Patents

Literature

286 results about "Adhesion belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

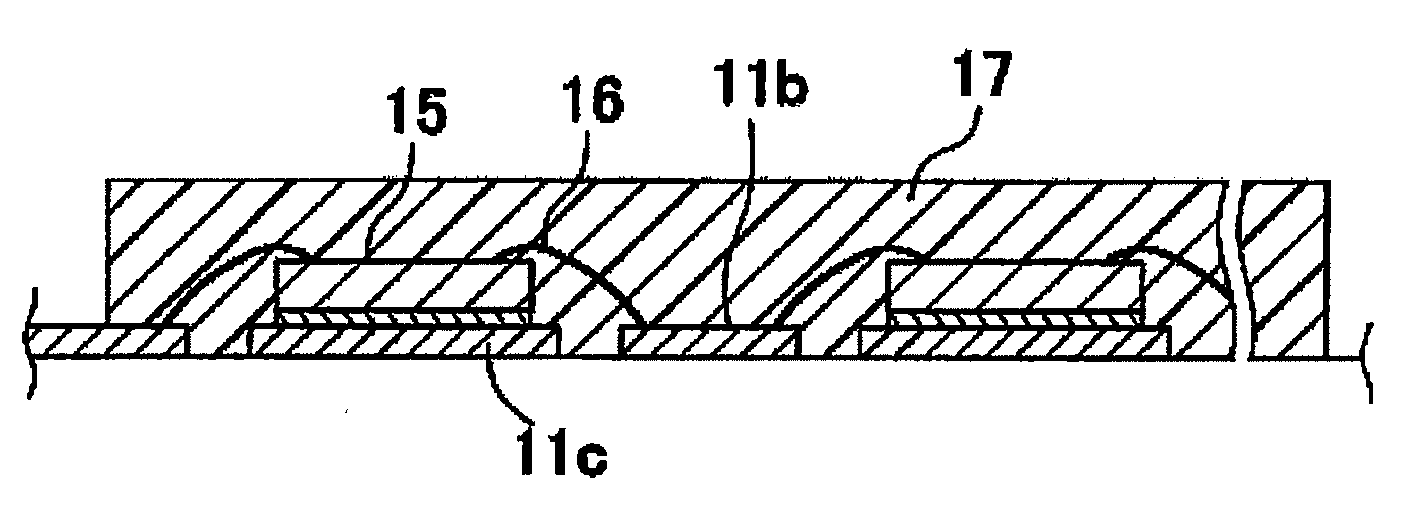

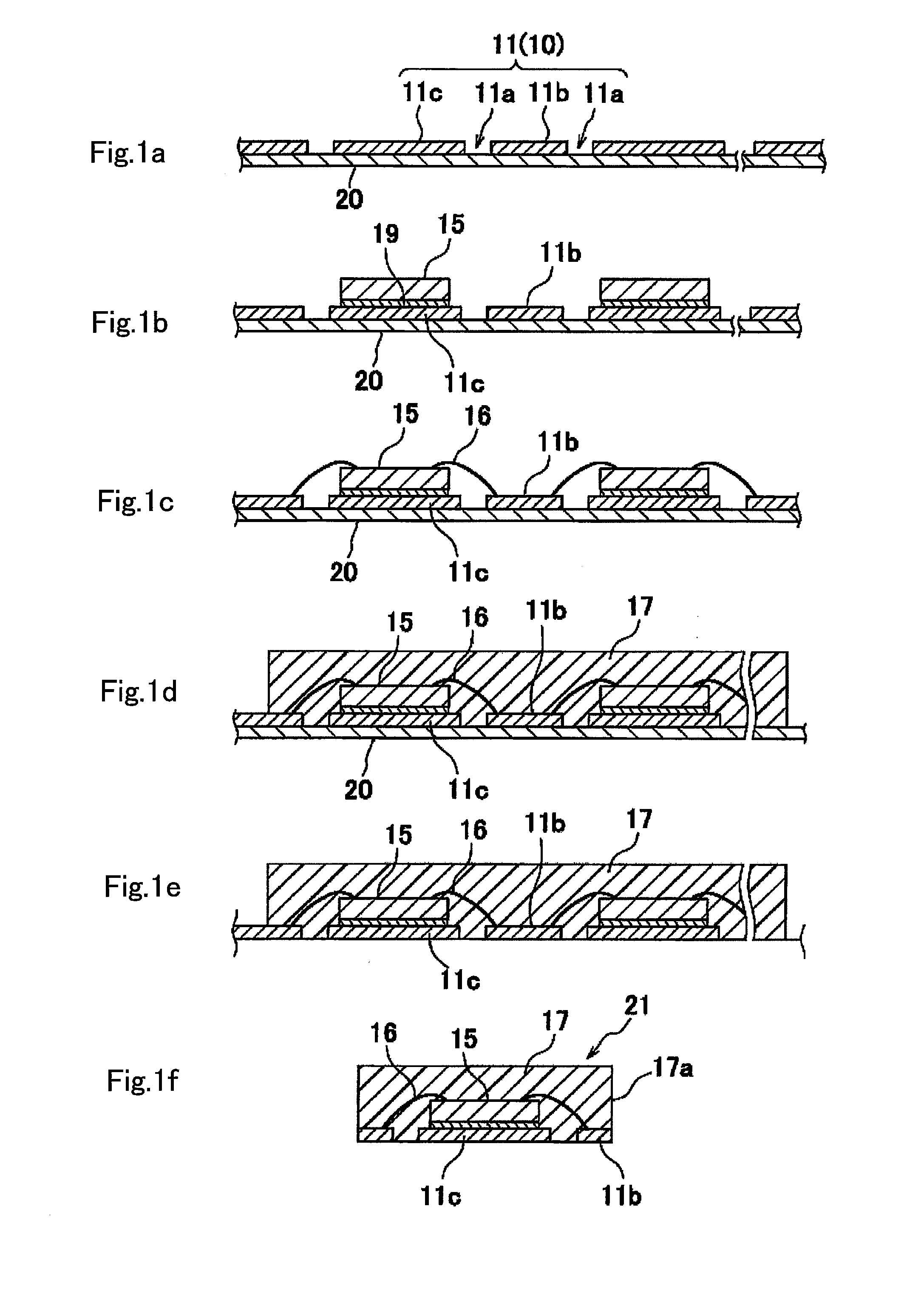

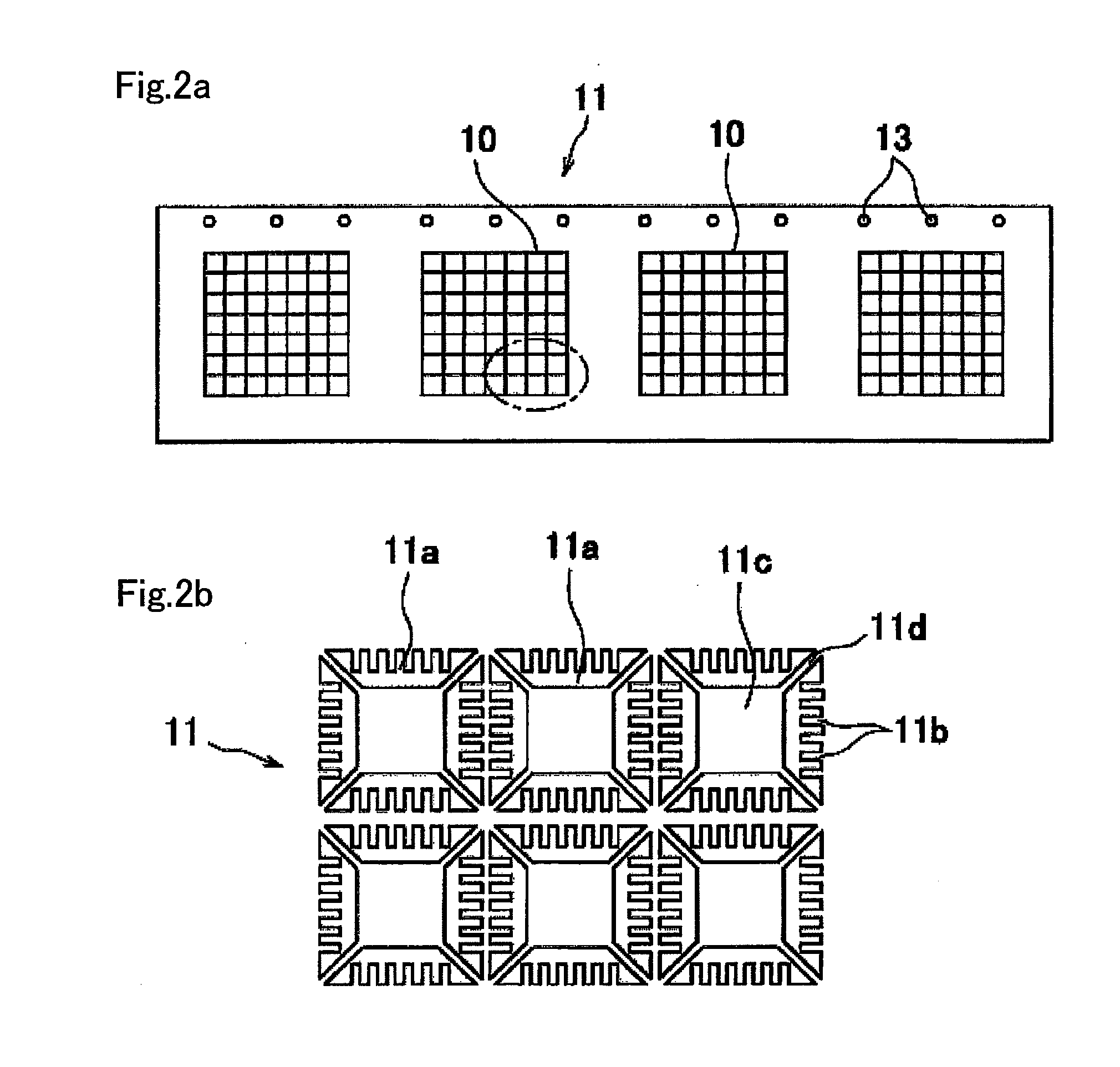

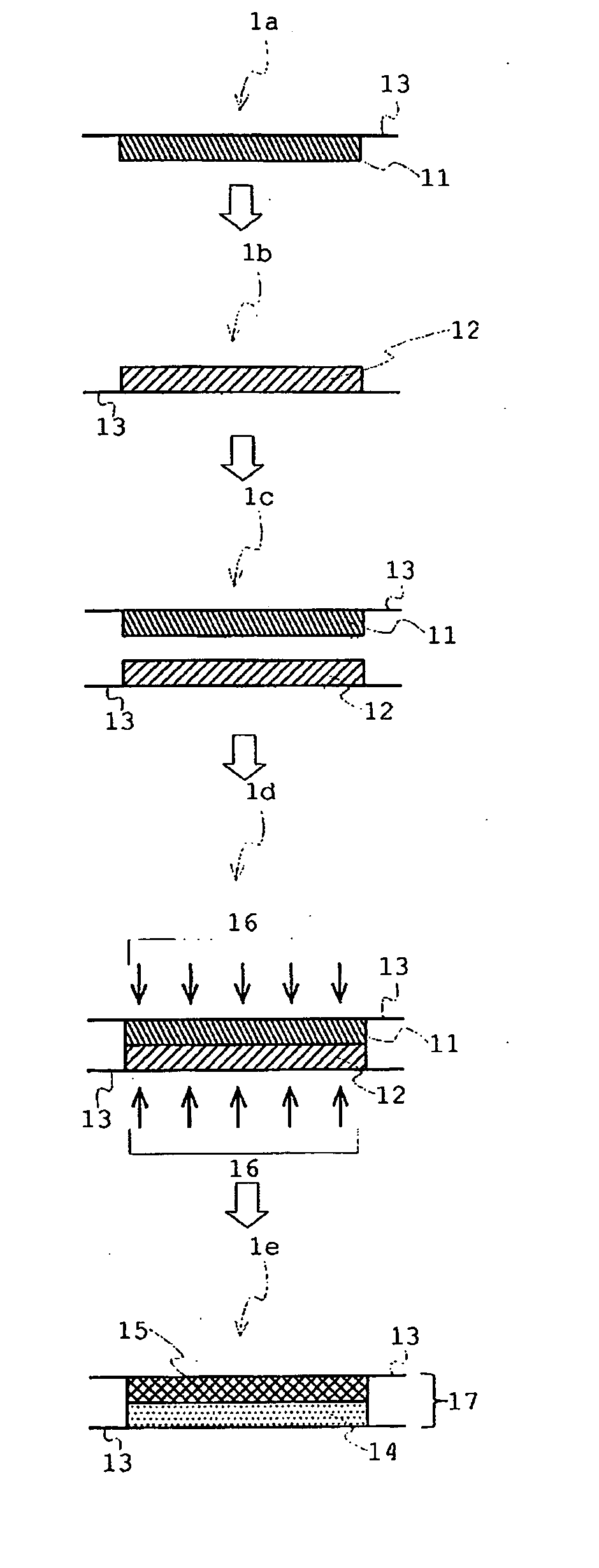

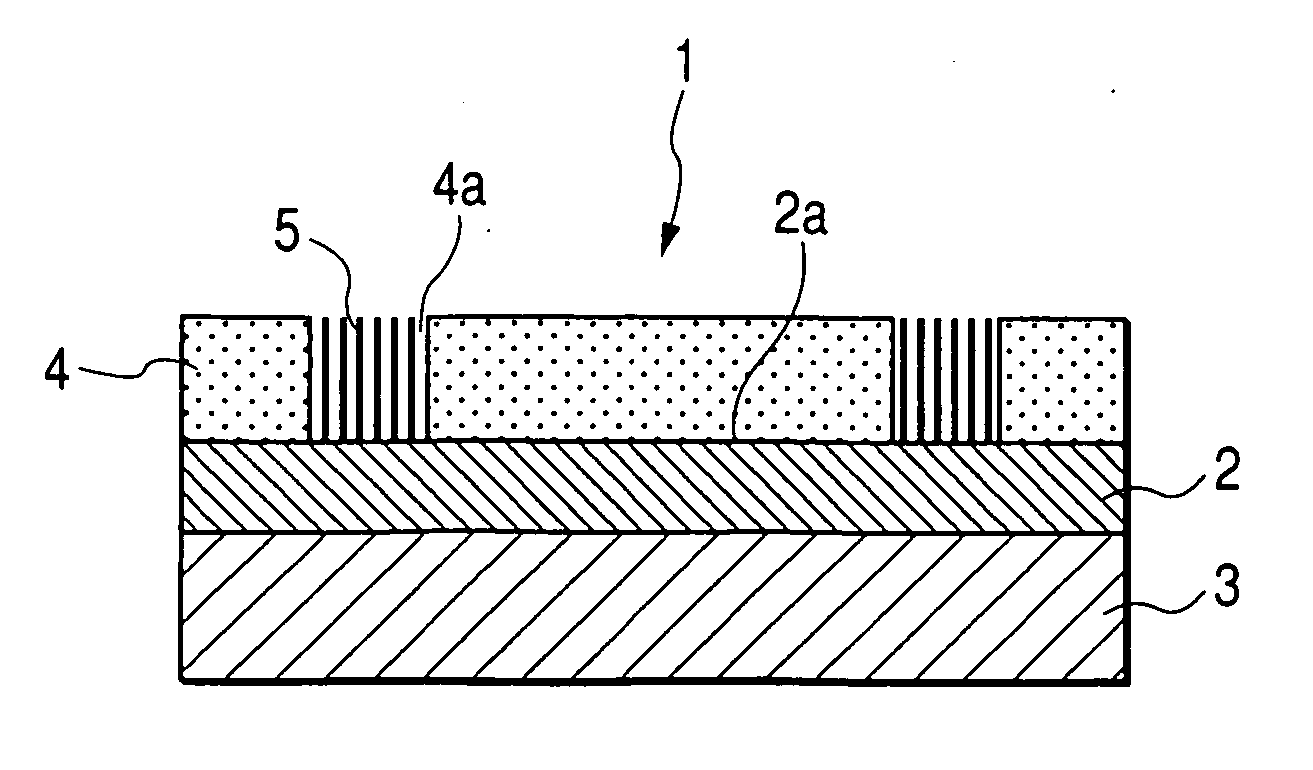

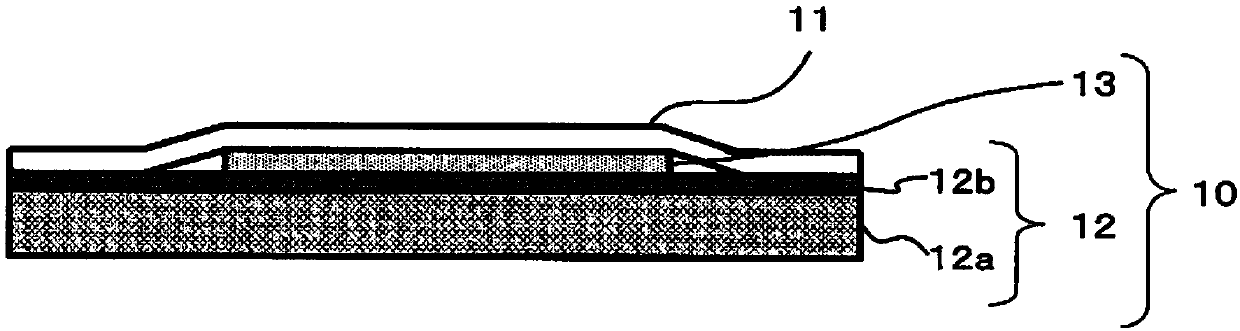

Adhesive tape for resin-encapsulating and method of manufacture of resin-encapsulated semiconductor device

InactiveUS20110111563A1Prevent resin leakageEffective preventionFilm/foil adhesivesSemiconductor/solid-state device detailsEngineeringSemiconductor

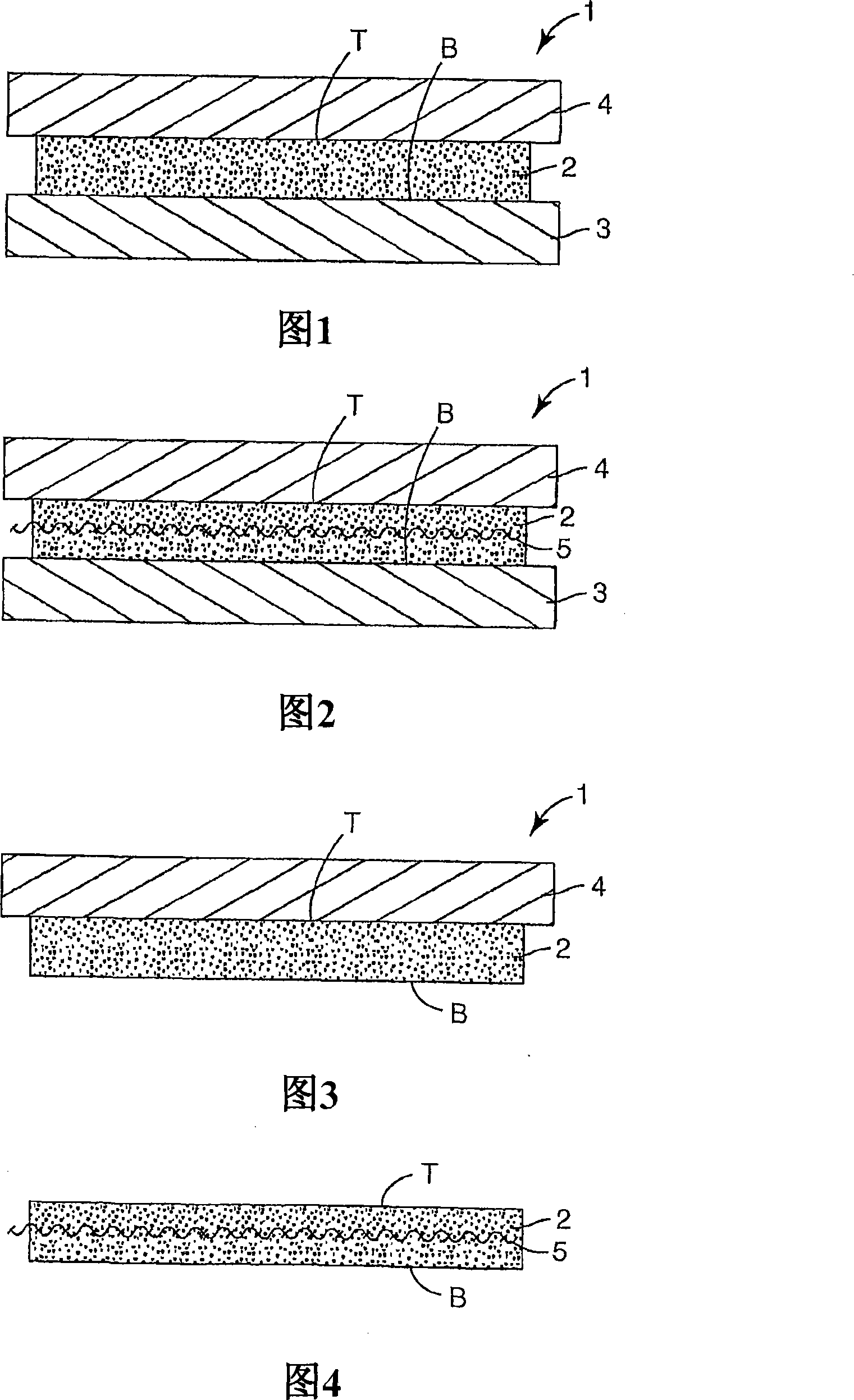

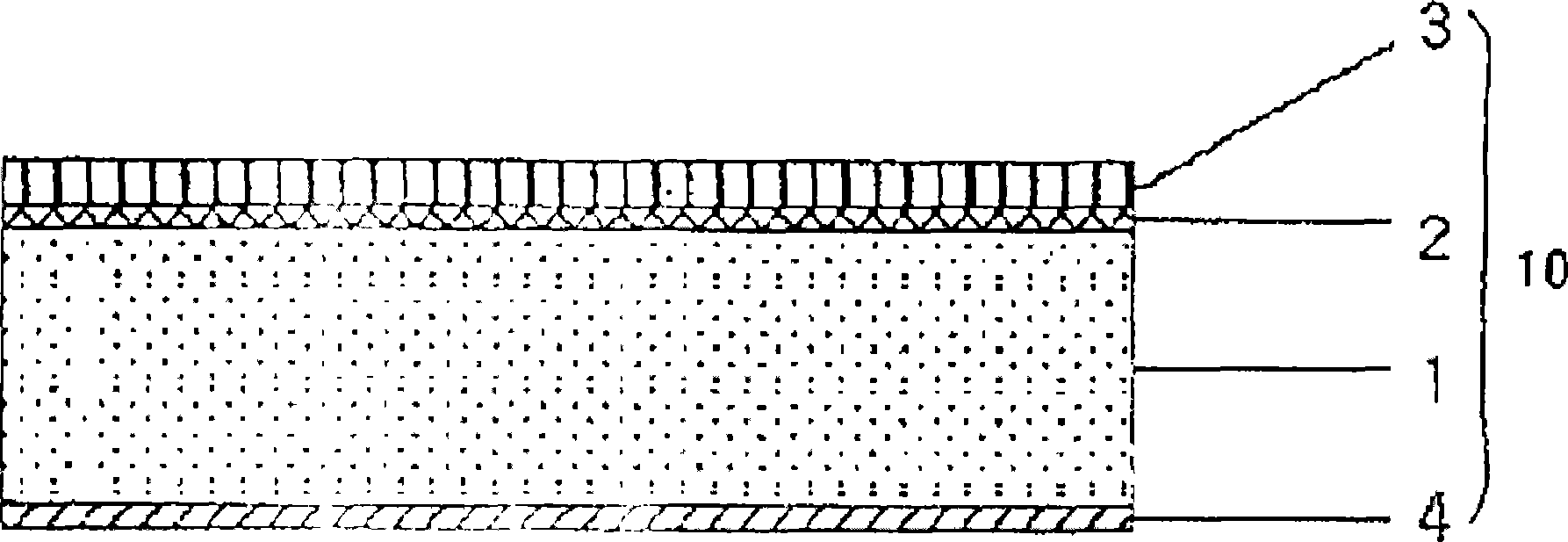

An adhesive tape for resin-encapsulating used in a method of manufacture of a resin-encapsulated semiconductor device has a base material layer and an adhesive agent layer laminated on the base material layer, a total film thickness of the base material layer and the adhesive agent layer of 25 to 40 μm. According to the adhesive tape for resin encapsulating of the present invention, resin leakage can be efficiently prevented during the resin encapsulating operation.

Owner:NITTO DENKO CORP

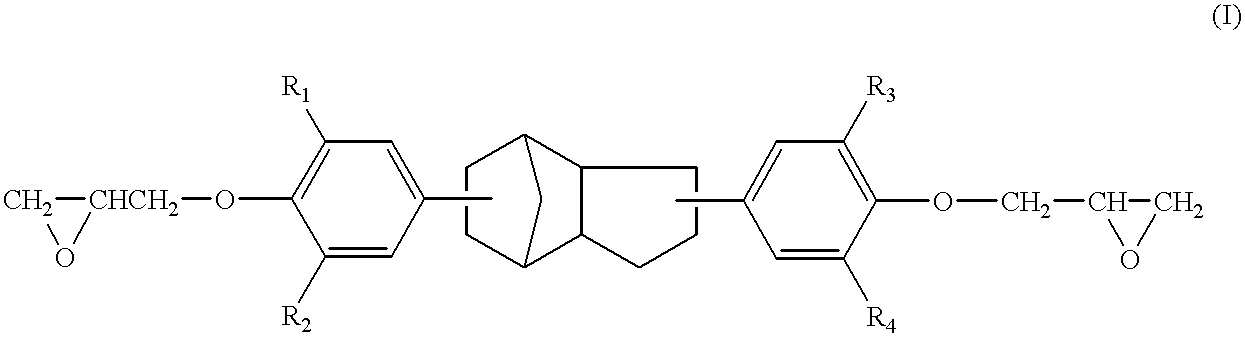

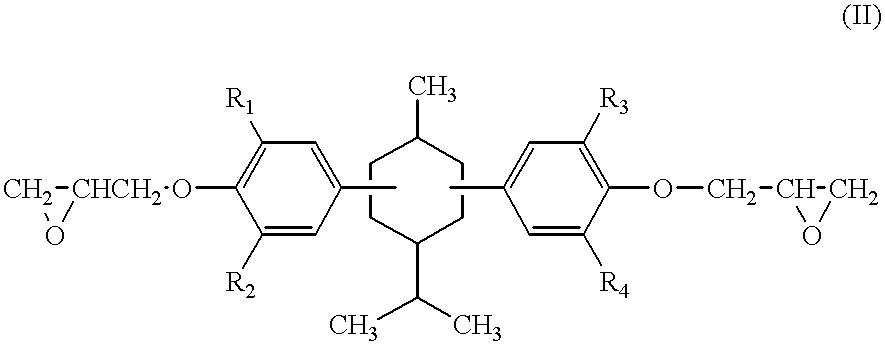

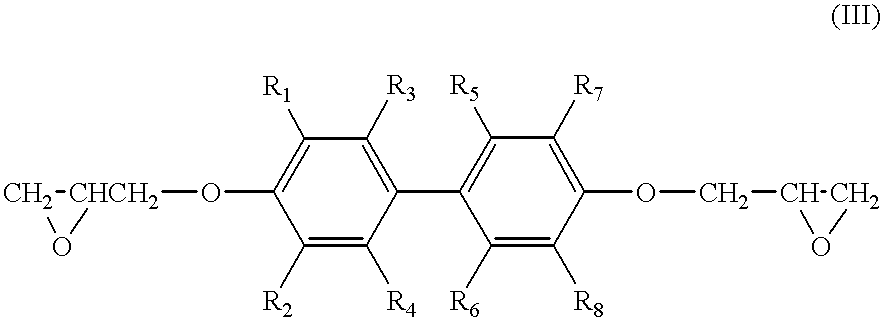

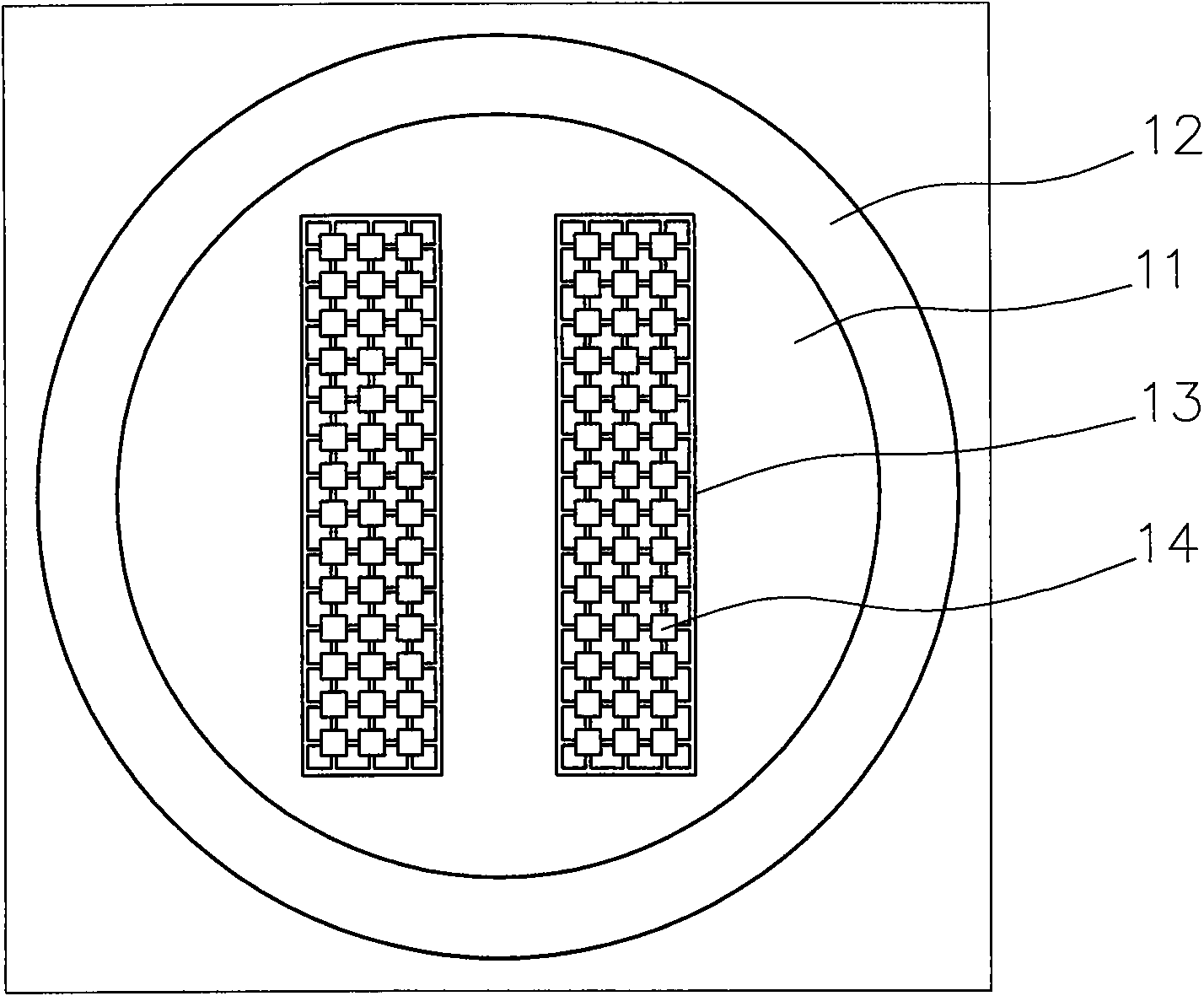

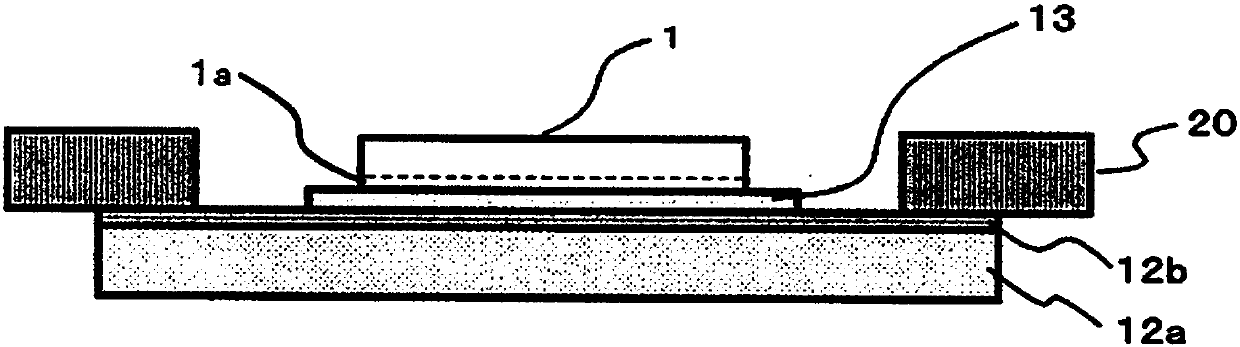

Adhesive sheet for semiconductor connecting substrate, adhesive-backed tape for tab, adhesive-backed tape for wire-bonding connection, semiconductor connecting substrate, and semiconductor device

InactiveUS6303219B1Semiconductor/solid-state device detailsSolid-state devicesInsulation resistanceChemistry

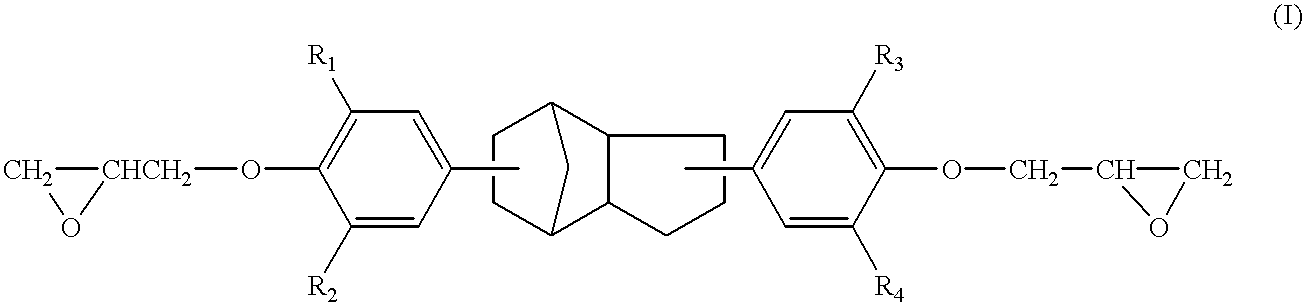

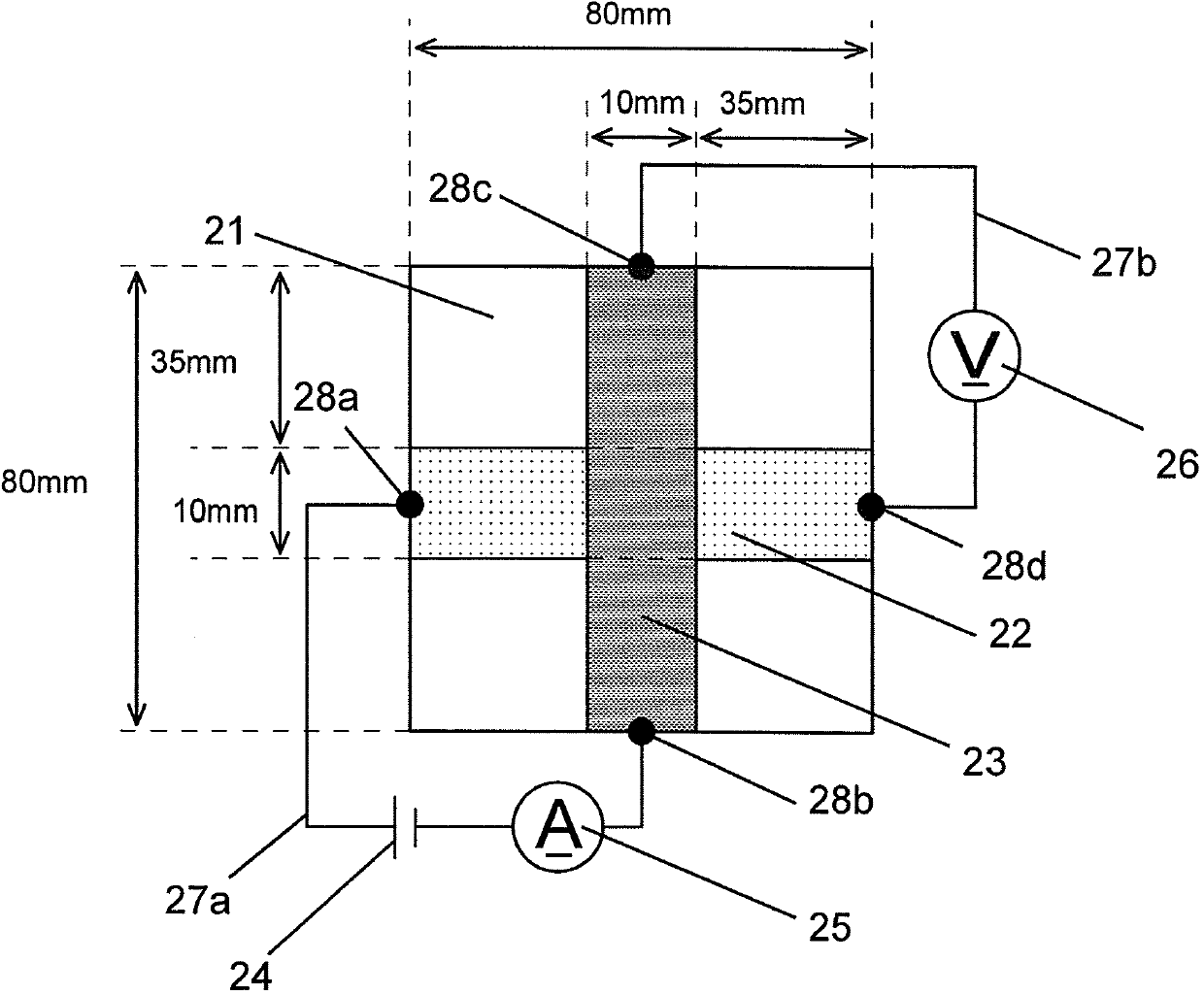

An adhesive sheet for a semiconductor connecting substrate consisting of a laminate having an adhesive layer on a substrate, wherein said adhesive layer contains a thermoplastic resin (A) and an epoxy resin (B) and said epoxy resin (B) contains at least one epoxy resin (B) selected from (I) dicyclopentadiene skeleton-containing epoxy resins, (II) terpene skeleton-containing epoxy resins, (III) biphenyl skeleton-containing epoxy resins and (IV) naphthalene skeleton-containing epoxy resins as an essential component; an adhesive-backed tape for TAB consisting of a laminate having an adhesive layer and a protective film layer on a flexible organic insulating film, wherein said adhesive layer has a softening temperature of 60 to 110° C. after having been cured and 50 hours or more in the insulation resistance dropping time after having been allowed to stand in an environment of 130° C. and 85% RH with DC 100 V applied; and a tape with adhesive for wire bonding connection consisting of a laminate having an adhesive layer and a protective film layer on a flexible organic insulating film, wherein said adhesive layer has a softening temperature of 120 to 170° C. after having been cured, a storage elastic modulus E' of 20 to 100 MPa at 150° C. and an insulation resistance dropping time of 50 hours or more after having been allowed to stand in an environment of 130° C. and 85% RH with DC 100 V applied. The adhesive sheet for a semiconductor connecting substrate, the adhesive-backed tape for TAB and the adhesive-backed tape for wire bonding connection of the present invention are excellent in adhesive strength, insulatability, dimensional accuracy, etc., and can improve the reliability of a semiconductor integrated circuit connecting substrate and a semiconductor device respectively for high density packaging.

Owner:TORAY IND INC

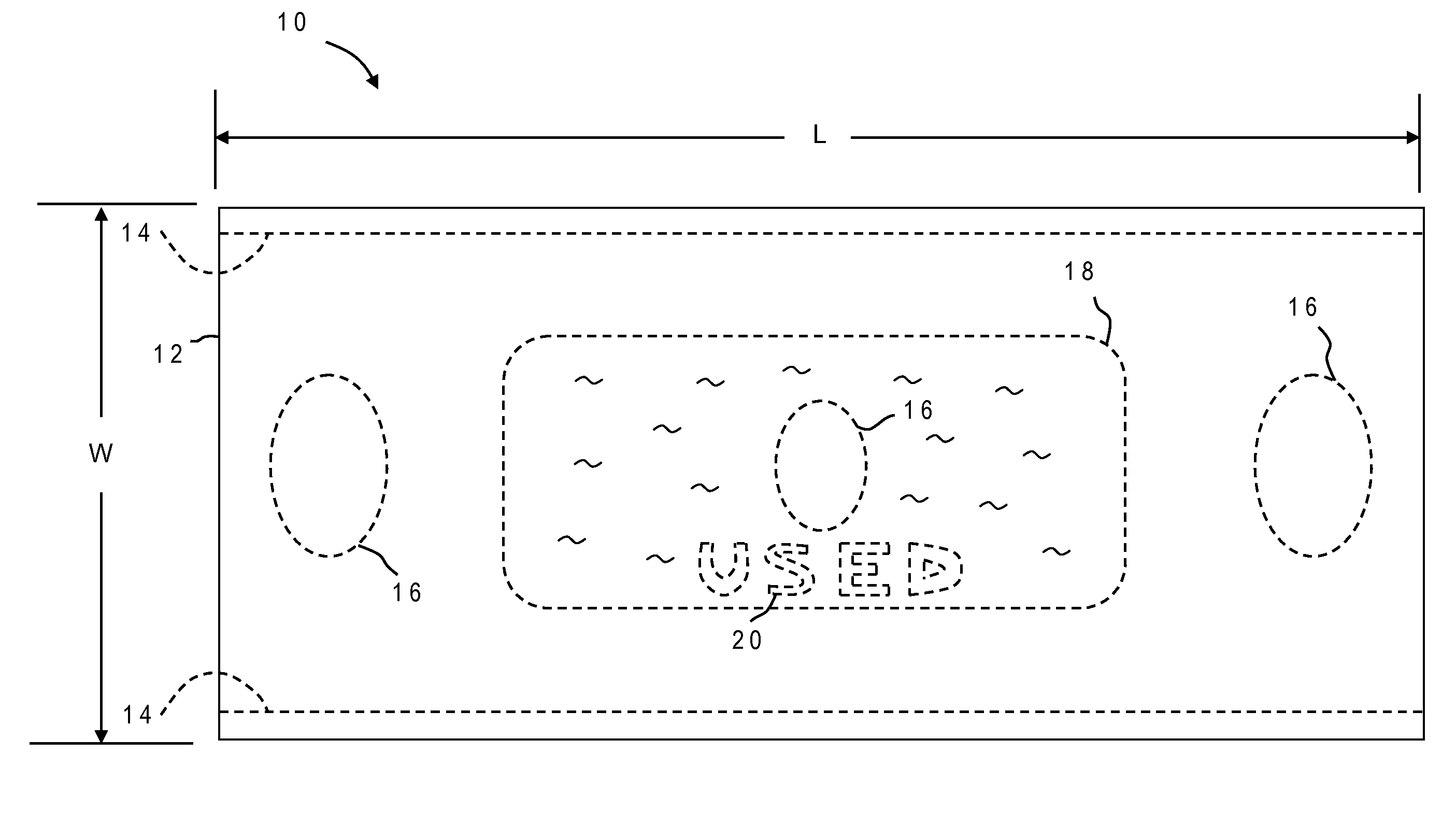

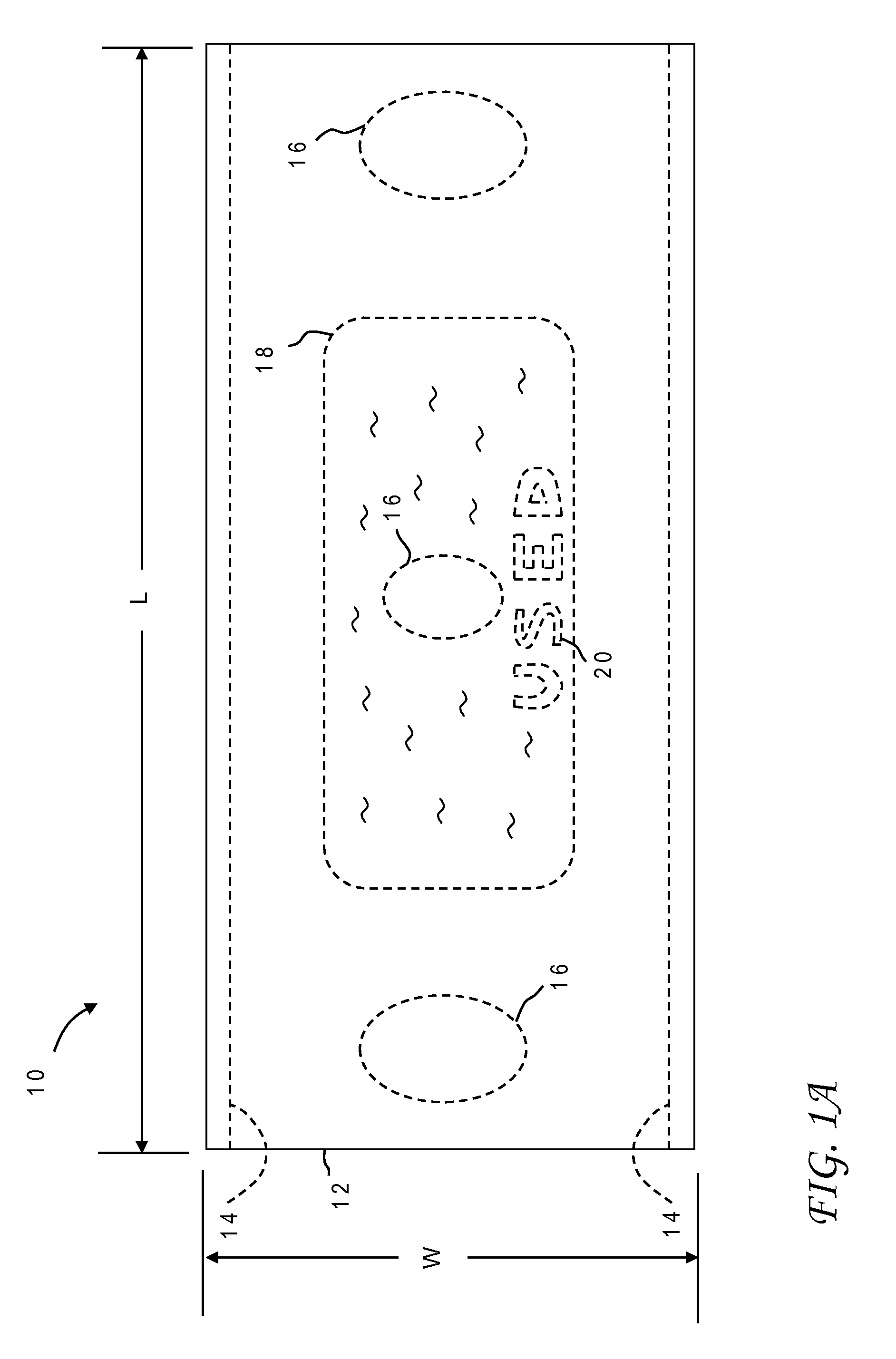

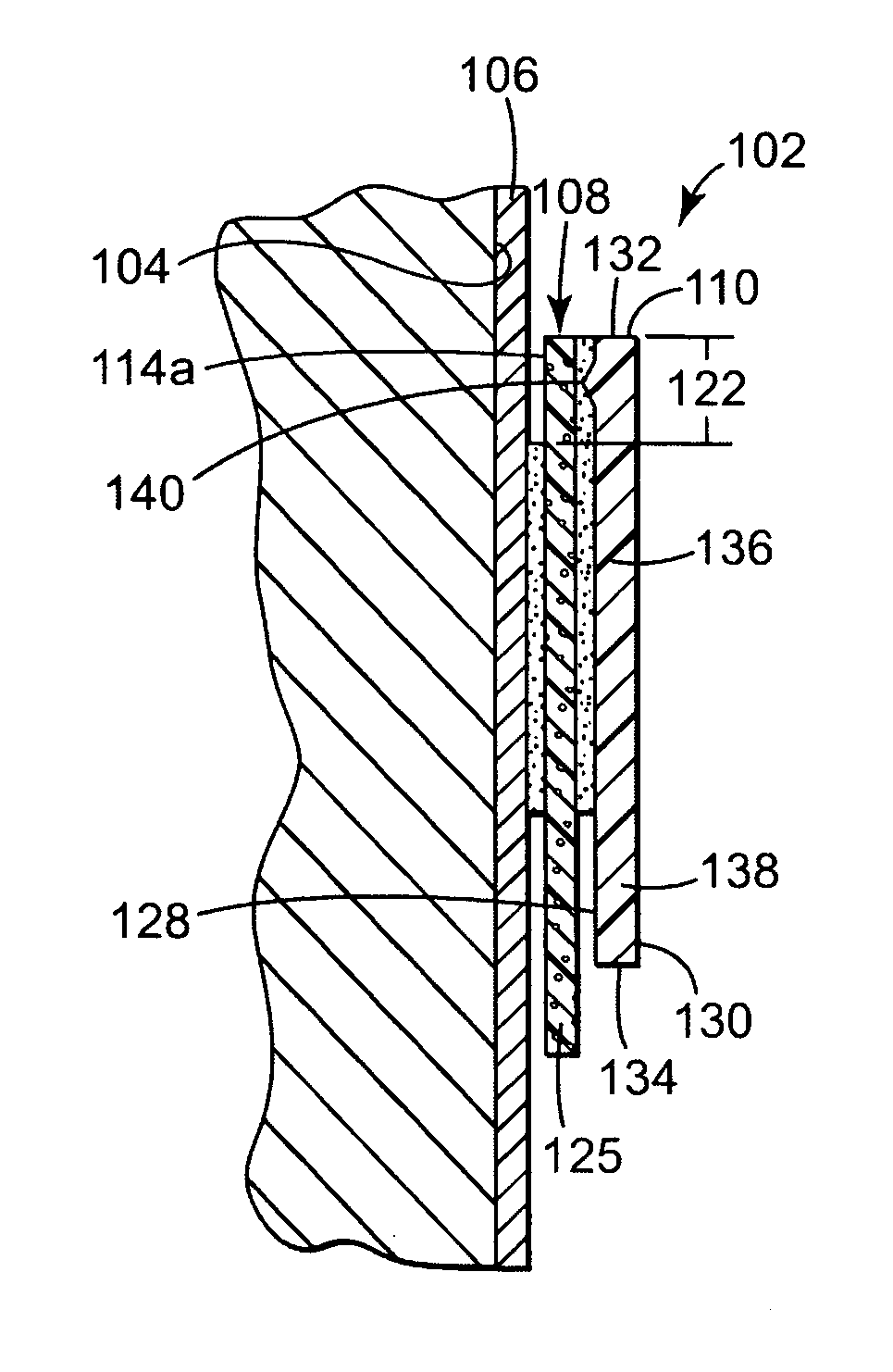

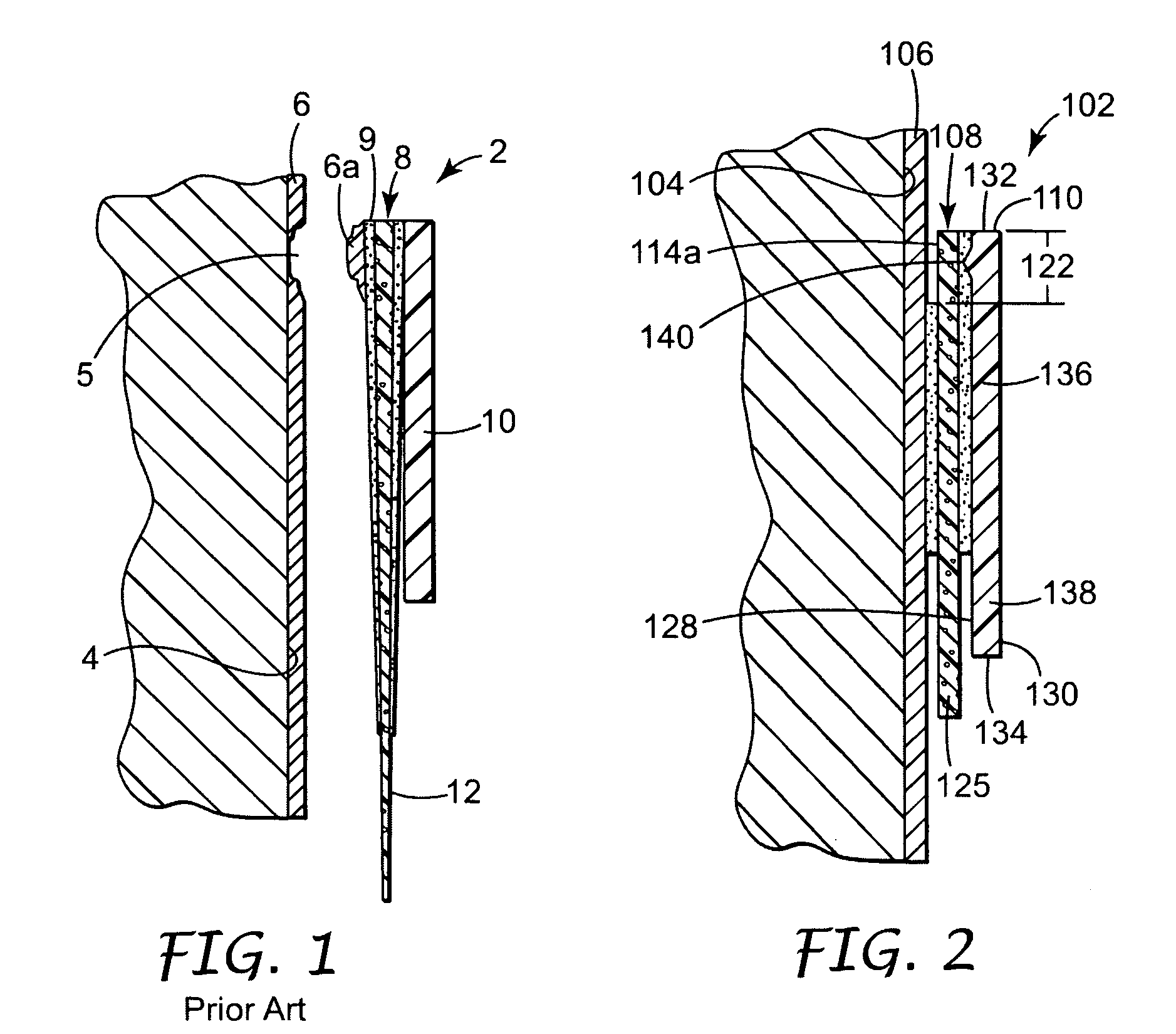

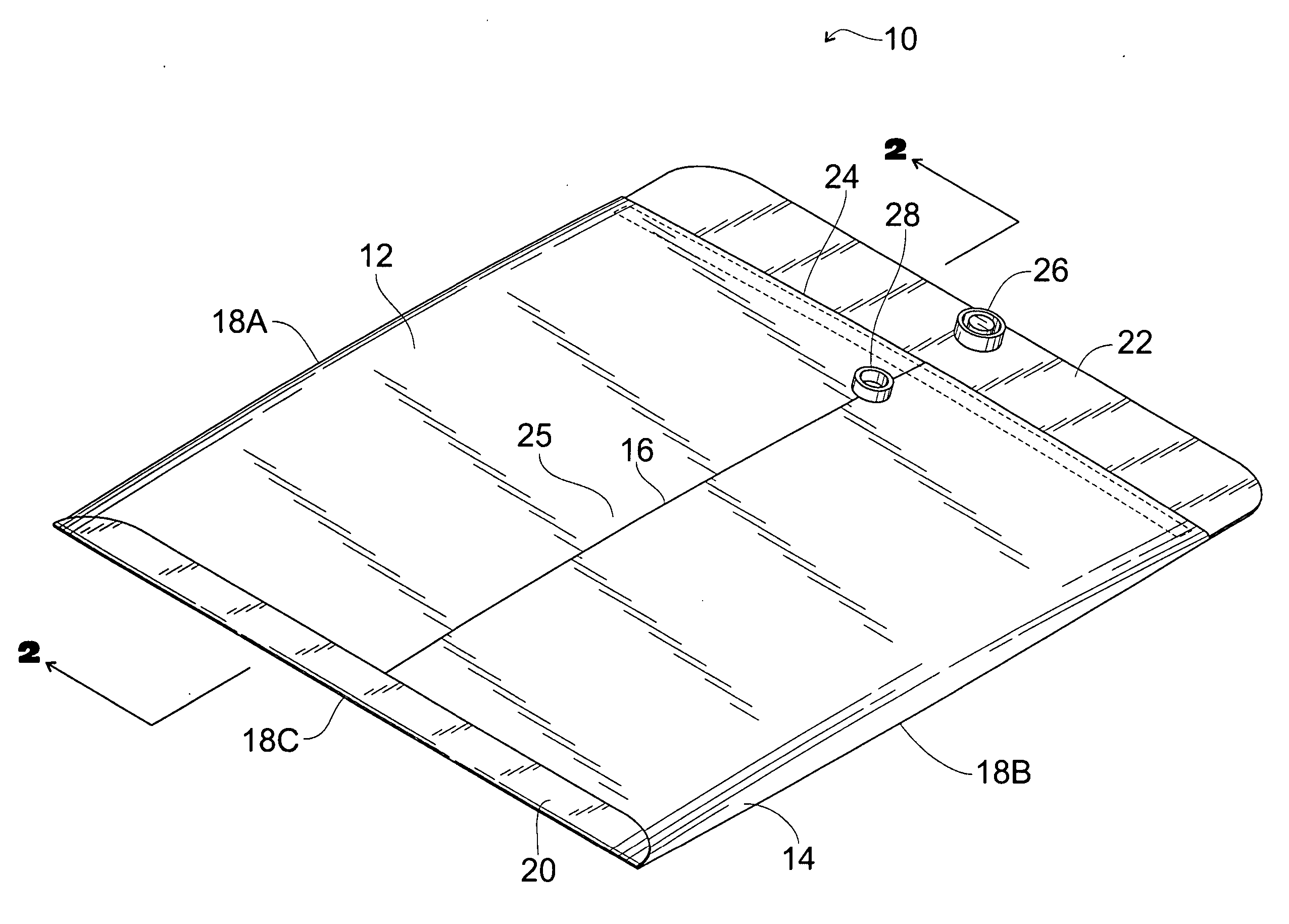

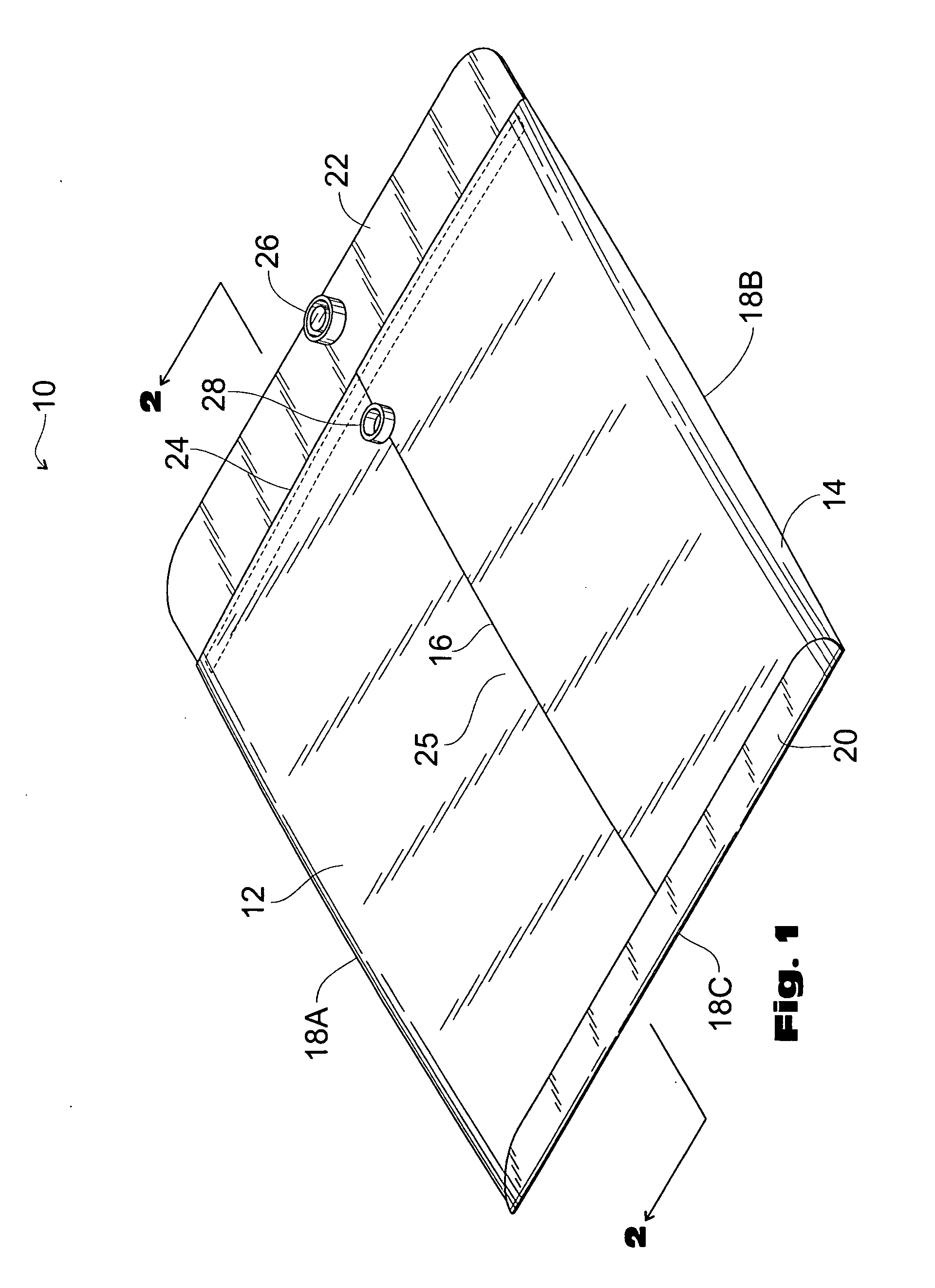

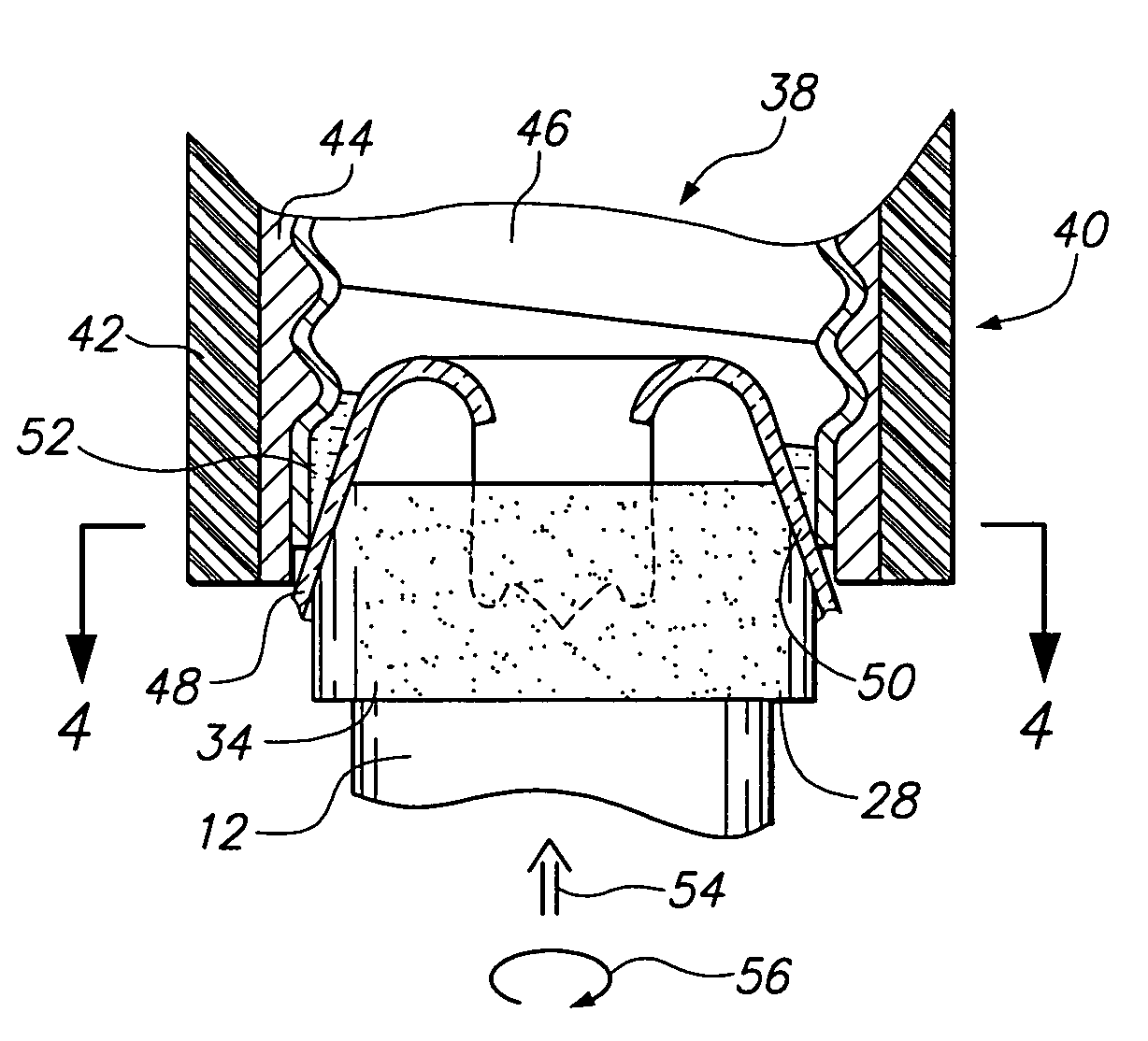

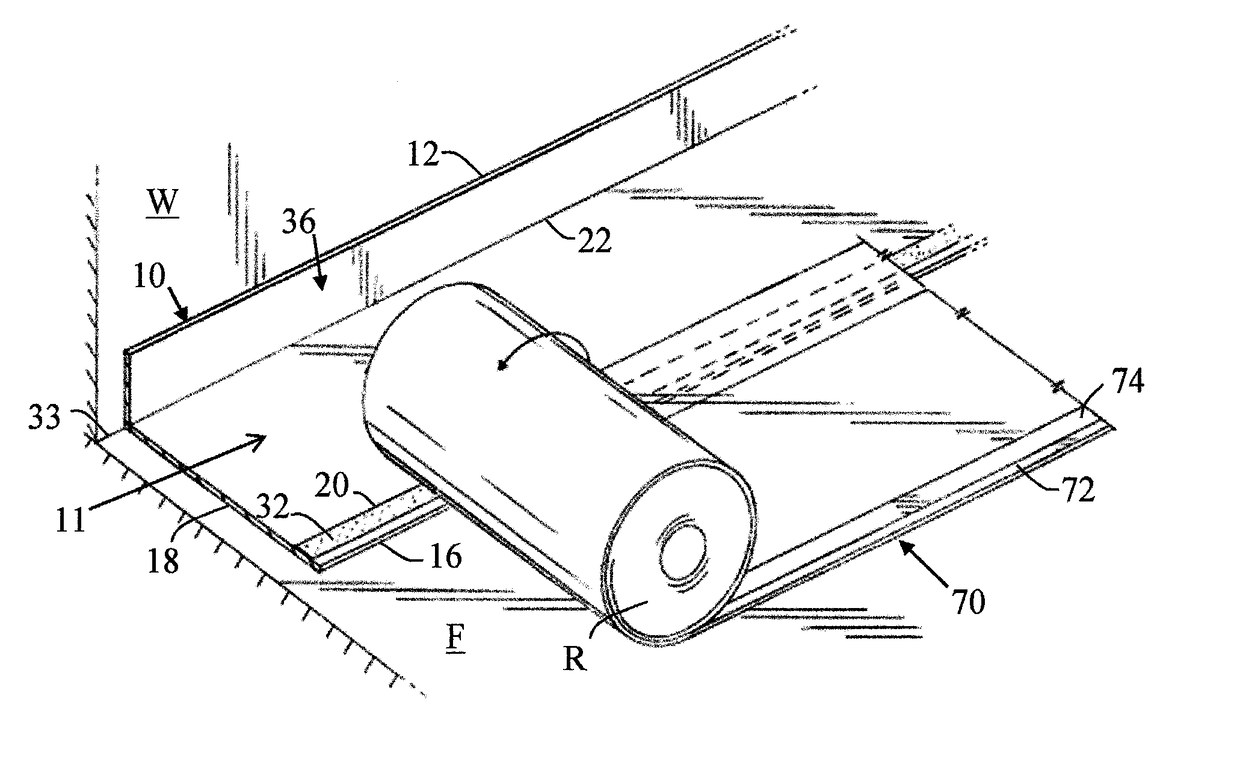

Disposable comfort sheet

A disposable comfort sheet has a waterproof layer and an absorbent layer, with adhesive strips applied to the waterproof layer along side edges. The sheet is adapted for use with a patient transfer device having upper and lower counter-rotating belts, and protects the upper belt against contamination. The patient transfer device may have registration marks for installation of the sheet, and indicator marks can be printed at predetermined locations on the waterproof layer for alignment with the registration marks. The sheet may include various means for indicating prior use by a patient, such as an ink pattern made of a heat-sensitive or moisture-sensitive ink. The sheet may further include a peel-away layer releasably bonded to the absorbent layer, with additional longitudinal adhesive strips applied to the side edges of the peel-away layer. The peel-away layer protects the lower belt against contamination from the sheet after a patient is delivered.

Owner:MEDIGLIDER

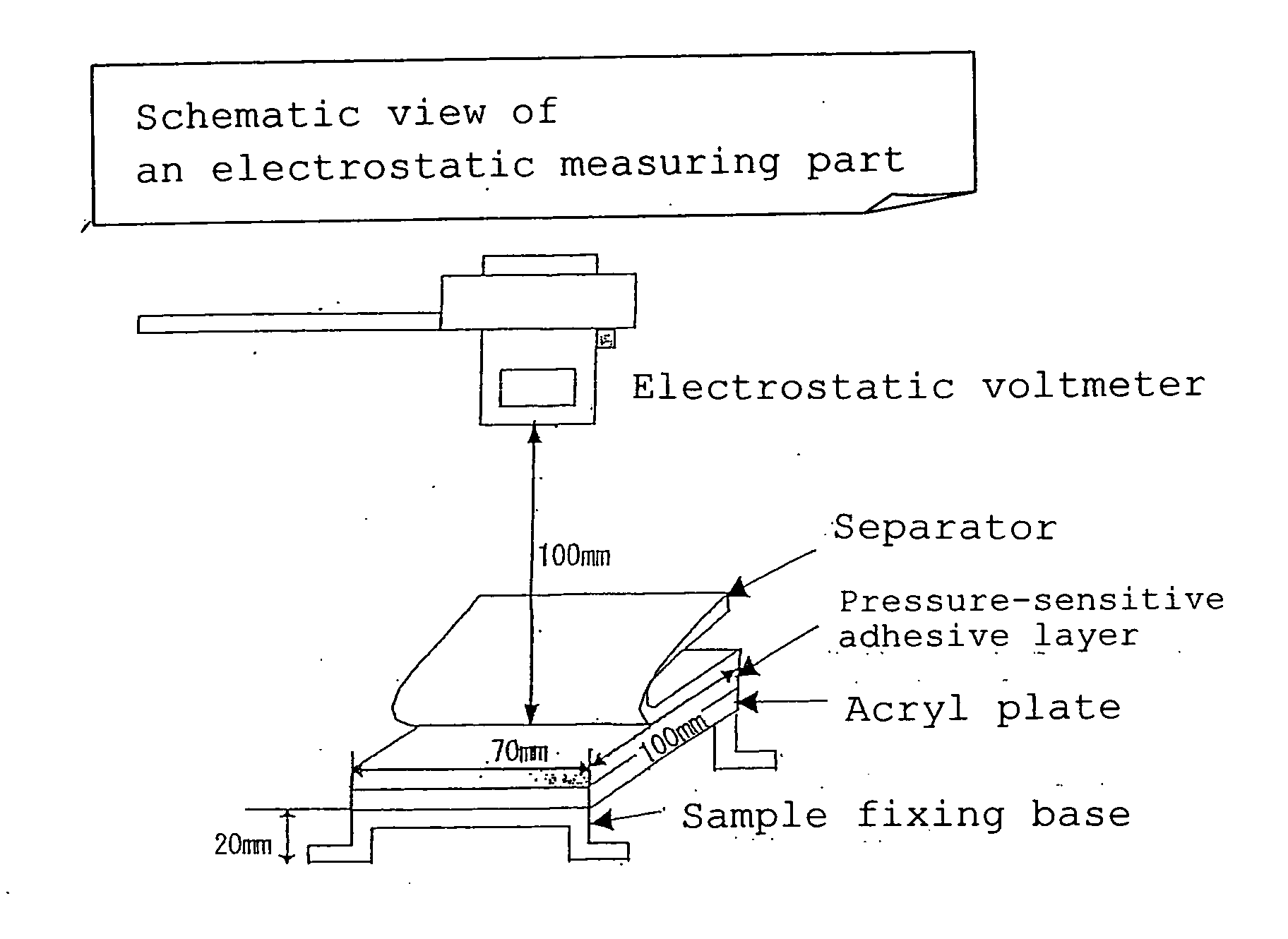

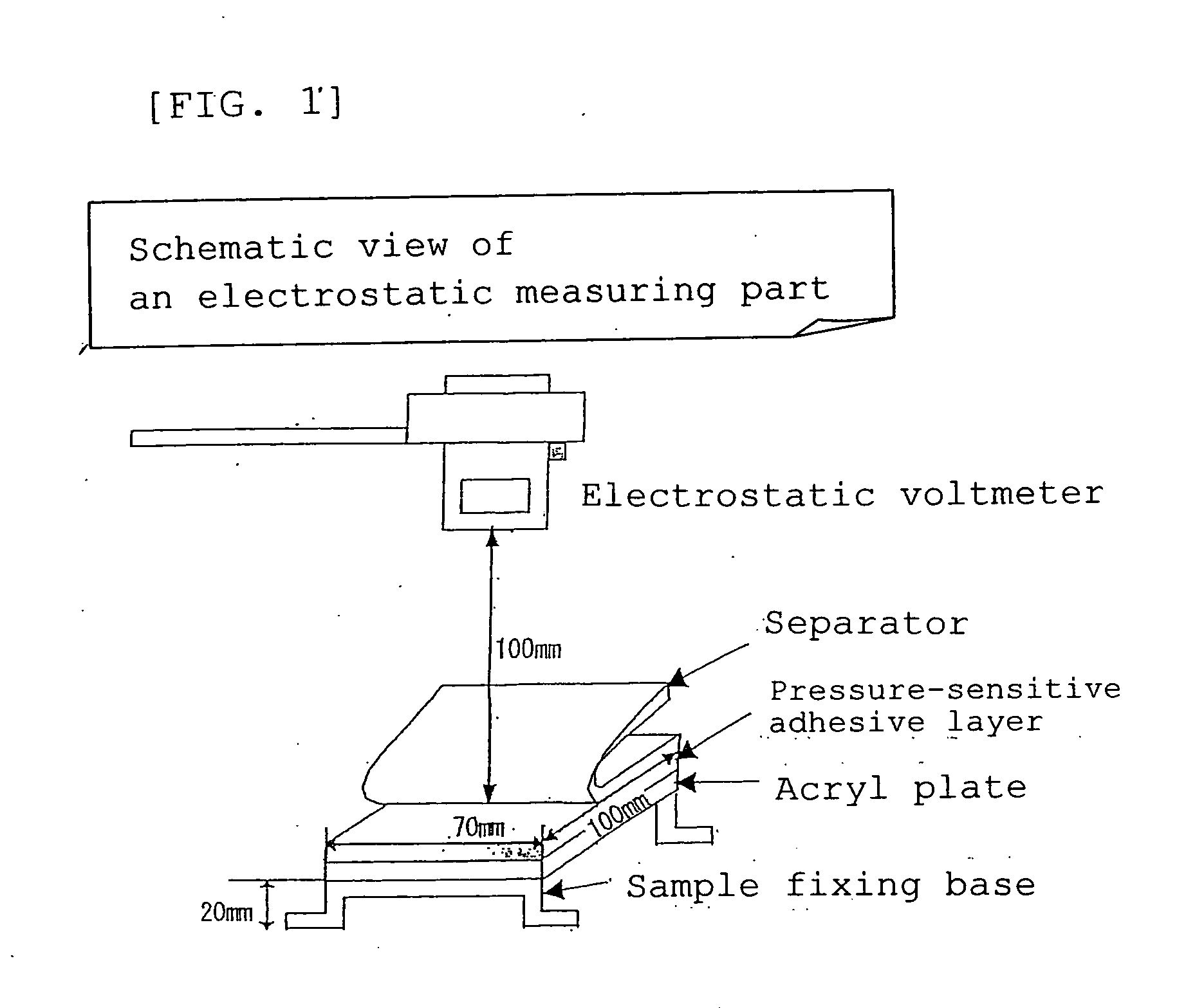

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets, and double-sided pressure- sensitive adhesive tapes

InactiveUS20060188711A1Easy to solveSimple compositionFilm/foil adhesivesSynthetic resin layered productsOligomerMeth-

An object of the present invention is to provide a pressure-sensitive adhesive composition which is excellent in antistatic property of a pressure-sensitive adhesive tapes when separators are peeled off, and has reduced stainability in an adherend, and excellent in transparency, and prevention of occurrence of peeling off and separation, and an antistatic pressure-sensitive adhesive sheet and a double-sided pressure-sensitive adhesive tape using the same. There is provided a pressure-sensitive composition comprising an ionic liquid, a (meth)acryl-based oligomer of weight-average molecular weight of 1,000 to 50,000, and a (meth)acryl-based polymer of glass transition temperature (Tg) of 0° C. or less as base polymer.

Owner:NITTO DENKO CORP

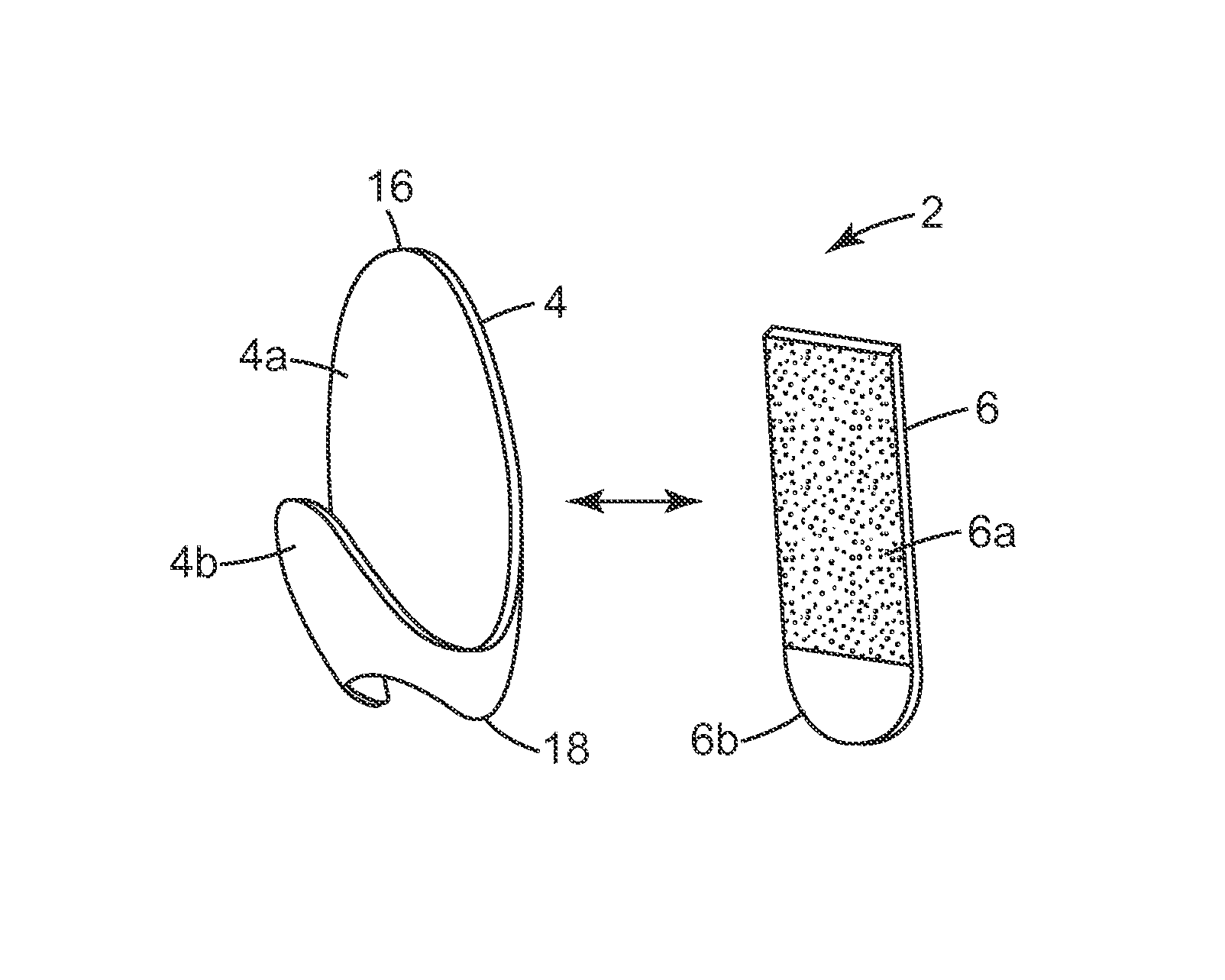

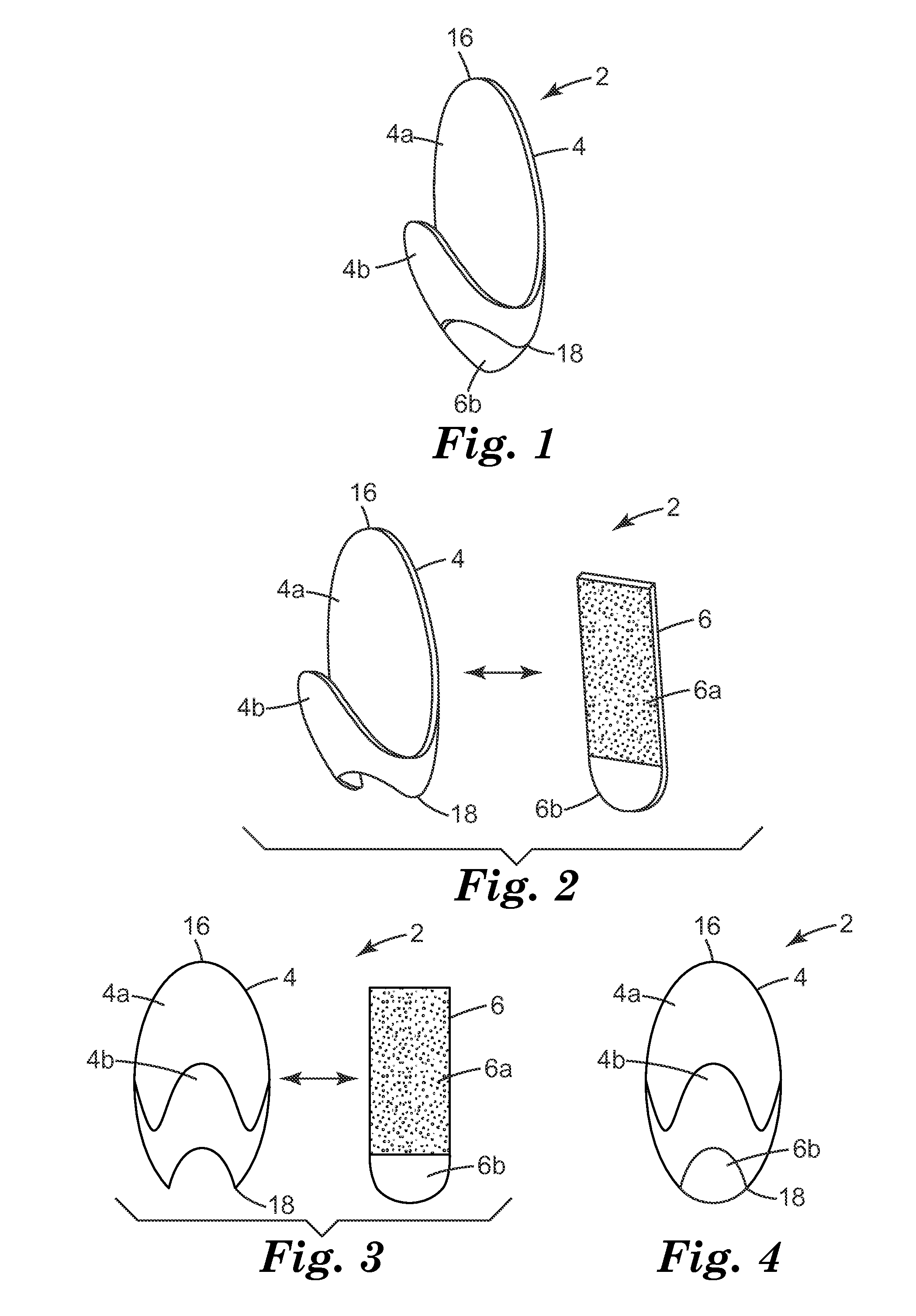

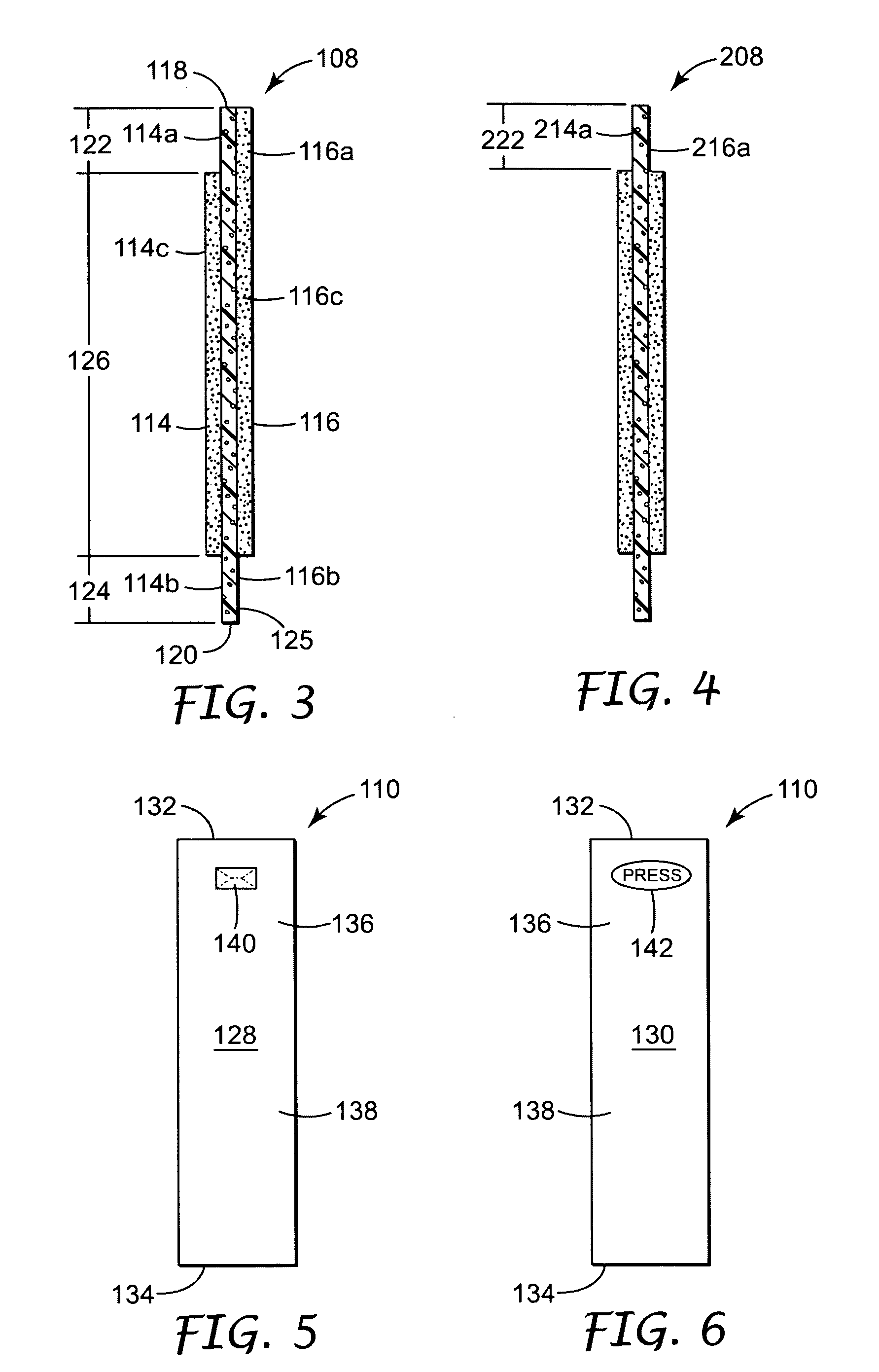

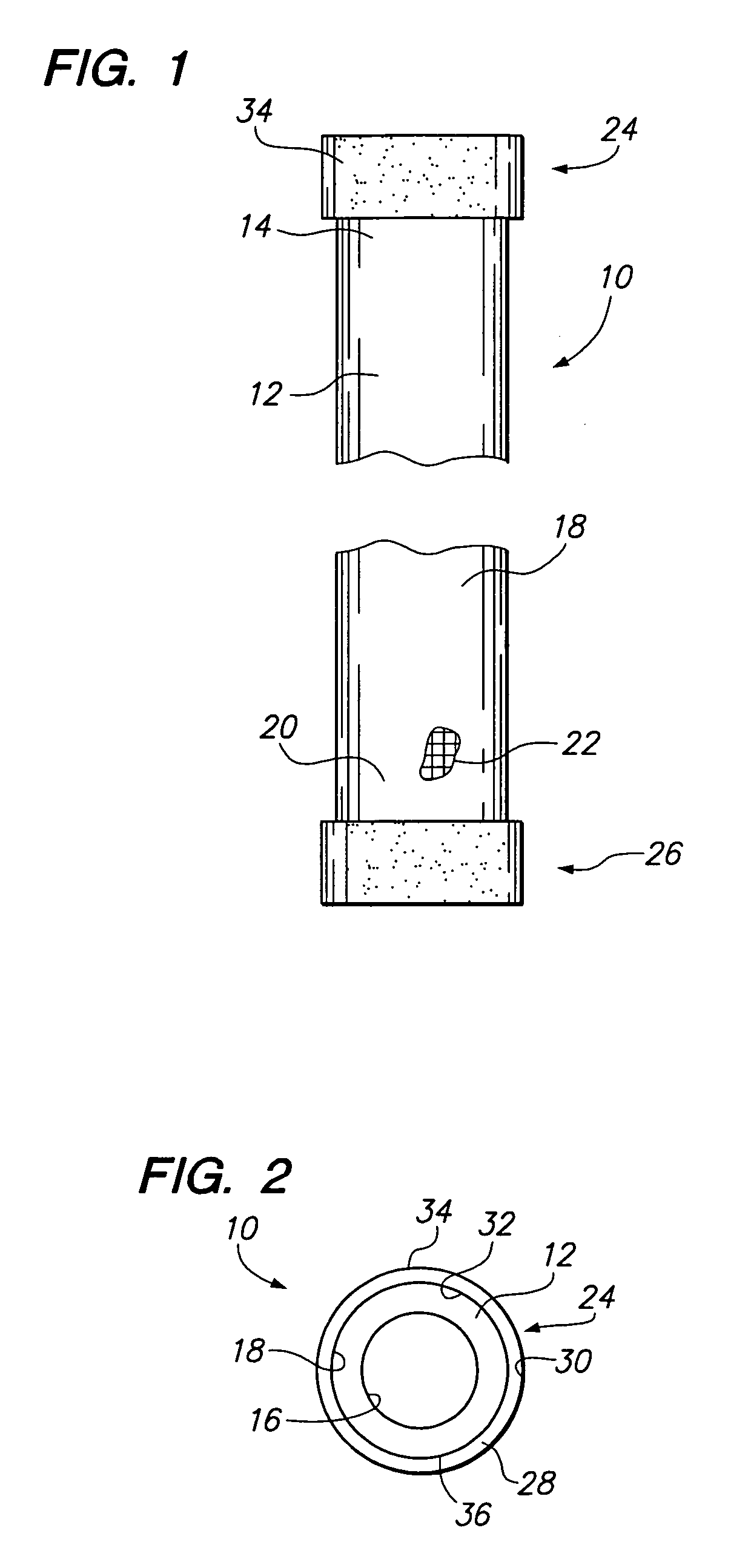

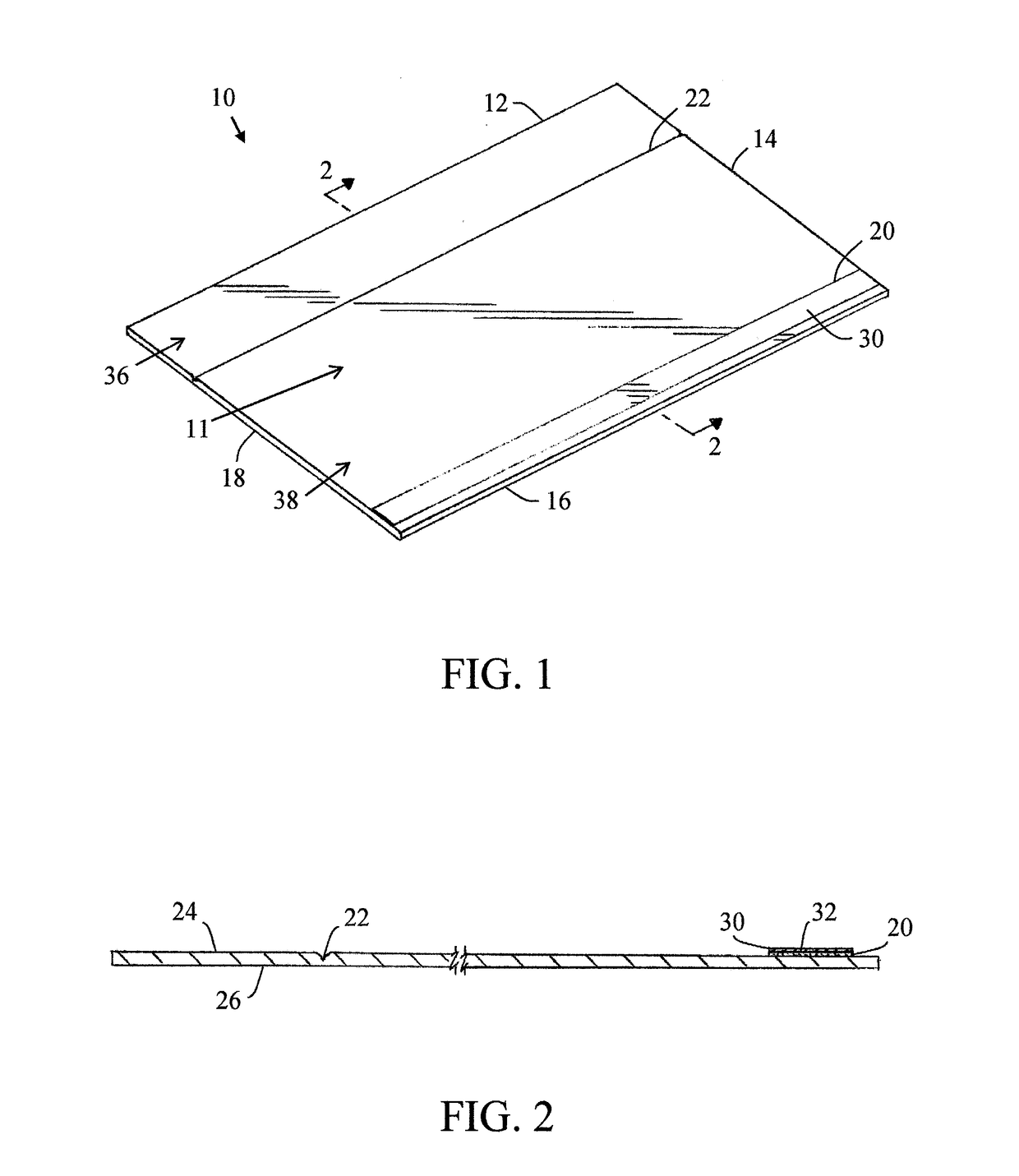

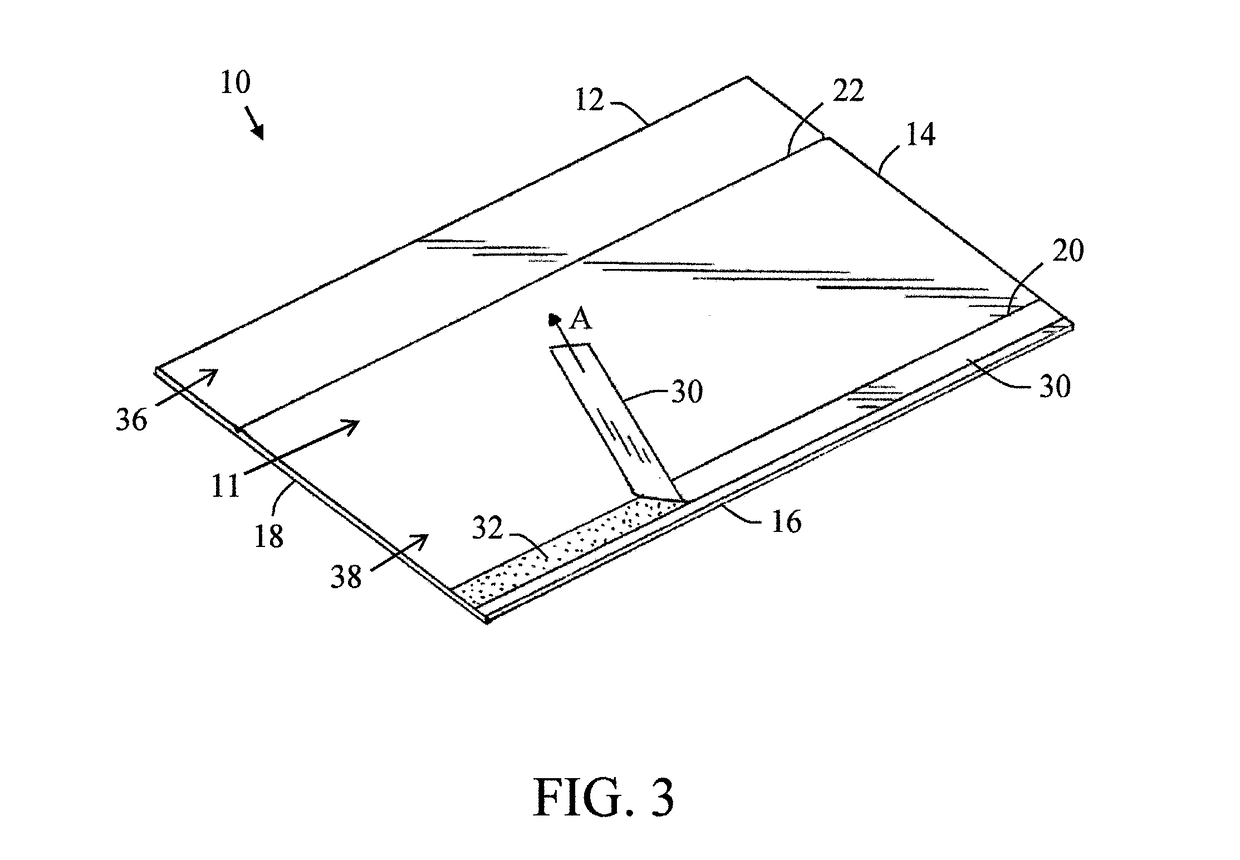

Adhesively mounted article support assembly with exposed pull tab

ActiveUS8708305B2Easy accessEasy and inexpensivePicture framesFilm/foil adhesivesMechanical engineeringAdhesion belt

An article support assembly includes a stretch releasable adhesive strip having an adhesive portion and a non-adhesive pull tab portion, and a unitary article support member arranged over at least a portion of the adhesive portion of the stretch releasable adhesive strip. The article support member and pull tab are configured so that when the article support member is mounted on a surface using the stretch releasable adhesive strip, the pull tab remains exposed but is visually inconspicuous.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure-sensitive adhesive tape or sheet for application to active surface in dicing and method of picking up chips of work

InactiveUS20070190318A1Easily pickedFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceDouble bond

The present invention relates to a pressure-sensitive adhesive tape or sheet for dicing which is to be applied to an active surface in the state of being not wholly covered with a native oxide film. The adhesive tape or sheet includes a substrate, and a radiation-curable pressure-sensitive adhesive layer disposed on at least one side of the substrate, in which the pressure-sensitive adhesive layer contains an acrylic polymer (A) having a weight-average molecular weight of 500,000 or higher and at least one radiation-polymerizable compound (B) selected from cyanurate compounds having one or more groups containing a carbon-carbon double bond and isocyanurate compounds having one or more groups containing a carbon-carbon double bond, and the ratio of the radiation-polymerizable compound (B) with respect to 100 parts by weight of the acrylic polymer (A) is 5 to 150 parts by weight.

Owner:NITTO DENKO CORP

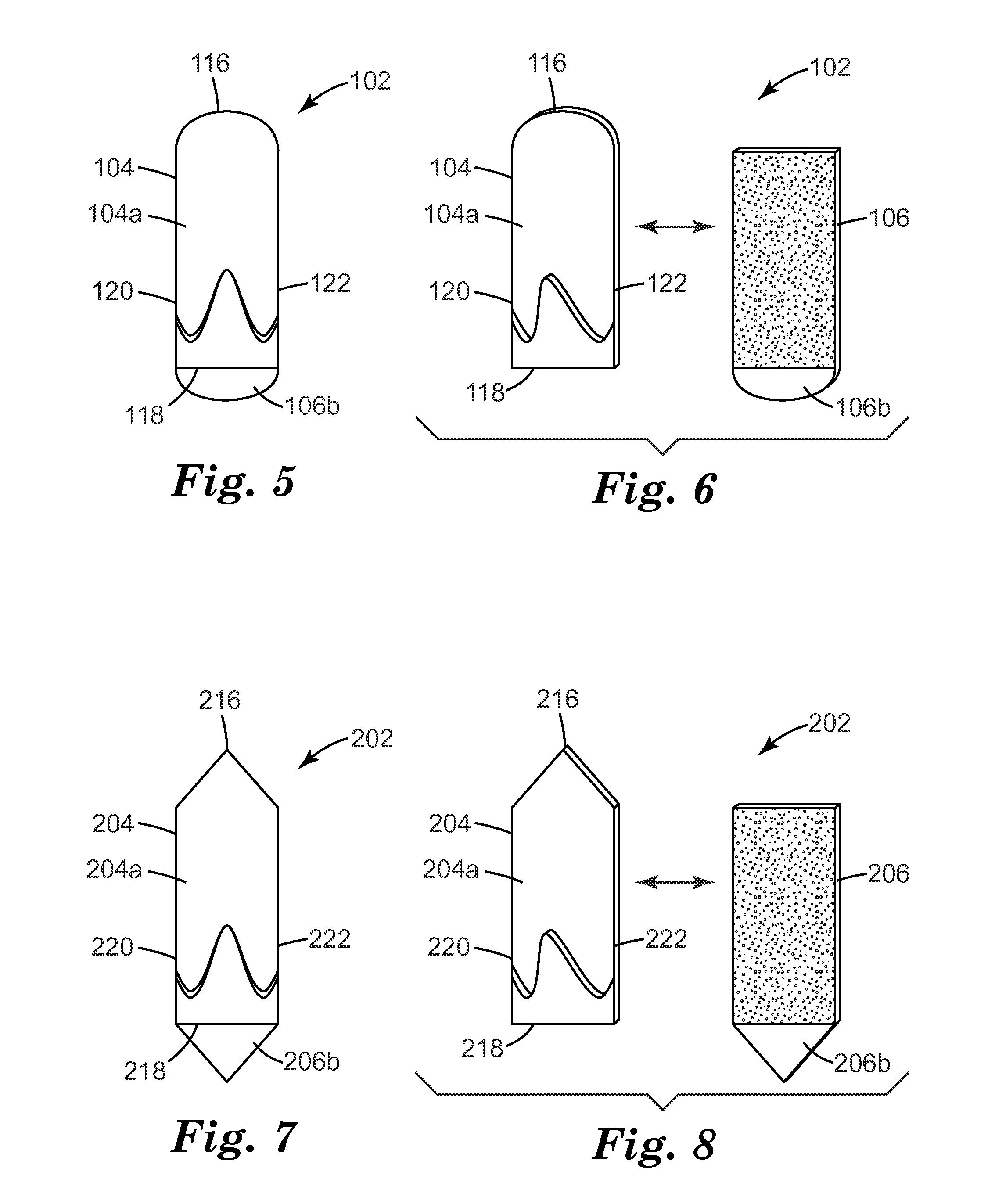

Stretch releasing adhesive article for fragile surfaces

ActiveUS20060068144A1Remove cleanCleanly removed from fragile substratesPicture framesFilm/foil adhesivesEngineeringMechanical engineering

A stretch releasing adhesive article for mounting on a wall surface includes an elongated stretch releasing adhesive strip having a first major surface with a non-adhesive contact surface adjacent the first end, and a backplate having a first major surface including a protrusion arranged in overlapping relation with the adhesive strip non-adhesive contact surface that serves to concentrate a force applied by a user in the region of the first end of the backplate in the region of the non-adhesive contact surface of the adhesive strip. A method of adhesively mounting an item to, and removing an item from, a wall surface that is susceptible to damage without damaging the surface is also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Heat-expandable removable acrylic pressure-sensitive adhesive tape or sheet

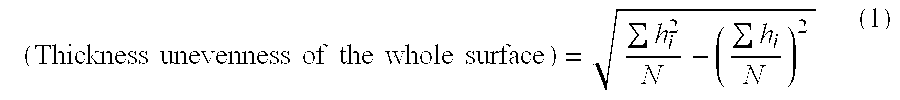

InactiveUS20100215947A1Improve adhesionReduced adhesion strengthFilm/foil adhesivesEster polymer adhesivesElastomerMeth-

Disclosed is a heat-expandable / peelable acrylic pressure-sensitive adhesive tape or sheet which maintains a high adhesion force but the bonded part can be easily separated / debonded regardless of whether the surface of the adherend is uneven. The heat-expandable / peelable acrylic pressure-sensitive adhesive tape or sheet includes a viscoelastic body containing both bubbles and microparticles, and on at least one side thereof, a pressure-sensitive adhesive layer containing a blowing agent. The heat-expandable / peelable acrylic pressure-sensitive adhesive tape or sheet preferably contains bubbles in an amount of 3 to 30 percent by volume based on the total volume of the viscoelastic body. The viscoelastic body containing both bubbles and microparticles is preferably a layer prepared by polymerization of a polymerizable composition containing a vinyl monomer mixture containing at least one alkyl(meth)acrylate whose alkyl moiety having 2 to 18 carbon atoms as a main component, or partially polymerized prepolymer of the monomer mixture; a photoinitiator; microparticles; a multifunctional (meth)acrylate; and bubbles.

Owner:NITTO DENKO CORP

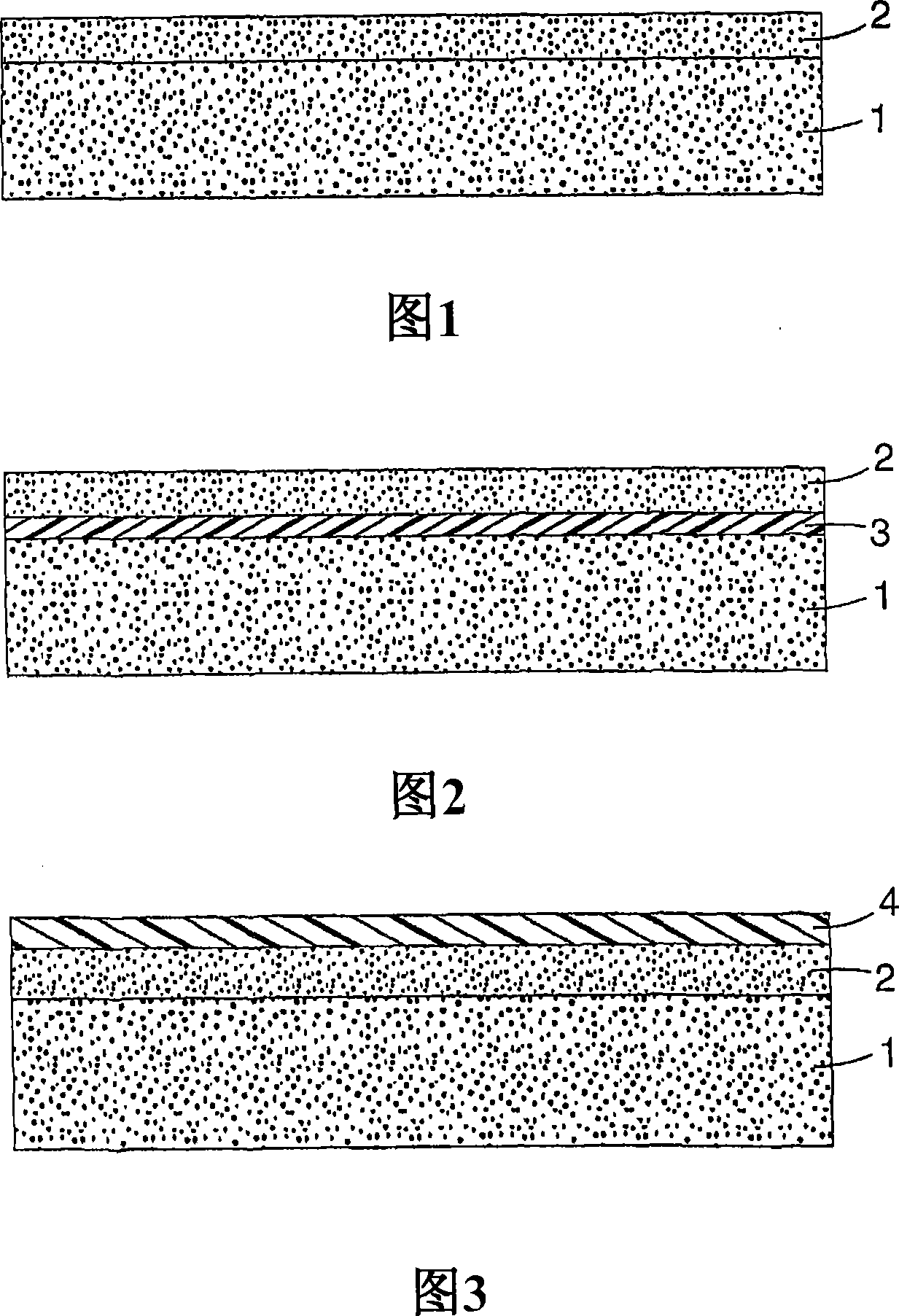

Heat-transferring adhesive tape with improved functionality

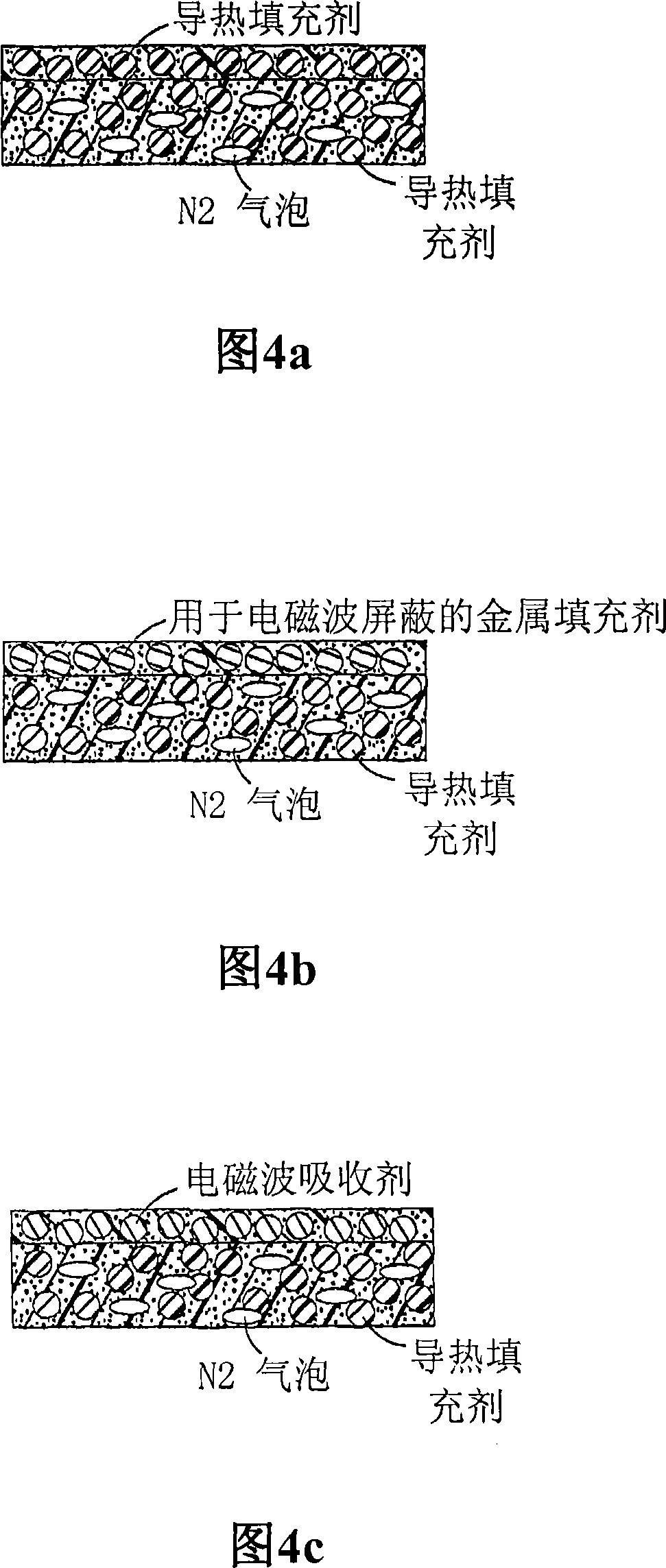

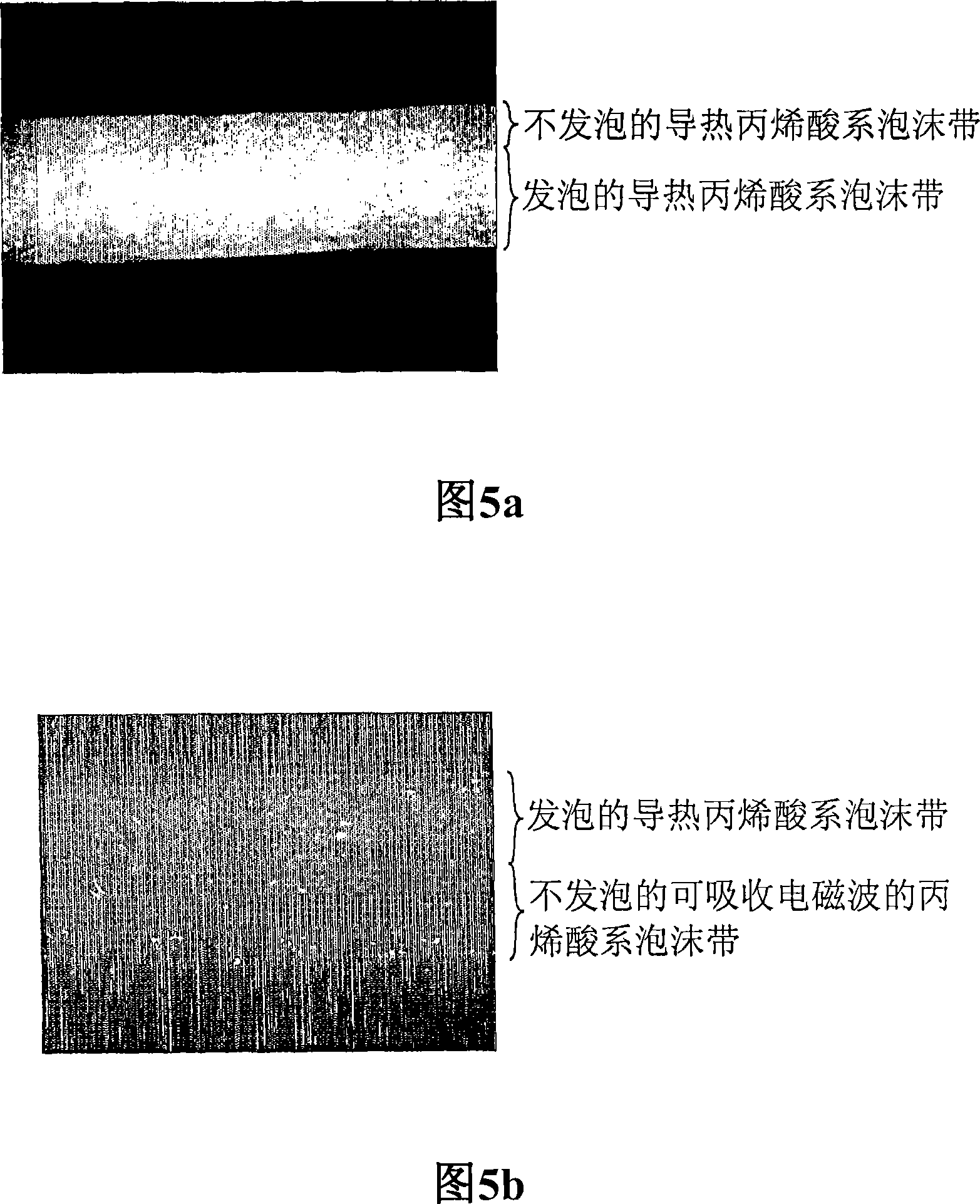

InactiveCN101243151AImprove thermal conductivityImprove shielding effectNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceAdhesion belt

Disclosed is an adhesive tape including a first adhesive layer and a second adhesive layer. More particularly, the first adhesive layer has a porous structure and contains a heat conductive filler, and the second adhesive layer has a non-porous structure and contains at least one filler selected from the group consisting of a heat conductive filler, an electromagnetic wave shielding filler and an electromagnetic wave absorbing filler. The adhesive tape may be applied to electronic products, especially to electronic products requiring a large area of adhesion, such as a plasma display panel (PDP).

Owner:3M INNOVATIVE PROPERTIES CO

Double-sided pressure-sensitive adhesive tape

InactiveUS20110014410A1Good inspection propertyPoor handling abilitySynthetic resin layered productsEster polymer adhesivesPressure sensitiveEngineering

The present invention provides a pressure-sensitive adhesive tape including a release liner A having a haze value of 5.0% or less. Since the double-sided pressure-sensitive adhesive tape of the invention has the aforementioned construction, it does not inhibit visual inspection of an adherend even in case that the visual inspection of adherend is carried out under a condition of still having the aforementioned release liner. Accordingly, it can be suitably used in the application for adhering optical members, and the like.

Owner:NITTO DENKO CORP

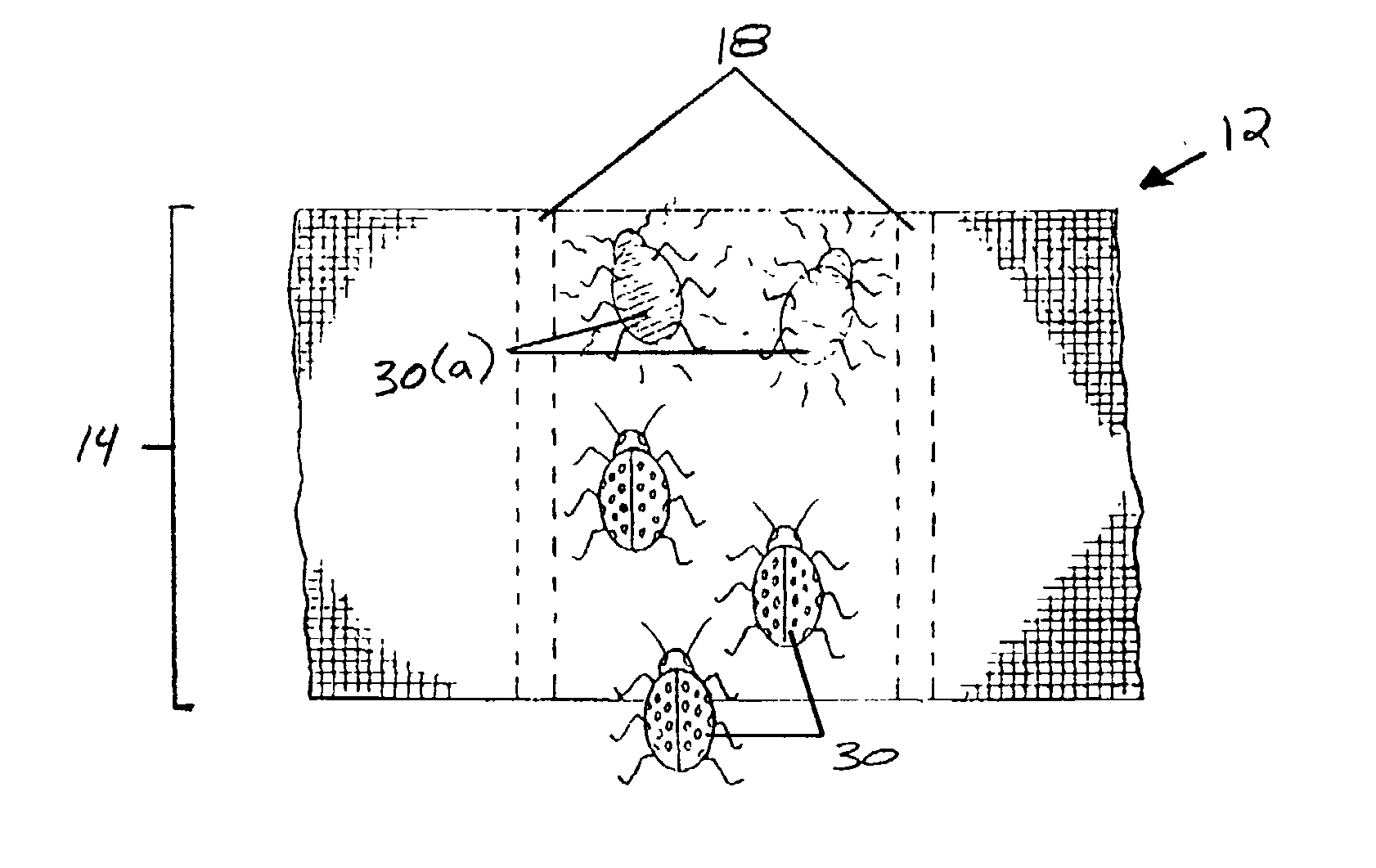

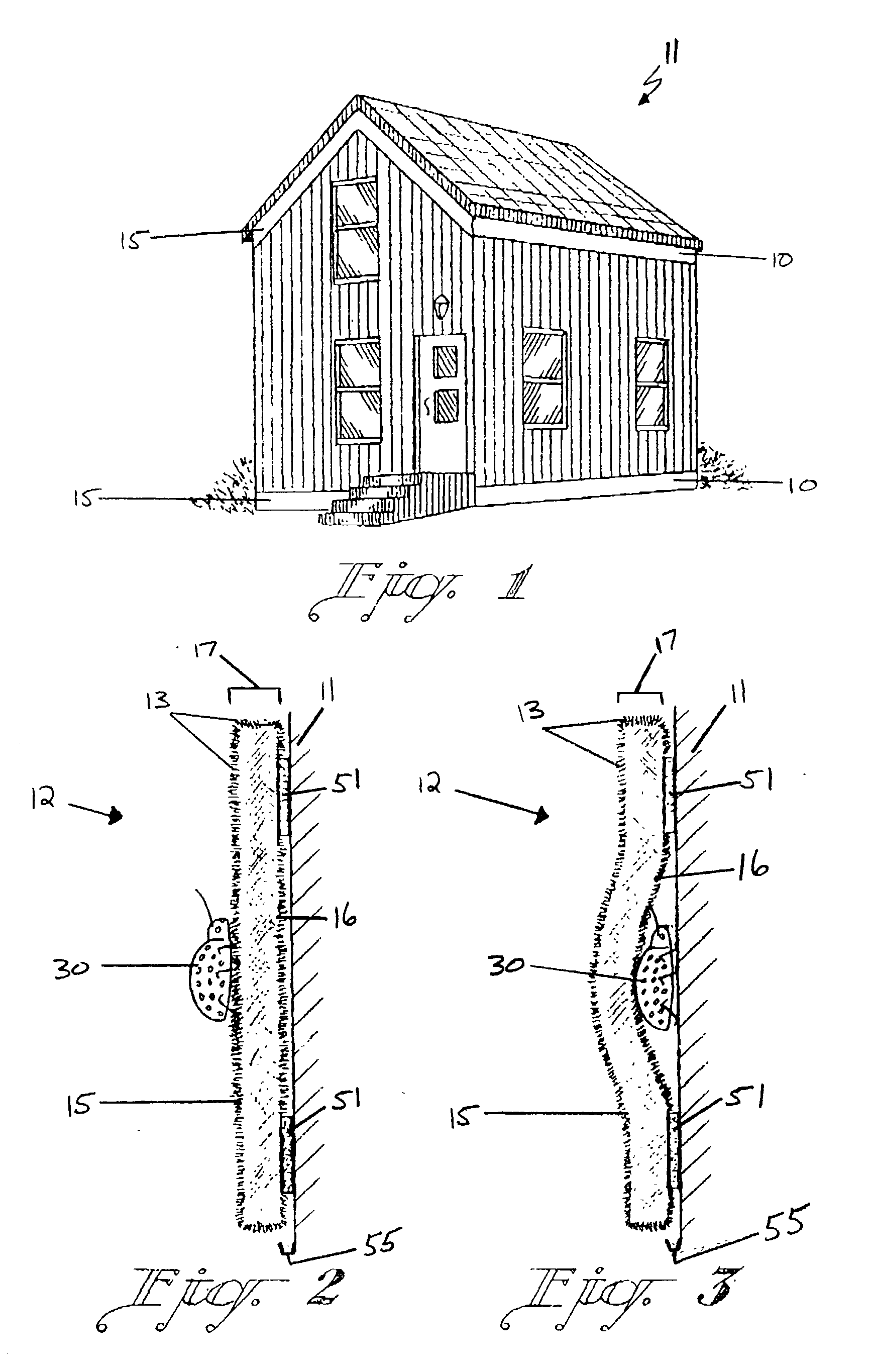

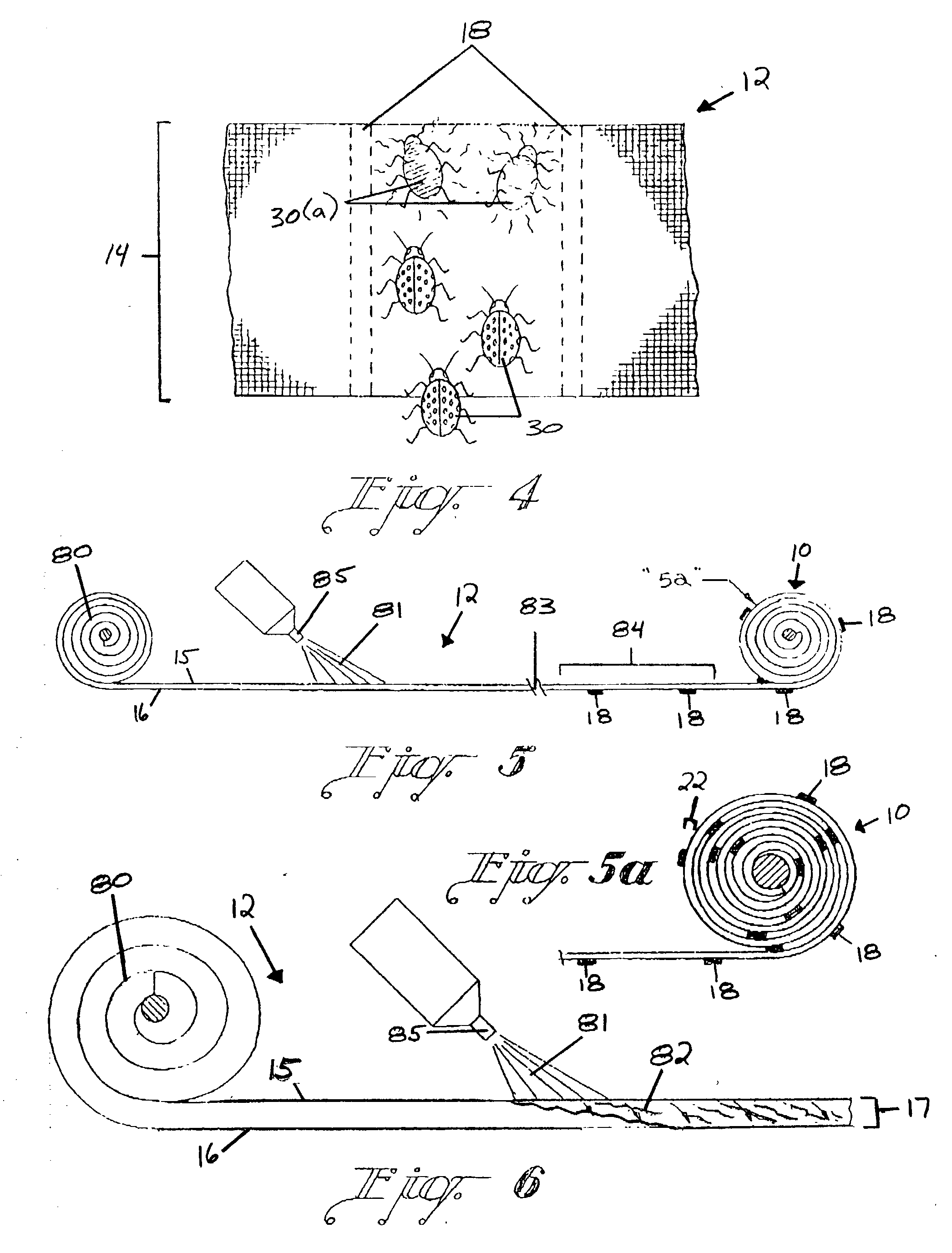

Article for preventing pests from entering a building structure and methods of using/manufacturing the same

InactiveUS20030186604A1Synthetic resin layered productsAnimal repellantsFiberAgricultural engineering

The present invention discloses an article for preventing pests from gaining entrance to a building structure. The article comprises a length of fibrous fabric and a plurality of adhesive strips. The fabric is designed for adhesive attachment to a dwelling or building structure adjacent points of entry and the adhesive strips are designed for adhesively attaching the fabric in snug adjacency to the outfitted building structure. The fabric is impregnated with at least one pesticide composition and has outwardly extending fibers for entangling the legs of pests attempting to gain entrance to the building structure by maneuvering across the fabric to points of entry. These outwardly extending fibers thus directly deposit pesticide composition on the pests for preventing them from gaining entrance to the building structure. Importantly, the fabric is brilliantly colored or has highly light reflective coloration for attracting the pests to the pesticide-impregnated fabric for contact treatment.

Owner:NOURIGAT ROBERT M

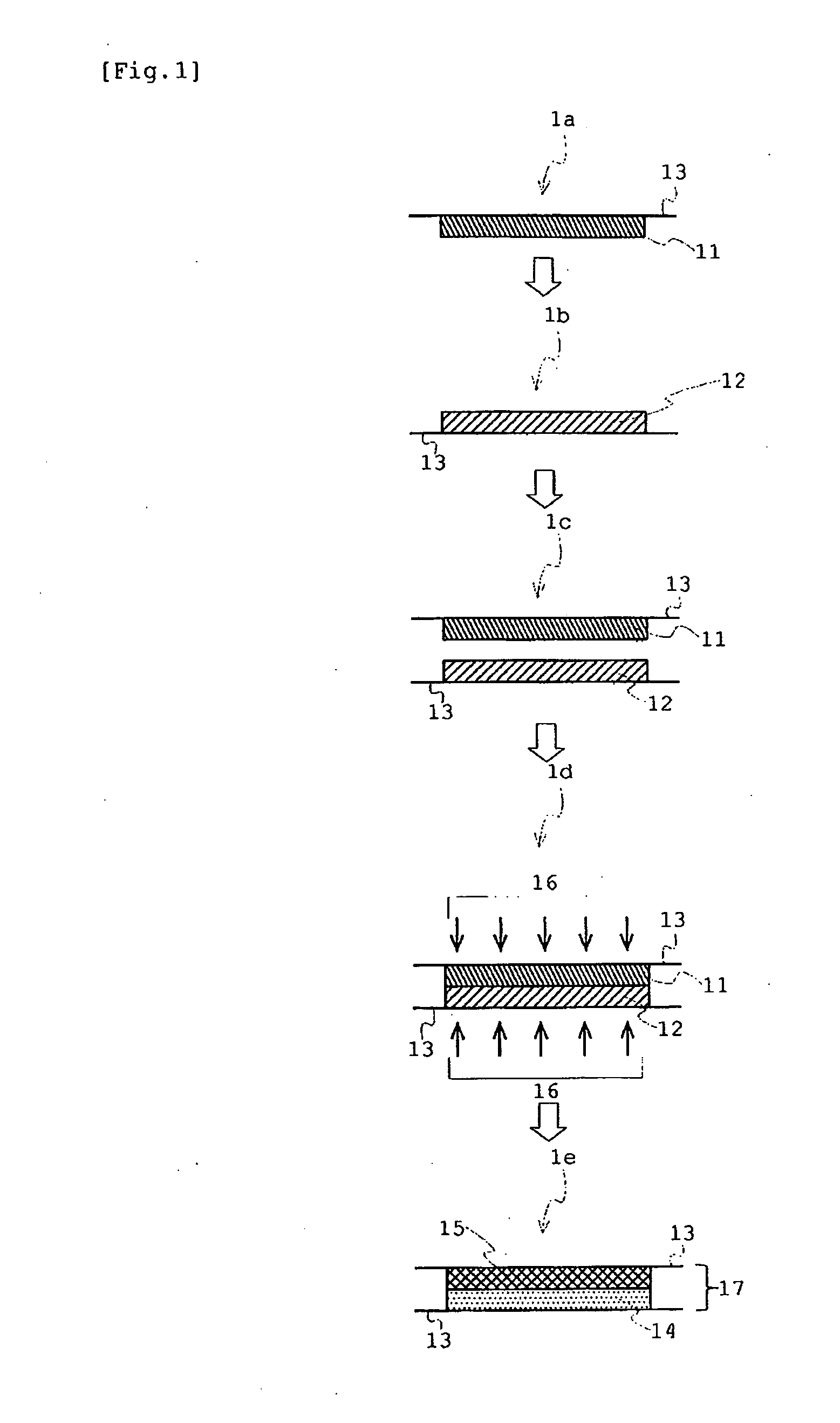

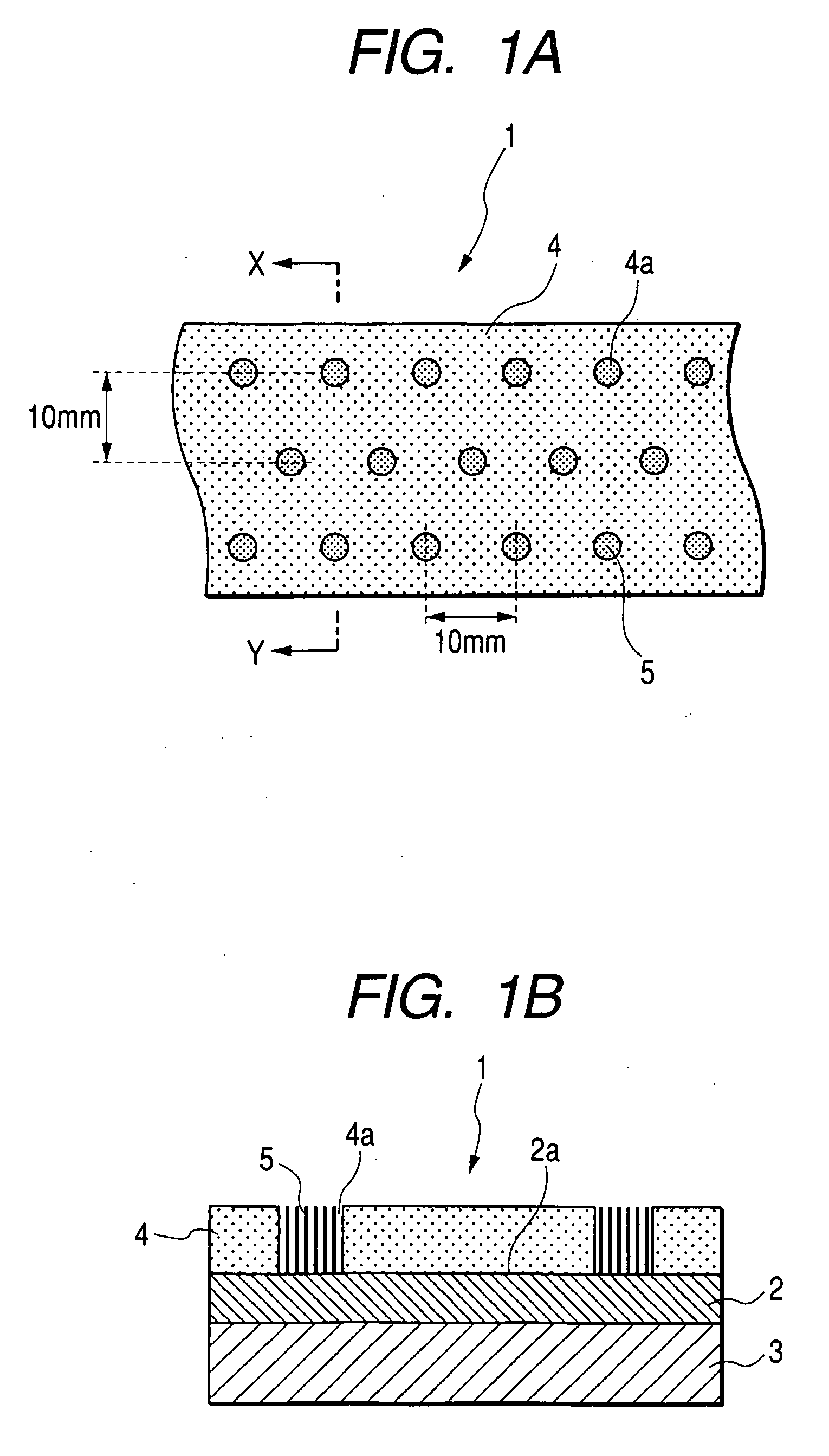

Adhesive sheet for semiconductor connecting substrate, adhesive-backed tape for TAB, adhesive-backed tape for wire bonding connection, semiconductor connecting substrate, and semiconductor device

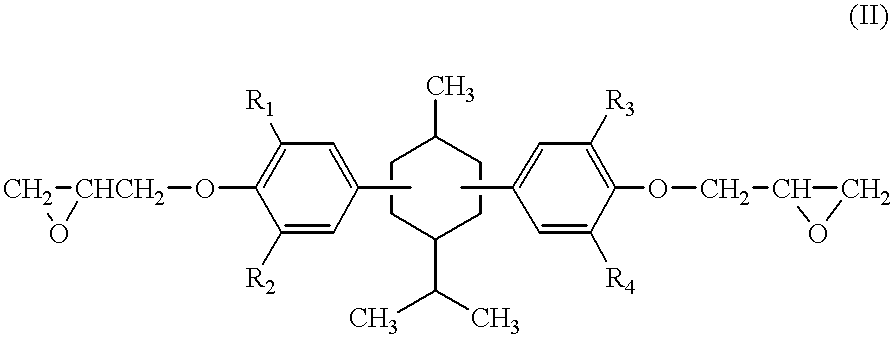

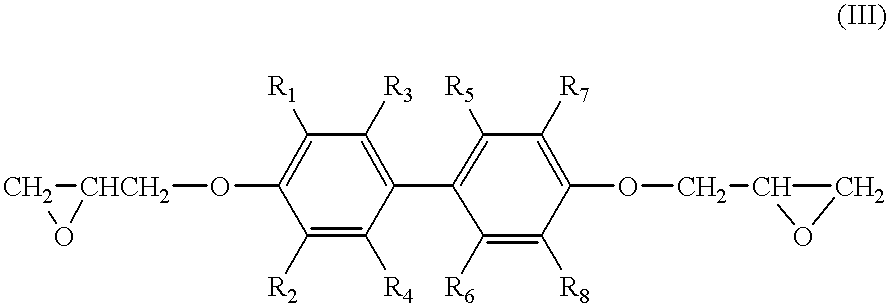

InactiveUS20020025431A1Moderate modulusModerate coefficientSemiconductor/solid-state device detailsSolid-state devicesEpoxyTectorial membrane

An adhesive sheet for a semiconductor connecting substrate consisting of a laminate having an adhesive layer on a substrate, wherein said adhesive layer contains a thermoplastic resin (A) and an epoxy resin (B) and said epoxy resin (B) contains at least one epoxy resin (B) selected from (I) dicyclopentadiene skeleton-containing epoxy resins, (II) terpene skeleton-containing epoxy resins, and (III) biphenyl skeleton-containing epoxy resins, as an essential component; an adhesive-backed tape for TAB consisting of a laminate having an adhesive layer and a protective film layer on a flexible organic insulating film. The adhesive sheet for a semiconductor connecting substrate, the adhesive-backed tape for TAB and the adhesive-backed tape for wire bonding connection of the present invention are excellent in adhesive strength, insulatability, dimensional accuracy, etc., and can improve the reliability of a semiconductor integrated circuit connecting substrate and a semiconductor device respectively for high density packaging.

Owner:TORAY IND INC

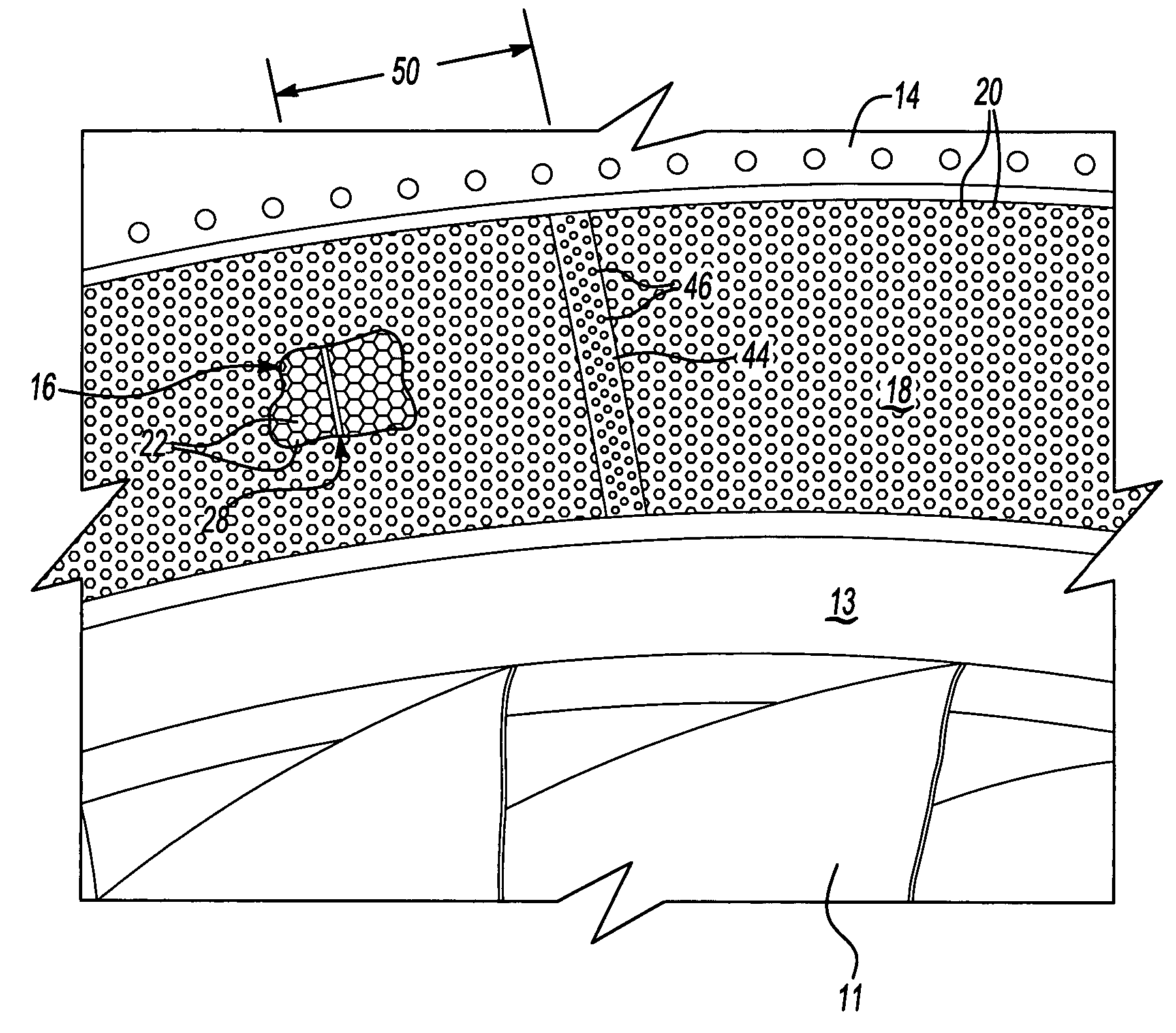

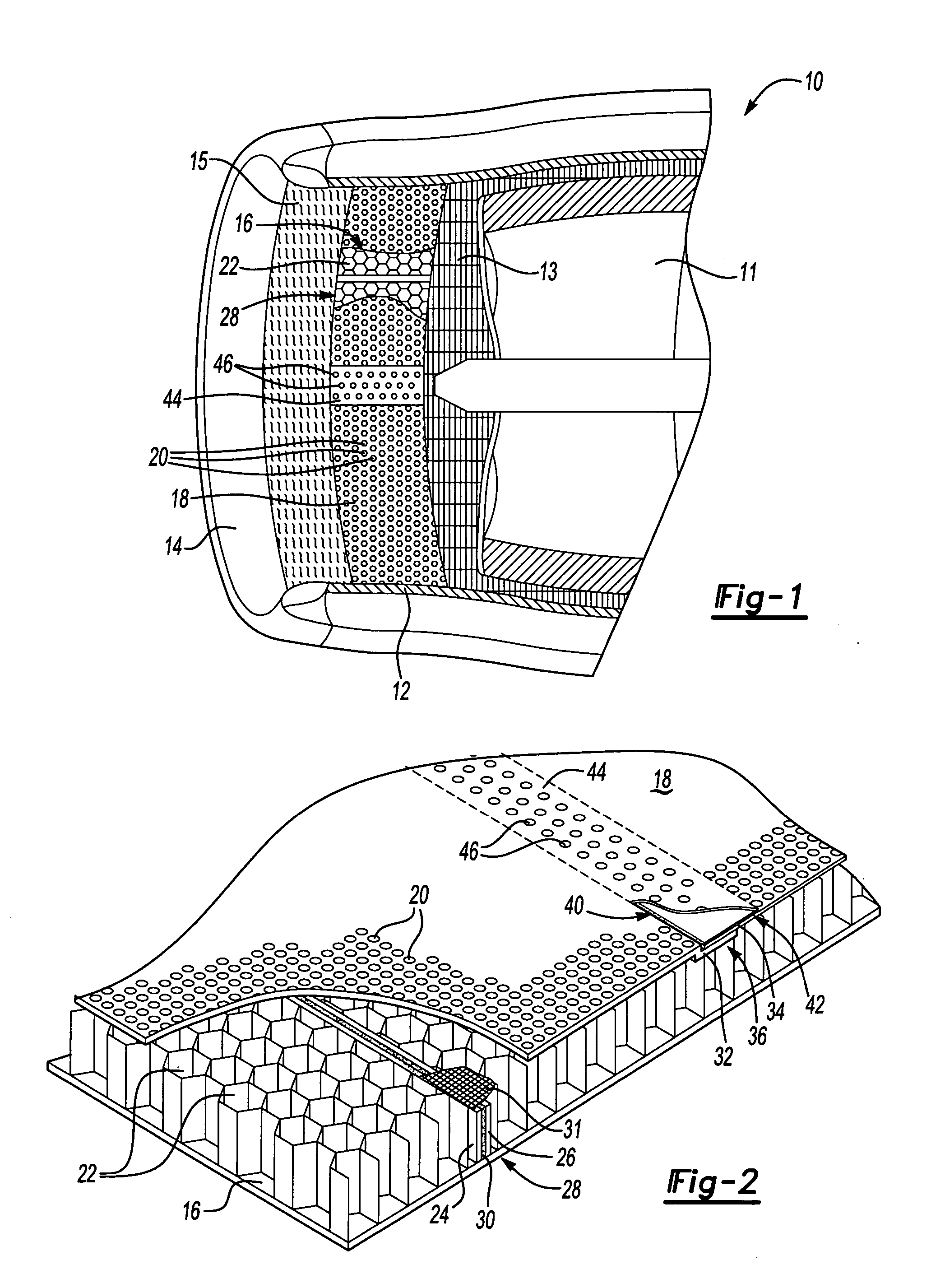

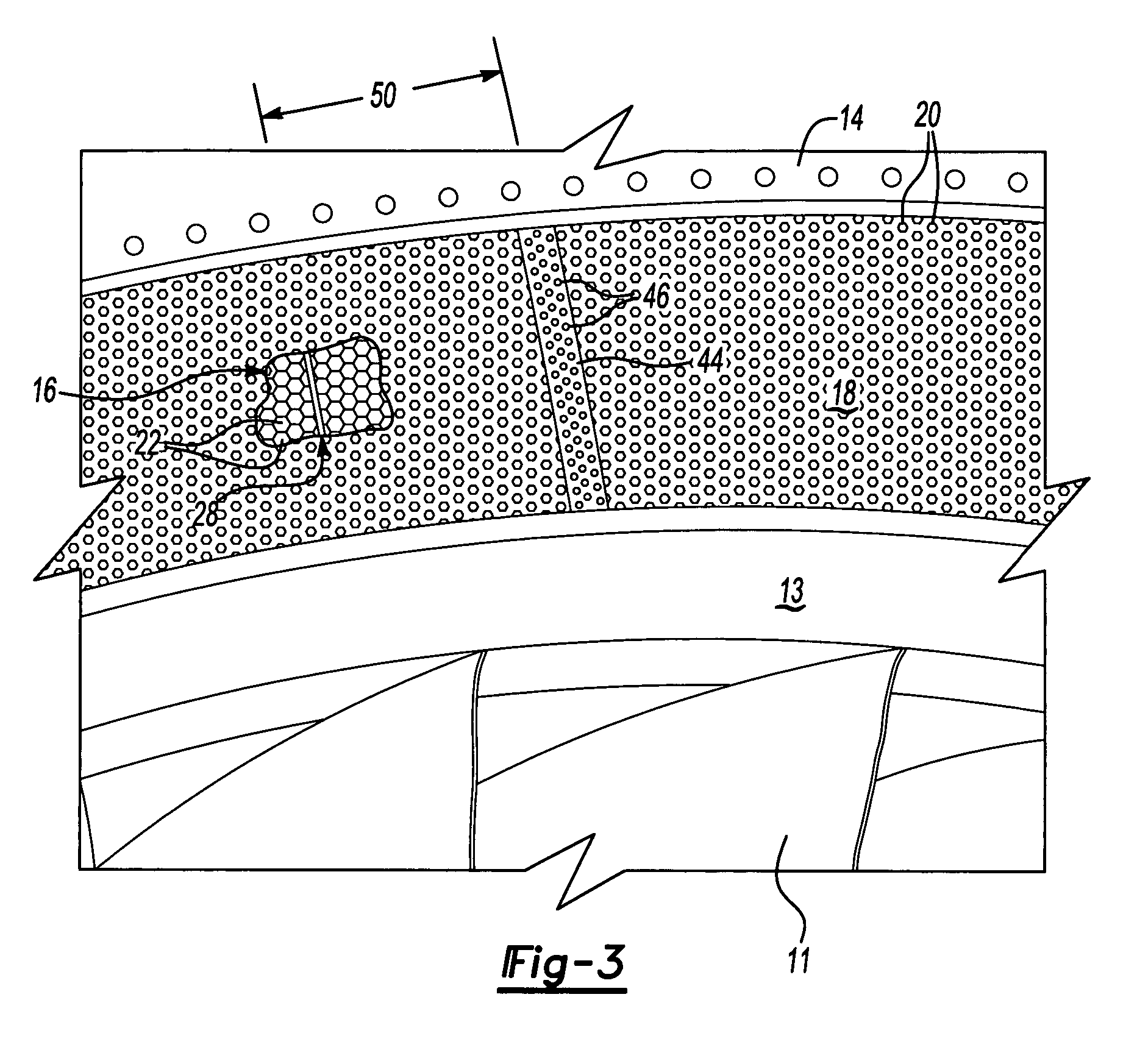

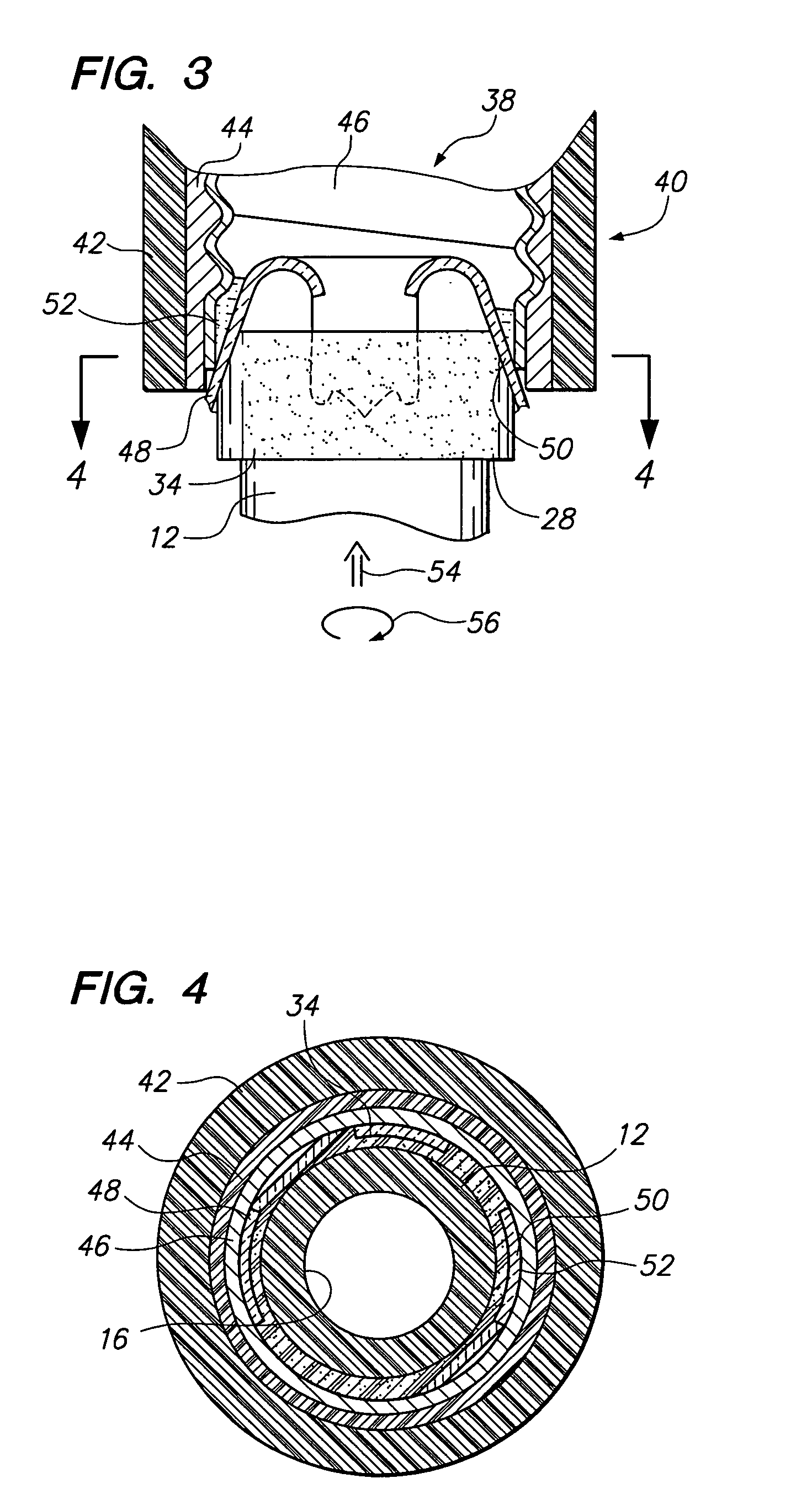

Zero acoustic splice fan case liner

ActiveUS20060024154A1Improved noise attenuation performanceImproved noise attenuationFuselage framesPump componentsAdhesiveEngineering

A liner assembly for a fan case includes a noise attenuation layer covered by a face sheet. The face sheet includes openings to the underlying noise attenuation layer. The face sheet and noise attenuation layer include acoustically transparent joints. The noise attenuation layer includes a first side joined to a second side at a seam by an adhesive strip. The adhesive strip bonds the first side to the second side without filling any chambers. The face sheet includes a joint filled with an adhesive providing the desired uninterrupted surface within the fan case. Openings are formed through the joint and the adhesive to communicate with the underlying noise attenuation layer. The joint and seam become essentially transparent acoustically to improve noise attenuation performance.

Owner:RTX CORP

Pressure-sensitive adhesive tape or sheet, and method for producing it

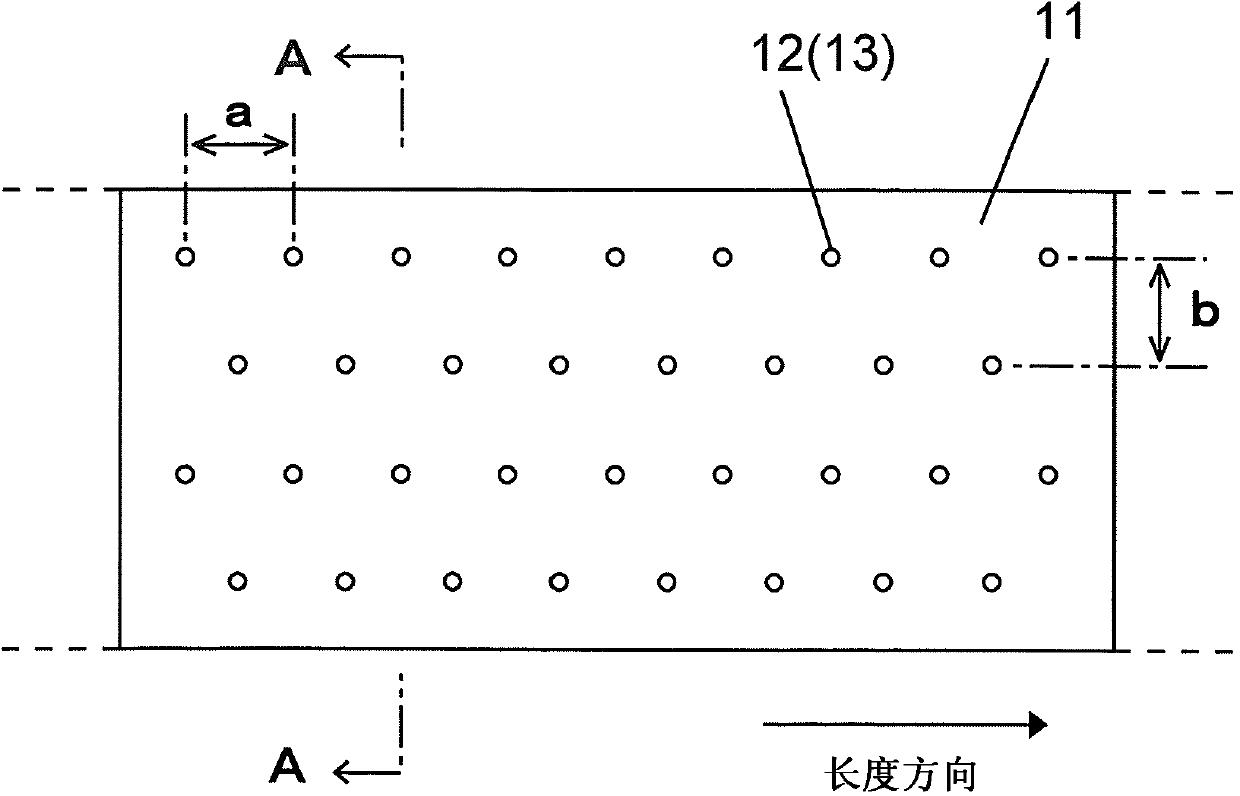

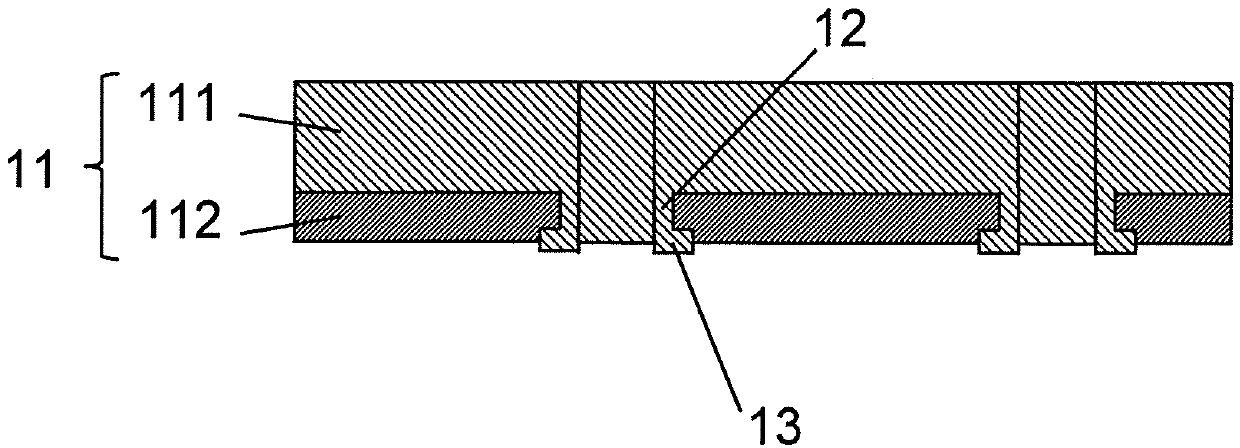

InactiveUS20060240209A1Good repositionabilityExcellent reworkabilityDecorative surface effectsDuplicating/marking methodsFiberEngineering

A pressure-sensitive adhesive tape or sheet having a pressure-sensitive adhesive layer formed on at least one surface of the support thereof, wherein the surface of the pressure-sensitive adhesive layer on at least one surface of the support partly has projected spots of fibers. The projected spots of fibers are preferably raised spots of fibers that are raised from the surface of the pressure-sensitive adhesive layer. The pressure-sensitive adhesive tape or sheet is favorable for flooring material fixation. The pressure-sensitive adhesive tape or sheet is produced according to a flocking method that comprises flocking the surface of the pressure-sensitive adhesive layer on at least one surface of the support to thereby form projected spots of fibers partly in the surface of the pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

Double-sided pressure-sensitive adhesive tape and method for attaching the same, and release liner

InactiveUS20100224312A1Release workability decreasesHigh inhibition effectFilm/foil adhesivesLaminationPressure sensitiveEngineering

A double-sided pressure-sensitive adhesive tape does not generate wrinkles or floating on a release liner even when the tape is attached to an adherend having a bend or curve, with the release liner held and with the tape bent in a width direction. A method is for attaching the double-sided pressure-sensitive adhesive tape to an adherend having a bend and / or curve. The double-sided pressure-sensitive adhesive tape of the present invention includes, on at least one side of a pressure-sensitive adhesive body, a release liner having a notch and / or slit in at least one edge in the width direction.

Owner:NITTO DENKO CORP

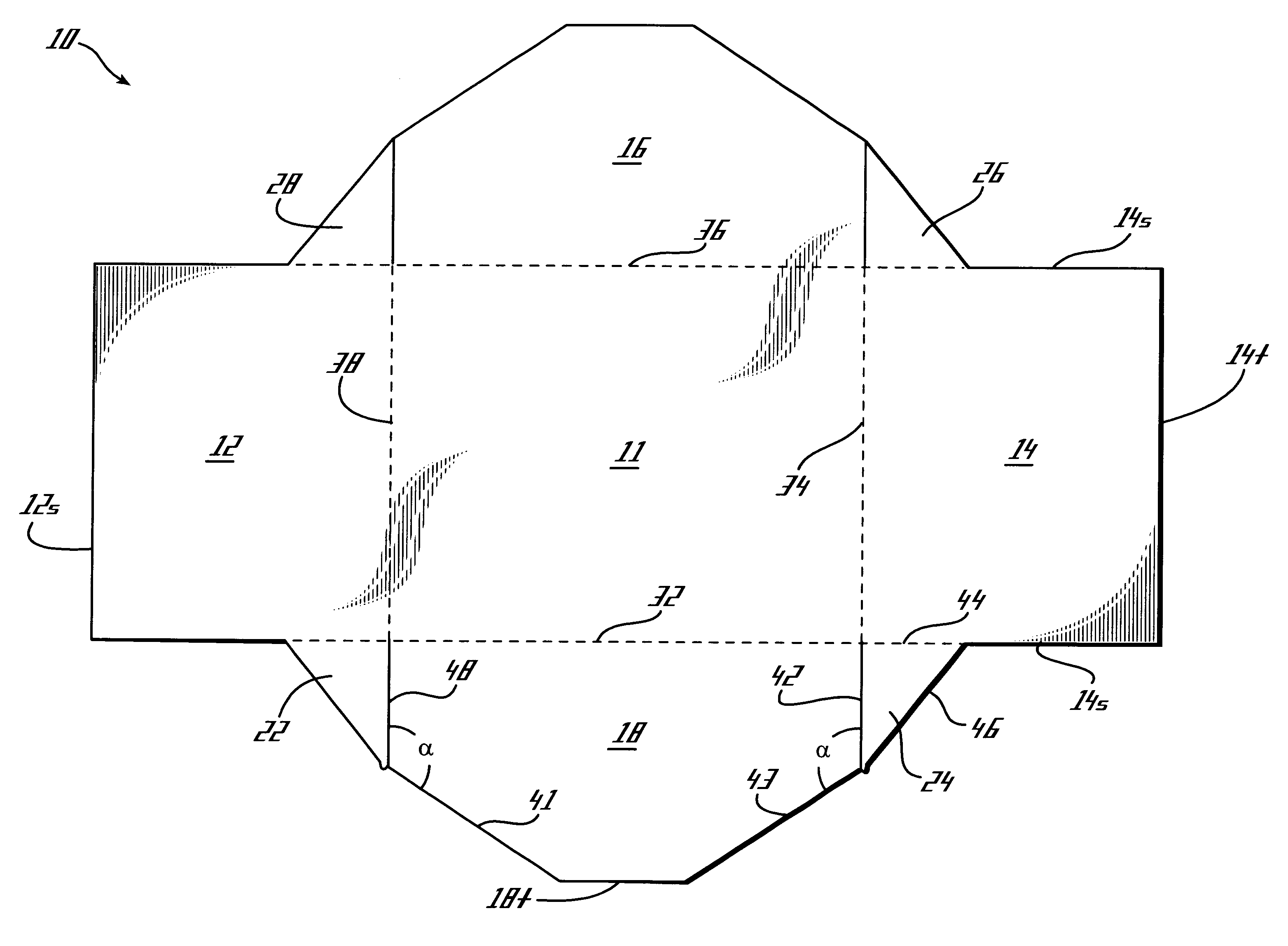

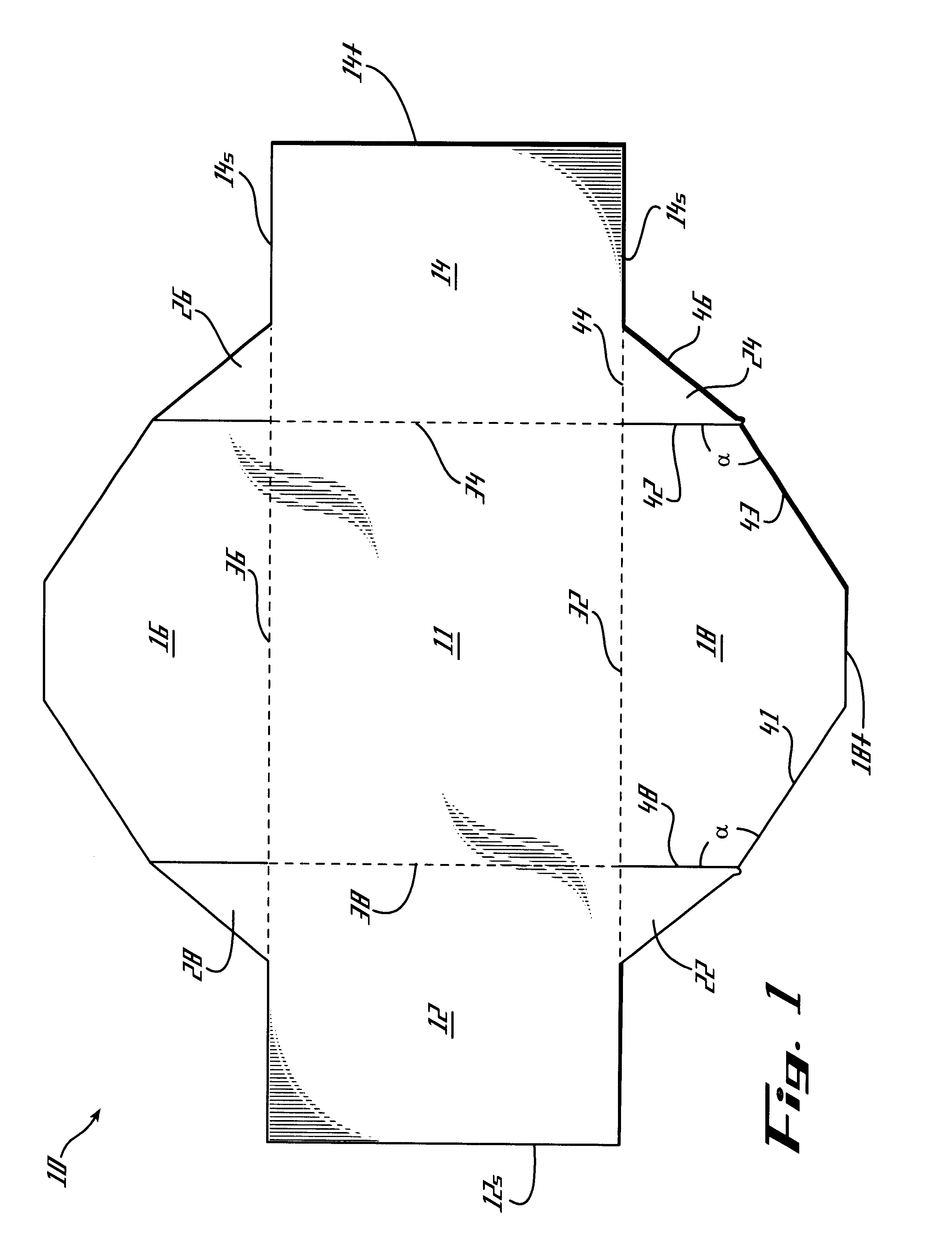

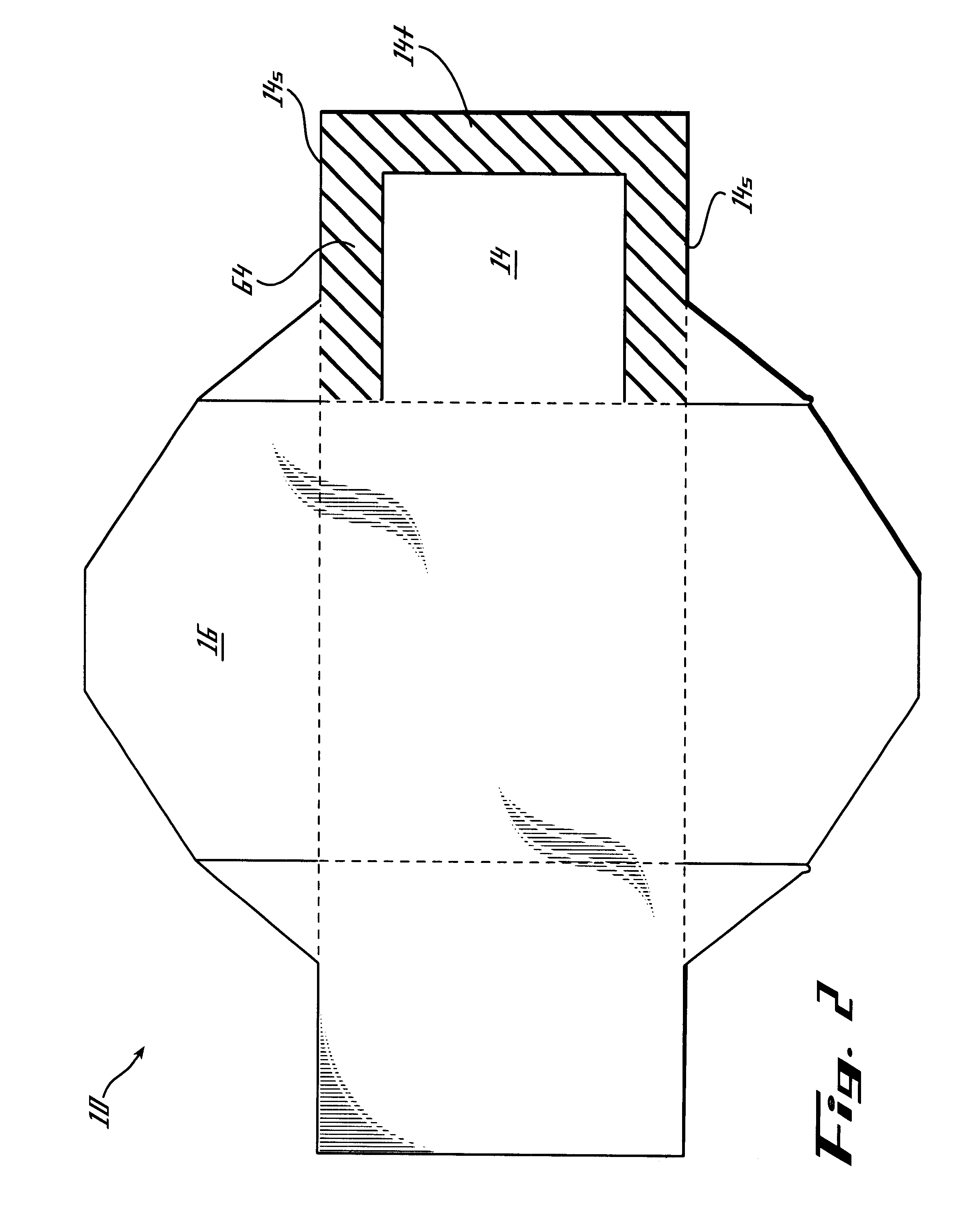

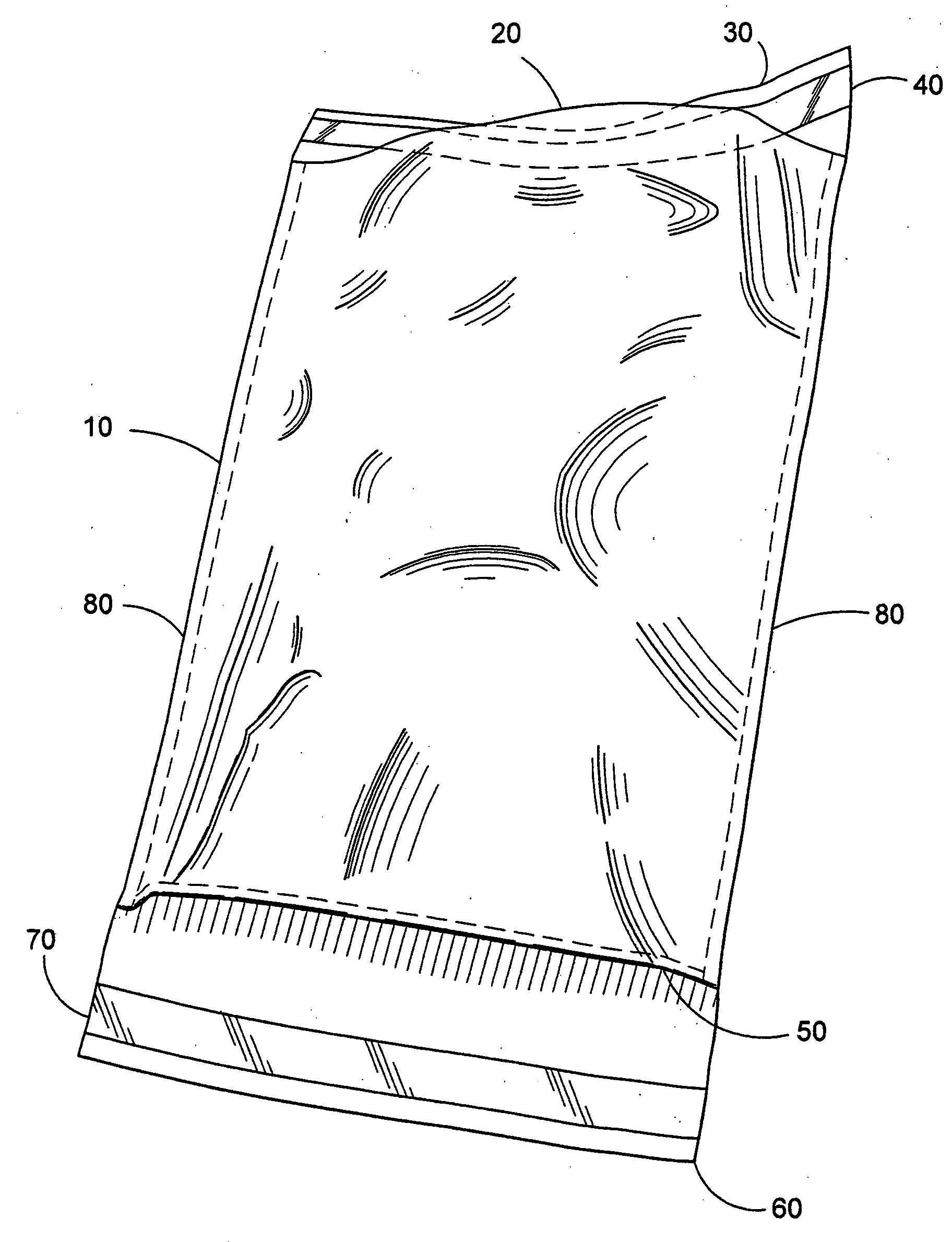

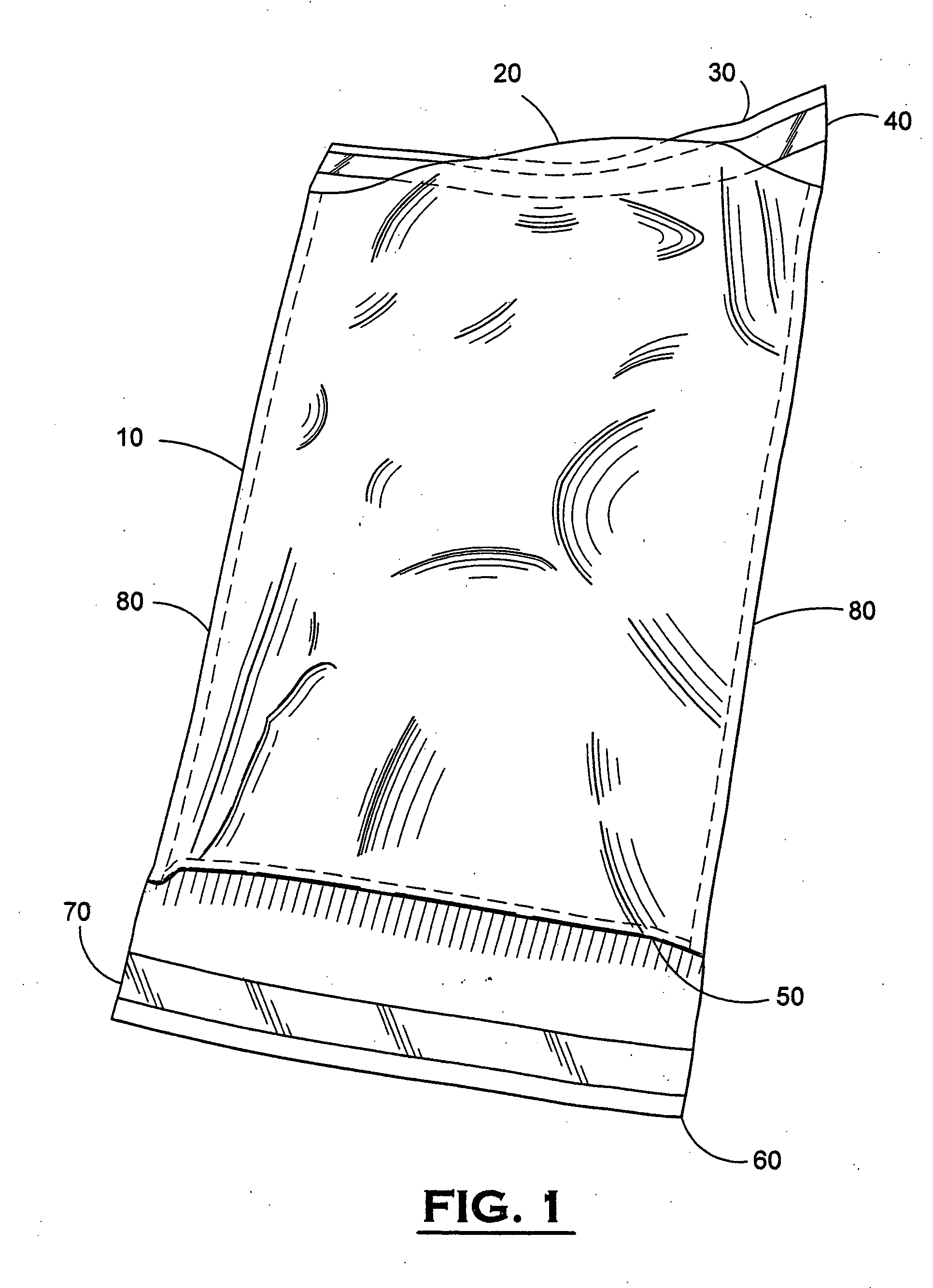

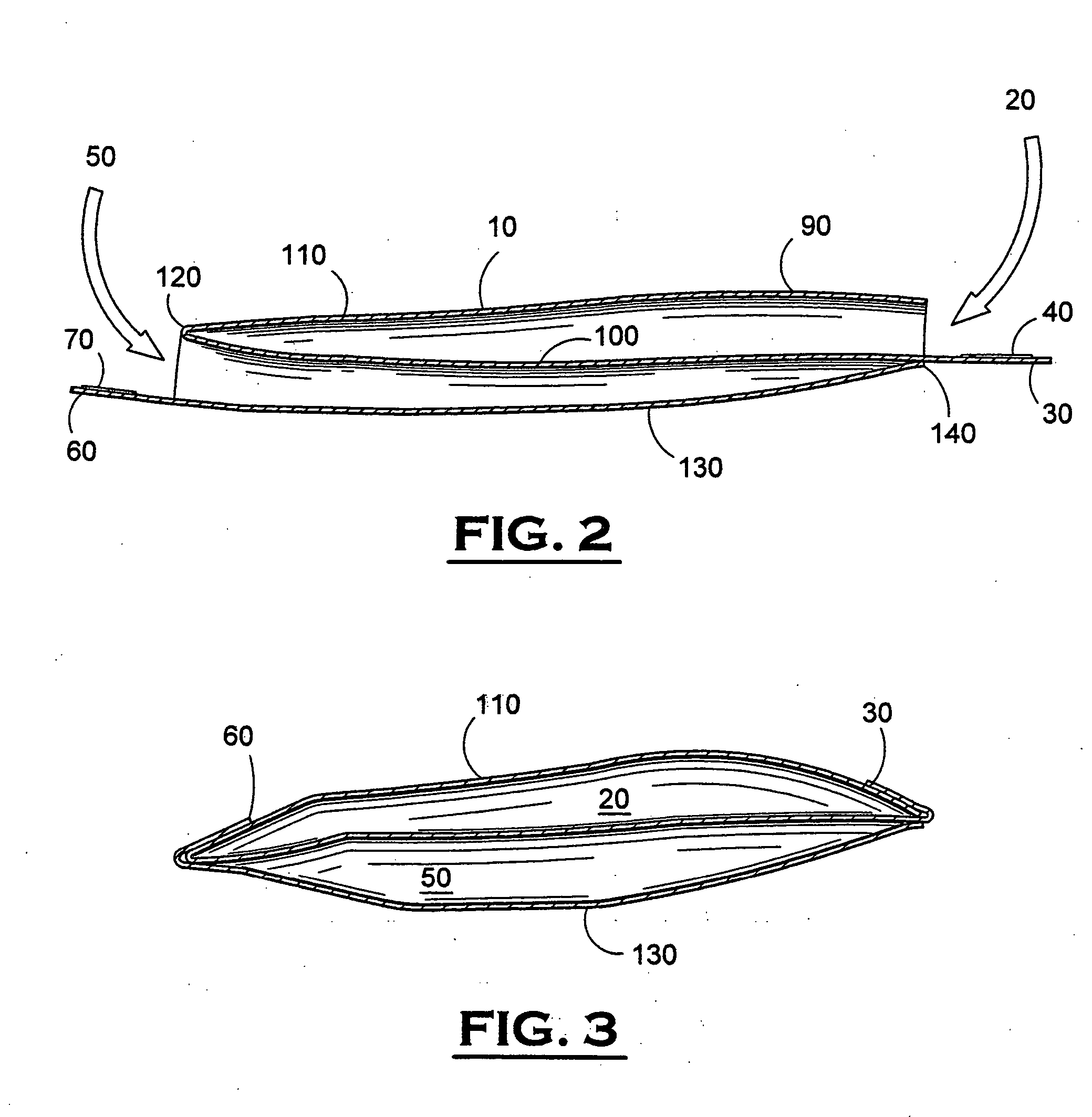

Gift wrap and method of wrapping

The present invention relates to pre-cut wrapping paper having peel-and-stick adhesive strips, which wrapping paper can be sized and cut to foldably wrap a variety of packages while limiting waste wrap. The paper can be used to cover and prepare boxed and unboxed items for presentation. The peel-and-stick adhesive strips secure the sheet to the gift, thus removing the need for a roll of tape.

Owner:SMITH LINDA A

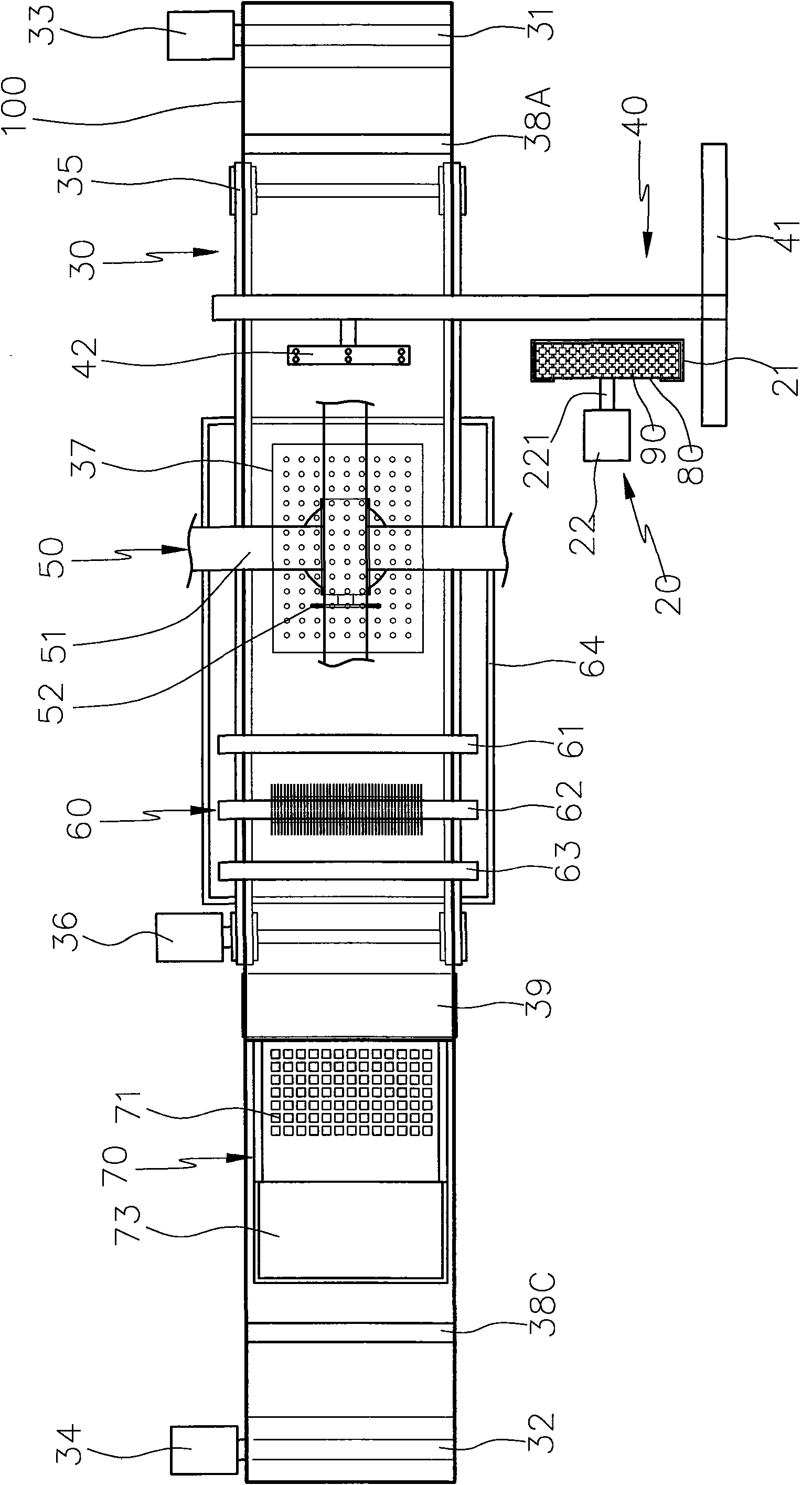

Electronic component cutting and stripping machine and method thereof

InactiveCN101901740AEasy to peelReduce processing timeSemiconductor/solid-state device manufacturingFine working devicesAdhesive beltAdhesion belt

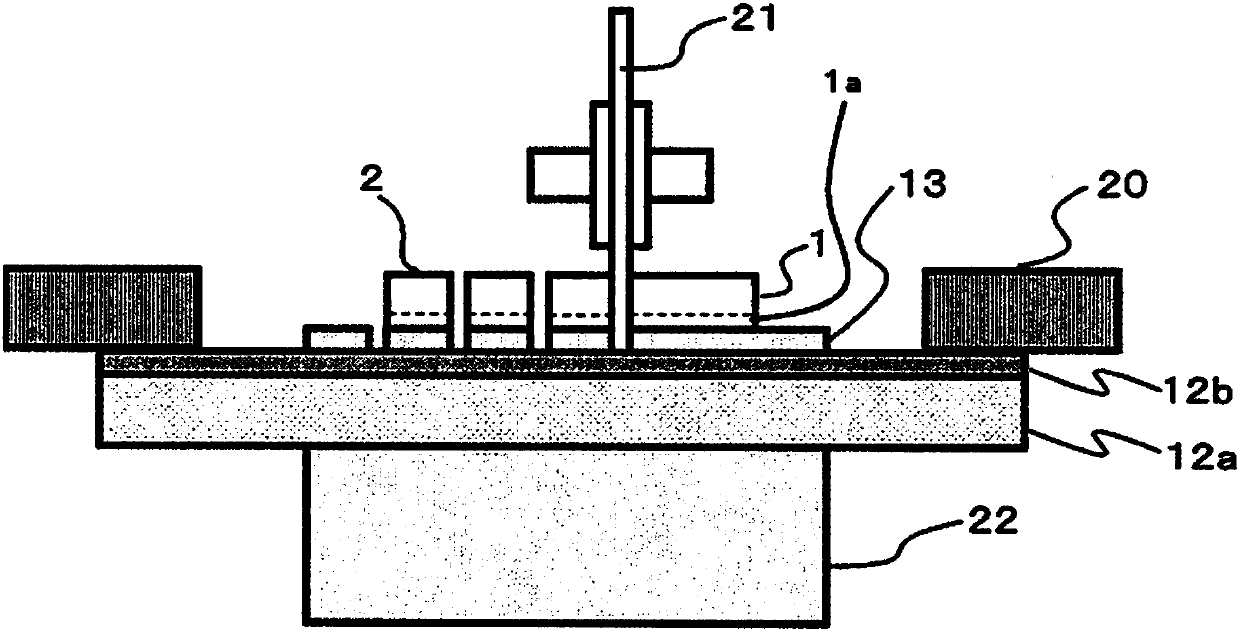

The invention provides an electronic component cutting and stripping machine and a method thereof. The electronic component cutting and stripping machine comprises a feeding device, a conveying device, a shifting device, a cutting device, a cleaning device and a receiving device; wherein the feeding device contains a plurality of lead frames provided with electronic components; the conveying device is provided with a conveying mechanism and a stripping platform provided with a bevel, and the conveying mechanism is used for conveying adhesive belts; the shifting device utilizes a picking and placing device to take out the lead frames provided with electronic components from the feeding device, the lead frames are shifted and adhered onto the adhesion belts on the conveying device, and then the adhesion belts and the lead frames are conveyed to the position below the cutting device; the cutting device utilizes a cutter to cut the lead frames on the adhesive belts, so as to obtain a plurality of independent electronic components, and the conveying mechanism conveys the independent electronic components and adhesive belts to the position below the cleaning device; and the cleaning device utilizes a cleaner to clean dust on the electronic components, then the conveying mechanism causes the adhesive belts to bend down along the bevel of the stripping platform, so as to strip the electronic components, and the electronic components are dropped into the receiving device to be received and contained.

Owner:PROV TECH CORP

Acrylic pressure-sensitive adhesive tape or sheet

InactiveUS20110076489A1High initial low-temperature adhesive strengthEnhanced inhibitory effectNon-macromolecular adhesive additivesSynthetic resin layered productsLow-density polyethylenePolymer science

Provided is an acrylic pressure-sensitive adhesive tape or sheet that shows high initial low-temperature adhesive strength, and is superior in suppression of the liner pop-off.The acrylic pressure-sensitive adhesive tape or sheet according to the present invention is characterized in that it is an acrylic pressure-sensitive adhesive tape or sheet having a pressure-sensitive adhesive layer and a release liner, in which: the pressure-sensitive adhesive layer is a bubble-mixed inorganic filler-containing acrylic pressure-sensitive adhesive layer containing an acrylic polymer formed from an acrylic monomer mixture containing an alkyl(meth)acrylate ester (a) having an alkyl group having a carbon number of 1 to 14 and a polar group-containing vinyl monomer (b), an inorganic filler, and bubbles; and the release liner is a release liner having a low-density polyethylene layer as one surface layer, a mixed resin layer containing a low-density polyethylene and a high-density polyethylene as resin components as the other surface layer, and additionally a high-density polyethylene layer as an intermediate layer.

Owner:NITTO DENKO CORP

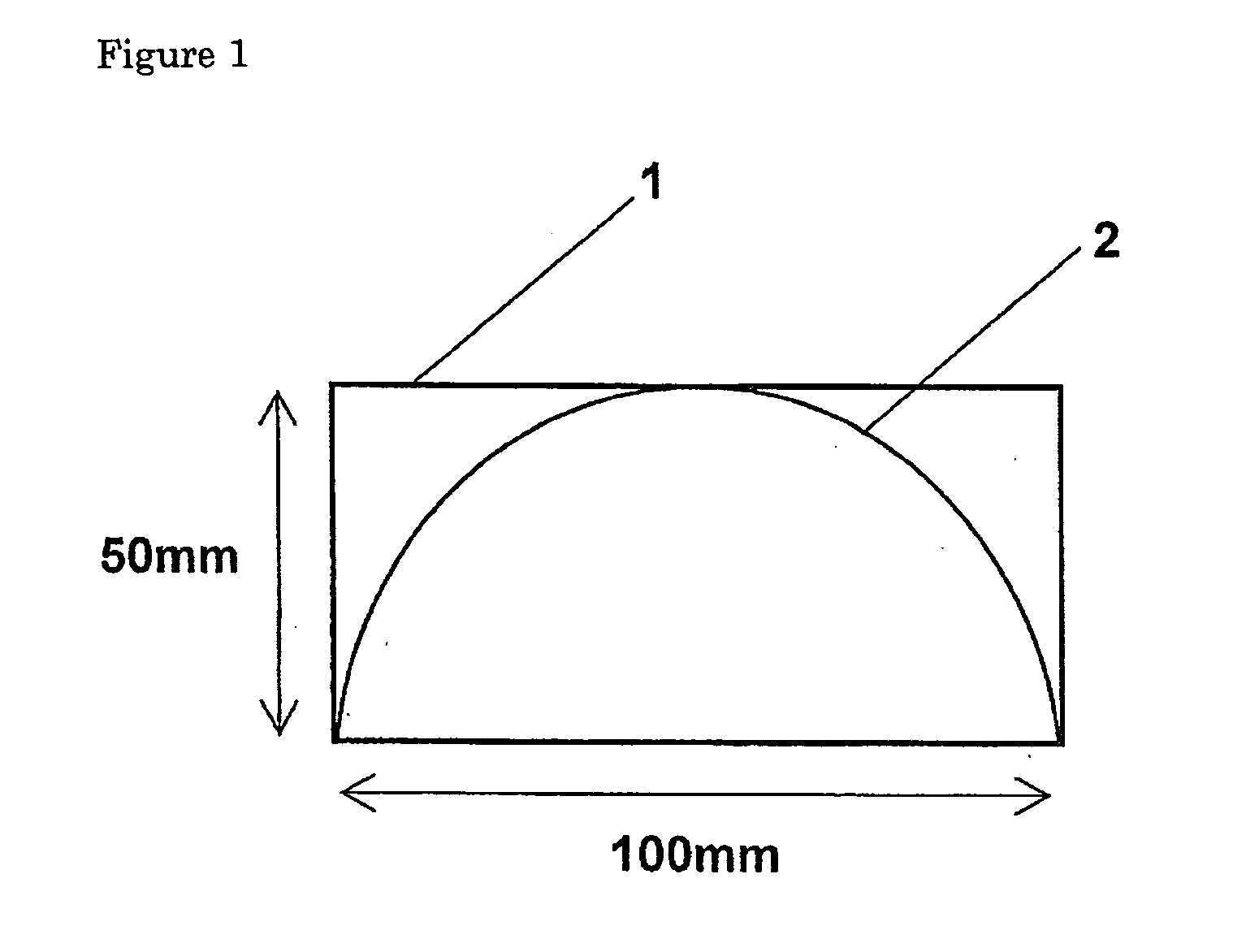

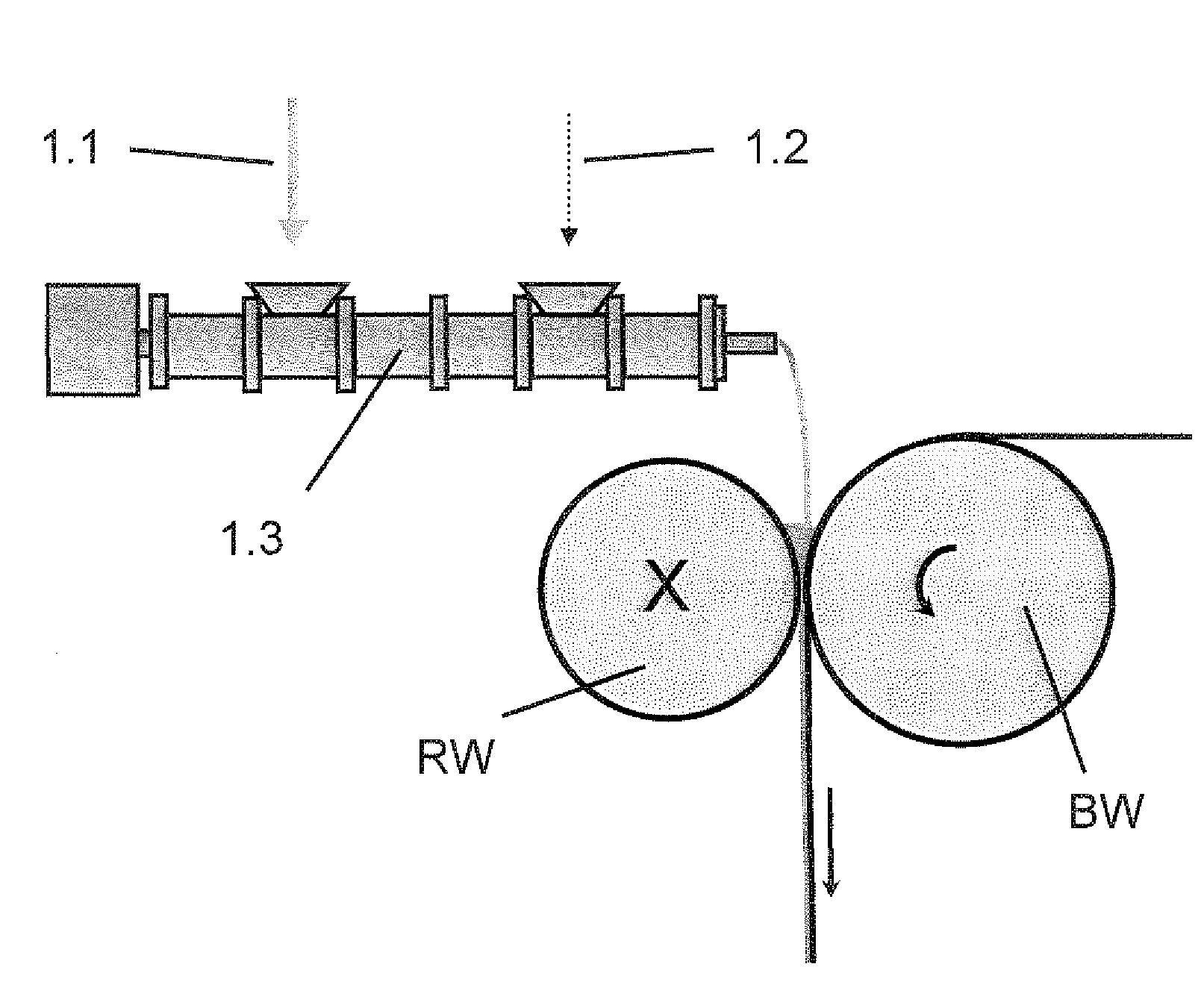

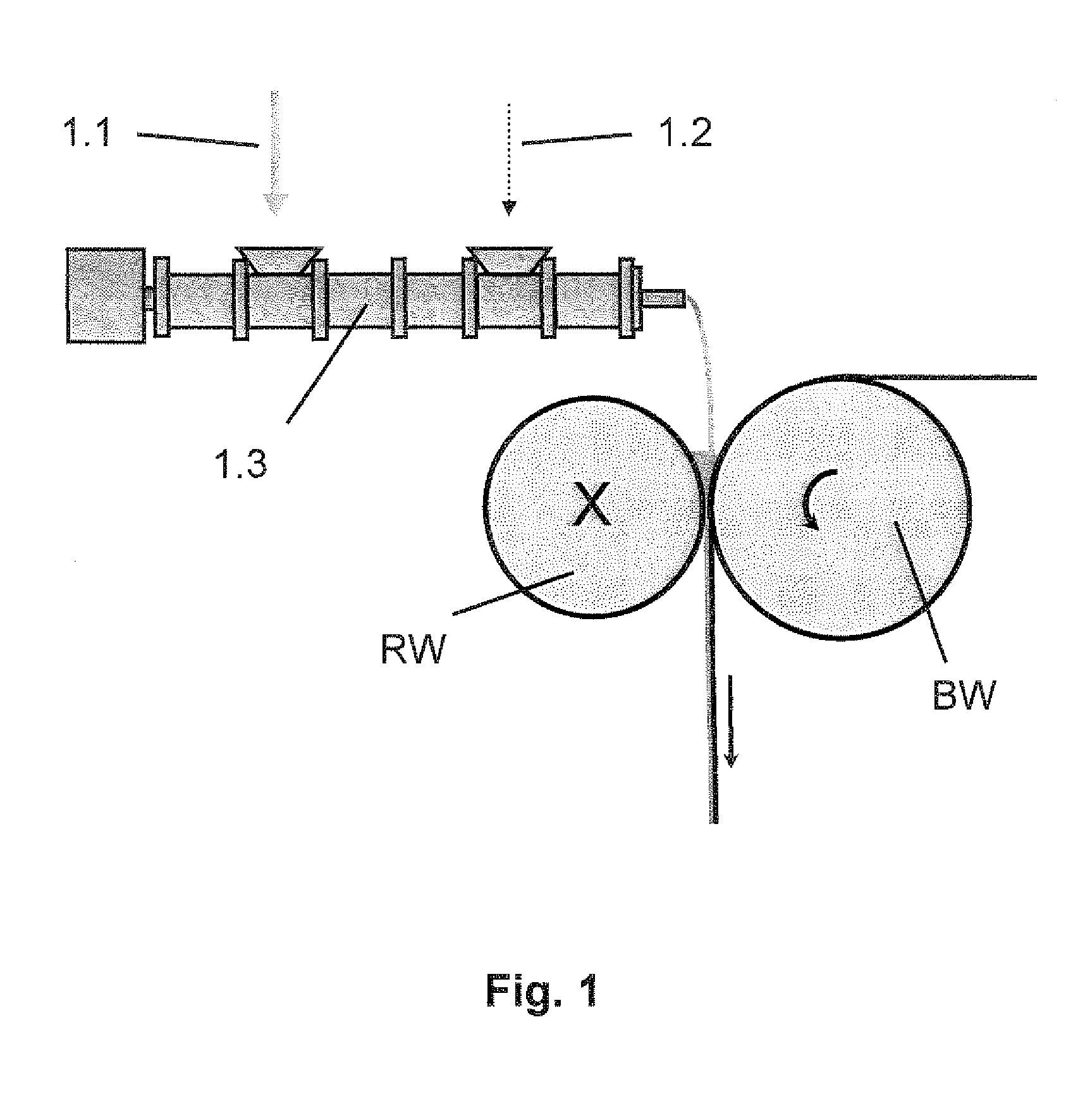

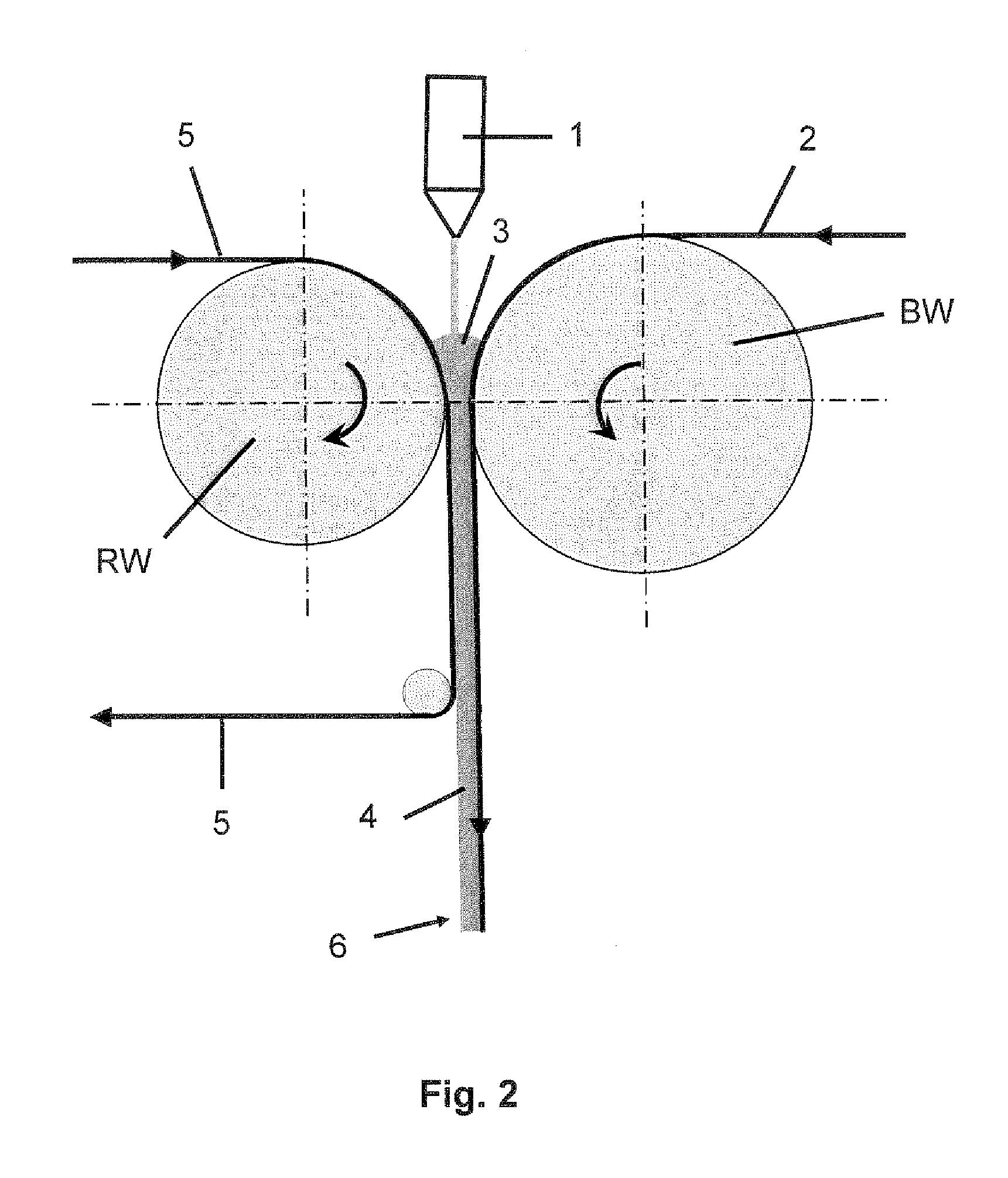

Method for producing an adhesive strip comprising a thermally cross-linked acrylate hot-melt adhesive layer

ActiveUS7910163B2Impair it propertyDiffusion transfer processesFilm/foil adhesivesMethacrylatePolymer science

A process for producing an adhesive tape with single- or double-sided crosslinked pressure-sensitive acrylate hotmelt adhesive layer, wherein a crosslinker is added in the melt to a polyacrylate copolymer (“polyacrylate”) based on acrylic and / or methacrylic esters, the polyacrylate with crosslinker is conveyed to a coating unit, where it is applied to a web-form layer and following application is homogeneously crosslinked, where the crosslinker is a thermal crosslinker and some of the acrylic and / or methacrylic esters contain primary hydroxyl groups and addition takes place preferably in an extruder.

Owner:TESA SE

Snap on envelope

InactiveUS20050141787A1Additional stability and protectionImprove sealingClosuresEnvelopesEngineeringFront panel

A resealable watertight mailing envelope has a Ziploc style strip for sealing the envelope closed. A flap portion is foldable over the Ziploc seal, secured in the closed position by a snap closure. The envelope also has an interior watertight lining joined with the Ziploc strip to seal the contents within from wetness or to prevent leakage of liquid items placed inside the envelope. In addition, a pair of adhesive strips can be attached to the inside of the flap portion for providing a water tight sealable closure of the envelope and also for alerting the individual that the envelope has been tampered with should the individual determine that the adhesive strips have been sundered from their engagement to the envelope's front panel.

Owner:BREIL GARY L JR

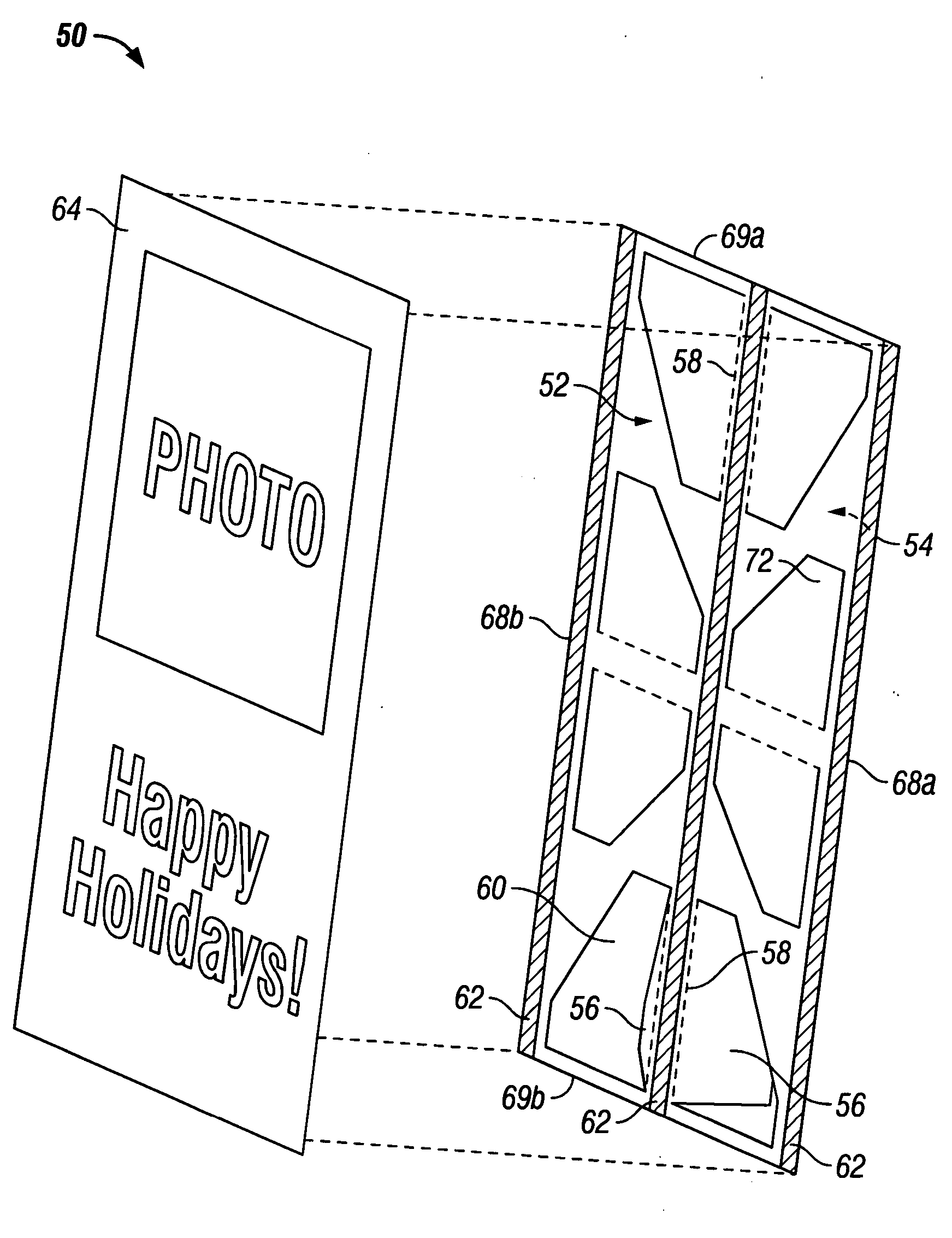

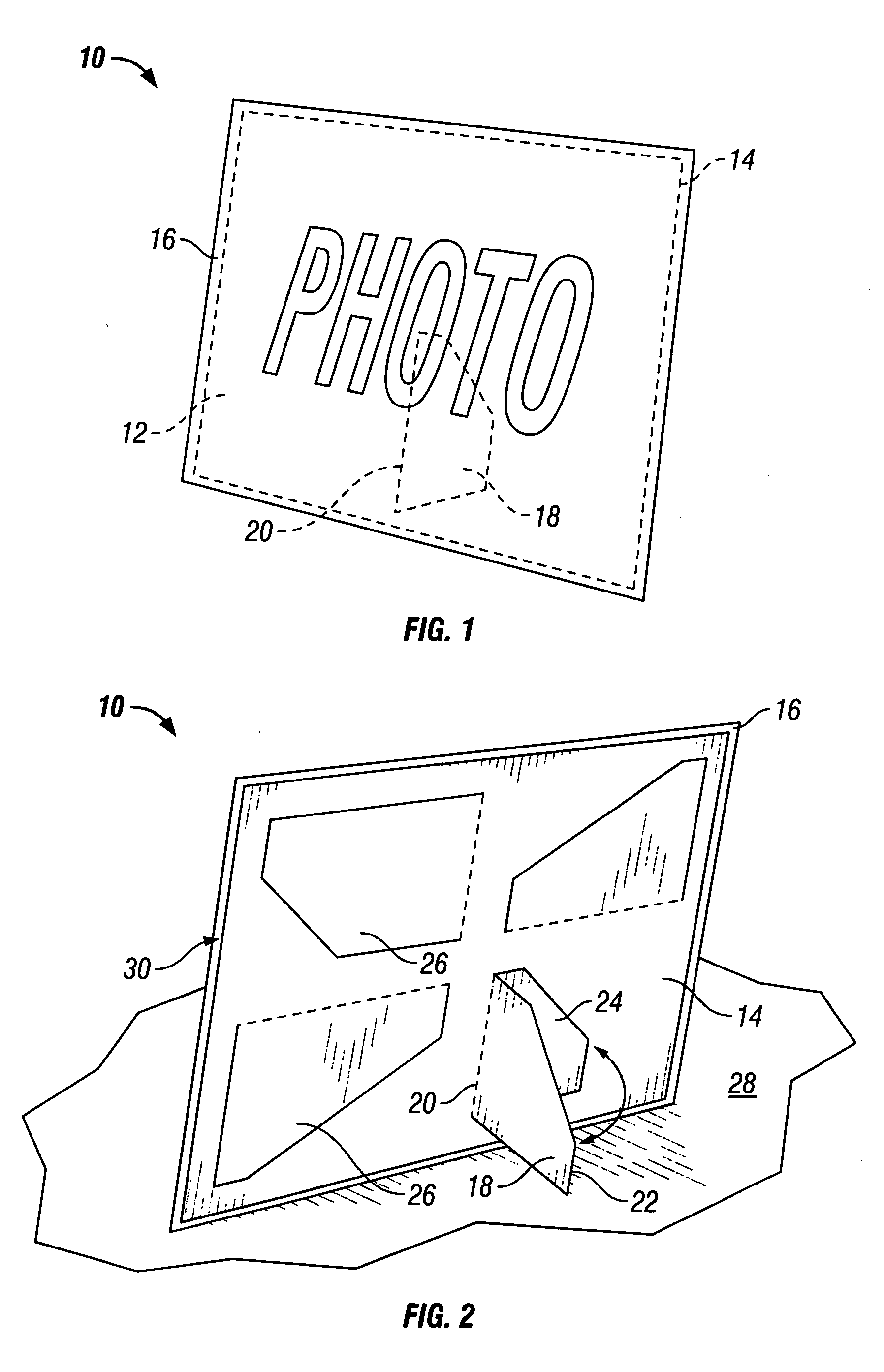

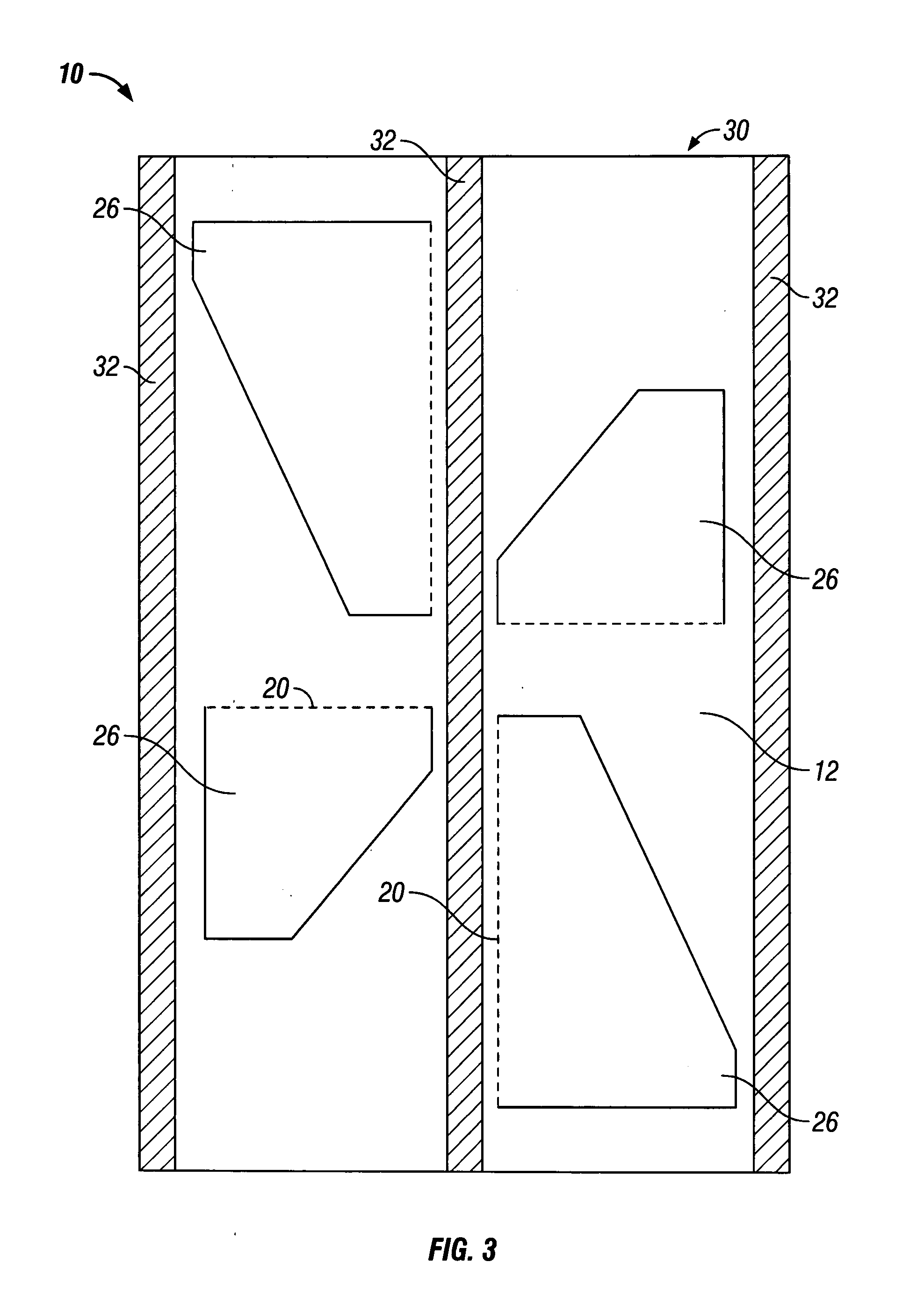

One-Piece Photograph Display Assembly and Methods of Use

A light-weight display easel assembly for use with photographs and photographic greeting cards is described, wherein the display device is a substantially planar sheet or panel of paperboard or similar cellulose-containing material having a plurality of die-cut flaps thereon, each of the die-cut flaps having one scored edge which allows for the outward folding of the flap. The display easel further comprises a plurality of adhesive strips on the front face of the paperboard, for attachment of a photograph or photographic greeting card thereto. The display easel, once assembled, is lightweight enough such that it can be mailed without the need for excess postage fees. Additionally, due to the attachment of the display easel to substantially the entire back face of a photograph, the entire photograph is fully supported and is therefore resistant to creases, indentations, warping, and other damages which can occur during the mailing process.

Owner:COLE & ASHCROFT

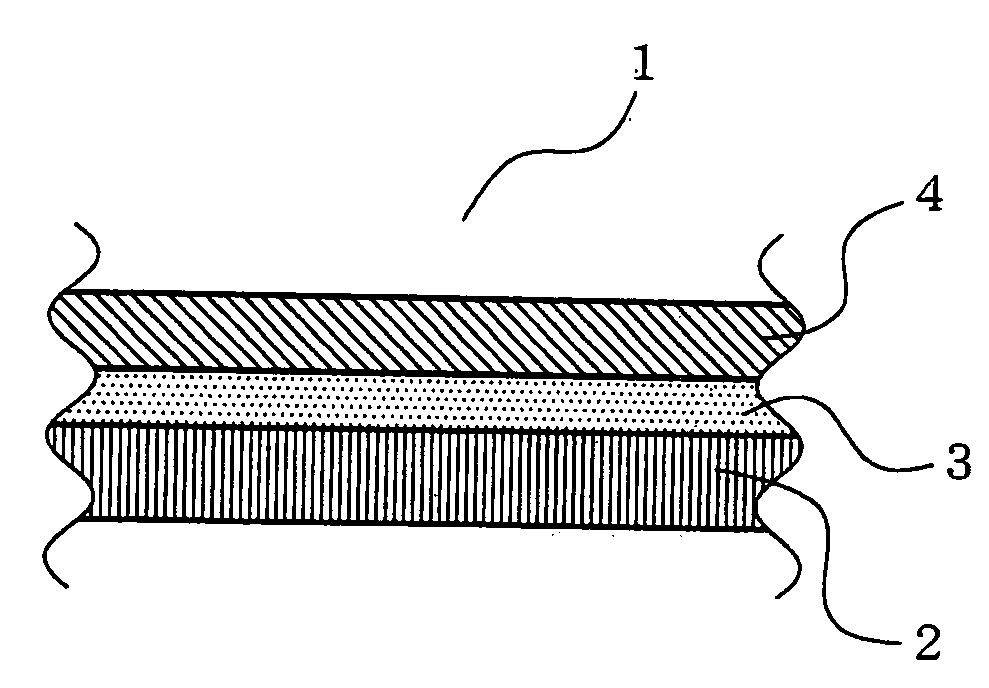

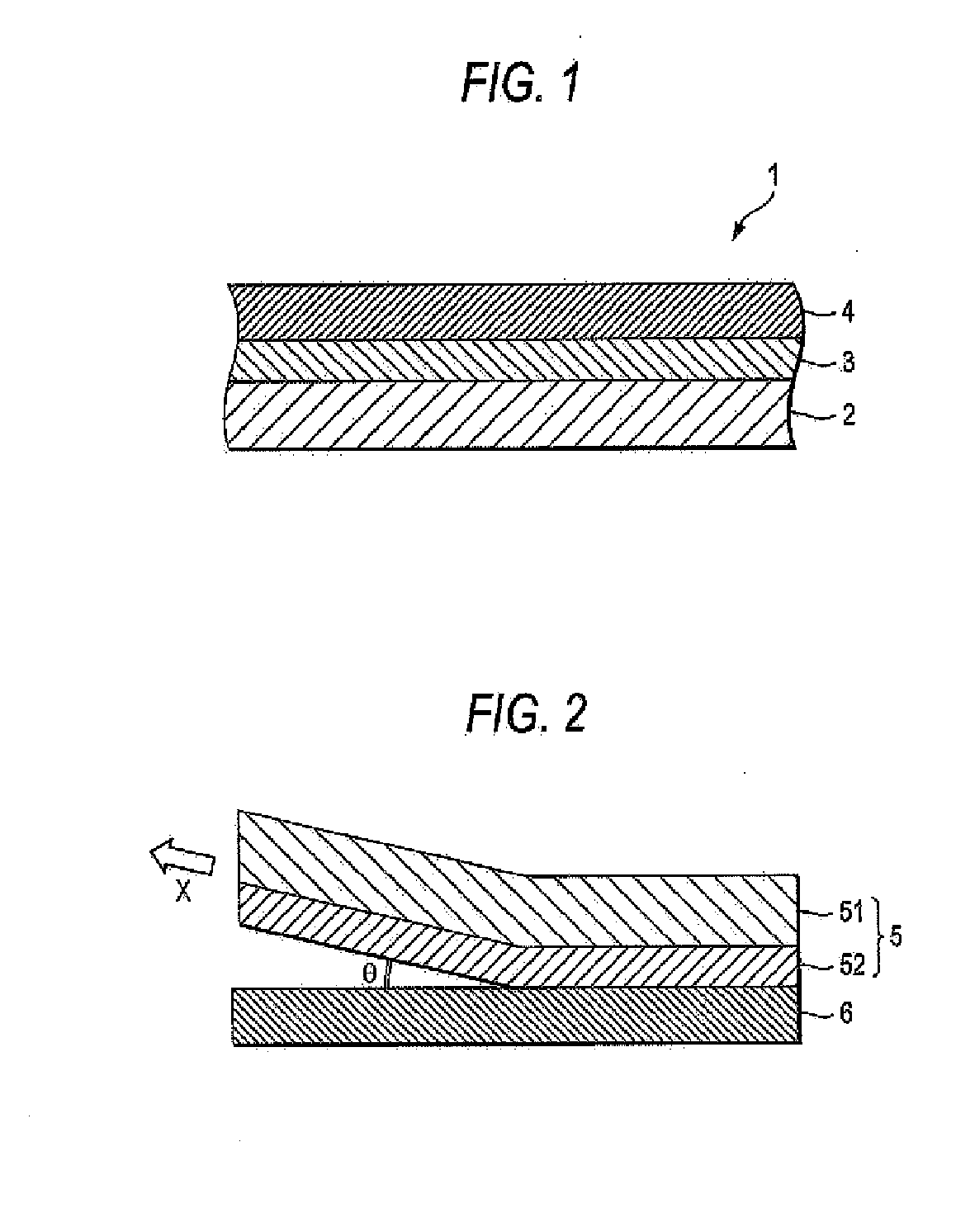

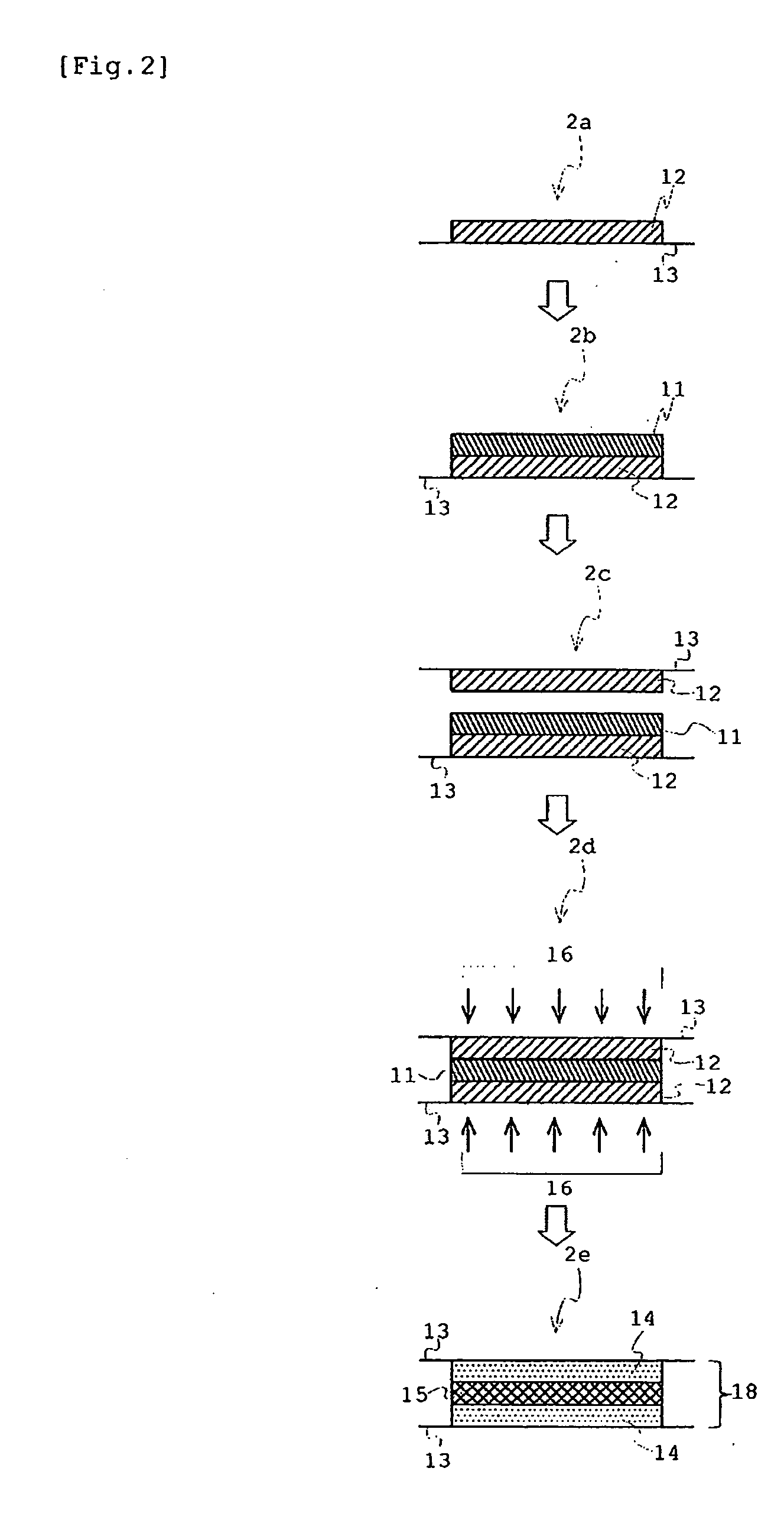

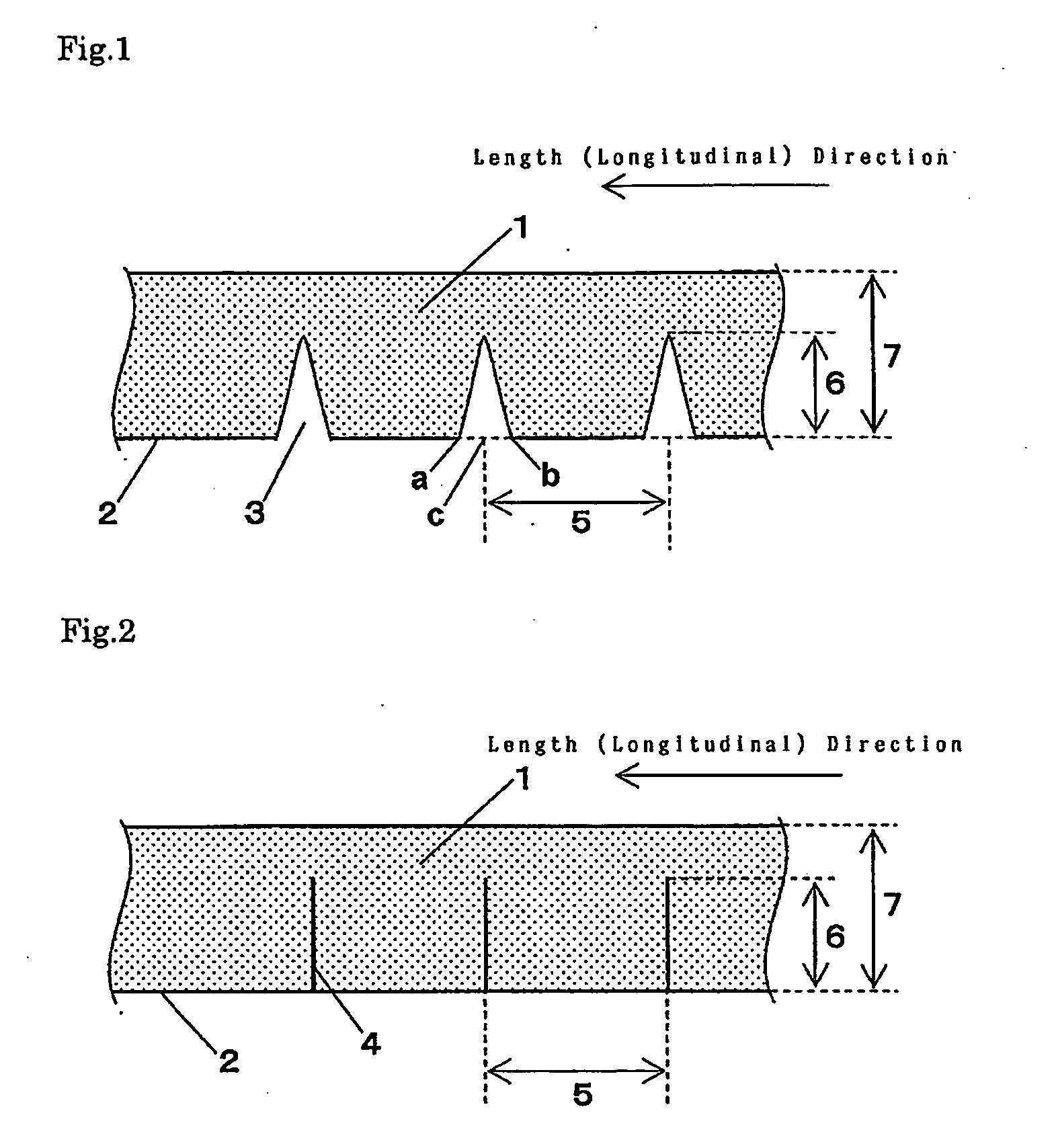

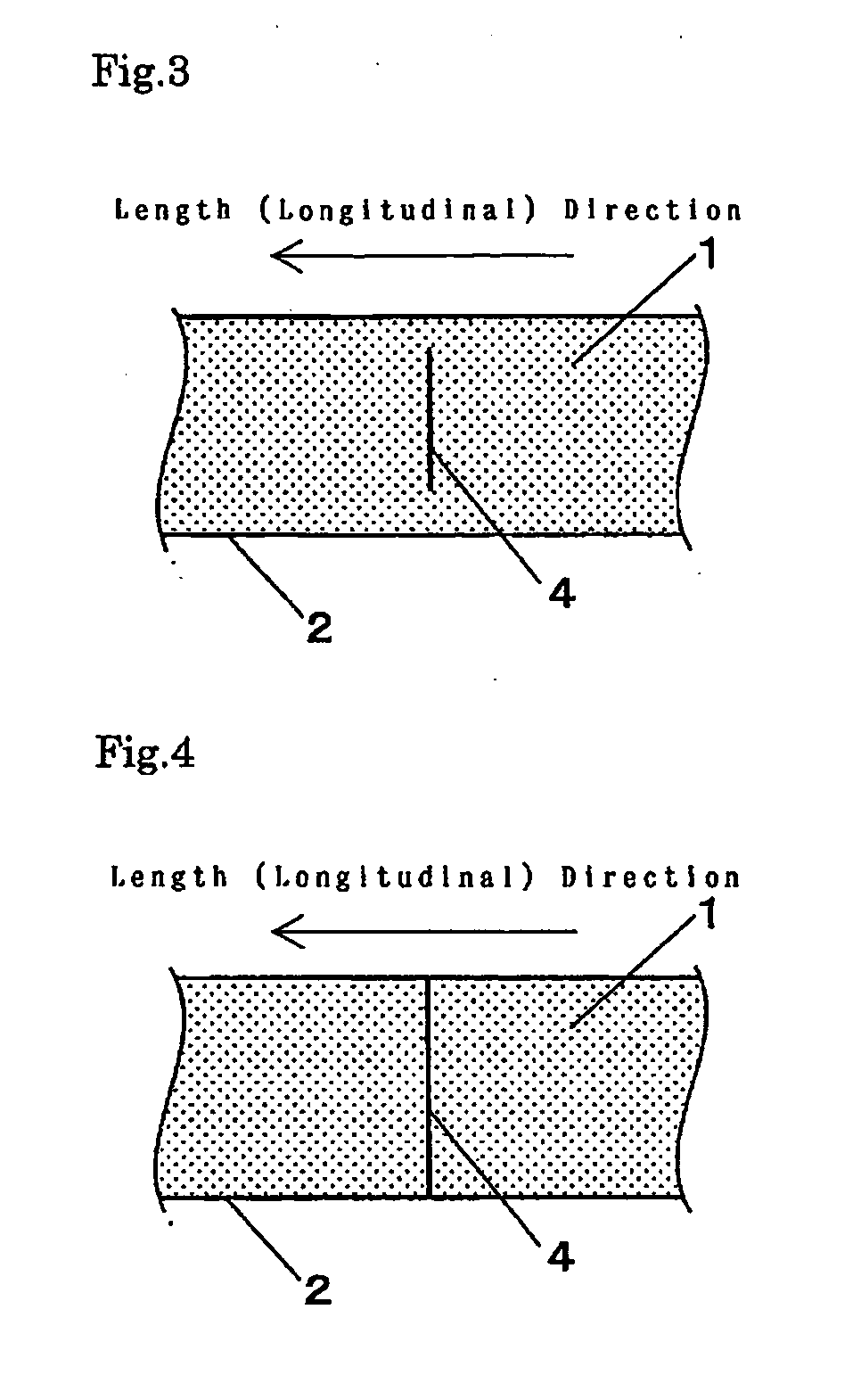

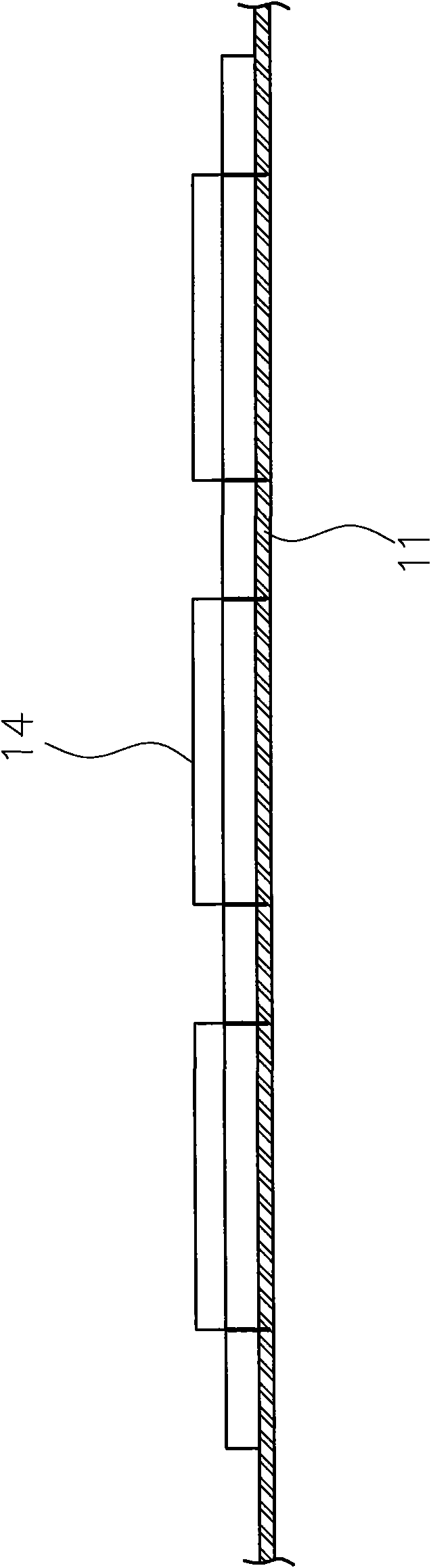

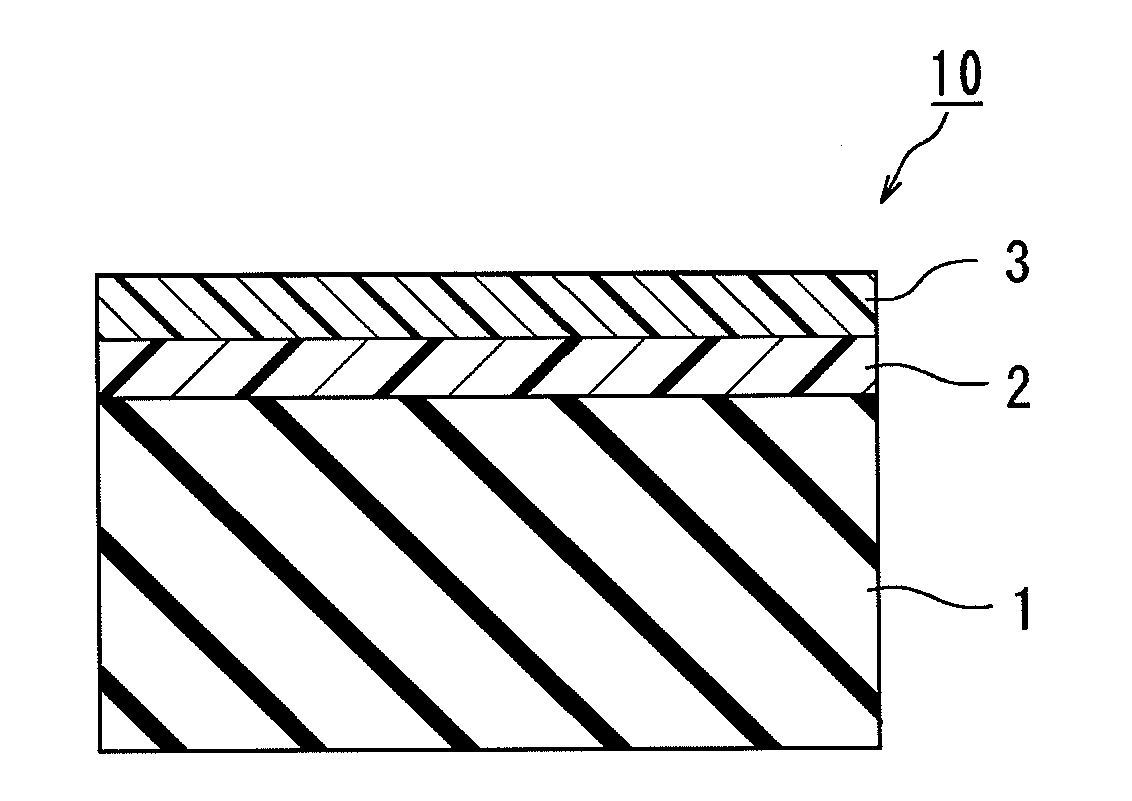

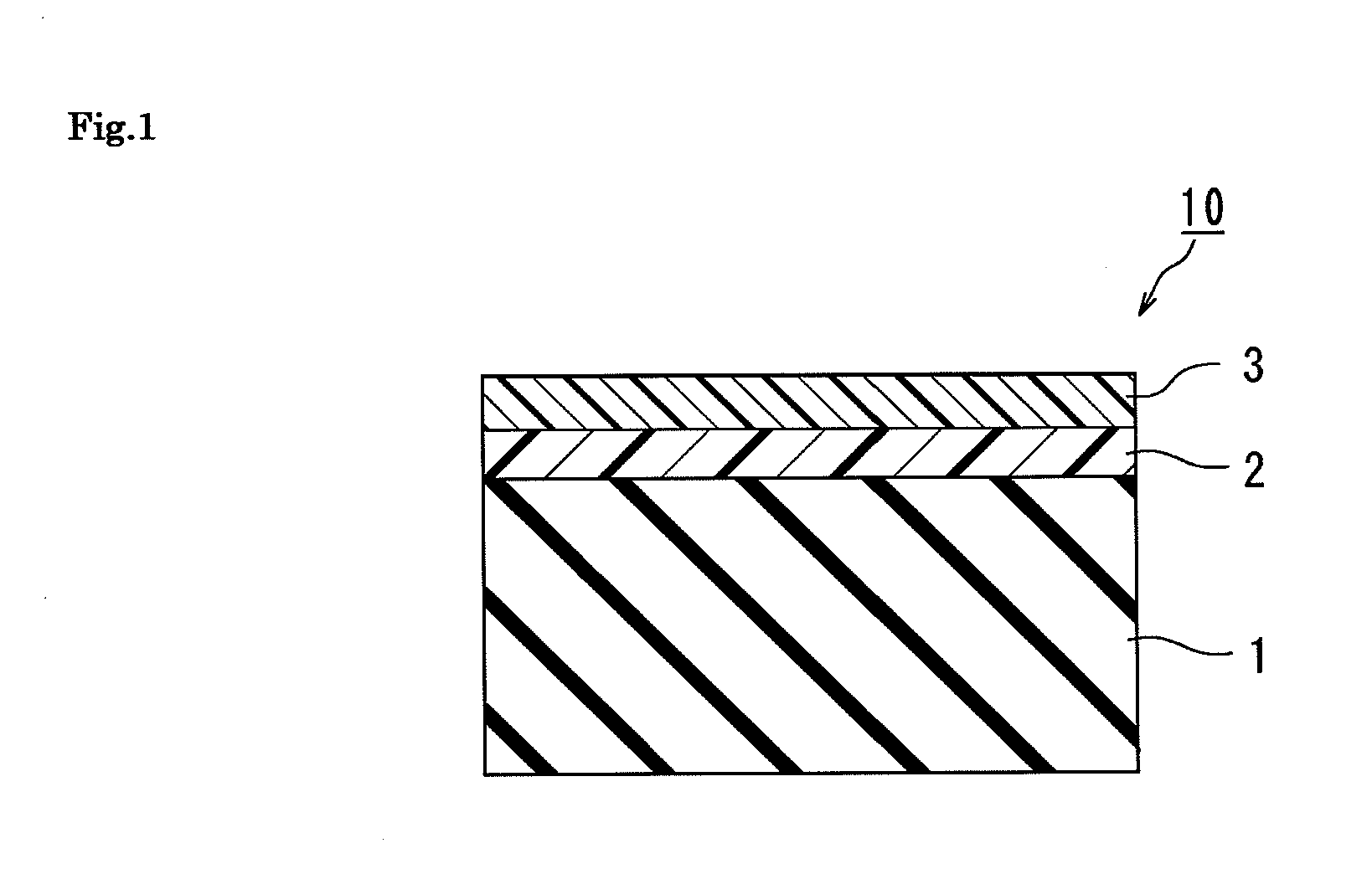

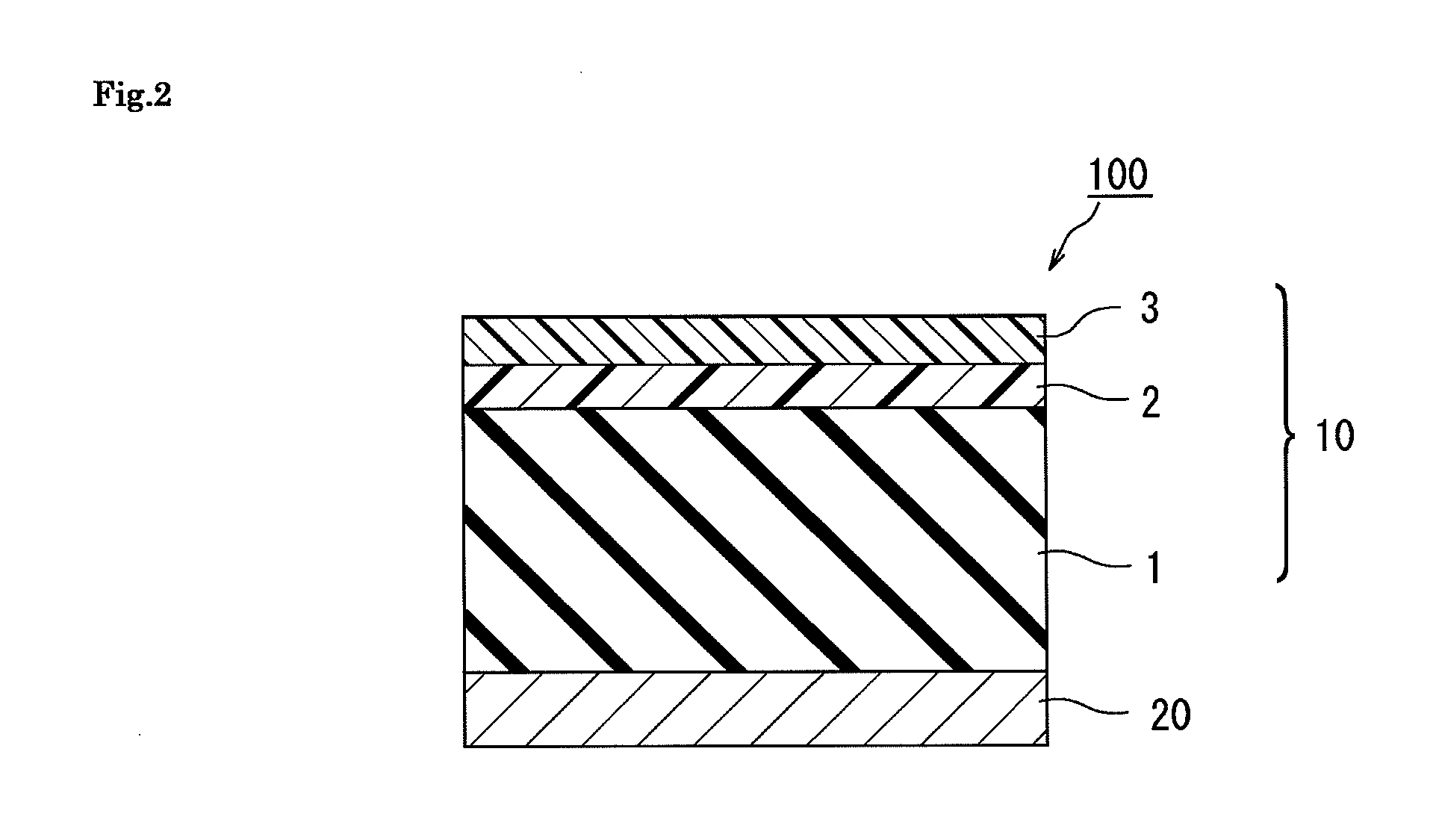

Laminated film and pressure-sensitive adhesive tape

InactiveUS20110033662A1Low propertyLarge surface roughnessFilm/foil adhesivesAdhesive articlesForeign matterThermoplastic elastomer

Provided are a laminated film and a pressure-sensitive adhesive tape each of which is adjusted so as to be capable of achieving compatibility between low haze property excellent in transparency and such large surface roughness that foreign matter such as a fish eye is hardly observed without fluctuations in mechanical properties of the entire laminated film or pressure-sensitive adhesive tape. Also provided is such a pressure-sensitive adhesive tape as described below capable of protecting the uneven surface of a member having unevenness on its surface. The pressure-sensitive adhesive tape brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the member. In addition, even upon deformation of the member protected with the pressure-sensitive adhesive tape by, for example, lamination or continuous winding, the uneven shape does not deform and a base material layer in the pressure-sensitive adhesive tape is not damaged, and further, the pressure-sensitive adhesive tape is adjusted so as to be capable of achieving compatibility between low haze property excellent in transparency and such large surface roughness that foreign matter such as a fish eye is hardly observed without fluctuations in mechanical properties of the entire pressure-sensitive adhesive tape. Also provided is such a pressure-sensitive adhesive tape as described below. When a prism sheet having multiple triangle pole-shaped prisms fixed on its surface is used as the above-mentioned member having unevenness on its surface, the pressure-sensitive adhesive tape functions as a surface protective film capable of effectively protecting a lens surface, and brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the prism sheet. In addition, when the prism sheet protected with the pressure-sensitive adhesive tape is brought into a state such as a laminated state or a continuously wound state, the emergence of irregularity (indentation) in the external appearance of the prism sheet to which the pressure-sensitive adhesive tape is attached can be suppressed. A laminated film of the present invention is a laminated film including a base material layer, a roughness-expressing layer, and a fine unevenness-erasing layer in the stated order, in which: the base material layer contains a thermoplastic resin; the roughness-expressing layer contains at least one kind of a resin component (A) selected from polyethylenes, ethylene-vinyl acetate copolymers, propylene-based polymers, and olefin-based thermoplastic elastomers; the fine unevenness-erasing layer contains a thermoplastic resin (B); an arithmetic average surface roughness Ra on the surface on the side of the fine unevenness-erasing layer is 1.0 μm to 3.0 μm; and the haze value of the laminated film is 30% or less.

Owner:NITTO DENKO CORP

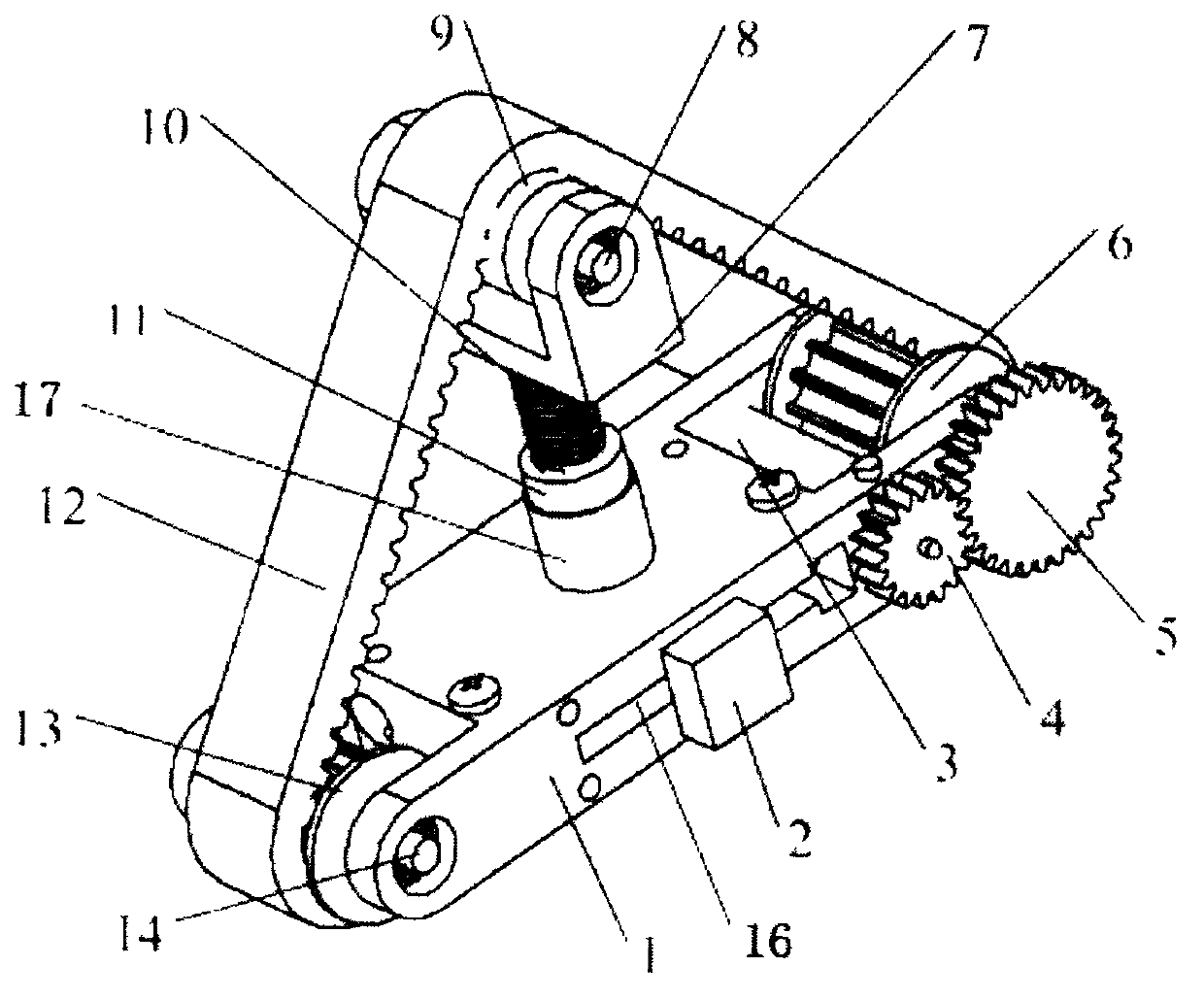

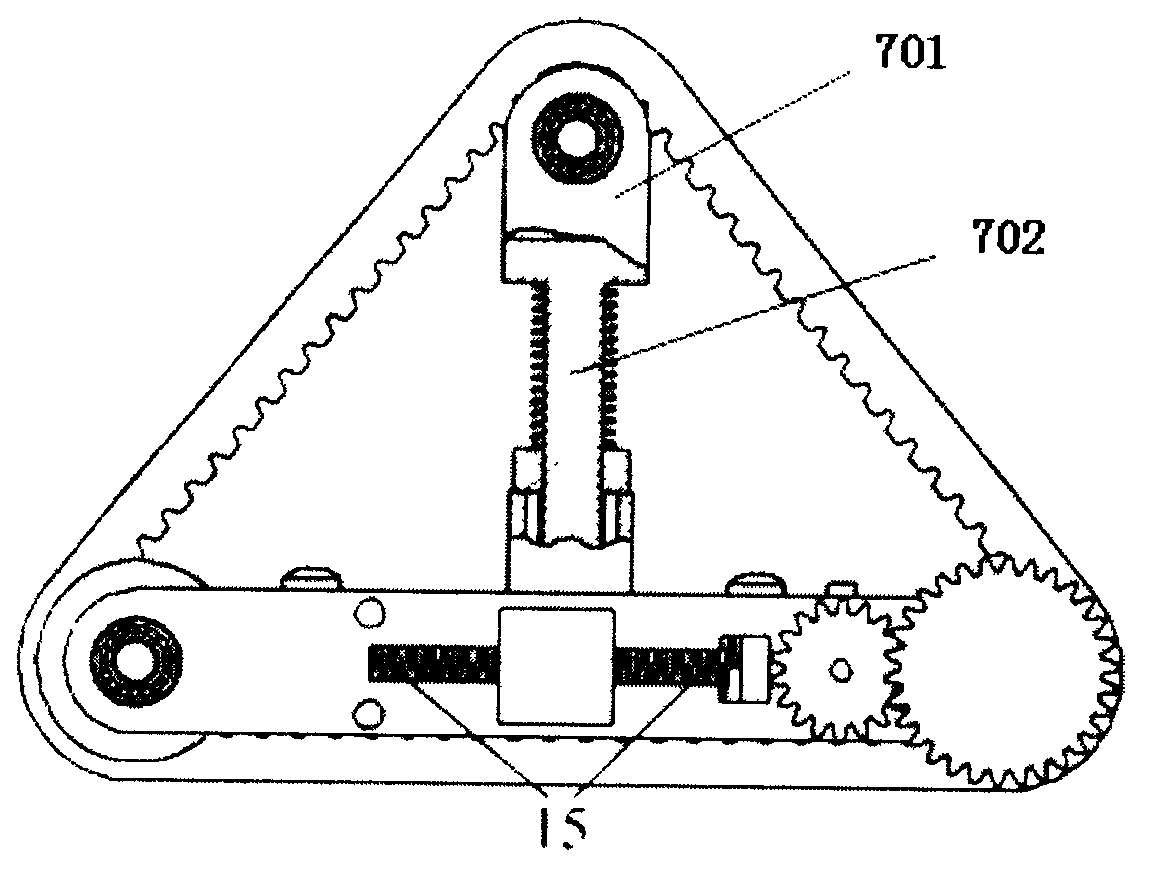

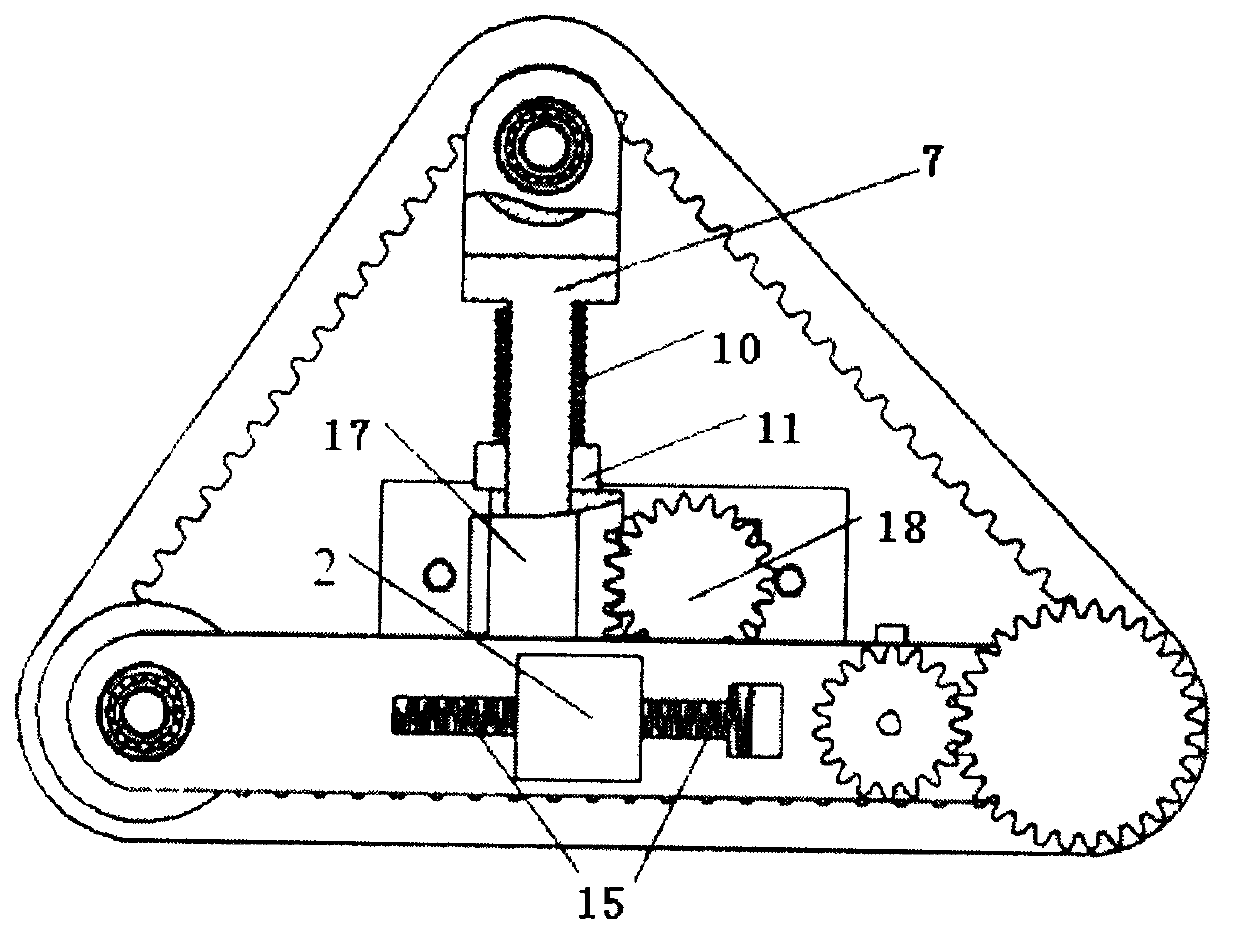

Bionic crawler-type adhesion walking mechanism and moving method thereof

The invention discloses a bionic crawler-type adhesion walking mechanism and a moving method thereof. The bionic crawler-type adhesion walking mechanism comprises a machine frame, a tensioning mechanism, a driving mechanism and an adhesion belt, wherein the driving mechanism comprises a driving motor, a driving motor gear, a driving wheel and a driven wheel; the driving wheel is connected with one end of the machine frame through a gear shaft; the driven wheel is connected with the other end of the machine frame through a driven wheel shaft; the driving motor gear is driven by the driving motor; the driving motor gear is meshed with the gear shaft; the tensioning mechanism comprises a tensioning wheel frame, a tensioning spring, a miniature force sensor, a tensioning wheel and a sleeve; the tensioning wheel, the driving wheel and the driven wheel are connected through the adhesion belt; the tensioning mechanism further comprises a mechanism connecting device arranged on the machine frame. A certain tangential displacement and a posture angle are outputted by a robot body, so that the adhesion, detachment and pressing of soles are realized and the walking and halting of a robot on a wall are assisted.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Conductive composition

InactiveCN107710336ALow priceReduce loadNon-macromolecular adhesive additivesSolid-state devicesConductive pasteHeat resistance

The purpose of the present invention is to provide a means which exhibits excellent heat resistance and mounting reliability when a semiconductor power element is bonded to a metal lead frame, and which is free from lead, thereby placing little burden on the environment. Namely, a conductive composition that contains, as essential components, at least a sulfide compound represented by R-S-R' (wherein R is an organic group containing at least carbon; R' is an organic group that is the same as or different from the R moiety; and the R and R' moieties may combine with each other to form a so-called cyclic sulfide) and metal particles containing at least Cu, Sn or Ni. A conductive paste and a conductive bonding film, each of which is produced using this conductive composition; and a dicing diebonding film which is obtained by bonding the conductive bonding film and an adhesive tape.

Owner:FURUKAWA ELECTRIC CO LTD

Ultraviolet-cured pressure-sensitive adhesive tape or film without supporting substrate

InactiveCN101163768ANon-pressure sensitive adhesivePrevent adhesionPolyureas/polyurethane adhesivesAbsorbent padsPolymer scienceOligomer

A pressure-sensitive adhesive tape or film obtained by curing a UV-curable pressure-sensitive adhesive composition containing a UV-curable polymer or oligomer, wherein the UV curing is controlled to give a higher degree of cure to one surface of the pressure-sensitive adhesive tape or film than that on the opposite surface and thereby the pressure-sensitive adhesive property is suppressed on the one surface and maintained on the opposite surface.

Owner:3M INNOVATIVE PROPERTIES CO

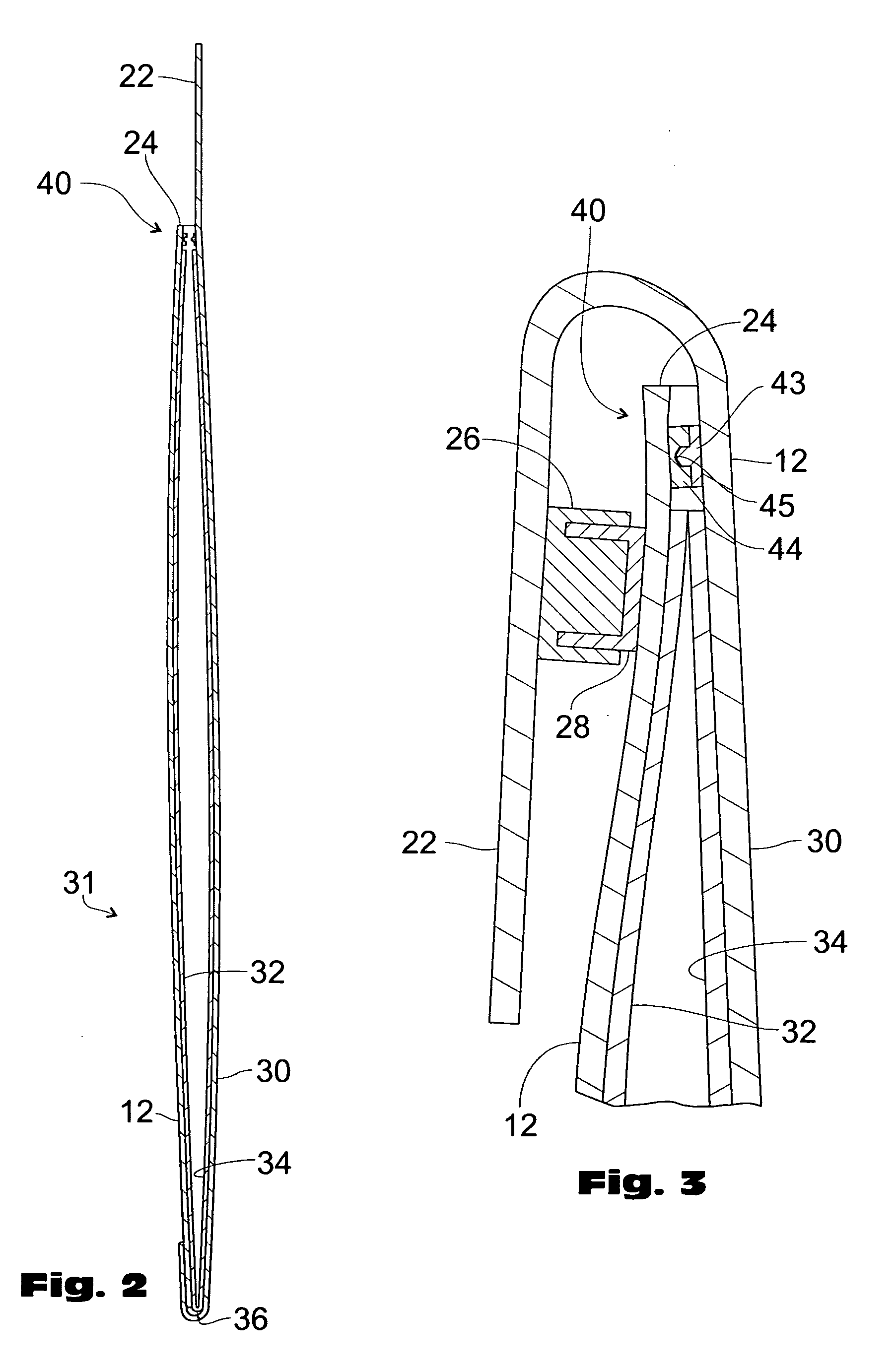

Device for removing a broken light bulb from a socket

A device for removing a hollow base of a broken light bulb utilizing a member terminating in an end surface which is capable of extending into the hollow base of a bulb. The member also includes a portion capable of receiving an applied torsional force. An adhesive band is fixed to the outer surface of the member. The adhesive band bonds with the hollow base of the broken light bulb to permit removal of the same via the torsional force.

Owner:RAININ EDGAR A +1

Dual compartment bag

A dual compartment bag is disclosed. The bag has a central panel with the two compartments being located on opposing sides of the central panel. The two other panels are positioned flat on opposing sides of the central panel, and fixed to the central panel around the perimeter of the panels. One edge of the perimeter of the central panel and a first of the other panels is not closed and another edge of the perimeter of the central panel and the second of the other panels is not closed. These unclosed edges provide access to the spaces between the central panel and the other panels in a preferred embodiment and these openings are located at opposing ends from each other around the perimeter of the bag. One of the edges at each opening may have a flap extending from the edge. The flap may have an adhesive strip for holding the flap closed and sealing the compartment.

Owner:ZIMMERMAN HARRY

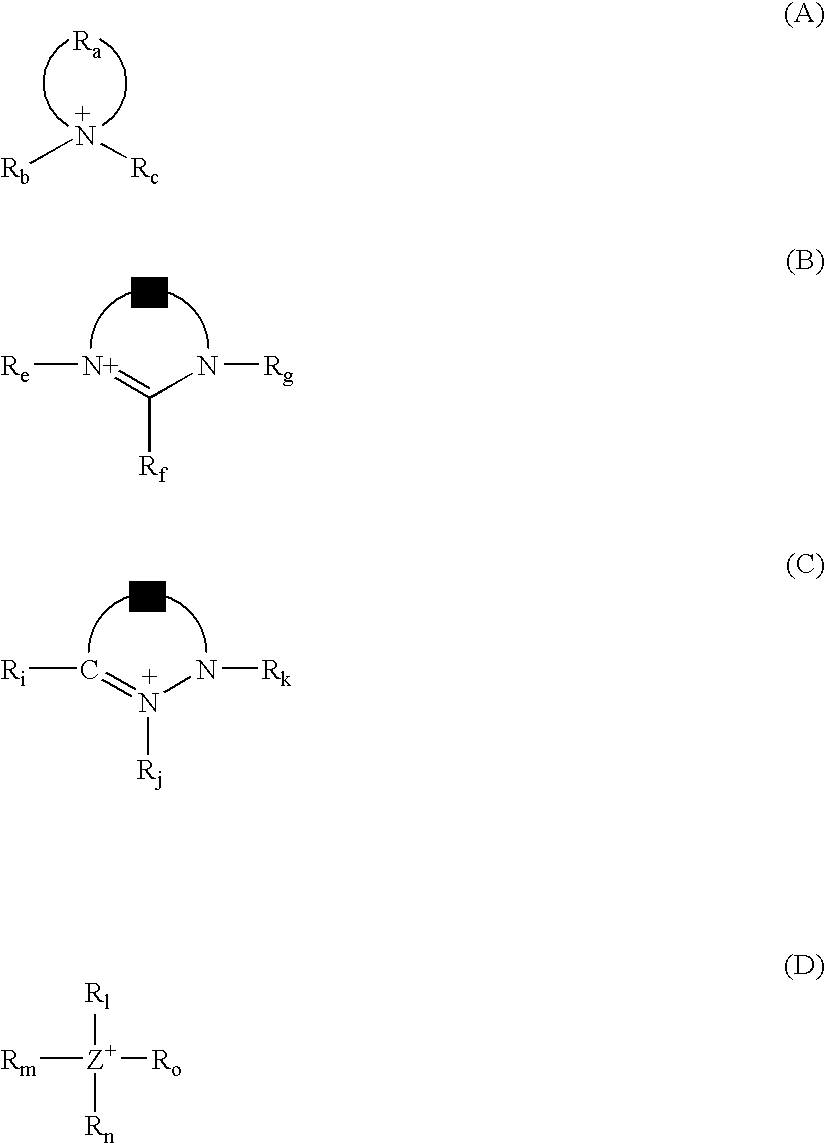

Antistatic tapes and method for producing thereof

InactiveCN1867643AGuaranteed antistatic effectImprove toleranceOpticsThin material handlingElectrical resistance and conductancePolymer science

The invention relates to a manufacturing method of an antistatic adhesive tape. More specifically, the present invention relates to an adhesive tape, wherein one surface of the tape has a resistance of 108-1011 ohm / square by forming a conductive polymer-based antistatic layer on the surface and forming an adhesive layer thereon. Surface resistivity, the other surface has a controllable surface resistivity of 103-1010 ohms / square meter by forming a conductive polymer-based surface hardening layer on it, and has good resistance to various solvents. The adhesive tape produced by the method of the present invention does not generate static electricity even when it is removed from the surface of the electronic component or film to which the tape is attached. Also, the tape has good antistatic properties on its surface when adhered or attached to the surface of an electronic component or film. In addition, the tape has good resistance to various solvents.

Owner:徐光锡

Conductive adhesive tape

ActiveCN102725369AImprove corrosion resistanceExcellent long-term corrosion resistanceNon-macromolecular adhesive additivesEster polymer adhesivesIon chromatographyAdhesion belt

Owner:NITTO DENKO CORP

Fiberboard Surface Protection System

ActiveUS20170183884A1Provide protectionFirmly connectedLamination ancillary operationsLaminationEngineeringProtection system

A surface protector is provided formed of a sheet having at least one preapplied adhesive strip used to connect together and an adjacently positioned surface protector to form a dust-proof and / or liquid-proof seal between the two surface protectors.

Owner:GARLAND INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com