Resist removal liquid

A technology of stripping liquid and resist, which is applied in the processing of photosensitive materials, etc., can solve the problems of weak chelation and weak resist stripping force, and achieve the effect of excellent bath life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

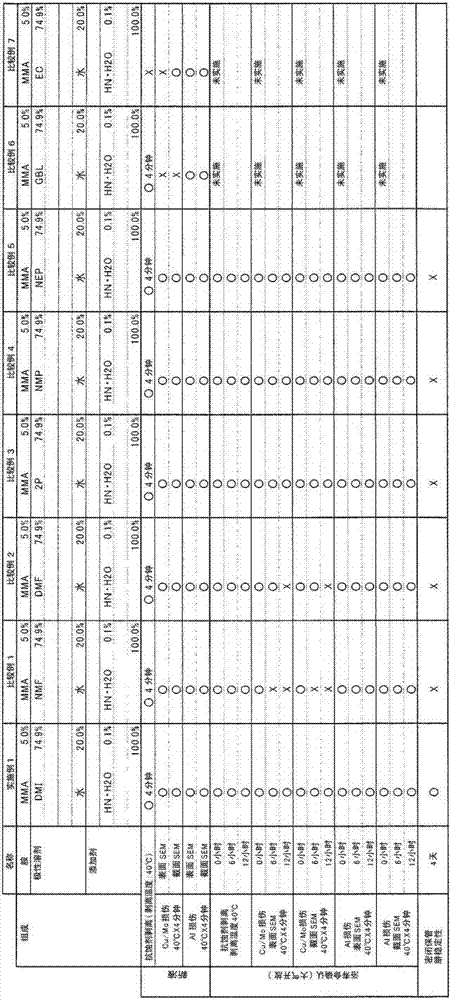

Embodiment 1

[0071] N-methylethanolamine is used as secondary amine.

[0072] N-methylethanolamine (MMA) 5.0% by mass

[0073] The polar solvent is a mixture of water and 1,3-dimethyl-2-imidazolidinone.

[0074] 1,3-Dimethyl-2-imidazolinone (DMI) 74.9% by mass

[0075] Water 20.0% by mass

[0076] Hydrazine is used as reducing agent.

[0077] Hydrazine monohydrate (HN·H 2 O) 0.1% by mass

[0078] The above components were mixed and stirred to prepare a sample resist stripping solution of Example 1.

[0079] In addition, 0.1 mass % of hydrazine monohydrate corresponds to 0.064 mass % of hydrazine. The remaining 0.036% by mass of hydrazine monohydrate was water. Therefore, the composition ratio of the above-mentioned water can be said to be 20.036% by mass even including the amount charged in the form of hydrazine monohydrate. In all of the following Examples and Comparative Examples, the same meaning applies when hydrazine monohydrate is used.

Embodiment 2

[0081] N-ethylethanolamine is used as secondary amine.

[0082] N-ethylethanolamine (EEA) 5.0% by mass

[0083] The polar solvent is a mixture of water and 1,3-dimethyl-2-imidazolidinone.

[0084] 1,3-Dimethyl-2-imidazolinone (DMI) 74.9% by mass

[0085] Water 20.0% by mass

[0086] Hydrazine is used as reducing agent.

[0087] Hydrazine monohydrate (HN·H 2 O) 0.1% by mass

[0088] The above components were mixed and stirred to prepare a sample resist stripping solution of Example 2.

[0089] Example 2 is a composition in which N-methylethanolamine (MMA), which is the secondary amine of Example 1, is changed to N-ethylethanolamine (EEA). In addition, 0.1 mass % of hydrazine monohydrate corresponds to 0.064 mass % of hydrazine. The remaining 0.036% by mass of hydrazine monohydrate was water. Therefore, the composition ratio of the above-mentioned water can be said to be 20.036% by mass even including the amount charged in the form of hydrazine monohydrate.

Embodiment 3

[0091] N-methylethanolamine is used as secondary amine.

[0092] N-methylethanolamine (MMA) 5.0% by mass

[0093] The polar solvent is a mixture of water and 1,3-dimethyl-2-imidazolidinone.

[0094] 1,3-Dimethyl-2-imidazolinone (DMI) 70.9% by mass

[0095] Water 24.0% by mass

[0096] Hydrazine is used as reducing agent.

[0097]Hydrazine monohydrate (HN·H 2 O) 0.1% by mass

[0098] The above components were mixed and stirred to prepare a sample resist stripping solution of Example 3.

[0099] Example 3 is a composition in which the ratio of DMI and water in the polar solvent of Example 1 was changed. In addition, 0.1 mass % of hydrazine monohydrate corresponds to 0.064 mass % of hydrazine. The remaining 0.036% by mass of hydrazine monohydrate was water. Therefore, the composition ratio of the above-mentioned water can be said to be 24.036% by mass even including the amount charged in the form of hydrazine monohydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com