Processing technology for corrosion-resistant stainless steel seamless steel tube

A technology of seamless steel pipe and processing technology, which is applied in the field of pipe processing, can solve the problems of long delivery time and high price, and achieve the effect of short pickling time and good pickling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

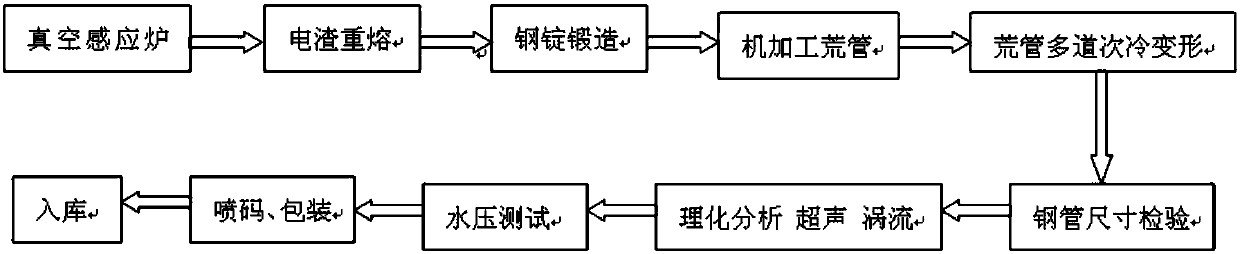

[0031] A processing technology of Hastelloy B-3 seamless steel pipe, see the process flow figure 1 . The seamless steel pipe processing requirements are:

[0032]

[0033] 1 tube billet smelting

[0034] The smelting uses a 1-ton vacuum induction furnace + electroslag remelting, casting 380X380mm-340X340mm steel ingots, and diffusion annealing after the steel ingots are demoulded.

[0035] 2 tube blank forging

[0036] The temperature of the steel ingot entering the furnace is 850°C, and the holding time after reaching the temperature is at least 1.2min / mm. The heating is uniform, and the flame cannot touch the steel ingot to ensure that the steel ingot is completely burned through; heating times. The starting forging temperature is 1246°C, and the final forging temperature is not lower than 954°C.

[0037] 3 Machining waste tube

[0038] According to the chemical composition of Hastelloy B-3 alloy, the content of Ni, Mo and W is relatively high, and the deformation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com