Patents

Literature

60results about How to "Small amount of corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

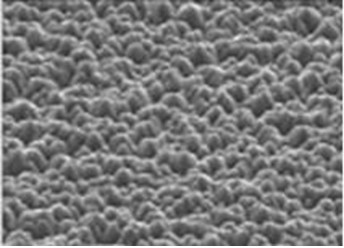

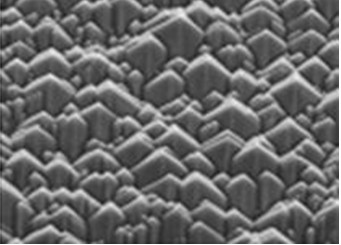

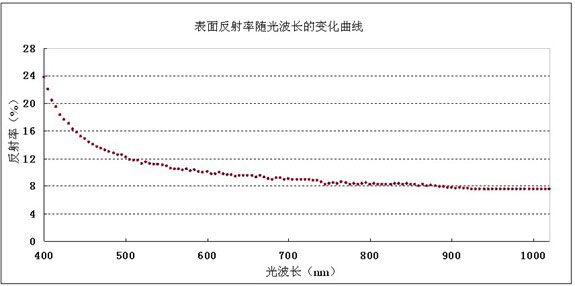

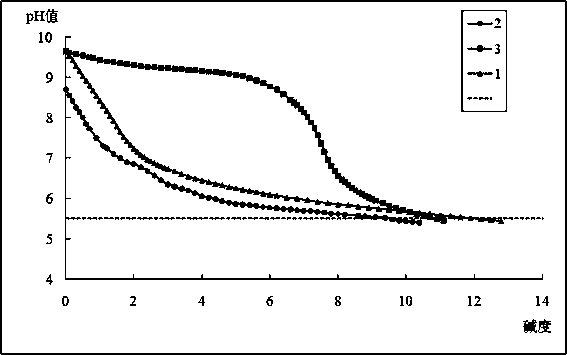

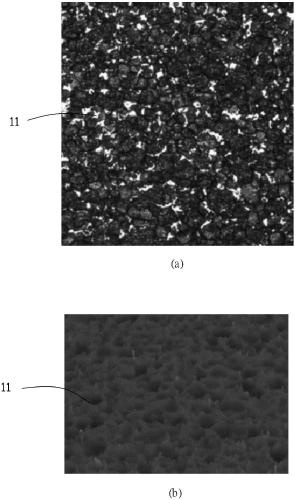

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

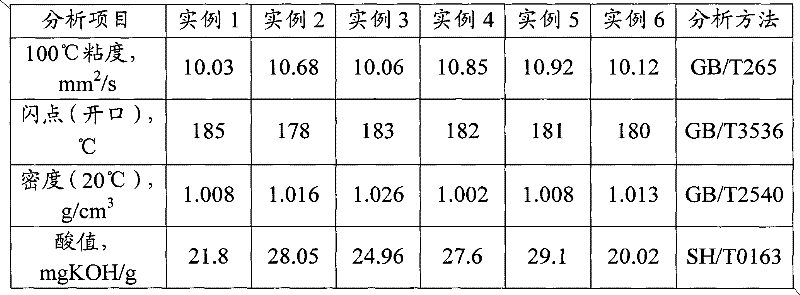

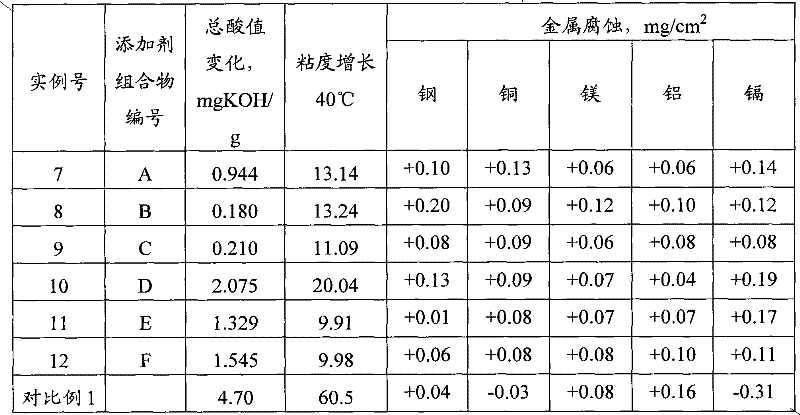

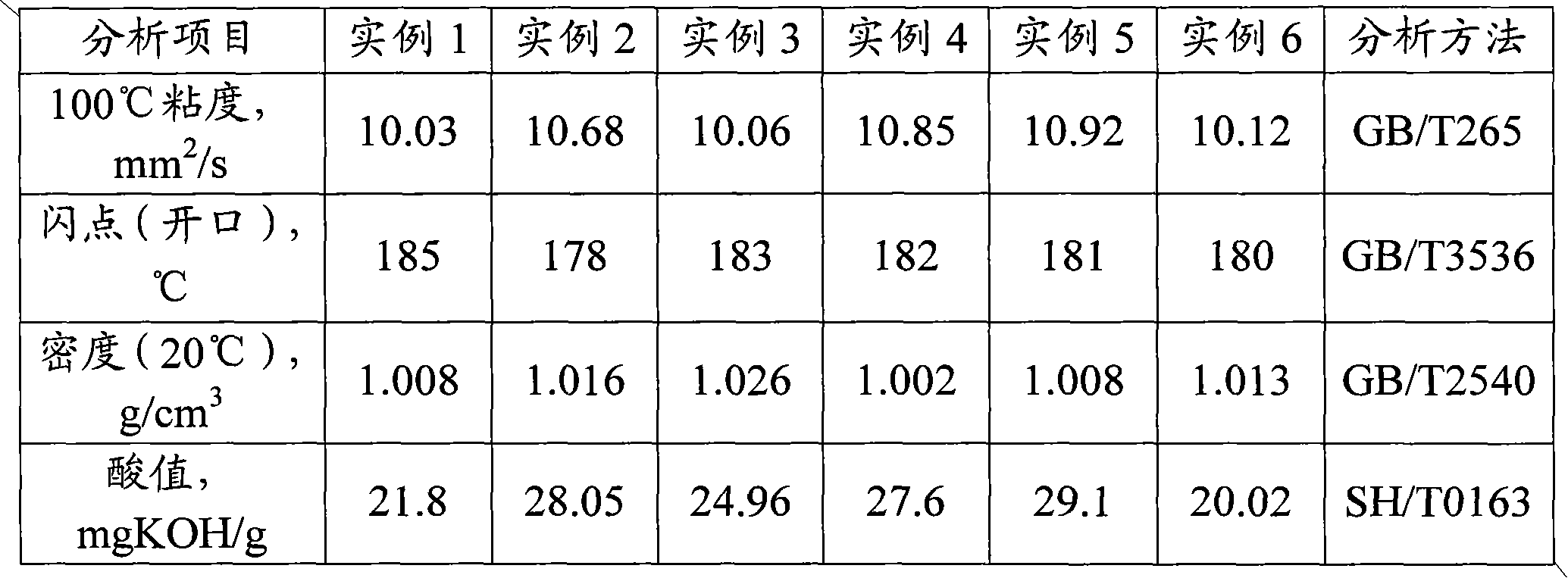

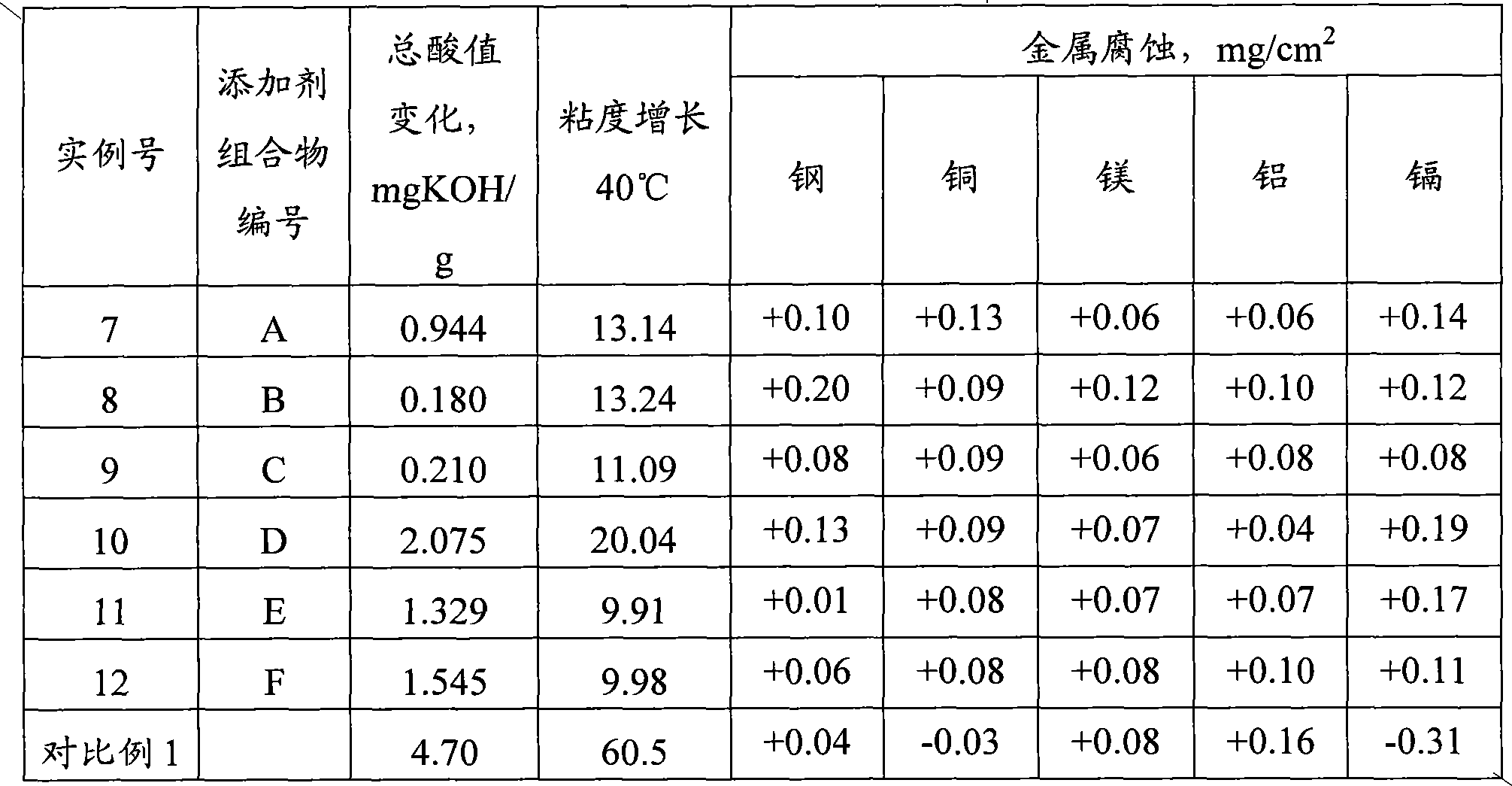

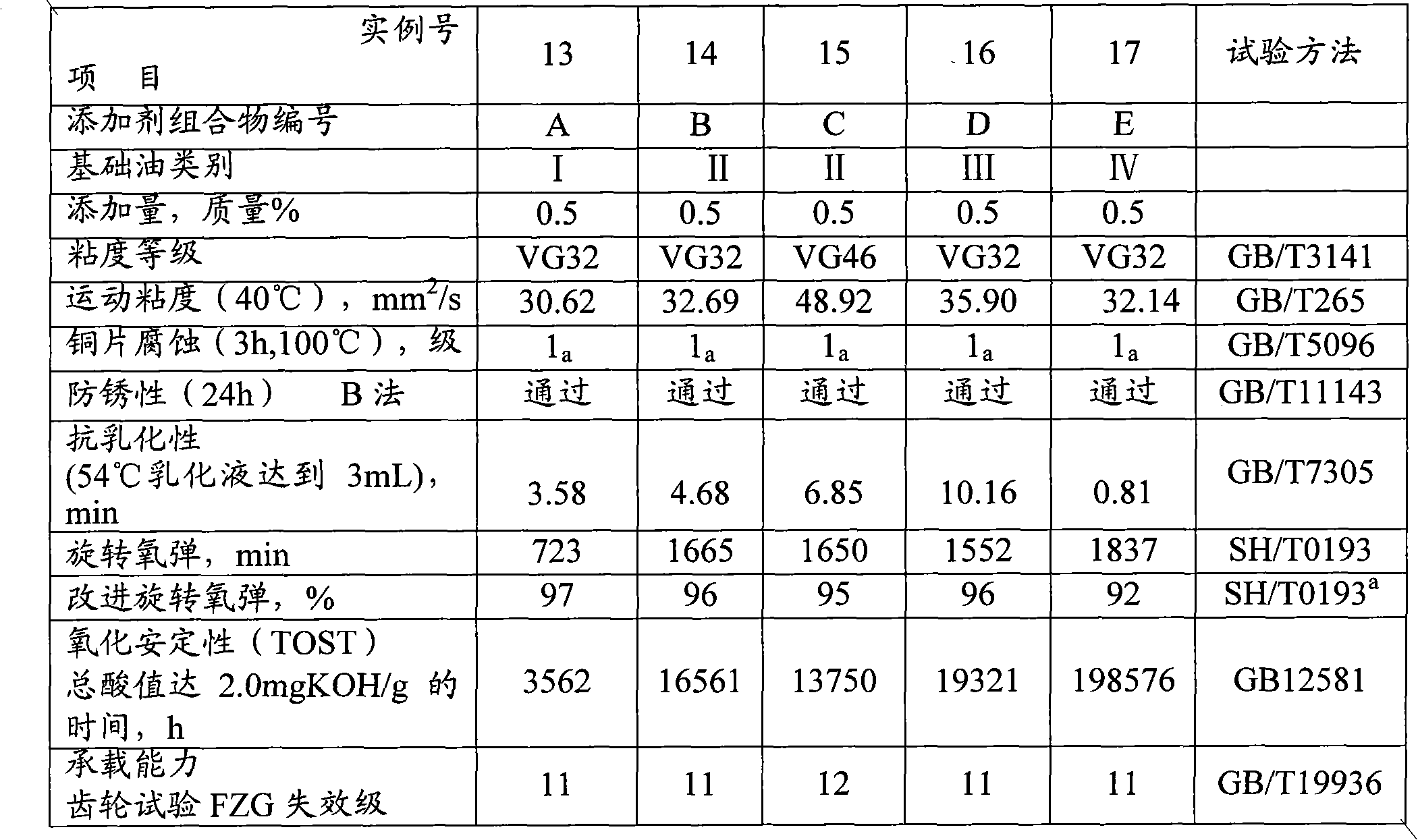

Turbine oil additive composition

ActiveCN102344849AImprove performanceSmall amount of corrosionAdditivesOil additivePhenolic antioxidant

The invention discloses a turbine oil additive composition, which comprises the following components in percent by mass: 8-30 percent of C4 / C8 alkyl substituted diphenylamine, 6-12 percent of phenyl-alpha-naphthylamine, 15-25 percent of phenolic antioxidant, 13-25 percent of methyl ester dibutyl dithiocarbamicacid, 8-10 percent of metal passivator, 5-25 percent of extreme-pressure anti-wear additive, 3-20 percent of anti-rusting agent and 0.5-5 percent of demulsifying agent. The additive composition does not contain diluent oil, is mixed into turbine oil with basic oil, and has superior oxidation stability, high-temperature stability, liquid phase rust-preventing characteristic and water separating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

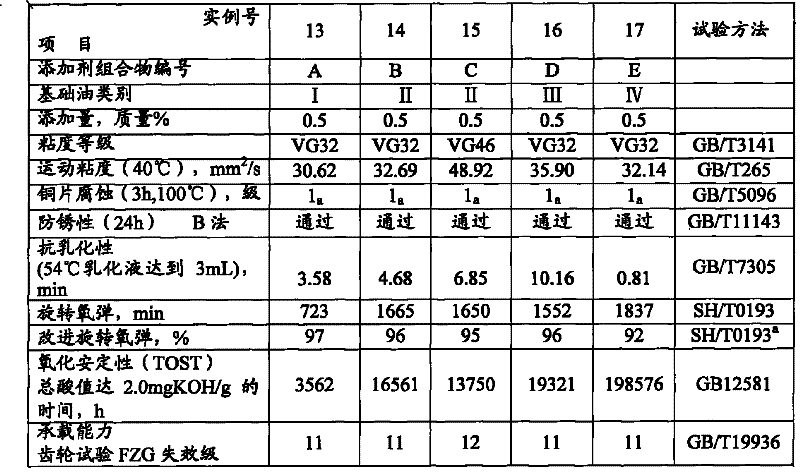

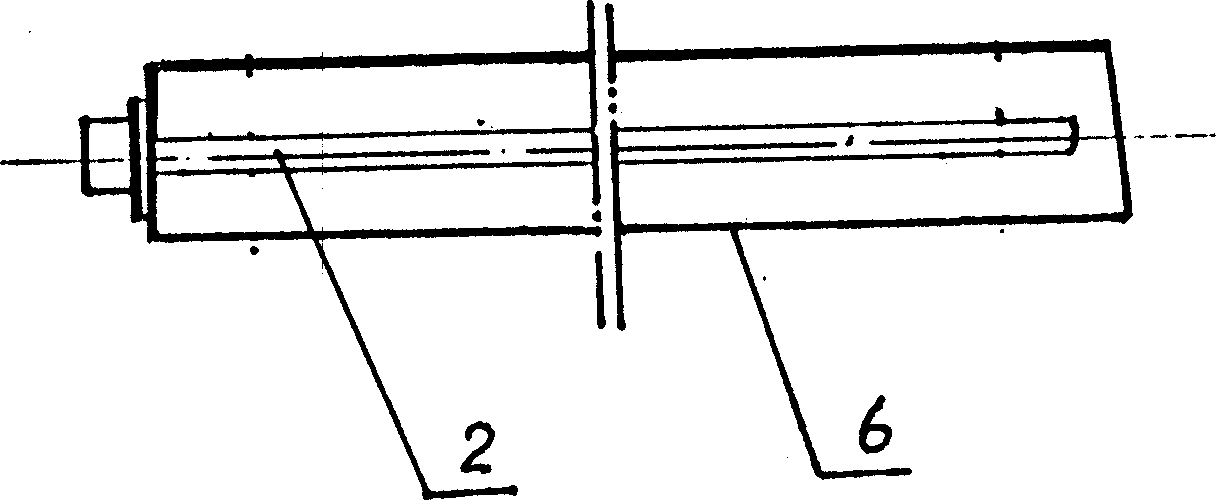

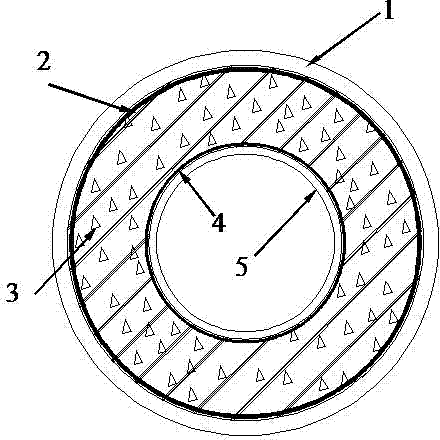

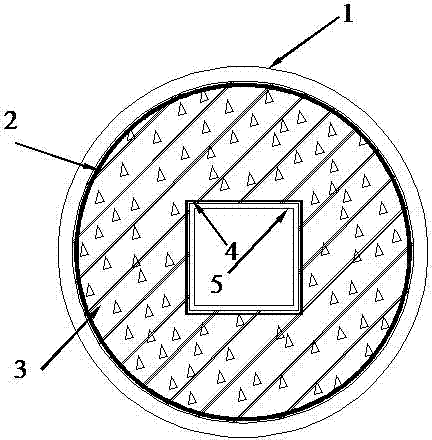

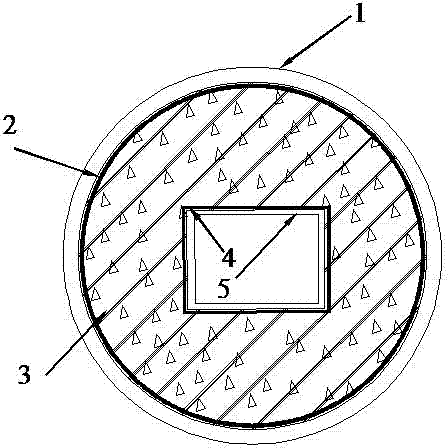

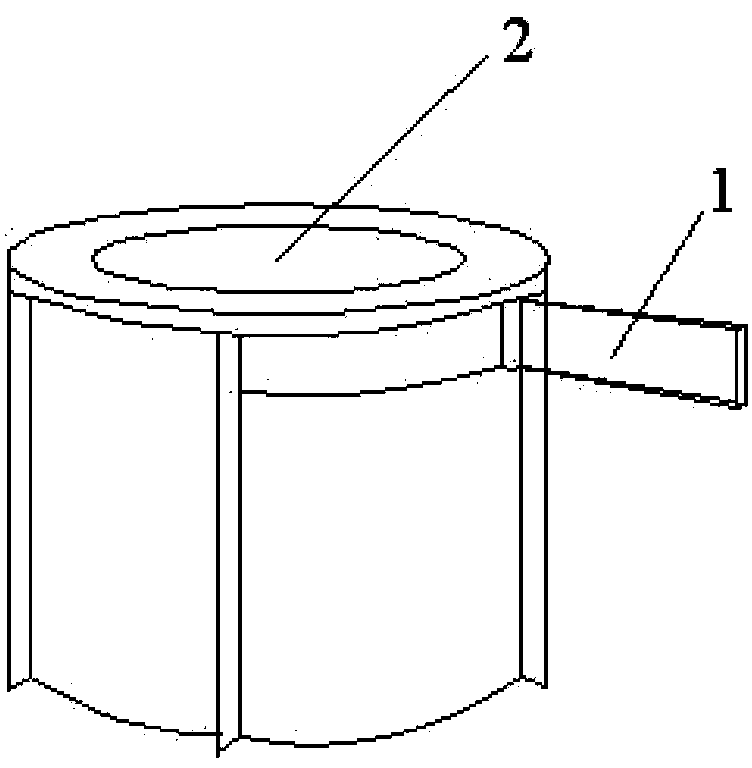

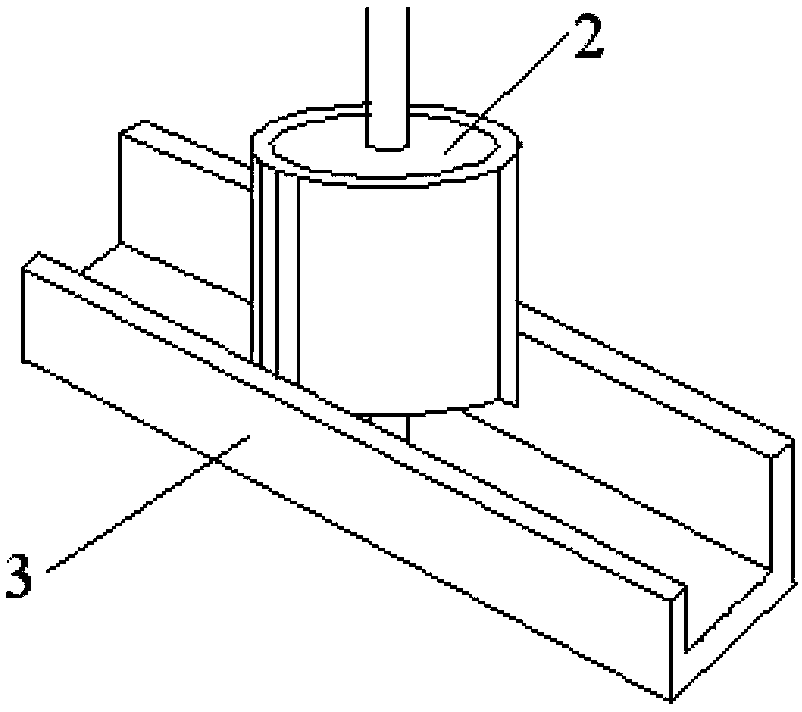

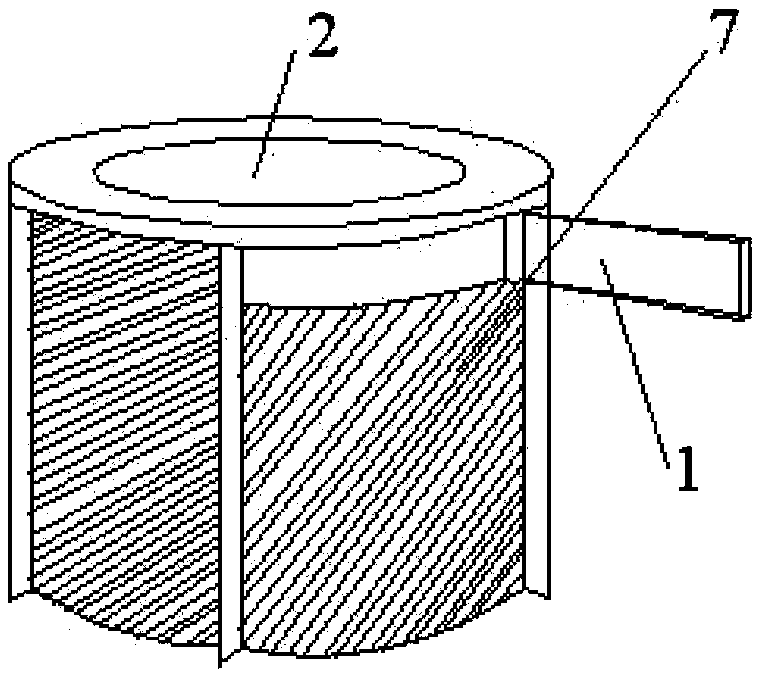

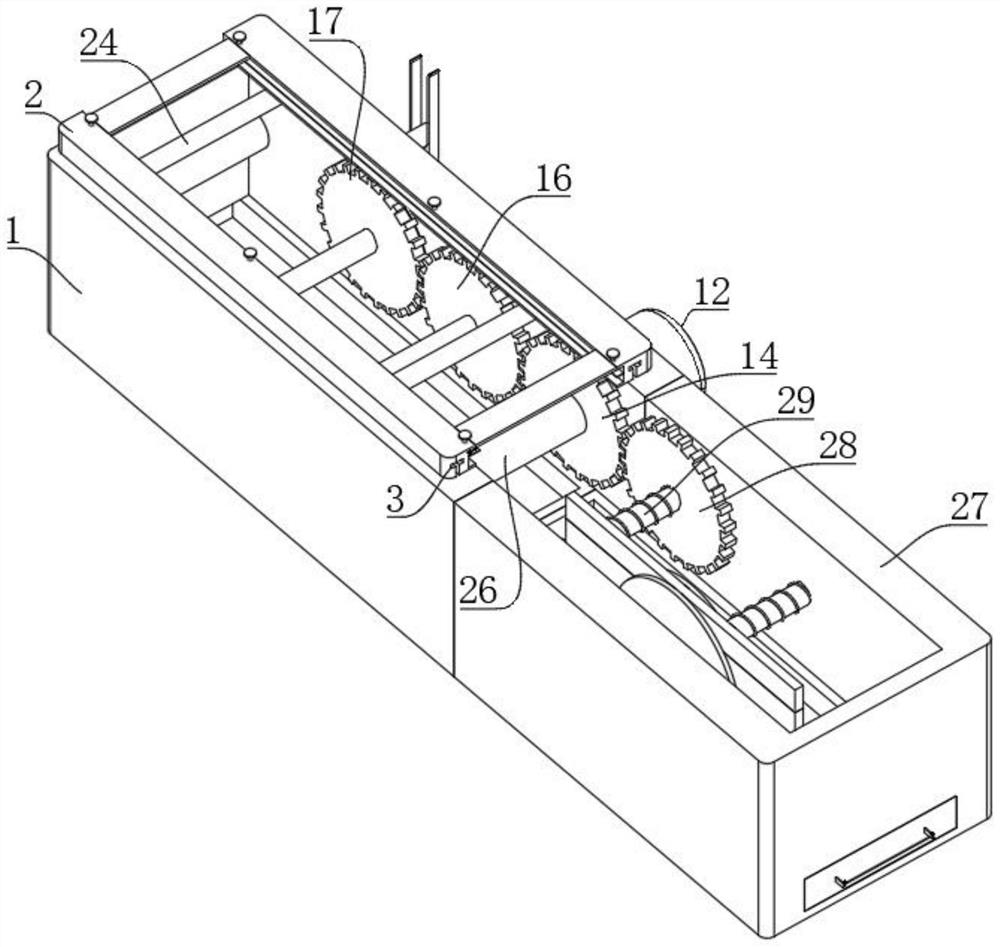

Reactor for treating supercritical water of waste organism

InactiveCN101560033AReduce corrosion rateReasonable temperature controlSolid waste disposalMultistage water/sewage treatmentEvaporationEngineering

The invention belongs to the field of treatment of waste organism, relates to supercritical water treatment of waste organism and discloses a reactor for treating supercritical water of waste organism; the reactor comprises a pressure-bearing chamber (2), an inner chamber (1) which is arranged in the pressure-bearing chamber (2) and composed of evaporation walls, a material feed pipe (4) and an overflow pipe (5) which run through the top part of the pressure-bearing chamber (2) and extend into the inner chamber (1), a salt outlet pipe which runs through the top part of the pressure-bearing chamber (2) and extend into the inner chamber (1); wherein, gaps are reserved between the inner chamber (1) and the pressure-bearing chamber (2), and the inner chamber (1) is provided with a water inlet pipe (7) for evaporating wall water.

Owner:XI AN JIAOTONG UNIV

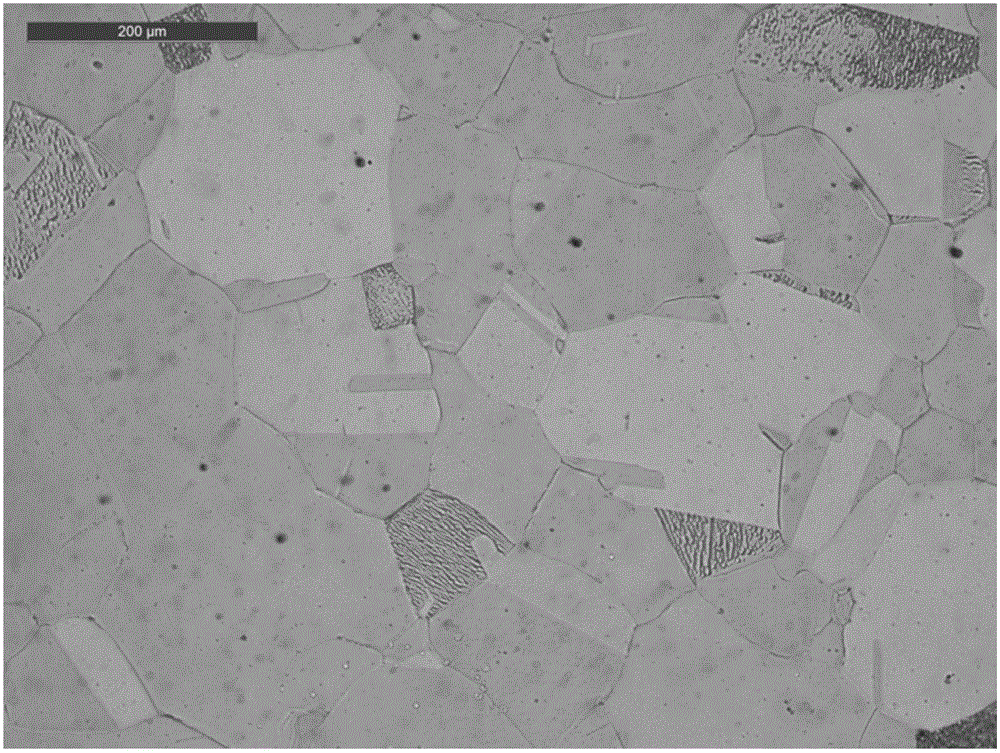

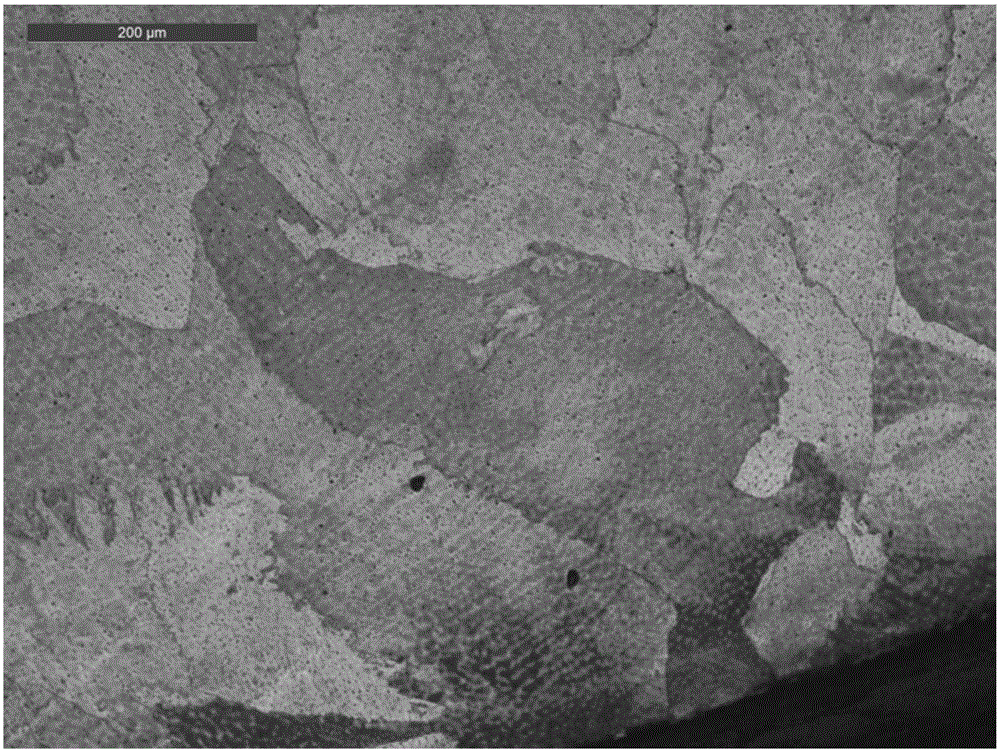

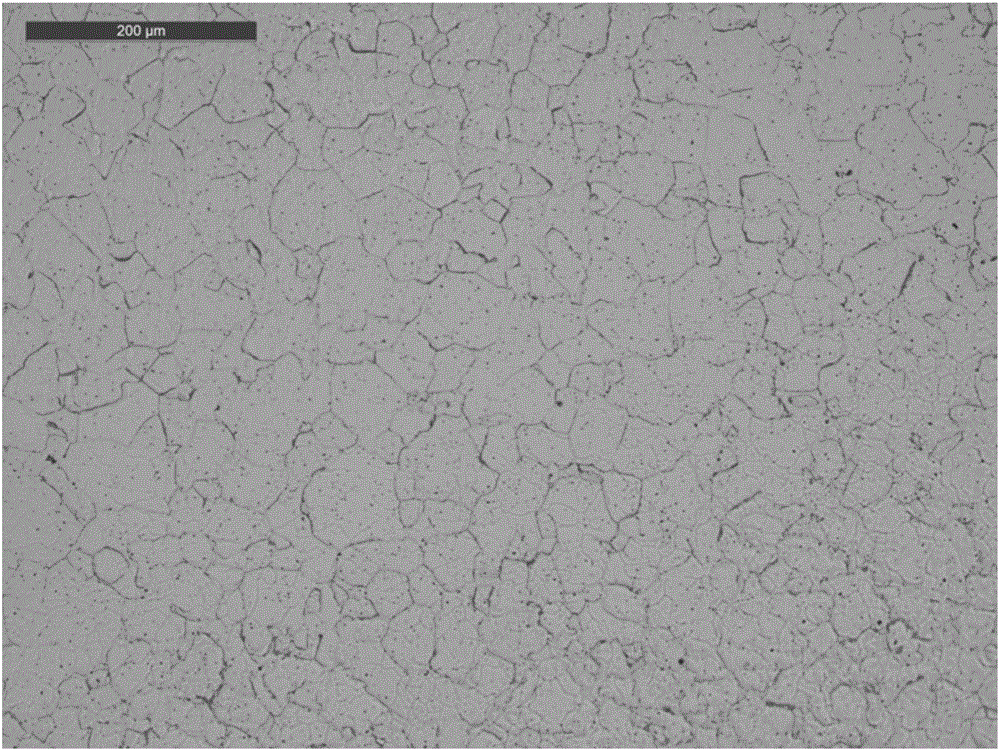

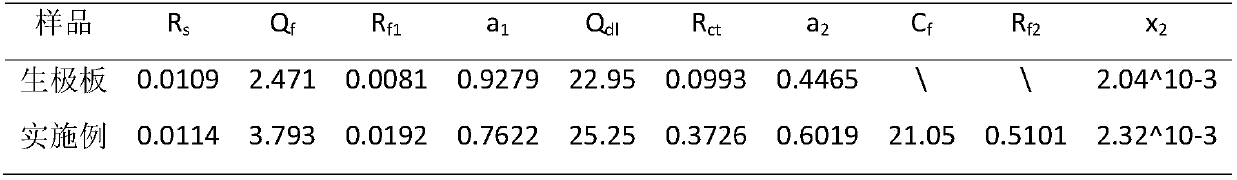

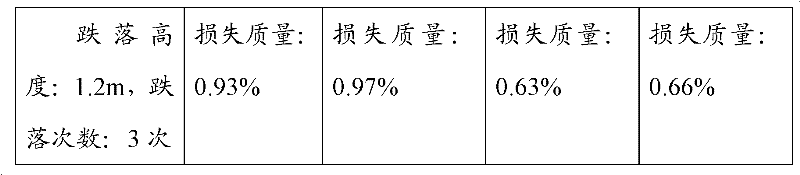

Preparation method of lead-acid battery grid alloy containing lead tin-rare earth-graphene

ActiveCN105977496AImproved grain boundary propertiesSmall grain sizeLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementCerium

The present invention discloses a preparation method of a lead-acid battery grid alloy containing lead tin-rare earth-graphene. The method includes a first step of preparing a lead-graphene composite material; a second step of preparing a grid mother alloy; and a third step of preparing the grid alloy, wherein the grid alloy includes the following components by mass percentage: 0.1-1.0% of tin, 0.01-0.2% of lanthanum, 0.05-0.5% of cerium, 0.5-10.0% of lead-graphene composite material, and the balance of lead. In the method, due to addition of the rare earth element, grain and grain boundary characteristics of the alloy are improved remarkably, grain size is reduced substantially, grain boundary area is increased, and corrosion amount is reduced substantially under the same current density. A lead-graphene composite material is deposited on a pure lead plate by using a composite electroplating technology, so as to be directly used as a material to be smelted in later preparation process of the grid alloy, so that the preparation method of the grid alloy is simplified.

Owner:TIANNENG BATTERY GROUP

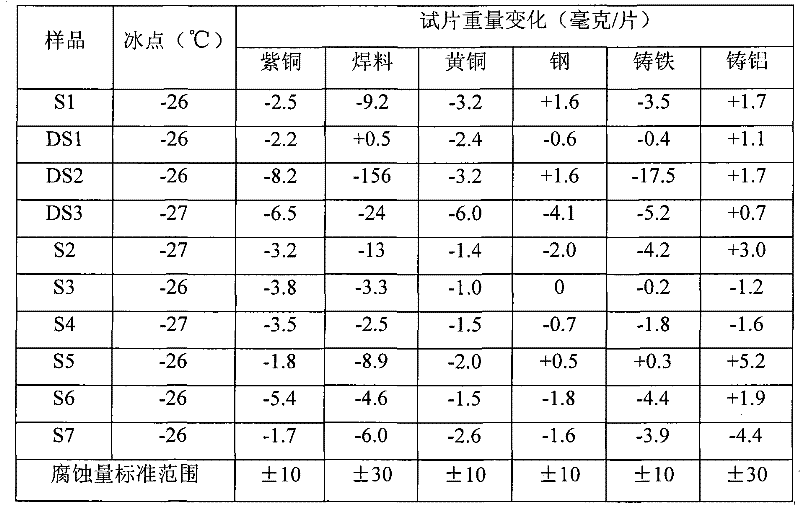

A kind of engine coolant and preparation method thereof

ActiveCN102286270AGood corrosion inhibition effectLow costHeat-exchange elementsEthylene diamineRare-earth element

The invention relates to engine cooling liquid, containing water, ethylene glycol, carboxylic acid or carboxylate with the number of carbon atoms being 1-2, silicate and an additive, wherein the additive contains EDTA (ethylene diamine tetraacetic acid) chelate of trivalent rare-earth elements. The invention also provides a preparation method of the engine cooling liquid. In the engine cooling liquid provided by the invention, the ice point is low, and the corrosivity for metal parts of an engine is less.

Owner:BYD CO LTD

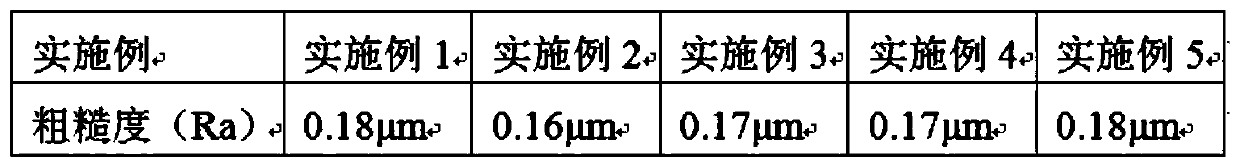

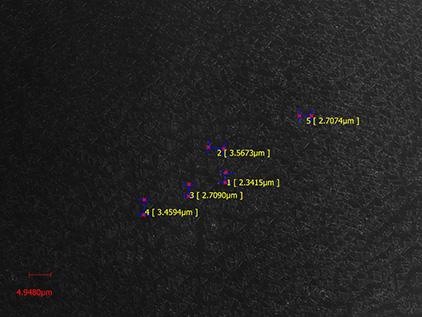

Electrochemical polishing method for surface of copper material

The invention relates to an electrochemical polishing method for a surface of a copper material. The electrochemical polishing method comprises the following step of preparing a polishing solution; and switching on a power supply to polish after a to-be-polished copper material is immersed into the polishing solution, wherein the step of preparing the polishing solution comprises the following steps of calculating the dosages of solutes according to the total volume of the to-be-prepared solution, the solutes comprising phosphoric acid, glycerin, thiourea and polyoxyethylene alkanolamide; weighing phosphoric acid and glycerin according to the calculating result and importing the same into a corrosion-resistant container, adding water to the total volume, and stirring and dissolving the mixture to obtain a first intermediate solution; weighing thiourea according to the calculating result and adding the thiourea into the first intermediate solution, and stirring and dissolving the mixture to obtain a second intermediate solution; and weighing polyoxyethylene alkanolamide according to the calculating result and adding the polyoxyethylene alkanolamide into the second intermediate solution, and uniformly stirring the mixture to obtain the polishing solution. According to the electrochemical polishing method, the surface roughness of a copper precision part can be increased from Ra0.4 [mu]m to Ra0.2 [mu], so that the using demand on a vacuum electronic apparatus is met.

Owner:NANJING SANLE GROUP

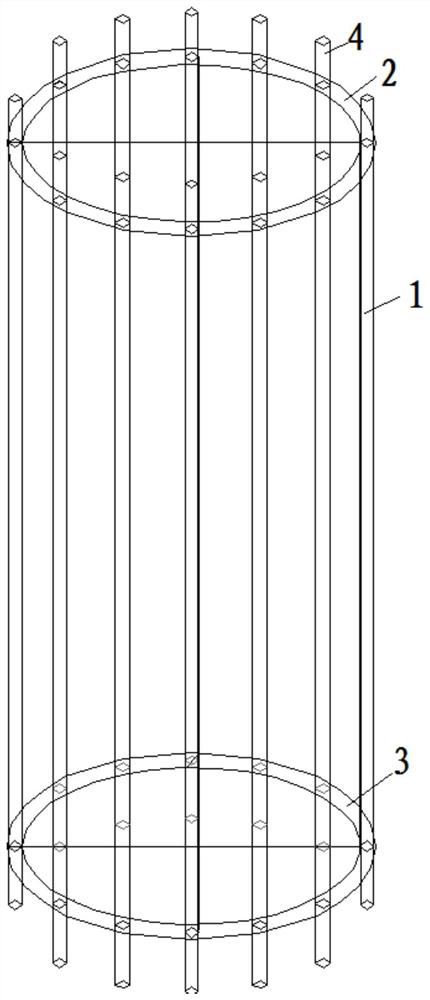

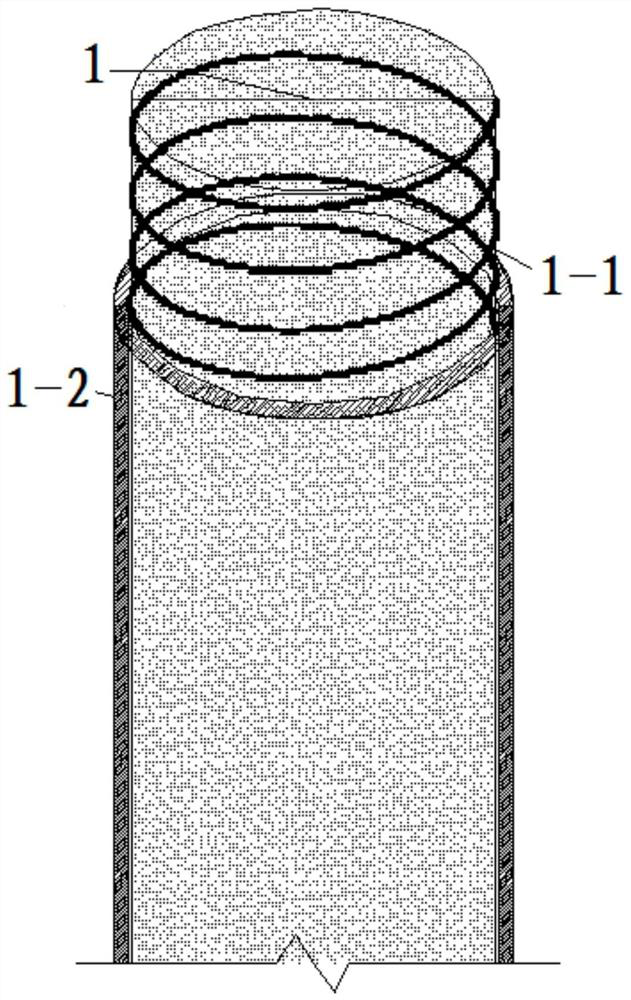

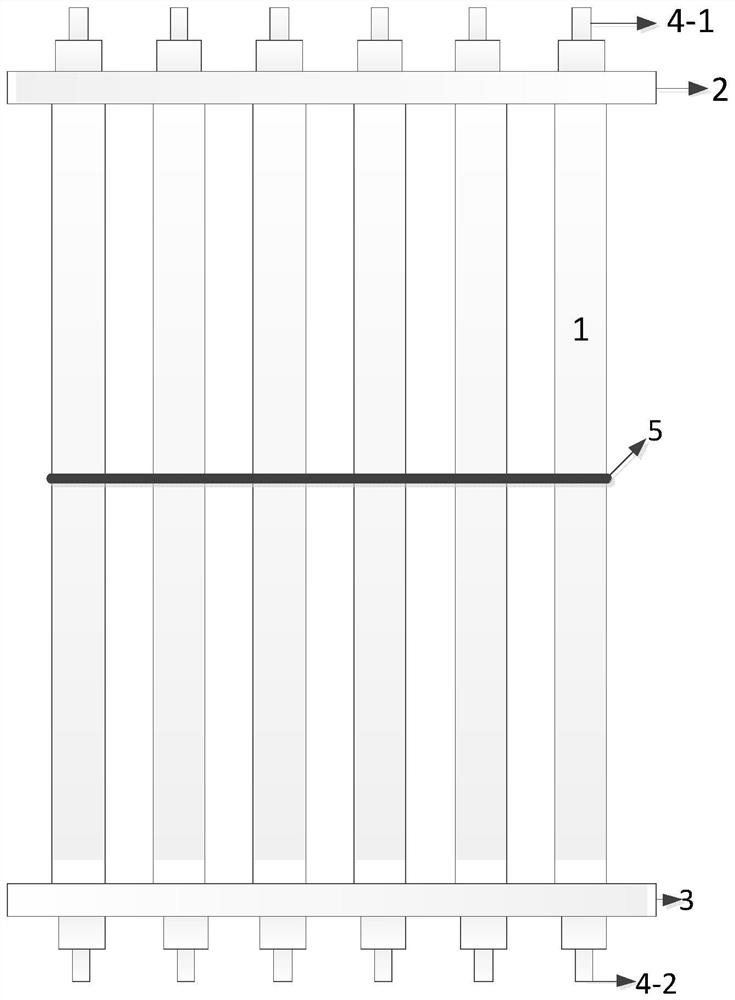

A recyclable steel cage

ActiveCN108951613BSmall amount of corrosionEasy to makeNutsBulkheads/pilesEngineeringResin-Based Composite

The invention discloses a recoverable reinforcement cage. The recoverable reinforcement cage is characterized by comprising longitudinal main ribs (1), an upper flange plate (2), a lower flange plate(3) and a protective cover nut (4); the upper flange plate (2) and the lower flange plate (3) are annular discs arranged in parallel; holes are formed in the annular discs; and the longitudinal main ribs (1) can penetrate through the upper flange plate (2) and the lower flange plate (3), so that the longitudinal main rib (1) are arranged in parallel. In the recoverable reinforcement cage, composite resin layers or PVC layers are wrapped on the longitudinal main ribs or rib bodies, so that the longitudinal main ribs can be pulled out after later casting is finished.

Owner:BEIJING JANDC GEOTECHNICAL CONSTR LTD

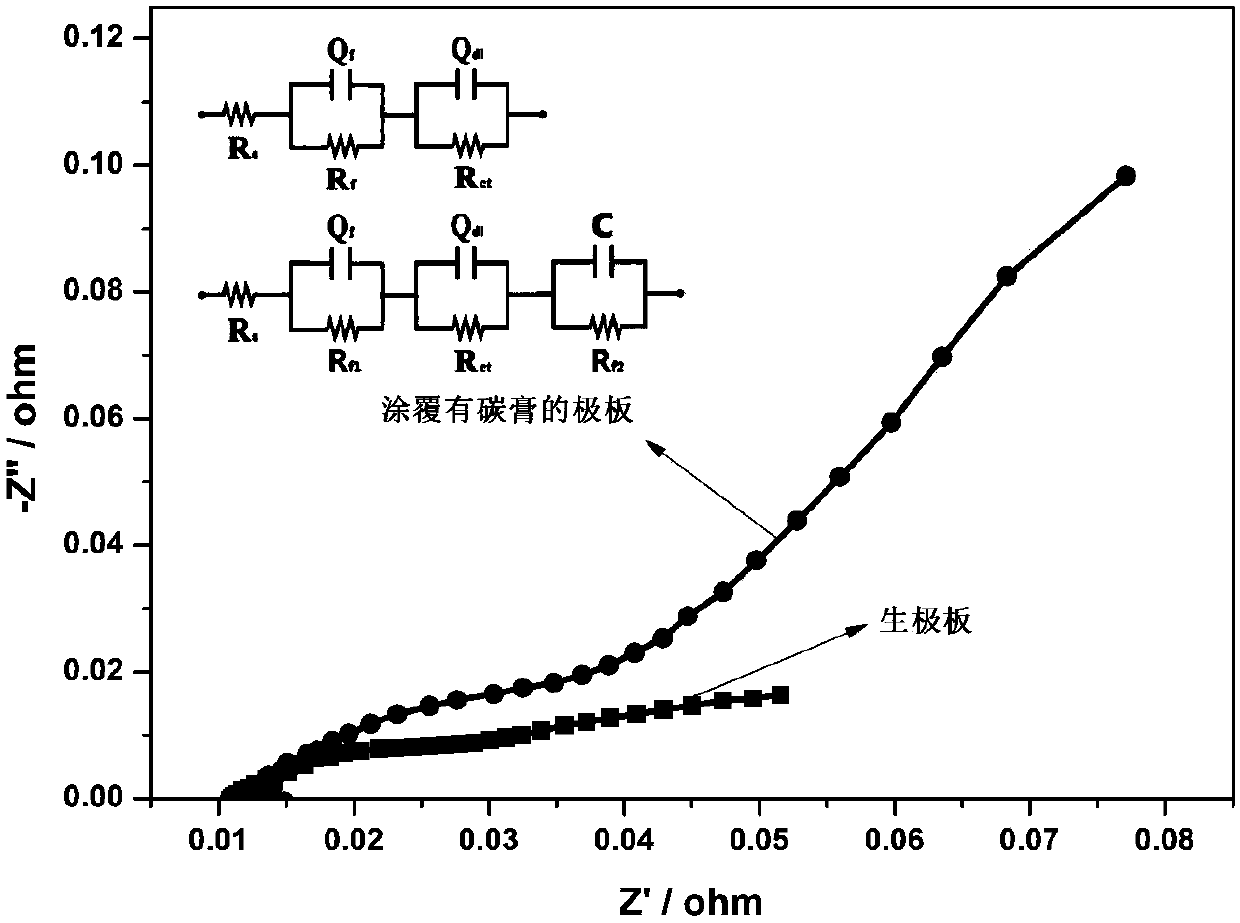

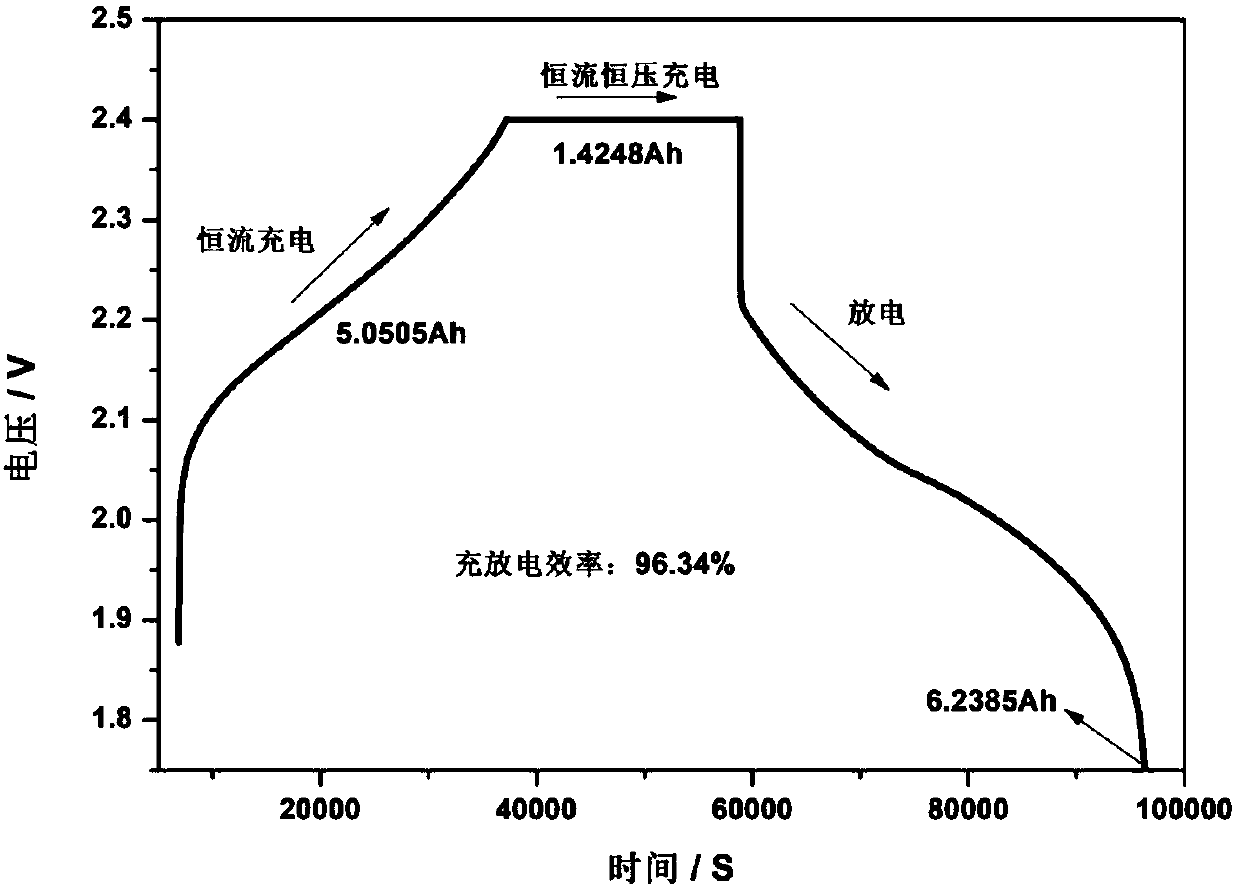

Method for preparing cathode of external applied lead-carbon battery

ActiveCN107742697AFirmly connectedDense appearanceLead-acid accumulator electrodesFiberHigh magnification

The invention discloses a method for preparing the cathode of an external applied lead-carbon battery. The cathode comprises an external applied carbon paste, wherein an electrode plate consists of lead powder, the carbon paste, humic acid, a short fiber, barium sulfate, sodium lignin sulfonate and acetylene black. An additive which can play a physical connection network function in a preparationprocess and can be polymerized in sulfuric acid to generat ester gel is added into the carbon paste, and the whole external applied electrode is wrapped in the gel with ion permeability, so that the physical connection of a carbon phase and a lead phase is enhanced. By adopting the electrode plate comprising the carbon paste, the carbon paste dropping velocity is effectively reduced, the advantages of an external applied electrode structure are sufficiently brought into play, the effective utilization rate of active substances is increased, a cathode sulfation phenomenon at a high magnification part charge state is alleviated, the energy density of the whole battery is improved, and the circulation service life of the battery is prolonged.

Owner:吉林省凯禹电化学储能技术发展有限公司

Kitchen degreasing agent and preparation method thereof

ActiveCN104818160AInhibit acid and alkali corrosionSkin irritationSurface-active non-soap compounds and soap mixture detergentsCitrate sodiumOrganic base

The invention discloses a kitchen degreasing agent and a preparation method thereof. The kitchen degreasing agent is made of, by weight, 0.3-6.0% of alcohol ethoxylate, 0.5-8.0% of fatty alcohol-polyoxyethylene ether, 0.1-5.0% of organic base, 0.1-6.0% of hydroxyethylidene diphosphonic acid, 0.1-3.0% of sodium carbonate, 0.1-3.0% of sodium metasilicate, 0.1-4.5% of sodium citrate, 0.1-2.5% of essences and the rest of deionized water. The preparation method includes: adding the alcohol ethoxylate and the fatty alcohol-polyoxyethylene ether into the deionized water while stirring, well mixing, adding the sodium carbonate, the sodium metasilicate, the sodium citrate, the organic base, the hydroxyethylidene diphosphonic acid and the essences while stirring, and well mixing. The kitchen degreasing agent is free of solvents and hydroxyl strong bases and has the advantages of mildness, low skin irritation, low corrosivity and excellent performance in cleaning and degreasing of range hoods, cooking ranges and the like.

Owner:WALCH GUANGZHOU COMMODITY

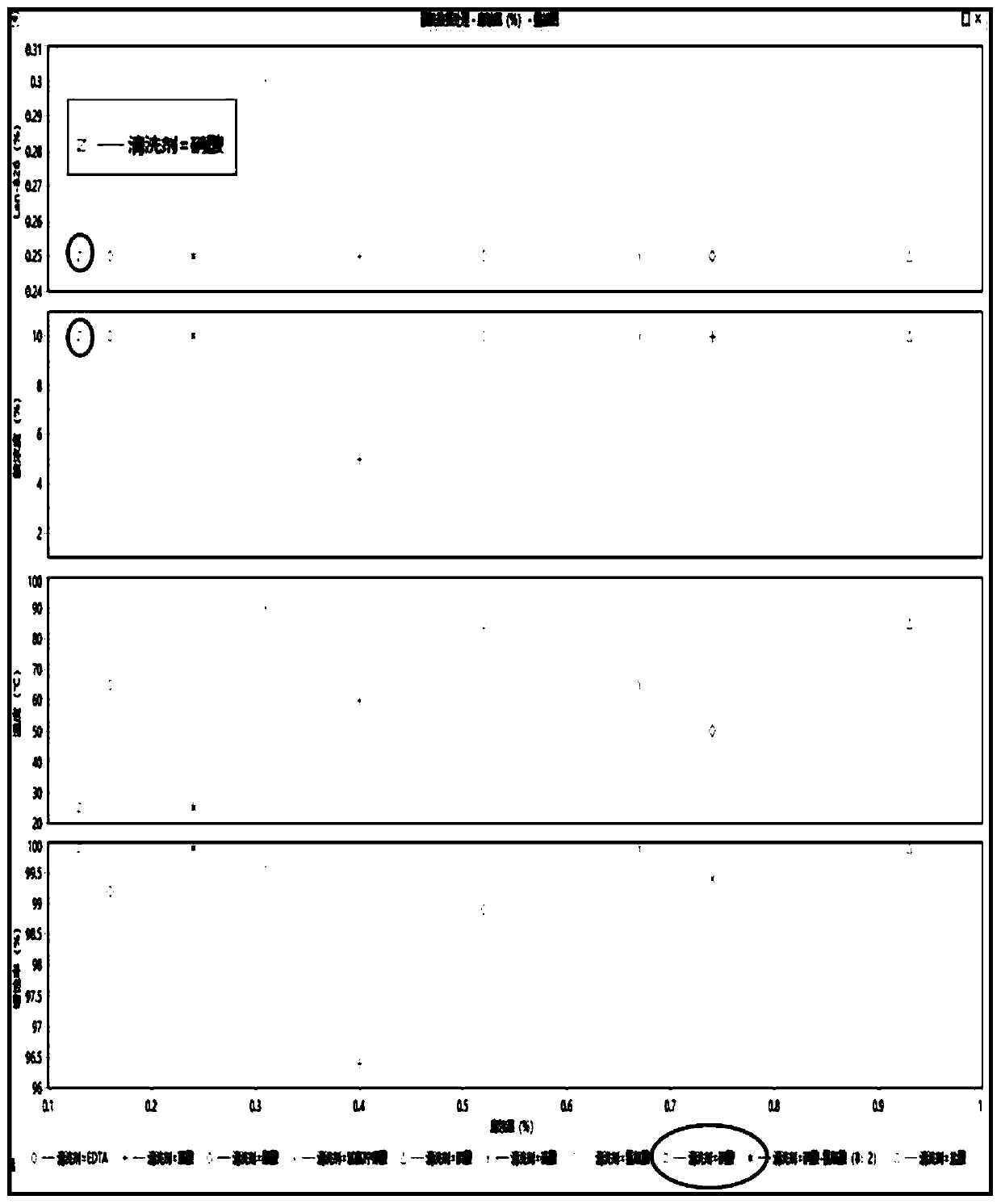

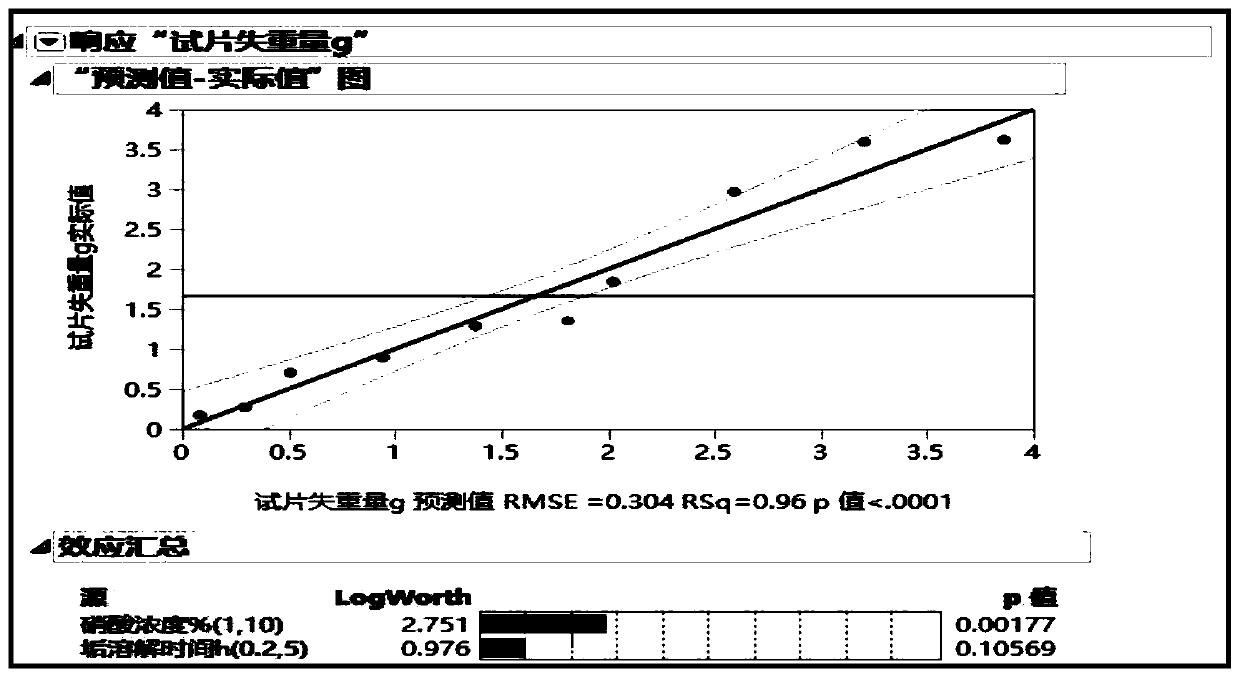

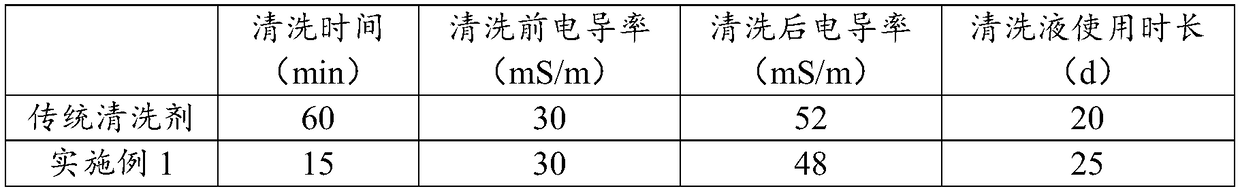

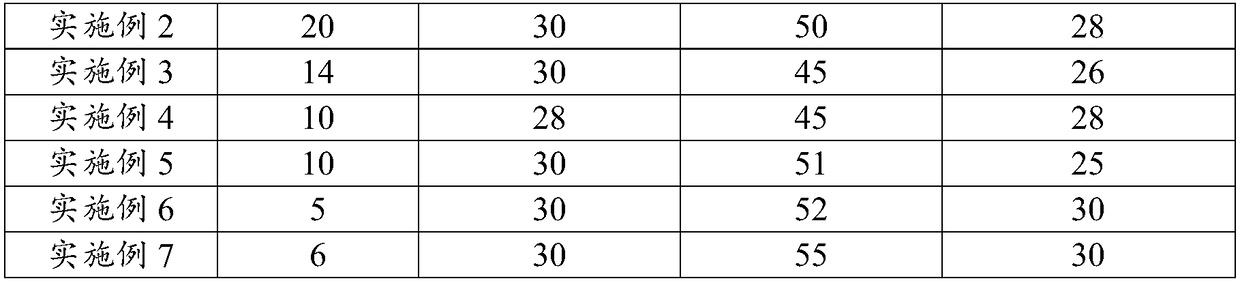

Optimization method of heat exchanger pickling process

ActiveCN111322904AEasy picklingSmall amount of corrosionFlush cleaningProcess engineeringIndustrial engineering

The invention belongs to the technical field of heat exchanger cleaning, and particularly relates to an optimization method of a heat exchanger pickling process. Firstly, according to scale layer components of a heat exchanger, comprehensive screening is conducted through a superposition graph of data statistical analysis software, and proper cleaning acid is found; under the effective concentration of the corrosion inhibitor, the screened standard test pieces with the cleaning acid and the heat exchanger shell made of the same material are used for carrying out a corrosion experiment, two sets of comparison data are obtained, the corrosion weight loss of the standard test pieces in acid with different concentrations is measured without adding the corrosion inhibitor in one set, and the weight loss of the standard test pieces is measured after the corrosion inhibitor is added in the other set; establishing a predicted value-actual value model of the corrosion weight reduction of the test piece, and finding out the optimal cleaning acid concentration by using a prediction descriptor of data software, and in the pickling process, the corrosion amount of the heat exchanger shell is minimum, and optimization of the heat exchanger pickling process is achieved. By the method, the problem of serious corrosion of the shell during pickling of the heat exchanger can be solved, and heat exchange efficiency of the heat exchanger is improved after pickling.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

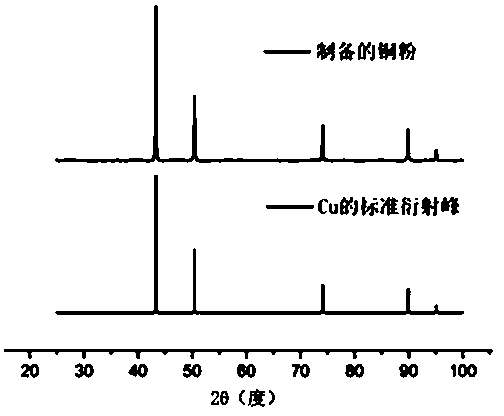

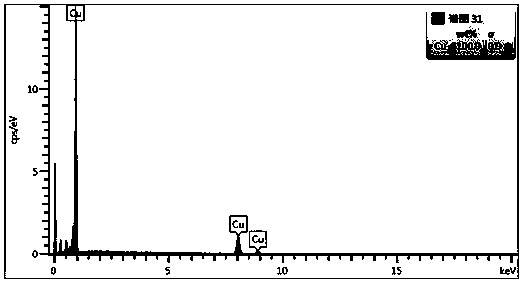

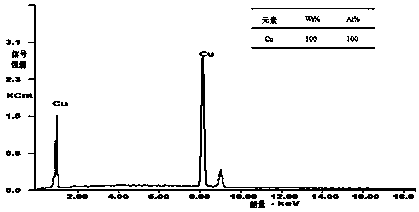

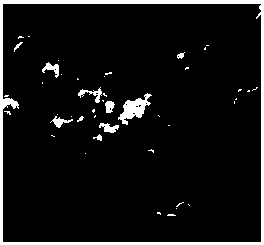

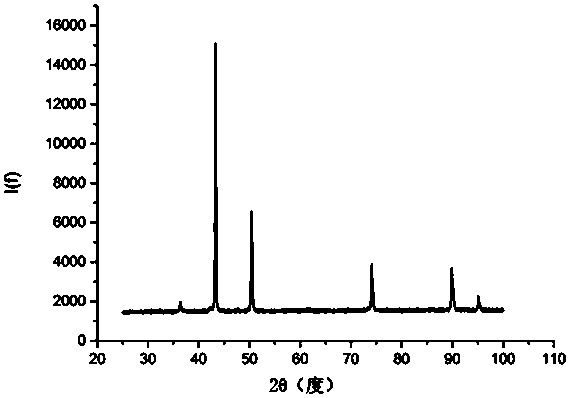

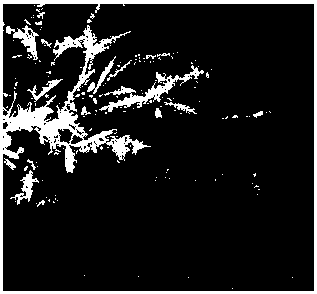

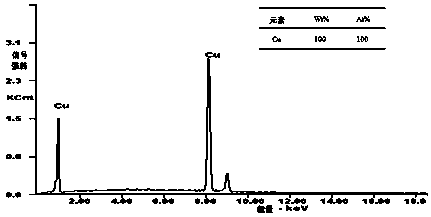

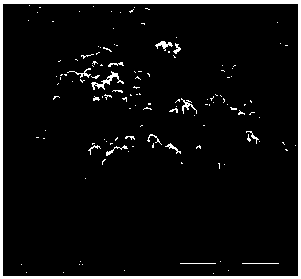

Method for preparing nano copper powder through fluorocarbon surfactant

A method for preparing nano copper powder through a fluorocarbon surfactant comprises the following steps that (1) an anionic fluorocarbon surfactant, a nonionic surfactant, an assistant, CuSO.5H2O and water are proportionally selected to prepare microemulsion; (2) the microemulsion is subjected to electrodeposition, and nano copper powder mixed liquor is obtained; (3) nano copper powder is extracted, the nano copper powder mixed liquor is subjected to filtering or centrifugal treatment, and after suction filtration and drying, nano copper powder is obtained; and (4) the nano copper powder isput into a packaging bag, and the packaging bag is sealed and stored after inert gases are injected into the packaging bag. According to the nano copper powder prepared through the method, the particle size is 20-100 nanometer, the purity is 99% or above, distribution of the particle size is uniform, and the appearance consistency is good; in the preparation process, the copper powder does not adhere to a cathode plate, the self-desorption performance is good, the cathode plate is easy to clean, and automatic continuous production can be achieved; the corrosion amount of an anode plates is small, environment pollution is small, and energy consumption is low; and the prepared nano copper powder is good in dispersity and easy to collect.

Owner:CENT SOUTH UNIV

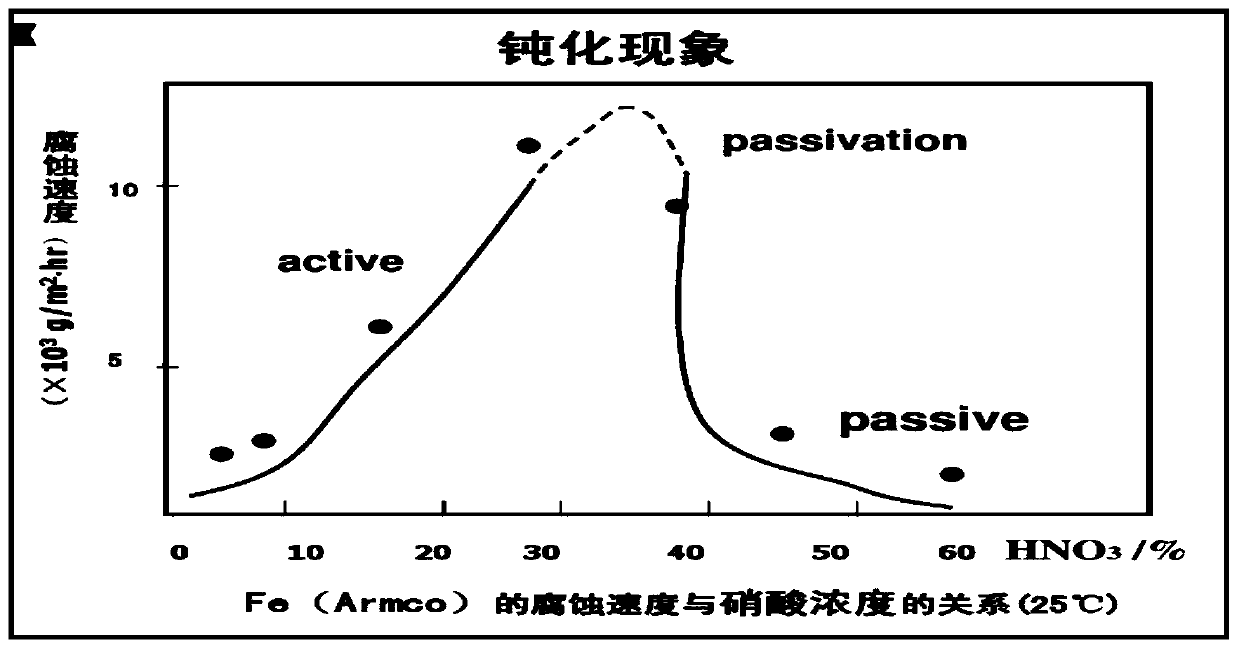

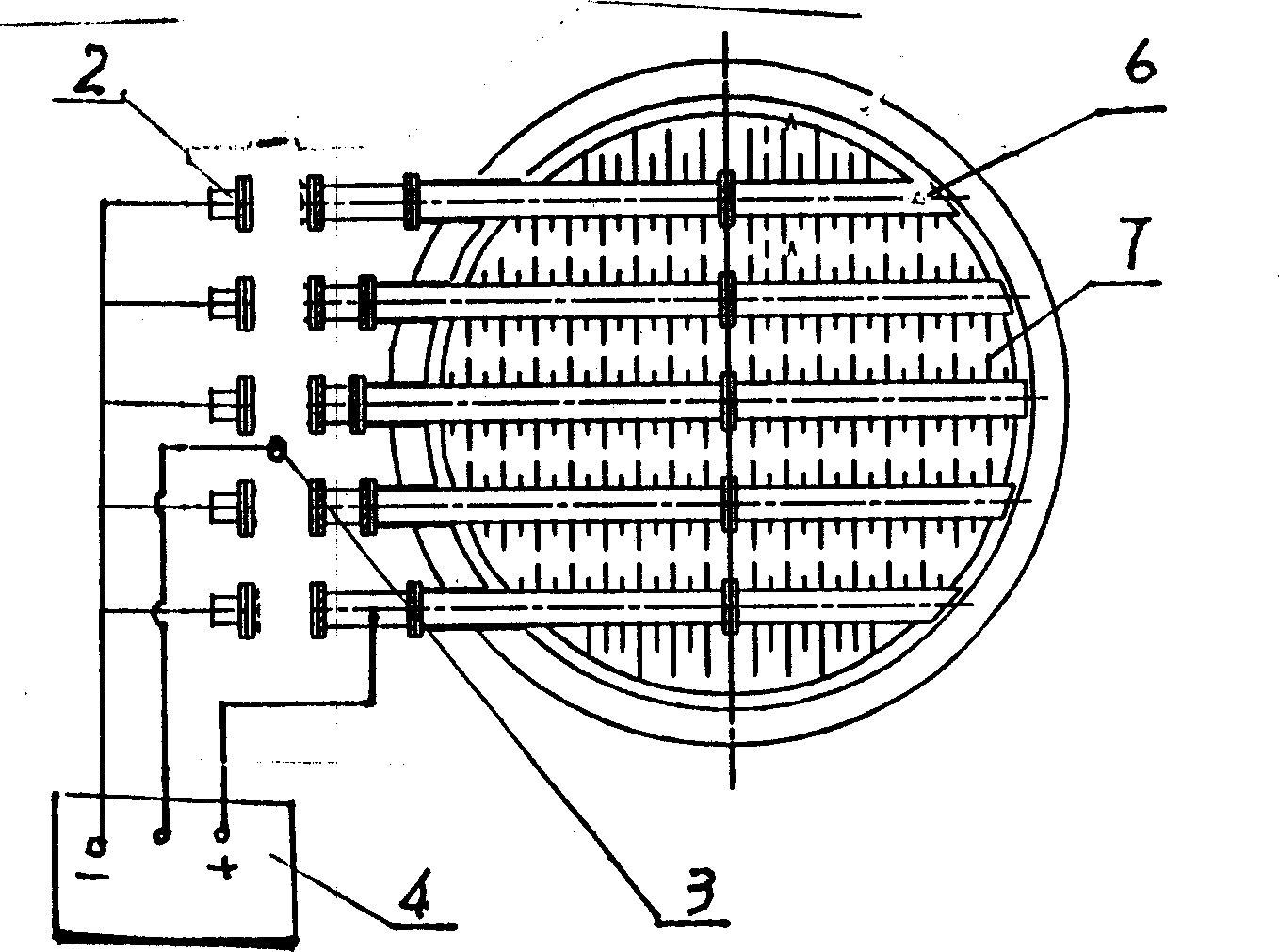

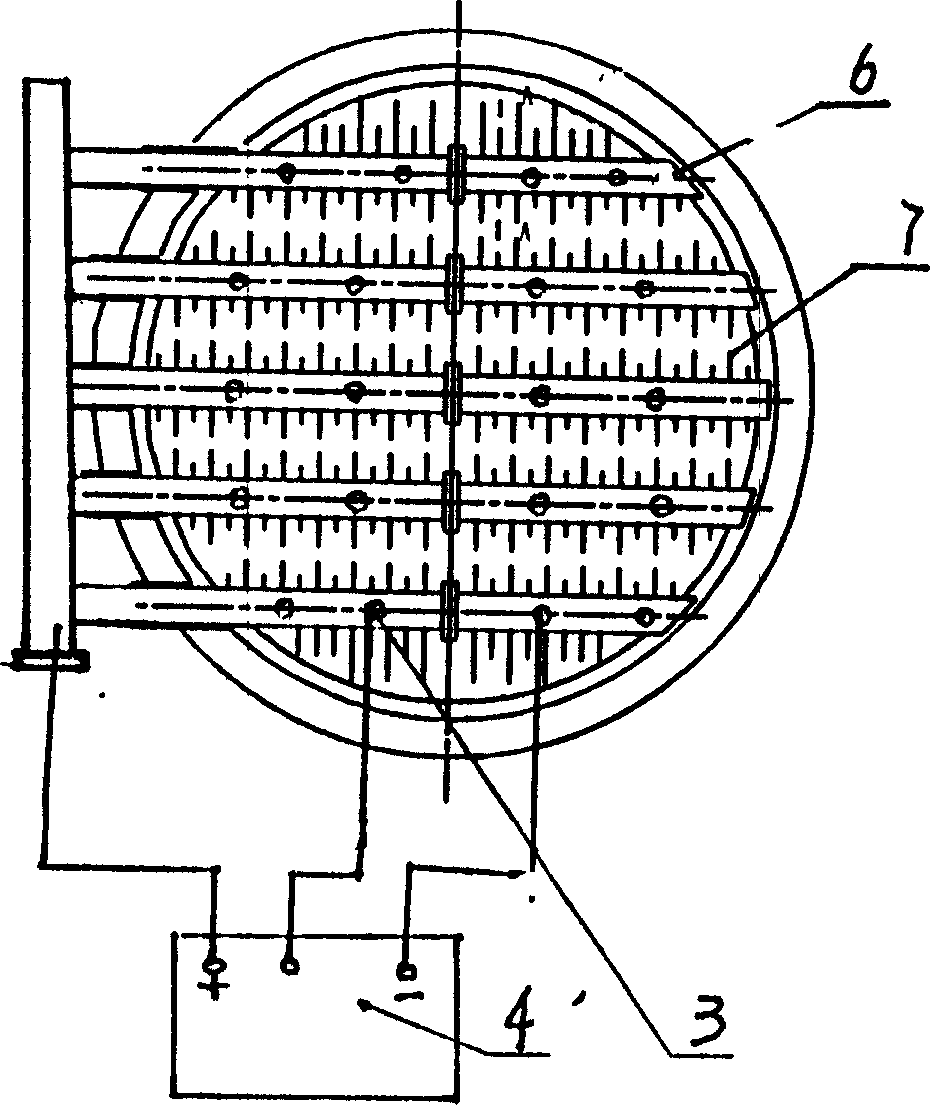

Anode protection anticorrosion method for acid separating device

The present invention relates to electrochemical corrosion preventing anode protecting technology and is used especially for acid separator in acid producting equipment. The anode protecting device includes acid separating pipes, cathode, reference electrode and constant potential instrument and features that the acid separating pipes as the anode are connected via wires to the positive electrode and zero potential of the constant potential instrument, the cathodes of the acid separating pipes in the acid separator are connected to the negative electrode of the constant potential instrument and the reference electrodes of the acid separating pipes are connected to the reference electrode of the constant-potential instrument. The said method can expand the anode protecting area to 2.5 m over area to protect the inner surfaces of the acid separating branches.

Owner:兰州兴业材料保护有限公司

Engine coolant and preparation method thereof

InactiveCN102453469BCushion platform raisedImprove the protective effectHeat-exchange elementsGlutaric acidBorate salt

The invention discloses an engine coolant, which comprises water, glycol, a fatty acid or fatty acid salt, an aromatic acid or aromatic acid salt, silicate and an additive, wherein the pKa of the fatty acid or fatty acid salt is 4.7-6.5; the pKa of the aromatic acid or aromatic acid salt is 3-5; and the additive contains a buffer platform elevator which is 2-aminoglutaric acid or a mixture of the 2-aminoglutaric acid and borate. The invention further provides a preparation method of the engine coolant. The engine coolant provided by the invention is provided with two buffer platforms, so that protection of metal iron can be enhanced on the premise of well protecting other metals with the engine coolant.

Owner:江苏三阳环保科技有限公司

Sea sand recycled concrete member for hollow double-skin steel pipe

InactiveCN104763094AImprove bending abilityEfficient use ofStrutsConstruction materialEpoxySurface layer

The invention belongs to the field of engineering structures, and particularly relates to a sea sand recycled concrete member for a hollow double-skin steel pipe. The member is characterized in that the inner surface of an outer steel pipe and the outer surface of an inner steel pipe are coated with epoxy resin; the space formed by encircling of the inner steel pipe and the outer steel pipe is filled with the sea sand recycled concrete. Because a form of the cross section of the hollow double-skin is adopted, the axial load strength of the hollow double-skin steel pipe sea sand recycled concrete is not smaller than that of solid steel pipe concrete, and the anti-bending bearing capability and the fireproof high-temperature resistant performance are greatly improved; the surface layers of the inner steel pipe and the outer steel pipe are coated with epoxy resin, the corrosion of the steel pipes is avoided; moreover, the inner part of the steel pipes is filled with the sea sand recycled concrete, so that the bearing capability and the deformation capability of the concrete can be improved, and the safety hidden danger of the sea sand can be reduced, and a combination function can be fully achieved. By using the member, the application of the sea sand recycled concrete member is improved, energy source conservation and renewable resource utilization are fully achieved, and the sea sand recycled concrete member has a good social and economic benefit.

Owner:SHANDONG UNIV OF SCI & TECH

Water-seal sealing cover for walking beam heating furnace

The invention discloses a water-seal sealing cover for a walking beam heating furnace. The water-seal sealing cover comprises a furnace bottom sheet frame (1), a translation framework (6), a plurality of sealing covers (2) and water sealing grooves (3) with the corresponding quantity, and is further provided with a blow-off pipe (5). The water-seal sealing cover is characterized in that the water sealing grooves (3) are communicated by communication pipes (4); the communication pipes (4) are arranged on the positions, which are close to the upper edge opening, of the water sealing grooves (3). With the adoption of the technical scheme, the water-seal sealing cover can adopt both turbid circulating water and pure circulating water; a layer of asphalt paint is brushed on each of the inner and outer surfaces of the water-seal sealing cover so as to effectively reduce the abrasion on a skirt cover and the water sealing grooves by water in the water sealing grooves. With the adoption of the improvement, the working amount of replacing the water-seal skirt cover by a maintenance bench worker can also be reduced, the working amount of cleaning sediments by post workers is reduced and the effective working rate of production is improved; the walking beam heating furnace can produce safely, stably and efficiently.

Owner:WUHU XINXING DUCTILE IRON PIPES

Texture liquid for preparing submicron suede-like monocrystalline silicon wafer and preparation method thereof

InactiveCN102747426AReduce surface tensionSmall amount of corrosionAfter-treatment detailsAlcoholSURFACTANT BLEND

The invention discloses texture liquid for preparing a submicron suede-like monocrystalline silicon wafer and a preparation method thereof. The texture liquid comprises the following components: inorganic base, lower alcohol, an anion or non-ionic surfactant and the balance of deionized water. The preparation method of the texture liquid comprises the following steps of: adding the deionized water into a texture etching groove; sequentially adding the inorganic base, the lower alcohol and the anion or non-ionic surfactant under the stirring condition; and continuously stirring for 10 to 30 minutes to ensure the raw materials to be sufficiently dissolved and mixed. A uniform and submicron pyramid structure can be formed on the surface of the silicon wafer by the texture liquid; and the texture liquid has high coverage rate, excellent texture effect and simple process and is easy to implement.

Owner:ZHEJIANG UNIV

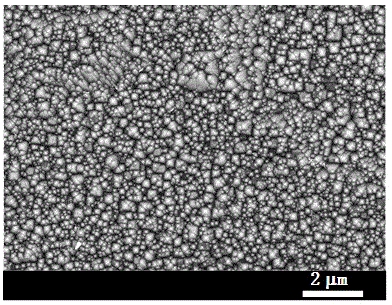

Preparation method of lead battery grid alloy containing lead-tin-rare earth-graphene

ActiveCN105977496BImproved grain boundary propertiesSmall grain sizeLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementCerium

The present invention discloses a preparation method of a lead-acid battery grid alloy containing lead tin-rare earth-graphene. The method includes a first step of preparing a lead-graphene composite material; a second step of preparing a grid mother alloy; and a third step of preparing the grid alloy, wherein the grid alloy includes the following components by mass percentage: 0.1-1.0% of tin, 0.01-0.2% of lanthanum, 0.05-0.5% of cerium, 0.5-10.0% of lead-graphene composite material, and the balance of lead. In the method, due to addition of the rare earth element, grain and grain boundary characteristics of the alloy are improved remarkably, grain size is reduced substantially, grain boundary area is increased, and corrosion amount is reduced substantially under the same current density. A lead-graphene composite material is deposited on a pure lead plate by using a composite electroplating technology, so as to be directly used as a material to be smelted in later preparation process of the grid alloy, so that the preparation method of the grid alloy is simplified.

Owner:TIANNENG BATTERY GROUP

Turbine oil additive composition

ActiveCN102344849BImprove performanceSmall amount of corrosionAdditivesOil additivePhenolic antioxidant

The invention discloses a turbine oil additive composition, which comprises the following components in percent by mass: 8-30 percent of C4 / C8 alkyl substituted diphenylamine, 6-12 percent of phenyl-alpha-naphthylamine, 15-25 percent of phenolic antioxidant, 13-25 percent of methyl ester dibutyl dithiocarbamicacid, 8-10 percent of metal passivator, 5-25 percent of extreme-pressure anti-wear additive, 3-20 percent of anti-rusting agent and 0.5-5 percent of demulsifying agent. The additive composition does not contain diluent oil, is mixed into turbine oil with basic oil, and has superior oxidation stability, high-temperature stability, liquid phase rust-preventing characteristic and water separating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Small tower footing silicon wafer alkali polishing auxiliary agent and application thereof

ActiveCN114133876ACorrosion inhibitionThe amount of corrosion is controllableFinal product manufactureSemiconductor/solid-state device manufacturingAmmonium sulfateSODIUM DODECYL BENZENE SULFONATE

The invention belongs to the technical field of crystalline silicon polishing. The alkali polishing auxiliary agent for the small tower footing silicon wafer comprises an auxiliary agent A and an auxiliary agent B, the auxiliary agent A is prepared from the following components in percentage by mass: 0.1 to 0.5 percent of silane coupling agent, 2 to 5 percent of ethanol, 0.05 to 0.2 percent of gelatin, 1 to 3 percent of n-butyl alcohol, 0.05 to 0.2 percent of sodium dodecyl benzene sulfonate, 0.01 to 0.05 percent of perfluoroalkyl polyoxyethylene ether and the balance of deionized water; the auxiliary agent B is prepared from the following components in percentage by mass: 0.5 to 1 percent of silane coupling agent, 0.1 to 0.4 percent of alkyl trimethyl ammonium bromide, 0.01 to 0.1 percent of perfluoroalkyl polyoxyethylene ether, 2 to 5 percent of ethanol, 1 to 3 percent of ammonium persulfate and the balance of deionized water. The alkali polishing auxiliary agent can effectively protect a non-polished surface from being corroded in the alkali polishing process, the alkali corrosion amount of the polished surface is controllable, and a polished silicon wafer pyramid base is small in size, uniform in surface and high in flatness.

Owner:西安蓝桥新能源科技有限公司

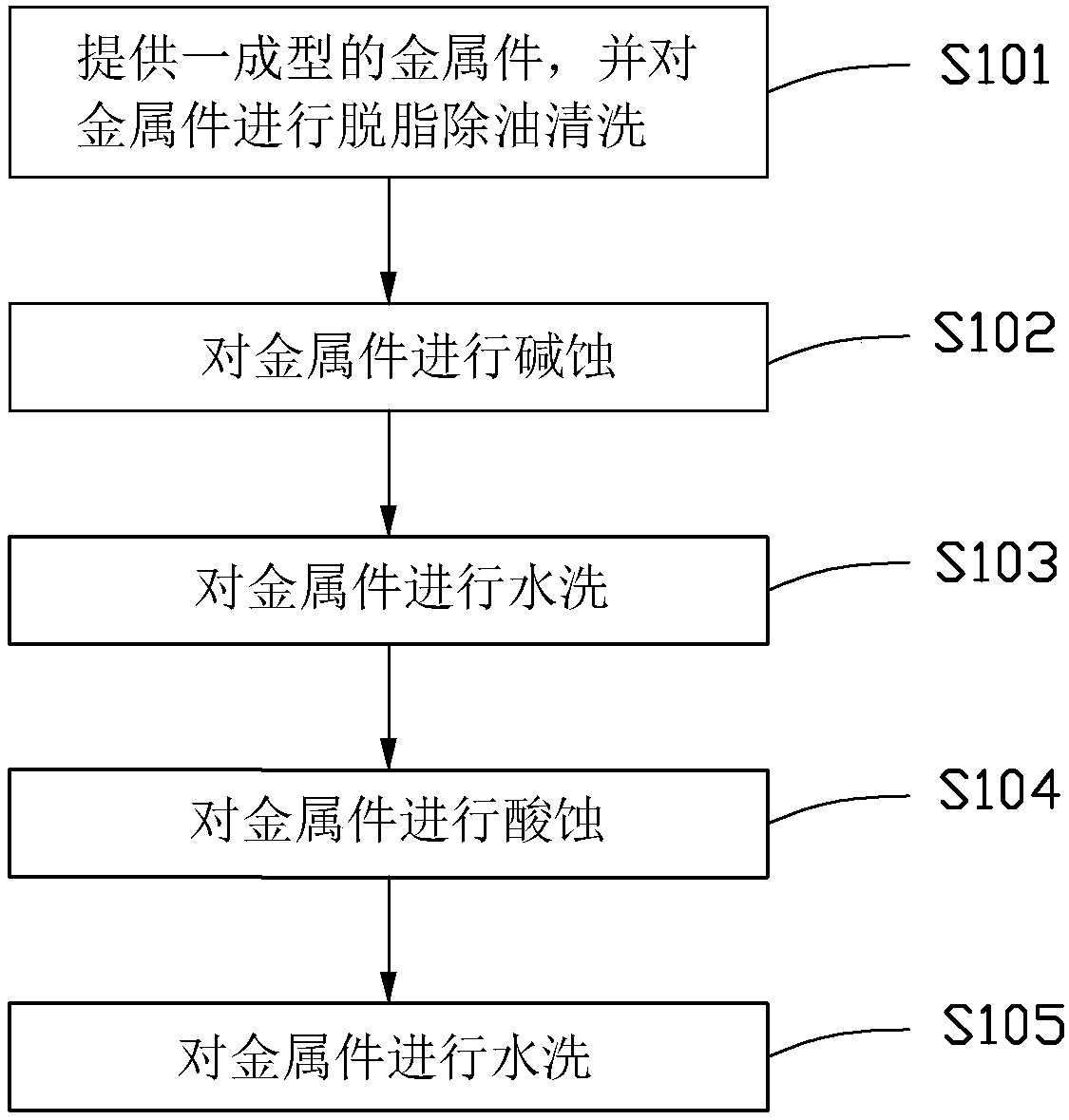

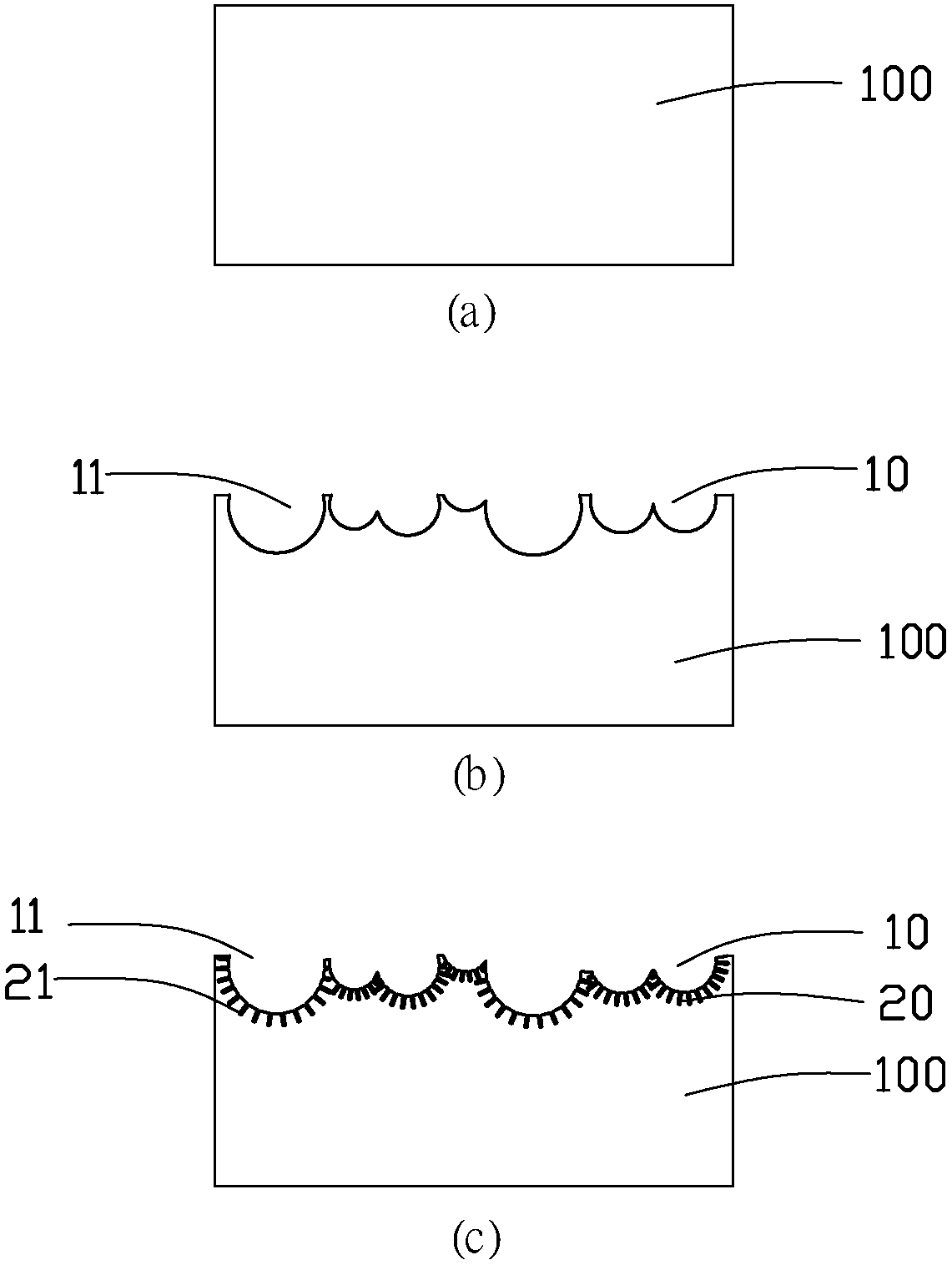

Aluminum alloy surface treatment method

ActiveCN110359047AHigh whitenessUniform, delicate and white atomized appearanceAcid etchingCompound (substance)

The invention provides an aluminum alloy surface treatment method. The aluminum alloy surface treatment method comprises the following steps that an aluminum alloy is subjected to alkali so that a first structure part can be formed on the surface of the aluminum alloy, wherein the first structure part comprises a plurality of first grooves which are uniformly distributed; water washing is carriedout on the aluminum alloy; and the aluminum alloy is subjected to acid etching to form a second structure part, wherein the second structure part comprises a plurality of second grooves uniformly distributed on the first structure part. According to the aluminum alloy surface treatment method, the treated aluminum alloy surface has a uniform and fine white atomized appearance; the chemical reagentused in the aluminum alloy surface treatment method is low in concentration, the corrosion amount of the aluminum alloy is smaller than 5%, and the size of the aluminum alloy is prevented from damage; and the use of fluorine-containing ion reagents is avoided, and the processing and production are safer.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

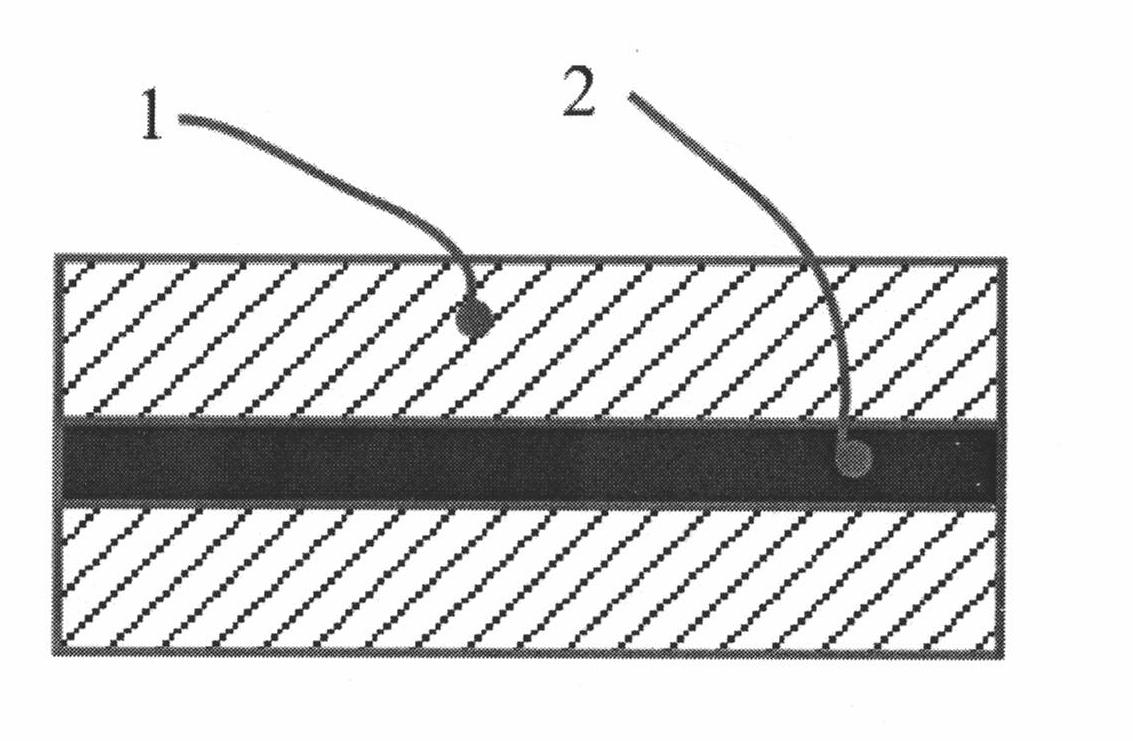

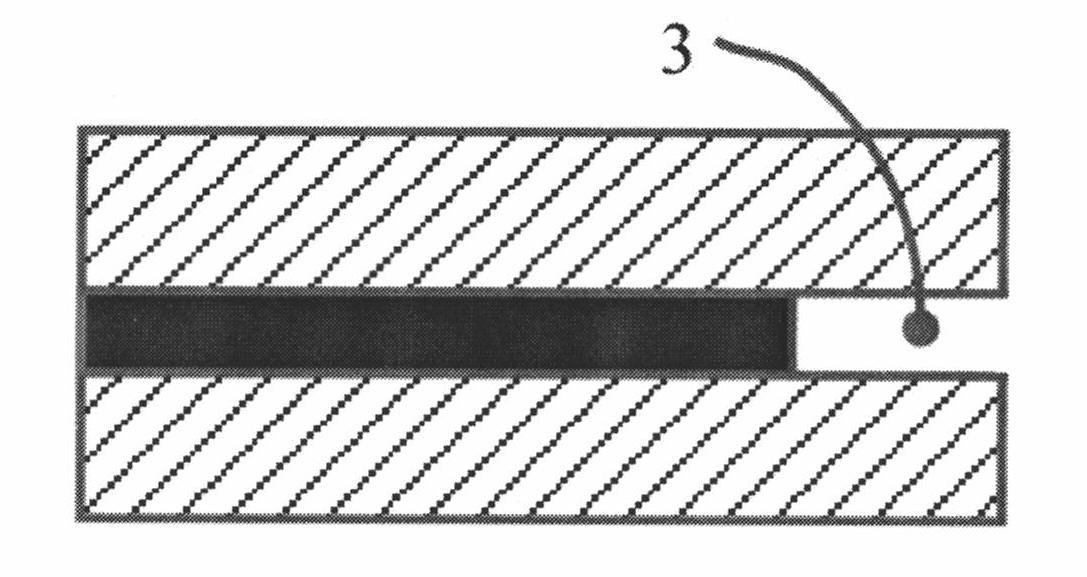

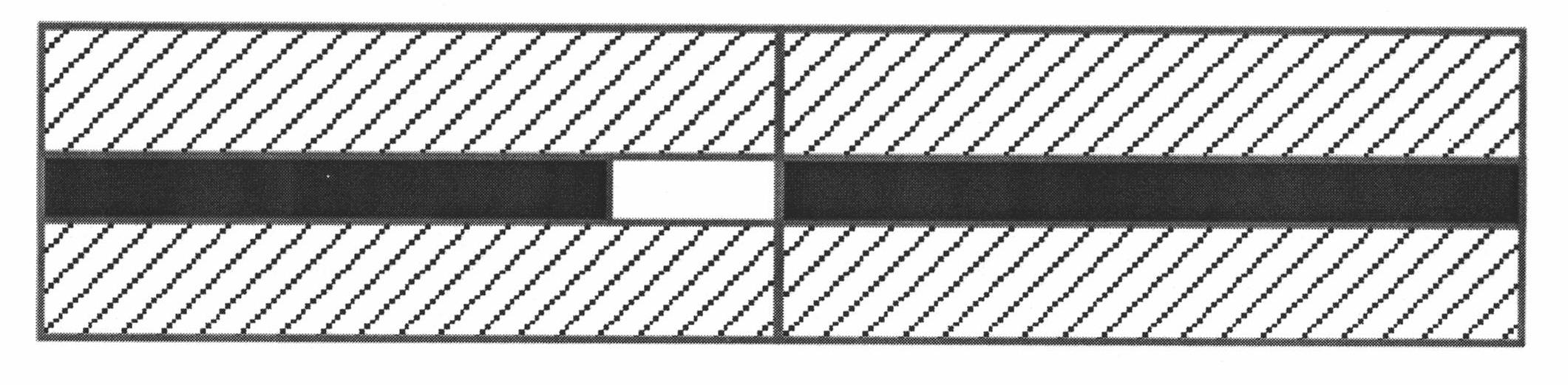

Preparation method for fabry-perot sensor based on corroded high doping optical fiber

InactiveCN101561295BImprove mechanical propertiesIncreased corrosion rate differenceConverting sensor output opticallyHydrofluoric acidMechanical property

The invention discloses a preparation method for a fabry-perot sensor based on a corroded high doping optical fiber. The preparation method comprises the following steps: soaking the end face of the high doping optical fiber into a corrosive liquor for corrosion so as to form micropores on the end face; and welding the micropores of two corroded optical fiber oppositely, or welding the microporesof one corroded optical fiber with the end face of a monomode optical fiber to form the optical fabry-perot sensor. A mixed liquor of hydrofluoric acid and strong inorganic acid is taken as the corrosive liquor; the used optical fiber is a fiber core high doping optical fiber; the high doping concentration further increases the corrosion rate difference between a cladding and the fiber core; the strong inorganic acid in the corrosive liquor reduces the concentration of the hydrofluoric acid, reduces the corrosion rate of the corrosive liquor on the cladding, reduces the corrosion of the cladding while simultaneously improving the corrosion depth of the fiber core, and consequently greatly improves the mechanical properties of the welded fabry-perot sensor.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

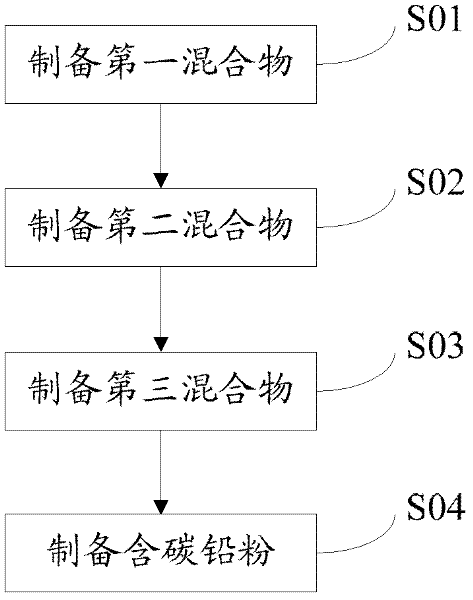

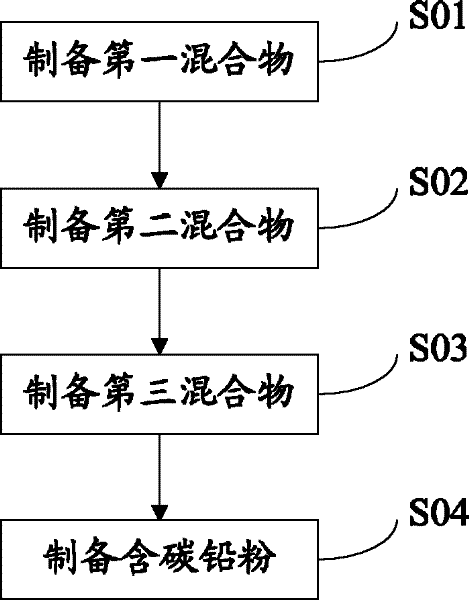

Carbonaceous lead powder, its preparation method, battery lead paste and its application

ActiveCN102522531AInhibit sheddingImprove bindingLead-acid accumulator electrodesCarbonizationBiological activation

The invention is suitable for the technical field of battery preparation and provides a carbonaceous lead powder, its preparation method, a battery lead paste and its application. The preparation method of the carbonaceous lead powder contains steps of: preparing a first mixture, preparing a second mixture, preparing a third mixture, preparing the carbonaceous lead powder and the like. According to the preparation method of the carbonaceous lead powder, an organic carbon monomer and a lead powder undergo mixing, carbonization and activation to make carbon particles clad the external surface of the lead powder, thus greatly raising the bonding force between the carbon particles and the lead powder. The battery lead paste is prepared by the application of the above carbonaceous lead powder. By good bonding force between the carbon particles and the lead powder, problems such as carbon particle shedding, material dropping of a pole plate and the like are effectively prevented. Conductive performance and cyclic performance of the battery lead paste are significantly realized.

Owner:SHENZHEN CENT POWER TECH

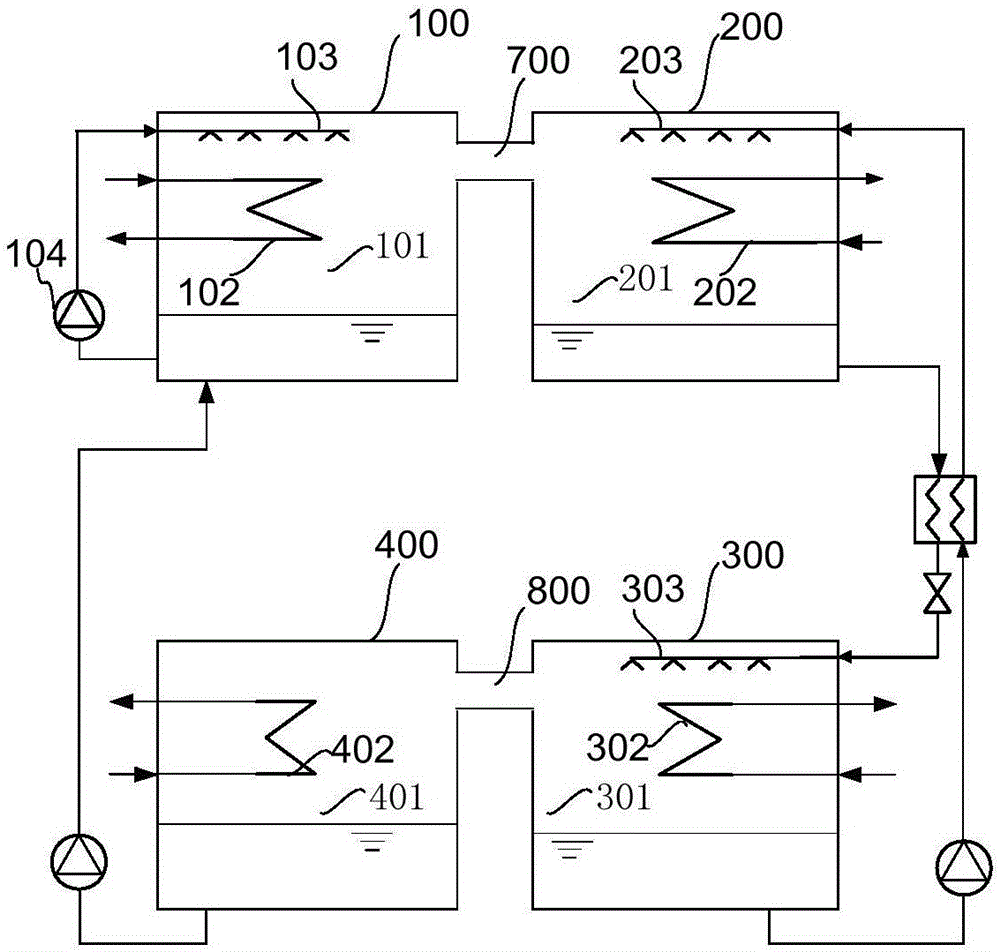

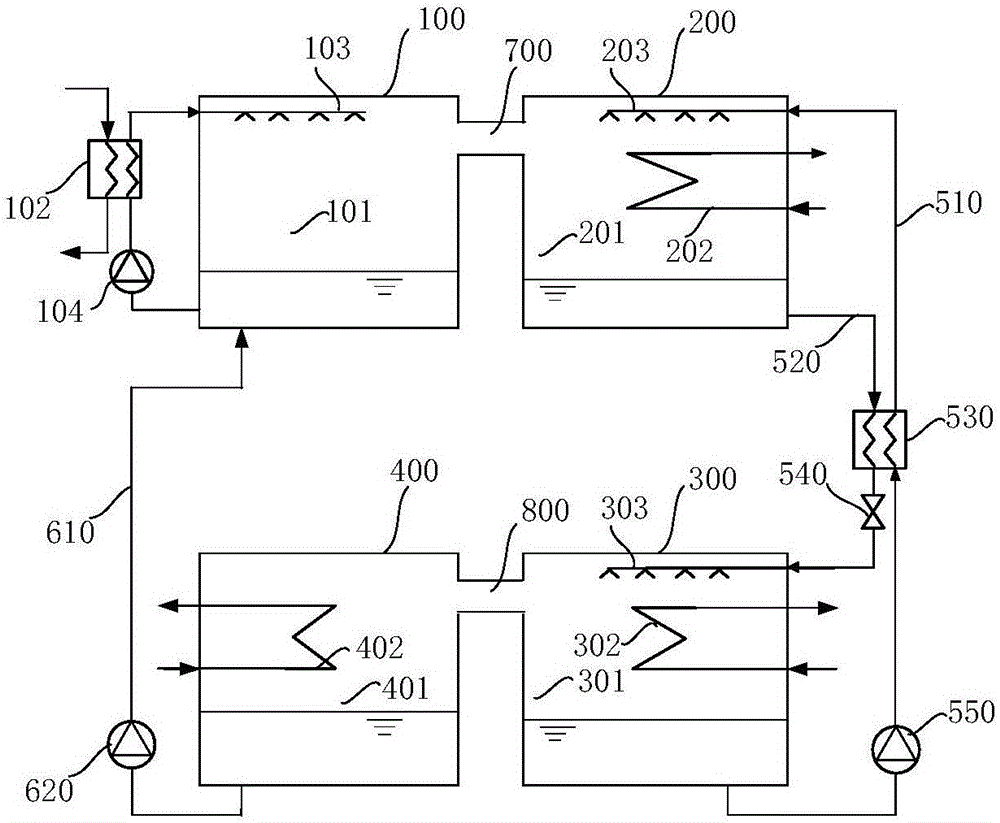

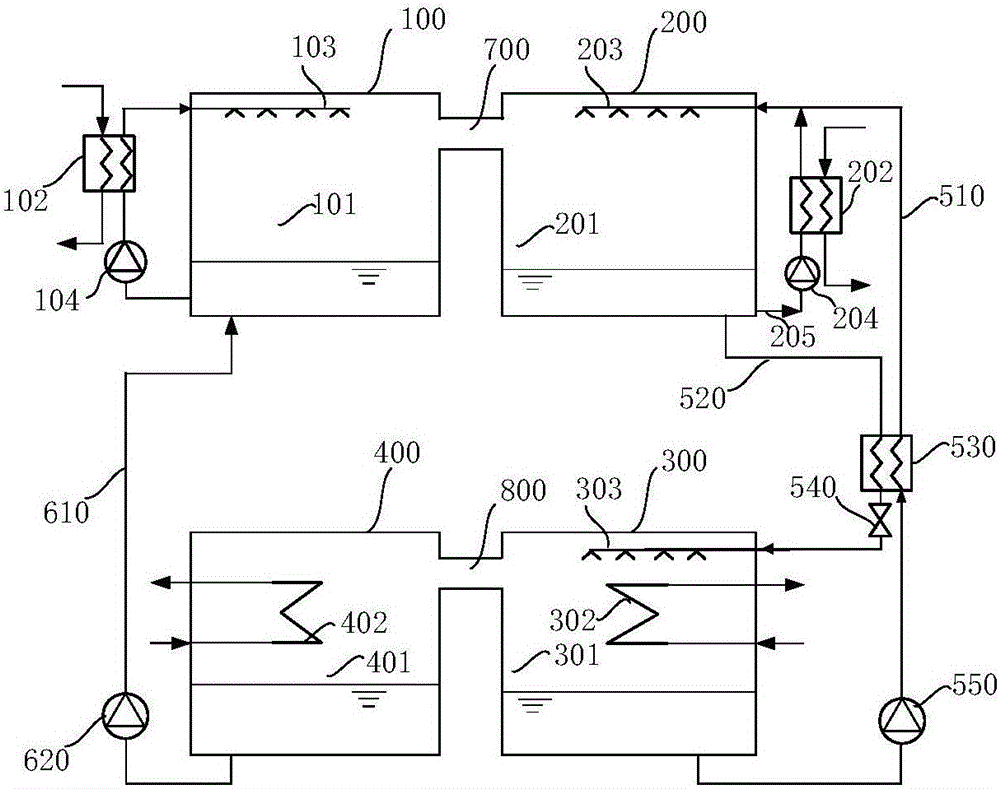

Absorption heat pump and evaporator and method thereof

InactiveCN105987544AReduce volumeImprove performanceClimate change adaptationEnergy efficient heating/coolingEvaporationAbsorption heat pump

The invention discloses an absorption heat pump and an evaporator and a method thereof. The evaporator of the absorption heat pump comprises a flashing cavity, an evaporation heat exchanger, an evaporator condensation working medium spraying pipeline, an evaporator condensation working medium spraying pump and an evaporator condensation working medium spraying device, wherein the evaporation heat exchanger is arranged outside the flashing cavity, the evaporator condensation working medium spraying pipeline is connected to the cold fluid side of the evaporation heat exchanger, the evaporator condensation working medium spraying pump arranged on the evaporator condensation working medium spraying pipeline conveys working media inside the flashing cavity to the evaporator condensation working medium spraying device through the evaporator condensation working medium spraying pipeline after the working media undergo heat exchange by the evaporation heat exchanger, the evaporator condensation working medium spraying device sprays the working media into the flashing cavity, and parts of the working media become steam inside the flashing cavity in a flashing mode. According to the absorption heat pump and the evaporator and the method thereof, the heat transfer and mass transfer process of evaporation of the condensation working media of the evaporator can be reinforced, and the size of the evaporator can be reduced.

Owner:BEIJING LIANLI ENERGY TECH CO LTD +1

Silicon nitride substrate, silicon nitride circuit board utilizing the same, and use thereof

InactiveUS8029903B2Excellent electrical propertiesHigh partial discharge inception voltageSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsPower control

Provided are a silicon nitride substrate and a silicon nitride circuit board with excellent electrical characteristics, and power control parts utilizing them.A silicon nitride substrate comprises a silicon nitride sintered body obtainable by sintering a silicon nitride powder in the presence of a sintering aid comprising MgO, Y2O3 and SiO2 in a proportion of (1) MgO / (MgO+SiO2)=34-59 mol %, and (2) Y2O3 / (Y2O3+SiO2)=50-66 mol %, and a silicon nitride circuit board utilizes it.

Owner:DENKA CO LTD

Anode production line hanger detergent as well as preparation method and cleaning method thereof

PendingCN109234074AEasy to cleanImprove conductivityOrganic/inorganic per-compounds compounding agentsOrganic non-surface-active detergent compositionsHydrofluoric acidCleansing Agents

The invention discloses an anode production line hanger detergent. The anode production line hanger detergent is prepared from a softening agent, hydrogen peroxide, a disintegration inhibitor, hydrofluoric acid and water. The detergent is fewer in high-toxicity and high-corrosion raw material, and is nontoxic, environmentally friendly and long in service life. Correspondingly, the invention also discloses a method for cleaning an anode production line hanger by using the detergent. The cleaning efficiency is high, the cleaning speed is high, and the operation is simple.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

A kind of electrolyte solution for preparing nanometer metal powder

The invention discloses an electrolyte for preparing nano-metal powder. The electrolyte comprises the following components of 0.5-7 g / L of a fluorocarbon anionic surfactant or nekal, 3-10 g / L of a nonionic surfactant, 3-15 g / L of an auxiliary agent, 15-50 g / L of metal salt and the balance water; the temperature of the electrolyte is controlled to be 25-50 DEG C, and the nano-metal powder is prepared under the condition of electrodeposition. The electrolyte is good in uniformity, high in stability, small in corrosion amount to polar plates and less in pollution; in the electrodeposition processusing the prepared electrolyte, the nano-metal powder cannot be adhered to an cathode, the self-desorption performance is good, polar plates are easy to clean, and automatic and continuous productioncan be realized; and the prepared nano-metal powder is good in dispersity and easy to collect.

Owner:CENT SOUTH UNIV

Method for preparing copper powder through environment-friendly surface active agent

A method for preparing copper powder through an environment-friendly surface active agent comprises the following steps that firstly, the environment-friendly surface active agent, addition agents, CuSO4.5H2O and water are selected according to a certain proportion to be prepared into an electrolyte; secondly, electrolytic deposition is carried out on the electrolyte, and copper powder mixed liquid is obtained; thirdly, copper powder is extracted, filtration or centrifugal treatment is carried out on the copper powder mixed liquid, and after suction filtration and drying, copper powder is obtained; and fourthly, the copper powder is put into a packaging bag, and after inert gases are fed into the packaging bag, sealing storage is carried out. According to the copper powder prepared throughthe method, the particle size range is 30-100 nm or 200-800 nm, the purity is 99% or above, the particle size distribution is uniform, and feature consistency is good; in the preparation process, thecopper powder cannot adhere to a negative plate, the self-desorption performance is good, the negative plate is easy to wash, and automatic and continuous production can be achieved; the corrosion amount to an anode plate is small, environment friendliness is achieved, no pollution is caused, and the energy consumption is low; and the prepared copper powder is good in dispersibility and easy to collect.

Owner:CENT SOUTH UNIV

Method for preparing ultrafine copper powder by adopting microemulsion

The invention discloses a method for preparing ultrafine copper powder by adopting a microemulsion. The method comprises the following steps that (1), anionic surfactant, nonionic surfactant, CuSO4.5H2O and water in a certain proportion are selected to prepare an electrolyte; (2), electrodepositing is carried out on the electrolyte, and a superfine copper powder mixed solution is obtained; (3), the superfine copper powder is extracted, wherein filtration or centrifugal treatment is carried out on the ultrafine copper powder mixed solution, after suction filtration and drying are carried out, the ultrafine copper powder is obtained; and (4), the ultrafine copper powder is put into a packaging bag, and the packaging bag is filled with inert gas, and then is sealed and stored. According to the method, the ultrafine copper powder prepared by the method has the characteristics that the particle size range is 200-600 nm, the purity is 99% or above, the particle size distribution is uniform,and the morphology consistency is good; in the preparation process, the copper powder cannot be adhered to a cathode plate, the self-desorption performance is good, polar plates are easy to clean, andautomatic and continuous production can be realized; the amount of corrosion to an anode plate is small, the environment pollution is little, and the energy consumption is low; and the prepared ultrafine copper powder is good in dispersibility and easy to collect.

Owner:CENT SOUTH UNIV

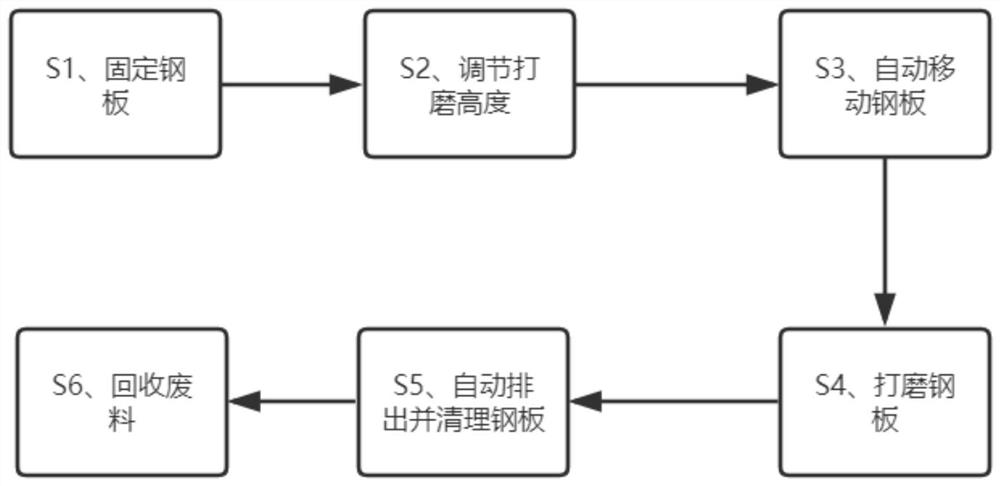

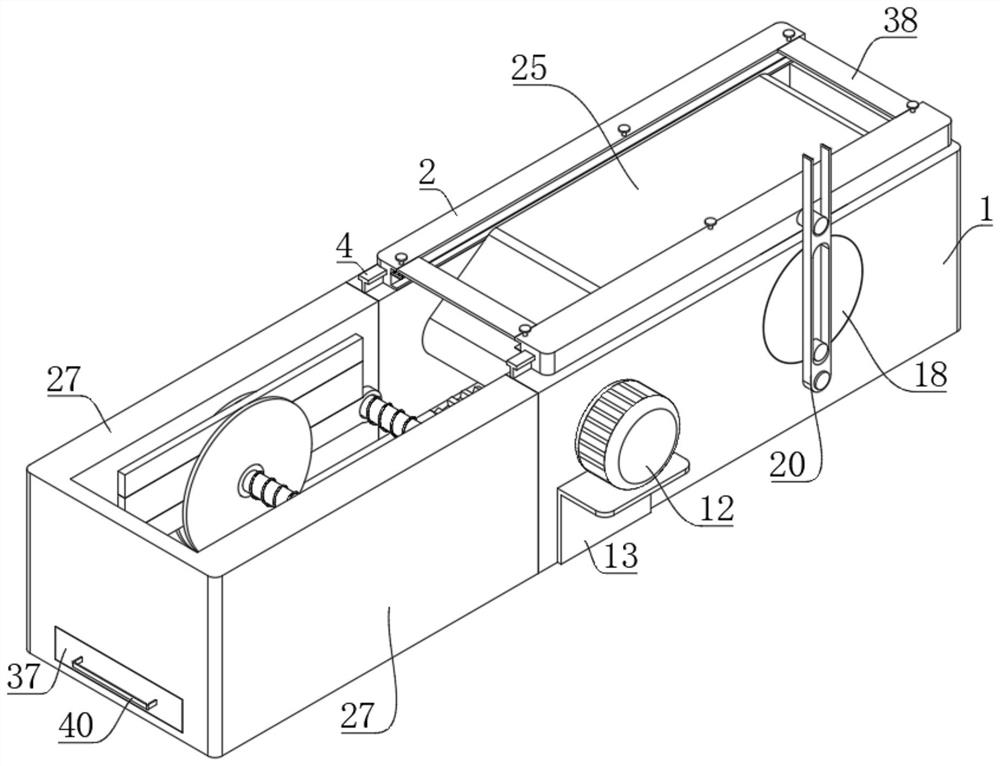

A kind of surface treatment preparation and surface pretreatment process for galvanized steel sheet

ActiveCN112195475BQuick clearReduce corrosionGrinding drivesBelt grinding machinesPhosphoric Acid EstersHydrogen Sulfate

The invention discloses a surface treatment preparation for galvanized steel sheet and a surface pretreatment process, belonging to the technical field of steel sheet surface treatment. First, the surface of the untreated steel sheet is ground and processed, and then further treated with a surface treatment agent. The surface treatment preparation for galvanized steel sheet includes the following raw materials: phosphate ester compound, potassium hydrogen persulfate compound salt, hydrogen sulfate salt, quaternary ammonium aniline compound, sodium carbonate, ammonium acetate, hydroxyethylidene phosphoric acid, imidazoline and its derivatives compounds, acid pickling fog suppressants, alkynyl alcohol derivatives, alcohol ether carboxylates, stabilizers, chelating agents, water. The surface treatment preparation for galvanized steel plate provided by the technical solution of the present invention can effectively remove oil stains, oxide films, rust spots and other adhesive impurities on the surface of the steel plate. Volatile substances, wastewater treatment is simple, safe and environmentally friendly. After the steel sheet is treated as above, it helps to improve the quality and efficiency of the galvanized steel sheet.

Owner:GUANGDONG XINTONGDA STEEL PIPE MILL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com