Steel wire material for spring with excellent acid rinsing property

A steel wire, quality technology, applied in the direction of springs, springs/shock absorbers, coil springs, etc., to achieve the effects of excellent surface properties, high fatigue characteristics, and excellent pickling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

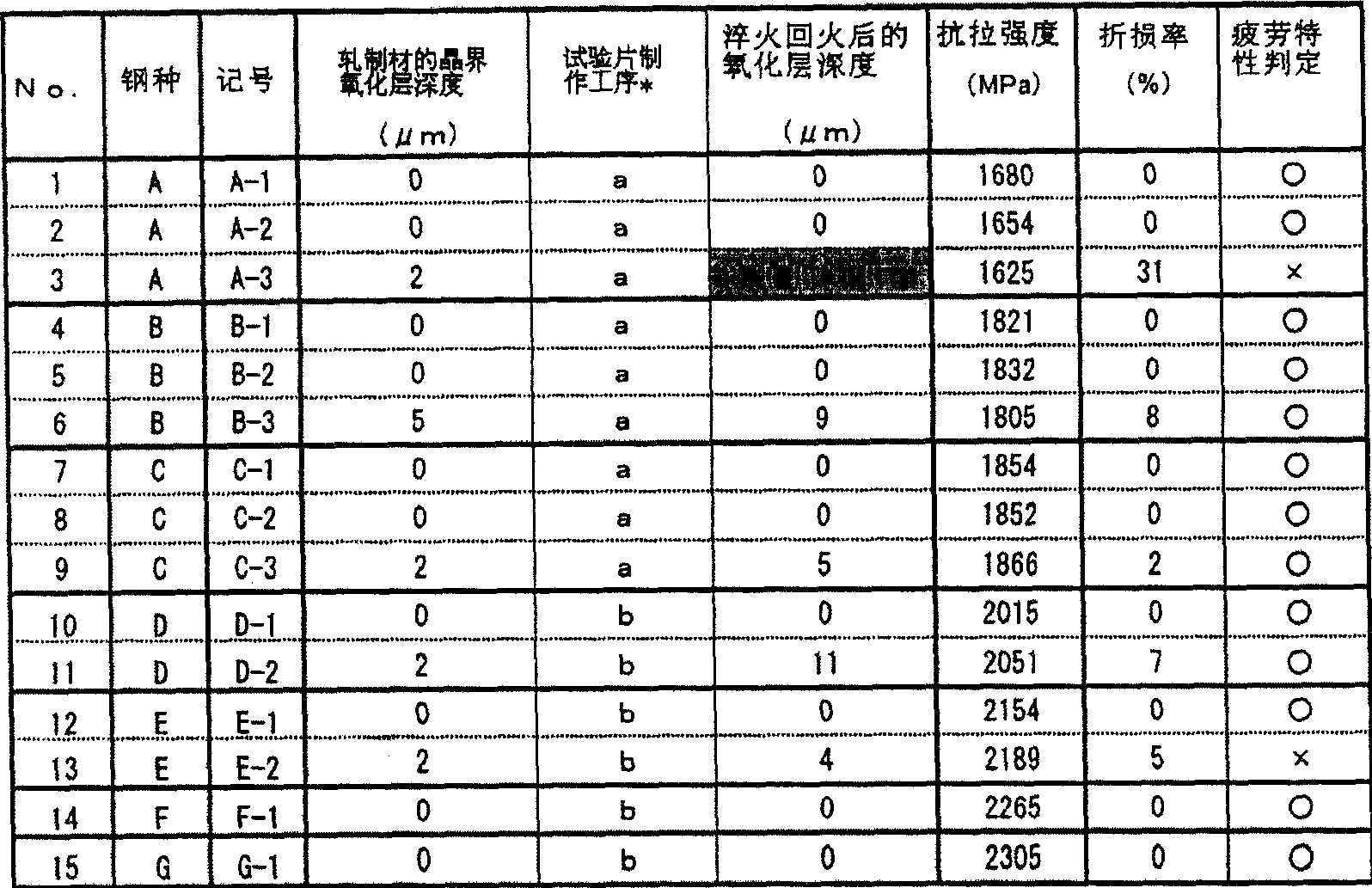

Examples

Embodiment Construction

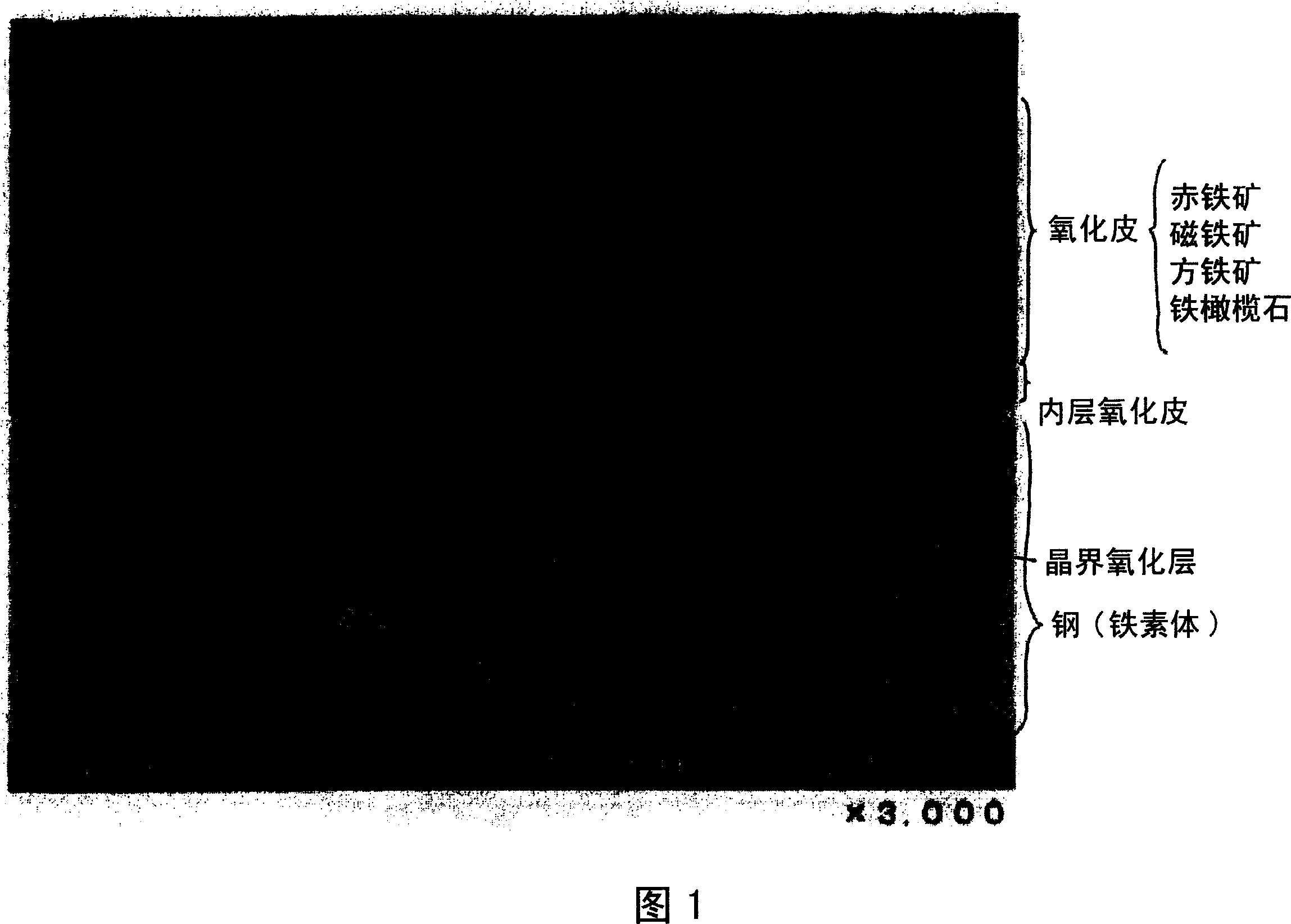

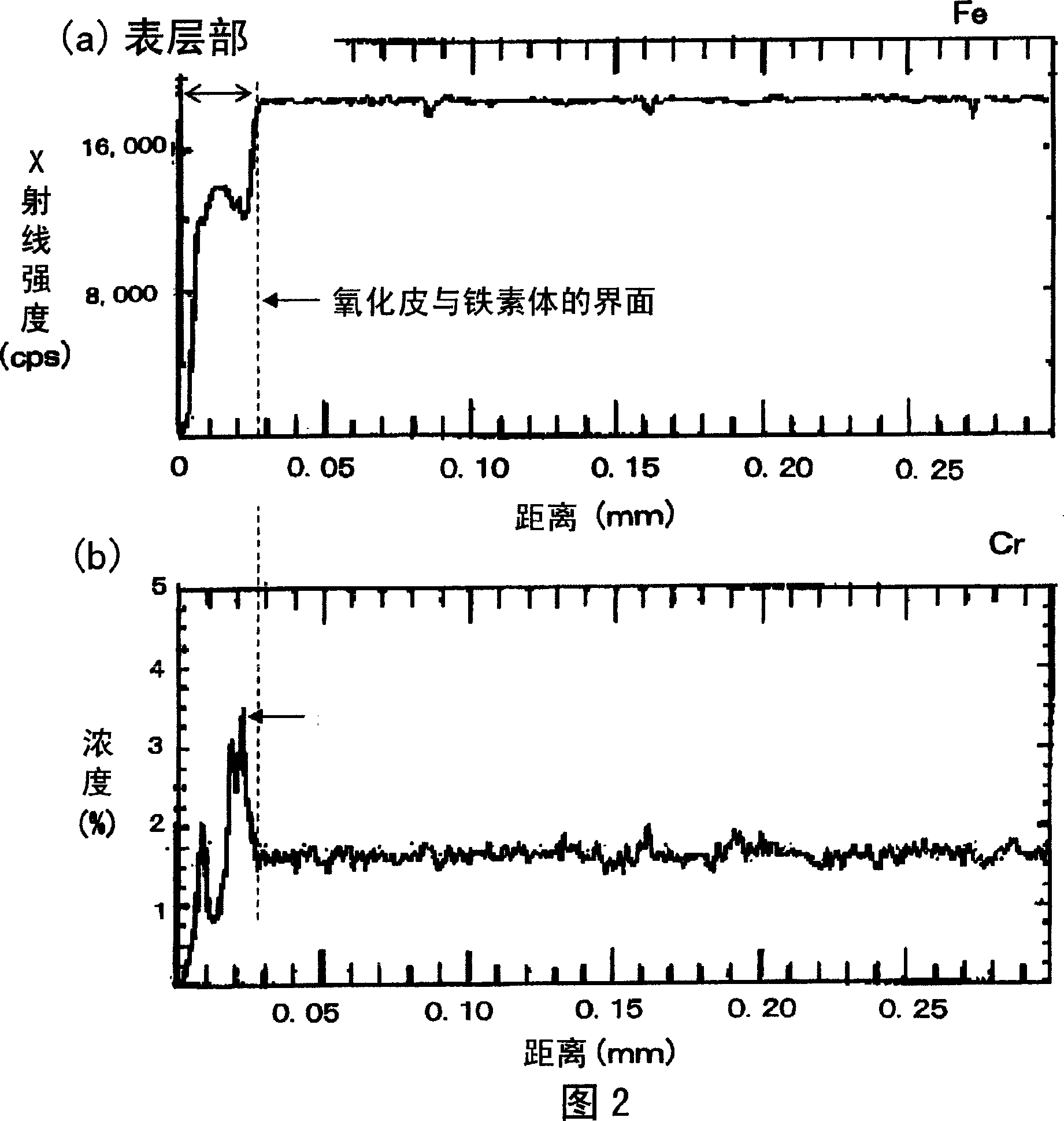

[0019] The inventors of the present invention have intensively studied to improve the pickling properties of steel wire materials for springs containing a large amount of Si and Cr. As a result, as will be described in detail later, it is pointed out that especially if the heating step and soaking step before hot rolling are properly controlled, the concentration of Cr on the surface of the wire rod (especially the concentration of Cr into fayalite) is suppressed, and the concentration of Cr on the surface layer is suppressed. The difference between the Cr concentration and the Cr concentration in the steel (hereinafter, may be abbreviated as ΔCr) is remarkably reduced, so that the pickling performance is exceptionally improved, and the present invention has been accomplished.

[0020] The present invention will be described in detail below.

[0021] As mentioned above, the steel wire material for spring of the present invention contains: C: 0.35-0.7%, Si: 1.40-2.5%, Mn: 0.05-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com