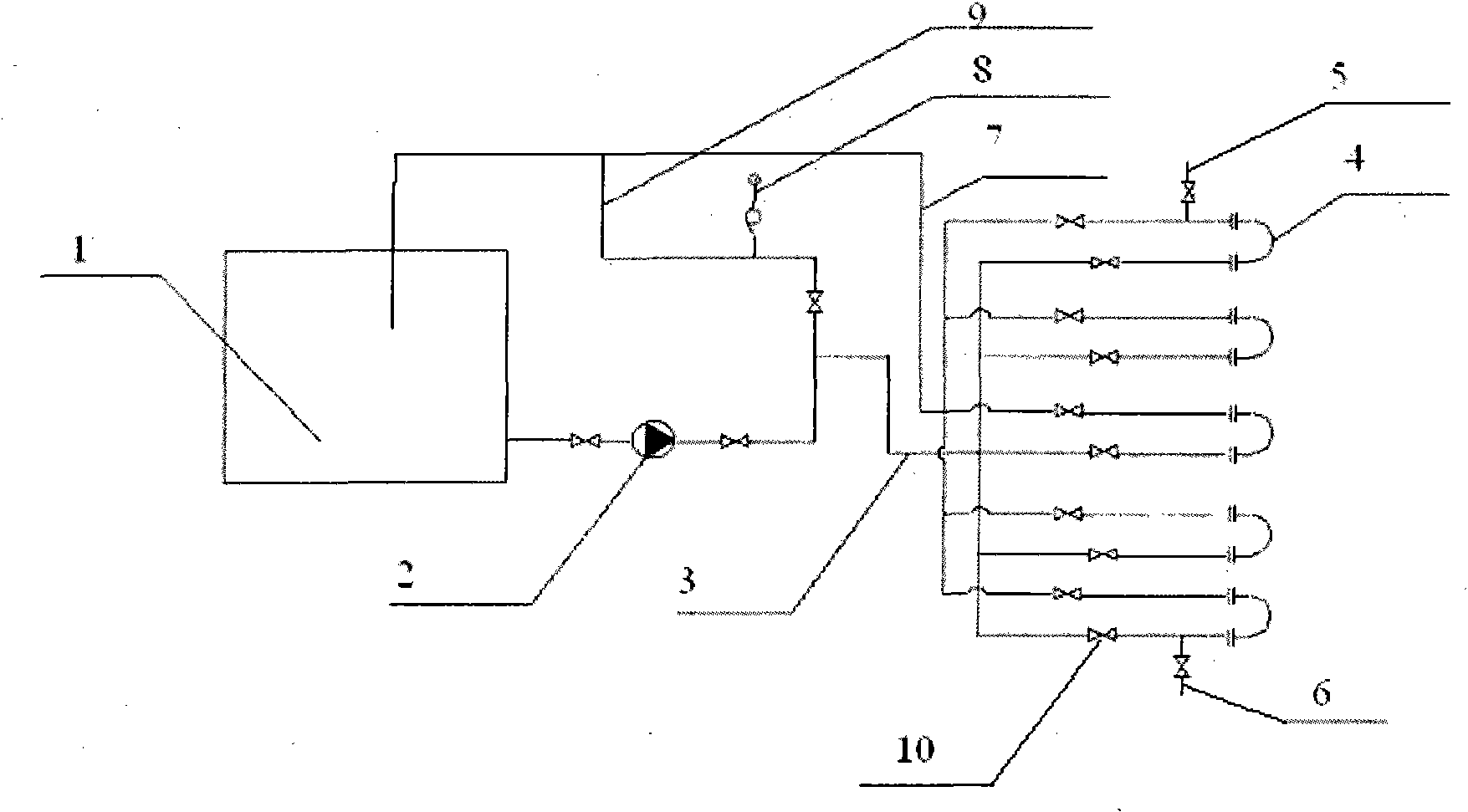

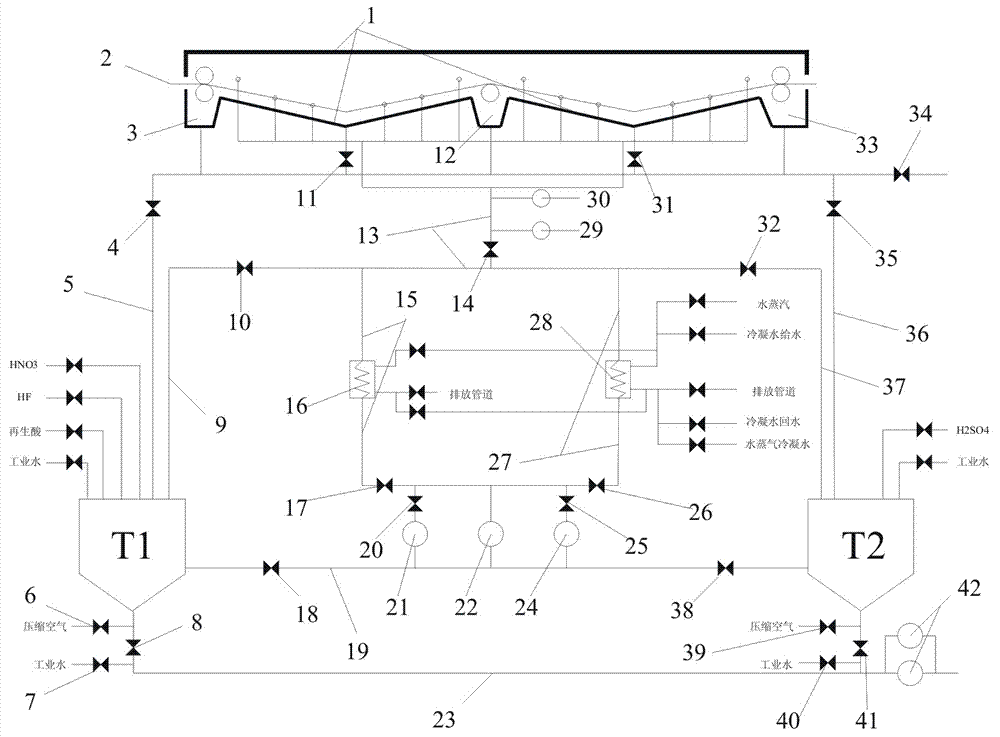

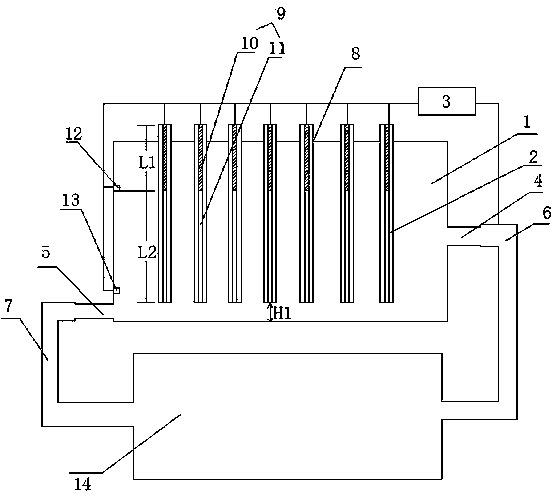

Pre-pickling acid liquor circulation system and method for hot-rolled stainless steel strip steel

The invention discloses a pre-pickling acid liquor circulation system and a pre-pickling acid liquor circulation method for hot-rolled stainless steel strip steel. The system comprises an acid mixing pickling circulation tank, a sulfuric acid pickling circulation tank, a heat exchange device, and a pickling bath; an outlet of the acid mixing pickling circulation tank and an outlet of the sulfuric acid pickling circulation tank are connected with a liquor inlet of an acid liquor circulation pump; a liquor discharge port of the acid liquor circulation pump is connected with an inlet of the heat exchange device; an outlet of the heat exchange device is connected with an inlet of the acid mixing pickling circulation tank, an inlet of the sulfuric acid pickling circulation tank, and an acid inlet of the pickling bath; and an acid discharge port of the pickling bath is connected with the inlet of the acid mixing pickling circulation tank and the inlet of the sulfuric acid pickling circulation tank. The circulation system is simple and practical; and by the circulation system, investment cost is reduced, the pickling parameters can be controlled continuously, the forming amount of sludge in a solution can be reduced, and the pickling effect can be improved.

Owner:WISDRI ENG & RES INC LTD

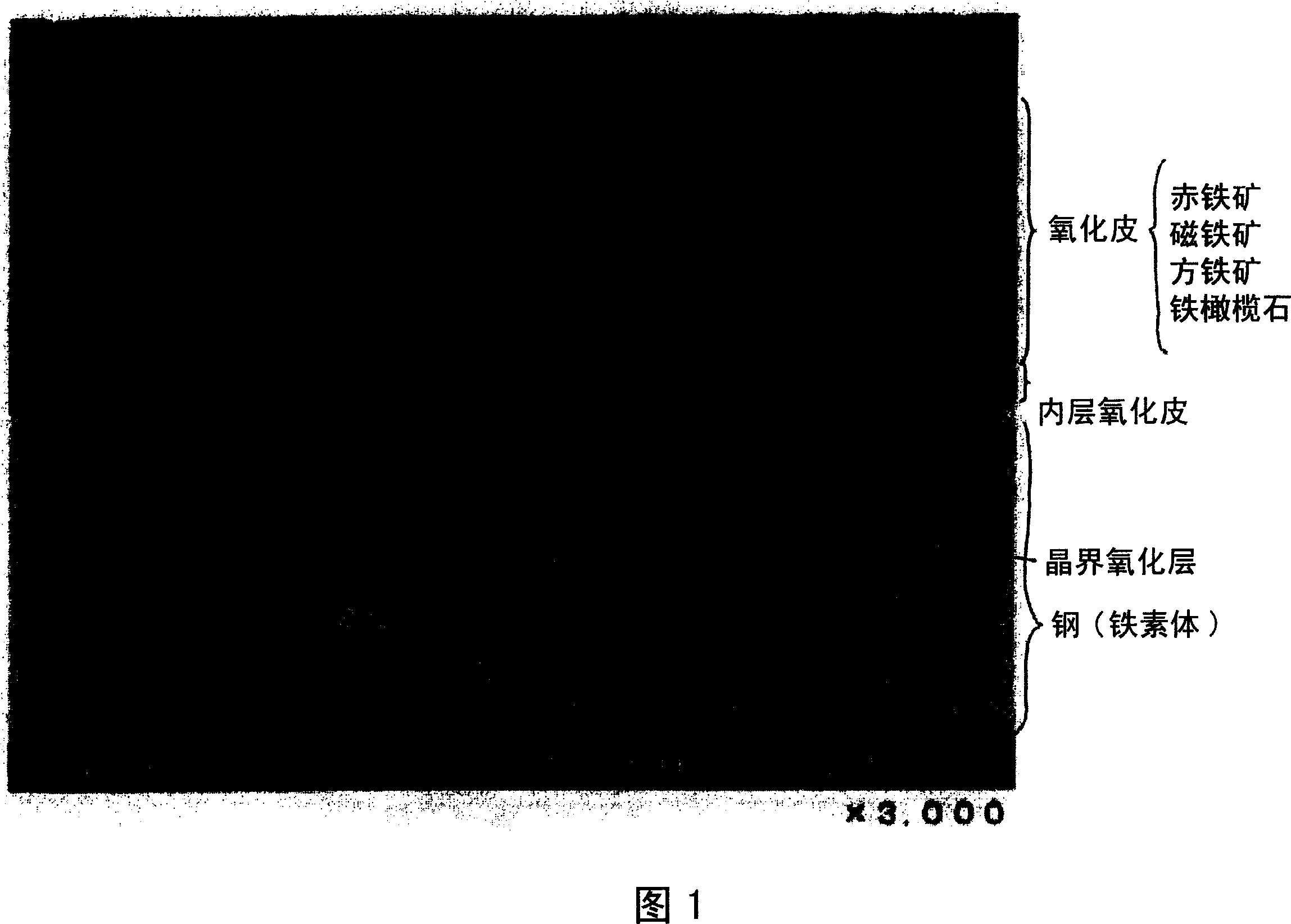

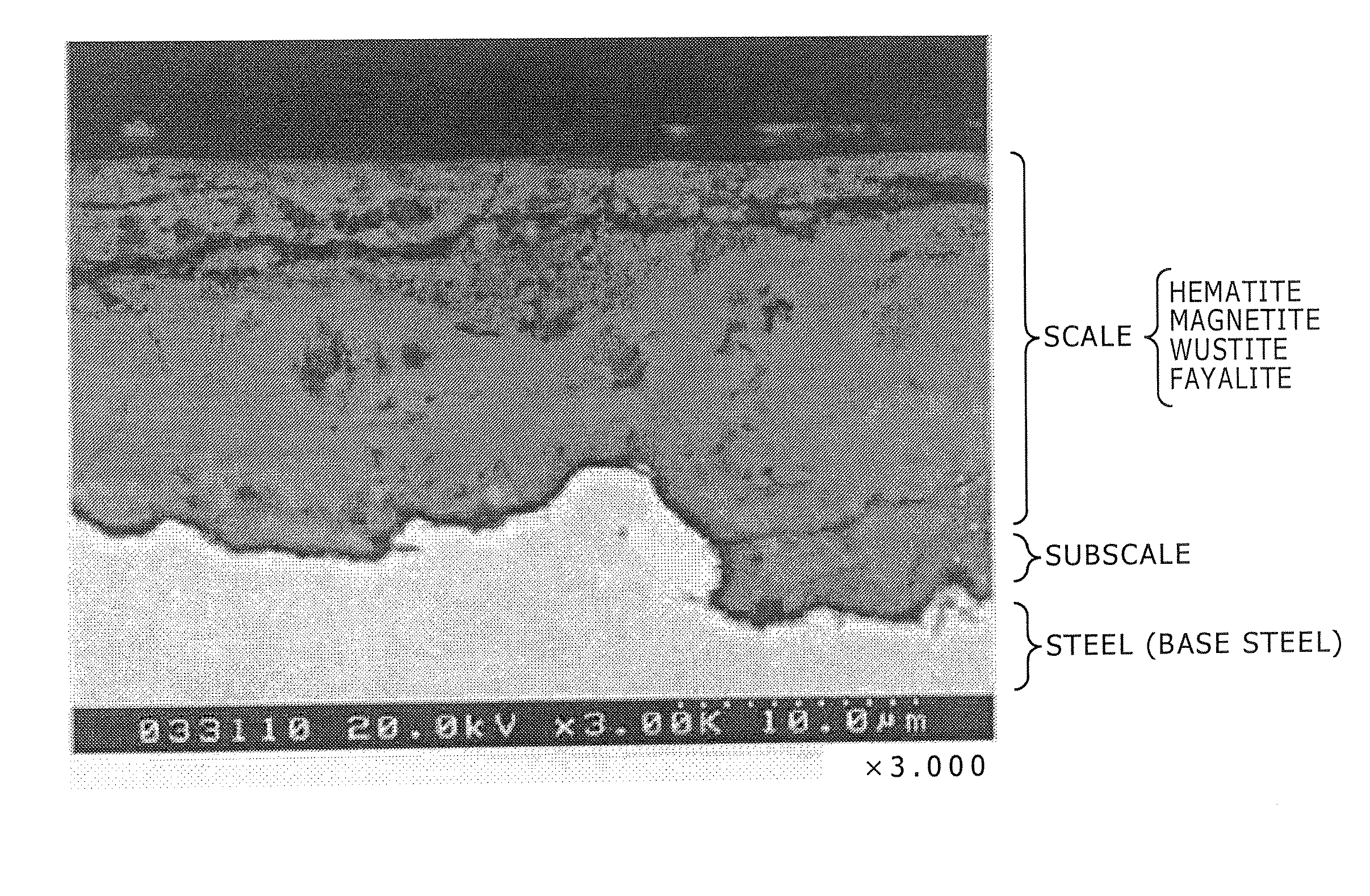

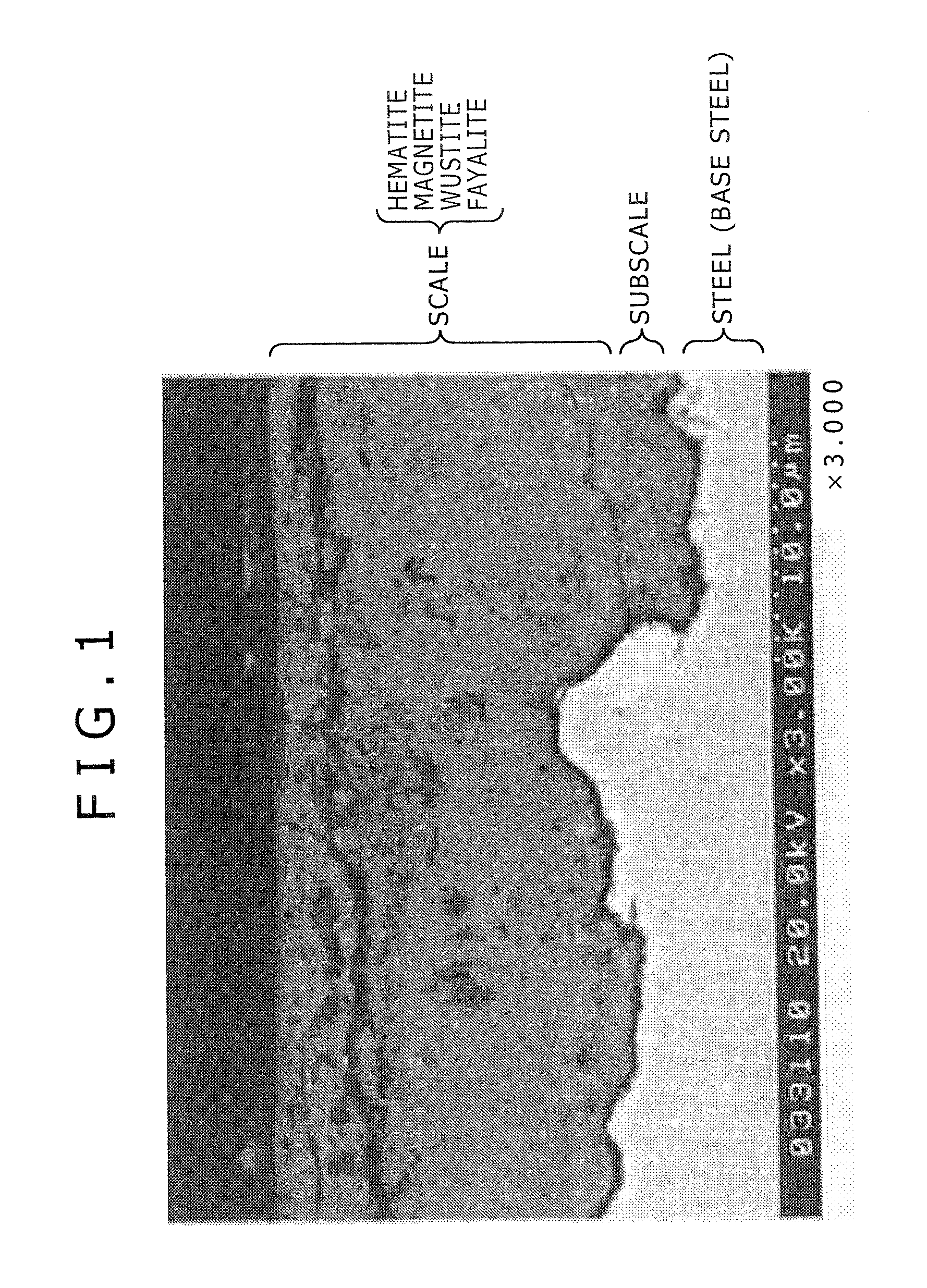

Spring steel wire rod excellent in pickling performance

InactiveCN1982494AImprove surface propertiesImprove pickling effectSpringsFurnace typesWire rodSurface layer

Owner:KOBE STEEL LTD

Method for enhancing acid pickling efficiency of stainless steel tubes

The invention discloses a method for enhancing the acid pickling efficiency of stainless steel tubes. The method comprises the following steps of (1) acid pickling tank equipment modification, wherein the bottom of each acid pickling tank is arranged to be in an arc shape, and movable supporting devices are adopted on the two sides of an acid tank; and (2) an acid pickling process, wherein the procedures of carrying out feeding and acidification in sequence and carrying out acid discharge and uncovering in sequence are adopted, the acid mist discharge amount is greatly reduced, movement of the two ends of a crown block track is controlled in the acid pickling process, the two ends alternately move up and down, the process is repeated, acid liquor is disturbed by the steel tubes to form a turbulent flow state, the flow of an acid liquor circulation system is increased, the turbulent flow effect is enhanced, sludge accumulation in the acid tank is reduced, the acid liquor is cyclically heated through a heat exchanger, the temperature is automatically controlled, and the acid pickling efficiency is improved. According to the method, the acid pickling effect of the steel tubes is enhanced; the acid pickling efficiency is improved; and by means of an empty tank feeding and automatic acid discharge system, the acid mist discharge amount is greatly reduced, and environment benefits are enhanced.

Owner:TAIYUAN IRON & STEEL GROUP

Heat treatment technology of cold-rolled strip steel

InactiveCN111850586APickling lastsImprove pickling effectFurnace typesMetal rolling arrangementsStrip steelMagnetic shield

The invention discloses a heat treatment technology of cold-rolled strip steel, and belongs to the technical field of heat treatment. According to the scheme, a semiconductor refrigeration sheet is started to refrigerate a hydrochloric acid solution, so that the temperature of the hydrochloric acid solution is maintained to be -5 DEG C; when acid pickling balls make contact with a casting blank roll, built-in rubber balloons quickly expand, on the one hand, the hydrochloric acid solution in the acid pickling balls can be squeezed out so that the casting blank roll is subjected to acid pickling, and on the other hand, a magnetic shielding state of built-in magnetic balls can be released because insulating hemispheres are away from one another; by means of the attraction action of a magnet on the built-in magnetic balls and the reset action of elastic traction ropes, the acid pickling balls can be pulled to move upwards to the upper side of a partition plate, and along with contraction of the built-in rubber balloons, the hydrochloric acid solution is sucked into the acid pickling balls through L-shaped flow guide holes, so that the built-in magnetic balls are in the magnetic shielding state again; and the acid pickling balls move downwards along with the increase of the mass, so that continuous acid pickling of the casting blank roll is carried out.

Owner:林璋

High-titanium slag selective leaching and quality improvement method

ActiveCN108300874AGuaranteed tightnessPromote precipitationProcess efficiency improvementHigh pressureOxygen

The invention provides a high-titanium slag selective leaching and quality improvement method. The method comprises the following steps of (1) crushing high-titanium slag and feeding the crushed high-titanium slag and a sodium hydroxide solution into a high-pressure kettle; (2) introducing oxygen into the high-pressure kettle, conducting heating, stirring and heat preservation and completing alkaline leaching; (3) filtering and separating the material subjected to alkaline leaching and conducting water washing on an alkaline leaching product to obtain an alkaline leaching slag material; (4) feeding the alkaline leaching slag material and hydrochloric acid into the high-pressure kettle, adding crystal seeds, conducting heating, stirring and heat preservation and completing acid leaching; and (5) filtering and separating the material subjected to acid leaching, and conducting water washing and drying on an acid leaching product to obtain high-purity titanium dioxide. Through the method,cyclic utilization of resources can be achieved, no industrial wastewater and waste residues are produced, and green production is achieved.

Owner:NORTHEASTERN UNIV

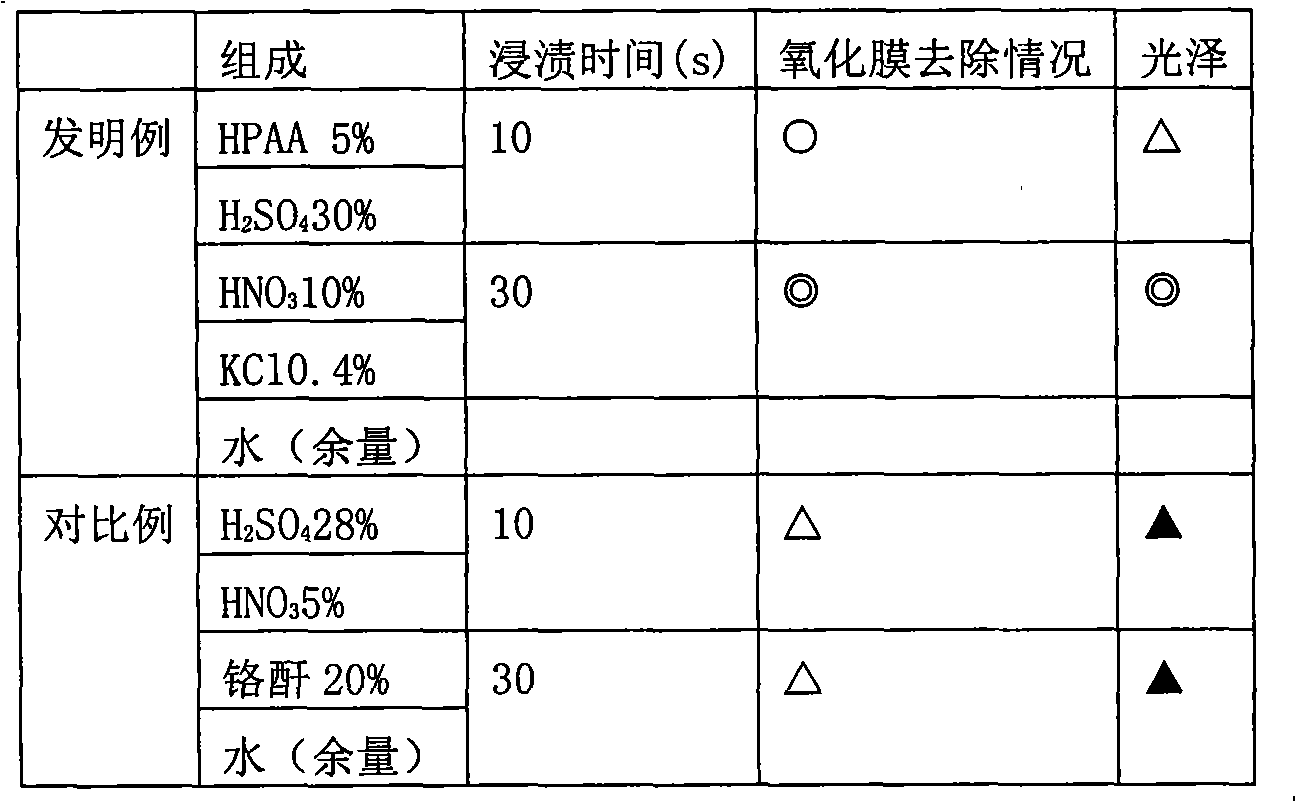

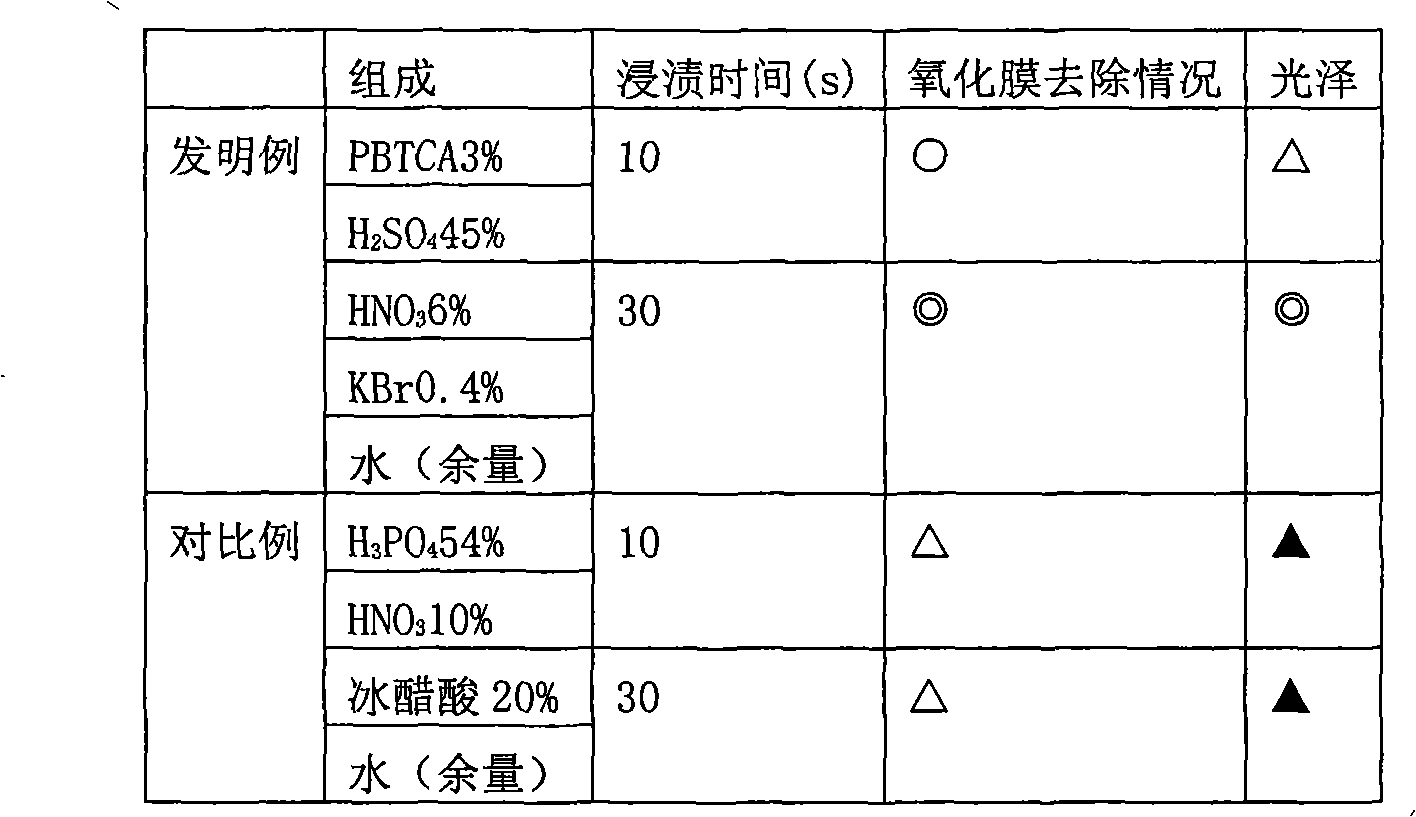

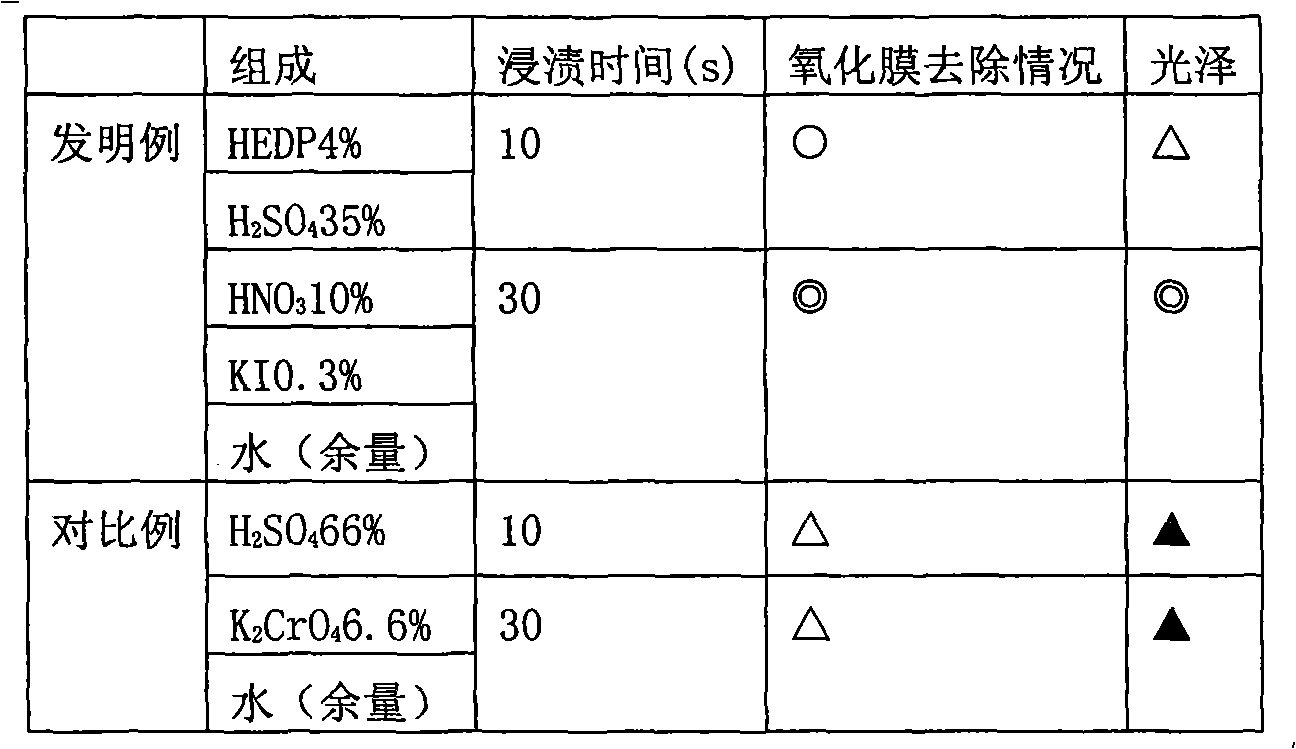

Beryllium bronze oxidation film cleaning agent and preparation method thereof

The invention relates to a beryllium bronze oxidation film cleaning agent and a preparation method thereof, belonging to the technical field of metal surface chemical treatment. The beryllium bronze oxidation film cleaning agent comprises the following components in terms of weight percent: 20-50% of sulfuric acid, 2-20% of nitrate ions, 2-10% of organic phosphonic acid, 0.01-1% of halogen ions and the balance of water. The preparation method is as follows: (1) preparing the components according to the weight percents; and (2) slowly adding the sulfuric acid into the organic phosphonic acid with the formula amount, fully stirring the mixture, cooling the mixture to the room temperature, then adding nitric acid, fully stirring the mixture, adding the halogen ions, and finally obtaining theberyllium bronze oxidation film cleaning agent. The beryllium bronze oxidation film cleaning agent adopts the complex system of the organic phosphonic acid, the sulfuric acid, the nitrate ions and thehalogen ions to solve the problem of difficult beryllium bronze oxidation film removal and to simultaneously replace a conventional hexavalent chromium pickling system; and the beryllium bronze oxidation film cleaning agent reduces the pollution and improves the pickling effect. After cleaned by the cleaning agent, a beryllium bronze surface is flat and bright, therefore the performance and the appearance of a beryllium bronze product are improved.

Owner:杭州百木表面技术有限公司

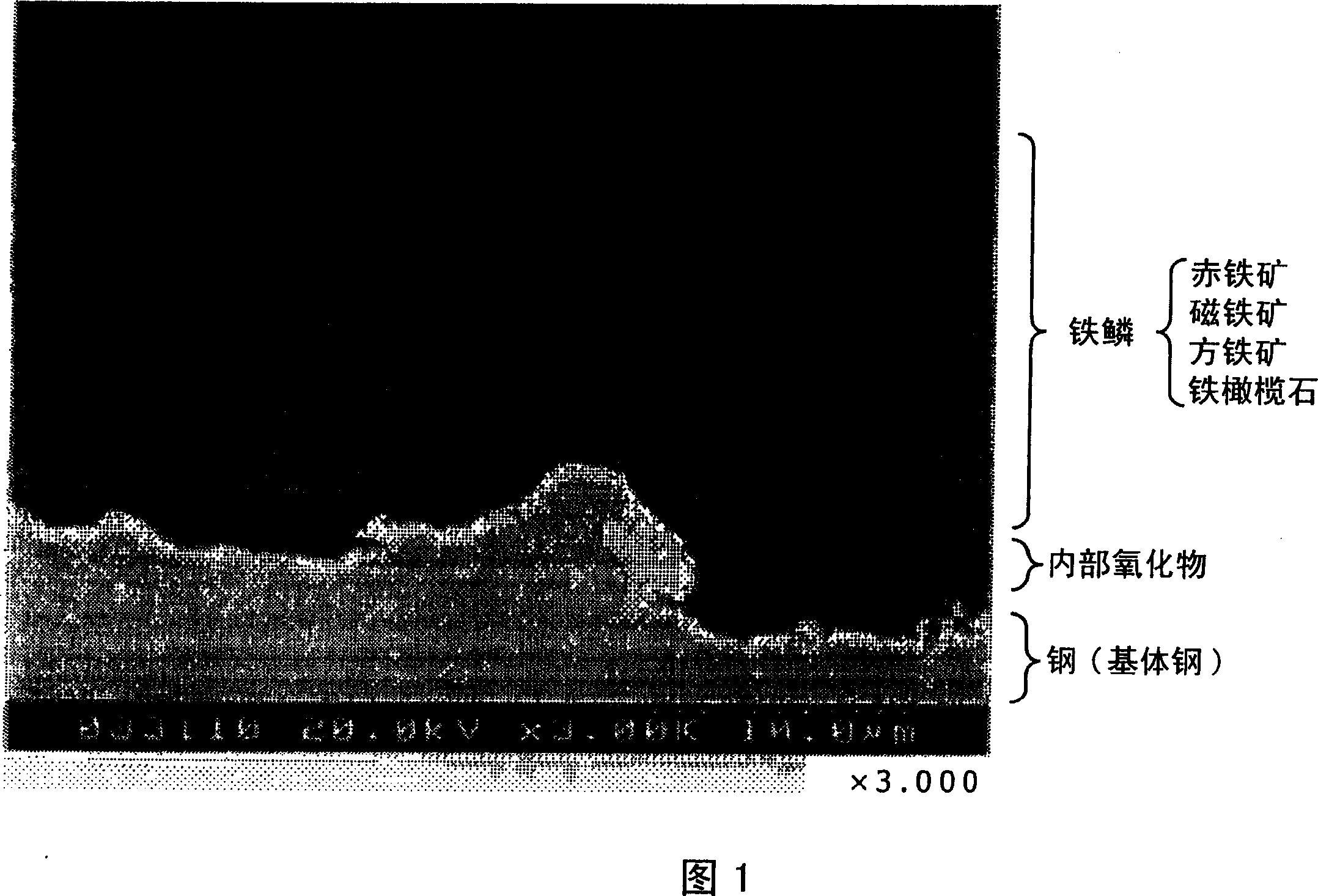

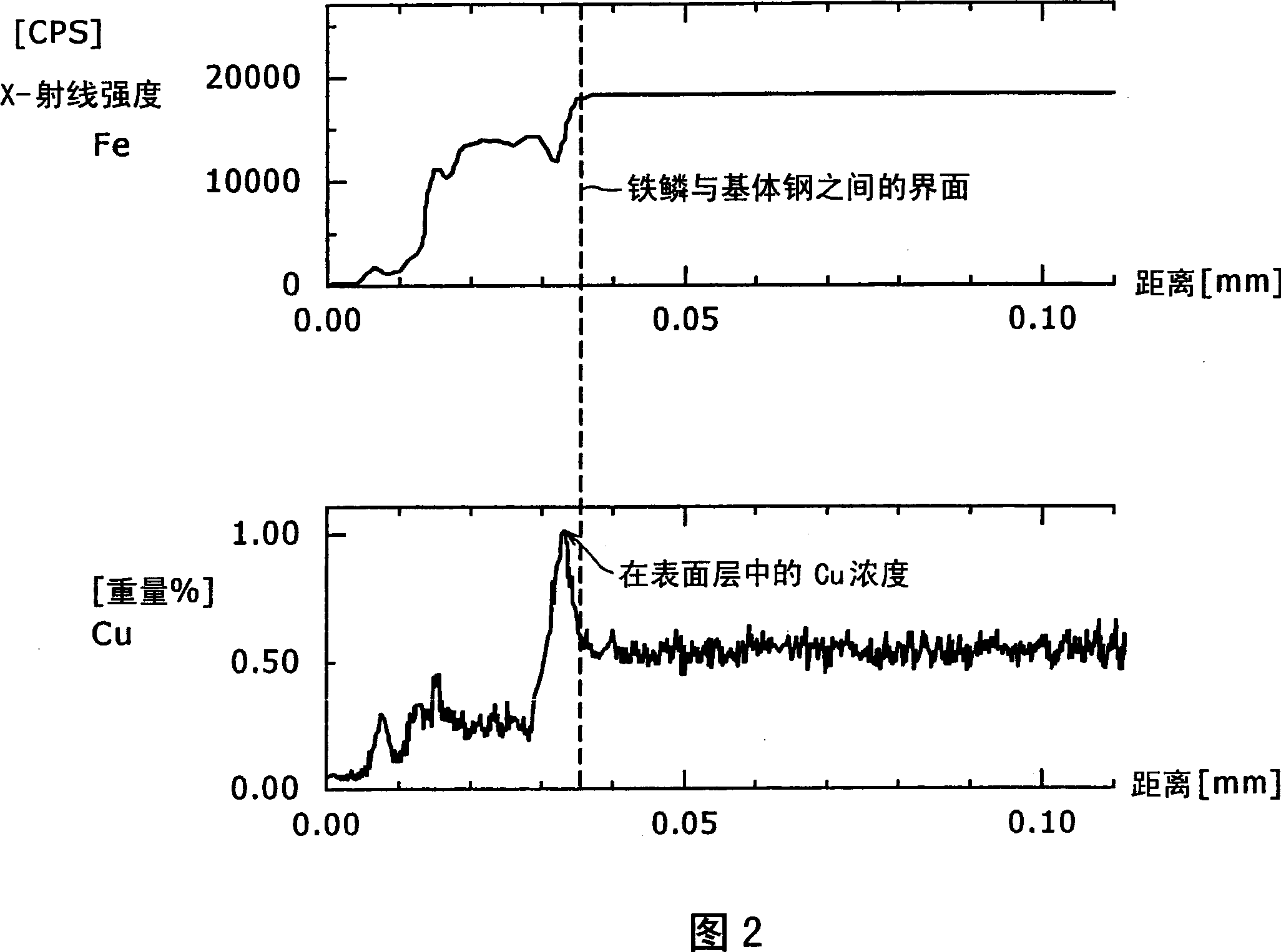

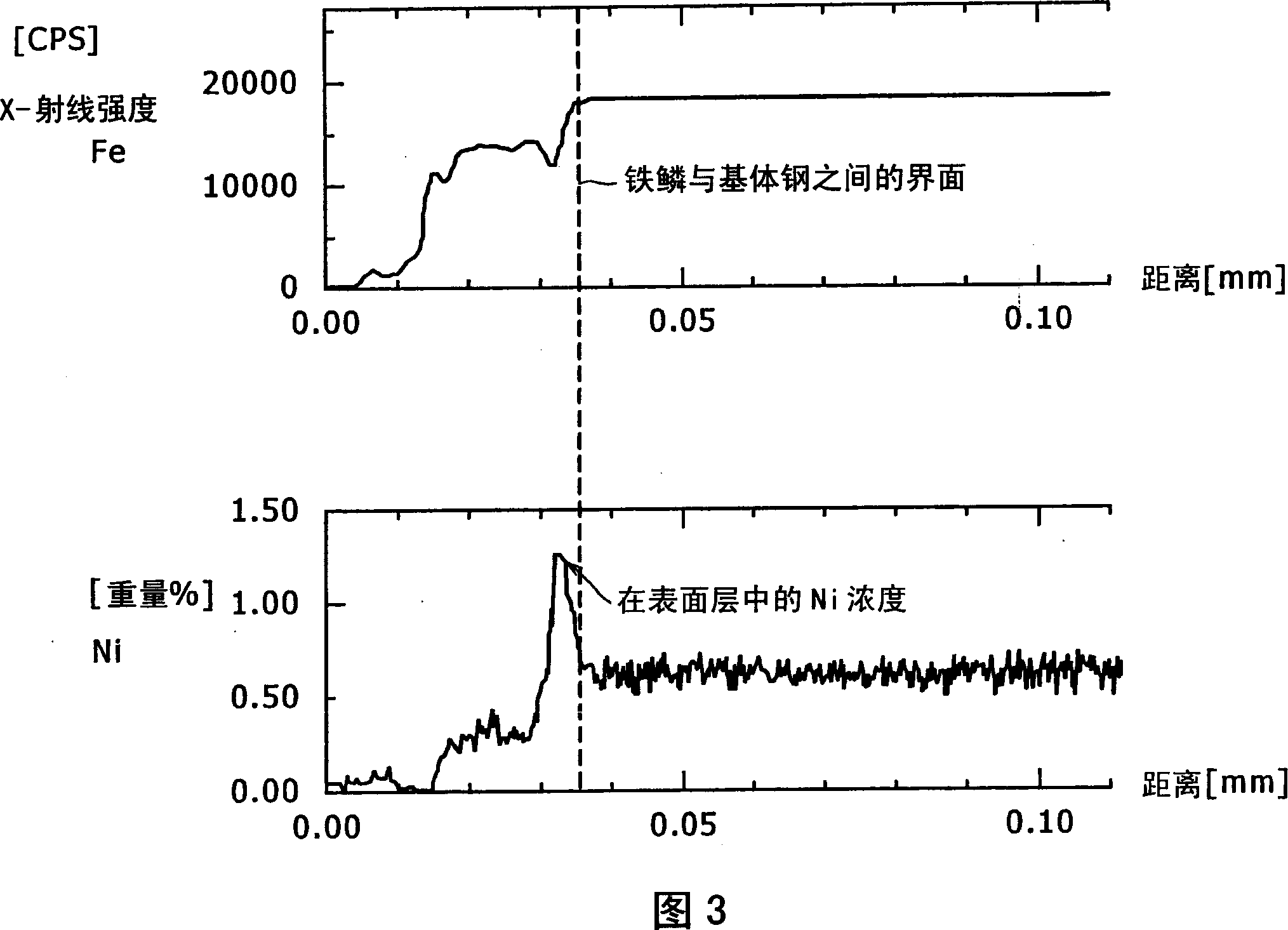

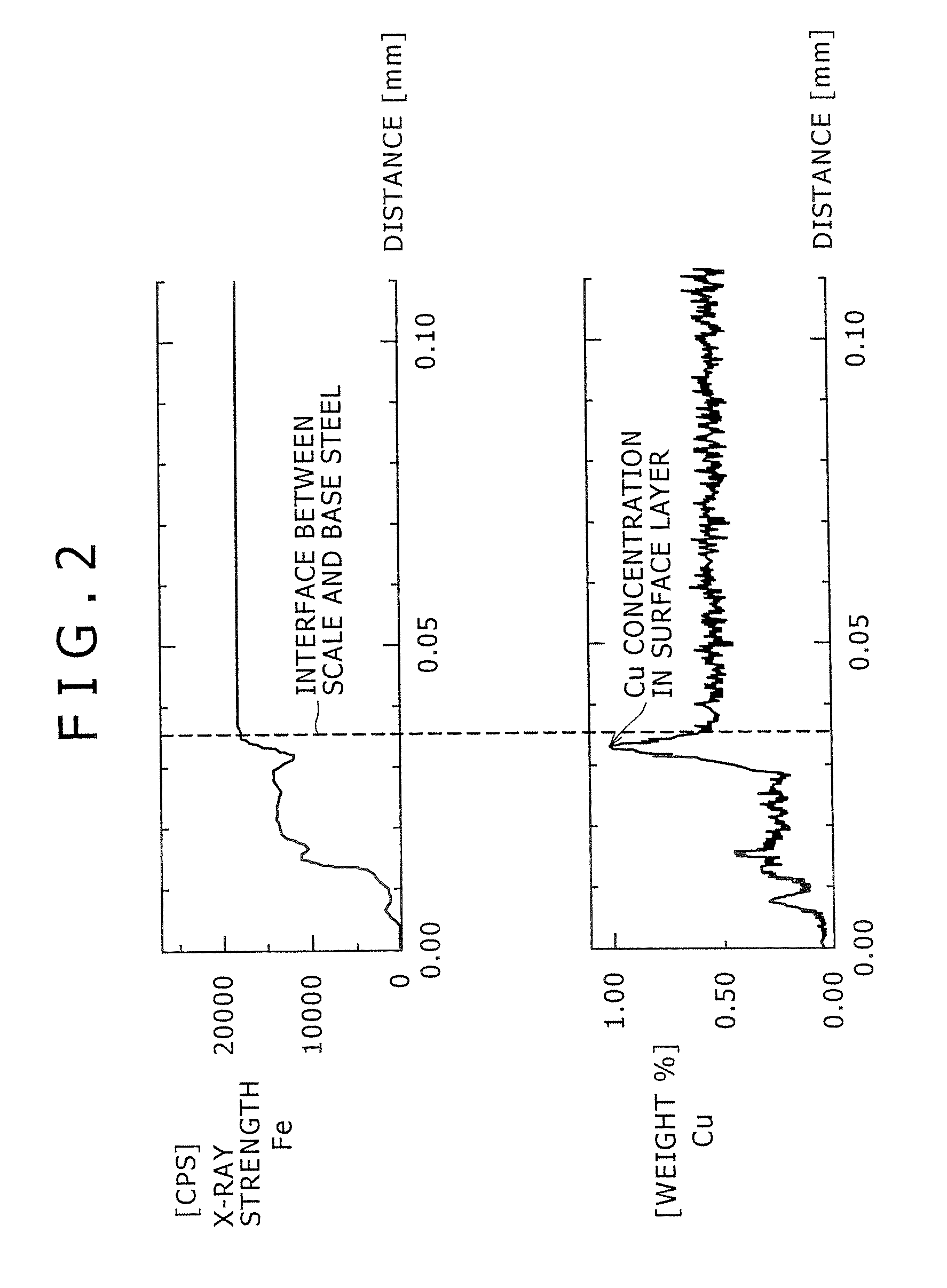

Spring steel wire rod excellent in pickling performance

InactiveUS20070125455A1Improve pickling effectImprove surface propertiesFurnace typesHeat treatment furnacesWire rodSpring steel

A spring steel wire rod according to the present invention is a spring steel wire rod wherein: the spring steel wire rod contains C: 0.35% to 0.7% (by mass, the same is hereunder applied), Si: 1.5% to 2.50%, Mn: 0.05% to 1.0%, Cr: 0.05% to 1.9%, Cu: 0.05% to 0.7%, Ni: 0.15% to 0.8%, P: 0.02% or less (excluding 0%), S: 0.02% or less (excluding 0%); and the balance being Fe and unavoidable impurities, wherein the ratio of Si to Cu (Si / Cu) is in the range of 4 or more; and the difference between the concentration of Cu in the surface layer and the concentration of Cu in the steel is 0.50% or less and the difference between the concentration of Ni in the surface layer and the concentration of Ni in the steel is 1.00% or less. The present invention makes it possible to improve pickling performance in a spring steel wire rod containing Si abundantly and further Cr, Cu, and Ni.

Owner:KOBE STEEL LTD

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

Medical catheter cleaning device

InactiveCN110328198ARealize integrated operationImprove pickling effectHollow article cleaningDrying machines with progressive movementsAcid washingSlide plate

The invention discloses a medical catheter cleaning device, and belongs to the technical field of medical catheters. The medical catheter cleaning device comprises a pay-off box and a cleaning box, wherein a cleaning device is arranged on the cleaning box, a first sliding plate is arranged on the inner wall of the pay-off box, an acid washing box is movably arranged on the first sliding plate, a placing block is arranged on the inner wall of the acid washing box, a stop block fixedly connected with the pay-off box is arranged at the bottom of the acid washing box, a first auxiliary box is arranged below the acid washing box, a second auxiliary box is arranged below a cleaning agent mixing chamber, a second vibration device is arranged inside the second auxiliary box, at least one drying machine is arranged inside a drying box, rotating wheels are arranged on the surfaces of vertical shafts, and a winding box is arranged outside the drying box. According to the medical catheter cleaningdevice, sundries carried on the surface of the medical catheter are effectively removed through vibration, and the integrated operation of acid washing, cleaning, drying and winding is realized.

Owner:上海璞康医疗器械有限公司

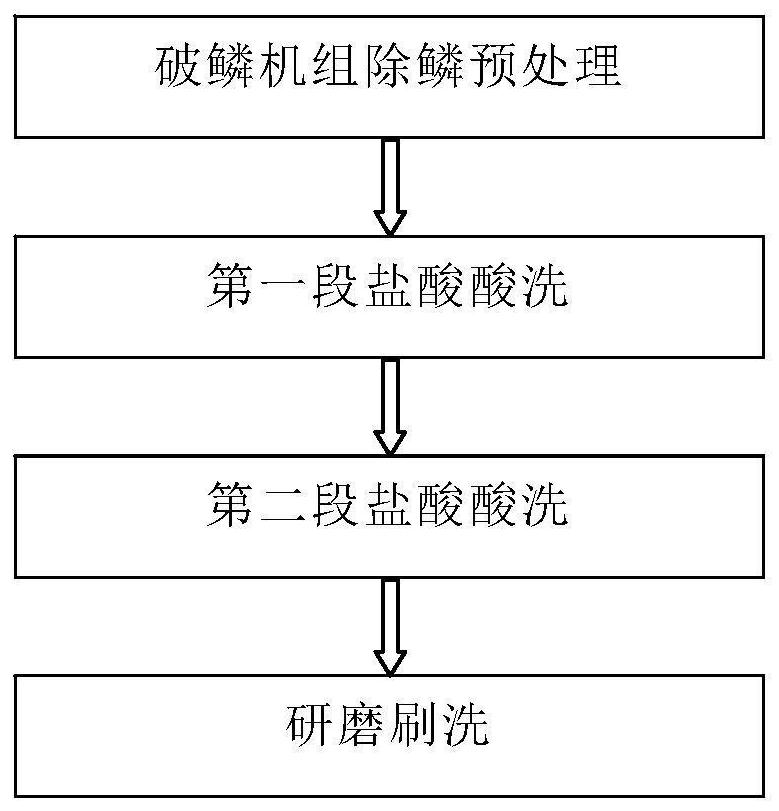

Stainless steel hot rolling strip steel acid pickling process

InactiveCN111604786AImprove surface qualityImprove pickling effectGrinding drivesGrinding machinesCarbide siliconStrip steel

The invention relates to a stainless steel hot rolling strip steel acid pickling process. The process comprises the steps of scale breaking unit scale removal pretreatment, wherein the total extensionrate of strip steel is controlled to be larger than or equal to 3.0%; first-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in first-segment hydrochloric acid acid pickling liquid to be subjected to first-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the first-segment hydrochloric acid acid pickling liquid is controlled to 50 to 300 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 60 to 80 DEG C, and the acid pickling time is controlled to 25 s to 50 s; second-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in second-segment hydrochloric acid acid pickling liquid to be subjected to second-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the second-segment hydrochloric acid acid pickling liquid is controlled to 50 to 250 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 50to 75 DEG C, and the acid pickling time is controlled to 25 s to 50 s; grinding scrubbing, wherein the strip steel is subjected to grinding scrubbing, the diameter of roller brush bristles is controlled to 0.7 to 1 mm, the bristles contain silicon carbide abrasives with meshes being 170 to 200 meshes, the rotating speed of a roller brush motor is controlled to 600 to 1000 rpm, and the current of the roller brush motor is controlled to 100 to 200 A.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Heating apparatus for pickling tank

InactiveCN104087963APrevention of dry burningReduce damage rateElectrical resistance and conductanceElectrical connection

A heating apparatus for a pickling tank comprises a heating box, acid-proof heating pipes and a PLC controller; the heating box is provided with a water inlet and a water outlet, and the water outlet is disposed below the water inlet; the water inelt is connected with a water pump; the water outlet is provided with a water outlet pipe; the top of the heating box is provided with a plurality of installation holes; the acid-proof heating pipes are fixedly disposed on the installation holes in an insertion manner and is vertically arranged in the heating box; each acid-proof heating pipe comprises a pipe body prepared from polytetrafluoroethylene material, and the pipe body is inside provided with a drawing-out rod and a resistance wire; a liquid-level sensor and a temperature sensor are arranged on the heating box; the liquid-level sensor is arranged at a same horizontal plane with the connection point of the drawing-out rod and the resistance wire; and the liquid-level sensor, the temperature sensor, the acid-proof heating pipes, the water pump and the PLC controller are in electrical connection. The heating apparatus is simple in structure and convenient to operate, helps to substantially improve the heating efficiency, enable a pickling solution to heated uniformly and increase the pickling effect.

Owner:扬中市盛华电热电器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com