Ultraviolet-cured pressure-sensitive adhesive tape or film without supporting substrate

A pressure-sensitive adhesive, pressure-sensitive adhesive technology, applied in the direction of film/sheet without carrier, film/sheet-shaped adhesive, adhesive type, etc., can solve disadvantages, etc.

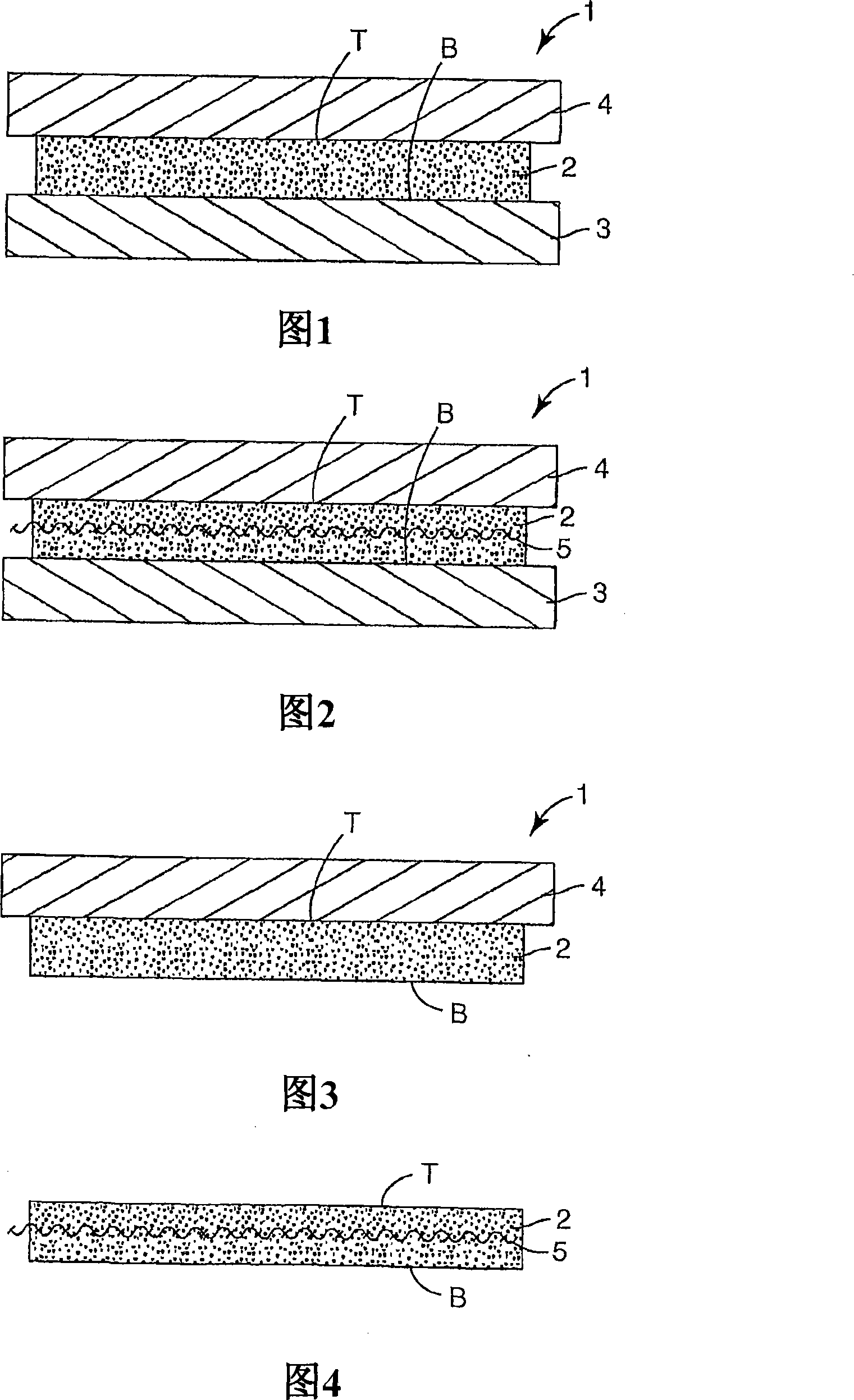

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of single-layer pressure-sensitive adhesive tape:

[0050] DaicelUCB, or LIGHT-TACK PUA 901 or Kyoeisha Chemical., Ltd.'s UV-curable urethane acrylate oligomer EBERCY 2001 (EB2001 ), IRGACURE-2959 of Ciba Specialty Chemicals as the UV initiator and IRGANOX-245 of Ciba Specialty Chemicals as the antioxidant, to obtain HEB2001 and PUA2300.

[0051] Table 1

[0052] HEB2001

[0053] HEB2001 and PUA2300 were respectively mixed with TINUVIN400 from Ciba Specialty Chemicals as the ultraviolet absorber at the mixing ratios shown in Table 2 and Table 3 below.

[0054] Table 2

[0055] HEB2001

[0056] table 3

[0057] PUA2300

[0058] The blended products respectively obtained above were coated by a hand coater to obtain a 0.1 mm seam between two sheets of OPP-40 manufactured by Tohcello Co., Ltd, a 40-μm-thick polypropylene liner. The absorbance of the mixed product was measured as follows. Absorbance was determined from the...

Embodiment 2

[0068] A UV-curable polyurethane oligomer having maleimide was used as the UV-curable oligomer. These UV-curable polyurethane oligomers are ARONTAC UVA-2200-2, UVA-2200-E3 and UVA-2103 (Toagosei Co., Ltd.). ARONTACUVA-2200-2 is a medical grade UV-curable polyurethane oligomer using polypropylene glycol as the polyol. ARONTAC UVA-2200-E3 is a medical grade UV-curable polyurethane oligomer using polyalkylene polyols based on block copolymers comprising 10% ethylene oxide and 90% propylene oxide as the polyol . UVA-2103 is a medical grade UV-curable polyurethane oligomer using polyester polyol as the polyol. To each of these curable oligomers, IRGANOX-245 from Ciba Specialty Chemicals was added as the antioxidant. In the case of UVA-2200-E3, a tackifier including ethyl acrylate / acrylic acid copolymer (AVALURE AC210 of BF-Goodrich) was further added to obtain higher tack and adhesion. The mixing ratios of various pressure-sensitive adhesive compositions are shown in Table 6. ...

Embodiment 3

[0077] A mixture of various UV-curable oligomers is used as the UV-curable oligomer. To the UV-curable oligomer mixture was added UV initiator (IRGACURE-2959), antioxidant (IRGANOX-245) and UV absorber (TINUVIN 400). The formulations of various pressure sensitive adhesive compositions are shown in Table 8 below.

[0078] Table 8

[0079] HA30

HE30

UVH-210T0.05

UVA-2200-2

69.93

69.87

UVA-2200-E3

69.93

UVA-2103

29.97

29.97

PSA-901-1

29.97

IRGANOXI-245

0.10

0.10

0.1

IRGACURE-2959

0.01

TINUVIN 400

0.05

total

100

100

100

[0080] The mixture of ARONTAC UVA-2200-2 and ARONTAC UVA-2103 was left at 90°C for one day until phase separation occurred after complete mixing of the oligomers. Since these blends do not undergo phase separation in a short time, the pressure-sensiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com