Stainless steel pipeline pickling method

A stainless steel and pipeline technology, applied in the field of chemical cleaning of metal materials, can solve the problems of unfavorable passivation film of pipelines, complicated pickling process, serious equipment damage, etc., achieve the effect of protecting pickling, simplify pickling process, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

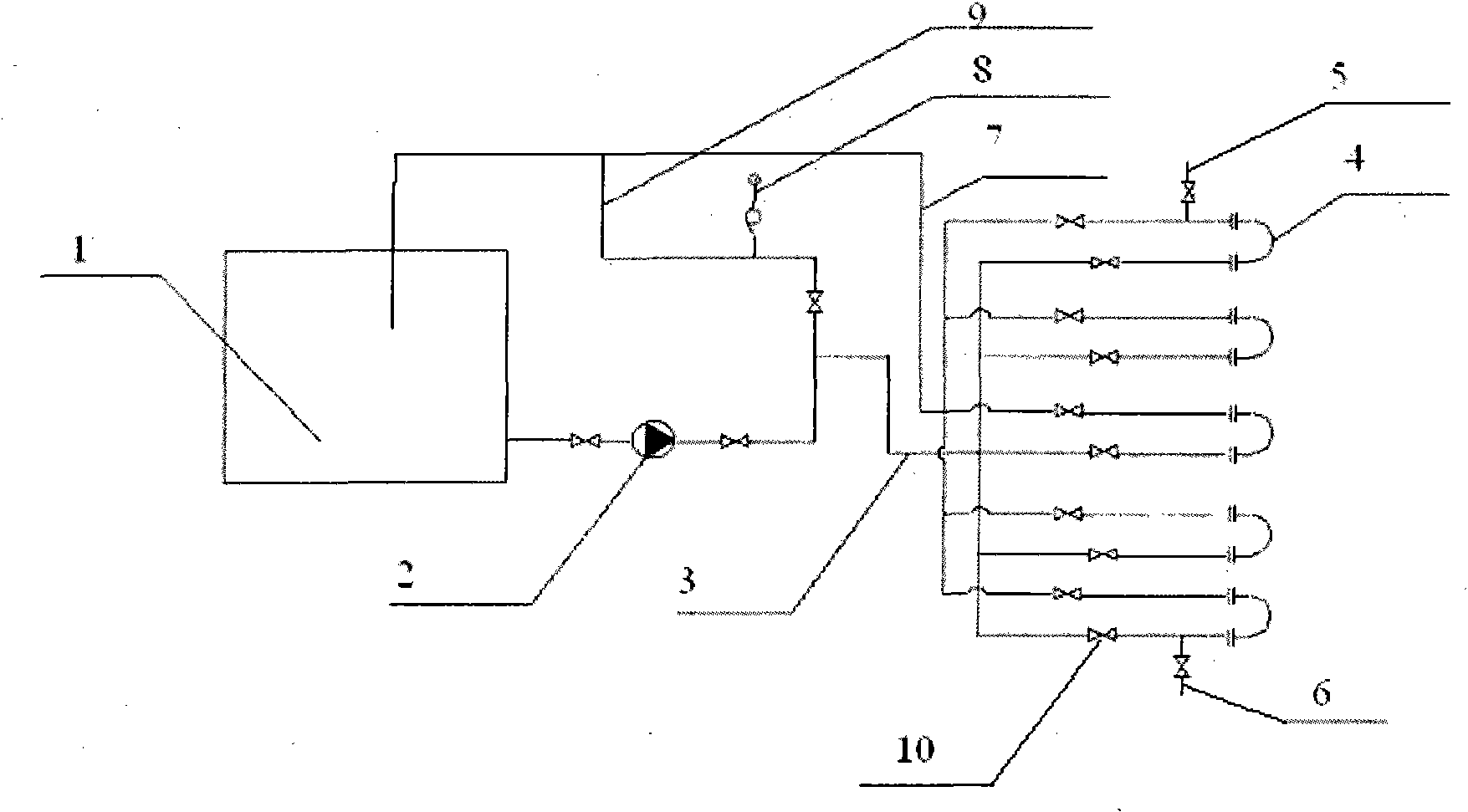

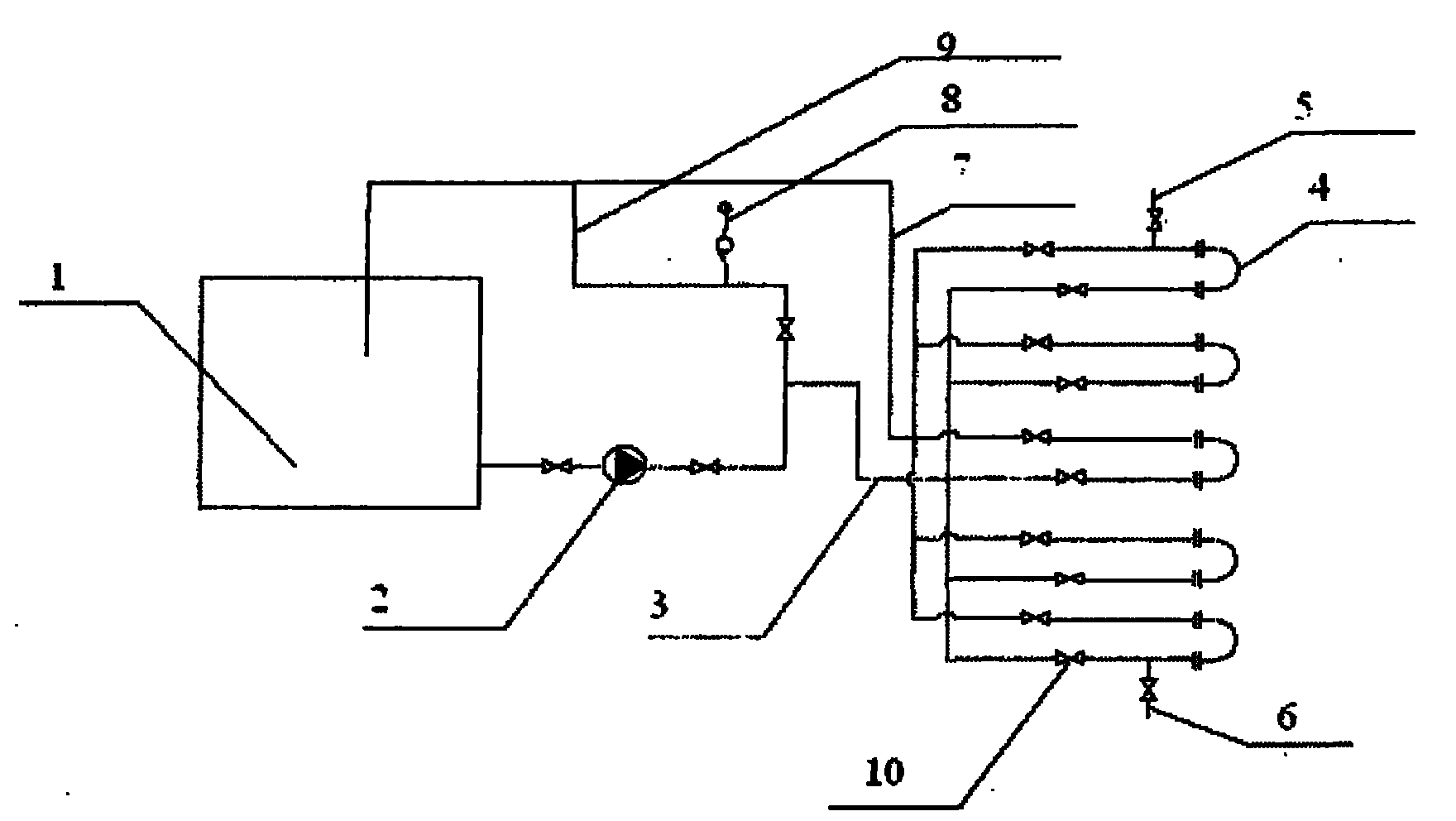

[0023] Blow the connected pickling pipeline with compressed air, check whether the connected pickling circuit is smooth, and whether there is any wrong connection; at the same time, conduct a pressure test to find out the leak and make up for it, so as to prepare for the water test Prepare, the pressure gauge 8 shows that the pressure is 8Kg / cm 2 . Exhaust the gas through the highest exhaust point 5, test the leak with clean water, the pressure is 6.5×10 5 Pa, at the same time the required solution volume is 4m 3 . Use 1g / L TX-10 to degrease for 2 hours, and the temperature of the degreasing solution is 50°C. Keep the TX-10 solution after degreasing, and then add 3Kg / m to the pickling solution tank 1 3 The citric acid is input to the acid supply pipeline 3 through the acid-resistant pump 2, the citric acid is filled with the pipeline and the temporary pipeline 4, and returns to the pickling solution tank 1 through the acid return pipeline 7 and the overflow pipeline 9 to f...

Embodiment 2

[0025] Blow the connected pickling pipeline with compressed air, check whether the connected pickling circuit is smooth, and whether there is any wrong connection; at the same time, conduct a pressure test to find out the leak and make up for it, so as to prepare for the water test Prepare, the pressure gauge 8 shows that the pressure is 10Kg / cm 2 . Exhaust the gas through the highest exhaust point 5, test the leak with clean water, the pressure is 6×10 5 Pa, while measuring the required solution volume is 10m 3 . Use a certain amount of sodium hydroxide to infiltrate industrial alcohol to degrease for 4 hours, and the temperature of the degreasing solution is 57°C. Keep the degreasing solution after degreasing, and then add 3.5Kg / m2 to the pickling solution tank 1 3 The acetic acid is input to the acid supply pipeline 3 through the acid-resistant pump 2, and the acetic acid is filled with the pipeline and the temporary pipeline 4, and returns to the pickling solution tank...

Embodiment 3

[0027] Blow the connected pickling pipeline with compressed air, check whether the connected pickling circuit is smooth, and whether there is any wrong connection; at the same time, conduct a pressure test to find out the leak and make up for it, so as to prepare for the water test Prepare, the pressure gauge 8 shows that the pressure is 16Kg / cm 2 . Exhaust the gas through the highest exhaust point 5, test the leak with clean water, the pressure is 7×10 5 Pa, while measuring the required solution volume is 8m 3 . Use a certain amount of white cat detergent aqueous solution to degrease for 3 hours, and the temperature of the degreasing solution is 52°C. Keep the degreasing solution after degreasing, and then add 4Kg / m2 to the pickling solution tank 1 3 The citric acid is input to the acid supply pipeline 3 through the acid-resistant pump 2, the citric acid is filled with the pipeline and the temporary pipeline 4, and returns to the pickling solution tank 1 through the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com