Heat-transferring adhesive tape with improved functionality

A technology of adhesive tape and adhesive layer, applied in the direction of film/sheet adhesive, film/sheet without carrier, non-polymer adhesive additive, etc., can solve electromagnetic wave shielding performance or electromagnetic wave absorption performance Decrease, decrease in adhesive thermal conductivity, electrical conductivity, impossibility to improve adhesive thermal conductivity, electrical conductivity, electromagnetic wave shielding performance or electromagnetic wave absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] It is possible to control the adhesive properties of the adhesive tape according to the production method using the crosslinking agent during the manufacture of the adhesive tape. Preferably, the crosslinking agent is used in an amount of about 0.05 to about 5 parts by weight based on 100 parts by weight of the adhesive polymer resin. Specific examples of crosslinking agents that can be used in the present invention include, but are not limited to, polyfunctional acrylates, including monomeric crosslinking agents such as 1,6-hexanediol diacrylate, trimethylolpropane triacrylate, Pentaerythritol triacrylate, 1,2-ethanediol diacrylate and 1,12-dodecanediol acrylate.

[0094] When a photoinitiator is used during the manufacture of the adhesive tape according to the present invention, it is possible to control the degree of polymerization of the adhesive polymer resin by adjusting the amount of the photoinitiator used. Preferably, the photoinitiator is used in an amount of...

Embodiment 1

[0102] 1) Preparation of partial polymerization mixture

[0103] First, 95 parts by weight (parts by weight based on 100 parts by weight of the adhesive polymer resin; the same will apply below) of 2-ethylhexyl acrylate and 5 parts by weight as polar comonomer The acrylic acid was partially polymerized to obtain a slurry with a viscosity of 3000 cPs. Next, make 100 parts of the slurry with 0.2 parts of α, α-methoxy-α-hydroxyacetophenone as photoinitiator and 0.65 parts of 1,6-hexanediol diacrylate (HDDA ) thoroughly, and stir the mixture well.

[0104] 2) Preparation of the first adhesive layer

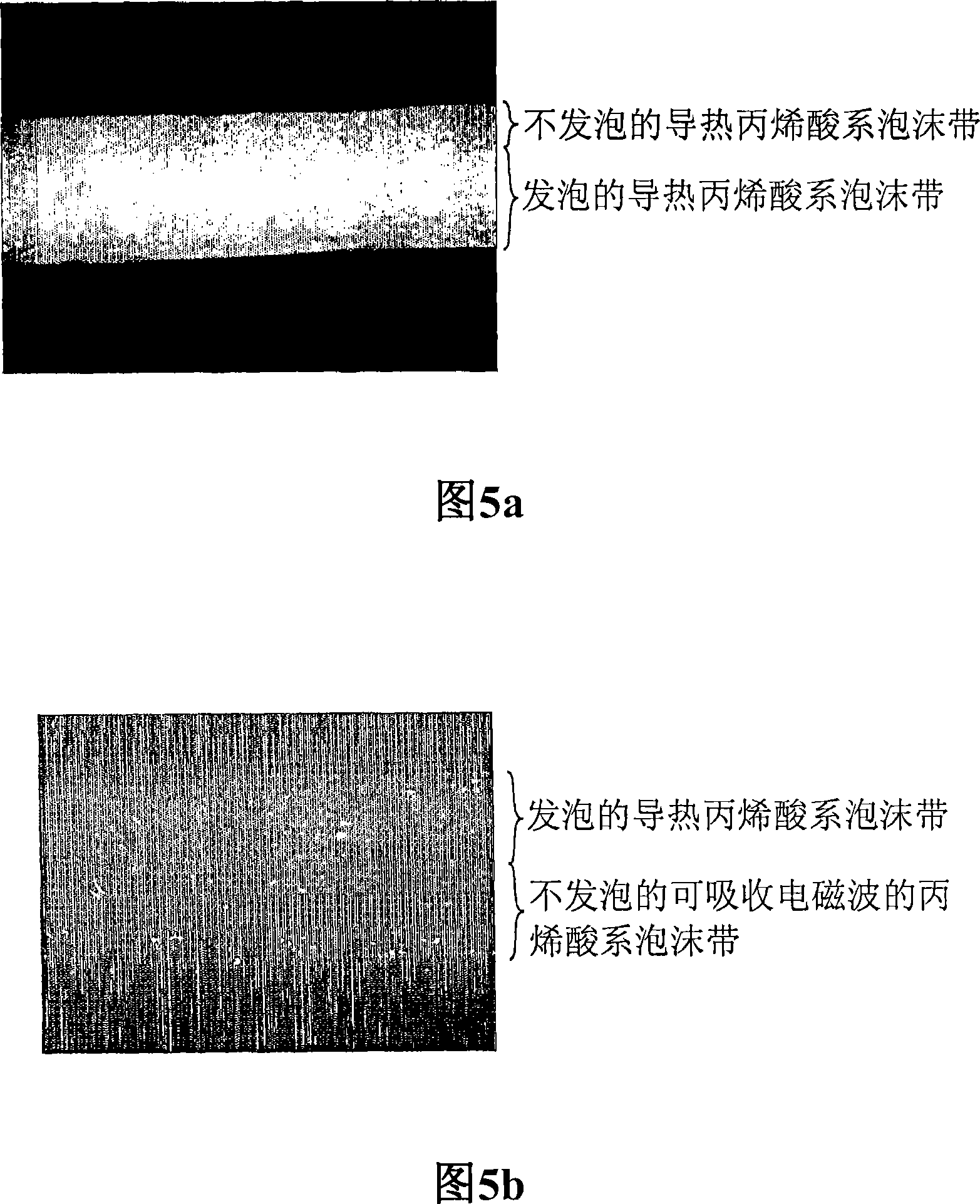

[0105] The mixture obtained above was divided into two parts, one part and 80 parts of aluminum hydroxide (Al(OH) 3 )mix. Next, the N 2 Gas is injected into the mixture and the mixture is subjected to a porous structure forming (foaming) process with high-speed stirring. Then, the resulting mixture was applied to a thickness of 1 mm on a release sheet, thereby forming a firs...

Embodiment 2

[0113] An adhesive tape was obtained in the same manner as in Example 1, except that carbonyl iron powder having a particle size of 50 μm was used as an electromagnetic wave absorbing filler instead of aluminum hydroxide (Al(OH) 3 ), in order to prepare the second adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com