Small tower footing silicon wafer alkali polishing auxiliary agent and application thereof

An auxiliary agent and silicon wafer alkali technology, which is applied in the field of small tower base silicon wafer alkali polishing auxiliary agent, can solve the problems of low efficiency, poor appearance and high cost, achieve high uniformity and flatness, inhibit corrosion effect, and reduce the amount of corrosion. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

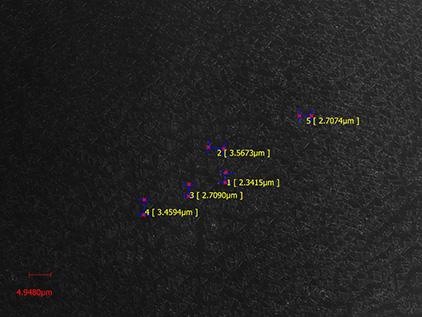

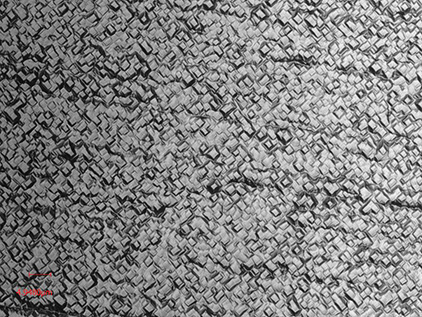

Image

Examples

Embodiment 1

[0032] A small tower base silicon base polishing auxiliary agent, including auxiliary agent A and auxiliary agent B; including auxiliary agent A and auxiliary agent B; said auxiliary agent A includes the following components calculated by mass percentage: silane coupling agent 0.25 %, ethanol 3%, gelatin 0.15%, n-butanol 2%, sodium dodecylbenzene sulfonate 0.15%, perfluoroalkyl polyoxyethylene ether 0.25%, and the balance is deionized water; the auxiliary agent B Including the following components calculated by mass percentage: silane coupling agent 0.75%, alkyltrimethylammonium bromide 0.3%, perfluoroalkyl polyoxyethylene ether 0.5%, ethanol 3%, ammonium persulfate 2%, the rest The volume is deionized water.

[0033] A kind of application of described small tower base silicon wafer alkali polishing auxiliary agent in silicon wafer two-step polishing, concrete method comprises the following steps:

[0034] S1. Soak the silicon wafer in hydrofluoric acid with a concentration o...

Embodiment 2

[0039] A small tower base silicon wafer alkali polishing auxiliary agent, including auxiliary agent A and auxiliary agent B; the auxiliary agent A includes the following components calculated by mass percentage: silane coupling agent 0.1-0.5%, ethanol 2-5% , gelatin 0.05-0.2%, n-butanol 1-3%, sodium dodecylbenzene sulfonate 0.05-0.2%, perfluoroalkyl polyoxyethylene ether 0.01-0.05%, and the balance is deionized water; Adjuvant B includes the following components calculated by mass percentage: silane coupling agent 0.5-1%, alkyltrimethylammonium bromide 0.1-0.4%, perfluoroalkyl polyoxyethylene ether 0.01-0.1%, ethanol 2 -5%, ammonium persulfate 1-3%, and the balance is deionized water.

[0040] A kind of application of described small tower base silicon wafer alkali polishing auxiliary agent in silicon wafer two-step polishing, concrete method comprises the following steps:

[0041]S1. Soak the silicon wafer in hydrofluoric acid with a concentration of 49% for 15s, use a volum...

Embodiment 3

[0045] A small tower base silicon wafer alkali polishing auxiliary agent, including auxiliary agent A and auxiliary agent B; the auxiliary agent A includes the following components calculated by mass percentage: silane coupling agent 0.1-0.5%, ethanol 2-5% , gelatin 0.05-0.2%, n-butanol 1-3%, sodium dodecylbenzene sulfonate 0.05-0.2%, perfluoroalkyl polyoxyethylene ether 0.01-0.05%, and the balance is deionized water; Adjuvant B includes the following components calculated by mass percentage: silane coupling agent 0.5-1%, alkyltrimethylammonium bromide 0.1-0.4%, perfluoroalkyl polyoxyethylene ether 0.01-0.1%, ethanol 2 -5%, ammonium persulfate 1-3%, and the balance is deionized water.

[0046] A kind of application of described small tower base silicon wafer alkali polishing auxiliary agent in silicon wafer two-step polishing, concrete method comprises the following steps:

[0047] S1. Soak the silicon wafer in hydrofluoric acid with a concentration of 49% for 30s, use a volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com